Page 1

Screw Pocket Machine

Model TSM-21

Operator Manual

Read and understand this manual

before using machine

1364 N. McDowell Blvd, Ste 1

Petaluma, CA 94954

(800)282-8338

U.S. Patent No. 4603719

Castle, Inc.

Page 2

Table of Contents

Customer Promise_______________ Page 1

Safety Notification_______________ Page 1

Introduction

Definition of Terms_______________________ 2

Operating Features and Controls_____________ 3

Manual Contents Notice___________________ 5

Safety

Types of Warnings_______________________ 6

General Safety Rules_____________________ 6

Machine Inventory_______________ Page 8

Electrical and Air Requirements____ Page 8

Set Up and Installation____________ Page 9

Initial Configuration ______________ Page11

Adjustments

Router Feed Rate _________________________ 13

Pocket Web _____________________________ 14

Pocket Depth Position__________________ ___ 15

Drill Feed Rate __________________________ 16

Pilot Drill Depth _________________________ 17

Pilot Drill Height ________________________ 18

Operation______________________ Page 19

Service and Maintenance

Tool Changes____________________________ 21

Machine Maintenance_____________________ 23

Motors and Bits_______________________ ___ 24

Troubleshooting

Dry Cycle Test __________________________ 26

Safety Switch ___________________________ 28

Foot Switch ____________________________ 29

Pressure Regulator _______________________ 30

Router Stop Switch ______________________ 31

Drill Stop Switch ________________________ 32

Warranty & Returns ______________ Page 33

Page 3

Customer Promise

In a perfect world, there would be no need for Technical Support and Service. At Castle, Inc. we

recognize that the world is not perfect (yet), so please call Castle Technical Support if you

encounter a problem with your Castle machine.

1 (800) 282- 8338

The jog and jostle of shipping and handling can undo even the most strict quality measures.

Many difficulties that may occur in a new machine can be identified with a simple test or

resolved with a simple adjustment right over the phone.

Castle’s innovative machines are designed to be user serviceable and many Castle dealers offer

top-notch technical know-how. In the event that you require on-site service or support we ask

that you first contact the dealer, distributor, or reseller from whom you purchased your Castle

machine.

No one can promise a complete absence of problems and inconveniences, but we do promise

prompt, courteous, and professional assistance if you ever need it.

Safety Notification

WARNING: The Castle Model TSM-21 Pocket Cutter

was designed with operator safety as a priority.

This machine was carefully prepared for shipment at

our factory. Upon receipt of the machine, inspect for

shipping damage. IMMEDIATELY report any

damage to the freight company, to your Castle dealer,

and to Castle, Inc. DO NOT attempt to operate the

machine if you observe any physical damage. Contact

Castle, Inc. at 800-282-8338 for instructions.

1

Page 4

Introduction

Fortify Your Shop

Thank you for making the Castle TSM-21 Screw Pocket Machine the latest addition to your

shop. Since 1985 our goal is to manufacture and develop machines that make cabinetmaking and

casework easier, faster, and more profitable for the woodworker. This machine represents our

patented screw pocket cutting technology. Castle machines are made in Petaluma, California

and are manufactured to the highest standards using local vendors wherever possible.

The Castle model TSM-21 is designed for use on a wide variety of materials. The machine

performs well in hardwoods, softwoods, melamine, particleboard and MDF. The machine will

work on materials varying in thickness from ½” to 1 ¾”.

This instruction manual is intended for use by any one working with this machine. It should be

kept available for immediate reference so that all operations can be performed with maximum

efficiency and safety.

Do not attempt to perform maintenance or operate this machine until you have read and

understand the information contained in this manual.

Definition of Terms

Pocket…………………………………….. The depression cut into material to allow for

toe-screw mortise joinery.

Pocket Cycle……………………………… The procedure by which the machine clamps

the work piece, cuts the mortising pocket,

drills the pilot hole, then releases the work

piece.

Web………………………………………. The offset distance from the end of the

pocket to the edge of the work piece.

2

Page 5

Identification of Operating Features and Controls

1. Power Switch: Located on the left side of the machine, this

toggle switch turns on the Pocket Router Motor and the

Pilot Drill Motor as well as energizing the Controls.

2. Clamp Cylinder: The large cylinder on the top of the

machine is a clamp that holds the work piece safely in place

during operation. This is a single-acting, spring-return,

pneumatic cylinder with a padded foot on the end of the

cylinder rod.

3. Clamp Guard: The yellow metal Clamp Guard on top of

the machine serves to secure the Clamp Cylinder and to

safeguard the operator from the clamping and pocket cutting

action.

4. Router Stop Plate: Located just inside the rear door, this

black metal plate extends through the top of the case and

along the right side of the Clamp Guard. The position of

this plate determines the size of the “Web.”

5. Foot Pedal and Guard: Mounted inside a yellow metal

guard, the Foot Pedal is connected to the machine by an

electrical cord. Pressing the Foot Pedal will activate the

machine cycle (but only if the Safety Buttons are depressed

by the work piece as well).

6. Safety Buttons: Two small, silver button-head screws

under the Clamp Guard detect if a work piece is in place for

pocketing. The machine will not cycle unless these buttons

are depressed simultaneously with the Foot Pedal.

3

Page 6

7. Safety Switch: This magnetic proximity switch is mounted

inside, near the top of the TSM-21. It is activated when the

Safety Buttons are depressed by the work piece.

8. Motor Carriage: The Motor Carriage is the yellow,

pivoting A-frame structure inside the machine. Both the

Router Motor and the Drill Motor are mounted to this

carriage. The forward and back carriage motion during the

machine cycle is provided by the Drive Cylinder.

