Page 1

Integra HE Remote Control

Inset Live Fuel Effect Gas Fire

Installation and

Users Instructions

These instructions should be read by the

installer before installation and then should be

handed to the end user when the installation

is complete.

This is an official requirement and is the

responsibility of the fitter of this

appliance.

Having installed the appliance, the installer

should take the necessary steps to ensure

that the user fully understands how to operate

the appliance and is also made aware of the

fire’s basic cleaning and maintenance

requirements.

Page 2

SECTION PAGE

Notes for the Installer and End User 3

Installation Requirements 4

Installation Procedure - Standard 22” x 16” 5

Installation Procedure - Decorative Cast 7

Commissioning 8

Technical Data 8

Replacement Parts 8

Trouble Shooting (GAS SAFE Engineer Only) 9

User Instructions 12

Cleaning and Maintenance 17

Fire Front Specifications 18

Modular Coal Layout Instructions 19

Guarantee 24

Trouble Shooting (User) 24

CONTENTS

2

Page 3

This appliance has been designed, tested and manufactured to the British Standard BS 7977-1:2002 relating to

Radiant Convector Gas Appliances and must be installed by a qualified Gas Safe Registered Installer in

accordance with the Gas Safety (Installation and use) regulations 1994 and all other relevant standards.

This appliance must be connected in accordance with the National Regulations. The appliance must be sealed

into a non-combustible fireplace (Fig. 2) whose only opening must be through a Class I (7” or 175mm diameter)

or Class II (5” or 125mm diameter) chimney / flue of at least three metres in height.

Before installation, ensure that the local conditions, (identification of gas type and pressure) and the adjustment

of the appliance are compatible. Never place combustible material directly in front of this appliance. Floor

covering such as carpet is acceptable but must be a minimum of 300mm from the incandescent flame.

NOTES FOR THE INSTALLER AND END USER

3

This fire is a very effective heating appliance and must be fitted against a wall of non-combustible material as

classified in BS 476-4:1970 (2007).

An air vent is not normally required for this application because its input does not exceed 7kW. We recommend

that the chimney/flue is swept prior to installation of this appliance and that any flue restrictor or damper plate

should be removed or fixed in the open position. The chimney/flue must always generate a positive up draught to

ensure safe operation.

The installer must then establish that all the products of combustion are entering the flue within ten minutes of

lighting from cold. This can be verified by inserting a lit smoke match into the left and right hand ducts

immediately above the glass retaing strip. It should NOT be inserted into the central convector duct.

This operation should be carried out before fitting the trim and louvred panel (see ‘Spillage Test’ page 4).

An isolation valve must be fitted adjacent to the appliance. When closed, this will allow the complete burner and

control assembly to be disconnected for maintenance or repair in accordance with national regulations.

The gas supply should be provided by a semi rigid pipe with an 8mm diameter and should be no longer than 1.5

metres in length.

NOTE: When the gas supply pipe is passed through masonry or other brickwork always ensure that the end

of the pipe is covered to avoid any debris passing through into the appliance controls.

The appliance is fitted with an Oxygen Depletion Sensor (ODS) that monitors the room for products of

combustion. If products are detected, the ODS will automatically shut down the appliance. If this situation

arises, re-light the appliance, referring to the user instructions (page 12). If shut down re-occurs, a qualified

person must be called to thoroughly check the appliance. The spillage monitoring system (ODS pilot) must

not be put out of operation or be tampered with or adjusted by either the installer or the user. If the unit is

found to be at fault it should be replaced with the manufacturers original replacement parts.

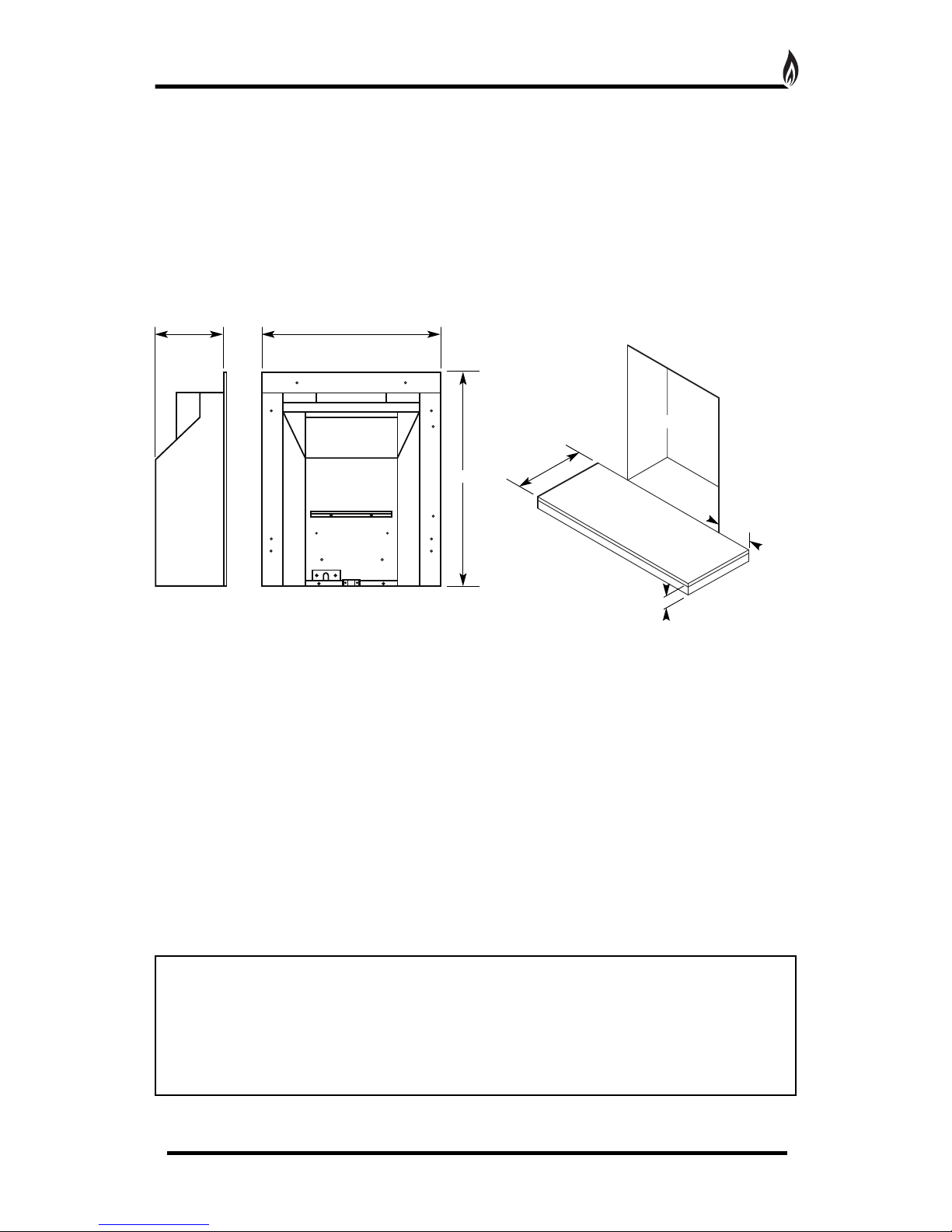

Fireplace Opening

150mm (min)

50mm (min)

300mm (min)

Fig. 1

Fig. 2

195mm 512mm

612mm

Page 4

This appliance must only be installed in Great Britain or Ireland.

