Caterham 7 Assembly Manual

ASSEMBLY GUIDE

EDITION 1.0

ASSEMBLY GUIDE

EDITION 1.0

Your feedback and comments are welcome: assemblyguide@caterham.com

ASSEMBLY GUIDE

i

Welcome to your new Caterham kit

Building your own Caterham is immensely rewarding and satisfying. Of course, it should be remembered

that you are building a high performance sports car, not a flat-pack wardrobe, so it will be a little challenging

from time to time; but we’ve set out to make it as easy as possible for anyone, whatever their skill level and

help is just a phone call away.

But before you do anything else, pop the kettle on or pour yourself a G&T with a slice; and

READ THE NEXT THREE PAGES – THEY ARE REALLY IMPORTANT

No, they will not be very exciting unfortunately, but they are important nonetheless and you will regret it later

if you don’t.

ASSEMBLY GUIDE

ii

So there are four important things we need to think about NOW before

picking up a spanner:

• This isn't the only guide you'll need

• When to apply for an IVA test

• Photography (no, really)

• Arranging a post build check

Although we have made this guide as comprehensive as possible, the requirements of IVA change from

time to time and even from test centre to test centre. Therefore, it MUST be read in conjunction with the ‘IVA

Checklist Guide’, the latest version of which can be downloaded from the Caterham website. You’ll find the

refer-to-IVA-manual symbol in the bottom of each illustration where attention is required. Reading through

it now, will save pain later! Don’t assume that because you’ve found a reference to one item relating to that

page, it is the only one…

Once you have completed the assembly of your Seven, you are required by law to present it for an ‘Individual

Vehicle Approval’ test (better known as IVA), which is conducted by the Vehicle and Operator Services

Agency (VOSA) at a regional test centre.

We STRONGLY recommend that you apply for your IVA appointment at least a month before you think you

will complete your build, to allow for the application form to be processed at the snail’s pace of bureaucracy.

Once accepted, your IVA application is valid for 6 months and test dates can be changed up to a minimum

of 3 working days prior to your appointment with VOSA (any later and you may incur a charge).

The application form and a guide on how to complete it, is contained within an envelope of documents

provided with your kit and which is probably acting as a coaster for your g&t at the moment. Take this

moment to find it and remove it from the garage and place it somewhere safe (and memorable).

ASSEMBLY GUIDE

iii

VOSA and the DVLA are a suspicious bunch and in order to register your car, you will need to provide proof

that it is amateur built. When you apply for registration, you will need to include photos from various stages

of you build, which will demonstrate to them that it is an ‘amateur build’.

Recruiting a few extras (your kids, your spouse, the cat, etc.) and some props (last year’s Xmas tree, a radio

from the 1980’s and a rusty bike) will all contribute to a more authentic home-garage feel; proving that no

professional help (i.e. commercial workshop/garage) was involved in the build. Of course, feel free to have

yourself working away on the kit in the photos if one of your ‘extras’ can be trusted with the camera (not the

cat; they never get the exposure right).

ASSEMBLY GUIDE

iv

Finally, we know you haven’t started yet, but we need to tell you about the Post Build Inspection now, due to

availability at our service centres and the time it takes to get you a slot. Plan ahead!

What is the Post Build Inspection? This is a free service oered by all Caterham service centres which we

wholeheartedly recommend you take up on prior to your IVA test. It ensures that your car is correctly

assembled and is road-worthy. All safety and operational aspects of your Seven will be checked, concluding

in a road test. This will enable us to advise you of any corrective work that may be required (which we will be

happy to carry out for you*). It is important to note that this is not the same as the IVA test and whilst every

eort will be made to ensure your car passes, there is NO GUARANTEE of a first time IVA pass.

*Obviously any additional work is not for free, but we will speak to you first so you can decide whether you

want to pay us to do the corrections or you want to do them yourself.

REMEMBER: Post Build Inspection slots are in high demand at our service centres and there may be a

two-month lead time at busy times, so please check on availability and book ahead!

All our service centres will be able to oer you a Post Build Inspection and IVA service, where they take the

car to IVA on your behalf. This tends to increase the likelihood of a first time pass and means you don’t need

to take a day out to endure the test, which is beyond dull.

As a guide, the Post Build Inspection through to registration can take around 6 weeks to complete.

v

ASSEMBLY GUIDE

That’s it, we’re ready to start assembly

ENJOY

ASSEMBLY GUIDE

vi

MY BUILD NOTES

Download the IVA Checklist Guide: www.caterhamcars.com

Book IVA Test

Take plenty of photos

Arrange post build check

This was more fun than I ever expected!

1

HINTS & TIPS

When using a torque wrench, listen/feel the click

and then stop. It does not need to be any tighter

and you might actually weaken the fixing by

‘over‑torquing’ it. Always wind your torque wrench

setting back to free when you’ve finished with it.

John K

A ‘caphead bolt’ has a circular head with a hexagonal drive

inside it. It is tightened with an allen key or hex drive socket.

Capheads are useful where there is limited space around

the head for a spanner or socket. They look nice too!

Richard T

Generally, metric Nyloc nuts have a

blue nylon insert and imperial ones a

white nylon insert.

Grant P

You can tell if you have ‘wide track suspension’ car by looking at the front

dampers. Wide track has a 25mm long hexagonal spacer between the top

spring retainer and the mounting bush.

Matt T

A bolt size is described by its diameter (e.g. M10=10mm)

by the length not including the head (e.g. 65mm).

James A

A ‘spring washer’ has a split in it and squashes up

closed when a fixing is tightened. It is usually used

under a bolt head to help resist it coming undone.

John S

A ‘nyloc’ nut is one with a nylon insert that gets cut by the bolt

thread, making it resistant to unwinding itself. This means that

they should not be repeatedly re‑used.

Chris B

Thread lock is used to stop

something coming undone, but

it only needs a little drop on

the thread to be effective.

Jamie A

Teabag, boiling water, then the milk, in that order.

Simon L

Left and right are as viewed

from the driver’s seat.

Harrison P

1Nm of torque equals 0.736lbft.

Mick F

When using a spanner, always use the ring end wherever

possible. The open end is really only for those times that access

is too limited for a ring spanner or socket.

Mick A

ASSEMBLY GUIDE

ASSEMBLY GUIDE

2

KEY

SYMBOLS

Repeat on other side

Required torque (where applicable)

S3 / S5 chassis specific instructions

S Pack / R Pack

specific instructions

Fixing item

Item number

Advice from factory

professionals

Now is a good time to take

some photos

Reminder to apply for your IVA test

Refer to IVA Checklist Guide

AA

AJ

AM

S3

S5

Nm

1

FIXINGS

PART

NUMBER

QTYUSED ON

1AA

BM12X100

2

Lower wishbone

rear

2AB

BM12X65

2

Lower wishbone

front

3AC

BM10X65

2

Upper wishbone

rear

4AD

BM10X60

2

Upper wishbone

front

5AE

BM8X40

4

Anti-roll bar

mounting brackets

6AF

NMPH14

1

Temporary use to

help lock upper

wishbone ball joint

7AG

NMYF12

2

Lower wishbone

rear

8AH

NMYF10

4

Upper wishbone

9AJ

WPCM12

18

Lower wishbone

10 AK

WPHM8

4

Anti-roll bar

mounting brackets

11 AL

WPH3/8

2

Brake pipe

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Bolt M12 x 100

Grade 10.9

Bolt M12 x 65

Grade 10.9

Bolt M10 x 65

Grade 10.9

Bolt M10 x 60

Grade 10.9

Bolt M8 x 40

Grade 10.9

Plain Nut M14

x 1.5 thread

Nyloc Nut M12

Plain Washer

⅜" x ¾"

