Cassese CS969 User & Parts Manual

1

USER & PARTS MANUAL

Version 3

10/2018

Read carefully before using the machine

© Cassese 2018

DOUBE MITRE SAW 45°

SCIE PNEUMATIQUE DOUBLE LAME 45°

RAPPORT VERITAS N°6058665-1-1-CS969

USER MANUAL

CS969

2

USER MANUAL

CS969

3

INDEX

1 / USER MANUAL / ENGLISH ......................................................................................... 6

SAFETY FEATURES .............................................................................................................................................. 6

1.A.a Position of the labels on the machine: ...........................................................................................................................6

USER RULES ....................................................................................................................................................... 9

WHAT SHOULDN’T BE DONE .............................................................................................................................. 9

SAFE USE OF THE MACHINE. ............................................................................................................................. 10

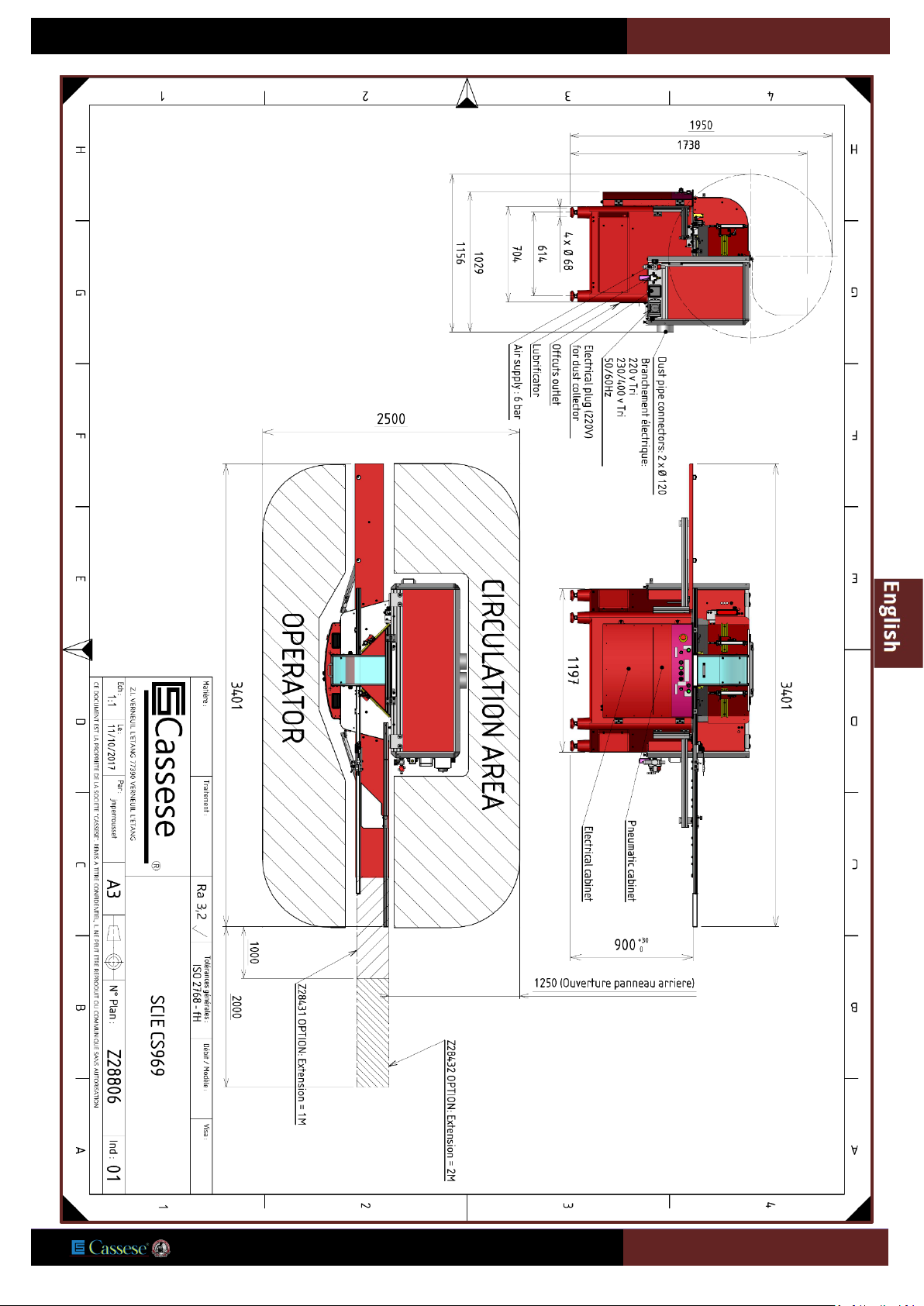

2 / DESCRIPTION .......................................................................................................... 11

DESCRIPTION OF THE CS969 MAIN PARTS ........................................................................................................ 11

3 / TECHNICAL DATAS ................................................................................................... 13

CUTTING CAPACITY .......................................................................................................................................... 14

OPTIONS : ........................................................................................................................................................ 14

4 / INTRODUCTION ....................................................................................................... 15

RESIDUAL RISKS ............................................................................................................................................... 15

WARRANTY ...................................................................................................................................................... 15

5 / HANDLING AND UNPACKING .................................................................................. 16

REMOVING OF TRANSPORTATION SAFETY ....................................................................................................... 19

6 / SETTING UP THE MACHINE ...................................................................................... 20

LEFT AND RIGHT ARM MOUNTING ................................................................................................................... 22

ELECTRICAL CONNECTION ................................................................................................................................ 25

AIR LINE FITTINGS ............................................................................................................................................ 25

ASPIRATION ..................................................................................................................................................... 26

7 / STARTING UP .......................................................................................................... 28

CONTROL PANEL .............................................................................................................................................. 28

MAIN SWITCH .................................................................................................................................................. 28

SAWING ........................................................................................................................................................... 29

7.C.a Setting the vertical and horizontal clamps ...................................................................................................................29

CUTTING FEED RATE ......................................................................................................................................... 30

FIRST CUT ON THE LEFT .................................................................................................................................... 30

MEASURING THE FIRST PIECE (MOBILE STOP) ................................................................................................... 31

7.F.a Measuring the rebate (internal) ...................................................................................................................................31

7.F.b External measurement .................................................................................................................................................32

RETRACTABLE STOP ......................................................................................................................................... 32

7.G.a Storing a second cutting point in the memory .............................................................................................................32

7.G.b Second cut ....................................................................................................................................................................33

7.G.c Cut on the end of a moulding (right cut) ......................................................................................................................33

8 / MAINTENANCE & SERVICING .................................................................................. 35

PROCEDURE TO ACCES INSIDE THE MACHINE ................................................................................................... 35

8.A.a Opening the main case .................................................................................................................................................35

USER MANUAL

CS969

4

8.A.b Removing the blades ....................................................................................................................................................35

8.A.c Refiting the blades .......................................................................................................................................................36

8.A.d Closing the main case ...................................................................................................................................................37

8.A.e Replacing the martyr cube ...........................................................................................................................................37

8.A.f Opening the electrical cabinet block ............................................................................................................................38

9 / MAINTENANCE ........................................................................................................ 39

TYPE OF BLADE RECOMMENDED FOR MULTI-PURPOSE CUTTING ..................................................................... 39

PANNES ........................................................................................................................................................... 39

LIST OF WEARING PARTS CS969 ........................................................................................................................ 40

1 / MANUEL D’UTILISATION / FRANCAIS ...................................................................... 41

CONSIGNES DE SECURITE ................................................................................................................................. 41

1.A.a Position des étiquettes sur la machine : .......................................................................................................................41

CONDITIONS D’UTILISATION ............................................................................................................................ 44

CE QU’IL NE FAUT PAS FAIRE ............................................................................................................................ 44

PRATIQUES DE TRAVAIL EN TOUTE SECURITE ................................................................................................... 45

2 /PRESENTATION ........................................................................................................ 47

DESCRIPTION DES PRINCIPAUX ELEMENTS DE LA CS969. .................................................................................. 47

3 / CARACTERISTIQUES TECHNIQUES ............................................................................ 49

CAPACITE DE COUPE ........................................................................................................................................ 50

OPTIONS : ........................................................................................................................................................ 50

4 / INTRODUCTION ....................................................................................................... 51

