Page 1

www.castlegroup.co.uk

Operating Manual

Pocket Sound Level Meter

GA113

Page 2

Thank you for buying a Castle product, I am sure you will find both the goods and

the service to be of the highest quality but if not, then please feel free to write to

me personally and I will ensure that your needs are dealt with immediately.

This manual is designed to show you the operation of the goods you have

purchased and a very brief insight into acoustics itself. If you would like to

become a competent person in the eyes of the law, then you may like to know

more about our Competent Persons training course for Noise at Work

Reulations. You can visit www.castle-training.com to find out more.

It is my intention for Castle Group Ltd to provide a wide range of technical health

and safety products and Services of the highest standard. If you would like to

know more about any of our other products and services then please telephone

on +44(0)1723 584250 or visit www.castlegroup.co.uk

Simon Bull

Managing Director

Page 3

Copyright

This manual is copyrighted with all rights reserved. Copying in part or in whole is

prohibited without the prior written consent of Castle Group Ltd.

Precautions

• Only operate the instrument as described in this manual.

• These are precision instruments, protect from shocks and vibrations.

• Ambient conditions for the operation of the unit are as follows:-

Temperature: -10°C to +50°C

Relative Humidity: 25 to 90%

• Protect the unit from extremes of temperature and humidity, direct sunlight

and air with a high salt or sulphur content.

• Always turn the unit off after use. Remove the batteries from the instrument

when not in use.

• Do not use any solvents or cleaning agents on the instrument. Use only a

soft dry cloth or a soft cloth lightly moistened with water when necessary.

• Do not allow any conductive objects, such as wire or metal particles to enter

the unit.

• Do not try to disassemble the instrument or attempt any repairs as this will

invalidate your warranty. Take a note of the condition of the instrument and

contact your authorised Castle service station.

• To ensure continued precision performance of your instrument have it

checked and serviced at regular intervals.

Contacting Castle Group

This manual contains complete operating instructions for the Castle Pocket

Sound Level Meter range, read it carefully and you will quickly become familiar

with your instrument and its operation.

If you do encounter problems with the operation of your instrument please feel

free to contact customer support with your enquiry on: -

Telephone: +44 (0)1723 584250

Fax: +44 (0)1723 583728

Website: www.castlegroup.co.uk

Email: techsupport@castlegroup.co.uk

sales@castlegroup.co.uk

Page 4

Contents

Introduction............................................................................................... 1

Using the Manual.................................................................................... 1

Sample Keypad Layout.......................................................................... 2

Operating Tips.......................................................................................... 3

Battery Installation / Check............................................................... 4

Microphone ............................................................................................... 4

Switching the Instrument On & Off.................................................. 5

Information Button................................................................................. 5

Pause / Play Button .............................................................................. 6

Display Button.......................................................................................... 6

Menu Button............................................................................................. 8

Calibration.......................................................................................................................... 8

Shift Duration ................................................................................................................... 9

Frequency / Time Weighting ................................................................................... 9

Exchange Rate ................................................................................................................. 9

Criterion ........................................................................................................................... 10

Threshold.........................................................................................................................10

Keypad Lock ...................................................................................................................10

Clear Button .......................................................................................... 11

Changing Range.................................................................................... 11

Technical Specifications.................................................................... 12

EC Declaration of Conformity.......................................................... 19

Instrument Disposal ........................................................................... 20

Accessories............................................................................................ 20

Instrument Details .............................................................................. 20

Warranty and After Sales Service................................................ 21

Trouble Shooting.................................................................................. 22

Disclaimer............................................................................................... 23

Page 5

Page 1

Introduction

Thank you for purchasing your product from Castle Group Ltd.

The GA113 has been designed to surpass the requirements of the new

international Class 1 sound level meter standard IEC 61672-1:2002. It may

be used in industry or for general purpose measurement to ascertain noise

levels accurately yet economically.

