Page 1

INSTALLATION INSTRUCTIONS

61301604805 Rev. A

®

Castle

7900

FLOOR MOUNTED

CART WASHER

Page 2

Page 3

INSTALLATION

INSTRUCTIONS

®

Castle

7900 FLOOR LOADING

CART WASHER

Getinge/Castle, Inc.

1777 East Henrietta Road

Rochester, New Yor k 14623- 31 33

Phone: (800) 950-9912 USA

Facsimile: (800) 950-2570

Page 4

INSTALLATION INSTRUCTIONS 61301604805

Rev. A (12/27/01)

Related Publication:

Operator Manual 61301604804

DESCRIPTION OF SYMBOLS AND NOTES IN MANUAL

The following symbols with related notes appear in this manual.

“Warning” notes alert the user to the possibility of personal injury.

WARNING

“Caution” notes alert the user to the possibility of damage to the equipment.

CAUTION

“Notes” alert the user to pertinent facts and conditions.

NOTE

NOTE

Castle

Copyright ©2001 by Getinge/Castle, Inc.

®

is a registered trademark.

This manual contains proprietary information of Getinge/Castle, Inc. It shall

not be reproduced in whole or in part without the written permission of

Getinge/Castle, Inc.

ii

Page 5

Section 1 Installation Requirements

GENERAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . 1–1

MODEL IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . 1–2

UTILITIES AND SPECIFICATIONS. . . . . . . . . . . . . . . . . . 1–3

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Hot Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Cold Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Steam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Condensate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Overall Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

INSTALLATION ADVISORY . . . . . . . . . . . . . . . . . . . . . . . 1–4

WASHER OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Floor Mount vs. Pit Mount . . . . . . . . . . . . . . . . . . . . . . 1–4

Left Side vs. Right Side Controls. . . . . . . . . . . . . . . . . 1–4

Barrier Flanges and Service Enclosure . . . . . . . . . . . . 1–4

Electrical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Seismic Anchoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

SHIPPING CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . 1–5

TOOLS AND MATERIALS REQUIRED. . . . . . . . . . . . . . . 1–6

Table of Contents

Section 2 Installation

ASSEMBLE THE WASHER STRUCTURE . . . . . . . . . . . . 2–1

Install the Base/Sump Assembly . . . . . . . . . . . . . . . . . 2–1

Assemble the Washer Panels . . . . . . . . . . . . . . . . . . . 2–5

Door Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

Trim Panels (Non-Service Side) . . . . . . . . . . . . . . . . 2–12

INSTALL COMPONENTS ON TOP OF THE WASHER . 2–13

Dryer and Condenser Assemblies. . . . . . . . . . . . . . . 2–13

Power Floor Tilt Pulley System . . . . . . . . . . . . . . . . . 2–17

Transformer and Emergency Stop Switch

Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–19

Rear Emergency Stop Switch . . . . . . . . . . . . . . . . . . 2–20

Plumbing Mounting Brackets. . . . . . . . . . . . . . . . . . . 2–21

61301604805 iii

Page 6

INSTALL COMPONENTS ON THE OUTSIDE

OF THE WASHER. . . . . . . . . . . . . . . . . . . . . . . . . . . 2–22

Spray Manifold Drive Motor. . . . . . . . . . . . . . . . . . . . 2–23

Exhaust Elbow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–25

Washer Light Assembly. . . . . . . . . . . . . . . . . . . . . . . 2–26

Front Dryer Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–27

Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

Junction Box Assembly. . . . . . . . . . . . . . . . . . . . . . . 2–30

Dispenser Float Switch Junction Box . . . . . . . . . . . . 2–31

Front Emergency Stop Switch. . . . . . . . . . . . . . . . . . 2–32

Detergent and Rinse Aid Dispensers . . . . . . . . . . . . 2–33

Unload End Indicator Panel Box . . . . . . . . . . . . . . . . 2–34

Door Proximity Switches . . . . . . . . . . . . . . . . . . . . . . 2–35

Sump Drain Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–36

Return Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–37

Circulation Tank Assembly . . . . . . . . . . . . . . . . . . . . 2–38

Wash Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–39

Tank Drain Valve, Tank Overflow, and Tank

Water Level Indicator . . . . . . . . . . . . . . . . . . . . . 2–40

Booster Heater Assembly . . . . . . . . . . . . . . . . . . . . . 2–41

Rinse Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–42

PLUMBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–43

Stainless Steel Plumbing. . . . . . . . . . . . . . . . . . . . . . 2–43

Black Iron (Steam) Plumbing. . . . . . . . . . . . . . . . . . . 2–44

Hot Water (Copper) Plumbing. . . . . . . . . . . . . . . . . . 2–44

Cold Water (Copper) Plumbing . . . . . . . . . . . . . . . . . 2–45

ELECTRICAL WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . 2–46

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–46

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–46

INSTALL COMPONENTS ON THE INSIDE OF

THE WASHER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–49

Rear Dryer Ducts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–49

Drive Chain Tension Idlers and Idler Bearings . . . . . 2–51

Chain Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . 2–52

Spray Manifold Supports and Manifold Assembly. . . 2–54

Manifold Cover and Spray Guard, Manifold Guard

Tubes, Wash Cart Tubes . . . . . . . . . . . . . . . . . . 2–56

Emergency Stop Switch Cables . . . . . . . . . . . . . . . . 2–58

FINAL INSTALLATION TASKS . . . . . . . . . . . . . . . . . . . . 2–60

Final Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 2–61

Dispenser Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–62

Sanitary Barrier Flanges . . . . . . . . . . . . . . . . . . . . . . 2–64

Pit Covers (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . 2–65

Service Area Enclosure (Option). . . . . . . . . . . . . . . . 2–66

Base Shrouds (Floor Mounted Option) . . . . . . . . . . . 2–67

Ramps (Floor Mounted Option). . . . . . . . . . . . . . . . . 2–68

iv

Page 7

7900 Floor Loading Cart Washer

Exhaust Connection. . . . . . . . . . . . . . . . . . . . . . . . . . 2–68

Plumbing System Connections . . . . . . . . . . . . . . . . . 2–68

Electrical Supply Connection. . . . . . . . . . . . . . . . . . . 2–69

Concluding Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–69

61301604805 v

Page 8

vi

Page 9

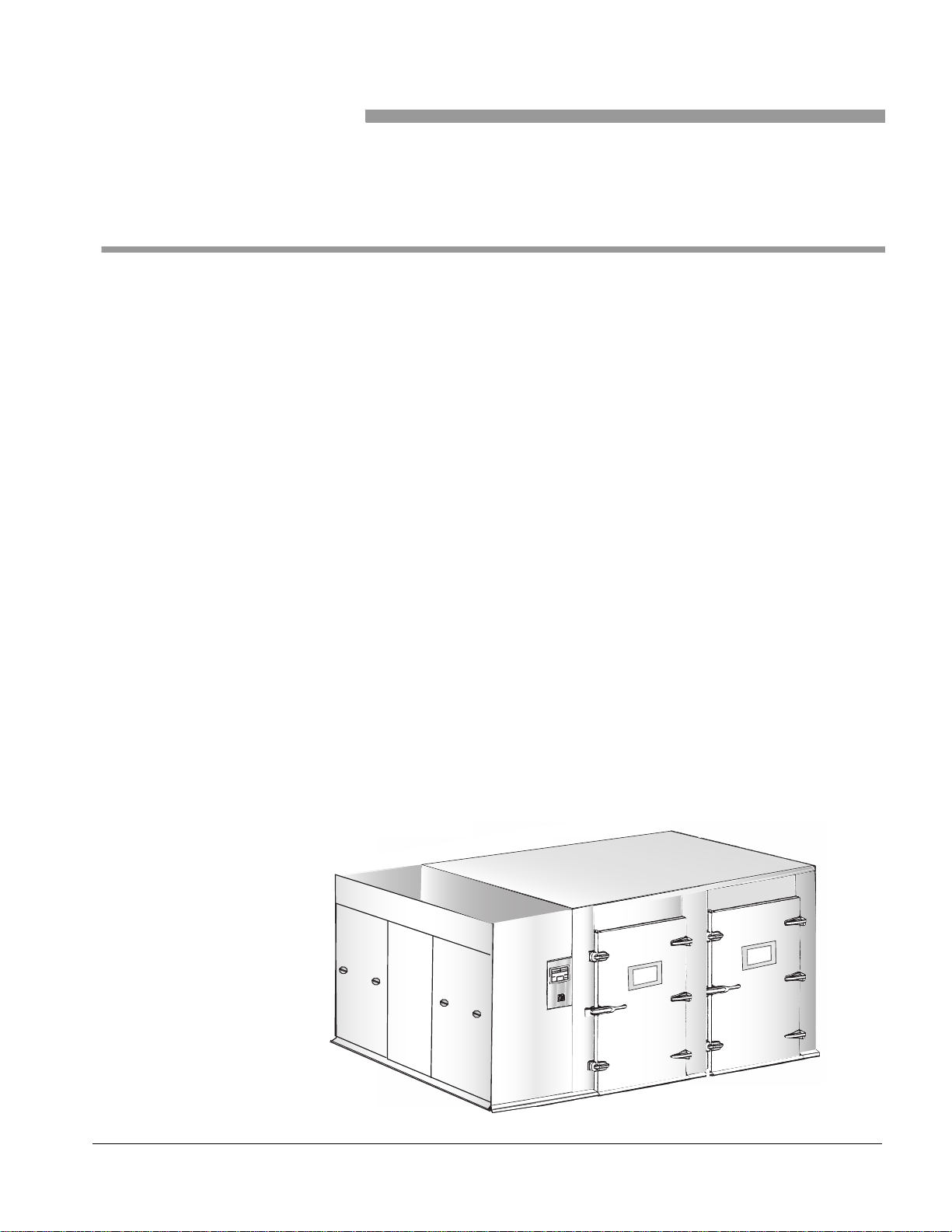

General Description

Section 1 Installation Requirements

The Castle 7900 Floor Loading Cart Washer is a fully automatic, floor

loading, hydro-spray cart washer with dual side-by-side wash compartments

that is used to clean and decontaminate case carts, stands, utensils,

containers, tote boxes, and similar bulk items.

Processing cycles are set up using a programmable controller equipped

with a touch screen interface (touch control panel). Four cycle definitions

are possible. The operator needs only to select and start a cycle.

A standard cycle consists of the following sequential phases: wash, rinse,

exhaust, and drying. The length of a cycle’s phase can be adjusted at the

touch control panel.

