Page 1

320

Hydraulic Excavator

Technical Specifications

Congurations and features may vary by region. Please consult your Cat® dealer for availability in your area.

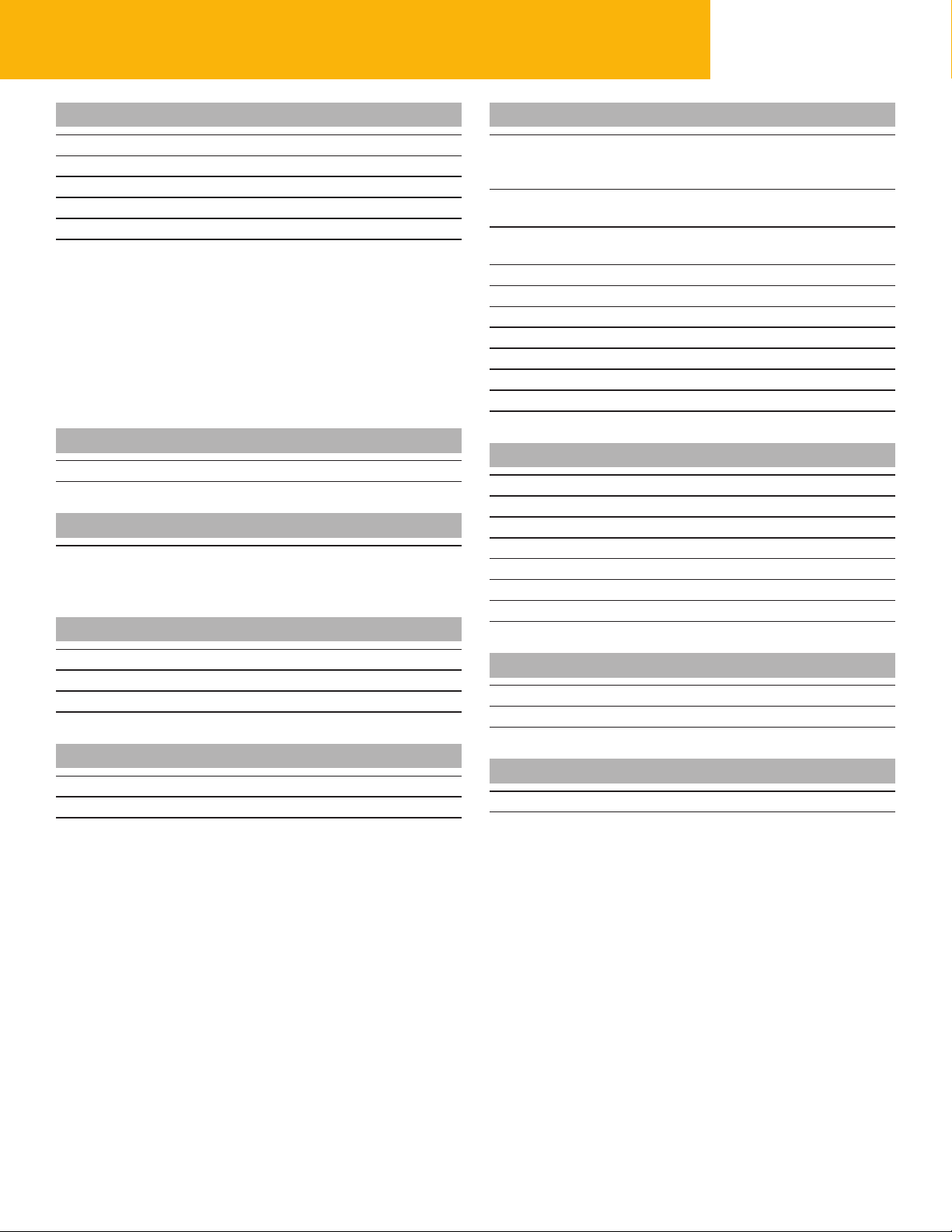

Table of Contents

Specications ..............................................................................................2

Engine ........................................................2

Swing Mechanism .............................................2

Weights.......................................................2

Track .........................................................2

Drive .........................................................2

Hydraulic System ..............................................2

Service Refill Capacities ........................................2

Standards.....................................................2

Sound Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Operating Weight and Ground Pressure...........................3

Major Component Weights ......................................3

Dimensions....................................................4

Working Ranges ...............................................5

Reach Boom Lift Capacities – Counterweight: 4.2 mt (9,300 lb) .......7

HD Reach Boom Lift Capacities – Counterweight: 4.7 mt (10,400 lb) ...8

Super Long Reach Boom Lift Capacities –

Counterweight: 4.7 mt (10,400 lb) ..............................9

Bucket Specifications and Compatibility .........................11

Attachments Offering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Thumb Specifications..........................................16

Standard and Optional Equipment ...........................................................................17

Dealer Installed Kit and Attachments ........................................................................20

Page 2

320 Hydraulic Excavator Specifications

Engine

Engine Model Cat® C4.4

Net Power (ISO 9249:2007) 128 kW 172 hp

Engine Power (ISO 14396:2002) 129 kW 174 hp

Bore 105 mm 4 in

Stroke 127 mm 5 in

Displacement 4.4 L 269 in

• The 320 meets U.S. EPA Tier 4 Final emission standards.

• Recommended for use up to 4500 m (14,764 ft) altitude with

engine power derate above 3000 m (9,842.5 ft).

• Net power is tested per ISO 14396:2002. Standards in effect at the

time ofmanufacture.

• Net power available at the ywheel when engine is equipped with

fan, air cleaner, aftertreatment, and alternator with engine speed at

2,200 rpm.

• Rated speed at 2,200 rpm.

Swing Mechanism

Swing Speed 11.30 rpm

Maximum Swing Torque 82 kN·m 60,300 lbf-ft

Weights

Operating Weight 22 500 kg 49,600 lb

• Reach boom, R2.9 (9'6") stick, HD 1.19 m (1.56 yd) bucket

790mm (31 in) triple grouser shoes, 4.2 t (10.400 lb) counterweight.

