Page 1

Cat® 317

Hydraulic Excavator

The 317 Hydraulic Excavator boosts productivity on your jobsite. Standard, easy-to-use Cat® technologies, performance upgrades,

and low fuel and maintenance costs allow you to move material all day with speed and precision while keeping more money in

your pocket.

Not all features are available in all regions. Consult your Cat dealer for specic congurations available in your region.

High Performance and Productivity

• Increased breakout forces and hydraulic power increase

productivit y by up to eight percent over the previous model.

• The advanced hydraulic system provides the optimum balance

of power and ef ciency while giving you the control you need for

precise digging requirements.

• Reduce fuel consumption by up to ve percent over the previous

model.

• Match your machine to the job with power modes. Let Smar t

mode automatically match engine and hydraulic power to working

conditions. Power mode constantly provides maximum productivity,

and ECO mode minimizes fuel consumption in less-demanding

applications.

• Get higher production in demanding applications, easier

penetration into piles, and faster cycle times with Cat Advansys

bucket tips. Quickly change tips with a simple lug wrench instead of

a hammer or special tool, improving safety and uptime.

• Auxiliary hydraulic options give you the versatility to use a wide

range of Cat at tachments.

• The Cat C4.4 engine meets U.S. EPA Tier 4 Final emission standards.

• Don’t let the temperature stop you from working. The 317 has an

optional cold-start capabilit y of -25°C (-13°F).

™

Boost Efciency and Productivity with

Cat Technology

• Boost productivity up to 45 percent versus traditional grading with

the standard Cat Grade with 2D system – includes indicate-only and

laser capability.

• Dig with guidance to depth, slope, and horizontal distance to grade.

You can set up to four different depth and slope targets to help save

time and money.

• Standard 2D E-Fence prevents your machine from moving outside

operator-dened parameters.

• Achieve precise load targets and increase loading efciency with

standard Cat Payload which provides on-the-go weighing and realtime estimates of your payload without swinging.

• Upgrade to Cat Grade with Advanced 2D to create and edit grade

designs with ease on a second high-resolution 254 mm (10 in)

touchscreen monitor.

• Upgrade to Cat Grade with 3D to create and edit designs with ease

and see the front linkage’s full range of motion on a second highresolution 254 mm (10 in) touchscreen monitor.

• Know the excavator ’s exact position relative to GPS and GLONASS

systems. The machine automatically compensates for excavator

pitch and roll caused by sloping ground conditions.

• Use the excavator’s onboard cell technology to quickly connect to

3D services like Trimble Connected Communit y or Virtual Reference

Station.

• Remote Troubleshoot connects you to a dealer service pro to help

solve your problem and quickly get you to work.

• Remote Flash works around your schedule to ensure your machine’s

software is up to date for optimal performance.

• The Cat App helps you manage eet location, hours, and

maintenance schedules; it also alerts you for required maintenance

and even allows you to request service from your local Cat dealer

• Standard Product Link

from your connected assets – any type and any brand. Information

such as location, hours, fuel usage, productivity, idle time,

maintenance aler ts, diagnostic codes, and machine health can be

viewed online through web and mobile applications.

™

automatically and accurately collects data

Page 2

Cat® 317 Hydraulic Excavator

Work in Comfort in the All-New Cab

• Increase operator productivity with an all-new, larger cab.

• The Comfort cab is equipped with a mechanical suspension seat.

The Deluxe seat is heated and air adjustable, while the Premium seat

is heated and cooled and adjusts automatically.

• Get in and out of the cab easier using the tip-up left console.

• Advanced viscous mounts reduce cab vibration.

• Control the excavator comfortably with easy-to-reach controls, all

located in front of you.

• Stow your gear with plenty of in-cab storage beneath and behind the

seat, overhead, and in the consoles. A cup holder, document holder,

and coat hook are also provided.

• Use the standard radio’s USB ports and Bluetooth

connect personal devices and make hands-free calls.

®

technology to

Simple to Operate

• Start the engine with the push of a but ton, a Bluetooth key fob, a

smartphone app, or the unique Operator ID function.

• Program your preferred power mode and joystick set tings using

your Operator ID. The excavator will automatically remember your

selections.

