Cassese CS 960 Instructions For Use Manual

Z15768

CS 960

Manual Operated Double-Mitre Saw 45°

Instructions for Use &

Technical Data

VERSION 2 - 09-2005

Cassese Communication

Left vertical clamp

handle

CS 960 DESCRIPTION

Blade carriage arms

Main case

Left vertical

clamp (option)

Left horizontal

clamp handle

Left horizontal

clamp

Left table

Left table support

bracket

Moulding guide

Right table

Main case handle

Right vertical clamp (option)

Right vertical clamp handle

Right table support

bracket

Cover safety screw

Electrical cabinet door

Foot locking nut

(x4)

Levelling foot (x4)

RIGHT SIDE OF MACHINE

Electrical

contactor

Isolation valve

Clamp control pedal

LEFT SIDE OF MACHINE

Extraction nozzles

Removable panel

Machine identity

plate

Offcut outlet

Air supply

A

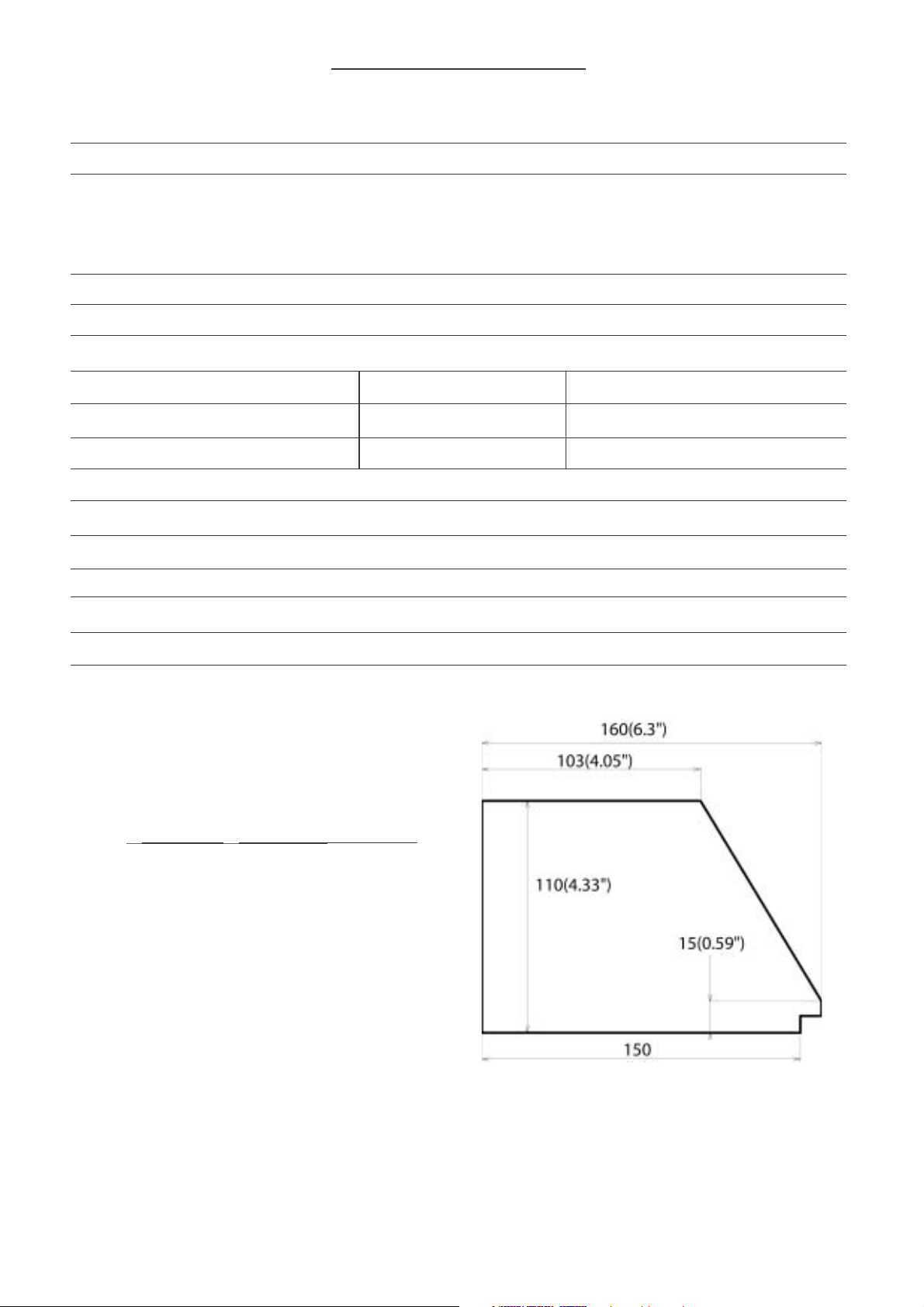

TECHNICAL DATA

PRODUCT NAME CS 960

Year of creation 2005

Cutting capacity:

maximum width 160 mm

maximum moulding height 110 mm

Blade dimensions

Bore

Ø 350 mm

Ø 30 mm

Maximium cutting length: 1500 mm

Rotation speed: 2800 rpm (

Electrical power supply

Power cable, standard, section

230v Mono/ 30A 230vTRI/ 16A - 400vTRI/ 10A

3x 2.5 H07 RNF 3G2.5 4x 1.5 H07 RNF 4G1.5

50-60Hz) 3400 rpm (60Hz)

2 power motors (compliant with standard EN 60204 ) 1.5 kW

Extraction nozzle, ext. dia. 2x100 mm

Extraction compliant with standards: 28 m

3/s at 4 m for Ø 100

Air supply: 4 bar min. / 4 to 6 bar

Max. consumption: 2,3l / cycle

Weight 950 kg (# < 58) / 710 Kg (# > 57)

Noise ( compulsory ear protection) 85 dB

CUTTING CAPACITY (OVERALL)

for max. width = 160

Dimensions in mm

Options: - Right extension arm:

- Z15732 : 2 metres - Z15731 : 1,00 metres

- Digital measuring stop* (on request / Factor Adaptation):

- Z15736 : Smart Stop - Z15735 : Quick Stop

B

C

Contents

CS 960 DESCRIPTION A

TECHNICAL DATA B

CS 960 OVERALL DIMENSIONS C

I - INTRODUCTION 1

II - UNPACKING & HANDLING 2, 3

III - SETTING UP THE MACHINE

