Page 1

www.castlegroup.co.uk

Vexo H - (GA2006H)

Hand Arm Tri-Axial Vibration Meter

&

O

perating Manual

Page 2

Vexo H

HARM Vibration Meter Operating Manual

Published by Castle Group Ltd

Castle Group Ltd

Salter Road

Scarborough

North Yorkshire

YO11 3UZ, UK

Copyright © Castle Group Ltd 2012

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without the prior permission

of the copyright holder.

Printed in the UK

Rev A

HB/2006/009/EL

Page 3

Thank you for buying a Castle product, I am sure you will find both the goods and

the service to be of the highest quality but if not, then please feel free to write to

me personally and I will ensure that your needs are dealt with immediately.

This manual is designed to show you the operation of the goods you have

purchased and a very brief insight into vibration itself. If you would like to become

a competent person in the eyes of the law, then you may like to know more about

our Competent Persons training course for Human Vibration. You can visit

www.castletrainingacademy.com to find out more.

Castle Group has become the leading supplier of solutions for health and safety,

environmental compliance and plant maintenance and monitoring, with an ever

expanding offer comprising equipment for sale or rent, residential or in-house

training courses, consultancy services and equipment calibration. If you would

like to know more about any of our other products and services then please visit

www.castlegroup.co.uk or telephone us on +44(0)1723 584250.

Simon Bull

Managing Director

Note: for ‘Getting Started’ section please turn to Chapter 4

Page 4

Precautions

• Only operate the instrument as described in this manual.

• These are precision instruments, protect from shocks and physical

extremes.

• Ambient conditions for the operation of the unit are as follows:-

Temperature: -10°C to +50°C

Relative Humidity: 25 to 90%

• Protect the unit from extremes of temperature and humidity, direct

sunlight and air with a high salt or sulphur content.

• Always turn the unit off after use.

• Do not use any solvents or cleaning agents on the instrument. Use only a

soft dry cloth or a soft cloth lightly moistened with water when necessary.

• Do not allow any conductive objects, such as wire or metal particles to

enter the unit.

• Do not try to disassemble the instrument or attempt any repairs as this will

invalidate your warranty. Take a note of the condition of the instrument and

contact your authorised Castle service station.

• To ensure continued precision performance of your instrument have it

checked and serviced at regular intervals.

Contacting Castle Group

This manual contains complete operating instructions for the Castle Vexo H

Vibration Meter, read it carefully and you will quickly become familiar with your

instrument and its operation.

If you do encounter problems with the operation of your instrument please feel

free to contact customer support with your enquiry on: -

Telephone: +44 (0)1723 584250

Fax: +44 (0)1723 583728

Website:

www.castlegroup.co.uk

Email: techsupport@castlegroup.co.uk

sales@castlegroup.co.uk

Page 5

Contents

CHAPTER 1 ....................................................................................... 14

Introduction ..................................................................................................................................... 14

Vexo H (GA2006H) – Tri Axial Hand Arm Vibration Meter (HARM) ...... 14

CHAPTER 2 ....................................................................................... 15

Accelerometer Type, Removal and Fitting ....................................................................... 15

Accelerometer Type .............................................................................................................. 15

Vexo H - Hand Arm Tri-Axial Accelerometer (KD1010) ...................................... 15

Attaching & Removing the Accelerometer ................................................................ 16

CHAPTER 3 ....................................................................................... 17

Measuring Vibration ................................................................................................................... 17

Hand Arm Vibration ............................................................................................................... 17

Hand Arm Vibration Transducer Mounting ......................................................... 17

Vibration Direction ............................................................................................................ 18

Vibration Level .................................................................................................................... 19

Frequency Weighting Filter .......................................................................................... 19

Under Range & Overload Conditions....................................................................... 20

Under Range Condition ............................................................................................ 20

Overload Condition ...................................................................................................... 20

CHAPTER 4 ....................................................................................... 21

Getting Started .............................................................................................................................. 21

Keypad Layout .......................................................................................................................... 23

Powering Your Vexo Meter ................................................................................................ 24

Battery Indicator ................................................................................................................ 25

Recharging the Battery Pack ...................................................................................... 26

Switching Your Vexo Meter On/Off ............................................................................... 27

CHAPTER 5 ....................................................................................... 28

Menu Structure ............................................................................................................................. 28

Menu Options............................................................................................................................ 30

Range ...................................................................................................................................... 30

Files .......................................................................................................................................... 31

Open All ............................................................................................................................ 31

Open Today’s ................................................................................................................. 32

Open 7 Days................................................................................................................... 33

Delete Single File .......................................................................................................... 34

Delete All Files ............................................................................................................... 35

Settings .................................................................................................................................. 36

Units ................................................................................................................................... 36

Brightness ...................................................................................................................... 37

Auto Dim .......................................................................................................................... 37

General ............................................................................................................................. 38

Time .............................................................................................................................. 38

Date .............................................................................................................................. 39

File Naming ............................................................................................................... 39

Meter ...................................................................................................................................... 40

Page 6

Reset ................................................................................................................................. 40

Configuration ................................................................................................................. 41

Exposure Points ...................................................................................................... 41

Show Results ........................................................................................................... 42

Information ..................................................................................................................... 42

Calibration ....................................................................................................................... 43

Measurement ......................................................................................................... 43

Sensitivity ................................................................................................................... 46

CHAPTER 6 ....................................................................................... 47

Using the Vexo H .......................................................................................................................... 47

Stop State ................................................................................................................................... 47

Record State ............................................................................................................................. 48

Playback ....................................................................................................................................... 49

Show Results - On ............................................................................................................. 50

Exposure Points - On ........................................................................................................ 51

Under Range Indicator ......................................................................................................... 52

Overload Indicator .................................................................................................................. 53

Parameters ............................................................................................................................... 54

Arms .................................................................................................................................. 54

Aeq ..................................................................................................................................... 54

Amax .................................................................................................................................. 54

Peak ................................................................................................................................... 54

Vector ............................................................................................................................... 54

Exposure .......................................................................................................................... 54

CHAPTER 7 ....................................................................................... 55

Downloading Saved Recordings to a PC ........................................................................... 55

CHAPTER 8 ....................................................................................... 56

Accessories ..................................................................................................................................... 56

CHAPTER 9 ....................................................................................... 57

Technical Specification ............................................................................................................... 57

Applicable Standards ............................................................................................................ 57

Noise Floors ............................................................................................................................... 57

Normal Operating Mode ..................................................................................................... 57

Overload & Under Range Triggering Points .............................................................. 57

Level Ranges ............................................................................................................................. 58

Frequency Weightings ......................................................................................................... 58

Accelerometer ......................................................................................................................... 59

Electrical Signal Input ............................................................................................................ 60

Maximum Electrical Signal Input For No Damage .................................................. 60

Environmental Stabilization Time .................................................................................... 60

Warm up Time ......................................................................................................................... 60

Settling Time ............................................................................................................................. 60

Temperature Operating Range ....................................................................................... 60

Effect of Air Temperature ................................................................................................... 61

Effect of Surface Temperature ........................................................................................ 61

Real Time Clock ....................................................................................................................... 61

Digital Signal Processing ..................................................................................................... 61

Analogue to Digital Converter & Microcontroller ................................................... 61

Displayed Measurement Resolution ............................................................................. 61

Page 7

Display .......................................................................................................................................... 61

Memory ....................................................................................................................................... 62

Overload ....................................................................................................................................... 62

Size and Weight ....................................................................................................................... 62

Connections ............................................................................................................................... 62

AC Output .............................................................................................................................. 62

Wiring Configuration – 4 Pole Jack Socket 3.5mm .................................. 62

Download ............................................................................................................................... 63

Wiring Configuration - Micro USB ‘B’ Socket ................................................ 63

Input Signal ........................................................................................................................... 63

Wiring Configuration – (Lemo Socket EGG.0B.305.CLL) ........................ 63

Battery Recharge ............................................................................................................. 63

Batteries ..................................................................................................................................... 64

EC Declaration of Conformity ............................................................................................ 65

CHAPTER 10 .................................................................................... 66

Function Equations ....................................................................................................................... 66

CHAPTER 11 .................................................................................... 68

Customer Instrument Support .............................................................................................. 68

Warranty and After Sales Service ................................................................................. 68

Disclaimer................................................................................................................................... 70

Instrument Details .................................................................................................................. 70

Table of Figures

Figure 1 - Recommended Axes for Hand Arm Vibration ................................................ 18

Figure 2 - Keypad Layout ................................................................................................................ 23

Page 8

Castle Group Ltd

If you want to keep up to date with the latest in health and safety, you

should attend a Castle FREE seminar. These are run around the country

and cover a wide range of topics. Packed with the latest information and

delivered with the help of practical demonstrations, these seminars are

a great way to really learn something at the same time as collecting cpd

points! Go to the website below to find the lasts dates and venues and to

see video clip samples.

www.need2know4free.com

Dedicated to professionals

in Health and Safety,

Environmental Compliance

and Plant Maintenance

Engineering, Castle set out

to help you in a way that

suits you best. We can

provide or rent equipment,

train you and your staff or

we can carry out work on

your behalf. We can even

mix it up to suit your way of

working.