Heavy duty

Page 1 of 2

Nyloc Nut M10

Plain Washer

M12

Chamfered

Plain Washer

M8

Heavy duty

PART

NUMBER

QTYUSED ON

1AA

BM12X100

2

Lower wishbone

rear

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Bolt M12 x 100

Grade 10.9

x4 (Indicates number of each fixing required)

(Greyed out area indicates fixings are not

required for current step)

REPEAT

ASSEMBLY GUIDE

3

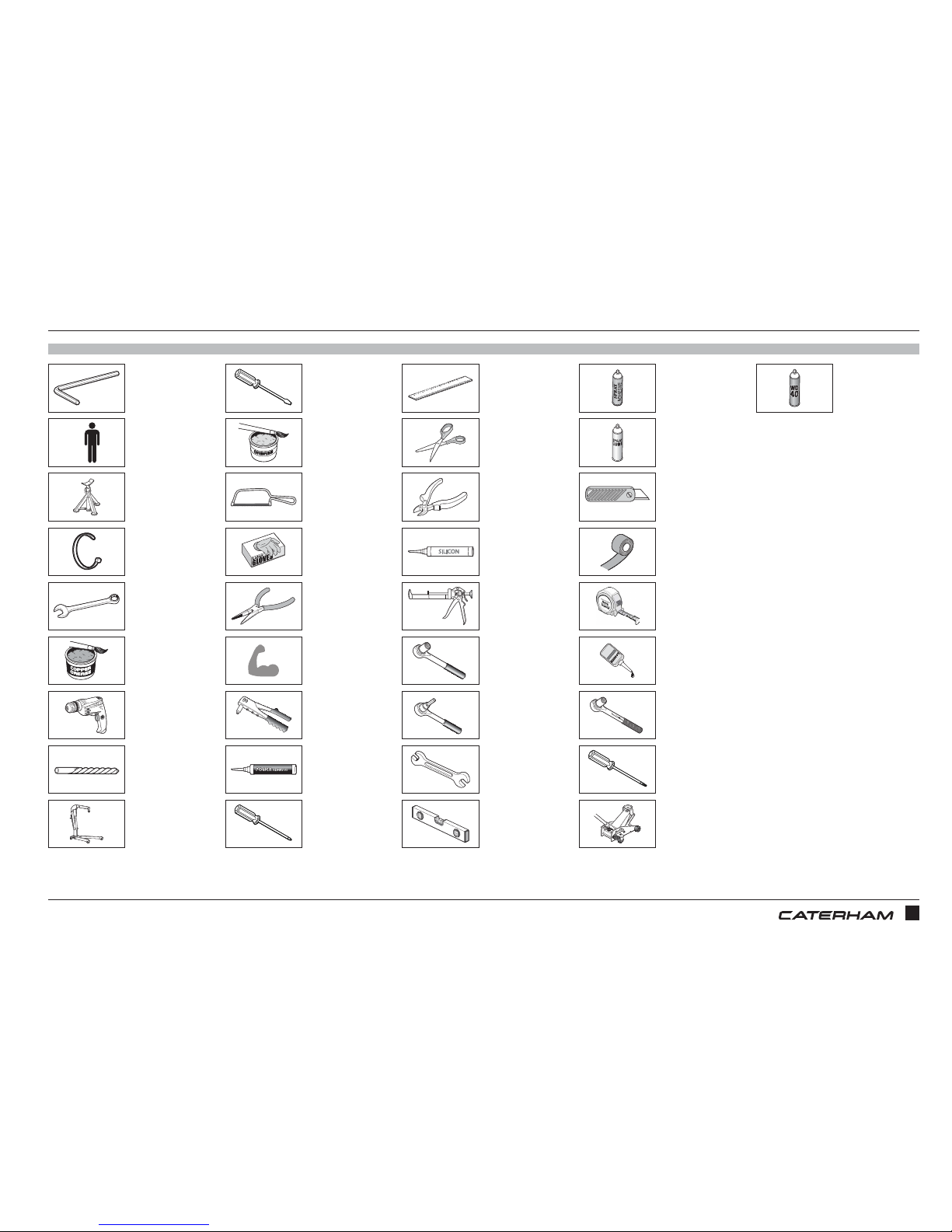

TOOLS

KEY

Spanner

Scissors

Grease

Latex gloves

Junior hacksaw

Long nose pliers

Pop rivet gun

Muscle

Pozidrive

screwdriver

Power adhesive

Flat head

screwdriver

Thread lock /

LocTite

LOCTITE

LOCTITE

Tape

Torx

Tape measure

Trolley jack

Torque wrench

WD40

Ruler

Side cutters

Silicon gun

Silicon

Socket wrench

Spray adhesive

Spray lube

Socket wrench

(allen)