RISQUES RESIDUELS ......................................................................................................................................... 51

GARANTIE ........................................................................................................................................................ 51

5 / DEBALLAGE ET MANUTENTION ............................................................................... 52

DEMONTAGE DE L’EQUERRE DE SECURITE TRANSPORT .................................................................................... 55

6 / MISE EN PLACE DE LA MACHINE .............................................................................. 56

MONTAGE DES BRAS GAUCHE ET DROIT .......................................................................................................... 58

BRANCHEMENT ELECTRIQUE ........................................................................................................................... 61

BRANCHEMENT PNEUMATIQUE ...................................................................................................................... 61

ASPIRATION. .................................................................................................................................................... 62

7 / MISE EN SERVICE ..................................................................................................... 64

TABLEAU DE COMMANDES. ............................................................................................................................. 64

SECTIONNEUR GENERAL .................................................................................................................................. 64

SCIAGE ............................................................................................................................................................. 65

7.C.a Réglage des presseurs verticaux et horizontaux ..........................................................................................................65

AVANCE DE COUPE........................................................................................................................................... 66

PREMIERE COUPE A GAUCHE ........................................................................................................................... 67

MESURE DU PREMIER MORCEAU (BUTEE MOBILE) ........................................................................................... 68

7.F.a Mesure fond de feuillure (Mesure intérieure) ..............................................................................................................68

7.F.b Mesure en cote extérieure ...........................................................................................................................................68

BUTEE ESCAMOTABLE ...................................................................................................................................... 69

USER MANUAL

CS969

5

7.G.a Mémorisation d’un deuxième point de coupe ..............................................................................................................69

7.G.b Deuxième coupe ...........................................................................................................................................................70

7.G.c Coupe sur fin de moulure (coupe à droite) ...................................................................................................................70

8 / MAINTENANCE ........................................................................................................ 72

PROCEDURE POUR ACCÉDER A L’INTÉRIEUR DE LA MACHINE ........................................................................... 72

8.A.a Ouverture du capot principal .......................................................................................................................................72

8.A.b Démonter les lames ......................................................................................................................................................73

8.A.c Remontage des lames ..................................................................................................................................................74

8.A.d Fermeture du capot principal .......................................................................................................................................74

8.A.e Remplacement du support de chute ............................................................................................................................74

8.A.f Ouverture de l’armoire électrique ................................................................................................................................75

9 / ENTRETIEN .............................................................................................................. 76

TYPE DE LAME CONSEILLEE POUR COUPES MULTI-USAGES ............................................................................... 76

PANNES ........................................................................................................................................................... 76

LISTE DES PIECES D’USURE CS 969 .................................................................................................................... 78

10 ANNEXE ..................................................................................................................... 79

BILL OF MATERIAL - NOMENCLATURE CS969. ................................................................................................... 79

6

1 / USER MANUAL / ENGLISH

SAFETY FEATURES

Your safety is our priority

1.A.a Position of the labels on the machine:

10

4

5 6 7

3 8 2

9

10

11

1

USER MANUAL

CS969

7

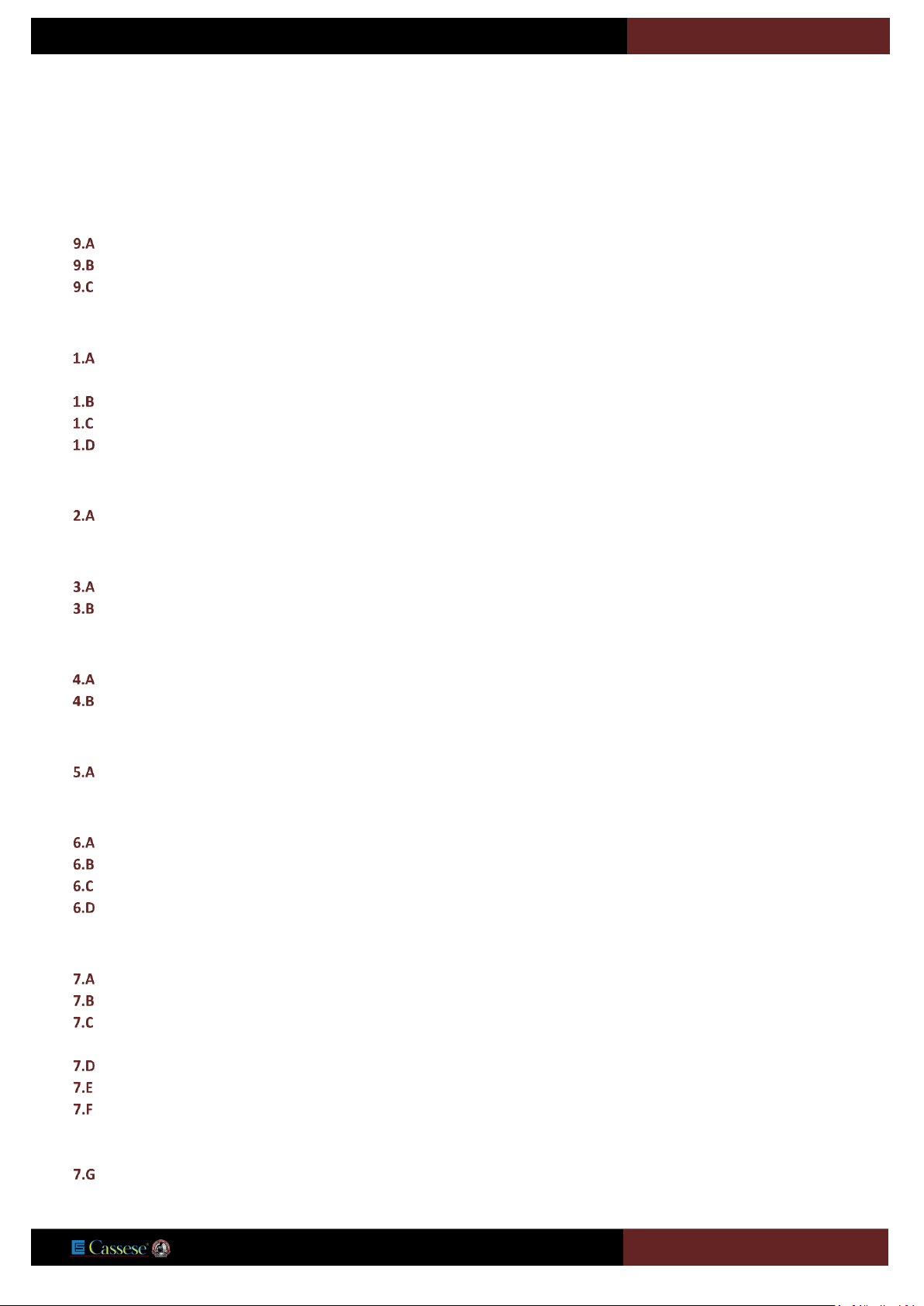

1/ CS969 identitying plate showing the technical datas of your

machine

3/ Information about maximum power of dust collector

2/ Information about pressure supply

4/ This label inform you about place of mandatory tools for

dismounting and mouting of saw blades.

