Page 1

M

fr

へ

SERVICE

MANUAL

©

Castle

5520

5525

C

Г

WARMING

MDT

Diagnostic

1777

Rochester,

5530

CABINETS

E.

Henrietta

PO.

Box

23077

New

York

Company

Road

14692

)

ER

Technology

q

for

Life

30926

Rev.

ノ

C

Page 2

SERVICE

Rev. A (11/

Rev. B (

Rev. C (11/18/87)

For

Complete

Installation

Operators

Parts

MANUAL

9/85)

3/21/86)

Manual

Instructions

Manual

Catalog

PEN)

30927

30926

GRAPHICS

GENERAL

Changed

Add:

30923

Rev.

DESCRIPTION

The

following

“Danger”

(1/18/84)

REVISED:

REVISION

Logos:

30971

Rev.

C

Rev.

B

symbols

notes

Pages

Front & Back

C

OF

SYMBOLS

with

related

apply

when

5,

21, 22, & 25

Covers & p.

&

NOTES

notes

there

is a possibility

ii

appear

IN

in

of

MANUAL

this

manual.

serious

injury

or

death.

“Warning”

“Caution”

NOTE

>

“Notes”

Ne

noreğp>

=

>

notes

notes

ㆍ

alert

the

All

to

This

Corporation,

produced

of

alert

alert

user

parts

the

Castle,

manual

the

MDT

the

user

the

user

to

pertinent

replaced

Rochester,

contains

Rochester,

in

whole

Corporation.

to

to

the

under

or

the

facts

in

possibility

possibility

and

conditions.

warranty

N.Y.,

for

proprietary

New

York,

part

without

of

personal

of

damage

shall

be

returned

evaluation.

information

and

it

shall not

the

written

injury.

to

the

equipment.

intact

of

the

MDT

be

re-

permission

EMDT

and

Castle

are

registered

trademarks.

Page 3

SECTION

GENERAL

1.

(Storage)

Switch

Filter

Will

Power

or

VAC

VAC

Warning

Panel

Recorder

AirFIOW:

МОЕ

Breaker

Not

Connections

Power

Power

Control

Center

Door

Reversible

Shelf

Adjustable

Optional

Temperature

Heatad

2.

WIRING

Warming

TROUBLE

3.

ПОЛ

Circuit

Unit

Jumper

UnitiNot'AtProper

+5V

+11.6V

18

24

Yellow

We

Heater/Fan

ADJUSTMENTS

4.

DESCRIPTION

Compartment

上

1

Door

(Models

Shelves

1

(Models

Conversion

DIAGRAM

Cabinet

Supply

-11.6V

Wiring

ANALYSIS

О

Trips

Up

Heat

Temperature

Problem

Power

Supply

Supply

Lit

Operational

&

TABLE

スー

ユー

トー

ーー

上

上

5530

&

5520

5520 & 5525

....1....%..........1%2...,.....

Chart

see

ee

Diagram

ео

of

J3

on

Supply

Problem

Problem

............

Checks

CALIBRATION

OF

CONTENTS

В

Assembly

Control

-

トー

Only)

Head

ーー

で

ドド

ドド

トド

..............

Only)

ドド

ーー

<

....

elele

e

ola

es

ŞA

lale

e

ele

.......................................

αρ

e

cen

Circuit

Printed

.....................

Problem

haa

ca

Board

...............

er

ドド

siye

ο

aida

emele

ος

aos

поме

оное

이이

이

еее

в

eje

우우

rea

PAGE

о

。

oe

ее

4

6

7

8

9

10

11

12

13

14

15

16

17

30926

Safety

Power

Temperature

DGOrAGiustMment

Recorder

REPAIR

5.

Safety.

Access

Access

Circuit

Fuse

Transformer

Low

EaniReplacemant:

Heater

Thermostat

Door

Recorder

Printed

Relay

Door

Reversing'DoonSwWing.

During

Supply

Calibration

DuringRepaif

Control

to

Control

to

Breaker

Replacement

Voltage

Replacement

Replacement

Switch

Replacement

Circuit

Meplacemente

Gasket

Adjustments

Voltage

Control

Replacement

Replacement

Power

Replacement

Board

Replacement

Calibration

Calibration

“tino

cdr

Head

Box

............

Supply

..........

Replacement

...................:0.x».5

Calibration

&

iene

e

Components

Components

............

.....

Replacement

MMM...

(Optional

Lu.

Equipment)

...............

.......................

....................,............

nie

pronao

ian

...........

........

uen

ο

enni

302

eee

eae

бое

siete

о

nec

sure

eme

sie

ие

Mala

eds

ани

zes

se

mee

ss

Kase

09

é

18

18

19

20

21

23

23

23

23

23

24

24

24

24

24

26

26

26

22

22

27

Page 4

—IMPORTANT—

CAREFULLY

SERVICING

SPECIAL

READ

THE

Do

not

flammable

electrical

cabinet.

explosion

eguipment

THE

UNIT,

STORAGE

store

agents

components

Contact

or

and

SAFETY

FOLLOWING

AND

items

in

the

into

with

fire,

resulting

surroundings.

FOLLOW

DANGER

VT

INSTRUCTIONS

Warming

the

cabinet

designed

an

to

airborne

in

serious

INSTRUCTIONS

INSTRUCTIONS

THE

Cabinet

atmosphere.

heat

flammable

personal

which

and

circulate

INSTRUCTIONS.

(p.

5)

could

This

agent

injury,

introduce

unit

air

within

may

or

damage

contains

BEFORE

the

cause

to

Hot

substances,

cause

may

temperatures

When

burn

contact

Warming

(120°F),

result

could

surfaces

is

ture

above

contact

when

TEMPERATURE

heated

damage

skin

above

to

tissue

49°C

to

skin

STORAGE

Cabinet

interior

with

to

burns

in

removing

49°C

(120°F).

SELECTION

temperatures

tissue.

when

(120°F).

used,

Goods,

should

INSTRUCTIONS

operating

at

is

surfaces

Avoid

skin.

replenishing

or

contact

(p.

above

49°C

solutions,

not

be

(p.

temperatures

heated

of

intertor

with

cabinet

if

stock

4)

(120°F),

etc.,

which

processed

5)

above

compartments

49°C

cabinet

tempera-

may

at

30926

Page 5

5520, 5525, & 5530

WARMING

CABINETS

RECORDER

(OPTIONAL)

REVERSIBLE

DOOR

5520, 5525, & 5530

ENTER

(STORAGE)

COMPARTMENT

=

|

|

DS

|

—

|

MODEL

(CABINET

|

!

LT

|

5520

MODEL)

CONTROL

ASSEMBLY

CONTROL

DOOR

SWITCH

SHELF

FILTER

|

|

>

ADJUSTABLE

BANER

EMO

COMPARTMENT

WARMING

ADJUSTABLE

REVERSIBLE

CENTER

(STORAGE)

CABINETS

RECORDER

(OPTIONAL

SHELVES

DOOR

CONTROL

HEAD

ASSEMBLY

CENTER

RE

SOMEZE

MODEL

(CABINET

5525

MODEL)

μεν

ASSEMBLY

COMPARTMENT

HEATED

DEFLECTOR

ÚNHEATED

COMPARTMENT

CONTROL

PANEL

DOOR

SWITCH

UPPER

HEATED

AIR

LOWER

30926

RECORDER

(OPTIONAL)

CONTROL

PANEL

DOOR

REVERSIBLE

DOOR

SHELF

FILTER

MODEL

(CABINET

5530

MODEL)

SWITCH

MODELS

(RECESSED

5520

MODEL)

&

5525

(RECESSED

MODEL

5530

MODEL)

Page 6

5520,

5525, 4 5530

WARMING

General

CABINETS

Information

6

GENERAL

Castle

are

designed

goods

air

shelves.

36°C

of

solutions,

or

filters

lower

is

heated

partment

range

5520

shelf

also

compartment

to

holding

tions,

dry

compartment

upward

recorder

record

(e.g.

The

evenly

(97°F)

holding

dry

goods

the

shelves.

adjustable.

The

compartment

for

Warming

capacities

the

same.

The

5530

provide

20

or

goods

from

Either

of

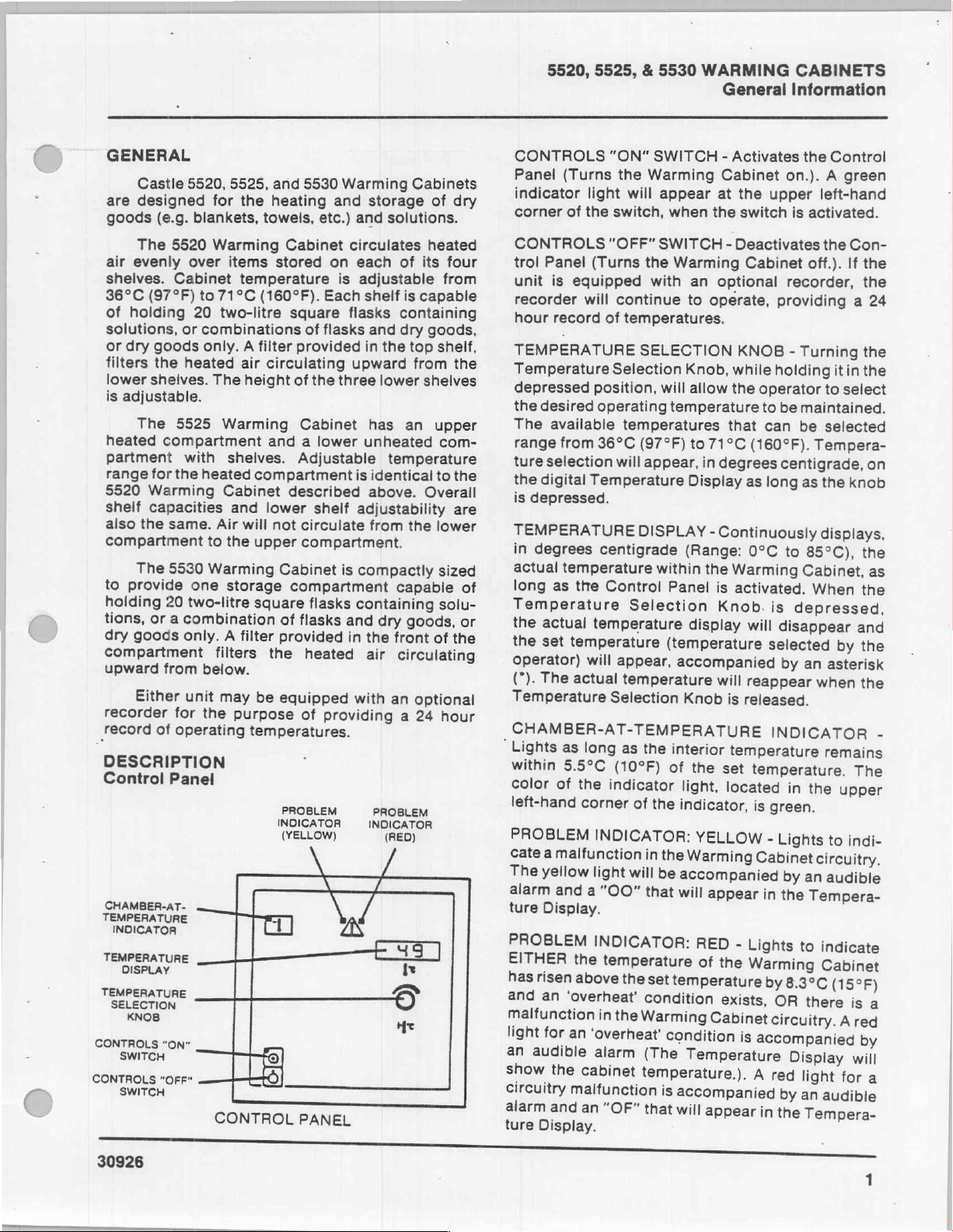

DESCRIPTION

Control

CHAMBER-AT-

TEMPERATURE

INDICATOR

TEMPERATURE

DISPLAY

TEMPERATURE

LON

SONTROLS

В

30926

Font

ώς

ОЕ

5520,

5525,

for

blankets,

5520

Warming

over

items

Cabinet

to

71°C

20

two-litre

or

combinations

only. A filter

heated

The

5525

the

with

heated

to

Warming

one

Warming

shelves.

Cabinet

and

Air

the

storage

two-litre

a

combination

only.

A

filters

below.

unit

may

for

the

purpose

operating

Panel

FT]

CONTROL

and

5530

the

heating

towels,

Cabinet

stored

temperature

(160°F).

square

of

provided

air

circulating

height

will

filter

of

the

Cabinet

and a lower

Adjustable

compartment

described

lower

upper

sguare

be

temperatures.

shelf

not

circulate

compartment.

Cabinet

compartment

flasks

of

flasks

provided

the

heated

eguipped

of

PROBLEM

INDICATOR

(YELLOW)

NY

>

2

PANEL

Warming

and

storage

etc.)

and

circulates

on

each

is

adjustable

Each

shelf

flasks

flasks

and

in

upward

three

has

unheated

is

identical

above.

adjustability

from

is

compactly

containing

and

in

the

air

with

providing

INDICATOR

N

Nød

EST

Cabinets

solutions.

heated

of

its

is

capable

containing

dry

goods,

the

top

from

lower

shelves

an

temperature

Overall

the

capable

dry

goods,

front

circulating

an

optional

a

24

PROBLEM

(RED)

人

ча

^

He

of

dry

four

from

shelf,

the

upper

com-

to

the

are

lower

sized

solu-

or

of

the

hour

of

“Lights

Cate

The

alarm

ture

PROBLEM

EITHER

has

and

malfunction

light

an

show

circuitry

alarm

ture

CONTROLS

Panel

(Turns

indicator

corner

CONTROLS

trol

Panel

unit

is

recorder

hour

record

TEMPERATURE

Temperature

depressed

the

desired

The

available

range

from

ture

selection

the

digital

is

depressed.

TEMPERATURE

in

degrees

actual

long

Temperature

the

the

operator)

(*).

Temperature

temperature

as

actual

set

The

“ON”

the

light

will

of

the

switch,

“OFF”

(Turns

equipped

will

continue

of

temperatures.