1. This fire is a natural gas appliance and has been designed for use with the following applications:

a) Class I - Conventional brick or stone chimney as used for a solid fuel fire with a cross sectional dimension of

225mm x 225mm (9” x 9”) or a lined flue with a minimum diameter of 175mm (7”), with the fireplace components

conforming to BS1251, or a builders opening a minimum of 560mm high and 406mm wide with a minimum depth

of 230mm to allow sufficient volume for debris collection (unlined chimney 12 dm3 and lined 2 dm3). To obtain this

depth it would not normally be necessary to remove the chair brick. Any permanent flue restrictions or variable

dampers are to be removed or locked in the fully open position. The chimney should also be swept prior to

installation.

b) Oversized Void - Where an oversized void is encountered it must be reduced in size by lining with bricks or

blocks or alternatively inserting a metal flue box. The nominal dimensions of the void should not exceed 650mm

wide x 475mm deep x 800mm high BS5871-2.

c) Class II - A double walled or insulated metal flue box built to the requirements of BS715 with an insulated flue

having a minimum diameter of 125mm (5”) and a minimum effective overall height of 3 metres (10’).

NOTE: If the flue box is to be used with an existing brick or stone chimney, a 125mm (5”) minimum diameter

flue liner conforming to BS715 may be used.

2. A non-combustible hearth must be provided to comply with current building regulations. Care should be taken to

prevent any damage being caused to surrounding soft furnishings or decoration, e.g. many embossed vinyl wall

coverings may become discoloured if placed too close to the appliance.

3. A suitable proprietary fire surround with 100

0

c rating may be used with a minimum clearance from hearth to

underside of shelf of 830mm, providing that the depth of shelf is 150mm or less.

4. Where the shelf depth is greater than 150mm, the minimum height clearance should be increased by 25mm

increments for each additional 12.5mm of shelf depth.

5. Minimum width between vertical sides of combustible surround should not be less than 800mm provided the

appliance is central to the surround and the surround legs do not exceed a 150mm profile.

6. If the 150mm profile is exceeded, the width of the surround (and the back panel) should be increased by

25mm for each additional 12.5mm of profile depth.

d) Pre-cast Flue conforming to BS 1289 Part 1 (It may be necessary to use a surround with a deeper rebate than

usual to accommodate a flush fit with certain starter blocks. Check the appliance dimensions against individual

applications.

FLUE FLOW TEST

A flue flow test (smoke test) is carried out to check the effectiveness of the flue and to ensure that there is no

leakage into another part of the premises (including any loft), or as appropriate other adjoining premises (this is

particularly important where a number of chimneys combine into a multiple stack).

The flue flow test should be carried out using a suitable smoke pellet which the pellet manufacturer claims to

generate 5m

3

of smoke in 30 seconds burn time.

These gas fires should have the flue flow test carried out with the appliance in position but not connected to the

gas supply so that the smoke test can be carried out with representative flue flow conditions.

A warm flue will be more effective than a cold flue. If the flue is reluctant to draw, which can be initially assessed

by lighting a smoke match at the intended position of the appliance flue connection, introduce some heat into the

flue for a minimum of 10 minutes using a blow torch or other means.

Other factors, such as weather conditions and a combination of materials used to construct the flue can all

influence the flue draught. The pre-heating process may require as much as half an hour before the flue behaves

satisfactory as a blow torch does not represent the volume of heat consistent with the normal appliance operation.

A Flue Flow Test should be checked as follows:

1. Carry out those visual checks as indicated previously, and continue only if satisfactory.

2. Establish that an adequate air supply is available for the combustion of the appliance

3. Close all doors and windows in the room that the appliance is to be installed.

4. Light a smoke pellet at the intended position for the appliance. Place the inset fire case into position.

5. The test is satisfactory if

- there is no significant escape of smoke from the appliance position.

- there is no seepage of smoke over the length of the flue.

- smoke is discharged only from the correct terminal.

VENTILATION

No special ventilation bricks or vents are required in the room containing the appliance, providing that normal

adventitious room ventilation exists. The installer must determine this by carrying out a spillage test.

SPILLAGE TEST

To check for satisfactory clearance of products of combustion, close all doors and windows and leave the fire

burning for ten minutes. Insert a lit smoke match into the left and right hand ducts immediately above the glass

retaing strip. It should NOT be inserted into the central duct. This operation should be carried out before fitting the

trim and louvred panel. All the smoke must be drawn into the flue. If spillage occurs, allow a further ten minutes

and repeat the test. Should spillage still occur turn the appliance off and seek expert advice. To continue the test:

If an extractor fan is situated in the room the test should be repeated with the fan running. If there is a connecting

room with an extractor fan the test should be repeated with all the doors to that room open and the extractor fan

running.

