Page 1

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

Firebox

INSET

INSET SOLID FUEL ROOM

HEATER

FOR INSTALLATION IN

STANDARD BRITISH or IRISH

FIREPLACES CONFORMING TO

BS1251 & BS8303

INSTALLATION AND OPERATING INSTRUCTIONS

LEAVE THIS DOCUMENT WITH THE HOUSEHOLDER!

Intermittent burning solid fuel room heater for installation in masonry

fireplace with a single dedicated chimney.

Wood logs

Mineral fuel (Ancit)

Approx. efficiency

51.4%

61.5%

Nominal Output

3.2Kw

5.0kW

Minimum air space

around fire

Back = 0mm, Sides + Top = 100mm

Minimum clearance to

combustible materials

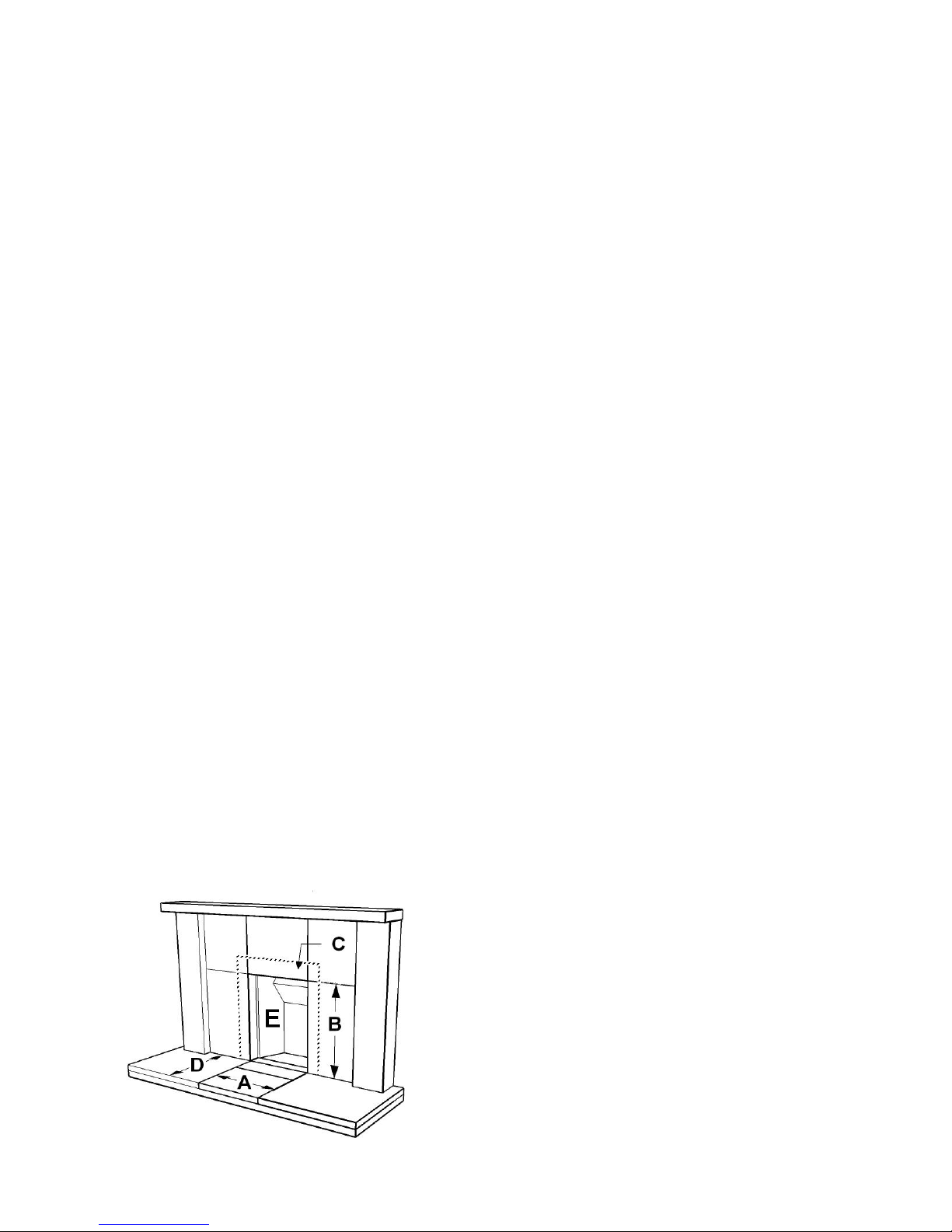

Must be maintained

Top: 400mm

All other faces: 250mm

Manufactured by Cast Tec Limited

East Side, Tyne Dock

South Shields

Tel. 0191 497 4280, Fax 0191 497 4288

EN

Page 2

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

Read these instructions! Use only recommended fuels!

IMPORTANT

Co2 DETECTOR

It is the responsibility of the installer to fit a fully operational Co2 detector in the same room as this appliance.

Contained in this box are the following components

3 x Stove securing bolts and washers

1 x Clamping bracket

1 x Operating tool

(Fig 1) Box contents

Fixing kit comprises three securing bolts and washers and a clamping bracket for securing the stove to your hearth.

INSTALLATION

INSTALLING: a stove is a 'controlled service', the law expects that it is either supervised by a qualified installer or that the building

inspector is informed. Check with your local authority.

ASBESTOS: Your stove does not contain any asbestos, but take care to avoid disturbing asbestos in an old installation.

WEIGHT: Your stove is heavy - take great care when moving it and ensure that the intended fireplace can support the weight- consider

fitting a load distributing plate.

THIS APPLIANCE CAN PRODUCE POISONOUS GASES IF NOT FITTED CORRECTLY. IT, AND ITS FIREPLACE

CAN BECOME EXTREMELY HOT

A fire-guard should be used if children or the infirm are present. The installer is required to EXACTLY follow these

instructions and to completely comply with all local, national and international standards.

Page 3