• Navigate quickly on the standard high-resolution touchscreen

monitor or with the aid of the jog dial control.

• The Cat PL161 Attachment Locator is a Bluetooth device that

makes nding your attachments and other gear quick and easy. The

excavator’s onboard Bluetooth reader or Cat App on your phone

will locate the device automatically.

• Save time and energy with work tool recognition. A simple shake

of the attached tool conrms its identity, ensuring all attachment

settings are correct , so you can get to work quickly and ef ciently.

• Not sure how a function works or how to maintain your machine?

Simply access the operator’s manual through the touchscreen

monitor.

Lower Maintenance Costs

• Expect up to 20 percent less maintenance costs over the previous

model.

• Quickly check and service your machine with all daily maintenance

points accessible from ground level.

• Check the engine oil level quickly and safely from the ground. Fill

and check engine oil on top of the machine with a conveniently

located second dipstick.

• Track your machine’s lter life and maintenance intervals on the

in-cab monitor.

• The new hydraulic oil lter provides improved ltration

performance, anti-drain valves to keep oil clean when the lter is

replaced, and longer life with a 3,000 -hour replacement interval –

50 percent longer than previous lter designs.

SM

• S·O·S

ports are located at ground level, simplif ying maintenance

and allowing for quick, easy ex traction of uid samples for analysis.

Safety

• Access all daily maintenance points from ground level – no need for

you to climb on top of the machine.

• The standard ROPS cab meets ISO 12117-2:2008 requirements.

• A ground-level shutof f switch stops all fuel to the engine and shuts

down the machine when activated.

• A rearview and right-side-view camera are standard. Upgrade

to 360° visibility to easily see objects and personnel around the

excavator in a single view.

• New service platform design provides easy, safe, and quick access

to the upper service platform. Prevent slipping with the anti-skid

punch plate on the plat form steps.

• Optional boom and stick lowering check valves prevent reverse

ow, keeping your front linkage securely in place should the

hydraulic system unexpectedly lose power.

• Brightly colored seatbelts allow easy recognition of properly

utilized safety restraints.

• Antennas have theft-prevention bolts; a special tool makes them

easy to remove at the end of a shift.

