Page 1

LB-23 Diagnostic Solutions Index

Air Pressure at Primary Regulator…………………………………………… 23.10

Air Pressure at Secondary Regulator………………………………….………23.40

Belt Adjustments……………………………………………………............... 23.65

Collet Adjustment…………………………………………………...……….. 23.21

Cutting Cycle-time Adjustment…………………………………………...…. 23.23

Electrical Supply Check……………………………………………………… 23.80

Foot Switch Mechanics………………………………………………………. 23.84

Head Lubrication……………………………………………………………... 23.01

Index Pin Setting & Resetting……………………………………...………… 23.43

Motor Operation……………………………………………………………… 23.60

Secondary Regulator Hose Check…………………………………………….23.42

SQE Check…………………………………………………………...………. 23.90

SQE Removal & Replacement……………………………………………….. 23.91

Tabletop Adjustments………………………………………………………... 23.70

Tooling Check & Replacement………………………………………………. 23.20

Travel Limiter Adjustments………………………………………………….. 23.82

Wing Table Adjustments……………………………………………………... 23.71

Revised 2/9/2007

Page 2

How To…

23.01

Head Lubrication

The head should be oiled every 30 to 40 hours of usage. The head, once it is broken in beyond its

initial start-up, should run very quietly with no loud metallic racket or grinding.

In order to maintain the machine in good working order, the head should never be run dry. The head

uses oil impregnated bushings that need to stay oiled for optimal performance.

The oil that is used in lubricating this machine consists of two ingredients: Non-Detergent, 30 WT

Motor Oil and Slick 50. The two are mixed at a ratio of 4:1 respectively.

SOLUTION STEPS:

1. Loosen the two plastic, tri-armed knobs that hold down the bit cover on top of the machine.

Remove the bit cover by lifting and sliding it to your right as you lift.