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

YOUR CHIMNEY: by becoming warm, makes the gas inside it rise, pulling fresh air into the stove to make it work. It must:

! Generate a draught in use of at least 12Pa (0.05ins wg)

! Be capable of withstanding the temperatures generated.

! Be incapable of leaking fumes into the dwelling

This will commonly be achieved by it:

! Being at least 5m high.

! Terminating at least 1m above any roof ridge.

! Having an internal cross-section not less than 0.018m² (e.g. 150mm diameter) and never more than 0.14m² (e.g. 375 x 375mm)

! Being free from even the slightest crack or source of leakage.

! Having no bends sharper than 45º.

! Being entirely free of obstructions and swept by a qualified chimney sweep.

! Being connected only to this one appliance.

! Being of thick masonry or otherwise adequately insulated.

! Conforming to local building regulations.

Special rules apply where the flue passes through timber, thatch or other vulnerable materials- take specialist advice.

Although it is possible to access the chimney through the fire with the throat plate removed, fit hatches to provide access if needed.

AIR SUPPLY: Your stove needs air to breathe - there must be a permanent fresh air supply into the room in which it is installed equal

to about 550mm² (e.g. 23mm square). This can often be provided by air naturally leaking into the building (it is commonly accepted

that this alone can suffice for appliances <5kW) but in any case of doubt, fit a purpose-made air vent. An extractor fan, or another fuelusing appliance, even in a different room, can remove this air.

LOCATION:

To prevent the risk of fire, the location into which your Stove is fitted must always:

• Have no combustible materials (such as a wooden surround) within 250mm of the stove sides or 400mm above

• Be made of materials able to continuously withstand 250ºC

• Even outside these distances take care in locating vulnerable materials such soft furnishings, decorations and other

flammable materials.

CHIMNEY SWEEPING:

Although it is often possible to sweep the chimney through the fire with the baffle plate removed, consider fitting cleaning hatches to

provide access if needed.

