Page 1

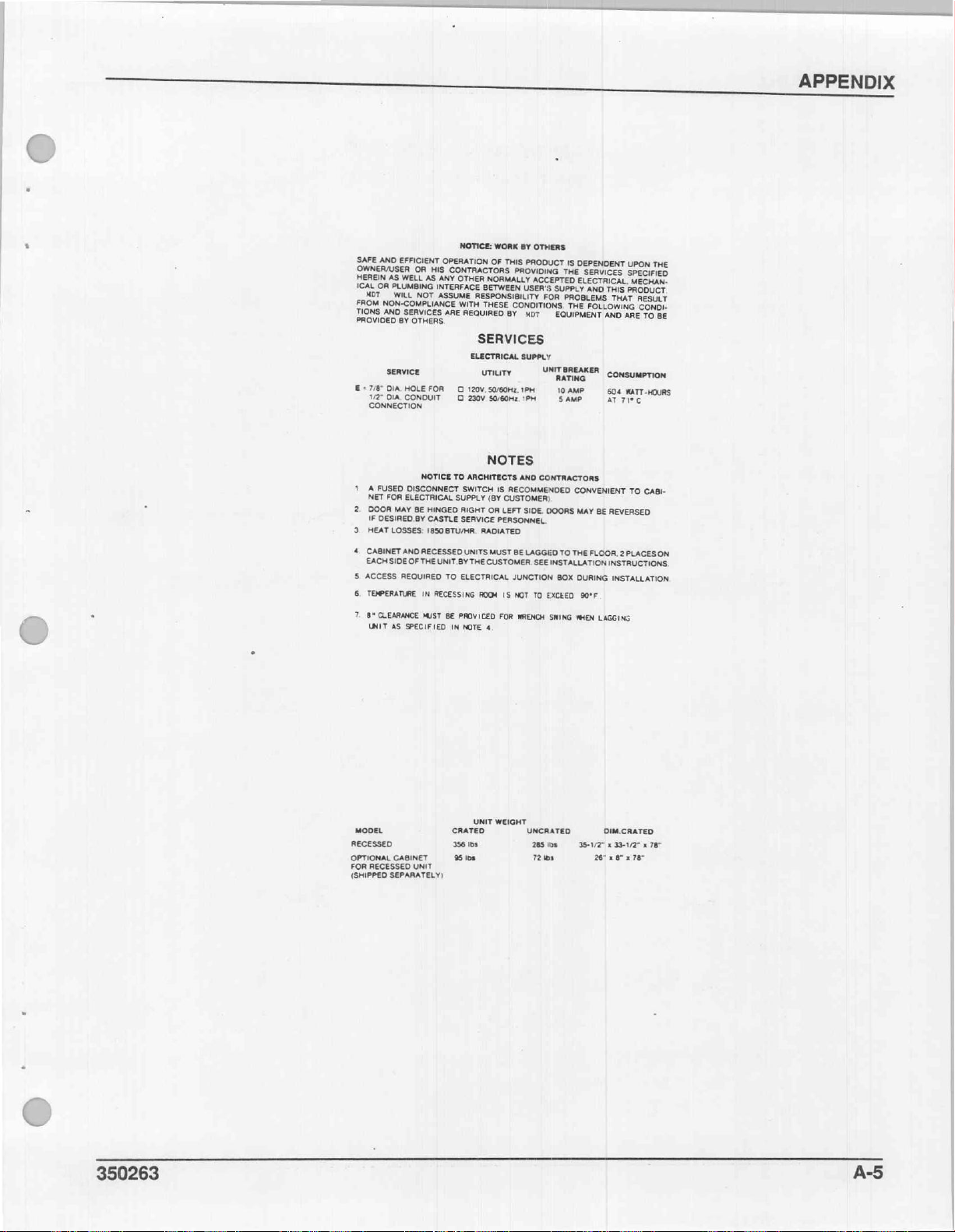

SERVICE

MANUAL

Castle

5540

5545

5550

WARMING

MDT

Biologic

1777

East

PO.

Rochester,

CABINETS

Company

Henrietta

Box

23077

New

York

14692,

Road

U.S.A.

M

mom

Technology

for

Life

350265

Page 2

SERVICE

MANUAL

350265

(6/4/90)

i

JD

Related

Installation

Operator

Parts

Special

It

is

Publications:

Manual

Catalog

safety

the

responsibility

Instructions

signs

and

of

The

“Danger”

“Warning”

350263

350264

350266

instructions

the

user

to

follow

DESCRIPTION

following

notes

notes

alert

alert

symbols

the

the

are

user

IMPORTANT

used

in

this

manual.

all

recommendations.

OF

SYMBOLS

are

related

to

the

possibility

user

to

the

possibility

Read

&

NOTES

notes

of

serious

of

them

th:t

appear

personal

personal

carefully

IN

injury.

MANUAL

In

this

injury

before

using

manual.

which

could

the

warming

be

fatal.

cabinet.

*

2

CAUTION

NOTE

je

NOTE

»

NOTE

»

©MDT

and

Castle

“Caution”

“Notes”

All

parts

This

manual

or

in

part

are

registered

notes

alert

the

replaced

contains

without

alert

the

user

user

to

pertinent

under

warranty

proprietary

the

written

trademarks.

to

the

possibility

facts

shall

information

permission

and

conditions.

be

returned

of

of

MDT.

of

damage

MDT

intact

to

the

to

MDT

Corporation.

equipment.

Corporation

It

shall

not

for

evaluation.

be

reproduced

in

whole

)

Il

350265

Page 3

a

Table

of

Contents

©

GENERAL

Description

elle

Temperature

HOMO

Control

WIRING

5540/5545/5550

Printed

TROUBLE

Diagnostie

Heater/FanOperationalChecks

CALIBRATIONS

Power

Temperature

Chart

Boot

DESCRIPTION

Of

Components

nefe)

ei

ea

Conversion

ANNEES

Board

Detail

DIAGRAMS

Circuit

Supply

Recorder

AGIISUTIARE

Board

ANALYSIS

Voltage

Control

Warming

AND

Galibraton

REPAIR

Safety

Access

Access

Circuit

FuseReplacement

Transformer

Low

molayiRepiacement

HeaterReniacement.

ThermostatHeplacementi.

Temperature

During

To

Control

To

Control

Breaker

Replacement

Voltage

o

EPrOMIRBPIAC

Printed

Recorder

Door

Witch

Door

Gasket

Power

Circuit

Replacement

Replacement

Repair

Replacement

Sensor

MEN

Board

Replacement

...............,:....4,...,,..,.,.....,,....,.

|

Chart

tr

64355450400

Schematic

...........................................

oC

4000

Cabinet

Wiring

Diagram

...........................

Diagram

...................................

O

ADJUSTMENTS

СайБгайоп

Calibration

te

Joe

ak

..........

Head

Components

Box

Components

..........................

i...

Supply

A

Replacement

LT

Replacement....................

cae

Replacement

(Optional

lc.

.................

................:...:ззнннннинининня

..............................

льна

ae

0.

eme

LC

o

о

ль

чела

II

RI

PR

........,........,........,.............

ыы,

Eguipment)

Vaia

ео

μμ

.................,..................

O

e

LC

PCR

ово

оо

"7"...

ce

................................

ei

o

SR

ο

ο

ie

......

SE

а

e

a

e

RSR

le

ας

meme

lee

04.0841105

ο

a

O

de

лено

νο

00.00

es

Sia

ο

O

1000

0000000

ori

önemi

εκ

νε

νο.

e

sema

ss

SRO.

408

ae

сони

πώ

«κο

κώνο.

yes

à

PETRI

e

corre

cer

rara

rie a cre è eee

esilsüsememe

sec.

N

suisse

een

вина

pe

ee

Sages

lada

Bern

지애,

ee

ee

2-2

2-4

SİNE

3-2

이이

3-10

4-2

4-2

4-3

4-4

5-2

5-2

se e 5-2

оков

5-2

5-3

5-3

5-3

dado

5-3

6

em

5-5

5-5

5-5

기 에 5-5

5-5

sia

5-6

5-7

5-7

5-7

1-3

1-4

1-5

1-5

1-6

复

350265

Ill

Page 4

5540,

5545, & 5550

WARMING

1.

General

CABINETS

Description

SECTION

DESCRIPTION

TOUCHCONTROL:PANEL

TEMPERATURE

EATEDIAIRIEOWI

CONTROL

OF

BOARD

COMPONENTS

CONVERSION

DETAIL

1.

GENERAL

0

RES

CHART

に

に に ee

............

DESCRIPTION

..................

...............

т.

aie

1-3

1-4

1-5

1-5

1-6

DESCRIPTION

GENERAL

1.

SECTION

350265

1-1

Page 5

5540,

1.

General

5545, & 5550

Description

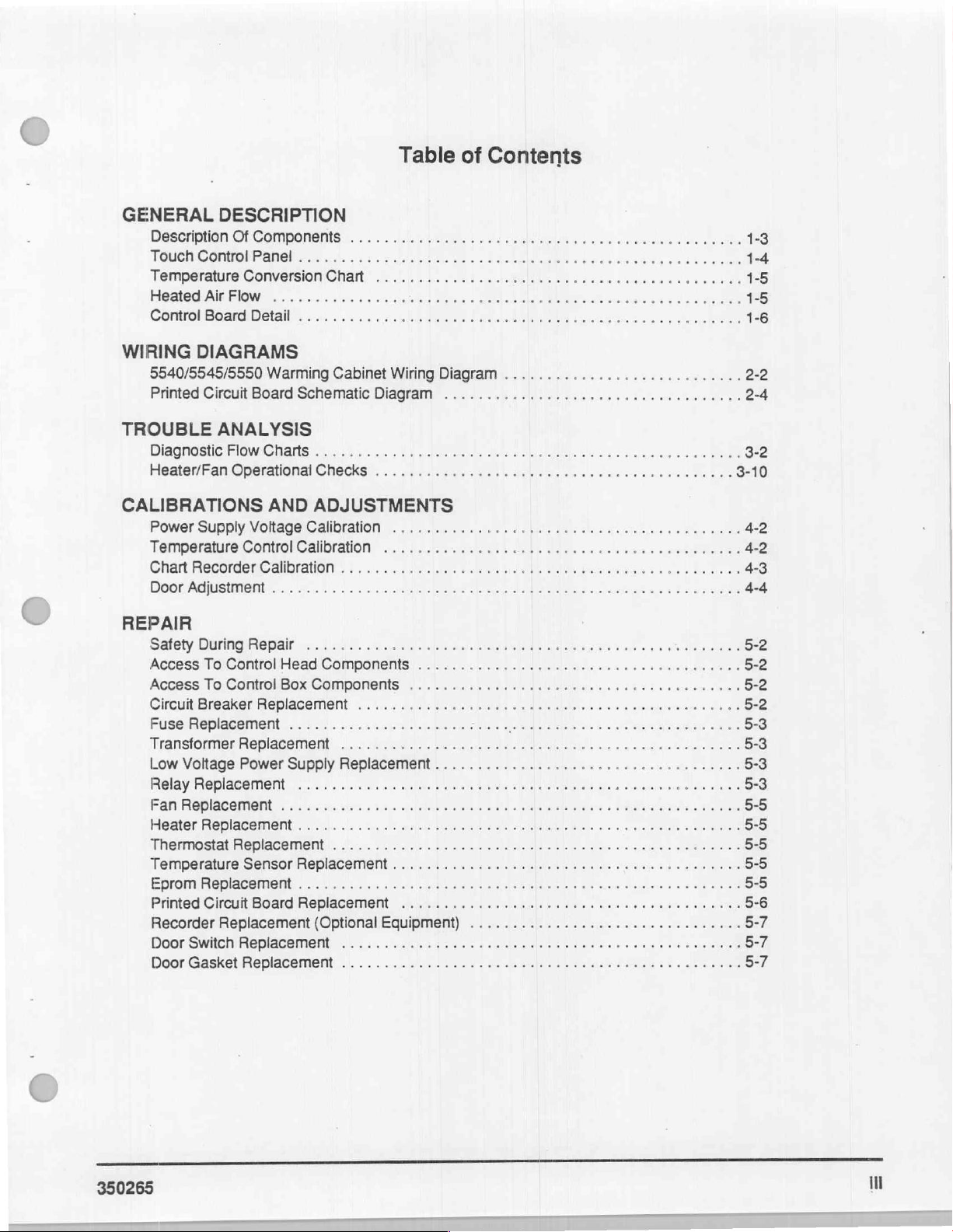

CENTER

(STORAGE)

COMPARTMENT

WARMING

CONTROL

ASSEMBLY

CABINETS

HEAD

CENTER

(STORAGE)

COMPARTMENT

CONTROL

HEAD

ASSEMBLY

RECORDER

(OPTIONAL)

RECORDER

(OPTIONAL)

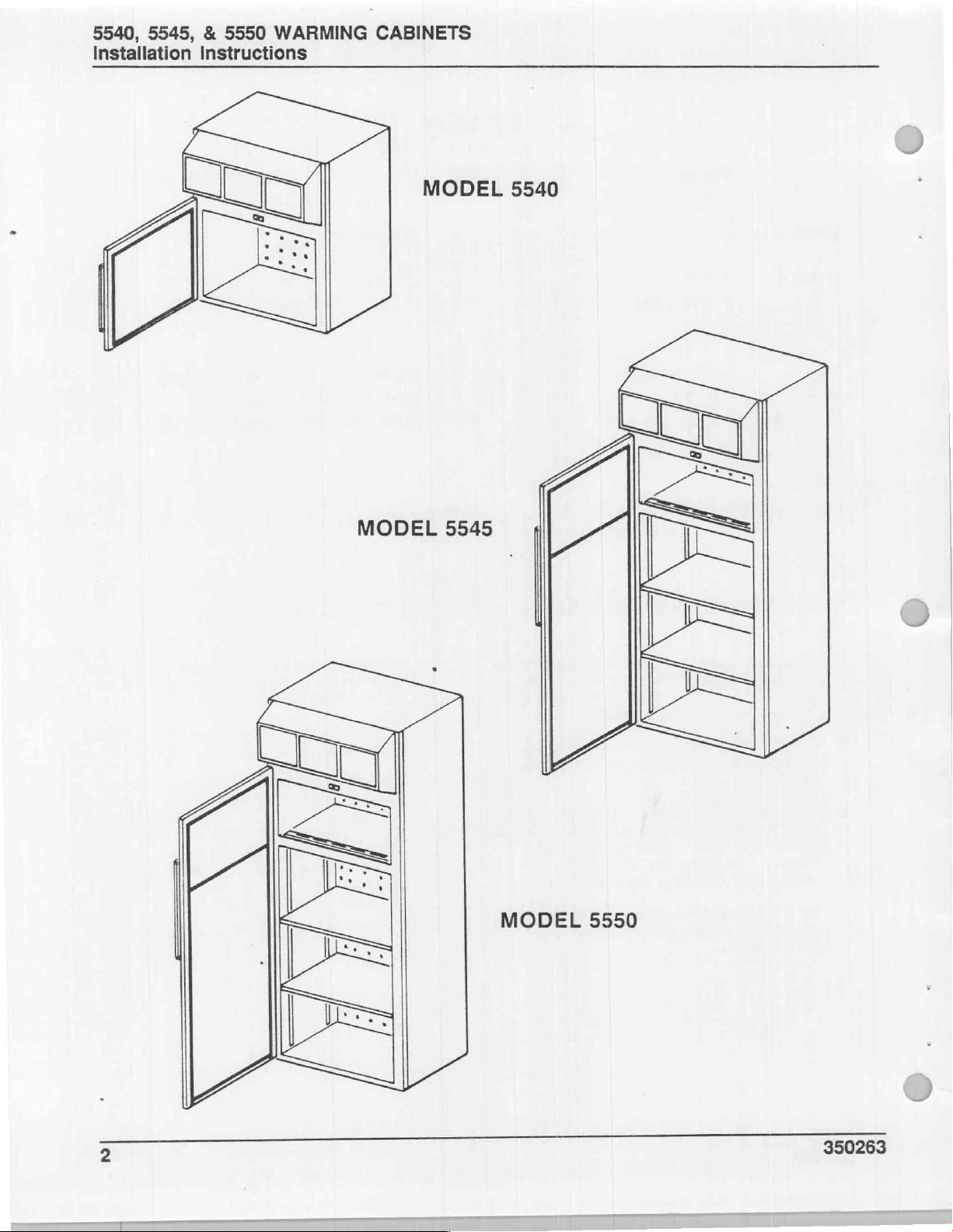

MODEL

(Cabinet

CENTER

(ЗТОВАСЕ)

COMPARTMENT

SHELF

FILTER

5550

Model)

CONTROL

ASSEMBLY

HEAD

PANEL

soar

SWITCH

SHELF

FILTER

ADJUSTABLE

SHELVES

CONTROL

PANEL

soda

SWITCH

RECORDER

(OPTIONAL)

ADJUSTABLE

SHELVES

|

RED PEN 一 一 一 一 |

DOOR

ACTUATED

SATO

a

MODEL

(Cabinet

o,

A

SNS

5545

Model)

jE

9

Eh

CONTROL

PANEL

DOOR

SWITCH

UPP

HEATED

ICOMPARTMENT

HEATED

DEFLECTOR

UNHEATED

OMPARTMENT

AIR

LOWER

о

1-2

MODEL

(Cabinet

5540

Model)

MODEL

MDT/CASTLE

5545 & 5550

(Recessed

Model)

5540,

5545,

and

5550

WARMING

OPTIONAL

CABINETS

RECORDER

MODEL

(Recessed

5540

Model)

350265

Page 6

GENERAL

Castle

designed

kets,

is

The

partment

located

air

The

partment

adjustable

does

lower

regardless

The

over

is

provided

lower

provided

lower

DESCRIPTION

Door

Closing

switch

circuit.

shuts

Filter

Keeps

the

upward.

5540,

for

towels,

adjustable

compact

capable

in

the

and

directs

5545

Warming

and a lower

not

circulate

compartment

5550

Warming

items

placed

capable

of

are

three

in

shelves

Switch

the

and

Opening

off

electrical

airborne

heated

DESCRIPTION

5545,

and

the

heating and

and

other

dry

from

36°C

5540

Warming

of

holding

front

of

the

it

upward.

Cabinet

unheated

shelves.

of

the

holding

adjustable,

compartments

the top

and

warming

allows

compartment,

Air

into

remains

upper

Cabinet

on

each

20

two-liter

shelf,

directs

OF

COMPONENTS

cabinet

electrical

the

door,

power

and

dust

5550

Warming

storage

goods.

(97°F)

Cabinet

20

of

Cabinet

to

71°C

provides

two-liter

compartment,

has

an

upper

compartment

from

the

upper

the

lower

compartment,

at

ambient

compartment's

circulates

of

its

four

shelves.

flasks.

thus

allowing

to

be

adjustable.

filters

the

heated

it

upward.

door

depresses

power

to

contact

releases

to

the

debris

and

the

heating

circulating

from

directs

Cabinets

solutions,

temperature

(160°F).

one

flasks.

filters

Its

the

heated

heated

with

compartment

so

temperature

temperature.

heated

The

the

air

evenly

Each

two

shelves

height

The

air

from

of

the

the

heating

door

switch

circuit

and

through

heated

the

are

blan-

com-

filter,

com-

two

the

shelf

the

filter,

the

door

and

fan.

air

5540,

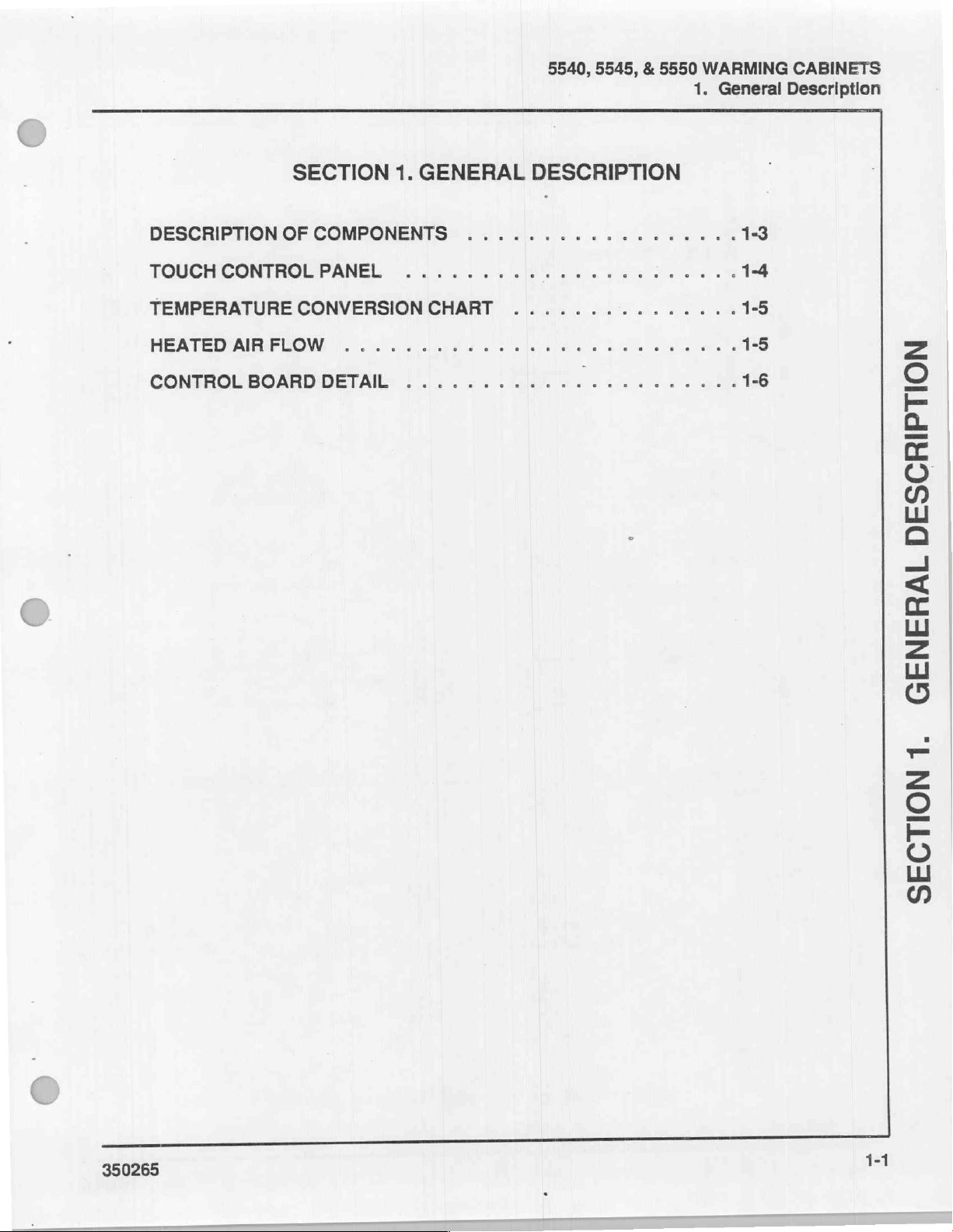

Optional

A

warming

recorde?

a

24

hour

DOOR

ACTUATED

SWITCH

Recorder

single

degree

over a 24

Door

Actuated

triggers

recorder

If

you

wish

recorder

switch

outward.

NOTE

|

5545, & 5550

Recorder

cabinet

to

record

period.

——8

OPTIONAL

Chart - The

increments

hour

period.

Switch - Closing

this

switch

door

triggers

to

record

door

is

open,

When

pen

and

will

door.

may

be

the

temperature

o

—

recorder

from 0 to

to

start

this

the

cabinet

simply

you

open

arm

automatically

moves

remain

WARMING

1.

