Page 1

TECHNICAL MANUAL

(without price)

DOT PRINTER

MD-910

JAN. 1997

Page 2

Features

The MD-910 series is a dot matrix compact printer that uses two serial print heads.

This printer has been developed as an output terminal for various applications such as POS terminals,

measuring/analyzing equipment, medical equipment and communication data equipment, and has

been designed to be as compact as possible.

• Compact and lightweight

• High-speed printing of up to 2.5 lines/sec. (for MD-910) or 1.8 lines/sec. (for MD-911)

• Clear printout with high resolution of 8 dots/mm

• Paper width of print head

• Longer life of print head

• Simple mechanism for high-reliability

Page 3

Contents

1 Printer usage and Care..................................................................................................................... 1

2 Specifications/Operating principles ................................................................................................... 2

2-1 Specifications............................................................................................................................ 2

2-2 Outline of mechanism ............................................................................................................... 3

2-3 Mechanism and operation principles ........................................................................................ 3

2-3-1 Power transmission mechanism ................................................................................... 3

2-3-2 Sensor mechanisms ..................................................................................................... 4

2-3-3 Print head mechanism.................................................................................................. 5

2-3-4 Paper feed mechanism................................................................................................. 8

2-3-5 Ribbon cartridge drive mechanism ............................................................................. 11

2-4 External connection terminals................................................................................................. 11

2-4-1 Terminal arrangement ................................................................................................ 11

2-4-2 Terminal mechanism .................................................................................................. 12

2-4-3 Terminal circuit diagram ............................................................................................. 12

3 Disassembly/Reassembly............................................................................................................... 13

3-1 Tools .................................................................................................................................... 13

3-2 Disassembly procedure .......................................................................................................... 13

3-3 Assembly procedure ............................................................................................................... 14

3-3-1 Setting paper feed solenoid assembly........................................................................ 14

3-3-2 Setting the head assembly ......................................................................................... 15

3-3-3 Setting the paper feed assembly ................................................................................ 16

3-3-4 Setting the main body assembly................................................................................. 18

4 Parts list .................................................................................................................................... 26

5 Exploded view................................................................................................................................. 28

Page 4

1 Printer usage and Care

(1) Use recommended register paper. Otherwise, printing quality and the life of the print head will not be

guaranteed. The width of paper must meet the specifications.

(2) Never allow a mechanical impact (including the entry of foreign matter) to the print head surface.

(3) Any dust on the print head surface must be wiped off by an applicator soaked in ethanol or the

equivalent.

(4) The dedicated ribbon cartridge should be taken off when the printer is carried or not used for a long

period.

(5) Do not feed current to the print head if it is wet or moist. If current is fed, the print head may be

damaged. If the print head is wet or moist, dry it fully and then start printing.