USER MANUAL

CS969

8

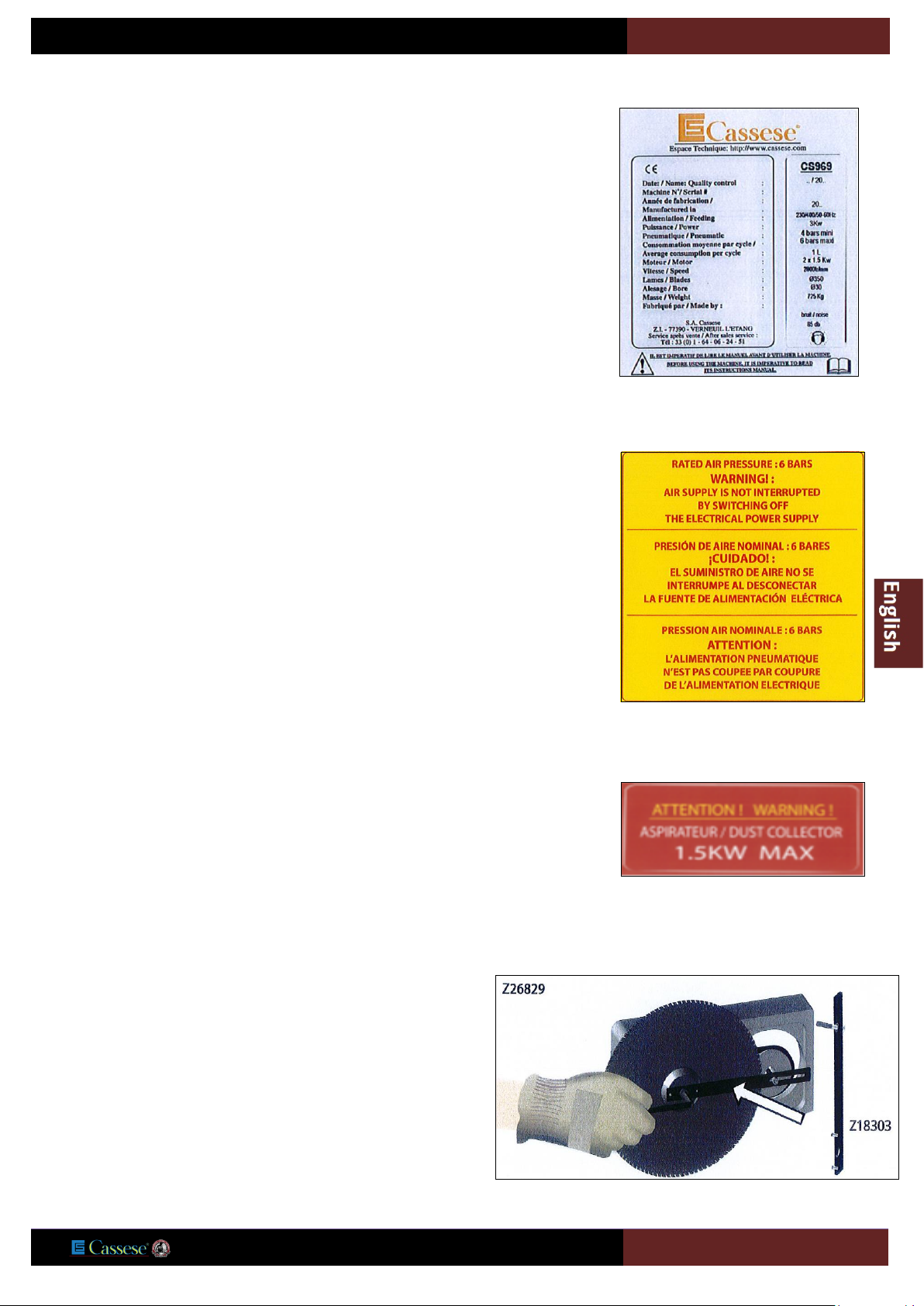

This icon in the manual mentions some tricks

that can help you saving time or improve your

production.

This symbol in the manual is to mention safety

instructions.

This icon in the manual will identify a list of

required tools to perform a procedure.

9/ This icon informs you about mandatory

grounding of machine electrical connection and

vacuum system.

5/ This symbol on the machine reminds the

operator to read this manual before operating

this machine.

BEFORE PERFORMING ANY MAINTENANCE ON THE MACHINE, UNPLUG AND LOCK THE ELECTRIC AND PNEUMATIC

SUPPLIES. DO NOT USE THE MACHINE IF ONE COVER IS MISSING.

7/ This symbol on the machine reminds the

operator to wear acoustic protections and

protection glasses before operating this

machine.

10/ This symbol on the machine asks you to

wear gloves before you touch the blades.

8/ This icon on the machine advises you to switch

off electric power before performing maintenance

on the machine.

6/ This symbol shows that it is advised to wear a

dust protecton mask

11/ These marks are showing the limit that you shouldn’t cross with your hands.

.

READ CAREFULLY THE SAFETY INSTRUCTIONS OF THAT BOOK BEFORE

OPERATING THE MACHINE.

USER MANUAL

CS969

9

USER RULES

Saw CS 969 is a machine used to cut 45° mitres on all mouldings with solid or reconstituted wood base, and with or without coating

(paint, varnish, plastic coating, paper, etc.).

Are excluded :

• Mouldings that don’t have a 90° angle back on at least 5mm,

• Metal profiles,

• Small plastic profiles (filets, etc...).

Its two circular blades are driven by two electric motors.

The moulding is held automatically by vertical and horizontal pneumatic cylinders.

A two-hand control, actuating both clamping and cutting, ensures operator safety by keeping hands out of range of the blades.

The electrical control equipment is placed in a cabinet in front of the machine and on the right side.

The pneumatic equipment is secured in the base of the machine behind the electrical cabinet.

This machine was built to meet safety and hygiene requirements. It is therefore forbidden to modify the electrical and pneumatic

equipment, remove protective equipment installed on delivery or modify the machine safety devices.

Saw CS 969 cannot be used by more than one operator at a time.

To prevent electric shocks and overload, some protections should be installed by the user on the electric supplying line to the machine,

according to EN60204-1 :2006, Article 7

WHAT SHOULDN’T BE DONE

- At no time the operator should engage his hands in the clamp area, nor in the cutting area behind the brushes. (blades are rotating

even when returned to the back position)

- Do not use steel blades (HS type)

- Prior to any maintenance operation, switch off electric and pneumatic supply by using and locking their switches. (14 & 16, Page 11).

- Switch off the machine by using the electric contactor on the right side of the machine and lock it with a padlock.

- Only one person at a time should use the machine. This person is responsible for the controls.

- All adjustments should be performed with the cover closed. At no moment the operator should put his hands inside the covers. This

measure is intended to guarantee the safety of the operator, who should under no circumstances insert his hands inside the cover.

- If none of the clamps can hold the mouldings, the cut of that moulding is forbidden.

- Do never use the machine with a missing panel.

- These particular mouldings cannot be cut on the CS969.

USER MANUAL

CS969

10

SAFE USE OF THE MACHINE.

It is essential that the operators are:

a) Trained about the use, the adjustment and the way of working of the machine.

b) Informed about the things that affect the noise exposition such as:

1) Blades that are designed to limit noise emission,

2) Selection of the optimal speed,

3) Maintenance of the blades and the machine.

c) Informed about the things that affect dust exposition such as:

1) Used type of material,

2) Importance of the dust extractor,

3) Correct setting of the covers/deflectors,

4) Dust collector should be turned on before you start cutting.

d) Informed about the necessity to wear sufficient individual protection such as:

1) Ear protections.

2) Mask protection against dust to avoid breathing dangerous material.

3) Protecting gloves when touching blades (it is also recommended to use a blade carrying tool to transport the blades).

e) It is important:

1) That the machine is installed on a flat and a cleaned floor,

2) To have a sufficient light in the working area,

3) To stocks and finished parts are kept close to the operator’s normal working position,

4) To stop the machine and lock the power sources before you perform any maintenance or when the machine

is left without supervision,

5) To report any failure of the machine such as missing cover or damaged parts, as soon as they are discovered,

6) To adopt safety procedures for cleaning and maintenance and remove chips and dust regularly to prevent any

risk of fire,

7) To not remove any waste or piece of moulding while the machine is in function,

8) To not use the machine if some protection covers are not installed and all in perfect condition,

9) To not do OFF/ON/OFF… in short time, this could damage the machine.

f) It is a necessity for the operator to:

1) Follow operating, maintenance and repair instructions of the cutting blades‘manufacture,

2) Respect the maximum cutting indicated speed of the blades,

3) Use blades that are correctly sharpened.

