Page 1

TM

8-6515-008-24&P

UNIT,

DIRECT

MAINTENANCE

(INCLUDING

SUCTION

TECHNICAL

SUPPORT,

REPAIR

SPECIAL

APPARATUS,

MODEL

MANUAL

AND

TOOLS

6003

GENERAL

MANUAL

PARTS

LIST)

SURGICAL

SUPPORT

AND

APPROVED

HEADOUARTERS,

v

FOR

6515-01-246-1938

PUBLIC

RELEASE;

DISTRIBUTION

DEPARTMENT

OF

IS

UNLIMITED

THE

9

SEPTEMBER

ARMY

1994

Page 2

SAFETY

STEPS

TO

FOLLOW

IF

SOMEONE

IS

THE

Do

not

If

possible,

If

you

person

other

Send

After

cannot

insulating

for

the

try to

turn

to

safety

help

injured

VICTIM

pull or

off

the

turn

as

off

using a dry

material.

soon

person

OF

grab

the

ELECTRICAL

the

electrical

electrical

as

possible.

is

individual.

power.

power,

wooden

free

pole

of

contact

SHOCK

pull,

or a dry

push,

with

rope,

the

source

or

or

lift

the

some

of

electrical

immediately

shock,

start

move

artificial

the

resuscitation.

person

a

short

distance

away

and

Page 3

TM

8-6515-008-24&P

Throughout

time

to

read

Procedures

this

manual

these.

which

They

must

are

are

be

observed

WARNINGS,

there

to

WARNING

to

CAUTIONS,

protect

avoid

you

and

personal

and

NOTES.

the

equipment.

injury,

and

even

Please

loss

of

take

life.

Procedures

which

must

Essential

be

equipment,

observed

information

to

long-term

or

avoid

that

damage

health

should

equipment,

to

hazards.

remembered.

be

destruction

of

Page 4

TM

8-6515-008-24&P

»

»

»

ELECTRICAL

Severe

with

alert

The

caused

assigned

should

The

the

injury

live

to

the

electrical

current

consider

physiological

following

or

death

electrical

dangers

to

live

circuits.

parameter

to

flow

electrical

all

effect

factors:

can

result

Medical

of

exposed

that

is

called

circuits,

voltages

current

of

AND

ELECTRONIC

HAZARDS

when

circuits,

injures

VOLTAGE.

of

30

any

Equipment

terminals,

and

kills

power

or

flowing

supplies, and

more

part

Voltage

to

through

of

your

Repairers

power

is

CURRENT;

ratings

be

hazardous.

the

body

transmission

human

comes

must

be

panels,

the

force

are

normally

body

especially

and

in

contact

the

like.

that

lines.

related

is

You

to

2

»

Alternating

phenomenon

current

skin

»

The

through

collapse,

The

path

of

The

magnitude

duration

The

frequency

The

susceptibility

The

repeated

voltage source,

and

effect

shocks.

current

of

away

the

from

current

of

body;

unconsciousness,

the

current

of

the

of

of

tends

“skin

internal

prolonged

a

through

the

current.

voltage

voltage

the

damage

of

concentrate

to

effect.”

more

the

becomes

shock

The

body

more

current

death.

or

the

body.

discharge

or

alternating

if

heart

your

to

near

higher

likely

organs.

the

the

severe

flow

current.

from

body’s

the

frequency

current

the

with

cause

can

that

the

tend

will

length

severe

causes

current

surface

the

of

to

time

of

from

or

in

that

burns,

flow.

near

flows

it

current

and

because

alternating

flow

internal

of

the

the

Page 5

TM

8-6515-008-24&P

TECHNICAL

NO.

8-6515-008-24&P

You

can

procedures,

Changes

Equipment

Army

furnished

MANUAL

(INCLUDING

help

please

to

Publications

Technical

Medical

directly

UNIT,

improve

let

Materiel

to

you.

DIRECT

SUPPORT,

MAINTENANCE

REPAIR

SUCTION

this

manual.

us

know.

and Blank

Publications)

Agency, ATTN:

Mail

AND

GENERAL

MANUAL

PARTS

APPARATUS,

MODEL

AND

6003

SPECIAL

SURGICAL

6515-01-246-1938

If

you

find

any

mistakes

your

memorandum,

Forms),

located

or

in

SGMMA-M,

DA

Form

the

back

Frederick,

DEPARTMENT

WASHINGTON,

SUPPORT

TOOLS

or

if

you

DA

Form

2028-2

of

(Recommended

this

manual

MD

21702-5001. A reply

HEADQUARTERS

OF

DC 9 SEPTEMBER

LIST)

know a way

2028

(Recommended

Changes

to:

Commander,

THE

to

improve

ARMY

U.S.

will

1994

to

be

CHAPTER

Section

CHAPTER

Section

Approved

HOW

TO

1.

INTRODUCTION

I.

General

Il.

Equipment

Ni.

Principles

2.

OPERATING

I. © Preparation

|.

Operating

Ni.

Operating

IV.

Vi.

V.

Operation

Cleaning,

Operation

for

public

TABLE

USE

THIS

MANUAL.

Information

Description

of

Operation

INFORMATION

for

Operation

Information

Instructions

of

Auxiliary

Disinfecting,

under

Unusual

release;

OF

and

Data

.......

AND

Equipment

and

Sterilizing

Conditions.

distribution

is

unlimited.

CONTENTS

.

INSTRUCTIONS

.

Procedures

......................,.............,

1-3

1-7

Page 6

TM

8-6515-008-24&P

CHAPTER

3.

UNIT

LEVEL

MAINTENANCE

Section

CHAPTER

Section

APPENDIX

È

Il

Ill.

IV.

V.

VI.

Vil.

Vill.

IX.

X.

4.

I

Il.

A.

B.

ο.

D.

E.

General

Service

Lubrication

Preventive

Operational

Information.

Upon

Receipt

Instructions . ....,....... s «

Maintenance

Testing).

TOUDIGSHOOTAG,

Circuit

Repalr

Voltage:

Storing

DIRECT

General

Maintenance

Descriptions

Procedures...

Convérsion.Instructions...

and

Shipping

SUPPORT

Information,

Procedures.

RERERENCES

MAINTENANCE

COMPONENTS

EXPENDABLE

REPAIR

PARTSANDSPECİALTOOLSLIST.....................

..................................................

of

Equipment

Checks

Ου

inc

ccs

so ie

and

Adjustments

Procedures

AND

GENERAL

.…

....

..

.….......,,

..

212.60 & emare a 18 e TE

ALLOCATION

OF

END

ITEM

AND

DURABLE

......................................

s 6 6 sur

and

Services

erman

....................................

..............................

sz

A

A

+3 2 à à smic à à à

Ὁώωσ

à

8 4 6 à à

16 É É

ο

pirate

ο

IEA

нежнее

.......................................

SUPPORT MAINTENANCE

mate

de

carbone

ο

address

ου

RR E EATER

CHART

AND

BASIC ISSUE

SUPPLIES

AND

ITEMS

MATERIALS

LIST

...............

LIST

8 3 8 à à 3-2

e 6 3-8

»

# € +

ο

πο.

à 5 nt

ο

ERE

PIRA

ω

ων

ων

ων εν

............

00002

o

3-11

3-14

3-23

3-24

3-1

3-2

3-2

3-6

4-1

4-1

A-1

B-1

C-1

D-1

E-1

GLOSSARY

INDEX

Figure

No.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

2-1

2-2

2-3

2-4

2-5

és

SaD

ου

Suction

apparatus . .

Components

Manufacturer

Operating

NWaming

Voltage

Cardboard

instructions

impRnt....

conversion

instruction

μη

Front

panel

1110111109 . .

Ms

Installation

Assembling

ο

χα ο ο

PVC

06 베 0196

tubiný

1009

of

the

CONAGGHONS . .

5

ga

6 E 8 5

LIST

OF

р

ο

E E USA

ILLUSTRATIONS

ο

RS

νο

ο

ρα

Title

ο

and

accessories

data

plate................................................

décal

οκ

decal...............................................

tag

ται

οσα

bacteria

filter

cap and

μμ

...........................................

αμ

κ

ον ο ον

..............................................

ο

ο

.

ο

erro

ο

es 6 dus

αν

à

.............................................

float

assembly

à

à à à 5 à aan

«κκ

...................................

à

à à à à 8

ο

ο

LAGUNA

αν

ενα

à 3 à 2 à mac

ο

Ευ

ο

6

masraneie à à 5 ÿ à Ed

αυ.

3 6 4

RER

GERE

GLOSSARY-1

TO

INDEX-1

REDE

RE

04

Ae rn

Be TE

NÆSE

TE

52465

ο.

ESR

зачать

Page

1-1

1-3

1-5

1-5

16

1-6

1-6

1-6

1-7

1-7

2-1

2-2

2-2

2-2

2-3

Page 7

TM

8-6515-008-24&P

Figure

2-6

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

E-1

E-2

E-3

E-4

E-5

E-6

No.

Title

Controls

Wiring

Schematie.diagrami:.......L------

Schematicdiagiam

PE

Swen

Suction

Bacteria

Control

Vacuumipumpiz

ος

Suction

Control/pump

Collection

Vacuum

Valve

Li

and

diagram...

ornentatlona

and

filter

circuit

πρ

apparatus

bottle

pump

and

manifold

mi

ye o Day

indicators

...

ON

POB":

pressure

PCB.

module

valves

Essa

components . .

components

assembly

Components:

assembly

. >

«-rororre

oros

ar

dini

..

components.

320

components

e

LIST

OF

TABLES

0A

altar

one

lo

a

nan

uao

LARE

4152

................................

ei

o

de

ο ο ο

Al

el

mora

ta

ET

ET

eine

OI

eo

Ria

e

eye

een

EP

EE

.

55

es

ce

.

..

...

©

Page

2-3

3-11

3-11

3-12

3-13

3-15

3-17

3-18

3-19

3-20

3-22

.

Е-2

.

Е-6

.

E-8

E-10

E-12

E-14

Table

1-1

1-2

1-3

2-1

3-1

3-2

3-3

3-4

No.

Nomenclature

Miscellaneous

Зее

Peak

Operator

Repairer

Operator/user

Medical

preventive

preventive

troubleshooting................

Equipment

Title

cross-reference

characteristics . . z

maintenance

maintenance

Repairer

list

.

checks

checks

troubleshooting

and

and

services

services.

Sia

.......................

.......................

A

Page

1-2

.

14

1-4

2-5

3-3

3-5

.

3-8

.

3-9

Page 8

TM

8-6515-008-24&P

HOW

This

manual

capabilities,

scribes

must

beginning a maintenance

The

lowed

Use

general subject

subjects.

Multiple

manual.

names

equipment.

how

familiarize

manual

by

the

of

provides

functions,

to

set up,

is

arranged

appendixes, a glossary,

table

of

area

figures

Words

that

components

TO

all

and

operate,

yourself

contents

needed.

and

tables

are

or

USE

the

characteristics

with

task.

by

chapters,

to

help

The

are

both

words

THIS

information

test,

the

entire

an

locate

index

provided

capitalized

that

MANUAL

needed

of

and

repair

manual

sections,

index,

you

the

will

for

and

and

chapter

help

your

will

to

this

equipment.

the

before

and

DA

or

locate

ease

in

quotation

actually

understand

equipment.

operating

paragraphs

Forms

section

more

in

using

marks

see

2028-2.

for

specific

on

It

You

this

the

the

de-

or

fol-

the

are

Chapter 3 provides a systematic

the

equipment.

they

become a major

habit

and

Only

allocation

specified

training;

of

doing

anything

perform

for

test,

In

the

wrong

maintenance

chart

for

higher

measurement,

this

way,

problem

checks

will

your

levels

level

small

causing

and

services

be

detected

functions

of

maintenance

of

and

method

defects

maintenance.

diagnostic

of

can

the

equipment

in

the

quickly.

specified

frequently

inspecting

be

detected

same

Maintenance

equipment;

the

in

require

order

and

servicing

early

before

to

fail.