FITTING:

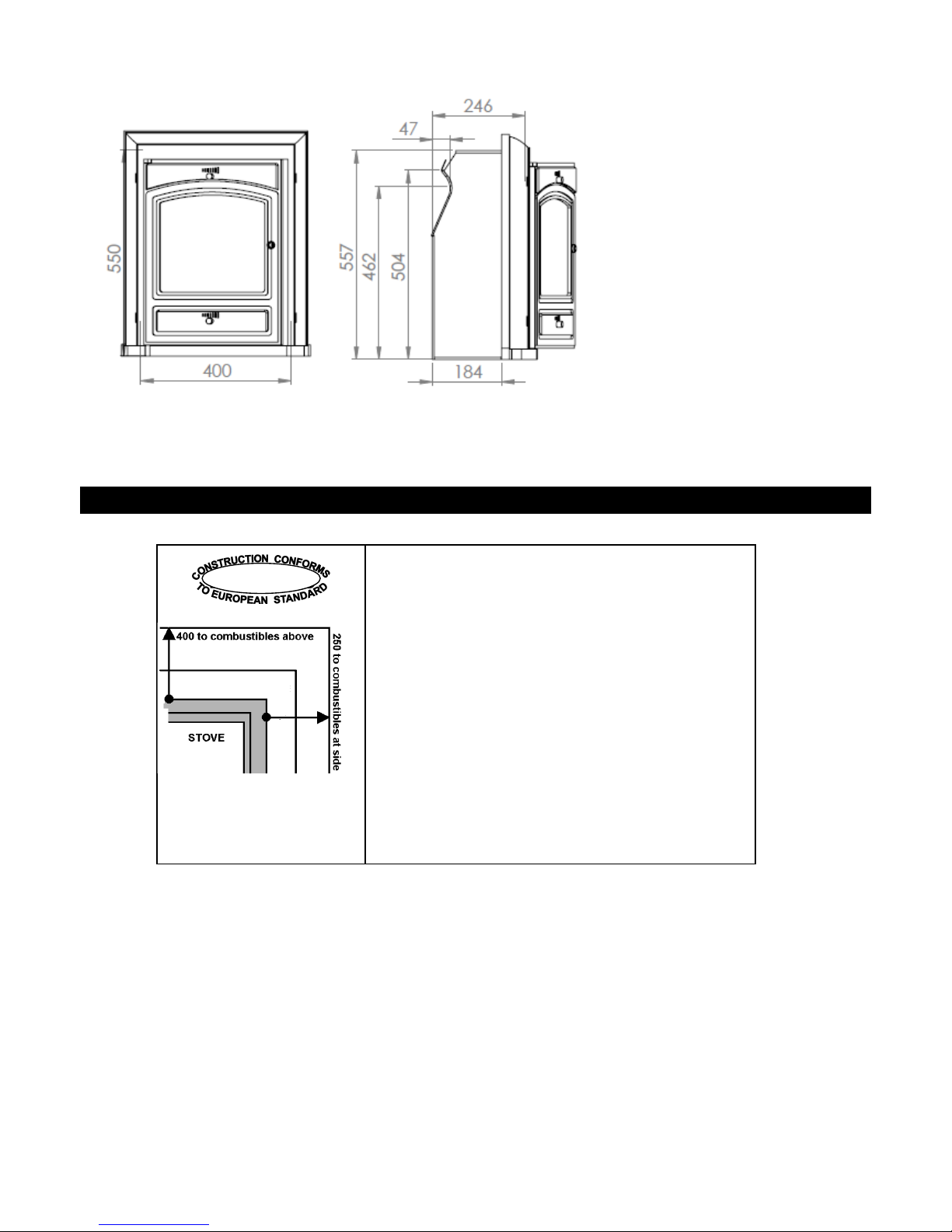

The stove can fit straight into a standard fireplace (Fig 2) conforming to BS1251 & BS8303, which will:

• Have an opening width (A) of between 400 and 420mm,

• An opening height (B) of between 540 and 560mm,

• A flat area (C) extending 70mm around the opening

• Have a heat-resistant hearth extending at least 300mm (D), without obstructions to prevent the door opening.

