CASTLE TSM-22 Owner's Manual

CASTLE, INC.

Owners Manual

TSM-22 Pocket Hole Machine

CASTLE INC PO BOX 750236 PETALUMA CA 94975

WWW.CASTLEUSA.COM

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 2 of 41

Table of Contents

1 INTRODUCTION ............................................................................................................................. 5

1.1 DEFINITION OF TERMS ................................................................................................................ 5

1.2 IDENTIFICATION OF OPERATING FEATURES AND CONTROLS ......................................................... 6

1.3 MANUAL CONTENTS NOTICE ....................................................................................................... 8

2 MACHINE SAFETY ......................................................................................................................... 9

2.1 SAFETY RULES .......................................................................................................................... 9

2.2 INVENTORY .............................................................................................................................. 10

2.3 MACHINE REQUIREMENTS ........................................................................................................ 11

3 SETTING UP YOUR TSM-22 ....................................................................................................... 12

3.1 INSTALLING THE WORK TOP ..................................................................................................... 14

3.2 INSTALLING THE GAS SPRING ................................................................................................... 15

3.3 INITIAL CONFIGURATION ........................................................................................................... 16

4 ADJUSTMENTS ............................................................................................................................ 19

4.1 ROUTER FEED RATE ADJUSTMENT ........................................................................................... 19

4.2 POCKET WEB ADJUSTMENT ...................................................................................................... 20

4.3 POCKET DEPTH ADJUSTMENT................................................................................................... 21

4.4 DRILL FEED RATE ADJUSTMENT ............................................................................................... 22

4.5 PILOT DRILL DEPTH ADJUSTMENT ............................................................................................ 23

4.6 PILOT DRILL HEIGHT ADJUSTMENT ........................................................................................... 24

5 OPERATION ................................................................................................................................. 25

6 SERVICE AND MAINTENANCE .................................................................................................. 27

6.1 TOOL CHANGES ....................................................................................................................... 27

6.2 ROUTER BIT ............................................................................................................................ 27

6.3 PILOT DRILL BIT ....................................................................................................................... 28

6.4 GENERAL MACHINE MAINTENANCE ........................................................................................... 28

6.5 MOTORS AND BITS ................................................................................................................... 29

7 TROUBLESHOOTING .................................................................................................................. 31

7.1 DRY CYCLE TEST ..................................................................................................................... 31

7.2 SAFETY SWITCH (STOCK SENSE) .............................................................................................. 33

7.3 FOOT SWITCH .......................................................................................................................... 34

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 3 of 41

7.4 PRESSURE REGULATOR ........................................................................................................... 35

7.5 ROUTER STOP SWITCH ............................................................................................................ 36

7.6 DRILL STOP SWITCH ................................................................................................................ 37

7.7 SERIAL NUMBER LOG ............................................................................................................... 38

8 WARRANTY INFORMATION ....................................................................................................... 39

8.1 WARRANTY .............................................................................................................................. 39

8.2 30-DAY REFUND POLICY .......................................................................................................... 40

8.3 WARRANTY SERVICE POLICY .................................................................................................... 40

8.4 WARRANTY PART REPLACEMENT ............................................................................................. 40

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 4 of 41

1 Introduction

Thank you for making the Castle TSM-22 Screw Pocket Machine (Toe Screw Mortise) the latest

addition to your shop. Since 1985 our goal is to manufacture and develop machines that make

cabinetmaking and casework easier, faster, and more profitable for woodworking professionals.

This machine represents our patented screw pocket cutting technology. Castle machines are

made in Petaluma, California and are manufactured to the highest standards using local vendors

wherever possible.

The Castle model TSM-22 is designed for use on a wide variety of materials. The machine

performs well in hardwoods, softwoods, melamine, particleboard and MDF. The machine will

work on materials varying in thickness from ½” to 1 ¾”.

This instruction manual is intended for use by any one working with this machine. It should be

kept available for immediate reference so that all operations can be performed with maximum

efficiency and safety.

Warning: Do not attempt to perform maintenance or operate this machine until you have

read and understand the information contained in this manual.

1.1 Definition of Terms

TERM DEFINITION

Pocket The depression cuts into material to allow for toe-screw mortise joinery.