• Measuring and Monitoring Instruments

• Equipment Rental

• Database and Data-management Software

• Training Courses and In-house Provision

• Calibration and Repair of Monitoring Equipment

• Consultancy for Health, Safety, Environment and Engineering

Solutions

• Online Knowledge

www.castlegroup.co.uk

Page 9

HEALTH AND SAFETY

Compliance with legislation and mitigation of claims is really what health

and safety is about for most companies. That is how we are set up to

help you; Our training courses are all geared to that end as is any

equipment we might supply or rent to you. If you need us in person, we’ll

be there too! Call NOW on 01723 584250 and get your health and

safety compliance on-track, the way you want to do it! There are many

issues you might like us to have a look at

• Noise and Vibration at Work

• Audiometry

• HAVS Health Surveillance

• Health Screening

• Air Sampling and Gas Detection

• Indoor Air Quality

• Airflow

• EMF Testing and Monitoring

• Portable Appliance Testing (PAT)

• General Compliance and Risk

Assessment

ENVIRONMENTAL COMPLIANCE

In an increasingly sensitive atmosphere to environmental issues,

businesses have to be careful. Neighbours are increasingly aware of

theirs ‘right’ to complain and the environmental agencies are looking for

industry to clean up its act. Simply call us on 01723 584250 if you

have any environmental compliance issues and we will work with you to

find the best way forward.

• Noise for Planning

• Complaint Management

• Ground-Bourne & Building Vibration

• Stack-Emissions Monitoring

• Environmental Air Sampling

• Water Quality Testing

Page 10

MAINTENANCE AND DIAGNOSTICS

Production plant needs maintenance and if this can be done only when

needed, then cost savings can be huge. Condition monitoring offers the

ability carry out predictive maintenance so shut-down is only when you

plan it and only when it’s needed. It is very simple to work out if this is the

right approach for your business, so give us a call on 01723 584250

so we find out how much you could save!

• Vibration Monitoring Systems

• Vibration Meters

• Temperature Monitoring System

• Thermometers

• Thermal Imaging

• Diagnostic Vibration Analysis

• Tachometers

• Inspection Endoscopes

Services

Castle Training Academy

Competence and Compliance training is essentially all about obtaining

the knowledge and skills required to get the job done. This is precisely

how Castle courses are set out, with a high degree of practical ‘handson’ experience mixed with some background theory and a lot of jobspecific information and discussion. If this doesn’t whet the appetite,

then there is also a fully inclusive dinner on the first nigh – perfect for

getting to know some of your peers! You can see a full list of courses on

our website.

• Health and Safety Compliance Courses

Noise, Vibration, COSHH, Asbestos

• Health Surveillance Courses

Audiometry, Lung Function, HAVS

• Environmental Monitoring Courses

Noise, Vibration, Air Quality

• Diagnostic Engineering Courses

• Maintenance and Monitoring Courses

Page 11

In-house and Bespoke Training

The benefits of in-house training can be extensive. Training can be

tailored to your company, the timing can be made to suit your needs, you

get to keep your staff on-site and you can train many people at one go!

You can pick any of our standard courses, a shortened version as an

awareness session or a toolbox talk, or you can design your own course

covering a large range of topics. Visit our website for a list of ideas!

Castle Consultancy

Sometimes, the comfort of using an independent expert can be

extremely valuable, whether that be for short-term help, Engineering

project work, or an on-going support contract. Castle consultants are

always at the top of their game and are waiting to hear from you. Have a

look at our website or call on 01723 584250.

• Noise and Vibration, COSHH

Assessments

• Light, Temperature, EMF

Assessments

• Environmental Monitoring

• Expert Witness

• Diagnostic Engineering

• Engineering Control Solutions

• Risk Management

• Health Surveillance Services

• Health and Safety ‘Department’

Support Service

Castle Care

Maintaining calibrations on measuring equipment is absolutely essential

to the integrity of your data. At Castle, we can calibrate virtually anything

you have that can measure. We pride ourselves in fast-as-possible

turnaround times and can normally give up-front prices for almost any

equipment. Whether you have an anemometer, or a ‘zero-g‘

accelerometer, then call us for a price on 01723 584250.

• If it Measures, and can be done - we’ll Calibrate it

• UKAS Certificates Available

• Multiple levels of Calibration

Page 12

Equipment Types Covered

• Air quality meters

• Air sampling pumps

• Air sampling calibrators

• Anemometers

• Audiometers

• Balances/Scales

• Barometers

• Dosemeters

• Electrical test equipment

• Force meters

• Gas Detectors

• Hygrometers

• Light meters

• Manometers

• Moisture meters

• Noise meters

• Pressure meters

• Sound level meters

• Sound analysers

• Strain gauges

• Tachometers

• Thermometers

• Thermo-hygrometers

• Thickness meters

• Timers

• Vibration meters

• Vibration analysers

• Weighing equipment

Castle Contract

If peace of mind for equipment calibrations is important to you – and it

should be, then check out our contract calibration deals. We will give you

discounted, fixed-annual-pricing for selections of equipment and we will

undertake to ensure calibration is maintained to your schedule. This is

designed to take all the hassle out of equipment calibration.

• Maintain Instrument Calibrations

• Hassle-Free Administration

• Discounted Calibration Fees

• Single-Source Supplier

Page 13

Castle Rent

Rental is a great way to have the use of measurement equipment

without having to own it – especially is capital budgets are tight or it tax

is an issue. If you need a short term solution, additional equipment to

boost your capabilities or if contract-based tax deduction is important,

then Rental could well be the way to go. Go to our website to find the

huge range of equipment we have available.

You might also like to make use of our ex-rental purchase as a way of

keeping your equipment costs down.

• Easy on Cash-Flow

• Short or Long Term

Rentals

• Let the Taxman Pay on

Contracts

• Try Before You Buy

• 4 weeks for the Price of 3!

• No On-going Maintenance

If it exists - we’ll even source equipment for you!

www.castlegroup.co.uk

01723 584250

Page 14

Page 14

Chapter 1

Introduction

Vexo H (GA2006H) – Tri Axial Hand Arm Vibration Meter (HARM)

Thank you for purchasing your product from Castle Group Ltd.

The Vexo H Tri Axial vibration meter brings simplicity, looks, value for money and

power to the world of vibration monitoring.

The instrument is fully compliant with the standard ISO 8041:2005 and has

been designed to make sure workers do not exceed the exposure to vibration

levels as stated by the Control of Vibration at Work Regulations (2005).

It boasts a clear easy to read colour LCD and has full data logging capabilities

with fast USB downloading to your laptop or PC. The Vexo incorporates internal

Flash memory to store all your recordings and the data can then be transferred

to the supplied software Vibdata LITE using the supplied USB cable or viewed

onscreen.

Not only does the Vexo H vibration meter have all these features in a small and

ergonomic case but it is also supplied with a rechargeable battery pack

featuring the latest NiMH technology which incorporates extremely low selfdischarge.

Every part of the Vexo has been thoughtfully designed. The case, accelerometer

and cable are all rugged for industrial use and the meter is extremely easy to

use with a simple three button operation, all you virtually need do is press the

power button and start recording.

With the Vexo H combating HAVS has become even easier.

Page 15

Page 15

Chapter 2

Accelerometer Type, Removal and Fitting

The accelerometer for use with the Vexo H produces a Voltage Output

proportional to the signal being measured.

The table below shows the output voltage and specifications for the

accelerometer where g is the acceleration due to gravity on the Earth’s surface

and is defined as 9.80665 ms

-2

.

Acceleration is measured in metres per second per second (m/s/s) which can

be written as either of the following: -

• ms

-2

• m/s

2

Accelerometer Type

Vexo H - Hand Arm Tri-Axial Accelerometer (KD1010)

Accelerometer

Type

Output

Voltage

Operating

Range

Frequency

Response

Hand Arm 10mV/g ±200g 2 to 5000Hz ±10%

Hand Arm Vibration

Tri-Axial

Accelerometer

(KD1010)

Page 16

Page 16

Attaching & Removing the Accelerometer

On the accelerometer cable connector locate the orientation key, and on the

instrument locate the RED keying identification mark of the 5 pin Lemo socket.

Position the accelerometer cable so that the orientation key is in line with the

RED mark and then gently push the accelerometer cable into the instruments

socket.

To unlatch and remove the accelerometer cable gently pull the on the knurled

part of the stem and pull the accelerometer from the instrument.

Do not twist the connector, doing so will likely damage internal wiring which

would not be covered under warranty.

Removal of the accelerometer can be achieved with the instrument powered on

or off.