Selection

position,

operating

temperatures

36°C

will

Temperature

centigrade

the

Control

Selection

temperature

temperature

will

appear,

actual

temperature

Selection

SWITCH - Activates

Warming

appear

when

SWITCH - Deactivates

the

Warming

with

SELECTION

will

temperature

(97°F)

appear,

DISPLAY

within

Panel

(temperature

accompanied

CHAMBER-AT-TEMPERATURE

as

long

as

the

of

the

in

will

that

interior

of

the

be

within

color

left-hand

5.5ºC

of

PROBLEM

a

malfunction

yellow

and

(10ºF)

the

indicator

corner

INDICATOR:

light

a

“OO”

Display.

uj

INDICATOR:

the

temperature

risen

abovethe

an

‘overheat’

for

an

audible

the

malfunction

and

Display.

in

‘overheat’

alarm

cabinet

an

set

condition

the

Warming

condition

(The

temperature.).

is

“OF”

that

temperature

accompanied

will

Cabinet

at

the

the

switch

Cabinet

an

optional

to

operate,

KNOB - Turning

Knob,

while

allow

the

that

to

71°C

in

degrees

Display

-

(Range:

display

Knob

the

light,

indicator,

as

Continuously

the

Warming

is

activated.

Knob.

will

will

reappear

is

released.

temperature

set

located

YELLOW

Warming

accompanied

will

appear

RED

-

Lights

of

the

Warming

exists,

Cabinet

is

Temperature

appear

the

on.). A green

upper

left-hand

is

activated.

the

off.).

recorder,

providing a 24

holding

operator

to

can

(160°F).

long

0°C

to

be

maintained.

be

selected

Tempera-

centigrade,

as

the

displays,

to

85°C),

Cabinet,

When

is

depressed,

disappear

selected

by

an

when

INDICATOR

remains

temperature.

in

the

is

green.

-

Lights

Cabinet

in

by

the

circuitry.

an

Tempera-

to

indicate

Cabinet

by

8.3°C

OR

there

circuitry.

accompanied

Display

A

red

light

by

an

audible

in

the

Tempera-

Control

Con-

If

the

the

the

it

in

the

select

on

knob

the

as

the

and

by

the

asterisk

the

The

upper

to

indi-

audible

(15°F)

is

a

Ared

by

will

for

a

°

-

Page 7

§520, 5525, & 5530

1.

General

Information

WARMING

CABINETS

Center

(Storage)

Assembly-

This

compartment

access

tridges,

Door

this

to

switch

heating

Reversible

the

desired, a door

in

the

should

personnel.

Shelf

Switch

Closing

switch

the

heating

A

Warming

left

the

opposite

door

Filter

storage

etc.

the

and

will

be

circuit

Door

or

right,

swing

only

(Models

Filters the

compartment.

Adjustable

Shelves

Compartment - Control

may

be

of

recorder

Warming

allow

electrical

circuit.

released

will

be

When

be

Cabinet

depending

may

be

direction.

are

in

undertaken

shut

converted

charts,

Cabinet

power

the

door

and

electrical

off.

door

swings

on the

Instructions

this

Service

by

5520 4 5530

upward

flow

(Models

of

heated

5520 4 5525

used

for

ink

pen

door

will

to

be

is

opened,

power

open

individual

so

it

swings

for

reversing

Manual,

Castle

Only)

air

Head

ready-

car-

depress

supplied

this

to

the

either

to

unit.

open

and

Service

into

Only)

If

a

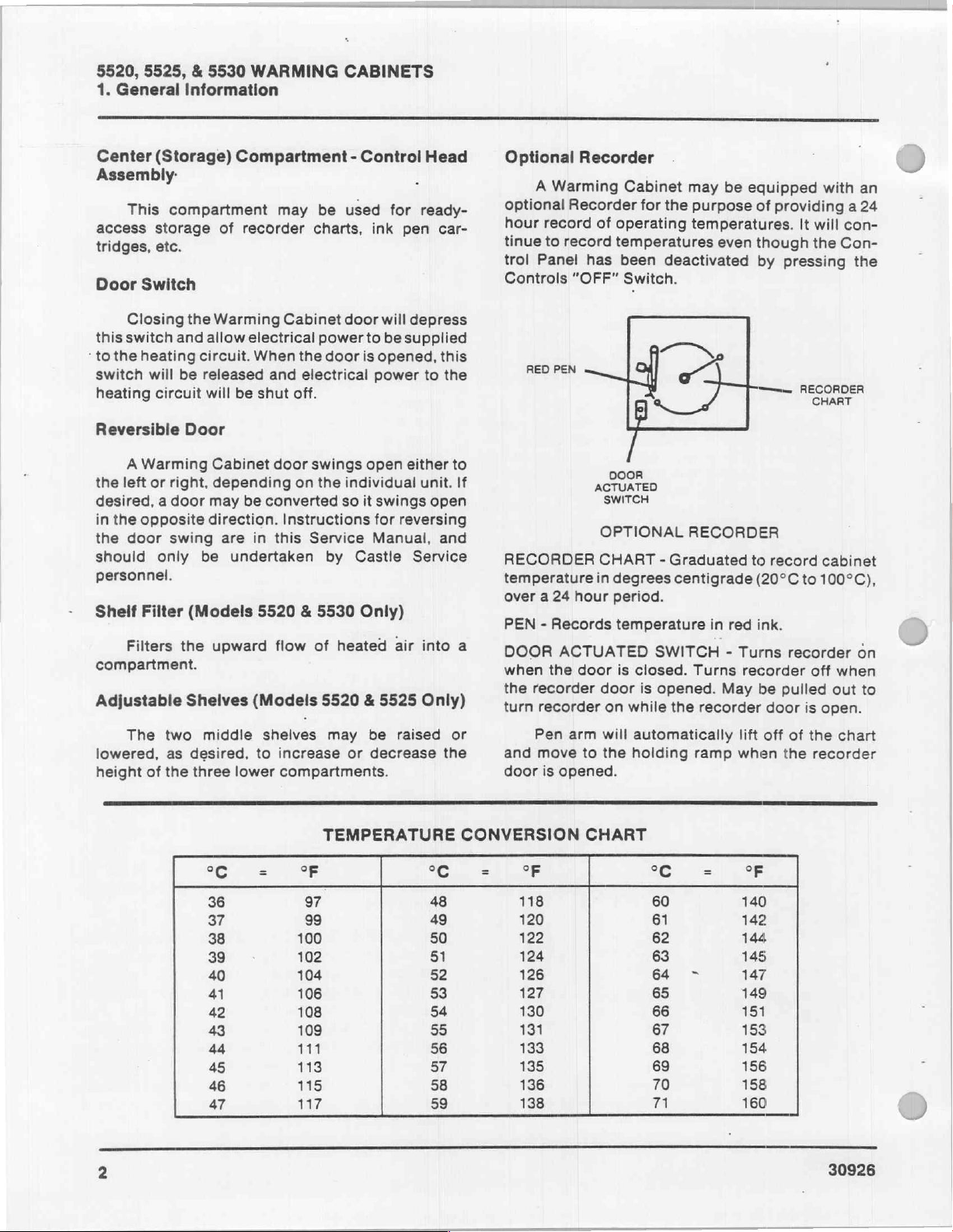

Optional

optional

hour

tinue

trol

Controls

RED

RECORDER

temperature

over a 24

PEN - Records

DOOR

when

the

turn

Recorder

A

Warming

Recorder

record

to

record

Panel

"OFF"

PEN

hour

ACTUATED

the

door

recorder

recorder

of

has

|

ACTUATED

in

Cabinet

for

operating

temperatures

been

Switch.

may

be

the

purpose

temperatures.

even

deactivated

So

:

/

DOOR

SWITCH

OPTIONAL

CHART - Graduated

degrees

period.

temperature

is

closed.

door

is

on

while

RECORDER

centigrade

in

SWITCH - Turns

Turns

opened.

the

May

recorder

equipped

of

providing a 24

though

by

-—_

to

record

(20°C

red

ink.

recorder

be

door

with

It

will

the

pressing

RECORDER

am

cabinet

to

100°C),

recorder

off

pulled

is

out

open.

an

con-

Con-

the

on

when

to

The

lowered,

height

of

two

middle

as

desired,

the

three

°C

36

37

38

39

40

41

42

43

44

45

46

47

shelves

to

lower

=

may

increase

compartments.

or

TEMPERATURE

oF

97

99

100

102

104

106

108

109

111

113

115

117

be

raised

decrease

or

the

CONVERSION

°C

48

49

50

51

52

53

54

55

56

57

58

59

and

door

°F

118

120

122

124

126

127

130

131

133

135

136

138

Pen

move

is

arm

to

opened.