INSTALLATION REQUIREMENTS

4

Page 5

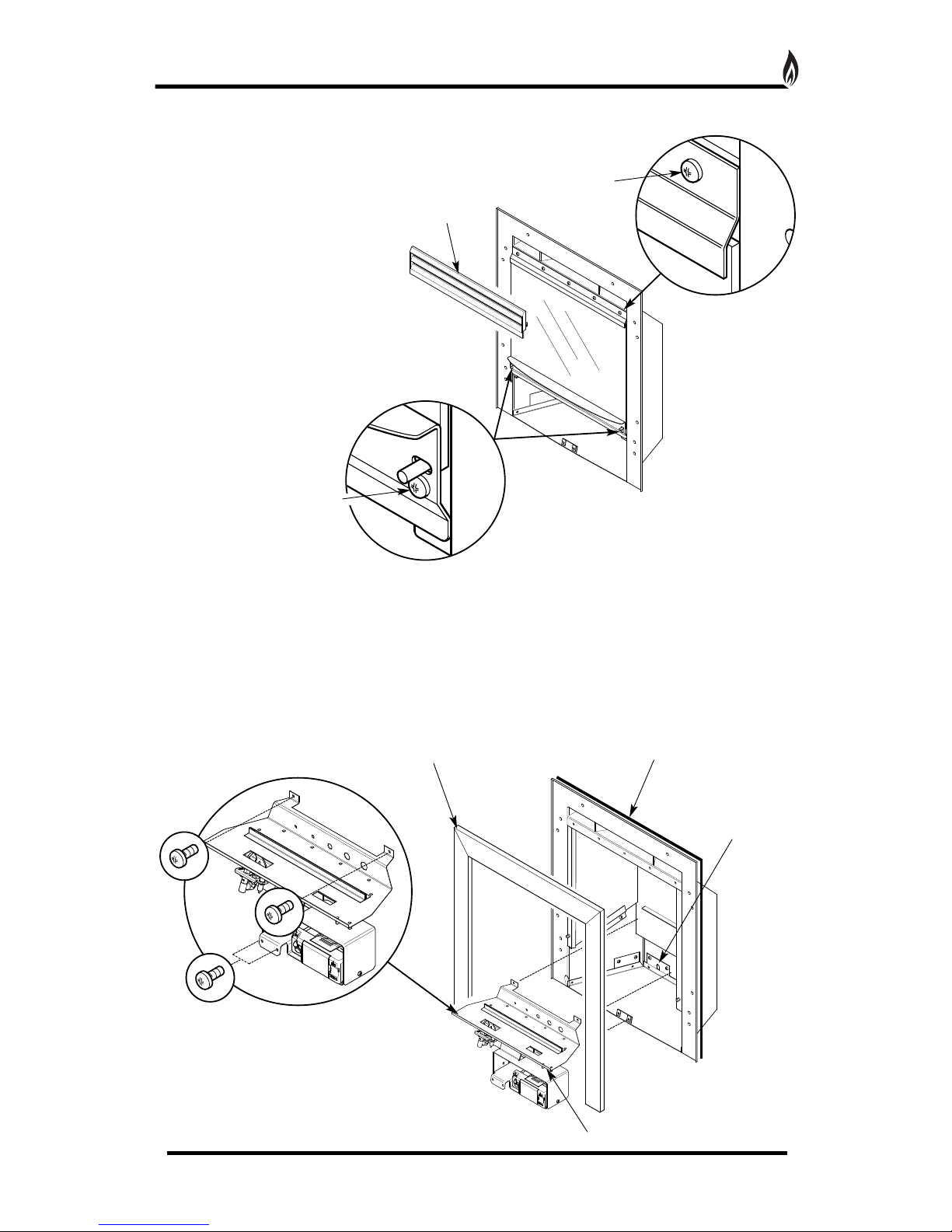

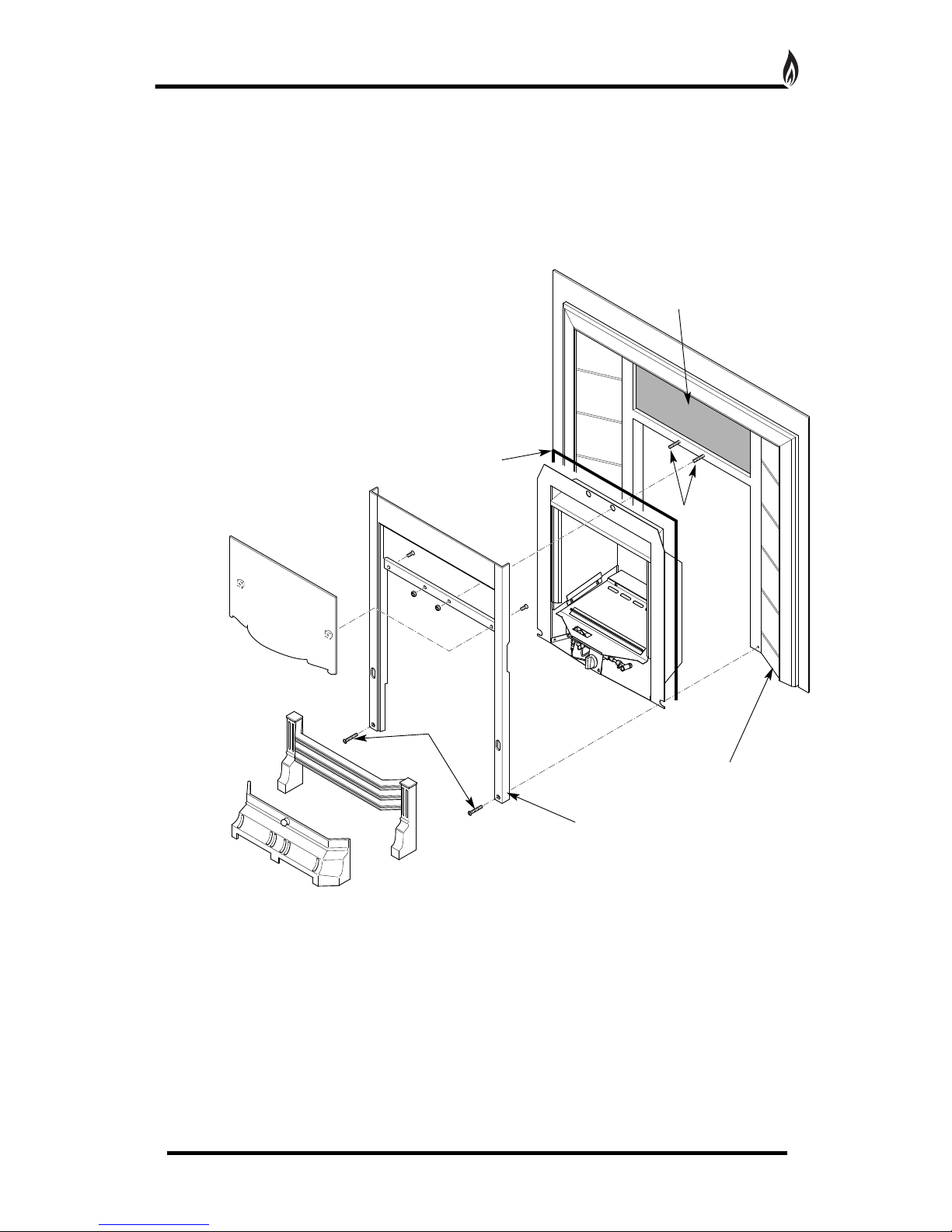

1. Carefully lift the appliance out of the packaging taking care not to damage the ceramic components in the

separate carton.

2. Remove the magnetic trim and store to one side to prevent any damage.

3. Remove the louvred panel by lifting

up and pulling forwards.

4. Slacken the five machine screws on

the top retaining strip (Fig. 3).

5. Unscrew the two securing screws

from the lower infill panel and remove the panel.

Tilt the glass forwards and slide out (Fig. 4).

6. Cut the foam sealing strip (in plastic bag supplied) to length and stick a continuous strip down the two sides

and across the top of the radiant box. When the box is placed against a flat surface the foam strip will form a

seal around the boxes flange.

7. Carefully lift the appliance into position in the fireplace opening and check that the flange of the radiant box

fits flush against the sealing face with no gaps present.

8. Remove the four screws that secure the burner tray to the box, two on the front leg and two at the rear of the

tray. Remove the burner tray and place to one side (Fig. 5).

INSTALLATION PROCEDURE FOR STANDARD 22” X 16” OPENING

5

Fig. 5

Burner tray

Blanking plate

Foam Sealing Strip

Magnetic Trim

2 x Securing Screws

Fig. 3

Fig. 4

5 x Machine Screws

Louvred Panel

Page 6

INSTALLATION PROCEDURE FOR STANDARD 22” X 16” OPENING CONTINUED

6

Radiant box

Hearth

Eye Bolts

Centre Line

Drill Holes for 4 eye bolts

on 112mm centre lines

between max and min height.