Track

Hydraulic System

Main System – Maximum Flow –

Implement

Maximum Pressure – Equipment –

Normal

Maximum Pressure – Equipment –

Lift Mode

Maximum Pressure – Travel 34 300 kPa 4,974 psi

Maximum Pressure – Swing 27 500 kPa 3,998 psi

Boom Cylinder – Bore 120 mm 4.7 in

Boom Cylinder – Stroke 1260 mm 49.6 in

Stick Cylinder – Bore 140 mm 5.5 in

Stick Cylinder – Stroke 1504 mm 59.2 in

Bucket Cylinder – Bore 120 mm 4.7 in

Bucket Cylinder – Stroke 1104 mm 43.5 in

429 L/min

(214.5 ×

2pumps)

35 000 kPa 5,075 psi

38 000 kPa 5,510 psi

113 gal/min

(56.5 ×

2pumps)

Service Refill Capacities

Fuel Tank Capacity 345 L 86.6 gal

Cooling System 25 L 6.6 gal

Engine Oil 15 L 4.0 gal

Swing Drive (each) 12 L 3.2 gal

Final Drive (each) 5 L 1.3 gal

Hydraulic System (including tank) 234 L 61.8 gal

Hydraulic Tank 115 L 30.4 gal

DEF Tank 39 L 10.3 gal

Standard Track Shoe Width 790 mm 31 in

Number of Shoes (each side) 49

Number of Track Rollers (each side) 8

Number of Carrier Rollers (each side) 2

Drive

Gradeability 35°/70%

Maximum Travel Speed 5.7 km/h 3.5 mph

Maximum Drawbar Pull –

Long Undercarriage

205 kN 45,996 lbf

Standards

Brakes ISO 10265: 2008

Cab/ROPS ISO 12117-2: 2008

FOGS (optional) ISO 10262-2: 1998

Sound Performance

ISO 6395:2008 (external) 99 dB(A)

ISO 6396:2008 ISO 6396 (inside cab) 70 dB(A)

• Hearing protection may be needed when operating with an open

operator station and cab (when not properly maintained or doors/

windows open) for extended periods or in a noisy environment.

2

Page 3

320 Hydraulic Excavator Specifications

Operating Weight and Ground Pressure

790 mm (31 in)

Triple Grouser Shoes

Weight Ground Pressure

4.2 mt (9,300 lb) Counterweight + Base Machine

Reach Boom + R2.9 (9'6") Stick + 1.19 m (1.56 yd) HD Bucket 22 500 kg 49,600 lb 35.5 kPa 5.2 psi

4.7 mt (10,400 lb) Counterweight + Base Machine

3

HD Reach Boom + HD R2.9 (9'6") Stick + 1.19 m

3

SLR Boom + SLR Stick + 0.53 m

All operating weights include a 90% fuel tank with 75 kg (165 lb) operator.

(0.69 yd3) GD Bucket 23 900 kg 52,700 lb 37.8 kPa 5.5 psi

Major Component Weights

Base Machine (with 4.2 mt [9,300 lb] counterweight, semi-HD swing frame, standard base frame with

HDtrack rollers and standard carrier rollers for long undercarriage, without boom cylinder – does not

include90% fuel and 75 kg [165 lb] operator)

Base Machine (with 4.7 mt [10,400 lb] counterweight, HD swing frame, HD base frame with SD track rollers

and SD carrier rollers for Long undercarriage without boom cylinder – does not include 90% fuel and 75kg

[165 lb] operator)

Track Shoes:

790 mm (31 in) Width, 10 mm (0.39 in) Thick Triple Grouser Track Shoes for Long Undercarriage

withStep Extension for ISO 2867:2011

Two Boom Cylinders 340 750

Weight of 90% Fuel Tank and 75 kg (165 lb) Operator 310 680

Counterweights:

4.2 mt Counterweight 4200 9,300

4.7 mt Counterweight 4700 10,400

Swing Frame:

Semi-HD Swing Frame 1910 4,210

Undercarriage:

Standard Base Frame with HD Track Rollers and Standard Carrier Rollers for Long Undercarriage 4390 9,700

Booms (including lines, pins, stick cylinder):

Reach Boom (5.7 m/18'8") 1710 3,800

HD Reach Boom (5.7 m/18'8") 2010 4,400

Super Long Reach Boom (8.85 m/29'0") 2170 4,800

Sticks (including lines, pins, bucket cylinder, bucket linkage):

Reach Stick (R2.9B1/9'6") 990 2,200

HD Thumb Ready Reach Stick (R2.9B1/9'6") 1300 2,900

Super Long Reach Stick (6.28A/20'7") 1340 3,000

Buckets (without linkage):

1.19 m (1.56 yd) HD 960 2,100

0.57 m (0.75 yd) Ditch Cleaning 390 900

Quick Coupler:

Pin Grabber QC 390 900

(1.56 yd3) HD Bucket 24 300 kg 53,600 lb 38.4 kPa 5.6 psi

kg lb

14 800 32,600

16 000 35,300

3370 7,400

3

Page 4

320 Hydraulic Excavator Specifications

2

Dimensions

All dimensions are approximate and may vary depending on bucket selection.

1

43

6

5

9

10

Boom Options HD Reach/Reach Boom SLR Boom

5.7 m (18'8") 8.85 m (29'0")

Stick Options HD TR Reach/Reach Stick SLR Stick

R2.9B1 (9'6") 6.28A (20'7")

Machine Height:

1

Top of Cab Height 2960 mm 9'9" 2960 mm 9'9"

Top of FOGS Height 3100 mm 10'2" 3100 mm 10'2"

Handrails Height 2950 mm 9'8" 2950 mm 9'8"

With Boom/Stick/Bucket Installed 3160 mm 10'4" 3190 mm 10'6"

With Boom/Stick Installed 2910 mm 9'7" 3070 mm 10'1"

With Boom Installed 2480 mm 8'2" 2650 mm 8'8"

Machine Length:

2

With Boom/Stick/Bucket Installed 9530 mm 31'3" 12 750 mm 41'10"

With Boom/Stick Installed 9500 mm 31'2" 12 760 mm 41'10"

With Boom Installed 8450 mm 27'9" 8920 mm 29'3"

Upperframe Width without Walkways 2780 mm 9'1" 2780 mm 9'1"

3

Tail Swing Radius 2830 mm 9'3" 2830 mm 9'3"

4

Counterweight Clearance 1050 mm 3'5" 1050 mm 3'5"

5

Ground Clearance 470 mm 1'7" 470 mm 1'7"

6

Track Length 4450 mm 14'7" 4450 mm 14'7"

7

Length to Center of Rollers 3650 mm 12'0" 3650 mm 12'0"

8

Track Gauge 2380 mm 7'9" 2380 mm 7'9"

9

Undercarriage Width:

10

790 mm (31 in) Shoes 3170 mm 10'5" 3170 mm 10'5"

Bucket Type HD Ditch Cleaning (DC)

Bucket Capacity 1.14 m 1.50 yd 0.57 m 0.75 yd

Bucket Tip Radius 1470 mm 4'10" 1070 mm 3'6"

8

7

4

Page 5

320 Hydraulic Excavator Specifications

m

)

15

10

20

10

15

20

25

30

35

ft

Working Ranges

All dimensions are approximate and may vary depending on bucket selection.