Make

each

maintenance

functions

additional

tools.

or

a

time

Page 9

TM

8-6515-008-24&P

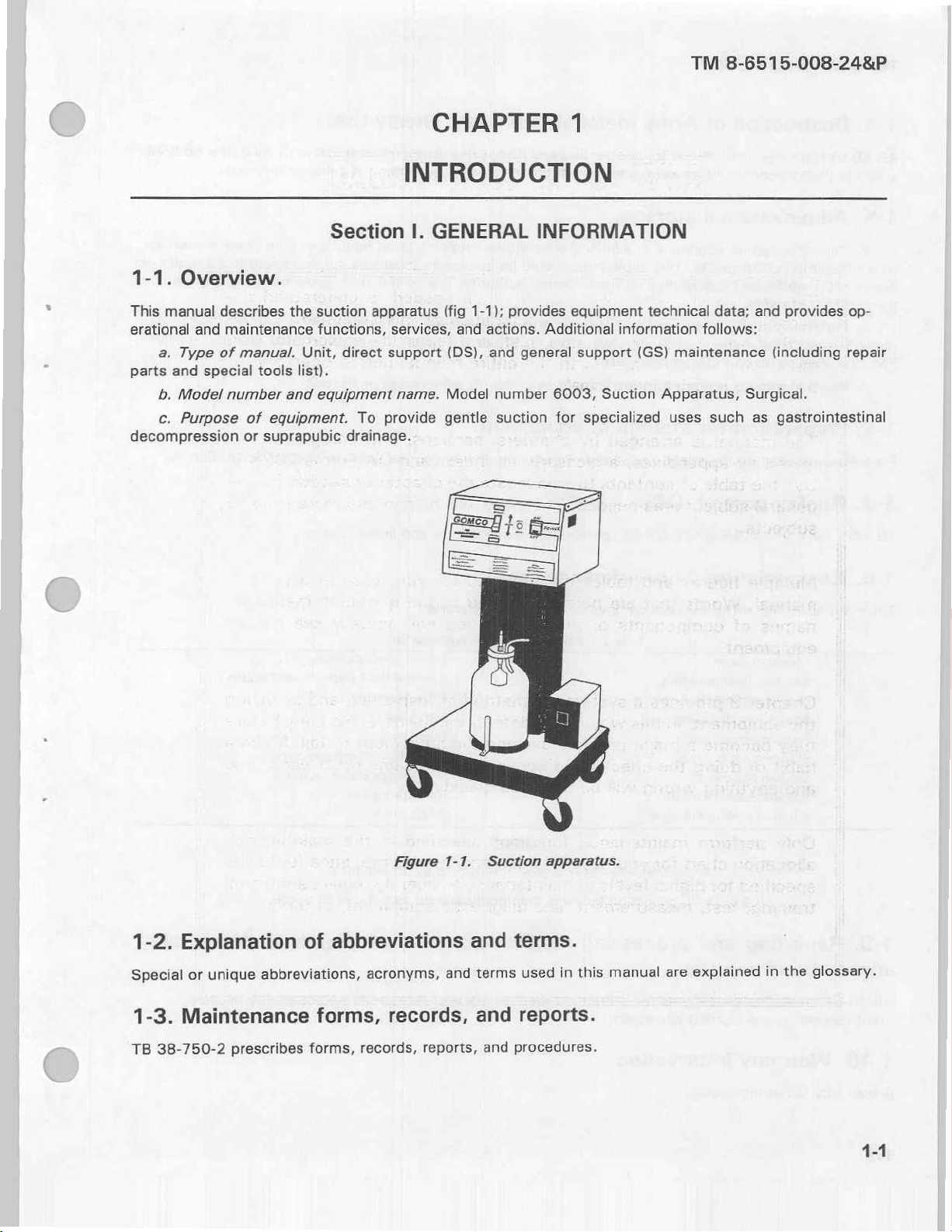

1-1.

This

erational

parts

decompression

Overview.

manual

and

a.

Type

and

special

b.

Model

c.

Purpose

describes

the

maintenance

of

manual.

tools

number

and

of

equipment.

or

suprapubic

Section

suction

functions,

Unit,

direct

list).

eguipment

drainage.

apparatus

services,

support

name.

To

provide

CHAPTER

INTRODUCTION

I.

GENERAL

(fig

1-1);

and

actions.

(DS),

and

Model

gentle

INFORMATION

provides

Additional

general

number

suction

6003,

for

1

eguipment

information

support

Suction

specialized

technical

(GS)

maintenance

Apparatus,

uses

data;

and

follows:

Surgical.

such

as

provides

(including

gastrointestinal

op-

repair

1-2.

Special

1-3.

TB

38-750-2

Explanation

or

unique

abbreviations,

Maintenance

prescribes

Figure

of

abbreviations

acronyms,

forms,

forms,

records,

records,

1-1.

and

and

reports,

Suction

terms

and

and

apparatus.

terms.

this

in

used

reports.

procedures.

manual

explained

are

in

the

glossary.

Page 10

TM

8-6515-008-24&P

1-4.

AR 40-61

series

1-5.

of

within

Destruction

contains

provides

Administrative

a.

Place

maintenance

the

time

maintenance

b.

Perform preventive

placing

PMCS

1-6.

Procedures

1-7.

TB

Army

to

ensure

c.

Inside

Preparation

Quality

740-10/DLAM

periodic

the

suction

effort

factors

records.

equipment

its

storage

to

prepare

of

instructions

information

apparatus

exists.

determined

in

operational

is

preferred

for

the

suction

control

4155.5/AFR

Army

materiel

for

destruction

and/or

storage.

in

administrative

This

equipment

by

maintenance

administrative

readiness.

for

equipment

storage

apparatus

(QC).

67-43

instructions

should

the

directing

checks

storage.

or

equipment.

for

contains

to

prevent

and

disposal

storage

be

authority.

and

services

When

selected

storing

QC

requirements

enemy

of

Army

on

the

destruction

for

only

in

mission

During

(PMCS)

equipment

for

administrative

or

shipping

medical

short

readiness

the

listed

is

are

listed

and

procedures.

use.

materiel.

of

medical

periods

condition

storage

in

removed

storage.

in

of

time

period,

tables

from

chapter

Also,

the

SB

materiel.

when a shortage

within

3-1

24

keep

appropriate

and

3-2

storage,

3,

section

hours

8-75

or

before

perform

X.

1-8.

Table

Nomenclature

1-1

identifies

1-9.

Reporting

Common

Cap

Overflow

Power

Pump

Stainless

Suction

Vacuum

Vacuum

improvement

AR

ment

40-61

prescribes

reports

for

official

name

and

float

protection

switch

cycle

indicator

steel

apparatus

select

setting

A

2800-mL

and

reports.

procedures

the

suction

cross-reference

versus

assembly

indicator

cover

switch

indicator

A

suction

commonly

Table

1-1.

device

apparatus

collection

bottle

processing

submitting

for

apparatus.

list.

used

nomenclatures.

Nomenclature

NOTE

is

also

is

commonly

medical

medical

cross-reference

Official

Cap

Float

Pilot

Cycle

Control/pump

Suction

Selector

White lamp

referred

to

known

materiel

materiel

list.

nomenclature

and

float

assembly

light

lamp

apparatus,

switch

as

an

aspirator.

as a 1-gallon

complaints

complaints

shut

off

module

surgical

and/or

mechanism

cover

bottle.

and/or

quality

>

quality

improve-

1-10.

A

warranty

1-2

Warranty

is

not

applicable.

information.

Page 11

Section

Il.

EQUIPMENT

DESCRIPTION

AND

DATA

1-11.

The

passages

120

incorporates

1-12.

Equipment

a.

The

suction

and

b.

The

c.

The

d.

The

mmHg.

e.

The

f.

The

suction

Component

a.

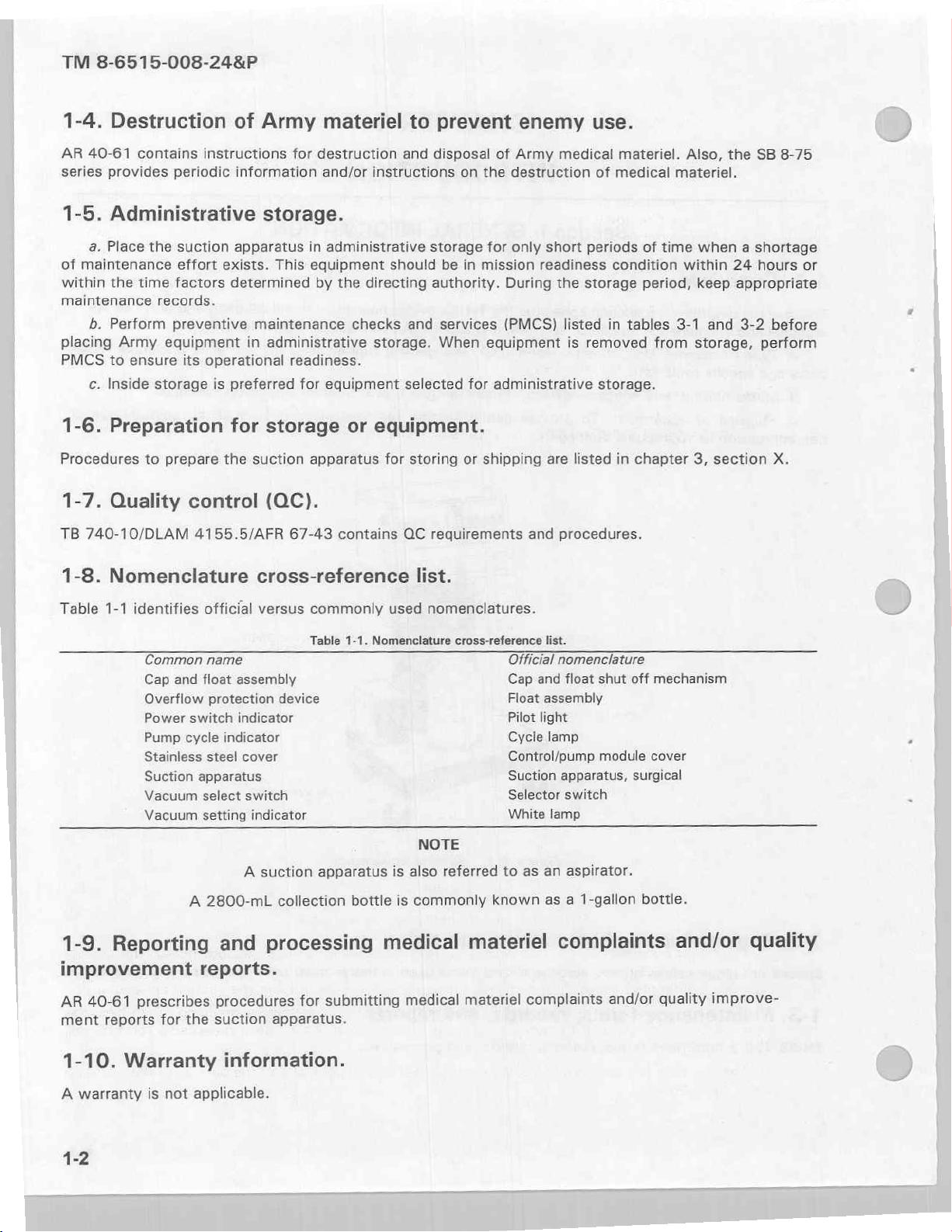

Components

suction

suction

integral

electronic

glass

apparatus

apparatus

connected

apparatus

cart

collection

an

overflow

apparatus

characteristics,

is a self-contained,

removes

control

(fig

to

has

protection

and

1-2).

accumulated

drainage

operates

four

non-marking

system

bottle

can

is

operate

accessory

tubing

marked

device.

capabilities,

fluids

that

from

multiple

casters.

regulates

with

continuously.

descriptions.

CONTROL/PUMP

mobile

empty

graduations

unit

through

into a collection

voltages

Two

the

vacuum

MODULE

and

with

tubing

and

casters

pump

to

2800

features.

an

integral

inserted

system.

frequencies.

include

to

provide

mL

brakes.

and

cart

into

its

designed

a

patient's

preset

cap and

for

indoor

oral

levels

float

use.

or

nasal

of

90

assembly

or

(1)

printed

A

rear

operation.

for

circuit

black

(2)

of

the

(3)

230-volt

plastic

Control/pump

board

handle

Electrical

right

Transformer.

operation.

power

side

UPRIGHT

module.

(PCB),

mounted

of

the

The

BACTERIA

FILTER

ASSEMBLY.

COLLECTION

BOTTLE

ASSEMBLY

Figure

The

and

the

on

cable

assembly.

control/pump

step-down

==

ΓΙ

1-2.

Components

control/pump

operational

the

rear

of

The

module,

transformer,

р

|

|

©

BASE

ASSEMBLY

and

accessories.

module

controls. A stainless

the

module

electrical

is

located

incorporates

provides

power

connected

on

ELECTRICAL

CABLE

—

TRANSFORMER

steel

for

cable

directly

the

right

POWER

ASSEMBLY

the

vacuum

cover

provides a work

moving

assembly,

side

the

hanging

into a receptacle

of

the

pump,

suction

base

assembly,

the

control

surface.

apparatus.

down

from

for

115-volt

is

the

used

1-3

Page 12

TM

8-6515-008-24&P

(4)

Base

operation.

(5)

Upright

for

the

control/pump

electrical

provide

bottle

apparatus.

while

chloride

power

for

storage

b.

Accessories.

(1)

Collection

cap,

and

(2)

Bacteria

The

blocking

(3)

Tubing.

(PVC).

assembly.

assembly.

module.

cable

assembly

of

the

bottle

an

overflow

filter.

filter

has a hydrophobic,

the

flow

of

The

disposable

Each

end

of

The

base

The

upright

The

of

suction

assembly.

protection

The

bacteria

aqueous

the

tubing

assembly

assembly

right

side

of

the

transformer.

apparatus

The

fluids.

tubing

electrical

collection

device.

filter

prevents

microporous

package

includes a graduated

incorporates

is

mounted

the

upright

Cable

bottle

contains a 15-inch

four

assembly

clips

power

assembly

fluid

membrane

size

casters

on

the

mounted

cable

and aerosol

which

connector.

and

base

provides

on

assembly.

consists

filters

and

the

transformer

assembly

cable

the

rear

of

of a 2800-mL

contamination

air

with

72-inch

length

and

provides

clips

the

upright

maximum

of

for

for

glass

of

the

clear

230-volt

support

storing

assembly

bottle,

suction

efficiency

polyvinyl

D

the

1-13.