9. Drive Cylinder: This double-acting pneumatic cylinder

connected to the Motor Carriage and the machine case,

moves the carriage through the routing and drilling phases

of the cycle. When the cylinder rod extends (moving the

carriage toward the rear) the router cuts the pocket. When

the cylinder rod retracts (moving the carriage forward) the

pilot drill bores the pilot hole into the pocket. Note: SQE

valves are replaced by elbow fittings in models with Serial

Number 62481 and higher.

10. Router Stop Switch: This magnetic proximity switch is

mounted on the Router Stop Plate inside of the machine. At

the full extension of the routing stroke, the carriage

interrupts this switch to signal the start of the drilling stroke.

11. Drill Stop Switch: This magnetic proximity switch is

mounted inside the machine case near the Safety Buttons.

At the full extension of the drilling stroke, the carriage

interrupts this switch to signal the end of the cutting cycle.

The carriage returns to the neutral position and the clamp

releases the work piece.

12. Control Box: The Control Box is the sheet metal enclosure

containing the electrical and pneumatic controls. Mounted

in the Control Box are the power switch and the power

outlets for the motors. Mounted on the underside of the

Control Box are the air inlet, the Pressure Regulator, the

Router Speed Control valve, and the solenoid valves.

4

Page 7

Manual Contents Notice

This manual is not totally comprehensive. It does not and cannot convey every possible safety

and operational problem which may arise while using this machine. The manual will cover

many of the basic and specific safety procedures needed in a shop environment.

All federal and state laws and any regulations having jurisdiction covering the safety

requirements for use of this machine take precedence over the statements in this manual. Users

of this machine must adhere to all such regulations.

Most national and international standards that may apply to your machines and accessories

contain requirements for manuals. These change from time to time and will require constant

monitoring to assure that your products and manuals are in compliance.

Castle products and the information in this manual are the proprietary property of Castle, Inc. or

its licensers, and may not be copied, disclosed, or used for any purpose not expressly authorized

by the owner thereof.

Since Castle, Inc. constantly strives to improve all of its products, we reserve the right to change

this manual and hardware mentioned therein at any time without notice.

5

Page 8

Safety

Types of Warnings

Obey all safety messages that follow this symbol to avoid possible injury or death.

This indicates an imminently hazardous situation which, if not avoided, WILL result in death or

serious injury.

This indicates a potentially hazardous situation which, if not avoided, COULD result in death or

serious injury.

This indicates a potentially hazardous situation which, if not avoided, COULD result in minor or

moderate injury.

IMPORTANT

This indicates useful information about proper operation of the machine.

General Safety Rules for Machine Operators

and Persons in the Operating Area

• USE CAUTION WHEN USING THIS MACHINE! Only skilled operators should use

this machine, or be within ten feet when the machine is in operation.

• Read the Operator Manual carefully before operating. An Operator Manual should be

attached to this machine. It contains important information and warnings concerning the

use and operation of this machine. Improper use of this machine may result in serious

injuries to persons and property.

• Always wear protective eyewear when operating or standing near an operating machine.

• Be certain that this machine is properly grounded before operating it.

6

Page 9

• Keep all body parts away from the moving parts of this machine whether it is in operation

or at rest.

• Do not place hands or fingers between the work piece and the clamp or near the cutters at

any time. Always use a securing device when undertaking close work.

• Do not wear gloves or loose clothing (such as sweaters, jackets, or jewelry) when

operating or standing near an operating machine.

• Keep two hands on the work piece when initiating a pocket cycle on this machine.

• Before attempting adjustments, maintenance, or repair, TURN OFF this machine,

disconnect it from its power source and air supply. Wait for all motion to stop. Failure to

disconnect this machine from its power source and air supply or wait for all motion to

stop could result in electrocution or injury.

• Always keep the area around this machine clean and uncluttered. Poor housekeeping

could result in slips, falls, or other injuries.

• Concentrate at all times. Failure to pay attention to the task at hand is the cause of most

accidents.

7

Page 10

Inventory

With your Castle machine you should have received the following:

Warranty Card (Please fill out & mail to Castle, Inc. to activate warranty)

TSM-21 Operator Manual and Parts Explosion

Two (2) PC 6902 Router Wrenches

One (1) PC 7301 Router Wrench

One (1) #2 x 6” Square Driver bit

Manual and Warranty Card for PC 6902 Router

Manual and Warranty Card for PC 7301 Router

Bit Gauge

Two Door Handle Assemblies

2- Door Springs

2- Bolts (¼ x 20)

2- T-handles

Electrical and Air Requirements

Power Supply: 115 VAC ± 10%, 60 Hz, 20 Amp Service

IMPORTANT Do not use an extension cord.

Using and extension cord to power your TSM-21 may void your Warranty!

Air Supply: 80psi (minimum), 150psi (maximum) 1.5cfm; Minimum ¼” ID air line

IMPORTANT

Failure to provide an adequate supply of CLEAN, DRY air may void your Warranty!

Dust Collection: The TSM-21 will function better with proper dust collection attached. A vent

for this purpose has been provided. When attaching a dust collection system, remove

the cover plate over the vent opening in the back door. Attaching dust collection will

prolong motor life by keeping the router motors cooler and free from sawdust buildup.

IMPORTANT

Failure to clean sawdust from your machine may void your Warranty!

8

Page 11

Set-up / Installation

Always use eye protection when operating power equipment.

Your Castle TSM-21 Pocket Cutter was set up and tested for proper operation at the

factory. It is normal to find a small amount of sawdust in the TSM-21 from this process.

Verify that the Power Switch is turned off. Remove the Power Cord and Foot Pedal from

inside the machine.