Stanley knife

Spirit level

Drill bit

Axle stand

Combination

spanner

Allen key

Engine hoist

Copper grease

Drill

Cable tie

Assistance

+

ASSEMBLY GUIDE

4

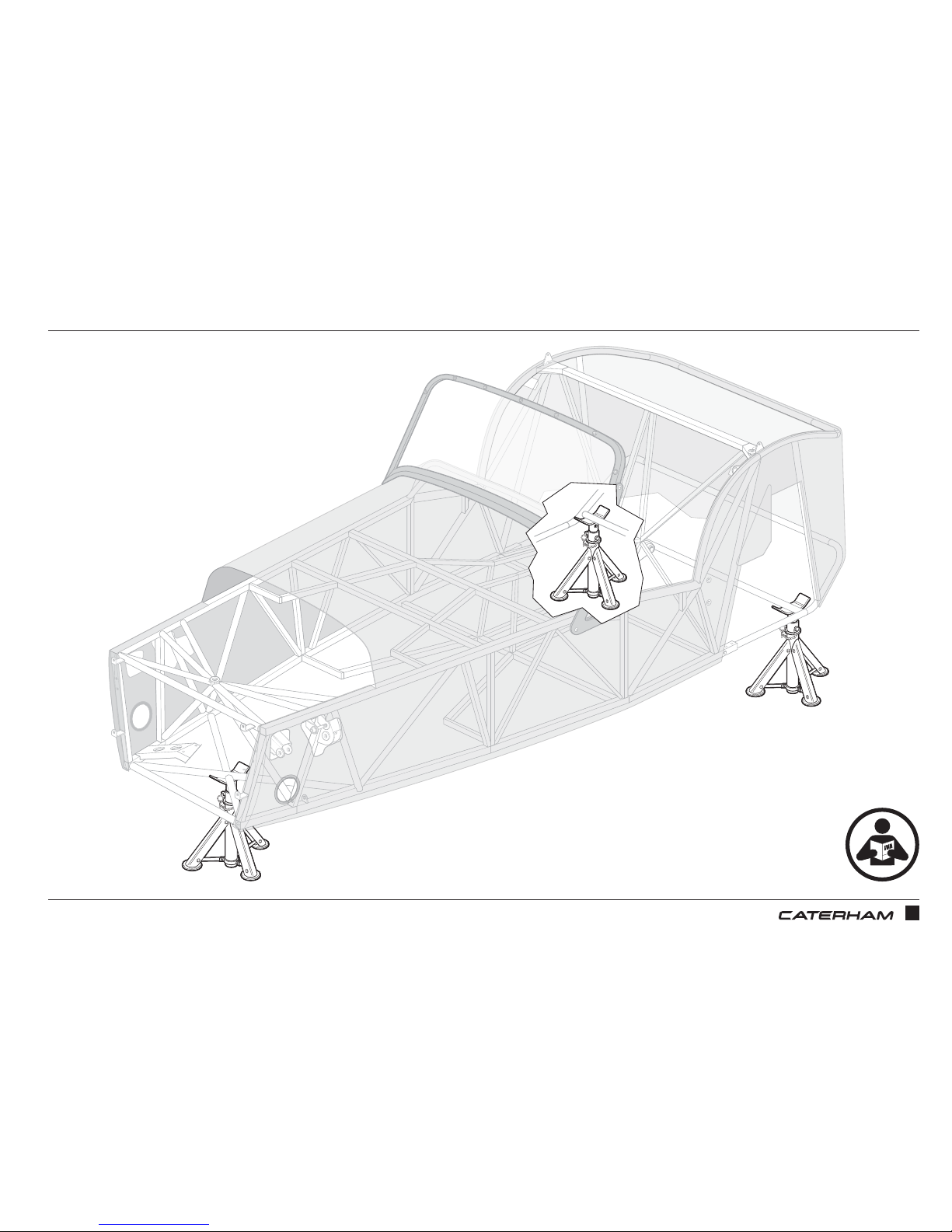

LET’S GET READY

PAR TS

FIXINGS

TOOLS

TIPS

x3

When deciding how high your axle stands

should be (the higher the better for working

on), don’t forget that a complete car will

need to come down off them, so make sure

your trolley jack can reach and lift the

height you set them too!

Mick F

Some tape or foam on the

top of the axle stands will

stop them scratching the

chassis.

Matt T

ASSEMBLY GUIDE

5

LET’S GET READY

ASSEMBLY GUIDE

6

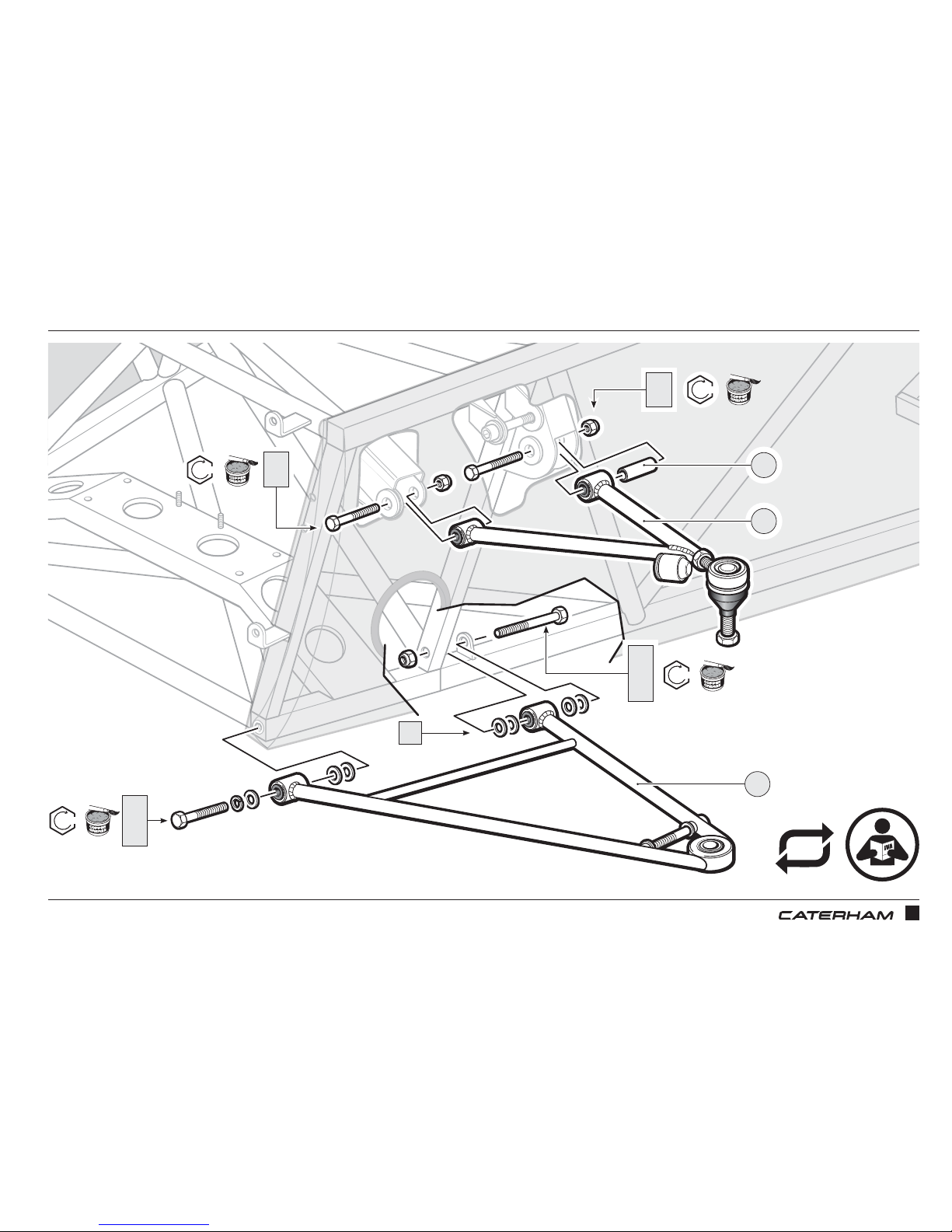

START WITH THE SUSPENSION WISHBONES

PAR TS

FIXINGS

TOOLS

TIPS

PART

NUMBER

QTYUSED ON

1AA

BM12X100

2

Lower wishbone

rear

2AB

BM12X65

2

Lower wishbone

front

3AC

BM10X65

2

Upper wishbone

rear

4AD

BM10X60

2

Upper wishbone

front

5AE

BM8X40

4

Anti-roll bar

mounting brackets

6AF

NMPH14

1

Temporary use to

help lock upper

wishbone ball joint

7AG

NMYF12

2

Lower wishbone

rear

8AH

NMYF10

4

Upper wishbone

9AJ

WPCM12

18

Lower wishbone

10 AK

WPHM8

4

Anti-roll bar

mounting brackets

11 AL

WPH3/8

2

Brake pipe

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Bolt M12 x 100

Grade 10.9

Bolt M12 x 65

Grade 10.9

Bolt M10 x 65

Grade 10.9

Bolt M10 x 60

Grade 10.9

Bolt M8 x 40

Grade 10.9

Plain Nut M14

x 1.5 thread

Nyloc Nut M12

Plain Washer

⅜" x ¾"

Heavy duty

Page 1 of 2

Nyloc Nut M10

Plain Washer

M12

Chamfered

Plain Washer

M8

Heavy duty

94

PART

NUMBER

QTYUSED ON

12 AM

WSHM12

2

Lower wishbone

front

13 AN

WSHM8

6

Anti-roll bar

mounting brackets &

upper damper

mount

14 AP

WSS3/8

2 Brake pipe

15 AR

NFYH1/2

2Wing stay

16 AS

NFYF1/2

2

Front brake, upright

mounting (std track

ONLY)

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Spring Washer

M12

Nyloc Nut ½"

Full height

Page 2 of 2

Spring Washer

M8

Washer ⅜"

Shake-proof

Nyloc Nut ½"

Half height

x2

x2

x2

x2

x2

x4

x14

x2

17mm

19mm

Lower wishbone

Wishbone bush sleeve

Upper wishbone

17mm

19mm

1

3

2

For now, only tighten the nuts/bolts lightly and then

torque them up when the car is finished and on the

ground. This sets the bushes correctly and ensures

the best handling.

