Cassese CS1 CART User Manual

FOOT OPERATED UNDERPINNER

Inventor and World No.1 Manufacturer of

Picture Framing Machines & Consumables Since 1976

CS1 CART

USER & PARTS MANUAL

Version 2 11/ 2014

Cassese® / Communication

Z26059

READ THIS MANUAL CAREFULLY

BEFORE USING THE MACHINE

Non contractual document - Cassese France® - Document non contractuel

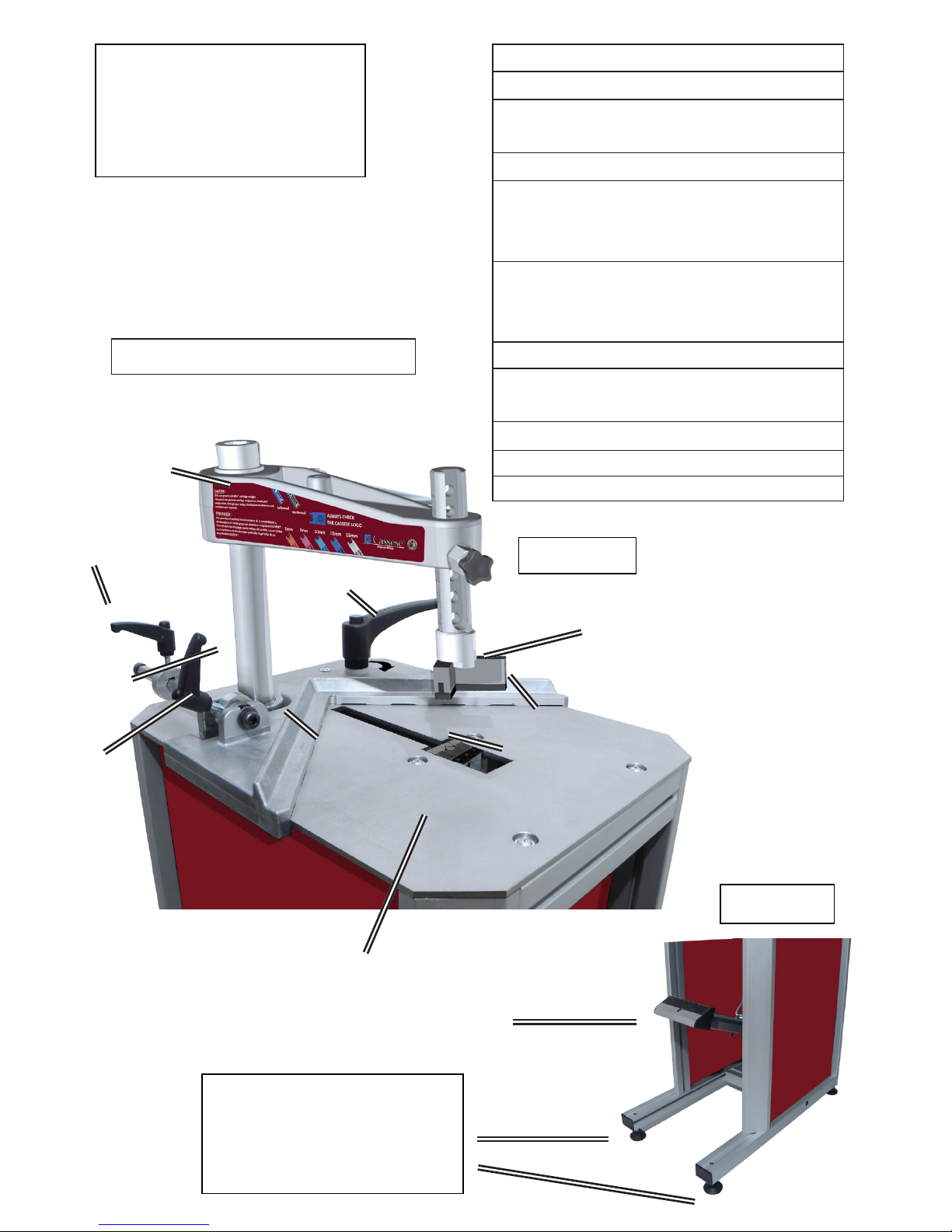

CS1 CART

FOOT OPERATED

UNDERPINNER

1st BACK FENCE 1

2nd BACK FENCE 2

HANDLE FOR LOADING

WEDGES 3

WEDGE DISTRIBUTOR BLOCK 4

WEDGE POSITION

STOP HANDLE

(inside of frame) 5

WEDGE POSITION

STOP HANDLE

(outside of frame) 6

PEDAL 7

MAGNETIC ADJUSTABLE

ROD CLAMP ASSEMBLY 8

CROSSBAR 9

STAPLING STOP 10

TABLE 11

WORK POSITION REFERENCE

9

6

5

10

2

1

8

3

4

11

7

Fig N°1

Fig N°2

AFTER UNPACKING THE

MACHINE, SET THE 4 FEET

TO LEVEL THE MACHINE

Non contractual document - Cassese France® - Document non contractuel

INTRODUCTION 2

ACCESSORIES SUPPLIED WITH THE MACHINE

TECHNICAL SPECIFICATIONS OF CS1 CART

OPTIONS

GUARANTEE

ADJUSTMENTS

SELECTION OF WEDGE POSITIONS 3

SETTING AND STORING THE WEDGE POSITIONS 3, 4

PROPER ADJUSTMENT OF MAGNETIC ADJUSTABLE 5

ROD CLAMP ASSEMBLY

USE

MEANS OF JOINING 6

LOADING CARTRIDGE WEDGES 6

CHANGING WEDGES SIZE 6

JOINING THE FRAME 7

MAINTENANCE

A) DISMANTLING THE WEDGE DISTRIBUTOR BLOCK 9

B) CLEANING AND LUBRICATION OF THE WEDGE DISTRIBUTOR BLOCK 10

C) REMOVAL OF THE WEDGE DRIVER BLADE 11

D) INSTALLATION OF NEW WEDGE DRIVER BLADE 12

E) UNJAMMING OF THE WEDGE DISTRIBUTOR BLOCK 13

F) REMOVING THE SIDE PANEL 14

G) REMOVING THE WORKING TABLE WITH THE PEDAL 14

H) REPLACEMENT OF THE WEDGE DISTRIBUTION CHANNEL

ELASTIC CORD 15

CS1 CART - USER & PARTS MANUAL

CONTENTS Page

1

Non contractual document - Cassese France® - Document non contractuel

CS1 CART - USER & PARTS MANUAL

INTRODUCTION

Thanks for having purchased the CS1 CART underpinner and for your trust in Cassese

products. The CS1 CART benets from Cassese’s experience since 1976 in designing and

manufacturing highest quality underpinners, for which we are world-famous. The CS1