11

10

9

8

7

6

5

3

4

3

2

5

1

0

0

1

5

2

7

3

1

4

5

6

7

4

5

2

6

01234567891011 –1

05101520253035 ft

R2.9B1 (9'6"

m

Boom Option HD Reach/Reach Boom

5.7 m (18'8")

Stick Option HD TR Reach/Reach Stick

R2.9B1 (9'6")

Maximum Digging Depth 6620 mm 21'9"

1

Maximum Reach at Ground Line 9760 mm 32'0"

2

Maximum Cutting Height 9330 mm 30'7"

3

Maximum Loading Height 6590 mm 21'7"

4

Minimum Loading Height 2270 mm 7'5"

5

Maximum Depth Cut for 2440 mm (8'0") Level Bottom 6440 mm 21'2"

6

Maximum Vertical Wall Digging Depth 5360 mm 17'7"

7

Bucket Digging Force (ISO) 163 kN 36,711 lbf

Stick Digging Force (ISO) 109 kN 24,486 lbf

Bucket Type HD

Bucket Capacity 1.14 m 1.50 yd

Bucket Tip Radius 1470 mm 4'10"

5

Page 6

320 Hydraulic Excavator Specifications

m

)

ft

10

15

20

25

30

40

35

10

15

20

25

30

40

35

45

Working Ranges

All dimensions are approximate and may vary depending on bucket selection.

14

13

12

11

10

9

9

8

8

7

7

6

6

5

5

4

4

3

2

5

1

0

0

1

5

2

3

4

5

6

Boom Option SLR Boom

Stick Option SLR Stick

Maximum Digging Depth 11 540 mm 37'10"

1

Maximum Reach at Ground Line 15 570 mm 51'1"

2

Maximum Cutting Height 13 540 mm 44'5"

3

Maximum Loading Height 11 440 mm 37'6"

4

Minimum Loading Height 2240 mm 7'4"

5

Maximum Depth Cut for 2440 mm (8'0") Level Bottom 11 440 mm 37'6"

6

Maximum Vertical Wall Digging Depth 11 020 mm 36'2"

7

Bucket Digging Force (ISO) 62 kN 13,841 lbf

7

8

9

10

11

12

Stick Digging Force (ISO) 49 kN 10,966 lbf

Bucket Type Ditch Cleaning (DC)

Bucket Capacity 0.57 m 0.75 yd

Bucket Tip Radius 1070 mm 3'6"

3

4

5

2

6.28A (20'7"

7

1

121315 10 911

1416181920 17

35 304045 25 20 15 10 5–50506065 55

87654

6

3210 –2 –3–1

m

ft

8.85 m (29'0")

6.28A (20'7")

6

Page 7

320 Hydraulic Excavator Specifications

Reach Boom Lift Capacities – Counterweight: 4.2 mt (9,300 lb) – without Bucket, Heavy Lift: On

2.9 m (9'6")

R2.9B1

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft

7.5 m kg *4950 *4950 *4300 *4300 6.15

25.0 ft lb *9,500 *9,500 20.00

6.0 m kg *5450 *5450 *3950 *3950 7.29

20.0 ft lb *12,000 11,900 *8,750 *8,750 24.17

4.5 m kg *6000 5400 *5650 3850 *3900 3450 7.99

15.0 ft lb *13,050 11,600 *12,400 8,200 *8,550 7,650 26.67

3.0 m kg *8750 7850 *6900 5150 5750 3750 *4000 3150 8.36

10.0 ft lb *18,900 16,900 *14,950 11,150 12,350 8,000 *8,750 6,950 27.50

1.5 m kg *10 650 7350 7850 4950 5600 3600 *4250 3050 8.45

5.0 ft lb *22,950 15,850 16,850 10,650 12,100 7,800 *9,300 6,700 28.33

0 m kg *6600 *6600 *11 650 7100 7650 4800 5550 3550 *4700 3100 8.26

0 ft lb *15,150 *15,150 *25,200 15,250 16,450 10,300 11,900 7,600 *10,300 6,850 27.50

–1.5 m kg *7050 *7050 *11 400 *11 400 *11 750 7000 7550 4700 5500 3500 5250 3350 7.78

–5.0 ft lb *15,750 *15,750 *25,850 *25,850 *25,500 15,100 16,250 10,150 11,850 7,550 11,550 7,400 25.83

–3.0 m kg *12 100 *12 100 *15 600 13 650 *11 000 7050 7600 4750 6200 3950 6.95

–10.0 ft lb *27,100 *27,100 *33,800 29,200 *23,800 15,200 16,350 10,200 13,700 8,700 23.33

–4.5 m kg *12 500 *12 500 *9000 7250 *6800 5400 5.60

–15.0 ft lb *26,700 *26,700 *19,100 15,650 *14,950 12,150 18.33

5.7 m (18'8")

790 mm (31")

Triple Grouser Shoes

2380 mm (7'9")

3650 mm (12'0")

4450 mm (14'7")

m

ft

ISO 10567:2007

* Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity

standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Weight of all lifting accessories must be deducted from the

above lifting capacities. Lifting capacities are based on the machine standing on a firm, uniform supporting surface. The use of a work tool attachment point to

handle/lift objects, could affect the machine lift performance.

Lift capacity stays with ±5% for all available track shoes.

Always refer to the appropriate Operation and Maintenance Manual for specific product information.