Harrison P

The big washers are chamfered and

the chamfered side should be towards

the wishbone.

Alex H

Leave bolt AD

loose for now,

as we have to

take it back out

again to put

the headlight

bracket on later.

John K

ASSEMBLY GUIDE

7

START WITH THE SUSPENSION WISHBONES

81Nm

AB

AJ

AM

1

2

3

AJ

81Nm

AA

AJ

AG

47Nm

47Nm

AD

AH

AC

AH

REPEAT

ASSEMBLY GUIDE

8

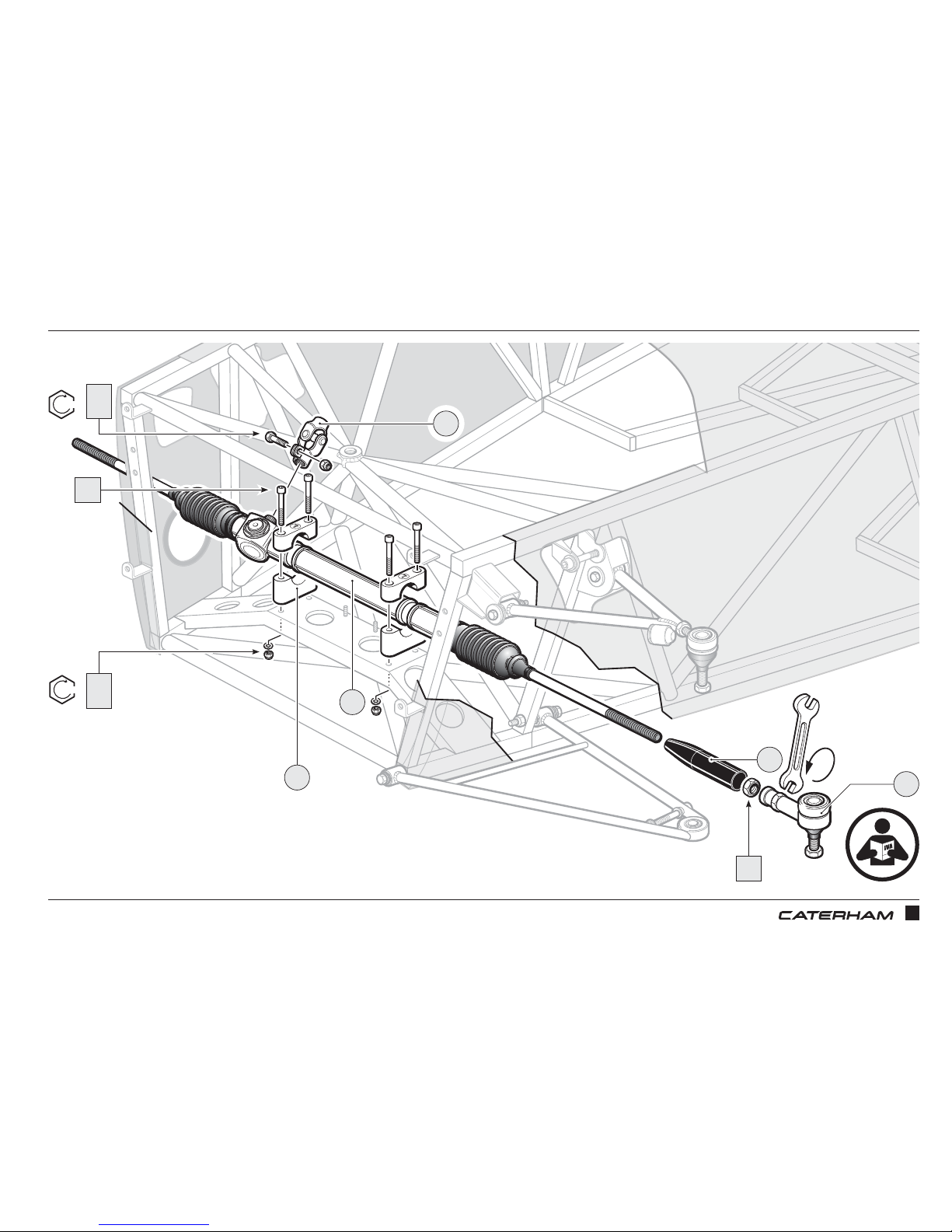

NOW FOR THE STEERING RACK

PAR TS

FIXINGS

TOOLS

TIPS

PART

NUMBER

QTYUSED ON

1BA

BMCH6X70

4Rack clamps

2BB

BF1/4X1.1/2

2Column clam p

3BC

BM8X35

2

Column to rack

universal joint

4BD

NFYH1/2

1Steering wheel boss

5BE

NFPF1/2

2Track rod lock nut

6BF

NFPFH7/16

1

Column clamp

grubscrew locknut

7BG

NMYF8

2

Column to rack

universal joint

8BH

NMYF6

4

Steering rack

clamps

9BJ

WPH1/2

1

Steering wheel boss

10 BK

WPH1/4

6

Rack clamps and

column clamp

11 BL

WSH1/4

2

Column clamp

Drawings are for illustrative purposes only and are not to scale.

B

SERIAL

NUMBER

55

Pack

PACK NUMBER

30S003B

STEERING DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Caphead Bolt

M6 x 70

DIN 912

Bolt ¼" x 1½"

Bolt M8 x 35

Grade 8.8

Nyloc Nut ½"

Half height

Plain Nut ½"

Plain Nut ⁷⁄₁₆"

Half height

Nyloc Nut M8

Spring Washer ¼

Heavy duty

Page 1 of 1

Nyloc Nut M6

Plain Washer

½" x 1⅛"

Chamfered

Plain Washer

¼"

Heavy duty

x4

x2

x2

x2

x4

x4

10mm

13mm

Steering rack

Column universal joint

Rack clamps

IVA cover

Track rod end

5mm

13mm

22mm

¾"

1

3

2

5

4

Finding the right IVA cover isn’t

obvious because it is effectively

a long cap. To use it, you cut the

closed end off.

Jamie A

The trackrod end needs to screw on

about 12 turns (it will be properly set

later when the tracking is done).

Matthew H

ASSEMBLY GUIDE

9

NOW FOR THE STEERING RACK

11Nm

BE

3

5

20Nm

BC

BG

BH

BK

BA

2

1

4

ASSEMBLY GUIDE

10

PART

NUMBER

QTYUSED ON

1AA

BM12X100

2

Lower wishbone

rear

2AB

BM12X65

2

Lower wishbone

front

3AC

BM10X65

2

Upper wishbone

rear

4AD

BM10X60

2

Upper wishbone

front

5AE

BM8X40

4

Anti-roll bar

mounting brackets

6AF

NMPH14

1

Temporary use to

help lock upper

wishbone ball joint

7AG

NMYF12

2

Lower wishbone

rear

8AH

NMYF10

4

Upper wishbone

9AJ

WPCM12

18

Lower wishbone

10 AK

WPHM8

4

Anti-roll bar

mounting brackets

11 AL

WPH3/8

2

Brake pipe

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Bolt M12 x 100

Grade 10.9

Bolt M12 x 65

Grade 10.9

Bolt M10 x 65

Grade 10.9

Bolt M10 x 60

Grade 10.9

Bolt M8 x 40

Grade 10.9

Plain Nut M14

x 1.5 thread

Nyloc Nut M12

Plain Washer

⅜" x ¾"

