Castex HS-1100, HS-1500, HS-1900 Operator And Parts Manual

HS-1100/HS-1500/HS -1900

U.S. PATENT NO.: D.343,932 & D.345,035

High Speed Floor Machine

Model No.:

608250 – HS-1100

607364 – HS-1500

607365 – HS-1900

Operator and Parts Manual

CASTEX INCORPORATED

12875 RANSOM STREET

HOLLAND MI 49424 U.S.A.

A TENNANT COMPANY

1–800-522–7839

616-786–2330

FAX: 1–800–678–4240

CUSTOMER S E RVICE: 1–800-964–9644

607368

Rev. 01 (08-99)

OPERATION

This manual is furnished with each new model. It

provides necessary operation and maintenance

instructions.

MACHINE DATA

Read this manual completely and understand the

machine before operating or servicing.

This machine will provide excellent service. However,

the best results will be obtained at minimum costs if:

The machine is operated with reasonable care.

The machine is maintained regularly - per the

machine maintenance instructions provided.

The machine is maintained with manufacturer

supplied or equivalent parts.

TABLE OF CONTENTS

SAFETY PRECAUTIONS 3. . . . . . . . . . . . . . . . . . . . . .

MACHINE COMPONENTS 4. . . . . . . . . . . . . . . . . . . .

Please fill out at time of installation for future reference.

Model No.Install. Date Serial No.-

2000 Tennant Company Printed in U.S.A.

Castex is a registered United States trademark of Tennant Company.

RECOMMENDED STOCK ITEMS 6. . . . . . . . . . . . . .

TROUBLE SHOOTING 7. . . . . . . . . . . . . . . . . . . . . . . .

MACHINE SETUP 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MACHINE OPERATION 5. . . . . . . . . . . . . . . . . . . . . . .

MACHINE MAINTENANCE 6. . . . . . . . . . . . . . . . . . . .

STORING MACHINE 6. . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS LIST 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL DIAGRAM 14. . . . . . . . . . . . . . . . . . . .

2

HS-1100/1500/1900 (03–01)

SAFETY PRECAUTIONS

This machine is intended for commercial use. It is

suited to burnish floors in an indoor environment and

is not constructed for any other use. Use only

recommended burnishing pads.

The following safety alert symbols are used throughout

this manual as indicated in their description.

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

The following information signals potentially dangerous

conditions to the operator or equipment:

FOR SAFETY:

1. Do not operate machine:

– Unless trained and authorized.

– Unless operator manual is read and

understood.

– In flammable or explosive areas unless

designed for use in those areas.

– Unless cord is properly grounded.

– With damaged cord or plug.

– If not in proper operating condition.

– In outdoor areas.

– In standing water.

– With the use of an extension cord.

2. Before operating machine:

– Make sure all safety devices are in place

and operate properly.

3. When using machine:

– Do not run machine over cord.

– Do not pull machine by plug or cord.

– Do not pull cord around sharp edges or

corners.

– Do not unplug by pulling on cord.

– Do not stretch cord.

– Do not handle plug with wet hands.

– Keep cord away from heated surfaces.

– Do not release handle grips until pad

comes to a complete stop.

– Go slow on inclines and slippery surfaces.

– Report machine damage or faulty

operation immediately.

OPERATION

4. Before leaving or servicing machine:

– Turn off machine.

– Unplug cord from wall outlet.

5. When servicing machine:

– Unplug cord from wall outlet.

– Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

– Use manufacturer supplied or approved

replacement parts.

WARNING: Hazardous Voltage. Shock or

electrocution can result. Unplug machine before

servicing.