Page 17

Page 17

Chapter 3

Measuring Vibration

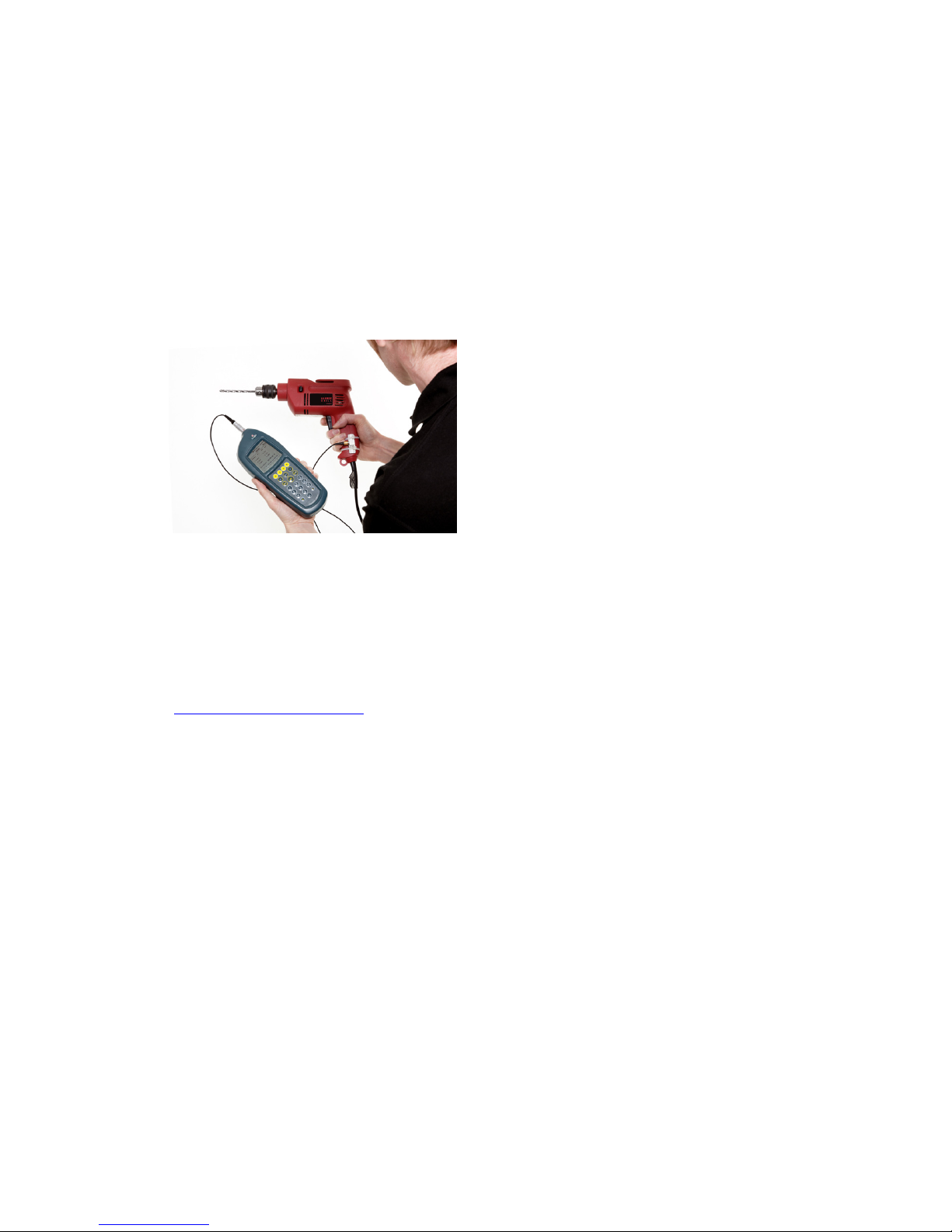

Hand Arm Vibration

It is advisable to validate your instrument prior to, and after taking

measurements using a known vibration source such as the Castle GA606

Vibration Calibrator.

To ensure measurements are as accurate and as repeatable as possible always

ensure that your cable is tightened securely to your accelerometer and that the

accelerometer is mounted as securely and as flush as possible to the vibration

source. The trailing cable of the accelerometer should also be attached to the

vibration source without creating a potential hazard for the operator or other

people.

Where possible always mount the accelerometer as near to the centre of

where the operator holds and grips the vibration source. In reality this is not

always possible and the best compromise must be achieved.

Measurement durations are dependant on the vibration source, and a minimum

period of 30 seconds for Hand Arm Vibration is recommended. Measurement

periods of 3 to 15 minutes are often used for Hand Arm vibration. These

increased durations will undoubtedly increase the accuracy and repeatability of

your measured results.

Hand Arm Vibration Transducer Mounting

The supplied mounting block can be attached to the HARM accelerometer using

the supplied screw and tightened using a Phillips screw driver. The mounting

block can then be mounted to the vibration source using hose clamps or plastic

ties. If plastic ties are used it is recommended that they are tightened using a

tie tensioning tool. Attaching devices such as clamps and the accelerometer to

hand held devices may alter the mass of the vibration source and will inevitably

slightly alter the vibration emitted from the device, it is therefore recommended

to keep the mass of hose clips or clamps to a minimum.

Other mounting possibilities to mount the accelerometer to the vibration source

are tapping a stud into the vibration source and attaching the accelerometer to

the stud. Alternatively the stud may be adhered to the device rather than

tapped with an adhesive that dries rigid. Castle Group Ltd can supply a glue and

stud pack if required, (order code KD1215). See Accessories for more options.

Page 18

Page 18

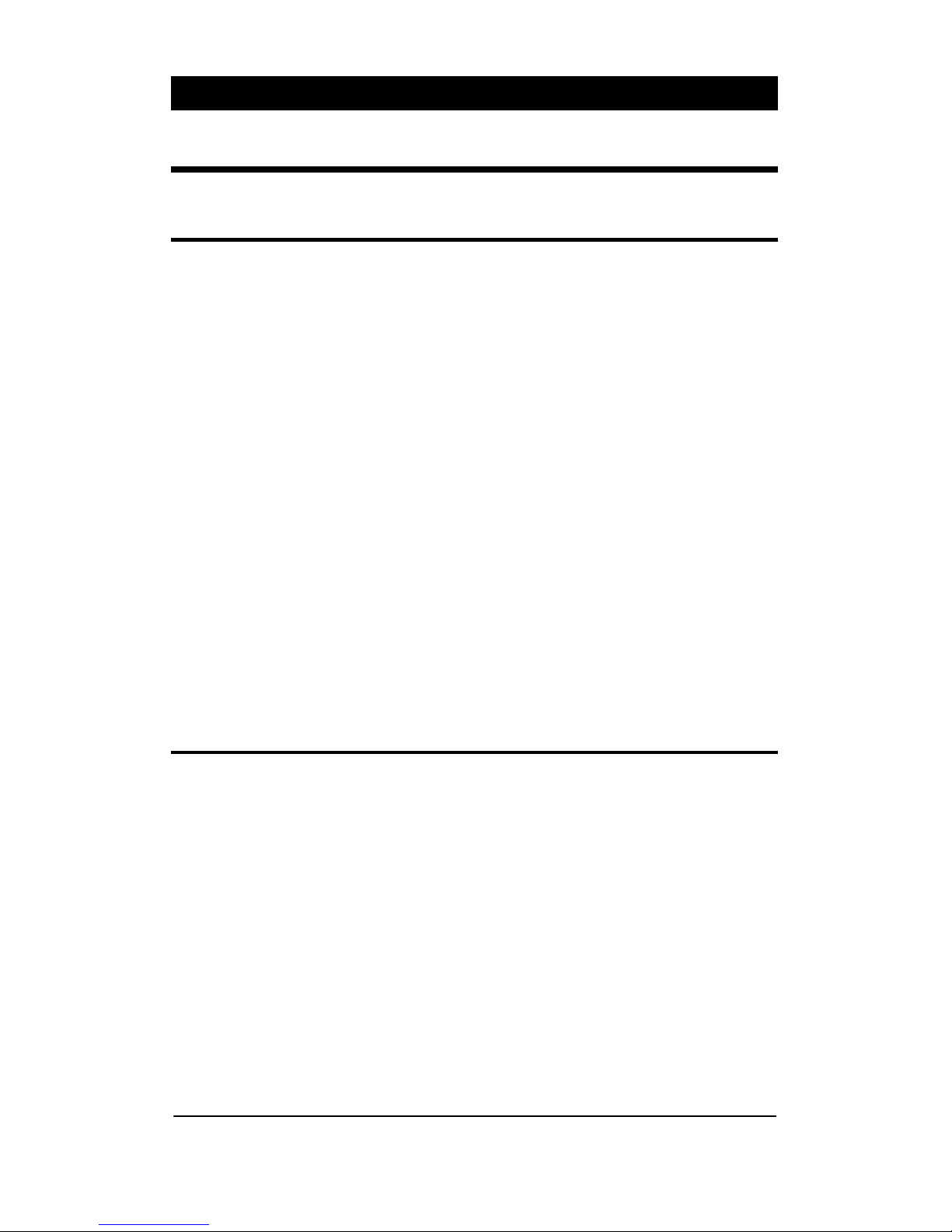

Vibration Direction

For Hand Arm vibration, the three axes being measured can be measured in any

orientation; however it is recommended that the suggested axes indicated in the

figure below are used. If this is not possible, then choosing other axes

orientation is permissible and will not affect your measured data.

In all cases it is strongly recommended to make notes on the axes used relative

to the vibration source. This information will be required if vibration control is to

be implemented on the vibration source.

Figure 1 - Recommended Axes for Hand Arm Vibration

Page 19

Page 19

Vibration Level

In some environments, high levels of vibration may occur. Before you record

measurements take the time to ensure you have selected the optimum range

for the process being recorded.