CHART

will

automatically

the

holding

°C

60

61

62

63

64

65

66

67

68

69

70

71

ramp

=

>

lift

when

°F

140

142

144

145

147

149

151

153

154

156

158

160

off

the

of

the

recorder

chart

Page 8

§520, 5525, & 5530

WARMING

CABINETS

Operation

o

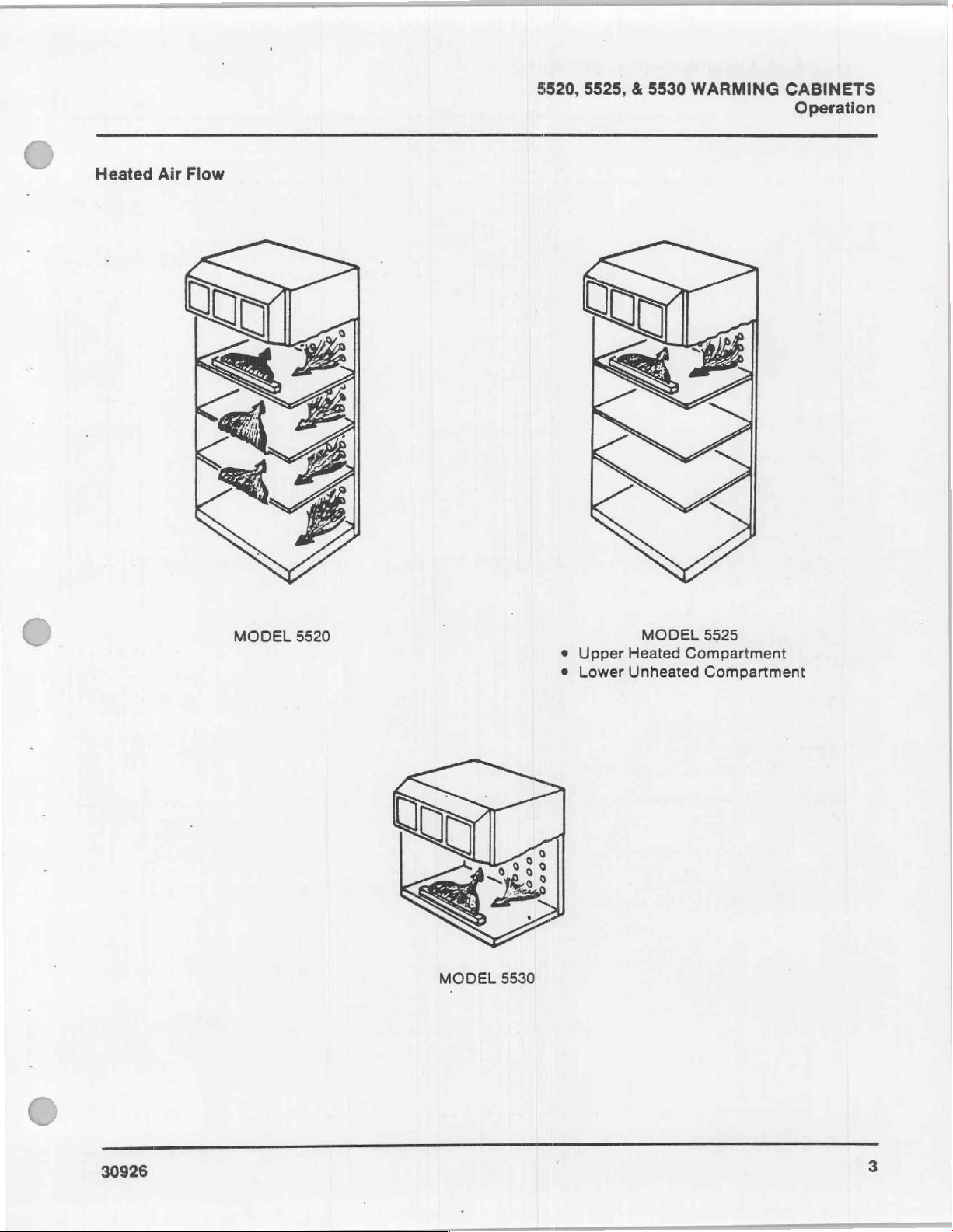

Heated

Air

Flow

MODEL

5520

|

MODEL

5530

e

e

Upper

Lower

MODEL

Heated

Unheated

5525

Compartment

Compartment

30926

Page 9

5520,

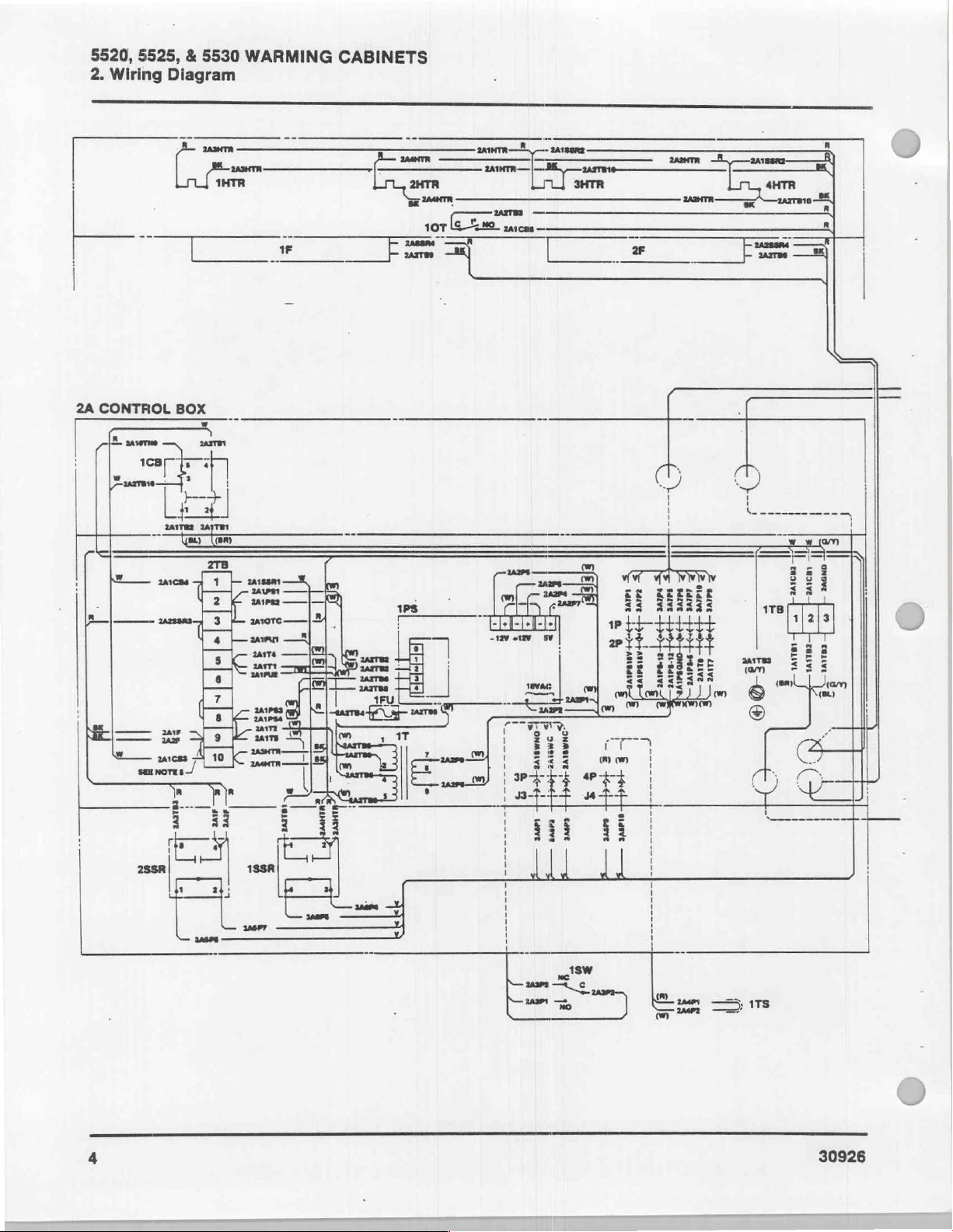

2.

5525, & 5530

Wiring

Diagram

WARMING

CABINETS

2A

CONTROL

fm

BOX

um

_

É

ZU

333

ЕН

PI

TTT

313

Li

|

ЕЕ

ЗЕЕЕЕЕ

33

333333

wit

it

tit

LESLEY

z

=

きま ま E3SEEE

日

=

ГГ

a

2

da

хх

|

|

ㅣ

|

i

!

|

|

1

i

i

1

i

o

z

SH

u

M!

|

U

το

ww

f

178

om

‘am < ミミ

©"

e

©

(ay)

Πρ

ὅτι ||

Bala

Tir

EEE

OÚ

SE

i

(BL)

(am

>

|

)

上

ii

|

ú

Hi

3/8

d

l

30926

Page 10

Ê

=

|

1A

Lee,

|

ann

3

arre

POWER

1TB

|

IT 一 -

i-

5A

SUPPLY

區

-

RECORDER

παν

super

{

une

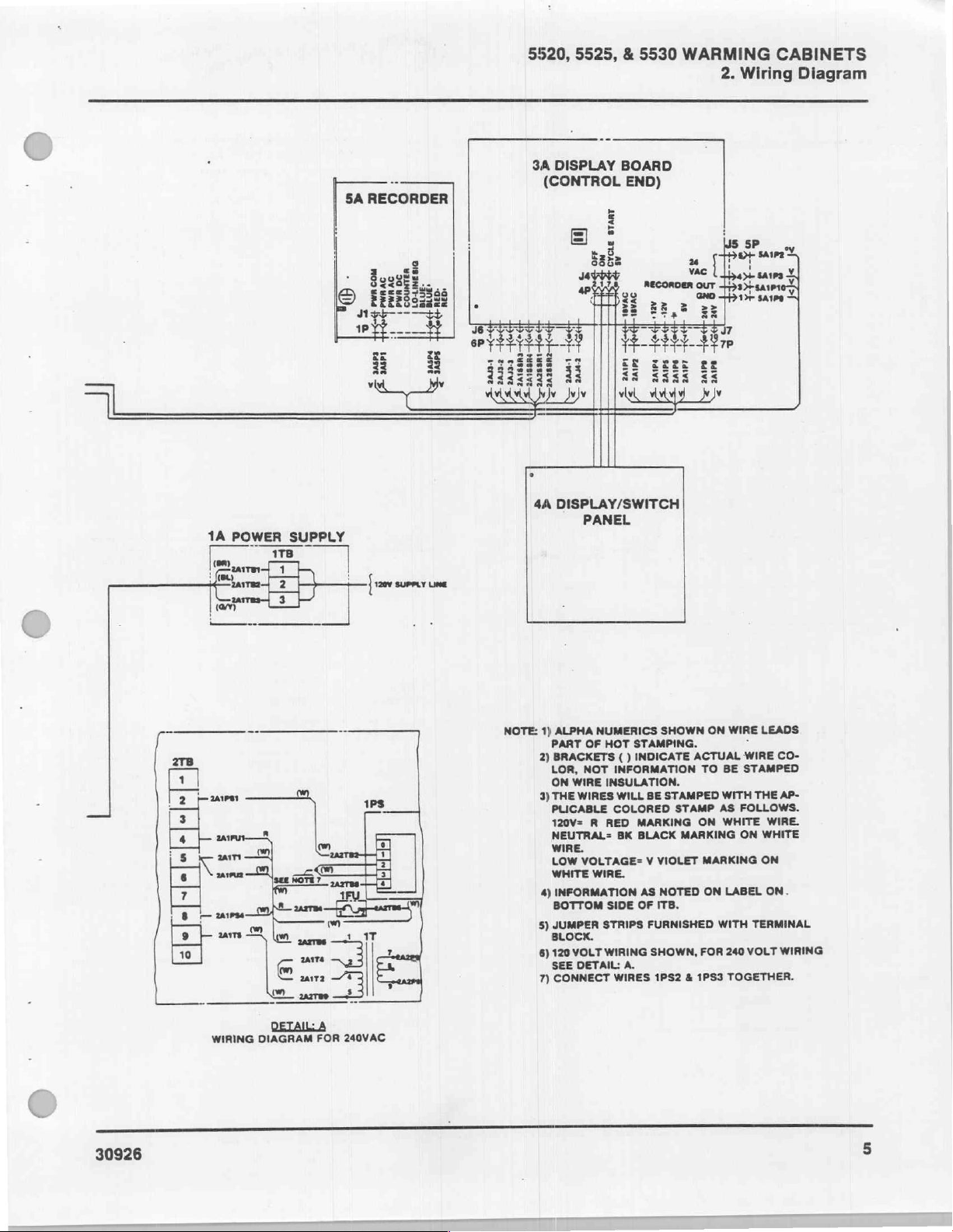

5520, 5525, & 5530

3A

DISPLAY

(CONTROL

-

什

+

ed

|

1

Ke《

Ke

一

二

-K

et

2A188R4

2A188R3

2

9

4A

DISPLAY/SWITCH

PANEL

BOARD

END)

WARMING

sv

stay

ar

ad}

acil

각서

2Atp4

2a1P6

Hav

|

24107

14109

2.

Wiring

24Y

于

2A1P8

CABINETS

Diagram

30926

ejelsjajujajuln

WIRING

DETAIL

DIAGRAM

A

FOR

240VAC

NOTE:

1)

ALPHA

PART

OF

2)

BRACKETS ( )

LOR,

NOT

ON

WIRE

3)

THE

WIRES

PLICABLE

120V= R RED

NEUTRAL=

WIRE.

LOW

VOLTAGE= V VIOLET

WHITE

WIRE.

4)

INFORMATION

BOTTOM

5)

JUMPER

BLOCK.

6)

120

VOLT

SEE

DETAIL:

7)

CONNECT

NUMERICS

HOT

STAMPING.

INDICATE

INFORMATION

INSULATION.

WILL

COLORED

MARKING

BK

BLACK

SIDE

OF

STRIPS

WIRING

A.

WIRES

SHOWN

BE

STAMPED

STAMP

MARKING

AS

NOTED

ITB.

FURNISHED

SHOWN,

1PS2 & 1PS3

ON

ACTUAL

TO

ON

MARKING

ON

WITH

FOR

WIRE

i

WIRE

BE

STAMPED

WITH

THE

AS

FOLLOWS.

WHITE

ON

LABEL

TERMINAL

240

VOLT

TOGETHER.

LEADS

CO-

AP-

WIRE.

WHITE

ON

ON.

WIRING

Page 11

5520,

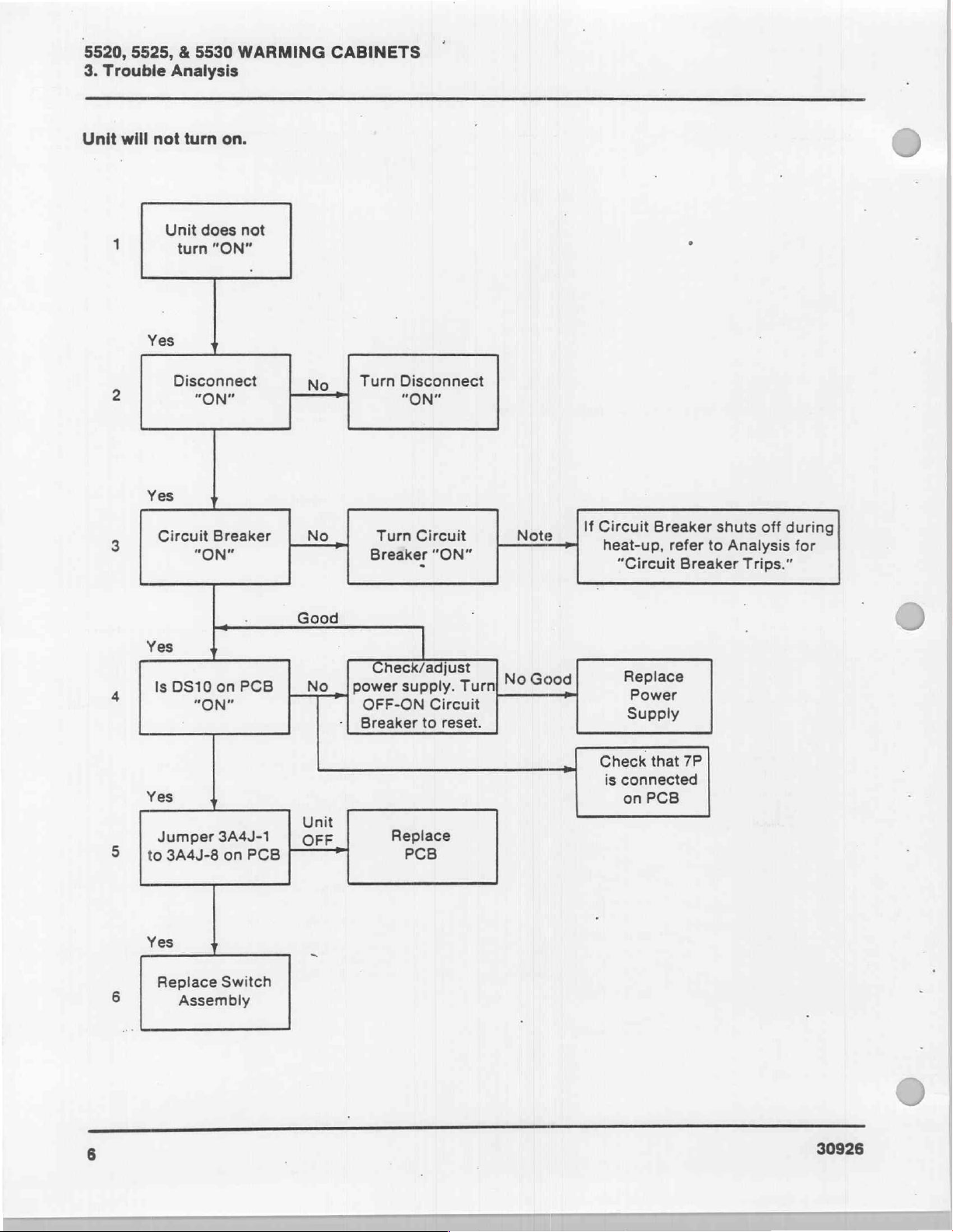

3.

Trouble

Unit

will

1

5525, & 5530

Analysis

not

turn

Unit

turn

on.

does

“ON”

WARMING

not

CABINETS

°

Yes

2

Yes

3

4

5 | to

e

Yes

Is

Yes

Jumper

Disconnect

"ON"

м

DS10

on

PCB | No,

ER"

"ON

3A4J-1

3A4J-8

on

a

PCB

No | Turn

Good

No

Unit

OFF

deo,

Check/adjust

|power

OFF-ON

Breaker

Disconnect

"ON"

V.

=

supply.

a.

Circuit

to

reset.

Replace

PCB

Turn}

NE

No

If

Circuit

heat-up,

“Circuit

Good

Replace

Check

is

connected

on

Breaker

Power

Subo!