Remove the swivel elbow from the black urethane hose by pushing the floating ring

toward the elbow and pulling the hose at the same time.

Thread the elbow into the top of the Clamp Cylinder. It is pre-primed and self-sealing.

Point it toward the rear of the machine and firmly push the hose back into the fitting.

(Figure 1)

Figure 1

Connect a clean, dry air supply to the left side of the machine with a minimum supply of

80psi. (Figure 2) Using an air supply of less than 80psi. will result in insufficient

clamping force, which can cause material shifting and possible injury to the operator.

We strongly recommend that you use an inline filter/water trap.

Figure2

IMPORTANT

Do not introduce lubricants, oils, or solvents into the pneumatic system. Irreparable

damage to pneumatic seals and components may occur.

Using lubricants in the pneumatics of your TSM-21 may

9

void your Warranty!

Page 12

The Motor Carriage on your machine is secured against movement during shipping.

Open the rear door and look toward the top of the machine just left of center for the black

Router Stop Plate. Cut the zip tie that secures the yellow Motor Carriage to the Router

Stop Plate and let the carriage move forward to its neutral position. Inspect the TKnobs and the U-Bolt on the carriage (Figure 3), making sure that the motors are secure

and tight.

Figure 3

Figure 4

Using the wrenches located inside the rear of the machine make sure the router bit and

the drill bit are secure in the respective collets.

Install the Work Top with the 4 flat head bolts and nylock nuts supplied. (Figure4)

From the rear of the machine rock the carriage fully forward and backward, by hand,

mimicking its working motion. Make sure that nothing is blocking the motion of the

carriage or the cutting bits.

Plug the machine into a grounded 115VAC, 20-amp outlet.

10

Page 13

Initial Configuration

Now that the machine is connected to a power source and air supply, it is suggested that you test

the machine’s controls for proper function.

Read the Operator Manual carefully before operating. Make sure that you have followed

all assembly and installation instructions correctly. Make sure that you are familiar with

the functions described in the rest of the manual as well. Failure to follow this warning

may result in serious injuries to persons and property.

Turn on the Power Switch.

Place a piece of scrap wood under the Clamp Guard against the Face Plate to depress the

Safety Buttons (Figure 5).

Figure 5

Be sure to keep your hands clear of the clamp, then step on the Foot Pedal. A full cycle

should take 1½ to 2 seconds.

11

Page 14

Inspect the pocket. If the drilled hole is off center (Figure 6), it can be centered using the

adjusting nut on the Pilot Hole Adjustment Bolt just below the drill motor. (Figure 7)

Figure 6

Figure 7

Tightening the nut moves the drill tip left relative to the operator. Adjust accordingly.

The Router Feed rate can be adjusted by using the flow control knob next to the air

supply port (Refer to the Adjustment chapter on page 14). Turning it clockwise will

reduce Router Feed rate, and turning it counter-clockwise will increase it. If the feed rate

is too slow it can cause burning of the bit and burning of the pocket. If the rate is too fast

it can cause the wood to shift.

Turn the Power Switch off when initial configuration is complete.

12

Page 15

Adjustments

Router Feed Rate Adjustment

Figure 8

The Router Feed Rate Adjustment knob is located just under the air inlet port on the left side of

the machine. (Figure 8) The adjustment knob only affects the cutting stroke of the pocket router.

Turning the knob clockwise selects a slower Feed Rate. Turning the knob counter-clockwise

selects a faster Feed Rate. A suggested Router Feed Rate Adjustment for hardwoods such as oak

or maple is described as follows:

Loosen the jam nut on the threaded stem and spin the nut counter-clockwise.

Turn the knob clockwise until it reaches a mechanical stop.

Turn the knob counter-clockwise two full revolutions.

Adjust slower or faster in small increments as required.

Tighten the jam nut.

IMPORTANT

If the work piece shifts noticeably during the Pocket Cycle, this usually means the Router

Feed Rate is faster than the tooling’s ability to clear the Pocket. In general the desired

Feed Rate is slower for harder, denser materials.

13

Page 16

Pocket Web Adjustment

The offset distance from the end of the pocket to the edge of the work piece is called the “Web.”

(Figure 9) It has been factory set at approximately

7

/8” to accommodate 1 ½” screws.

Figure 9

If you are using 1¼” screws you may choose to shorten the Web to

5

/8”.

IMPORTANT

The minimum recommended Web under any circumstance is 5/8”.

The Web is adjusted by shortening or lengthening the travel of the router’s cutting stroke.

Locate the Router Stop Plate nut on the right side of the yellow Clamp Guard on top of

the machine. (Figure 10)

Figure 10

Loosen the nylon locking nut.

To shorten the Web, slide the black Stop Plate toward the rear of the machine slightly.

To lengthen the Web, slide the plate toward the front of the machine slightly.

IMPORTANT

When the desired position has achieved, tighten the nylon locking nut securely to prevent

shifting during operation. Subsequent adjustment of the Router Stop Switch may also be

necessary (Page 31).

14

Page 17

Pocket Depth Adjustment

The router bit for cutting the pocket is inserted into the router collet at the factory for a distance

of 1 5/16” from the tip of the bit to the collet. This setting cuts at an optimal depth of

approximately

To cut a shallower pocket (in ½” material for example):

Place a shim with a known thickness on the work top and place your work piece over it.

To cut a shallower pocket:

Remove the router motor as described in the section for “Tool Changes”.

Loosen the motor collet and slide the bit to the desired exposure. (If the bit does not

move easily, try gently tapping on the bit near the collet with a wrench.)

Secure the collet and reinstall the router motor.