Heavy duty

Page 1 of 2

Nyloc Nut M10

Plain Washer

M12

Chamfered

Plain Washer

M8

Heavy duty

94

PART

NUMBER

QTYUSED ON

12 AM

WSHM12

2

Lower wishbone

front

13 AN

WSHM8

6

Anti-roll bar

mounting brackets &

upper damper

mount

14 AP

WSS3/8

2 Brake pipe

15 AR

NFYH1/2

2Wing stay

16 AS

NFYF1/2

2

Front brake, upright

mounting (std track

ONLY)

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Spring Washer

M12

Nyloc Nut ½"

Full height

Page 2 of 2

Spring Washer

M8

Washer ⅜"

Shake-proof

Nyloc Nut ½"

Half height

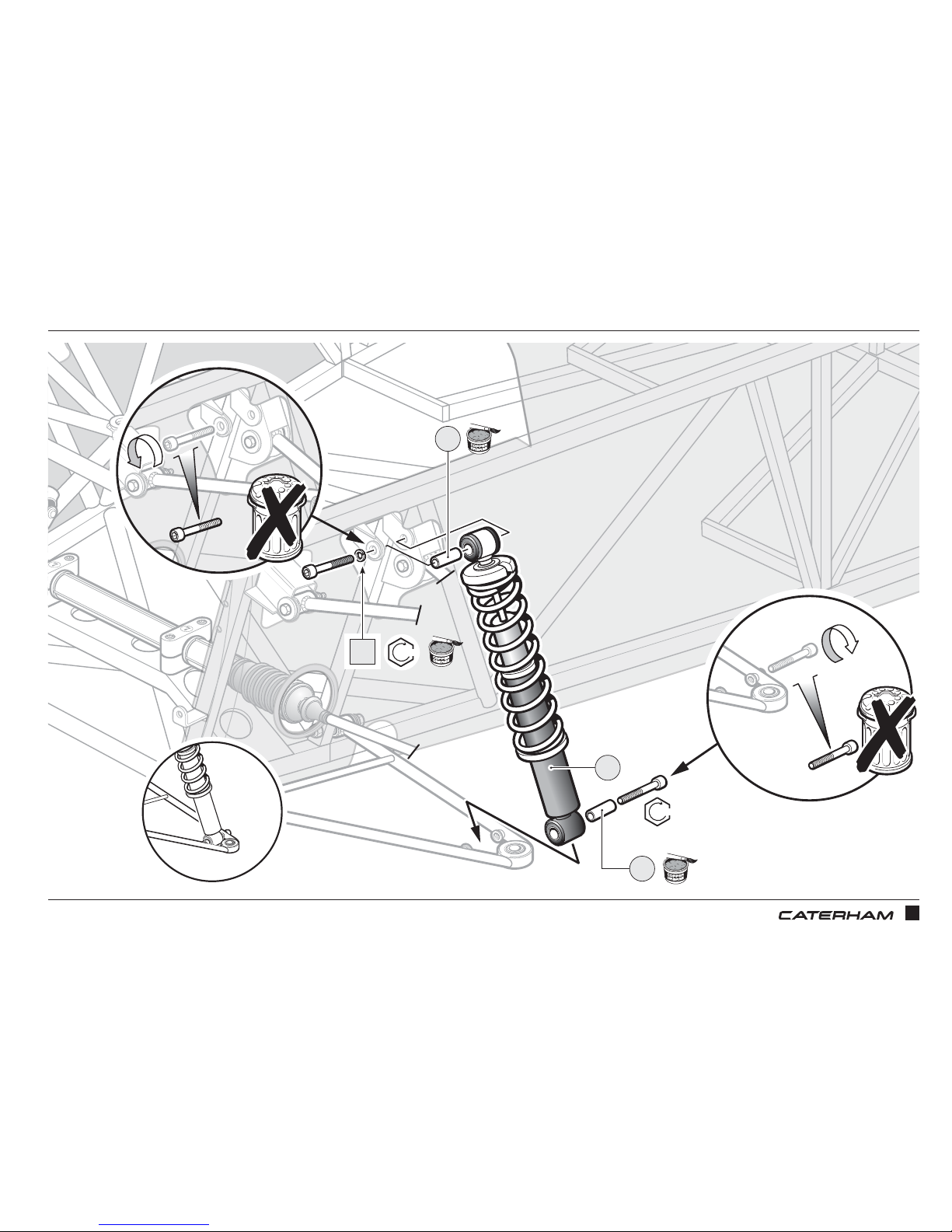

AND THEN THE DAMPERS

PAR TS

FIXINGS

TOOLS

TIPS

6mm

Spring / damper

Upper damper eyelet

Lower damper eyelet

6mm

6mm

1

3

2

Put the top of the damper on first

and be careful not to let it swing into

the side of the chassis.

Grant P

The bottom can be a tight fit!

Mick F

x2

Fixings not contained in the pack will be

supplied loosely fitted to the chassis and

the wishbone

ASSEMBLY GUIDE

11

AND THEN THE DAMPERS

25Nm

1

2

3

25Nm

AN

ASSEMBLY GUIDE

12

PART

NUMBER

QTYUSED ON

1AA

BM12X100

2

Lower wishbone

rear

2AB

BM12X65

2

Lower wishbone

front

3AC

BM10X65

2

Upper wishbone

rear

4AD

BM10X60

2

Upper wishbone

front

5AE

BM8X40

4

Anti-roll bar

mounting brackets

6AF

NMPH14

1

Temporary use to

help lock upper

wishbone ball joint

7AG

NMYF12

2

Lower wishbone

rear

8AH

NMYF10

4

Upper wishbone

9AJ

WPCM12

18

Lower wishbone

10 AK

WPHM8

4

Anti-roll bar

mounting brackets

11 AL

WPH3/8

2

Brake pipe

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Bolt M12 x 100

Grade 10.9

Bolt M12 x 65

Grade 10.9

Bolt M10 x 65

Grade 10.9

Bolt M10 x 60

Grade 10.9

Bolt M8 x 40

Grade 10.9

Plain Nut M14

x 1.5 thread

Nyloc Nut M12

Plain Washer

⅜" x ¾"

Heavy duty

Page 1 of 2

Nyloc Nut M10

Plain Washer

M12

Chamfered

Plain Washer

M8

Heavy duty

94

PART

NUMBER

QTYUSED ON

12 AM

WSHM12

2

Lower wishbone

front

13 AN

WSHM8

6

Anti-roll bar

mounting brackets &

upper damper

mount

14 AP

WSS3/8

2 Brake pipe

15 AR

NFYH1/2

2Wing stay

16 AS

NFYF1/2

2

Front brake, upright

mounting (std track

ONLY)

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Spring Washer

M12

Nyloc Nut ½"

Full height

Page 2 of 2

Spring Washer

M8

Washer ⅜"

Shake-proof

Nyloc Nut ½"