CART will allow you to join wooden, plastic and MDF proles (patent n° 7522814). Joining

operation is carried out by using Genuine Cassese® Cartridge Wedges, specially designed

to perform perfect and tight frame corners.

ACCESSORIES SUPPLIED WITH THE MACHINE

A) 1 Magnetic adjustable rod clamp + 1 Chevron holder + 1 Magnetic chevron clamp + 1

Chevron rubber.

B) 1 box of 7mm Softwood + 1 box of 10mm Hardwood + 1 box of 10mm Softwood.

C) 1 Wedge driver blade for using CASSESE® Genuine Cartridge Wedges.

D) 1 Allen Key 2.5 mm + 1 Allen Key 3 mm.

E) 1 Grease Tube.

TECHNICAL SPECIFICATIONS OF CS1 CART

Minimum moulding width: 5mm (1/4”) / Minimum moulding height : 7 mm (11/16”)

Maximum moulding width: ∞ mm / Maximum moulding height : 85 mm ( 3 11/32” )

Maximum stroke between rst and last wedge (at 45°) : 140 mm (5 1/2”)

CASSESE® Genuine Cartridge Wedges sizes: 5, 7, 10, 12 and 15 mm.

3 wedge types : Softwood, Hardwood & MDF. Use only CASSESE® Genuine cartridge

wedges.

Machine gross weight : 23 kg (51 lbs) - Dimensions : Width 360mm (14’’) x Depth (w/

out extension table) 610mm (23’’

3/4

) x Height 1200 mm (47’’).

OPTIONS (page 24)

- Z1791 Green round clamp - Z1783 Yellow round clamp - Z25510 Stainless steel

table extension - Z25147 Stainless steel shelf for wedges and accessories - Z25450

Extension arms -

GUARANTEE

One year guarantee for parts and labour against manufacturing defects. Wear

parts and those damaged as a result of non compliance with the instructions of the

present manual are excluded from the guarantee. Loading spring and wedge driver

blade are considered as wear parts.