Using the Manual

In the course of this manual a named button written in BOLD means press

that button E.g. OK means press the OK button

Page 6

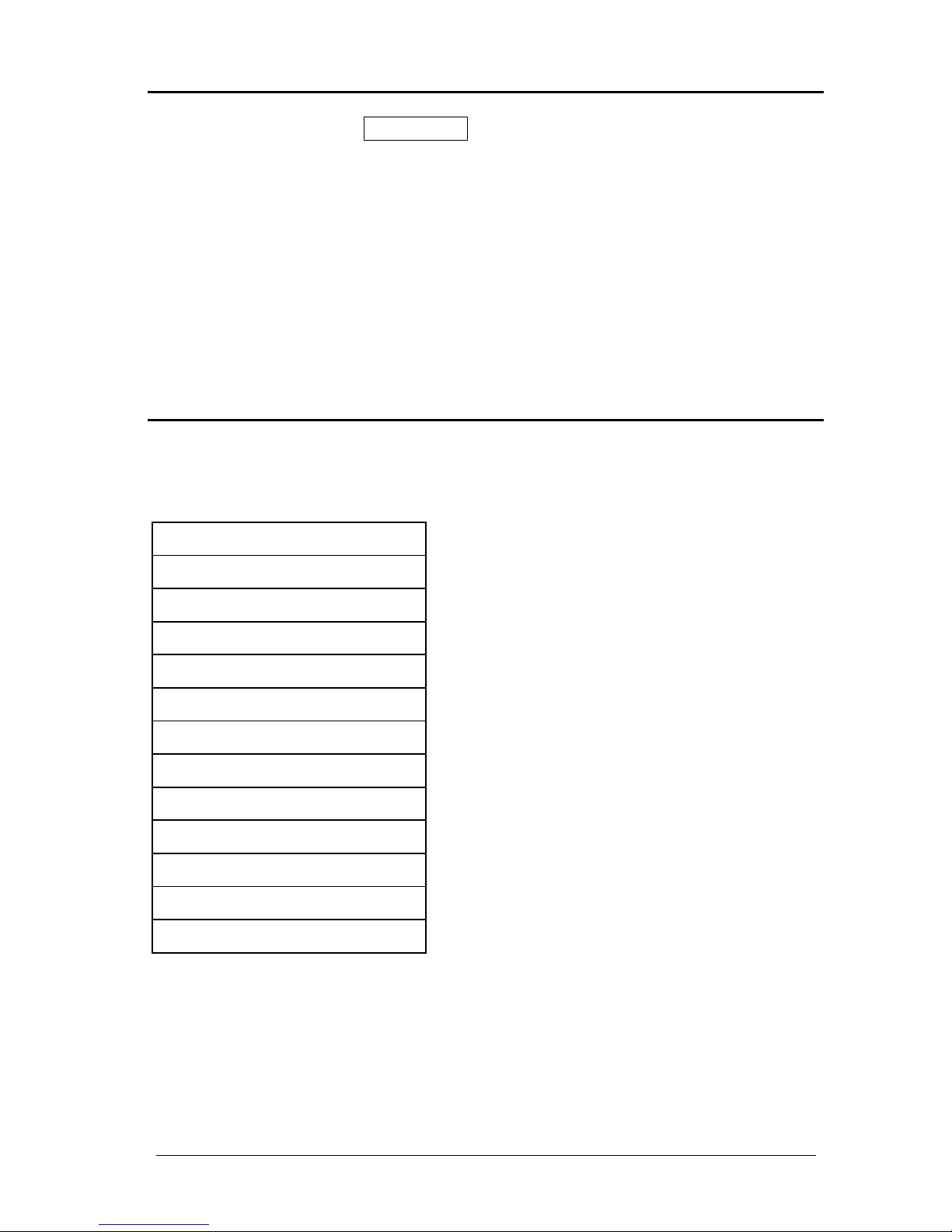

Page 2

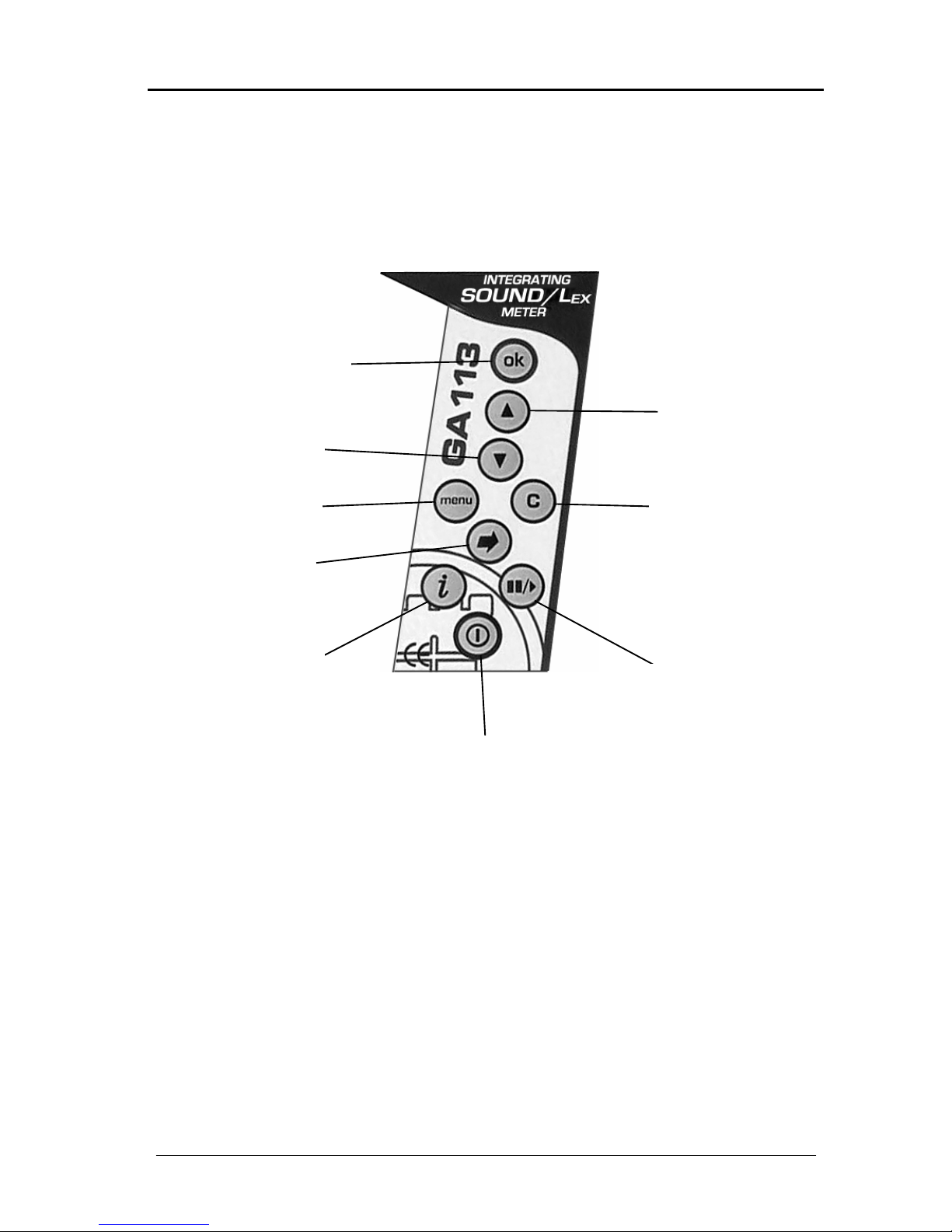

Sample Keypad Layout

POWER ON/ OFF

PAUSE/ PLAY

INFORMATION

MENU

OK

UP ARROW

CLEAR

DISPLAY

DOWN ARROW

Page 7

Page 3

Operating Tips

This section is designed to enable you to get the best measurement results

out of your instrument.

• Always check the battery status of the instrument before use.

• Always calibrate the instrument prior to carrying out any

measurements.

• Always CLEAR any previous data recorded prior to taking new readings

and after calibrating.

• The instrument can be set-up in advance to the required frequency and

time weightings/ criterion and exchange rates for the measurements

that you are wanting to carry out.

• To work out the most suitable range to select first take initial samples

of the expected noise levels from the area you will be measuring in.

Then select the range which these levels fall nearest the middle of e.g. if

the levels expected are around 85dB then select the ‘55 – 120 range’

• When taking noise measurements hold the instrument as far in front of

the body as is comfortable to minimise interference of the sound field.

• If using the instrument as a dosemeter with the optional dosemeter

microphone then clip the dosemeter microphone as near to the

operators ear as possible e.g. shirt collar.

• Use the ‘Shift Duration’ feature to automatically calculate the projected

dose functions if your workers shift duration is different to 8 hours.

• To prevent accidental keypresses which could affect the results, use

