Catalina Capri 22 Owner's Manual

~~·

. . : ' . . .

CATALI.NA ,

CAPRI22--

...

( i

.

..

....

4th

Edition August 21,

OWNER'S

MANUAL-_·

2001

(

FOREWORD

Congratulations on the acquisition

and

designed

a minimum

Before attempting maintenance

Yachts/Capri Sailboats Limited Warranty booklet

card.

The registration card enables Catalina to inform

enhance the performance or comfort

owners to comply with

The commissioning

yard

personnel under the direction

Maintaining

inspection is the best preventive maintenance. It will help keep your boat safe

condition while in use,

Take

good

built with care using quality materials to assure

of

upkeep

your

care

and

maintenance.

Coast Guard notification requirements.

and

rigging

boat properly can become a satisfying

and

insure peace

of

your boat

of

your new Capri 22 sailboat.

you

or

operation

of

of

your Capri 22 sailboat should be handled

of

your authorized dealer.

and

take the time to learn

of

your sailboat, please read the Catalina

and

fill

out the enclosed warranty registration

you

of

developments

your yacht. It is also important to be able to contact

part

of

of

mind when the boat is left unattended.

and

practice good seamanship.

All

Capri sailboats are

years

of

sailing enjoyment with

and

modifications to

your sailing activities. A regular

by

experienced boat

and

in

good

4'h

Edition

August

21,

2001

(

PREFACE

This manual is intended

answer common questions about maintenance

This manual is not intended to provide sailing instructions.

books written

for

the safe operation

The systems descriptions

publication. Our policy

Capri sailboat since its introduction. Therefore, these illustrations

to boats built before the time

Owners

dealer,

The maintenance checklists contained within this manual are intended as guidelines

normal service under typical conditions.

Climate

local boat

your purposes

AN

IMPORTANT

electricity.

injury or death. Stay away from overhead electrical power lines when sailing and/or launching the

boat.

for

that purpose, or take sailing lessons or courses to gain the knowledge necessary

of

earlier hulls, who have questions not answered herein, should consult their local Capri

or

write to the builder. Please include your hull number

and

use will vary

yard

or Catalina dealer

and

Coming in contact with or near an electrical power line or lightning can cause severe

and

of

the vessel.

and

of

climate.

WORD

supplied to help owners

illustrations in this manual apply to boats built

constant improvement necessitates that changes have been made to the

of

publication.

and

may require additional or special maintenance. Consult with you

for

specific maintenance

OF

CAUTION:

The

of

Capri sailboats understand their boats

and

systems design specific to Capri sailboats.

It

is assumed the operator will consult

at

the time

and

descriptions may not apply

in

all correspondence.

and

precautions recommended for

aluminum

and

other metal parts conduct

for

and

of

boats in

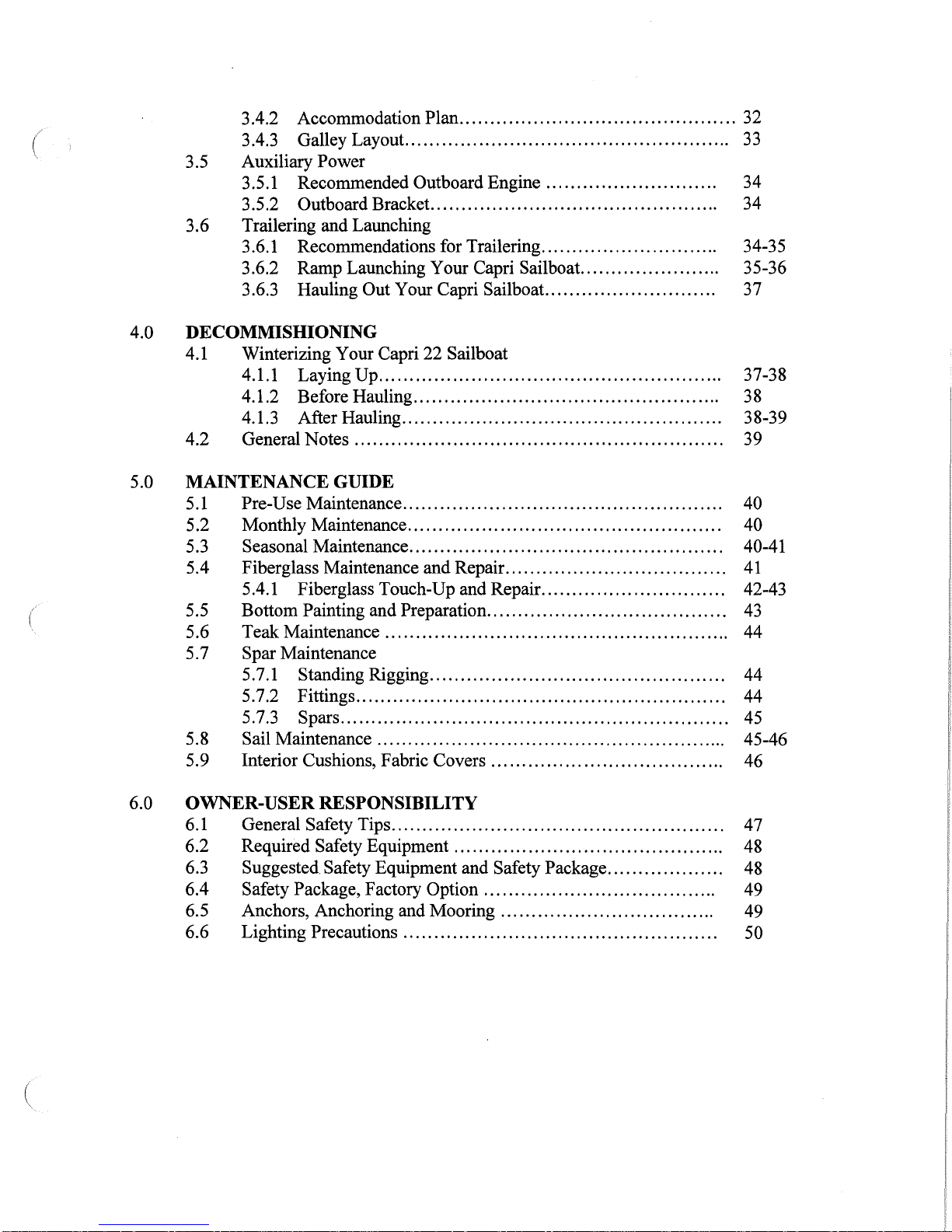

1.0

SPECIFICATIONS

1.1

Owner's

Record..........................................................

1.2 Reference Data

INDEX

Sheet....................................................

5

6

2.0 COMMSSIONING

2.1

Wing Keel

Model.........................................................

2.2 Pre-Launch Check

2.3

In The Water Check

2. 3 .1

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.2 Hull and

2.3.3 Rigging and

2.4 Sailing Check List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.0 Yacht Systems

3.1

Rigging

3.1.1 Stepping the

3 .1.2 Tuning the Mast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 RiggingtheBoom

3 .1.4 Bending on the

3.1.5 Bending on the

3

.1.

6 Rigging Length Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

.1.