2

Page 3

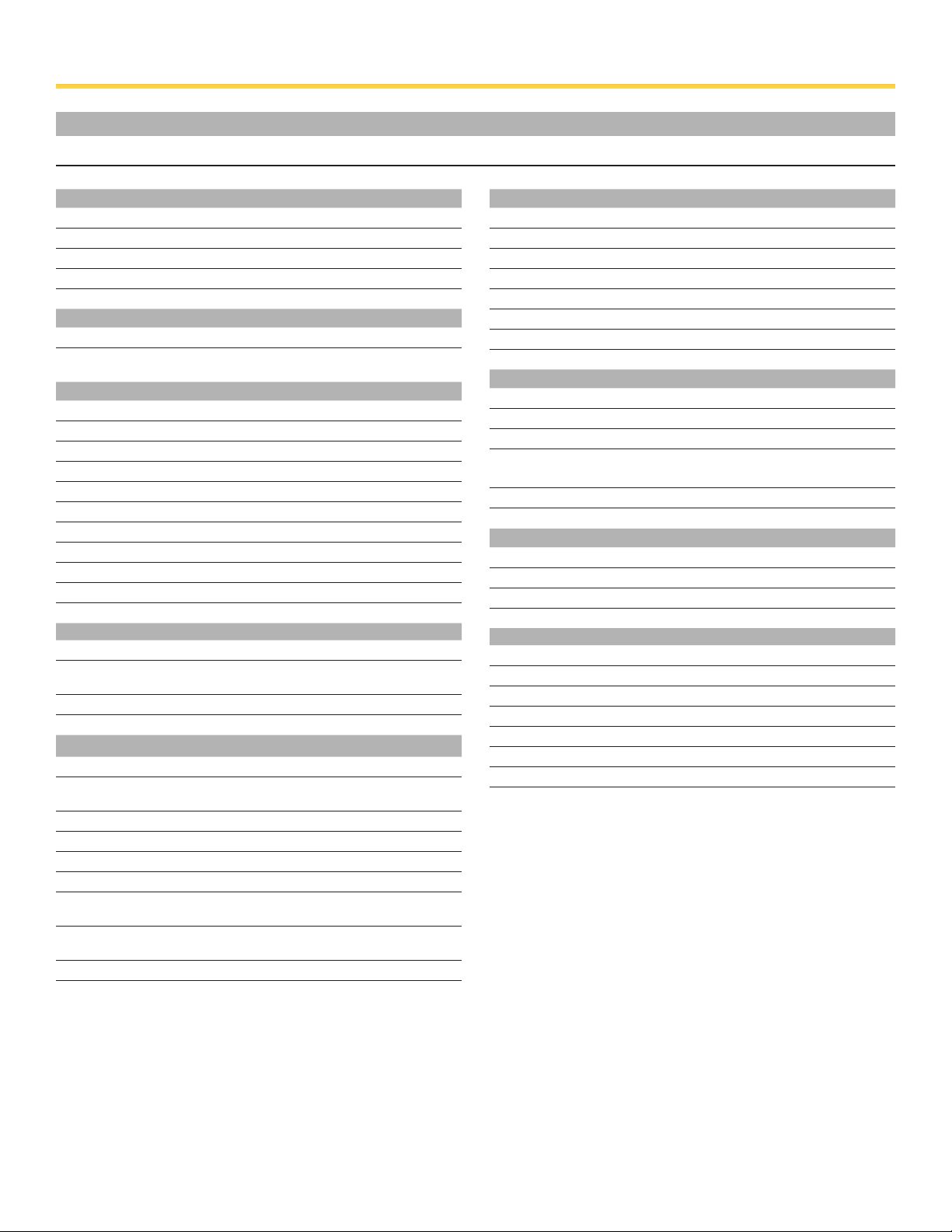

Standard and Optional Equipment

Standard and optional equipment may vary. Consult your Cat dealer for details.

Cat® 317 Hydraulic Excavator

BOOMS AND STICKS

5.1 m (16'9") Reach boom

R2.6 m (8'6") stick

R2.9 m (9'6") stick

2.9 m (9'6") thumb ready stick

R3.1 m (10'2") stick

CAB

ROPS, sound suppression

Deluxe cab: air suspension heated seat, 10"

touchscreen monitor

CAT TECHNOLOGIES

Cat Product Link

Cat Grade with 2D

Cat Grade with Advanced 2D

Cat Grade with 3D

Cat Payload

2D E-Fence

Remote Flash capability

Remote Troubleshoot capability

Work tool recognition

Work tool tracking

Auto hammer stop

ELECTRICAL SYSTEM

Maintenance free battery

LED chassis light, left-side/right-side boom lights,

cab lights

Programmable time-delay LED working lights

360° lighting

ENGINE

C4.4 Tier 4 Final diesel engine

One-touch low idle with automatic engine speed

control

Automatic engine shutdown

-18°C (-0°F) cold start capability

-25°C (-13°F) cold start capability

Electric fuel priming pump

Two-stage fuel ltration system with water

separator and indicator

Sealed double element air lter with integrated

precleaner

Electric cooling fans

Biodiesel capability up to B20

Standard Optional

HYDRAULIC SYSTEM

Boom and stick regeneration circuits

Automatic hydraulic warm up

Automatic two-speed travel

Electric main control valve

Boom and stick drift reduction valve

Boom and stick lowering check valves

Element-type main hydraulic lter

Single-type electronic main pump

SAFETY AND SECURITY

Rear- and right-side-view cameras

360° visibility

Ground level engine shutoff switch

Service platform with anti-skid plate and

countersunk bolts

Signaling/warning horn

Hydraulic lock out lever

SERVICE AND MAINTENANCE

Side entry to service platform

Grouped engine oil and fuel lters

Ground level engine oil dipstick

S·O·S sampling ports

UNDERCARRIAGE AND STRUCTURES

Grease lubricated track link

Tie-down points (ISO 15818:2017 compliant)

600 mm (24") triple grouser shoes

600 mm (24") rubber track shoe

700 mm (28") triple grouser shoes

3.05 mt (6,720 lb) counterweight

3.57 mt (7,870 lb) counterweight

Standard Optional

3

Page 4

Cat® 317 Hydraulic Excavator

Technical Specifications

Engine

Engine Model

Engine Power – ISO 14396:2002 98 kW 131 hp

Net Power – ISO 9249:2007 97 kW 130 hp

Bore

Stroke

Displacement

• No engine power derate required below 3000 m (9,840 ft) altitude.