2

A B

C

D

E

Z1879

Z506

Z1896Z1882

Z21525

Z21524

1 box of 7mm SW

+

1 box of 10mm HW

+

1 box of 10mm SW

Z24703

Z26999

Non contractual document - Cassese France® - Document non contractuel

3

ADJUSTMENTS

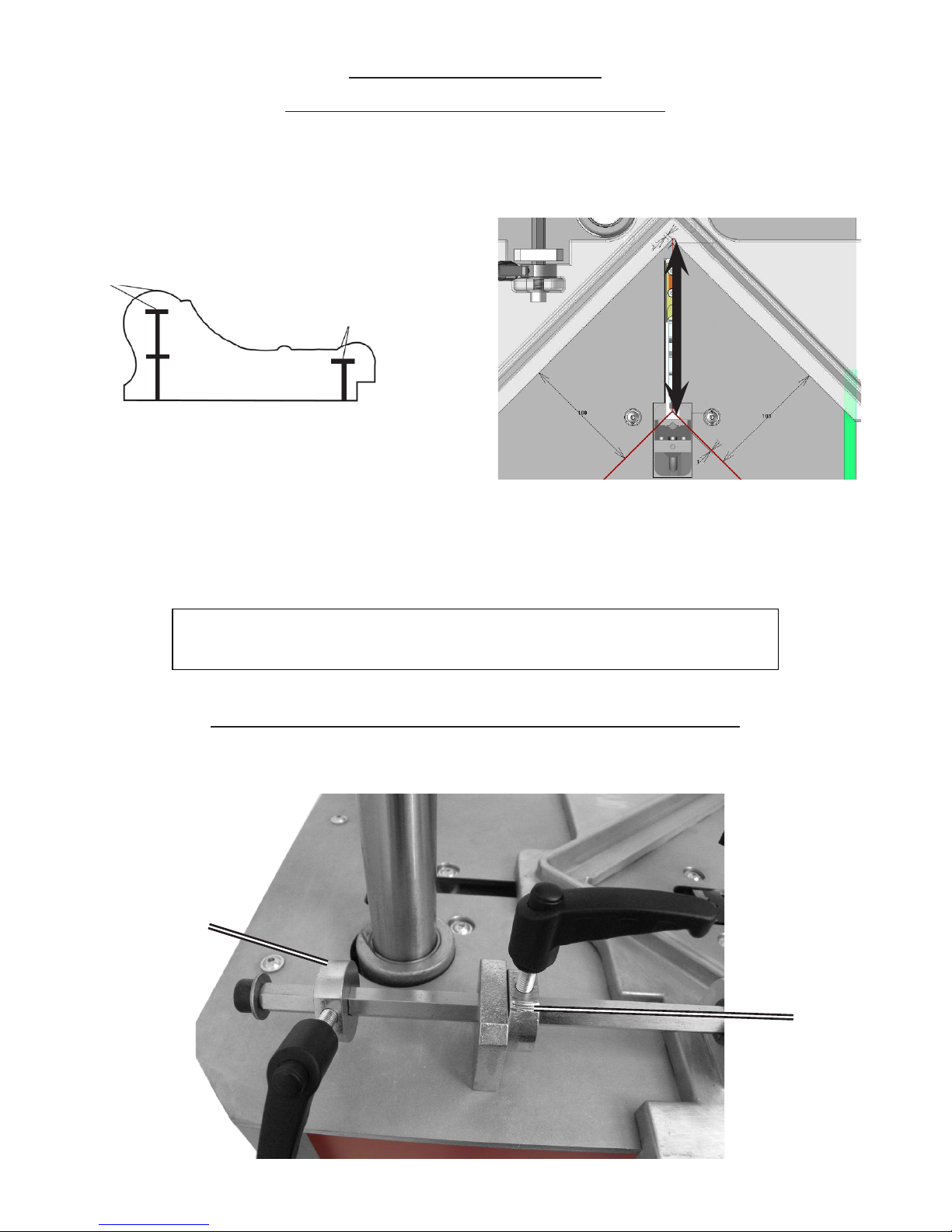

SELECTION OF WEDGE POSITIONS

The CS1 CART is designed to join mouldings in one, two or more positions without

limitation of the number of wedges in any of those places. The selection depends

on the width and height of the moulding to join.

As a general rule, a MINIMUM 2 mm clearance (less than 1/8”) above the wedges

shall be respected.

Same size wedges can be stacked in order to avoid changing the size of wedge

when joining tall mouldings.

AS A GENERAL RULE, THE WEDGE POSITIONS MUST BE SELECTED

VERTICALLY TO THE HIGHEST POINTS OF THE MOULDINGS.

SETTING AND STORING THE WEDGE POSITIONS

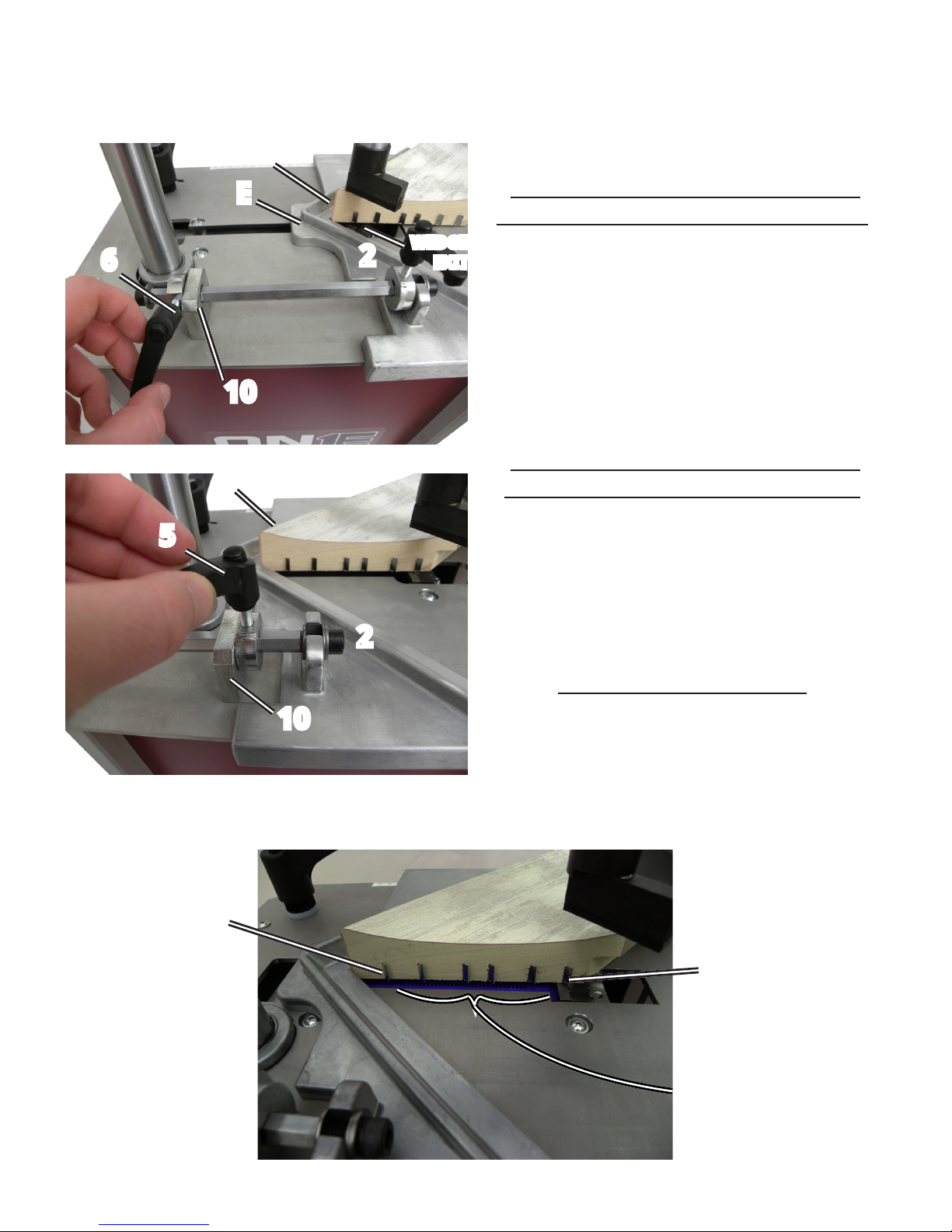

Unlock the wedge position stop handles 5 and 6.

140mm

stroke

2mm MINIMUM

2mm MINIMUM

6

5

Non contractual document - Cassese France® - Document non contractuel

4

Put the rst moulding in front of the back fence 1 and slide the moulding in

contact with the 2nd back fence 2.

Setting up the stapling position

close to the outside of the frame :

Move forward the sliding table E until the

place where you want to insert the wedge(s)

has been reached by the WEDGE EXIT (see

picture). Then bring the wedge position

stop handle 6 against the stapling stop 10

and tighten it.

Setting up the stapling position

close to the inside of the frame :

Move backwards the sliding table E until

you have reached the furthest position to

the inside of the frame where you want to

insert wedge(s).