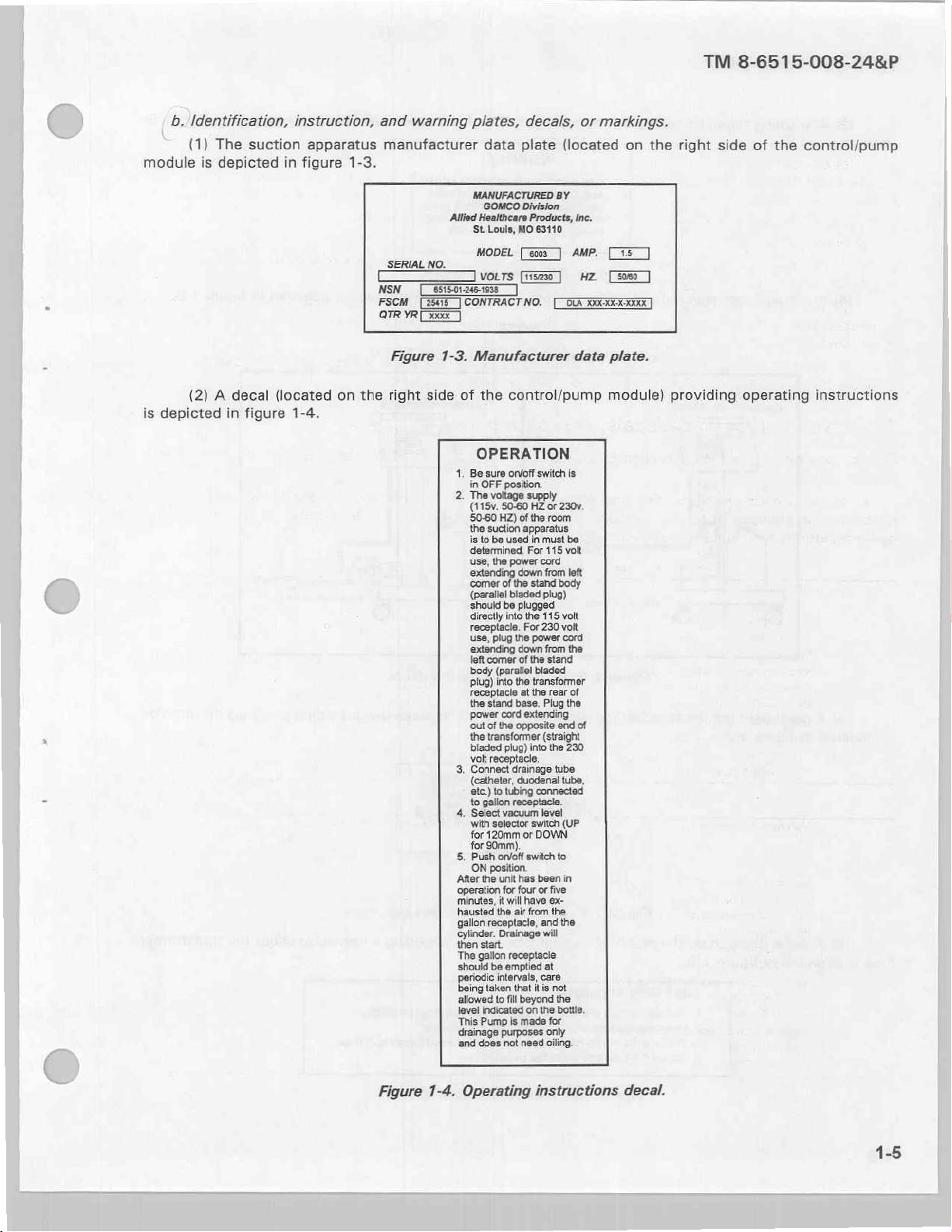

The

suction

miscellaneous

operating/storing

Tabulated

tabulated

apparatus.

a.

Miscellaneous

Dimensions

A

data

characteristics

Height

Width

Depth;

Vacuum

Collection

Bacteria

Dütyeeyelei

Operating/storing

RMI

Temperature

Voltages/frequencies

Vacuum

90-mm

Flow

90-mm

Vacuum

ON

OFF

Vacuum

ON

OFF

data,

provides

characteristics

temperature

.

pump

resistance

bottle

filter

efficiency . . . .

ye

ranges

position

120-mm

rates

position

(air)

position

120-mm

position

pump

cycles,

TIME

TIME

pump

cycles,

TIME

TIME

decals,

miscellaneous

and

and

specifications

os

ranges,

ος

dimensions,

Table

ο

range

capacity

.

e

ula a ll

ranges

Sin

ey

yere

range

.......

..............

90-mm

position

120-mm

position

and

data

characteristics,

specifications.

to

include

and

weights.

1-2.

Miscellaneous

e

enti

세서

년

ee

va

in

a

yim

4.4.1444.

Table

1-3.

Specifications.

plates.

specifications,

Table

1-2

and

operating

characteristics.

83.2

cm

46.4

cm

42.5

cm

19.5

kg

155

to

2800

mL

.

0.3

micron

Continuous

90%

maximum

-17.78°C

115

VAC,

230

VAC,

85.5

to

114

to

0.25

Ipm

0.3

Ipm

2.1

to

19.0

to

3.4

to

19.0

to

and

table

voltages,

(32.75

(18.25

(16.75

(43

Ib)

160

ohms

(particles

(O°F)

to

50/60

or

50/60

Hz

99

mmHg

132

mmHg

2.25

sec

22.0

sec

3.75

sec

22.0

sec

other

1-3

provide a broad

vacuum

in)

in)

in)

in

air)

48.9°C

Hz

information

ranges,

(120°F)

for

range

flow

the

of

rates,

Page 13

b.

module

Identification,

(1)

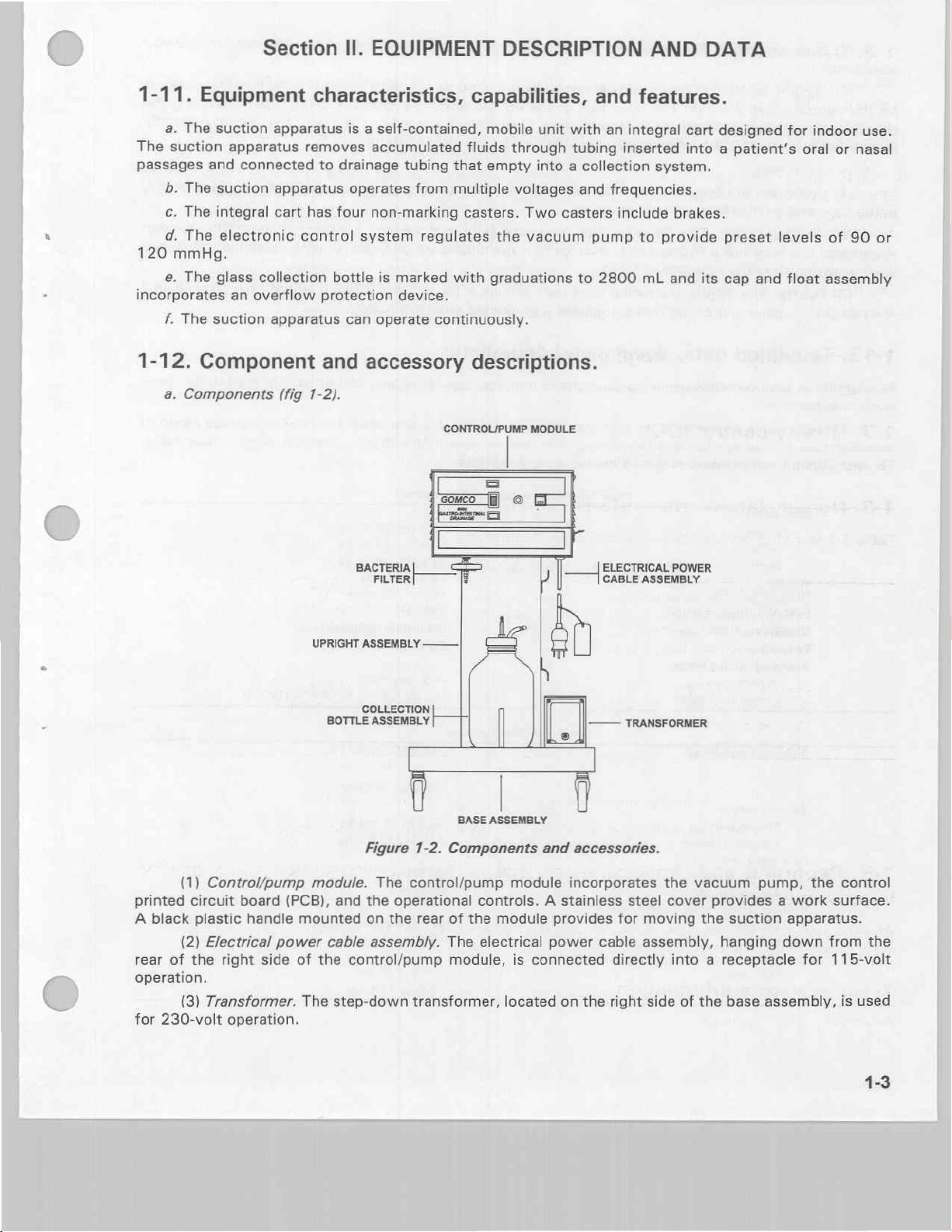

The suction

is

depicted

in

instruction,

apparatus

figure

1-3.

and

warning

manufacturer

Allied

plates,

MANUFACTURED

St

decals,

data

plate

GOMCO

Division

Healthcare

Products,

Louis,

MO

63110

BY

or

markings.

(located

Inc.

on

the

TM

right

8-6515-008-24&P

side

of

the

control/pump

is

depicted

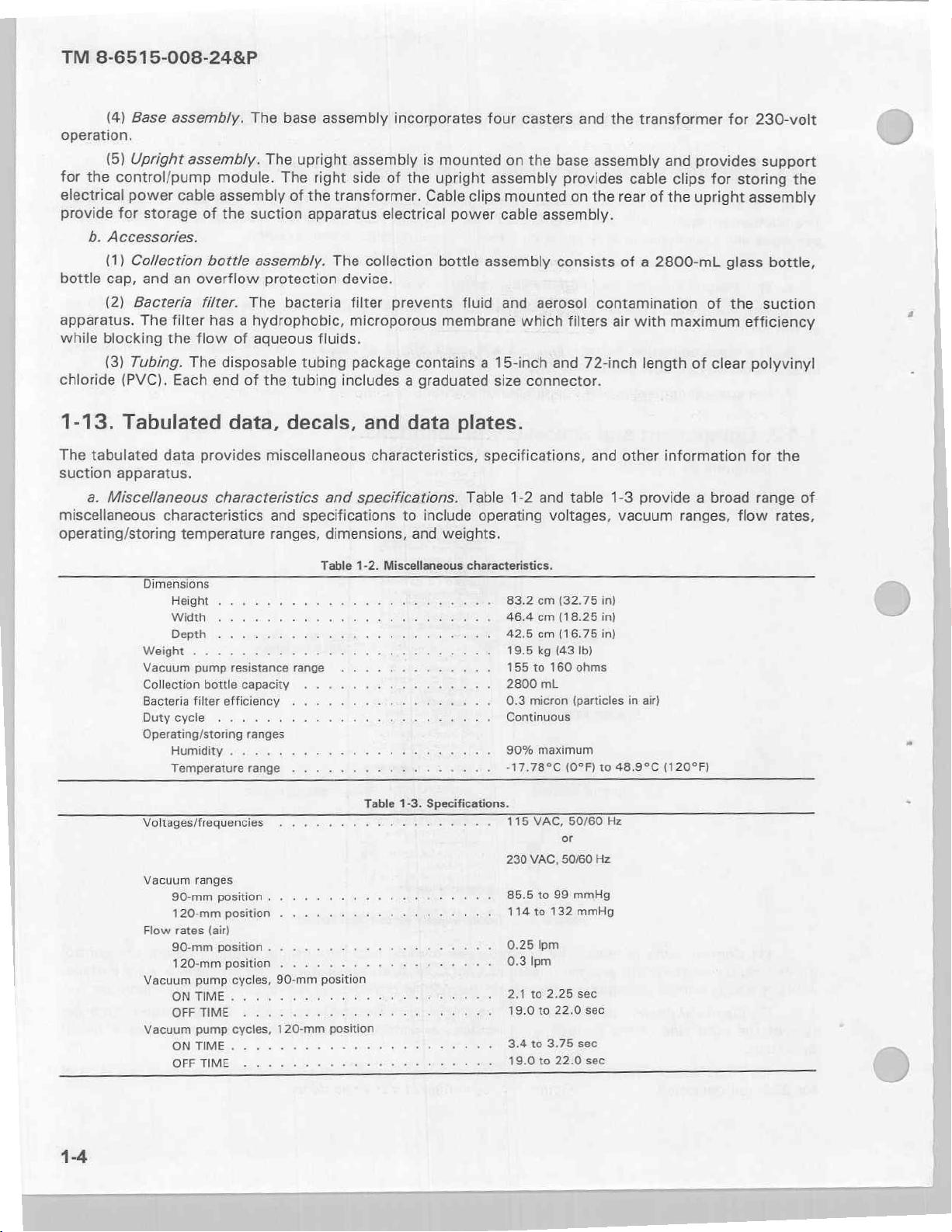

(2) A decal

in

figure

(located

1-4.

on

SERIAL

NSN

FSCM

QTRYR

Figure

the

right

NO.

[OE

]CONTRACT

DE]

1-3.

side

of

1.

2.

MODEL

VOLTS

[EEE]

NO.

Manufacturer

the

control/pump

OPERATION

Be

sure

onloff switch

in

OFF

position.

The

voltage

(115v.

50-60

the suction

is

determined.

use,

‘comer

(parallel

should

directly

plug)

receptacle

the

power

‘out

the

bladed

volt

Connect

“

supply

50-60

HZ

HZ)

to

be

the

into

stand

of

transformer

receptacle.

or

of

the

room

apparatus

used

in

must

For

115 volt

power

cord

ing

down

from

of

the

stand

bladed

plug)

be

plugged

into

the

115

the

transformer

at

the

base.

Plug

cord

extending

the

opposite

(straight

plug)

into

drainage

AMP,

НЕ

data

is

230v.

be

left

volt

rear

of

the

end

of

the

230

tube

TEE)

plate.

module)

providing

operating

instructions

Figure

i

with

selector

for

120mm

5.

Push

on/off

ON

position.