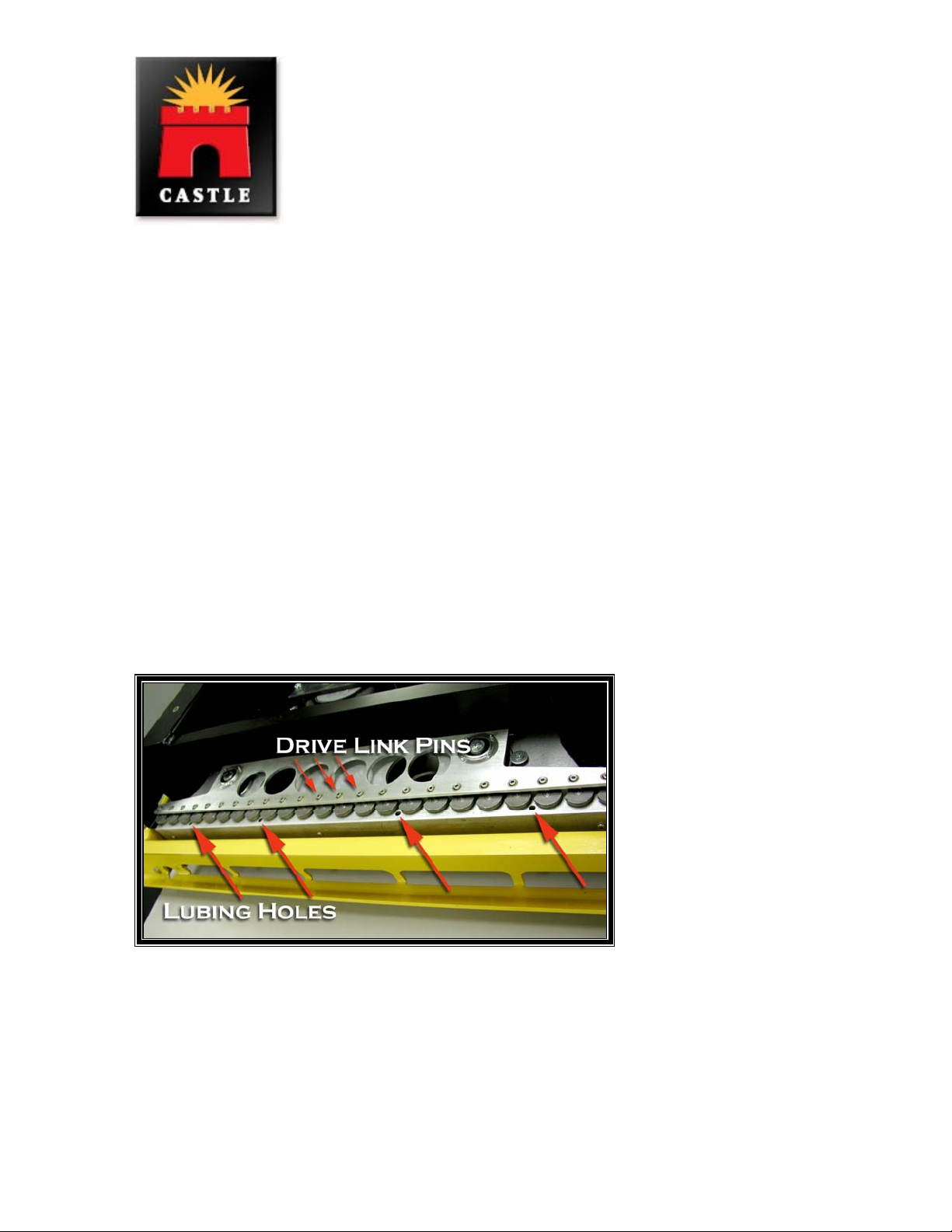

2. Locate the 4 lubrication holes in the top of the head. These may be partly covered by the spindle

housings, requiring a slight repositioning of the housings

Revised 2/9/2007

Page 3

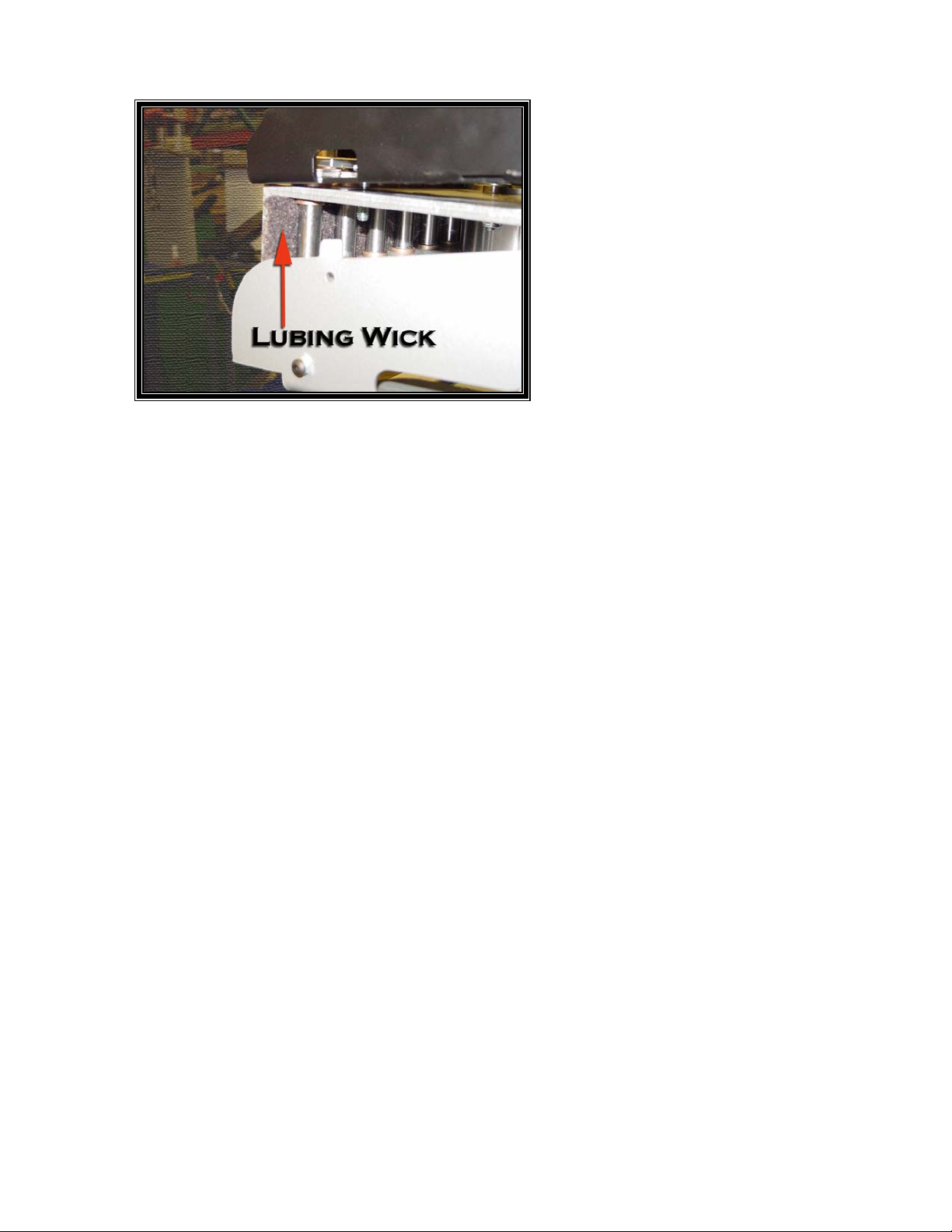

3. Add 10 to 15 drops of oil to each of the holes. The oil is picked up by the wick and distributed

evenly among the spindles

4. Locate the Drive Link Pins and add 1 or 2 drops of oil to each. The pins can be oiled once every

30 hours of usage. However, this should only be done if the head is in good adjustment, but still has a

metallic rattle.

5. After the oil is added the machine should be left running for AT LEAST 30 minutes and then all

excess oil wiped off. If the clean up of the oil is not thorough enough, the machine will throw oil on

the stock.

Revised 2/9/2007

Page 4

How To…

23.10

Resetting Air Pressure at the

Primary Regulator

The primary regulator is located on the right side of the machine, just below the tabletop. There are

two regulators located in this spot. The primary regulator is located closer to the rear of the machine

of the two.

SOLUTION STEPS:

1. Setting internal pressure for the head can be achieved by turning the primary regulator counterclockwise until the knob stops.

2. Next, mark the knob of the regulator so that you have a reference point to start from.

3. Using the reference point turn the regulator 5 ½ to 6 ½ turns to reach a sufficient air pressure.

(Approximately 80 to 85 PSI)

Revised 2/9/2007

Page 5

How To…

23.20

Tooling Check and Replacement

The tooling for a Line Boring machine is designed to give maximum performance for an extended

period of time. Typically, all the bits will need to be replaced at the same time, but occasionally

individual bits will become damaged and need replacement.

SOLUTION STEPS:

1. To check the tooling turn off the machine and lift up the yellow guard by pulling the plunger locks

on either side of the guard.

2. Inspect all the bits. Look for bits that are chipped, angled, or significantly lower/higher than the

others. Another sign of uneven wear is if the bit (or bits), have changed in color to a dark blue.