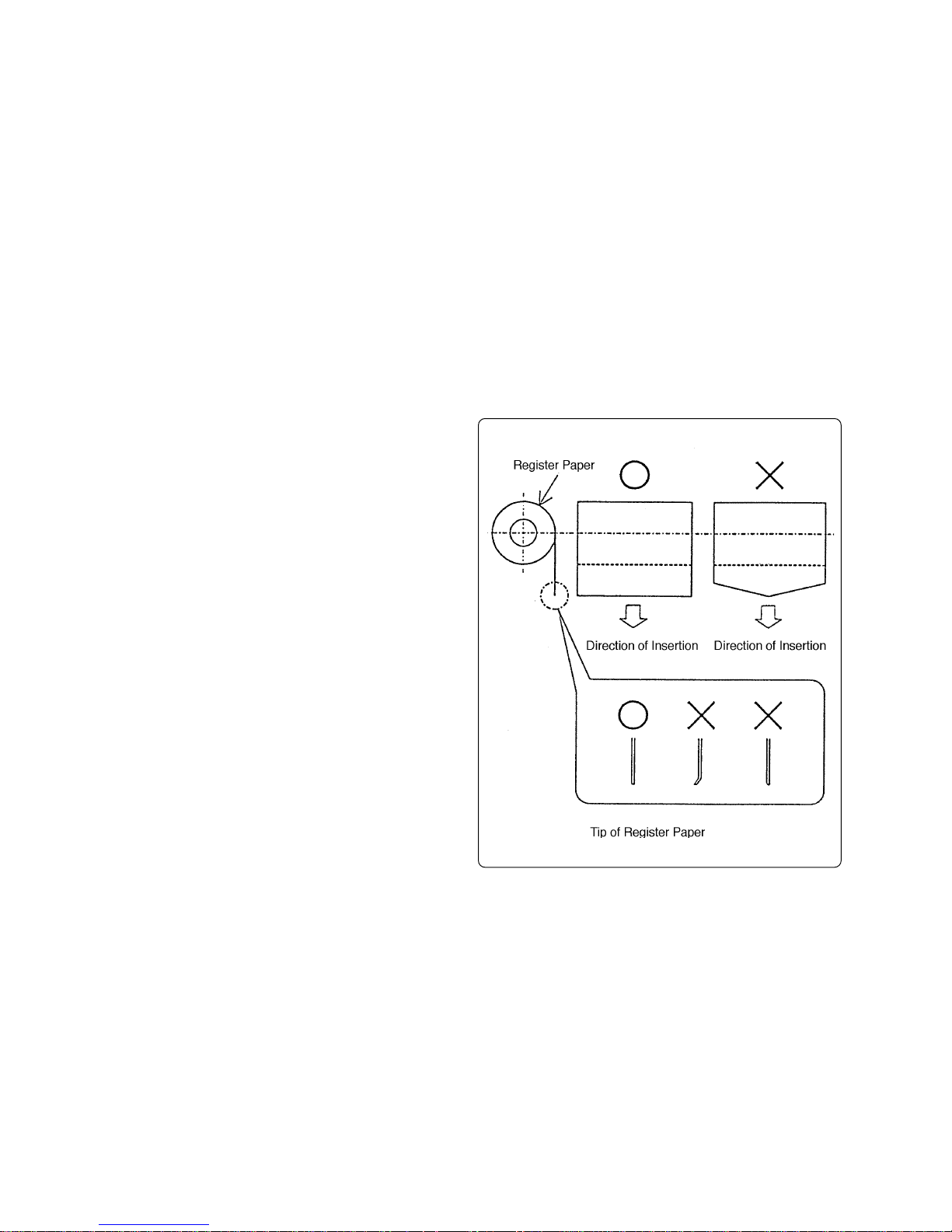

(6) Inserting register paper

• Cut the top end of the register paper

straight (it should never be fluffed or bent)

and insert it.

• When the top end of the register paper

comes out of the print head, check that it

is set straight and then pull it.

(7) Removing register paper

• Before removing the register paper, be sure

to stop feeding current to the print head.

• Pull out paper straight in the direction of

paper exit.

— 1 —

Page 5

2 Specifications/Operating principles

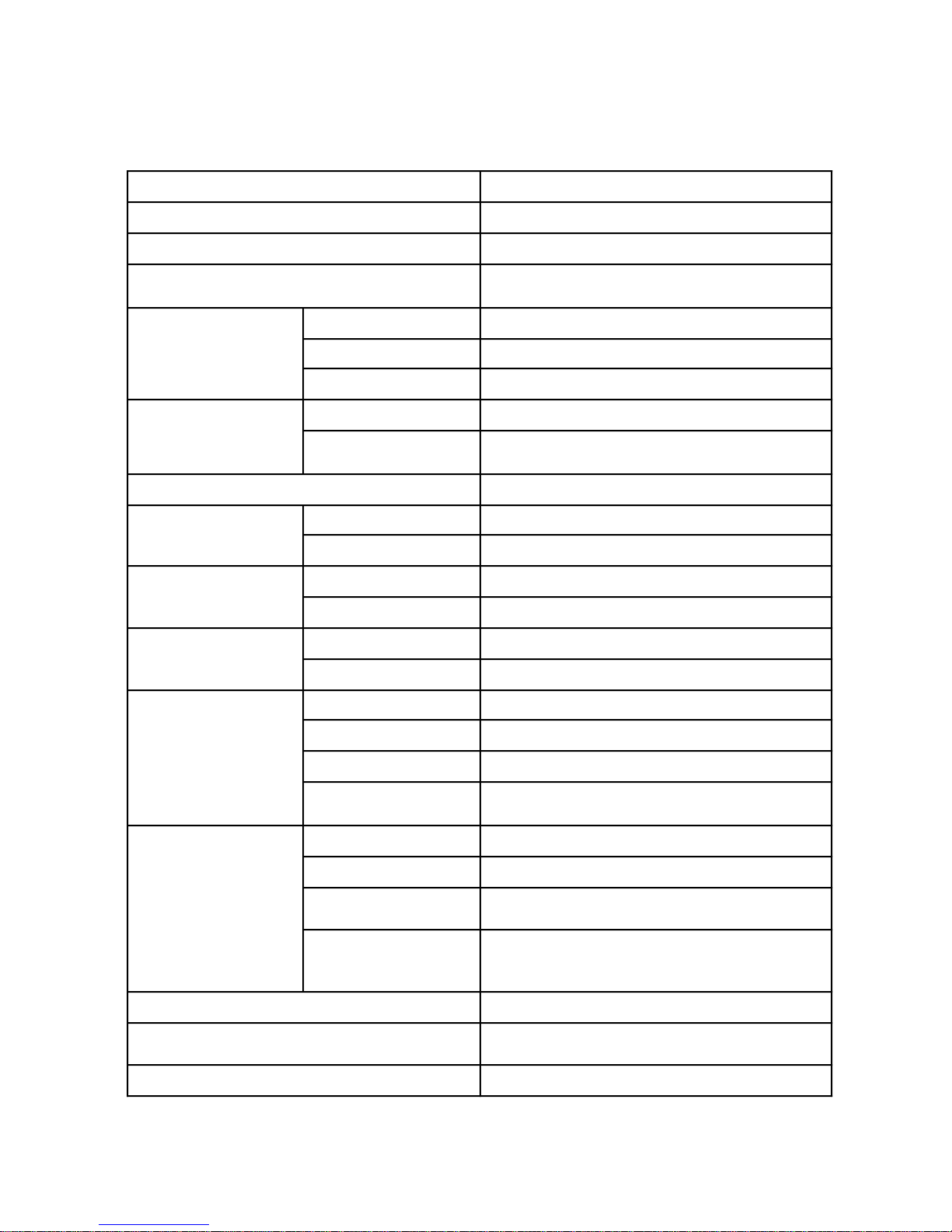

2-1 Specifications

Item Specifications

Printing method Dot matrix system

Printing direction Unidirectional printing

Printing speed 2.5 lines/sec. ± 20 %; DC 5.0 V, 25 °C in

continuous printing

Printing format Number of dots 144 dots/line

Character configuration (5 + 1) × 8

Number of columns 24

Paper feeding Paper feeding pitch 3.52 mm (10 dots/line)