• Have the chair brick removed.

• Where thin slabs of mineral material (marble, limestone etc.) are used to face a fireplace, we recommend using separate panels, as

shown, to allow for differential expansion.)

• In the case of fixing the stove directly to a flue pipe, a cast iron spigot 6” diameter flue converter can be purchased

separately which fits to the stove via two bolts (Fig 10). This can be reduced down to fit a 5” flue pipe via a reducing ring if

needed.

• Position the stove into the fireplace opening, ensuring that the rope seal on the rear of the stove forms an absolutely airtight seal

against the fireplace. In some cases it may be necessary to knock-out part of the old fireback.

• Position the clamping bracket to the base of the hearth ensuring that it overlaps the rear inside lip at the back of the stove (Fig 3)

Secure the stove with a securing bolt into the hearth through the hole in the base of the clamping bracket (Fig 3) and two securing

bolts into the bottom front of the opening (Fig 4). It is not necessary to fill any small gap behind the appliance – larger gaps can be

filled with rubble, vermiculite granules or mineral fibre.

(Fig 2)

Page 4

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

Position the stove into the fireplace opening to ensure a perfect fit

(Fig 3) (Fig 4) Fixing Holes

Install base plate (Fig 5) then LH side brick, back brick then RH side brick as (Fig 6)

(Fig 5) (Fig 6)

Install grate so that it sits firmly upon the back brick ledge (Fig 7) and install the baffle (Fig 8) as described on page 5 (Fig 13/14)

(Fig 7) (Fig 8)

Page 5

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

Rear view of stove without baffle (Fig 9), Cast iron spigot 6” diameter flue converter (PURCHASED SEPERATELY) (Fig 10)

(Fig 9) (Fig 10)

Air control slider (Fig 11), Inside of door showing rope seal, Air control slider and glass fixings (Fig 12)

(Fig 11) (Fig 12) Door handle catch Top glass tabs

Baffle plate fitting and removal – Place the baffle inside the stove with the folds facing upwards and the small fold to the back of the

stove (Fig 13). Lift the baffle at an angle and push the small folded end through the flue at the back in the roof of the stove (Fig 14).

Lift up the front of the baffle to the roof of the inside of the stove then pull towards the front so that it locates onto the two ledges located

inside the stove. This should then sit firmly in place. Should you wish to sweep the chimney then remove the baffle plate by reversing

instructions for fitting the baffle.

(Fig 13) (Fig 14)

Page 6

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

CHECK THE INSTALLATION !

Once installed, light the fire, demonstrate it to the householder and check that:

• It burns controllably and does not emit fumes to the room

• The route for gases from the stove to the chimney terminal is completely airtight, unobstructed and able to be swept.

• The entire construction is of durable fireproof materials.

• The flue presents a draught in use of at least 12Pa

LIVING WITH YOUR STOVE

Every fuel, chimney and condition of use is different. Only experience will show which the best settings for you are.

LIGHTING If lighting after a period of non-use, do check that the flue ways and chimney are completely

clear. Empty the ashes. Place firelighters or screwed-up paper covered with dry sticks at the back of the

grate and light them. When they are burning well gently fill the fire with dry fuel, close the door and set the

air control slides to the 'high' (right) position. As soon as the fire is burning well, move the controls to the

lowest practical setting. During the ignition stage you should not overload the fire, it is better to load little

and often.

CONTROL How fast the fire burns depends on how much air reaches the fuel. The stove when not

burning in a smoke control zone has two air controls, one above the window ('air wash control' ") and

one below the window ('primary' #). Move the slides to the right for highest output, to the left for 'low'. Our

tests indicate highest efficiency on wood with the primary control all but closed and the air wash 2/3 open. Anthracite works best with

the air wash closed and the primary 1/3 open. But the best settings will depend on your fuel, air supply and flue draught and can only

be found from experience.

EMPTYING ASHES use the tool or handle or a glove to open the door. Stir the fire with a poker and use the tool to lift out the ashpan.