USER MANUAL

CS969

11

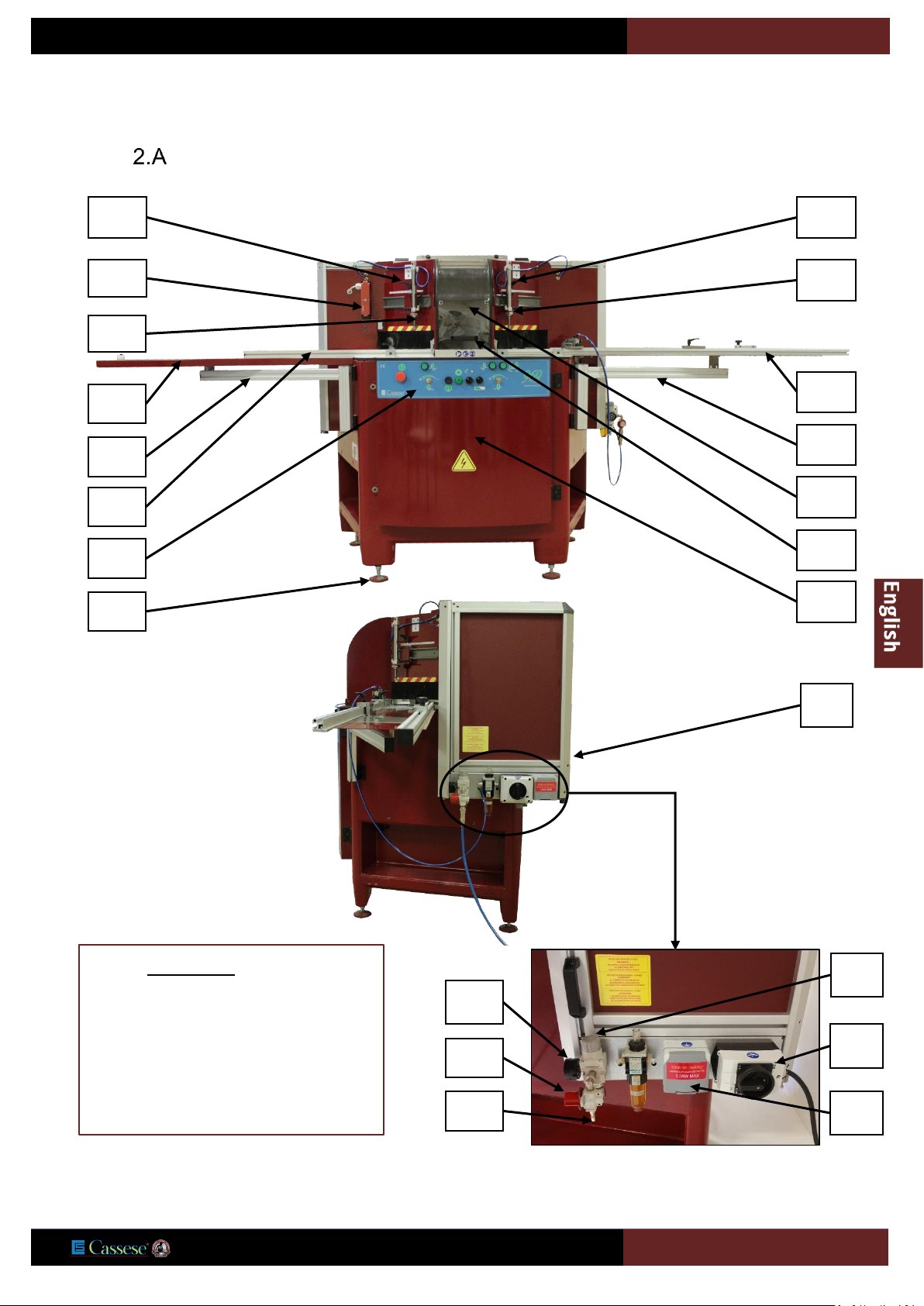

2 / DESCRIPTION

DESCRIPTION OF THE CS969 MAIN PARTS

2

12

4

OPTIONS:

Right extension arm:

Z28432 = 2 Meters/Z28431=1 Meter.

Digital measuring stop “Smart Stop”(on

request / Can not be retrofitted

afterwards):

7

9 6 15

20

3

5

8

10

1

19

11

21

14

22

13

16

17

18

USER MANUAL

CS969

12

Description

Label

Main Cover

1

Left vertical clamp handle

2

Right vertical clamp handle

3

Left vertical clamp

4

Right vertical clamp

5

Moulding guide

6

Left arm

7

Right arm

8

Left table bracket

9

Right table bracket

10

Electrical cabinet door

11

Safety lock

12

Air pressure-regulating valve

13

Air switch (can be locked with a locker)

14

Control panel

15

Main circuit Isolating switch

16

Electrical plug (220V) for dust collector,.1.5 Kw MAX

17

Dust pipe connectors Ø 120 mm

18

Main Cover handle

19

Levelling feet + locking nuts (x4).

20

Air pressure gauge

21

Pneumatic quick coupling

22

USER MANUAL

CS969

13

3 / TECHNICAL DATAS

DESCRIPTION :

CS969

Year of manufacturing:

see label 1 on the machine

Cutting capacity:

Maximum width:

Maximum height of moulding:

160 mm

110 mm

Dimension of the blades:

Ø 350 mm

Bore:

Ø 30 mm

RPM:

3500 tr/mn for 60Hz and 2800 tr/mn for 50Hz

Maximum length to be cut:

1500 mm

Electrical supply:

230v MONO-30 A /

230v TRI-16 A /

400 TRI-10 A

Power cord:

3 x 2.5 HO7RNF 3G2.5 (230v MONO) /

4 x 1.5 HO7RNF 4G1,5 (230v and 400 v TRI).

2 Motors, power: (conformity EN 30204)

(2x) 1,5 Kw

Dust pipe connectors:

(2x) Ø 120mm

Dust collector type in accordance with standards:

To ensure correct extraction of the dust, suction flow should be:

2500m3/h

Thermal Protection/Electrical socket:

8A for 220V TRI / 5 A for 380V TRI

Pneumatic supply:

4 bars mini / 6 bars maxi

Maximum air consumption for 700 cuts per hour:

2.5 Nl per cycle at 6 bar

Weight:

720 Kg

Noise: (ear protections must be wear) Noise information: Measured

according ISO 7960-1995 standard).

see below

Operating condition of noise measurement:

1 Metering at operator position, not cutting, dust collector off: 81dB (A )

9 Metering at one meter not cutting, dust collector on / reference surface: 85dB (A )

9 Metering at one meter, machine in cutting process, dust collector on / reference surface: 89dB (A )

These values are measured values; they are not necessarily showing safe working conditions.

Even if there is a correspondence between emission and exposure level, these measures can’t be used to determine the necessary

protections to wear.

Parameters such as workshop configuration, other noise sources and machinery or other manufacturing process can affect the

exposure noise level of the operator.

Also allowed exposure level can fluctuate from a country to another one.

However, these values will help the user to evaluate the risk of using this machine.

Measurement report: BUREAU VERITAS N° 6164860-1/1-Z49SOP.