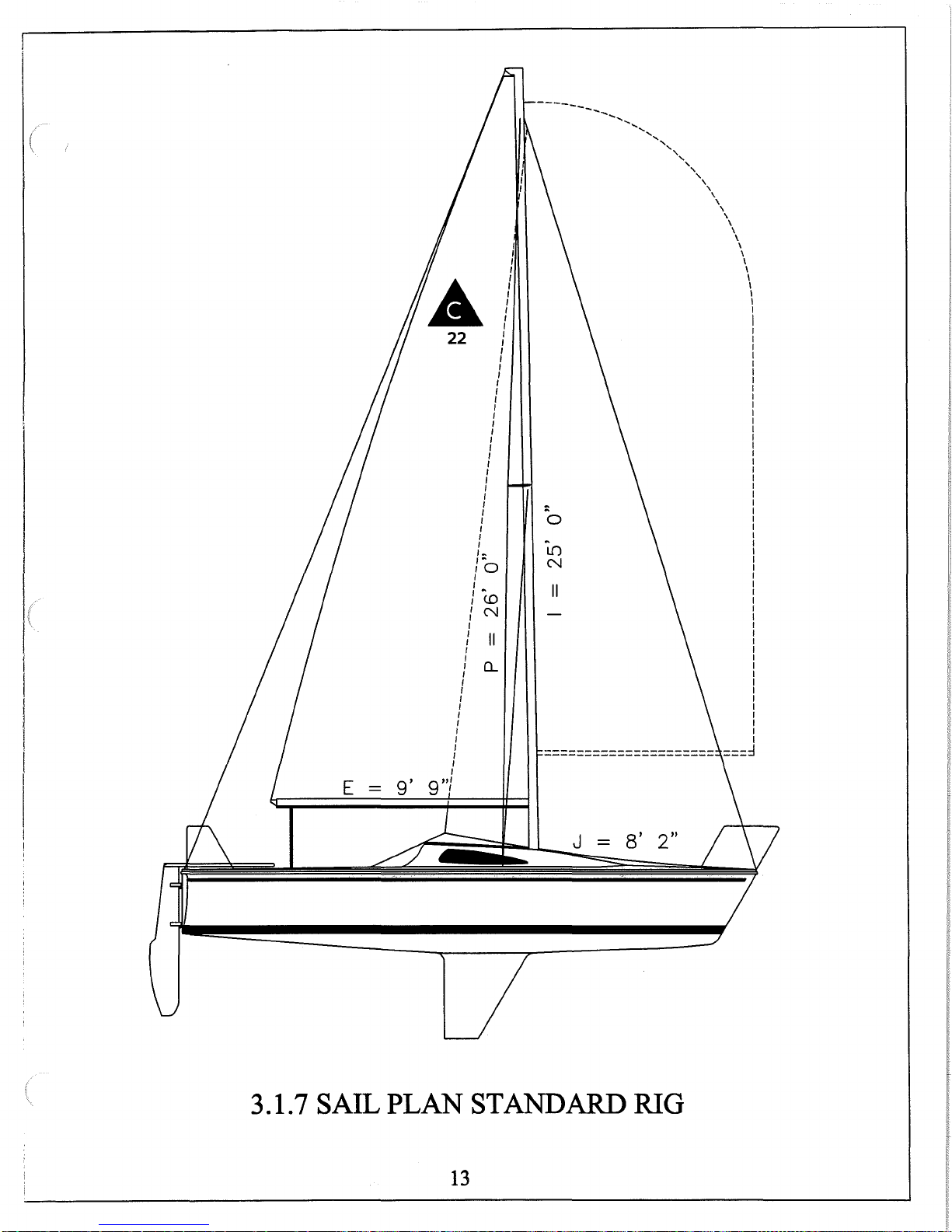

7 Sail Plan Standard Rig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

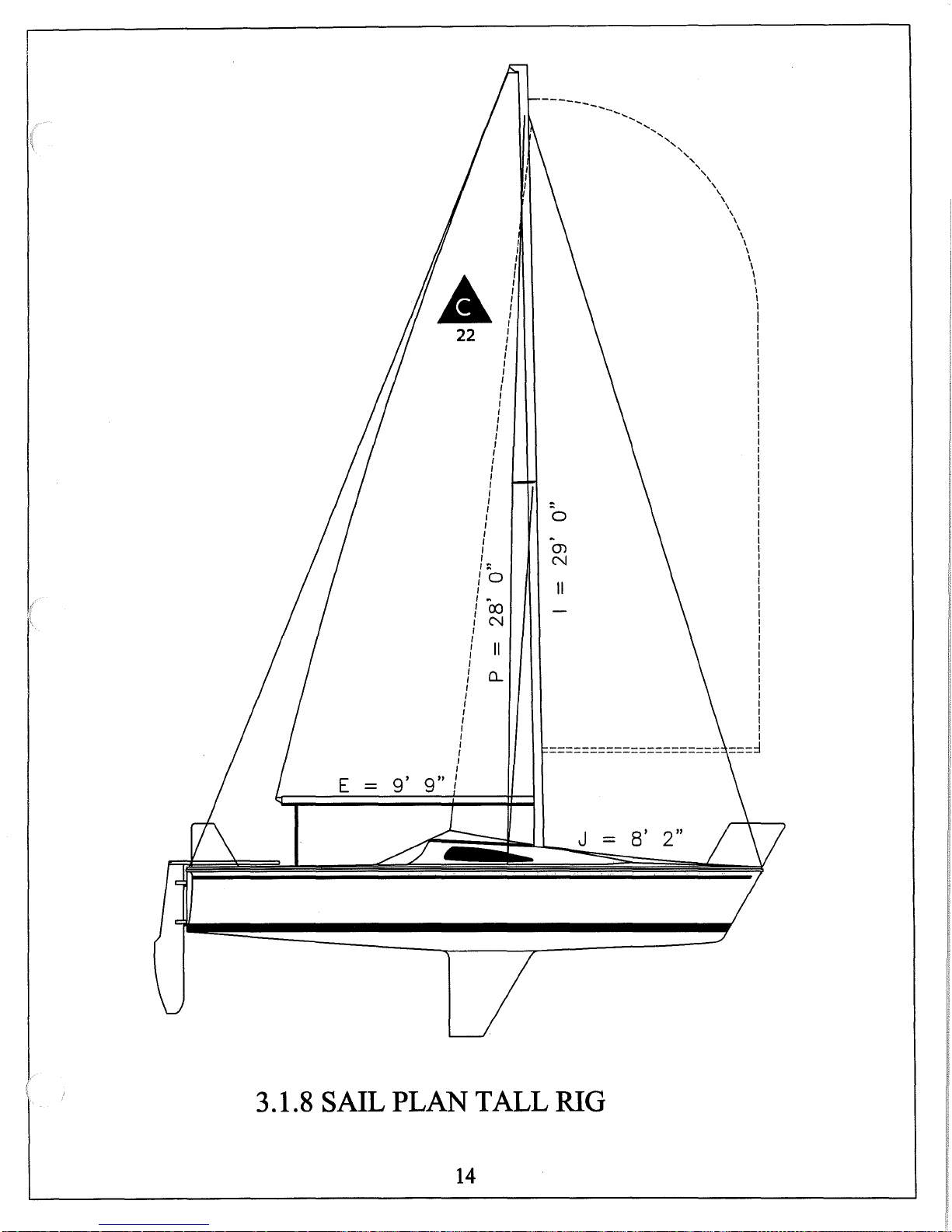

3.1.8 Sail Plan Tall

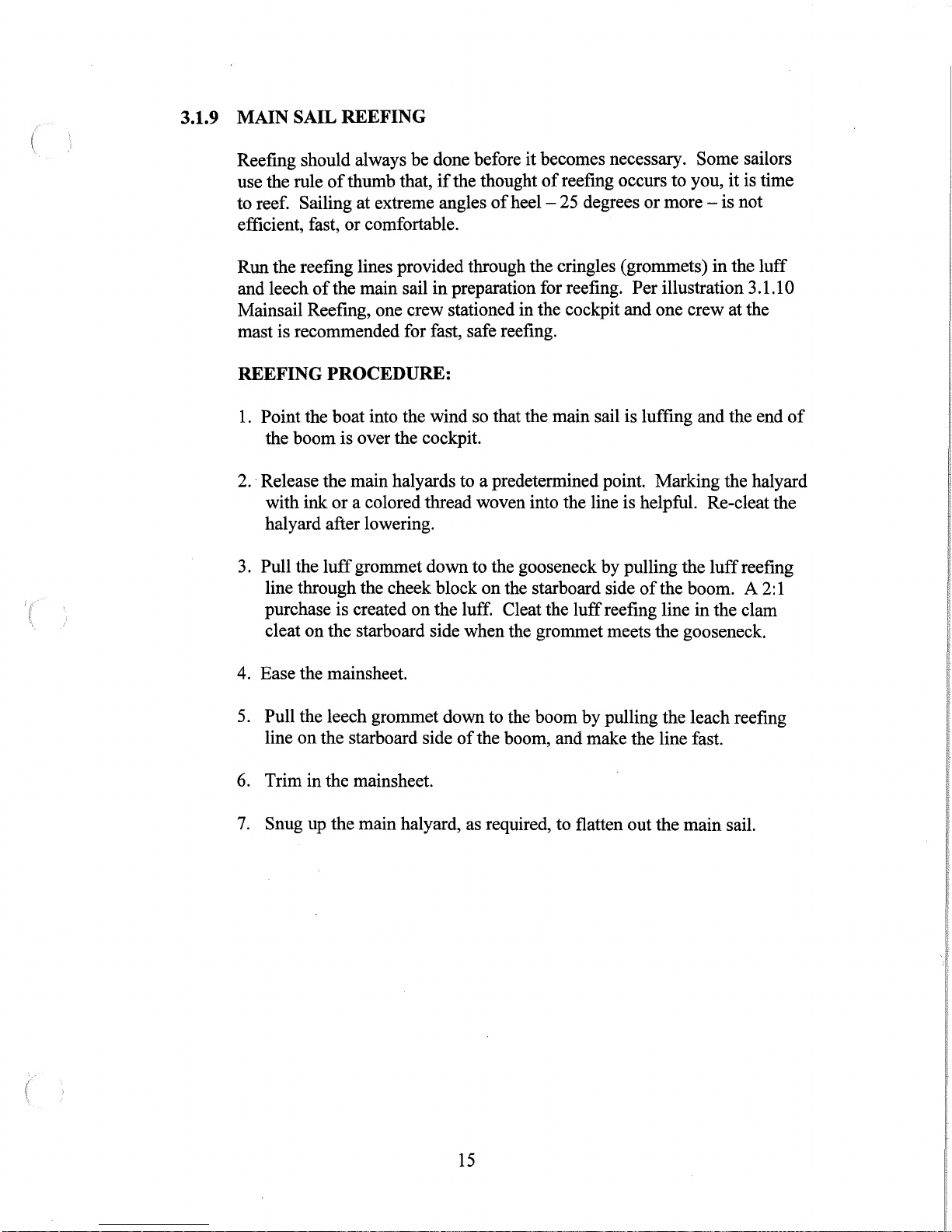

3.1.9 Main Sail

3

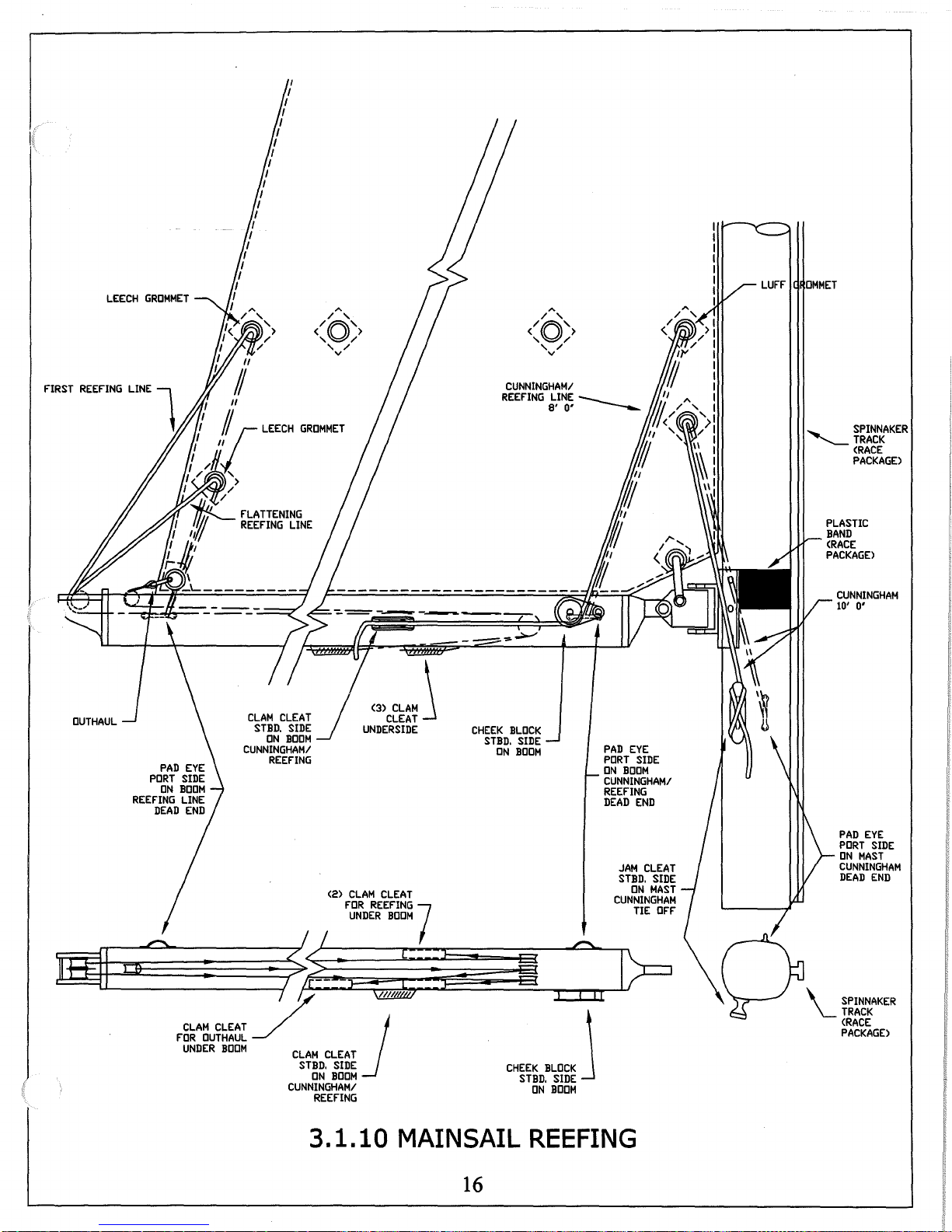

.1.1

0 Main Sail Reefing Illustration........................ . . . . . . . . .

3.1.11 Backstay Tensioner

3 .1.12 Mainsheet and V ang Arrangement... . . . . . . . . . . . . . . . . . . . . . . .

3 .1.13 Spreader

3.1.14 Control Arrangement Racing

3 .1.15 Deck Hardware Standard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 .1.16 Deck Hardware Racing...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 Sailing and Docking Tips

3.2.1

Hoisting and Setting

3.2.2 Positioning The Jib Fairlead

3.2.3 Boom Vang

3.2.4 Docking Under Various

3.2.5 Points

3.2.6 Rules

3.3

Electrical

3.3.1

3.3.2

Batteries..........................................................

12

Volt wiring

3.3.3 Electrical Panel

3.3.4 Navigation

3.4 Accommodation

3.4.1 Galley Unit, Equipment and

CHECK

LIST

List...................................................

List................................................

Deck...................................................

Hardware..........................................

..

Mast..............................................

..............................................

Mainsail.........................................

Jib..............................................

..

Rig..............................................

Reefing...............................................

Purchase..................................

Assembly........................

. . . . . . . . . . . . . . . . . . . . .

Package.......................

Sails.....................................

Blocks..........................

.......................................................

Conditions..........................

of

Sail....................................................

of

the Road (Partial List) ... . .. ... . .. . .. . . . .. . . .. . . . .. . 25-26

Diagram.......................................

Functions.....................................

Lights...............................................

Operation

........................