the LOCK feature to lock-out the keypad.

• Always point the microphone towards the main source of the noise to

be measured (0° reference direction).

• When measuring low noise levels on the bottom range, be aware of the

self generated noise levels of the instrument – see specifications.

Page 8

Page 4

Battery Installation / Check

To prepare the equipment for use a heavy duty alkaline battery type 6LR61

should be fitted, such as a Procell/Duracell MN1604, Ever Ready 6LF22

Gold Seal, or equivalent.

The battery door is located on the bottom left hand side of the instrument.

Open the battery door cover by sliding the cover downward towards the

bottom of the instrument. The cover will now swing open exposing the

battery compartment. Insert the battery observing the correct polarity as

marked on the case wall.

Close the battery compartment door by reversing the procedure above. The

instrument is now ready for calibration and use.

The battery condition is shown on the LCD during the power-on sequence, but

can also be checked at any time by pressing the ‘

i'

key. Pressing the key once

will display the battery status screen, with the battery condition indicated by a

series of vertical bars – 4 bars shows a fully charged battery, while1 bar

shows one that is almost flat. It is recommended that the battery should be

replaced if only 1 bar is displayed. The screen will flash BAT. LOW when the

battery level drops below a sustainable level whilst the instrument is in use. If

this happens, replace the battery.

Microphone

The microphone capsule fitted to your instrument is a high quality class 1

instrumentation grade 1/2 inch capsule.