Rapid feed rate 5 lines/sec. ± 20 %; DC 5.0 V, 25 °C in

continuous printing

Inking Dedicated cartridge (black or purple)

Detection Dot pulse Photointerrupter

Reset pulse Leaf switch detector

Paper feeding solenoid Drive voltage DC 5.0 V

Resistance 7 h ± 3 (temperature: 25 °C)

Printing solenoid Drive voltage DC 5.0 V

Resistance 1.7 h ± 0.3 (temperature: 25 °C)

Motor Type DC brush motor

Drive voltage DC 5.0 V

Max. current Approx. 1 A

Average current 0.3 A or less; DC 5.0 V, 25 °C in continuous

printing

Paper Type Plane or recommended paper

Paper width 57.5 mm

Cut sheet 45 to 55 kg

(thickness: 0.06 to 0.085 mm)

Copies Original paper (34 kg) + single copy (34 kg)

(Total thickness: 0.13 mm or less) Non-carbon

paper

Life of print head 1,500,000 lines

Exterior dimensions 90 (w) × 45.5 (d) × 15.8 (h) ± 0.5 mm

(excluding paper feeding nob and feet)

Weight 105 g ± 10 %

— 2 —

Page 6

2-2 Outline of mechanism

This printer mechanism is divided roughly into the following seven blocks:

• Power transmission

• Sensor

• Print head

• Paper feed

• Ribbon cartridge drive

• Frame

• Motor

For example external control circuits attached to this printer, please see the appropriate operating

manuals.

2-3 Mechanism and operation principles

The mechanism and operating principles are described for five blocks out of seven (i.e., excluding

the frame and motor).

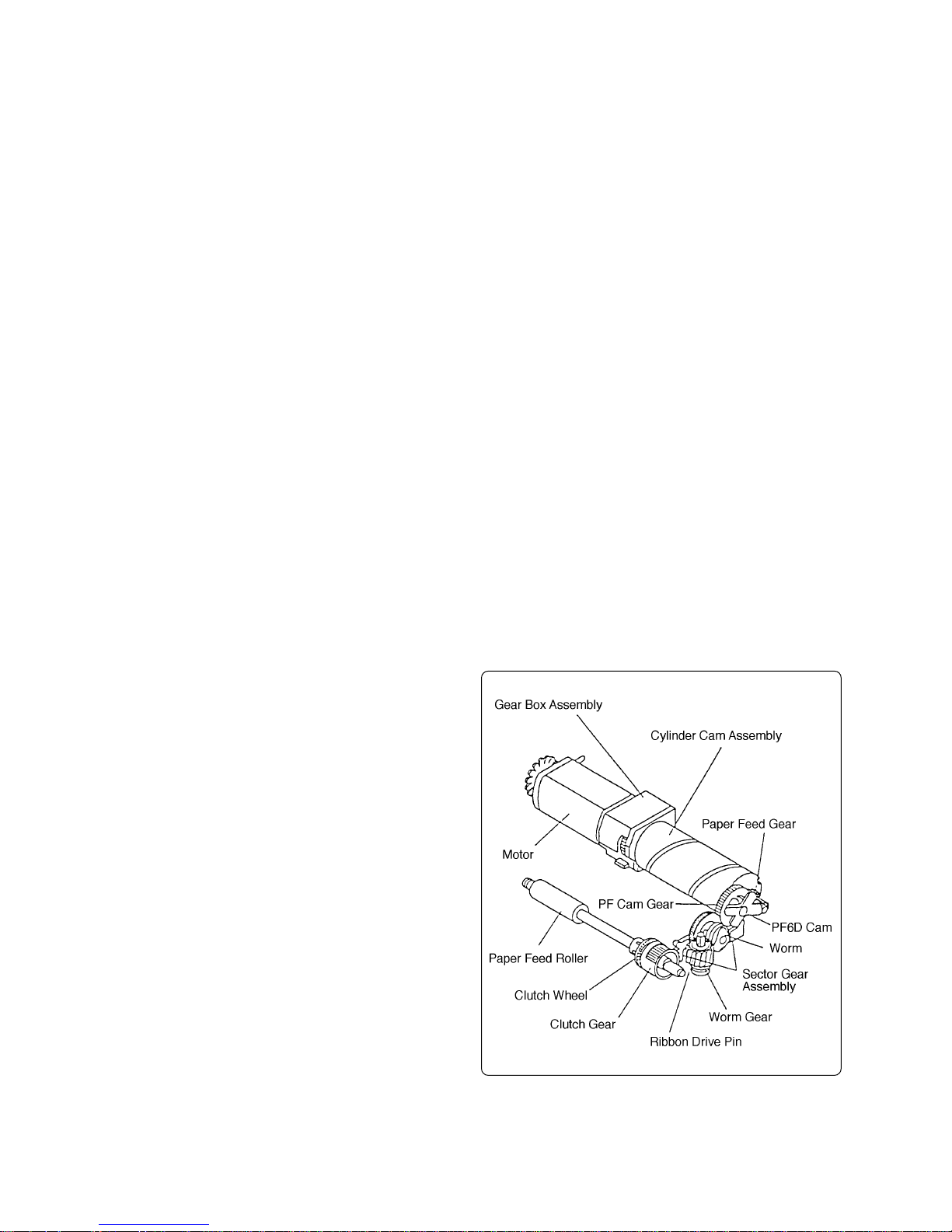

2-3-1 Power transmission mechanism

This mechanism transmits a motor driving force to the head assembly, paper feed roller and ribbon

cartridge.