After

the

unit

‘operation

for

minutes,

it

hausted

gallon

cylinder.

then

The

should

periodic

being

allowed

level

This

drainage

and

1-4.

will

the

air

receptacle,

Drainage

start.

gallon

receptacle

be

emptied

intervals,

taken

that

to

fill

indicated

Pump

is

purposes

doss

not

Operating

i

switch

(UP

or

DOWN

switch

to

has

been

in

four

or

five

have

ex-

from

the

and

the

will

at

care

it

is

not

beyond

the

on

the

bottle.

made

for

only

need

oiling.

instructions

decal.

1-5

Page 14

TM

8-6515-008-24&P

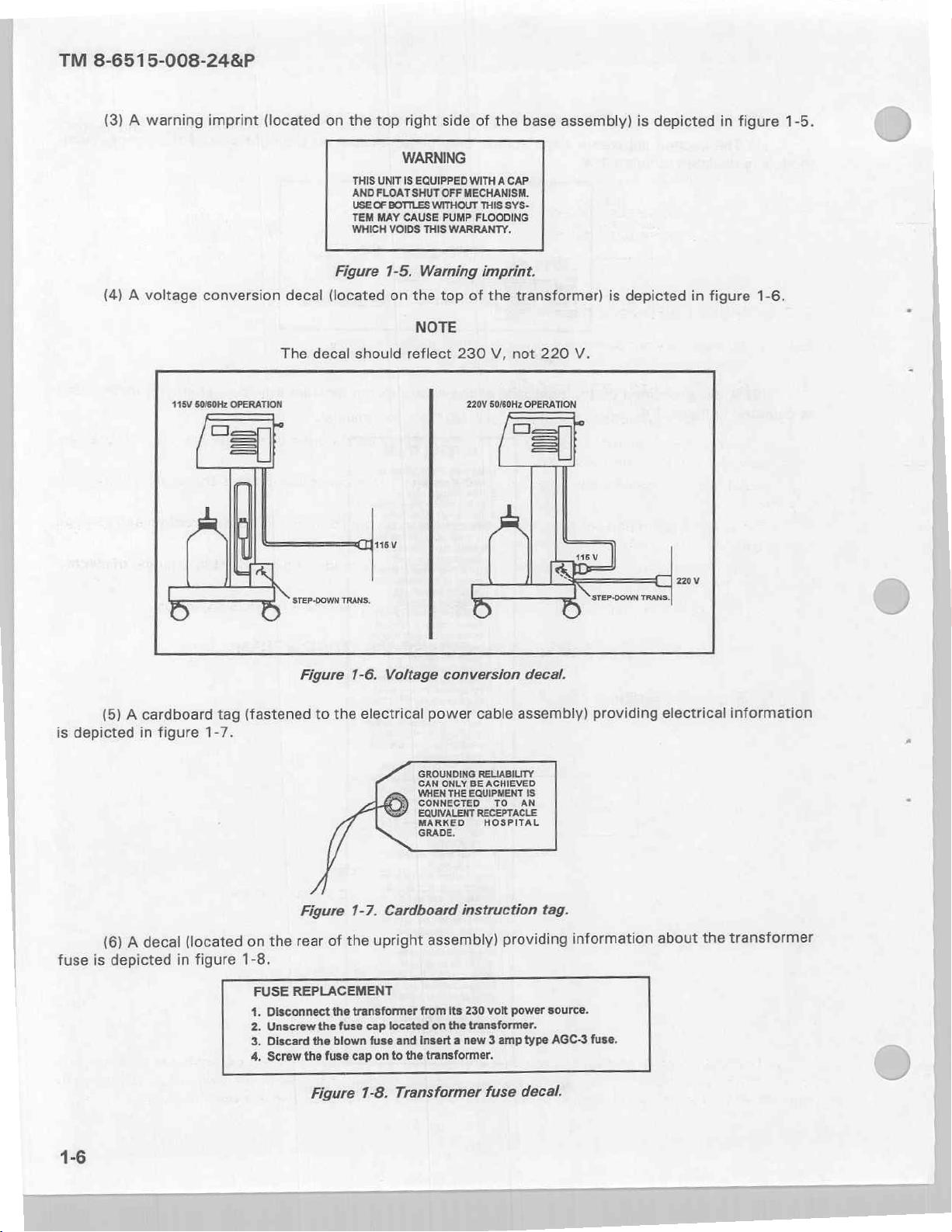

(3) A warning

(4) A voltage

115V

imprint

conversion

50/60Hz

OPERATION

=]

(located

decal

The

‘STEP-DOWN

on

Figure

(located

decal

TRANS,

the

top

WARNING

THIS

UNIT

AND FLOAT

USE

TEM

WHICH

should

IS

OF

BOTTLES

MAY

CAUSE

VOIDS

1-5.

on

fsv

right

side

EQUIPPED

SHUT

OFF

WITHOUT

PUMP

THIS

WARRANTY.

Warning

the

top

NOTE

reflect

of

the

base

WITH A CAP

MECHANISM.

THIS

SYS-

FLOODING

imprint.

of

the

transformer)

230

V,

not

220V

50/60Hz

OPERATION

220

assembly)

is

V.

sv

‘STEP-DOWN

is

depicted

depicted

TRANS.

in

in

figure

figure

1-5.

1-6.

(5) A cardboard

is

depicted

(6)

fuse

is

depicted

tag

in

A

figure

decal

1-7.

(located

in

figure

Figure

(fastened

Figure

rear

the

on

1-8.

FUSE

REPLACEMENT

4.

Disconnect

2.

Unscrew

3.

Discard

4,

Screw

the

to

the

the

of

the

the

fuse

the

blown

fuse

Figure

1-6.

Voltage

electrical

1-7.

Cardboard

upright

transformer

cap located

fuse

and

cap

on

to

the

1-8.

Transformer

conversion

power

GROUNDING

CAN

WHEN

CONNECTED

EQUIVALENT

MARKED

GRADE.

assembly)

from

insert a new 3 amp

transformer.

ONLY

BE

THE

EQUIPMENT

instruction

its

230

on

the

transformer.

cable

RELIABILITY

ACHIEVED

TO

RECEPTACLE

HOSPITAL

providing

volt

fuse

decal.

assembly)

IS

AN

tag.

power

source.

type

AGC-3

decal.

providing

information

fuse.

electrical

the

about

information

transformer

Page 15

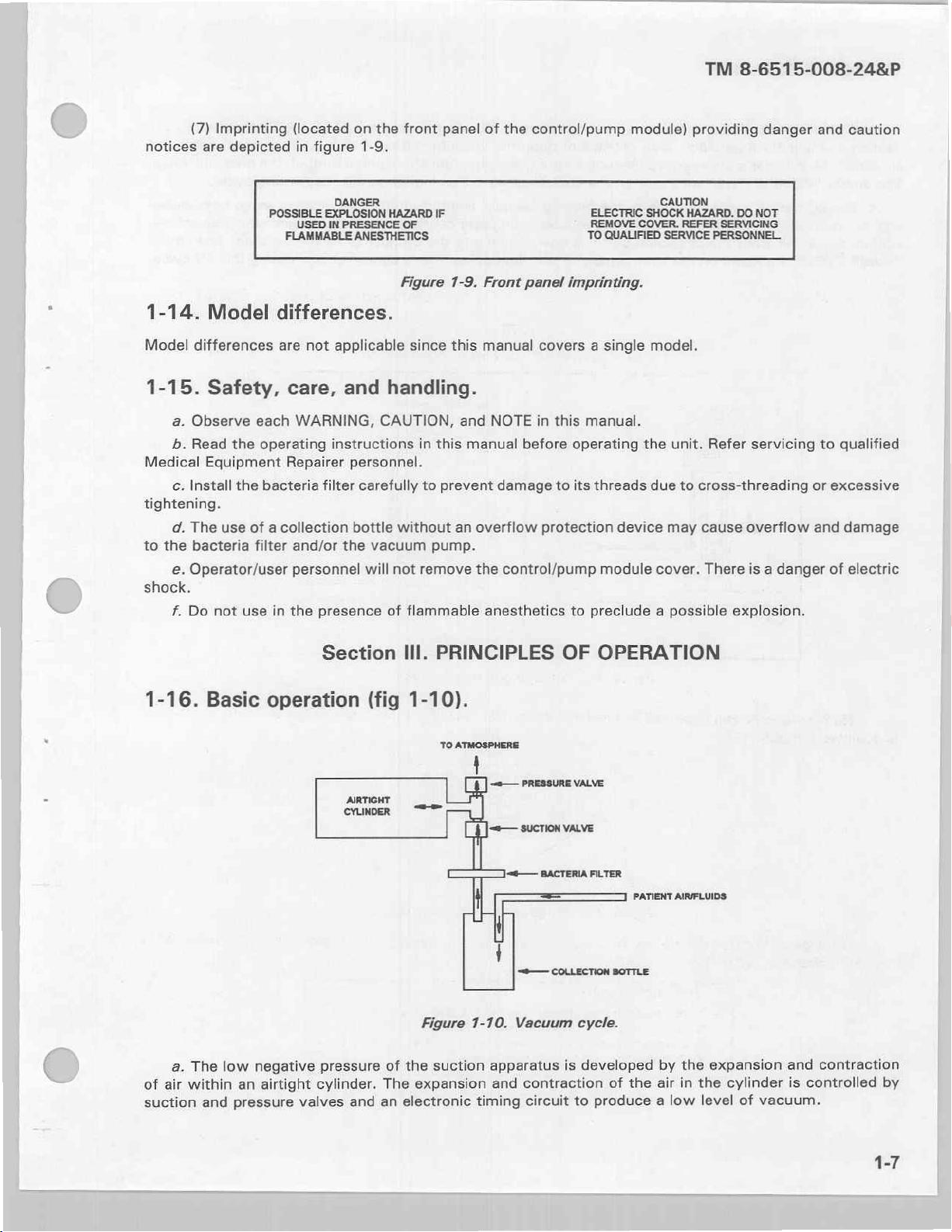

notices

(7)

Imprinting

are

depicted

POSSIBLE

(located

in

figure

DANGER

EXPLOSION

USED

IN

FLAMMABLE

PRESENCE

on

the

front

1-9.

HAZARD

ANESTHETICS

OF

Figure

panel

IF

7-9.

of

the

Front

control/pump

ELECTRIC

REMOVE

TO

panel

imprinting.

module)

‘CAUTION

SHOCK

COVER.

QUALIFIED

SERVICE

TM

providing

HAZARD.

REFER

SERVICING

PERSONNEL

8-6515-008-24&P

DO

danger

NOT

and

caution

/

<=

1-14.

Model

1-15.

Medical

tightening.

to

Model

differences

Safety,

a.

Observe

b.

Read

Equipment

c.

Install

d.

The

use

the

bacteria

e.

Operator/user

the

the

of a collection

shock.

f.

Do

not

use

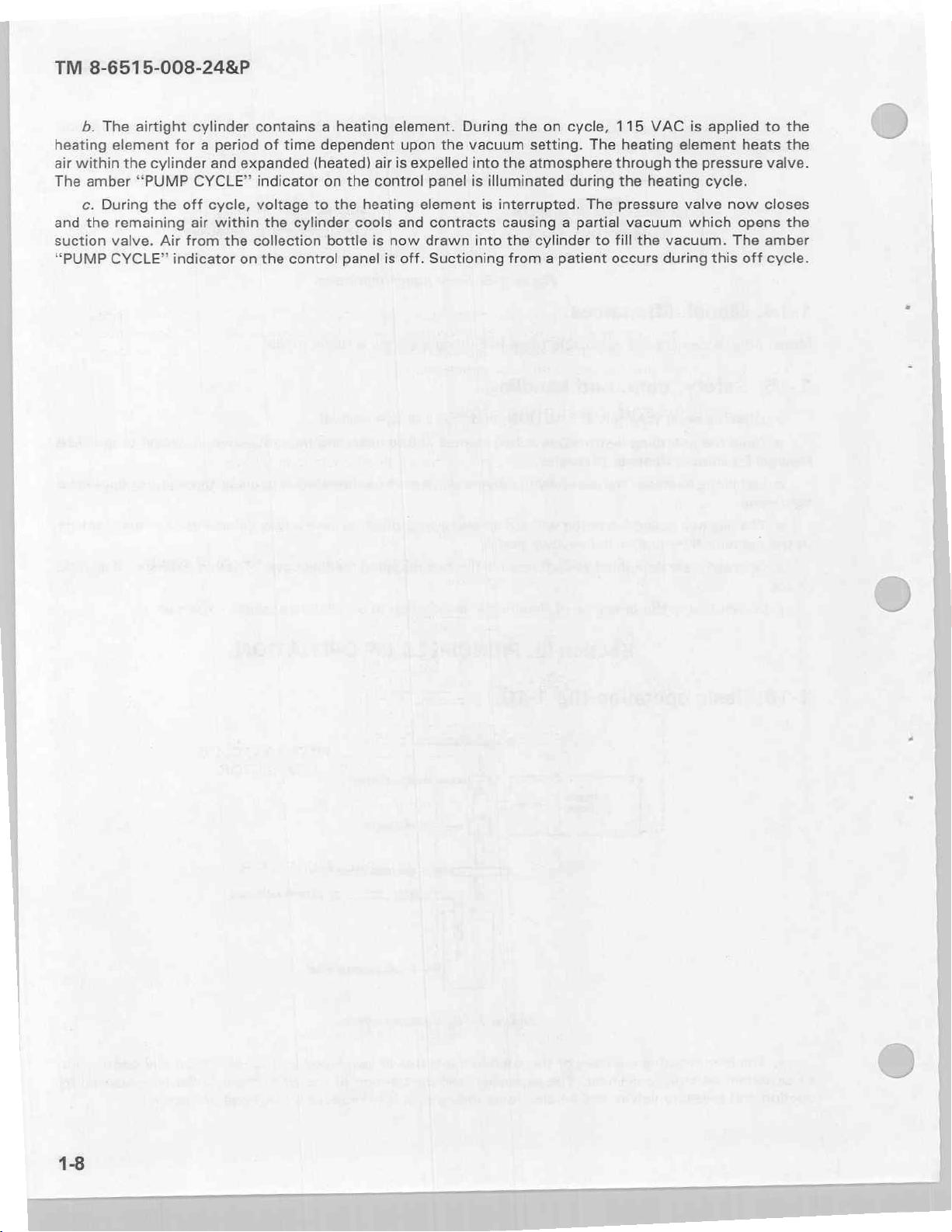

1-16. Basic

differences.

are

not

applicable

care,

each

WARNING,

operating

Repairer

bacteria

filter

and/or

personnel

in

the

operation

and

instructions

personnel.

filter

carefully

bottle

the

presence

Section

since

handling.