Remember to let ash cool before disposing in plastic sacks or dustbins. There is no need to empty every last speck, but ash from

mineral fuels should never be allowed to build up so that it comes into contact with the underside of the grate.

CLEANING Wipe the stove body with a slightly damp cloth when cool, don't use abrasives, metal polish or 'cream' cleansers as they

can scratch the surface. NEVER use aerosol sprays near the hot fire – they can ignite.

KEEPING THE WINDOW CLEAN With most fuels the window will require no cleaning other than an occasional wipe with a dry cloth

when the stove is cold. Operating the stove at high output will usually burn-off any deposits left by tarry or wet fuels. Severe stains can

be removed with a proprietary cleaner. After a period of use tiny hairline cracks may appear on the window, this is not a fault, but is

characteristic of the toughest and most heat-resistant material currently available. Reduce the risk of staining by using only very dry

fuel and having the air wash control always slightly open.

OPENING THE DOOR This stove is designed to be operated only with the door closed. Open the door very slowly to minimise fume

emission and prevent hot fuel falling out.

FUELS

There is no 'perfect' fuel, so we strongly recommend that you try a selection of fuels (or mixtures) to find which suits you best. Do avoid

dusty materials like sawdust; they can burn far too violently.

SMOKE CONTROL AREAS:

In certain areas of the UK (Smoke Control Areas) special rules apply to reduce smoke nuisance. This appliance is only

exempt when burning dry wood logs of suitable size detailed below or authorised fuels. Details of authorised fuels can be

obtained from your local authority.

When an appliance is installed in a smoke control area the appliance must be fitted with a mechanical stop to fix the

secondary air control open. This may be removed if you are not within a smokeless zone or do not intend to burn wood.

WOOD: Wood only emits as much carbon to the atmosphere as the tree took in when growing, so wood is considered the 'carbon

neutral' fuel. When wood is cut down its cells are full of water. Burning such wet or 'green' wood wastes heat in making steam and

produces flammable acidic tars which will cling to and rapidly damage your stove and chimney. Split logs will typically take two years to

become reasonably dry, round logs much longer. Cracks in the ends, a hollow sound when tapped and bark falling away are all signs

that a log may be ready for use. The fine, white residue produced when wood burns is not ash, but the remains of cell walls which can

burn if kept hot enough, so don't de-ash the fire until absolutely necessary.

Page 7

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

For best performance on wood, and always if low smoke emission is expected:

• Split logs lengthways for drying

• Use logs no bigger than about 100mm x 250mm

• Ensure logs are absolutely dry (less than 20% moisture)

• Fill the stove criss-cross, so air can circulate between logs.

• Fill 'little and often'

• Always have the air wash control (1) at least a little open. (in Smoke control areas this must be permanently fixed open)

• When first lighting, or reviving a fire from embers, use only very small, thin, dry, sticks.

JOINERY WASTE: Dry wood offcuts will burn well, but don't expect softwood waste to burn as cleanly or for as long as hardwood logs.

PEAT: Sod turf must be thoroughly dry. BNM peat briquettes are approved for use in Smokeless Zones in the RoI.

LIGNITE: (not smokeless) is a natural mineral, between peat and coal. It lights easily and burns well, but produces much ash

HOUSECOAL or BITUMINOUS COAL: (not smokeless) makes lots of tarry smoke and large volumes of flammable gas which make it

difficult to control and risk explosions. Despite its low cost, it rarely represents value for money. Don't use house coal.

ANTHRACITE: (Smokeless) is a natural hard, shiny form of coal. Slow to light, it can burn for very long periods with great heat. Despite

its high price-per-bag it generally works out to be one of the cheapest of all fuels. Use the 'small nuts' size. Anthracite works best with

the air wash closed and the primary 1/3 open. But the best settings will depend on your fuel, air supply and flue draught and can only

be found from experience.

COKE: (Smokeless) is coal from which the smoke has been removed. Sometimes difficult to light, it burns very cleanly.