PPY

that

PCB

refer

Breaker

7P

shuts

to

Analysis

Trips.”

off

during

for

Yes

Replace

6

6

Switch

Assembly

30926

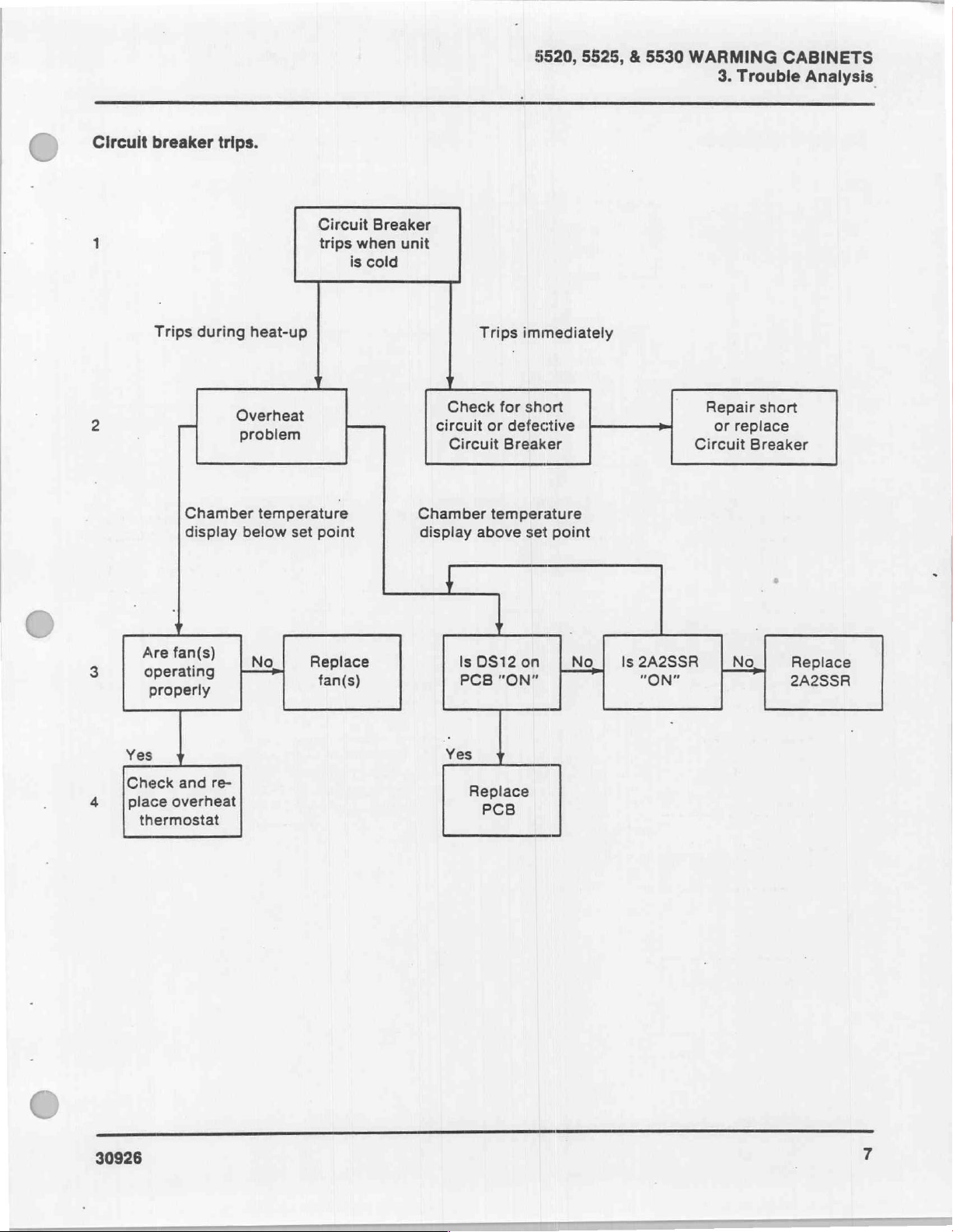

Page 12

5520,

5525, & 5530

WARMING

3.

Trouble

CABINETS

Analysis

(

Circuit

1

2

breaker

Trips

during

Chamber

display

trips.

Circuit

trips

heat-up

Overheat

problem

temperature

below

set

point

when

is

cold

Breaker

unit

Chamber

display

Trips

immediately

1

πώς

Circuit

above

ον

Breaker

temperature

set

ft

point

Hi

Circuit

P

Breaker

Yes

Check

place

4

Are

one

operating

properly

and

overheat

thermostat

No | Replace

re-

fan(s)

ls

DS12on | No | ls2A2SSR | No | Replace

PCB

"ON"

Yes

y

Replace

PCB

2A2SSR

30926

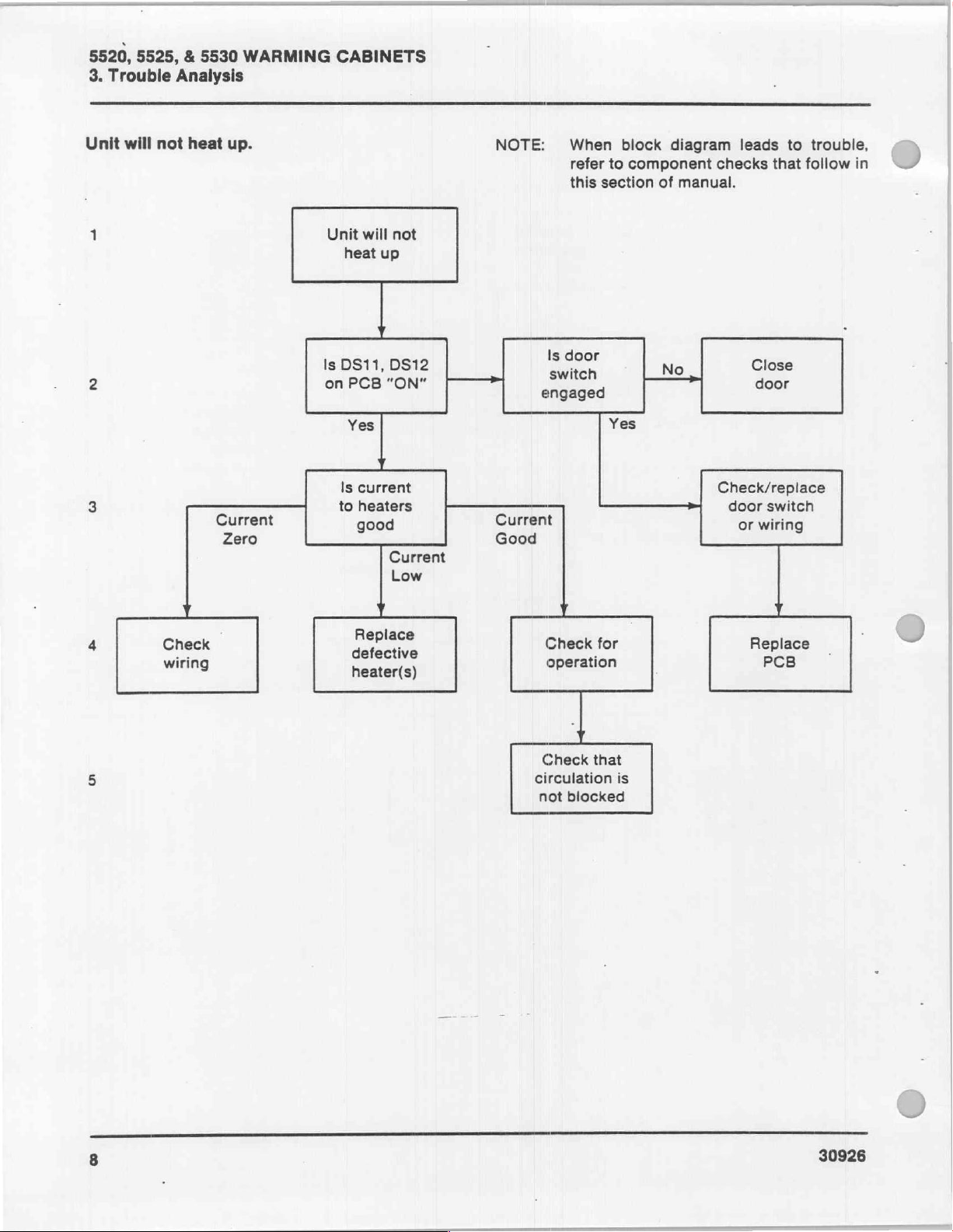

Page 13

5520,

3.

Unit

2

3

5525, & 5530

Trouble

will

1

Analysis

not

heat

WARMING

up.

Current

Zero

CABINETS

Unit

Is

S

on

to

will

not

heat

up

DS11,

Is

PCB

"ON"

PCB

Yes

current

heaters

good

DS12

Current

Low

NOTE:

Current

Good

When

refer

this

taser

switch

engaged

block

to

component

section

Yes

diagram

of

manual.

No

leads

checks

οι

E

oor

Check/replace

door

or

wiring

to

that

follow

을

switch

trouble,

in

4

5

Y

Check

wiring

bel

heater(s)

| 4

Check

operation

Check

circulation

not

for

that

blocked

is

Replace

PCB

3

30926

Page 14

§520,

‘

Jumper

proper

follows:

Connections

Jumpers

operation

on

J3

of

of

a50

the

on

J3

printed

Hz

or

of

Printed

circuit

60

Hz

supply

3

J6 J7

==

Circuit

board

circuit.

CUT-OUT

(Time

Selector

Switch)

ES

5525, & 5530

Board

must

be

Proper

properly

connections

WARMING

3.

connected

Trouble

for

are

as

CABINETS

Analysis

MIE)

д

|

add

wle—

а

во

a

50/60

JUMPER

33

e

|<

|<

|< >|

|<

HZ

CONNECTIONS

>

>

>

)

5

so

30926

Page 15

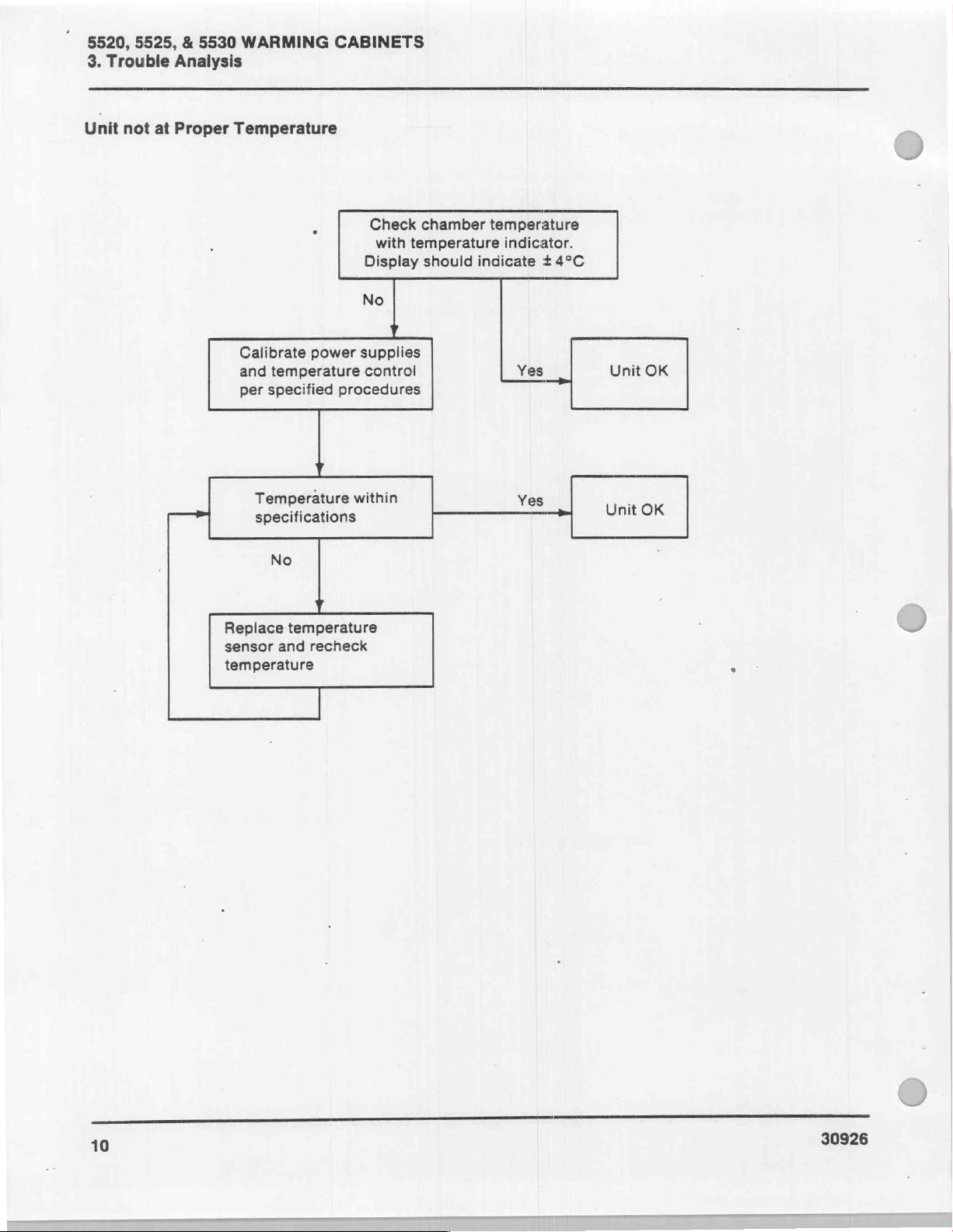

5520,

3.

Unit

5525, & 5530

Trouble

not

at

Analysis

Proper

WARMING

Temperature

Calibrate

and

per

power

temperature

specified

CABINETS

Check

with

Display

No

у

supplies

control

procedures

chamber

temperature

should

temperature

indicate + 4°C

indicator.

Yes

Unit

OK

Temperature

specifications

No

Replace

sensor

temperature

temperature

and

y

Y

recheck

within

Yes

Unit

OK

10

30926

Page 16

+5V

Power

Supply a Problem

5520,

5525, & 5530

WARMING

3.

Trouble

CABINETS

Analysis

less

than

Check

good

good

good

ysis.

turn

Turn

breaker

Recalibrate

fied

Check

place

if

required.

y

Trouble

"Unit

on.”

procedure.

will

off

circuit

to

reset

у

per

Still

y

wiring

power

and

supply

Anal-

not

Still

low

OVP

Still

low

speci-

low

re-

+5V

y À

+5V

supply

5.00V + .01V

ibration

procedure.

=+5V

|

Power

supply

not

per

good.

at

cal-

greater

Recalibrate

fied

Replace

than

+5V

Y

per

procedure.

Unable

calibrate

power

speci-

to

supply

good

30926

1

Page 17

5520, 5525, & 5530

3.