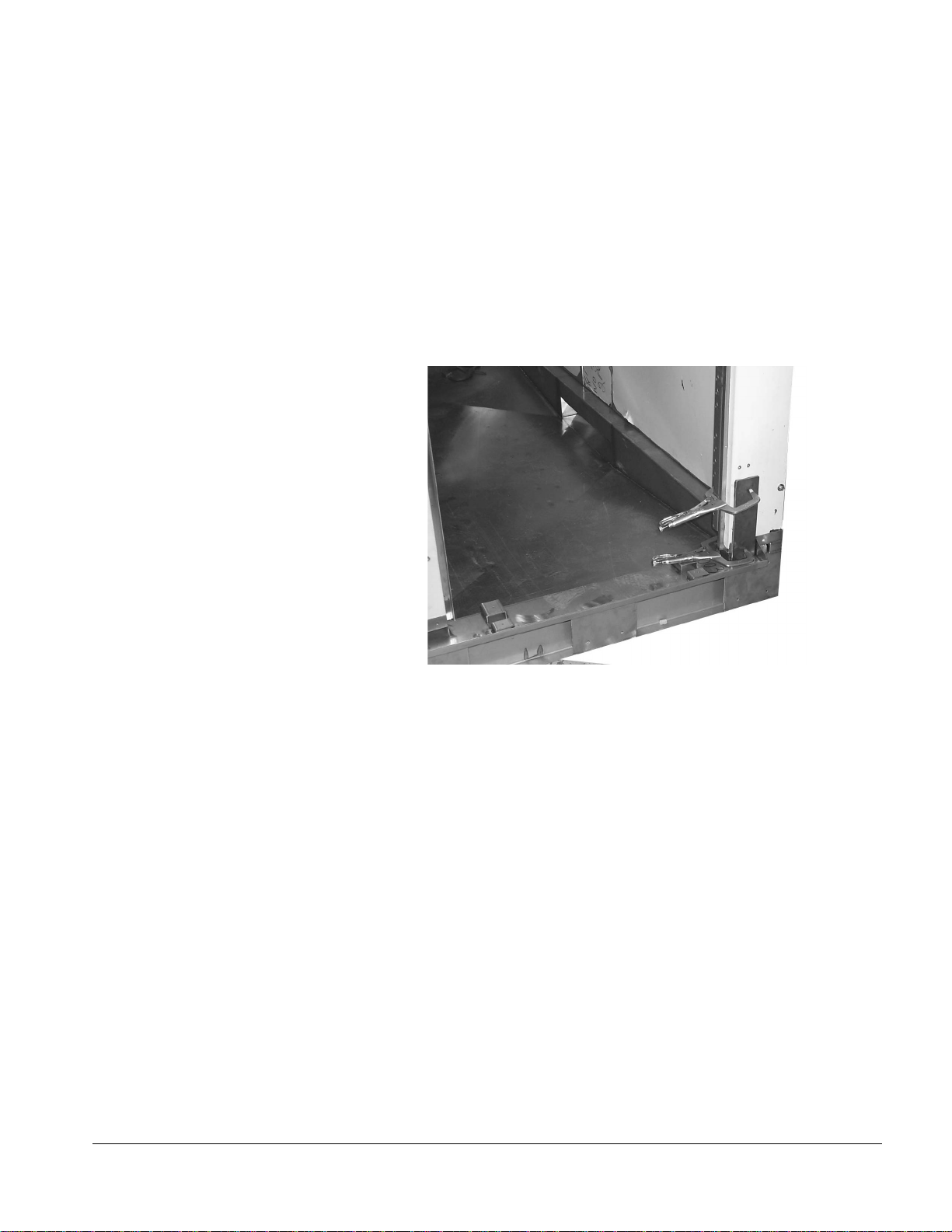

The washer can be installed in a shallow pit or at floor level. When installed

in a pit, the floor of the washer’s chamber is level with the room floor, which

allows the direct loading and unloading of carts. When the washer is

installed at floor level, the floor is higher than the room floor. Ramps are then

provided as standard equipment to facilitate loading and unloading.

The washer is designed for pass-through operation. Items to be cleaned are

placed in the washer’s compartment through one of the load end doors.

After cleaning, the items are removed from the opposite end of the washer

through the unload end doors.

The washer is generally installed in a facility’s decontamination room with

the unload end doors opening out into a clean-preparation area. The unit is

110" (2794 mm) wide and 108" (2743 mm) high. The washer is currently

available in only one compartment size: 98" (2489 mm).

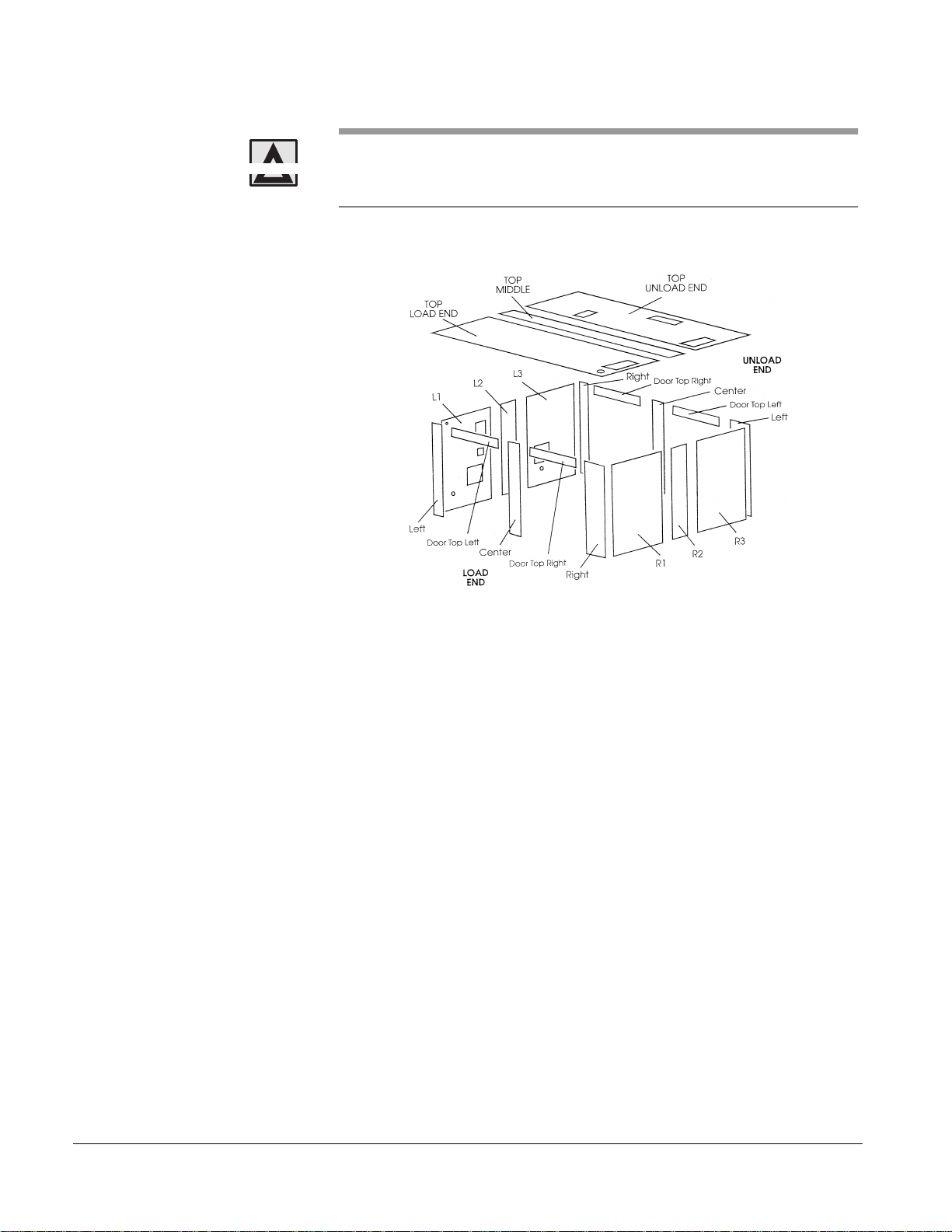

Figure 1–1. 7900 Floor Loading Cart Washer

HW-006

61301604805 1–1

Page 10

Installation Requirements

Model Identification

The rating plate for a 7900 washer is affixed to the inside of the control box

door.

Record the model type and serial number (S/N) from the rating plate.

TYPE: _________________________________

SERIAL NO: ____________________________

Include the model type and serial number when communicating with

Getinge/Castle.

Figure 1–2. Rating Plate Location

1–2

Page 11

Utilities and Specifications

7900 Floor Loading Cart Washer

Electrical

Hot Water

Cold Water

Steam

Condensate

208 V, 60 Hz, 3 phase, 100 A, 5-wire with neutral and ground

240 V, 60 Hz, 3 phase, 60 A, 4-wire with ground

380 V, 50 Hz, 3 phase, 60 A, 4-wire with ground

415 V, 50 Hz, 3 phase, 60 A, 4 wire with ground

480 V, 60 Hz, 3 phase, 30 A, 4-wire with ground

600 V, 60 Hz, 3 phase, 30 A, 4-wire with ground

1" IPS (25.4 mm)

40–60 PSI (276–414 kPa)

780 gal/hr (2953 l/hr) demand rate

12 gal/cycle (47 l/cycle) consumption

120° F min. (49° C)

3/4" IPS (19 mm)

40–60 PSI (276–414 kPa)

600 gal/hr (2271 l/hr) demand rate

10 gal/cycle (38 l/cycle) consumption

1-1/2" IPS

40–50 PSI (276–345 kPa)

1200 lb/hr demand rate

85 lb/cycle consumption

3/4" IPS (19 mm)

Drain

Exhaust

Weight

Overall Size

3" IPS (76. 1 mm) minimum

45 gal/cycle (170 l/cycle)

12" square flanged (304.8 mm)

3

/hr (22.7 m3/hr)

800 ft

1/4" static pressure

1800–2200 lb (811–991 kg) approximate

108" high x 110" wide x 106" long (2743 mm x 1321 mm x 1829 mm)

61301604805 1–3

Page 12

Installation Requirements

Installation Advisor y

A 7900 washer is assembled at the factory, tested, then disassembled for

shipment. Extensive on-site reassembly is required. The installation

instructions in this manual are intended as the primary reference for

accomplishing this reassembly. Every effort has been made to make this

information as accurate as possible. No two washers are exactly alike,

however.

Each washer is uniquely configured to meet the demands of its operational

site. These demands most often necessitate variances in the location of a

washer's exterior components. These variances, in turn, impact the

configuration of related plumbing and electrical wiring assemblies.

For this reason, some instructions or illustrations carried here may not

reflect the actual location or configuration of selected component

assemblies for a specific site. Where applicable, installers should refer to

specifications contained in the product information documents, such as

Rough-In and Assembly drawings, that have been forwarded to local

Getinge/Castle product support personnel.

Wa sher Options

Floor Mount vs. Pit Mount

Left Side vs. Right Side

Controls

Barrier Flanges and Service

Enclosure

Electrical Service

Printer

There are a number of options that may be included with your washer.

These options affect the procedures that apply to your specific installation.

A floor mounted washer will require the installation of ramps to provide

access to the washer. The two options may have different plumbing

specifications.

The location of controls on your washer will also determine the location of

the service area, as well as the barriers flanges and service enclosure that

may be provided with your washer.

Your installation may have barrier walls at the load or unload end of the

washer, or both, as well as have a service enclosure. These structures will

be designed specifically for your site.

The electrical service at your facility determines the specific high voltage

devices (motors, pumps, etc.), transformer, and control box provided with

your washer.

If your washer has the printer option, the printer will already be mounted on

the control box.

Seismic Anchoring

1–4

Washers with the seismic anchoring option have base/sump assemblies

that are mounted differently.

Page 13

Shipping Configuration

7900 Floor Loading Cart Washer

A disassembled 7900 washer is shipped on 4 to 8 pallets of various lengths.

The maximum size of any one pallet may be as large as 10' x 5'

(approximate). For stability during transit, selected pallets are often pegged

(with nails) to the floor of the truck.

Moving the disassembled washer from the truck to the installation site

requires the use of any available combination of the following:

• fork lift

• pallet jack

• dollies

• Johnson bars

A sufficient supply of commonly used fasteners (#10-32 and 1/4-20, for

example) is bagged for shipment. Speciality hardware and fasteners (door

latches and hinges, for example) are labeled and bagged separately for

shipment.

Many disassembled items, such as plumbing and panel sections, are

marked with handwritten numbers with black grease pen to identify their

location, orientation, or connection points. Take care not to inadvertently

smudge or erase these identifying marks.