Revised 2/9/2007

Page 6

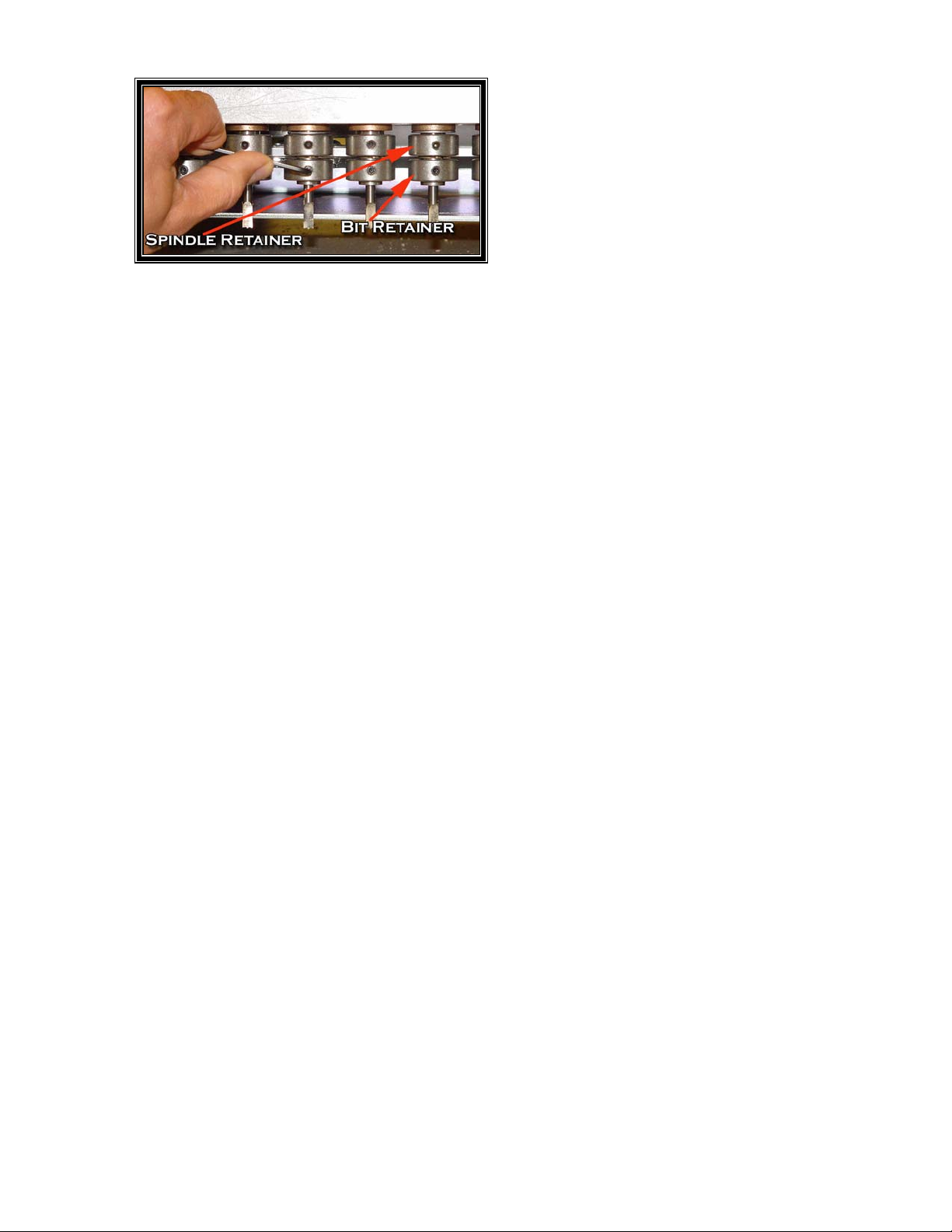

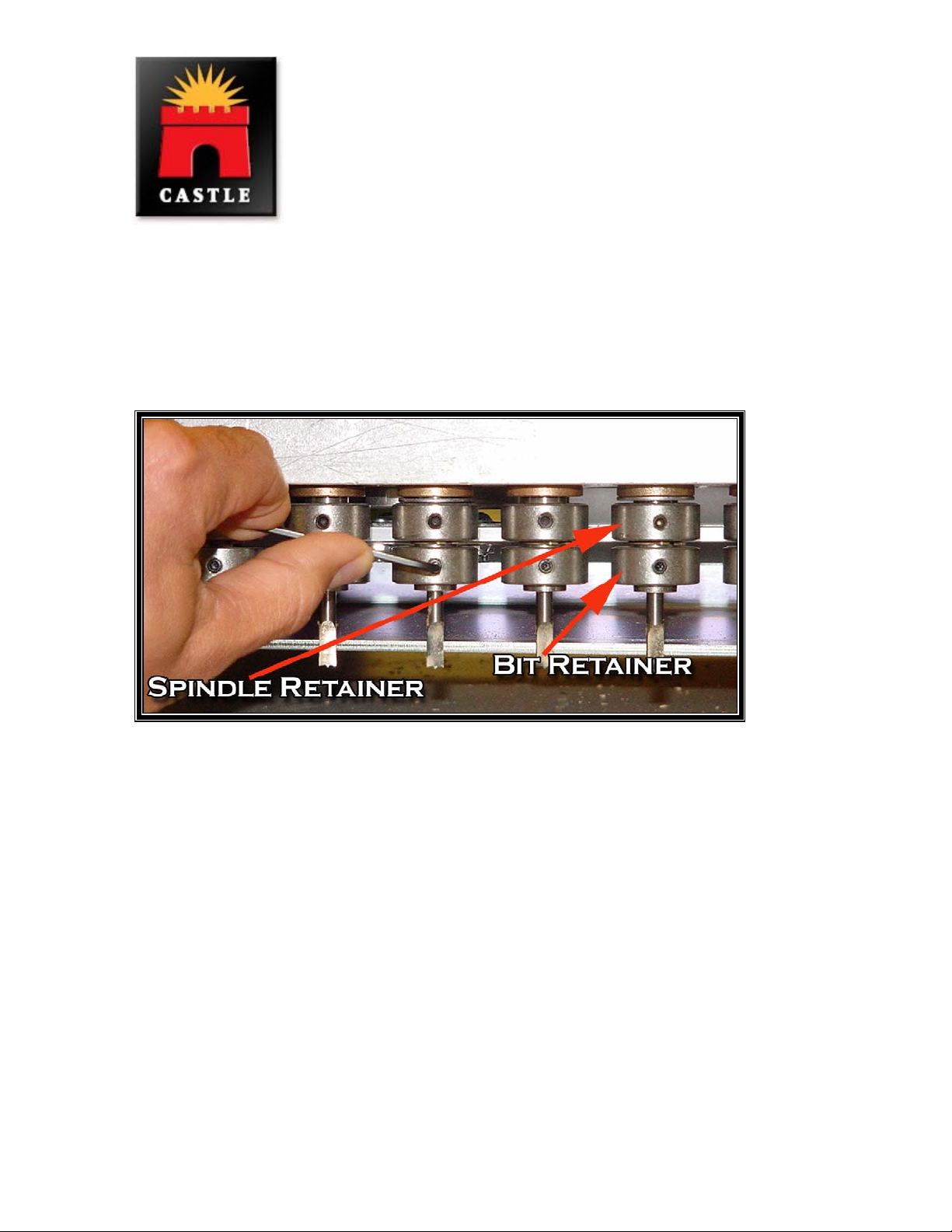

3. To replace bits use a 3/32 allen wrench to loosen the set screw in the bottom collar of the spindle.

4. Remove the old bit by pulling down on it while grasping it firmly.

5. Do the reverse to install. Make sure that the flat part of the bit shank is aligned with the set screw

for tightening.

Revised 2/9/2007

Page 7

How To…

23.21

Collet Adjustment

There are two collets per spindle, making 46 collets per head. The collet on the bottom of the spindle

is used to lock the drill bit into the spindle assembly.

The upper collet is used to hold the entire assembly to the head.

To get the best results the upper shaft collar should pushed as close to the snap ring as possible, and

then tightened.

Revised 2/9/2007

Page 8

How To…

23.23

Cycle Time Adjustment

Two adjustments control the amount of time that the cutting cycle takes to complete:

1. The air pressure to the head is set at the primary regulator closest to the rear of the machine.

2. The first valve activated in the foot switch is supplied with air from the secondary regulator,

which is the one closest to the front of the machine. This, in turn, supplies air to the index

pins.

The primary regulator should be set at 80 to 85 PSI.

SOLUTION STEPS:

1. Setting internal pressure for the head can be achieved by turning the primary regulator

counter-clockwise until the knob stops.

2. Next, mark the knob of the regulator so that you have a reference point to start from.

3. Using the reference point turn the regulator 5 ½ to 6 ½ turns to reach a sufficient air pressure.

(Approximately 80 to 85 PSI)

4. The foot switch can also effect the cycle time of the machine. The valve should be fully

closed when the pedal is not depressed. If the valve is left partially open then the pressure to the

air bladder will need longer to build up, thus adding time onto the cycle. Likewise, if pressing the

foot pedal doesn’t fully open up the valve then full pressure will not be reached either.