7

7

7

7

8

8

9

9-10

10

10-11

11

12

13

14

15

16

17

18

19

20

21

23

23

23

23-24

24-25

26-27

28

29-30

30

31

(

3.4.2 Accommodation Plan

3.4.3 Galley

3.5

3.6 Trailering and Launching

Auxiliary Power

3.5.1 Recommended Outboard

3.5.2 Outboard

3.6.1 Recommendations for Trailering. .. .. .. .. . .. . .. . .. .. . .. . .. ... 34-35

3.6.2 Ramp Launching Your Capri

3.6.3 Hauling

Layout.....................................................

Bracket...............................................

Out Your Capri

.............................................

Engine............................

Sailboat.......................

Sailboat............................

32

33

34

34

35-36

37

4.0

5.0

(

DECOMMISHIONING

4.1

4.2 General Notes

MAINTENANCE GUIDE

5.1

5.2 Monthly Maintenance

5.3

5.4 Fiberglass Maintenance and Repair

5.5 Bottom

5.6 Teak Maintenance

5.

5.8

5.9 Interior Cushions, Fabric Covers

Winterizing Your Capri

4.1.1

4.1.2 Before Hauling

.1. 3 After Hauling

4

Pre-Use Maintenance

Seasonal Maintenance

5.4.1

7 Spar Maintenance

5.

5.7.2 Fittings

5.7.3

Sail Maintenance

Laying Up

...........................................................

Fiberglass Touch-Up and Repair

Painting and Preparation

7.1

Standing Rigging

...........................................................

Spars

..............................................................

22

Sailboat

.......................................................

.................................................

...................................................

...................................................

..................................................

..................................................

......................................

.......................................................

...............................................

........................................................

.....................................

...................................

.............................

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

37-38

38

38-39

39

40

40

40-41

41

42-43

43

44

44

44

45

45-46

46

6.0 OWNER-USER RESPONSIBILITY

6.1

6.2 Required Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3

6.4 Safety Package, Factory Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

6.5

6.6 Lighting Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety

Suggested Safety Equipment and Safety

Anchors, Anchoring and

(

Tips......................................................

Package...................

Mooring...................................

47

..

48

48

49

49

50

REGISTRATION

DATE

OF

DR

DOCUMENTATION

COMMISSIONING

N'

YACHT

NAME

PORT

HULL

OF

CALL

NUMBER

(

0\o/NER'S

HULL

LENGTH

LENGTH

BEAM

FUEL CAPACITY

SAIL

OF

'vi

..........................................................................

AREA

MAIN

................................................................

TOTAL

..............................................

ATERLINE

................

(SQ.

FT.>

100%

'WI

NAME

......................................

MOLDED

FOR

FDRETRIANGLE

22'-0'

20'-0'

8'-2'

COMPARTMENT

A 6 GAL.

.......

TANK

STD.

127 137

229

TALL

255

DRAFT

DRAFT

DISPLACEMENT

DISPLACEMENT

FIN

KEEL

SHOAL

ENGINE

INSURANCE

0\.JNER'S

KEEL

FIN KEEL

SHOAL

ENGINE

INSURANCE

ADDRESS

11111UIIIIOIIIII1HO>IIIIOIIIIIHIIIIIHIIIIIHI

...............................................

............................

KEEL

.....................

MFG.

AND

SEAL

NUMBER

COMPANY

POLICY

MODEL

NUMBER

2200

2250

4'-0'

2'-8'

lbs.

lbs.

SAIL

(

NUMBER

5

RADIO

TELEPHONE

CALL

NUMBER

Capri

22

Specifications

Rev:

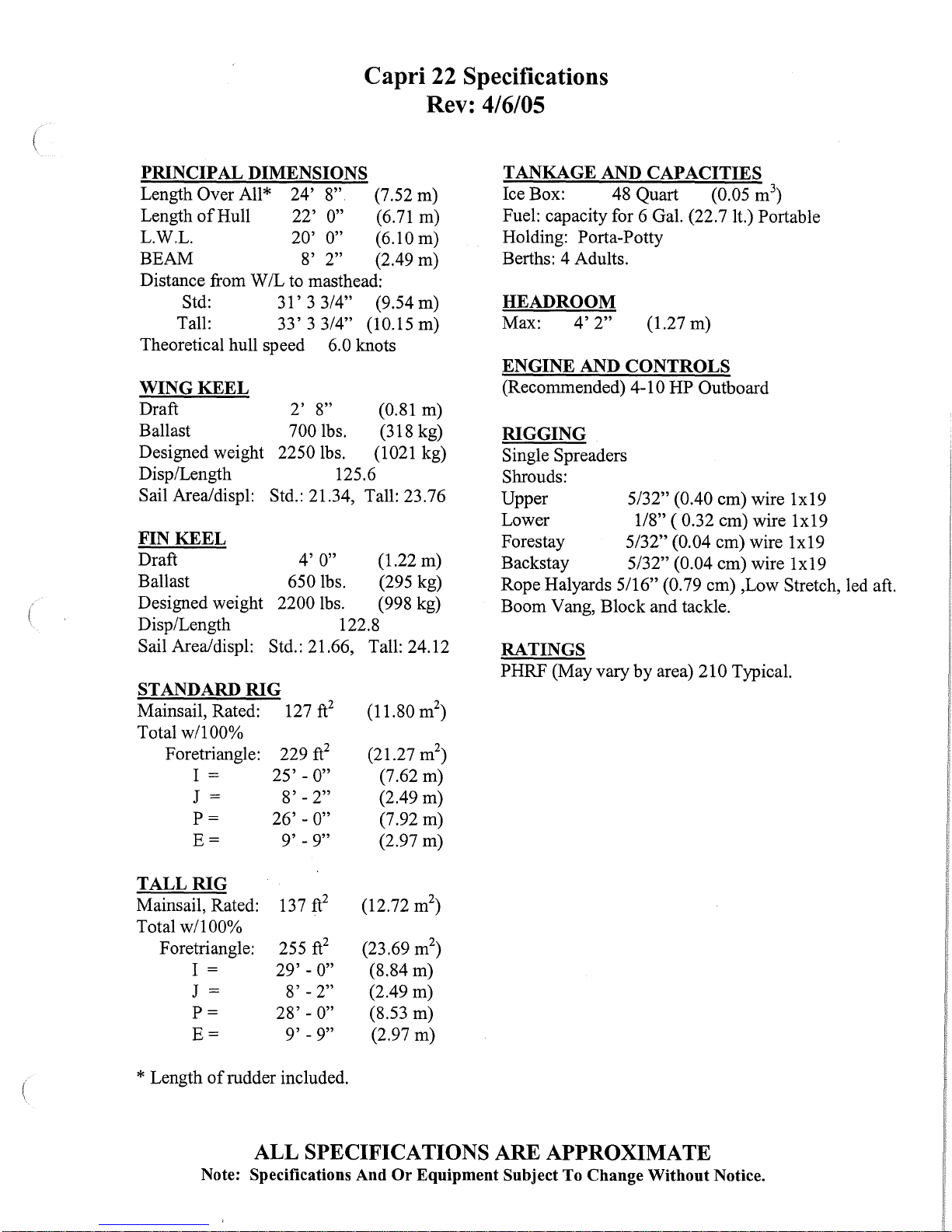

PRINCIPAL DIMENSIONS

Length Over All* 24' 8" (7.52 m)

Length ofHull 22'

0"

L.W.L. 20' 0" (6.10 m)

BEAM 8'

2" (2.49 m)

Distance from W /L to masthead:

Std: 31' 3 3/4" (9.54 m)

Tall: 33' 3

Theoretical hull speed

WING

KEEL

Draft

Ballast

Designed weight

3/4" (10.15 m)

6.0 knots

2'

8" (0.81

700 lbs. (318 kg)

2250 lbs. (1021 kg)

Disp/Length

Sail Arealdispl:

FIN

KEEL

Draft

Std.: 21.34, Tall: 23.76

4'

0" (1.22

Ballast 650 lbs. (295 kg)

2200

Designed weight

lbs.