61301604805 1–5

Page 14

Installation Requirements

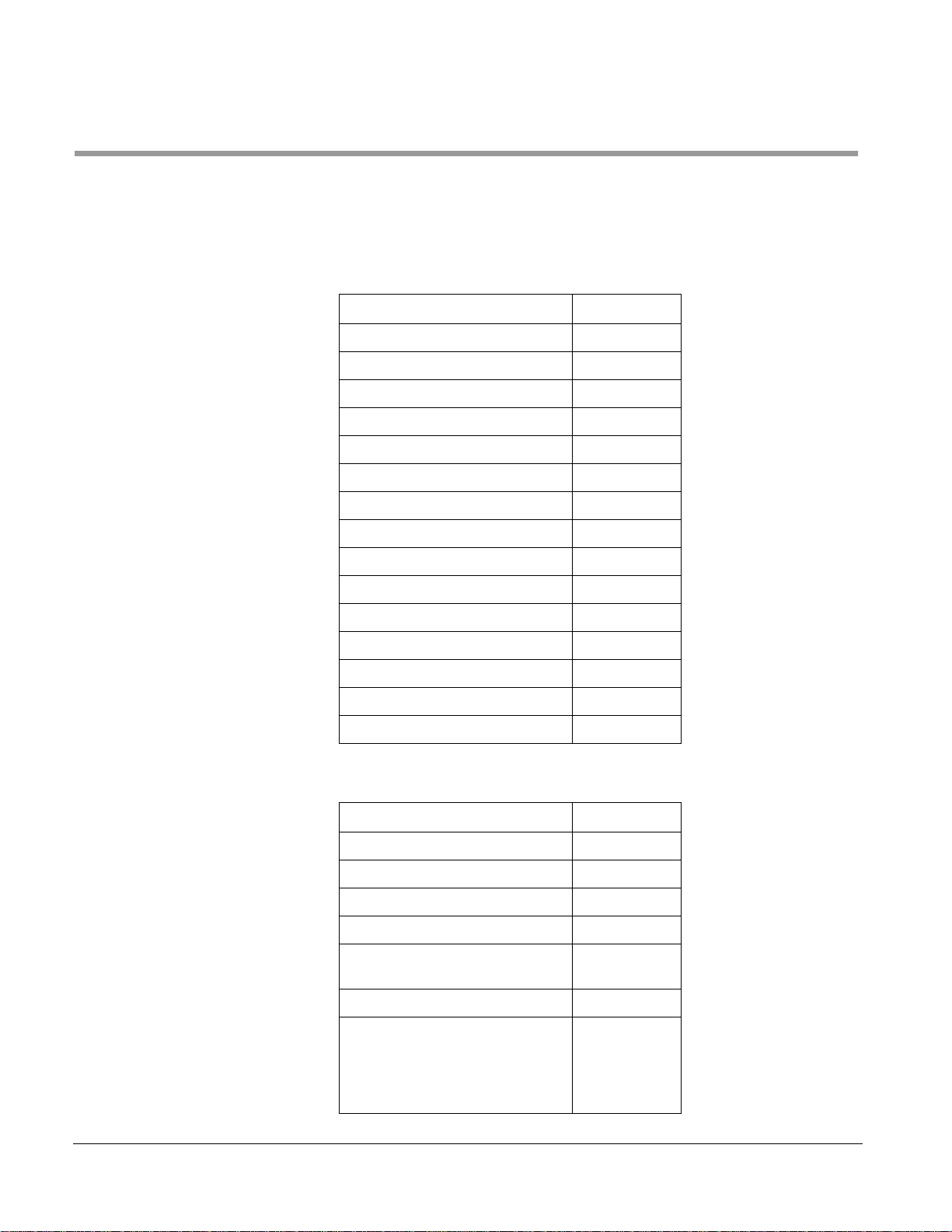

Tools and Materials Required

The following tables list the specific tools and materials required at the

installation site. Items marked with an asterisk * are supplied by Getinge/

Castle.

Table 1–1. Tools Required

Tool Quantity

Common hand tools Assorted

Bar clamp 2

C-clamp 2

Johnson bar 1

Pry/pinch bar 2

Caulking gun 1

1/4-20 tap, short 1

1/4-20 tap, long 1

10-32 tap, short 1

10-32 tap, long 1

#7 drill bit 2

#21 drill bit 2

Torpedo level 1

4’ level 1

Scratch awl 2

Table 1–2. Materials Required

Material Quantity

* Silicone adhesive 8 tubes

* Silicone primer 1 pt

* Thinner 1 pt

* Polish 1 container

* Stainless steel nuts, bolts,

washers, lock washers

Assorted

1–6

* Wire nuts, ti e wraps Assorted

* 3" x 6" stainless steel shims:

• 12 ga

• 14 ga

• 16 ga

• 18 ga

12

12

12

12

Page 15

7900 Floor Loading Cart Washer

Material Quantity

1" x 4" x 6" wood block 2

2" x 4" x 52" wood block 4

The following items are recommended for use if a floor mounted washer is

to be assembled out-of-position, then moved to its intended operational site:

* 4’ x 8’ x 1/8" Masonite, smooth 2 to 3

Pipe, rigid 3/4" x 60" L 4

The Masonite protects the floor during assembly . The pipe is used to roll the

washer into position after assembly.

61301604805 1–7

Page 16

Installation Requirements

1–8

Page 17

Assemble the Washer Structure

This section contains procedures for assembling the basic structure of the

washer compartment. Refer to the following sections.

• “Install the Base/Sump Assembly” on page 2-1

• “Assemble the Washer Panels” on page 2-5

• “Door Assembly” on page 2-10

• “Trim Panels (Non-Service Side)” on page 2-12

Section 2 Installation

Install the Base/Sump

Assembly

NOTE

WARNING

General Instruction

The base/sump assembly is shipped in two halves that you must assemble

on the site. If the load or unload ends of the base are not marked, check the

configuration of the base’s sump against the rough-in drawing to determine

the correct orientation.

Some installation sites may have an existing wall in close proximity to the

non-service side of the washer that could interfere with the assembly of the

washer's side panels. If this situation exists, you will have to seat the base

temporarily out-of-position until the side, top, and non-service side trim

panels are assembled. You can then maneuver the unit to its operating

position, where you can level and anchor it, if required.

Installation

Silicone primer (orange) is extremely flammable, harmful if

swallowed or inhaled, and harmful to eyes or skin. Wear

protective clothing, gloves, and eye wear when using this

product. Keep it away from heat, sparks, and flames. Store

upright in a cool place (less than 30°C (85°F). Keep the

container closed when not in use. Use only in a well-ventilated

area. Avoid breathing vapors.

Silicone Primer stains/discolors clothing, stainless steel surfaces, flooring,

CAUTION

etc. Avoid accidental spills. Avoid spreading this substance onto exterior

surfaces of the washer.

61301604805 2–1

Page 18

Installation

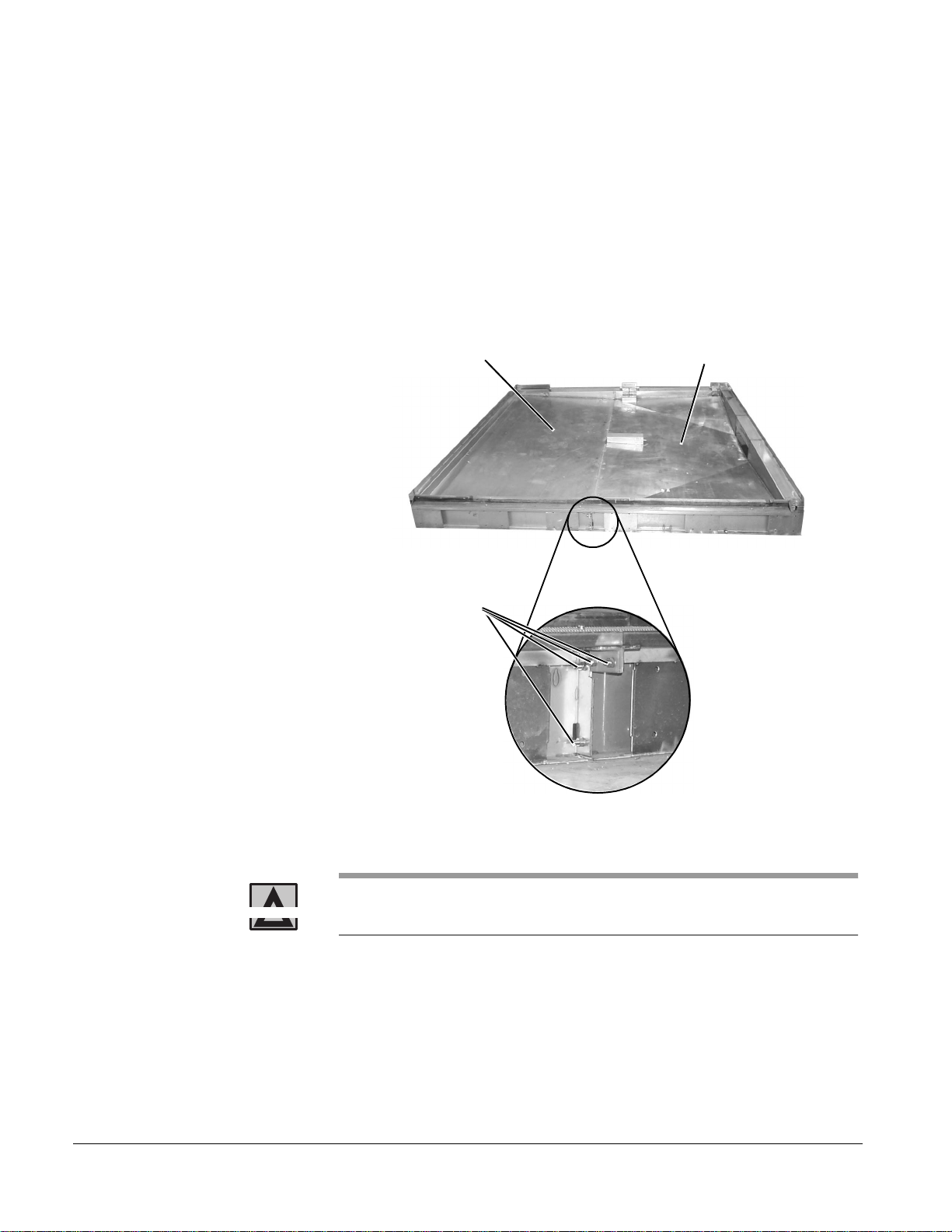

1/4-20 FASTENERS

(4 PLACES EACH END)

REAR BASE HALF

FRONT BASE HALF

1. Clean all mating surf aces w here the tw o ha lv es of the base

meet with thinner, treat with silicone primer, and then apply

a generous amount of silicone sealant.

2. Move the two halves of the washer base together and

attach the halves together:

a. At each end , secure the front and rear halves together

with 1/4-20 fastene r s (four each 1/2" hex head bolts

and lock washers) as shown in Figure 2–1.

Figure 2–1. Attaching Ends of Base Assembly

2–2

WARNING

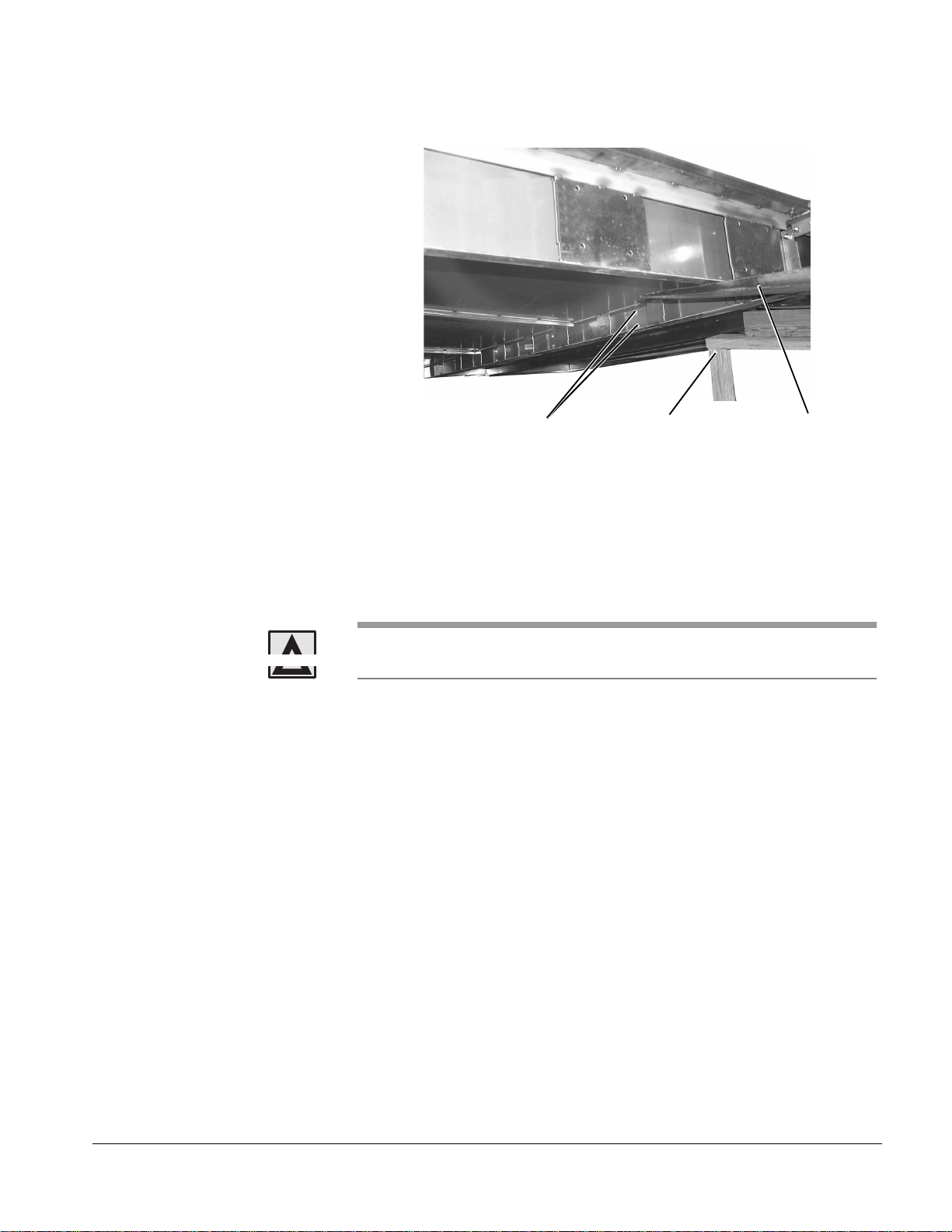

b. Use a fork lift to raise one end of the as sembly.