The optimum range is generally the lowest range that can be selected that does

not produce an overload condition for the process being monitored.

Where high levels of vibration are encountered the meter may register an

overload and in these circumstances the meter will display that this has

occurred. In such cases you will need to select the high range to accommodate

the higher peak levels and if Overload conditions are still occurring on the high

range it may be necessary to use an impact filter on the accelerometer.

If the vibration levels are too low for the range selected then the meter will

display an under range condition. Under these circumstances you will need to

select the low range if possible.

For more detailed information see Under Range & Overload Conditions.

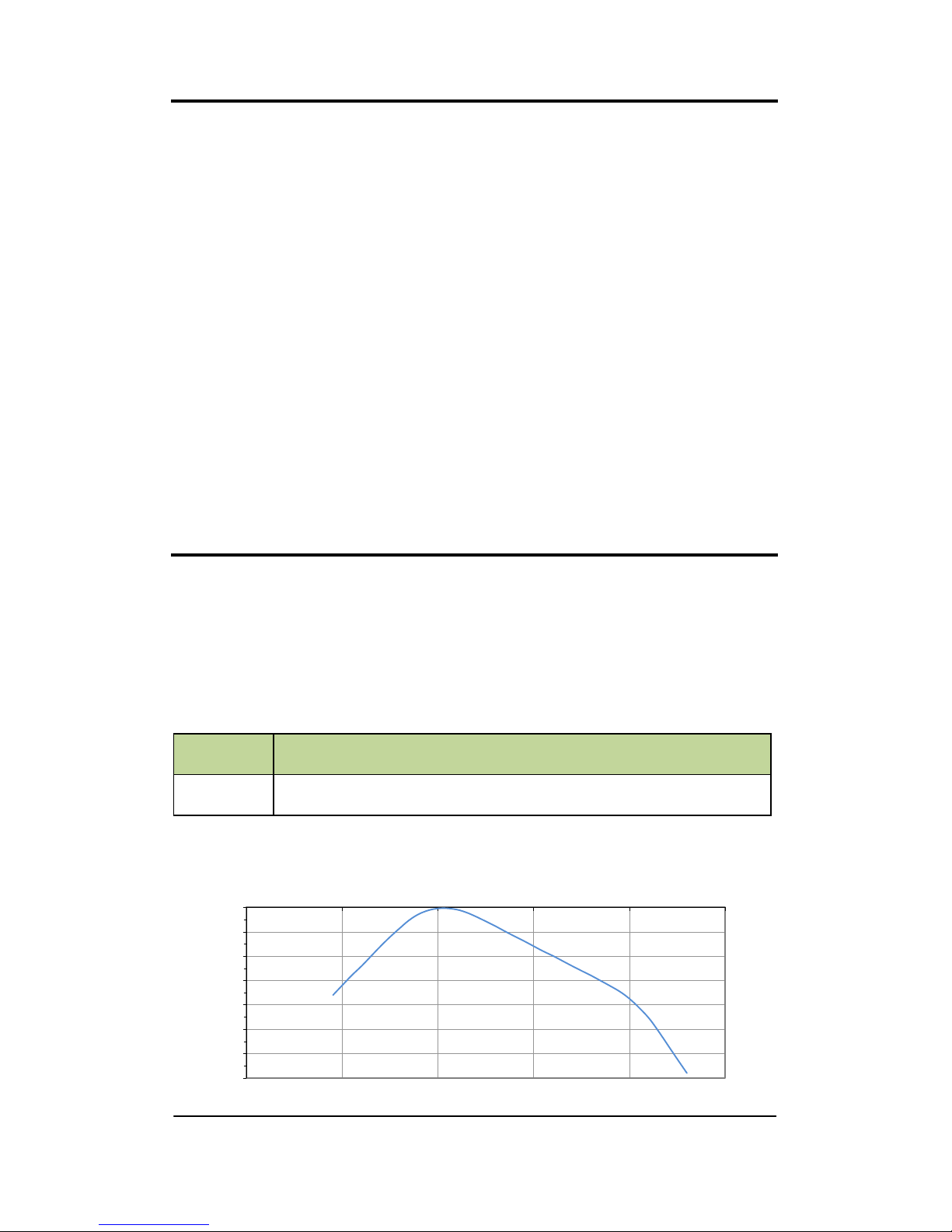

Frequency Weighting Filter

The human body’s discomfort level to vibration alters depending on the vibration

frequency and where the vibration is in contact with the body.

Your Vexo H meter therefore has the following frequency weighting filter which

is applied to the measured vibration signal using a fast processor for superior

accuracy: -

Hand Arm Vibration

Filter Description

Wh

Always used for Hand Arm Vibration measurement in the X, Y

and Z Axis.

Wh Filter Frequency Response:

-70

-60

-50

-40

-30

-20

-10

0

0.10 1.00 10.00 100.00 1000.00 10000.00

Gain (dB)

Frequency (Hz)

Page 20

Page 20

Under Range & Overload Conditions

Under Range Condition

An under range condition occurs when the vibration level is equal to, or lower

than the bottom of the current range the meter is set to. If this condition

occurs then the UR (Under Range) indicator will be displayed on your

instrument. In such circumstances it is highly recommended to change to a

lower range with a higher sensitivity as your meter will be out of specification.

The under range indicator will remain on for a minimum of 2 seconds or while

the under range condition remains.

Placement of the under range indicator can be found under Under Range

Indicator in Chapter 6.

See Technical Specification for a complete list of Under Range triggering

points.

Overload Condition

An overload condition occurs when either the peak signal starts to exceed the

signal handling capability of the specialised amplifier circuitry or if the vibration

level exceeds the top of the selected range by 5%. If the vibration source

saturates the input circuitry or is 5% greater than top of the selected range an

Overload condition occurs and an OL (Overload) indicator is displayed on your

instrument.

If an overload condition occurs it is highly recommended to change to a higher

range with a lower sensitivity as your meter will be out of specification.

The overload indicator will remain on for a minimum of 2 seconds or while the

overload condition remains.

Please be aware that the selected frequency weighting may attenuate the

displayed signal level below the overload triggering point but an overload can still

occur. This is because the overload operates from the unweighted input signal.

Placement of the overload indicator can be found under Overload Indictor in

Chapter 6.

See Technical Specification for a complete list of Overload triggering points.

Page 21

Page 21

Chapter 4

Getting Started

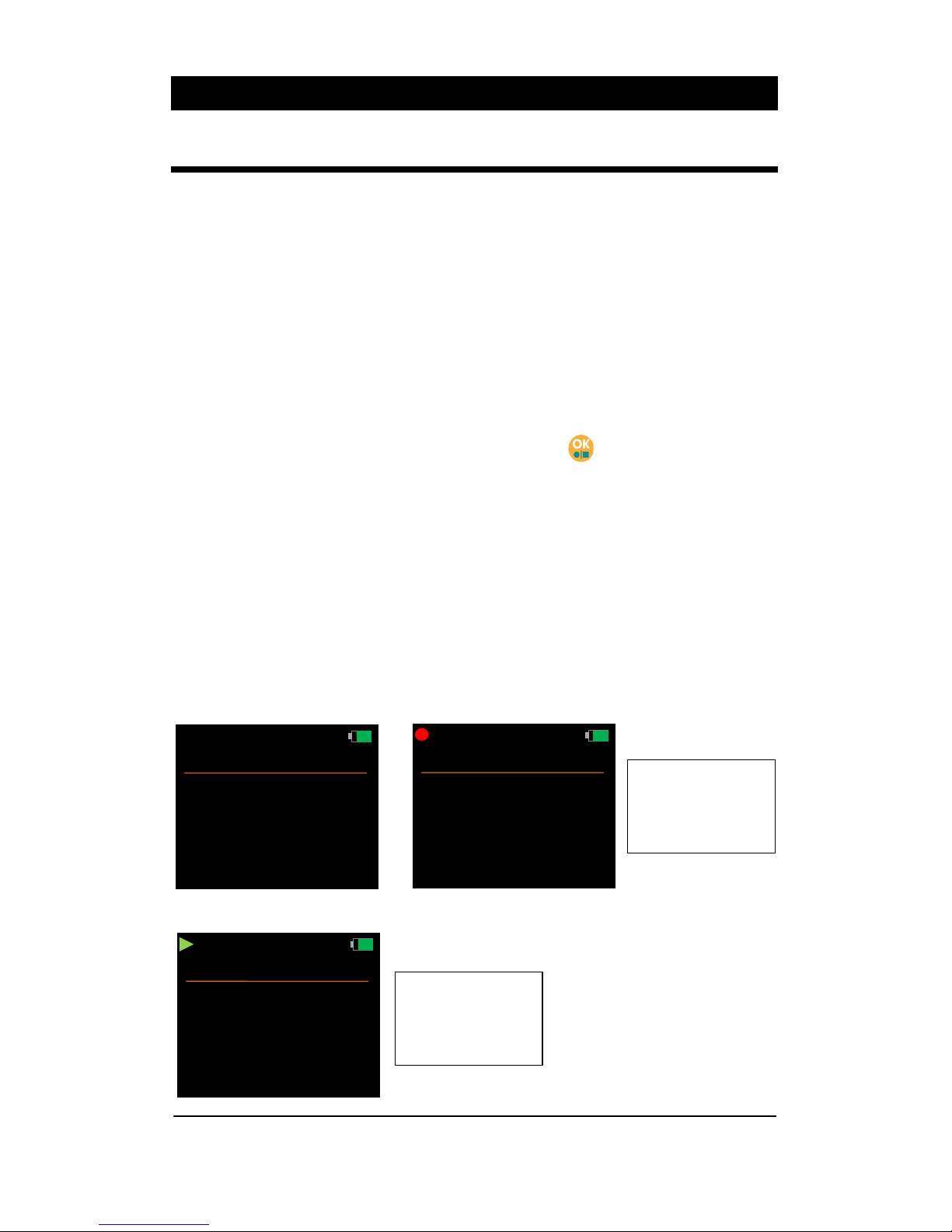

The Vexo H instrument has three states of basic operation: -

• Stop State

• Record State

• Playback

Whilst the instrument is in the Record State the vibration activity is analysed

and all parameters available on your instrument are calculated.