Disp/Length 122.8

Sail Arealdispl: Std.: 21.66, Tall: 24.12

00%

RIG

25'-

26' - 0"

127

229

8'

9'

ft

2

ft

0"

- 2"

- 9"

2

STANDARD

Mainsail, Rated:

Total

w/1

F oretriangle:

I =

J =

P=

E=

125.6

(11.80 m

(21.27 m

(6.71

m)

m)

m)

(998 kg)

(7.62 m)

(2.49 m)

(7.92

m)

(2.97

m)

2

)

2

)

4/6/05

TANKAGE AND CAPACITIES

Ice Box:

48

Quart (0.05 m

Fuel: capacity for 6 Gal. (22.7 lt.) Portable

Holding: Porta-Potty

Berths: 4 Adults.

HEADROOM

Max:

ENGINE AND

4'

2"

(1.27 m)

CONTROLS

(Recommended) 4-10 HP Outboard

RIGGING

Single Spreaders

Shrouds:

Upper

Lower

Forestay

Backstay

Rope Halyards

5/32" (0.40 em) wire 1x19

1/8" ( 0.32 em) wire 1x19

5/32" (0.04 em) wire 1x19

5/32" (0.04 em) wire 1x19

5/16" (0.79 em) ,Low Stretch, led aft.

Boom Yang, Block and tackle.

RATINGS

PHRF (May vary by area)

210 Typical.

3

)

TALL

Mainsail, Rated:

RIG

137

ft

Total w/100%

F oretriangle:

I =

J = 8' - 2" (2.49

P=

E=

* Length

of

rudder included.

255

29' -

28'-

9'

ft

0"

0"

- 9"

ALL SPECIFICATIONS ARE APPROXIMATE

Note: Specifications And

2

2

(12.72 m

(23.69 m

(8.84 m)

m)

(8.53

m)

(2.97 m)

Or

Equipment Subject To Change Without Notice.

2

)

2

)

2.0 COMMISIDONING CHECK LIST

2.1

WING KEEL MODEL

The Capri 22 is available with a wing keel option. The wing keel decreases the

draft by approximately

of

The intent

and improve performance to weather.

of

weight and the effect

Generally wing keel boats tend to be stiffer, resist heeling, and are more stable both

at anchor and underway.

Wing keels tend to

so quickly as to loose flow over the keel and cause excessive leeway.

the wing keel design is to increase the effectiveness

1'

4"

and increases ballast weight

It

also increases the stability by the addition

of

the wing shape in the water.

tum

more quickly than fin keels, however you should not tack

by

approximately 50 lbs.

of

the keel foil

2.2 PRE-LAUNCH CHECK LIST:

____

1.

____

2.

3.

----

4.

----

5.

----

6.

---____

7.

____

(

8.

9.

10.

11.

12.

13.

____

____

__

____

____

Antifouling paint applied

Hull sides clean, gel coat OK.

Decks clean.

Teak cleaned and oiled.

Interior finished, oiled, and clean.

Cushions,

Hatch lids present and fit OK.

Lifelines and pulpits rigged and OK.

Spreaders taped and drilled at base end; upper shroud wired to tip end and taped.

Standing rigging pinned to mast.

___;_____

Rigging lengths verified with checklist

Mast boom inspected; cotter pins, sheaves, tangs, and spreaders OK.

Check overhead for electrical wires that may interfere with the space required

to raise the mast to its full upright position.

anywhere near the boat, do not raise the mast. Move boat to another location,

away from any wires. Contact with wire can be fatal.

galley-

clean and in place.

if

required.

in

kit.

If

there are wires

of

any kind,

2.3 WATER CHECK:

2.3.1 ELECTRICAL

1.

____

2.

____

3.

4. Check battery terminals for tightness.

2.3.2 HULL

1.

2.

3.

AND

____

Electrical equipment operational:

__

Check battery hold down.

Check battery fluid level.

Running Cabin

---

Master Panel

DECK

Main hatch: no leaks, slides freely; hatch boards fit OK.

Cabin windows, hose tested for leaks.

Forward hatch, hose tested for leaks.

7

2.3.3 RIGGING

1.

____

2.

3.

4.

5.

AND

HARDWARE

Mast stepped.

Pin, tape, and tune standing rigging.

Backstay adjuster, boom vang (if required).

Blocks, cars, cleats rigged, OK.

Test winches; winch handle present.

2.4 SAILING CHECK LIST

1.

____

2.

3.

4.

5.

6.

Tiller moves freely,

Sails and halyards, OK.

Boat performance under sail, OK.

All accessory equipment operates, OK.

All boat, engine, and accessory literature and/or manuals aboard.

Warranty cards completed and mailed, owner registration card attached,

owner informed

45

degrees minimum, to each side

of

warranty responsibilities.

of

center line.

8

3.0 YACHT SYSTEMS

3.1

RIGGING:

3.1.1 STEPPING

CAUTION: The aluminum and other metal parts conduct

electricity. Coming into contact with or near an electrical power line or

lightning can cause severe injury or death.

electrical power lines when sailing and/or launching the boat.

When trailering your boat, always

is necessary only to detach the forestay before lowering the mast.

1.

Before raising the mast, make sure halyards are neatly tied down and

that they are

to raise the mast unless the upper shrouds (those that pass over the

spreaders) and the aft lower shrouds are attached to the deck fittings and

the turnbuckles are well

must not be completely tightened, however, because slack is needed in

the shrouds to enable the mast to be fully raised. The backstay should be

attached to the transom chain plate. The upper shrouds, aft lower

shrouds, and backstay will keep the mast from falling over when it is

raised, therefore, all

the mast is raised.

THE

on

MAST:

proper sides

"started" into their barrels. The turnbuckles

of

these must be attached to the chain plates before

Stay away from overhead

try to undo as little rigging as possible.

of

the spreaders. You should never attempt

It

(

2. Make sure that the shrouds and stays are not fouled. Backstay should lie

clear

in

the water. It seems to be easier

stable. Also, it keeps other sailors form getting impatient while they

wait for you to move out

3.

Walk the mast aft and drop the mast foot into the mast step located

top

of

bolt and locking nut.

4.

One crew member should pull

while another pushes up

forward. With the mast erect, attach the forestay.

3.1.2 TUNING

Your mast is held aloft by the standing rigging (forestay, backstay,

upper shrouds, and aft, lower shrouds). The term

adjustment

of

the transom. You may step the mast on land or while the boat is

on

land because the boat is more

of

the launch area.

the deck, keeping the mast in centerline

on

a line tied securely to the forestay

on

the mast and walks from the cockpit

THE

MAST:

of

the standing rigging so that the mast remains

ofboat,

"tuning" refers to

insert the pivot

"in

column" (not

on

9

bent) when under load. This is accomplished by following the procedure

outlined below:

AT THE DOCK:

1.

Adjust forestay and backstay so that the mast is straight

Tie a bolt to a 6 to 7 foot long piece

of

bob, and tape the free end

as you can reach. This device will help

mast is perpendicular or not.

of

a building.

2. Adjust the upper shrouds so that the mast is deflected forward at the

spreaders, approximately 3 inches. This is called

should not

3. The upper shrouds should

upper shroud about 1" at shoulder height.

4. The aft lower shrouds (2

tighter than the upper shrouds. The lowers shrouds should be tensioned

equally until the middle

1-1

Y:z''.

middle

the mast aft, stabilize the mast and prevent "pumping" or excessive

movement

be

deflected sideways or athwartship.

The dynamic tension created by the spreaders pushing the

of

the mast forward and the lower shrouds pulling the middle

of

the middle

the line to the front

Otherwise, sight your mast with a comer

be

firm. A 50 pound push should deflect the

of

them) should be adjusted so that they are

of

the mast is pulled aft to reduce the prebend to

of

the mast fore and aft, when sailing.

of

light line to make a quick plumb

of

you

to determine whether the

"prebend". The mast

up

and down.

the mast as high up

of

3.1.3 RIGGING THE BOOM

1.

Attach the mainsheet block with becket to the "outboard" or aft end

the boom.

2.

Shackle mainsheet fiddle block with cam-cleat to the backstay traveler.