The GA113 can be fitted with an optional dosemeter microphone assembly

(MK279DP1B) in order that it can be attached to the collar of a noise

exposed worker. Please note that the MK279DP1B assembly is only to be

used when using the instrument as a dosemeter. It is not designed to be used

for taking sound meter readings to Class 1 accuracy.

Measurement microphones by the very nature of their manufacture are

precision components that are easily damaged through incorrect use. Great

care must be taken when using the instrument to ensure the longevity of the

microphone.

PLEASE NOTE THAT THE INSTRUMENT IS NORMALLY SUPPLIED WITH A

PROTECTIVE WHITE PLASTIC CAP COVERING THE END OF THE

MICROPHONE WHEN DELIVERED. THIS CAP MUST BE REMOVED PRIOR TO

USING THE INSTRUMENT.

Page 9

Page 5

Switching the Instrument On & Off

Press and release the POWER button once and the instrument turns on.

Allow the instrument to scroll through its start-up sequence before pressing

any other button; this will take approximately 3 seconds.

When the instrument has completed its start-up sequence the display will

change to LP in PAUSED mode using the settings that were last selected.

To switch off, press and release the POWER button once and the display

goes blank.

PLEASE ENSURE THAT ALL REQUIRED READINGS FROM THE INSTRUMENT

HAVE BEEN COLLECTED BEFORE TURNING OFF THE INSTRUMENT AS ALL

DATA IS LOST WHEN THE INSTRUMENT IS TURNED OFF.

i

(Information) Button

A scrolling sequence exists with this button, repeated pressing of the button

will allow you to scroll through the various information screens available on

your instrument.

BAT ▌▌▌▌

Battery capacity remaining

dBA SLOW Indicates the current frequency and time weighting

SD 08:00 Shows the shift duration setting

90/3 Indicates the current criterion and exchange level

TH -10dB

Shows the threshold setting

(relative to the criterion level)

VER1.04 Indicates the firmware version number

PLAY Indicates the instrument is in PLAY mode

PAUSED

Indicates when the instrument is in pause mode

(only displayed if instrument is in pause mode)

Page 10

Page 6

/ (Pause / Play) Button

Press / button

PAUSED

All functions can be held so that they do not update by pressing the /

button. Once PAUSED the display may be read as normal, allowing the user

to take note of any required readings.

For normal operation of the instrument to continue press the / button

once more and the instrument will briefly show PLAY before returning to the

currently displayed parameter. Please note instrument automatically powers

on in PAUSED mode.

Ö

(Display) Button

A scrolling sequence exists with this button, repeated pressing of the button

will allow you to scroll through the various measurement screens available on

your instrument.

Lp (SPL)

Leq

Lmx

Pmx

Elapsed Time

Lex

Plx

LE

Do%

Pr%

Hr%

P2h

Overload (if triggered)

Under-range / Overload Indication

The display will also flash UR to indicate an under-range condition, or

OVERLOAD to show the range has been exceeded. UR will continue to display

as long as the condition persists. The OVERLOAD indicator will latch as shown

in the table, and can only be reset by pressing the C (Clear) key. (See page

11).

You may leave the display menu by pressing any other button.

Page 11

Page 7

The table below is a breakdown of the display parameters and is

accompanied by a brief description of each one: -

Display Description

93.7dBC Level Pressure (Lp)

Leq 93.7 Displays the LEQ

Lmx 97.3 Maximum Lp

Pmx 98.8 Maximum Peak

00:01:33 Run time duration (Elapsed Time)

Lex 87.1 Displays the Lex (Lep’d)

Plx 78.6

Displays the projected Lex (Lep’d) assuming a shift length

set in the Shift Duration

LE 93.1 Sound Exposure Level (SEL)

Do % 67 Dose (dependent on exchange and criterion)

Pr % 0 Displays the projected DOSE assuming an 8 hour shift

Hr% Dose per Hour

P2h 0.02 Indicates the energy that has been received in Pa

2

hours

OVERLOAD

Indicates if an OVERLOAD has occurred

(Can only be reset by pressing the Clear key)

—–.—

Indicates when values are at 0 e.g. when instrument is first

powered on or after a reset in PAUSED mode.

Page 12

Page 8

Menu Button

A scrolling sequence exists with this button, repeated pressing of the button

will allow you to scroll through the following menu screens available on your

instrument: -

Calibration

It is recommended that the instrument’s calibration is checked and adjusted

where necessary with a calibrator before readings being taken. The

calibration should be re-checked after taking readings to confirm the validity

of the results. The calibrators recommended for use are the Castle

GA601/GA607, which supply typically 94dB/ 104dB (relative to 20μPa

pressure) at a frequency of 1kHz.

Press i to check the battery condition. Replace the battery if the indication is

low.