Make sure that the base/sump assembly is properly supported

and secured before getting underneath the assembly.

c. Underneath the sump, secure the halv es to ge the r wi th

5/16-18 fasteners (1-1/2" hex head bolts and lock

washers), two each at six places, as shown in Figure

2–2.

Page 19

7900 Floor Loading Cart Washer

5/16-18 FASTENERS

(2 EACH AT 6 PLACES)

WOOD SUPPORT

FORK LIFT

Figure 2–2. Attaching Base Assembly Underneath

3. Move the base assembly into its final operating position.

4. Check the base for level.

Use the 4' level to check from all sides of the base and in

all directions. Adjust the level if necessary using the

stainless steel shims that are provided.

CAUTION

Failure to critically level the base will result in the misalignment of mounting

holes and will make assembly of the washer panels difficult.

If seismic anchoring is required, a 3" flange (with anchor bolt holes) is

welded to the bottom frame of the base for this purpose.

5. Drill holes for the anchors through the holes in the base

flanges.

Table 2–1. Drilling Specifications

Drill Bit Size

Embedment

Torque 50 ft.-lb.

1/2

1 1/4

"

to 3 1/2

"

"

6. Secure the base to the floor using the 1/2 x 4-1/2" stud

anchor bolts provided.

61301604805 2–3

Page 20

Installation

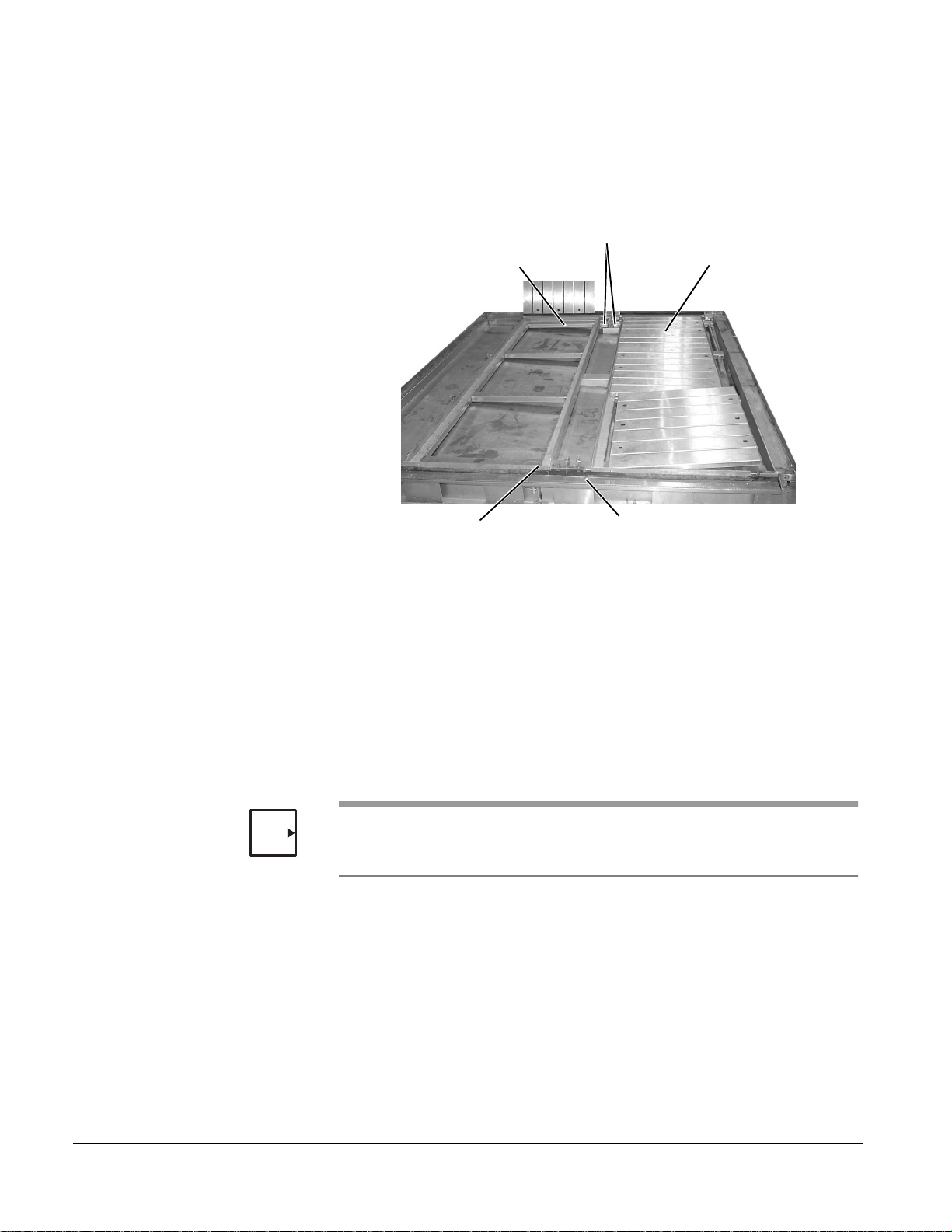

FLOOR LIFT WELDMENTS

TRACK/FR AME ASSEMBLY

FLOOR GRATES (6)

CHANNEL FILLERS

THRESHOLD ASSEM BLI ES

(2 PLACES AT EACH END)

(2 PLACES AT EACH END)

7. Lay the two track/frame assemblies into the base so that

the floor lift weldments are to wa rd the center of the w asher ,

as shown in Figure 2–3. Base/Sump Components

Figure 2–3. Base/Sump Components

8. Lay the six floor grates in the tracks into the track/frame

9. Lay the masoni te sheets over the floor grates to protect

10. Position the four channel fillers (two on each end of the

11. Install the four threshold assemblies in the floor.

NOTE

There are two sizes: the longer threshold is installed on the rear (nonservice side) of the washer, one on each end. The shorter threshold is

installed on the front (service side) of each end.

assemblies.

from scratches while you complete the installation.

washer) in the floor and secure each with two #10 -32 x 3/8"

phillips head screws.

a. Position one threshold assembly in its appropriate

location with the gasket facing toward the inside of the

washer.

b. Secure the assembly to the washer base with two #10-

32 x 3/8" phillips head screws.

2–4

Page 21

7900 Floor Loading Cart Washer

Assemble the Washer Panels

Objective

Assemble the door, side, and top panels. Install the required number of

interior side panel seam cover strips and the center mounting bracket.

There are six side panels and three top panels. Each of the end (door)

panels in turn consists of five panels: three vertical panels and two

horizontal panels (one over each door) that connect to the vertical panels.

Door panels and side panels are marked to indicate their location. Top

panels are not marked (check this). The unload end top panel has two

rectangular cutouts for the condenser mountings, a cutout for one of the rear

dryer ducts, and numerous threaded holes on its exterior surface for

mounting the dryer assemblies. The load end top panel one cutout for the

second rear dryer duct and has fewer mounting holes (for a transformer and

plumbing mounting plates). the middle panel has mounting brackets for the

floor tilt actuators. The width of a top panel is the width of the washer (92").

The side panels have 7/16" diameter holes that carry 3/8" thru bolts (five on

each side of the washer) to hold the panels together. The top panels have

holes to carry five thru bolts.

There is no established order to follow for panel assembly. You can start

from the load or the unload end. You can assemble all the vertical panels

first, followed by the top panels; or you can add individual top panels as you

erect the vertical panels. The method illustrated below starts from the load

end and progressively adds top panels as the vertical panels are erected.

NOTE

WARNING

You must clean all mating surfaces with thinner, then treat with silicone

primer, and then apply a generous amount of silicone sealant.

Installation

Refer to Figure 2–4. Assembling the Washer Panels for help to identifying

washer panels.

You must clean all mating surfaces with thinner, then treat with silicone

primer, and then apply a generous amount of silicone sealant.

Silicone primer (orange) is extremely flammable, harmful if

swallowed or in haled, and harmful to eyes or skin. Wear

protective clothing, gloves, and eye wear when using this

product. Keep it away from heat, sparks, and flames. Store

upright in a cool place (less than 30°C (85°F). Keep the

container closed when not in use. Use only in a well-ventilated

area. Avoid breathing vapors.

61301604805 2–5

Page 22

Installation

CAUTION

Silicone Primer stains/discolors clothing, stainless steel surfaces, flooring,

etc. Avoid accidental spills. Avoid spreading this substance onto exterior

surfaces of the washer.

Figure 2–4. Assembling the Washer Panels

1. Clean all mating surfaces with thinner, treat with silicone

primer, and then apply a generous bead of silicone sealant

wherever a wall panel is atta ched to the base or to ano the r

panel.

2. Attach the load end door panels to the base.

There are three vertical panels. The service side panel is

narrow and has thr ee mounting holes at the top to a ttach to

the horizontal panels. The middle panel is narrow and has

six mounting holes at the top. The non-service-side panel

is wide.

a. Position a vertic al panel.

b. Secure the bottom legs of the panel to the base frame

with 1/4-20 fasteners (1/2" hex head bolts, flat

washers, and lock washers).

c. Repeat steps a and b for the other vertical panels.

d. Secure each horizontal panel between two vertical

panels with 1/4-20 fasteners (six each 3/4" hex head

bolts and lock washers).

2–6

Page 23

7900 Floor Loading Cart Washer

3. Attach the load end sid e panels to the bas e and to the l oad

end door.

a. Position one of the load end side panels.

b. Partially insert five 3/8" diameter thru rods through the

7/16" diameter holes to stabilize and align the side

panel with the door panel.

c. Use pipe clamps to draw the panels tight as shown in

Figure 2–5.

Figure 2–5. Installin g Washer Panels

d. Secure the bottoms o f the side p anel to the ba se frame

with 1/4-20 fasteners (1/2" hex head bolts and lock

washers).

e. Repeat steps a through d for the other load end side

panel.

4. Attach the middle side panels to the base and to the load

end panels.

a. Remove the pipe clamps.

b. Position one of the middle side panels.

c. Extend the five thru bolts to stabilize and align the

panels with the load end side panel.

d. Attach the pipe clamps to draw these pan els tight.

e. Secure the bottoms of the middle Side panel to the

base frame with 1/ 4-20 fasteners (1/2" hex head bolts

and lock washers).

61301604805 2–7

Page 24

Installation

f. Repeat steps a through d for the other middle side

panel.

g. To ensure side panel alignment, attach C-clamps and

2x4" wooden blocks across the top edge of the

adjoining panels at the vertical seam.

5. Attach the load end top panel to the door panel and to the

load end side panels.

a. Position the load end top panel.

b. Secure the top panel to the door and load end side

panels with 1/4- 20 fast eners (1-3/4" hex hea d bolts, fl at

washers, and lock washers).

c. Partially i nsert the five remaining 3/8" diameter thru

bolts through the 7/16" diameter holes in the panel.