3.

"Dead-end" tie the mainsheet to the becket on the block

and then

through the fiddle block pulleys and the block pulley. Tie a

eight"

while under sail.

"reeve" the mainsheet by passing the line back and forth

knot at end

of

mainsheet to keep from losing the end

3.1.4 BENDING ON THE MAINSAIL

1.

Feed the clew

gooseneck fitting and pulling out the end

if

done by two persons, one feeding and the other pulling out.

2. Insert tack

grommet. Release the outhaulline (starboard, aft clam cleat underside

of

boom) and attach the outhaul shackle to the clew (aft end)

Pull

in

the line to remove wrinkles and re-cleat.

of

the mainsail into the groove

pin

at the gooseneck fitting, passing the

on

the boom

"figure

of

mainsheet

on

the

boom

of

boom. This is much easier

pin

starting at

through the sail's

of

the sail.

of

(

10

3.

Insert the battens noting that the battens are different lengths. The

correct battens must be used, shorter ones at the head and longer ones at

the foot

Shackle headboard

4.

of

the sail.

of

the mainsail to the halyard. Look aloft to ensure

that halyard is not fouled.

..

Start headboard sail slug and insert all slugs under in the correct order,

5

pushing the sail up the mast slightly as you go. Insert the stop in the

track after all the sail slugs have been inserted.

on

the mast just above the sail feed slot in the mast. With the stop in

Secure the stop in place

place the sail can be lowered or reefed without the slugs coming out

the track on the mast. Sail is now ready for hoisting.

of

3.1.5 BENDING

1.

Find tack

to the stem fitting at the bow using a shackle.

2.

Connect

the top snap in sequence.

3.

Shackle head

halyard is running clear and not wrapped around the forestay or

spreader.

4. Find middle

the

jib

outside

fairlead blocks that have been previously attached to the tracks that are

located

the ends

when you tack.

5.

Boats equipped with the factory-supplied roller furling gear for the jib,

should read all instructions supplied with the furling gear, before

operating the furling unit. The sail will sheet to the cabin top in the

normal fashion.

6.

The optional genoa will sheet to the tracks

sheets should lead around the shrouds to the blocks on the tracks and aft

to the optional winches, figure-eight knots in the ends

recommended.

ON

THE JIB

of

sail-

this is the forward lower comer

jib

to forestay by starting at the bottom snap and working up to

of

jib

to rope halyard, again sighting aloft to ensure that

of

jib sheet line and attach the

sail. Run the

of

the shrouds. Pass the ends

on

the cabin top

of

the

jib

sheet lines back to the cockpit keeping them

of

the boat. Tie figure-eight stopping knots

jib

sheets to keep them from pulling through the blocks

of

the

jib

jib

on

of

jib. Fasten the sail

sheet lines to the clew

sheets through the jib

the cockpit coaming. The

of

the sheets are

of

in

11

STANDARD

RIG

EXTRUSION

28'-0"

I

d

TALL

RIG

EXTRUSION

30'-0"

I

CHECK

OVERHANG

LENGTHS

BEFORE

Sic_PPING

J r

I

STANDARD

TALL

TOP

FITTING

BOTTOM

FITTING

FORESTAY

-

I

1'-4

1/2"

T-BOLT

5/16"

STUD

\

UPPER

SHROUDS

-

l

0'-5

1/4"

T-BOLT

5/16"

STUD

\

l

LOWER

SHROUDS

-

o'-6"

T-BOLT

1/4"

STUD

\

I

I

69-3/8"

BACKSTAY

FIXED

(std.) I

-

3'

- 3

5/8"

EYE

5/16"

PIN

5/16"

STUD

\,

~~

1'

-7"

EYE

5/16"

PIN

FORK

1/4"

PIN

BACKSTAY

(opt.)

ADJUSTABLE

11

2

"

H-

\

1/8"

Wire

Pennan~~,~-

STANDING

RIGGING

.w/

SnaP.

Hook

N.P.

to backstay

DESCRIPTION

LENGTH

MATERIAL

QTY.

RUNNING

RIGGING

STD.

TALL

DESCRIPTION

MATERIAL

LENGTH

QTY.

BACKSTAY

FIXED

5/32"

WIRE

1x19

31'-5

5/8"

32'-11

3/8"

1

SPINN

TOPPING

LIFT

(Performance

Opt.)

5/16"

LOW

STRCH

4o'

o"

1

BACKSTAY ADJUSTABLE

(opt.)

5/32"

WIRE

1x19

26'-6" 27'-9"

1

BACKSTAY ADJUSTER

LINE

(Perf.

Opt.)

1/4"

DACRON

17' o"

1

FORESTAY

5/32"

WIRE

1x19

25'-5"

29'-5

3/4"

1

REEFING

LINE

(on

boom)

1/4"

DACRON

23'

0"

2

UPPER

SHROUDS

5/32"

WIRE

1x19

24'-2

1/2"

28'-2

3/4"

2

BOOM

VANG

LINE

5/16"

DACRON

28'

0"

1

LOWER

SHROUDS

1/8"

WIRE

1x19

12'-5

1/2"

14'-4

1/2"

2

~

FORE

GUY

(Performance

Option)

5/16"

DACRON

25'

0"

1

BACKSTAY PURCHASE

(opt.)

5/32"

WIRE

7x19

7'-8" 7'-8"

1

N

GENOA

SHEET

(150% Genoa

Option)

3/8"

DACRON

55'

o"

1

B.S. SAFETY PENNANT

(opt.)

1/8"

WIRE

1x19 P.C.

3'-9"

3'-9"

1

JIB

SHEET

(135%

Std.) (delete

w/

150 Opt.)

3/8"

DACRON

40'

0"

1

TRAVELER

CONTROL

LINES

1/4"

DACRON

13' o"

2

SPINNAKER SHEET

(Performance

Option)

5/16"

DACRON

50'

0"

2

HALYARDS

MAIN

SHEET

3/8"

DACRON

45'

o"

1

DESCRIPTION

MATERIAL

LENGTH

QTY.

OUTHAUL

(on

boom)

1/4"

DACRON

2o'

o"

1

STD.

TALL

CUNNINGHAM

1/4"

DACRON

1o' o"

1

MAINSAIL HAL

YARD

5/16"

LOW

STRETCH

64'-o"

70'-0"

1

CUNNINGHAM -REEFING

LINE

1/4"

DACRON

8'

o"

1

JIB

HALYARD

5/16"

LOW

STRETCH

57'-o"

61'-0"

1

SPINNAKER

HALYARD

(Perf. Opt.)

1 /

4"

LOW

STRETCH

60'-Q" 64'-Q"

1

BACKSTAY

PURCHASE

!---,

WIRE

BLOCK~

©&~~D

Sailboats

t})

~

21200 VICTORY

BLVD.

/.

TOGGLE

~

WOODLAND HILLS, CA.

91367-(818)884-

7700

BACKSTAY

SAFETY

PENNANT

SCALE:

NONE

APPROVED

BY:

DRAWN

BY

NOTES:

1)

TOLERANCES

±1/2"

DATE:

10-22-91

DANIEL

CASAL

2)

MEASUREMENTS

FROM

CENTER

OF

EYE

TO

CENTER

OF

EYE

OR

END

OF

STUD

TITLE:

REV.

18

FURLING

LINE

DELETED

FOR

COl

FF2

FURLING

6/28/04

RIGGING

LENGTH

REV.

17

B.S.

ADJ.

LINE

TO

1/4" x 17'

was

5/16" x 28'

1/19/04

REV.

16

BACKSTAY

ADJUSTER

LINE

TO

5/16"

was

3/8"

11/17/03

REV.

15

ADDED

FURLING

LINE

FOR

SCHAEFER

SNAP

FURLING

HULLS

1032 + 5/15/03

BOAT:

DRAWING

NUMBER

REV.

14

LABELED

LINES

FOR

OPTIONS

8.16.02

REV.