Trouble

Analysis

WARMING

CABINETS

+11.6

Good

Good

or

-11.6

Power

Check

ysis

“Unit

will

Recalibrate

fied

procedure

Check

power

inals

Supply

0

or

Trouble

not

Still

plow

per

Still

low

voltage

supply

Voltage

good

low

Anal-

turn

V

speci-

V

at

term-

Problem

voltage

on”

Supply

-11.6

spectively

Power

Voltage

is

voltage

or

+11.6V

supply

0

not

re-

Voltage

Correct

good

at

Voltage

is

higher

Recalibrate

supply

Replace

supply

value

L

power

Unable

calibrate

y

power

to

Good

Good

Good

12

Repair

Check

tage

Check

Replace

supply

faulty

input

to

AC

power

input

power

wiring

vol-

supply

wiring

Input

voltage

OK

30926

Page 18

5520,

5525, & 5530

WARMING

3.

Trouble

CABINETS

Analysis

18VAC

Power

Voltage

Check

ysis

“Unit

will

Check

power

to

Supply

less

than

Problem

18

VAC

18

not

VAC

at

power

18

VAC

1

supply

+4

Voltage

correct

VAC

Voltage

more

Trouble

1 1

input

Anal-

not

turn

Still

low

voltage

supply

Input

incorrect

on”

Input

Voltage

good

OK

power

supply

Check

supply

Replace

than

that

power

input

power

18

VAC

is

correct

supply

183008

Check

Replace

wiring

power

.

supply

30926

13

Page 19

5520,

3.

Trouble

24V

Voltage

DI

9

Voltage

good

Voltage

good

5525, & 5530

Analysis

Power

Supply

Check

ysis

“Unit

Check

and

Check

WARMING

Problem

Trouble

will

not

:

input

wiring

if

Voltage

turn

Voltage

low

voltage

Voltage

low

fuse

is

Anal-

on”

bad

CABINETS

low

24

24

24V

VAC

supply

VAC

+5V

transformer

not

good

at

Voltage

Check

Replace

high

input

transformer

wiring

24V

good

Voltage

good

14

Check

Replace

24V

wiring

transformer

30926

Page 20

Yellow

Warning

Lit

Yellow

00

play

Is

ply

Warning

in

temperature

1

-11.6V

good? power

power

code,

dis-

sup-

No

§520, 5525, & 5530

Adjust

or

supply

replace

WARMING

3.

Trouble

CABINETS

Analysis

Disconnect

PC

board.

>

Check

shorts.

erature

Replace

sensor.

Yes

P6

from

code

sull

No

wiring

for

temp-

Yes

Fieplace

PC

board

30926

15

Page 21

5520,

3.

Trouble

Red

Warning

5525, & 5530

Analysis

Lit

WARMING

CABINETS

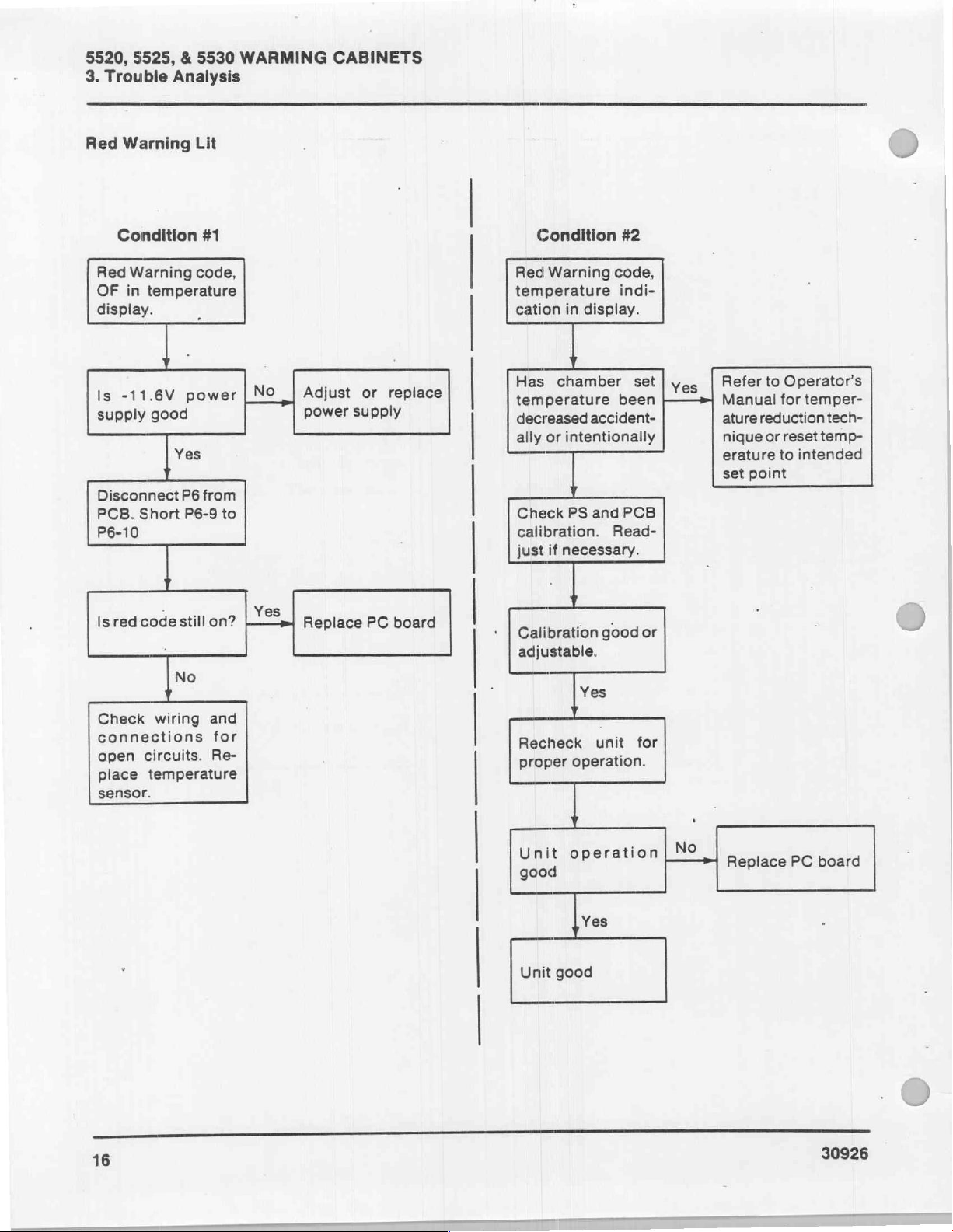

Condition

Red

Warning

OF

in

temperature

display.

-11.6V

Is

Short

red

code

circuits.

temperature

good

wiring

supply

Disconnect

PCB.

P6-10

Is

Check

connections

open

place

sensor.

#1

code,

power

Yes

1

P6

from

P6-9

still

on?

No

and

Re-

Adjust

|

NO

|

to

for

Yes

power

Replace

replace

or

supply

PC board

Condition

Red

Warning

temperature

cation

Has

temperature

decreased

ally

Check

calibration.

just

Calibration

adjustable.

in

chamber

or

intentionally

PS

if

necessary.

Recheck

proper

Unit

good

display.

accident-

and

1

Yes

operation.

operation

#2

code,

indi-

been

PCB

Read-

good

unit

set

or

for

Yes

No

Refer

Manual

ature

nigue

erature

set

Replace

to

Operator's

for

temper-

reduction

or

reset

to

intended

point

PC

tech-

temp-

board

16

Yes

Unit

good

30926

Page 22

HEATER/FAN

Check

も

controls

OPERATIONAL

that

circuit

"ON"

switch

breaker

and

CHECKS

is

“ON”,

close

the

press

door.

the

5520,

Open

out

(off).

Close

5525, & 5530

chamber

chamber

door.

door.

WARMING

3.

Trouble

DS11

and

CABINETS

DS12

Analysis

should

go

O

Set

at

chamber.

DS11

circuit

fans

"ON."

and

are

COMPONENT

temperature

DS12

board)

"ON"

DS12

should

and

DS11

J6

to

require

on

the

display

be

lit.

DS12

CUT-OUT

Já

LOCATIONS

DS11

that

bo

heat-up

PCB

indicates

the

heaters

&

POWER

(Other

J7

ON

PCB

of

(printed

LED

Side

+

the

the

are

of

(DS9)

PCB)

Check

a.

Check

2A2SSR4

Voltage

and

closed.

b.

Place

With

be

0.1A

Check

a.

Check

2A1SSR2

VAC

240

b.

Place

2A1SSR2.

age

supply

supply.

fan

electrical

voltage

should

either

amprobe

the

0.2A

on a 240

heater

with

VAC

amprobe

should

or

with a DVM

be 0 VAC

120

or

on

door

closed,

on a 120

VAC

electrical

voltage

with a DVM.

the

door

with

the

on

With

the

be

4.5A

2.25A

supply

circuit.

between

(digital

240

VAC

2A1F

and

the

VAC

electrical

electrical

supply

between

Voltage

open

door

closed.

2A4HTR

door

on a 120

on a 240

2A2TB10

with

the

with

2AF2

amperage

supply.

circuit.

2A2TB10

should

and

either

and

closed,

VAC

VAC

and

voltmeter).

door

open

the

door

of

2SSR4.

should

supply

2A3HTR

the

electrical

electrical

or

and

be

120

or

or

amper-

0

©

30926

17

Page 23

5520, 5525, & 5530

4.

Adjustments & Calibration

WARMING

CABINETS

SAFETY

CALIBRATION

TEMPERATURE

If

required, a temperature

changing

on

Page 2 of

POWER

1.

2.

degrees

SUPPLY

Raise

the

Remove

head

assembly

components.

DURING

The

power

electrical

Prevent

which

personal

during

adjustments

the

could

contact

adjustments

CONVERSION

Celsius

this

manual.

VOLTAGE

control

the

three

for

head

screws

ADJUSTMENTS

circuit

access

must

possibility

cause

injury,

with

and

conversion

to

degrees

CALIBRATION

assembly

that

to

the

be

“ON”

to

and

calibrations.

of

electrical

by

not

electrical

calibration.

CHART

chart

Fahrenheit

cover.

secure

the

the

power

make

shock,

making

circuit

,

for

power

supply

&

is

+5

Volt

a.

Place

probe

-Pin 7 of

b.

Adjust

power

is

+11.6

a.

Place

the

b.

Adjust

power

Vdc

-11.6

a.

Place

the

b.

Adjust

until

Adjustment

DVM

on

the

supply

+5.00

Volt

Adjustment

DVM

positive

the

supply

on

the

Volts

Calibration

DVM

positive

the

the

(digital

J1 - Pin 6 and

the

PCB.

+5V

adjustment

until

+0.01

Vdc

on

negative

probe

on

+11.6V

until

meter.

negative

probe

-11.6V

DVM

POT

reading

voltmeter)

positive

the

reading

the

meter.

probe

adjustment

the

on

on

J1 - Pin

reading

probe

on

J1 - Pin 8 of

on

the

is

-11.6

negative

probe

on

POT

on

the

on

the

DVM

J1 - Pin 6 and

10

of

the

PCB.

POT

on the

is

11.6

+0.01

J1- Pin 6 and

the

PCB.

power

+0.01

supply

Vdc.

>

J1

3.

Check

engaged

switch

temperature

for

that

to

on

the

15

minutes.

ADJUSTABLE

the

"ON."

front

in

the

circuit

Press

panel

Warming

VOLTAGE

breaker

the

controls

to

“ON”

Cabinet

POTS

has

and

been

“ON”

let

the

stabilize

DOT

ON

INDICATES

LOCATION

PC

BOARD

PIN1

J2

J 自 中

@

1

on

Nour

OF

J1

CUT-OUT

J1

ON

PC

14

13

12

11

10

BOARD

18

30926

Page 24

After

making

ments,

‘a.

check

Depress

on the

should

18

VAC

a.

Connect

Pin

2.

b.

DVM

24

VAC

a.

Connect

Pin

10.

b.

DVM

TEMPERATURE

Calibrate

U

under

Power

making

Adjust

a.

b.

R23

R26 R28

the

2.5

Connect a DVM

probe

J1 - Pin

Adjust

reading

HO

ro

the

for

the

front

read

from

Voltage

DVM

reading

Voltage

DVM

reading

CONTROL

the

power

Supply

Temperature

Vdc

on

to

J1 - Pin 6 and

2.

R28

of

2.500

power

proper

temperature

control

supply

adjustments

panel

36°

to

Check

probes

should

Check

probes

should

between

be

between

be

supply

Voltage

Control

the

PCB

(digital

if

required

+0.005

voltage

as

set

point

and

the

71°C.

J7 - Pin 1 and

18.00

+3

-0

J7 - Pin 9 and

24.00

+6

-0

CALIBRATION

voitage

Calibration

display.

voltmeter)

the

to

Vdc.

J1

as

Calibration.

positive

provide a DVM

J2

I

adjust-

follows:

control

display

VAC.

VAC.

outlined

before

negative

probe

to

CUT-OUT

§520, 5525, & 5530

Connect a temporary

J1 - Pin

control

Connect a jumper

Adjust

Remove

NOTE]

Procedure

Procedure | requires

vide

0°C

temperature

o

Remove

trol

PCB

ture

TS

Immerse

R41

the

temperature

Immerse

Adjust R40

same

the

to

Repeat

accurate

12

to

display.

R23

jumper

One

used

which

ture

|

and a boiling

for

the

box

assembly.

and

jumper

sensor)

to

J6

-Pin

tip of

so

that

bath

temperature.

tip of

as

the

bath

temperature

read

1000.

Steps 2 and 3 three

adjustment.

WARMING

4.

Adjustments & Calibrations

jumper

turn

on

third

digit

from

top

of

so

that

the

display

between

of

two

calibration

to

calibrate

is a continuation

Control

water

immersing

temperature

the

to

J6 - Pin 9 and

R29

the

Calibration

an

ice/water

bath

the

temperature

sensor

Remove

red

wire

CABINETS

from

J1 - Pin 3 to

in

temperature

R29

to

reads

and

J1 - Pin

procedures

temperature

of

the

Instructions.

bath

to

provide

from

plug

J6

of

TS

the

white

10.