Press MENU

CAL <OK

Press OK and the instrument will now display the previous calibration level

e.g. >94.0. The calibration will be performed at the selected level e.g. 94.0dB

but may be changed in 0.1 dB steps to match the calibrator output by

repeated pressing of the

or

arrow buttons or in 1dB steps by repeated

pressing of the i / / keys. Ensure the calibrator is attached to the

microphone by gently inserting the microphone into the cavity of the

calibrator. A certain amount of resistance should be felt whilst inserting the

microphone as the o-ring seal on the calibrator forms a seal around the

microphone. Ensure that the calibrator is switched on and set to the chosen

level and all correction factors for atmospheric pressure and microphone

type have been accounted for. The pressure to free-field correction value to

be applied when used with a Castle calibrator GA601, GA607, and a

B&K4231 is as follows:

Castle GA607 Calibrator Pressure To Free Field Correction = -0.2

Castle GA601 Calibrator Pressure To Free Field Correction = -0.2

B&K4231 Calibrator Pressure To Free Field Correction = -0.2

Press OK and the instrument will calibrate to the level of the calibrator. The

display will show CAL WAIT while calibrating to the chosen level. When

calibrated the display will show COMPLETE and will return to LP for the

GA213/215 and DOSE for the GA256. It is recommended that the unit is

then put into PAUSED mode and data is cleared. The instrument is now ready

to take measurements.

If the calibration is interrupted or the input level is not within +/- 3dB of the

chosen reference level then the display will show NO INPUT or CAL FAIL.

Check to make sure the calibrator is switched on and emitting the correct

level before proceeding again as indicated above.

Page 13

Page 9

Shift Duration

It is possible to select an alternative shift duration in hours and minutes of an

employee for calculating projected dose and projected Lex calculations.

Press MENU repeatedly until

SD < OK

is displayed.

Press OK once and the instrument will display the currently selected shift

duration in hours. Repeated pressing of the

/ arrow keys will alter this

figure between 00 and 24. Press OK again and the instrument will display the

currently selected number of minutes. Repeated pressing of the

/ arrow

keys will alter this figure between 00 and 59.

Frequency / Time Weighting

Press MENU repeatedly until

WTG < OK

is displayed.

Press OK and the instrument will display the options available for WTG

SETUP.

To change WTG use either the

or

arrow buttons. Pressing either of these

two buttons allows you to scroll through the four available weighting choices,

A SLOW, A FAST, C SLOW or C FAST.

Note: The symbol > indicates the current selection as you move around the

weighting options

.

Exchange Rate

Press MENU repeatedly until

EXCH < OK

is displayed.

Press OK and the instrument will display the options available for EXCHANGE

RATE Setup.

To change the EXCHANGE RATE use either the

or

arrow buttons.

Pressing either of these two buttons allows you to scroll through the three

available exchange choices, 3dB, 4dB, 5dB

Note: The symbol > indicates the current selection as you move around the

exchange options.

Page 14

Page 10

Criterion

Press MENU repeatedly until

CRIT < OK

is displayed.

Press OK and the instrument will display the options available for CRITERION

Setup.

To change the CRITERION use either the

or

arrow buttons. Pressing

either of these two buttons allows you to scroll through the three available

exchange choices, 80dB, 85dB, 90dB

Note: The symbol > indicates the current selection as you move around the

criterion options.

Threshold

It is possible to select a threshold level for the lower limit of noise levels which

are used to measure dose.

Press MENU repeatedly until

THR < OK

is displayed.

Press OK once and the instrument will display the currently selected

threshold level, relative to the selected Criterion level. Repeated pressing of

the

or

arrow buttons will alter this figure between 0, -5, -10.

Note: The symbol > indicates the current selection as you move around the

threshold options.

Keypad Lock

Press MENU repeatedly until

LOCK?

is displayed.

Press OK and the instrument will lock the keypad. The status of the battery

will be displayed while the keypad is in lock mode

To UNLOCK the keypad press C, OK then C respectively.

The LOCK feature is used to lock the instrument keypad. All keypad functions

are therefore disabled including the POWER button. The function is often

used to avoid inadvertent operation or tampering while the instrument is

being used.

Note: The LOCK function is only available when the instrument is in PLAY

mode.

Page 15

Page 11

C (Clear) Button

The C button is used to reset ALL data* (including overload indication). This

feature should be used prior to taking new readings and after calibration.

Press C

CONFIRM?

Press OK to reset the data or any other button to cancel the request.

The instrument then returns to the previously displayed parameter.

* Use caution when using the C button as reset data cannot be recovered.

Changing Range

A range change can be performed by the use of the /

arrow buttons while

in any of the DISPLAY modes (instrument displaying LP dBA etc).

Press the

or

arrow buttons repeatedly to scroll through the three

available range choices, 35, 55, 75 until the required range comes into view,

then press OK to select.