7

Page 8

320 Hydraulic Excavator Specifications

HD Reach Boom Lift Capacities – Counterweight: 4.7 mt (10,400 lb) – without Bucket, Heavy Lift: On

2.9 m (9'6")

HD

R2.9B1-

TRS

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft

7.5 m kg *4900 *4900 *4250 *4250 6150

25.0 ft lb *9,400 *9,400 19'9"

6.0 m kg *5350 *5350 *3900 *3900 7290

20.0 ft lb *11,750 *11,750 *8,650 *8,650 23'8"

4.5 m kg *5900 5700 *5500 4000 *3850 3600 7990

15.0 ft lb *12,800 12,200 *12,100 8,600 *8,450 8,000 26'1"

3.0 m kg *8600 8300 *6750 5450 *5900 3900 *3950 3300 8360

10.0 ft lb *18,500 17,850 *14,650 11,700 *12,850 8,400 *8,600 7,250 27'4"

1.5 m kg *10 400 7750 *7650 5200 5900 3800 *4150 3200 8450

5.0 ft lb *22,450 16,650 *16,600 11,150 12,650 8,150 *9,150 7,000 27'8"

0 m kg *6750 *6750 *11 400 7450 8000 5000 5750 3700 *4600 3250 8260

0 ft lb *15,450 *15,450 *24,700 16,000 17,200 10,750 12,400 7,950 *10,150 7,100 27'1"

–1.5 m kg *7200 *7200 *11 650 *11 650 *11 500 7350 7900 4900 5750 3650 *5400 3500 7780

–5.0 ft lb *16,050 *16,050 *26,450 *26,450 *24,950 15,800 17,000 10,600 12,350 7,900 *11,950 7,700 25'5"

–3.0 m kg *12 350 *12 350 *15 300 14 300 *10 800 7400 7950 4950 6450 4100 6950

–10.0 ft lb *27,750 *27,750 *33,100 30,650 *23,300 15,950 17,100 10,650 14,300 9,100 22'8"

–4.5 m kg *12 150 *12 150 *8750 7650 *6600 5650 5600

–15.0 ft lb *26,050 *26,050 *18,600 16,450 *14,500 12,700 18'0"

5.7 m (18'8")

790 mm (31")

Triple Grouser Shoes

2380 mm (7'9")

3650 mm (12'0")

4450 mm (14'7")

m

ft

ISO 10567:2007

* Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity

standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Weight of all lifting accessories must be deducted from the

above lifting capacities. Lifting capacities are based on the machine standing on a firm, uniform supporting surface. The use of a work tool attachment point to

handle/lift objects, could affect the machine lift performance.

Lift capacity stays with ±5% for all available track shoes.

Always refer to the appropriate Operation and Maintenance Manual for specific product information.

8

Page 9

320 Hydraulic Excavator Specifications

Super Long Reach Boom Lift Capacities – Counterweight: 4.7 mt (10,400 lb) – without Bucket

6.28 m (20'7")

Super

Long

Reach

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft

12.0 m kg *1300 *1300 10.35

40.0 ft lb *2,850 *2,850 33.33

10.5 m kg *1200 *1200 11.66

35.0 ft lb *2,600 *2,600 38.33

9.0 m kg *1150 *1150 12.66

30.0 ft lb *2,500 *2,500 41.67

7.5 m kg *1100 *1100 13.41

25.0 ft lb *2,450 *2,450 44.17

6.0 m kg *1100 *1100 13.97

20.0 ft lb *2,400 *2,400 45.83

4.5 m kg *1100 *1100 14.34

15.0 ft lb *2,450 *2,450 47.50

3.0 m kg *4700 *4700 *6050 *6050 *4450 *4450 *3600 *3600 *1150 *1150 14.55

10.0 ft lb *11,900 *11,900 *12,900 *12,900 *9,600 *9,600 *7,800 *7,800 *2,500 *2,500 48.33

1.5 m kg *6750 6550 *5250 4500 *4100 3350 *1200 1150 14.60

5.0 ft lb *16,000 14,150 *11,300 9,750 *8,900 7,200 *2,600 2,500 48.33

0 m kg *2050 *2050 *4700 *4700 *5900 4100 *4550 3050 *1300 1100 14.49

0 ft lb *4,550 *4,550 *10,750 *10,750 *12,700 8,800 *9,800 6,600 *2,800 2,450 47.50

–1.5 m kg *2100 *2100 *2750 *2750 *4650 *4650 *6250 3800 *4850 2850 *1400 1150 14.23

–5.0 ft lb *4,600 *4,600 *6,100 *6,100 *10,550 *10,550 *13,550 8,150 *10,450 6,150 *3,000 2,450 46.67

–3.0 m kg *2850 *2850 *3550 *3550 *5200 *5200 *6450 3650 4750 2750 *1500 1200 13.79

–10.0 ft lb *6,350 *6,350 *7,900 *7,900 *11,750 11,750 *13,900 7,850 10,200 5,850 *3,300 2,550 45.83

–4.5 m kg *3700 *3700 *4450 *4450 *6100 5500 *6400 3650 4700 2700 *1700 1250 13.17

–15.0 ft lb *8,200 *8,200 *9,900 *9,900 *13,750 11,800 *13,800 7,800 10,050 5,750 *3,800 2,750 43.33

–6.0 m kg *4550 *4550 *5450 *5450 *7250 5600 *6150 3650 4700 2700 *2000 1400 12.34

–20.0 ft lb *10,150 *10,150 *12,200 *12,200 *16,350 12,050 *13,250 7,900 10,100 5,800 *4,500 3,100 40.83

–7.5 m kg *5500 *5500 *6600 *6600 *7300 5800 *5650 3800 *4550 2750 *2550 1650 11.24

–25.0 ft lb *12,300 *12,300 *14,850 *14,850 *15,650 12,500 *12,150 8,150 *9,800 5,950 *5,700 3,650 36.67

–9.0 m kg *8000 *8000 *6150 6100 *4850 3950 *3950 2900 *2700 2100 9.80

–30.0 ft lb *17,500 *17,500 *13,100 *13,100 *10,350 8,550 *8,300 6,300 *5,900 4,700 31.67

8.85 m (29'0")

790 mm (31")

Triple Grouser Shoes

2380 mm (7'9")

3650 mm (12'0")

4450 mm (14'7")

m

ft

ISO 10567:2007

* Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity

standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Weight of all lifting accessories must be deducted from the

above lifting capacities. Lifting capacities are based on the machine standing on a firm, uniform supporting surface. The use of a work tool attachment point to

handle/lift objects, could affect the machine lift performance.