The data captured is saved to the internal flash memory and can be viewed

onscreen or downloaded to Castle’s vibration analysis software Vibdata LITE or

VibdataPro as and when required.

To Start or Stop a recording press the following key

Whilst the instrument is in the Stop State, calculations are displayed on screen

but are not stored in flash memory.

Exposure Points are only available at the end of a recording or when viewing a

saved recording. The option to display Exposure Points must also be set to On.

During Stop State it is possible to change the Settings and undertake Calibration

of the instrument.

Stop State, Record State and playback can easily be distinguished: -

Record State

shows Record

Symbol and

Time Recorded

A

eq

m/s

2

OL

X: 4.12

m/s

2

OL

Y: 3.25

m/s

2

OL

Z: 4.01

00:02:01

W

h

Playback

Playback shows

Play Symbol

and Total Time

Recorded

W

h

A

rms

m/s

2

OL

X: 3.51

m/s

2

OL

Y: 2.18

m/s

2

OL

Z: 1.04

W

h

A

rms

m/s

2

OL

X: 3.51

m/s

2

OL

Y: 2.18

m/s

2

OL

Z: 1.04

00:00:01

Stop State

Record State

Page 22

Page 22

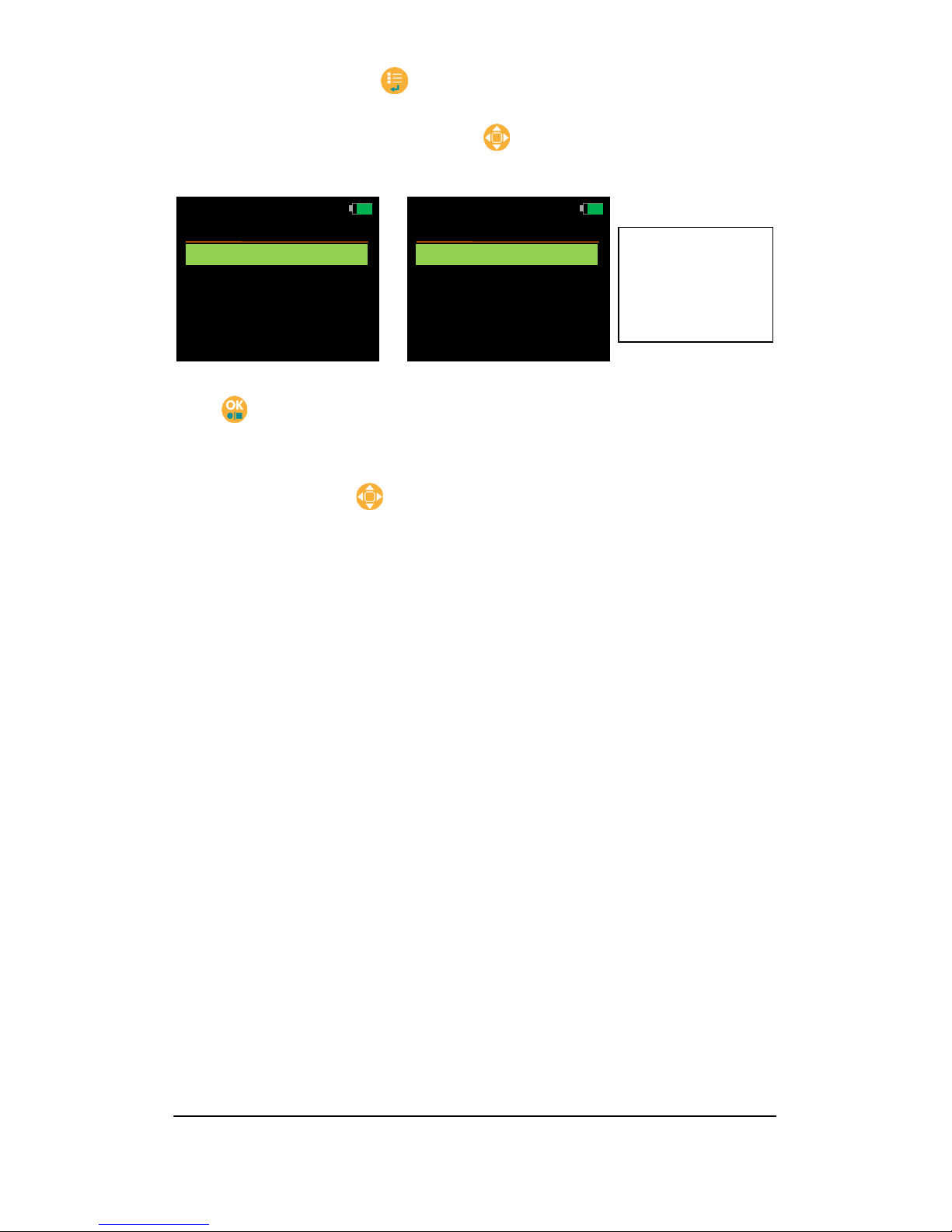

Whilst in Stop State press to open the Main Menu. This key is also used to

step back to the previous screen.

With the Main Menu screen open, use to scroll down the list of available

options: -

Press to select the required option. Note that a recording cannot be started

from within the Main Menu.

Some options may also have further sub-menus where further options are

available. Again use the

key to scroll through the available options.

The menu structure is described in detail in Chapter 5.

Please be aware that your Vexo H instrument has a built in battery saving

function that automatically dims the display. Any key can be pressed to exit this

power saving function. See Auto Dim in Chapter 5 for more details.

If the instrument

has no files

saved then the

Files option is

not selectable

Menu

14:32 23/08/12

Range

Files

Settings

Meter

Menu

14:32 23/08/12

Range

Files

Settings

Meter

Page 23

Page 23

Figure 2 – Keypad Layout

Keypad Layout

Please note that some keys have a dual function.

Power On / Off

Record / Stop

Main Menu

Scroll

OK

Back

Page 24

Page 24

Powering Your Vexo Meter

Your Vexo meter is powered from a Castle rechargeable 2.4V NiMH battery

pack. The battery pack employs the latest battery technology for maximum

battery life between instrument uses.

The battery compartment is located on the underside of your instrument. Open

the battery door by sliding the cover downwards towards the bottom of the

instrument.

The cover can now be removed exposing the battery compartment and battery

pack if fitted.

To fit a battery pack, plug the battery pack into the connector and insert the

battery pack at an angle as shown below: -

Page 25

Page 25

Push the raised end of the battery pack downwards as indicated until the

battery pack sits comfortably in place.

Ensure battery cabling does not overlap or obstruct where the battery door is

inserted.

Battery Indicator

Your Vexo meter is equipped with a four stage battery level indicator and is

visible in the top right hand corner of all screens.

With a fully charged battery pack the indicator with a full Green bar is displayed

and as the battery pack discharges the relevant indicator is displayed.

The approximate values are 100%, 75%, 50% and 25%

When the battery pack is below 10% it will flash Red indicating that the battery

pack is flat and requires a recharge.

When the battery pack is below 4% it will automatically power the unit down and

save any data if the instrument is in Record State.

Page 26

Page 26

Recharging the Battery Pack

With a battery pack inserted and your instrument switched off plug your

supplied charging unit into the DC socket indicated below: -

The Vexo instrument will not operate while the battery pack is charging and will

immediately switch off when the charger is plugged in to the DC socket, even if

the charger is not switched on. This is normal.

If the unit switches off due to the charger plug being inserted then no settings or

recordings will be saved.

A completely discharged battery pack may need several hours to become fully

charged.

Observe the LED on the charging unit to determine the charging cycle.

When the charging unit displays a constant Green LED then charging is

complete.

For safety only use the charging unit and battery pack supplied by Castle.

LED Colour Mode Output

Yellow No Battery 6.4V

Yellow Initialisation 30mA

Orange Fast Charge 1.3A

Green/Yellow Top-off Charge 160mA

Green Trickle Charge 30mA

Orange/Green Error 30mA

Page 27

Page 27

Switching Your Vexo Meter On/Off

To turn on your instrument press and hold the Power On/Off key for

approximately two seconds.

