Page 1

Page 2

Thank you for buying a Castle product, I am sure you will find both

the goods and the service to be of the highest quality but if not, then

please feel free to write to me personally and I will ensure that your

needs are dealt with immediately.

This manual is designed to show you the operation of the goods you

have purchased and a very brief insight into acoustics itself. If you

would like to become a competent person in the eyes of the law, then

you may like to know more about our Competent persons training

course for the Noise at Work Regulations.

It is my intention for Castle Group Ltd to provide a complete range of

Noise and Vibration products and Services of the highest standard. If

you would like to know more about any of our other products and

services then please complete the reply paid card in this manual and

return it to us for prompt action or telephone on +44(0)1723 584250.

Simon Bull

Sales and Marketing Director

Page 3

Precautions

Operate the unit only as described in this manual.

• The GA112 is a precision instrument. Protect the instrument from shocks and

vibrations.

• Use only the microphone/preamplifier as supplied with the unit. Take special

care not to touch the microphone top as it can easily be damaged.

• Ambient conditions for operation of the unit are as follows : temperature

range - 10°C to +50 °C, relative humidity 30 to 90%.

• Protect the unit from water, dust, extreme temperatures, humidity, and direct

sunlight during storage and use. Also keep the unit away from air with high

salt or sulphur content, gases, and stored chemicals.

• Always turn the unit off after use. Remove the batteries from the unit if it is

not to be used for a long time (a week or more) . When disconnecting the cable, always unscrew the plug and do not pull the cable.

• Clean the unit only by wiping it with a soft, dry cloth or, when necessary,

with a cloth lightly moistened with water. Do not use any solvents, cleaning

alcohol or chemical cleaning agents.

• Take care that no conductive objects such as wire, metal scraps, conductive

plastics etc. can get into the unit.

• Do not try to disassemble or alter the unit. Otherwise type certification will

become invalid. In case of an apparent malfunction, do not attempt any repairs. Note the condition of the unit clearl y and contact the supplier or Castle

Group direct.

NOTE

Castle Group sound level meters are electronic instruments and should be handled

accordingly. Damage caused by misuse, abuse and leaking batteries is not covered by the warranty. If the instrument fails to function correctly, firstly check the

condition of the batteries. When changing the batteries, replace all three at any

one time. In order to conserve battery life do not leave the instrument turned on

when not in use.

Page 4

CONTENTS

TITLE PAGE NO

Instrument Introduction 5

Battery Installation 6

Preparation of Equipment and Controls 7

Calibration 12

Measuring Sound Levels 13

Measuring Maximum Sound Levels 14

Use of Filters for Octave Band Analysis 15

Use of the Output Socket 16

Instrument Description 18

Circuit Description 19

Environmental Effects 19

Technical Specification 20

Warranty and After Sales Service 24

Page 5

Instrument Introduction

The instrument covered by this handbook is an analogue sound level

meter built into our award winning, tough die-cast body, which is

both stylish and ergonomically designed. The instrument has ‘A’

weighting and ‘LIN’ (linear) frequency responses as well as a set of

ten octave band filters. The filter’s ‘AUTO’ facility allows a chart

recorder to display the results of a noise spectrum analysis. ‘SLOW’,

‘FAST’ and ‘PEAK’ responses are available. A maximum hold button, ‘MAX’, allows the accurate recording of the ‘maximum rms’ of

a transient noise event. The instrument conforms to the relevant sections of BS5969, IEC651, ANSIS1.4, BS2475 and BS EN60651

standards.

5

Page 6

Battery Installation

To prepare the equipment for service batteries must first be fitted. Remove the lower rear black plastic ‘clip in’ cover by pushing the locking

clip at the foot of the instrument upwards and push the cover out; this will

expose the battery compartment. Connect three new 6D22 type batteries,

preferably heavy-duty types which give greater economy and are less

prone to leakage, to the snap conductors ensuring correct polarity and

making sure that each stud is a firm fit. Replace the battery cover and

push the retaining clip firmly home. The instrument is now ready for calibration and use.

Re m o v e C o v er

to change B atter ies

Serial No. 012345

Release the spring catch

and remove the battery

compartment cove

r

Tel: (0723) 584250 Fax: 0723 583728

Castle Associates

Lim ite d

Salter Roa d, Scarborou gh,

England.