Lift capacity stays with ±5% for all available track shoes.

Always refer to the appropriate Operation and Maintenance Manual for specific product information.

(continued on next page)

9

Page 10

320 Hydraulic Excavator Specifications

Super Long Reach Boom Lift Capacities – Counterweight: 4.7 mt (10,400 lb) – without Bucket (continued)

6.28 m (20'7")

Super

Long

Reach

9.0 m/30.0 ft 10.5 m/35.0 ft 12.0 m/40.0 ft 13.5 m/45.0 ft

12.0 m kg *1300 *1300 10.35

40.0 ft lb *2,850 *2,850 33.33

10.5 m kg *2200 *2200 *1200 *1200 11.66

35.0 ft lb *4,750 *4,750 *2,600 *2,600 38.33

9.0 m kg *2200 *2200 *2000 2000 *1150 *1150 12.66

30.0 ft lb *4,800 *4,800 *3,700 *3,700 *2,500 *2,500 41.67

7.5 m kg *2250 *2250 *2250 1950 *1100 *1100 13.41

25.0 ft lb *4,950 *4,950 *4,900 4,150 *2,450 *2,450 44.17

6.0 m kg *2400 *2400 *2300 1900 *1850 1500 *1100 *1100 13.97

20.0 ft lb *5,200 *5,200 *5,000 4,050 *3,250 3,100 *2,400 *2,400 45.83

4.5 m kg *2800 *2800 *2600 2350 *2400 1850 *2300 1450 *1100 *1100 14.34

15.0 ft lb *6,050 *6,050 *5,600 5,000 *5,250 3,900 *4,650 3,050 *2,450 *2,450 47.50

3.0 m kg *3100 2800 *2800 2200 *2550 1750 2300 1400 *1150 *1150 14.55

10.0 ft lb *6,750 6,000 *6,050 4,700 *5,550 3,700 4,900 2,950 *2,500 *2,500 48.33

1.5 m kg *3450 2600 *3000 2050 *2700 1650 2250 1350 *1200 1150 14.60

5.0 ft lb *7,450 5,550 *6,500 4,350 5,800 3,500 4,800 2,800 *2,600 2,500 48.33

0 m kg *3750 2400 3200 1900 2600 1550 2200 1250 *1300 1100 14.49

0 ft lb *8,050 5,150 6,800 4,100 5,600 3,300 4,650 2,700 *2,800 2,450 47.50

–1.5 m kg 3800 2250 3050 1800 2550 1500 2150 1250 *1400 1150 14.23

–5.0 ft lb 8,150 4,800 6,600 3,850 5,450 3,150 4,600 2,600 *3,000 2,450 46.67

–3.0 m kg 3700 2150 3000 1750 2500 1450 2100 1200 *1500 1200 13.79

–10.0 ft lb 7,950 4,600 6,400 3,700 5,350 3,050 *3,700 2,600 *3,300 2,550 45.83

–4.5 m kg 3650 2100 2950 1700 2450 1400 *1700 1250 13.17

–15.0 ft lb 7,850 4,500 6,350 3,650 5,300 3,050 *3,800 2,750 43.33

–6.0 m kg 3650 2100 2950 1700 2500 1450 *2000 1400 12.34

–20.0 ft lb 7,850 4,500 6,400 3,700 *5,150 3,150 *4,500 3,100 40.83

–7.5 m kg 3700 2150 3050 1800 *2550 1650 11.24

–25.0 ft lb *8,000 4,650 *6,450 3,850 *5,700 3,650 36.67

–9.0 m kg *3150 2300 *2700 2100 9.80

–30.0 ft lb *6,550 5,000 *5,900 4,700 31.67

8.85 m (29'0")

790 mm (31")

Triple Grouser Shoes

2380 mm (7'9")

3650 mm (12'0")

4450 mm (14'7")

m

ft

ISO 10567:2007

* Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity

standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Weight of all lifting accessories must be deducted from the

above lifting capacities. Lifting capacities are based on the machine standing on a firm, uniform supporting surface. The use of a work tool attachment point to

handle/lift objects, could affect the machine lift performance.

Lift capacity stays with ±5% for all available track shoes.

Always refer to the appropriate Operation and Maintenance Manual for specific product information.

10

Page 11

Bucket Specifications and Compatibility

320 Hydraulic Excavator Specifications

4.2 m ton

(9,300lb)

Counterweight

Width Capacity Weight Fill

Linkage

Pin-On (No Quick Coupler)

General Duty Capacity B 600 24 0.55 0.72 620 1,366 100

B 750 30 0.75 0.98 717 1,580 100

B 900 36 0.95 1.24 793 1,747 100

B 1050 42 1.16 1.52 848 1,869 100

B 1200 48 1.38 1.80 924 2,038 100

B 1350 54 1.59 2.08 1002 2,210 100

General Duty Capacity –

WideTip

Heavy Duty B 600 24 0.46 0.60 647 1,426 100

Heavy Duty Power B 1050 42 0.96 1.26 898 1,980 100

Severe Duty B 600 24 0.46 0.61 683 1,506 90

Severe Duty Power B 900 36 0.79 1.03 853 1,881 90

Clean Up B 1800 72 1.60 2.09 979 2,157 100

Ditch Cleaning B 1500 60 1.01 1.32 651 1,436 100

Ditch Cleaning Tilt B 1500 60 0.90 1.18 948 2,090 100

Tamping B 2200 86 0.72 0.94 868 1,913 100

General Duty 312 900 36 0.53 0.69 403 888 100

Ditch Cleaning 312 1200 48 0.57 0.74 386 851 100

The above loads are in compliance with hydraulic excavator standard EN474-5:2006 + A3:2013,

they do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity with front linkage

fully extended at ground line with bucket curled.

Capacity based on ISO 7451:2007.

Bucket weight with General Duty tips.