6. Attach the unload end side panels to the base and to the

middle (or load end) side panels.

a. Remove the pipe clamps.

b. Position one of the unload end side panels.

c. Extend the five thru bolts to stabilize and align this

panels with the previously erected panels.

d. Attach the pipe clamps to draw these panels tight.

e. Secure the bottom of the unload end side panel to the

base frame with 1/ 4-20 fasteners (1/2" hex head bolts

and lock washers).

f. Repeat steps a throug h d f or th e other u nload end si de

panel.

g. Move the C-clamp and 2" x 4" wooden block

assemblies to the vertical seams created by the

installation of t hese panels.

7. Attach the middle top panel to the load end top panel and

to the middle side panels.

a. Position the middle top panel.

b. Extend the two thru bolts.

c. Secure this panel to the mid dle side panel s with 1/4-20

fasteners ( 1-3/4" hex head bolts, flat washer s, an d loc k

washers).

2–8

Page 25

7900 Floor Loading Cart Washer

8. Attach the unload end door panels to the base and to the

unload end side panels.

a. Remove the pipe clamps.

b. Position a vertical panel.

c. Secure the bottom legs of the panel to the base frame

with 1/4-20 fasteners (1/2" hex head bolts, flat

washers, and lock washers).

d. Repeat st eps a and b for the other vertical panels.

e. Secure each horizontal panel between two vertical

panels with 1/4-20 fasteners (six each 3/4" hex head

bolts and lock washers).

f. Extend the ten side thru bolts.

g. Attach the pipe clamps to draw the door panels tight.

h. Secure the thru bolts at both ends of the washer with

3/8" acorn nuts and flat washers.

9. Attach the unload end top panel to the unload end side

panels and to the unload end door panel.

a. Remove the C-clamp assemblies.

b. Position the unload end top panel.

c. Extend the five thru bolts.

d. Secure this panel to the unload end door panels and

side panels with 1/4-20 fasteners (1-3/4" hex head

bolts, flat washers, and lock washers).

e. Secure the thru bolts at both ends of the washer with

3/8" acorn nuts and flat washers.

10. Inside the washer, attach the four panel seam cover strips

over the vertical seams between adjoining side panels

using #10-32 screws and lock washers.

11. Attach the center mounting plate inside the washer, from

the load end to the unload end.

a. Align the holes in the mounting plate with the threaded

holes along the center of the washer.

b. Secure the mounting plate to the washer with six 1/4-

20 fasten ers ( 3/ 4" hex head cap screws, lock washers,

and flat washers). The mounting plate is attached to

the top panels in four places and once in each center

end panel.

61301604805 2–9

Page 26

Installation

HINGE MOUNT

DOOR HINGE

(3 PER DOOR)

DOOR LATCH

RETAINERS

(2 PER DOOR)

DOOR HANDLE

DOOR LATCH

(2 PER DOOR)

(3 PER DOOR)

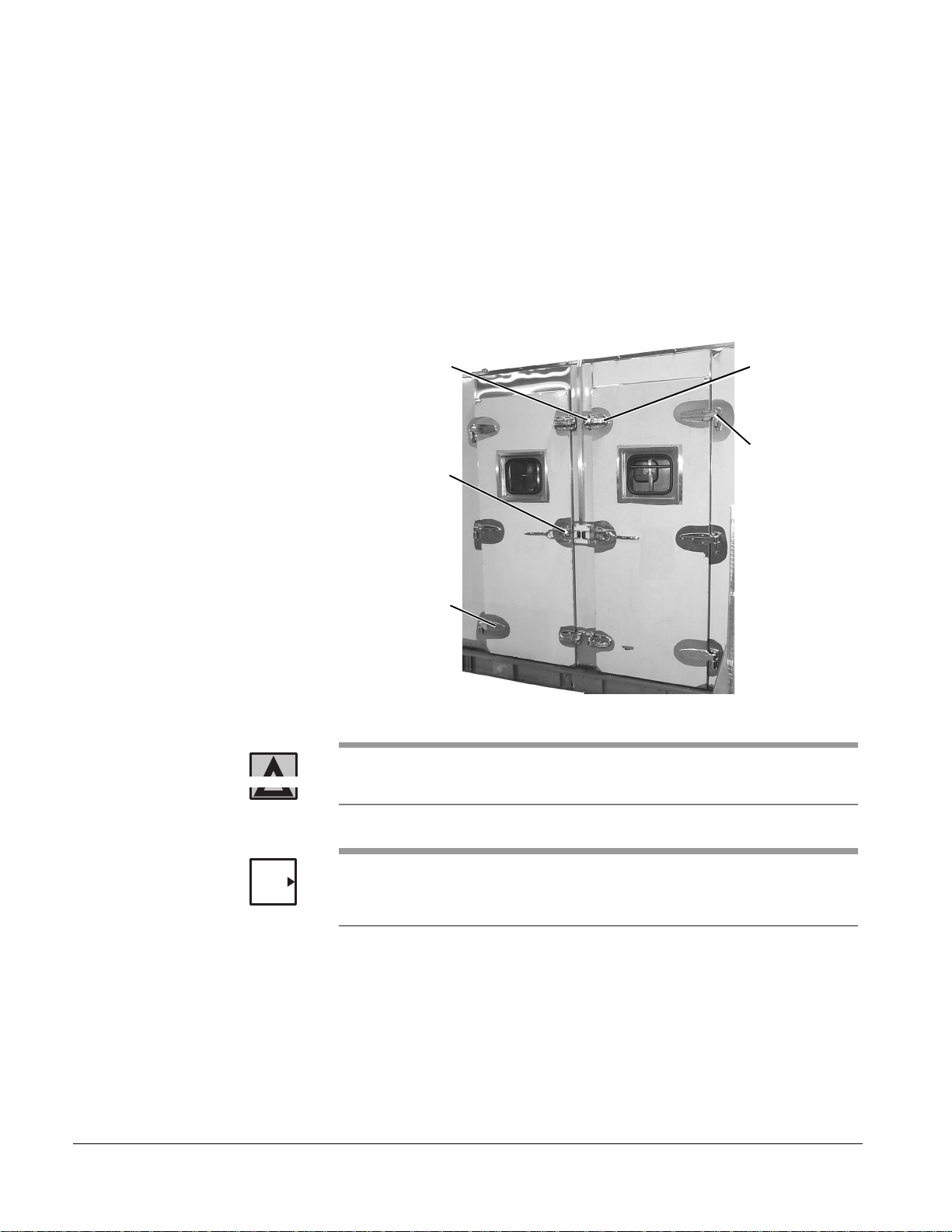

Door Assembly

Objective

Attach hardware to the doors and related door panels. Install two doors

each on both the load and unload ends of the washer. Plumb and square all

four doors.

Installation

Refer to Figure 2–52. Door Assembly.

Figure 2–6. Door Ass embly

2–10

WARNING

NOTE

A washer door is heavy and awkward to handle. Take care to

avoid crushing or strain injuries.

The washer may be shipped with all of the hardware (hinges, latches, striker

plates, etc.) already mounted on both the doors and the door panels. If so,

start with step 3 below.

Page 27

7900 Floor Loading Cart Washer

1. Attach the following items to each door panel:

a. Attach three hinge m oun ts u s ing ni ne 1/ 4- 20 fasteners

(1" phillips head screws).

b. Attach two door latch retain er s, two door latch shims,

and two spacers using four 5/16-18 fasteners (2" hex

head cap screws and lock washers).

2. Attach the following items to each door:

a. Attach two door latches using four 5/16-18 fasteners

(1" hex head cap screws and lock washers).

b. Attach three hinges using twelve 1/4-20 fasteners

(1" phillips head screws).

c. Attach the door handle using four 5/16-18 fasteners

(1" hex head cap screws and lock washers).

3. Mount the door on the washer.

a. Raise and maneuver the door until its hinge posts are

in vertical alignment over the three hinge mounts

attached to the door panel.

NOTE

b. When aligned, lower the door and properly seat al l

three posts in their respective mounts.

4. Repeat steps 1 through 3 for the other door assemblies.

5. Check all door openings for plumb and square. If

necessary, use the shims that are provided.

After the plumb and square of all doors is checked and corrected, it may be

easier to lift the doors off their hinges and set them aside until the end of the

installation of the washer.

61301604805 2–11

Page 28

Installation

Trim Panels (Non-Service

Side)

Objective

The narrow width of the trim panels and the presence of a restrictive wall

may require that you assemble the washer out-of-position up to this point.

After you attach the panels, you can move the washer to its exact

operational position, where you can level the washer, and seismically

anchor it if required.

Installation

1. Attach any required trim panels to the non-service side of

the washer using #10-32 fasteners (3/8" pan head screws

and lock washe rs).

2. If necessary, move the washer to its final position. Level

and, if required, anchor the washer.

2–12

Page 29

Install Components on Top of the Washer

There are a number of components that are installed on the top panels of

the washer. Although there is no specific order in which the components

should be installed, the list below presents the items in a recommended

order. Refer to the following sections.

•“Dryer and Condenser Assemblies” on page 2-13

•“Power Floor Tilt Pulley System” on page 2-17

•“Transformer and Emergency Stop Switch Junction Box” on page 2-19

•“Rear Emergency Stop Switch” on page 2-20

•“Plumbing Mounting Brackets” on page 2-21

Before installing any components on top of the washer, you must ensure

CAUTION

that the door openings are plumb and square. Failure to do so can result in

doors that do not open and close correctly, as well as water leaks.

7900 Floor Loading Cart Washer

Dryer and Condenser

Assemblies

Objective

Assemble the two dryer/blower assemblies, the two condenser duct

assemblies, and the rear top dryer duct.

Generally, the dryer assemblies are mounted on top of the washer. When

sufficient space is not available, these assemblies are redesigned for

installation in the unit’s service area. These configurations vary and are not

accurately represented in these Installation Instructions. To install the dryer

assemblies in the washer's service area, refer to the Rough-In Drawing for

guidance.

61301604805 2–13

Page 30

Installation

CONDENSER

HEATING COIL

DRYER/BLOWER

ASSEMBLY

UNLOAD END

FRONT SIDE

Installation

1. Install the front dryer/blower assembly and the condenser

on the washer. Refer to Figure 2–7. Front Dryer and

Condenser Assembly Locations.

Figure 2–7. Front Dryer and Condenser Assembly Locations

NOTE

a. Position the front dryer/blower assembly on top of the

unload end top panel.

The front (service side) dryer is normally located at the unload end of the

washer and oriented so that the heating coil faces the side of the washer.

b. Align the holes in the assembly’s mounting frame with

the matching #10-32 threaded holes in the panel.

c. Apply sealant to the screw threads and secure the

frame to the panel with eight #10-32 fasteners (3/4"

slotted pan head screws, lock washers, and flat

washers).

d. Apply silicone sealant to the edge of the front

condenser cut out in the top panel.

e. Position the front condenser duct assembly on the

unload end top panel.

f. Align the holes in the assembly’s flange to the

matching #10-32 threaded holes around the outside of

the opening in the panel.

g. Secure the condenser’s flange to the top panel with

eight #10-32 (3/4" phillips head screws, lock washers,

and flat washers).

h. Attach the 9" vent hose to the condenser and to the

dryer with hose clamps.

2–14

Page 31

7900 Floor Loading Cart Washer

CONDENSER

HEATING COIL

DRYER/BLOWER

ASSEMBLY

UNLOAD END

REAR SIDE

TOP DRYER DUCT

2. Install the rear dryer/blower assembly, condenser, and top

dryer duct on the washer. Refer to Figure 2–8. Rear Dryer

and Condenser Assembly Locations.

Figure 2–8. Rear Dryer and Condenser Assembly Locations

NOTE

a. Position the rear dryer/blower assembly on top of the

unload end top panel.

The rear (non-service side) dryer is normally located near the middle of the

washer and oriented so that the heating coil faces the side of the washer.

b. Align the holes in the assembly’s mounting frame with

the matching #10-32 threaded holes in the panel.

c. Apply sealant to the screw threads and secure the

frame to the panel with #10-32 fasteners (eight each

3/4" slotted pan head screws, lock washers, and flat

washers).

d. Apply silicone sealant to the edge of the front

condenser cut out in the top panel.

e. Position the front condenser duct assembly on the

unload end top panel.

f. Align the holes in the assembly’s flange to the

matching #10-32 threaded holes around the outside of

the opening in the panel.

g. Secure the condenser’s flange to the top panel with

#10-32 (eight each 3/4" phillip s head screws, lock

washers, and flat washers).

