Page 1

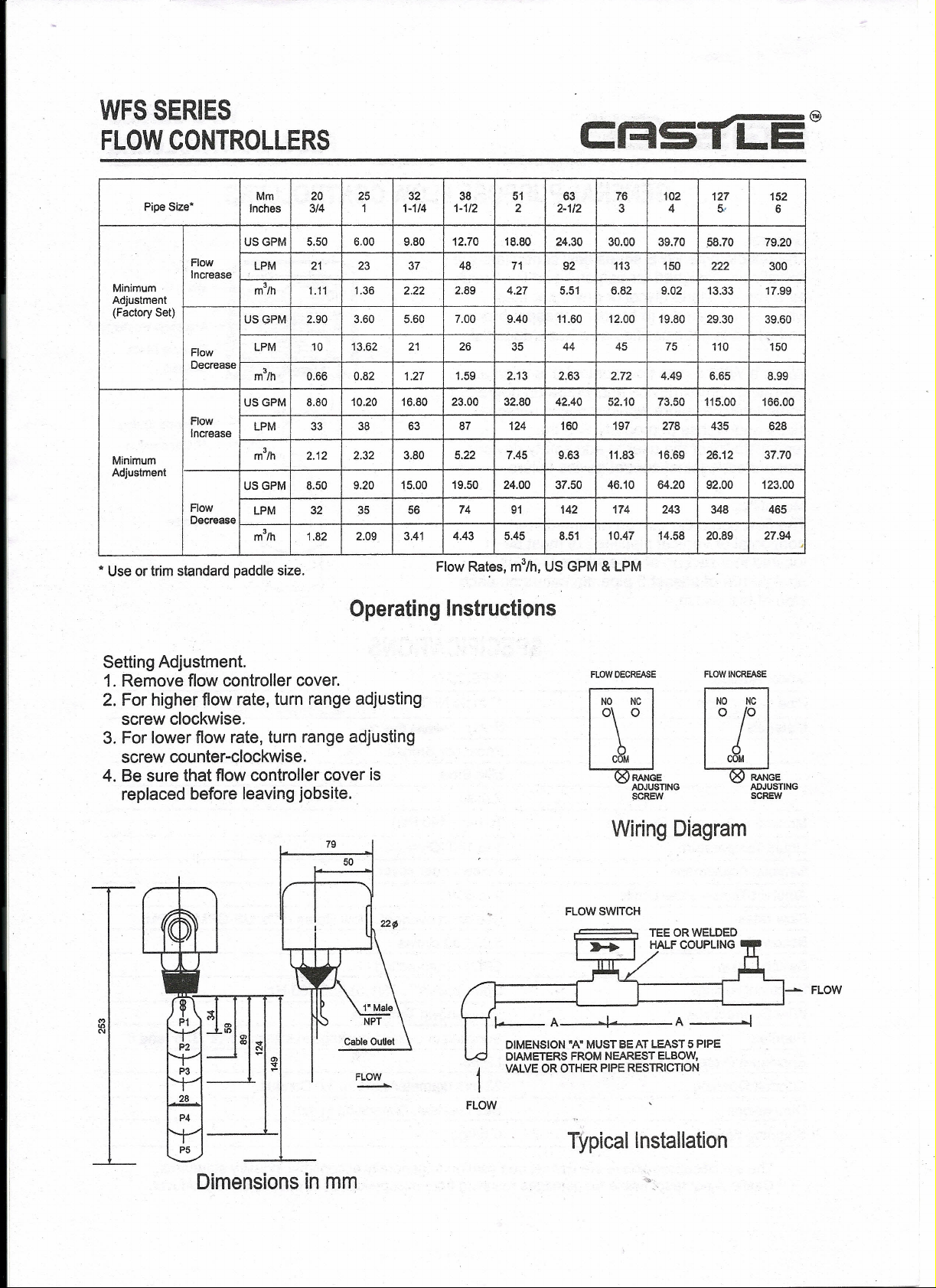

WFS SERIES

FLOW CONTROLLERS

C:RSTLE@

Pipe Size"

Minimum

Adjustment

(Factory Set)

Flow

Increase

Mm 20 25 32 38 51 63 76 102 127

Inches 3/4 1 1-1/4 1-1/2 2 2-1/2

USGPM

LPM 21 23 37 48 71

m3/h

USGPM

I

Flow

Decrease

Flow

Increase

Minimum

Adjustment

Flow

Decrease

*

Use or trim standard paddle size.