Then bring the wedge position stop handle

5 against the stapling stop 10 and tighten it.

Now the two positions of joining are

set and the sliding table can move only

within the limits of these two positions.

WEDGE

EXIT

E

10

6

10

5

Wedges between

the rst and the

last position

1st position

Last

position

2

1

2

1

Non contractual document - Cassese France® - Document non contractuel

5

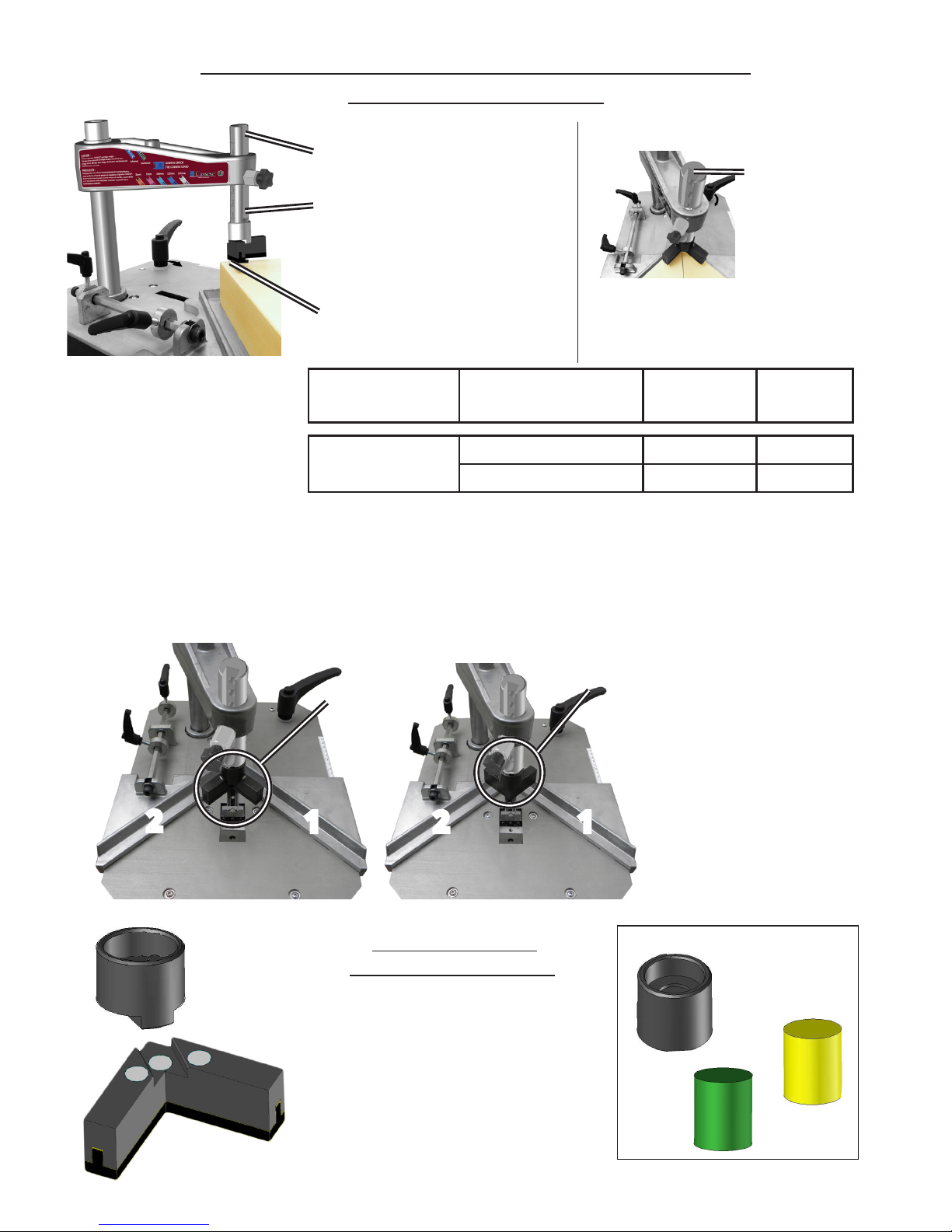

PROPER ADJUSTMENT OF MAGNETIC ADJUSTABLE

ROD CLAMP ASSEMBLY

A magnetic adjustable rod

clamp comes with your

machine as a standard

feature. It ts the crossbar

thanks to the locking ring

pin and can be set at 1 to 7

positions.

You must have 30mm (1 1/4”)

max between the clamp and

the mouldings.

It helps to avoid any mistakes in

the joining of the frame.

ACCESSORIES SUPPLIED WITH THE MACHINE: Magnetic chevron clamp is ideal for at

mouldings or for hard to reach surfaces.

OPTIONS: The round clamps are dedicated to complicated forms and sloped mouldings.

NEW MAGNETIC

ADJUSTABLE CLAMPS

Now with quick-change magnetic

clamps, it is easy to change from

chevron to a round clamp.

Accessories supplied

with the machine

Magnetic Chevron Clamp

HARDWOOD &

SOFTWOOD

ONE SIZE

Z21525

Z18065

Z1783

Z1791

OPTIONAL

Z24703

GOOD

BAD

Pay attention to properly

position the magnetic

chevron clamp : the sides of

the chevron must be parallel

to back fences 1 and 2.

Options

Green Round Clamp HARDWOOD 30 & 45mm

Yellow Round Clamp SOFTWOOD 30 & 45mm

Always have

the notch

(mark) turned

to the front of

the machine.

2

1 2 1

Non contractual document - Cassese France® - Document non contractuel

6

USE

Boxes of 40

cartridges (app.

275 wedges)

=

11.000 wedges/

box

Boxes of 6

cartridges (app.