CAUTION,

in

to

without

vacuum

will

not

remove

of

flammable

III.

(fig

1-10).

this

manual

and

NOTE

this

manual

prevent

an

pump.

overflow

the

before

damage

control/pump

anesthetics

PRINCIPLES

TO

ATMOSPHERE

covers a single

in

this

manual.

operating

to

its

threads

protection

to

OF

device

module

preclude a possible

OPERATION

model.

the

unit.

due

may

cover.

Refer

servicing

to

cross-threading

cause

overflow

There

is a danger

explosion.

to

qualified

or

excessive

and

damage

of

electric

ーー

PRESSURE

VALVE

PATIENT

AIRFLUIDS

Figure

|

a.

of

air

within

suction

The

and

low

negative pressure

an

airtight

pressure

valves

cylinder.

and

of

the

The

expansion

an

electronic

1-10.

suction

timing

Vacuum

apparatus

and

contraction

circuit

cycle.

is

developed

of

the

to

produce a low

by

air

the

in

the

level

expansion

cylinder

of

vacuum.

and

contraction

is

controlled

by

Page 16

TM

8-6515-008-24&P

b.

The

airtight

heating

air

The

and

suction

“PUMP

element

within

amber

c.

During

the

valve.

CYCLE”

the

cylinder

“PUMP

the

remaining

cylinder

for a period

and

CYCLE”

off

cycle,

air

within

Air

from

indicator

contains a heating

of

time

expanded

indicator

voltage

the

the

collection

on

the

(heated)

to

cylinder

control

dependent

air

on

the

control

the

heating

cools and

bottle

is

panel

element.

upon

is

expelled

element

now

is

off.

During

the

vacuum

into

panel

is

illuminated

is

contracts

drawn

into

Suctioning

the

on

cycle,

setting.

the

atmosphere

interrupted.

causing a partial

the

cylinder

from a patient

The

during

The

to

115

VAC

heating

through

the

heating

pressure

vacuum

fill

the

occurs

is

applied

element

the

pressure

cycle.

valve

which opens

vacuum.

during

this

heats

now

The

off

to

the

the

valve.

closes

the

amber

cycle.

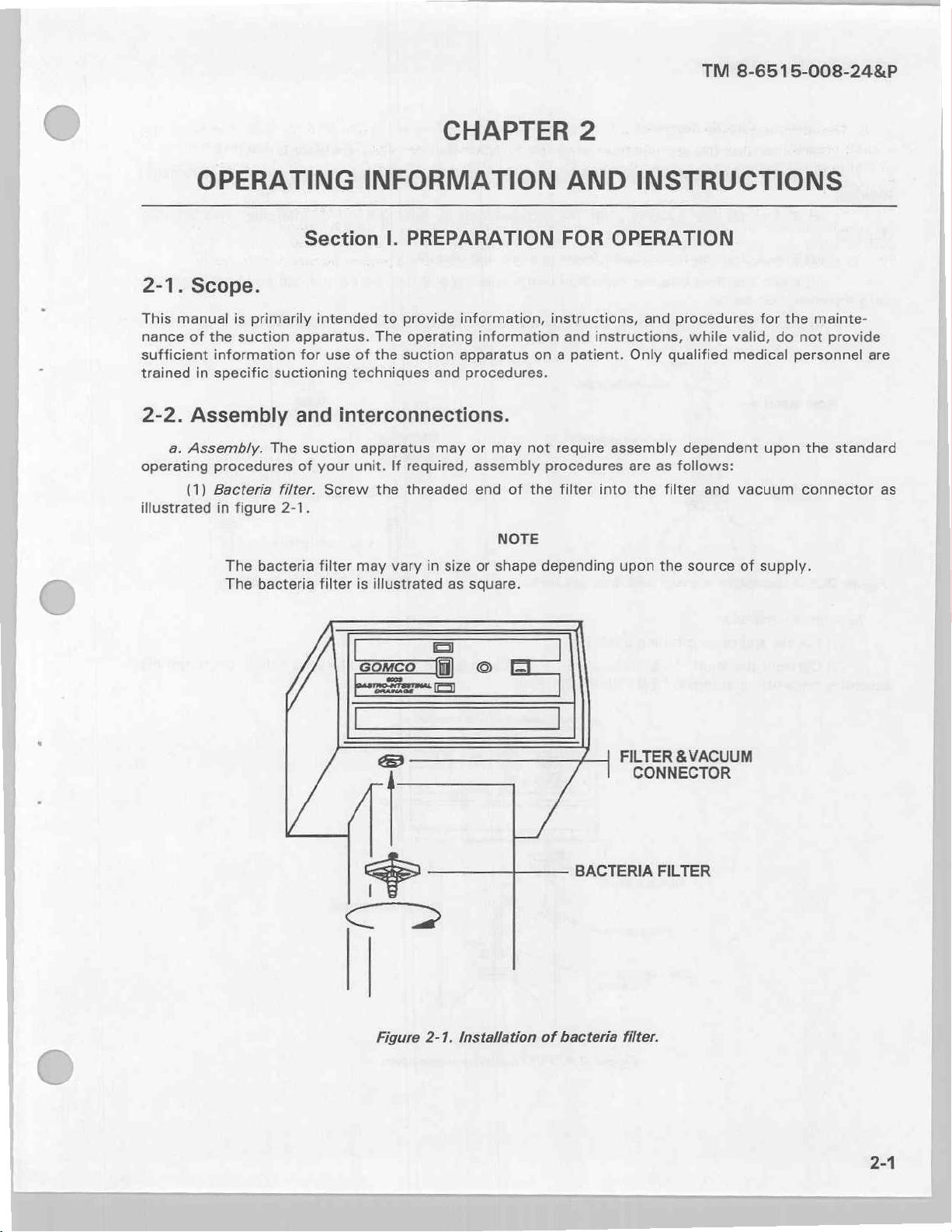

Page 17

TM

8-6515-008-24&P

OPERATING

2-1.

This

nance

sufficient

trained

2-2.

operating

illustrated

Scope.

manual

of

the

information

in

specific

Assembly

a.

Assembly.

procedures

(1)

Bacteria

in

is

primarily

suction

figure

The

bacteria

The

bacteria

Section

intended

apparatus.

for

use

suctioning

and

The

suction

of

your

filter.

Screw

2-1.

filter

filter

CHAPTER

INFORMATION

I.

PREPARATION

to

provide

The

operating

of

the

suction

techniques

interconnections.

apparatus

unit.

If

required,

the

threaded

may

vary

is

illustrated

information,

apparatus

and

procedures.

may

in

size

as

square.

information

or

may

assembly

end

or

shape

on a patient.

not

of

the

NOTE

depending

2

AND

FOR

instructions,

and

require

procedures

filter

OPERATION

instructions,

assembly

into

upon

INSTRUCTIONS

and

Only

are

the

procedures

while

qualified

dependent

as

follows:

filter

the

source

and

for

valid,

medical

upon

vacuum

of

supply.

do

the

mainte-

not

provide

personnel

the

standard

connector

are

as

E

二

|

Figure

一

2-1.

Installation

一

|

of

bacteria

FILTER & VACUUM

CONNECTOR

BACTERIA

filter.

FILTER

2-1

Page 18

TM

8-6515-008-24&P

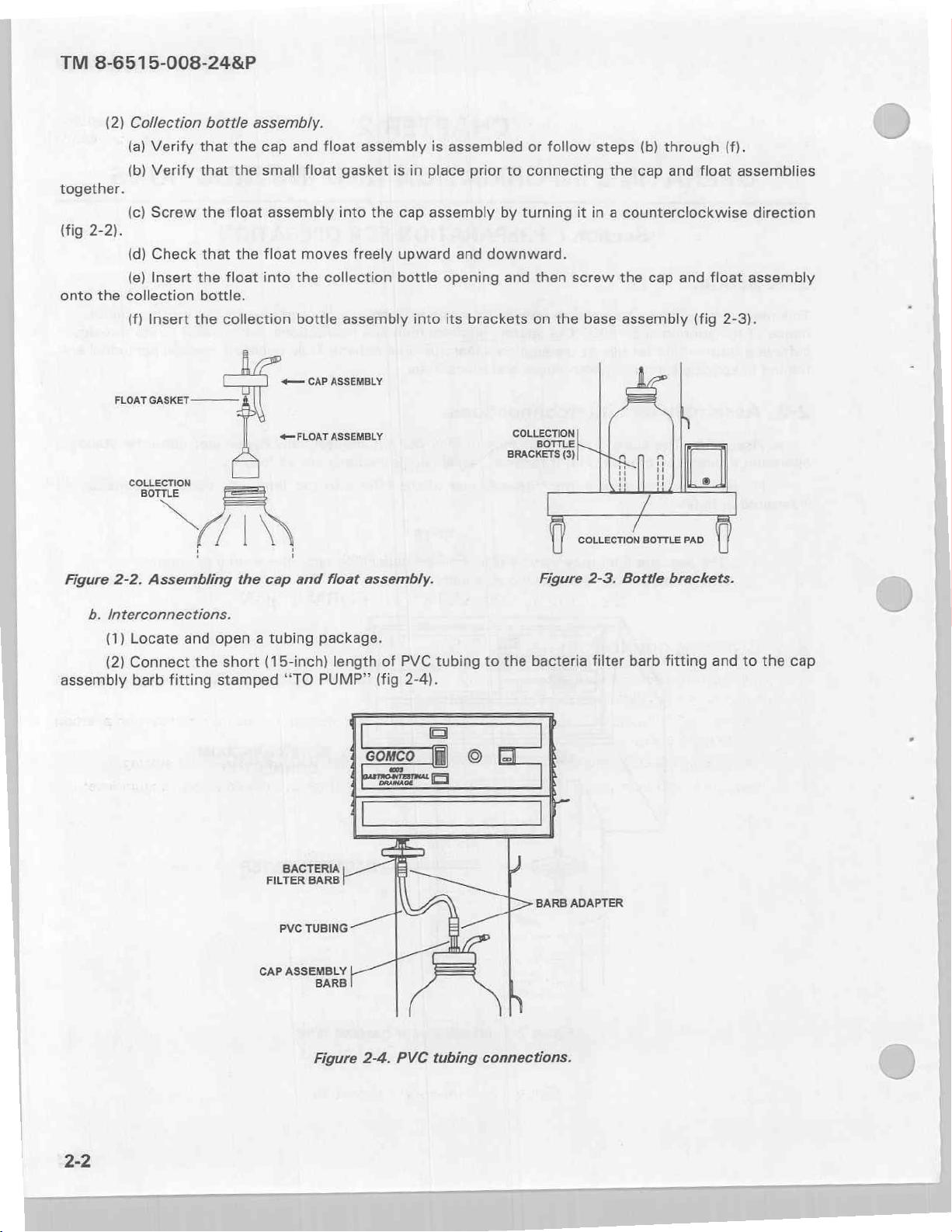

(2)

Collection

(a)

Verify

(b)

Verify

together.

(c)

Screw

(fig

2-2).