General Description

equipped

o

of

CABINETS

with

an

the

cabinet

CHART

RECORDER

chart

is

graduated

100°C

(32

to

the

recorder

the

recorder;

switch

temperature

pull

the

to

the

until

you

to

holding

opening

stop

the

the

door

recorder

lifts

off

ramp

close

the

recorder.

while

door,

the

optional

over

in

212°F)

door

the

the

actuator

the

chart

where

it

recorder

en

Control

Center

be

May

cartridges,

pens,

350265

Head

Assembly

Storage

for

used

Compartment

access

ready

etc.

recorder

of

charts,

ink

Page 7

5540, 5545, & 5550

1.

General

Description

WARMING

CABINETS

Adjustable

(Models

To

increase

partments,

adjustable

Main

Turning

located

power

to

the

Transformer

The

transformer

to

provide

Overtemperature

This

switch

from

the

192°F,

Heaters

The

warring

ers.

These

sockets

Fans

Two

“Heated

5545

shelves.

Power

off

under

from

circuit

24V

heaters.

inside

fans

circulate

Air

Shelves

and

or

decrease

you

Switch/Circuit

the

the

the

control

breaker

for

closes

cabinet

heaters

the

Flow.”

5550

Only)

may

raise,

main

power

control

circuit.

output.

steps

down

the

chart

Switch

at

212°F

The

overtemperature

uses

screw

control

the

the

height

lower,

Breaker

switch/circuit

head,

removes

Power

the

electrical

recorder.

to

remove

two

500W

into

the

two

box.

heated

air

of

the

or

remove

all

is

still

electrical

switch

cone-type

middle

as

illustrated

three

com-

the

breaker,

electrical

present

power

input

power

resets

heat:

electrical

two

up

at

in

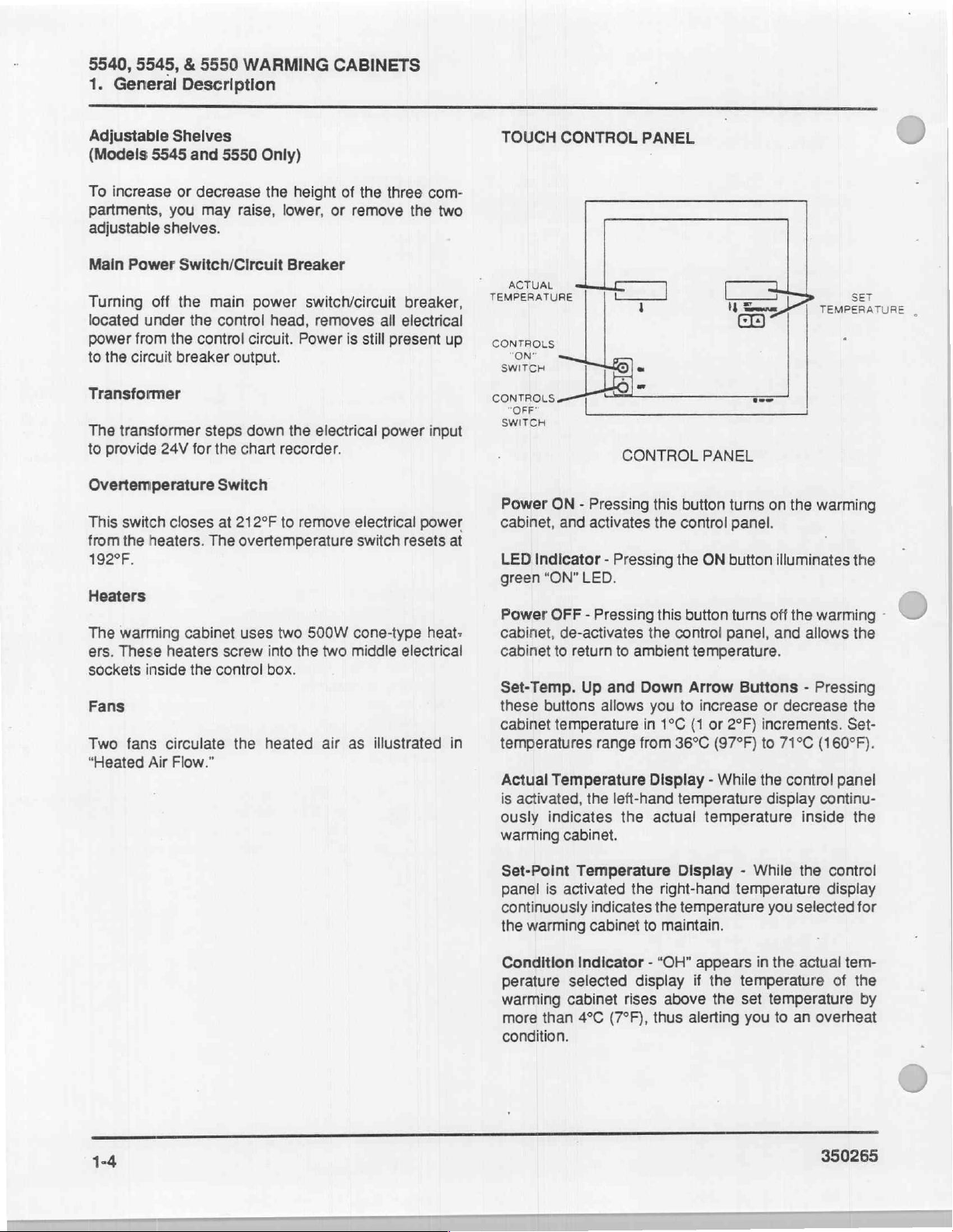

TOUCH

TEMPERATURE

CONTROLS

SWITCH

CONTROLS

"OFF"

SWITCH

Power

cabinet,

LED

green

Power

cabinet,

cabinet

Set-Temp.

these

cabinet

temperatures

Actual

is

ously

warming

CONTROL

| | ヒー

ON"

ON - Pressing

Indicator - Pressing

“ON”

OFF - Pressing

to

buttons

temperature

Temperature

activated,

indicates

LE

|

CONTROL

and

activates

LED.

de-activates

return

to

Up

and

allows

range

the

left-hand

the

cabinet.

PANEL

|

1

-

=

PANEL

this

button

the

control

the

ON

this

button

the

control

ambient

Down

in

from

temperature.

Arrow

you

to

increase

1°C

(1

or

36°C

(97°F)

Display - While

temperature

actual

temperature

İP

$

=

TEMPERATURE

CD

=

turns

on

the

warming

panel.

button

panel,

2°F)

illuminates

turns

off

the

warming

and

allows

Buttons - Pressing

or

decrease

increments.

to

71°C

(160°F).

the

control

display

continu-

inside

se

|

the

the

the

Set-

panel

the

Set-Point

panel

continuously

the

warming

Condition

perature

warming

more

condition.

Temperature

is

activated

indicates

cabinet

Indicator - “OH”

selected

cabinet

than

4°C

(7°F),

the

the

to

display

rises

thus

Display - While

right-hand

temperature

maintain.

above

temperature

appears

if

the

the

alerting

temperature

set

you

the

you

selected

in

the

actual

temperature

to

an

overheat

control

display

for

tem-

of

the

by

350265

Page 8

5540,

5545, & 5550

WARMING

1.

General Description

CABINETS

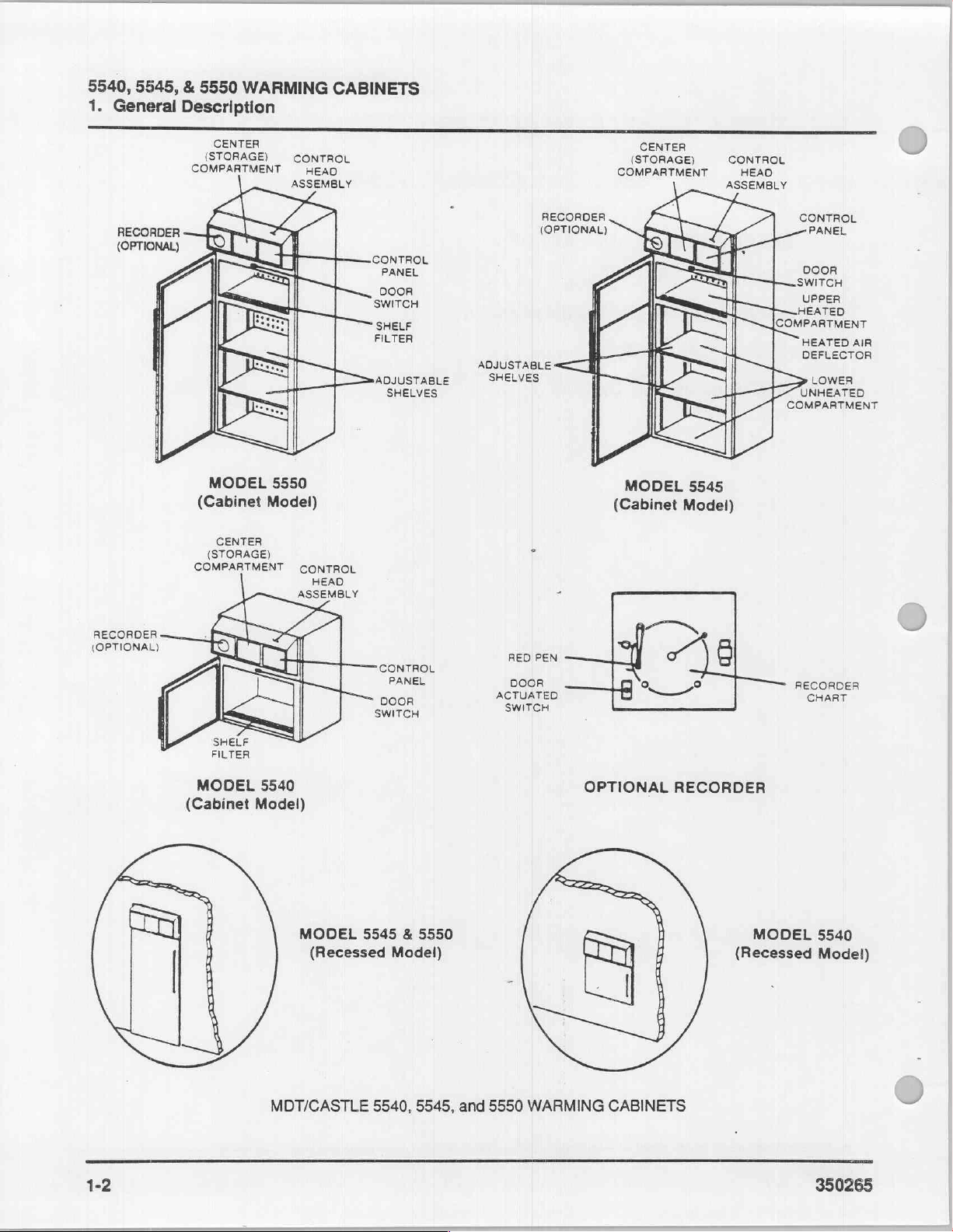

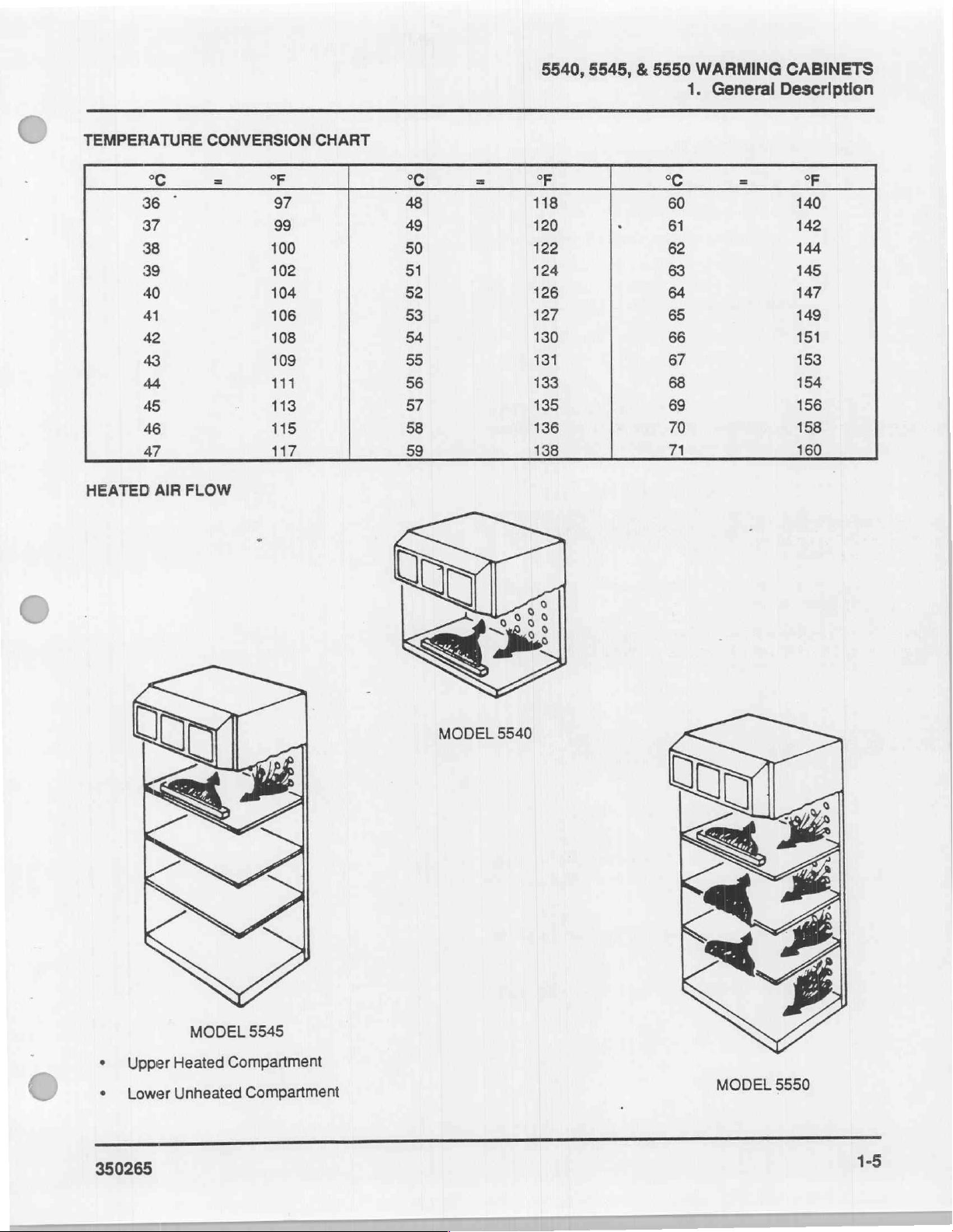

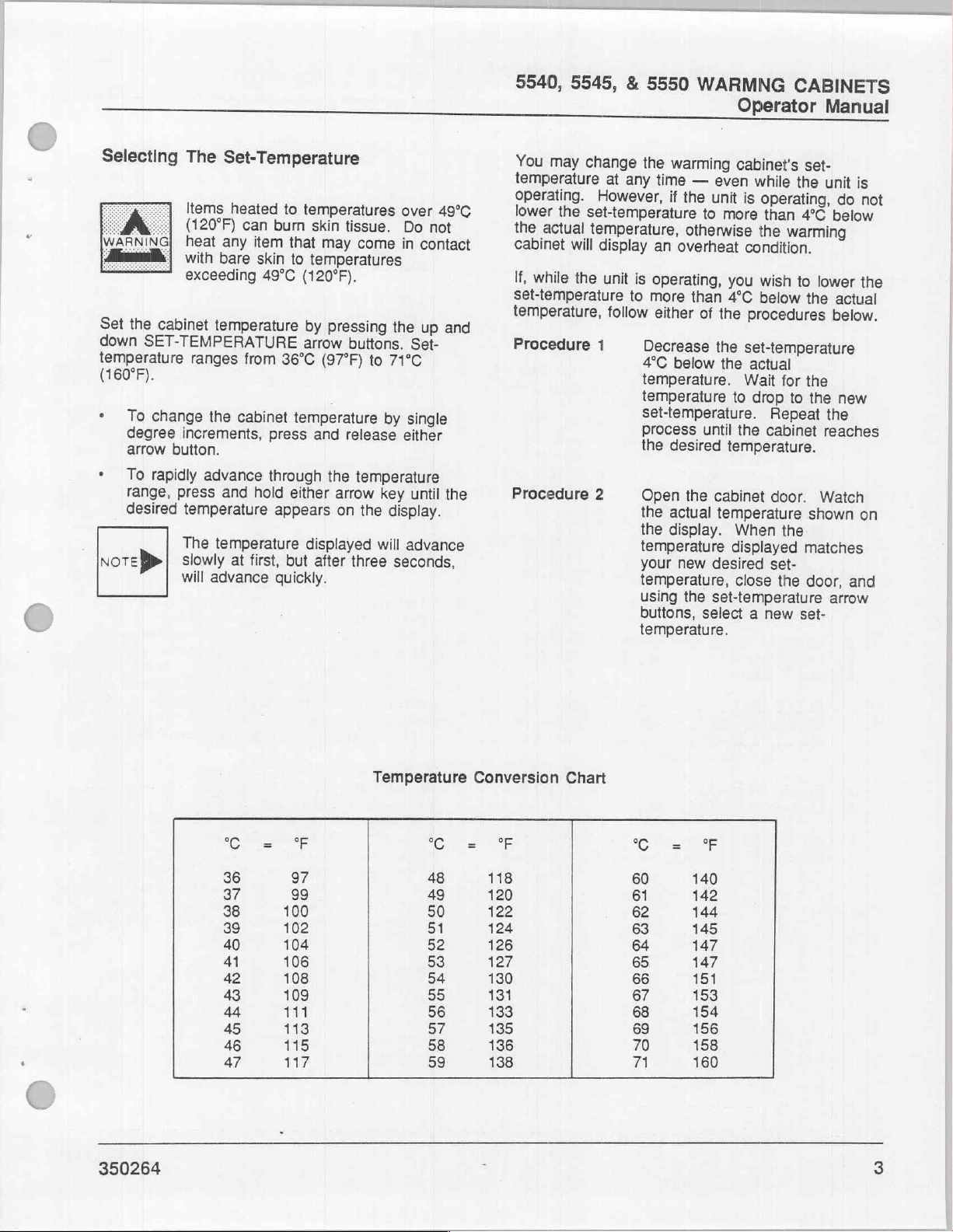

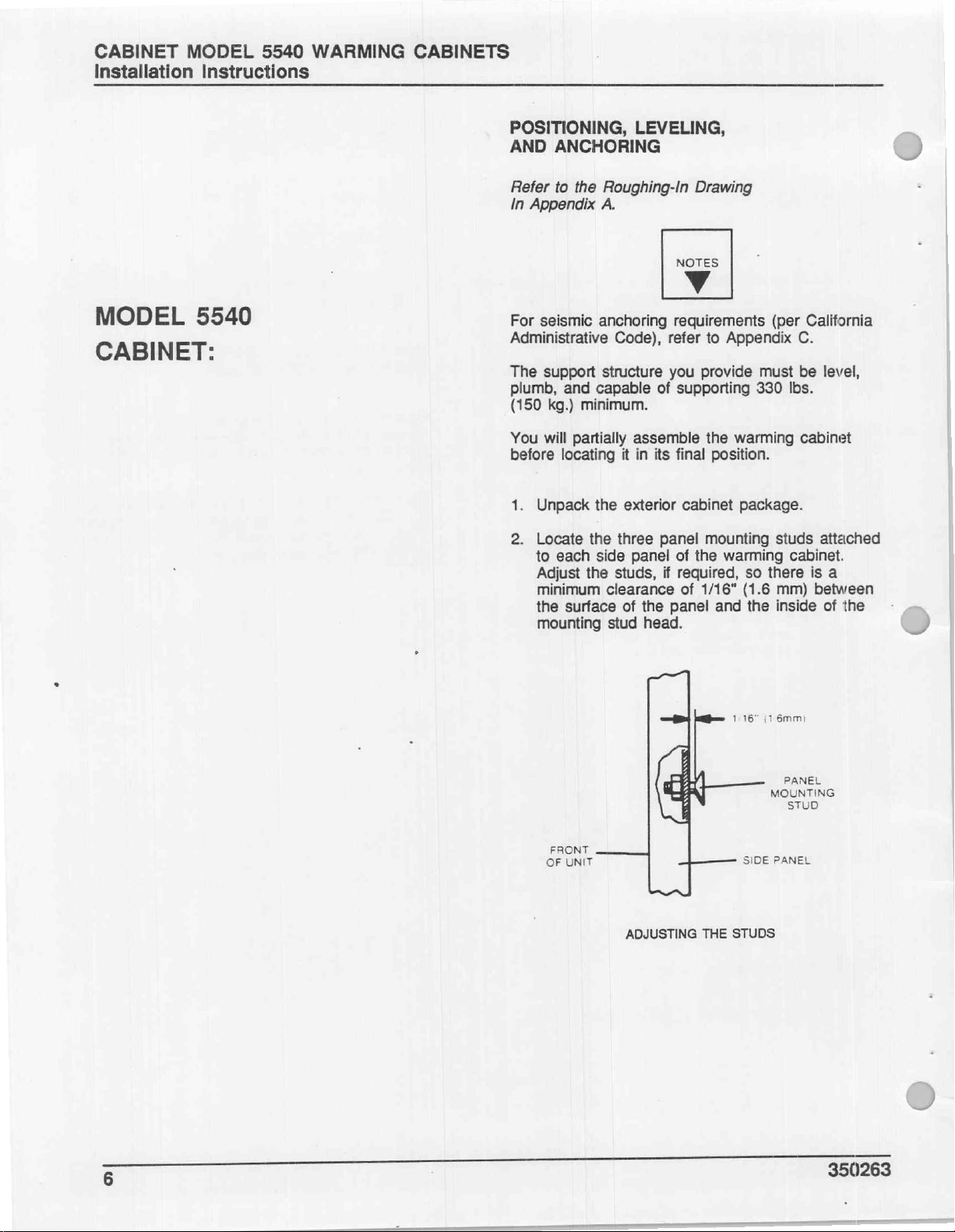

TEMPERATURE

HEATED

°C

36

37

38

39

40

41

42

43

44

45

46

47

AİR

CONVERSION

*

FLOW

=

SE

97

99

100

102

104

106

108

109

111

113

115

117

CHART

26

48

49

50

51

52

53

54

55

56

57

58

59

=

SE

118

120

122

124

126

127

130

131

133

135

136

138

°С

60

61

62

63

64

65

66

67

68

69

70

71

a

oF

140

142

144

145

147

149

151

153

154

156

158

160

*

Upper

‧

Lower

350265

MODEL

Heated

Unheated

5545

Compartment

Compartment

MODEL

5540

MODEL

5550

1-5

Page 9

5540, 5545,

General

1.