61301604805 2–15

Page 32

Installation

h. Attach the 9" vent hose to the condenser and to the

dryer with hose clamps.

i. Apply silicone sealant to the mating flange surrounding

the rear dryer’s heating coil and to the mating surfaces

surrounding the tw o 18" x 7-1 /2" re ctangu lar cuto uts in

the top pane ls.

j. Position the rear dryer duct on top of the washer.

k. Secure the duct to the heating coil flange with #10-32

fasteners (fifteen each 1/2" phillips head screws, lock

washers, and flat washers).

l. Secure the duct to the top panel with nine #10-32

fasteners per cutout (nine each 1/2" phillips head

screws, lock washers, and flat washers).

m. Inside the washer compartment, apply additional

sealant to the interior joints formed between the duct

and the panel.

3. Connect the dr ain output from each of the con de nse rs and

the elbow fitti ng located beneath each blo wer to dr ain using

3/4" diameter flexible tubing, hose clamps, and tee

connectors. Refer to Figure 2–9.

Figure 2–9. Condenser and Dryer Drain Tubing

FRONT

CONDENSER

TO

DRAIN

REAR

CONDENSER

REAR

BLOWER

TEE

CONNECTORS

FRONT

BLOWER

2–16

Page 33

7900 Floor Loading Cart Washer

ACTUATOR

1/4-20 FASTENERS

(6 PLACES)

RETRACT LIMIT SWITCH

EXTEND LIMIT SWITCH

Power Floo r Tilt Pulley

System

Objective

Install the power floor tilt pulley system. The top panels have 1/4-20

threaded holes to mount the system’s five components. The actuator

assembly is installed on the top middle panel, with the actuator mounted on

the front (service) side and the pulleys in the middle. The pulley cables run

the length of the washer from the middle to ends of the washer above the

load and unload end doors.

Installation

Figure 2–10. Power Floor Tilt Actuator Assembly

1. Install the following components on the service side of the

washer's top panels:

a. Align the actuator assembly with the holes in the top

panel and secure with six 1/4-20 fasteners. Refer to

Figure 2–10. Power Floor Tilt Actuator Assembly.

b. Secure the two lo ad end pulle y mou nts to the middle o f

the load end top panel with 1/4-20 fasteners (two each

1/2" hex he ad scre ws, loc k w ashers , and f lat w ashers).

Refer to Figure 2–11. Power Floor Tilt Pulley Mounts.

c. Secure the two unload end pulle y mounts to the middle

of the unload end top panel with 1/4-20 fasteners (two

each 1/2" hex head screws, lock washers, and flat

washers).

61301604805 2–17

Page 34

Installation

1/4-20 FASTENERS

(2 PLACES EACH)

PULLEY MOUNTS

FLOOR LIFT

WELDMENTS

CABLE

FASTENERS

Figure 2–11. Power Floor Tilt Pulley Mounts

2. Route the four pulley cables from the actuator, through the

pulley mounts, and then down through the four gasketed

cable holes in the paneling to the compartment floor.

NOTE

You may have to enlarge a gasket hole with a drill if the cable does not fit

through the hole.

3. Slide the black cable sleeves over the section of cable

inside the washer.

4. Using a cable fastener, secure each of the four pulley

cables to its corresponding floor lift weldment. Ref er to

Figure 2–12. Attaching Cables to Floor Lift Weldments.

Figure 2–12. Attaching Cables to Floor Lift Weldments

2–18

5. Using #6-32 fasteners, attach the two limit switches to the

actuator's mounting plate.

Page 35

7900 Floor Loading Cart Washer

EMERGENCY STOP SWITCH

JUNCTION BOX

TRANSFORMER

Transformer and Emergency

Stop Switch Junction Box

Objective

Install the transformer and the junction box for the emergency stop switches

to the top of the washer. The specific transformer used with your washer

depends on the house-supplied voltage.

Figure 2–13. Transformer and Emergency Stop Junction Box Locations

Installation

Refer to Figure 2–13. Transformer and Emergency Stop Junction Box

Locations.

1. Install the transformer.

Transformers are siz ed d ifferently but are gene ra lly loca ted

on the service side of the load end top panel and

positioned so that the output power cable is facing the

service side fo the washer.

1. Align the transformer’s mounting holes to the thread ed

holes in the panel.

a. Secure the transformer to the panel with four 1/4-20

fasteners.

2. Install the emergency stop switch junction box.

a. Remove the face plate of the box.

b. Align the mounting holes in the back of the bo x with the

two #10-32 threaded holes on the top panel near the

transf ormer you installed above.

c. Use #10-32 fasteners to secure the box to the washer.

d. Install the face plate.

61301604805 2–19

Page 36

Installation

EMERGENCY STOP

SWITCH

1/4-20 FASTENERS

MOUNTING BRACKET

Rear Emergency Stop Switch

Objective

Attach the rear emergency stop switch to the top of the washer. The switch

is mounted on the rear (non-service side) of the washer at the load end.

Installation

Refer to Figure 2–14. Rear Emergency Stop Switch.

Figure 2–14. Rear Emergency Stop Switch

1. Mount the emergency stop switch to the mounting bracket

using 1/4-20 fasteners (two each hex head cap screws,

lock washers, and flat washers).

2. Align the two holes in the mounting bracket with the holes

on the load end top panel.

3. Secure the bracket and switch to the washer with 1/4-20

fasteners (two each hex head cap screws, lock washers,

and flat washers).

2–20

Page 37

7900 Floor Loading Cart Washer

CONDENSATE (BI) PIPE BRACKET

RINSE (SS) PIPE BRACKET

STEAM (BI) PIPE BRACKET

WASH (SS) PIPE BRACKET

Plumbing Mounting Brackets

Objective

Attach four mounting brackets to the top of the washer to support the piping

for the rear side of the washer.

Installation

Refer to Figure 2–15. Plumbing Mounting Brackets for the location and

relative size of each bracket.

Figure 2–15. Plumbing Mounting Brackets

1. Determine the correct location for each bracket. The

brackets are marked with index markers that match

numbers on the top panel.

2. Align the holes in one mounting bracket with the two holes

in the top of the washer.

3. Secure the bracket with 1/4-20 fasteners (two each hex

head cap screws, lock washers, and flat washers).

4. Repeat st eps 2 and 3 for the other brackets.

61301604805 2–21

Page 38

Installation

Install Components on the Outside of the Washer

This section provides instructions for installing equipment on the outside of

the washer. The procedures are presented in a recommended order (some

larger components are easier to install if they are done earlier, f or example).

Refer to the following sections.

•“Spray Manifold Drive Motor” on page 2-23

•“Exhaust Elbow” on page 2-25

•“Washer Light Assembly” on page 2-26

•“Front Dryer Ducts” on page 2-27

•“Control Box” on page 2-29

•“Junction Box Assembly” on page 2-30

•“Dispenser Float Switch Junction Box” on page 2-31

•“Front Emergency Stop Switch” on page 2-32

•“Detergent and Rinse Aid Dispensers” on page 2-33

•“Unload End Indicator Panel Box” on page 2-34

•“Door Proximity Switches” on page 2-35

•“Sump Drain Valve” on page 2-36

•“Return Pump” on page 2-37

•“Circulation Tank Assembly” on page 2-38

•“Wash Pump” on page 2-39

•“Tank Drain Valve, Tank Overflow, and Tank Water Level Indicator” on

page 2-40

•“Booster Heater Assembly” on page 2-41

•“Rinse Pump” on page 2-42

2–22

Page 39

7900 Floor Loading Cart Washer

FLANGE BEARING

3/8-16 FASTENERS

(4 PLACES)

LOAD END

1/4-20 FASTENERS

(6 PLACES)

Spray Manifold Drive Motor

Objective

Assemble the spray manifold drive's flange bearing and the spray manifold

drive motor.

Installation

Figure 2–16. Manifold Drive Flange Bearing

1. Use 3/8"-16 fa sten ers (four each 1" hex head cap screws

and lock washers) to loosely secure the flange bearing in

position at the upper corner of the load end side panel, as

shown in Figure 2–16.

NOTE

You will tighten the bearing after you assemble the drive shaft and couple it

to the drive motor (refer to “Chain Drive Assembly” on page 2-52).

Figure 2–17. Spray Manifold Drive Motor

61301604805 2–23

Page 40

Installation

2. As shown in Figure 2–17, position the spray drive manifold

motor and bracket over the six threaded holes located in

the panel directly below the flange bearing and use 1/4-20

fasteners (six each 3/4" hex head cap screws, lock

washers, and flat washers) to secure the mounting fixture

to the panel.

3. Slip the proximity switch collar over the drive shaft of the

motor and secure by tightening the hex head cap screw.

2–24

Page 41

7900 Floor Loading Cart Washer

Exhaust Elbow

Objective

Install the exhaust elbow on the side of the washer.

Installation

Refer to Figure 2–18. Exhaust Elbo w.

Figure 2–18. Exhaust Elbow

1. Apply silicone sealant to the mating surface surrounding

the 12" cutout next to the spray manifold drive motor.

2. Position the exhaust elbow against the cutout and secure

with 1/4-20 faste ne rs (e ight each hex head cap screw s,

lock washers, and flat washers).

3. Inside the washer comp artment, apply additional sealant to

the interior joint formed between the elbow and the side

panel.

61301604805 2–25

Page 42

Installation

#10-32 FASTENERS

(4 PLACES)

#10-32 FASTENERS

(8 PLACES)

Washer Light Assembly

Objective

Install the interior light in the cutout located on the front (service side) wall.

Installation

1. Remove and retain the nine fasteners securing the interior

cover of the light assembly.

2. Align the holes in the light assembly with the holes

surrounding the cutout in the front panel.

3. Secure the light assembly to the front panel with four #1032 fasteners (phillips head screws and flat washers) as

shown in Figure 2–19.

Figure 2–19. Washer Light Assembly (Outside)

4. On the inside of the washer, apply silicone sealant around

the edge of the light assembly.

5. Place the gasket and cover over the light assembly and

secure with eight #10-32 fasteners (phillips he ad screws,

lock washers, and flat washers) as shown in Figure 2–20.

Figure 2–20. Washer Light Assembly (Inside)

2–26

Page 43

7900 Floor Loading Cart Washer

HORIZONTAL SECTION OF

FRONT DRYER DUCT

Front Dryer Ducts

Objective

Mount the dryer ducts.

The front (service side) dryer duct connects the dryer’s heating coil to two

13-1/4" x 18" cutouts in the side panels. Generally, the duct work consist of

a vertical and a horizontal section. However, other configurations are

possible if the dryer is mounted against the side of the unit. The rear (nonservice side) dryer duct connects to two cutouts on the top panel of the

washer, which in turn, connect to the two rear dryer ducts on the inside of

the washer.

Installation

1. Install the lower (horizontal) section of the front (service

side) dryer duct. Refer to Figure 2–21. Horizontal Section

of Front Dryer Duct.

Figure 2–21. Horizontal Section of Front Dryer Duct

a. Apply silicone sealant to the mating surfaces

surrounding the 18" x 13-1/4" rectangular cutouts in

the front (service side) side panels.

b. Secure the horizont al secti on o f the duct to the cutout s

with ten #10-32 fasteners (1/2" phillips head screw,

lock washer, and flat washer) per cutout.

c. Inside the washer compartment, apply additional

sealant to the interior joints formed between the duct

and the panel.

61301604805 2–27

Page 44

Installation

VERTICAL SECTION OF

FRONT DRYER DUCT

HORIZONTAL SECTION

STEAM HEATER

#10-32 FASTENERS

(9 PLACES)

#10-32 FASTENERS

(10 PLACES)

2. Install the upper (vertical) section of the front dryer duct.

Refer to Figure 2–21. Horizontal Section of Front Dr yer

Duct.

Figure 2–22. Vertical Section of the Front Dryer Duct

NOTE

a. Apply silicone sealant to the mating flange surrounding

the dryer’s heating coil and to the mating surface

between the vertical and horizontal ducts.

b. Position the vertical duct on the horizontal duct.

c. Secure the upper end to the heating coil flange with

#10-32 fasteners (fifteen each 1/2" phillips head

screws, lock washers, and flat washers).

d. Secure the lower end to the horizontal duct with #10-

32 fasteners (nine 1/2" phillips head screws, lock

washers, and flat washers).