275 wedges)

=

1.650 wedges/

box

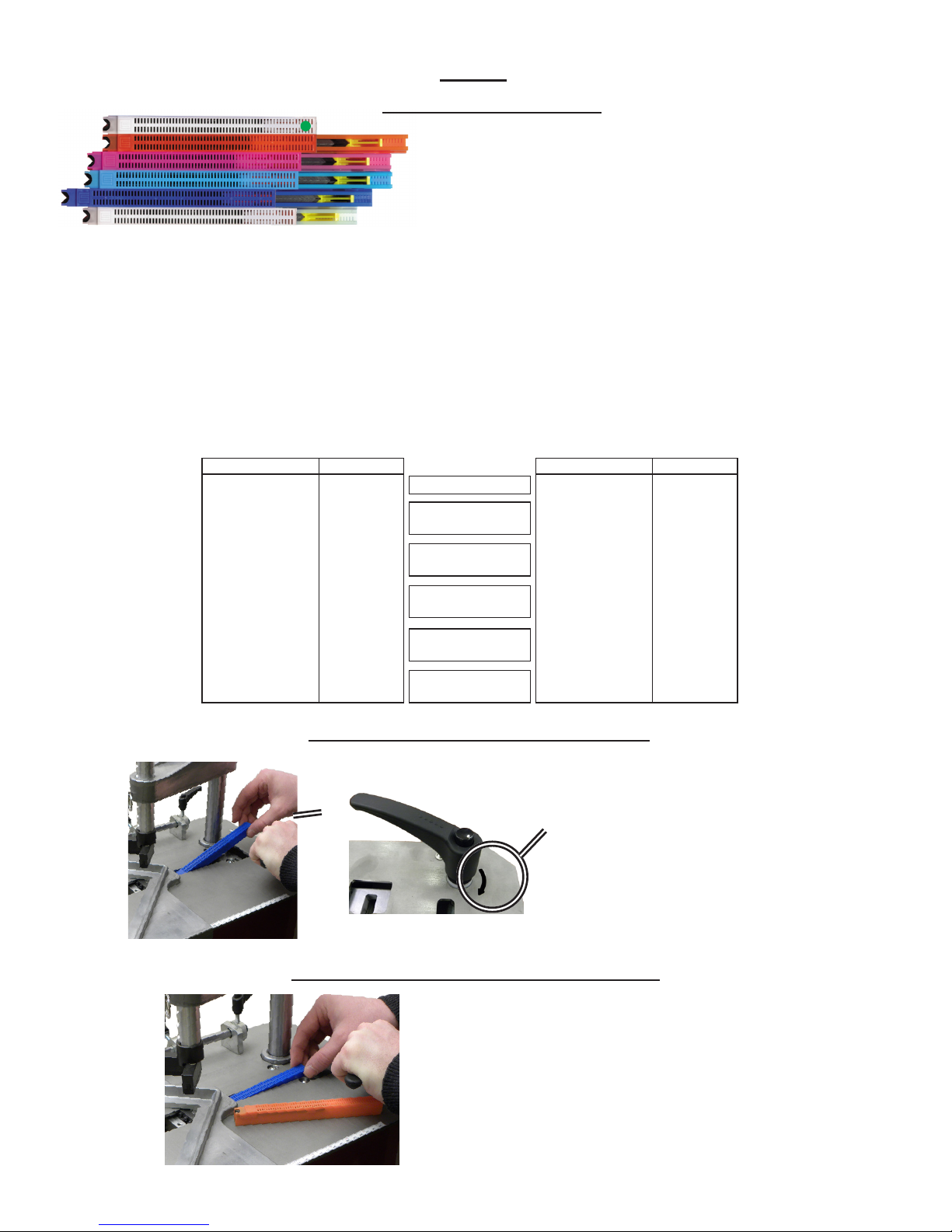

MEANS OF JOINING

Joining is performed by using metal wedges, a Cassese

invention, specially designed to ensure perfect

corners.

Six standard sizes are available : 3, 5, 7, 10, 12 and

15mm.

They come in eco-friendly cartridges, thanks to a recyclable plastic, that are color-coded per size

for easy identication. Cartridge wedges exist in 3 versions: NORMAL for SOFTWOOD (identiable

by their white plastic pusher), HW for HARDWOOD (identiable by their yellow plastic pusher)

and MDF (identiable by their red plastic pusher or red sticker on individual boxes).

Your CS1 CART underpinner is designed for using all sizes of CASSESE® Genuine Cartridge Wedges

without having to change any parts on the machine or having to adjust anything.

For the best corner join, reliability and performance, use only CASSESE® Genuine Cartridge

Wedges.

WHITE

REFERENCE

30303NCOI

30305NCOI

31305BDCO

30307NCOI

31307BDCO

30310NCOI

31310BDCO

30312NCOI

31312BDCO

30315NCOI

31315BDCO

TYPE

3mm

5mm

5mm HW

7mm

7mm HW

10mm

10mm HW

12mm

12mm HW

15mm

15mm HW

TYPE

3mm

5mm

5mm HW

7mm

7mm HW

10mm

10mm HW

12mm

12mm HW

15mm

15mm HW

REFERENCE

30403NCOI

30405NCOI

31405BDCO

30407NCOI

31407BDCO

30410NCOI

31410BDCO

30412NCOI

31412BDCO

30415NCOI

31415BDCO

ORANGE

PINK

LIGHT BLUE

DARK BLUE

WHITE

LOADING CARTRIDGE WEDGES

CHANGING THE SIZE OF WEDGES

Repeat the procedure of loading cartridge

wedges but remove the cartridge.

Then insert the new size of cartridge wedges.

Then release the handle for wedges’ loading 3.

Turn handle for loading wedges 3 in

direction of arrow in order to bring

back cartridge wedges pusher.

While holding handle in this position,

insert cartridge into cartridge channel.

Then gently release the handle for

loading wedges 3.

3

Non contractual document - Cassese France® - Document non contractuel

JOINING THE FRAME

After selecting and setting the wedge positions (page 4 & 5), check the distance

between the clamp and the moulding (page 6). Load the required type (softwood,

hardwood or MDF) and size of wedges (page 4).

1

st

step : Put the rst moulding in front of the back fence 1 and push it so that its

mitre end reaches the other back fence 2.