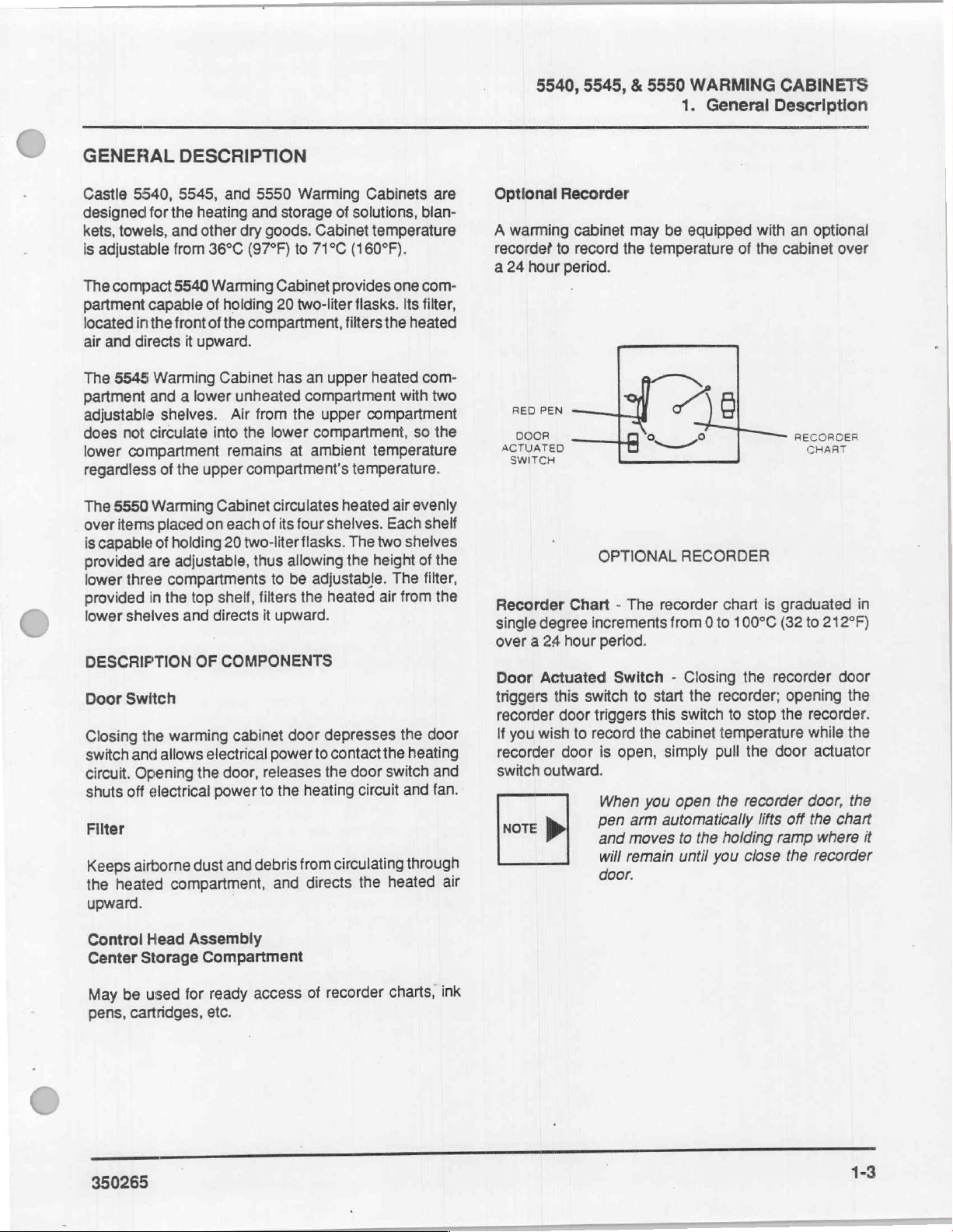

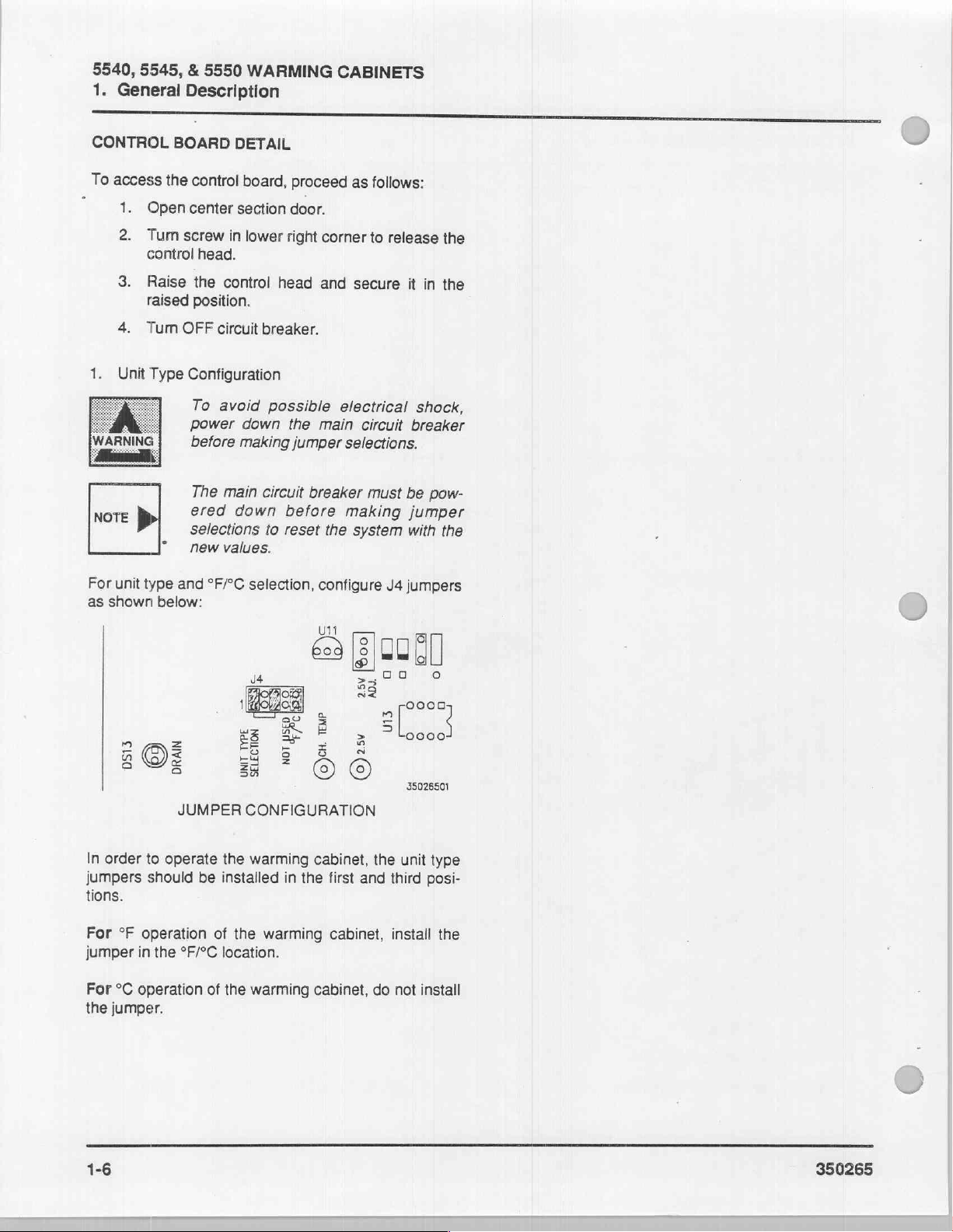

CONTROL

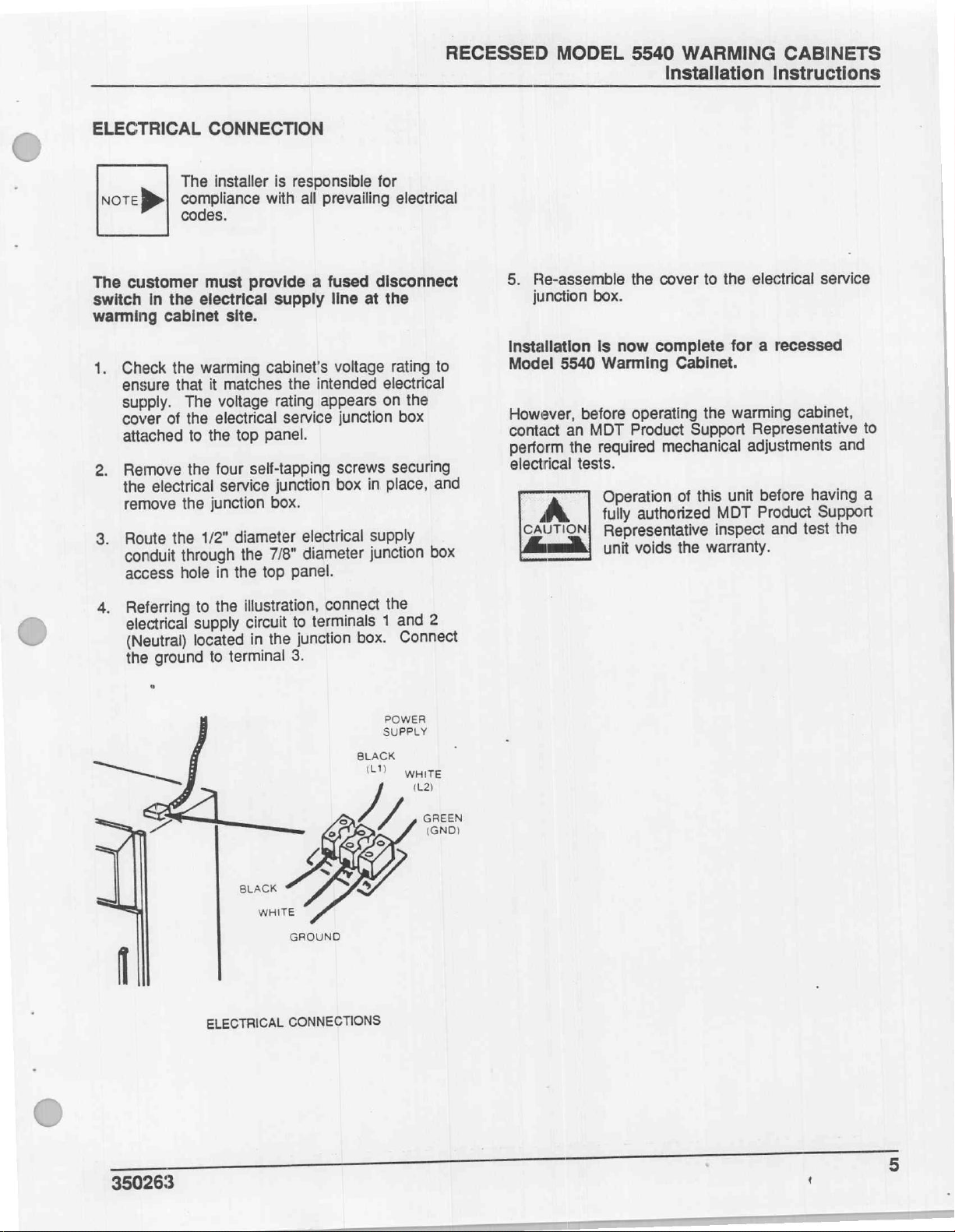

To

access

1.

Open

2.

Tum

control

3.

Raise

raised

4.

Tum OFF

1.

Unit

Type

WARNING

NOTE

|

|

&

5550

Description

BOARD

the

control

center

screw

in

head.

the

control

position,

circuit

Configuration

To

avoid

Power

before

The

main

ered

selections

new

values.

WARMING

DETAIL

board,

section

down

making jumper

down

lower

right

head

breaker.

possible

circuit

before

to

reset

proceed

door.

corner

and

the

main

breaker

the

CABINETS

as

follows:

to

release

secure

electrical

selections.

making

system

circuit

must

it

be

jumper

with

the

in

the

shock,

breaker

pow-

the

For

unit

as

shown

In

order

jumpers

tions.

For

°F

jumper

For

°C

the

jumper.

type

and

below:

3

DS13

5

JUMPER

to

operate

should

operation

in

the

°F/°C

operation

°F/°C

125956

ES

EE

35

the

be

installed

of

the

location.

of

the

selection,

configure

UN

oa

=

+

5,

BSE

5

BS

©

CONFIGURATION

warming

warming

warming

cabinet,

in

the

cabinet,

first

cabinet,

J4

=

[8]

00

>50

0

RE!

|

5) > laces

the

unit

and

third

install

do

not

jumpers

(|

o

0008

2

35026501

type

posi-

the

install

1-6

=

350265

Page 10

С

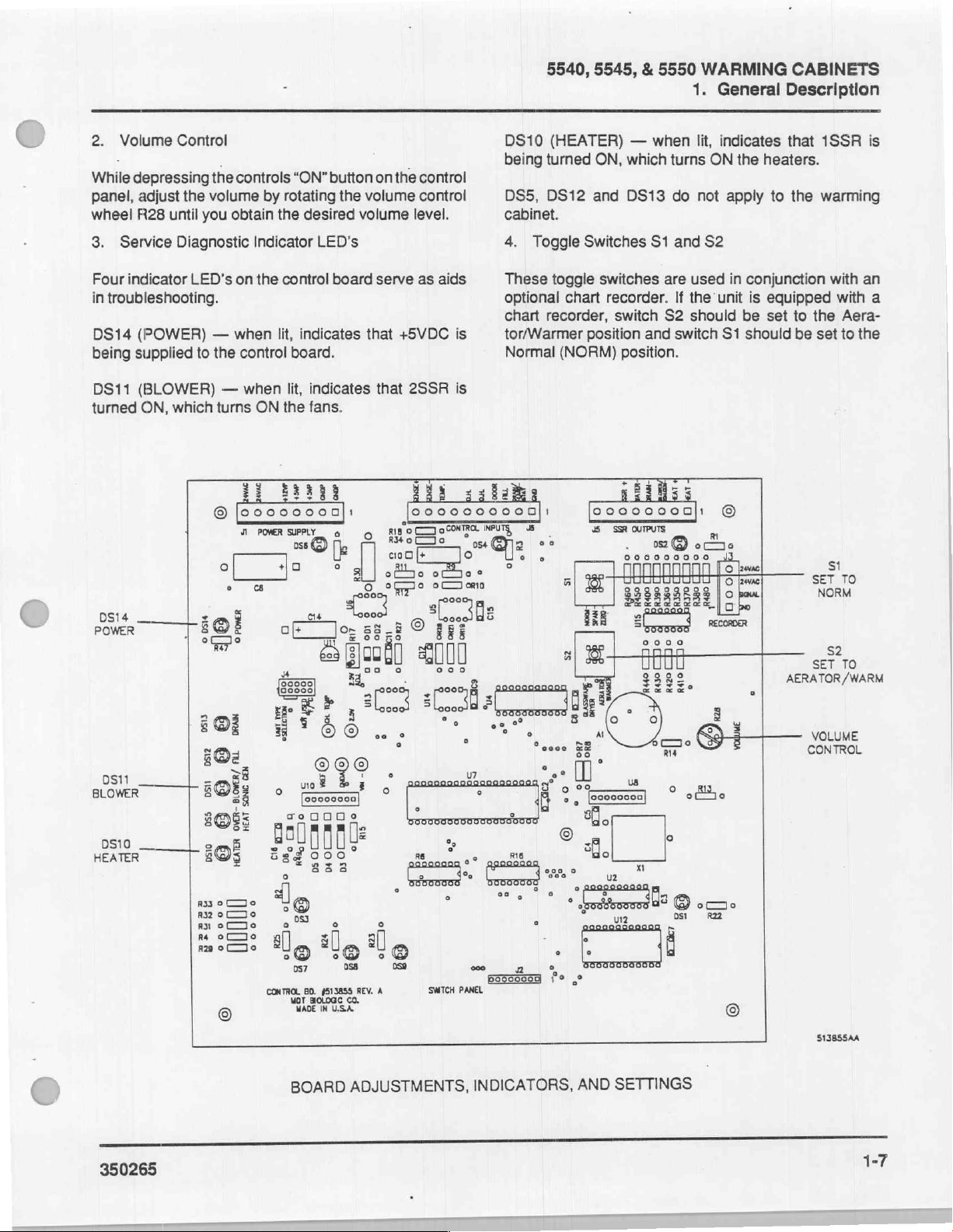

2.

Volume

While

panel, adjust

wheel R28

3.

Service

Four

indicator

in

troubleshooting.

DS14

being

DS11

turned

Control

depressing

until

Diagnostic

(POWER)

supplied

(BLOWER)

ON,

which

al

the

you

LED's

to

pnl

°°

the

controls

volume

obtain

on

—

when

the

control

—

when

turns

1

©

|ooooo000|:

q

οἱ

ㆍ

“ON”

by

rotating

the

desired

Indicator

the

ON

LED's

control

lit,

indicates

board.

lit,

indicates

the

fans.

O

do

a

um

Jo;

of

&

a

=

button

the

volume

volume

board

that

fi

o

|

Я

°

o

yi

Los

58-8

food]

3

dk

33,

on

the

level.

serve

+5VDC

that

2SSR

ΕΠΗ:

0000000000]!

no]

Bore

cio

оо

oro

®

i

E

С

control

control

as

aids

is

is

ocoNTRO

+

обще»

ooo

A:

Е

BE

2000

2

DS10

being

DS5,

cabinet.

4.

These

optional

chart

tor/Warmer

Normal

INPUT

Oz

°

y

:

5540, 5545, & 5550

(HEATER)

turned

DS12

Toggle

toggle

chart

recorder,

(NORM)

—

ON,

which

and

DS13

Switches

switches

recorder.

switch

position

position.

Gil;

00000000)

o o

点

ος

45

ζω]

5

=

FRE

s

x

FI

SSR

OUTPUTS

.

0060000000

ΠΠΠΠΠΠΠΠΠ

HHHHHHHHH

22322585

НЕЕ

se

when

turns

do

S1

are

S2

and

O

oooo

ロロ

ロロ

0000

9382,

WARMING

1.

General Description

lit,

ON

not

and

S2

used

If

the

unit

should

switch

indicates

the

apply

in

S1

©

that

heaters.

to

conjunction

is

equipped

be

set

should

Do

µε

{ο

eme

Го

[o

ecooa

AERATOR/WARM

.

CABINETS

1SSR

the

warming

with

with

to

the

Aera-

be

set

to

st

TO

SET

NORM

s2

TO

SET

is

an

a

the

0511

_

BLOWER

0510 — o

HEATER

350265

à

>

802.

l

oi

mi

si

e

호

so};

SOR

|

205

6033

ㅇㄷㅇ

032 ㅇ ㄷ ㅋ ㅇ

ryote

moe:

©

emi

no)

«ορ

isd

o

a)

05

©

İş

o

DS7

CONTROL

BD.

Mahe

BOARD

몰

e

ilç

o

058

[513855

REV.

UA

ADJUSTMENTS,

a

il

©

o

059

À

SWITCH

осо

PANEL

2

INDICATORS,

erim

[

pores

2

u

ğ

©

*

ci

ca

i

SETTINGS

AND

VOLUME

CONTROL

513855AA

1-7

Page 11

5540, 5545,

General

1.

NOTES

&

5550

WARMING

Description

CABINETS

350265

Page 12

5540,

5545, & 5550

WARMING

2.

Wiring

CABINETS

Diagrams

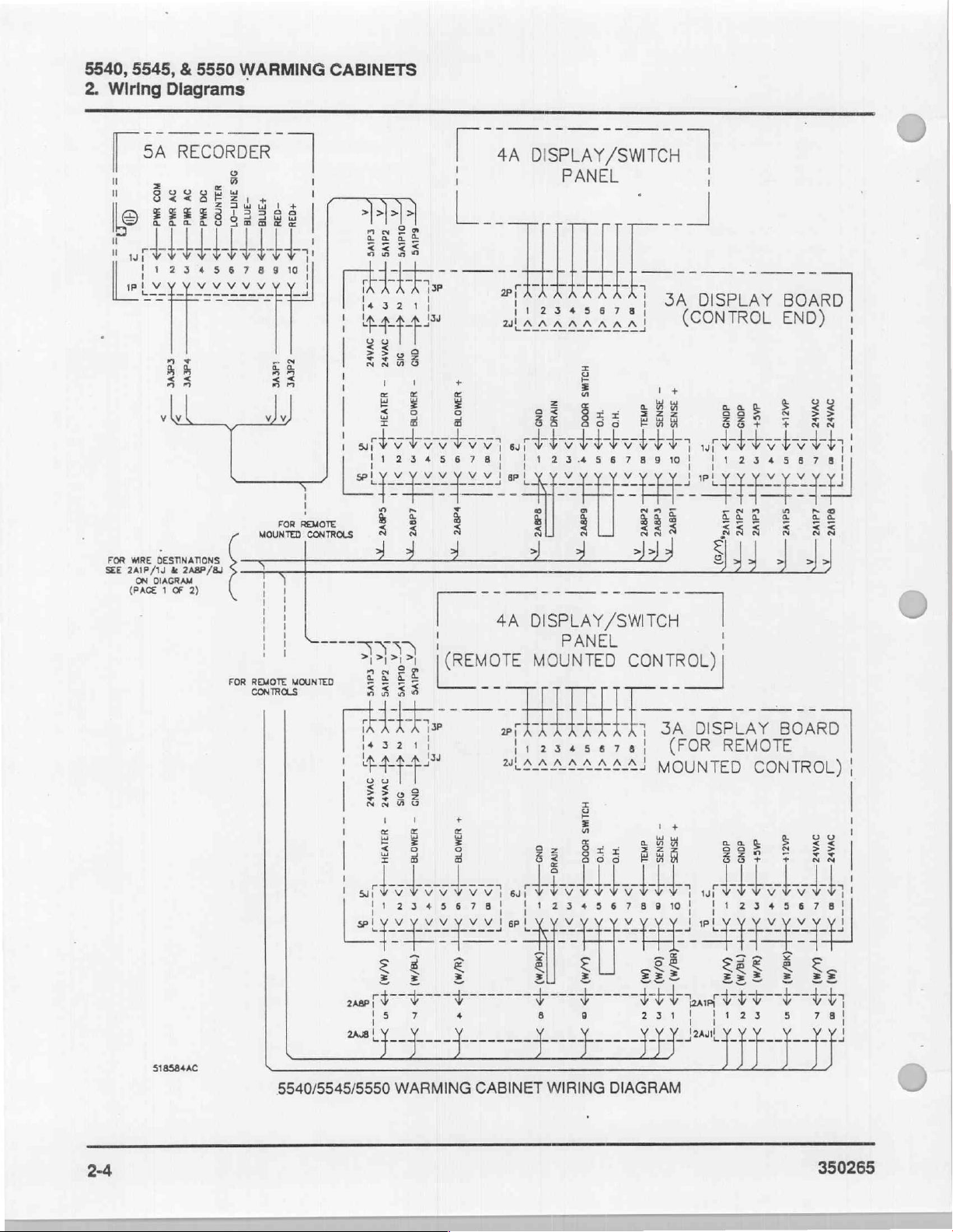

5540/5545/5550

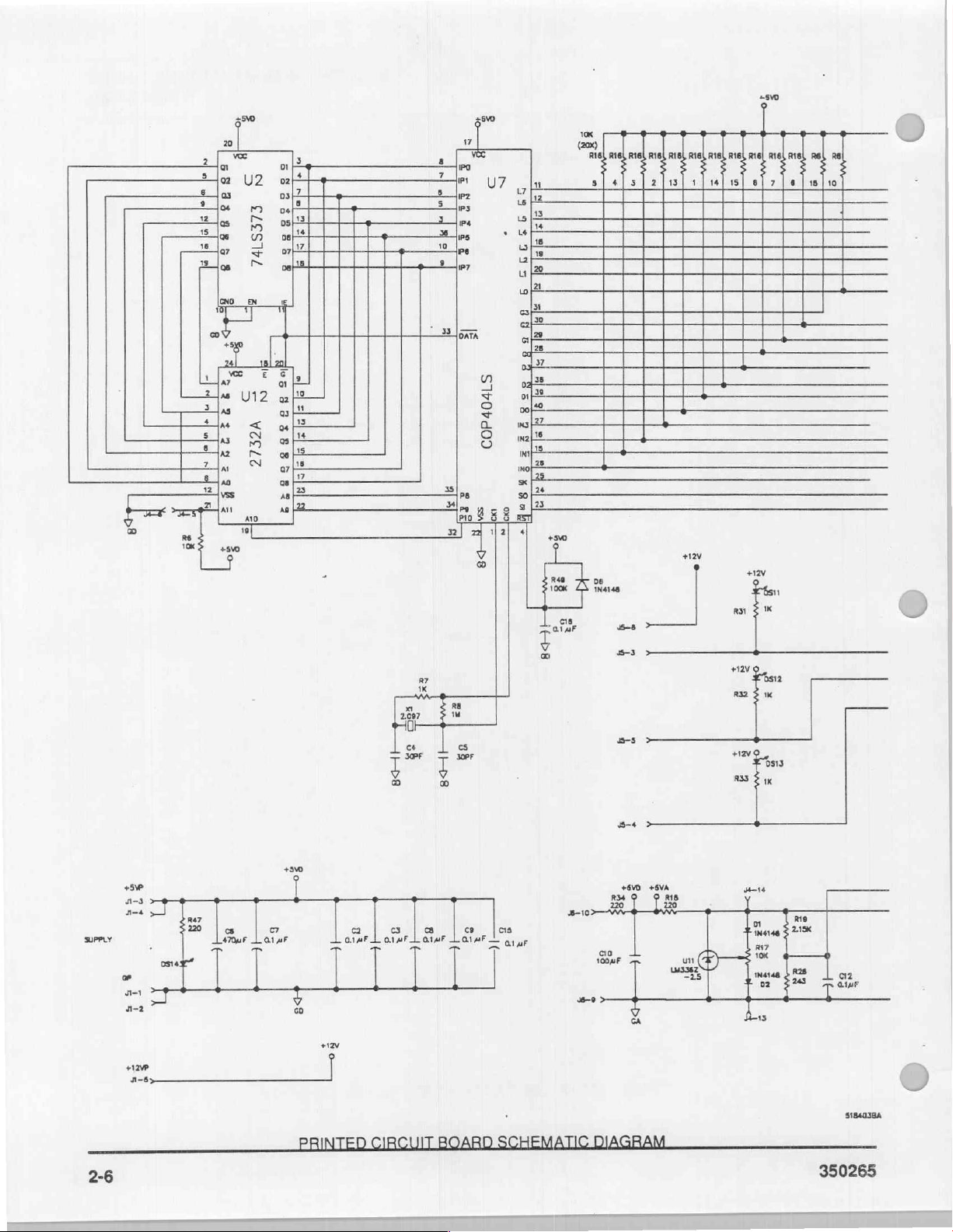

PRINTED

CIRCUIT

SECTION

WARMING

BOARD

2.