The head assembly is driven by the cylinder cam assembly connected to the gear box assembly

which encloses the motor.

The driving force transmitted to the cylinder cam assembly is sent to the PF cam

gear and PF6D cam through the paper

feed gear. Either the driving force transmitted to the PF cam gear or the driving

force transmitted the PF6D cam can be

selected, depending on the operation status, and is sent to the clutch gear through

the sector gear assembly.

The driving force of the clutch gear is

transmitted to the clutch wheel connected

to the paper feed roller, driving the paper

feed roller.

The driving force of the PF cam gear is

transmitted to the worm, worm gear and

ribbon drive pin respectively, so that the

ribbon cartridge is driven by the ribbon

drive pin.

— 3 —

Page 7

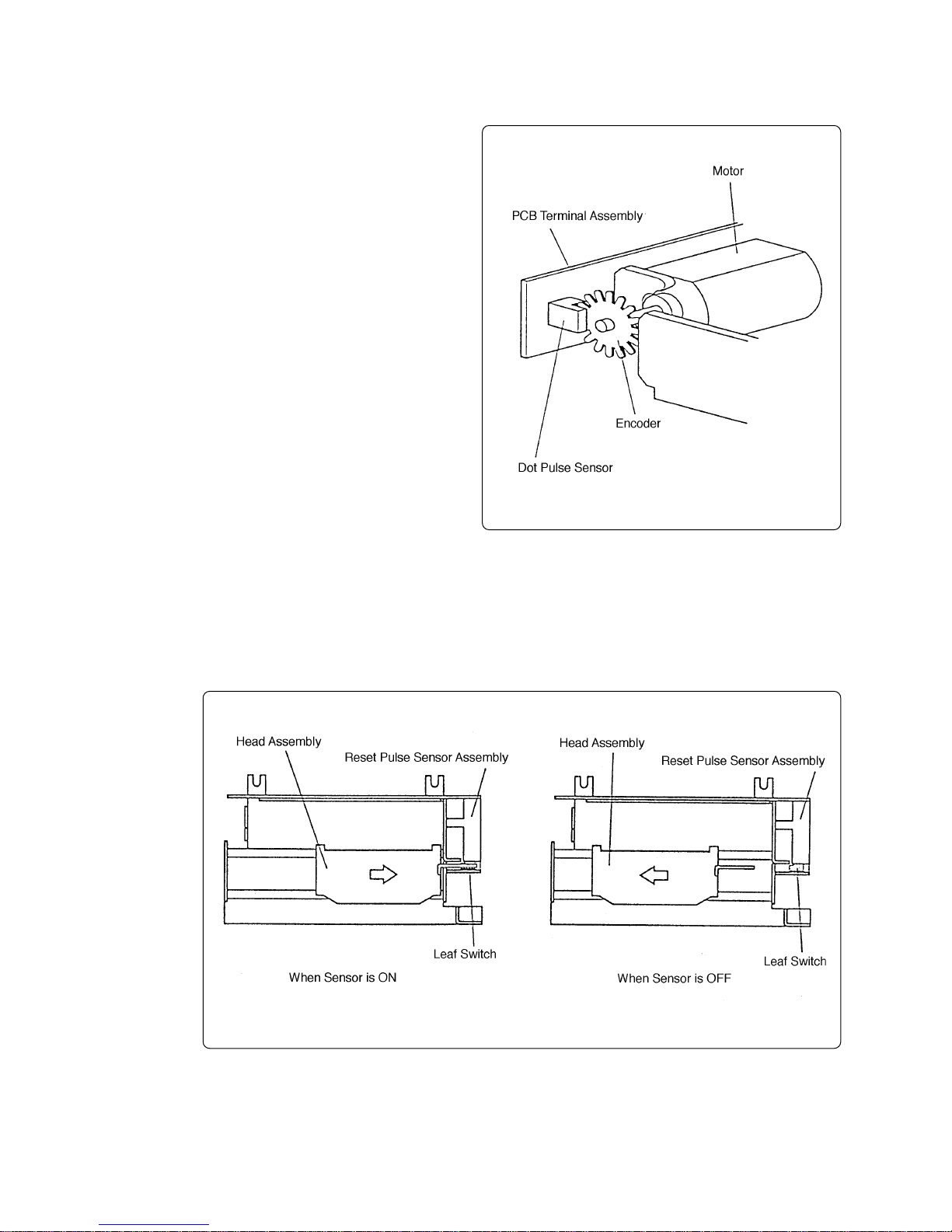

2-3-2 Sensor mechanisms

This mechanism has two sensors for detection, a dot pulse sensor and a reset

pulse sensor.

(1) Dot pulse sensor

The dot pulse sensor consists of an

encoder (slit disk) directly connected

to the motor and a photointerrupter

reading the rotation. The rotation read

(number of slits counted) is treated as

the DP signal that is the core of the

printing control.