2

nd

step : Holding it so, put the second moulding against back fence 2 and slide it

until it reaches the rst moulding.

3

rd

step : Holding the mouldings in place against each other, hold the back fences 1

& 2 with your thumbs. Move the sliding table E backwards until the wedge position

stop handle 5 reaches the stapling stop 10.

4

th

step : Keeping the mouldings secure, slowly push down the pedal 7.

When the the magnetic adjustable rod clamp assembly 8 will press down on the

mouldings, speed up the movement so that the wedge is inserted more easily.

5th step : If there is a second wedge position (with wedge position stop handle 6),

just repeat the same operation by moving forward the mouldings and the sliding

table E until wedge position stop handle 6 reaches the stapling stop 10 and repeat

step 4.

NOTE* : If stapling more than one wedge in any position is desired then repeat 4th

step.

7

9

6

5

10

2

1

8

3

4

11

7

Non contractual document - Cassese France® - Document non contractuel

8

CAUTION! To ensure your safety, it is imperative to disconnect the air supply coupler before

any intervention on the mechanical and pneumatic components of the machine.

MAINTENANCE

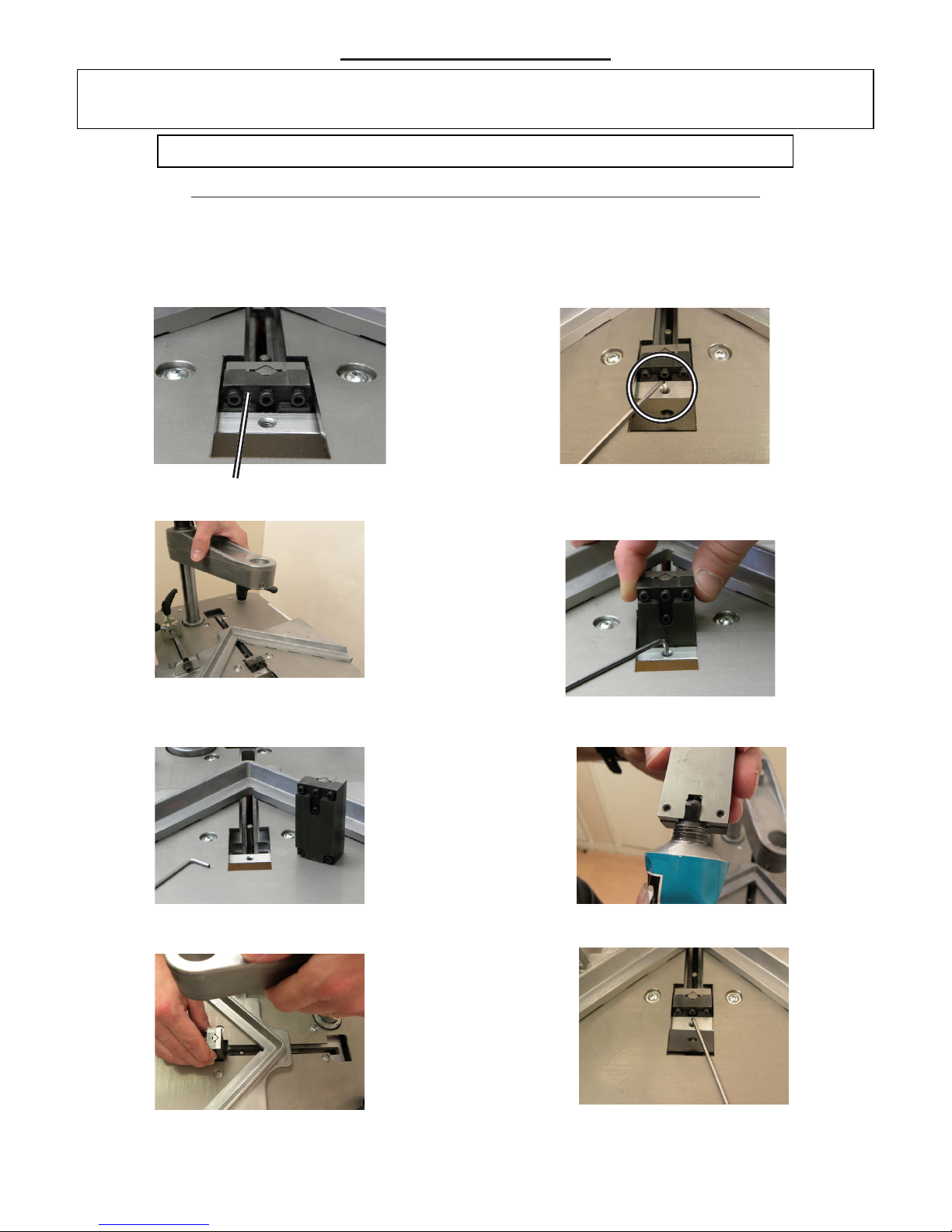

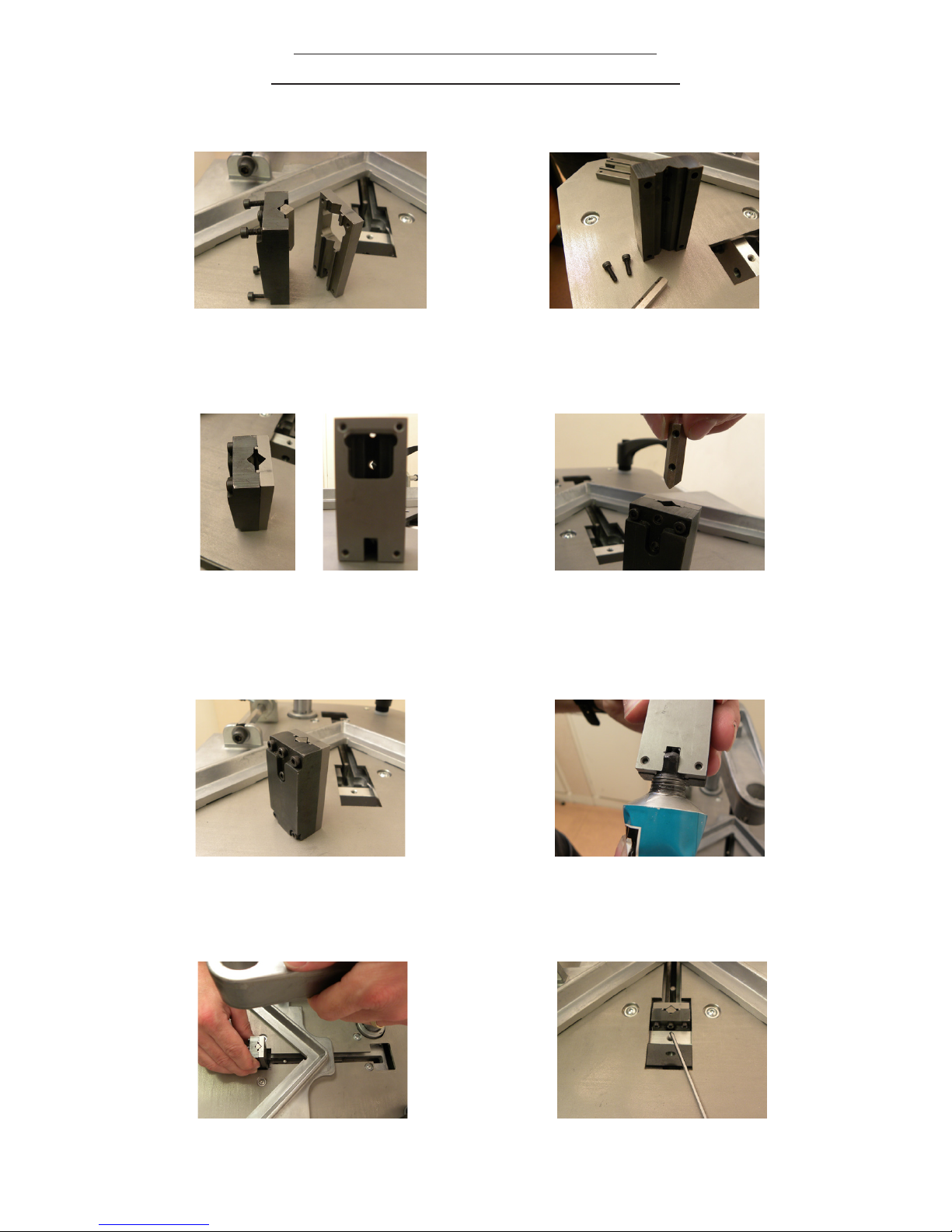

A) DISMANTLING THE WEDGE DISTRIBUTOR BLOCK

