CAT 250 Schematic

SIB BF08-001 Arm Angle Switch Location Change 2

SIB CC07-005 New ETAC Card Part Numbers 3

SIB CE06-004 Battery Discharge Indicator Troubleshooting 4

SIB CE11-005 New Switch Bridge 6

SIB CE13-001 7BWS10-13 Tiller Switch Arm Failures 9

SIB DM10-001 Drive Motor Cable Routing 12

SIB MA07-007 GNB Charger Pack Troubleshooting 13

Body and Frame

BF08-001

January 11, 2008

Arm Angle Switch Location Change

6HBW23, 7HBW23, 7BWS10-13

SERVICE INFORMATION BULLETIN

Subject: Arm Angle Switch Location Change Page 1 of 1

MODEL APPLICATION:

6HBW23, 7HBW23, 7BWS10-13

Return To BF Index

Return To Main Index

GENERAL INFORMATION:

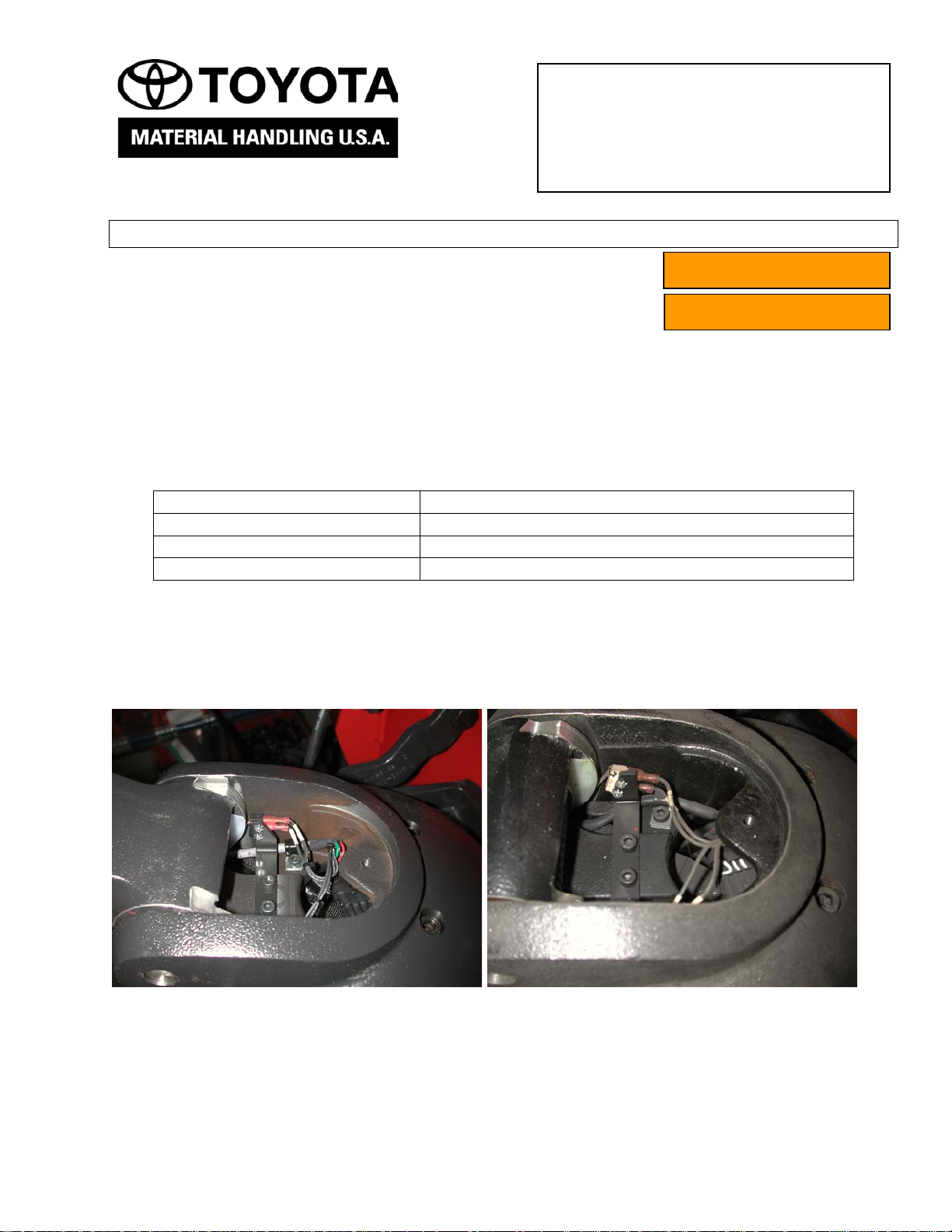

There has been a change made to the arm angle switch bracket and handle stem. The

previous style arm angle switch bracket will still be available, but the previous handle stem will

not. If a handle stem is to be replaced, it will need to be updated with the kit listed in the table

below.

Note: Do not mix new style handle stems with old style switch brackets.

Part Number Description

00590-47633-71 Kit (includes new handle stem and switch bracket)

00590-47607-71 New Handle Stem

00590-47608-71 New Switch Bracket

EFFECTIVE SERIAL NUMBER:

7HBW23-29531 and up

7BWS13-40698 and up

New Style handle and bracket Old Style handle and bracket

SERVIC INFORMATION BULLETIN

ubject: New ETAC Card Part Numbers

S Page 1 of 1

E

Control Circuit

CC07-005

November 16, 2007

ETAC part numbers

6/7HBW23, 6/7BWS10-13

ODEL APPLICATION: M

6

HBW23, 7HBW23, 6BWS10-13, 7BWS10-13

Return To CC Index

Return To Main Index

GENERAL INFORMATION:

In order to help identify the card needed for a particular truck, separate part numbers have

been created for the ETAC cards on the above models. This also will allow for stocking of

these cards instead of the previous requirement of ordering a card as needed. It is important

to keep these cards with the box that they came in since there is no physical difference

etween cards. The

b

cards are shipped.