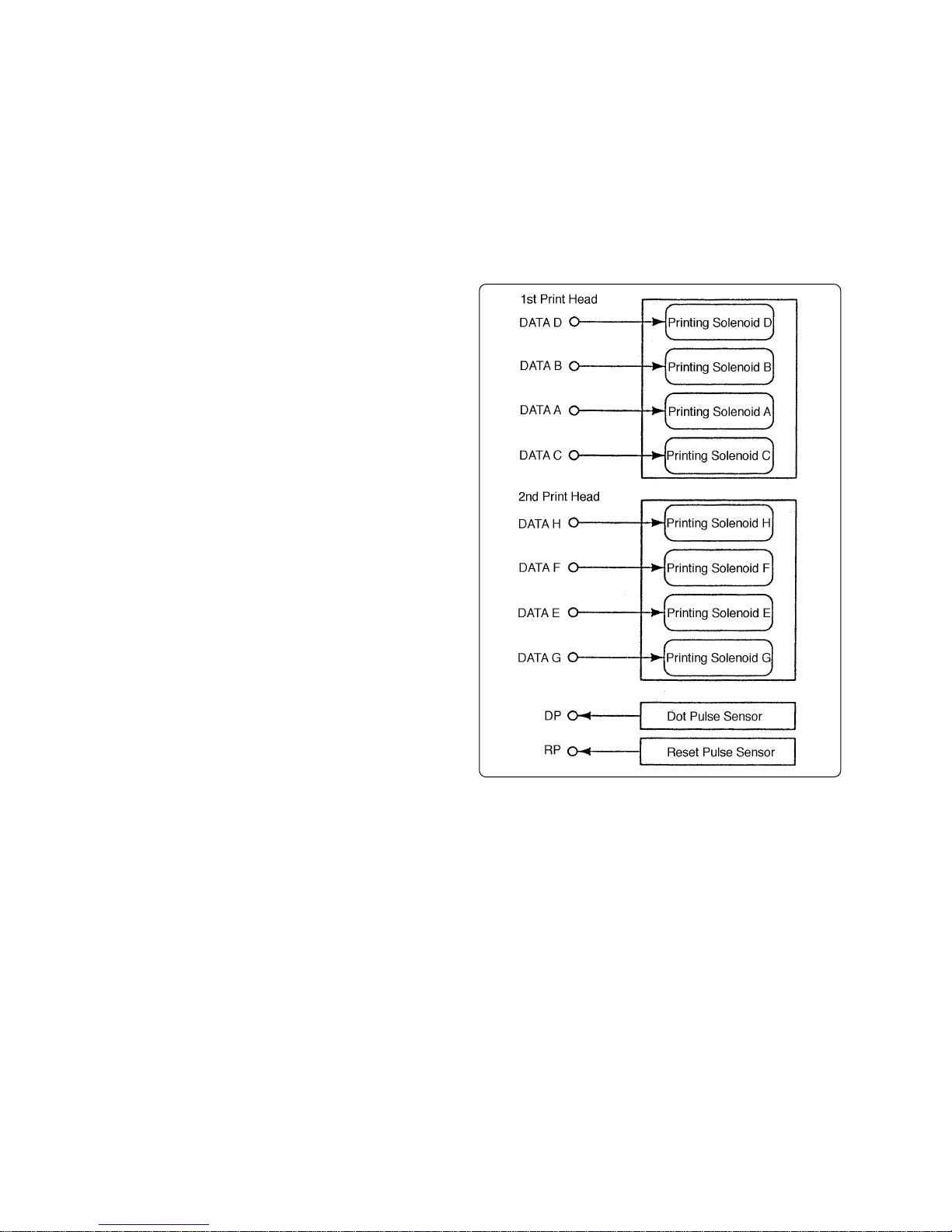

(2) Reset pulse sensor

The reset pulse sensor uses a leaf switch which turns ON/OFF according to the head assembly position.

This sensor detection signal represents the RP signal that specifies the print head home position and printing start base position.

— 4 —

Page 8

2-3-3 Print head mechanism

This printer has two print heads arranged at intervals on the left and right, so that the left half and

the right half of the register paper can be printed simultaneously as it is moved from left to right.

One movement causes the upper part of one line to be printed and the next movement causes the

lower part of the line to be printed. Therefore, two print head movements complete printing of one

line. The print heads, however, print the register paper only when they move from left to right.