The instrument will return to the LP screen.

Note: The symbol > indicates the current selection as you move around the

range options.

Page 16

Page 12

Technical Specification

The individual characteristic applies to each instrument unless specifically

worded otherwise.

Instrument Standards:

IEC 61672-1 : 2002 Class 1 Group X

IEC 60651 : 1979 Type 1 + A1:1993 + A2:2000 Group X

BS EN 60651 : 1994 Type 1 Group X

IEC 60804 : 2000 Type 1 Group X

BS EN 60804 : 2001 Type 1 Group X

IEC 61252 : 1993

BS EN 61252 : 1993 + A1:2000

Measurement Parameters:

Lp, Leq, Lmax, Pmax, LE, Pa2h, Lex, Projected Lex, DOSE%, Projected DOSE%,

Dose Per Hour, Elapsed time

Peak Frequency Weighting:

C weighting to IEC 61672-1 Class 1

Time Weightings:

SLOW and FAST according to IEC 61672-1 Class 1, IEC 60651 Type 1

RMS Frequency Weighting:

A and C weightings according to IEC 61672-1 Class 2, IEC60651 Type 2

Level Ranges (dB) for A & C Weighting:

Linear Operating Range, IEC 61672-1:2002

31.5Hz 1kHz 4kHz 8kHz

41.0 – 60.6 41.0 – 100.0 41.0 – 100.0 41.0 – 99.0

55.0 – 80.6 55.0 – 100.0 55.0 – 100.0 55.0 – 119.0

75.0 – 100.6 75.0 – 140.0 75.0 – 140.0 75.0 – 139.0

Page 17

Page 13

Primary Indicator Range

IEC 60651:1979 (1kHz)

41.0 – 93.0

55.0 – 113.0

75.0 – 133.0

(Primary Indicator Range allows for a crest factor of 3 or approximately 7dB)

Linearity Range & Pulse Range

IEC 60804:2000

41.0 – 100.0

55.0 – 120.0

75.0 – 140.0

Level Ranges (dB) for Peak Hold Display

(wrt 1kHz)

63 .0 – 103.0

83.0 – 123.0

103.0 – 143.0

Typical Electrical Self Generated Noise Level:

32 dBA, 38 dBC

Total Measuring Range:

The difference between the lowest possible measurement on the most

sensitive range and the highest level on the least sensitive range at a

frequency of 1kHz.

A Weighted C Weighted

41.0 – 140.0 47.0 – 140.0

Reference Points:

Description Value

Sound Level 94.0dB

Range 55 - 120

Frequency 1kHz

Page 18

Page 14

Starting Points for IEC 61672-1:2002 Linearity Testing:

The following apply at 31.5Hz, 1kHz, 4kHz, and 8kHz: -

35-100 range: 74.0dB

55-120 range: 94.0dB

75-140 range: 114.0dB

Display:

Digital 1 x 8 alphanumeric, digit size 7mm x 5mm Liquid Crystal Display

Display Refresh Rate:

250ms

Detector Characteristics:

RMS and Peak

Warm up time:

< 2 minutes

Electrical Signal Input:

Electrical signals can be applied to the Castle Pocket range of sound level

meters by removing the acoustical microphone and replacing with a dummy

microphone having a series capacitor of 18pF ±2%. The BNC termination is

then used to interface with a suitable signal generator with an output

impedance of 600W at 1kHz.

Maximum Peak to Peak Electrical Signal Input For No Damage:

7 Volts

Upper Frequency for Periodic Acoustic Testing (IEC 616723:2006):

4kHz

Windshield:

The effects of using the KG205 (60mm) windshield

31.5Hz 0.0 1kHz 0.2

63Hz 0.1 2kHz 0.2

125Hz 0.1 4kHz 0.7

250Hz 0.1 8kHz 0.0

500Hz 0.2

The meter conforms to the Standards quoted on Page 12 when fitted with

the windshield.

Page 19

Page 15

Microphone:

ACO ½“ Electret Condenser Microphone Cartridge Type 7146A. Microphone

reference point is the centre of the diaphragm.

Type MK80 (Aco 7146A) Specification

Diameter (inch) 0.5

Response Type Free-Field

Polarisation (V) 0.0

Frequency Range (Hz) 20 - 8000

Sensitivity (mV/Pa) 25.0

Sensitivity (dB re 1V/Pa) -32.0 ±1.5dB

Capacitance (pF) 18.0

Max. Sound Pressure Level (dB) 146.0

Temperature Coefficient (dB/°C) -0.01

The pressure to free-field correction value to be applied when used with a

Castle calibrator GA601/GA607 or B&K4231 is as follows: -0.2dB

The capsule can be removed by unscrewing anti-clockwise although great

care must be taken when doing this to avoid damage to either the capsule or

the instrument. Re-fitting is a reverse of the above.