TS

in

the

the

is

so

bath

0.5°C,

display

TS

that

ice/water

reading

For

adjust

display

in

the

boiling

the

display

temperature.

is

100.0°C,

bath.

is

the

example,

to

water

reading

For

example,

adjust

times

J1 - Pin

000.

6.

may

6.

be

sensor

Tempera-

to

pro-

100°C

sensor.

the

con-

from

the

(tempera-

wire

of

Adjust

same

as

if

bath

read

005.

bath.

is

the

display

to

assure

if

i

3.

30926

LOCATION

Adjust

a.

b.

2.0

Connect

and

Adjust

reading

Vdc

the

COMPONENTS

OF

on

DVM

a

positive

if

R26,

of

2.000

the

PCB

display.

to

to

Vdc.

probe

J1

negative

probe

reguired,

+0.005

PCB

ON

to

1.

Pin

-

provide

J1

-

a

|

Pin

DVM

6

Reassemble

trol

box

assembly.

Reconnect

jumper

from

the

temperature

J6

to

the

J1 - Pin 3 to

sensor

PCB

J1 - Pin

and

to

the

remove

12.

con-

the

19

Page 25

5520,

5525, & 5530

4.

Adjustments & Calibrations

WARMING

CABINETS

Procedure

Procedure

supply

1.

2:

from 0 to 5 Vdc.

Disconnect

Connect

-Pin

Adjust

and

000.

Adjust

and

1000.

Repeat

adjustment.

Remove

PCB,

J1 - Pin

Il

II

requires

plug

J6

power

10.

power

10

of

power

10

of

J6.

Steps 3 and 4 to

power

and

supply

J6.

Adjust

supply

Adjust

remove

supply + to

supply,

the

12.

an

from

PCB.

to

2.730

R41

for

to

3.730

R40

for a display

reconnect

jumper

adjustable

J6 - Pin

Vdc

across

display

Vdc

across

assure

from

power

9,

and

to

Pins

reading

Pins

reading

accurate

plug

J6

J1 - Pin3

J6

9

of

9

of

to

to

DOOR

Loosen

27

hinge

hinges

Place

square

ing

Tighten

ADJUSTMENT

and

to

blocking

and

Cabinet.

hinges

to

the

the

the

the

two

hex

the

lower

Warming

under

aligned

hex

Warming

head

with

head

screws

hinge

Cabinet.

the

door

the

front

screws

Cabinet.

that

that

on

the

secures

so

that

of

the

secure

upper

the

it

Warm-

the

is

20

30926

Page 26

Recorder

x

ore

>

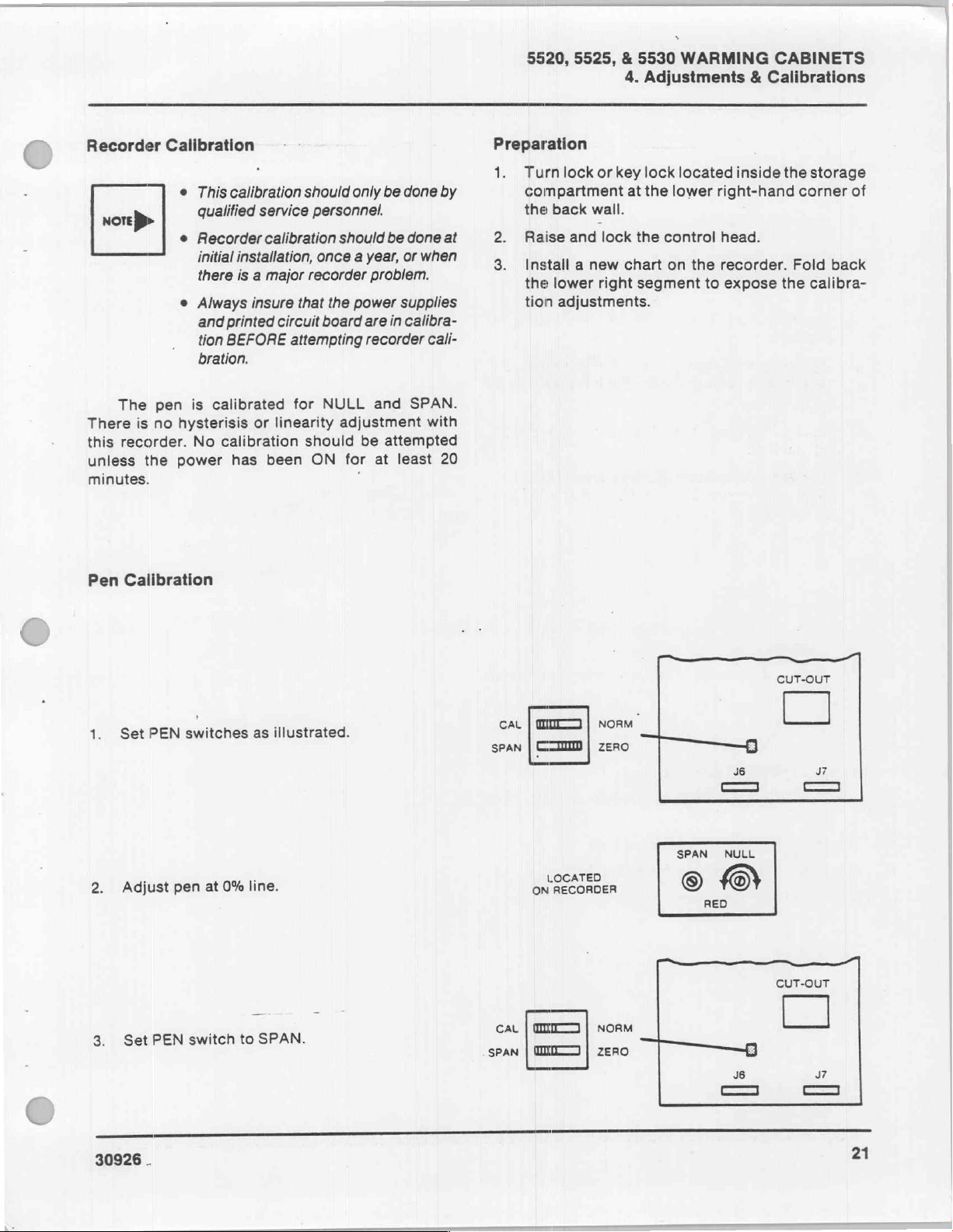

The

There

this

unless

minutes.

is

recorder.

the

Calibration

e

This

qualified

e

Recorder

initial

there

e

Always

and

tion

bration.

pen

is

calibrated

no

hysterisis

No

calibration

power

calibration

service

calibration

installation,

is a major

insure

printed

BEFORE

has

circuit

attempting

or

linearity

been

that

for

should

should

only be

personnel.

should

once a year,

recorder

the

power

board

are

recorder

NULL

adjustment

be

ON

for

i

done

be

done

or

when

problem.

supplies

in

calibra-

and

SPAN.

attempted

at

least

by

at

cali-

with

20

5520, 5525, & 5530

Preparation

1.

Turn

lock

compartment

the

back

wall.

Raise

and

Install a new

the

lower

tion

adjustments.

WARMING

4.

Adjustments & Calibrations

or

key

lock

at

lock

chart

right

the

lower

the

control

on

segment

located

right-hand

head.

the

recorder.

to

expose

inside

CABINETS

the

storage

corner

Fold

the

calibra-

of

back

Pen

Calibration

1.

Set

2.

Adjust

3.

Set

PEN

PEN

switches

pen

at

switch

0%

as

illustrated.

line.

to

SPAN.

CAL

SPAN

CAL

SPAN

mm

CI

LOCATED

RECORDER

ON

mm

mr

|

|

|

|

NORM

ZERO

NORM

ZERO

CUT-OUT

SPAN

NULL

GO

RED

©)

CUT-OUT

30926

.

21

Page 27

5520,

4.

4.

5.

6.

7.

5525, & 5530

WARMING

Adjustments & Calibrations

line.

100%

to

Adjust

Repeat

required.

Again

tion

Set

pen

Steps 1 thru 4 several

thru

1

pen

at 0 and

i

switches

Steps

100%.

for

repeat

of

PEN

NORMal

CABINETS

and

4

Make

times,

operation.

check

last

setting

Readjust

for

correct

at

0%.

pen

as

posi-

CAL | CCI

SPAN | a

LOCATED

ON

RECORDER

|

NORM

|

zero | ーーーーB

SPAN NULL

——————1

RED

CUT-OUT

J6

SS

J7

6

Manually

8:

position.

Secure

9.

Secure

Remove

1.

recorder.

Raise

2.

Raise

Lower

4.

push

the

Warming

test

latch

and

secure

and

and

the

Warming

Cabinet

chart

the

the

lock

door

Cabinet

and

control

control

the

control

actuated

as

install

head.

box

head.

switch

outlined

new

a

cover.

the

into

below.

chart

middle

the

on

DOOR

ACTUATED

SWITCH

—H

22

30926

Page 28

5520,

5525, & 5530

4.

Adjustments & Calibrations

WARMING

CABINETS

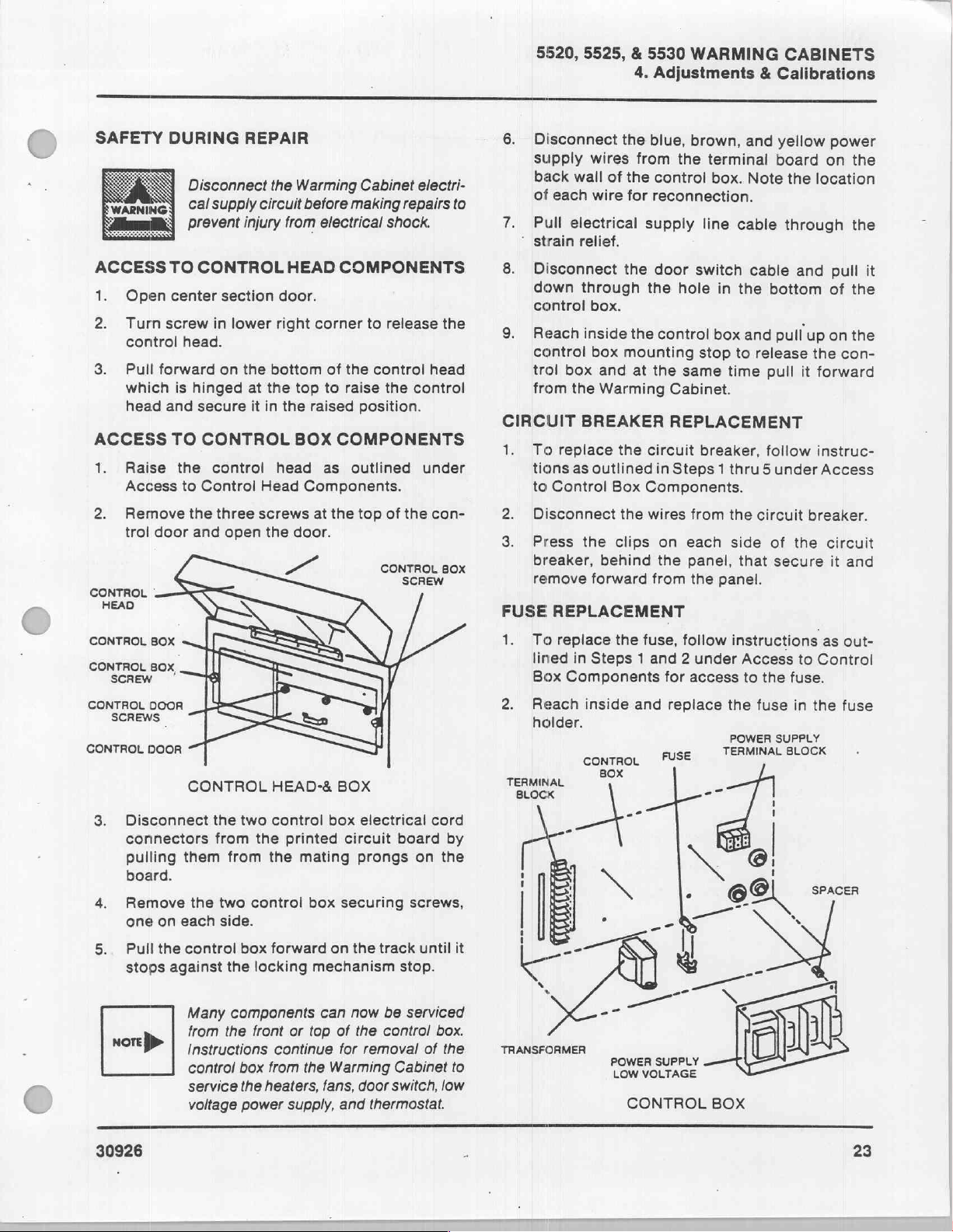

SAFETY

DURING

SV

es

ACCESS

1.

2.

3.

ACCESS

1.

2.

CONTROL

HEAD

Open

Turn

screw

control

Pull

forward

which

head

and

Raise

Access

Remove

trol

door

.

TO

center

head.

is

TO

the

to

REPAIR

Disconnect

Cal

supply

prevent

injury

CONTROL

section

in

lower

on

the

hinged

secure

at

it

CONTROL

control

Control

the

three

and

open

the

Warming

circuit

from

HEAD

door.

right

bottom

the top

in

the

BOX

head

Head

screws

the

door.

Cabinet

before

making

electrical

COMPONENTS

corner

raised

of

to

the

raise

to

control

position.

COMPONENTS

as

outlined

Components.

at

the

top

electri-

repairs

shock.

release

the

control

of

the

CONTROL

SCREW

to

the

head

under

con-

BOX

6.

Disconnect

supply

back

of

each

7.

Pull

‘

strain

8.

Disconnect

down

control

9.

Reach

control

trol

from

CIRCUIT

1.

To

tions

to

Control

2.

Disconnect

3.

Press

breaker,

remove

FUSE

REPLACEMENT

wires

wall

of

wire

electrical

relief.

through

box.

inside

box

box and

the

Warming

BREAKER

replace

the

as

outlined

Box

the

the clips on

behind

forward

the

blue,

from

the

the

control

for

reconnection.

supply

the

door

the

hole

the

control

mounting

at

the

same

Cabinet.