LPM 10

m3/h 0.66

USGPM

LPM 33

m3/h 2.12

USGPM

LPM

m3/h 1.82

5.50 6.00 9.80 12.70 18.80 24.30

92 113 150 222

1.11

1.36 2.22 2.89 4.27 5.51 6.82

2.90 3.60 5.60 7.00

13.62 21 26

0.82 1.27 1.59 2.13 2.63 2.72

8.80 10.20 16.80

38 63

2.32 3.80 5.22

8.50 9.20

32

15.00 19.50 24.00 37.50 46.10 64.20 92.00 123.00

35 56

2.09 3.41

23.00

87 124

74 91 142 174 243 348 465

4.43 5.45

9.40

35

32.80

7.45

11.60 12.00 19.80 29.30

44 45 75 110

42.40

160

9.63 11.83

8.51

Flow Rates, m3th, US GPM&LPM

Operating Instructions

3

30.00 39.70

52.10 73.50 115.00 166.00

197

10.47

4

9.02 13.33 17.99

4.49

278 435 628

16:69

14.58 20.89 27.94

5.-

.58.70 79.20

6.65 8.99

26.12

152

6

300

39.60

150

37.70

.I

Setting Adjustment.

1. Remove flow controller cover.

2. For higher flow rate, turn range adjusting

screw clockwise.

3. For lower flow rate, turn range adjusting

screw counter-clockwise.

4. Be sure that flow controller cover is

replaced before leaving jobsite.

79

50

FI.OW

---'"-

FLOW OECREASE

NO NC

\0

COM

Wiring Diagram

FLOW SWITCH

DIMENSION "AMMUST BE AT LEAST 5 PIPE

DIAMETERS FROM NEAREST ELBOW,

VALVE OR OTHER PIPE RESTRICTION

FLOW

RANGE

ADJUSTING

SCREW

FLOW INCREASE

~!

COM

RANGE

ADJUSTING

SCREW

- FLOW

P5

Dimensions in mm

Typical Installation

Page 2

C:r-ISTLE@

GENERAL PURPOSE FLOW CONTROLLERS

General,

The paddle type WFS series flow controllers are

specifically designed for use on liquid lines such

as water, ethylene glycol or any other fluid

which is not harmful to brass or phosper bronze

and which is not classified as a hazardous fluid.

When a WFS series flow controller is used as an

operating control device and where an operating

control device failure would result in personal

injury and/or loss of property, it is the

responsibility of the user to add safety devices

that protect against control device failure.

Mounting.

The flow controller can be mounted in a

horizontal or vertical pipeline but must be

located in a section of pipe where there is a

straight run of atleast 5 pipe diameters on each

side of the switch.

WFS SERIES-

FLOW CONTROLLERS

Cover

~~~~~~ Micro81W

Adjusting Screw

IU

J'~~~~f

Ik

Seesaw Plate,

Bellows

Balance Spring

1" Connection

SPECIFICATIONS

Model Number WFS-25-S

Pipe Connection 1" male NPT

Materials Brass

Maximum Operating Pressure

Liquid Temperature

Setpoint Adjustment

Ambient Temperature Limits

Flow rates

Bellow life

Switch Action

Electrical Ratings

Wire Connections

Paddles

Enclosure Protection Class

Conduit Opening

Dimensions

Shipping Weight

I

Stainless Steel 304

Phosphor Bronze

Mild Steel

Palstic

10 bar ( 140 Psi)

1 to 100° C

Screw under cover.

o

to 60°C

See chart overleaf. Flow Rates m3/h, US GPM&LPM

5.00,000 cycles

SPOT, Snap-acting.

Upto 250VAC, 15(7.5) A, 50/60 Hz

Screw-down Terminals

Supplied in 5-piece package in sizes of 1",2",3",5" and 6"

I.P 55

22 mm diameter hole for%"Conduit.

See overleaf. Dimension in mm. '

O.6/kgs

The specifications above are normal and confirm to generally acceptable industry standards.

Castle is not responsible for damages resulting from misapplication or misuse of it's products.

Loading...

Loading...