BRIQUETTES: Are compressed blocks of fuel, generally able to burn for long periods and remarkable for their consistency. 'Homefire'

and 'Phurnacite' are smokeless types while other brands are made from lignite, peat or house coal.

PETROLEUM COKE: sold as 'Petcoke', 'Longbeach' and under various proprietary names, is made from oil. Easy to light and to

control, its exceptional heat and lack of protective ash mean that it MUST NOT be used unless mixed with another fuel. Grate and liner

life will be drastically reduced when using petroleum coke

HOUSEHOLD WASTES: Some plastics give off toxic fumes when burned and remember that batteries and aerosols explode! The

stove is not an incinerator, so only ever use the recommended fuels and NEVER use liquid fuels in any form.

Operation to Avoid Smoke Emission when Loading and Re-lighting

To prevent the likelihood of smoke emission it is advised that:

The appliance is not overloaded

• Fuel should be added to fill the stove criss-cross, so air can circulate between logs.

• Fuel should be added 'little and often'

• Always have the air wash control (1) at least a little open.

Kindling is used to relight from a low fire-bed

• use only very small, thin, dry, sticks

• only when alight larger fuel should be added

PROBLEMS?

Problems like those listed here are usually due to some difficulty with the installation, chimney or fuels, so please check back through

this leaflet carefully. If necessary seek specialist advice.

POOR HEAT OUTPUT: A stove can heat a typical room of about 12m³ volume for each kW of output, so a 5kW model can heat up to

(12 x 5) 63m³, a room of about 5m square. The actual size depends on the insulation and air-change ratio of the room. To attempt to

heat a larger room will result in excessive fuel consumption and damaging overheating. Use the recommended very dry fuels.

LACK OF CONTROLLABILITY: Wood and some other fuels may burn excessively until the gases in them have been used up. You

can reduce this effect by making sure that the fire is set to 'low' for a while before refuelling and checking that the door seals fully. For

stoves with a Smoke Stop - adjust the heat output by how much fuel you put on, as well as by using the controls. Check that the door

seals are sound.

Page 8

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

DIFFICULTY BURNING FOR EXTENDED PERIODS If the fire goes out with fuel still in the firebox, then this is probably because too

little air has been reaching it, try leaving the air controls open a little more. Check that the door seals are sound and that there are no

cracks or gaps anywhere in the flue. For longest burning, we recommend hard fuels such as anthracite.

CONDENSATION: Condensation onto cool stove surfaces can be severe if fuel is in any way damp. Even an apparently dry 1 kg log

can hold 200 ml, a cupful, of water. Use only very dry fuel.

OVER-FIRING: It is possible to leave the fire too long with the controls set too high leading to 'over firing', seen as glowing metal parts,

excessive chimney temperature and risk of parts failing or chimney fires. Always set controls to the lowest practical setting.

SMOKE COMING INTO ROOM: Fumes are poisonous- smoke emission must NEVER be tolerated, causes might be:

INADEQUATE SEALS: Are all flue pipes and connectors absolutely gas-tight? Check that an inset appliance is fully sealed against the

fireplace. Even the tiniest crack or gap can spoil the draught.

BLOCKED THROAT PLATE: Has soot and ash can collected on the 'throat plate' above the inner back part of the firebox? See the

'maintenance' section.

UNSUITABLE, BLOCKED OR UN-SWEPT CHIMNEY: The first requirement for correct operation is a sound chimney. Check the

requirements earlier in this document and in any case of doubt have the chimney professionally swept.

POOR AIR SUPPLY: Is there enough air? Lack of air to the fire is a common cause of smoking and poor performance. Air supply

problems may be worse in certain wind conditions (often incorrectly ascribed to 'downdraught', which is in fact very rare), where air can

be sucked out of the room. The answer is to fit an air vent, as near to the fire as possible, facing into the usual wind direction.

DOWNDRAUGHT: Wind can blow down a chimney if there is something higher nearby such as a tree, hill or high building. Fitting an

anti-downdraught cowl to the chimney top can cure this. Types which cannot be swept through are not recommended.