REPLACEMENT

circuit

in

Steps 1 thru 5 under

Components.

wires

each

the

from

brown,

terminal

box.

line

switch

in

box

stop

breaker,

from

panel,

the

panel.

and

Note

cable

cable

the

and

to

time

the

side

that

yellow

board

the

through

and

bottom

pull

release

pull

follow

circuit

of

the

secure

power

on

location

pull

of

up

on the

the

con-

it

forward

instruc-

Access

breaker.

circuit

it

the

the

it

the

and

CONTROL

CONTROL

SCREW

CONTROL

SCREWS

CONTROL

3.

Disconnect

connectors

pulling

board.

4.

Remove

one

5.

Pull

stops

мот

BOX

80x,

DOOR

L

DOOR

CONTROL

them

on

each

the

control

against

Many

from

}>

Instructions

control

service

voltage

the

from

the

two control box

side.

the

HEAD-&

two

control

the

printed

from

the

box

forward

the

locking

components

front

continue

box

from

the

heaters,

power

supply,

mating

mechanism

can

or

top

the

fans,

BOX

box

electrical

circuit

prongs

securing

on the

now

of

the

for

removal

Warming

door

and

thermostat.

board

on the

screws,

track

stop.

be

serviced

control

Cabinet

switch,

cord

by

until

box.

of

the

low

1.

2.

it

TRANSFORMER

to

To

lined

Box

Reach

holder.

TERMINAL

BLOCK

replace

Components

the

fuse,

in

Steps 1 and 2 under

inside

and

contro,

NOE

POWER

SUPPLY

LOW

VOLTAGE

CONTROL

follow

for

access

replace

FUSE

e

instructions

Access

to

the

the

fuse

POWER

TERMINAL

SUPPLY

--

O

BOX

to

Control

fuse.

in

the

BLOCK

SPACER

)

as

out-

fuse

30926

>

23

Page 29

5520, 5525, & 5530

4.

Adjustments & Calibrations

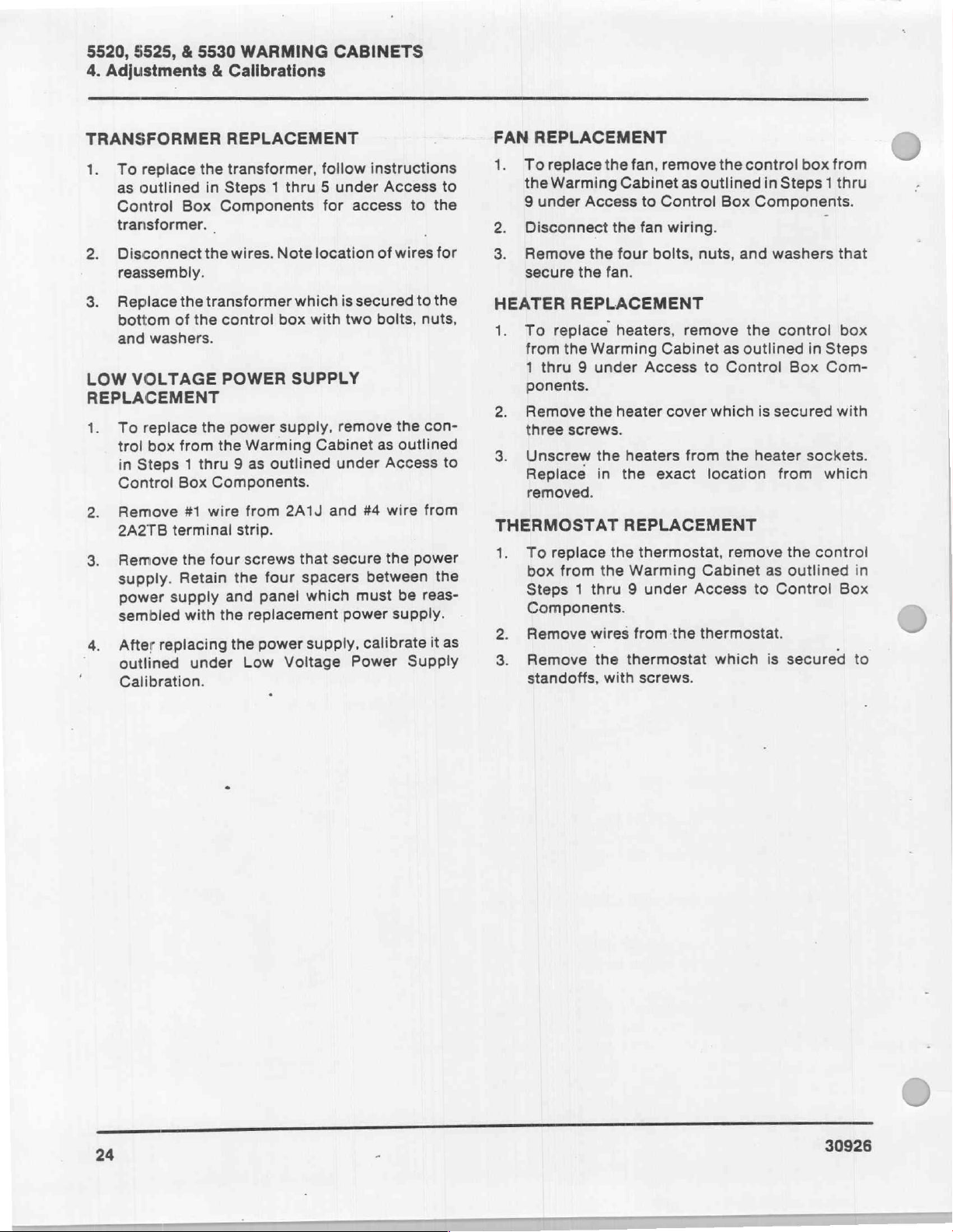

TRANSFORMER

Us

To

replace

as

outlined

Control

transformer.

Disconnect

Box

WARMING

REPLACEMENT

the

transformer,

in

Steps 1 thru 5 under

Components

.

the

wires.

Note

reassembly.

CABINETS

follow

for

access

location

instructions

Access

of

wires

to

to

the

for

FAN

REPLACEMENT

Toreplace

È

the

9

under

Disconnect

Remove

secure

Warming

Access

the

the

the

fan,

Cabinet

the

four

fan.

remove

to

Control

fan

bolts,

the

as

outlined

wiring.

nuts,

control

Box

Components.

and

box

from

in

Steps 1 thru

washers

that

Replace

bottom

and

LOW

of

washers.

VOLTAGE

REPLACEMENT

To

E

replace

trol

box

in

Steps 1 thru 9 as

Control

Remove

2A2TB

Remove

supply.

power

sembled

After

outlined

terminal

supply

replacing

Calibration.

the

transformer

the

control

POWER

the

from

the

Box

Components.

#1

wire

the

four

Retain

with

the

under

power

Warming

outlined

from

strip.

screws

the

four

and

panel

replacement

the

power

Low

which

box

with

SUPPLY

supply,

Cabinet

2A1J

that

spacers

which

supply,

Voltage

is

secured

two

remove

under

and

secure

must

power

Power

to

bolts,

the

as

outlined

Access

#4

wire

the

power

between

be

supply.

calibrate

Supply

the

nuts,

con-

to

from

the

reas-

it

as

HEATER

1.

REPLACEMENT

То

replace

from

the

1

thru 9 under

Warming

ponents.

Remove

three

Unscrew

Replace

removed.

the

screws.

the

in

THERMOSTAT

To

1.

replace

box

from

the

Steps 1 thru 9 under

Components.

Remove

Remove

standoffs,

wires

the

with

heaters,

heater

heaters

the

remove

Cabinet

Access

cover

from

exact

REPLACEMENT

the

thermostat,

Warming

from

the

thermostat

screws.

the

as

outlined

to

Control

which

location

Cabinet

Access

is

the

heater

remove

to

as

thermostat.

which

is

control box

in

Steps

Box

Com-

secured

with

sockets.

from

the

which

control

outlined

Control

secured

Box

in

to

24

30926

Page 30

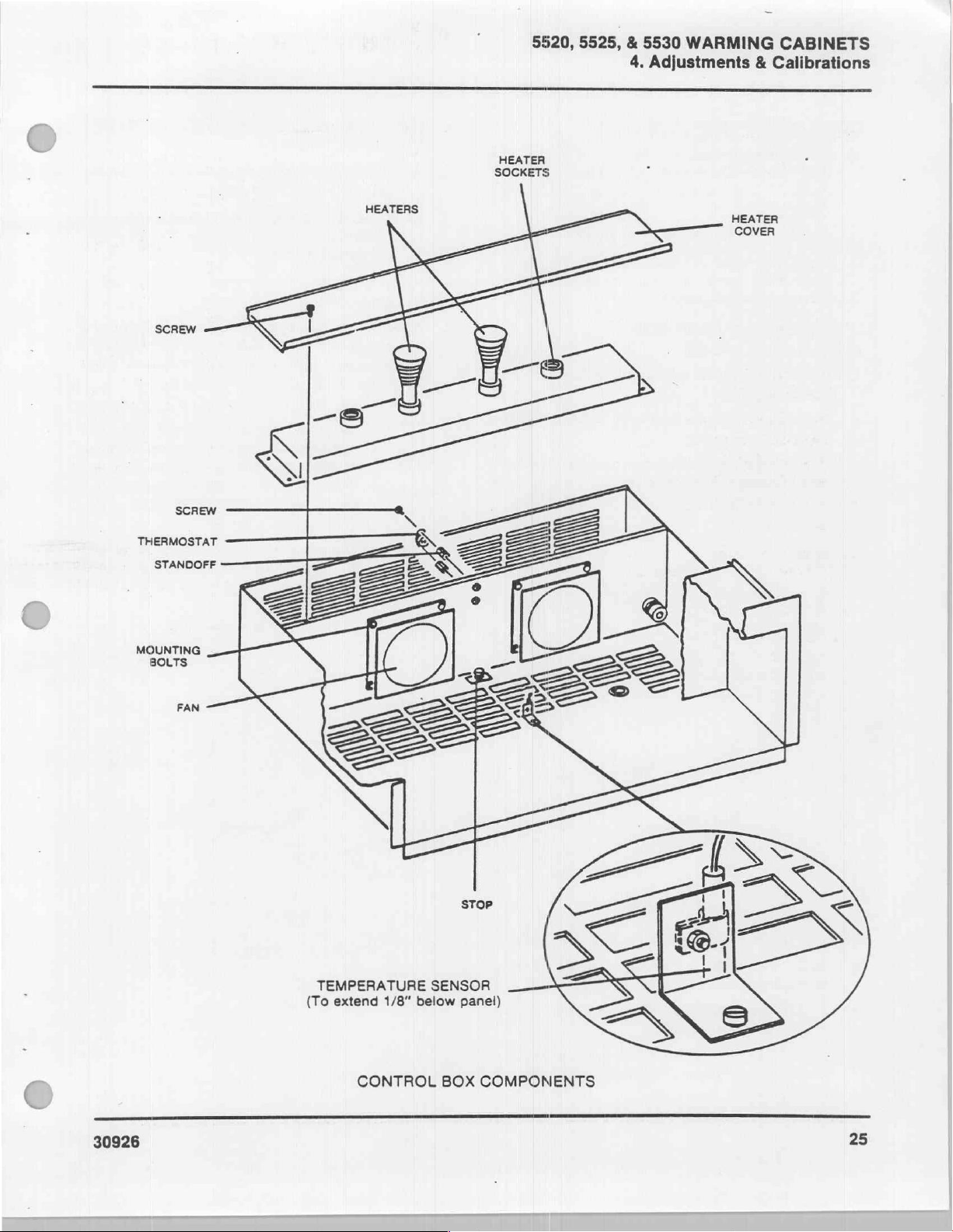

5520, 5525, & 5530

4.

HEATER

SOCKETS

WARMING

Adjustments & Calibrations

CABINETS

MOUNTING

BOLTS

РАМ

SN

|

—

TEMPERATURE

(To

extend

H

1/8“

=>

SENSOR

below

2

>

STOP

panel)

<>

==

30926

CONTROL

BOX

COMPONENTS

25

Page 31

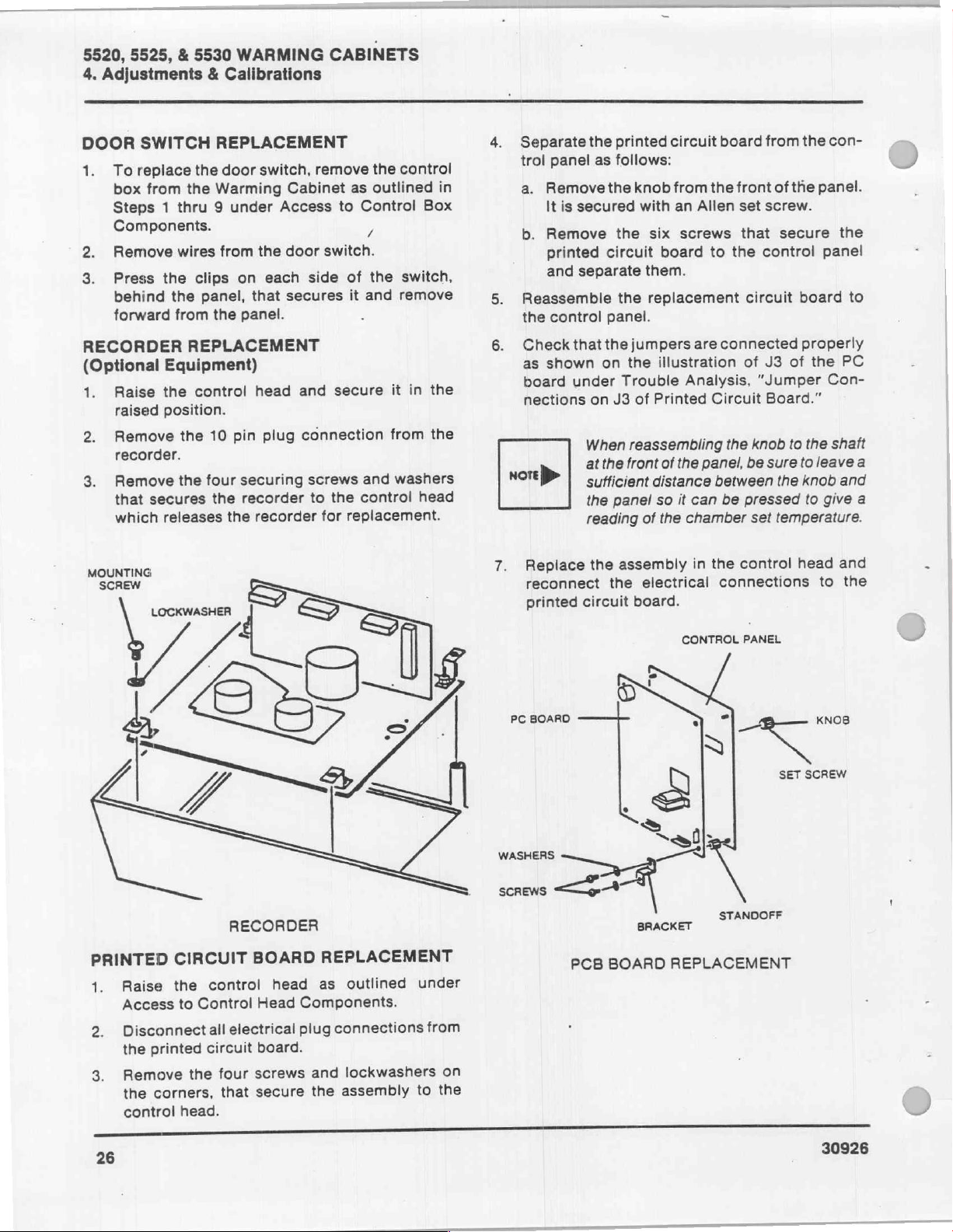

5520, 5525, & 5530

4.