Revised 2/9/2007

Page 9

5. This can be checked by partially dismantling the foot switch and checking the foot

switch spring against this photo to make sure the part is in good condition. It should retain the

illustrated shape when not under pressure.

* Please note that it is not necessary to dismantle the foot switch to the point illustrated here in

order to view the spring.

6. If the pedal spring needs to be reset please see procedure 23.84

Revised 2/9/2007

Page 10

How To…

23.40

Adjusting Secondary Regulator

The secondary regulator is the one towards the front of the machine and controls pressure delivered

to the index pins. It is called the secondary regulator. While there is no gauge to check the internal

pressure driving the machine, there is an easy way to reset the regulator to factory settings.

SOLUTION STEPS:

1. Turn the secondary regulator knob all the way to the left, counter-clockwise so that it is completely

closed.

2. With the knob all the way to the left, push both of the index pins down manually.

3. Slowly turn the secondary regulator back up to the right until BOTH index pins just go up.

4. At the point when both pins go up, turn the regulator knob a half turn further to set.

5. To decrease the force with which the index pins come down, turn the regulator to the right until the

desired pressure is reached.

Revised 2/9/2007

Page 11

How To…

23.42

Checking Index Pin Hoses

The hoses that supply the air to the Index Pins run from the secondary regulator through the Guard

Frame, and are visible when looking into the opening at the rear of the machine. If air pressure is

unusually low despite adjustment at the regulator, it's a good idea to check these hoses as well as the

fittings where the hoses connect into the cylinders.

SOLUTIONS STEPS:

1. Use a bright light to trace the hoses from the secondary regulator to the white & black barbs on the

Index Pins.

**Inside machine view

**Rear machine view

Revised 2/9/2007

Page 12

2. When tracing the hoses, you should be looking for kinks or splits in the material. These are most

likely to occur in places where the hoses run out of the machine and are open to being pinched.

3. If you trace the hoses all the way back to the Index Pin, then make sure that you have a firm

connection at the barb that connects into the pins.

Revised 2/9/2007

Page 13

How To…

23.43

Adjusting the Indexing Pins

If it appears that the pins are out of alignment, you can straighten them out by drilling a test board

and realigning a Pin in one of the drilled holes. Follow the testing procedure to confirm they are out

of alignment.

TESTING PROCEDURE:

1. Use a scrap of at least two feet in length and cut a set of holes with the front Drop Gauge down.

2. Slide the board over so that either the left or right Index Pin can enter one of the holes that you just

drilled.

3. Cycle the machine, insuring that the Index Pin is firmly in the hole before bringing the head down.

4. When drilling, the bits should re-enter the holes without chipping out the edges or kicking the

board out. If either of these things happen then the Index Pins need to be re-calibrated.

SOLUTION STEPS:

1. To adjust an Index Pin loosen the two bolts holding the Index Pin bracket in place.

Revised 2/9/2007

Page 14

2. Use a piece of board to cut a full row of holes in. Make sure that there isn't much sawdust

remaining in the holes.

3. Slide the board over so that the Index Pin will enter the last hole, but still leave the majority of

holes underneath the head.

4. Bring the head down into the previous holes while watching very closely that the bits are entering

in the exact center.

5. While the head is down place the Index Pin into the hole (if not already there), and tighten the nuts

on the bracket.

Revised 2/9/2007

Page 15

How To…

23.60

Motor Check

The machine uses an electrical motor that draws a great deal of amperage. If the motor isn't running

then the following steps should be followed.

SOLUTION STEPS:

1. Switch off the machine, make sure that it is plugged in. The machine should not be powered

through an extension cord of more than six feet.

2. Switch the motor back on.

3. If the motor doesn't activate then try hitting the reset button on the side of the motor housing.

4. Open the rear of the machine and locate the pulley with a good light source.

Revised 2/9/2007

Page 16

5. Make sure that the pulley at the bottom of the motor shaft is spinning

6. If the pulley is not spinning, check the motor shaft to make sure that it is spinning.

7. If the above steps do not resolve the issue, then please contact Castle, Inc.

Revised 2/9/2007

Page 17

How To…

23.65

Checking the tension on the belt

If the head significantly slows down or stops while you are drilling, then you may need to check the

tension on your belt.