POOR CHIMNEY DRAUGHT- Chimney draught in use MUST beat least 12Pa.

CHIMNEY FIRE: In the rare event of deposits inside the chimney igniting (roaring sound + dense smoke and sparks from the chimney)

immediately close the door, shut all air controls and call the fire brigade. Prevent fires by using very dry fuel and having your chimney

swept regularly.

MAINTENANCE

ANNUALLY- SWEEP THE CHIMNEY The entire length of the chimney from stove to outlet should be swept annually or more often if

smoky fuels are used.

SUMMER SHUT DOWN: Before a long period of non-use, empty fuel and ash, remove the throat plate and leave all the air controls

open to allow ventilation to reduce condensation.

NEW PARTS - Your stove has been extensively tested for safety - please don't try to modify it and always make sure to obtain genuine

spare parts.

Your stove generates VERY high temperatures. Eventually the internal parts will require replacement. A full list of replacement parts

can be found on the back page of the instruction booklet.

Help parts to last by:

• Using only recommend, very dry, fuels.

• Emptying the ash very regularly when using mineral fuel -never allow it to touch the underside of the grate.

• Cleaning the baffle plate regularly.

• Avoiding 'over-firing'

IMPORTANT: Excessive force closing the door may result in the door glass breaking and this will not be covered under the

stoves warranty.

Page 9

Installation and Operating Instructions Reference: Casttec Firebox INSET version 5 January 2011

Read these instructions! Use only recommended fuels!

This document, when completed by the installer, constitutes a 'Hearth Notice' for purposes of the England and Wales

Building Regulations 2000. It must be left with the householder and placed where it can easily be found.

APPLIANCE SERIAL NUMBER:

INSTALLED AT LOCATION:

BY:

EMERGENCY TELEPHONE:

Flue Draught measured

on commissioning:

Fuel used on

commissioning

SIGNED: DATE:

Who certifies that this installation is safe, has been demonstrated to the

householder, conforms with current building regulations and with these

instructions

TO FIND A QUALIFIED INSTALLER, FUEL SUPPLIER or CHIMNEY SWEEP, CONTACT:

UK: The Solid Fuel Association, 7 Swanwick Court, Alfreton, Derbyshire DE55 7AS Tel:0845-601-4406 www.solidfuel.co.uk

RoI: Irish Nationwide Fireplace Organisation, 162 Chapel Street, Dublin 1 Tel:01-801-5959 www.fireplace.ie

!"#$%&'(%

)*+"%&,$-#+%

.#/0+!)"!'&%

1"2%3%34556778%

0*/"%!+'&%-*09%-+!09%

3%5%3455677:%

0*/"%!+'&%/!.#%-+!09%

5%

;%

34556773%

0*/"%!+'&%<+*"#%

3%

=%

3455673>%

*/?)*&%

3%>%3455673;%

-*@@A#%)A*"#%

3%4%34556737%

"')%*&.%-'""'$%/A!.#+%-*+%

5%

B%

3455673=%

-'""'$%<A*//%0A!)%

3%8%34556%

"')%<A*//%"*-/%

5%

:%

34556733%

.''+%<A*//%

3%

37%

34556734%

/A!.#+%0'&"+'A%9&'-%

5%

33%

34556757%

.''+%)!&%

3%

35%

3455677BC%

0A*$)!&<%-+*09#"%

3%

3;%

3455677B%

0*/"%!+'&%-*/#%)A*"#%

3%

3=%

34556738%

+')#%/#*A%4$$%

3%

3>%

3455673:%

.''+%?*&.A#%

3%

34%

34556753%

.''+%?*&.A#%0*"0?%

3%

3B%

3455%0CDE%

')#+*"!&<%"''A%

3%

38%

3455%0CDE%

0*/"%!+'&%/)!<'"%4F%.!*%@A,#%0'&G#+"#+%

3%

Pa

ins.wg

10

11 9 5 3 2

10

1 6 9

4

Loading...

Loading...