Half height

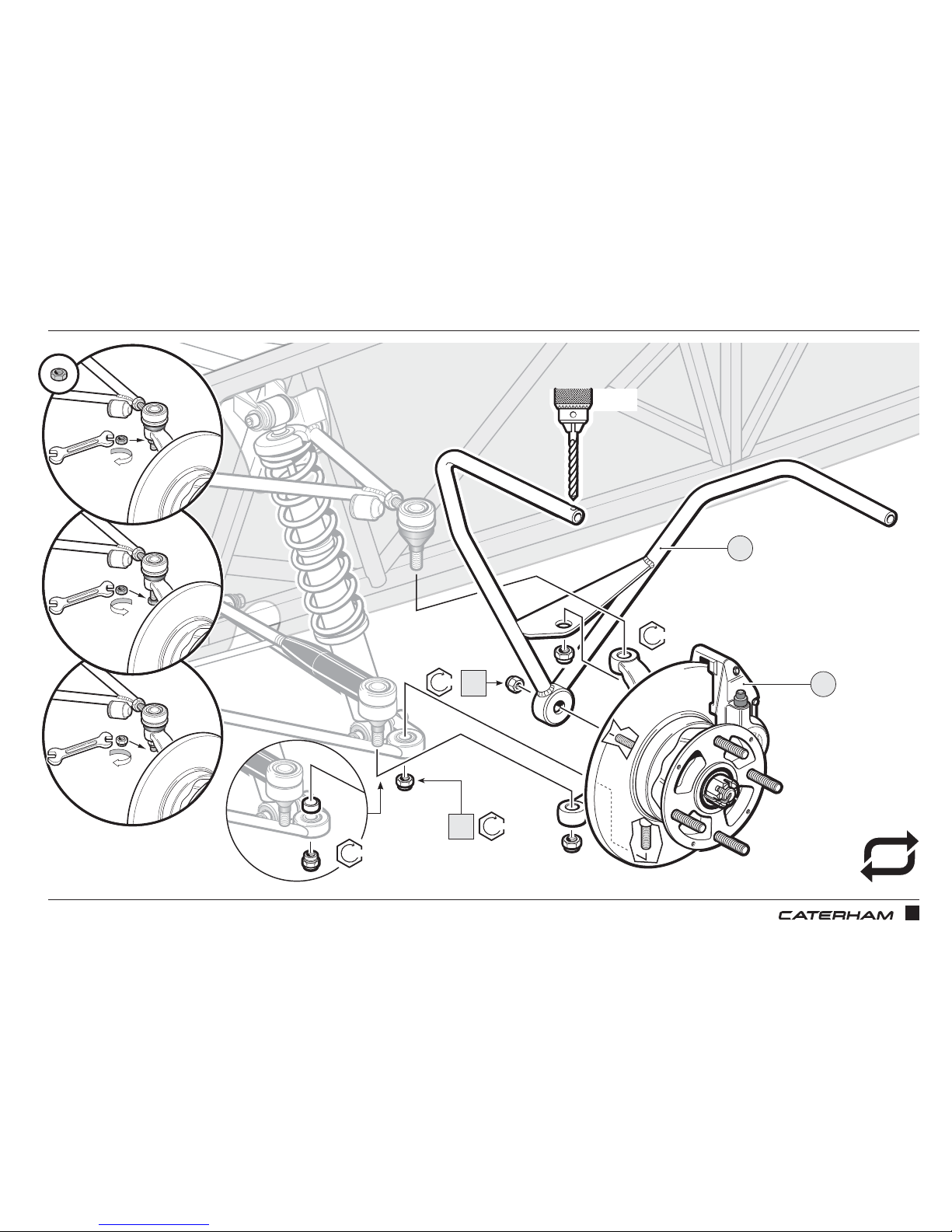

IT’S TIME FOR THE WINGSTAYS

PAR TS

FIXINGS

TOOLS

TIPS

19mm

22mm

¾"

22mm

Wingstay

Front brake & upright assembly

x2

x2

1

2

Some of the fixings

required and shown

on the drawings,

such as the ball

joint nut, are already

on the part and not

in the fixing pack.

Anthony L

Use the plain

nut to pull the

top ball joint

home before

using a nyloc,

otherwise the

thread will spin.

Chris N

The drilled hole is for the side repeater earth that we’ll fit later. It’s easier to

drill from the top and down through both sides of the tube, rather than through

one side from the bottom (where the earth will be fixed).

Tiago O

Put the ‘upright’ into the lower

wishbone joint then attach

the steering before tightening

the bottom nut. This stops it

all swinging around hitting the

side of the chassis.

John S

"

13

ASSEMBLY GUIDE

1 x ⅛

IT’S TIME FOR THE WINGSTAYS

WIDE

TRACK

54Nm

81Nm

61Nm

AS

AR

STANDARD TRACK

1

2

REPEAT

54Nm

ASSEMBLY GUIDE

14

Now is a good time to take some photos

15

Have you applied for your IVA yet?

ASSEMBLY GUIDE

ASSEMBLY GUIDE

16

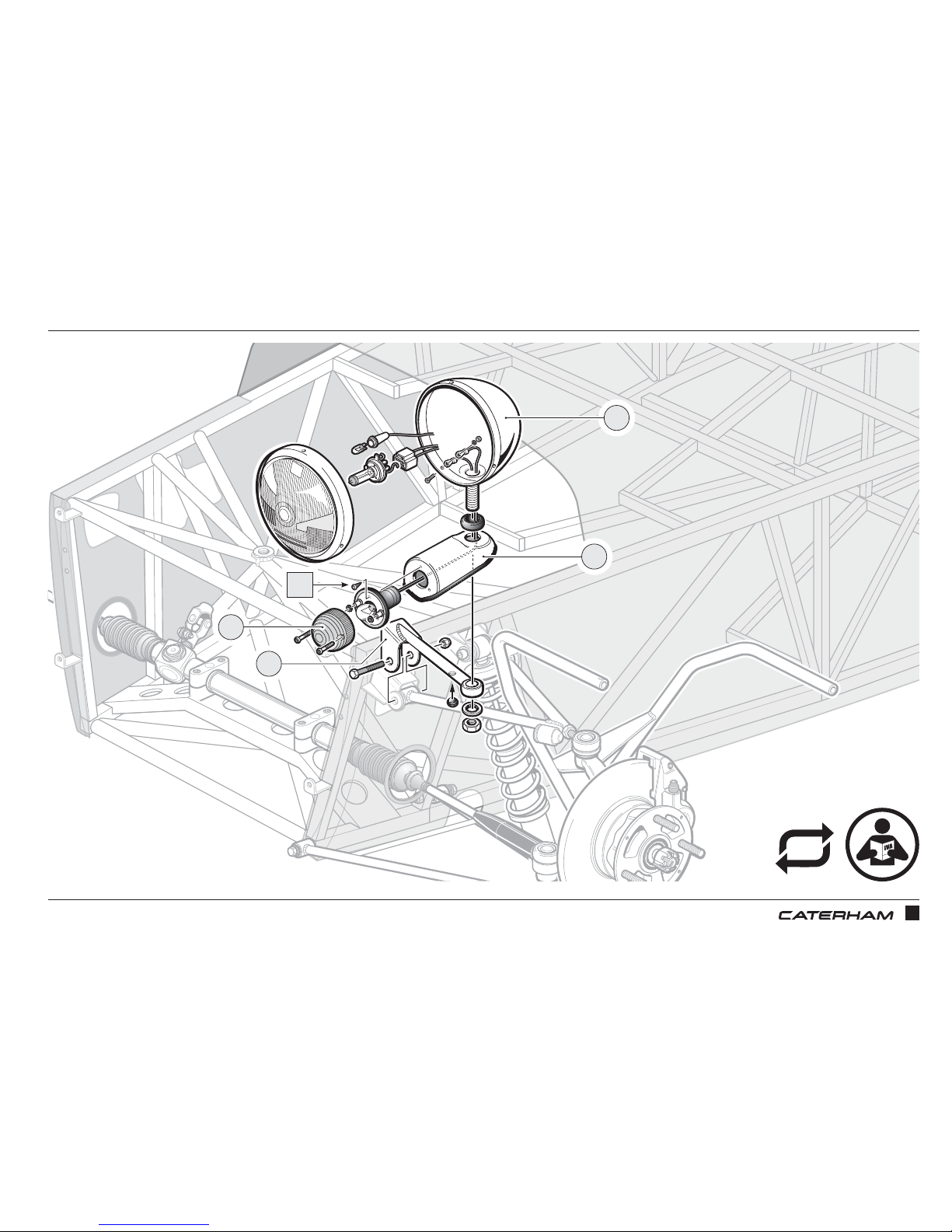

LET THERE BE LIGHTS

PAR TS

FIXINGS

TOOLS

TIPS

PART

NUMBER

QTYUSED ON

1CA

71080

6

Indictor assembly to

indicator pod

2CB

71077

2

Side repeater earth

on wingstay

3CC

71079

4

Rear light cluster

upper fixing

4CD

71078

4

Rear light cluster

lower fixing

5CE

NMYF6

2

Horn bracket to

steering rack

platform

(160/270/310)

6CF

WPH1/4

2

Horn bracket to

steering rack

platform

(160/270/310)

7CG

BM8X50

1

Through steering

rack platform &

spacer

(420)

8CH

WPH5/16

2Bolt head/nut

9CI

NMYF8

1Horn bolt

Drawings are for illustrative purposes only and are not to scale.