(d)

Check

(e)

Insert

onto

the

collection

(f)

Insert

FLOAT

GASKET-——

bottle

that

the

that

the

the

float

that

the

the

float

bottle.

the

collection

assembly.

cap

and

small

float

assembly

float

moves

into

the

bottle

+—

CAP

float

assembly

gasket

into

the

freely

collection

assembly

ASSEMBLY

is

in

cap

upward

bottle

into

is

assembled

place

prior

assembly

and

opening

its

brackets

or

to

connecting

by

turning

downward.

and then

on

follow

steps

the

cap and

it

in a counterclockwise

screw

the

base

the

assembly

(b)

cap

through

float

and

(fig

(f).

assemblies

float

assembly

2-3).

direction

Figure

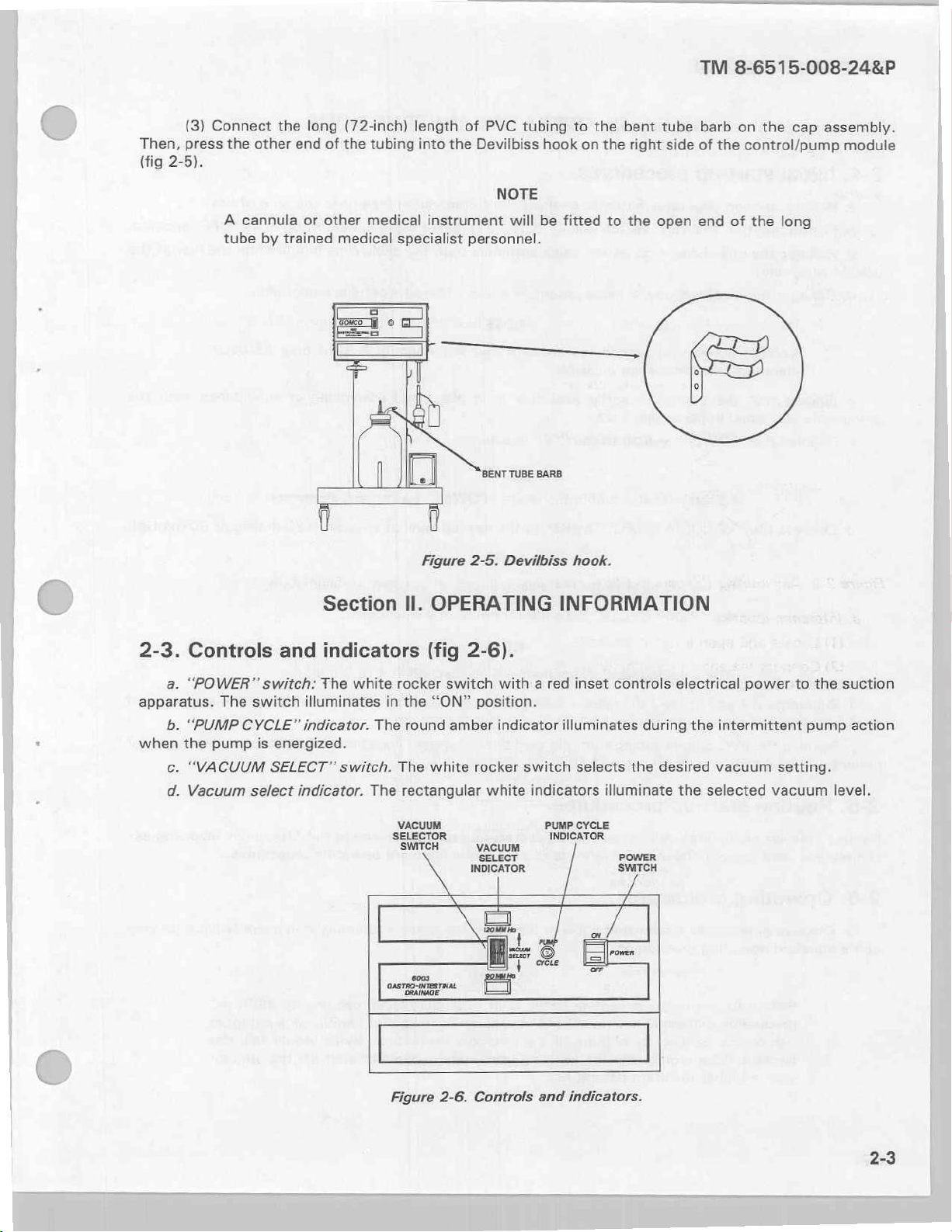

b.

Interconnections.

(1)

(2)

assembly

COLLECTION

gi

FN

2-2.

Assembling

Locate

Connect

barb

fitting

the

and

open a tubing

the

short

stamped

«FLOAT

cap

and

package.

(15-inch)

“TO

PUMP”

BACTERIA

FILTER

BARB

PVC

TUBING

ASSEMBLY

float

length

assembly.

of

PVC

(fig

2-4).

tubing

to

the

COLLECTION

Figure

bacteria

2-3.

filter

Bottle

barb

BOTTLE

brackets.

fitting

PAD

and

to

the

cap

[>

BARB

ADAPTER

2-2

CAP

ASSEMBLY

BARB

Figure

2-4.

PVC

tubing

connections.

Page 19

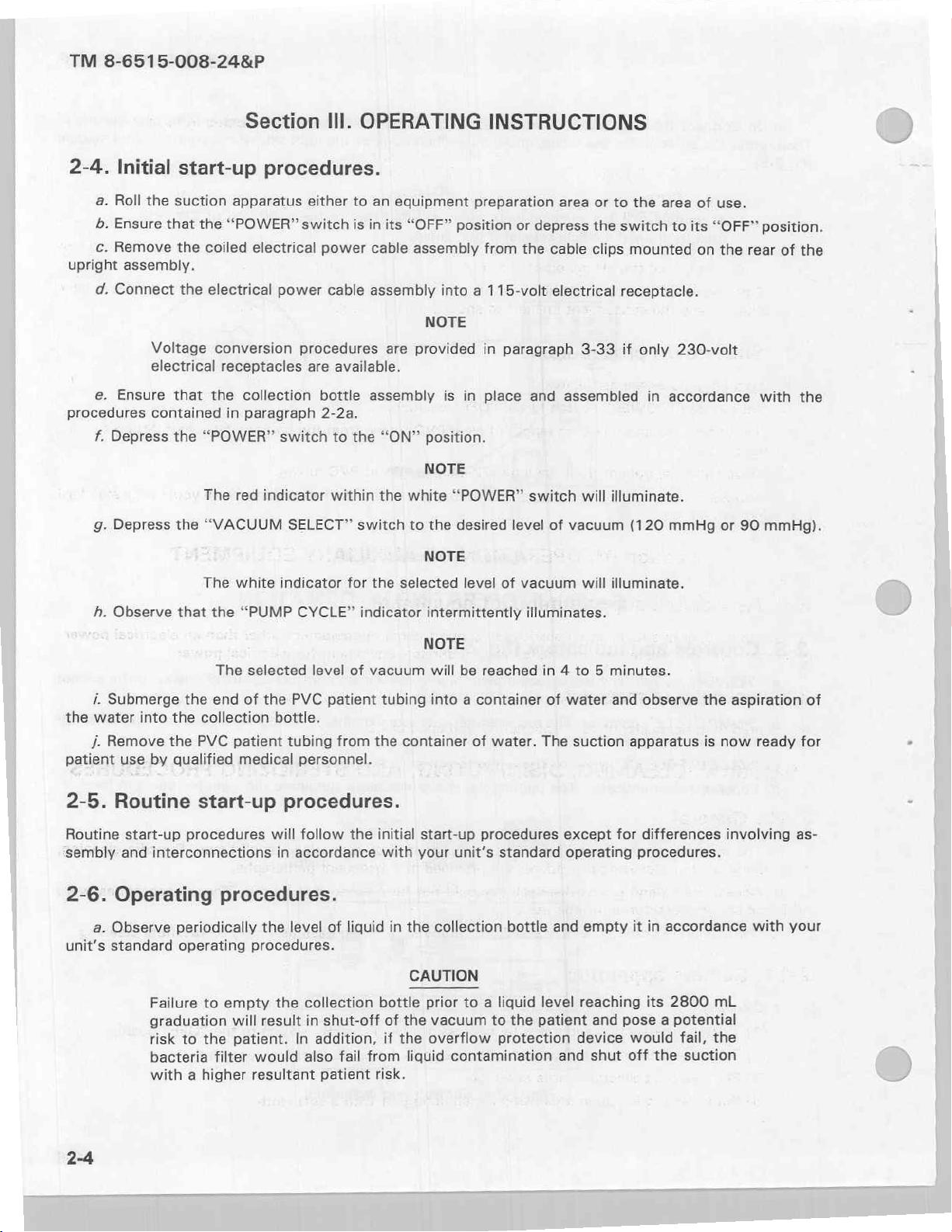

Then,

(fig

(3)

press

2-5).

Connect

the

A

cannula

tube

the

other

by

trained

long

(72-inch)

end

of

the

or

other

medical

medical

tubing

specialist

length

of

into

the

instrument

PVC

tubing

Devilbiss

NOTE

will

personnel.

hook

be

to

the

on

fitted

the

to

bent

right

the

tube

side

open

TM

8-6515-008-24&P

barb

on

the

cap

of

the

control/pump

end

of

the

long

assembly.

module

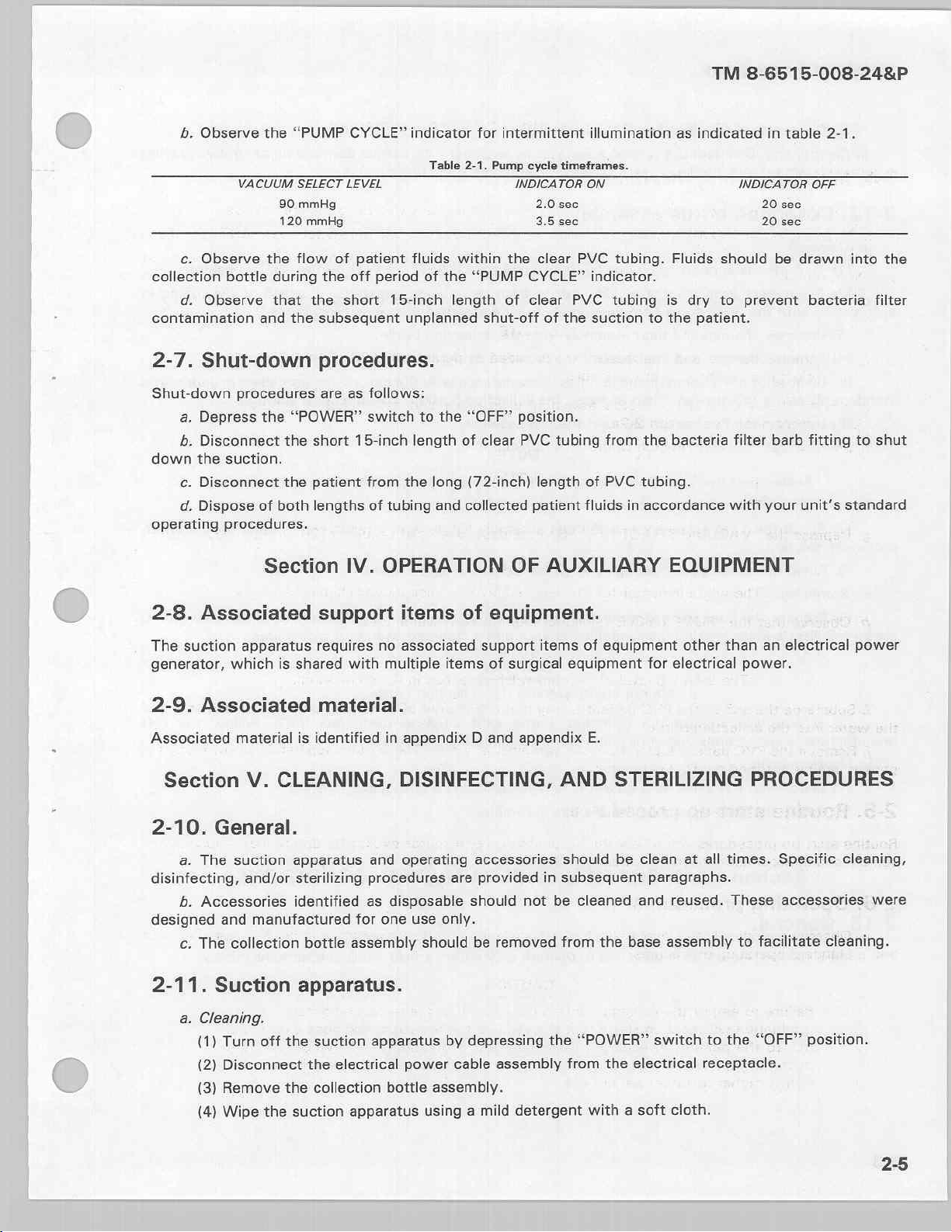

2-3.

apparatus.

when

Controls

a.

“POWER”

b.

“PUMP

the

c.

“VACUUM

d.

Vacuum

The

pump

and

switch:

switch

CYCLE”

is

energized.

SELECT”

select

Section

indicators

The

white

illuminates

indicator.

switch.

indicator.

|

Figure

Il.

OPERATING

(fig

2-6).

rocker

in

The

The

The rectangular

VACUUM.

SELECTOR

the

“ON”

round

white

SWITCH

switch

amber

BENT TUBE

2-5.

Devilbiss hook.

with a red

position.

indicator

rocker

VACUUM

INDICATOR

white

SELECT

switch

indicators illuminate

|

BARB

PUMP

INFORMATION

inset

controls

illuminates

selects

CYCLE

INDICATOR

I

during

the

POWER

SWITCH

electrical

the

desired

the

selected

power

intermittent

vacuum

to

setting.

vacuum

the

pump

level.

suction

action

από

Figure

2-6.

몰

ra

ΕΤ

Controls

and

indicators.

同一

=

Page 20

TM

8-6515-008-24&P

2-4.

upright

procedures

Initial

a.

Roll

b.

Ensure

c.

Remove

assembly.

d.

Connect

e.

Ensure

f.

Depress

g.

Depress

start-up

the

suction

that

the

the

the

Voltage

electrical

that

contained

the

“POWER”

The

the

The

Section

procedures.

apparatus

“POWER”

coiled

“VACUUM

electrical

electrical

conversion

receptacles

the

collection

in

paragraph

red

indicator

white

III.

either

switch

power

power

switch

indicator

cable

procedures

are

available.

bottle

2-2a.

to

within

SELECT”

OPERATING

to

an

equipment

is

in

its

“OFF”

cable

assembly

assembly

NOTE

are

provided

assembly

the

“ON”

position.

NOTE

the

white

switch

for

the

selected

to

the

NOTE

INSTRUCTIONS

preparation

position

into a 115-volt

is

in

“POWER”

desired

level

or

from

the

in

paragraph

place

level

of

vacuum

depress

and

switch

area

or to

the

cable

clips

electrical

3-33

assembled

will

of

vacuum

will

the

area

switch

receptacle.

if

to

mounted

only

in

accordance

its

230-volt

illuminate.

(120

mmHg

illuminate.

of

on

use.

“OFF”

the

or

90

position.

rear

of

with

mmHg).

the

the

р.

i.

Submerge

the

water

J.

Remove

patient

2-5.