Pocket Cycle

The machine function that clamps the work piece, cuts the mortised pocket,

drills the pilot hole and then releases the work piece.

Web The offset distance from the end of the pocket to the edge of the work piece.

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 5 of 41

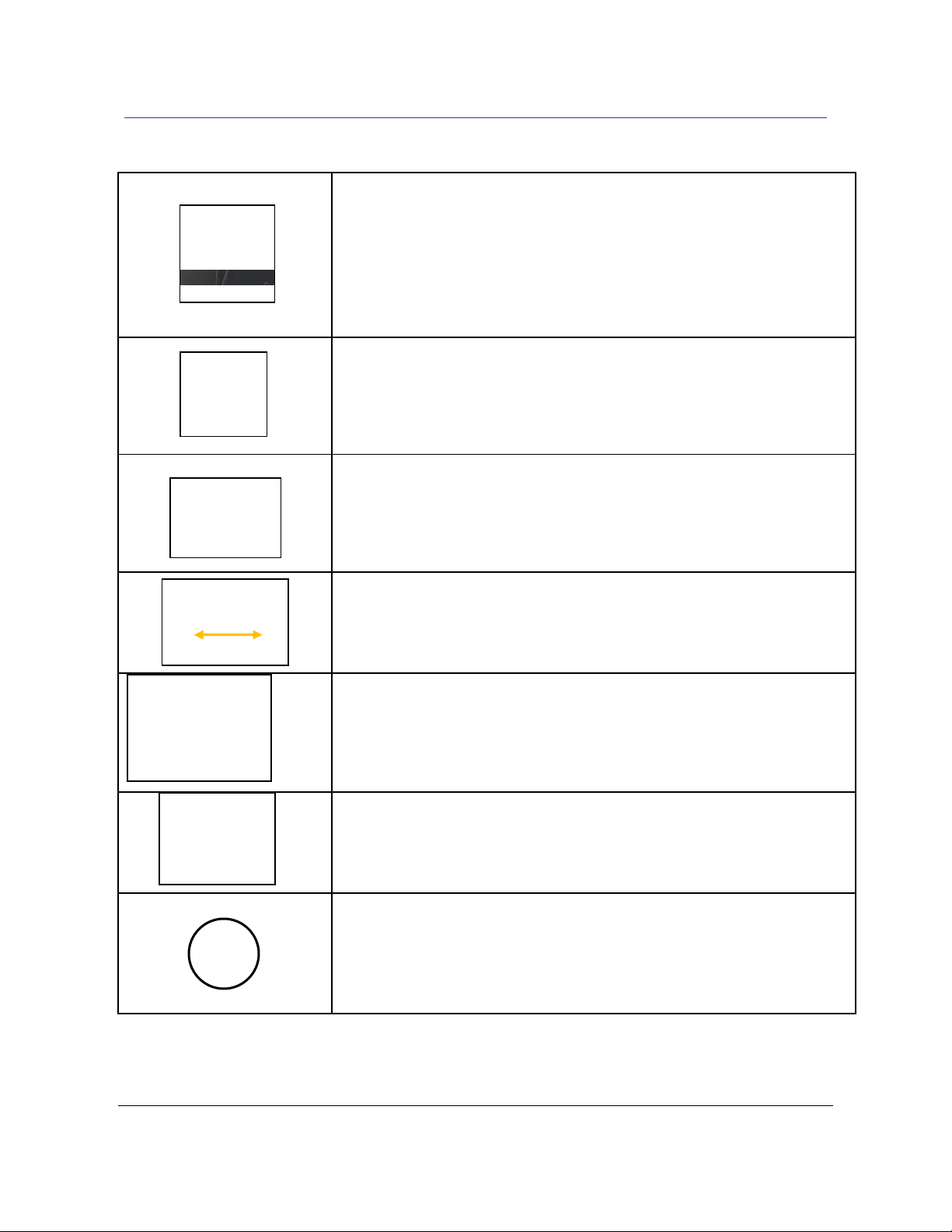

1.2 Identification of Operating Features and Controls

Power Switch: Located on the left side of the machine, this toggle

switch turns on the Pocket Router Motor and the Pilot Drill Motor as

well as energizing the Controls.