Serial No. 012345

6

Page 7

Preparation of Equipment and Controls

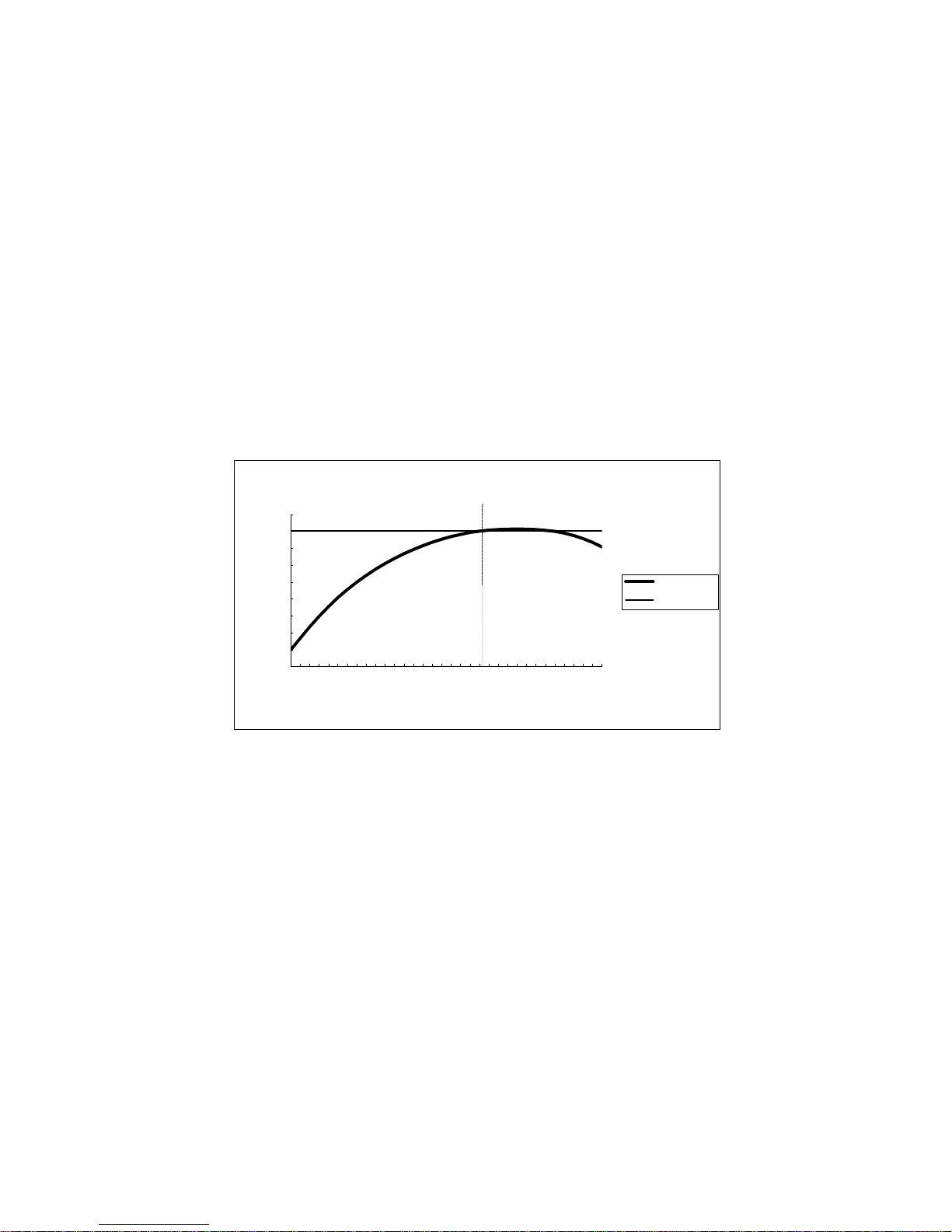

Power/Weighting Switch

This is a three-position switch labelled OFF-A-LIN. In the OFF position all power is removed from the instrument. The ‘A’ position

allows sound levels to be measured with ‘A’ weighting, (see figure

1). For a linear or ‘flat’ frequency response the LIN is used.