One or more standoffs may have been welded to the dockworker to support

a plumbing assembly. Clamps are provided to secure plumbing to standoffs.

2–28

Page 45

7900 Floor Loading Cart Washer

1/4-20 FASTENERS

CONTROL BOX

(4 PLACES)

Control Box

Objective

Attach the control box to the load end side panel.

Installation

Refer to Figure 2–23. Control Box.

Figure 2–23. Control Box

1. Remove the pins from the door hinges and set the door

aside.

2. Position the control box on the load end side panel and

align the mounting tabs on the top and bottom of the box

with the four threaded holes in the panel.

3. Use 1/4-20 fasteners (4 each 3/4" hex head cap screws,

flat washers, and lock washers) to s ecure the control bo x to

the panel.

4. Install the door on the control box.

61301604805 2–29

Page 46

Installation

#10-32 FASTENERS

(4 PLACES)

LOWER DRYER DUCT

EXHAUST ELBOW

Juncti on B ox Assembly

Objective

Install the junction box assembly to the side of the washer.

Installation

Refer to Figure 2–24. Junction Box Assembly.

Figure 2–24. Junction Box Assembly

1. Position the junction box and align its mounting holes with

those on the front panel of the exhaust elbow and on the

top of the lower dryer duct.

2. Secure the junction box to the exhaust elbow and to the

dryer duct using #10- 3 2 fasteners (four each 3/8"pa n head

screws and lock washers).

2–30

Page 47

7900 Floor Loading Cart Washer

JUNCTION BOX

LOAD END

WASH MANIFOLD

FITTING

Dispenser Float Switch

Junction Box

Objective

Install the junction box for the detergent and rinse aid dispenser float

switches on the front (service side) panel at the load end of the washer.

Installation

Refer to Figure 2–25. Dispenser Float Switch Junction Box.

Figure 2–25. Dispenser Float Switch Junction Box

1. Remove the face plate of the box.

2. Align the mounting ho les in the bac k of the b ox wi th the two

#10-32 threaded holes on the front side panel at the load

end of the washer.

3. Use #10-32 fasteners to secure the box to the panel.

4. Install the face plate.

61301604805 2–31

Page 48

Installation

EMERGENCY STOP

SWITCH

1/4-20 FASTENERS

MOUNTING

(4 PLACES)

BRACKET

Front Emergency Stop Switch

Objective

Attach the front emergency stop switch to the side panel of the washer. The

switch is mounted at the load end of the washer, over the detergent

dispenser.

Installation

Refer to Figure 2–26. Front Emergency Stop Switch.

Figure 2–26. Front Emergency Stop Switch

1. Mount the emergency stop switch to the mounting bracket

using two 1/4-20 fasteners (hex head cap screws, lock

washers, and flat washers).

2. Align the two holes in the mounting bracket with the holes

on the load end side panel.

3. Secure the bracket and switch to the washer with two 1/420 fasteners (hex head cap screws, lock washers, and flat

washers).

2–32

Page 49

7900 Floor Loading Cart Washer

#10-32 FASTENERS

(4 PLACES)

DRYER DUCT

Detergent and Rinse Aid

Dispensers

Objective

Mount the detergent dispenser on the load end side panel (below the control

box) and the rinse aid dispenser to the top of the lower dryer duct.

Installation

Refer to Figure 2–27. Detergent Dispenser.

Figure 2–27. Detergent Dispenser

1. Remove the cover of the detergent dispenser.

2. Align the mounting holes in the back plate with the

threaded holes in the panel.

3. Use two #10-32 fasteners to secure the dispenser in place.

4. Replace the c over.

Figure 2–28. Rinse Aid Dispenser

5. Position the rinse aid pump on the top of the bottom dryer

duct (between the junction box and the top dryer duct) and

align with the holes in the duct.

6. Secure the pump mount to the top of the dryer duct with

four #10-32 fasteners (phillips head screws and lock

washers).

61301604805 2–33

Page 50

Installation

Unload End Indicator Panel

Box

Objective

Mount the indicator panel box on the unload end of the washer.

Installation

Refer to Figure 2–29. Unload End Indicator Panel Box.

Figure 2–29. Unload End Ind icator P anel Box

1. Remove the face plate of the box.

2. Align the mounting ho les in the bac k of the b ox wi th the two

#10-32 threaded holes at the edge of the unload end

barrier panel.

3. Use #10-32 fasteners to secure the box to the panel.

4. Install the face plate.

The box overhangs the panel to permit the routing of its electrical cable.

2–34

Page 51

7900 Floor Loading Cart Washer

PROXIMITY SWITCH

ASSEMBLY

Door Proximity Switches

Objective

Install a proximity switch assembly on both the load and the unload end door

panels.

Installation

Refer to Figure 2–30. Door Proximity Switches.

Figure 2–30. Door Proximity Switches

1. Orient the two ends of the switch assembly as shown in

Figure 2–30 and align with the threaded mounting holes in

the panel.

2. Use three #10-32 fasteners (phillips head screw and lock

washer) to secure the top of the assembly to the middle

panel above and between the doors.

3. Use four #10-32 fasteners (phillips head screw and lock

washer) to secure the bo ttom of the assembly to the middle

panel between the door latches.

4. Route the as sembly’s cables to the junction box on the

service side of the washer:

The load end cables, P3 and P5, connect to the junction

box at J3 and J5, respectively. The unload end cables, P4

and P6, connect to the junction box at J4 and J6,

respectively.

5. Repeat st eps 1 through 4 for the other door assembly.

61301604805 2–35

Page 52

Installation

SUMP

DRAIN VALVE

TO DRAIN

Sump Drain Valve

Objective

Install the motorized sump drain valve assembly.

Installation

Refer to Figure 2–31. Sump Drain Valve.

Figure 2–31. Sump Drain Valve

1. As shown in Figure 2–31, use a hose clamp to attach one

flexib le hose o n the dra in va lve assembly t o the 2" outl et on

the sump.

2. Use a hose clamp to atta ch the hose from the d rain v alve to

the intake on the return pump box.

3. Route the last hose to drain.

2–36

Page 53

7900 Floor Loading Cart Washer

RETURN PUMP

LOW SUCTION

COLLAR

SPLASH COVER

FRONT SUMP

5/16-18

FASTENERS

(2 PLACES)

1/4-20

FASTENERS

(2 PLACES)

COVER

Return Pump

Objective

Attach the return pump to the sump framework.

Installation

Refer to Figure 2–32. Return Pump.

Figure 2–32. Return Pump

1. Slide the low suction collar over the bottom of the return

pump and position the pump in the su mp.

2. Secure the pump to the flange on the front sump cover by

attaching the two ends of the metal strap with 5/16"-18

fasteners (2" hex head cap screws and lock washers) to

the flange.

Figure 2–33. Return Pump

3. Place the two halves of the splash cover around the pump

and secure with two 1/4-20 fasteners (1" hex head cap

screws and nuts).

61301604805 2–37

Page 54

Installation

ADJUSTABLE LEGS

(4 PLACES)

BOLTS

(6 PLACES)

TANK

TANK BASE

Circul ati on Tank Assembly

Objective

Assemble, position, and level the circulation tank.

Installation

Refer to Figure 2–34. Circulation Tank.

Figure 2–34. Circulation Tank

1. Refer to the rough-in drawing and position the tank base at

the correct location.

2. Use the adjustabl e le gs to level the tank.

3. Place the tank on the base so that th e drain flange fits

through the hole in the base and the small holes fit o ve r the

anchoring bolts in the base.

4. Secure the tank to the base with six fasteners (nuts, flat

washers, and lock washers).

2–38

Page 55

7900 Floor Loading Cart Washer

FASTENERS

(4 PLACES)

CIRCULATION TANK

BOTTOM SHELF

W a sh Pum p

Objective

Install the wash pump in the bottom shelf of the tank.

Installation

Refer to Figure 2–35. Wash Pump.

Figure 2–35. Wash Pump

1. Place the pump on the bottom rack of the circulation tank

assembly and align the ho les in the pump with the bolts in

the mounting plate.

2. Secure the pump to the tank with four fasteners (lock

washers, flat washers, and nuts).

61301604805 2–39

Page 56

Installation

DRAIN PIPE

DRAIN VALVE

TO DRAIN

FROM TANK

TO DRAIN

OVE RFLOW FITTI NG

WATER L EVEL

INDICATOR FITTINGS

Tank Drain Valve, Tank

Overflow, and Tank Water

Level Indicator

Objective

Install the motorized tank drain valve assembly, the tank overflow drain, and

the tank water level indicator.

Installation

Figure 2–36. Tank Drain Valve

1. As shown in Figure 2–36, use a hose clamp to attach one

flexible hose to the drain valve assembly and to the 2"

outlet on the wash pump.

2. Use a hose clamp to atta ch the hose from the d rain v alve to

drain.

3. As shown in Figure 2–36, secure the flexible drain hose to

the tank with a hose clamp. Use additional hose to rout e

the overflow to drain.

Figure 2–37. Tank Overflow Drain and Water Level Indicator

2–40

4. Secure the transparent indicator hose to the top and

bottom fittings with hose clamps.

Page 57

7900 Floor Loading Cart Washer

1/4-20 FASTENERS

(4 PLACES)

CIRCULATION TANK

BOTTOM SHELF

Booster Heater Assembly

Objective

Install the booster heater assembly.

Installation

Refer to Figure 2–38. Booster Heater Assembly.

Figure 2–38. Booster Heater Assembly

1. Position the booster heater assembly in the bottom shelf of

the circulation tank and align with the holes in the shelf.

2. Secure the assemb ly to the tank with 1/4-20 f a steners (f our

each 3/4" hex head cap screws, flat washer s , and lo ck

washers).

61301604805 2–41

Page 58

Installation

1/4-20 FASTENERS

(4 PLACES)

CIRCULATION TANK

WASH PUMP

BOTTOM SHELF

RINSE PUMP

Rinse Pump

Objective

Install the rinse pump on the bottom rack of the circulation tank.

Installation

Refer to Figure 2–39. Rinse Pump.

Figure 2–39. Rinse Pump

1. Position the pump on the bottom shelf of the circulation

tank and align with the holes in the bottom of the shelf.

2. Secure the pump to the tank with fasteners (four each hex

head cap screws, lock washers, and flat washers).

2–42

Page 59

Plumbing

7900 Floor Loading Cart Washer

The washer plumbing is designed with a large number of quick-disconnect

joints that enable service personnel to isolate problems and to replace

components easily. When a washer is disassembled at the factory for

shipment to a customer, plumbing sections are removed for efficient packing

and quick assembly at the installation site. All plumbing sections are tagged

at both ends to indicate what the section is connected to. The following

information provides only general descriptions of the completed plumbing.

For details of the plumbing for your site, refer to the drawings provided with

your washer and to the information tagged to each plumbing section.

Stainless Steel Plumbing

Objective

Install the washer’s stainless steel tubing.

Installation

Refer to Figure 2–40. Typical Stainless Steel Plumbing Connector.

Figure 2–40. T ypical Stainless Steel Plumbing Connector

The stainless steel plumbing for the washer consists of the following

sections:

• Return pump to the intake of the circulation tank.

• The circulation tank drain to the wash pump and to the tank drain valve.

• The wash pump to two 2-1/2" sanitary fittings on the front wall, and over

the top of the washer to a 2-1/2" sanitary fitting on the rear of the load

end top panel.

• The inside front wall to the two front wash manifold hoses.

• The inside rear wall to the rear wash manifold hoses.

• The copper fitting near the output of the booster heater two 1-1/4"

sanitary fittings on the front wall, and over the top of the washer to a 11/4" sanitary fitting on the rear of the load end top panel.

• The inside front wall to the two front rinse manifold hoses.

• The inside rear wall to the two rinse manifold hoses.

61301604805 2–43

Page 60

Installation

Black Iron (Steam) Plumbing

Hot Water (Copper)

Plumbing

Objective

Install the steam supply line and the condensate return line.