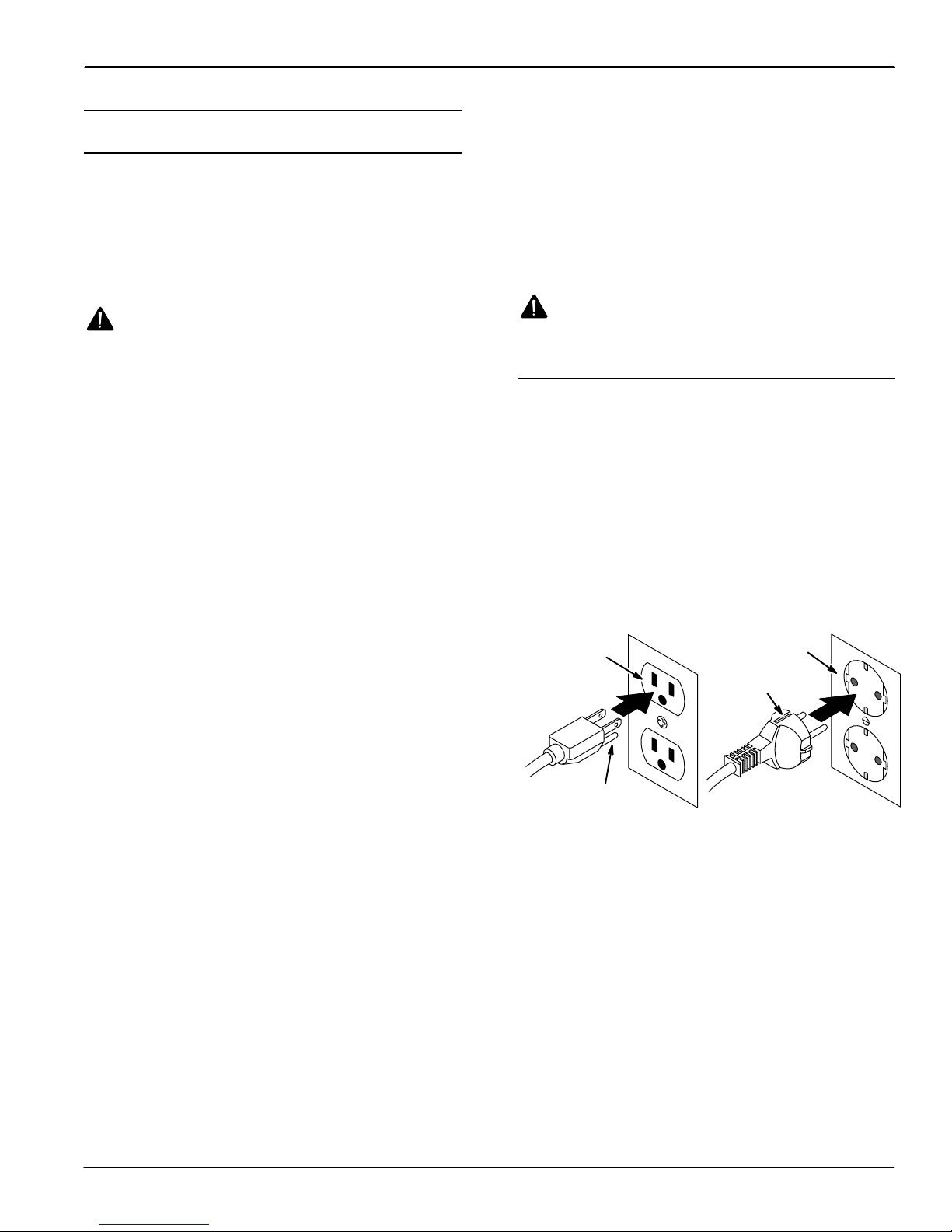

GROUNDING INSTRUCTIONS

Machine must be grounded. If it should

malfunction or breakdown, grounding provides a

path of least resistance for electrical current to

reduce the risk of electrical shock. This machine

is equipped with a cord having an

equipment–grounding conductor and grounding

plug. The plug must be plugged into an

appropriate outlet that is properly installed in

accordance with all local codes and ordinances.

Do not remove ground pin; if missing, replace

plug before use.

Grounded

3 Hole Outlet

Ground Pin

(120V)

Grounded Outlet

Grounding

Edge/hole

(230V/240V)

HS-1100/1500/1900 (03–01)

3

OPERATION

MACHINE COMPONENTS

1

2

7

6

3

12

9

11

2

4

10

5

13

MACHINE SETUP

1. Carefully check carton for signs of damage.

Report damages at once to carrier.

2. Unfold handle to the upright position and lock

handle using the handle lock knob (Figure 1).

FIG. 1

3. Install burnishing pad, with handle locked in the

upright position, carefully tilt machine back on

8

handle.

4. Remove centerlock from pad driver. Position

burnishing pad on pad driver and replace

centerlock securely (Figure 2).

1. Control Handle Grips

2. Control Triggers

3. Safety Lock Button

4. Circuit Breaker Button

5. Quick Release Power Cord Hook

6. 23 m (75 ft) Power Cord

7. Cord Grip

8. Handle Release Foot Lever

9. Motor Cover

10. Transport Wheels

11. Pad Driver

12. Burnish Pad

13. Handle Lock Knob

FIG. 2

NOTE: Burnishing pads are sold separately. Consult

your authorized distributor for pad recommendations.

Pad Specifications:

For 2000 RPM Burnishing.

25 mm (1.0 in) Thickness

510 mm (20 in) diameter with 90 mm (3.5 in) center

hole.

NOTE: Spray buffing is only recommended with the

1100 model. The 1500/1900 models should not be

used for spray buffing; circuit breaker may trip or

machine overloading may occur. The 1500/1900

models require more power at increased amp draw

due to higher speeds.

4

HS-1 100/1500/1900 (08–99)

OPERATION

5. Return machine to upright position after pad is

installed.

6. For easy power cord removal, pull and turn cord

hook upward (Figure 3).

FIG. 3

7. Plug power cord into a grounded wall outlet

(Figure 4).

Grounded

3 Hole Outlet

Ground Pin

Grounded Outlet

(120V)

Grounding

Edge/hole

FIG. 4

(230V/240V)

FOR SAFETY: Do not operate machine unless

cord is properly grounded or with the use of an

extension cord.

2. To begin burnishing, depress safety lock button

and pull triggers. Release safety lock button once

machine starts (Figure 6).

FIG. 6

ATTENTION: Use caution when starting out.

Machine will jolt when triggers are pulled.

3. Push machine forward or use a “W” pattern

motion.

ATTENTION: Keep machine moving to prevent

floor surface damage.

4. To prevent motor overload, periodically check pad

for excessive soil build-up. Turn pad over, clean or

replace when necessary.

NOTE: If circuit breaker trips while operating, unplug

power cord, wait 15 seconds and reset breaker switch

to resume operation ( Figure 7).

MACHINE OPERATION

FOR SAFETY: Do not operate machine unless

operator manual is read and understood.

NOTE: Before operating machine, be certain that

floor is dry and clean of debris.

1. Lower handle by stepping down on handle release

foot lever (Figure 5).

FIG. 5

HS-1 100/1500/1900 (03–01)

FIG. 7

5. To stop machine, release triggers and the safety

lock button will automatically engage.

FOR SAFETY: When using machine, do not

release handle grips until pad comes to complete

stop.

6. When finished burnishing, perform the

maintenance procedures.

5

Loading...

Loading...