USER MANUAL

CS969

14

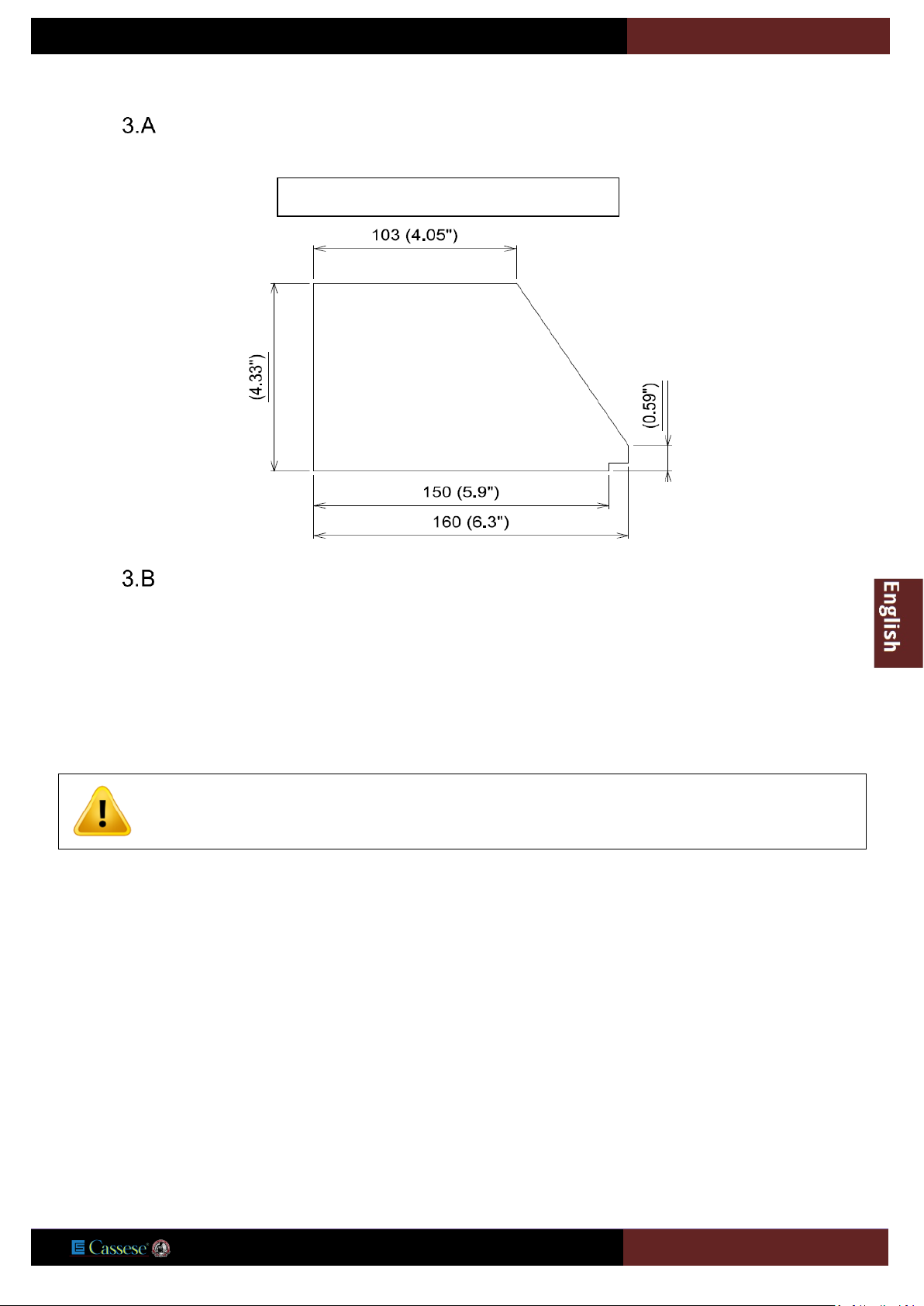

CUTTING CAPACITY

OPTIONS :

- S/A RIGHT EXTENSION ARM 1M Z28431.

- S/A RIGHT EXTENSION ARM 2M Z28432.

- S/A NUMERIC STOP “SMART STOP” Z28600.

- S/A RIGHT EXTENSION ARM 1M for SMART STOP Z18220.

NUMERIC SMART STOP Sub-assembly requires a factory mounting.

Cutting Capacity (Overall)

USER MANUAL

CS969

15

4 / INTRODUCTION

Saw CS 969 is a machine used to cut 45° mitres on all mouldings with solid or reconstituted wood base, and with or without coating

(paint, varnish, plastic coating, paper, metal leaf such as gold, bronze, aluminium, etc.).

It cannot be used for:

- Moulding profiles that do not have a 90° heel greater than 5 mm in height,

- Any metal profiles,

- Thin extruded plastic profiles: (plastic cords, trimmings, etc.)

Its two circular blades are driven by two electric motors.

The moulding is held automatically by vertical and horizontal pneumatic cylinders.

A two-hand control, actuating both clamping and cutting, ensures operator safety by keeping hands out of range of the blades.

The electrical control equipment is placed in a cabinet in front of the machine.

The pneumatic equipment is secured in the base of the machine behind the electrical cabinet.

This machine was built to meet safety and hygiene requirements. It is therefore forbidden to modify the electrical and pneumatic

equipment, remove protective equipment installed on delivery or modify the machine safety devices.

Saw CS 969 cannot be used by more than one operator at a time.

RESIDUAL RISKS

Hands must never be inserted inside the beyond the plastic screens of the top protection cover as this section contains the pressure

cylinders and rotating saw blades in their high idle position.

WARRANTY

This machine is covered by a one-year warranty, parts and labor included. Wearing parts and damaged parts due to bad use of the

machine are not covered by the warranty.

USER MANUAL

CS969

16

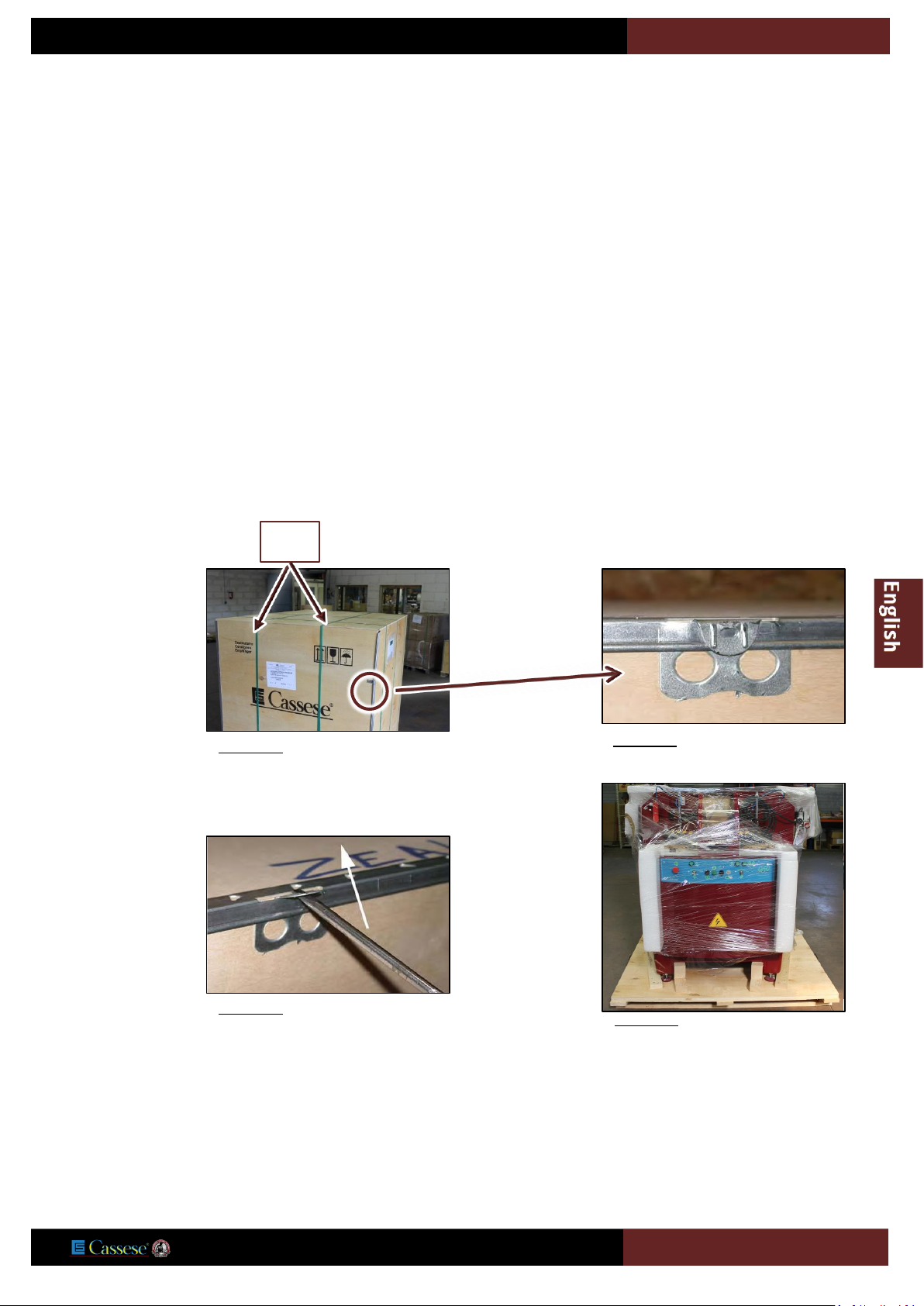

5 / HANDLING AND UNPACKING

This machine is packaged in a crate containing:

-1 Right extension arm with rebate measuring system

-1 Fixed stop

-1 Retractable stop

-1 Left extension arm

-1 Accessories box containing:

-1 S/A blades dismounting tool(Z18303)

-1 10-mm Allen key (to remove blades)

-1 6-mm Allen key (to assembly tables)

-1 5-mm Allen key

-1 4-mm Allen key

-1 2.5-mm Allen key

-1 Allen key for sensor

-1 Quick-fit coupling ¼ (fitted on the machine) / 1 quick-fit coupling

-1 Fuse: 1.25 Amp aM - (2 Amp aM ) glass fuse:1,25 A 5 x20.