WEDGE DISTRIBUTOR BLOCK

Periodically, remove the wedge distributor block and clean it with an air gun.

It is recommended to lubricate the wedge driver blade (use the Cassese’s grease Z1896).

To do so, you will have to remove the wedge distributor block with the 2,5mm Allen Key and

perform this procedure. First, remove the cartridge of wedges from the underpinner.

CAUTION: WHEN USING COMPRESSED AIR, WEAR SAFETY GLASSES.

Unlock half a turn the locking screw of the

wedge distribution block with the 2.5mm Allen

key that is supplied with the machine.

Pull up the wedge

distributor block.

Remove the wedge distributor

block from the machine.

Pull up the crossbar in order to move

the wedge distributor block out of its

place.

1. 2.

3.

4.

5.

Pull up the crossbar in order to insert the

wedge distributor block on the wedge

driver blade with the window in direction

of the cartridge of wedges.

Apply a small amount of grease at the

bottom of the wedge distributor block.

Tighten the locking screw of the wedge

distributor block, paying attention to

level it with the working table.

7.

6.

8.

Non contractual document - Cassese France® - Document non contractuel

9

To clean up the wedge distributor block in order to avoid any stapling problem,

follow steps 1 to 5 of instructions of A) (ref. page 9), then proceed with step 1 :