For your convenience, a blank Bit Gauge (Figure 11) is included with your machine so that you

may scribe a mark to record the depth that is most suitable for your purposes. Refer to the “Pilot

Drill Depth Adjustment” for this procedure.

3

/8” for material between 5/8” and 7/8” thickness.

Figure 11

15

Page 18

Drill Feed Rate Adjustment

The stroke speed with which the machine drills the pilot hole (and clamps the work piece) is

solely a function of the air pressure set at the internal Pressure Regulator. There is no separate

adjustment knob.

IMPORTANT

If the Drill Feed Rate is so fast that the machine shakes violently during the Pocket Cycle

or if the Drill Feed Rate is so slow that the Pocket Cycle is significantly longer than two

seconds, then it may be necessary to adjust the Pressure Regulator . Do not adjust the

internal Pressure Regulator unless absolutely necessary.

Figure 12

The internal Pressure Regulator knob is located on the Control Box (Figure 12), just below the

duplex power outlet for the Router and Drill motors. If in doubt whether the internal Pressure

Regulator is set correctly, follow the steps described below:

Unlock the knob by pulling it slightly away from the Control Box.

Turn the knob counter-clockwise until it reaches a mechanical stop.

Turn the knob clockwise five full revolutions (it’s helpful to make an index mark on the

knob.)

Lock the knob by pushing it slightly toward the Control Box.

16

Page 19

Pilot Drill Depth Adjustment

The Pilot Drill operation works best when the drill depth is adjusted so that the drill bit just

barely breaks into the pocket. If the drill bit extends farther than necessary, it can cause shorter

bit life and over-size holes. The drill bit is set at the factory for a length of approximately 1

from tip to drill motor collet (this is a suitable distance for the factory default 7/8” Web). As a

general rule, if the Web is decreased, then the Pilot Drill depth should also be decreased.

To adjust the Pilot Bit Depth:

Remove the Pilot Drill Motor as described in the section for “Tool Changes”.

Loosen the motor collet and slide the bit to the desired exposure. (If the bit does not

move easily, try gently tapping on the shank of the bit near the collet with a wrench.)

Secure the collet and reinstall the router motor.

For your convenience, a blank Bit Gauge (Figure 13) is included with your machine so that you

may scribe a mark to record the depth that is most suitable for your purposes.

13

/16”

Figure 13

Simply set the Bit Gauge on top of the collet and use an awl to scratch a reference line in

the soft aluminum where each bit should be. (Figure 14)

Figure 14

The plate has two sides that can be used as settings for different processes in the shop.

17

Page 20

Pilot Drill Height Adjustment

The position of the Pilot Hole can be raised or lowered slightly to accommodate various

thickness in work pieces or various pocket depths.

On the sides of the machine case, secure the Carriage Centering Screw with a

1

/8” allen

wrench. Loosen - but do not remove - the nylon lock nuts securing the set screw of the

Motor Carriage to the machine case. (Figure 15)

IMPORTANT

The left-to-right alignment of the Motor Carriage may shift if care is not taken during the

loosening of the nylon lock nuts. Make sure that each preload set screw is secured with an

allen wrench before loosening each lock nut.

From the Rear Door of the machine locate the Bearing Jack plate on the inner wall of the

cabinet. (Figure 16)

Figure 15

Figure 16

Loosen, but do not remove, the nut on the plate that is nearest to the carriage axle.

Remove the nut and bolt on the plate that is farthest from the carriage axle. Typically this

nut and bolt are factory set to the center hole of the five holes on this end of the plate.

To raise the pilot hole, slide the plate upward one or two hole positions (each hole

position equals

1

/16” of drill position). To lower the pilot hole, slide the plate downward.

Reattach the nut and bolt in the new hole position, and secure in place.

Tighten the nut on the plate that is nearest to the carriage axle.

Repeat for the other side.

On the outside of the machine, secure the Carriage Centering Screw with a

1

/8” allen

wrench and tighten the nuts securing the pivot point of the Motor Carriage to the machine

case.

18

Page 21

Operation

Read the Operator Manual carefully before operating. Make sure that you are familiar

with the functions described in the rest of the manual as well. Failure to follow this

warning may result in serious injuries to persons and property.

IMPORTANT

Always use eye protection when operating power equipment.