Clamp Cylinder: The large cylinder on the top of the machine is a

clamp that holds the work piece safely in place during operation. This

is a single-acting, spring-return, pneumatic cylinder with a padded foot

on the end of the cylinder rod.

Clamp Guard: The yellow metal Clamp Guard on top of the machine

serves to secure the Clamp Cylinder and to safeguard the operator

from the clamping and pocket cutting action.

Router Stop Plate: Located on the operator right side, this black

metal plate extends through the top of the case and along the side of

the Clamp Guard. The position of this plate determines the size of the

“Web.”

Foot Pedal and Guard: Mounted inside a yellow metal guard, the

Foot Pedal is connected to the machine by an electrical cord.

Pressing the Foot Pedal will activate the machine cycle (but only if the

Safety Buttons are depressed by the work piece as well).

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 6 of 41

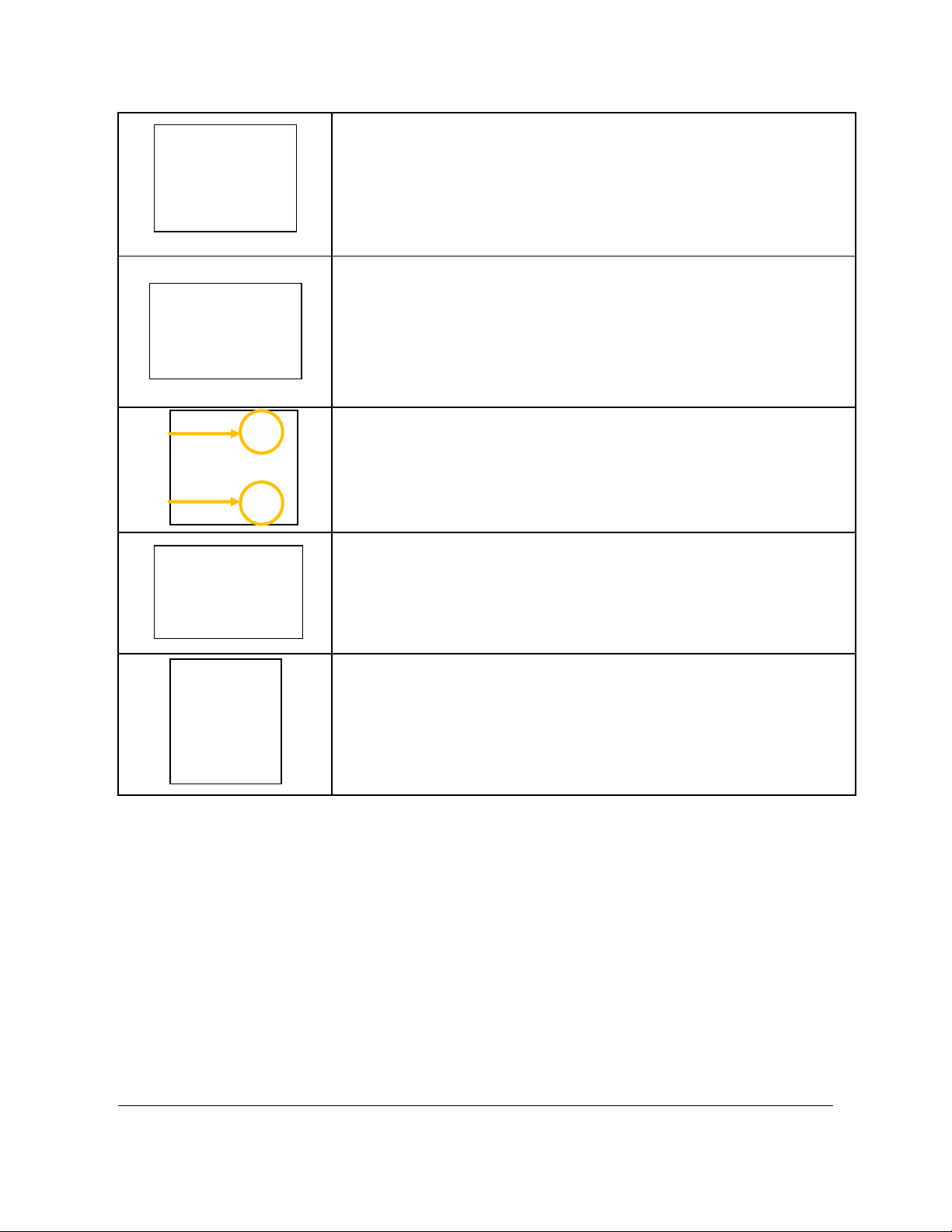

Safety Buttons: Two small, silver button-head screws under the

Clamp Guard detect if a work piece is in place for pocketing. The

machine will not cycle unless these buttons are depressed

simultaneously with the Foot Pedal.