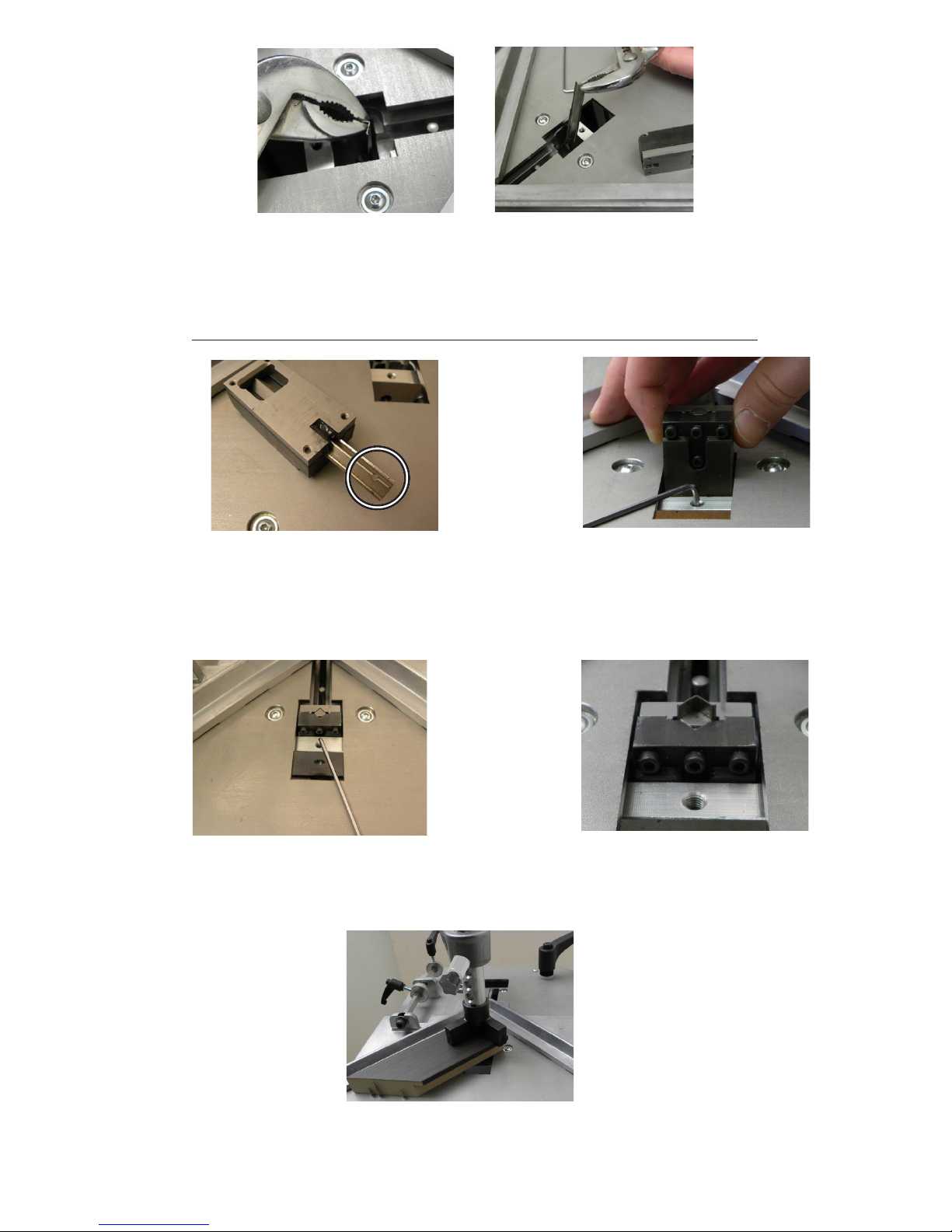

B) CLEANING AND LUBRICATION

OF THE WEDGE DISTRIBUTOR BLOCK

Unlock the two remaining screws to

remove the center post of the wedge

distributor block. Caution! : These are

the smallest screws of the block.

Unlock the four corner screws of

the wedge distributor block with the

2.5mm Allen key supplied with the

machine. Separate the two pieces.

Insert the last piece as shown in

the picture.

Before tightening the screws, check the

level of the pieces on the top of the wedge

distributor block in order to have a perfect

reassembly as shown in the picture.

Pull up the crossbar in order to insert the

wedge distributor block on the wedge

driver blade with the window facing the

cartridge channel.

After having cleaned up the wedge distributor

block, assemble these both pieces rst. Pay

attention to level them on the top before

tightening the screws. The window must be

facing to the both screws’ holes.

Apply a small amount of

grease at the bottom of the

wedge distributor block.

Tighten the locking screw of the wedge

distributor block, paying attention to

level it with the working table.

1. 2.

3. 4.

5.

7.

6.

8.

Non contractual document - Cassese France® - Document non contractuel

C) REMOVAL OF THE WEDGE DRIVER BLADE

First, you have to

take this piece with

all the elements on

the picture.

Put the piece next to the axis of the

crossbar in this position.

Rotate the piece as on the picture.

Now, the piece is in its place in order

to help to slide the wedge driver blade

up.

TO SLIDE THE WEDGE DRIVER BLADE UP WITH THE PEDAL

10

1. 2.

3.

4.

Push the pedal and maintain it.

Now, the wedge driver blade is pulled

up so you can remove it from its place.

1

st

step

2

nd

step

It is possible that you have to change the wedge driver blade.

Please follow the previous procedures A steps 1 to 5 and follow this procedure

with the wedge distributor block outside of the machine.

Remove the cartridge of wedges and the magnetic adjustable rod clamp

assembly.

Non contractual document - Cassese France® - Document non contractuel

3

rd

step

11

Take pliars to remove the wedge driver blade and twist it to unlock it.

DO NOT PULL IT STRAIGHT UP !

Apply some grease at the bottom

of the wedge distributor block and

insert a new wedge driver blade into

the block with its hole (in the circle)

downwards.

Replace the wedge distributor block in

its housing with the window towards the

cartridge channel and install the wedge

distributor block. Then, lock it using the

2,5mm Allen key.

1. 2.

D) INSTALLATION OF A NEW WEDGE DRIVER BLADE

Push the wedge driver blade fully in with a piece of wood or moulding

; press the pedal to engage the wedge driver blade entirely.

Check the wedge driver blade installation, it should slide smooth with

no resistance.

The upper end of the wedge driver blade

stays out of the block. Reinstall the magnetic

adjustable rod clamp assembly in order to

proceed with the following step.

3.

4.

5.

Tighten the screw of the wedge

distributor block paying attention to

level it with the working table.

Non contractual document - Cassese France® - Document non contractuel

12

E) UNJAMMING OF THE WEDGE DISTRIBUTOR BLOCK

-Try to pull up the wedge distribution block. If it still doesn’t come out, then call your

distributor for further instructions.

If you have succeeded in removing the wedge distributor block :

-If the old wedge driver blade is stuck in the wedge distributor block :

PERFORM THE PROCEDURE B STEP 1 TO STEP 5,

THEN PROCEED TO PROCEDURE E COMPLETELY.

-If the old wedge driver blade is damaged and remains in the machine :

PERFORM THE PROCEDURE B STEP 1 TO STEP 5,

THEN PROCEED TO PROCEDURE C + D COMPLETELY.

If the wedge driver blade or a wedge is jamming your wedge distributor block, please

follow this procedure :

-Remove the cartridge located inside the underpinner, and the magnetic adjustable rod

clamp assembly.

-If the cartridge doesn’t come out, loosen the screw of the wedge distributor block with a

2.5mm Allen key, unlock the handle for loading wedges 3 and remove the sliding table E.

-Pull up the wedge distributor block. If the cartridge was jammed inside, ask for the help

of someone to turn the handle for loading wedges 3. Then pull up the wedge distribution

block and the cartridge.

-If the wedge distributor block doesn’t come out, perform a quick hard compression on

the crossbar as in the picture.

Loading...

Loading...