WIRING

CABINET

SCHEMATIC

WIRING

DIAGRAM

DIAGRAMS

DIAGRAM

......

........

2-2

2-6

DIAGRAMS

WIRING

2.

SECTION

350265

2-1

Page 13

5540,

2.

Wiring

5545, & 5550

Diagrams

WARMING

CABINETS

©

PE

1

i

1HTR

a

1

Г

1

i

|

|

1

1

Rİ

©

1

|

MAC

LR

ote

i

RE

|

|

|

1

we

mm

ep

R

zome-、

1CB

BU

er ae

2A2ssRs

=.

nr

2AiC83

2A2TB10 十 15

Ca

2TB

u

2

4

=

LE

a

X

a

[ek

9

10

ami

Cron

mm

Е.

von

]

[ls

A]

L

2A1TB2

En ae

a

2A1PSIPS

моек

2A1T4

2A1Fu2

am

24175 © に

AMRS

rem В |

|

| |

|

2SSR

|

RIR

]R

Bu BE

ssa

ca

30

à

=

2

15585

10

DE

2A3HTR

2A4HTR

トー

2HTR SHTR

ет

oe

ーー ーー ae

Naam

>

BR

№

E

—0

(W

(ゆめ

em

cl

RR

353

Sy

1

zů

eee

—

Da

—

29)

=

W

N

242785:

ateo?

ζω,

ATE!

00.

2A2TB

E

2

1SSR

m

(I

2A

CONTROL

R

242782

EK 2 A2FU1

1FU

ana

я

5

2A8J4

2A8J5

call

=

vel

5h>

[418

3

`

2A1PS1P3

-алатаз

Г

7

8

3o-

<

—

PUM

aK

リア

αν

2A4HTR

ohN9

2A1HTR

-一 一 2Aic85

mi

2A2TB3

Ex

A

Ass

EN

Eu

に

POWER

E

SUPPL

ーー

BOX

ーー

(PS.

ый

2d2e

+1

[2]

+05]

-v[6]

Fi

=

2FU

2A2TB8

90

O

m

24147

wm プ 3Pr 大 大 大 4PT た た]

Mm

518584AA

on

E

z

Ê

aaa

‘yaa!

i

SU

qu

vi vi İv

533

きき

if

È

Vas-

[24143

[as

a

___

È

14]!

DASE

3

|

7

F-

|

um

1

i

|

|

|

|

|

i

|

I

|

|

i

A

À

iy

sg

5

3

aa

dizi

7

viv

23

きき

|

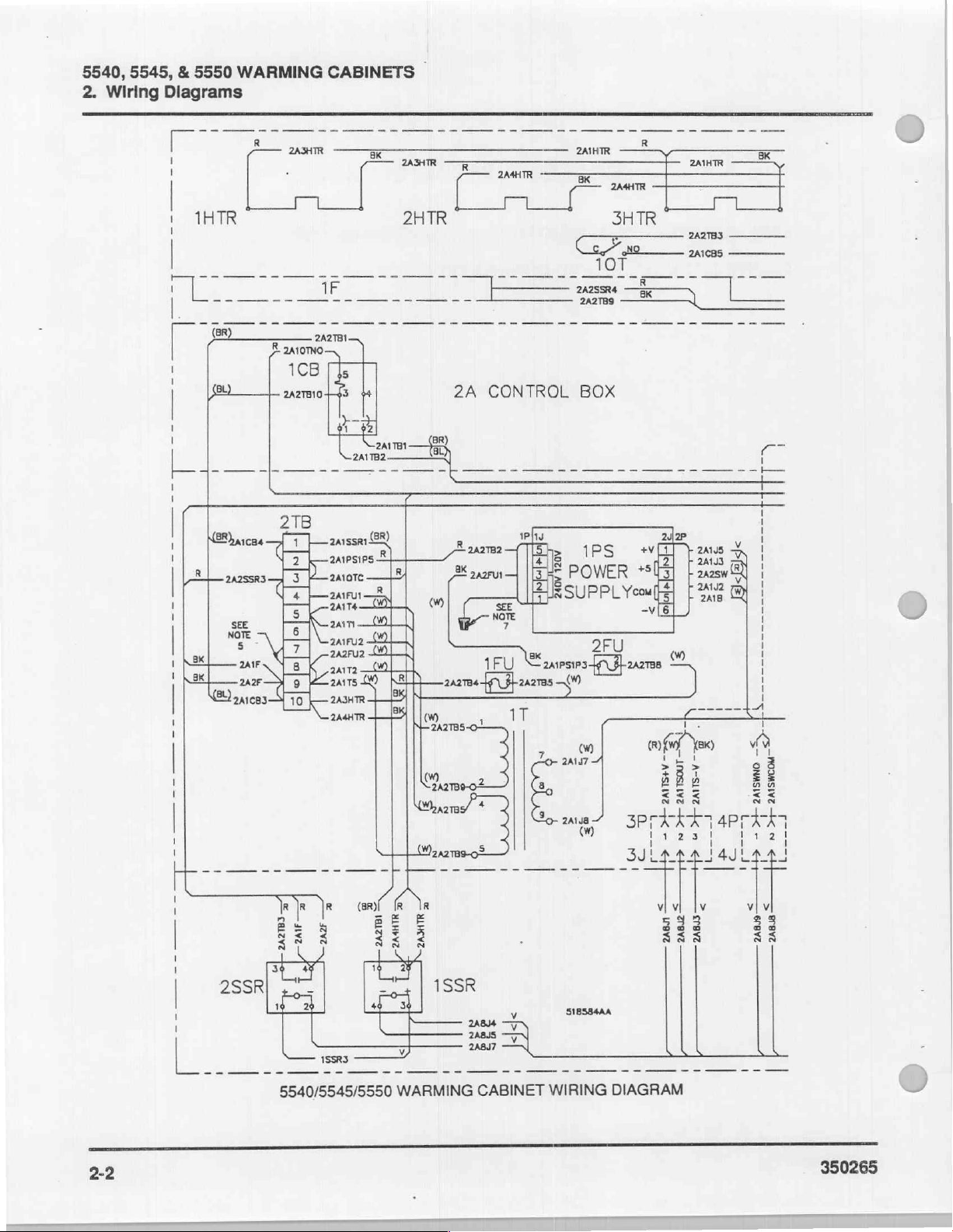

5540/5545/5550

2-2

WARMING

CABINET

WIRING

DIAGRAM

Page 14

2A2HTR

nr

R

4HTR

2F

=

--

2A2HTR

ーー

2AISSR2 一 ak

ーー

F

2A2TB10

ZA1SSR2

2A2T810

2A2SSR4

2A2TB9

ーー

BK

Y

=

an

ーー

©

r 1

5540,

R

—R

вк

一

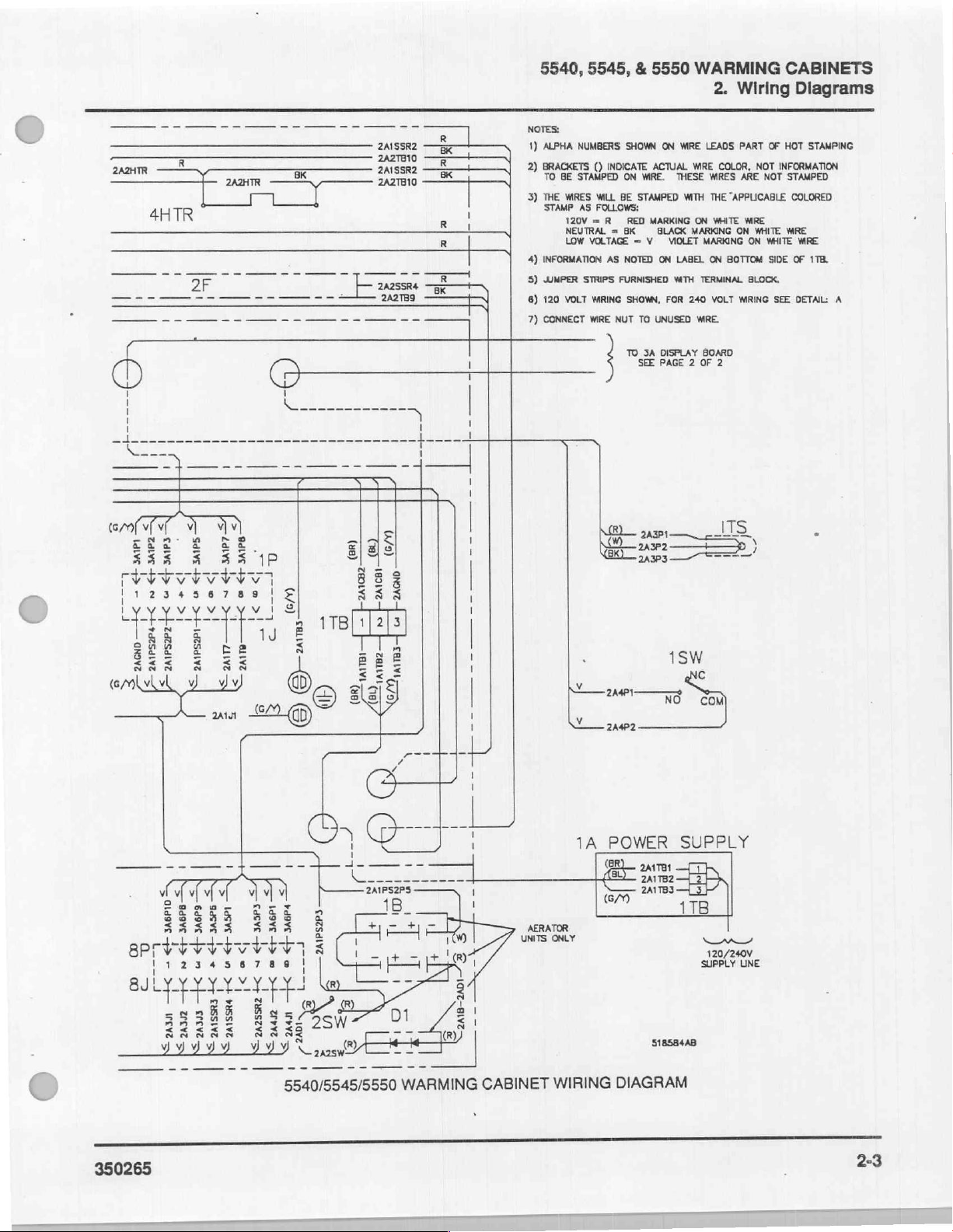

NOTES:

1)

2)

3)

|

4)

=

E]

i

1

5)

8)

7)

5545, & 5550

ALPHA

NUMBERS

BRACKETS

TO BE

STAMPED

THE

WIRES

STAMP

AS

120V = R

NEUTRAL

LOW

VOLTAGE = У

INFORMATION

JUMPER

STRIPS

120

VOLT

MRING

CONNECT

WIRE

()

INDICATE

WILL

BE

FOLLOWS:

=

AS

FURNISHED

NUT

3

SHOWN

ON

WIRE.

STAMPED

RED

MARKING

BK

NOTED

SHOWN,

TO

TO JA

SEE

ON

WIRE

ACTUAL

THESE

WITH

BLACK

MARKING

VIOLET

ON

LABEL

WTH

FOR 240

UNUSED

DISPLAY

PAGE 2 OF

WARMING

2.

Wiring

LEADS

PART

WIRE

COLOR,

MRES

ARE NOT

THE

“APPLICABLE

ON

WHITE

MRE

ON

MARKING

ON

ON

BOTTOM

TERMINAL

WIRE.

VOLT

BOARD

2

BLOCK.

MRING

CABINETS

OF

HOT

NOT

INFORMATION

STAMPED

WHITE

MRE

WHITE

SIDE

SEE

Diagrams

STAMPING

COLORED

MRE

OF

1TB

DETAIL:

A

|

ss

ipo

一 一 一

eV

fy 出 二

1

RE

(Mv

一

gam

zie

545

yy

YY ツマ VI

LS

233

Ве

さき

ささ

VI

3A6P8

3A6PID

『

D

©

<+

=

c

œ

(===

1

Y

&

Я

4

à

る

weps

ト

人

和

<

e

©

—{<

—İ<

MY

Re

ЕЁ.

35

re

=

ささ

34506

는

1

М5Р!

<

<

è

и

1

<

すく

«ος

し

ARTE

ele

1

(P

а

MÉ

@)

3Α5Ρ5

«ἰ-

3AGP1

で

m

ie

—+<

la

을

x

Φ

34604

<T-

©

—<

enna

alae

=

=

m

ES

5

882

Sais

EBE

ЕЯ

SES

um

Lo

1

由

1

1

1

|

i

1

!

ㅣ

E

AERATOR

UNITS

ONLY

R

2A3P1

а

24303

ο

“一

2A4p2

1A_POWER

GR

241781

トー

2Aimms

>

1SW

τὸ

182

1TB

ITS

==

><)

=

c

Ma

SUPPLY

|

NA

120/240V

SUPPLY

-

LINE

350265

2A3J1

<

<

1

24343

ЗАЗ

< < <

1

2A1SSR3

2A1SSR4

1

1

2442

zm

2А25582

2401

<

S

<

~

È

5540/5545/5550

WARMING

518584АВ

CABINET

WIRING

DIAGRAM

2-3

Page 15

5540,

2.

5545, & 5550

Wiring

Diagrams

WARMING

CABINETS

ここ

===.

ニー

His

@,

=

2

5

Sabe

бы

Sy

woo

ov

ma

>

&

-

>!

serve

yi

5388

eR

2830

oy

518584AC

WALNNOD

ov

owa

MdA

—>

一

w

2

0

>

>!

개

|!

parve

88,

ua

SIS

INN-OI_l>

‘amato

n

o

>!

3!

хм

sv

é

e

~~

ER

mbe:

a

Tps

>

sos!

o

>

m

ii

¡deve

ны

3

2

レト

ーーーーーーーー-

3

98

oF

=

age

a

2

ŞE

88

9

)

3

1

!

i

È

a

a

В

a

5540/5545/5550

Edive

zdlys

TH

4L<

-THT<

+

9

の

<

«L

<4—

ovasz

ovArz

98

-

alvaH-

bal,

BERN

ラ

>

ー

>

オーcdmve

|

Nİ

LE

as

o

cave

er.”

НЕ

|<

M

+

<

<|-

эми

OVA

—

VVS

Deli

43

—

>-

WM)

>

33

0

>

WARMING

ua

十

Da

|

ce

-

<t—

흐

ano

-

yoe

下

i>o

1>

PP

”>

<

>!

>

1

deve

x

L

CE

ÈS

me

H<

ias

ÇÜ

—

«ian

-

знову

>

e

E

>!

>

(18/M)

Pr

|

>

|

La

i

0

+

mole»

Des

I>n

wo

>|

>I

dove

n

|

il

o

을

|

i

MIMO

—İ>

peg

Dr

©

>-

(WM)

P

!

SO

+

>

|

CABINET

+

1

に

이

a

ww

ec

É

yi

|

|

<

」

t<

ヒーーー

—

ニ

J

<I

2

-4

оу

<

Ly

y

а

LS

2

as

gı

|

1

1

o

>

=

=

Sel

ic

Муна

ano

>

м

>!

save

!

o

O.

o

3

-=

-<<

aa

SI

m—p

Nvua—+>

-

6

>

===>

Fan

-

|

©

HA

i

WIRING

su

2

Ga

<

4

HA

Hed

더

을

I<

n<l

xl

<I

HOLWS

80000

mo

Hols

ban

a

à

of

1

SL!

sdgvz

M

Nİ

i

I

SUA

4

マラ

ZE

о

mrk

HK

ded

pre

lew

<

<i

19

a

west]

ob

bel!

1

>

tl

wo

|

1

起。

>

|

1

|

DIAGRAM

=

은

fo

=

SNS

ara

>

=

a

EL

coeve

20068

-

一

시

i

©

=

z

!

ーーーー

=

ュ

-

ssNds

di

+>

15

o

w

>

(0/0)

の

や

>

>]

|

T

==

|

|

!

LE

no

=

OS

+anst>

Ea

a

를

©

>

|

r

=

GB

o

E

|

4

1955

|

se

GK

F

=

+

35N

—I>

n

Lt

2

2

>

a

uen

on

-

A

RN

2

y

I

SISI

の

<O

Pe

ast—t>

oo

dano—t>

一

I>*

>

©

—

m

>

cave

dI

>

вам

ινε

τη

AN]

一

人

ーー

1

JU

a

3

Cw

a

o

©

ded»

da

dm

一

<>

1>

已 -

+

n

E

HI

>

>

t+

teva)

wm)

ws)

τος

ba

+>

AS

E

sn

Е

i

i

Ip

O

mu

9vAvz

Att

>

一

booli

>

~

n

>

4010

i

Sdivz

|

1

го

mp

<

É

0

그

oz

dz

一

—>

>

e

に

B

>

トー

>

мун)

Wm

+>

©

n

m

>

一

E

OMZ

>

원

=

VE

>

©

=

>=

o

=

-m

===

]

SE

=

=

+

2-4

350265

Page 16

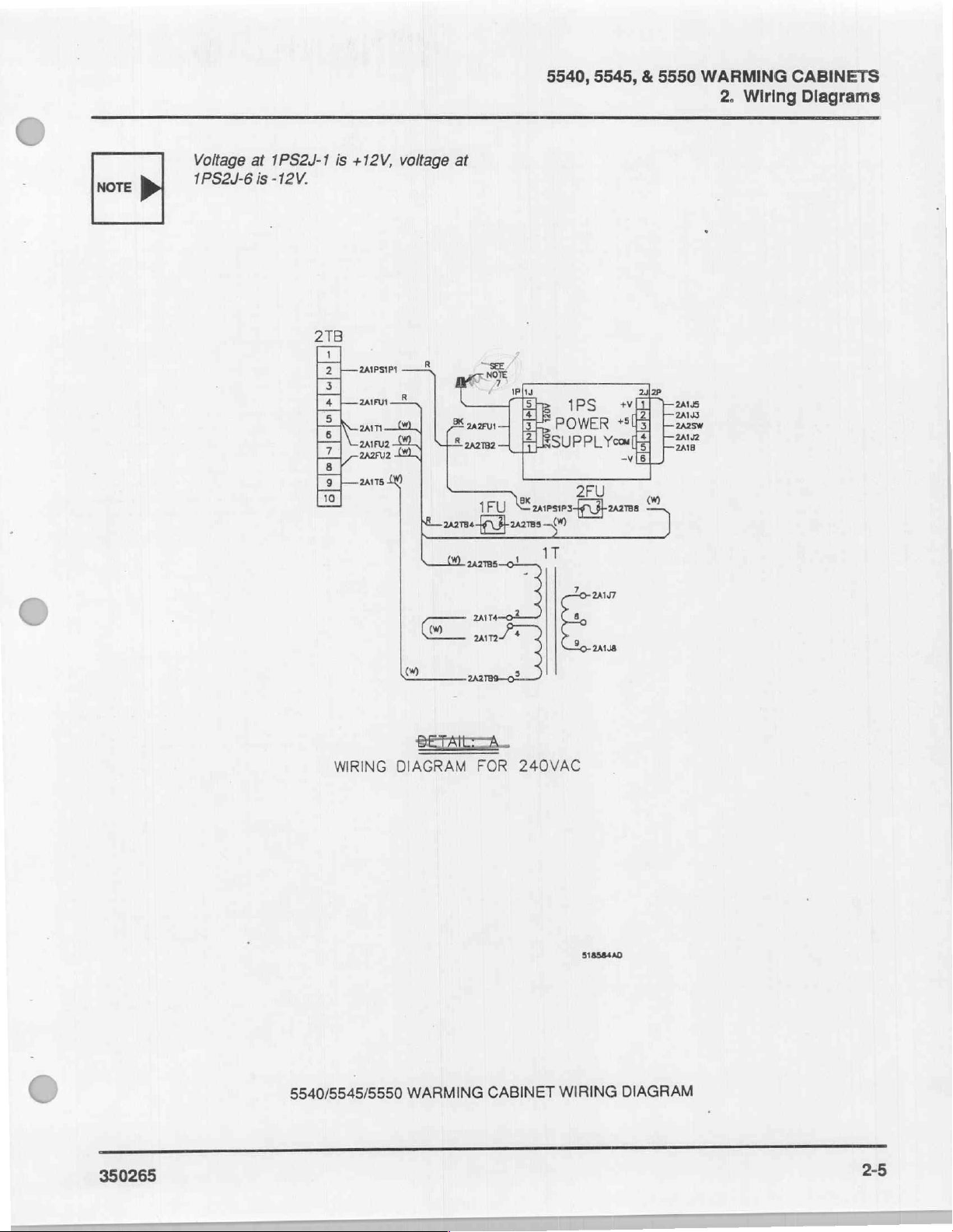

5540,

5545, & 5550

WARMING

2.