TESTING PROCEDURE:

1. Make sure the machine is unplugged.

2. Reach through the rear of the machine and test the tension on the belt by squeezing it together.

3. It should be very difficult to get the belt sides to touch each other. If it is relatively easy to get the

sides to touch then the belt is too loose.

Revised 2/9/2007

Page 18

SOLUTION STEPS: You will need another person to complete these steps.

1. Using a wrench, LOOSEN the four 5/16 carriage bolts that hold the motor and motor bracket in

place. DO NOT REMOVE these bolts.

2. Use a 2x4 as a wedge and a 4x4 as a fulcrum.

3. Stand in front of the machine and pull the 2x4 towards your body in order to create enough tension

on the belt. Do this while someone else tightens the four carriage bolts.

4. Once the bolts are tight, test the belt tension through the rear of the machine again and drill a set of

test holes.

5. Repeat these steps, if necessary, until there is enough tension on the belt.

Revised 2/9/2007

Page 19

How To…

23.70

Table Top Adjustment

The table top is adjustable in relation to the guard frame and head. There should be between a 1/8 "

and a ¼ " gap with wood in place. If it is greater then this, the table needs to be adjusted in order for

a proper depth hole to be cut.

SOLUTION STEPS:

1. Locate and LOOSEN the three brackets that lock the table into position. There is one bracket in

front and one on each side underneath the table. The brackets are held in place by 9/16"

hex head nuts.

Revised 2/9/2007

Page 20

2. Once the table is loose, locate the four leveling bolts. There are two on each side of the machine on

the underside of the table.

3. Adjust the bolts up or down and check that the table is level and has the appropriate clearance from

the guard.

4. It is important to maintain the table in the same level position it was in before the adjustment. To

do this, the leveling bolts must be turned the SAME NUMBER OF TURNS AS ONE ANOTHER. It

may be helpful to mark one face of the hex head to use as a reference point as the bolt turns.

5. Retighten the bracket nuts and drill a set of test holes to make sure that the table stayed level.

Revised 2/9/2007

Page 21

How To…

23.71

Adjusting the Wing Table

The wing tables fold out on either side of the table top to extend the work surface. The adjustment for

the wing table is inside the body of the machine. Another person will be needed for this adjustment.

SOLUTION STEPS:

1. Open the front door of the machine.

2. Locate the nuts that secure the wing table arm to the case side.

**Inside machine view

Revised 2/9/2007

Page 22

2. Using a 9/16" wrench, LOOSEN the nuts while someone else holds the wing table in the desired

position.

3. Once the proper position has been achieved, tighten down the nuts.

4. Repeat for the other side.

Revised 2/9/2007

Page 23

How To…

23.80

Power loss during drill cycle

If the machine is experiencing power loss during the drill cycle the following items will need to be

checked. If either is found to exist, it is possible that the amperage of the machine is falling too low to

allow proper operation of the machine.

SOLUTION STEPS:

1. If you are running the machine off of an extension cord, it must be AT LEAST 14 ga. and it must

be no longer than 6 feet.

2. If you are running the machine off of a power strip, make sure that the machine is not the last in

the line of plugs AND that nothing else on the strip has a large simultaneous amperage draw.

3. Check that the felt oiler is charged with oil so that the head is meeting with as little resistance as

possible.

Revised 2/9/2007

Page 24

How To…

23.82

Adjusting the depth of the head

The travel limiter controls how far down the head can move towards the table top and into the stock.

If your holes are not deep enough or they are too deep you may need to make an adjustment to the

Travel Limiter bolt.

SOLUTION STEPS:

1. Locate the 1/2" hole just left of center in the bit cover on the top of the machine. You'll know you

have the right hole because when you look in it there will be a large phillips head screw inside.

2. Using a large phillips head screwdriver adjust the screw through the hole by a 1/2 turn at a time.

The adjustments can be made with the machine on or off, but should be made with the drill head UP.

3. To drill deeper turn the screw counter-clockwise 1/2 turn at a time. To drill to less depth turn the

screw clockwise 1/2 turn at a time.