13

(2)

TRAVELER

LINES

13'

WAS

8'

7.26.02

HULL#

996 -UP

CAPRI

22

220-34001-18

REV.

12

(2)

REEFING

LINES

23'

WAS

1X17',

OUTHAUL

WAS

4'.

8.21.01

22

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I~

:a

I

I

!<D

fN

I

I

II

I

I

:()._

I

-------

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

,,

'-..

............................

,

'

'

'

'

'

\

'

\

\

\

\

\

I

\

I

I

I

I

I

I

I

I

I

0

L()

C'\1

II

3.1.7

SAIL

PLAN

13

J

STANDARD

8'

2"

RIG

-------

,,

.........................

,

'

'

'

'

\

'

\

'

\

'

\

\

\

\

I

I

I

I

I

\

I

22

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

ll:

/0

I

I

I

CX)

I

I

N

I

I

I

II

I

I

I

Q_

I

0

~

m

N

II

===========

3.1.8

E

SAIL

PLAN

14

TALL

J

-

RIG

8'

2"

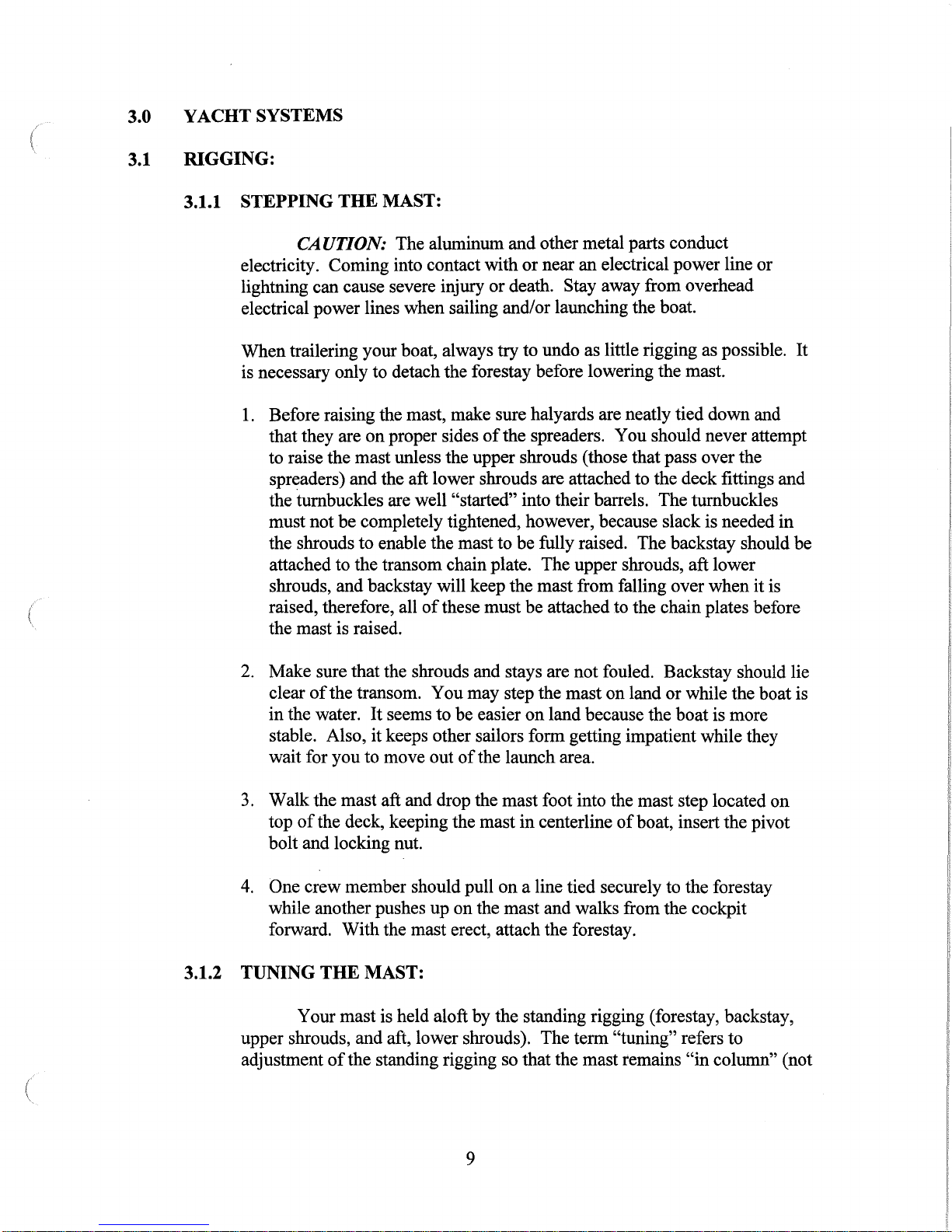

3.1.9 MAIN SAIL REEFING

Reefing should always be done before it becomes necessary. Some sailors

of

use the rule

thumb that,

to reef. Sailing at extreme angles

or

efficient, fast,

Run

the reefing lines provided through the cringles (grommets)

and leech

of

comfortable.

the main sail

Mainsail Reefing, one crew stationed in the cockpit and one crew at the

mast is recommended for fast, safe reefing.

REEFING PROCEDURE:

1.

Point the boat into the wind so that the main sail is luffing and the end

the

boom

2. Release the main halyards to a predetermined point. Marking the halyard

with ink

halyard after lowering.

3.

Pull the

line through the cheek block

purchase is created

cleat

is over the cockpit.

or

a colored thread woven into the line is helpful. Re-cleat the

luff

grommet down to the gooseneck

on

on

the starboard side when the grommet meets the gooseneck.

if

the thought

ofheel-

in

preparation for reefing.

on

the luff. Cleat the

of

reefing occurs to you,

25 degrees or

the starboard side

luff

more-

Per

illustration 3 .1.1 0

by

pulling the

of

the boom. A 2:1

reefing line

it

is

in

the

luff

in

the clam

is time

not

luff

of

reefing

4. Ease the mainsheet.

5.

Pull the leech grommet down to the boom

line

on

the starboard side

6. Trim

7.

in

the mainsheet.

Snug up the main halyard, as required, to flatten out the

of

the boom, and make the line fast.

by

pulling the leach reefing

main

sail.

15

I

F"IRST

LEECH

REEF"ING

GROMMET

LINE

LEECH

FLATTENING

REEF"ING

LINE

"'

/ '

/Q\

,y/

v

' /

GROMMET

"'

/ '

<O>

' / v

'-

SPINNAKER

-.........____TRACK

<RACE

PACKAGE>

Im...___l

:_:

CLAM

F"IlR

UNDER

<3)

CLAM

\

CLEAT

CLEAT

BOOM

j

CHEEK

STBD.

ON

BLOCK

SIDE

BOOM

CLAM

CLEAT

STBD.

SIDE

ON

BOOM

CUNNINGHAM/

REEF"ING

<2>

UNDERSIDE

CLAM

F"llR

REEF"ING

UNDER

7

•

----~·

CLEAT

OUTHAUL

BOOM

~i;,_

/

~

__/'

CLAM

CLEAT

STBD.

ON

CUNNINGHAM/

REEF"ING

=~~i

I

J~----

SIDE

BOOM

CHEEk

STBD.

PAD

EYE

PORT

ON

BOOM

CUNNINGHAM/

REEFING

DEAD

:I>=

"'"''

I

SIDE

BOOM

J

ON

SIDE

END

CUNNINGHAM

10'

0'

PAD

EYE

PORT

SIDE

ON

MAST

CUNNINGHAM

DEAD

END

~\_SPINNAKER

yu

TRACK

<RACE

PACKAGE>

3.1.10

MAINSAIL

16

REEFING

-

-l

P

URCHASE

BACKSTA! X

7'

8'

-----...__

SIS~~.