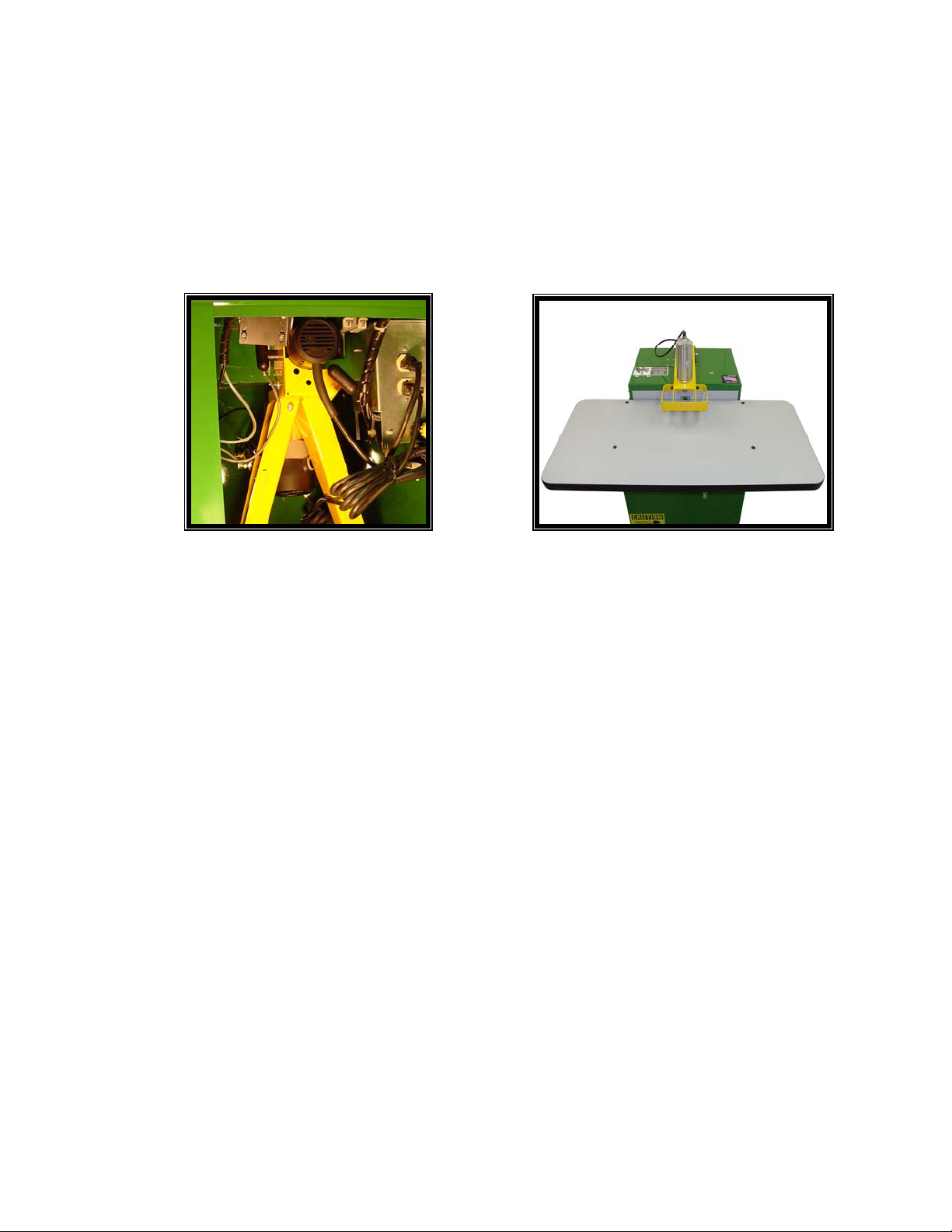

With the Power Switch turned off, check to see that the carriage moves freely by hand

and returns to the neutral position (Figure 17). Neither the router bit nor the drill bit

should be protruding from the machine while at rest.

Figure 17

Place the Foot Pedal in front of the machine in a safe and comfortable position

(Figure 18).

Figure 18

19

Page 22

Turn the Power Switch on (Figure 19).

Figure 19

Place the work piece to be pocketed on the Work Top. Slide it under the Clamp Guard

and firmly push it against the face plate of the machine to press the Safety Buttons.

(Figure 20)

Figure 20

Be sure to keep your hands clear of the clamp, then press and release the Foot Pedal to

activate the cutting cycle.

The pocket will be cut at the point directly under the center of the Clamp Cylinder.

When the Pocket Cycle has been completed the Clamp Foot will automatically release

the material.

A typical machine cycle will take from 1½ to 2 seconds to complete.

Reposition the same work piece or a new work piece under the Clamp Guard, then press

and release the Foot Pedal again to activate the next cutting cycle.

Be sure to turn off the Power Switch when you are finished.

If the machine fails to cycle properly, call Castle at (800) 282-8338

20

Page 23

Service and Maintenance

Tool Changes

DO NOT ATTEMPT TO CHANGE TOOLING WITH COMPRESSED AIR OR POWER

SUPPLIED TO THE MACHINE!!

To change the Pocket Router Bit or the Pilot Drill Bit you will need to remove the respective

motor from the carriage. You do not need to remove the Work Top to change the bits.

Pocket Router Bit

Open the rear door and unplug the router motor.

Locate the black T-Knob to the right of the drill motor at the top of the carriage. The

black T-Knob is threaded onto a large U-bolt that secures the Router Motor.

Support the bottom of the Router Motor with your left hand (Figure 21). Use your right

hand to loosen the T-Knob a few turns to provide slack on the U-bolt. (Push slightly

forward on the T-knob if necessary.)

Allow the motor to drop into your left hand, then lift it out the rear door and change the

tooling.

Figure 21

When re-installing, slide the motor through the curve of the U-bolt. Make sure that the

motor’s power cable is pointing toward the front-right corner of the machine, and that

the motor’s brush screw “ears” are in line perpendicular the case sides.

Push the Router Motor fully toward the top of the Motor Carriage. Make sure that the

motor contacts the angled tabs on the yellow carriage (Figure 22). If unsure remove

Work Top to confirm location.

Use your right hand to tighten the T-Knob until the U-bolt is hugging the Router Motor

tightly to the Motor Carriage. When fully secured the motor should be in contact or

very close to contacting the angled tabs on the yellow carriage.

21

Figure 22

Page 24

Pilot Drill Bit

Open the rear door and unplug the drill motor.

Locate the black T-Knob to the left of the drill motor at the top of the carriage (Figure

23). The black T-Knob is threaded onto a set screw that secures the Drill Motor.

Unscrew and remove the T-knob. Slide the motor slightly to the right until the set screw

clears the mounting hole, then lift the motor out through the rear door and change the

tooling.

Figure 23

When re-installing, position the set screw through the mounting hole. Make sure that

the motor’s power cable is pointing toward the floor of the machine. Reinstall and

tighten the T-knob.