Wiring

CABINETS

Diagrams

NOTE

>

Voltage

1PS2J-6

at

1PS2J-1

is

-12V.

is

+12V,

voltage

at

Ш

5

1PS

4

POWER

digo

2422

+

+803]

$

2A1J2

6

WE

2A1J5

Dias

2418

rem,

WIRING

DIAGRAM

2A2

FOR

ES

240VAC

518584AD

(

350265

5540/5545/5550

WARMING

CABINET

WIRING

DIAGRAM

2-5

Page 17

Cc

N

74LS373

50

の

—

s

о

+

a

o

o

+50

SUPPLY.

on

2-6

+5№

Sed

ich

d

ES

2

ad

4

|

ATF

9

n

“ae >

1-8

LL

4

è

Ot

o

AF

]

$

9

av

PRINTED

‘i

é

a

어

고

싸

CIRCUIT

내

© o

es

|

©

어

그

싸

어

c9

그

싸

BOARD

los

그

싸

어

SCHEMATIC

마사

ㆍ

‘Gone

iz

DIAGRAM

5-4

+6\0

+5\А

RM

Bi

|

Y

RIS

18

M

=25

G)

CON

R33 る jk

54-14

Nara

ao

ος

개

66

우

dos

서 세

—

ZIK

328

|

q

To

350265

51840384

5

D

ㅅ

Page 18

人

ESSA

一

мЙ——

一

一

re | ne

[121

13

一

16

Las | rel

2

|7

一

一

re

Lats

12

а|

RIO

썼

5

2 4

и

+

9

————<

Vo

02

U6

715

o

e

$

+50

:

04

05

Lz

이주

1N5409

€

+

me

126

44

pa

PL

|,

mma?

an

sl

зак

vara

|

uo

RIGHT

DISPLAY

vss

y

+svo

RIS

1.2K

İZ

de

ax

|.

εκ

DISPLAY

|

|

J

z

+SVA

8-3

πα

M

ua

44

49

es

Vo

5

16

一

di

из

410

2:

m

та

το

US

mS

и

pa

5

lea

[^^

|3_

sir

sin

CCN

É

ca

,

Co

OOF

is

wt

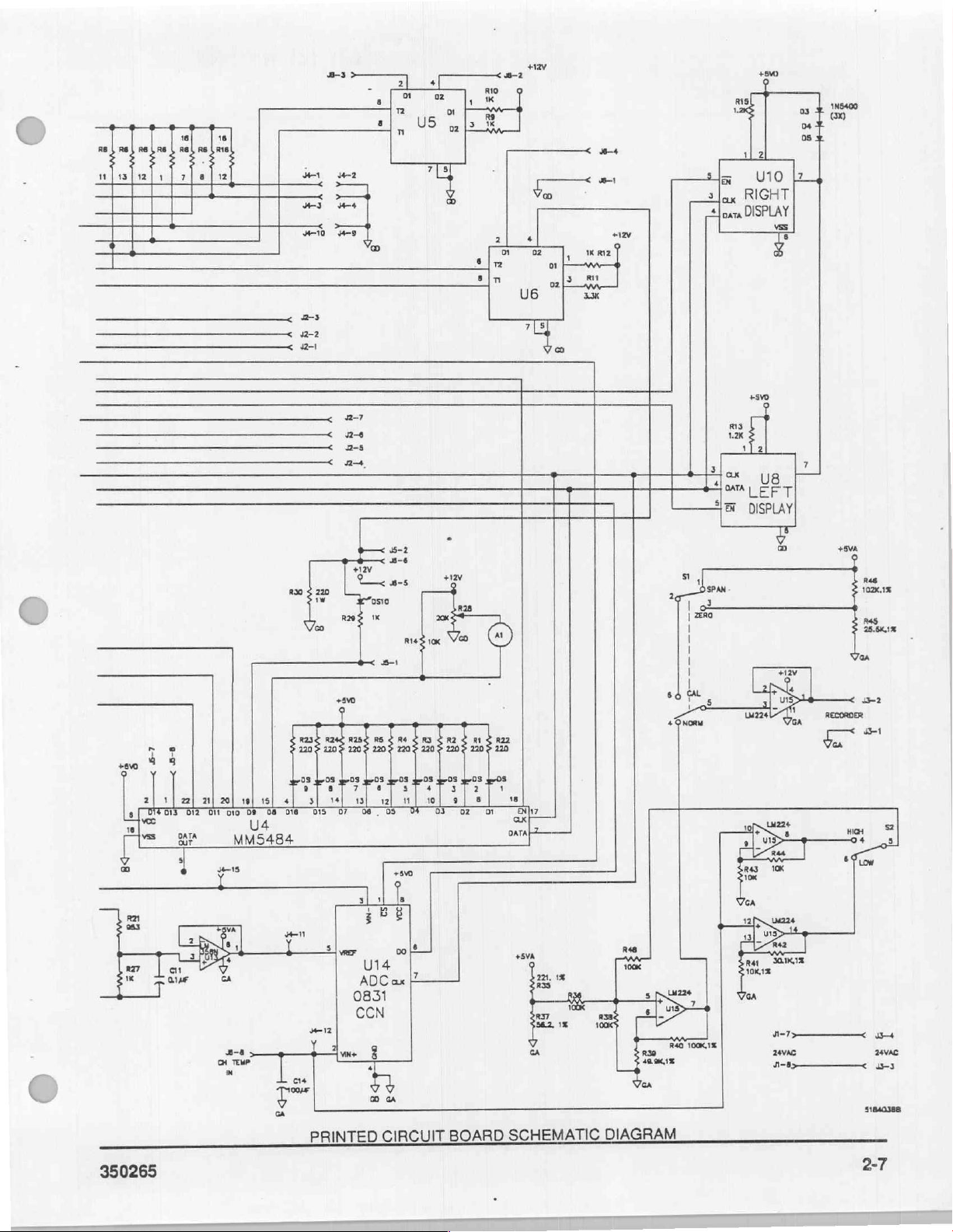

PRINTED

8

<

Da

CIRCUIT

BOARD

SCHEMATIC

=

ee

350265

DIAGRAM

24VAG

———

ap

ош

24VAC

3-3

31840388

2-7

Page 19

5540, 5545, & 5550

2.

Wiring

|

NOTES

Diagrams

WARMING

CABINETS

2-8

Page 20

5540, 5545, & 5550

WARMING

3.

Trouble

CABINETS

Analysis

DIAGNOSTIC

Unit

Circuit

UnitiDoos

Unit

+5V,

“OH”

Temperature

“OH”

Temperature'Display

HEATER/FAN

SECTION

FLOW

Does'Not

Breaker

Not

At

+12V

Warning

Warning

OPERATIONALCHECKS

CHARTS

Turn

Trips

NobHeat

Proper

Power

Indicated

Display

Indicated

Temperature . ..,.............

Supply

3.

TROUBLE

..........

On

..........,.........

ee

Check

In

Actual

ls

In

Set-point

e.)

................

sad.

e

..............

ANALYSIS

κ ο ενος

ea

a

e e

laa

e

it!

Sl

e

e

ος

...34

9

ὃν ο o

3-10

3-2

3-3

3-5

3-6

3-7

3-8

3-9

ANALYSIS

TROUBLE

3.

SECTION

350265

3-1

Page 21

5540, 5545,

3.

Trouble

TROUBLE

&

5550

WARMING

Analysis

ANALYSIS

CABINETS

DIAGNOSTIC

FLOW

ELECTRICAL

of

control

Power

should

sonnel

the

trouble

CHARTS

box

activated.

be

and

SHOCK

analysis

components

This

conducted

extreme

with

HAZARD.

requires

with

trouble

qualified

by

caution.

Some

access

main

the

analysis

per-

to

3-2

=

350265

Page 22

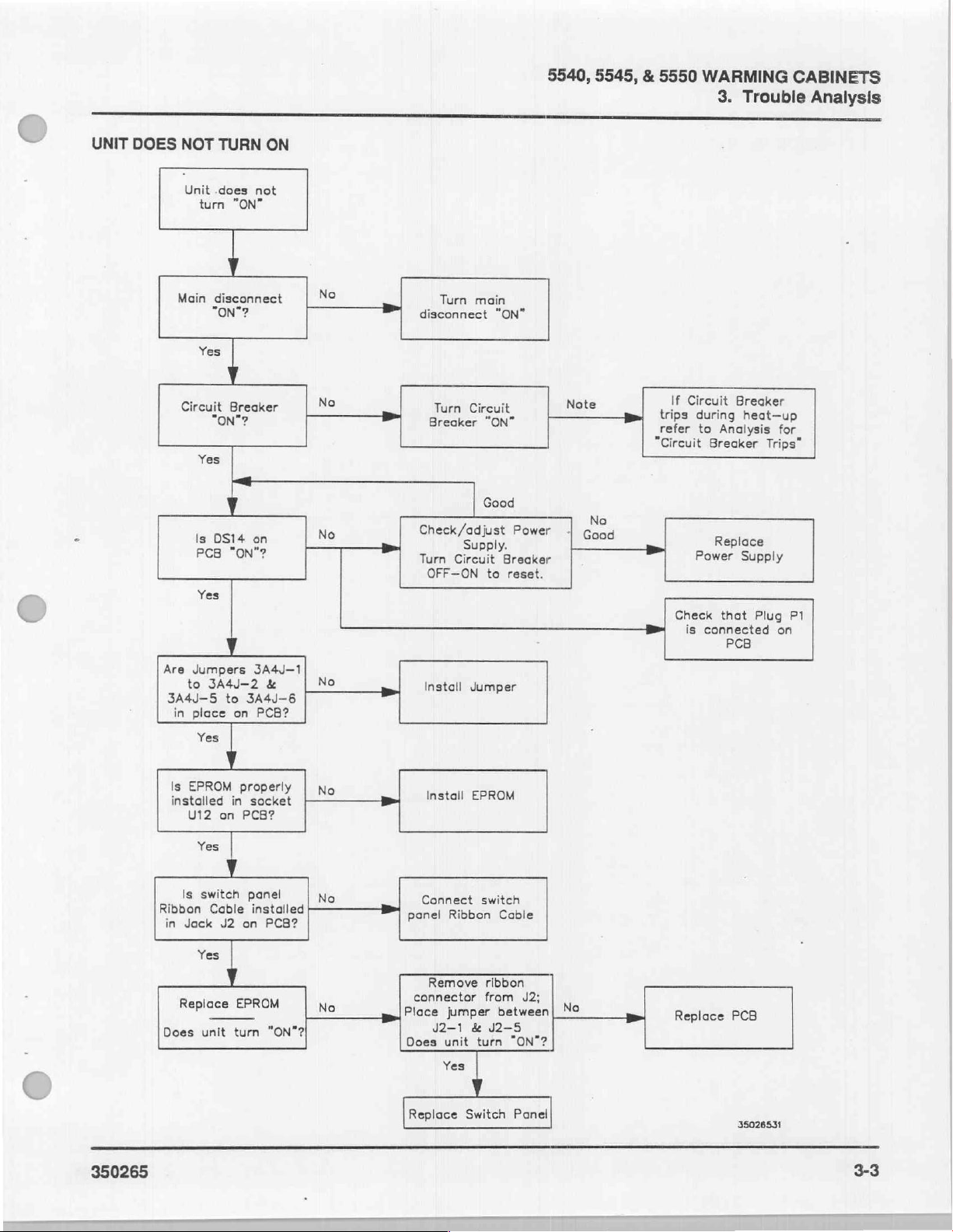

C

UNIT

DOES

NOT

Unit

turn

TURN

.does

"ON"

ON

not

5540,

5545, & 5550

WARMING

3.

Trouble

CABINETS

Analysis

Main

disconnect

“ON”?

Yes

Circuit

où"

Yes

Is

DS14

PCB

Yes

Are

Jumpers

to

3А4/-2

3A4J-5

in

place

Yes

4

|

Breaker

ON

?

on

し

ON

3A4J—1

to

3A4J-6

on

|

?

&

PCB?

No

No

—

fm

No

№

>

Turn

Turn

Circuit

Breaker

eck/a

Circuit

Jumper

main

"ON?

Good

EN

disconnect

Check/adjust

Turn

OFF—ON

Install

“ON”

"ON

e

Breaker

to

reset.

P

Su

—

er

Note

Good

——

Ja

>>>

refer

"Circuit

>

Check

B

о

to

Breaker

Replace

Power

is

connected

Analysis

Trips”

Supply

that

Plug

PCB

e

for

P1

on

Is

EPROM

installed

U12

hi

ibbon

in

Jack

Replace

Does

Yes

Cable

Yes

unit

properly

in

socket

on

PCB?

|

은

p

installed

J2 on

|

EPROM

turn

x

PCB?

"aw

"ON"?

No

-}—————_B>

No

—2

No

install

ROM

Connect

M

Remove

connector

po

Place

42-1

Does

Replace

|

Ribbon

jumper

unit

Yes

switch

Cabl

ribbon

from

between

&

J2-

turn

|

Switch

SES

J2;

“ON”?

Panel

늘

.

Replace

PCB

men

Page 23

5540, 5545, & 5550

3.

Trouble

Analysis

ARMING

W

CABINETS

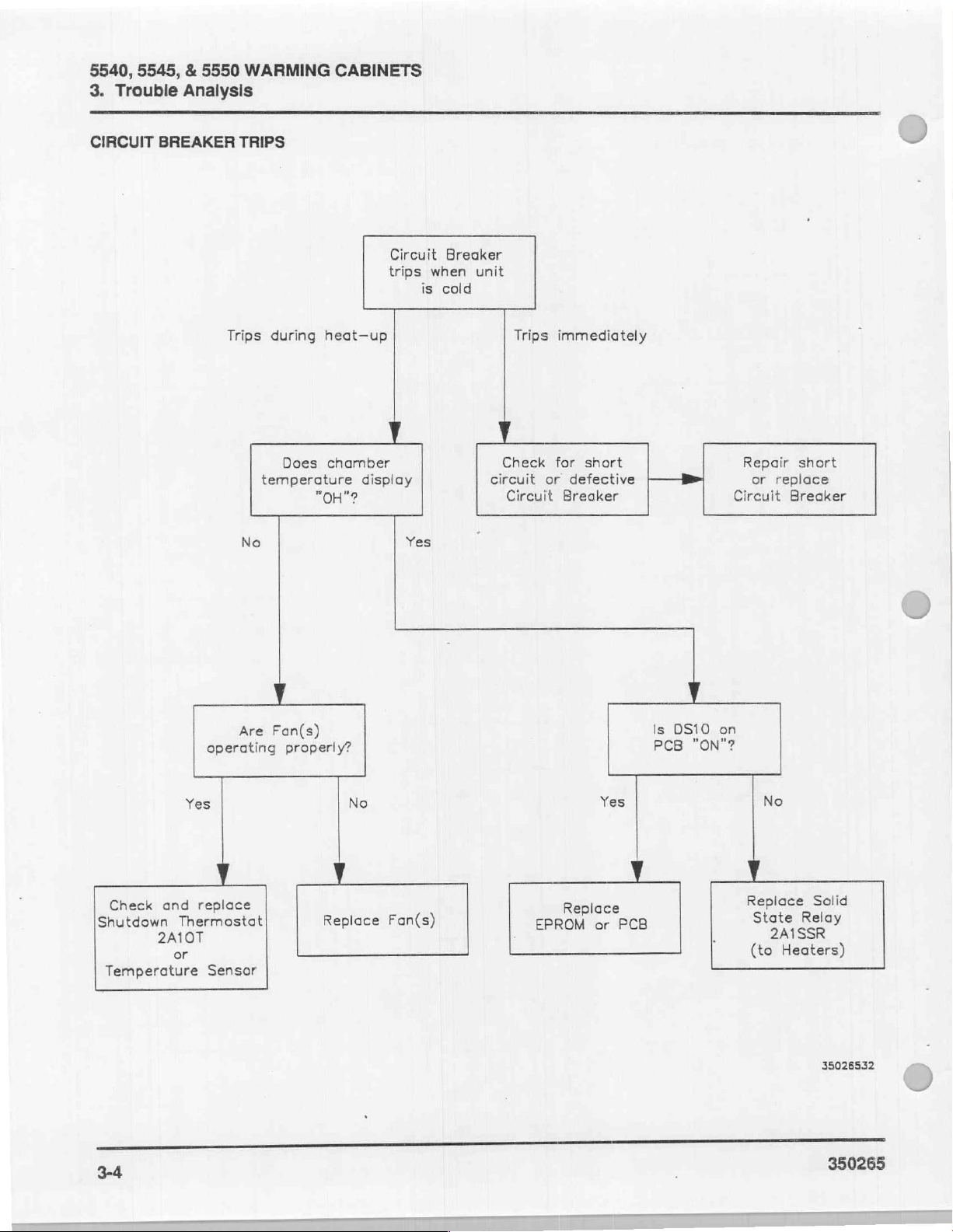

CIRCUIT

BREAKER

TRIPS

Trips

temperature

No

during

Does

heat-up

chamber

"OH"?

Circuit

trips

display

Breaker

when

is

cold

Yes

unit

Check

circuit

Circuit

Trips

immediately

for

short

or

defective

Breaker

——B»

Repair

or

replace

Circuit

short

Breaker

Check

Shutdown

Temperature

operating

Yes

replace

and

Thermostat

2A10T

or

Sensor

Are

Fan(s)

properly?

No Yes

Replace

EPROM

Replace

Fan(s)

or

PCB

Is

PCB

DS10

on

"ON"?

No

Replace

State

2A1SSR

Heaters)

(to

Solid

Relay

35026532

3-4

350265

Page 24

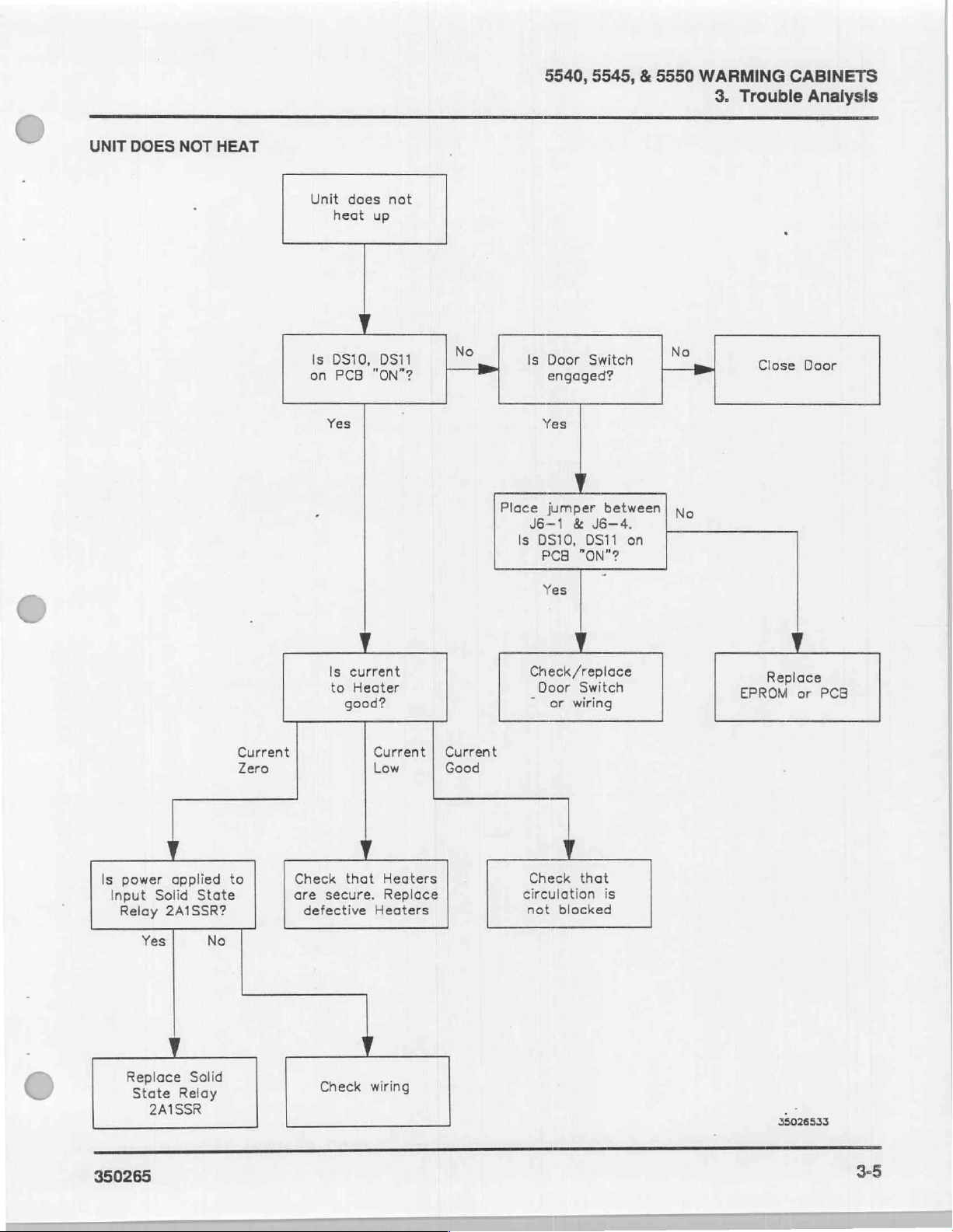

UNIT

DOES

NOT

HEAT

Unit

heat

19

0910,

on

PCB

Yes

does

not

up

ost | №

"ON"?

Place

5540,

5545, & 5550

ls

Door

Switch | №

engaged?

Yes

jumper

J6—1 & ὁ6--4.

Is

DS10,

PCB

Yes

between|

DS11

"ON"?

on

re

No

WARMING

3.

Trouble

CABINETS

Analysis

a

Is

Input

power

Relay

applied

Solid

2A1SSR?

Yes

Y

Replace

State Relay

Solid

2A1SSR

State

No

Current

Zero

to

Check

are

defective

Is

current

to

good?

that

secure.

Check

Heater

Current | Current

Low

Good

Heaters

Replace

Heaters

wiring

Check

/replace

Door Switch

©

or

wiring

Check

circulation

not

that

blocked

is

ai

35026533

350265

Page 25

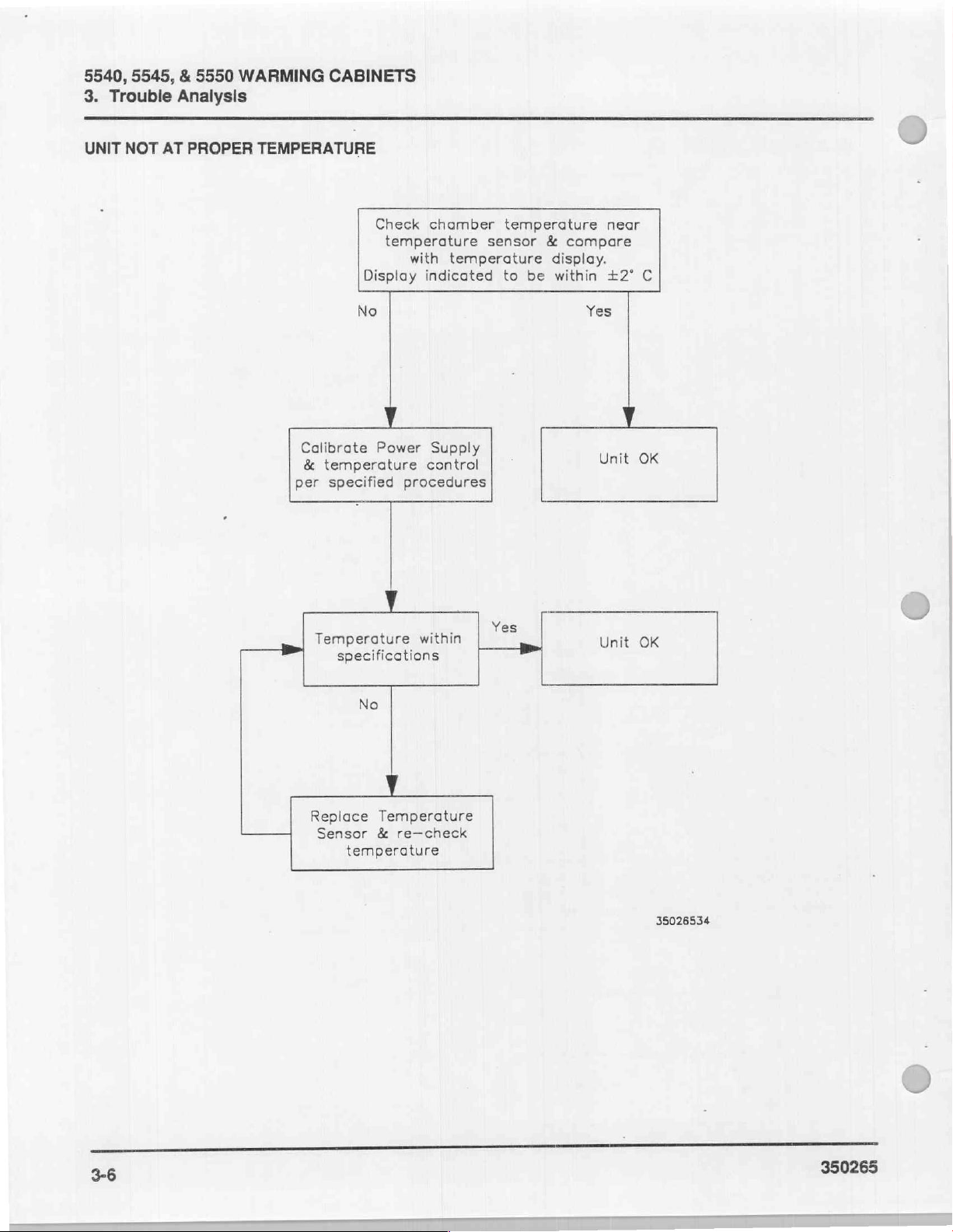

5540, 5545, & 5550

3.