Figure 1 – ‘A’ weighting curve

Battery Check Button

A push button labelled BATT is provided to allow periodic checking of the battery condition. A meter deflection in the area marked

‘BATT’ shows the batteries are in good condition.

'A' AND LINEAR FREQUENCY WEIGHTINGS

-80

-70

-60

-50

-40

-30

-20

-10

0

10

10

100

1K

10K

Frequency/ Hz

SPL/d

B

'A' Weighting

Linear

7

Page 8

Peak/Slow/Fast Switch

This three position slide switch, labelled SLOW-FAST-PEAK,

determines the damping coefficient of the analogue meter. The

SLOW position sets the instrument for the standardised ‘slow’ meter

response with a time constant of 1 second. In the fast setting the instrument has a time constant of 125ms for the standardised fast meter

response. When the meter is used in the PEAK mode, the meter has

minimum damping and allows quick acting transient sounds to be

shown.

Maximum Hold Button

The MAX button is a momentarily acting push button which holds

the maximum sound level whilst the button is depressed. Once the

button is released the meter returns to normal operation. This facility

is very useful for capturing the maximum rms sound level of transient sound events.

Filter Mode Switch

The octave band filters can be used by placing the switch in either

the MAN or the AUTO position. When in the OUT position the meter operates as a normal sound level meter with a ‘linear’ (‘flat’) or

‘A’ weighted response. When using the filters the ‘A’ weighted response can also be used if desired.

The filters can be used in two different modes, MAN or AUTO. In

the MAN (or manual mode), the centre frequency of the filters is

changed by depressing either of the select buttons, ‘frequency up’ or

‘frequency down’. The frequency of the filter currently in operation

is displayed by means of ten LED’s (light emitting diodes) ,

positioned on the front panel.

8

Page 9

Ten standard centre frequencies are used 31.5Hz, 63Hz, 125Hz,

250Hz, 500Hz, 1kHz, 2kHz, 4kHz, 8kHz and 16kHz. These allow the

engineer to gain a clearer ‘picture’ of the frequency distribution of the

noise. Typical responses of these filters are shown below (Figure 2).

A memory facility is provided to allow the user to switch the filters

‘in’ and ‘out’ and still remain on the same frequency.

Figure 2 – Filter Responses

The filter’s AUTO mode facility allows a chart recorder to give an

octave band plot for a ‘hard’ copy of the noise spectrum. The frequency control buttons are assigned different ‘roles’ in this mode,

labelled RESET and START-STOP.

Depressing the RESET button at any time causes the filter frequency

to reset to the lowest centre frequency, 31.5Hz. By depressing the

START-STOP button once, the filter will step up through all the frequencies in turn, staying on each frequency for 3 to 4 seconds. This

allows enough time for the meter circuitry and chart recorder to settle.

Immediately after depressing the START-STOP button, and between

each change of frequency, a short downward stroke is drawn onto the

chart recorder to enable each octave band sound level to be separated

and therefore clearly seen.

9

Page 10

By depressing the START-STOP button a second time, the filter will

stop on it’s current frequency. If the filter is left running in the

AUTO mode when it reaches the highest centre frequency, it will remain there until the reset button is depressed.

Ranging Buttons and LED Indicators

The range of the instrument is indicated by a series of five LED’s.

To change the range ‘up’, depress the button marked with an up arrow, to change the range ‘down’, the button marked with a down arrow is depressed. The five base ranges on the GA112 are shown below (figure 3).

Figure 3 – Table of available ranges

As can be seen from the table above, a 10dB overlap occurs between

the ranges, this means that if a meter reading in the bottom ‘third’ is

observed the range can be changed down.

Generally it is better to select a range which gives you the greatest

deflection on the meter. However if the meter reading passes fullscale deflection, or the overload LED (found in the lower right corner of the meter) indicates an overload, the instrument must be

changed up a range.

Base range Meter range

30dB 30-60dB

50dB 50-80dB

70dB 70-100dB

90dB 90-120dB

110dB 110-140dB

GA112

10

Page 11

Calibration Control

This is a screwdriver-adjusted control, which alters the input sensitivity of the instrument. A small flat bladed screwdriver, no larger

than 2mm, should be used when calibrating the instrument. Calibration should only be carried out in conjunction with a known

sound source.