22

Page 25

General Machine Maintenance

The model TSM-21 requires some maintenance. To ensure productivity and longevity of your

Castle Pocket Cutter, it is essential to follow a few simple steps. How often these steps are

performed depends upon the number of hours the machine is operated each day. As a general

rule, operators should visually inspect the machine at the start of each work shift in the following

manner:

Check the Power Cord and the Foot Switch cord for wear or damage.

Ensure that the Router Bit and the Drill Bit are clean, sharp, and undamaged.

Keep the Router and Drill Motors free from dust build up.

Check for proper Safety Switch function. Turn the machine on and press the Foot Pedal

without a work piece against the Safety Buttons. The machine should not cycle if the

Safety Buttons are not pressed. If you suspect a Safety Switch malfunction, contact a

Castle, Inc. Support Technician at 1-800-282-8338 as soon as possible for corrective

action.

IMPORTANT

Do not introduce lubricants, oils, or solvents into the pneumatic system. Irreparable

damage to pneumatic seals and components may occur.

Using lubricants in the pneumatics of your TSM-21 may void your Warranty!

23

Page 26

Motors and Bits

Castle modifies the configuration of the Pocket Router Motor and the Pilot Drill Motor ex

factory from Porter-Cable for suitable mounting on the Motor Carriage.

IMPORTANT

If you replace motors on your machine, be sure to reconfigure the replacement motors to

match the mounting characteristics of the original motors.

The life of the machine is directly related to the care of the motors that cut the pocket and drill

the pilot hole. Because the motors are enclosed in the machine care must be taken to ensure that

they do not overheat. Use the motors as you would use typical router motors in your shop. It is

important that the maintenance guidelines provided in the Porter-Cable instruction manual be

strictly followed.

Regularly blow out the air passages on both motors with compressed air.

Always wear safety goggles when using compressed air.

Do not run the motors for more than one hour at a time.

To prolong motor life, and avoid costly downtime, it is strongly recommended that a dust

collection system be connected to the machine. A port has been provided on the left side

of the machine for this purpose. An air inlet vent on the rear door works with the dust

collector to help keep the motors cool.

IMPORTANT

Failure to clean sawdust from your machine may void your Warranty!

To ensure safe and effective operation, make certain that there is at least 80psi air

pressure to the machine. Pay attention to the cycle time of machine. A typical cycle will

last from 1½ to 2 seconds. A cycle significantly longer than this may indicate low Router

Feed rate, or low internal air pressure. This will lead to excessive bit wear and shortened

motor life.

24

Page 27

Castle provides premium versions of the Router Bit and Drill Bit in the TSM-21 as standard

equipment from the factory. Castle recommends these bits for all applications.

B00338 Solid Carbide,

3

/8” Rough Mill, Three Flute Bit

B02964 TiN Coated,

9

/64” Brad and Spur Bit

Other bits available are:

B00038 Cobalt Steel,

3

/8” Rough Mill, Four Flute (RM-38)

An alternative when cutting pockets exclusively in solid woods such as maple, oak, ash or

alder. The RM-38 will cut in any material, however exposure to glue and resin found in

particle board, plywood, MDF, Melamine, etc. will lead to premature wear on the bit.

B00138 Carbide Tip,

3

/8” Two Flute Twist (CUR-38)

An alternative when pocketing in materials where glues are used in binding the stock

(particleboard, plywood, MDF, Melamine, etc.). The CUR-38 is not recommended for solid

woods because it will likely leave a ragged pocket.

B00438 Cobalt Steel,

3

/8” Rough Mill, Three Flute (RT-38)

An economic alternative to the RM-38. Based on the geometry of our premium solid carbide

bit, this product is suitable for similar applications as the RM-38.

B00964

9

/64” Brad and Spur Bit w/ 1/4” Shank (CDB-964)

An economic alternative based on the geometry of our premium TiN coated pilot bit.

B01964

9

/64” Split Point Bit w/ 1/4” Shank

An alternative to the CDB-964. The split point construction is stiffer and sometimes

preferred in plywood and tightly grained hard woods.

B00764

7

/64” Split Point Bit w/ 1/4” Shank

An alternative for smaller diameter pilot hole

B00316

3

/16” Split Point Bit w/ 1/4” Shank

An alternative for larger diameter pilot hole

All of the tooling is available through Castle, Inc. Feel free to contact your local Castle dealer or

contact our Parts Department TOLL FREE at 800-282-8338 for information and pricing on

tooling and accessory products for your TSM-21.

25

Page 28

Troubleshooting

Electrical Hazard: Do not attempt to service Control Box components. Contact a Castle,

Inc. Support Technician for proper service information.

Dry Cycle Test

Dry Cycling is an extremely useful troubleshooting technique if your Pocket Machine’s

performance and cycling sequence seem irregular or questionable. It affords the opportunity to

closely observe the mechanical, electrical, and pneumatic systems without routing pockets or

drilling holes.

1. Locate the ON/OFF switches on the motor housings and turn them off, or simply unplug

the motors at the Control Box outlet.

2. Connect air and power to the machine. Turn the machine’s Power Switch ON.

3. Place a piece of scrap wood on the Table Top but do not cover the router slot. Align the

piece with one of the Safety Buttons so that the button can be depressed but the piece will

not block the path of the router bit or the drill bit.

4. Start a Pocket Cycle by pressing the scrap of wood against one of the Safety Buttons and

stepping on the Foot Pedal. Observe the following actions in the described order:

The Clamp Foot extends to rest partly on the wood scrap while the router bit extends toward

the rear of the Table Top slot. Almost immediately the router bit returns beneath the slot and the

drill bit extends forward through the Pilot Hole under the Clamp Guard. Almost immediately the

drill bit retracts while the Clamp Foot releases the wood scrap. (The Clamp Foot will not

release until the final drill stroke is complete.)