Adjustments & Calibrations

DOOR

1.

SWITCH

To

replace

box

from

the

Steps 1 thru 9 under

WARMING

REPLACEMENT

the

door

switch,

Warming

Access

Components.

2.

Remove

Press

behind

forward

RECORDER

(Optional

1.

Raise

raised

Remove

2.

wires

from

the

clips

the

panel,

from

the

REPLACEMENT

Equipment)

the

control

position.

pin

10

the

the

on

each

that

panel.

head

plug

recorder.

securing

four

3.

Remove

that

which

the

secures

releases

the

the

recorder

recorder

CABINETS

remove

Cabinet

door

switch.

side

secures

and

connection

screws

to

the

for

the

control

as

outlined

to

Control

y

of

the

switch,

it

and

remove

secure

it

from

washers

and

control

replacement.

in

head

Box

the

the

in

4.

5.

6.

nore

Separate

trol

panel

a.

Remove

It

is

secured

b.

Remove

printed

and

separate

Reassemble

the

control

Check

as

board

nections

that

shown

under

>

the

printed

as

follows:

the

knob

with

the

six

circuit

them.

the

replacement

panel.

the

jumpers

on

the

Trouble

on

J3

of

When

reassembling

at

the

front

sufficient

the

panel

reading

of

circuit

from

board

illustration

Printed

of

distance

so

the

the

an

Allen

screws

to

are

Analysis,

Circuit

the

panel,

between

it

can

chamber

board

connected

the

be

front

set

that

the

control

circuit

of

“Jumper

knob

be

pressed

set

from

the

con-

of

the

panel.

screw.

secure

panel

board

properly

J3

of

the

Con-

Board.”

to

the

shatt

sure

to

leave

the

knob

to

give

temperature.

the

to

PC

a

and

a

MOUNTING

SCREW

PRINTED

Raise

1.

Access

Disconnectall

2.

the

Remove

3.

the

control

LOCKWASHER

CIRCUIT

the

Control

to

printed

the

corners,

head.

RECORDER

control

electrical

circuit

four

that

BOARD

head

Head

board.

screws

secure

REPLACEMENT

outlined

as

Components.

connections

plug

lockwashers

and

assembly

the

under

from

on

the

to

Replace

reconnect

printed

PC

WASHERS

재배

BOARD

=

the

assembly

the

circuit

electrical

board.

in

the

CONTROL

control

connections

PANEL

+,

SET

head

to

KNOB

SCREW

and

the

STANDOFF

30926

PCB

BRACKET

BOARD

REPLACEMENT

Page 32

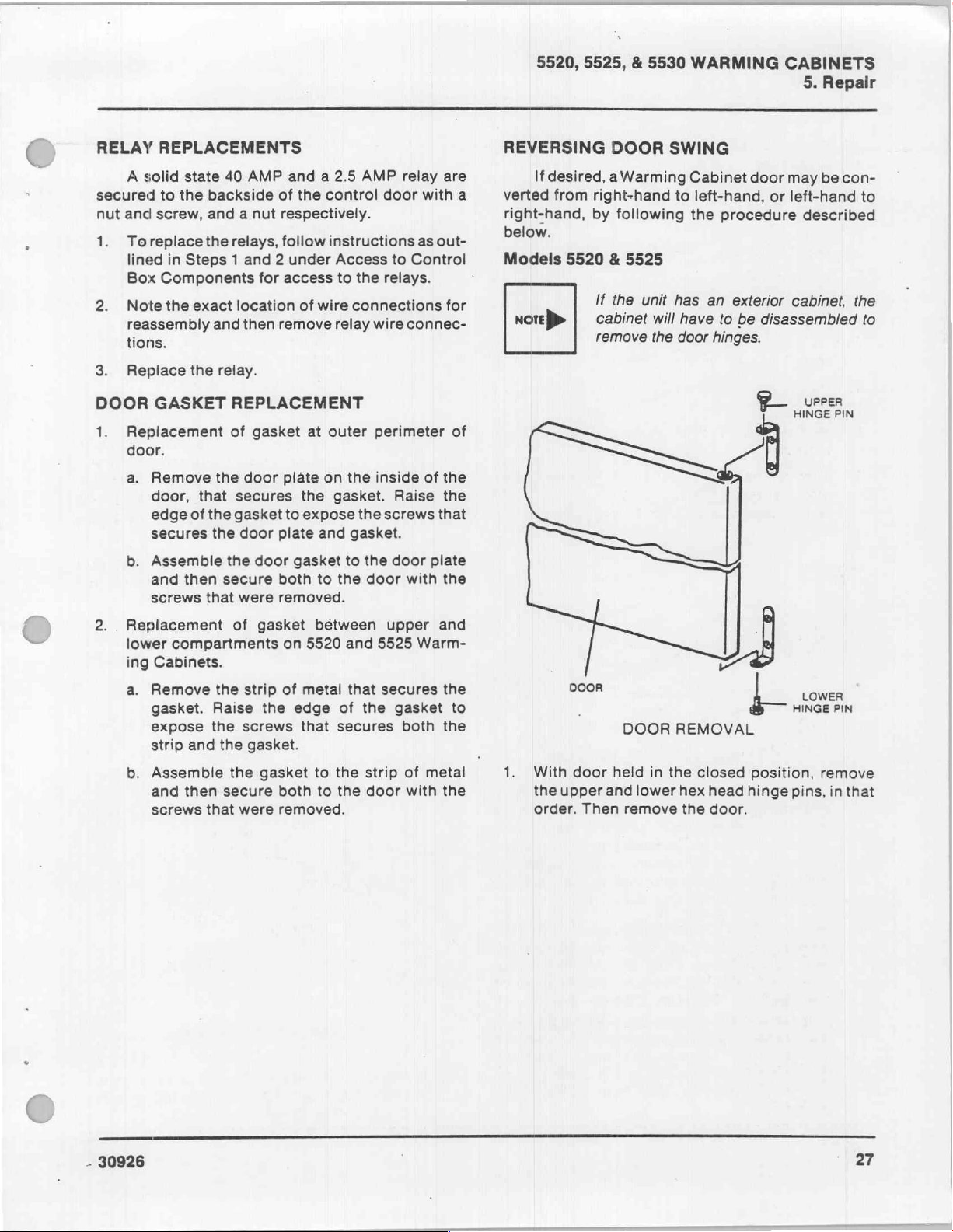

5520,

5525, & 5530

WARMING

CABINETS

5.

Repair

RELAY

A

secured

nut

and

1.

Toreplace

lined

Box

2.

Note

reassembly

tions.

3.

Replace

DOOR

1.

Replacement

door.

a.

b.

REPLACEMENTS

solid

state

40

to

the

backside

screw,

Components

GASKET

Remove

door,

edge

secures

Assemble

and

screws

and a nut

the

relays,

in

Steps 1 and 2 under

the

exact

and

the

relay.

REPLACEMENT

of

the

that

secures

of

the

gasket

the

the

then

secure

that

AMP

and a 2.5

of

respectively.

follow

for

access

location

then

remove

gasket

door

plate

to

door

plate

door

gasket

both

were

removed.

the

control

instructions

Access

to

of

wire

relay

at

outer

on

the

gasket.

expose

and

to

the

AMP

relay

door

as

to

Control

the

relays.

connections

wire

connec-

perimeter

the

inside

Raise

the

screws

gasket.

to

the

door

door

with

are

with

out-

for

of

the

the

that

plate

the

a

of

REVERSING

If

desired, a Warming

verted

right-hand,

below.

Models

ноге

}>

from

5520 & 5525

DOOR

right-hand

by

following

If

the

unit

cabinet

remove

will

the

SWING

Cabinet

to

left-hand,

the

has

an

have

door

door

procedure

exterior

to

be

disassembled

hinges.

P

may

or

left-hand

described

cabinet,

UPPER

HINGE

be

con-

to

the

to

PIN

2..

Replacement

lower

ing

a.

b.

compartments

Cabinets.

Remove

gasket.

expose

strip

Assemble

and

screws

Raise

the

and

then

that

of

the

strip

screws

the

the

secure

were

gasket

on

of

the

gasket.

gasket

both

removed.

between

5520

metal

edge

that

to

to

and

that

of

the

secures

the

strip

the

door

upper

5525

Warm-

secures

gasket

both

of

with

and

the

to

the

metal

the

1.

DOOR

With

the

upper

order.

L

door

Then

DOOR

held

in

and lower

remove

REMOVAL

the

closed

hex

head

the

door.

|

HINGE

position,

hinge

pins,

LOWER

PIN

remove

in

that

-

30926

27

Page 33

5520, 5525,

5.

Repair

2.

Remove

bracket

&

5530

WARMING

the

upper

assemblies.

and

lower

CABINETS

hinge

mounting

DOOR

А

SCREWS

&

WASHERS

STRIKER

PLATE

ASSEMBLY

SCREWS

&

WASHERS

TRIM

TRIM

3

“一 一 |

SWITCH

=

se

SWITCH

E

Е

SWITCH

E

|

—

HINGE

MOUNTING

BRACKET

SELF-TAPPING

SCREW

k

i

INSIDE

PANEL

ss

PANEL & GASKET

the

inside

Cabinet

#8-32

self-tapping

panel

door.

REMOVAL

and

It

is

secured

screws.

gasket

from

with

forty

the

>

Gi

À

WASHER-

HEAD

SCREWS

Е

HINGE

ll

MOUNTING

BRACKET

ASSEMBLY

&

GASKET

5.

Remove

Warming

five

3.

Remove

and

Warming

holes

previously

the

side

4.

Removethe

mounting

side

screws

the

Reassemble

the

had

the

viously

assembly.

28

DOOR

hinge

holes

washer-head

HARDWARE

the

two

stiffeners

Cabinet,

where

been

mounting

of

the

Warming

door

position

panel.

from

the

opposite

the

where

previously

occupied

sets

from

the

hinge

assembled.

striker

Remove

identical

Warming

door

the

been

screws

RELOCATION

of

screws,

the

opposite

and

assemble

mounting

brackets

Cabinet.

plate

on the

the

mounting

Cabinet

striker

three

washer-head

located,

by

the

In

assembly

Warming

three

plate

to

the

door

trim

side

them

brackets

turn,

assemble

to

the

washer-head

position

side

assembly

and

reassemble

position

striker

washers,

of

the

in

the

had

opposite

from

its

Cabinet

on

panel.

to

screws

pre-

plate

SPEED

6.

CLIP

Remove

speed

and

reassemble

NAMEPLATE

the

nameplate.

clips.

Rotate

to

ROTATE

ROTATION

the

the

same

180°

DOOR

It

is

secured

nameplate

holes.

180

NAMEPLATE

with

two

degrees

30926

>

Page 34

QXX

+

|

DOOR

HANDLE

a

À

SWING

180°

5520,

DOOR

o

5525, & 5530

DOOR

REMOVAL

WARMING

£

pees

CABINETS

5.

Repair

UPPER

HINGE

PIN

LOWER

HINGE

PIN

(O)

アー

Remove

located

directly

24

door

Remove

opposite

allow

reassemble

had

washer.

other end

#10-32

had

Rotate

inside

rotate

Reassemble

hex

pin

with

to

Model

nore

DOOR

the

in

below

screw

panel

the

the

previously

Tighten

screw

originally

the

door

the

head

first.

the

upper

secure

5530

If

will

>

door

HANDLE

#10-32

the

that

in

other

end

door

the

of

door

panel

panel

the

hinge

Fit

door

door

unit

have

hinges

bottom

the

door

secures

the

vicinity

#10-24

of

the

handle

unattached

held

the

the

fastener

the

door

and

trim

secured

180

degrees.

and

and

gasket.

door

pins.

Assemble

onto

hinge.

has

to

Warming

an

to

be

Assemble

exterior

to

RELOCATION

screw

to

gasket

disassembled

be

and

portion

handle.

the

door

of

screw

door

handle.

swing

end

#10-32

handle.

washer

the

door

to

to

the

the

pin

Cabinet.

cabinet,

moved.

Loosen

the

that

downward

to

screw

that

Assemble

to

handle.

Reassemble

the

hinges

the

and

upper

trim

of

the

handle

door

secures

Carefully

the

hole

and

secures

the

hole

door.

using

lower

align

hinge

the

to

allow

washer

door,

the

#10-

to

the

latch.

the

and

that

trim

the

the

that

the

Do

not

the

hinge

door

pin

cabinet

the

|

SCREWS

&TRIM

WASHERS

LATE

ASSEMBLY

SCREWS

&TRIM

WASHERS

With

door

held

in