Caterpillar recommends using appropriate work tools to maximize the value customers receive from our products. Use of work tools, including buckets, which are

outside of Caterpillar’s recommendations or specifications for weight, dimensions, flows, pressures, etc. may result in less-than-optimal performance, including

but not limited to reductions in production, stability, reliability, and component durability. Improper use of a work tool resulting in sweeping, prying, twisting and/or

catching of heavy loads will reduce the life of the boom and stick.

B 600 24 0.55 0.72 617 1,360 100

B 750 30 0.75 0.98 715 1,576 100

B 900 36 0.95 1.24 791 1,743 100

B 1050 42 1.16 1.52 861 1,899 100

B 1200 48 1.38 1.80 938 2,069 100

B 1350 54 1.59 2.08 1016 2,241 100

B 750 30 0.64 0.84 752 1,658 100

B 900 36 0.81 1.06 835 1,841 100

B 1050 42 1.00 1.31 892 1,967 100

B 1200 48 1.19 1.56 975 2,150 100

B 1350 54 1.38 1.81 1060 2,336 100

B 1200 48 1.14 1.49 983 2,167 100

B 750 30 0.64 0.84 795 1,753 90

B 900 36 0.81 1.06 885 1,950 90

B 1050 42 1.00 1.31 948 2,091 90

B 1200 48 1.19 1.56 1038 2,289 90

B 2000 78 1.76 2.31 1045 2,303 100

B 1800 72 1.24 1.62 739 1,630 100

B 1800 72 1.11 1.45 1063 2,344 100

B 1800 72 1.40 1.83 1105 2,437 100

B 2000 79 1.23 1.61 1132 2,496 100

B 2200 86 0.90 1.18 891 1,965 100

mm in m

Maximum load with pin-on (payload + bucket) kg 3010 3245 800

3

3

yd

kg lb % R2.9 (9'6")

lb 6,636 7,154 1,764

Reach Reach HD

X X

X X

Maximum Material Density:

2100 kg/m3 (3,500 lb/yd3)

1800 kg/m3 (3,000 lb/yd3)

1500 kg/m3 (2,500 lb/yd3)

1200 kg/m3 (2,000 lb/yd3)

900 kg/m3 (1,500 lb/yd3)

Not Recommended

X

4.7 m ton

(10,400lb)

Counterweight

R2.9 (9'6")

HDTRS

SLR

(continued on next page)

11

Page 12

320 Hydraulic Excavator Specifications

Bucket Specifications and Compatibility (continued)

4.2 m ton

(9,300lb)

Counterweight

Width Capacity Weight Fill

Linkage

With Cat Pin Grabber Coupler

General Duty Capacity B 600 24 0.55 0.72 620 1,366 100

B 750 30 0.75 0.98 717 1,580 100

B 900 36 0.95 1.24 793 1,747 100

B 1050 42 1.16 1.52 848 1,869 100

B 1200 48 1.38 1.80 924 2,038 100

B 1350 54 1.59 2.08 1002 2,210 100

General Duty Capacity –

WideTip

Heavy Duty B 600 24 0.46 0.60 647 1,426 100

Heavy Duty Power B 1050 42 0.96 1.26 898 1,980 100

Heavy Duty Pin Grabber

Performance

Severe Duty B 600 24 0.46 0.61 683 1,506 90

Clean Up B 1800 72 1.60 2.09 979 2,157 100

Ditch Cleaning B 1500 60 1.01 1.32 651 1,436 100

Ditch Cleaning Tilt B 1500 60 0.90 1.18 948 2,090 100

The above loads are in compliance with hydraulic excavator standard EN474-5:2006 + A3:2013,

they do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity with front linkage

fully extended at ground line with bucket curled.

Capacity based on ISO 7451:2007.

Bucket weight with General Duty tips.

Caterpillar recommends using appropriate work tools to maximize the value customers receive from our products. Use of work tools, including buckets, which are

outside of Caterpillar’s recommendations or specifications for weight, dimensions, flows, pressures, etc. may result in less-than-optimal performance, including

but not limited to reductions in production, stability, reliability, and component durability. Improper use of a work tool resulting in sweeping, prying, twisting and/or

catching of heavy loads will reduce the life of the boom and stick.

B 600 24 0.55 0.72 617 1,360 100

B 750 30 0.75 0.98 715 1,576 100

B 900 36 0.95 1.24 791 1,743 100

B 1050 42 1.16 1.52 861 1,899 100

B 1200 48 1.38 1.80 938 2,069 100

B 1350 54 1.59 2.08 1016 2,241 100

B 750 30 0.64 0.84 752 1,658 100

B 900 36 0.81 1.06 835 1,841 100

B 1050 42 1.00 1.31 892 1,967 100

B 1200 48 1.19 1.56 975 2,150 100

B 1350 54 1.38 1.81 1060 2,336 100

B 1200 48 1.14 1.49 983 2,167 100

B 600 24 0.44 0.57 682 1,503 100

B 750 30 0.60 0.79 787 1,735 100

B 900 36 0.76 1.00 876 1,931 100

B 1050 42 0.93 1.22 940 2,072 100

B 1200 48 1.11 1.45 1031 2,272 100

B 1350 54 1.28 1.67 1122 2,474 100

B 750 30 0.64 0.84 795 1,753 90

B 900 36 0.81 1.06 885 1,950 90

B 1050 42 1.00 1.31 948 2,091 90

B 1200 48 1.19 1.56 1038 2,289 90

B 900 36 0.79 1.03 853 1,881 90

B 2000 78 1.76 2.31 1045 2,303 100

B 1800 72 1.24 1.62 739 1,630 100

B 1800 72 1.11 1.45 1063 2,344 100

B 1800 72 1.40 1.83 1105 2,437 100

B 2000 79 1.23 1.61 1132 2,496 100

mm in m

Maximum load with coupler (payload + bucket) kg 2636 2825 600

3

3

yd

kg lb % R2.9 (9'6")

lb 5,811 6,228 1,323

Reach Reach HD

Maximum Material Density:

2100 kg/m3 (3,500 lb/yd3)

1800 kg/m3 (3,000 lb/yd3)

1500 kg/m3 (2,500 lb/yd3)

1200 kg/m3 (2,000 lb/yd3)

900 kg/m3 (1,500 lb/yd3)

4.7 m ton

(10,400lb)

Counterweight

R2.9 (9'6")

HDTRS

SLR

12

Page 13

320 Hydraulic Excavator Specifications

Attachments Offering Guide

Not all Attachments are available in all regions. Consult your Cat dealer for congurations available in your region.