Type MK80 (Aco 7146A) Typical Microphone Response

16Hz 0.0 1kHz 0.0

31.5Hz 0.0 2kHz 0.0

63Hz 0.0 4kHz -0.1

125Hz 0.0 8kHz -0.7

250Hz 0.0 16kHz 1.0

500Hz 0.0

Typical Actuator to free field correction factors(dB) of an MK80

(Aco 7146A) microphone (Based on 500Hz = 0)

250Hz 0.0 2.5kHz 1.0

315Hz 0.0 3.15kHz 1.2

400Hz 0.0 4kHz 1.5

500Hz 0.0 5kHz 2.0

630Hz 0.0 6.3kHz 2.5

800Hz 0.0 8kHz 3.8

1kHz 0.0 10kHz 4.6

1.25kHz 0.2 12.5kHz 6.8

1.6kHz 0.4 16kHz 8.8

2kHz 0.5 20kHz 10.0

Maximum SPL at the Microphone for No Damage:

146 dB

Page 20

Page 16

Calibration Reference Conditions:

Sound Field Free Field

Air Temperature 23°C (73°F)

Relative Humidity 50%

Atmospheric Pressure 101.325 kPa

Sound Pressure Level 94.0dB

Reference Level Range 55 – 120dB

Reference Frequency 1kHz

The reference direction of incidence for all microphones is perpendicular to

the front face (diaphragm surface) of the microphone.

Operating range:

0°C to +40°C

Warning: DO NOT subject the instrument to temperatures greater than 70°C

or less than -20°C for any length of time.

Effect of Temperature:

Accuracy better than ± 0.5 dB over the range 0 to +40°C

Effects of Humidity:

Less than 0.5 dB over the range 25 to 90% relative humidity (provided there

is no Condensation), relative to the value at 50% relative humidity and 40°C.

Storage range: 0 to 90% relative humidity in the absence of condensation

Effects of Vibration:

From 20Hz to 1kHz at 1ms

-2

no noticeable effect

Magnetic Field:

No noticeable effect

Operator Presence in Free Field:

No noticeable effect when operator standing more than 2 metres behind

instrument.

Batteries:

1x MN1604 (size PP3) alkaline cell

Life Expentancy: 12 hours continuous use (approx)

Min Battery Level: 5.4V DC

Max Battery Level: 9.4V DC

Page 21

Page 17

Overall Dimensions:

210mm x 60mm x 35mm (approx.)

Overall Weight including Batteries:

220g

Case Reflections:

GA113 using the Aco 7146A microphone

Stalk length 75mm from front of microphone grid to top of case body

Frequency (Hz) Case Effect (dB) Frequency (Hz) Case Effect (dB)

31.5 0.0 800 0.2

40 0.0 1000 0.0

50 0.0 1250 -0.3

63 0.0 1600 -0.2

80 0.0 2000 -0.5

100 0.0 2500 0.4

125 0.0 3150 -0.2

160 0.0 4000 -0.2

200 0.0 5000 0.1

250 0.1 6300 0.1

315 0.1 8000 0.0

400 0.1 10000 0.0

500 0.1 12500 -0.2

630 0.1 16000 0.0

Page 22

Page 18

AC Output:

Vout ≈ 16.4mVrms at 94.0dB

The output is un-weighted and not affected by the measurement range.

DC Output:

Vout ≈ 40mV/dB

Vout ≈ 3.3 – [((top of range +3) - (reading in dB)) x 0.04]

Output affected by: -

• Frequency Weighting

• Measurement Range

Output Socket:

Both AC and DC outputs require load impedance's to exceed 10kΩ, however

load impedance's > 100KΩ are recommended.

Radio Frequency Fields:

The GA113 instrument falls into classification X for the susceptibility to Radio

Frequency Fields.

DC Output

GND

AC Output

Front View

Page 23

Page 19

EC Declaration of Conformity:

The CE marking of this Castle Product indicates compliance with the EMC Directive.

Castle Group Ltd declares that the: -

•

GA113 Pocket Sound Level Meter

has in accordance with the following Electromagnetic Compatibilty Directives: -

•

89/336/EEC

been designed and manufactured to the following specification:

•

EN61326-1:1997 + A1:1998

with the following Tests:

•

Radiated Emissions: EN55022:1995 Class: B

•

ESD: EN61000-4-2:1995 Levels: ±4kV (C) , ± 8kV (A)

•

Radio-frequency EM field amplitude mod: EN61000-4-3:1996 Level: 3V/m

No differences in radio frequency emissions are apparent between the available ranges on GA113

instrument.

We hereby declare that the instruments named above have been designed to comply with the relevant

sections of the above referenced specifications, and that the above named instruments comply with all

essential requirements of the specified Directives.