EPAIR INFORMATION:

R

difference is in the programming that is loaded into memory before these

Model

6HBW23, 7HBW23 00590-47051-71

6BWS10-13 00590-47052-71

7BWS10-13 00590-47599-71

ETAC Card Part Number

SERVICE INFORMATION BULLETIN

Subject: Battery Discharge Indicator Troubleshooting Page 1 of 2

Chassis Electrical

CE06-004

July 31, 2006

B.D.I. Troubleshooting

6HBW23, 7HBW23, 6BWS10-13,

7BWS10-13

MODEL APPLICATION:

6HBW23, 7HBW23, 6BWS10-13, 7BWS10-13

GENERAL INFORMATION:

When troubleshooting a function like the Battery Discharge Indicator (BDI), it can be helpful to

understand how the system works. This bulletin provides a brief description of how the BDI

works on these trucks as well as some scenarios to be wary of when troubleshooting a

possible BDI issue.

REPAIR INFORMATION:

When determining what percentage should be displayed for the operator, the ETAC card looks

at 4 things.

1. Battery voltage present on wire 22 (red) to the ETAC card.

2. Drive motor armature current.

3. Value set in Parameter 21.

4. To reset to 100%, the ETAC card must see 25.3 Volts or higher.

If battery voltage at wire 22 is incorrect, then the ETAC cannot accurately determine battery

charge level. This means that not only should the positive side of the circuit (red wire 22) be in

good condition, but also the negative side of the circuit (black wire 40) should be in good

condition. This means no breaks or shorts to the frame and no sources of high resistance in

the circuit.

Drive motor armature current is read by the Curtis traction amplifier and this information is sent

via the CAN high and CAN low wires to the ETAC card. A minimum of 7 amps of armature

current at the drive motor must be present for the ETAC card to begin computing the discharge

rate of the battery. If the ETAC card never receives a signal that there is 7 or more amps of

drive armature current, the battery meter will never come down. When troubleshooting a

meter that is not coming down, use a Curtis handset in Monitor mode and observe the drive

motor current. If under full acceleration and travel the current does not show above 7 amps,

the Curtis amplifier may be at fault for the battery meter not changing.

The value set in Parameter 21 tells the ETAC card the capacity of the battery. It will change

how quickly the battery meter will come down based on the value in Parameter 21. The

maximum discharge level of a battery will be determined by the individual battery manufacturer

and can even vary somewhat from battery to battery in the same battery type. The rule of

thumb to follow is that if the battery is over-discharged when the battery meter shows 0%, the

value in Parameter 21 should be decreased. If the battery has not discharged enough when

the battery meter shows 0%, then the value in Parameter 21 should be increased.

When a battery is first plugged into the truck, the ETAC looks at the voltage and compares it to

the last stored voltage. If the battery voltage is not 25.3 volts or higher, the ETAC card will use

CE06-004 Battery Discharge Indicator Troubleshooting Page 2 of 2

the last stored voltage for calculating what should be displayed on the discharge meter. For

trucks that are not resetting to 100% battery charge, verify that the battery is reaching a

voltage above 25.3 volts when it is finished charging. The battery must be plugged in and

used for 20 seconds of travel with this voltage maintained for the fully charged battery to be

accepted and the meter changed to show 100%. This is to prevent a surface charge from

“tricking” the ETAC card into thinking that a partially charged battery is fully charged.

Scenarios That Can Cause an Incorrect Battery Meter Reading:

When understanding the information that the ETAC card is looking for to determine the

remaining charge in the battery, we can understand that certain situations will feed incomplete

information to the ETAC card and cause a false reading on the battery meter. These are

important to keep in mind so that time and parts are not spent on troubleshooting an issue that

is being caused by how the truck is used. Keep in mind that these scenarios are assuming

that all parts are working and that the Parameter 21 is set correctly.

“Battery is over-discharged and display shows 80% charged.”

This can be caused by an application where hydraulics are heavily used with little to no travel.

In this case, the voltage of the battery is being pulled down, but the ETAC card is not seeing

enough travel current reported by the Curtis amplifier to change the meter reading.

Occasionally the operator travels long enough for the meter to begin changing, but not long

enough for the meter to drop to the actual battery level. This may be combated by adjusting

the value of Parameter 21 down to cause the meter to drop faster.

“Battery is at 24.5 volts, but meter shows 20%.”

This can happen when the operator is opportunity charging the battery, but never allows a

complete charge. Since the battery is never charged to a voltage of at least 25.3 volts, the

ETAC card never resets the meter to 100%. (The battery meter is designed to gradually

decrease, it does not gradually increase.) The customer should allow the battery to fully

charge at least once in a 24 hour period to bring battery voltage up.

“Battery voltage is below 23 volts, but meter shows good charge”

This can occur if the truck is powered off with the keypad/key switch but the master control

on/off switch (red rocker switch) is left on. This keeps the Curtis traction amplifier powered on.

When powered on, the Curtis traction amplifier has a constant amount of field current flowing

which is used for fault detection. If the truck is parked for a long period of time in this state,

this small amount of field current will slowly discharge the battery. Since the truck is not turned

on and no travel is occurring, the ETAC card will not be calculating the change in battery

voltage and will have to use the last voltage stored. If turned on and traveled for a long

enough distance, the meter will decrement to the correct level.

Loading...

Loading...