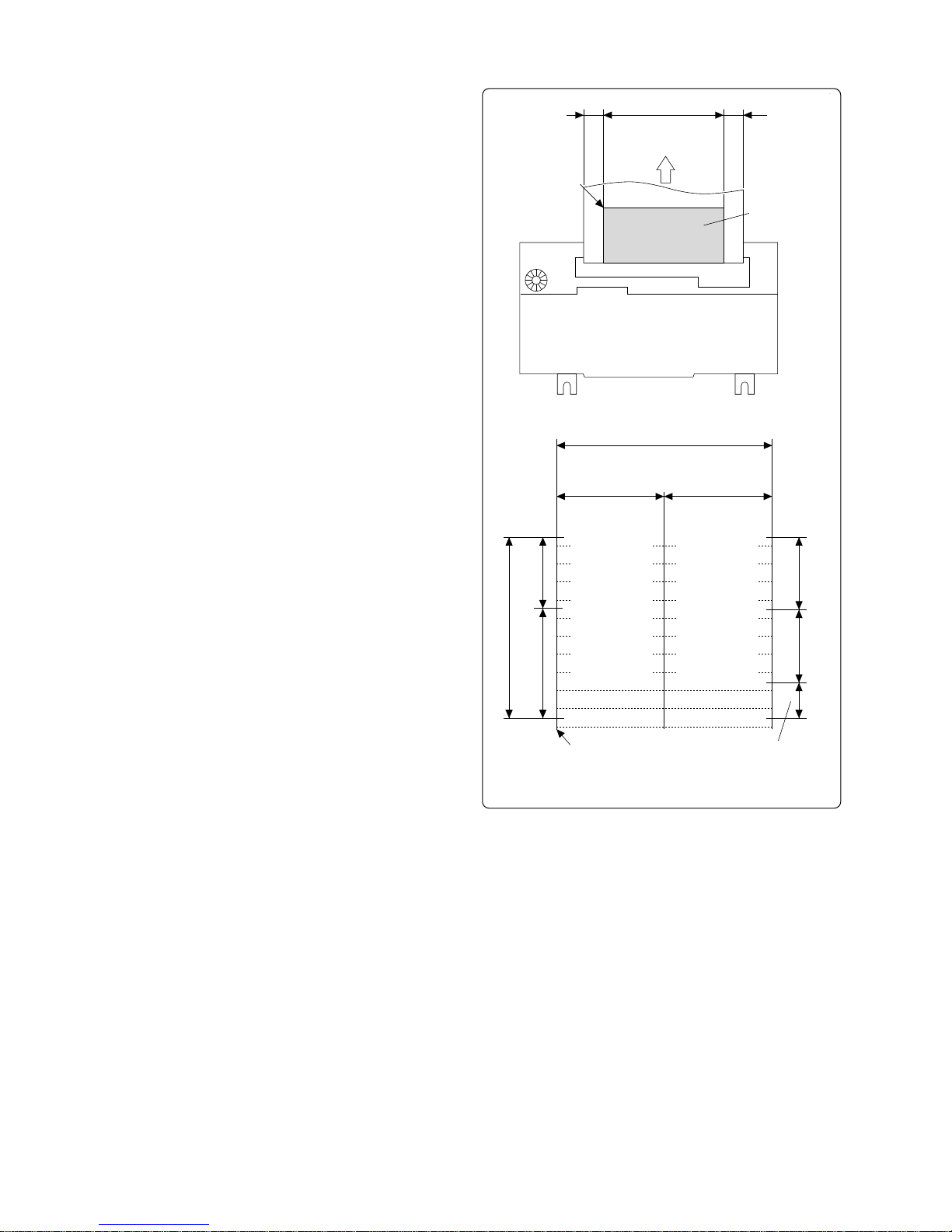

(1) Printing control

Each print head has four printing solenoids and each solenoid is turned

ON/OFF according to the printing data

and the corresponding printing pins

are activated to form character dots.

This printer, however, does not have

a serial/parallel conversion circuit.

Therefore, ON (L level)/OFF (H level)

signals are directly provided to the

eight data lines for each printing solenoid.

Printing timing is controlled by the DP

signal which is detected by the dot

pulse sensor and is treated as a clock

pulse and the RP signal which is detected by the reset pulse sensor and

is treated as a starting point.

— 5 —

Page 9

(2) Printing data and printing position

The number of printing columns and

one character dot matrix vary , depending on whether the printer is the MD910 or MD-911.

For the MD-910, the number of printing columns is 24, and each 12 columns of printing on the left and right is

performed by each print head. 4 dots/

line is produced by one print head

movement.

6 (5 + 1) horizontal dots make up one

character and the total number of horizontal dots in the printable area is 144

(12 columns × 2 × 6 dots).

For the MD-911, the number of printing columns is 40, and each 20 columns of printing on the left and right is

performed by each print head. 4 dots/

line is produced by one print head

movement. 4.5 (4 + 0.5) horizontal dots

make up one character and the total

number of horizontal dots in the printable area is 180 (20 columns × 2 × 4.5

dots).

5 mm 47.5 mm 5 mm

Home Position

12 (20) Columns

One Line

2/2 Line 1/2 Line

Direction of

Paper Feed

Printing Position

Printable Area

144 (180) Dots

1st Print Head 2nd Print Head

12 (20) Columns

72 (90) Dots

Printing Solenoid A

Printing Solenoid B

Printing Solenoid C

Printing Solenoid D

Printing Solenoid A

Printing Solenoid B

Printing Solenoid C

Printing Solenoid D

72 (90) Dots

Printing Solenoid E

Printing Solenoid F

Printing Solenoid G

Printing Solenoid H

Printing Solenoid E

Printing Solenoid F

Printing Solenoid G

Printing Solenoid H

Printable Area

4 Dots/Line 4 Dots/Line

— 6 —

2 Dots/Line: LFHome Position

Printable Area in Detail

(Values parenthesized are for MD-911)