65mm

min

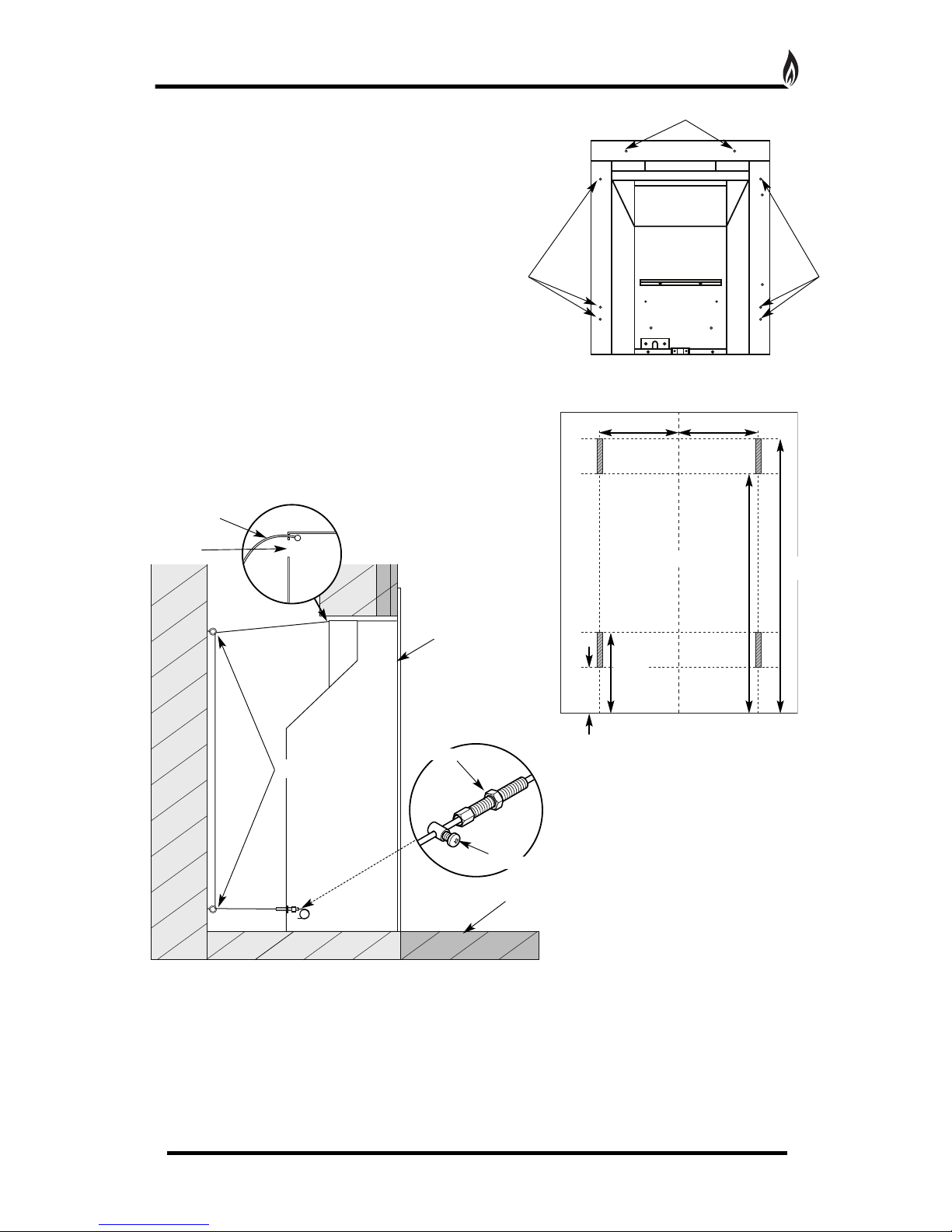

Fix the radiant box into the opening, securing into position using the cable fixing kit (Fig. 8). Do not cut off the

loose ends as the full length is required should the radiant box need refitting at any time. Coil up and securely

store underneath the burner tray.

1. Position the burner tray into the box in order to determine the length of 8mm gas supply needed and cut to

length.

2. Before making the final connection, thoroughly purge the supply pipe to clear any foreign matter, i.e. masonry

dust etc, as this could lead to blockages in the control valve and/or pilot assemblies.

3. Fix the burner in place using the four screws and make the gas connection. Carry out a gas soundness test.

ALTERNATIVE FIXING METHOD

Where the drilling of the back panel is not practical, an alternative

fixing method may be employed using the optional cable fixing kit

provided. Drill four holes in the rear of the fireplace opening (Fig. 7).

Securely fix the four eye bolts provided using suitable rawl plugs.

Feed one cable through each of the top holes in the rear of the

fire box.

115mm

max

500mm

min

550mm

max

112mm

112mm

Tension Nut

Cable Clamping Screw

Fig. 7

Fig. 8

Cable

Rectangular

Cutout

Insert cable into rectangular cutout

and feed the end back through the

small hole above the cutout.

Fixing

Holes

Fixing

Holes

Fixing Holes

9. When the burner tray has been removed, decide which

side of the appliance the gas supply will be entering the

radiant box and remove the relevant blanking plate. The

gas supply should be concealed as much as possible. Both

blanking plates MUST be re-fitted or this could seriously

impair performance.

10. With the radiant box placed in the opening, mark out

four of the eight fixing holes. Remove the box and carefully

drill and fit rawl plugs.

11. Pass the 8mm gas connection through the back of the

box and secure the box into place using four screws

(straight shank screws are recommended for marble).

Check that the outer flange of the appliance is completely

sealed against the back panel.

Fig. 6

Page 7

INSTALLATION PROCEDURE FOR DECORATIVE CAST SURROUND

7

1. Install the decorative cast surround into the fireplace opening and ensure it is fully sealed including the open

area above the fire (see Fig. 9).

2. Carefully lift the fire box out of the packaging taking care not to damage the ceramic components in the

separate carton.

3. Cut the foam sealing strip (in plastic bag supplied) to length and stick a continuous strip up one side, across

the top and down the other side of the rear of the radiant box. When the box is placed against the cast surround

the foam strip will form a seal around the boxes flange.

4. Lift the fire box on to the two studs at the top of the surround and

check that the flange of the radiant box fits flush against the sealing

face with no gaps present.

5. Locate the decorative frame on to the studs and secure with the

two nuts provided.

6. Insert the two screws into the lower holes in the decorative frame

and carefully tighten ensuring the fire box is securely clamped

between the frame and the surround.

Fig. 9

Decorative Cast

Surround

Securing

Studs

Securing Screws

Decorative Frame

ENSURE THIS AREA

IS SEALED

Foam Sealing Strip

Page 8

1. Modular Coal Set - The ceramic coals supplied with this appliance can be replaced at service intervals

depending on their condition. If the coals do require replacement, the consumer can do so provided that the

Ceramic Component Layout Instructions (pages 19-20) are adhered to. Under no circumstances should

additional/extra coals be added. Only genuine Legend replacement parts should be used.

Order Ref: EVCS01

2. Oxygen Depletion Sensing Pilot - In the unlikely event of a pilot failure, the pilot assembly should only be

replaced by a Gas Safe Registered Engineer. The user must not carry out this work.

Order Ref: LEG62

3. TESC Valve - In the unlikely event of control valve failure, the assembly should only be replaced by a Gas

Safe Registered Engineer. The user must not carry out this work. Order Ref: ETH02

4. Glass Panel - Should the glass become cracked or broken, the fire should not be used under any

circumstance.

Order Ref: LEG59

5. Glass Rope Seal - The integrity of the glass rope seal should be checked on service and replaced if

necessary by a Gas Safe Registered Engineer.

Order Ref: LEG58

COMMISSIONING

8

Gas Type Natural Gas (G20) Cat I

2H

Gas Connection 8mm

Number of Injectors One

Injector size Stereomatic 1.70mm

Control Max Operating Temperature 80

o

c

Inlet Pressure Cold 20 mbar

Heat Input (Gross) 4.6 kW (Full) 3.0 kW (Reduced)