Total elapsed time: approximately two seconds.

5. If the cycle does not begin, inspect the Power Switch, the machine power cord, the Safety

Switch (page 28), or the Foot Switch (page 29). Make sure that your air supply is

connected to the machine and inspect the internal Pressure Regulator (page 30).

6. If the Clamp Foot begins to extend but suddenly retracts and there is no further cycle

motion, inspect the Drill Stop Switch (page 32).

7. If the Clamp Foot extends but the router does not, inspect or reset the Router Feed Rate

Adjustment (page 13).

8. If the router extends at an excessive rate, inspect or reset the Router Feed Rate

Adjustment (page 13).

26

Page 29

9. If the Clamp Foot extends but the cycle stalls with the router extended or if the cycle

skips over the router stroke entirely, inspect the Router Stop Switch (page 31).

10. If the router retracts and the drill extends at an excessive rate, inspect or reset the internal

Pressure Regulator (page 16).

11. If the cycle stalls with the drill extended or if the cycle skips over the drill stroke entirely,

inspect the Drill Stop Switch (page 32).

12. If the cycle takes significantly longer than two seconds to complete, inspect the Air

Supply, the Pressure Regulator (page 30), or the Router Feed Rate Adjustment (page 13).

13. If the Dry Cycle is successful, but a regular cycle fails when routing pockets and drilling

holes, inspect the Tooling (pages 21, 22), or the Motor Operation (Porter-Cable

instruction manual).

14. After Dry Cycling is completed, turn the Power Switch OFF and turn the motor switches

ON (or plug them into the Control Box outlet).

The list of possible behaviors described in Steps 5 through 13 is by no means exhaustive.

Careful observation and description of the cycle behavior is essential when troubleshooting

or seeking Technical Support.

27

Page 30

Safety Switch

The Safety Switch on the TSM-21 consists of a magnet (no wires) mounted near a magnetic reed

switch (with wires). (Figure 24) When the Safety Buttons are pushed by the work piece, they

raise an L-shaped metal blade that rests between the reed switch and the magnet inside the

machine. The assembly is wired in such a way that when the blade is raised the switch closes

allowing electricity to flow to the Foot Pedal.

Figure 24

Turn the power to the machine off.

First make sure that the side of the magnet housing with the notch in it is facing the

Safety Blade. This ensures that the magnet is as close to the reed switch as possible.

If there is no notch in the housing, then detach it from the machine and visually inspect it.

Make sure that the magnet is turned so that it is closest to the Safety Blade.

If the above steps don't work then test for proper function at the switch by connecting

ohmmeter leads to the screw terminals on the reed switch.

When the blade is resting between the reed switch and magnet, an open circuit should be

registered (a few kilo ohms of resistance is acceptable).

When the blade is raised a closed circuit should be registered (approximately 0 ohms). If

an open circuit is still registered, then the distance between the mounted assembly may

need to be reduced by

to the case top, then pinch them slightly closer and retighten the nuts.

If this still doesn't fix the problem then a new switch assembly (magnet and reed switch)

should be installed.

1

/16” on each side. Loosen the nuts holding the switch and magnet

28

Page 31

Foot Switch

Designed to work in series with the Safety Switch, the Foot Switch is a simple mechanical

micro-switch operated by a spring-loaded pedal. At rest the switch condition should be normally

open. Closing the switch begins the cycle.

Turn the power to the machine off.

Turn the Foot Pedal and guard over and remove the two small screws that hold the pedal

to the base.

Use a flat tip screwdriver to pry the pedal free from the yellow guard (it is held by a

silicone caulk).

Using a flat or phillips screw driver, remove the two screws on the left and right side of

the pedal. This will allow the pedal to come apart exposing the switch underneath.

Use two leads of the ohmmeter to probe the wire terminals while the switch is still in the

pedal. (Figure 25)

Figure 25

Without depressing the spring plate, the switch should register as an open circuit. When

depressing the plate, the switch should register as a closed circuit (approximately 0

ohms).

If an open circuit is still registered, then a new switch should be installed.

29

Page 32

Pressure Regulator

The Pressure Regulator determines the Drill Feed rate and overall speed of the machine. It’s

important that at least 80 PSI is going into the machine from the compressor. Other machines on

the same line as your Castle machine can affect this pressure.

IMPORTANT

Do not adjust the internal Pressure Regulator unless absolutely necessary.

The internal Pressure Regulator knob is located on the Control Box, just below the duplex power

outlet for the Router and Drill motors. (Figure 26) If in doubt whether the internal Pressure

Regulator is set correctly, follow the steps described below:

Unlock the knob by pulling it slightly away from the Control Box.

Turn the knob counter-clockwise until it reaches a mechanical stop.

Turn the knob clockwise five full revolutions (it’s helpful to make an index mark on the

knob as a reference.)

Lock the knob by pushing it slightly toward the Control Box.

Figure 26

IMPORTANT

Cycling too slow will burn drill bits and cause separation at the shank. Cycling too fast will

put too much pressure on the drill bits and cause them to break and/or cut over-size holes.

30

Page 33

Router Stop Switch

The Router Stop Switch consists of a magnet (no wires) mounted near a magnetic reed switch

(with wires) on the Router Stop Plate. At the full extension of the routing stroke, a tab on the

Motor Carriage interrupts this switch to signal the start of the drilling stroke. If the clamp doesn’t

release and the pilot drill hasn’t come out, then the Router Stop Switch may require a simple

adjustment.