Your meter will display the start-up screen and initialise any saved settings.

The start-up screen is shown below: -

Once the start-up sequence is complete the instrument is placed in its Stop

State displaying the parameter measuring screen.

To turn off your instrument press and hold the Power On/Off key for

approximately three seconds and the following screen will be displayed: -

Release the Power On/Off key

to shut down.

Your Vexo meter is also equipped with an automatic shut down if no key is

pressed for 3 minutes after power on.

If any key is pressed after the instrument is turned on then the automatic

shutdown will not occur.

Vexo

GA2006H V1.00

www.castlegroup.co.uk

Serial No: 067909

Shut Down

14:32 23/08/12

Release

Power Key

To Shutdown

Page 28

Page 28

Chapter 5

Menu Structure

Whilst in Stop State press to open the Main Menu. This key is also used to

step back to the previous screen.

With the Main Menu screen open, use to scroll down the list of available

options: -

Press to select the required option. Note that a recording cannot be started

from within the Main Menu.

Some options may also have further sub-menus where further options are

available. Again use the

key to scroll through the available options.

The complete menu structure is shown below: -

If the instrument

has no files

saved then the

Files option is

not selectable

Menu

14:32 23/08/12

Range

Files

Settings

Meter

Menu

14:32 23/08/12

Range

Files

Settings

Meter

Page 29

Page 29

Page 30

Page 30

Menu Options

Each Menu option is described fully below: -

Range

Select this option to change the measuring range of your Vexo instrument.

Use the

key to highlight the required option and press to select. The

range will be selected and the previous menu screen will be displayed.

Range details are as follows: -

Range (m/s2) (g)

High 0.50 – 2000 0.051 – 204

Low 0.05 – 200 0.0051 – 20.4

Press

to return to the previous screen without making a selection.

Red Tick

indicates

current

selection

Range

14:32 23/08/12

High

Low

Page 31

Page 31

Open

14:32 23/08/12

10:25:30

11:36:30

11:23:35

1/3

06/08/12

05/08/12

05/08/12

Files

Select this option to manage saved recordings on your Vexo instrument.

Use the key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Open All

Select this option to show all saved recordings on the instrument. Recordings

are listed by file name, date and time order showing the most recent first.

The file number and amount of recorded files are also shown in Red: -

Use the

key to highlight the required file and press to open it.

If more than 5 files exist then use the

key to scroll through the available

recordings: -

Press

to return to the previous screen without making a selection.

If no files have

been recorded

today or in the

last 7 days

then these

options will not

be selectable

Files

14:32 23/08/12

Open All

Open Today’s

Open 7 Days

Delete Single File

Delete All Files

Files

14:32 23/08/12

Open All

Open Today’s

Open 7 Days

Delete Single File

Delete All Files

Open

14:32 23/08/12

12:13:03

16:55:00

16:33:45

15:15:30

13:26:35

126/144

09/08/12

08/08/12

08/08/12

08/08/12

08/08/12

Page 32

Page 32

Open

14:32 23/08/12

09:35:20

09:22:25

09:12:12

1/3

23/08/12

23/08/12

23/08/12

Open Today’s

Select this option to show all saved recordings made today on the instrument.

The recordings are listed by file name, date and time order showing the most

recent first.

Note that this option is not selectable if no recordings have been made today.

The file number and amount of recorded files are also shown in Red: -

Use the

key to highlight the required file and press to open it.

If more than 5 files exist then use the

key to scroll through the available

recordings: -

Press

to return to the previous screen without making a selection.

Open

16:32 23/08/12

10:55:00

10:33:45

10:15:30

09:56:35

09:43:03

6/23

23/08/12

23/08/12

23/08/12

23/08/12

23/08/12

Page 33

Page 33

Open

14:32 23/08/12

09:12:12

09:35:20

09:22:25

1/3

20/08/12

17/08/12

17/08/12

Open 7 Days

Select this option to show all saved recordings made in the last 7 days.

The recordings are listed by file name, date and time order showing the most

recent first.

Note that this option is not selectable if no recordings have been made in the

last 7 days.

The file number and amount of recorded files are also shown in Red: -

Use the

key to highlight the required file and press to open it.

If more than 5 files exist then use the

key to scroll through the available

recordings: -

Press

to return to the previous screen without making a selection.

Open

16:32 23/08/12

10:55:00

10:33:45

10:15:30

09:56:35

09:43:03

6/23

20/08/12

20/08/12

20/08/12

20/08/12

20/08/12

Page 34

Page 34

Delete

14:32 23/08/12

09:12:12

09:35:20

09:22:25

1/3

20/08/12

17/08/12

17/08/12

Delete

14:32 23/08/12

09:35:20

09:22:25

1/2

20/08/12

17/08/12

Delete Single File

Select this option to delete an individual file from the instruments flash memory.

Deleted files cannot be recovered.

The recordings on the instrument are listed by file name, date and time order

showing the most recent first.

All recordings will be available for selection and the file number and amount of

recorded files are shown in Red: -

Use the

key to highlight the required file and press to delete it.

The selected file will be immediately deleted: -

If more than 5 files exist then use the

key to scroll through the available

recordings: -

Press

to return to the previous screen without making a selection.

Open

16:32 23/08/12

10:55:00

10:33:45

10:15:30

09:56:35

09:43:03

6/23

20/08/12

20/08/12

20/08/12

20/08/12

20/08/12

Page 35

Page 35

Delete

14:32 23/08/12

No

Yes

Delete All

Delete All

Delete All Files

Select this option to delete all recordings from the instruments flash memory.

Proceed with caution as deleted files cannot be recovered: -

Use the

key to highlight the required option and press to proceed.

Select No or press

to return to the previous screen without deleting any

files.

Select Yes to delete all saved files. Delete All Files will be highlighted red: -

When all files are deleted the Main Menu is displayed: -

Files

14:32 23/08/12

Open All

Open Today’s

Open 7 Days

Delete Single File

Delete All Files

Menu

14:32

Range

Files

Settings

Meter

Page 36

Page 36

Settings

Select this option to manage settings on your Vexo instrument.

Use the key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Units

Select this option to change the units of measure of your Vexo instrument.

Use the

key to highlight the required option and press to select. The

unit will be selected and the previous menu screen will be displayed.

Press

to return to the previous screen without making a selection.

Current

selections

are shown

at the right

hand side

Settings

14:32 23/08/12

Units

Brightness

Auto Dim

General

S

Met

60%

OnG

S

Red Tick

indicates

current

selection

Units

14:32 23/08/12

Metric

g

Page 37

Page 37

Brightness

Select this option to change the display brightness of your Vexo instrument.

Use the

key to change the brightness level and the press to return to

the previous screen with the selected brightness level.

The display brightness can be adjusted between 20% and 100% in 20% steps.

Press

to return to the previous screen without altering the brightness level.

Note that the brightness may be affected by the Auto Dim function - see below.

Auto Dim

Select this option to determine if your Vexo instrument should use the Auto Dim

function or not.

The Auto Dim function is a battery saving feature that automatically reduces the

display brightness of all screens to 10% if no key has been pressed for 30

seconds.

For optimum battery life, the Auto Dim should be switched On.

Use the

key to highlight the required option and press to select. The

option will be selected and the previous menu screen will be displayed.

Press to return to the previous screen without making a selection.

Whilst the Auto Dim feature is active press any key to deactivate it and return to

the selected brightness level.

Brightness

14:32 23/08/12

60%

Red Tick

indicates

current

selection

Auto Dim

14:32 23/08/12

Off

On

Page 38

Page 38

General

Select this option to open another menu level of General options.

Use the

key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Time

Select this option to change the time stored on your Vexo instrument.

Use the

key to change the value highlighted then press to move the

highlight to the next position.

If an invalid time is selected the warning message Invalid Time will be displayed

in red.

Press to return to the previous screen with any valid changes made.

General

14:32 23/08/12

Time

Date

File Naming

Time

14:32 23/08/12

1 4:32: 15

Time

14:32 23/08/12

2 4:32: 15

Invalid Time

Invalid

Time

warning

Message

Page 39

Page 39

Date

Select this option to change the date stored on your Vexo instrument.

Use the

key to change the value highlighted then press to move the

highlight to the next position. If an invalid date is selected the warning message

Invalid Date will be displayed in red.

Press to return to the previous screen with any valid changes made.

File Naming

Select this option to determine if your Vexo instrument should store File Names

with saved recordings or not.

A file name must be entered when ending a recording if this option is turned on.

Use the key to highlight the required option and press to select. The

option will be selected and the previous menu screen will be displayed.

Press to return to the previous screen without making a selection.

Date

14:32 23/08/12

2 3:08: 12

Date

14:32 23/08/12

3 3:08: 12

Invalid Date

Invalid

Date

warning

Message

Red Tick

indicates

current

selection

File Naming

14:32 23/08/12

Off

On

Page 40

Page 40

Meter

Select this option to change operational configuration settings, calibrate your

instrument and view system information.

Use the key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Reset

Select this option to reset all measurement parameter values.

The highlight turns red for 3 seconds to indicate that a reset has been

performed.