Output Socket

This socket is designed for use with chart recorders and similar

equipment. A 3-pin LEMO connector (type FGGOB303CLAD52Z)

must be used to connect external equipment.

Overload LED

This indication is on the meter scale and warns when the selected

range is exceeded. In such an overload situation, frequency analysis

is distorted as the signal is clipped. Generally this can be avoided

be choosing a higher range.

Please note the overload indicator detects the overload conditions in

all critical points of the instrument and it is possible to have such a

situation without a high reading shown on the analogue meter.

11

Page 12

Calibration

The calibrator recommended for use with the GA112 is the Castle

GA607, a dual level calibrator which supplies 94dB and 104dB

(relative to 20 uPa pressure) at a frequency of 1kHz.

Procedure

1 Turn ‘on’ the instrument by switching it into ‘A weighting’ mode

and check the conditions of the batteries by depressing the BATT

button.

2 Place the filter control switch in the OUT position, ideally the

response switch should be placed in the FAST position.

3 Turn the calibrator on to the 94dB and check that the battery status is

as per the calibrator manual. A 1kHz tone should be audible at this

time.

4 Position the calibrator firmly over the microphone using a

“clockwise” twist.

5 Place the meter on its 70 d B ran ge and adju s t th e CAL control un ti l

the meter reads 94dB.

6 If using the Castle GA607 calibrator, it is also possible to check the

sound level meter on its 90dB range, switch the calibrator to the

104dB position and check that the reading is within 0.4 dB. This

serves as a cross check for the type 1 instrument.

7 Two additional tests can be carried out in order to establish correct

calibration of the instrument. Firstly at the 1kHz calibration

frequency, switching the instrument to the LIN weighting mode, this

should give the same sound levels as the ’A’ weighting mode (within

1dB).

12

Page 13

Secondly by keeping the weighting in the LIN mode and

putting the filter into the MAN mode (as detailed on pages 8 & 9),

on its 1kHz centre frequency, the calibration should be within

+0.5dB and –1dB.

Measuring Sound Levels

Use as a normal sound level meter

1 Turn on the meter by selecting the ‘A’ weighting or LIN

response, and switch the filters OUT.

2 Check the battery voltage and the calibration of the sound

level meter.

3 Select the 110dB range.

4 Point the instrument towards the source of the sound to be

measured.

5 Progressively step down the ranges until a reading in the

upper two thirds of the meter scale is obtained.

6 If it proves difficult to read the meter because of excessive or

unsteady needle movement, switch the response to SLOW.

7 Record the sound level reading as the meter deflection

(between 0 and 30), plus the selected range, in dB’s if LIN or

in dB (A)’s if ’A’ weighted.

Eg. A sound level of 94.0dB(A) would appear as a needle deflection of 24, while using the unit on 70dB range.

13

Page 14

Measuring Maximum Sound Levels

1 Turn on the meter by selecting A weighting or LIN

response, and switch the filters OUT.

2 Check the battery voltage and the calibration of the

sound level meter.

3 Select a suitable range so that the maximum expected

sound level would be registered on the meter without

causing it to go off the scale. By trying several ranges

the most suitable will soon be found.

4 Set the response switch to FAST or PEAK.

5 Point the instrument towards the source of the sound to

be measured.

6 Press the MAX button and hold it down until the

transient sound has occurred and the meter has reached

its maximum value. The button must be held until the

reading has been recorded, as once the button is

released the meter returns to normal operation.

14

Page 15

Use of Filters for Octave Band Analysis

1 Turn on the meter by selecting ‘A’ weighting or LIN

response and switch the filters to MAN.

2 Check the battery voltage and calibration of the sound

level meter.

3 Select the lowest filter frequency (31.5Hz) and the

100dB range.

4 Point the instrument towards the source of the sound to

be measured.

5 Progressively step down the ranges until a reading in

the upper two thirds of the meter scale is obtained.

6 Record the reading and select the next centre frequency.

Repeat the measuring procedure until the highest filter

frequency (16kHz) is reached.