Routine

sembly

2-6.

a.

unit's

Observe

use

into

by

that

the

the

the

qualified

Routine

start-up

and

procedures

interconnections

Operating

Observe

standard

periodically

operating

Failure

graduation

risk

to

bacteria

with a higher

the

“PUMP

The

selected

end

of

the

collection

PVC

patient

medical

start-up

will

procedures.

the

procedures.

to

empty

will

result

the

patient.

filter

would

resultant

CYCLE”

level

PVC

indicator

of

patient

bottle.

tubing

from

personnel.

procedures.

follow

in

accordance

level

the

In

the

of

liquid

collection

in

shut-off

addition,

also

fail

patient

vacuum

tubing

the

container

initial

with

in

the

bottle

of

the

if

the

from

risk.

intermittently

NOTE

will

be

reached

into a container

of

water.

start-up

your

CAUTION

prior

vacuum

overflow

liquid

procedures

unit's

collection

to a liquid

to

contamination

illuminates.

in 4 to 5 minutes.

of

water

The

suction

except

standard

bottle

the

protection

operating

and

level

patient

and

and

observe

apparatus

for

differences

procedures.

empty

reaching

device

it

and

pose a potential

would

shut

off

the

in

accordance

its

2800

fail,

the

suction

aspiration

is

now

involving

mL

the

ready

with

of

for

as-

your

2-4

Page 21

b.

Observe

c.

Observe

collection

contamination

d.

bottle

Observe

the

VACUUM

the

and

“PUMP

SELECT

90

mmHg

120

mmHg

flow

during

that

the

CYCLE”

LEVEL

of

patient

the

off

the

short

subsequent

indicator

period

15-inch

unplanned

Table

fluids

of

the

for

2-1.

within

“PUMP

length

shut-off

intermittent

Pump

cycle

timeframes.

INDICATOR

2.0

sec

3.5

sec

the

clear

CYCLE”

of

clear

of

the

illumination

ON

PVC

tubing.

indicator.

PVC

tubing

suction

to

as

indicated

Fluids

is

dry

the

patient.

TM

8-6515-008-24&P

in

table

INDICATOR

should

to

prevent

20

20

sec

sec

be

OFF

drawn

bacteria

2-1.

into

the

filter

2-7.

Shut-down

down

operating

2-8.

The suction

generator,

2-9.

Associated

Shut-down

a.

Depress

b.

Disconnect

the

suction.

ο.

Disconnect

d.

Dispose

procedures.

Associated

Associated

Section

procedures

the

the

the

of

both

Section

apparatus

which

is

material

V.

CLEANING,

procedures.

are

as

follows:

“POWER”

short

patient

lengths

switch

15-inch

from

of

IV.

support

requires

shared

with

material.

is

identified

to

the

“OFF”

length

the

tubing

long

and

of

clear

(72-inch)

collected

OPERATION

items

no

associated

multiple

in

appendix D and

of

equipment.

support

items

of

DISINFECTING,

position.

PVC

tubing

length

patient

OF

AUXILIARY

items

surgical

appendix

from

of

PVC

fluids

of

equipment

equipment

E.

AND

the

bacteria

tubing.

in

accordance

filter

with

EQUIPMENT

other

than

for

electrical

STERILIZING

barb

fitting

your

unit's

an

electrical

power.

PROCEDURES

to

shut

standard

power

2-10.

disinfecting,

designed

2-11.

General.

a.

The

b.

Accessories

and

ο.

The

Suction

a.

Cleaning.

(1)

Turn

Disconnect

(2)

(3)

Remove

Wipe

(4)

suction

collection

apparatus

and/or

sterilizing

identified

manufactured

bottle

apparatus.

off

the

suction

the

the

collection

suction

the

and

procedures

as

disposable

for

one

assembly

apparatus

electrical

bottle

apparatus

operating

are

use

only.

should

by

power

cable

assembly.

using

accessories

provided

should

be

depressing

a

removed

assembly

mild

not

detergent

should

in

subsequent

be

cleaned

from

the

“POWER”

from

with

the

the

be

base

a

clean

at

paragraphs.

and

reused.

assembly

switch

electrical

cloth.

soft

all

times.

These

to

facilitate

to

the

“OFF”

receptacle.

Specific

accessories

cleaning,

cleaning.

position.

were

2-5

Page 22

TM

8-6515-008-24&P

(5)

Dry

the

it

b.

Disinfecting.

with

disinfectant

suction

apparatus

Disinfect

in

accordance

the

with a soft

suction

with

apparatus

your

unit's

cloth.

by

standard

wiping

it

with a liquid

operating

disinfectant

procedures.

or

lightly

spraying

2-12.

accordance

standard

detergent

steam

Collection

a.

Cleaning.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

b.

Sterilizing.

(1)

sterilizer’s

Turn

off

Disconnect

with

the

Unscrew

Immerse

Dispose

operating

Unscrew

Ensure

assembly.

Scrub

the

solution.

Rinse

the

Sterilize

bottle

the

suction

both

lengths

procedures

the

cap and

the

cap

and

of

any

patient

procedures.

the

float

that

the

small

float

assembly

assemblies

the

float

and

manufacturer

assembly.

apparatus

of

contained

float

float

assembly

drainage

Then

assembly

float

and

thoroughly

cap

assemblies

instructions

by

PVC

tubing

in

assembly

fluids

immerse

from

the

gasket

the

in

and

depressing

from

your

unit’s

from

the

in a warm

in

accordance

the

collection

cap

assembly.

NOTE

is

not

dislodged

cap

assembly

warm

water

in a steam

your

the

“POWER”

the

standard

collection

detergent

lightly

and aerate

sterilizer

unit’s

suction

operating

bottle.

with

the

bottle

and

lost

with a nylon

standard

switch

apparatus.

solution.

procedures

in

the

detergent

while

them.

for

15

minutes

operating

to

the

“OFF”

Dispose

procedures.

contained

solution.

cleaning

the

bristle

in

accordance

procedures.

of

float

brush

position.

the

tubing

in

your

in

the

with

in

unit's

warm

the

(2)

If

manufacturer's

c.

Reassembling.

(1)

Check

(2)

Screw

Section

2-13.

The

General.

mobile

suction

required,

instructions

that

the

the

float

apparatus

Do

sterilize

small

VI.

the

and

your

float

assembly

OPERATION

is

designed

not

steam

collection

unit's

gasket

into

the

to

CAUTION

sterilize

bottle

standard

is

in

place

cap

assembly.

UNDER

operate

the

collection

with

ethylene

operating

or

procedures.

install a replacement

UNUSUAL

only

within a field

bottle.

oxide

CONDITIONS

medical

gas

(EtO).

gasket.

treatment

Follow

facility.

the

Eto

2-6

Page 23

TM

8-6515-008-24&P

3-1.

unit

personnel

checking

operator

disassembly

tools.

Medical

fication/certification

modules,

class

information,

services

equipment,

the

personnel

the

Overview.

a.

Unit

level

on

its

assigned

(1)

Operator

and

for

accessories,

(2)

Specialist

Equipment

(a)

(b)

or

(c)

repair

(d)

(e)

(f)

in

accordance

(g)

Maintenance

b.

of

scope

will

vacuum

maintenance.

equipment.

maintenance.

consists

frayed

or

assembly

maintenance.

Repairers.

Scheduling

Performing

PCBs,

Operating a repair

parts

assemblies,

pump,

when

used

Maintaining a library

and

related

Conducting

Establishing

Notifying

functions.

operator/user

the

perform

PCB,

UNIT

Section

This

of

equipment

cables, and

and

replacing

of

the

The functions

and

performing

(CVC)

services.

unscheduled

available.

on

medical

materials.

inspections

administrative

with

TB

support

or

modules.

are

majority

the

stand.

or

CHAPTER

LEVEL

I.

GENERAL

level

of

maintenance

Responsibilities

This

segment

operational

stowing

operator

end

This

parts

equipment.

of

38-750-2.

maintenance

Maintenance

assigned

of

items

repair

item,

critical

segment

and

PMCS,

maintenance

program

technical

on

new

or

procedures

functions,

to

maintenance

MAINTENANCE

INFORMATION

is

the

are

stratified

of

unit

level

functions;

not

parts.

adjustments

of

services

electrical

to

include

manuals

transferred

battalions

level

unit

required

routine

in

use;

and

Replacing

unit level

include—

safety

functions

Class

(TMs),

equipment.

for

the

of

requirements

preventive

both

Maintenance

for

3

responsibility

as

follows:

maintenance

services

checking

operator

after

replacement,

maintenance

inspections

with

emphasis

VIII

repair

manufacturers’

control

the

and

and

Equipment

equipment

of

and

is

performed

like

cleaning,

for

loose

parts

will

or

is

performed

and

tests,

on

parts

as

well

literature,

administration

and/or

evacuating

corrective,

Repairer

except

performed

by

dusting,

hardware,

not

require

the

extensive

only

and

calibration/veri-

replacing

as

other

of

which

personnel.

tasks

some

by a using

operator/user

washing,

replacing

extensive

use

of

by

trained

assemblies,

commodity

repair

maintenance

unserviceable

beyond

are

These

involving

parts

3-2.

Common

pendix

(MTOE)

3-3.

Components

Tools

B,

for

Components

and

and

tools

section

authorized

end

of

test

III

test

equipment

this

of

items.

item

equipment.

required

manual.

item

end

of

issue

basic

and

Refer

for

your

to

and

items

maintenance

level

unit

modified

units

basic issue

appendix

in

listed

are

of

of

table

items.

C,

equipment

the

organization

sections

II

and

are

and

III

listed

equipment

manual.

this

of

in

ap-

3-1

Page 24

TM

8-6515-008-24&P

3-4.

Expendable

appendix

3-5.

Repair

3-6.

Special

this

3-7.

box

Expendable

Repair

parts

Special

tools

manual.

Unpacking

a.

Remove

b.

Open

c.

Lift

d.

Remove

e.

Lift

f.

Open

aside.

g.

Verify

(1)

(2)

(3)

(4)

(5)

(6)

(7)

and

durable

D,

section

parts.

reguired

tools.

required

Section

the

straps

the

top

upward

and

Suction

Maintenance

Operation

Collection

Bacteria

Tubing

Pressure

the

roll

the

small

receipt

on

foam

the

apparatus.

filters

(1

valve

supplies.

supplies

İl

of

this

for

unit

for

unit

Il.

the

suction

from

flaps

of

the

the

shipping

blocks

suction

cardboard

of

the

following

and

service

manuals

bottle

with

(3/pg).

15-inch

and 1 72-inch

and

and

materials

manual.

level

maintenance

level

maintenance

SERVICE

the

cardboard

container.

container

from

under

apparatus

carton

materiel:

manuals

(2).

cap

and

manifold

required

are

of

UPON

apparatus.

shipping

body

and

the

base

off

the

shipping

setting

float

assembly

on

(2).

assembies.

tubing

(spare).

lengths).

for

listed

in

the

equipment

RECEIPT

container.

remove

assembly.

container

the

base

maintenance

appendix

are

OF

it.

Set

it

Set

them

base.

assembly

of

the

equipment

E,

section

listed

Il

in

appendix

EQUIPMENT

aside.

aside.

Set

it

aside.

and

remove

of

this

the

are

listed

manual.

E,

section

contents.

Ill

Set

=>

in

of

the

3-8.

No

General.

lubrication

Section

3-9.

operation

serious

General.

The

a.

damage

of

suction

all

at

Section

the

suction

PREVENTIVE

IV.

apparatus

times.

or

Inspection

failure.

Ill.

apparatus

be

must

will

LUBRICATION

is

required.

MAINTENANCE

serviced

inspected

allow

and

defects

to

INSTRUCTIONS

CHECKS

systematically

discovered

be

and

AND

ensure

to

corrected

SERVICES

is

it

that

before

they

ready

result

for

in

Page 25

©

b.

Table

table

is

also

is

not

limited

should

operational

PMCS

to

procedures

found

equipment

During

With

do

c.

Table

table

d.

Some

provide

e.

The

in

(1)

(2)

Operation,

daily

each

/tem

Interval.

3-1

contains

referred

to

performing

any

time

indicators,

3-2

contains

is

also

items

to

a

quality

to

be

accomplished

following

column:

No.

This

area

on

This

A

use

of

the

When

service

checks

the

a

to

as

they

need

and

referred

be

inspected

control

is

a

list

column

the

Equipment

column

-

After

equipment.

suction

only

those

and

services

list

of

items

“-10

PMCS”

the

checks

to

be

maintaining

a

list

of

items

to

as

‘“-20

will

check

on

by

unit

of

both

shows

Inspection

shows

Operation,

apparatus

items

when

to

be

requirements.

and

services

done,

multiple

that

the

to

PMCS”

be

listed

level

PMCS

the

sequence

when

Q

-

Quarterly,

must

will

the

equipment

such

proper

be

performed

Preventive

in

table

as

checking

quantities

performed

requirements.

in

both

table

operator/user

Medical

table

and

each

not

Equipment

column

in

which

Maintenance

PMCS

and

S

NOTE

be

kept

disrupt

can

by

unit

level

3-1.

There

general

of

accessories.

by

unit

level

3-1

and

personnel,

Repairers.

headings

to

do

Worksheet,

item

is

to

-

Semiannually.

in

continuous

operation.

be

shut

operator/user

maintenance

are

things

cleanliness,

Medical

table

3-2

and

to

with

a

description

the

PMCS,

DA

be

serviced: B -

B,

operation,

Perform

down.

the

TM

by

operator/user

operator/user

Equipment

to

stress

identify

and

Form

D,

and

complete

8-6515-008-24&P

personnel.

observing

more

of

is

used

2404.

Before

A

should

check

This

personnel

personnel

for

improper

Repairers.

their

importance,

comprehensive

the

information

to

identify

Operation, D -

be

performed

and

daily

PMCS

This

the

(3)

be

checked

(4)

unavailable

ITEM

NO

1

2

/tem

to

or

serviced.

Equipment

or

unusable.

BlplAlols

x

XI

X

x

be

Inspected

is

not

INTERVAL

x

XI

X

X

X

and

Procedure.