BASIC

DESCRIPTION

ILLUSTRATION

Screw 10 x ¾

"

Black Supaflange

Page 1 of 1

Screw 12 x 1"

Self tapping

Screw 8 x ½"

Black Supaflange

Screw 12 x 1½

"

Self tapping

LIGHTING & HORNS

ITEM

Pack

45

SERIAL

NUMBER

PACK NUMBER

30L002B

C

Nyloc Nut M6

Plain Washer

¼"

Heavy duty

Bolt M8 x 5

Grade 8.8

Plain Washer

5/16"

Nyloc Nut

M8

x6

Headlight assembly

Indicator assembly

Indicator pod

17mm

24mm

17mm

1

3

2

The wiring for the headlights is attached to the chassis when

you receive your kit. The wires go through the hole in the end

of the headlight bracket and out of the other hole in order to

go up into the headlight and over to the indicator.

Jamie A

Headlight bracket

4

ASSEMBLY GUIDE

17

LET THERE BE LIGHTS

7

7

1

2

3

4

CA

REPEAT

ASSEMBLY GUIDE

18

PART

NUMBER

QTYUSED ON

1AA

BM12X100

2

Lower wishbone

rear

2AB

BM12X65

2

Lower wishbone

front

3AC

BM10X65

2

Upper wishbone

rear

4AD

BM10X60

2

Upper wishbone

front

5AE

BM8X40

4

Anti-roll bar

mounting brackets

6AF

NMPH14

1

Temporary use to

help lock upper

wishbone ball joint

7AG

NMYF12

2

Lower wishbone

rear

8AH

NMYF10

4

Upper wishbone

9AJ

WPCM12

18

Lower wishbone

10 AK

WPHM8

4

Anti-roll bar

mounting brackets

11 AL

WPH3/8

2

Brake pipe

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Bolt M12 x 100

Grade 10.9

Bolt M12 x 65

Grade 10.9

Bolt M10 x 65

Grade 10.9

Bolt M10 x 60

Grade 10.9

Bolt M8 x 40

Grade 10.9

Plain Nut M14

x 1.5 thread

Nyloc Nut M12

Plain Washer

⅜" x ¾"

Heavy duty

Page 1 of 2

Nyloc Nut M10

Plain Washer

M12

Chamfered

Plain Washer

M8

Heavy duty

94

PART

NUMBER

QTYUSED ON

12 AM

WSHM12

2

Lower wishbone

front

13 AN

WSHM8

6

Anti-roll bar

mounting brackets &

upper damper

mount

14 AP

WSS3/8

2 Brake pipe

15 AR

NFYH1/2

2Wing stay

16 AS

NFYF1/2

2

Front brake, upright

mounting (std track

ONLY)

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Spring Washer

M12

Nyloc Nut ½"

Full height

Page 2 of 2

Spring Washer

M8

Washer ⅜"

Shake-proof

Nyloc Nut ½"

Half height

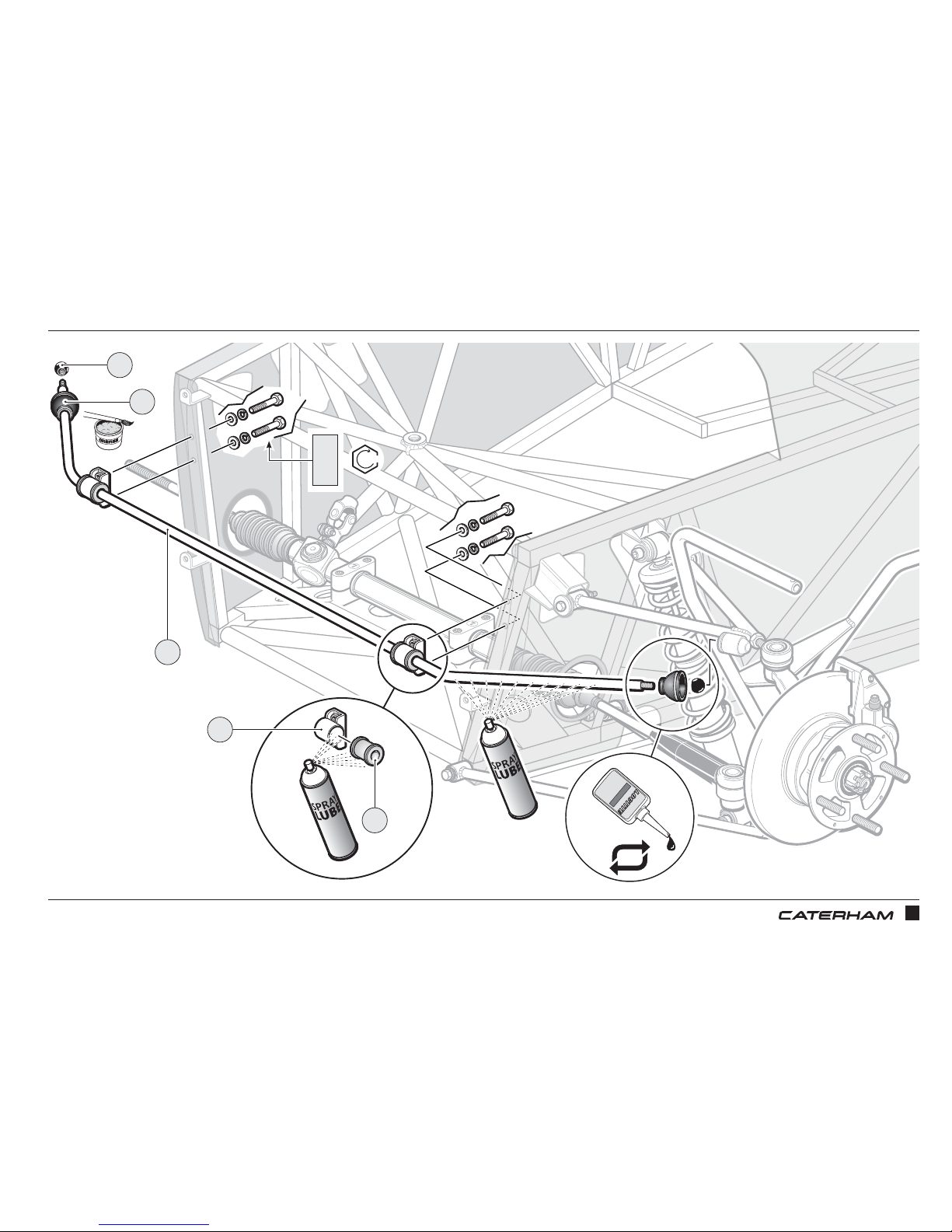

LAST PART OF THE FRONT SUSPENSION: CONNECTING THE TWO SIDES TOGETHER

PAR TS

FIXINGS

TOOLS

TIPS

x4

x4

13mm

Anti-roll bar

Anti-roll bar rubber

Anti-roll bar bracket

Anti-roll bar dust cover

Anti-roll bar ball

x4

LOCTITE

LOCTITE

1

3

2

5

4

Getting the assembled anti‑roll

bar fully into both cups on the

upper wishbone can be a bit of a

fight. It’s made of springy stuff,

so don’t worry that you are

bending it.