Page 10

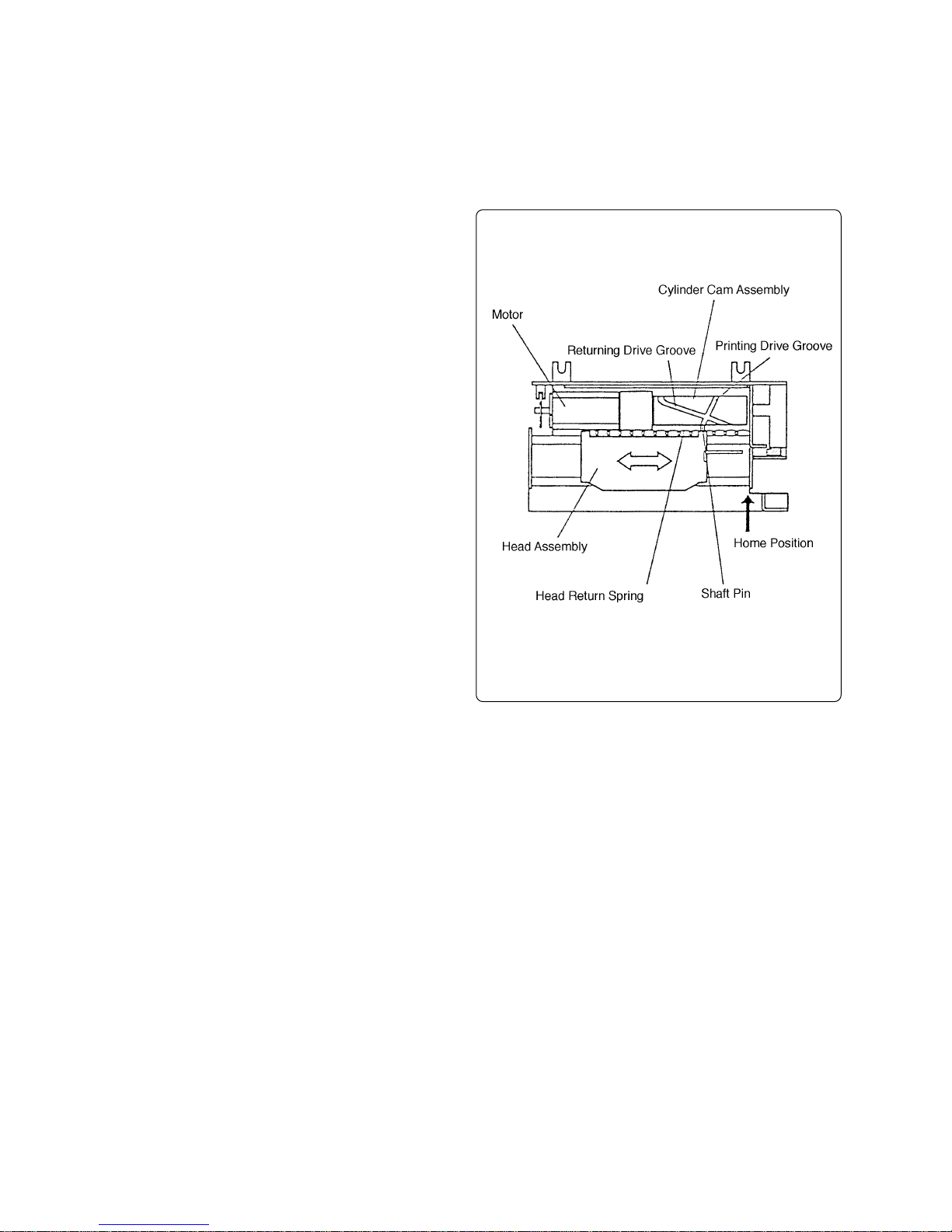

(3) Head drive mechanism

The head assembly is connected to the cylinder cam assembly via a shaft pin. The shaft pin is

inserted in a scribed groove on the outside of the cylinder cam assembly and moves along the

groove when the cylinder cam assembly is turned to drive the head assembly.

When the head assembly travels beyond the home position, the shaft pin

goes through a sharp curve in the

scribed groove, so it moves slowly.

At this time, printing is performed.

When the head assembly travels beyond the printable area, the direction

of movement is changed to the home

position because the direction of

groove is reversed and the head return spring tension is activated.

At this time, the head assembly travels at high-speed because the groove

is turned to the slow curve.

Register paper feeding is performed

when the head assembly returns.

When the head assembly travels to

the home position, it returns to the

original groove position, and the operation is repeated.

— 7 —

Page 11

2-3-4 Paper feed mechanism

Since this printer completes one line of printing by dividing it into upper and lower halves, two types

of paper feeding are provided; one is paper feeding without LF (line feed) because the lower half is

printed after the upper half.

The other is paper feeding with LF because upper half of the next line is printed after completing

one line.

(1) Paper path

The register paper is loaded from the

back of the printer and moved to the

paper feed roller and the pressure

roller along the paper pressure guide.

The register paper moved is pressed

against the paper feed roller by the

pressure roller and fed upward when

the paper feed roller turns.

The register paper then passes

through the platen and the print head

and comes out to the back again.

When the register paper passes

through the platen and the print head,

it is printed by the ink ribbon of the

ribbon cartridge on the print head.

— 8 —

Page 12

(2) Paper feeding without LF (line feed) mechanism

The PF cam gear that drives paper feeding turns one time per head assembly shuttle.

The cam inside the PF cam gear presses down the protrusion (part A) of the sector gear

assembly when the head assembly returns. The sector gear assembly has teeth on the opposite side of the protrusion which engage with the clutch gear that is concentric to the paper feed

roller .