4. If a loud rattling or clanking sound can be heard when the head is down, then the Travel Limiter

bolt has been adjusted to drill too deeply and should be backed off JUST until the sound stops. If this

adjustment ends up being made, then you may need to raise the tabletop to drill deeper.

Revised 2/9/2007

Page 25

How To…

23.84

Foot Switch Test

The foot switch has two micro-switches and a spring inside the pedal. In order for the pedal to

function properly the spring needs to contact the first valve before the second. This sends the Index

Pins down before the drill head. When the pedal is released the spring should completely back off of

the valves.

SOLUTION STEPS:

1. Make sure the machine power is off and the air is still connected.

2. Remove the screws that fasten the pedal guard to the pedal and remove the pedal from the guard.

First Valve Second Valve

3. Locate the phillips screw and 6/32" nylock nut that hold the pedal spring loosely in place.

Revised 2/9/2007

Page 26

4. Remove the nylock nut while holding the screw tightly and remove the pedal spring.

5. With the spring out of the pedal, bend the spring about 1/8" whichever direction it needs to be

adjusted.

6. Re-assemble the pedal being careful to tighten the spring retaining, 6/32" nylock nut ONLY to the

point that the screw tip is flush with the nylon.

7. Attach the pedal guard to the pedal and test the operation of the machine. Repeat steps until the

appropriate spring curvature has been reached.

Revised 2/9/2007

Page 27

How To…

23.90

SQE Check

The SQE may need to be cleared if the head is not operating normally. Occasionally debris will work

it’s way in and keep the air from flowing freely. This clearing can only be done by first removing the

rear stop.

SOLUTION STEPS:

1. Make sure the machine power is off and the air is disconnected

2. Locate the Fixed Rear Stop. It is held in place by two 7/16" nylock nuts on the underside

of the stop.

3. Remove the stop, but DO NOT adjust the Rear Stop bolts sticking out of the rear of the machine

that butt up against the rear stop.

Revised 2/9/2007

Page 28

4. Once the Rear Stop is removed, you should be able to fit your arm into the rear of the machine.

Reach in to the rear of the machine and remove the white Muffler from the SQE.

5. Cycle the machine several times to clear out any debris.

6. Inspect the Muffler to ensure that it is also clear of any debris or obstruction.

7. Replace the Muffler and test. If this procedure doesn’t fix the problem then replace the SQE.

Revised 2/9/2007

Page 29

How To…

23.91

SQE Replacement

The SQE may need to be replaced if the head is not operating normally. This can only be done by

first removing the rear stop.

SOLUTION STEPS:

1. Make sure the machine power is off and the air is disconnected

2. Locate the Fixed Rear Stop. It is held in place by two 7/16" nylock nuts on the underside

of the stop.

3. Remove the stop, but DO NOT adjust the Rear Stop bolts sticking out of the rear of the machine

that butt up against the rear stop.

Revised 2/9/2007

Page 30

4. Remove the drill cover on the top of the machine by loosening the three-pronged knobs.

5. Locate the two 1/2" nylock nuts that secure the air bar that runs across the top of the air bladder.

6. Use a pointed file or a scribe to mark a reference line across the nylock nuts and the bolts they are

attached to. This line will be used as a reference mark for reassembling the air bladder assembly.

7. After scribing a clear line, use an open or boxend 1/2" wrench to remove the two nylock nuts.

VERY IMPORTANT: Count the number of turns from the scribed reference lines it takes to remove

the nuts. When reassembling, this count will be used to recalibrate the air bladder factory setting.

8. Remove the nylock nuts, but be careful to keep them in a way that they do not get mixed up. It's

important that the nuts go back on the bolts they came off of.

9. With the nylock nuts removed, you can lift the air bar off of the air bladder enough that it clears the

drill frame.

10. Turn the air bladder and the air bar counter-clockwise until you hear the SQE fall inside the

machine.

11. Reach inside the rear of the machine with one hand (or get assistance) and turn the air bladder

with the other until the SQE is fully unscrewed from the air intake for the bladder.

12. Disconnect the large air hose from the push-in fitting attached to the SQE and remove the SQE

from the rear of the machine.

13. Replace the SQE by following the above instructions in reverse.

Revised 2/9/2007

Loading...

Loading...