Jamie A

Use four small cable

ties to secure the

dust cover.

Mick F

Grease the balls and cups generously.

Matt T

Check that the colour of the

mounting rubbers matches the

colour spot on the bar.

John K

ASSEMBLY GUIDE

19

LAST PART OF THE FRONT SUSPENSION: CONNECTING THE TWO SIDES TOGETHER

1

2

3

4

5

AE

AK

AN

20Nm

LOCTI TE

LOCTI TE

REPEAT

ASSEMBLY GUIDE

20

PART

NUMBER

QTYUSED ON

1AA

BM12X100

2

Lower wishbone

rear

2AB

BM12X65

2

Lower wishbone

front

3AC

BM10X65

2

Upper wishbone

rear

4AD

BM10X60

2

Upper wishbone

front

5AE

BM8X40

4

Anti-roll bar

mounting brackets

6AF

NMPH14

1

Temporary use to

help lock upper

wishbone ball joint

7AG

NMYF12

2

Lower wishbone

rear

8AH

NMYF10

4

Upper wishbone

9AJ

WPCM12

18

Lower wishbone

10 AK

WPHM8

4

Anti-roll bar

mounting brackets

11 AL

WPH3/8

2

Brake pipe

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Bolt M12 x 100

Grade 10.9

Bolt M12 x 65

Grade 10.9

Bolt M10 x 65

Grade 10.9

Bolt M10 x 60

Grade 10.9

Bolt M8 x 40

Grade 10.9

Plain Nut M14

x 1.5 thread

Nyloc Nut M12

Plain Washer

⅜" x ¾"

Heavy duty

Page 1 of 2

Nyloc Nut M10

Plain Washer

M12

Chamfered

Plain Washer

M8

Heavy duty

94

PART

NUMBER

QTYUSED ON

12 AM

WSHM12

2

Lower wishbone

front

13 AN

WSHM8

6

Anti-roll bar

mounting brackets &

upper damper

mount

14 AP

WSS3/8

2 Brake pipe

15 AR

NFYH1/2

2Wing stay

16 AS

NFYF1/2

2

Front brake, upright

mounting (std track

ONLY)

Drawings are for illustrative purposes only and are not to scale.

A

SERIAL

NUMBER

44

Pack

PACK NUMBER

30F015B

FRONT SUSPENSION DeDION CARS (METRIC)

This pack may include extra fasteners to cover different options

ITEM

BASIC

DESCRIPTION

ILLUSTRATION

Spring Washer

M12

Nyloc Nut ½"

Full height

Page 2 of 2

Spring Washer

M8

Washer ⅜"

Shake-proof

Nyloc Nut ½"

Half height

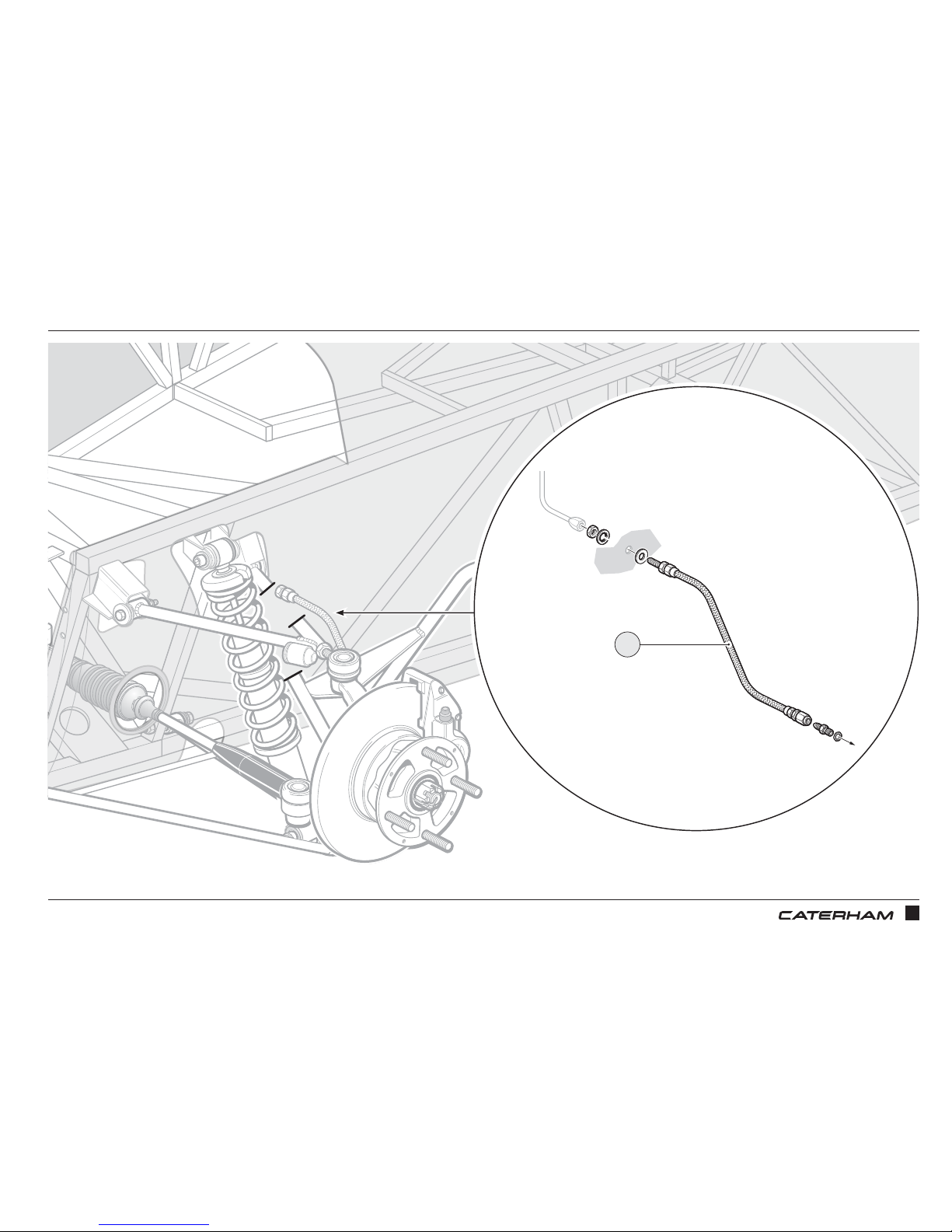

PAR TS

FIXINGS

TOOLS

TIPS

Brake hose

1

FITTING THE BRAKE HOSES

13mm (x2)

⁄"

The hose will want to curve once fitted.

Make sure the curve points towards

the front of the car.

Khalfani D

Brake hoses come in

packs of 3: 2 front, 1 back.

Anthony L

x2

x2

ASSEMBLY GUIDE

21

FITTING THE BRAKE HOSES

1

ASSEMBLY GUIDE

22

PAR TS

FIXINGS

TOOLS

TIPS

10mm

Horn kit (x2)

Bolt for spacer

Spacer (miscellaneous box)

13mm

6mm

1

3

2

LET'S MAKE SOME NOISE

Miscellaneous box

Loading...

Loading...