Page 24

Page 20

Instrument Disposal:

The symbol shown here can be found on your instrument and

means that the product is classed as electrical or electronic

equipment and should be disposed of at the end of its life separately

to your commercial or household waste.

The Waste of Electrical and Electronic Equipment Directive (2002/96/EC)

has been established to help reduce the influx on landfill sites and effectively

treat hazardous substances by using best practices for the recovery and

recycling of products.

There are various collection systems in place within the EU for the disposal of

your product. To find the nearest UK waste recyling point in your area, enter

your postcode in the website www.recycle-more.co.uk

For more information please contact your local authority, the dealer where

you purchased your product or Castle Group Ltd.

Accessories:

GA607 – Dual Level Calibrator (Class 1)

MK279DP1B – Dosemeter Plug-in Microphone

KG204 – Dosemeter Windshield

KG205 – Sml Windshield

KA010 – Sml Attaché Case (Holds Instrument and Calibrator)

6LR61 – 9V Battery (Pack of 10)

Instrument Details:

For your records and for future correspondance with Castle Group Ltd

regarding your instrument, please complete the following details: -

Instrument Serial Number

Purchase Date

Page 25

Page 21

Warranty and After Sales Service:

Castle Group Ltd design and manufacture precision instruments, which if

treated with reasonable care and attention should provide many years of

trouble free service.

In the event of a fault occurring, during the warranty period, the instrument

should be returned to Castle Group Ltd, in its original packaging, or to an

authorised agent. Please enclose a clear description of the fault or symptom.

Details of the warranty cover are available from Castle Group Ltd or an

authorised agent.

All instruments are designed to meet rigid British and International

Standards. An annual calibration is recommended to ensure that these high

standards are maintained. This is particularly important for cases in which

instrument readings are to be used in litigation or compliance work.

For warranty and service return to: -

The Service Department

Castle Group Ltd

Salter Road

Cayton Low Road Industrial Estate

Scarborough

North Yorkshire

YO11 3UZ

Telephone: +44 (0)1723 584250

Fax: +44 (0)1723 583728

Email: techsupport@castlegroup.co.uk

Web: www.castlegroup.co.uk

Any misuse or unauthorised repairs will invalidate the warranty.

Damage caused by faulty or leaking batteries is not covered by the warranty.

Page 26

Page 22

Trouble Shooting:

Question Answer

My instrument will not turn on?

Check that there is a battery fitted to the

instrument.

Check that the battery is not flat.

What is this white plastic cap

fitted to the top of the

microphone?

This is a protective cover for the sensitive

microphone. You must remove it before

using the instrument.

Where have my results gone?

The GA113 does not have a backup

memory so all readings are lost when the

instrument is switched off. Always take a

note of important readings before

switching off the instrument

My instrument is on but will not

respond to keypad presses?

Have you locked the keypad – see page 10

for details on this function.

I keep getting CAL FAIL when

t

rying to calibrate my instrument

– what am I doing wrong?

Is the instruments microphone properly

inserted in the calibrator?

Is the calibrator switched on and working?

Has the instrument and/or calibrator

been knocked or moved as the calibration

routine is taking place?

Has the microphone been damaged?

What is the black o-ring inside my

calibrator’s cavity for?

The o-ring is essential to seal around the

microphone stabilising the pressure in the

calibrator’s cavity. If the o-ring is missing

and/or damaged the instrument will not

calibrate properly (see above).

When taking readings the display

is constantly flashing *UR* –

what does this mean?

This means that the noise you are

measuring is below the bottom of the

range you have the instrument selected to.

Try selecting a lower range (see page 11

for details).

My readings are within range but

I keep getting **OL** flashing

on the screen – why is this?

The overload is triggered by the Peak

reading whereas LP and LEQ are rms

figures which are lower. Some noises

feature very high peaks compared to the

rms.

Page 27

Page 23

Question Answer

My instrument has stopped

responding to noise since I

calibrated it?

Is the microphone capsule loose on the

instrument? When removing the

microphone from the calibrator it is

possible to accidentally unscrew the

microphone.

Why is my projected LEX not the

same as the LEQ?

The shift Duration (see page 9) may be set

to a time other than 8 hours

After taking my readings the

figures are a lot higher than

expected?

Did you clear the memory after

calibration?

Disclaimer:

Whilst every effort is made to ensure the accuracy and reliability of both the

instrument described and the associated documentation, Castle Group Ltd

makes no representation or warranties as to the completeness or accuracy

of this information.

Castle Group Ltd assumes no responsibilty or liability for any injury, loss or

damage incurred as a result of misinterpreted or inaccurate information.

Any documentation supplied with your product is subject to change without

notice.

HB/0113/005/A5 Rev B

Loading...

Loading...