:IRE

7X19

---.._

RIVIT

'WI

COTTER

RING

RIVET

'WI

COTTER

PIN

-~~---------------------------------------------------------------------------

FORK

ON

BACKSTAY

'~

'-"-

'WIRE

BLOCK

BACKSTAY

_/

ADJUSTER LINE

318'

Ill X 28'

DACRON

FIDDLE

BLOCK

'WI

SAFTEY

PENNANT

118'

Ill X 3'

9'

r

PLASTIC

COATED

1X19

'WIRE

BECKET

AND

-----

CAM

CLEAT

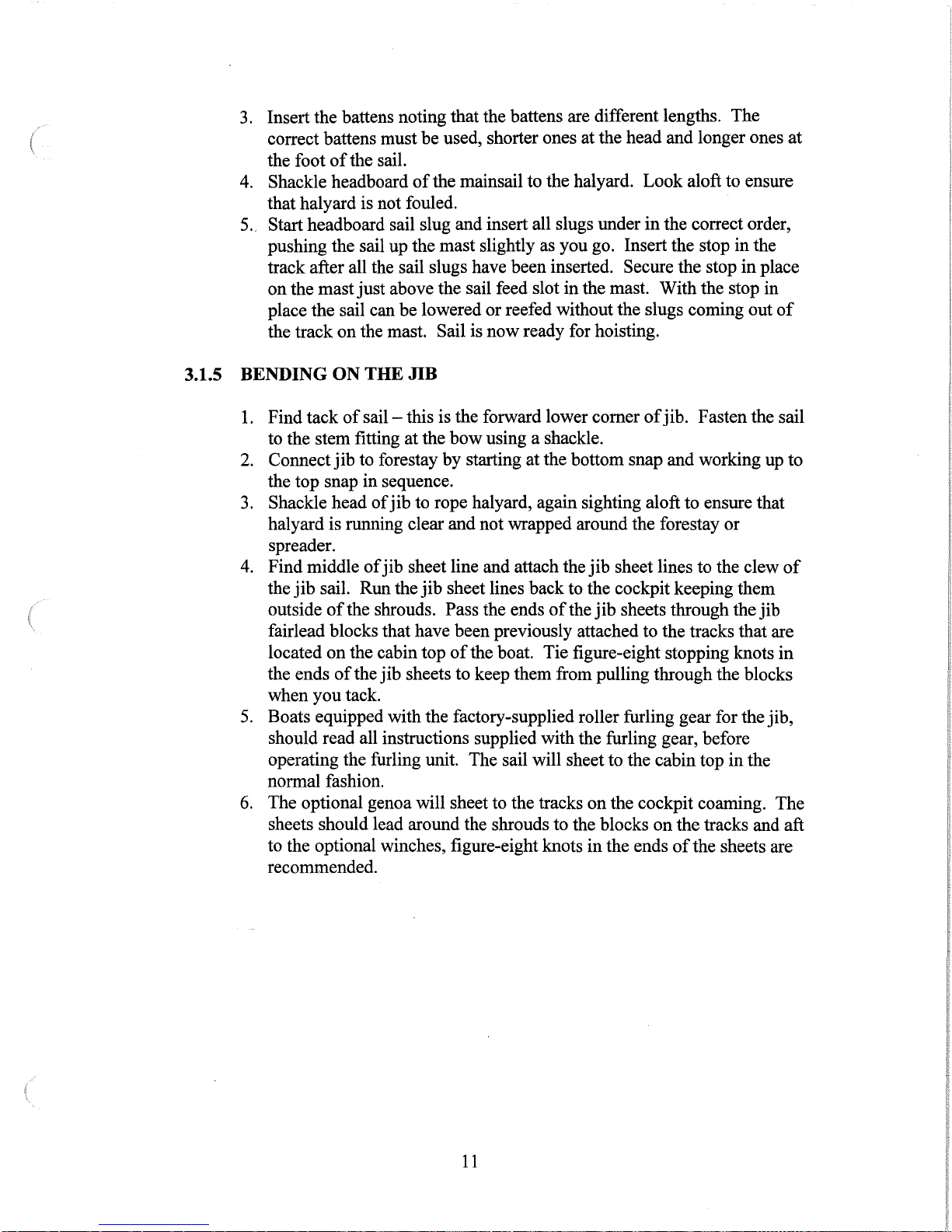

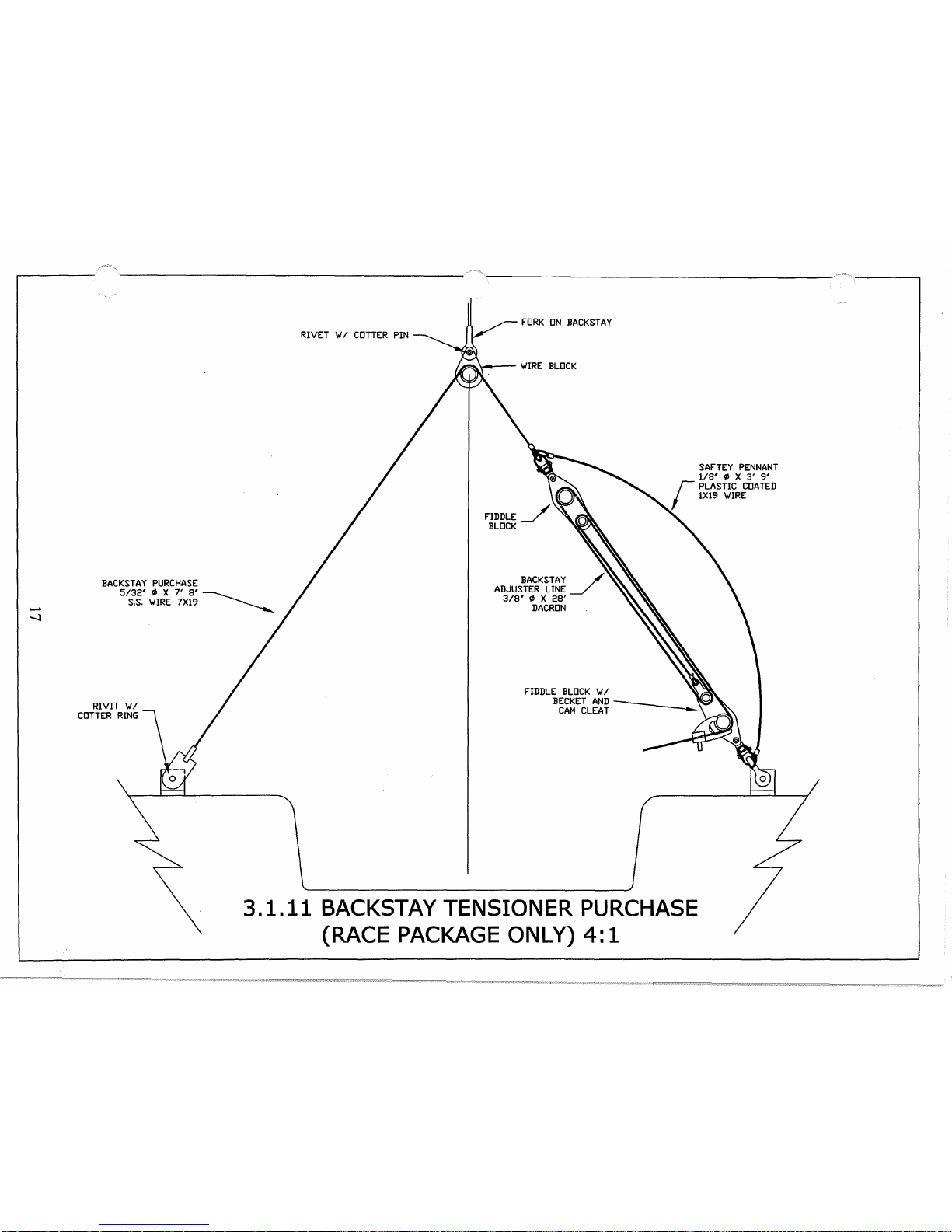

3.1.11

BACKSTAY TENSIONER PURCHASE

(RACE

PACKAGE

ONLY)

4:1

Loading...

Loading...