Trouble

UNIT

NOT

Analysis

AT

PROPER

WARMING

TEMPERATURE

Calibrate

&

per

CABINETS

Check

Display

No

Power

temperature

specified

chamber

temperature

with

temperature

indicated

Supply

control

procedures

temperature

sensor & compare

display.

to

be

within

Yes

Unit

near

+2°

C

OK

Temperature

specifications

Replace

Sensor

temperature

No

Temperature

&

re—check

within

Yes

Unit

OK

35026534

3-6

350265

Page 26

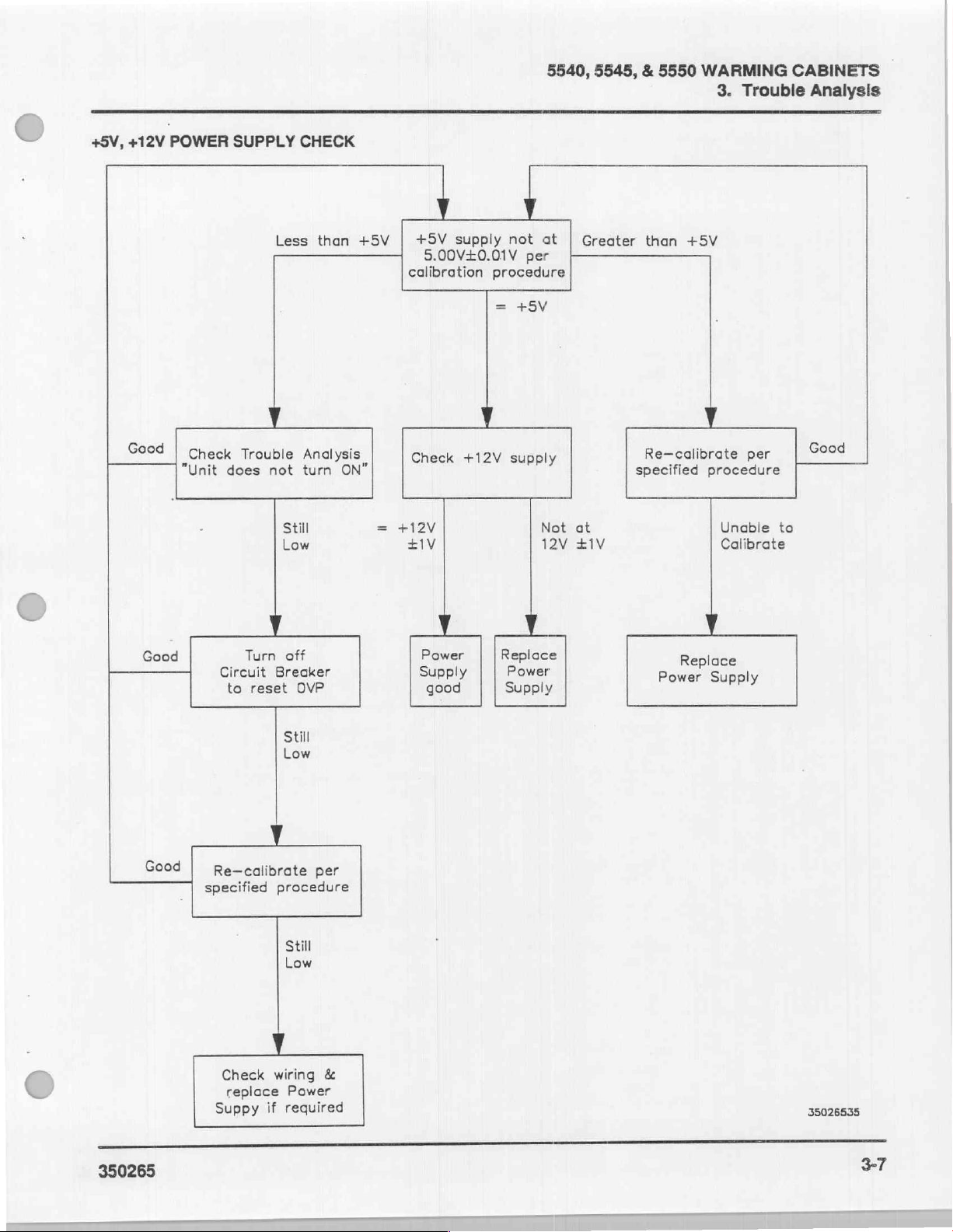

5540,

5545, & 5550

WARMING

3.

Trouble

CABINETS

Analysis

C

+5V,

+12V

Good

POWER

Check

"Unit

SUPPLY

Trouble

does

CHECK

Less

than

Analysis

not turn

Still

Low

+5V

ON”

+12V

+5V

supply

5.00V+0.01V

calibration

Check

士

+12V

1V

not

at

per

procedure

=

+5V

supply

Not

12V

Greater

at

+1V

than

Re—calibrate

specified

+5V

procedure

Unable

Calibrate

per

to

Good

4,

Good

Good

350265

Turn

Circuit

to

reset

Re-calibrate

specified

Check

replace

Suppy

off

Breaker

OVP

Still

Low

procedure

Still

Low

wiring

Power

if

required

per

&

Power

Supply

good

Replace

Power

Supply

Replace

Power

Supply

35026535

3-7

Page 27

5540, 5545, & 5550

3.

Trouble

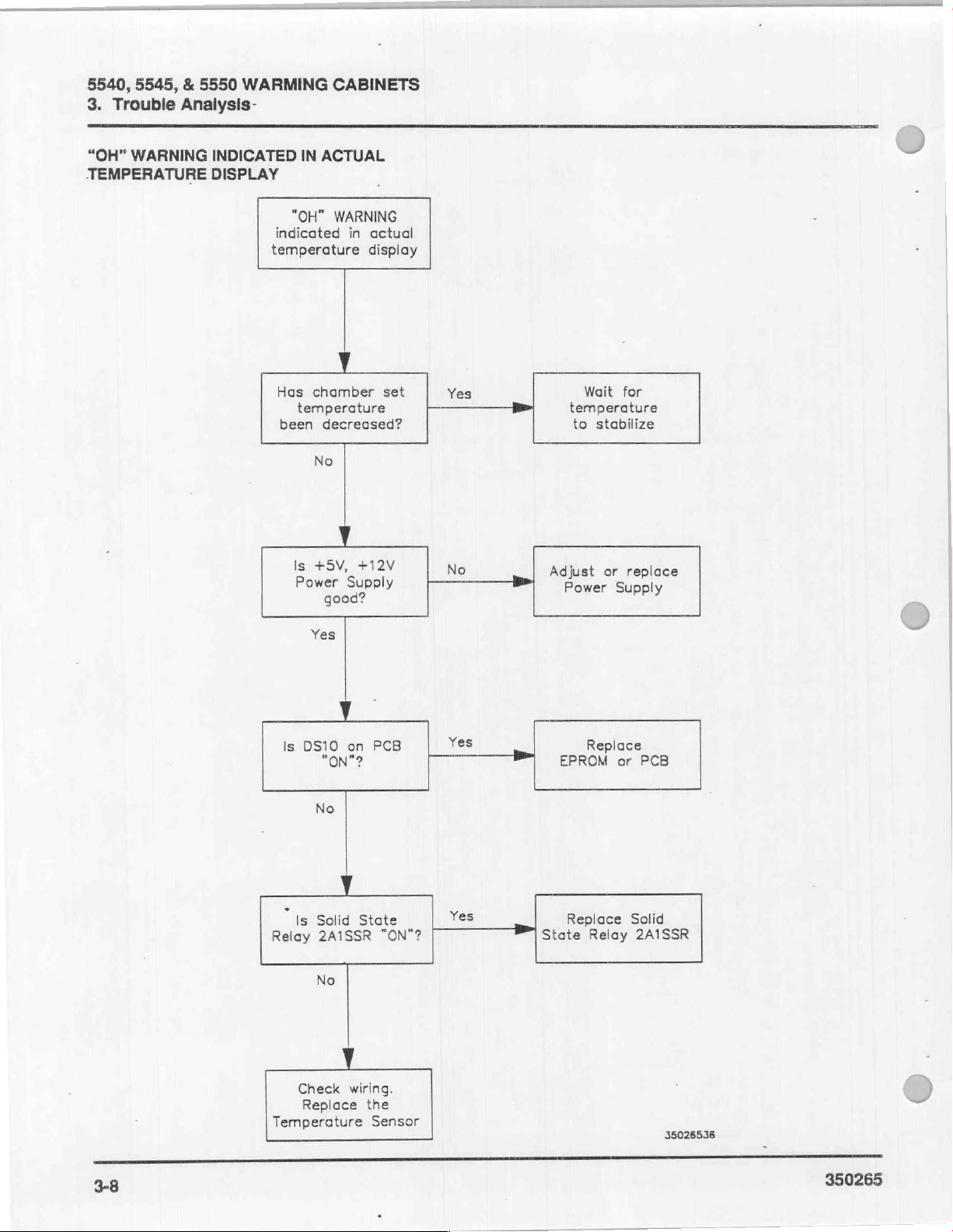

“OH”

WARNING

TEMPERATURE

Analysis-

INDICATED

DISPLAY

WARMING

"OH"

indicated

temperature

Has

temperature

been

CABINETS

IN

ACTUAL

WARNING

chamber

decreased?

No

in

actual

display

set

Yes

Wait

for

temperature

to

stabilize

Relay

Is

Power

Yes

Is

DS10

“is

+5V,

+12V

Supply

good?

у

on

"ON"?

No

Solid

State

2A1SSR

No

PCB

"ON"?

No

Yes

Yes

Adjust

State

Power

Replace

EPROM

Replace

Relay

or

replace

Supply

or

PCB

Solid

2A1SSR

38

Check

Replace

Temperature

wiring.

the

Sensor

35026536

350265

Page 28

€

_

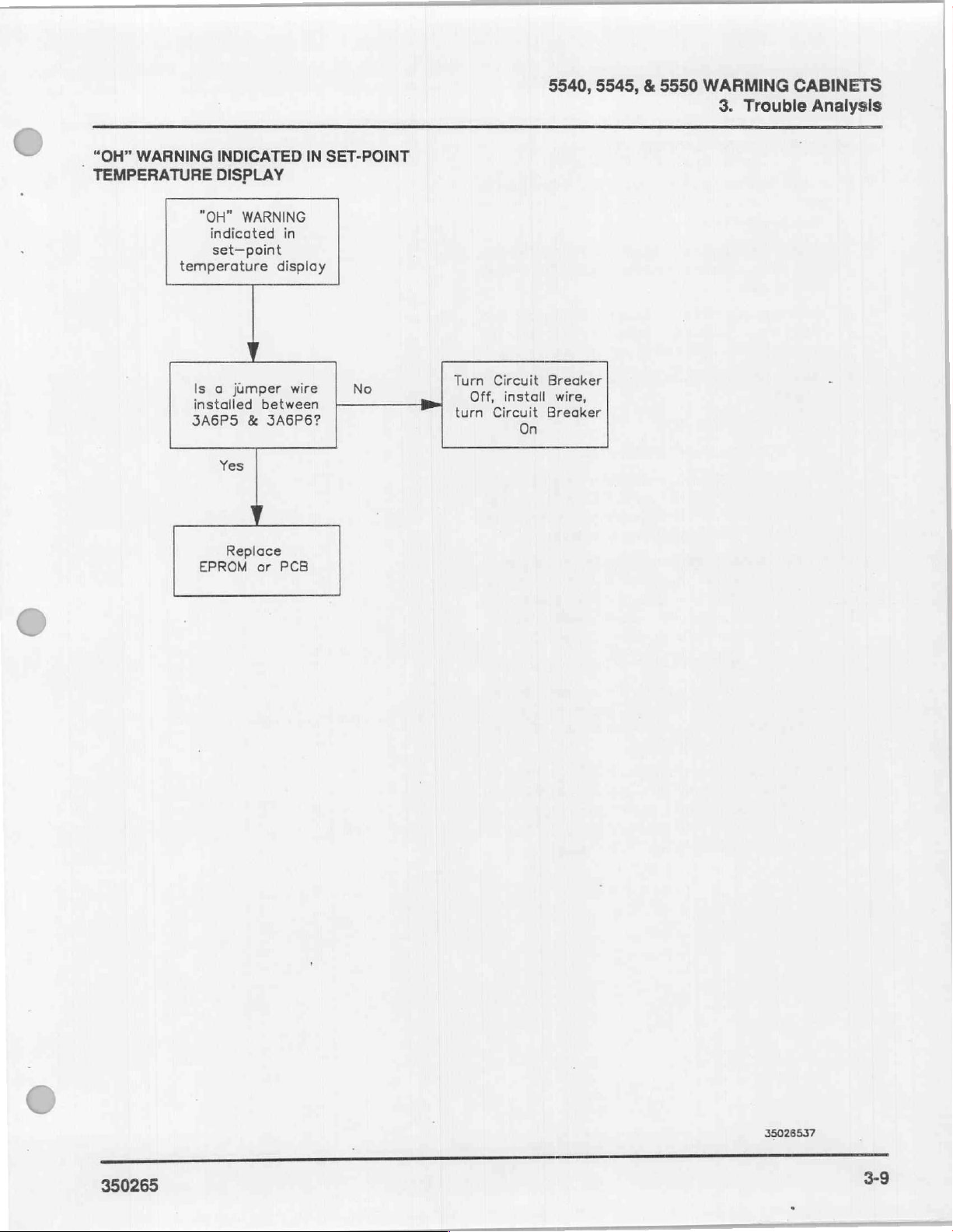

“OH”

WARNING

TEMPERATURE

INDICATED

DISPLAY

"OH"

indicated

set—point

temperature

Is a

installed

JA6PS

Yes

WARNING

jumper

between

&

3A6P6?

IN

in

display

wire

SET-POINT

No

Turn

Off,

turn

Circuit

install

Circuit

On

5540,

Breaker

wire,

Breaker

5545,

€:

5550

WARMING

3.

Trouble Analysis

CABINETS

Replace

EPROM

or

PCB

350265

35026537

3-9

Page 29

5540, 5545, & 5550

3.

Trouble

Analysis

WARMING

CABINETS

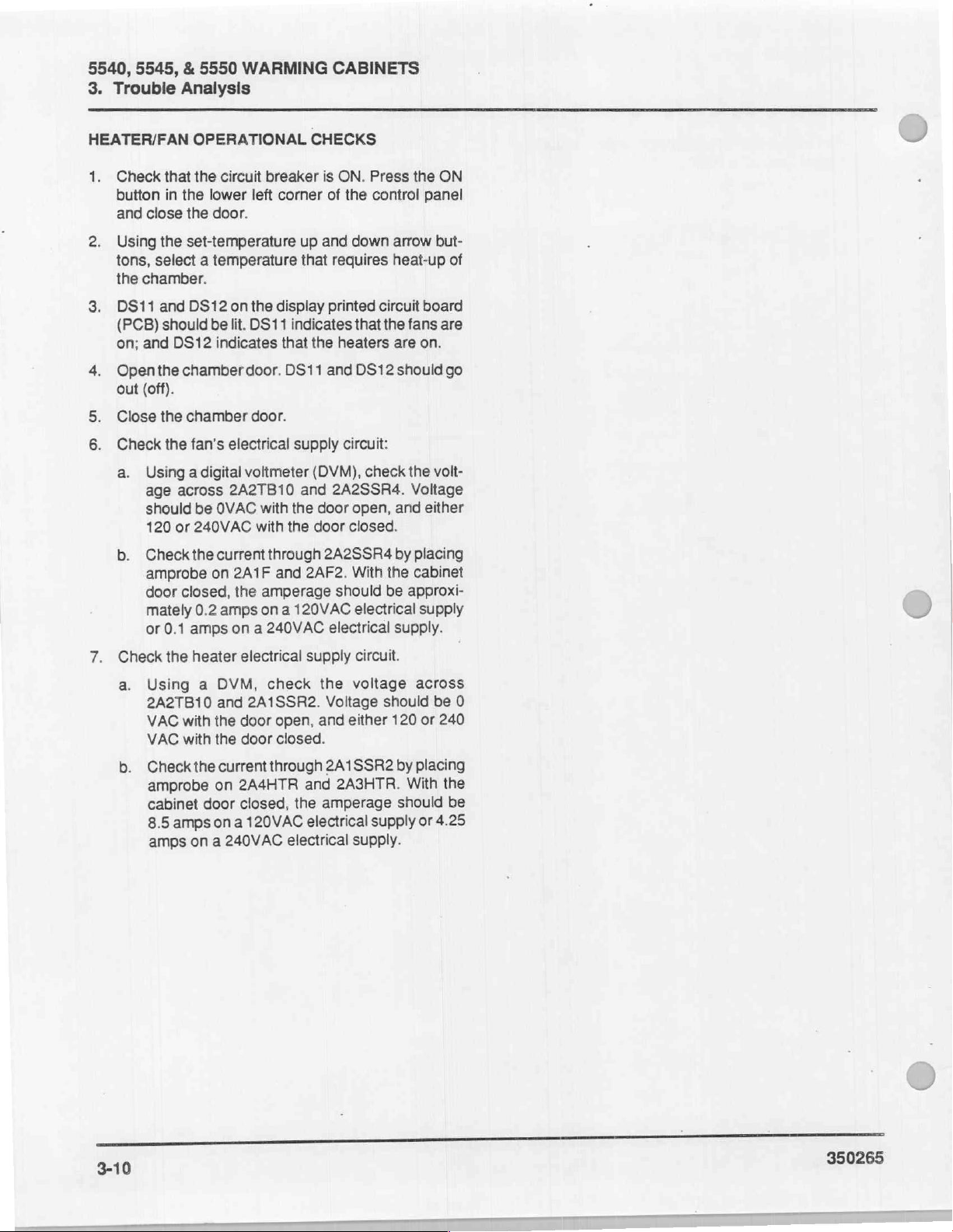

HEATER/FAN

n

Check

button

and

close

Using

the

tons,

select a temperature

the

chamber.

DS11

and

(PCB)

should

on;

and

Open

the

out

(off).

Close

the

Check

a.

Using a digital

age

should

120

b.

Check

amprobe

door

mately

or 0.1

OPERATIONAL

that

the

circuit

in

the

lower

the

door.

set-temperature

DS12

on

the

be

lit.

DS11

DS12

indicates

chamber

chamber

the

fan’s

door.

door.

electrical

voltmeter

across

or

closed,

be

OVAC

240VAC

the

current

on

0.2

amps

amps

2A2TB10

2A1F

the

on a 240VAC

CHECKS

breaker

left

corner

up

that

display

indicates

that

the

DS11

supply

(DVM),

and

with

the

with

the

door

through

and

2AF2.

amperage

on a 120VAC

is

ON.

Press

of

the

control

and

down

requires

printed

that

heaters

and

DS12

circuit:

check

2A2SSR4.

door

open,

closed.

2A2SSR4

With

should

electrical

electrical

the

panel

arrow

heat-up

circuit

board

the

fans

are

on.

should

the

Voltage

and

either

by

placing

the

cabinet

be

approxi-

supply

supply.

ON

but-

of

are

go

volt-

Check

a.

b.

the

Using a DVM,

2A2TB10

VAC

with

VAC

with

Check

amprobe

cabinet

8.5

amps

amps

heater

the

on a 240VAC

and

the

the

current

on

door

ona

2A4HTR

electrical

2A1SSR2.

door

door

closed,

120VAC

supply

check

open,

closed.

through

and

the

electrical

electrical

circuit.

the

voltage

Voltage

and

either

2A1SSR2

2A3HTR.

amperage

supply.

should

120

by

With

should

supply

across

be

0

or

240

placing

the

be

or

4.25

3-10

350265

Page 30

5540, 5545, & 5550

4.

Calibrations

WARMING

and

CABINETS

Adjustments

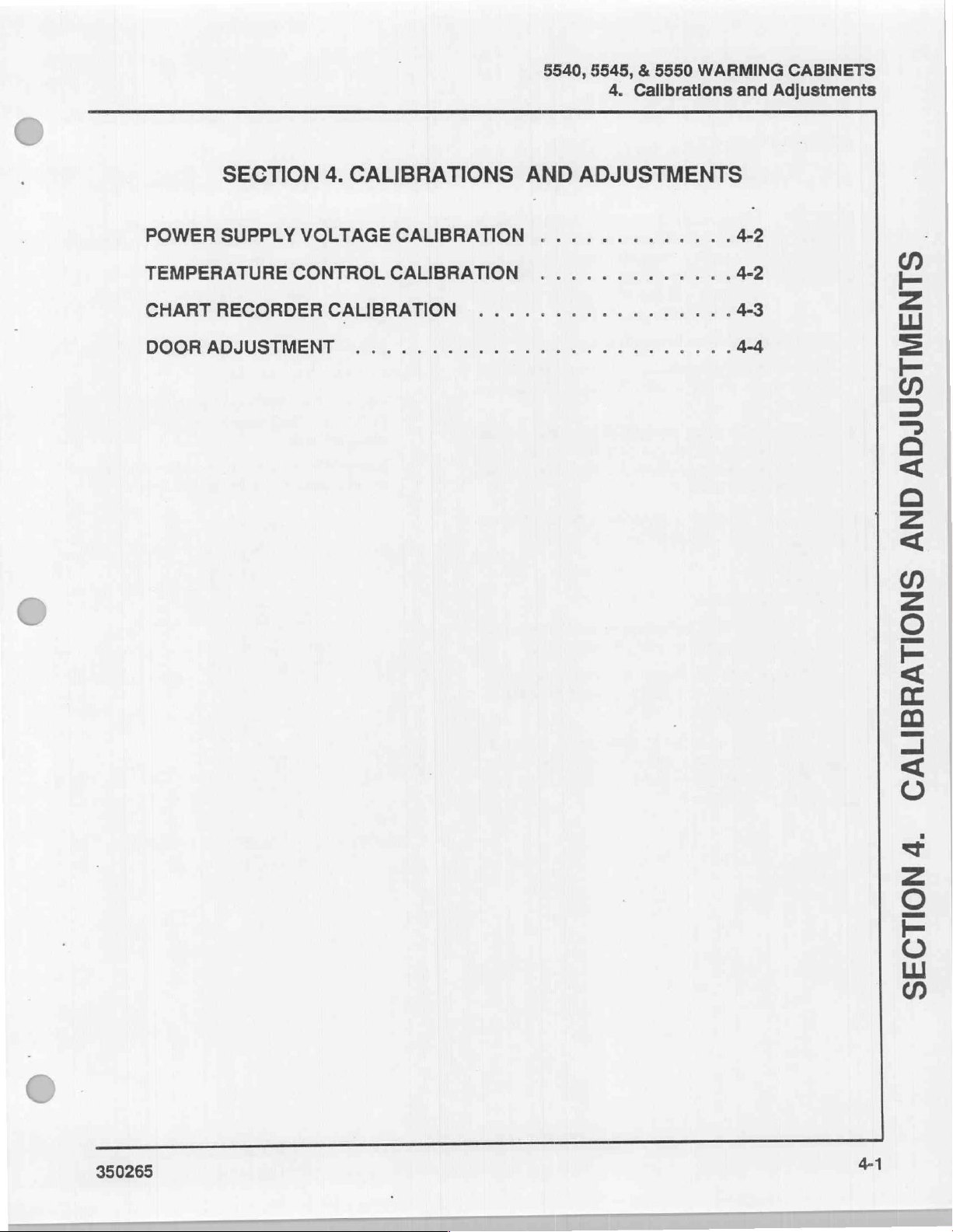

SECTION

POWER

TEMPERATURE

CHART

DOORADIUSTMENIT

SUPPLY

RECORDER

4.