Weight 10.4 kg

NOx Level Class 5

REPLACEMENT PARTS

TECHNICAL DATA

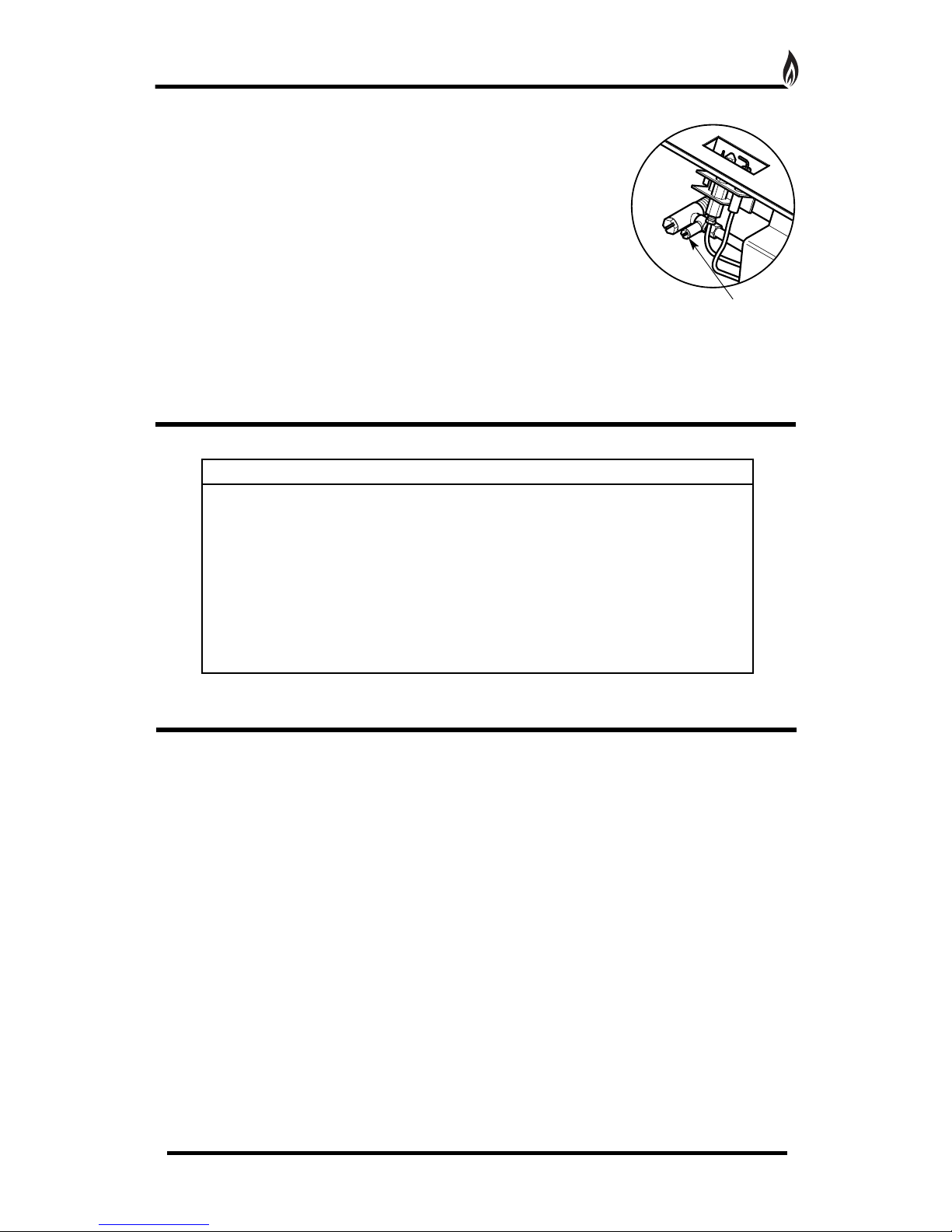

1. Unscrew the inlet pressure test point sealing screw (Fig. 10) and fit a manometer.

Consult the user instructions (page 12). Ignite the appliance and turn to the high position.

2. Take a pressure reading and consult the technical data (below) to establish the

correct working pressure.

3. Once the pressure has been checked and verified, turn off the appliance.

Consult the ceramic component set up diagrams (pages 19-20) and fit the

ceramics as per the instructions.

4. Re-install glass panel. The glass should be positioned centrally to ensure the

decorative trim will fit over it.

5. Carry out a Spillage Test (page 4).

Inlet Pressure

Test Point

Fig. 10

Page 9

TROUBLE SHOOTING (GAS SAFE ENGINEER ONLY)

9

NOTE: The purpose of the Error code is to give some information as to the potential reason for the fire not

starting rather than just no flame. The appearance of an error code does not mean there is necessary a fault

with the control or the appliance, it could be external factors outside the control that could cause error codes to

appear from time to time and they could just be a one off event , so please check and work through the

suggested service actions below before considering changing the control box. These codes are there to help

with a more certain and efficient servicing of the appliance. Changing the box without working through the guide

could lead to an unnecessary and expensive service and probably a repeat visit to fix the real fault.

SERVICING MUST ONLY BE CARRIED OUT BY COMPETENT PERSONAL WHO HAVE CURRENT

QUALIFICATIONS AND ACCREDITATION (I.E. GAS SAFE)

NOTE: After correcting fault, perform a restart to reset error display to normal standby mode. Also depending

upon the repair, air will need to be bled out of the system and it may take several start attempts to do so. E00

may appear and need to be reset a few times during the purging process, depending upon the length of supply

pipe. Bleeding the supply pipe via the isolation valve pressure test point will help speed up this process.

NOTE: Before undertaking any actions on the servicing as detailed below , replace the batteries in the control

and handset (if applicable) with new and know to be good batteries. Faulty batteries will cause error codes.

There is a difference between old and faulty batteries and they may give false errors if the batteries are faulty.

ALWAYS CHANGE ALL THE BATTERIES TOGETHER AND NOT JUST ONE OR TWO AND ALWAYS OF

THE SAME MAKE AND TYPE (I.E MANUFACTURER AND MODEL TYPE).

Generally : After replacing the batteries, to clear the error code perform a start cycle by pressing the start button

as normal. Then press again in the same way to attempt a new start cycle. The error code must be cleared this

way after every error code is displayed to start again.

Page 10

TROUBLE SHOOTING (GAS SAFE ENGINEER ONLY)

10

Reset control by pressing start button for 1 second and releasing. Then press again the same way

to attempt a normal start command. Repeat up to 10 times as necessary to see if this overcomes

the issue as it may resolve itself eventually.

Check to see if gas is present at gas appliance inlet. (Check gas supply is on, the gas line purged of

air and the supply pipework is free of blockages or contamination)

Rectify and perform start

cycle to clear the Error code.

Try to light the fire as normal.

No gas on appliance

inlet

Clean the pilot free of any dirt, dust carbon granules or lint, especially around the brass body of the

bunsen burner and its gas and electrical connection and the area around the flame ports and the

spark plug and electrode tip. Check the electrode gap is 3- 4 mm.

Rectify and perform start cycle

to clear the Error code. Try to

light the fire as normal.

Replace pilot if necessary

Pilot contaminated with

lint or other materials

Check ignition cable for damage and listen and watch for tracking out of spark to see if it is present

but not making it to the electrode tip on the pilot burner.

If cable damaged, replace

cable. Reset error by

performing a normal start

cycle and try to start again.

Replace pilot if necessary.

Reset and try again

Reset and try again

No Spark at Electrode

(fire not igniting pilot

burner)

Clear pipe and consider changing pilotPilot pipe or pilot injector

could be blocked)

E00

Code Comment Apperance Possible Cause Action

TESC locked due to

failed ignition

Red Led is

permanently on

TESC unit ( and

E00 on handset, if

used)

Temporary air

disturbance around pilot

burner

Check pilot pipe, check flame appearance of pilot flamesE01 Low current from

thermocouple but

flame: possibly CO

alarm

Flashing Red LED

on TESC Co ntrol

Pilot pipe blocked - no

gas reaching pilot

burner

Occurs if started ok then subsequently loss of thermocouple current. Check for flue problems. Fire

cuts out to prevent over heating

E02 Too high ambient

temperature ( >73 °C)

around control

Negative flue pull or

blocked flue or similar

Reset and try againCheck if connected correctly and terminations are soundE03 No, defective, or bad

connected

thermocouple

Bad connection

Reset and try againSensing flame on pilot when no flame should be there. Investigate.E04 False flame signal Occurs during stopping

fire

Reset and try againReplace batteriesE06 Too low voltage on

power supply to start

the burner

Weak or old or defective

batteries

Reset and try againReplace batteries / power adaptorE07 Power supply

breakdown during

peak current

consumption

Check/change all the

batteries or check power

adaptor. : Note always

change all batteries

together never only 1 or 2

Reset and try againReplace if necessaryE08 Error caused by

external pressure

switch

Check the pressure

switch

Reset and try againCheck pressure switch connections, check to see if jumpers are in place on back of TESC.E09 Error caused by

external pressure

switch

Pressures switch action

connection or jumpers

missing or not connected

properly

Reset and try againCheck pressure switch connections, check to see if jumpers are in place on back of TESC.E10 Error caused by

external pressure

switch

Pressure switch action

connection or jumpers

missing or not connected

properly

Reset and try againCheck switch for damage, contamination across terminals or damaged wiring. Disconnect wired

thermostat if fitted and try a start, if it works replace thermostat

E11 Short circuit on wired

thermostat (if used)

Check switch

Reset and try againCheck switch for damage, contamination across terminals or damaged wiring. Disconnect wired

thermostat if fitted and try a start, if it works replace thermostat

E12 Open circuit on wired

thermostat (if used)

Check wiring and

thermostat

Reset and try againCheck switch for damage, contamination across terminals or damaged wiring. Disconnect wired

thermostat if fitted and try a start, if it works replace thermostat

E13 Wired thermostat is

out of tolerance

Check wiring and

thermostat

Reset and try againClean as necessary. Replace switch panel as necessary if damaged or too contaminated.

disconnect wired control panel and try again – if it works replace wired control panel

E14 Button (-) sticks

either on TESC or on

wired control panel (if

used)

Check for contamination

around buttons

Reset and try againClean as necessary. Replace switch panel as necessary if damaged or too contaminated.

disconnect wired control panel and try again – if it works replace wired control panel

E15 Button (+) is shorted

to other buttons

either on TESC or on

wired control panel (if

used)

Check for contamination/

damage

Reset and try againClean as necessary. Replace switch panel as necessary if damaged or too contaminated.

disconnect wired control panel and try again – if it works replace wired control panel

E16 Button (ON/OFF) is

shorted to other

buttons either on

TESC or on wired

control panel (if used)

Check for contamination

/ damage and replace

wired switch panel if

necessary

Reset and try againJumpers on back of

valve missing

Check to see if jumpers

are in 10 way connector

Reset and try againCheck and clean around the area of the pilot for lint and other contamination. Check where the

thermocouple connects to the TESC control for the same contamination. Clean these areas.