Meter

14:32 23/08/12

Reset

Configuration

Information

Calibration

S

Meter

14:32 23/08/12

Reset

Configuration

Information

Calibration

S

Page 41

Page 41

Configuration

Select this option to change operational configuration settings.

Use the key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Exposure Points

Select this option to determine if your Vexo H instrument should display

exposure points after ending a recording.

Use the

key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Exposure points were developed in the UK by the Health and Safety Executive

such that combinations of vibration magnitude and exposure time are given in

Exposure Points rather than in values in m/s

2

.

Exposure points may be easier to work with as they can simply be added

together.

Configuration

14:32 23/08/12

Exposure Points

Show Results

S

Red Tick

indicates

current

selection

Exposure

14:32 23/08/12

Points Off

Points On

Page 42

Page 42

Show Results

Select this option to determine if your Vexo instrument should display calculated

results after ending a recording.

Use the

key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Information

Select this option for instrument details.

Red Tick

indicates

current

selection

Show Results

14:32 23/08/12

Off

On

Information

14:32 23/08/12

Vexo

Model GA2006H

Version 1.09

S/N: 069000

Free Memory 100%

Page 43

Page 43

Calibration

Select this option to calibrate your Vexo instrument using accelerometer

sensitivity figures or using a calibrator.

Use the key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Measurement

Select this option to choose between calibrating your Vexo instrument using a

calibrator and selecting the output level of the calibrator.

Use the key to highlight the required option and press to select.

Press

to return to the previous screen without making a selection.

Calibration

14:32 23/08/12

Measurement

Sensitivity

S

Measurement

14:32 23/08/12

Calibrate

Value

S

10.00m/s2

S

Page 44

Page 44

X:

Y:

Z:

10.00

0.004

0.005

Cal Value = 10.00 m/s

2

Axis Calibrated

m/s2

m/s2

m/s2

Calibrate

Select this option to calibrate your Vexo instrument using a calibrator.

Attach the accelerometer to the calibrator such that the vibration travels

through your chosen Axis.

Use the

key to highlight the relevant axis and press to select ensuring

your calibrator is also switched on.

Calibration of each axis takes 15 seconds to complete.

If calibration is successful Axis Calibrated will be shown in Yellow for 5 seconds

or if the calibration fails Calibration Failed will be displayed in Red for 5 seconds.

Press

to return to the previous screen.

Calibrate

14:32 23/08/12

X:

Y:

Z:

10.05

0.004

0.005

Cal Value = 10.00 m/s

2

OK to Calibrate

m/s2

m/s2

m/s2

Calibrate

14:32 23/08/12

X:

Y:

Z:

10.02

0.004

0.005

Cal Value = 10.00 m/s

2

Calibrating Axis

m/s2

m/s2

m/s2

Calibrate

14:32 23/08/12

X:

Y:

Z:

0.005

0.004

0.005

Cal Value = 10.00 m/s

2

Calibration Failed

m/s2

m/s2

m/s2

Calibrate

14:32 23/08/12

Page 45

Page 45

Value

Select this option to change the value that your vibration calibrator outputs in

m/s

2

.

Use the

key to change the value highlighted then press to move the

highlight to the next position.

Valid levels are between 9.00 and 11.00 m/s

2

.

If an invalid value is selected the warning message Value Not Valid will be

displayed in red.

Press

to return to the previous screen with any valid changes made.

Value Not

Valid

warning

Message

Value

14:32 23/08/12

m/s2

1 0:00

Calibration Value:

Value

14:32 23/08/12

m/s2

2 0:00

Calibration Value:

Value Not Valid

Page 46

Page 46

Sensitivity

Select this option to set the sensitivity value for each axis that has been supplied

with your accelerometer.

No vibration calibrator is required for this option.

Press

to return to the previous screen with any valid changes made.

Use the key to highlight the relevant axis and press to select and change

its value.

Use the

key to change the value highlighted then press to move the

highlight to the next position.

Valid levels are between 5.00 and 15.00 mV/g.

If an invalid value is selected the warning message 05.00 to 15.00 only will be

displayed in red.

Press to return to the previous screen cancelling any changes made.

Repeat for all axes as required.

Value

14:32 23/08/12

X Value

Y Value

Z Value

10.00

10.00

10.00

mV/g

mV/g

mV/g

Sensitivity

14:32 23/08/12

X Sensitivity Value:

mV/g

1 0:00

Value Not

Valid

warning

Message

Sensitivity

14:32 23/08/12

X Sensitivity Value:

mV/g

2 0:00

05.00 to 15.00 only

Page 47

Page 47

Chapter 6

Using the Vexo H

The Vexo H instrument has three states of basic operation: -

• Stop State

• Record State

• Playback

Stop State

This is the default state of the Vexo H instrument and whilst in this state limited

calculations are displayed on the instruments screen but no values are recorded

in the internal flash memory.

It is only possible to change Settings and undertake Calibration of the instrument

whilst in Stop State. Exposure Points are not available when in Stop State.

Scroll through the available parameters using the

key.

The parameters available in Stop State are: -

• Arms

• Aeq

• Peak

• Vector

Weighting is fixed to Wh (Hand Arm) on the Vexo H instrument, the range can

be changed through the Main Menu.

To start a recording (Record State) press the key at any time.

Parameter

Weighting

Range

Battery Level

Measurements

W

h

A

rms

m/s

2

OL

X: 3.51

m/s

2

OL

Y: 2.18

m/s

2

OL

Z: 1.04

Page 48

Page 48

Record State

Whilst the instrument is in the Record State the vibration activity is analysed

and all parameters available on your instrument are calculated.

Record State is easily identified by the Record Symbol and the Recording Time in

the top left hand corner of the screen.

It is not possible to enter the Menu system or turn the instrument off whilst in

Record State.

Scroll through the available parameters using the

key.

The parameters available in Record State are: -

• Arms

• Aeq

• Peak

• Vector

To end a recording press the

key.

If File Naming is turned on then you will be prompted to enter a file name. See

page 39 for more information.

The data is saved to the internal flash memory. If Show Results or Exposure

Points are turned on, then the instrument will automatically display the relevant

parameters.

If neither of the above are turned on then the instrument is placed back into

Stop State.

Recordings saved on your instrument will not be lost if the battery pack is

removed.

Parameter

Weighting

Range

Battery Level

Measurements

W

h

A

rms

m/s

2

OL

X: 3.51

m/s

2

OL

Y: 2.18

m/s

2

OL

Z: 1.04

00:02:01

Record Symbol &

Recording Time

Page 49

Page 49

Playback

Playback is identified by having a green play symbol in the top left hand corner

and is where a recorded file is opened to be viewed on screen.

When Playback is started manually, all parameters are available to view

including Exposure Points, even if Exposure Points are turned off.

Scroll through the available parameters using the

key.

The parameters / screens available whilst in Playback Mode are: -

• File Details

• Arms

• Aeq

• Peak

• Vector

• Exposure

Exit Playback by pressing either

or and the instrument is placed into

Stop State.

Play Symbol &

Recording Time

File Name (if Entered)

File Start and End

Time/Date

HARM

File:

Start:

End:

00:02:01

Sample01

14:30 23/08/12

14:32 23/08/12

File Details

W

h

Page 50

Page 50

Show Results - On

When a recording is stopped and the option Show Results is turned on then the

instrument will automatically enter Playback and display the recorded

parameters.

Playback is identified by having a green play symbol in the top left hand corner.

Scroll through the available parameters using the

key.

The parameters / screens available whilst in Playback Mode are: -

• File Details

• Arms

• Aeq

• Peak

• Vector

• Exposure

Exit Playback by pressing either

or and the instrument is placed into

Stop State.

HARM

File:

Start:

End:

00:02:01

Sample01

14:30 23/08/12

14:32 23/08/12

File Details

W

h

Only Available if Exposure Points are On

Play Symbol &

Recording Time

File Name (if Entered)

File Start and End

Time/Date

Page 51

Page 51

15m:

30m:

1hr:

51

204

408

Exposure Points - On

When a recording is stopped and the option Exposure Points is turned on then

the instrument will automatically enter Playback and display the Exposure Point

values.

See Show Results – On if Show Results are also turned on.

Playback is identified by having a green play symbol in the top left hand corner.

Exposure Points are shown for periods of 15 minutes, 30 minutes and 1 hour.

The values are also colour coded to give instant visual indication and are based

on the following criteria in the UK specified by the HSE: -

Exit Playback by pressing either or and the instrument is placed into

Stop State.

In accordance with the European Union Physical Agents Directive, the Action

Level and upper Limit Level are set as follows: -

Hand Arm

Action Level

2.50 ms

-2

100 Points

Limit Level

5.00 ms

-2

400 Points

Play Symbol &

Recording Time

00:02:01

Exposure

W

h

Less than Action Value

Aware - Action Value Exceeded

Warning - Limit Level Reached

Page 52

Page 52

Under Range Indicator

Each axis on the Vexo H has independent Under Range indicators which are

visible in Stop State or Record State.

Unlike overload, the under range condition is not saved with the recording and is

therefore not available in Playback.