-1 Male US connector M ¼ TEFLONE-Z701

-1 Groove connector M ¼ Cyl. -Z556

Using scissors, cut

the straps rep: C

which belt the crate

C

Figure 5-1

Figure 5-2

Using a screwdriver

open the fasteners

on the crate

Figure 5-3

then remove the

cover and its 4

sides.

Figure 5-4

USER MANUAL

CS969

17

For handling, a lift truck with forks at least 115 cm long must be used.

The forks must be positioned correctly below the frame: see next figure.

Gross weight of the machine: 725 kg

Remove the table

extension arms

(behind the

machine)

Figure 5-5

Remove the

accessories box

(below the

machine)

Figure 5-6

Remove the

wooden hold from

the feet of the

machine.

Figure 5-7

Screwdriver

Scissors

CAUTION: Setting the forks spacing for moving pallet to the floor:

Front panel = 675 mm - side: 530 mm.

Then set the forks spacing for the remaining movement (see drawing below).

Position of the forks: equidistant from the frame axis. (see drawing below)

USER MANUAL

CS969

18

Once the machine is installed, remove the protection.

Handling from the front

Safety distance = 50 mm

Wooden block 120 x 150 x 850 mm

Fork of the lifting equipment

Handling from the side

Wooden block120 x 150 x 1200 mm

Fork of the lifting equipment

Safety distance = 50 mm

Figure 5-8

USER MANUAL

CS969

19

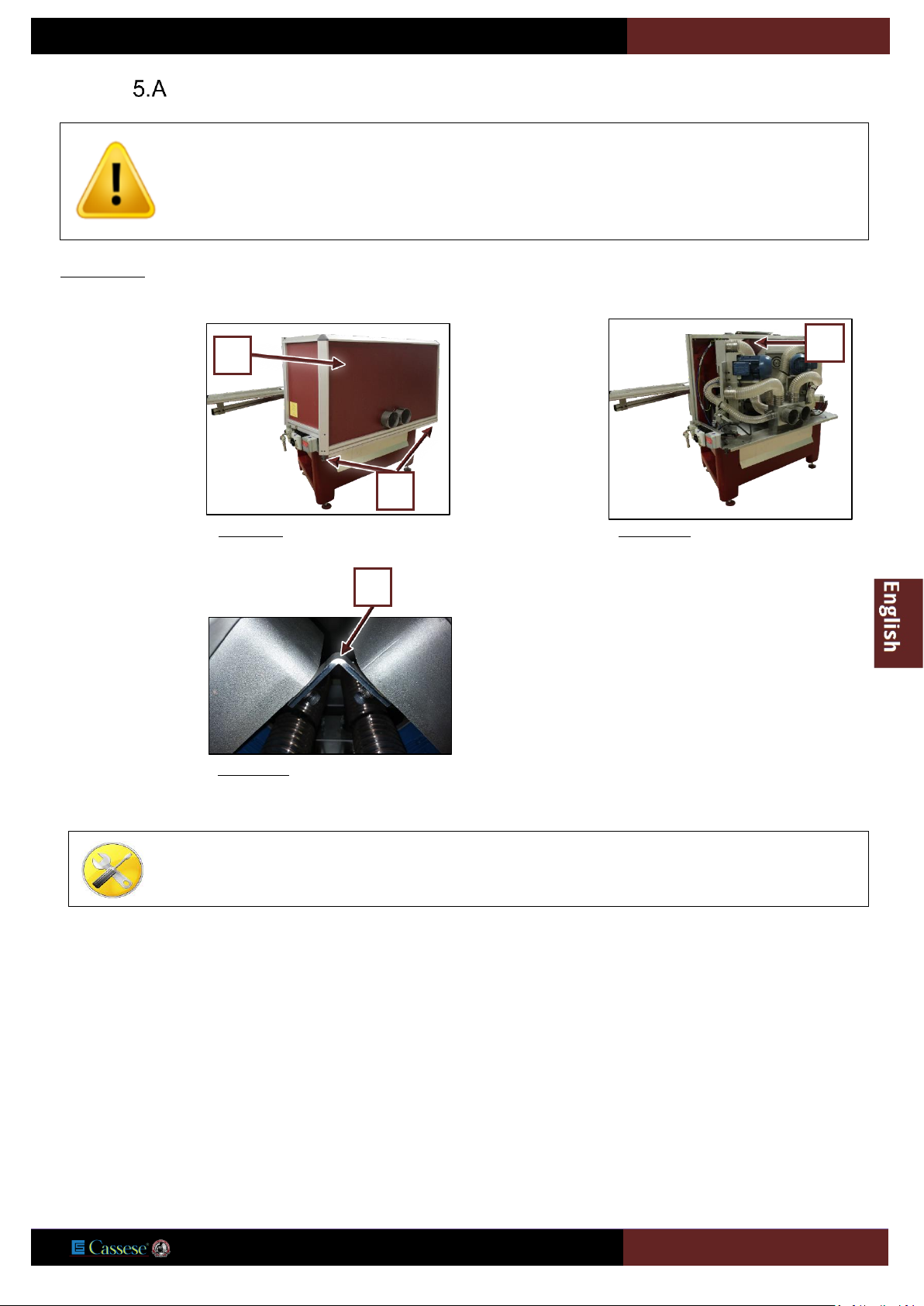

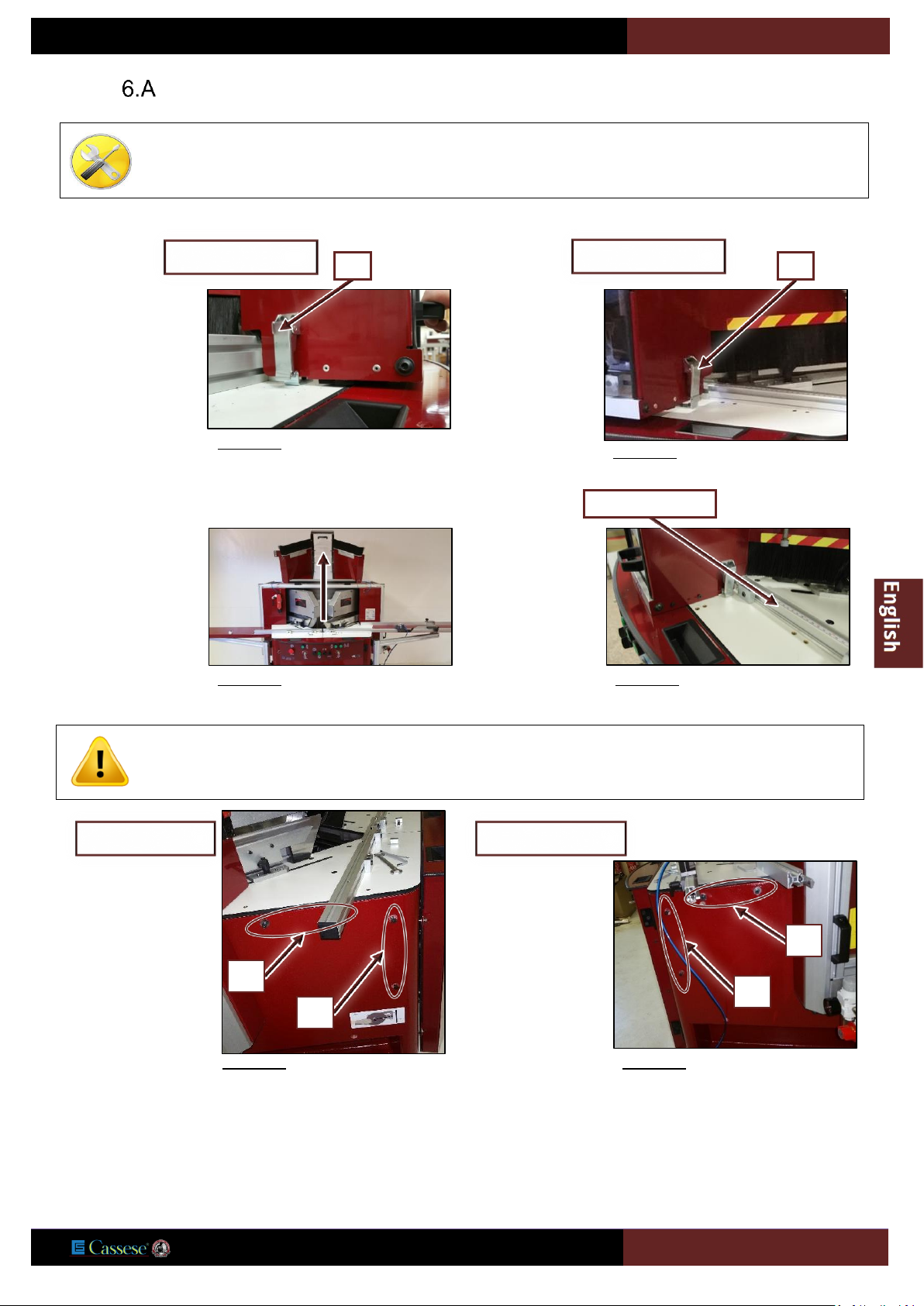

REMOVING OF TRANSPORTATION SAFETY

IMPERATIVE: before setting up your machine,

WARNING

DO NOT PLUG AIR !