Installation

The black iron steam plumbing for the washer consists of the following

sections:

• The utility connection to the booster heater, to the circulation tank, and

over the top of the washer to the two dryer heaters.

• Condensate from the dryer heaters to the booster heater and the

circulation tank.

Objective

Install the hot water supply line.

Installation

The copper plumbing for hot water consists of the following sections:

• The utility connection to the intake for the circulation tank and to the

intake of the rinse pump.

• The rinse pump to the booster heater.

• The booster heater to a stainless steel fitting on the front side of the

washer.

2–44

Page 61

7900 Floor Loading Cart Washer

DRAIN HOSE

TANK HOT WATER

FILL PIPE

Cold Water (Copper)

Plumbing

Objective

Install the cold water supply line.

Installation

The copper plumbing for cold water consists of the following sections:

• The utility connection up over the top of the washer to the two

condensers on the unload end top panel.

• The condensers to a connect flexible drain hose, which then connects to

the fitting at the fill pipe of the tank, as shown in Figure 2–41. Secure the

flexible drain hose with hose clamps.

Figure 2–41. Dryer Heater Condensate Feed to Tank

61301604805 2–45

Page 62

Installation

Electrical Wiring

Objective

Make all required electrical wire connections between the electrical

components and the control box and junction boxes.

Installation

1. Route all component electrical cables, including

thermocouple cables, from the control box or junction box

to the appropriate elect rical component.

Refer to Table 2–2 and Table 2–3 for the routings.

2. Connect the cables to the corresponding electrical

component.

Most cables have keyed connectors that plug in and are secured with

threaded fittings. Cables that must be wired to the component are noted in

Table 2–2 and Table 2–3.

NOTE

Attach all solenoid coil housings to their related solenoid valve bodies, as

shown in Figure 2–42.

Figure 2–42. Solenoid Valve Assembly

The actual configuration for your washer may vary from that listed here.

2–46

Page 63

7900 Floor Loading Cart Washer

Table 2–2. Junction Box Cable Connections

Jack Cable P/N Cable Label Destination

J2 61301603973 P1 – P2 Control Box Jack J1

J3 Y960788 P3 – 1PS Load End Proximity Switch

1PS

J4 Y960788 P4 – 2PS Unload End Proximity Switch

2PS

J5 Y960788 P5 – 3PS Load End Proximity Switch

3PS

J6 Y960788 P6 – 4PS Unload End Proximity Switch

4PS

J7 61301603975 P7 – 1LS Retract Limit Switch 1LS

J8 61301603975 P8 – 2LS Extend Limit Switch 2LS

J9 61301603976 P9 –2MV Tank Drain Valve 2MV

J10 61301603988 P10 – 7MTR Exhaust Elbow Damper 7MTR

J11 61301603978 P11 – 6MTR Front Condenser Damper

6MTR

J12 61301603978 P12 – 8MTR Rear Condenser Damper

8MTR

J13 Y960456 P13 – 3SOL Tank Hot Water Solenoid

Valve 3SOL

J14 Y960456 P14 – 4SOL Tank Steam Solenoid Valve

4SOL

J15 Y960456 P15 – 5SOL Booster Heater Steam Sole-

noid Valve 5SOL

J16 Y960456 P16 – 1SOL Front Dryer Steam Solenoid

Valve 1SOL

J17 Y960456 P17 – 8SOL Rear Dryer Steam Solenoid

Valve 8SOL

J18 Y960456 P18 – 2SOL Front Condenser Cold Water

Solenoid Valve 2SOL

J19 Y960456 P19 –9SOL Rear Condenser Cold Water

Solenoid Valve 9SOL

J20 Not used.

J21 Not used.

J22 61301603980 P22 – P22A Unload End Indicator Box

J23 61301603981 P23 – 9MTR Detergent Pump 9MTR

J24 (part of rinse

aid dispenser)

J25 61301603982 P25 – 1E/2E Circulation Tank High and Lo w

J26 61301603983 P26 – 1ACT Floor Tilt Actuator 1ACT

J27 61301603984 P27 – 1DS Washer Compartment Light

J28 Not used.

J29 Not used.

J30 Not used.

P24 – 10MTR Rinse Aid Pump 10MTR

Water Level and Refresh

Probes

1DS

61301604805 2–47

Page 64

Installation

Table 2–3. Control Box Cable Connections

Jack Cable P/N Cable Label Destination

J1 61301603973 P1 – P2 Junction Box Jack J2

J31 61301603985 P31 – 1TC Circulation Tank Thermocou-

ple 1TC

J32 61301603985 P32 – 2TC Front Dryer Thermocouple

2TC

J33 61301603985 P33 – 3TC Rear Dryer Thermocouple

3TC

J34 61301603985 P34 – 4TC Rinse Water Thermocouple

4TC

J35 Not used.

J36 61301604134 P36 – 1MTR Wash Pump 1MTR

J37 61301603987 P37 – 2MTR Front Dryer Blower 2MTR

J38 61301603987 P38 – 3MTR Rear Dryer Blower 3MTR

J39 61301603988 P39 – 4MTR Manifold Drive Motor 4MTR

J40 61301603989 P40 – TTransformer T

J50 61301603976 P50 – 1MV Sump Drain Valve

J51 P51 – JB2 Dispenser Float Switch Junc-

tion Box

J53 P53 – 3S Emergency Off Switch 3S

J55 P55 – 11SOL Rinse Hot Water Solenoid

Valve 11SOL

J58 P58 – 14 MTR Return Pump 14 MTR

J59 P59 – 5PS Manifold Drive Motor Monitor

(Proximity Switch)

J60 P60 – 15 MTR Rinse Pump 15MTR

2–48

Page 65

Install Components on the Inside of the Washer

REAR DRYER

DUCTS

MOUNTING PLATE

This section provides instructions for installing equipment on the inside of

the washer. The procedures are presented in a recommended order. Refer

to the following sections.

•“Rear Dryer Ducts” on page 2-49

•“Drive Chain Tension Idlers and Idler Bearings” on page 2-51

•“Chain Drive Assembly” on page 2-52

•“Spray Manifold Supports and Manifold Assembly” on page 2-54

•“Manifold Cover and Spray Guard, Manifold Guard Tubes, Wash Cart

Tubes” on page 2-56

•“Emergency Stop Switch Cables” on page 2-58

7900 Floor Loading Cart Washer

Rear Dryer Ducts

Objective

Attach the two rear interior ducts to the rear wall of the washer and to the

cutouts in the ceiling. Attach the mounting plate between the dryer ducts.

Installation

Figure 2–43. Interior Dryer Ducts

1. Inside the washer, apply silicone sealant to the two 18" x 7-

1/2" rectangular cutouts in the top of the washer

compartment.

61301604805 2–49

Page 66

Installation

2. Position one of the dryer ducts on the wall and align the

mounting holes with those in the compartment wall and

ceiling.

3. Secure the duct to the wall with eight #10-32 fasteners

(1/2" phillips head screws, lock washers, and flat washers).

4. Secure the duct to the ce iling cutouts with nine #10-32

fasteners per cutout (1/2" phillips head screws, lock

washers, and flat washers).

5. Repeat steps 2 through 4 for the o ther duct.

6. Install the mounting plate between the two dryer ducts.

Secure to the dryer ducts and to the top panel with seven

#10-32 fasteners.

2–50

Page 67

7900 Floor Loading Cart Washer

Drive Chain Tension Idlers

and Idler Bearings

Objective

Install the following components inside the washer compartment:

• Four drive chain tension idlers

• Two idler bearings

Installation

Refer to Figure 2–44. Drive Chain Idler and Idler Bearing.

Figure 2–44. Drive Chain Idler and Idler Bearing

1. Mount the f our driv e cha in tension i dlers , one on eith er side

of the compartment and two in the middle. The front drive

chain tension id ler is atta ched to the w asher pan el, the re ar

idler is attached to the moun ti ng bracket between the two

dryer ducts, and the middle idlers are attached to either

side of the center mounting bracket.

Secure each with four 1/4-20 fasteners (3/4" hex head cap

screw and lock washer).

2. Mount the two idler bearings for the manifold drive shaft at

the load end of the rear side panel and of the front side of

the center mounting bracket. Secure each with three 1/420 fasteners (1" hex head cap screw, loc k n ut, loc k w asher,

and flat washer).

61301604805 2–51

Page 68

Installation

Chain Drive Assembly

Objective

Install the drive shaft, drive chains, and push rod that comprise the chain

drive assembly.

Installation

Refer to Figure 2–45. Chain Driv e Assem bly.

Figure 2–45. Chain Drive Assembly

2–52

1. Insert the drive shaft key into the keyway in the spray

manif old drive motor that you in sta ll e d previously.

2. Mount the front drive shaft seal to the inside of the upper

corner of the load end side panel, opposite the flange

bearing that you installed previously.

a. Position the seal so its rubber side is against the panel.

b. Secure in place with #10-32 fasteners (3/8" pan head

screw and lock washer).

3. Insert, but do not fasten, the motor and idler ends of each

shaft assembly into the shaft coupling.

4. Hang the two push rod/chain ass emblies from the shaft

assembly.

5. Fit the idler end into the idler bearing that you installed

previously.

Page 69

7900 Floor Loading Cart Washer

6. Extend the moto r e nd through the seal a nd fl an ge bearing,

and then engage the key (installed in step 1) with the

shaft’s keyway.

7. Rotate the idler end of the shaft until its sprocket key is in

alignment with the sprocket key at the shaft's motor end.

8. Secure the shaft ends to the sha ft coupling with two #10-32

bolts and jam nuts.

9. Adjust the proximity switch so that the gap between the

switch an d the se nsin g colla r on the driv e sh af t is less t han

or equal to 2 mm.

10. Use #10-32 f asteners (f ou r each 1/4" pan head scre ws and

lock washers) to attach the drive coupling guard to the

motor’s mounting fixture.

NOTE

You can wait until the operation of the motor has been checked by Product

Support personnel before installing the drive coupling guard.

11. Insert the ends of the push rod chain assembly into the

push rod sleeve.

12. Fit the chains onto their r ela ted sprockets at the driv e sha ft

and at the drive chain tension idlers that you installed

previously.

Make sure the ends of the push rod ar e seated on

matching sprocket teeth.

13. Adjust the chain tensi on so there is no more tha n 1" of pla y

in either line.

You can loosen a tension idler’s 3/8-16 bolt to permit

move m ent of it s sprocket. Turning the 1/4-20 adjustmen t

bolt repositions the sprocket, thereby increasing or

decreasing chain tension.

14. Repeat steps 2 through 11 for the rear chain drive

assembly.

61301604805 2–53

Page 70

Installation

Spra y Manifold Supp orts and

Manifold Assembly

Objective

Install the three spray manifold supports, one on either side of the washer

compartment and one in the middle, and then install the two spray manifold

assemblies.

Installation

Refer to Figure 2–46. Spray Manifold Support.

Figure 2–46. Spray Manifold Support

2–54

1. Seat the ends of the outside ( front and rear ) spra y manif old

supports in the uppermost captive brac k ets that are welde d

to the inside of the end panels.

2. Apply silicone se alant to f our #10- 32 fa steners, t hen secure

the mounting angle of the front support to the front side

panel.

3. Use four #1 0- 32 fasteners to secure the moun ti ng ang le of

the rear support to the mounting plate between the two

dryer ducts.

4. Attach 1/4-20 fasteners to the captive brackets to ensure

the ends of the spray manifold supports remain in place.

Page 71

Figure 2–47. Spray Manifold Assembly

7900 Floor Loading Cart Washer

5. Attach two rinse an d tw o w ash hose conn ectors to th e inl et

port s in the front side panel. Repeat for the rear panel.

When tight, all c onnectors should point toward the unload

end of the unit at an angle of approximately 45 degrees.

6. Set the two spray manifolds on the manifold supports.

7. Seat the ends of the middle spray manifold support in the

uppermost captive br ack ets that ar e welded to the in side of

the end panels.

8. Attach 1/4-20 fasteners to the captive brackets to ensure

the ends of the spray manifold supports remain in place.

9. Connect the manif olds at th e top with tw o stringer s in each

compartment. Orient the stringers so that their push pins

are directed toward the load end. Use 5/16-18 fastener s to

secure the stringers to the manifolds.