The under range indicator ‘UR’ is placed in red at the far right of each axis

where the condition occurs: -

The under range indicator remains on for a minimum of 2 seconds or whilst the

under range condition remains.

For Vector Sum where cumulative figures are used the location of the under

range indicator is as below. The indicator on this screen identifies that at least

one axis has at some stage gone under range.

Under Range Indicator

W

h

A

rms

m/s

2

OL

Y: 2.18

m/s

2

OL

Z: 1.04

m/s

2

UR

X: 0.47

Under Range Indicator

W

h

Vector

Amax

4.47

Aeq

2.46

m/s

2

m/s

2

UR

Page 53

Page 53

Overload Indicator

Each axis on the Vexo H has independent Overload indicators which are visible in

Stop State, Record State and Playback.

Unlike under range, the overload condition is saved with the recording and is

therefore also available in Playback.

The overload indicator ‘OL’ is placed in red at the far right of each axis where the

condition occurs: -

The overload indicator remains on for a minimum of 2 seconds or whilst the

overload condition remains however during Stop State or Record State the

overload indicator is latched on the following screens: -

• Aeq

• Vector

It is possible to remove the latched overload indicator during Stop State by

selecting Reset under Meter from the Main Menu.

The overload indicator cannot be reset during Record State or Playback.

For Vector Sum where cumulative figures are used and where Exposure Points

are being displayed the location of the overload indicator is as below. The

indicator on this screen identifies that at least one axis has at some stage

overloaded.

Overload Indicator

Overload Indicator

W

h

A

rms

m/s

2

OL

Y: 2.18

m/s

2

OL

Z: 1.04

m/s

2

OL

X: 2001.0

W

h

Vector

Amax

46.47

Aeq

21.46

m/s

2

m/s

2

OL

Page 54

Page 54

Parameters

The parameters that are recorded and displayed on your Vexo H instrument are

as follows: -

Parameters measured as Acceleration are identified as Acceleration with a

preceding ‘A’.

Brief descriptions of each parameter are given below and for full mathematical

descriptions see Chapter 10, Function Equations.

Arms

The Arms is the Wh weighted, running RMS (Root Mean Square) acceleration

value.

Aeq

The Aeq is time averaged and Wh weighted acceleration value.

Amax

The Amax is the maximum Arms level reached.

Peak

Peak is the highest peak level of the Wh weighted instantaneous acceleration.

Vector

This is the Vector Sum calculation from the Aeq and Amax.

Exposure

The vibration exposure point system is based on the UK’s Health & Safety

Executive’s system where vibration magnitude and exposure time are given in

exposure points rather than m/s2.

Only available by downloading files

Page 55

Page 55

Chapter 7

Downloading Saved Recordings to a PC

Using the supplied software VibdataLITE or VibdataPro (available separately) it is

possible to download the stored recordings on your meter to your PC allowing

the data to be viewed and printed in professional reports.

Communication between a PC and your Vexo meter is made via the USB

connector at the top of your instrument. The correct Castle Vexo USB driver will

need to be installed on your PC, and is automatically installed whilst installing

VibdataLITE.

To ensure data does not become corrupt please ensure that Stop State is

selected on the instrument before downloading saved recordings.

1. Ensure the Vexo instrument is OFF

2. Connect the Vexo instrument to the PC via the USB lead

3. Switch the Vexo instrument ON

Your Vexo instrument is now ready to download data into VibdataPro.

For comprehensive instructions please refer to the VibdataPro user manual.

Page 56

Page 56

Chapter 8

Accessories

GA606 Vibration Calibrator

KA010V* Carry Case for Vexo and Accessories

KD1010* HARM Tri-axial Accelerometer

KD1202 Mounting Studs (Pk 5)

KD1211 Cable Ties Metal Barbed (Pk 100)

KD1215 Transducer Mounting Glue and Stud Pack

KD1217 Transducer Petro wax Mounting Compound

PC009** VibdataPro Vibration Analysis Software

TT4KIT Tensioning Tool and 100 Cable Ties Metal Barbed

01KD1218* Transducer Mounting Block and Screw

01VIBBATT* 2.4V 2100mAh NiMH Battery Pack

01PSU5* NiMH Battery Pack Recharger

01ZL1065-01 AC Output Cable (1 metre)

01ZL1108-01* USB Download Cable (1 metre)

* supplied with the Vexo H

** upgrade from supplied Vibdata LITE

Page 57

Page 57

Chapter 9

Technical Specification

Applicable Standards

ISO 8041:2005 Human Response to Vibration – Measuring Instrumentation

Noise Floors

Axis

Range m/s2 rms

Low High

X 0.002 0.02

Y 0.002 0.02

Z 0.002 0.02

Normal Operating Mode

Fitted with Hand Arm accelerometer KD1010

Overload & Under Range Triggering Points

Points when calibrated with an accelerometer of sensitivity 10.0mV/g

Acceleration : Metric m/s

2

RANGE UR OL

LOW 0.050 200.0

HIGH 0.500 2000.0

Acceleration : g

RANGE UR OL

LOW 0.0051 20.40

HIGH 0.0510 204.0

Page 58

Page 58

Level Ranges

Acceleration : Metric

Acceleration : g

LOW

0.05 – 200 m/s

2

LOW 0.0051 – 20.4g

HIGH

0.50 – 2000 m/s

2

HIGH 0.051 – 204g

Frequency Weightings

Wh weighting as defined in ISO 8041:2005.

Wh Filter Frequency Response: -

-70

-60

-50

-40

-30

-20

-10

0

0.10 1.00 10.00

100.00 1000.00

10000.00

Gain (dB)

Frequency (Hz)

Deviations re 80Hz in dB and tolerances required for a typical Vexo H

instrument: -

Frequency

(Hz)

Wh Tolerance

1 0.2 +2, -∞

2 0.2 +2, -∞

4 0.2 +2, -∞

8 0.1 ±2

12.5 0.0 ±1

20 0.0 ±1

40 0.0 ±1

80 REF ±1

160 0.0 ±1

315 0.0 ±1

630 -0.1 ±1

1000 -0.2 ±2

2000 -1.3 +2, -∞

4000 -6.1 +2, -∞

Page 59

Page 59

Accelerometer

Specification

KD1010

Output Voltage

10mV/g

±20%

Operating Range

±200g

Frequency Response

0.3 to 10000 Hz

±3dB

Resonant Frequency

>30kHz

Weight

30 Grams

Operating Temperature Range

-54°C to 85°C

-65°F to 185°F

Thermal Sensitivity Coefficient

0.18% / °C

0.10% / °F

Linearity

±1%

Electrical Noise Floor

0.003g pk

Transverse Sensitivity

5%

Maximum Shock

7000g pk

Page 60

Page 60

Electrical Signal Input

Electrical signals at frequencies >2Hz can be applied to the Vexo H instruments

by interfacing a suitable signal generator with an output impedance of 600Ω to

the 5 pin Input Lemo Socket, type (EGG.0B.305.CLL).

Each individual axis shall be subject to the following circuitry, (see Signal Wiring).

AGND

SIGNAL

AGND

SIGNAL

+5V

R1

3K3

C1

1000uF

R2

3K3

SIGNAL

GENERATOR

TRANSDUCER

INPUT SOCKET

Maximum Electrical Signal Input For No Damage

5 Volts (Peak to Peak)

Environmental Stabilization Time

30 minutes

Warm up Time

≤ 2 minutes

Settling Time

It is recommended that a calculation settling period of ≥30 seconds is allowed

for in any recording.

Temperature Operating Range

-10°C to +50°C

(Pin 1)

Page 61

Page 61

Effect of Air Temperature

Accuracy better than ±5% over the range -10°C to +50°C

Effect of Surface Temperature

Accuracy better than ±4% over the range -10°C to +50°C

Real Time Clock

Day, Month, Year, Hour, Minute and Seconds at ±2ppm accuracy per day

Digital Signal Processing

Direct processing using digital recursive filters (infinite impulse response)

Analogue to Digital Converter & Microcontroller

ADC: Word Length: 24 bits, Sampling Rate: 16kHz

Processor Operating Frequency: 25MHz (max.)

Displayed Measurement Resolution

High range – 0.01 m/s² up to 99.99, 0.1 m/s² 100.0 – 2000.0 m/s²

Low range – 0.001 m/s² up to 9.999, 0.01 m/s² 10.00 – 200.00 m/s²

Display

OLED Module (160x128 pixels) with 262,144 colours

Refresh Rate ≤ 500mS

Displayed parameter at each update interval is the value at the time of the

update interval.

Page 62

Page 62

Memory

2Mb On-board FLASH allowing up to 992 recordings to be saved.

Overload

Positive overload warning when the input circuit saturates. See

Overload &

Under Range Triggering Points

for overload triggering points.

Size and Weight

Dimensions: (H):117mm (without Cable) x (W) :78mm x (D): 24mm

Weight: 182g approximately (including batteries)

Connections

AC Output

Unweighted

Short circuit Protected

Load Impedance >10k recommended

AC Output Voltages

Range Output Voltage rms at full scale ±1.5dB

LOW 1000mV

HIGH 1000mV

Wiring Configuration – 4 Pole Jack Socket 3.5mm

AC Output

Pin Number

Description

1 Analogue Ground