It is possible to switch the filter OUT and back to MAN

again and still maintain the last selected centre

frequency.

7 With the results obtained an octave band plot can be

drawn. This plot gives the spectrum of the noise source

being measured, from which the nature and cause of the

noise can be determined and cured.

15

Page 16

Use of the Output Socket

The GA112 is equipped with a three-pin lemo connector on the right

hand side of the instrument. The connector provides an AC and a

DC signal output (see figure 4).

The AC output is a logarithmic output and is direct representation of

the sound present at the microphone. This output is actually suitable

for recording the noise by means of a tape recorder for analysis at a

later date. A full-scale deflection on the meter corresponds to a

120mV rms signal into a 10kohm loading.

The DC output is a linear signal suitable for chart recorders. A voltage of 1.5V is given for a full-scale deflection on the meter, zero on

the meter corresponds to approximately zero volts. The DC output is

designed to drive a load of 10kohm.

A suitable connector for the lemo socket is the, LEMO type

FGGOB303LAD52Z.

Figure 4 – LEMO socket connections

16

Page 17

When using a chart recorder the following settings can be used as an initial guideline: -

Paper speed (or X-axis travel) 0.5cm/sec.

Sensitivity (or Y-axis trav el) 200mV/cm (using 180mm paper)

The following procedure can then be used: -

1 Connect the chart recorder (or X-Y plotter) to the sound level meter.

2 With the filters switched OUT measure the sound level .

3 Keeping the meter on the same ‘range’ switch the meter to the AUTO mode. Press

RESET and the 31.5Hz LED should be lit.

4 Start the chart recorder moving and when ready press the START/STOP button

once. A downward ‘stroke’ of recorders pen will indicate w her e the star t was, and

also each change of frequency.

5 When the filter has reached the top (16kHz) frequency it will remain there. To

repeat the procedure depress the RESET button in order to start from 31. 5Hz fre

quency again. Pressing the START-STOP button during the stepping procedure

will STOP the filter on its current centre frequency , pressing the button once more

will START the stepping once more. The START-STOP button therefore acts as an

effective ‘pause’ facility.

Note

The horizontal (or X-axis) is logarithmic frequency in Hz, or k Hz corresponding to the ten filter centre frequencies as indicated on the front panel of the sound level m eter. The vertical

scale (or Y-axis) is in dB’s and ther efore linear. Some calibration and setting up of the chart

recorder will be necessary if direct readings are to be taken from the rulings on the chart recorder paper.

17

Page 18

Figure 5 – Block diagram of instrument

OCTAVE

BAND

FILTERS

LED DISPLAY

FREQUENCY

SELECT

A

WEIGHTING

amp

AC OUTPUT

OVERLOAD

DETECTOR

OVERLOAD

LED

amp

SLOW, FAST, PEAK

BATTERY

CHECK

MAX

HOLD

DC OUTPUT

amp

METER

PRECISION

RMS TO LOG DC

CONVERTER

amp amp

CALIBRATION

RANGE CONTROL

LED DISPLAY

FILTER OFF,

MAN. AUTO

Instrument Description

18

Page 19

Circuit Description

The AC voltage coming from the microphone is amplified in three amplifier stages. The first stage being an ultra-low noise pre-amplifier,

this is followed by an amplifier variable gain for calibration. These

amplifiers also form the ranging circuit calibrated in 20dB steps.

Range changing logic selects the desired attenuation and controls the

gain of the pre-amplifiers, indicating the range on a series of LED’s.

This is then fed into a series of octave band filters which can be

switched in and out when required and then through the ‘A’ or LIN

weighting network. The frequency changing logic selects the filter frequency and displays it by way of LED’s.

This signal is passed to the true rms converter and logged. This is then

converted to a linear signal in order to drive the meter, which is linearly

scaled in dB. A maximum hold facility is used to maintain the maximum meter deflection while readings are being taken and a battery

check facility also drives the meter in order to monitor the condition of

the batteries.

Environmental Effects

The GA112 is designed for operation between the temperature limits

of –10°C to +50°C. The unit may be stored, without batteries, between –20°C and +60°C, but should not be subjected to temperatures

beyond these ranges for long periods.