E05 False flame signal Flame sensing on pilot

before start of ignition

sequence or after valve

has shut off.

Contamination of

electrode to ground

Reset and try againReplace PilotDefective thermocouple

Check and clearBlocked flue

Reset and try again

Check manual for correct placementPoor position of

Ceramic parts

Check flueChimney blocked

causing Co / Co2 to

build up in the room

build

Change pilot or thermocouplePilot thermocouple

defective / old

Clear error and restart to check ignition okPossible temporary air

disturbance on pilot

flame

Page 11

TROUBLE SHOOTING (GAS SAFE ENGINEER ONLY)

11

Reset and try againClean as necessary. Replace switch panel as necessary if damaged or too contaminated.

disconnect wired control panel and try again – if it works replace wired control panel

E17 Button (-) is shorted

to other buttons

either on TESC or on

wired control panel (if

used)

Check for contamination

/ damage and replace

wired switch panel if

necessary

Reset and try againClean as necessary. Replace switch panel as necessary if damaged or too contaminated.E18 Button (AUX) is

shorted to other

buttons on switch

panel

Check for contamination

/ damage and replace

wired switch panel if

necessary

Reset and try againCheck if wired correctly and replace IR eye if necessaryE19 Infrared receiver

defective (if used)

Check connection of IR

or damage - replace if

necessary IR eye

Reset and try againCheck if wired correctly and replace IR eye if necessaryE20 Illegal setup

parameters

Check connection of IR

or damage - replace if

necessary IR eye

Reset and try againUsually only a factory assembly error. Could happen if done in error in servicing.E21 Tried to config a

TESC as Clusterslave

while a wired

thermostat is

connected

Factory assembly

warning on setup

configuration not a

maintenance error

Reset and try againDisconnect thermostat before attempting using Easy test unit.E22 Tried to calibrate

TESC with TESC

easy test while a

wired thermostat is

connected

Not field error

Reset and try againIndicated that control has performed a high number of operations and so fire should be serviced and

control replacement should be considered as preventative maintenance. (should not really occur

before 10 years from new).

E23 Warning: end of life is

near, should be

replaced soon

Not field error

Reset and try againCheck and correct Thermocouple wiring. Replace thermocouple if necessaryE24 Thermocouple

doesn't reach final

current - damaged or

aged

Replace Pilot

Reset and try againCheck pilot thermocouple connections and connections to TESCE25 Poor thermocouple

signal

Tired or bad connection

of thermocouple or bad

or unstable flame on pilot

or poor grounding return

Reset and try againReplace with new USB power supply of the correct type.E26 Defective or wrong

wired USB-power

supply

Try again and if

repeatedly fails replace

Reset and try againCheck and correct Thermocouple wiring. Replace thermocouple if necessaryE48 Short circuit on

thermocouple, or

thermocouple

reversed polarity

Wrongly wired

Reset and try againCheck if and clean around the area of the pilot for lint and other contamination and clean. Check

where the thermocouple connect to the TSC control for the same contamination. Clean these areas.

E49 False flame signal Flame detected during

operation of fire when it

should not be detected contamination of

electrode circuit to

ground

Reset and try againCheck if and clean around the area of the pilot for lint and other contamination and clean. Check

where the thermocouple connect to the TSC control for the same contamination. Clean these areas.

E50 Internal error

Reset and try againCheck pressure switch connections , check to see if jumpers are in place on back of TESC.E51 Error caused by

external pressure

switch

Reset and try againE52 Error

Reset and try againE27 Error

Reset and try againE28 Error

Reset and try againE29 Error

Reset and try againE30 Error

Reset and try againE31 Error

Reset and try againE32 Error

Reset and try againE33 Error

Reset and try againE34 Error

Reset and try againE35 Error

Reset and try againE36 Error

Reset and try againE37 Error

Reset and try againE38 Error

Reset and try againE39 Error

Reset and try againE40 Error

Reset and try againE41 Error

Reset and try againE42 Error

Reset and try againE43 Error

Reset and try againE44 Error

Reset and try againE45 Error

Reset and try againE46 Error

Reset and try againE47 Error

Reset and try againE53 Error

Reset and try againE54 Error

Reset and try againE55 Error

Reset and try againE56 Error

Reset and try againE57 Error

Reset and try againE58 Error

Reset and try againE59 Error

Reset and try againE60 Error

Reset and try againE61 Error

Reset and try againE62 Error

Reset and try againE63 Error

Flame detected during

operation of fire when it

should not be detected contamination of

electrode circuit to

ground

Reset and try againCheck and correct Thermocouple wiring. Replace thermocouple if necessaryCheck pilot connections

Reset and try againClear pipe, replace pilot as necessaryPilot pipe may be

blocked completely

Code Comment Apperance Possible Cause Action

Page 12

USERS INSTRUCTIONS

12

Warnings

All parts of the appliance become hot while running and should therefore be considered to be

working surfaces.

A suitable guard may be required to take account of special hazards that exist in nurseries and other

places where there are young children, aged or infirm persons.

Curtains are not to be placed directly above the appliance.

It is recommended that combustible materials are not placed directly above this appliance.

This appliance should not be used if the glass door has been removed, broken or is open.

Fire Control

This control is situated on your fire. The drawing shows the main features of the control.

Check the power isolator switch is in the On position (I).

To start the fire, press the power button and hold for 1 second then release. The burner will light within around 1

to 10 seconds, adjust to the maximum power setting.

The power of the burner can be adjusted up and down by pressing the – and + buttons.

To stop the fire, simply press the power button again and the burner will stop.

If for any reason the fire should be switched off, either intentionally or unintentionally, no attempt should be made

to re-light the gas until at least 3 minutes have elapsed.

If you are not intending to use the fire for a long period (i.e. over summer time months), the battery life can be

extended even more by sliding the white isolator switch to the left (away from the On position to (O)).

Indicator light

Decrease flame

Increase flame

Battery compartment cover

Battery compartment

cover opening lever

Power button

White power isolator switch (sliding)

Fig. 11

Page 13

USER INSTRUCTIONS

13

Handset

Ensure the Power Isolator Switch on the front corner of Fire Control is in the on position (I).

Note: For safety reasons a button must be pressed and released for the command to be recognised. Keeping

hold of the button when pressing (unless otherwise instructed) will not be recognised as a command press.

Grasp around the handset to unlock its functions. The green unlock light will illuminate to show when the

handset is unlocked and ready to accept commands. (N.B. Keep a grip of handset to keep it unlocked, to

continue to operate the command buttons.)

Mode - MAN (Manual), Zzz (Snooze), thermostat or timed.

Time (12 hour or 24 hour display

In range of fire

(missing if not in range or if

fire controlled turned off)

Room temperature

can be set to

fahrenheit/celsius

Handset unlocked when

illuminated

To change handset

settings (see handbook)

Press to increase flame

Day of the week

Gas fire burner status

Battery condition

RC handset, FC fire control

Light sensor

(for display backlight)

To change mode

(see handbook)

Press to decrease flame

Power button – To start the fire, (after ensuring the fire control is turned on as described above), with one hand

grasp around the rear of both sides of the button area control. The green unlock light will illuminate. Keep the

handset held to keep the control unlocked, to enable operation of the buttons. Then with the other hand touch

and hold a finger on the power button for about 3 seconds. A short beep and a flash of the unlock light will

happen upon touching. When the word “pilot” appears at the bottom left hand corner of the display, immediately

release the power button. The Fire should be lit within a few seconds.