- Installing the right and left tables 4,5

- Electrical connections 6

- Air connections 6

- Dust extraction 6

IV - START-UP

- Control panel 6, 7

V - SAWING

- Horizontal clamp setting 7

- Vertical clamp setting 8

- First cut on the left 8

- Measuring the first piece 9

- Cutting the first piece 10

VI - PREVENTIVE AND CORRECTIVE MAINTENANCE

- Opening the main case 11

- Removing / refitting the blades 11

- Replacing the martyr cube 12

- Preventive maintenance / Troubleshooting 12

LIST OF WEARING PARTS

TECHNICAL DRAWINGS AND PARTS LISTS

I- INTRODUCTION

The CS 960 saw is used to produce 45° mitre cuts on all mouldings made

from solid or reconstituted wood, with or without coating (paint, varnish,

plastic, paper, metal leaf such as gold, bronze, aluminium, etc.).

It cannot be used for:

· Moulding profiles that do not have a 90° heel at least 5 mm high,

· Any metal profiles,

· Thin extruded plastic profiles:

(plastic cords, trimming, etc.).

Its two circular blades are driven by two electric motors

The moulding is clamped automatically by vertical (option) and horizontal

(standard) pneumatic cylinders.

A control, actuating the release of the blade carriage ensures operator safety

by keeping hands out of range of the blades.

The electrical control equipment is installed in a cabinet at the front of the

machine.

The pneumatic equipment is installed in the base and on the right-hand side

of the machine.

This machine was built to meet safety and hygiene requirements. It is

forbidden to modify the electrical and pneumatic equipment, remove

protective equipment installed on delivery or modify the machine safety

devices.

Saw CS 960 cannot be used by more than one operator at a time.

.

Residual Risks

Hands must never be inserted inside the main case as this contains the

clamping cylinders and rotating saw blades in their rest position.

For any other work inside the machine:

See the «Maintenance» section of this manual (page 11).

1

Loading...

Loading...