Safety Switch: This magnetic proximity switch is mounted inside,

near the top of the TSM-22. It is activated when the Safety Buttons

are depressed by the work piece.

Motor Carriage: The Motor Carriage is the red, pivoting A-frame

structure inside the machine. Both the Router Motor and the Drill

Motor are mounted to this carriage. The forward and back carriage

motion during the machine cycle is provided by the Drive Cylinder.

Drive Cylinder: This double-acting pneumatic cylinder connected to

the Motor Carriage and the machine case, moves the carriage

through the routing and drilling phases of the cycle. When the

cylinder rod extends (moving the carriage toward the rear) the router

cuts the pocket. When the cylinder rod retracts (moving the carriage

forward) the pilot drill bores the pilot hole into the pocket.

Router Stop Switch: This magnetic proximity switch is mounted on

the Router Stop Plate inside of the machine. At the full extension of

the routing stroke, the “Castle” plate on the carriage interrupts this

switch to signal the start of the drilling stroke.

Drill Stop Switch: This magnetic proximity switch is mounted inside

the machine case near the Safety Buttons. At the full extension of the

drilling stroke, the carriage interrupts this switch to signal the end of

the cutting cycle. The carriage returns to the neutral position and the

clamp releases the work piece.

Control Box: The Control Box is the sheet metal enclosure

containing the electrical and pneumatic controls. Mounted in the

Control Box are the power switch and the power outlets for the

motors. Mounted on the underside of the Control Box are the air inlet,

the Pressure Regulator, the Router Speed Control valve, and the

solenoid valves.

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 7 of 41

1.3 Manual Contents Notice

This manual is not fully comprehensive. It may not convey every possible safety and operational

problem that may arise while using this machine. The manual will cover many of the basic and

specific safety procedures needed in a shop environment.

All federal and state laws and any regulations having jurisdiction, covering the safety

requirements for use of this machine, take precedence over the statements in this manual.

Users of this machine must adhere to all such regulations.

Most national and international standards that may apply to your machines and accessories

contain requirements for manuals. These change from time to time and will require constant

monitoring to assure that your products and manuals are in compliance.

Castle products and the information in this manual are the proprietary property of Castle, Inc. or

its licensers, and may not be copied, disclosed, or used for any purpose not expressly

authorized by the owner thereof.

Since Castle, Inc. constantly strives to improve all of its products, we reserve the right to change

this manual and hardware mentioned therein at any time without notice.

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 8 of 41

2 Machine Safety

The Castle Model TSM-22 pocket machine was designed with operator safety as a priority. This

machine was carefully prepared for shipment at our factory. Upon receipt of this machine,

inspect for shipping damage. Report any damage

Castle dealer and to Castle, Inc. DO NOT attempt to operate this machine if you observe any

physical damage. If you detect any damage to your machine contact Castle, Inc. at 800-2828338 for instructions.

IMMEDIATELY to the freight company, your

2.1 Safety Rules

The Castle Model TSM-22 Pocket Machine was designed with operator safety as a priority,

which is why Castle highly recommends the following:

1. USE CAUTION WHEN OPERATING THIS MACHINE! Only skilled operators should

use this machine, or be within ten feet when the machine is in operation.

2. Read the Operator Manual carefully before operating. An Operator Manual should be

attached to this machine. It contains important information and warnings concerning the

use and operation of this machine. Improper use of this machine may result in serious

injuries to persons and property.

3. Always wear protective eyewear when operating or standing near an operating machine.

4. Be certain that this machine is properly grounded before operating it.

5. Keep all body parts away from the moving parts of this machine whether it is in operation

or at rest.