(N.B. If power button is held for more than a few seconds after second flash/beep/word pilot appears, the

command is ignored for safety reasons. Similarly if it is released too soon before the word “pilot” appears, the

command would also be ignored.

Fig. 12

Page 14

USERS INSTRUCTIONS

14

Operating instruction (Detailed)

THE HANDSET AND CONTROLS SHOULD ALREADY BE PAIRED AND THE DAY AND TIME SET

CORRECTLY.

SHOULD ANY ADJUSTMENTS BE NECESSARY SEE INSTRUCTIONS BELOW:

Setting the time

Following pressing “SET” at paring above, the display will be as shown, as the time is not set yet

and will progress automatically to the next screen shown below.

Note: the legend at the bottom shows the battery condition of both the batteries in the hand set

and in the fire control alternately. RC = Remote Control handset and FC = Fire control. The

control is designed to get the most out of the batteries but when eventually the display shows

they are spent(when the battery legend is a empty area, we recommend you change the batteries

in the handset before they are flat, to avoid having to re-program the time of day in again.

N.B. Pairing is not lost, even if the batteries are removed or flat.

Setting the display for 12 or 24 Hour display

As always when pressing the remote control buttons keep the control held to keep the green light

on and therefore handset safety feature, unlocked. The H indicates that it is time to set the timer

to either 24 hour display or 12 Hour (AM or PM ) display. Press the + or – button on the handset

to toggle between the two settings. When you are ready to confirm the setting you want press the

“SET” button to progress to setting the day of the week.

Setting the day of the week

Press and release the + and – buttons until the correct day of the week is shown on the display.

(Mo = Monday, Tu= Tuesday, We=Wednesday, Th=Thursday, Fr=Friday, Sa= Saturday and

Su=Sunday).

Press “SET” to accept the day of the week and to progress to setting the Hour of the day.

Note: Whilst doing this setup pressing “SET” advances to the next display and pressing “MODE”

will return you to the previous display setting.

Setting the Hour

Press and release the + or – button to change the hour to the correct hour and press set to store

and to move to setting the minute. Repeat this for setting the minutes.

Setting the temperature display to Celsius or Fahrenheit.

Press and release the + or - button to toggle between C and F. When the display shows the

desired symbol, press and release the “SET” button to store.

As the important settings above have now been done. Press and hold (not releasing straight

away) the “SET” button for a few seconds and this will exit the setup menu.

The control is now ready for use with the Fire Control.

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Page 15

USERS INSTRUCTIONS

15

Paging the handset

If you have misplaced the handset you can page it by pressing the + button only on the fire control for around 5

seconds. The handset will flash and make a noise to help you to locate it. Once you pick up the TESC it knows

you hold it and so the sound stops. The flashing and sound will last for 60 seconds each time the handset is

paged as described. If not found in 60 seconds,

page again and so on.

NOTE: Press “+” button ONLY, NOT “+” and “-” together. This will break the handset pairing and have to

reset handset to factory state and pair again.

Advanced settings Menu

In the event that you may want to change the other preset settings of the control features. Do not do a long

press and hold above but a normal short press and release will take you into the advanced settings area.

Advanced settings options are:-

• Back light –

• A = Automatic (default setting). The back light comes on in the dark but not in the light.

• 0 = Light never comes on.

• 1 = Light comes on when ever handset is unlocked.

• Display contrast – 8 levels from 0 to 7 (default level 4) .

• P = pairing with other devices other than the fire control. The hand set can pair with other modules to:-

• L= Operate an electric light – which is the dimmable in 9 steps

• F= operate an electric fan –which can have 9 speed levels

• A= operate an auxiliary contact to operate another device.

Other Modes than Manual Mode

Depending upon the model of Fire your handset maybe enabled to have some automatic features, namely,

Thermostat mode, timed thermostat mode and snooze mode. Snooze mode can be selected to work with in

conjunction with either manual or thermostatic modes. You can switch between modes at any time with the

handset unlocked by pressing and releasing mode button to toggle between modes.

Note: If at any time the power button is pressed during operation, this will stop the fire and exit any automatic

mode and return the handset to manual (MAN) operation mode.

Factory Reset of Display Handset (to enable handset to be paired again)

To reset a handset to factory conditions to enable it to be paired with a new control. Hold the handset to unlock.

Press and hold set until handset beeps and release the set button. PROG will be at the top left corner. Press

and release the mode button until the word SETUP is flashing in the top right corner.

Press and release SET to enter the SETUP menu.

Press and release the set button around 9 times until you see CA0 on the display.

Press then release the + (or – button) to change the display to CA1 and press and release the SET button again.

The word TESC will appear in the window to show that this handset is now reset and ready to pair again.

Snooze mode in manual operation

Snooze mode is a time period you can set which will turn off the fire after a certain time period has elapsed.

The snooze time period can be set before or during manual operation of the fire. Hold the handset to unlock as

described previously and press the mode button as many times as necessary until the word MAN and the Zzz

symbols are flashing at the top of the display. Press and release the set button and this will put the control into

Manual snooze mode.

The default time period for the snooze time period is 1:00 hour. Pressing the set button again will show you the

snooze time period remaining. This can be adjusted by pressing the “+” or “-“ buttons. The timer period that can

be set is from 1 minute to 4:00 hours.

After adjusting the time, press set again to enter the time setting required (or if left for a few seconds this time is

now stored and used).

Once this countdown timer has reached zero the fire will turn off (as if you had pressed off manually, it does not

recycle).

Page 16

USERS INSTRUCTIONS

16

Snooze mode in Thermostatic mode

The same thing as above can be done before or during a thermostatic mode operation (see below).

Thermostatic mode only

The handset has within it a thermostat sensor and this can be set so the fire will heat the room to match the

temperature set in the handset.

There are 3 temperature types that can be set:-

-Day mode temperature that has a sun symbol on the display – the default

temperature is 24 °C

- Night temperature that has a half moon symbol on the display- the default

temperature setting is 18 °C

-frost protection that has a snowflake symbol on the display – the default

temperature setting is 5 °C

Hold handset and press and release the mode button several times as necessary until the display has a

thermometer symbol flashing at the top of the display. Press the set button to enter this mode.

Press the set button again to see the temperature setting that is set and the mode (the default is 24 C ) and on

the left of the display is a sun symbol showing it’s the day temperature.

If a different set temperature is required, while the display is showing this set temperature , press the + and –

buttons to alter the setting. When finished either press set or leave and after a few seconds the new setting

will be accepted and the display will return to the time of day screen.

On the anniversary of the net minute of the clock, the set temperature will be compared to the actual

temperature displayed on the handset(i.e. the room ambient temperature around the handset).

Note: If at any time the power button is operated during Thermostat mode, the control will cancel any thermostat

operation and return the control to manual mode.

For ease of setting there are two other modes that can be selected as stated above. Night mode (moon symbol)

and frost protection setting (a snow flake). These can be selected (and adjusted if necessary) by pressing set

then mode while in thermostat mode. Pressing mode button toggles through from day to frost modes.

Note: As stated in an earlier section, snooze function can also be operated in conjunction with thermostat mode.

The thermostat symbol and the Zzz symbol will be on together when in this mode.

The remote control display handset supplied with this fire will have already been factory set and should

not need to be adjusted or re-paired. Read the operation instructions fully before attempting to de-pair

the handset.

De-pairing and re-pairing the handset.

Note: Reading this instruction fully, will help the user to carry out the quick set-up procedure, it may take a few

attempts to learn the sequence of commands due to the fast handset time-out period.