Open the rear door of the machine and observe if the Motor Carriage has stalled with the

router fully extended into the pocket. If the carriage is fully extended then it’s likely that

the magnet is too close to the reed switch.

Turn the power to the machine off.

Loosen the two lower screws on the Router Stop Plate and slide the magnet (no wires)

approximately a

1

/16” further away from the reed switch. (Figure 27)

Figure 27

Manually pull the Motor Carriage toward the rear of the machine to ensure that the tab

does not strike the magnet or the magnetic reed switch.

Turn on the power to the machine and make a test pocket.

If the router still stalls in the pocket, repeat the above steps again. You’ll know you’ve

moved the magnet too far away if the cycle skips the router stroke entirely. Continue to

adjust the magnet until the machine cycles normally.

31

Page 34

Drill Stop Switch

The Drill Stop Switch consists of a magnet (no wires) mounted near a magnetic reed switch

(with wires) mounted inside the machine case near the Safety Buttons. (Figure 28) At the full

extension of the drilling stroke, the carriage interrupts this switch to signal the end of the drilling

stroke and the end of the cycle. If the clamp doesn’t release and the pilot drill won’t retract, then

the magnet is too close to the reed switch.

Figure 28

Figure 29

Turn the power to the machine off.

Remove the Work Top

Loosen, but do not remove, the screws (Figure 29) that secure the magnet and the reed

switch to the machine case (you may need to remove a portion the laminate strip on the

front of the machine to access the mounting screws). Although the mounts are not

slotted, spread the magnet and the reed switch as far from each other as possible, then

retighten the screws.

Turn on the power to the machine and make a test pocket.

If the drill still stalls in the pocket, loosen and remove the screws that secure the magnet

and the reed switch to the machine case.

Make sure that the side of the magnet housing with the notch in it is facing away from the

reed switch. This ensures that the magnet is as far from the reed switch as possible.

If there is no notch in the housing, then detach it from the machine and visually inspect it.

Make sure that the magnet is turned so that it is farthest from the reed switch.

If possible, use a small file or drill bit to slot the mounting holes on the plastic housings,

then reinstall the magnet and the reed switch.

Turn on the power to the machine and make a test pocket. Continue to adjust the Drill

Stop Switch until the machine cycles normally.

32

Page 35

Warranty & Returns

Warranty

Your Castle Machine is warranted for one (1) full year from the date of purchase against

workmanship or material defects under recommended use and service. Castle, Inc. is not liable

for failures or injuries due to negligence, misuse, alteration, unauthorized service, or accidents.

Castle, Inc., at its sole discretion, will elect to either repair or replace a machine (or machine

component) that is found to be defective. This shall be the purchaser’s sole remedy under this

warranty. Castle will not, under any circumstances, be liable for consequential, incidental,

special or exemplary damages, or for loss of time, revenue or production. Further, Castle

disclaims any warranty, expressed or implied, as to the merchantability or fitness of a

Castle product for any particular purpose.

We suggest any and all machine maintenance or repair be discussed with an authorized Castle

Representative prior to any disassembly. Warranty service will not be provided without

registration, so please complete and return your warranty registration card within ten (10) days of

taking delivery.

Castle’s innovative machines are designed to be user serviceable and many Castle dealers offer

top-notch technical know-how. In the event that you require on-site service or support we ask

that you first contact the dealer, distributor, or reseller from whom you purchased your Castle

machine.

Porter Cable warrants the two (2) electric motors for one (1) year from date of purchase. We

suggest you keep your receipt in a safe place will need a copy for any repairs or replacements.

After the first year, check the Porter Cable manuals (enclosed) for the service station nearest you.

30 Day Refund Policy

Any Castle machine may be returned by the End User, for any reason within 30 days of the

purchase date for a full refund.

Upon approval by Castle, Castle will initiate an RMA (Return to Manufacturer Authorization)

and arrange for the return of the machine to Castle’s factory. Upon receipt of the machine Castle

will issue a full credit to the Dealer (including any freight charges incurred). Once the credit

memo has been issued, the Dealer will issue a full credit or refund to the End User.

NOTE: The machine must be returned to Castle with reasonable packaging precautions and with

substantially all parts and accessories included for a full credit to be issued to the Dealer.

33

Page 36

Warranty Service Policy

In the event that the End User requires service, support, or assistance, End Users are expected to

first contact the Dealer, Distributor, or Reseller (DDR) from whom the Castle machine was

purchased.

Castle does not employ on-site service technicians. On-site technical support and service are to

be provided by the DDR or by an authorized Castle agent. If a DDR cannot provide on-site

technical support and service, the DDR is expected to partner with an authorized Castle agent.

Owners of new machines are obligated to contact the DDR and Castle before contracting for or

attempting repairs and service.

If Castle or DDR support professionals determine that reasonably simple adjustments or tests are

necessary in delivering remedy to a failed machine, owners of warranted machines are obligated

to exercise due diligence while assisting in the execution of these simple adjustments or tests.

Warranty Part Replacement

New product (within 30 days)

Castle is obliged to provide replacement parts at no charge.

Castle is obliged to ship overnight if requested by End User.

30 days to 12 months

Castle is obliged to provide replacement parts at no charge.

Castle is obliged to ship UPS 2-day if requested by End User.

If needed next-day, the End User will be charged to cover difference.

Certain original parts and assemblies are expected to be returned by the End User if Castle is

providing replacements. Castle will initiate an RMA and provide pre-paid shipping for these

returned items. In order to protect Castle’s assets, the customer will be billed for replacement

parts if the returned parts are not received at the Castle factory within 30 days of the End User’s

receipt of the replacement parts.

Revised June 2008

34

Loading...

Loading...