Untight captives

screws (A

) and

open the back

cover (C)

Figure 5-9

C

A

Figure 5-10

E

Remove the locking

square (E

) of the

blades' carriage

(6mm Allen key

required)

Figure 5-11

E

5-mm Allen key

6-mm Allen key

USER MANUAL

CS969

20

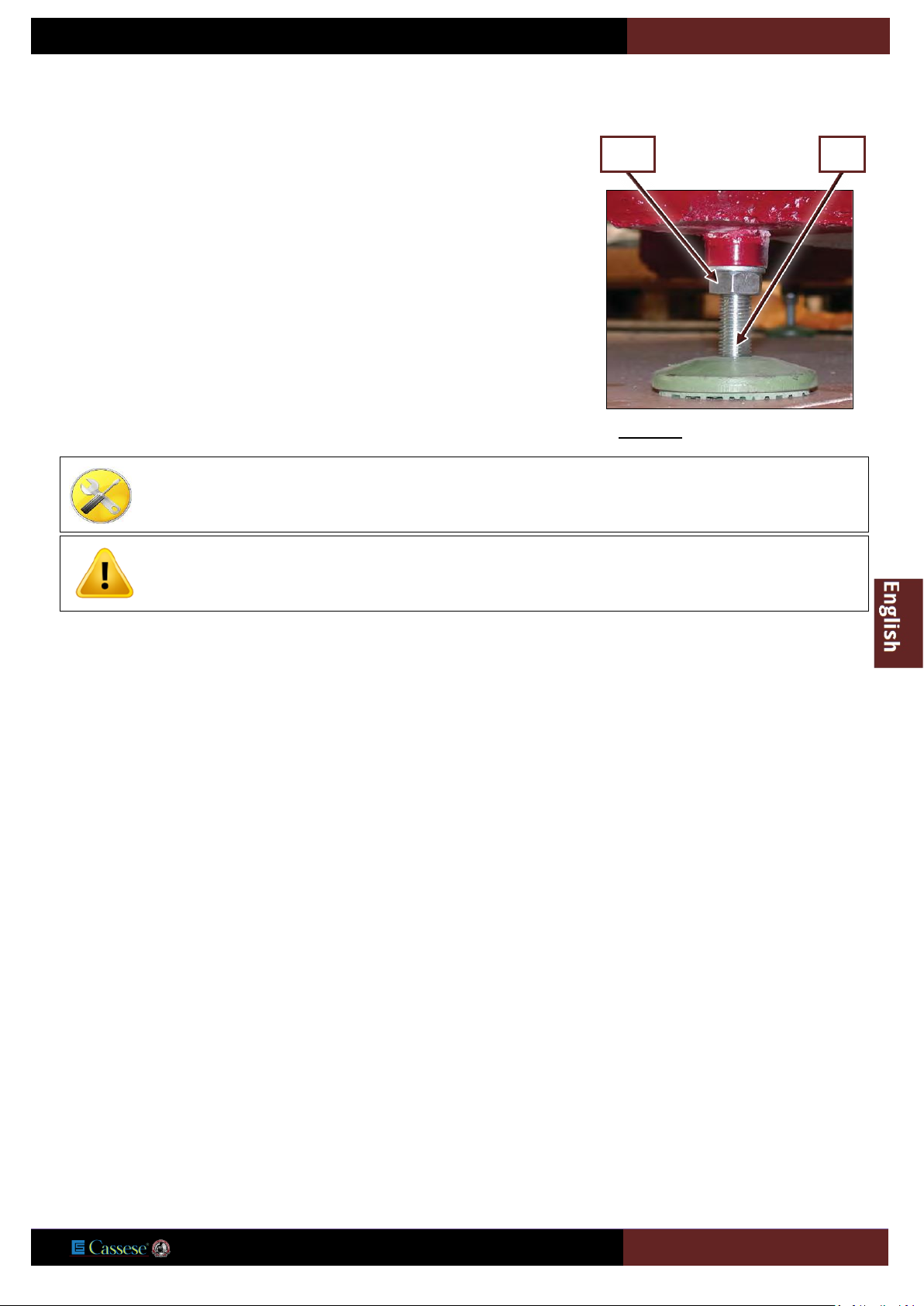

6 / SETTING UP THE MACHINE

There must be sufficient clearance around the machine to allow free

movement and access for maintenance.

The CS969 saw must be placed on a stable and generally flat floor.

Floor must be able to support load of 1250 Kg/m² and 315 Kg for

each foot.

Before making any electrical or pneumatic connections, level the

machine by means of the adjustable feet.

Use a 24-mm open-end spanner for locking nut (CE) and a 12-mm open-end spanner

for base (B).

Tighten locking nut (CE) firmly after adjustment and levelling.

As the work surface is 900 mm from the floor, it may be necessary to install a platform

for operators of short stature.

Sufficient space must be reserved around the machine to ensure a freedom of

movement and good acces for maintenance (see next page)

Open-end spanner 12

Open-end spanner 24

When installing the machine, make sure the floor is leveled and can support the weight of the machine.

The machine must be installed in a dry and temperate place. Choose a location where light will be sufficient to

ensure a comfortable use of equipment.