Should the handset fail to operate the fire control (and batteries are new), it may be necessary to re-pair it with

the gas fire control system.

To do this the handset may need to be returned to factory settings.

1. Pick up in a grasp to activate handset and then press set button until PROG shows on top left of screen.

2. Use the mode button pressing twice to show SETUP on top right of screen.

3. Again press SET button and H24 should show, scroll through menu with 9 more presses of set button until

CA0 shows, then immediately press + so CA1 shows, then again quickly press set so screen

shows 7ESC r4.

The handset is now ready for repairing with the gas fire control.

The handset must be within 1 metre of the fire when pairing and must be initially held to illuminate

and also initiate set up.

Simultaneously press the hold the – and + buttons on the gas fire control (i.e. not the handset)

unit the red neon on top left of fire control begins to flash rapidly, then immediately release – and

+ quickly pressing the power button below. An audible command signal is sent out to the handset

which is accepted by immediately pressing the set button (there is a 2 second time window to

press the power button or – and + will have to be repeated).

The handset will make a noise and the handset will show a pattern (7- - r).

Immediately Press the Set button on the illuminated handset to accept the command for pairing.

Scroll through the menu using handset SET button, adjusting the day, time with buttons – and + then press SET

button 6 times until screen shows a full display with wi- fi symbol.

Fig. 18

Page 17

It is recommend that this appliance is serviced at regular 12 monthly intervals. The chimney or flue

should also be checked regularly to ensure that all products of combustion are entering the flue and

there is no excessive build up of soot.

It is the users responsibility to ensure that the appliance is kept in a clean serviceable condition.

To remove the glass

1. Remove the magnetic trim.

2. Remove the louvred panel by lifting

up and pulling forwards.

3. Slacken the five machine screws on

the top retaining strip (Fig. 19).

4. Unscrew the two securing screws

from the lower infill panel and remove the panel.

Tilt the glass forwards and slide out (Fig. 20).

5. Clean the glass with a damp cloth. For stubborn stains use

a proprietary cream cleaner or ceramic hob cleaner.

Ceramic Components and Fuel Bed

Debris from any source should be removed with a soft brush.

Please ensure that any debris including soot deposits are

removed from the appliance and not left on the fuel bed.

It is recommended that the user should, on a regular quarterly

basis, carefully remove all ceramic components and thoroughly

clean the stainless steel burner strip and the pilot assembly.

Any build up of debris in this area could affect the

operation of the appliance (Fig. 21).

NOTE: It is common to find surface cracks in the ceramic components. This is due to the expansion and

contraction of the ceramic fibres caused by the intense heat that the burner generates. The cracks will not

affect the safe operation of this appliance. However great care must be taken when handling the ceramic

components as they will break if handled incorrectly. Do not use a vacuum cleaner to clean the ceramics.

Radiant Box Ceramic Liners - Use only a soft brush to remove any soot deposits from the ceramic liners

during cleaning as this is the only method that can be used to remove deposits. The ceramic liners are very

delicate and should be treated accordingly.

6. Reassemble in reverse order. The screws should be tightened enough to ensure the glass is sealed. The

glass should be positioned centrally to ensure the decorative trim will fit over it.

Trims and Frets - The trim and fret should be removed from the appliance for cleaning, please ensure that the

appliance has cooled thoroughly. Metal trims and frets maybe lacquer coated and therefore do not require

polishing.

CLEANING AND MAINTENANCE

17

Stainless Steel Burner Strip

Pilot Assembly

2 x Securing Screws

Fig. 19

Fig. 20

Fig. 21

5 x Machine Screws

Louvred Panel

Page 18

Fire fronts are now available in many different designs and finishes. The user can now choose their own

particular style of fire front to suit their individual fireplace setting, providing the fire front complies with the

following dimensions -

Fire Front - (X) Max: 210mm Min: 190mm

Ash Pan Cover - (W) Max: 90mm Min: 65mm

(Y) Max: 345mm Min: 320mm

SAFETY WARNING - This appliance has a naked flame and as with all heating appliances a fireguard

should be used for the protection of children, the elderly and infirm. Fireguards should conform to

BS 6539 (1984 Fireguards for use with solid fuel appliances). This fire is not fitted with an integral

guard. In normal use consideration may be given to the use of a fireguard confirming to BS 6539,

such that the approach to the naked flame is minimised.

FIRE FRONT SPECIFICATIONS

18

w

Y

X

Minimum area free space 15cm

2

Minimum area free space 5cm

2

Fig. 22

Page 19

MODULAR COAL LAYOUT INSTRUCTIONS

19

1. Place the main fuel bed on to the back section of the

metal burner tray. It is important that the front edge of

the fuel bed is located behind the burner strip, and the

holes in the fuel bed line up with the holes in the

Burner tray (Fig. 24).

3. Position the front coal piece on the front coal

retainer, making sure that the back edge is pushed up

against the front of the burner strip (Fig. 25).

CAUTION: The coals are extremely fragile and must be handled accordingly. Gloves should be worn

and any inhalation of dust should be avoided. The coals must be kept away from children at all times.

Never put additional coals on the fire. Never use coals other than those originally supplied, or

genuine Legend Spare Parts.

Fig. 23

Fig. 24

Fig. 26

Fig. 27

Fig. 25

Burner Strip

Burner Tray Holes

Fuel Bed Holes

Fuel Bed

4. Locate the remaining coal pieces in order as shown in Figs. 26 & 27.

Page 20

MODULAR COAL LAYOUT INSTRUCTIONS CONTINUED

20

Fig. 28

It is very important that all the coals are used and arranged as shown in order to

achieve the desired flame picture.

It may be necessary to remove some or all of the coals to clean them at some time.

Cleaning must only be done using a soft brush.

5. Finally check that all the coal pieces are ‘nested’ together correctly (Fig. 28) and a close fit is achieved on the

middle joint (this will stop gas surge through the gap).

Page 21

Page 22

Page 23

Page 24

Your appliance is guaranteed for one year from proof of purchase. Should the appliance prove defective within

that period we agree to repair or replace (at our discretion) the component or appliance provided that:

1. The user can produce a receipt for proof of purchase/installation.

2. The appliance has been supplied by an authorised stockist and has been installed by a qualified installer, all

installation and operating instructions have been strictly adhered to.

3. No alterations have been carried out on the appliance or component parts without our written consent.

4. The appliance has not been used for any purpose other than those intended.

5. The appliance has not been damaged accidentally or due to fair wear and tear.

Guarantee claims should be made through your appliance supplier. The Guarantee is restricted to UK Mainland

and is additional to your statutory rights.

TROUBLE SHOOTING (USER)

1. The Fire will not light.

Remove the decorative fret and ash pan door and check the pilot area for soot.

If soot is present remove all the loose coals and the front coal and thoroughly clean any debris

in and around the pilot area.

If the fire will still not light contact your installer.

2. The flames appear blue - excessive soot deposits.

The ceramic components including the coal need relaying (pages 19-20).

Too much or too little room ventilation. Seek professional advice.

3. Roaring noise coming from the pilot.

The front coal is not seated correctly. Turn the appliance off and allow to cool down. Re-seat

front coal, ensuring it is flat to the base of the front coal retainer (page 19).

4. All the Ceramic Components are discolouring.

The ceramic sets and liners are all manufactured from ceramic fibre. As these fibres are

naturally white, dyes are used to give a realistic appearance. These dyes discolour after they

have been subjected to intense heat. However the discolouration does not affect the operation

of the appliance. The realistic appearance can be restored with the use of a good replacement

dye that can be purchased from most good fireplace showrooms.

GUARANTEE

Unit 404 Glenfield Park Business Centre Blakewater Road Blackburn Lancashire BB1 5QH

Tel: 01254 695244 Fax: 01254 695255 Web: www.legend-fires.com Email: info@legend-fires.com

Draft B - 19/07/16

Loading...

Loading...