6. Do not place hands or fingers between the work piece and the clamp or near the cutters

at any time. Always use a securing device when undertaking close work.

7. Do not wear gloves or loose clothing (such as sweaters, jackets, or jewelry) when

operating or standing near an operating machine.

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 9 of 41

8. Keep two hands on the work piece when initiating a pocket cycle on this machine.

9. Before attempting adjustments, maintenance, or repair, TURN OFF this machine,

disconnect it from its power source and air supply. Wait for all motion to stop.

Failure to disconnect this machine from its power source and air supply or wait for all

motion to stop could result in electrocution or injury.

10. Always keep the area around this machine clean and uncluttered. Poor housekeeping

could result in slips, falls, or other injuries.

11. Concentrate at all times. Failure to pay attention to the task at hand is the cause of

most accidents.

2.2 Inventory

With your Castle machine you should have received the following:

CASTLE TSM-21 POCKET CUTTER MACHINES HARDWARE PACK

Part # Part Description Qty

S90022 TSM-22 Operator Manual with Warranty Activation Card 1

Router Wrench Bosch 1617 2

Trimmer Wrench Bosch PR10E 2

B00622 #2x 6” Square Driver Bit 1

G00234 Bit Gauge 1

G00101 Door Spring 1

F14125 ¼ x 20 Bolt 1

H00141 T-Handle 1

F51616 5/16 SAE Flat Washer 4

F51699 5/16 -18 Nylon Locknut 2

H24002 Gas Spring – 20.12” Extended 1

F14553 ¼-20 x 1-1/4 FH Socket Head Cap Screw 6

F01420 ¼-20 Nylon Locknut 9

F01410 1/4 SAE Flat Washer 9

F44100 ¼-20 X 1 FH Socket Head Cap Screw 1

M24010 Stainless Lid Plate 1

F14340 ¼-20 x ¾ Carriage Bolt 2

T00532 Allen Hex L-Key – 5/32” 1

H55202 Rare Earth Magnet 1

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 10 of 41

2.3 Machine Requirements

Power Supply: 115 VAC ± 10%, 60 Hz, 20 Amp Service

Warning: Do not use an extension cord. Using an extension cord to power your TSM-22 may void

your warranty!

Air Supply: 80psi (minimum), 150psi (maximum) 1.5cfm; Minimum ¼” ID air line

Warning: Failure to provide an adequate supply of CLEAN, DRY air may void your warranty!

Dust Collection: The TSM-22 will function better with proper dust collection attached. A vent

for this purpose has been provided. Attaching dust collection will prolong motor life by keeping

the router motors cooler and free from sawdust buildup.

Warning: Failure to clean sawdust from your machine may void your warranty!

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 11 of 41

3 Setting Up Your TSM-22

Caution: Always use eye protection when operating power equipment.

Your Castle TSM-22 Pocket Cutter was set up and tested for proper operation at the factory.

It is normal to find a small amount of sawdust in the TSM-22 from this process.

Verify that the Power Switch is turned off. Remove the Power Cord and Foot Pedal from

inside the machine.

Remove the swivel elbow from the black urethane hose by pushing the floating ring toward

the elbow and pulling the hose at the same time.

Thread the elbow into the top of the Clamp Cylinder. It is pre-primed and self-sealing. Point

it toward the rear of the machine and firmly push the hose back into the fitting. (Fig 1)

Connect a clean, dry air supply to the left side of the machine with a minimum supply of

80psi. (Fig 2) Using an air supply of less than 80psi will result in insufficient clamping force,

which can cause material shifting and possible injury to the operator.

Fig 1 Fig 2

We strongly recommend that you use an inline filter/water trap.

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 12 of 41

Warning: Do not introduce lubricants, oils, or solvents into the pneumatic system. Irreparable

damage to pneumatic seals and components may occur. Using lubricants in the pneumatics of your TSM-22 may void your Warranty!

Inspect the U-Bolts on the carriage (Fig 3), making sure that the motors are secure and tight.

Fig 3

Using the wrenches located inside the rear of the machine make sure the router bit and the

drill bit are secure in the respective collets. (Fig 4)

Fig 4

CASTLE, INC TSM-22 OWNERS MANUAL V1.0 Page 13 of 41

Loading...

Loading...