Match

ü

PIN-ON ATTACHMENTS

Undercarriage L

Counterweight 4.2 mt (9,300 lb)

Boom Type Reach

Stick Length 2.5 m (8'2") 2.9 m (9'6") 2.9 m TR (9'6")

Hydraulic Hammers H115 S

Multi-Processors MP318 Concrete Cutter Jaw

Demolition and Sorting Grapples G318

Mobile Scrap and Demolition Shears S3025

Pulverizers P215

Compactors (Vibratory Plate) CVP110

Mulchers HM4015 with Bite Limiter

Orange Peel Grapples GSH420-500

†

Allowed usage on machine lessthan 50%

H120 GC

H120 GC S

H120 S

H130 GC

H130 GC S

H130 S

MP318 Demolition Jaw

MP318 Pulverizer Jaw

MP318 Shear Jaw

MP318 Universal Jaw

G318 WH-800

G318 WH-1100

S3025 Flat Top

GSH420-600

GSH420-750

GSH425-750

GSH425-950

GSH425-1150

GSH520-500

GSH520-600

GSH520-750

GSH525-750

No Match 1800 kg/m3 (3,000 lb/yd3) 1200 kg/m3 (2,000 lb/yd3)

ü ü ü

ü ü ü

ü ü ü

ü ü ü

*ü†

*ü†

ü *ü† ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

(continued on next page)

ü

ü

13

Page 14

320 Hydraulic Excavator Specifications

Attachments Offering Guide (continued)

Not all Attachments are available in all regions. Consult your Cat dealer for congurations available in your region.

Match

ü

CAT PIN GRABBER COUPLER ATTACHMENTS

Undercarriage L

Counterweight 4.2 mt (9,300 lb)

Boom Type Reach

Stick Length 2.5 m (8'2") 2.9 m (9'6") 2.9 m TR (9'6")

Hydraulic Hammers H115 S

Multi-Processors MP318 Concrete Cutter Jaw

Demolition and Sorting Grapples G318

Mobile Scrap and Demolition Shears S3025

Pulverizers P215

Compactors (Vibratory Plate) CVP110

Mulchers HM4015 with Bite Limiter

Working range front only

*

H120 GC

H120 GC S

H120 S

H130 GC

H130 GC S

H130 S

MP318 Demolition Jaw

MP318 Pulverizer Jaw

MP318 Shear Jaw

MP318 Universal Jaw

G318 WH-800

G318 WH-1100

S3025 Flat Top

†

Allowed usage on machine lessthan 50%

ü ü ü

*ü† *ü† ü

*ü† *ü† ü

*ü† *ü† ü

*ü† **ü†* ü

*ü† *ü† ü

*ü† *ü† ü

ü ü ü

ü ü ü

ü *ü* ü

ü ü ü

ü ü ü

ü ü ü

ü ü ü

ü *ü* *ü*

ü *ü* ü

ü *ü* ü

ü ü ü

ü ü ü

ü ü ü

(continued on next page)

14

Page 15

320 Hydraulic Excavator Specifications

Attachments Offering Guide (continued)

Not all Attachments are available in all regions. Consult your Cat dealer for congurations available in your region.

Match

ü

TRS18-S70 ATTACHMENTS

Undercarriage L

Counterweight 4.2 mt (9,300 lb)

Boom Type Reach

Stick Length 2.5 m (8'2") 2.9 m (9'6")

Hydraulic Hammers H115 S

Compactors (Vibratory Plate) CVP75

BOOM-MOUNT ATTACHMENTS

Undercarriage L

Counterweight 4.2 mt (9,300 lb)

Boom Type Reach

Mobile Scrap and Demolition Shears S2050

†

Allowed usage on machine lessthan 50%

H120 GC S

H120 S

CVP110

S3035

ü ü

*ü† *ü†

*ü† *ü†

ü ü

ü ü

ü

ü

15

Page 16

320 Hydraulic Excavator Specifications

Thumb Specifications

Match

ü

Bucket Type

General Duty 5 902 36

Heavy Duty 5 902 36

Heavy Duty Power 5 1056 42

Severe Duty 5 902 36

Pin Grabber

Performance

Buckets

^ Maximum bucket payload will vary depending on thumb’s mass, stick length, counterweight, and coupler type; please select bucket using the bucket matchingguide.

Tooth

Quantity

5 1056 42

6 1208 48

7 1350 54

5 1056 42

6 1208 48

7 1350 54

6 1208 48

5 1056 42

6 1208 48

5 902 36

5 1056 42

6 1208 48

7 1350 54

Width

Not Recommended No Match

^

Pro Plus Pro Stiff Link Utility

Pin-on

Cat Pin

Grabber Pin-on

Cat Pin

Grabber Pin-on

ü ü ü ü ü ü ü ü

ü ü ü ü ü ü ü ü

ü^ ü^ ü^ ü^ ü^ ü^ ü^ ü^

ü^ ü^ ü^ ü^ ü^ ü^ ü^ ü^

ü ü ü ü ü ü ü ü

ü ü ü ü ü ü ü ü

ü^ ü^ ü^ ü^ ü^ ü^ ü^ ü^

ü^ ü^ ü^ ü^ ü^ ü^ ü^ ü^

ü ü ü ü ü ü ü ü

ü^ ü^ ü^ ü^ ü^

ü ü ü ü ü ü ü ü

ü ü ü ü ü ü ü ü

ü^ ü^ ü^ ü^ ü^ ü^ ü^ ü^

ü ü ü

ü ü ü ü

ü^ ü^ ü^

ü^ ü^

Cat Pin

Grabber Pin-on

Cat Pin

Grabbermm in

16

Page 17

320 Standard and Optional Equipment

Standard and Optional Equipment

Standard and optional equipment may vary. Consult your Cat dealer for details.