CALIBRATIONS

VOLTAGE

CONTROL

CALIBRATION

O

CALIBRATION

CALIBRATION

.................

AND

ADJUSTMENTS

.............

.............

NN

4-2

4-2

4-3

4-4

.

ADJUSTMENTS

AND

350265

CALIBRATIONS

4.

SECTION

4-1

Page 31

5540, 5545, & 5550

4.

Calibrations

and

WARMING

Adjustments

CABINETS

CALIBRATIONS

POWER

SUPPLY

The

electrical

To

personal

contact

adjustments

1.

Raise

the

control

2.

Remove

head

omponents.

3.

Check

button

and

stabilize

bi

NOTE

+5

4.

a.

b.

the

assembly

oe

that

the

in

the

let

the

for

The

conducting

Adjustment:

Volt

the

Place

positive

the

Adjust

supply

+5.00+0.01

NOTE

№

The

tom

head

adjustment.

AND

ADJUSTMENTS

VOLTAGE

power

prevent

with

CALIBRATION

circuit

adjustments

possible

injury,

the

and

head

assembly

three

screws

for

access

circuit

breaker

lower

left

corner

temperature

15

minutes.

control

DVM

probe

+5V

the

until

adjustment

of

panel

ing

callorati

calibrations.

negative

3A1P3

on

adjustment

reading

the

the

on

VDC

power

the

screw

driver

must

be

ON

to

and

calibrations.

electrical

do

not

electrical

shock

make

personal

circuit

calibration.

cover.

that

in

secure

to

the

is

ON.

of

the

the

warming

must

probe

of

pot

power

be

on

the

on

the

Press

the

control

cabinet

ON

prior

3A1P1

PCB.

the

on

DVM

the

meter.

pot

is

located

supply.

is

at

small

A

required

the

for

make

and

during

power

supply

ON

panel

to

and

power

is

bot-

flat

this

TEMPERATURE

1.

Calibrate

Supply

Temperature

ноте

>

2.

5

E

な <

a

=,

Adjust

a.

Connect

GNDA

using

b.

Adjust

a

È

ES

do

©:

Me

2.5

. .

DVM

202

=

=

©:

=

E:

sa

CONTROL

the

power

Voltage

Calibration”)

Control

The

control

conducting

VDC

on

the

the

DVM

and

the

test

R17

reading

positive

clips.

(2.5V

of

af

29900

ae

=

+

ss

に 8 8

©

zá

ina Β So

o

CALIBRATION

supply

Calibration.

voltage

panel

must

before

be

(see

making

ON

calibrations.

PCB:

negative

adjust),

2.500

5

=

(o

©

probe

to

probe

to

test

point

. . ,

if

required,

+0.005

os

558-8

AGG

33

2

3

@——

to

VDC.

É

0

[

0000

*

SG

Li

~

“Power

the

-

prior

to

test

point

2.5V,

provide

ADJUST

R17

4

PROBE

ae

02022

42

TEMPERATURE

CALIBRATION

ADJUSTMENT

VOLTAGE

350265

Page 32

5540, 5545, & 5550

4.

Calibrations

WARMING

and

CABINETS

Adjustmenis

CHART

NOTE

The

RECORDER

lb

pen

is

hysteresis

calibration

been

ON

C8

GLASSWARE

DRYER

AERATOR

WARMER

SER

RECORDER

This

qualified

Recorder

initial

there

Always

and

printed

tion

calibration.

Calibration”

Calibration”).

calibrated

or

linearity

should

for

at

least

be

-

|

CALIBRATION

calibration

should

service

calibration

installation,

is a major

ensure

recorder

that

circuit

BEFORE

(See

and

for

NULL

adjustment

attempted

20

minutes.

52

Se

KOD

oO

CALIBRATION

SWITCHES

only

personnel.

should

once a year,

problem.

the

power

board

are

attempting

“Power

Supply

“Temperature

and

SPAN.

with

this

recorder.

unless

the

Nanna

ORM)

SPAN

ZERO+

TOGGLE

be

done

be

done

or

when

supplies

in

calibra-

recorder

Voltage

Control

There

power

Si

QO

OT

35026503

is

has

by

at

no

No

Pen

Calibration

NOTE

|

1.

Set

PEN

switch

Adjust

p

chart

the

(innermost

LOCATED

ON

RECORDER

Ensure

Warmer

GLASSWARE

DRYER

S1

NORM

null

until

switch

S2

is

in

position.

L

s2

AERATOR/

WARMER

to

the

ZERO

LL

51

SPAN

ZERO

pen

aligns

line).

SPAN

position.

at

the

NULL

RED

the

Aerator/

0%

line

of

the

Preparation

1.

Tumlockorkey

ment

at

Raise

3.

Install a new

right

lower

ments.

tion.

350265

the

and

Pull

located

lower

right-hand

lock

the

chart

section

recorder

inside

control

on

the

expose

to

door

the

storage

corner

of

head.

recorder.

calibration

the

switch

into

the

back

Fold

the

compart-

wall.

back

the

adjust-

posi-

out

3.

Set

S1

to

the

SPAN

NORM

position.

1

51

SPAN

ZERO

4-3

Page 33

5540,

4.

4.

5545, & 5550

Callbratlons

Adjust

the

the

chart

ON

RECORDER

WARMING

and

Adjustments

span

until

(outermost

pen

aligns

line).

SPAN

(©

CABINETS

at

the

NULL

RED

100%

line

of

Secure

1.

Remove

recorder.

Raise

Raise

Lower

Warming

test

and

latch

and

secure

and

Cabinet

chart

lock

the

the

and

control

the

control

control

install a new

head.

box

cover.

head.

chart

on

the

5.

6.

NOTE

7.

Repeat

correct

as

Set

position

reguired.

S1

to

5

pr

Manually

middle

position.

steps 1 thru 4 several times and

of

pen

Make

last

the

NORM

NORM

Switch

S2

tor/Warmer

push

the

door

at 0 and

setting

position.

A

S1

SPAN

position.

100%.

at

ZERO

remains

actuated

0%.

in

switch

Readjust

the

check

Aera-

into

for

pen

the

DOOR

É

ADJUSTMENT

Open

the

screws

inet.

Close

the

aligned

Open

the

ment

tighten

hinges

to

door

that

door

with

door

the

and

secure

and

the

front

and

the

hex

warming

loosen

the

hinges

realign

of

the

while

head

cabinet.

slightly

to

so

that

warming

keeping

screws

the

two hex

the

warming

it

is

cabinet.

it

in

that

square

proper

secure

head

cab-

and

align-

the

„

Secure

8.

paragraph.

0008

ACTUATED

SWITCH

the

warming

HM

cabinet

=

outlined

as

in

the

next

350265

Page 34

5540, 5545, & 5550

WARMING

CABINETS

5.

Repair

SAFETY

ACCESS

ACCESS

CIRCUIT

FUSE)REPLAGEMENT

TRANSFORMER

LOW

RELAY

FAN'REPIEACEMENT

HEATER

ΤΗΕΗΜΟΡΤΑΤΠΕΡΕΑΟΕΜΕΝΤ

TEMPERATURE

DURING

TO

CONTROL

TO

CONTROL

BREAKER

VOLTAGE

REPLACEMENT

REPLACEMENT

REPAIR

REPLACEMENT

REPLACEMENT

POWER

SENSOR

SECTION

CS.

HEAD

BOX

n

SUPPLY

COMPONENTS

COMPONENTS

.........

dio

Lil.

REPLACEMENT

5.

REPAIR

...........

............

.................

e

e

..................

REPLACEMENT

P

ola a a

e

toda

a

.............

a o

oa

.........

a

ee

5-2

5-2

5-2

5-2

ее

o

bas

a

ον 5 5-5

o

5-3

5-3

5-3

5-3

5-5

5-5

5-5

REPAIR

5.

EPROM

PRINTED

RECORDER

(Optional

DOOR

DOOR

REPLACEMENT.

SWITCH

GASKET

CIRCUIT

REPLACEMENT

Equipment)

BOARD

REPLACEMENT

REPLACEMENİ

0...

.....

oo.

REPLACEMENT

2.00 o ala

.............

o.

...................

......

にし

に

easy

e

2

5-5

5-6

5-7

5-7

5-7

SECTION

350265

5-1

Page 35

5540,

5.

5545,

Repair

REPAIR

&

5550

WARMING

CABINETS

-

SAFETY

ACCESS

1.

Open

2.

Tum

control

3.

Raise

position.

4.

Tum

ACCESS

1.

Raise

to

2.

Tum

warming

top

DURING

TO

center

screw

head.

the

OFF

TO

the

Control

OFF

cabinet,

of

the

REPAIR

Turn

off

inet

electrical

repairs

shock.

CONTROL

section

in

lower

control

circuit

breaker.

CONTROL

control

Head

Components.”

or

disconnect

control

door,

or

disconnect

to

prevent

HEAD

door.

right

head

and

BOX

head

as

the

remove

and

the

supply

before

injury

from

COMPONENTS

corner

secure

COMPONENTS

outlined

electrical

the

open

three

the

to

it

under

screws

warming

making

electrical

release

in

the

“Access

supply

control

cab-

the

raised

to

the

at

the

door.

4.

Remove

on

5.

Pull

against

NOTE

6.

Disconnect

ply

the

of

7.

Pull

relief.

8.

Disconnect

through

9.

Reach

up

control

the

the

side.

each

the

control

the

Many

pe.

wires

back

each

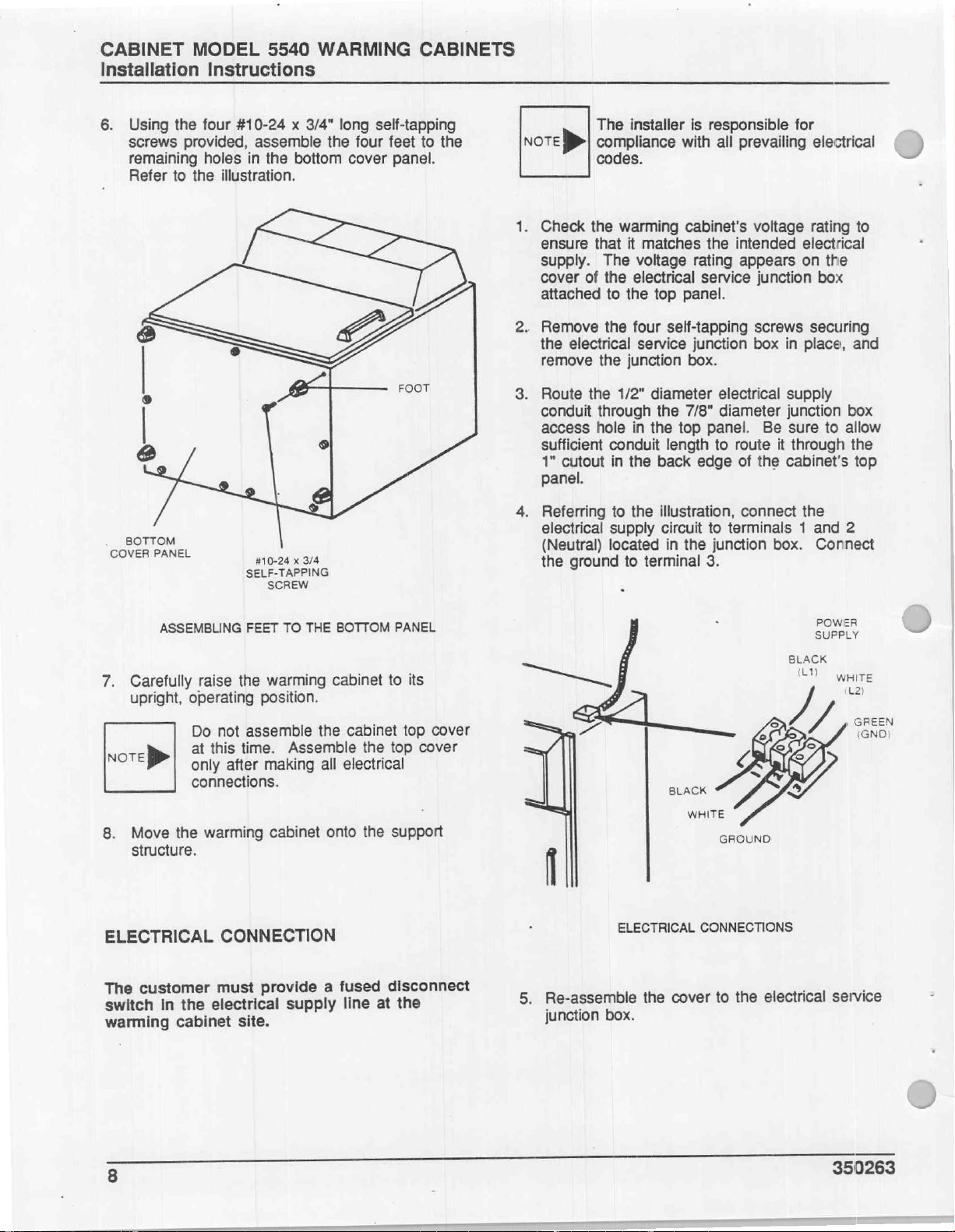

on

warming

from

Instructions

control

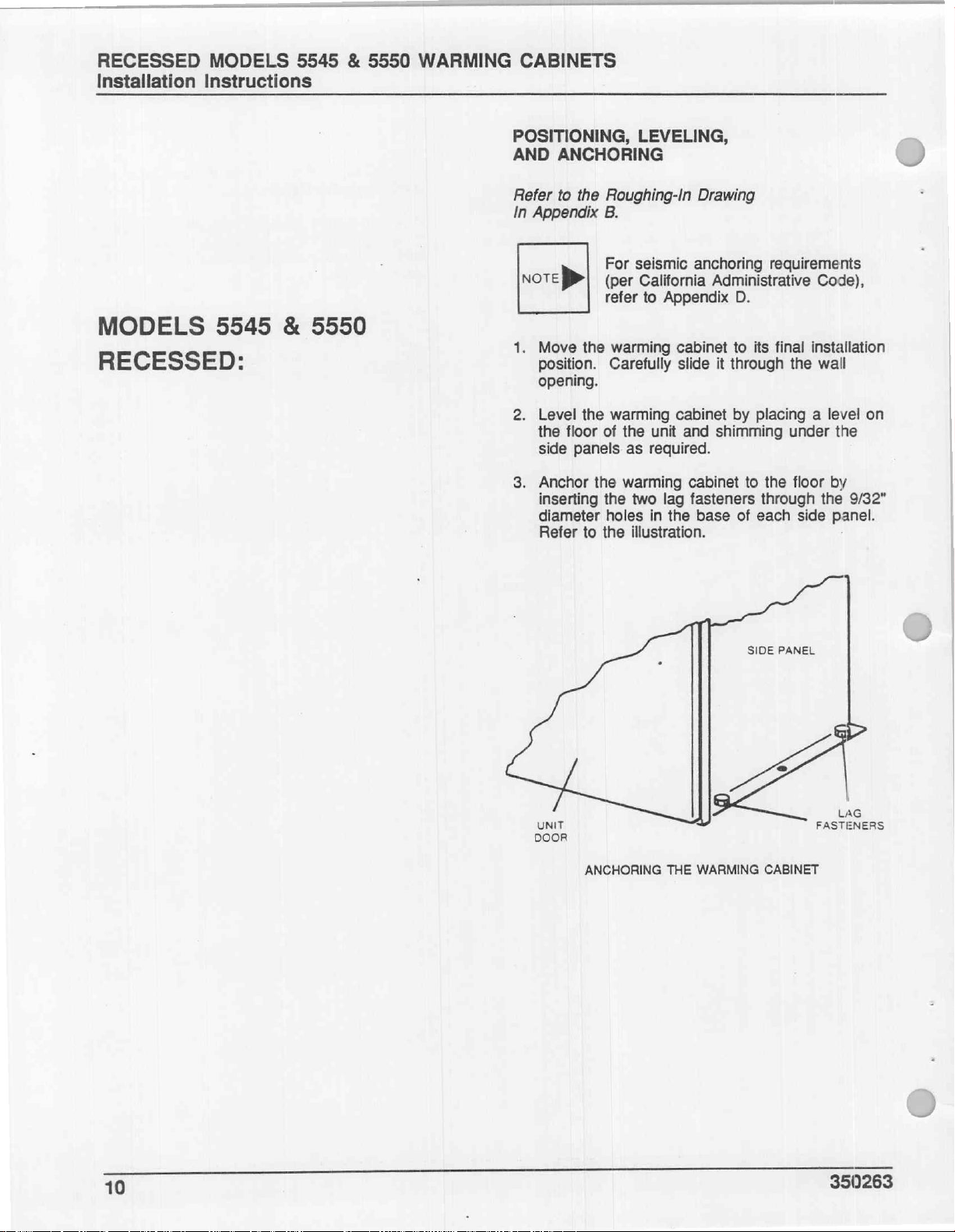

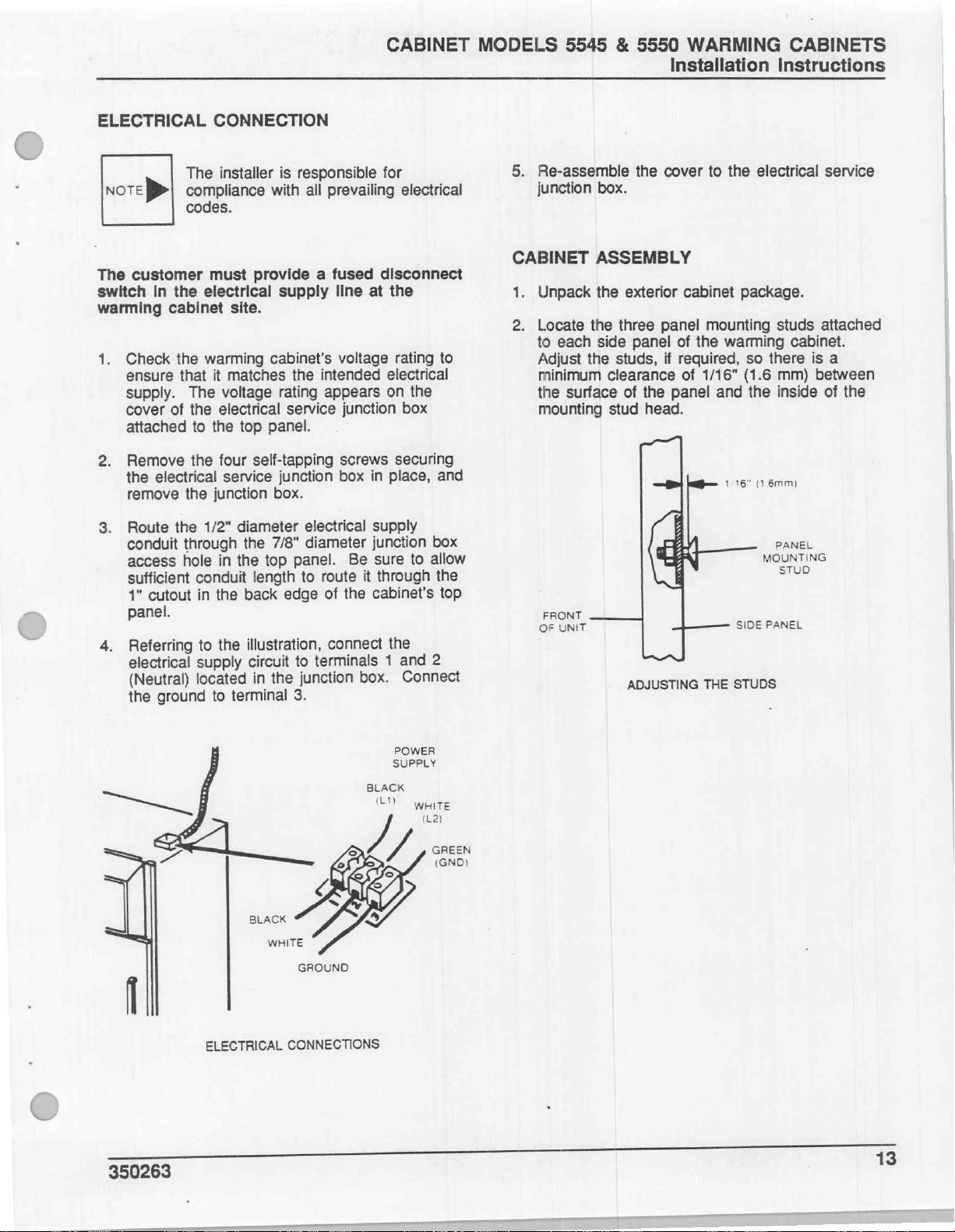

service

low

Stat.

from

wall

wire

electrical

the

inside

the

control

box

two

control

box

forward

locking

the

for

the

hole

and

cabinet.

mechanism

components

the

box

the

voltage

blue,

the

power

of

the

reconnection.

supply

door

in

the

the

control

box

at

the

box

front

or

continue

from

heaters,

power

brown,

supply

control

line

cable

switch

bottom

box

mounting

same

securing

on

the

stop.

can

top

of

for

the

warming

fans,

supply,

and

green

terminal

box.

Note

through

cable

of

the

from

stop

time

pull

screws,

track

now

the

removal

door

and

the

and

control

the

top

to

it

forward

until

it

stops

be

serviced

control

of

cabinet

switch,

thermo-

power

block

location

the

strain

pull

it

down

box.

and

release

from

one

box.

the

to

sup-

on

pull

the

CONTROL

HEAD

CONTROL

CONTROL

SCREW

CONTROL

SCREWS

CONTROL

3.

Disconnect

connectors

them

BOX

80x

DOOR

DOOR

from

CONTROL

the

three

from

the

mating

the

control

printed

sockets

HEAD & BOX

box

electrical

circuit

board

on

the

CONTROL

cord

by

board.

BOX

plug

pulling

CIRCUIT

1.

To

outlined

Box

2.

Disconnect

location

3.

Press

behind

from

BREAKER

Turn

(off

unit)

replace

the

circuit

in

steps 1 and 2 under

Components.”

the

of

wires

the

clips

the

panel,

the

panel.