The instrument may be subjected to continuous vibration of up to 3g

without damage.

19

Page 20

Technical Specification

Measuring Range

Detector

Characteristics: RMS

Signal to noise ratio: >5dB at bottom scale

Crest factor capability: 13dB at FSD

Frequency weighting

‘A’ to BS EN 60651

LIN to BS EN 60651

Time weighting

Slow to BS EN 60651 Type 1

Fast to BS EN 60651 Type 1

Peak Onset time 2.3mS as specified by

BS EN 60651

Display

Type: Analogue moving coil meter with overload

LED indication.

Scale: 0 to 30dB mirrored linear scale with battery

condition indication and overload indication.

Range Measuring Range Max. Peak Level

30 30-60dB 73dB

50 50-80d|B 93dB

70 70-100dB 113dB

90 90-120dB 133dB

110 110-140dB 153dB

20

Page 21

Display Parameters

Sound Pressure Level either ‘A’ or Linear weighted with or without

Octave Band Filters. Battery condition indication.

Filters

Built in Octave Band Filters to BS EN 61260 : 1996

Filter centre frequencies 31.5Hz, 63Hz, 125Hz, 250Hz,

500Hz, 1kHz, 2kHz, 4kHz,

8kHz, 16kHz.

Switch selectable OFF/MANUAL/AUTO.

Overload

Positive overload condition shown when Crest Factor is exceeded

(see also description on page 11).

Output Socket

AC Output: 120mV rms for FSD.

Output impedance approx 600ohm.

Load impedance 10kohm or more.

Short circuit protected.

DC Output: 1.5V for FSD.

Output impedance approx 600ohm.

Load impedance 10kohm or more.

Short circuit protected.

Connector: Lemo FGG0B303CLAD52Z

Microphone/Preamp

Pre-polarized ½” (12.7mm) Condenser Microphone

Sensitivity 12mV/Pa

Capacitance 15pF

Preamp output impedance 550R

21

Page 22

Calibration

Acoustic using GA607 (or GA602) at 94 dB or 104db at 1 KHz

Potentiometer adjustment.

Batteries

Type: 3xPP3

Life: >40 hours at 3hrs/day

>12 hours continuous

Temperature

Operating range: -10oC to +50oC

Storage without batteries: -20oC to +70oC

Effect of temperature: <0.5dB from –10oC to +50oC

Humidity

Operating range: 30% RH to 90%RH

Effect of humidity: <0.5dB

Vibration

A 40Hz 1m/s vibrating force produces <0.5dB error.

Magnetic field

80A/m (1 Oersted) at 50Hz produces <0.5dB error

Standards

BSEN60651

IEC651 Type1

BS5969 Type 1

22

Page 23

Overall Dimensions and Weight

280x85x60mm

800g with batteries

Accessories available

KA003 Attaché style carry case with tripod*

KA005 Shoulder bag carrying Case

GA607 Dual level acoustic calibrator 94dB and 104dB at 1kHz

*Tripod purchased separately

23

Page 24

Warranty and After Sales Service

Castle Group design and manufacture precision instruments, which if treated

with reasonable care and attention should provide many years of trouble free

service.

In the event of a fault occurring, during the warranty period, the instrument

should be returned to Castle Group Ltd, in its original packaging, or to an

authorised agent. Please enclose a clear description of the fault or symptom.

Details of the warranty cover are available from Castle Group Ltd or an

authorised agent.

All instruments are designed to meet rigid British and International

Standards. An annual calibration is recommended to ensure that these high

standards are maintained. This is particularly important for cases in which

instrument readings are to be used in litigation or compliance work.

For warranty and service return to:

The Service Department

Castle Group Ltd

Salter Road

Cayton Low Road Industrial Estate

Scarborough

North Yorkshire

YO11 3UZ

Telephone UK: (01723) 584250

INT: 44 1723 584250

Fax UK: (01723) 583728

INT: 44 1723 583728

Any misuse or unauthorised repairs will invalidate the warranty.

Damage caused by faulty or leaking batteries is not covered by the warranty.

H:\Research & Development\Manuals\GA112 manual

24

HB/0112/006/A5 Issue B

Loading...

Loading...