CE

B

Figure 6-1

USER MANUAL

CS969

21

USER MANUAL

CS969

22

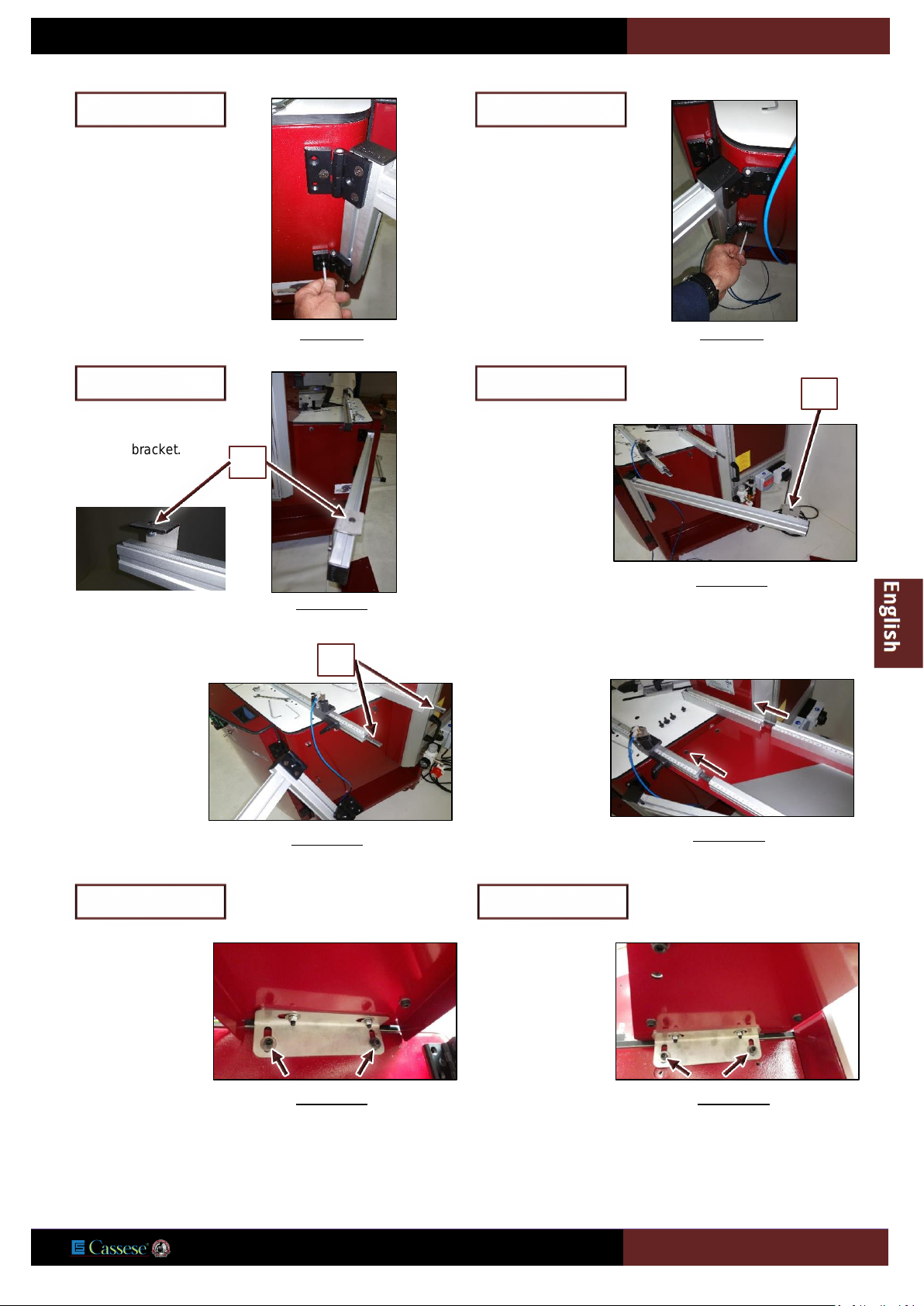

LEFT AND RIGHT ARM MOUNTING

5-mm Allen key

4-mm Allen key

Open-end spanner 10

Release the left

spring clips, SG.

Figure 6-2

SG

Left table side

Release the right

spring clips, SD

Figure 6-3

Right table side

SD

Open the main case

to its highest

position.

Figure 6-4

Figure 6-5

Moulding guide

Do not untighten screws of the moulding guide (factory setting)

Remove screws A

and B

on the left

side of the machine

frame with a 5-mm

Allen key.

Figure 6-6

Left table side

A

B

Remove screws C

and D

on the right

side of the machine

frame with a 5-mm

Allen key.

Figure 6-7

Right table side

C

D

USER MANUAL

CS969

23

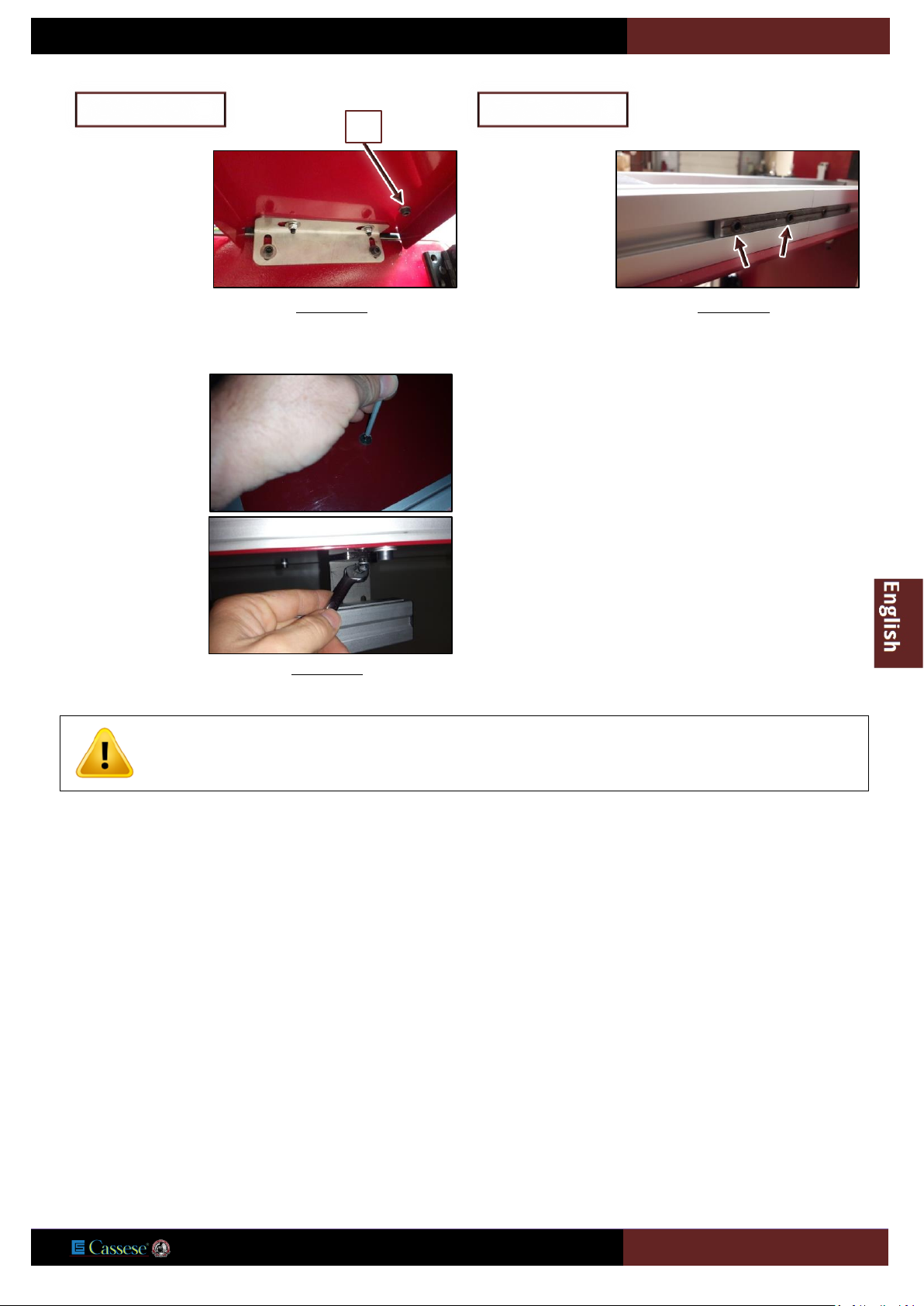

Put in place the left

extension support

bracket, tightening

it with previously

removed screws

(B).

Figure 6-8

Left table side

Put in place the left

extension support

bracket, tightening

it with previously

removed screws

(C).

Figure 6-9

Right table side

Put off the screw (E)

from the bracket.

Figure 6-10

Left table side

E

Put off the screw (F)

from the bracket.

Figure 6-11

Right table side

F

For each side of the

machine, make

sure the splints (G

)

are in place.

Figure 6-12

G

For each side slide

the arm in place.

Figure 6-13

Tighten the arm

with previously

removed screws

(A).

Figure 6-14

(Left table side)

Tighten the arm

with previously

removed screws

(D).

Figure 6-15

(Right table side)

USER MANUAL

CS969

24

Tighten the screw

(H).

Figure 6-16

Left table side

H

Tighten the splint

(G).

Figure 6-17

Right table side

For each side, bring

the bracket under

the table and

tighten together

with screw (E

and

F).

Figure 6-18

Do not untighten screws of the moulding guide (factory setting).

USER MANUAL

CS969

25

ELECTRICAL CONNECTION

AIR LINE FITTINGS

Provide a supply pipe with an inside Ø of 8 that will withstand the maximum pressure of the source, which must not be less than 6

bar.

Source characteristics: dry air, no lubrication

The machine must be connected to air power supply between 6 and 8 bar.

Included with the machine

Supplied by the customer

The user must connect the power supply cable to a source complying with the regulations in force and protect

the machine by fitting fuses: 25 Amp aM for 220 Volt single-phase or 16 Amp aM for 380/220 Volt 3-phase.

Quick release (Q/R) Female

Air connector Z749.

Female quick

connector

Z749

standard connector - Z556

USA male quick connector - Z701

Figure 6-19

Loading...

Loading...