• Net power available at the ywheel when the engine is equipped with fan, air

cleaner, aftertreatment, and alternator with engine speed at 2,200 rpm.

105 mm 4 in

127 mm 5 in

4.4 L 269 in

C4.4

3

Hydraulic System

Main System – Maximum Flow 296 L/min 78 gal/min

Maximum Pressure – Equipment 35 000 kPa 5,076 psi

Maximum Pressure – Travel 35 000 kPa 5,076 psi

Maximum Pressure – Swing 25 800 kPa 3,741 psi

Swing Mechanism

Swing Speed 8.7 rpm

Maximum Swing Torque 61 kN-m 44,990 lb-ft

Weights

Operating Weight 18 200 kg 40,200 lb

3

• Long undercarriage, Reach boom, R3.1 (10'2") stick, GD 0.76 m

bucket, 700 mm (28") triple grouser shoes and 3.57 mt (7,870 lb) counterweight.

(0.99 yd3)

Service Rell Capacities

Fuel Tank Capacity 271 L 71.6 gal

Cooling System 28 L 7.4 gal

Engine Oil 15 L 4 .0 gal

Final Drive 6 L 1.6 gal

Hydraulic System (including tank) 9 4 L 24.8 gal

Hydraulic Tank 87 L 23.0 gal

DEF Tank 22 L 5.9 gal

Dimensions

Boom Reach 5.1 m (16'9 ")

Stick Reach R2.9 m (9'6")

Bucket GD 0.76 m3 (0.99 yd3)

Shipping Height (top of cab) 29 30 mm

Handrail Height 29 40 mm

Shipping Length 8570 mm

Tail Swing Radius 2500 mm

Counterweight Clearance 1010 mm

Ground Clearance 4 30 mm

Track Length 3970 mm

Length to Center of Rollers 3170 mm

Track Gauge 1990 mm

Transpor t Width – 70 0 mm (28 ") Shoes 2690 mm

Working Ranges

Boom Reach 5.1 m (16'9 ")

Stick Reach R2.9 m (9'6")

Bucket GD 0.76 m3 (0.99 yd3)

Maximum Digging Depth

Maximum Reach at Ground Line

Maximum Cutting Height

Maximum Loading Height

Minimum Loading Height

Maximum Depth Cut for 2400 mm (8'0") Level

Bottom

Maximum Ver tical Wall Digging Depth

Minimum Working Equipment Radius

Bucket Digging Force (ISO)

Stick Digging Force (ISO)

64 00 mm

9010 mm

8900 mm

6280 mm

199 0 mm

6170 mm

49 60 mm

29 40 mm

123 kN

75 kN

27,650 lbf

16,86 0 lbf

Air Conditioning System

• The air conditioning system on this machine contains the uorinated

greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The

system contains 0.9 kg of refrigerant which has a CO2 equivalent of 1.287

metric tonnes.

9'7"

9'8"

28'1"

8'2"

3'4"

1'5"

13'0"

10'5"

6'6"

8'10"

21'0"

29'7"

29'2"

20'7"

6'6"

20'3"

16'3"

9'8"

For m ore comple te infor mation o n Cat produc ts, deal er servi ces, andind ustry s olutio ns, visi t us on the web a twww.cat.com.

© 20 21 Cater pillar

All rights reserved

Mate rials and sp ecicat ions are su bject to chan ge with out notic e. Featu red machine s in photo s may include a ddition al equipme nt. See yo ur Cat deale r

for available options.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, Advansys, Product Link, S•O•S, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat

“Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

AE XQ 3069-01 (01-20 21)

Replaces AEXQ3069-00

Build Number : 07A

(N Am)

Loading...

Loading...