CAB

ROPS, standard sound suppression

High-resolution 254 mm (10 in) LCD

touchscreen monitor

High-resolution 254 mm (10 in) LCD

touchscreen monitor + additional

monitor (for Cat Grade with Advanced

2D or Cat Grade with 3D)

Auto bi-level air conditioner

Jog dial and shortcut keys for

monitorcontrol

Keyless push-to-start engine control

Height-adjustable console, innite

withno tool

Heated seat with air-adjustable

suspension

51 mm (2 in) seat belt

Tilt-up left-side console

®

Bluetooth

withUSBports

12V DC outlets

Document storage

Cup and bottle holders

Rear head storage net and lunchbox

storage net

Openable two-piece front window

Upper radial wiper with washer

Openable polycarbonate skylight hatch

LED dome light

Floor welcome light

Roller front sunscreen

Roller rear sunscreen

Washable oor mat

Beacon ready

Straight travel pedal

integrated radio

Standard Optional

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ENGINE

Three selectable power modes

Auto engine speed control

Auto engine idle shutdown

Work up to 3000 m (9,842.5 ft) above sea

level without engine power de-rating

52° C (125° F) high-ambient cooling

capacity

Cold starting capability for

–32° C (–25° F)

Double element air lter

withintegratedpre-cleaner

Electric fuel priming pump

Electric cooling fans

withauto-reversefunction

Biodiesel capability up to B20

HYDRAULIC SYSTEM

Boom and stick regeneration circuits

Boom and stick lowering check valves

Electronic main control valve

Auto hydraulic oil warm up

Auto two-speed travel

Boom and stick drift reduction valve

Element type main hydraulic lter

Slider joysticks

Tandem type electronic main pump

Hammer return lter circuit

Advanced Tool Control (two pump,

one/two way high-pressure ow)

Medium pressure auxiliary circuit

Quick coupler circuit for Cat Pin Grabber

Fine swing control

Standard Optional

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

(continued on next page)

17

Page 18

320 Standard and Optional Equipment

Standard and Optional Equipment (continued)

Standard and optional equipment may vary. Consult your Cat dealer for details.

UNDERCARRIAGE AND STRUCTURES

790 mm (31 in) triple grouser track shoes

Tie-down points on base frame

Segmented track guiding guards

Full-length track guiding guards

Bottom guards

HD bottom guards

Swivel guard

Travel motor guards

HD travel motor guards

Grease lubricated track links

4200 kg (9,300 lb) counterweight

4700 kg (10,400 lb) counterweight

forSuper Long Reach

Semi-HD swing frame

Base frame with HD track rollers

andstandard carrier rollers

Storage tray in pump compartment

BOOM, STICKS AND LINKAGES

5.7 m (18'8") Reach boom

5.7 m (18'8") HD Reach boom

2.9 m (9'6") Reach stick

2.9 m (9'6") HD Reach Thumb

Readystick

Super Long Reach 8.85 m (29'0") boom

Super Long Reach 6.28 m (20'7") stick

Bucket linkage, B1-family with

liftingeye,Cat Grade

Bucket linkage, A-family with

liftingeye,SLR

ELECTRICAL SYSTEM

1,000 CCA maintenance-free

batteries(×2)

Centralized electrical disconnect switch

Programmable time-delay LED

workinglights

LED chassis light, LH and RH boom

lights for Reach and SLR, cab lights

Premium surround lighting package

Standard Optional

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

CAT TECHNOLOGY

Cat Product Link™

Work tool recognition

Work tool tracking*

Laser catcher

Cat Grade with 2D and offset memory

(not available on SLR)

Cat Grade with Advanced 2D

(notavailable on SLR)

Cat Grade with 3D connectivity

(notavailable on SLR):

– Virtual Reference Station**

– Internet Base Service Station**

– Trimble Connected Community**

Cat Assist:

– Grade Assist

– Boom Assist

– Bucket Assist

– Swing Assist

– Lift Assist

Cat Payload:

– Static weigh

– Semiautomatic calibration

– Payload/cycle information

– USB reporting capability

2D E-Fence:

– E-ceiling

– E-oor

– E-swing

– E-wall

– E-cab avoidance

Auto hammer stop

Auto Dig Boost

Remote Services capability

*Paired with PL161 attachment locator.

**Subscription required.

Standard Optional

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

(continued on next page)

18

Page 19

320 Standard and Optional Equipment

Standard and Optional Equipment (continued)

Standard and optional equipment may vary. Consult your Cat dealer for details.

SERVICE AND MAINTENANCE

Scheduled Oil Sampling (S·O·S

QuickEvac™ maintenance ready

Grouped location for engine oil

and fuel lters

Ground-level second dipstick for engine oil

Radiator screen

SM

) ports

Standard Optional

ü

ü

ü

ü

ü

SAFETY AND SECURITY

Cat Command remote control

Rearview and right-hand-sideview

cameras

360° visibility

Cat PL161 Attachment Locator

Neutral lever (lock out) for all controls

Anti-skid plate and countersunk bolts

onservice platform

Ground-level accessible secondary engine

shutoff switch in cab

RH handrail and handhold

(ISO 2867:2011 compliant)

Travel alarm

Standard Optional

ü

ü

ü

ü

ü

ü

ü

ü

ü

19

Page 20

320 Attachments

Dealer Installed Kit and Attachments

Attachments may vary. Consult your Cat dealer for details.

CAB

• Radial lower wiper

• LH/RH electrical pedal for tool control

• Dual exit rear window kit

• Rain protector plus cab light cover

• 75 mm (3") retractable seat belt

SAFETY AND SECURITY

• Bluetooth key fob

SERVICE AND MAINTENANCE

• Grease gun holder

ELECTRICAL

• Jump start wiring

GUARDS

• Side rubber bumper

• Falling object guard system (not compatible

with cab light cover, rain protector)

• Mesh guard full front (not compatible with

cab light cover, rain protector)

• Mesh guard lower half front

• Full protecting vandalism guard

For more complete information on Cat products, dealer services, andindustry solutions, visit us on the web

atwww.cat.com

© 2020 Caterpillar

All rights reserved

Materials and specications are subject to change without notice. Featured machines in photos may include

additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow,” the

“PowerEdge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein,

aretrademarks ofCaterpillar and may not be used without permission.

AEXQ2161-04 (11-2020)

Replaces AEXQ2161-03

Build Number: 07D

(North America)

Loading...

Loading...