REPLACEMENT

OFF

power

to

remove

breaker,

wires

from

for

reassembly.

on

each

side

that

secure

at

the

main

all

incoming

follow

“Access

circuit

of

the

it

and

disconnect

power.

instructions

to

Control

breaker.

circuit

breaker,

remove

forward

350265

box.

as

Note

Page 36

«

©

=

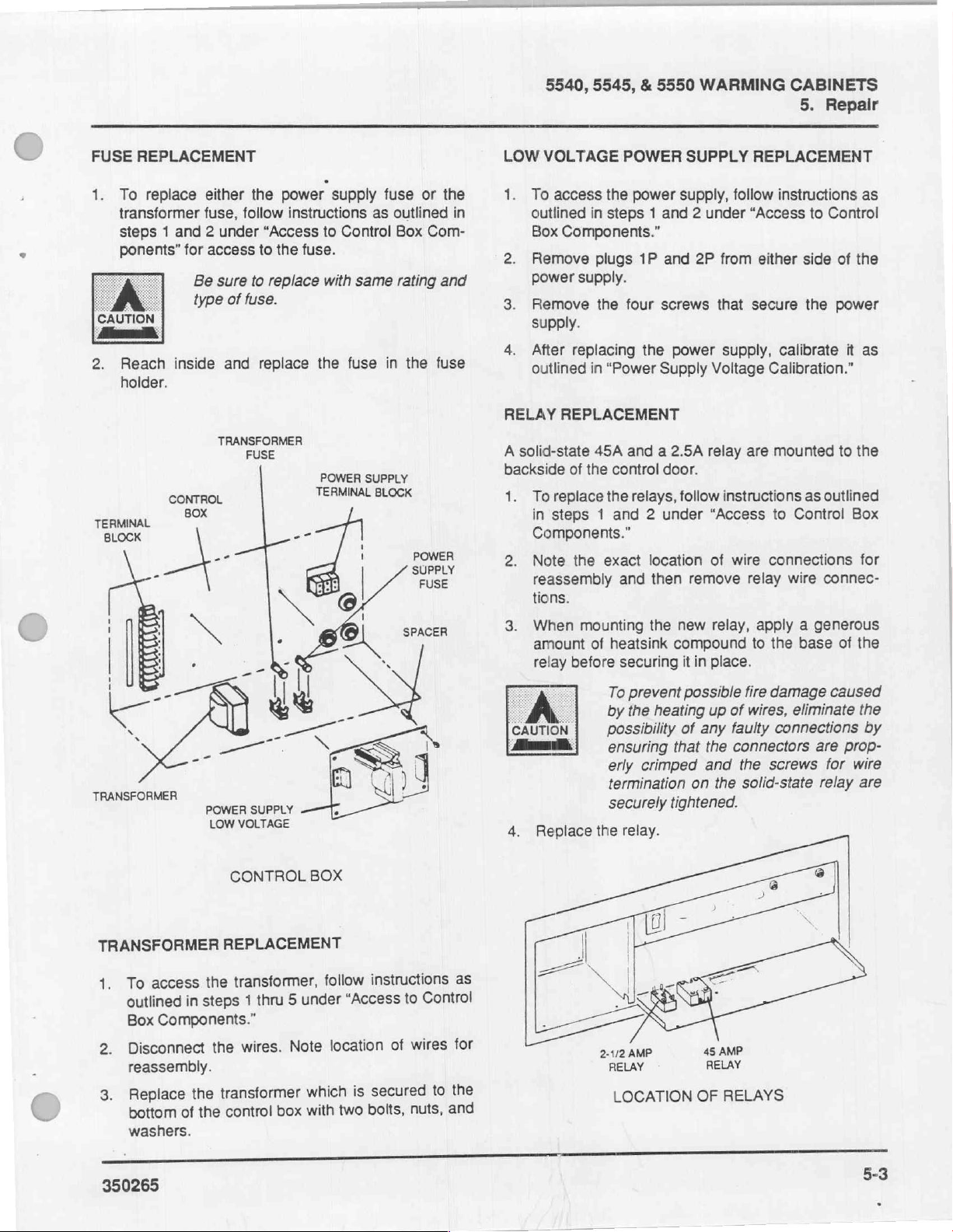

FUSE

REPLACEMENT

1.

To

replace

transformer

steps 1 and 2 under

ponents”

CAUTION

áno

2.

Reach

holder.

for

Be

type

inside

TERMINAL,

BLOCK

either

the

fuse,

follow

“Access

access

to

sure

to

replace

of

fuse.

and

replace

TRANSFORMER

FUSE

power

the

supply

instructions

to

Control

fuse.

with

the

POWER

TERMINAL

same

fuse

SUPPLY

fuse

as

outlined

Box

rating

in

BLOCK

the

or

Com-

and

fuse

the

in

5540,

LOW

VOLTAGE

U

To

access

outlined

Box

Components."

2.

Remove

power

3.

Remove

supply.

4.

After

outlined

RELAY

A

backside

US

REPLACEMENT

solid-state

To

replace

in

steps 1 and 2 under

Components.”

Note

reassembly

tions.

5545, & 5550

POWER

the

power

in

steps 1 and 2 under

plugs

1P

and

supply.

the

four

screws

replacing

in

45A

of

the

the

the

“Power

and a 2.5A

control

the

relays,

exact

and

Supply

door.

location

then

WARMING

SUPPLY

supply,

2P

power

Voltage

relay

follow

“Access

of

remove

CABINETS

5.

REPLACEMENT

follow

instructions

“Access

from

either

that

secure

supply,

instructions

wire

calibrate

Calibration.”

are

mounted

to

Control

connections

relay

wire

Repair

to

Control

side

of

the

power

to

as

outlined

connec-

the

it

the

Box

as

as

for

©

When

amount

CAUTION

Alim

TRANSFORMER

TRANSFORMER

fi

access

To

outlined

Components."

Box

Disconnect

reassembly.

Replace

bottom

washers.

in

the

of

POWER

LOW

the

steps

the

the

SUPPLY

VOLTAGE

CONTROL

REPLACEMENT

transformer,

5

thru

1

wires.

transformer

control

Note

box

BOX

follow

under

location

which

with

instructions

“Access

of

secured

is

bolts,

two

Control

to

wires

to

nuts,

as

for

the

and

4.

relay

before

A,

Replace

mounting

of

heatsink

securing

To

prevent

by

the

possibility

ensuring

erly

crimped

termination

securely

the

relay.

2-1/2

AMP

RELAY

LOCATION

the

new

compound

it

in

possible

heating

of

any

that

on

tightened.

OF

relay,

place.

up

of

faulty

the

connectors

and

the

the

solid-state

45

AMP

RELAY

RELAYS

apply a generous

to

the

base

of

fire

damage

wires,

caused

eliminate

connections

are

screws

for

relay

the

the

by

prop-

wire

are

350265

5-3

Page 37

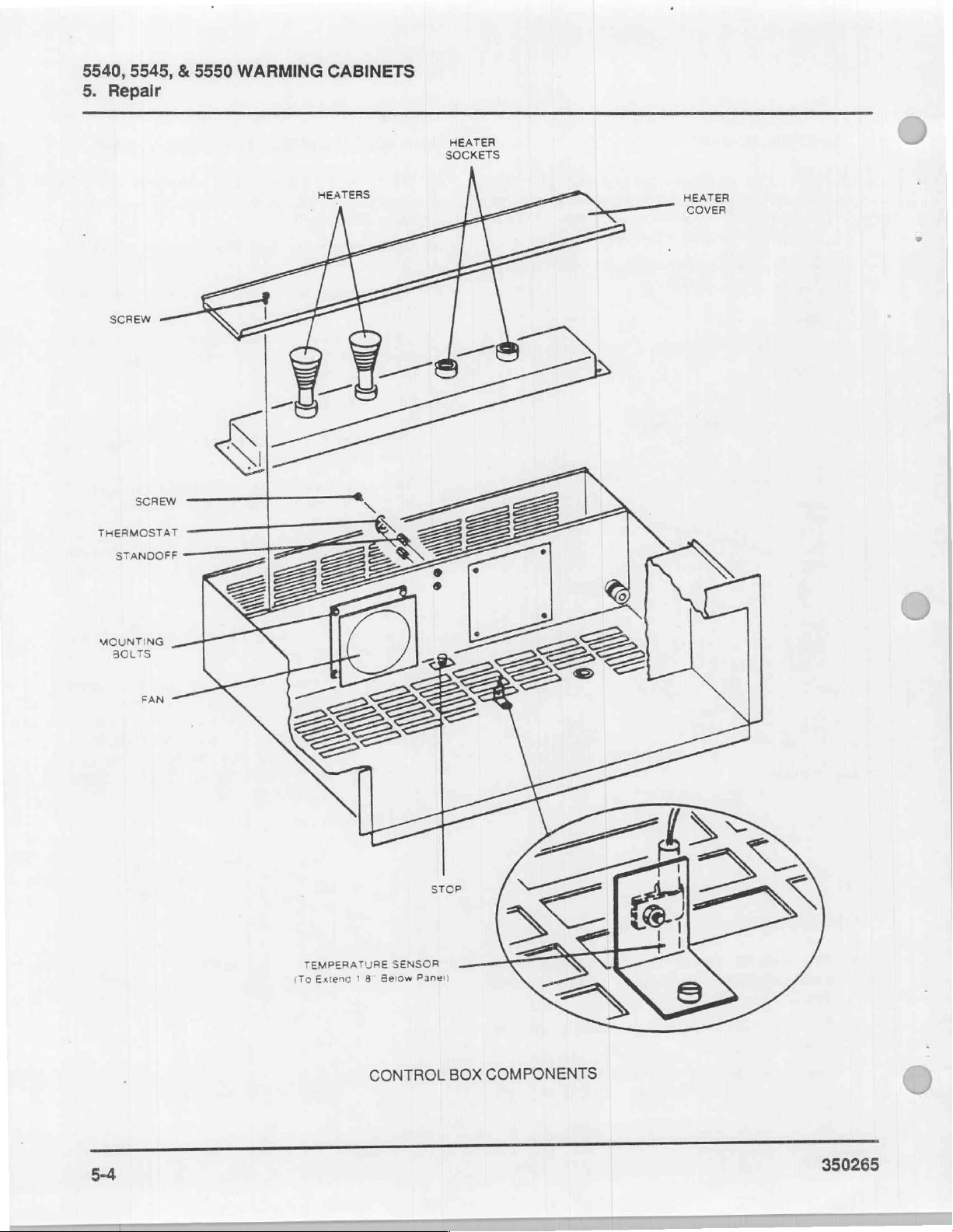

5540, 5545, & 5550

5.

Repair

WARMING

CABINETS

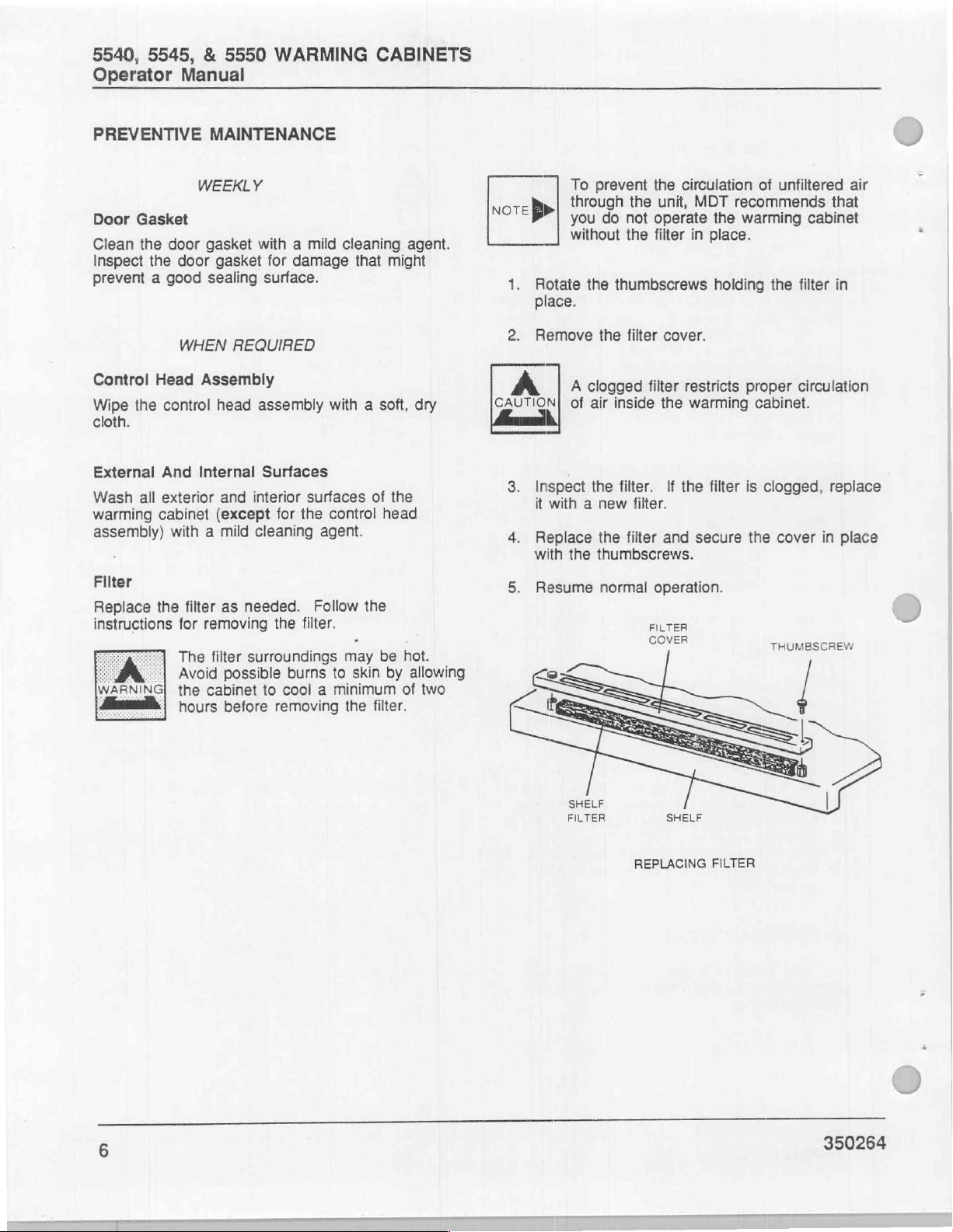

HEATER

SOCKETS

=,

8

MOUNTING

BOLTS

FAN

=

TEMPERATURE

(To

Extend 1 8"

BEB

SENSOR

Below

<

STOP

Panel)

=

D

<=

5-4

CONTROL

BOX

COMPONENTS

350265

Page 38

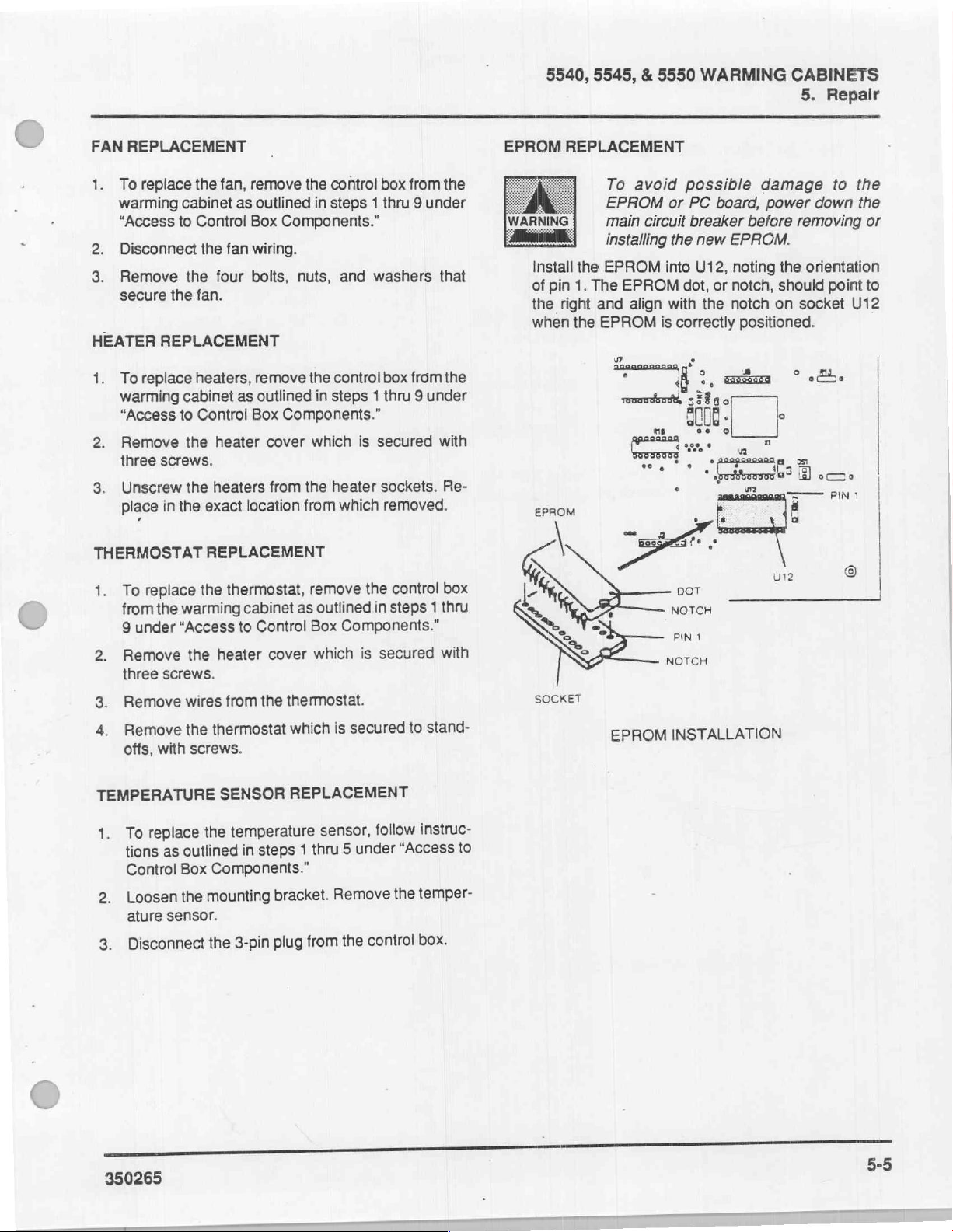

FAN

REPLACEMENT

5540, 5545, & 5550

EPROM

REPLACEMENT

WARMING

CABINETS

5.

Repair

1.

To

replace

warming

“Access

Disconnect

Remove

secure

HEATER

1.

2.

3.

THERMOSTAT

1.

REPLACEMENT

To

replace

warming

“Access

Remove

three

screws.

Unscrew

place

in

To

replace

from

the

9

under

the

cabinet

to

Control

the

the

the

fan.

heaters,

cabinet

to

Control

the

the

heaters

the

exact

REPLACEMENT

the

warming

“Access

fan,

remove

as

outlined

Box

Components.”

fan

wiring.

four

bolts,

remove

as

outlined

Box

Components.”

heater

cover

from

location

thermostat,

cabinet

to

Control

the

control

in

steps 1 thru 9 under

nuts,

the

control

in

steps 1 thru 9 under

which

the

heater

from

remove

as

outlined

Box

box

and

washers

box

is

secured

sockets.

which

removed.

the

control

in

steps 1 thru

Components.”

from

from

the

that

the

with

Re-

box

©

上

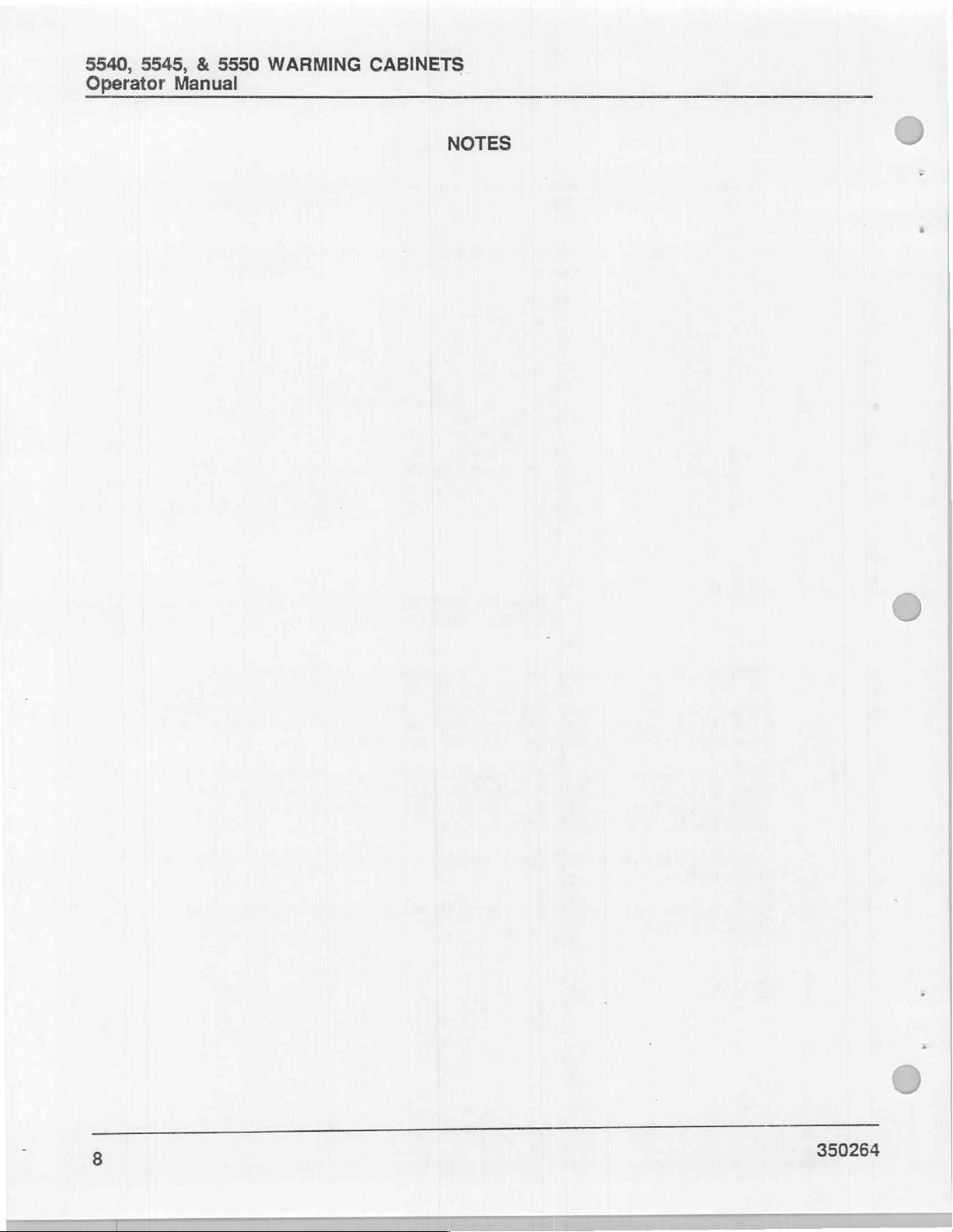

Install

the

of

pin

1.

the

right

when

the

EPROM

To

avoid

EPROM

main

circuit

installing

EPROM

The

EPROM

and

align

EPROM

>

possible

or

PC

breaker

the

new

into

U12,

dot,

with

the

is

correctly

pekin

damage

board,

or

power

before

EPROM.

noting

notch,

notch

positioned.

ο

down

removing

the

orientation

should

on

socket

E

ecos

ğ

U12

to

point

U12

PIN

©

the

the

or

to

1

|

2.

Remove

three

screws.

3.

Remove

Remove

4.

offs,

with

TEMPERATURE

replace

To

1.

as

tions

Control

Loosen

2.

ature

sensor.

Disconnect

3.

the

heater

wires

from

thermostat

the

screws.

SENSOR

temperature

the

outlined

Components.”

Box

mounting

the

3-pin

the

in

the

steps

cover

bracket.

plug

which

thermostat.

which

REPLACEMENT

thru

1

from

is

secured

is

sensor,

under

5

Remove

the

secured

to

follow

“Access

the

control

with

stand-

instruc-

to

temper-

box.

SOCKET

EPROM

INSTALLATION

5-5

Page 39

5540,

5.

Repair

5545, & 5550

WARMING

CABINETS

PRINTED

To

È

2.