Ready/Available

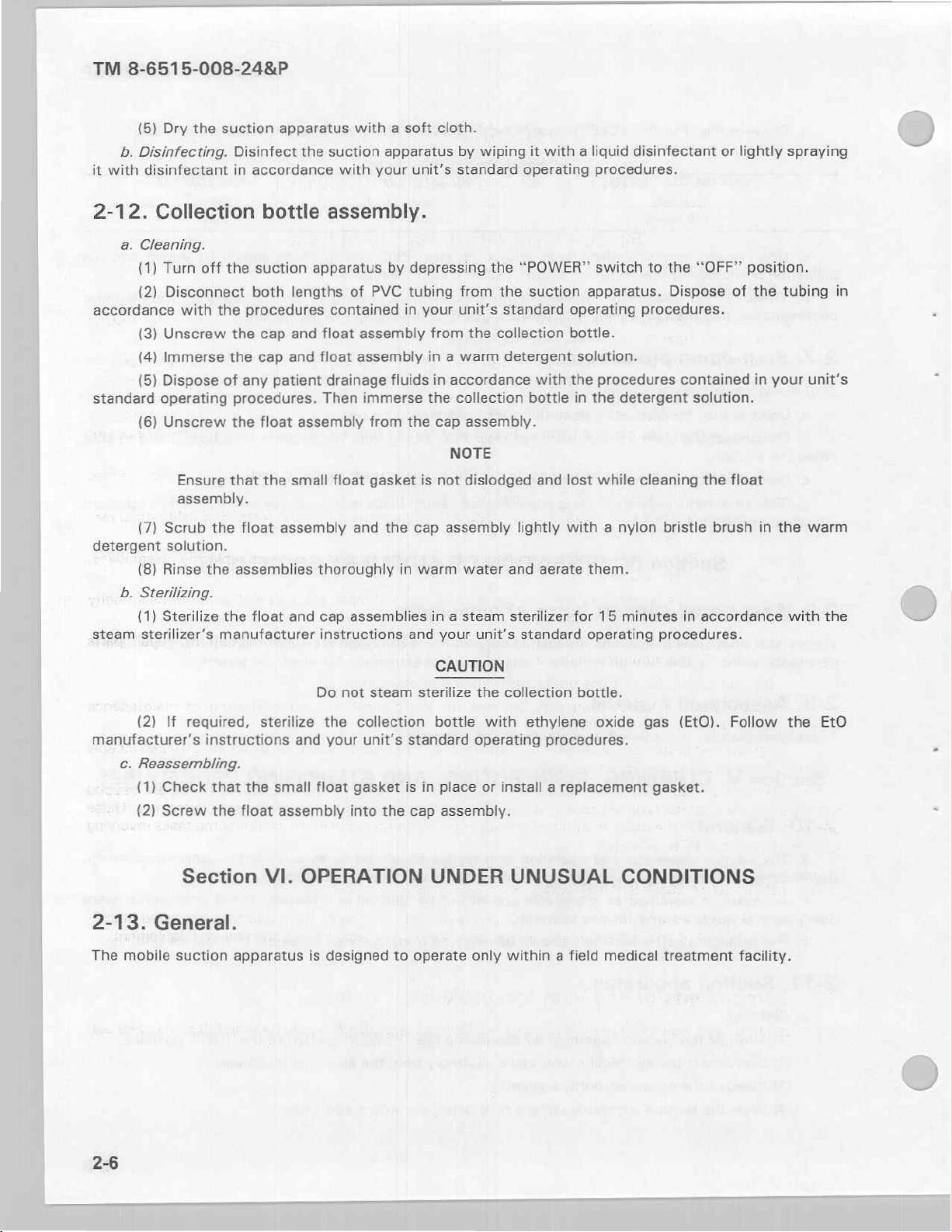

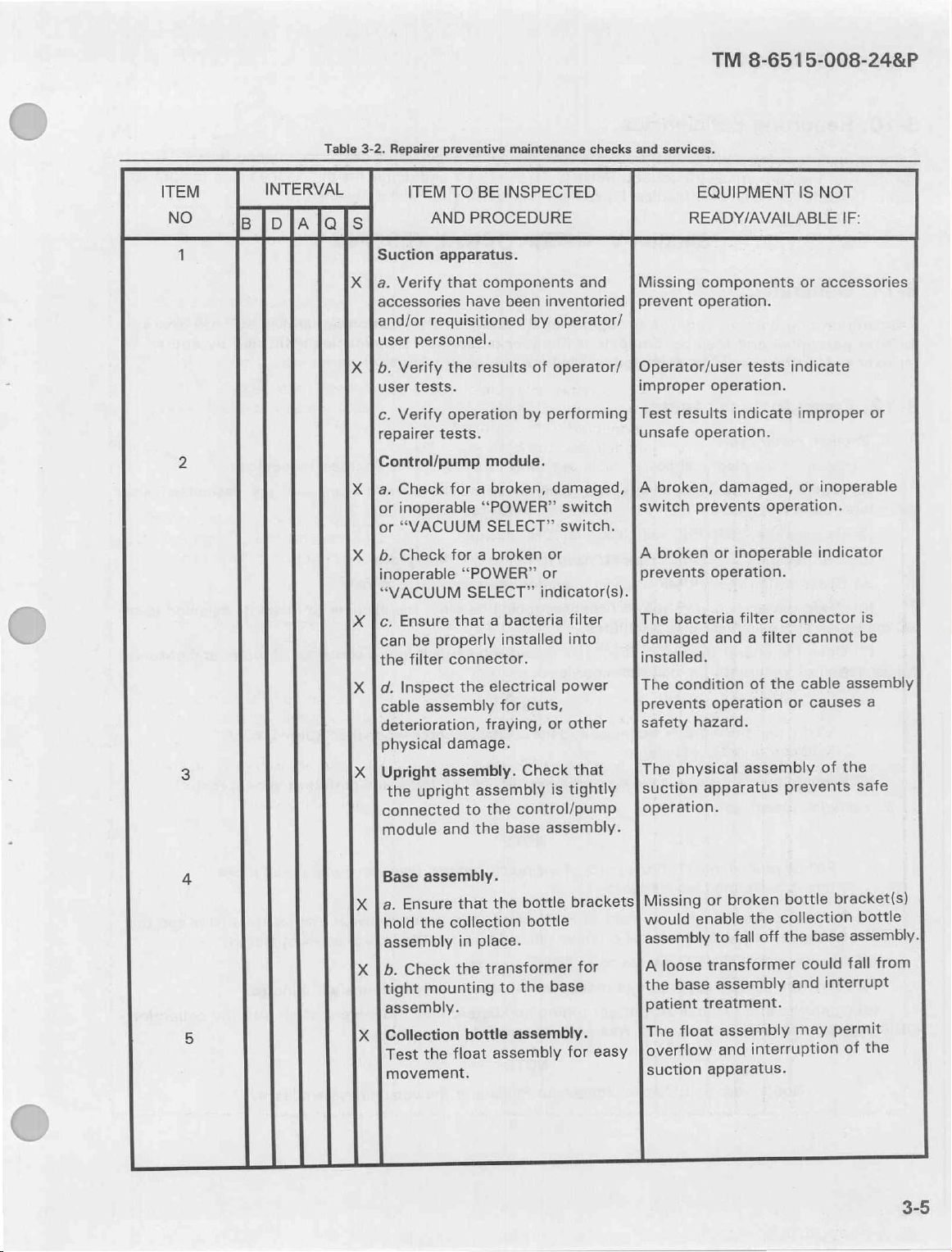

Table

3-1.

Operator

ITEM

Suction

X]

a.

Ensure

and

accessories

Xİ

6.

Verify

operational

Control/pump

a.

Check

or

inoperable

or

“VACUUM

b.

Check

inoperable

“VACUUM

This

If:.

preventive

TO

BE

AND

PROCEDURE

apparatus.

that

all

performance

tests.

module.

for a broken,

“POWER”

SELECT”

for a broken

“POWER”

SELECT”

column

This

column

maintenance

INSPECTED

components

are

on

of

damaged,| A broken,

or

indicator

indicator(s).

identifies

lists

checks

hand.

the

switch | switch

switch.

the

conditions

and

Missing

prevent

apparatus.

The

incorrect

situation.

A

or}

prevents

services.

broken

general

EQUIPMENT

READY/AVAILABLE

operational

area

that

components

operation

operation

damaged,

prevents

or

inoperable

operation.

make

tests

operation.

or

specific

the

equipment

IS

NOT

IF:

or

accessories

of

the

suction

indicate

or a hazardous

or

inoperable

indicator

part

to

Page 26

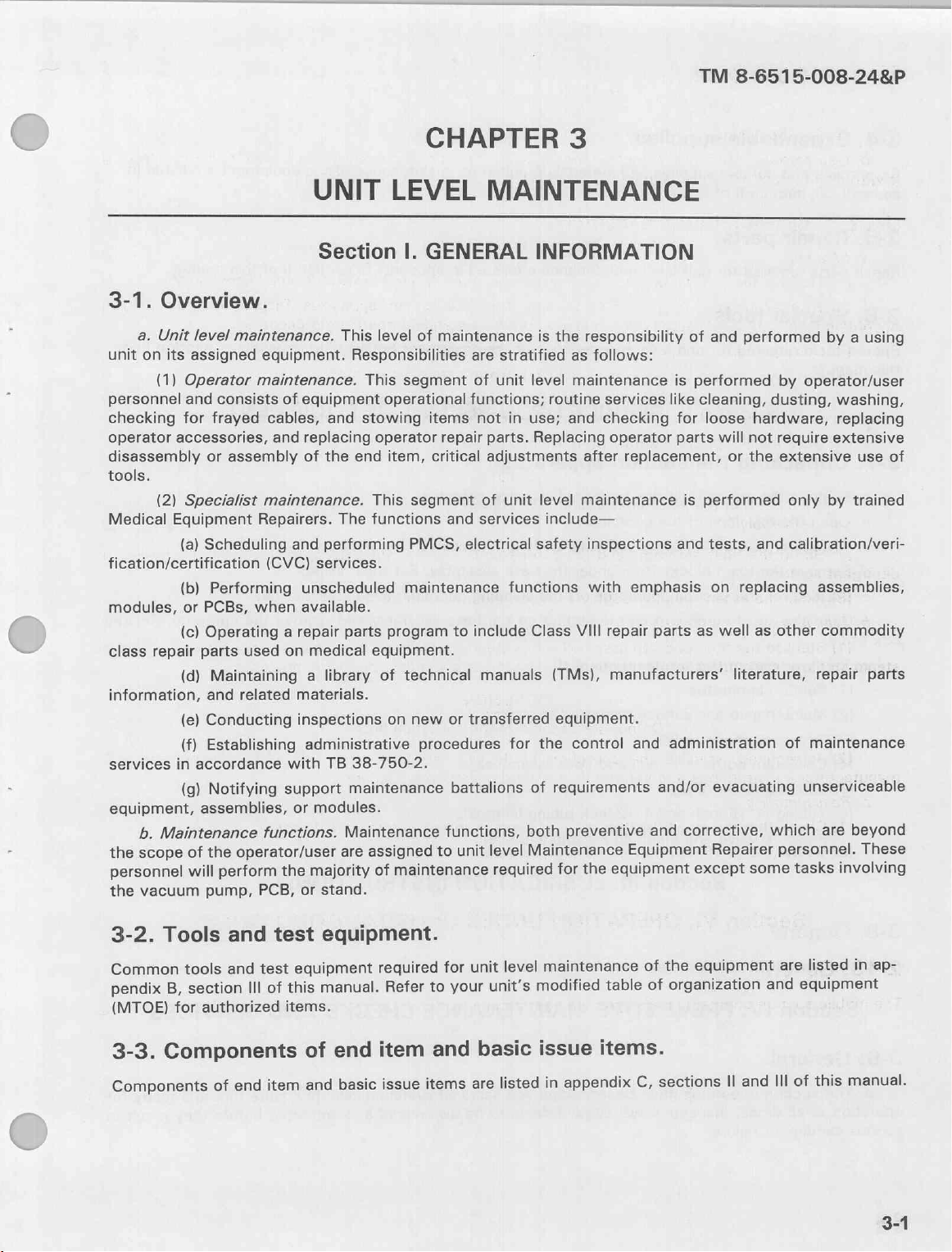

TM

8-6515-008-24&P

ITEM

NO

3

Table

INTERVAL

DIA

3-1.

la

Operator

preventive

ITEM

c.

Ensure

can

be

the

filter

d.

Inspect

cable

assembly

deterioration,

physical

Upright

the

upright

connected

module

maintenance

TO

BE

INSPECTED

AND

PROCEDURE

that a bacteria

properly

connector.

damage.

assembly.

and

installed

the

electrical

for

fraying,

assembly

to

the

the

base

checks

and

services - continued.

EQUIPMENT

READY/AVAILABLE

filter

into

power

cuts,

or

other

Check

control/pump | operation.

that

is

tightly

assembly.

The

bacteria

damaged

installed.

The

condition

prevents

safety

The

suction

hazard.

physical

apparatus

filter

connector

and a filter

of

the

operation

or

assembly

prevents

IS

NOT

cannot

cable

causes

of

IF:

is

be

assembly

a

the

safe

4

E

X

Base

assembly.

a.

Ensure

hold

the

assembly

b.

Check

tight

mounting

assembly.

Collection

a.

Check

nicks

or

cracks.

b.

Test

the

easy

movement.

that

the

collection

in

place.

the

transformer

to

bottle

assembly.

the

bottle

float

assembly

bottle

brackets | Missing

bottle

for

the

base

opening

for

for

or

broken

would

assembly

assembly.

A

the

patient

The condition

bottle

operation.

The

overflow

suction

loose

base

assembly

float