The paper feed roller has a clutch

wheel next to the clutch gear to transmit the driving force.

Normally this clutch wheel is not in contact.

The sector gear assembly has a fulcrum at the middle, so if the protrusion

is pressed down, the teeth are raised

to turn the clutch gear. The clutch gear

then is pushed out by the PF clutch

spring and engages with the clutch

wheel to rotate the paper feed roller.

This rotation, i.e., the paper feeding,

depends on the amount of ascent of

the teeth of the sector gear assembly.

4 dots/line is ensured without LF.

When the cam inside the PF cam gear

goes past due to rotation, the protrusion of the sector gear assembly is

raised again by the sector gear spring

so that the clutch gear separates from

the clutch wheel and stops the paper

feed roller.

— 9 —

Page 13

(3) Paper feeding with LF (line feed) mechanism

In paper feeding with LF mechanism, only the protrusion pressing down mechanism is different

from that of paper feeding without LF mechanism.

Two cotter pins are set on the outside of the PF cam gear and turn together with the PF cam

gear. The cotter pins are always exerting a force to uncoil but are restrained by the return ring.

One part of the return ring is thin, so that when the cotter pin passes through this thin part while

rotating, it springs out of the return ring.

When performing paper feeding without LF, no cotter pin spring is required, so the armature

assembly is inserted in the thin part of the return ring instead. The armature assembly is linked

with the paper feed solenoid.

When performing paper feeding with

LF, the paper feed solenoid turns ON

and the armature assembly is detached from the return ring.

The PF6D cam is set on the outside

of the return ring and the driving force

of the PF cam gear is transmitted by

the cotter pin spring.

As the PF6D cam turns, the outer protrusion (part B) of the sector gear assembly is lowered and the paper feed

roller rotates in the same manner as

during paper feeding without LF

mechanism. At this time, the PF6D

cam is larger than the cam inside the

PF cam gear, so the rotation of the

paper feed roller is 6 dots/line, i.e., 2

more dots per line than with paper

feeding without the LF.

— 10 —

Page 14

2-3-5 Ribbon cartridge drive mechanism

The PF cam gear that drives paper feeding is also used to turn the ribbon cartridge.

The driving force of the PF cam gear is

transmitted to the worm where the direction of operation is changed 90 °.

The driving force converted is transmitted

from the worm to the worm gear and the

ribbon cartridge is turned by the ribbon

drive pin. Therefore, the ribbon cartridge

is always moving while printing is being

performed.

2-4 External connection terminals

External connection terminals are located within the PCB terminal assembly and their connections

are implemented by directly soldering the print pattern surface.

2-4-1 Terminal arrangement

— 11 —

Page 15

2-4-2 Terminal mechanism

Terminal No. Terminal name Remarks

1 Motor (–) Motor is ON with GND

2 Phototransistor emitter Dot pulse sensor

3 Phototransistor collector

4 LED cathode

5 LED anode

6 Printing solenoid D (–) 1st print head

7 Printing solenoid B (–) Each solenoid is ON with GND

8 Printing solenoid A (–)

9 Printing solenoid C (–)

10 Common (+) Power side of print head, motor and paper

11 Printing solenoid H (–) 2nd print head

12 Printing solenoid F (– ) Each solenoid is ON with GND

feeding solenoid

13 Printing solenoid E (–)

14 Printing solenoid G (–)

15 Paper feeding solenoid (–) Solenoid is ON with GND

16 Reset pulse sensor output Power side

17 Reset pulse sensor output GND side

2-4-3 Terminal circuit diagram

Paper Feeding Solenoid

Motor Dot Pulse Sensor 1st Printing Head 2nd Printing Head Reset Pulse Sensor

Printing

+

Solenoid

D

Printing

Solenoid

A

Printing

Solenoid

H

Printing

Solenoid

E

M

–

Printing

Solenoid

B

Printing

Solenoid

C

Printing

Solenoid

F

Printing

Solenoid

G

2345 6789 1110 161512 13 14

1

17

Note: 1. For motor polarity, terminal No. 1 should be minus.

2. For reset pulse sensor, terminal No. 17 should be GND.

— 12 —

Page 16

3 Disassembly/Reassembly

Prior to maintenance work, be sure to observe the following caution:

CAUTION

(1) When the printer is operating satisfactorily , do not unnecessarily disassemble, reas-

semble or adjust the printer. In particular, do not loosen any screws on the compo-

nents.

(2) Check that the printer is in good condition before turning on the power.

(3) Never try to print without register paper in the printer.

(4) Check that the register paper is set properly.

(5) In maintenance work, never leave any parts or screws in the printer.

(6) In disassembly and reassembly, check that any wires and cords are not damaged

and are laid out properly. Handle these wires and cords carefully.

3-1 Tools

The list of necessary tools is as follows:

1. Philips head screwdriver

2. Tweezers

3. Small radio pliers

4. Oil brush

5. Small pincers

3-2 Disassembly procedure

To perform disassembly, reverse the assembly procedure (item 3-3).

Disassemble each part gradually from the frame.

— 13 —

Page 17

3-3 Assembly procedure

The assembly procedure is described by major assembly blocks.

Part names in text are the same as those in Parts List.

3-3-1 Setting paper feed solenoid assembly

(1) Place the core in core base as-

sembly. At this time, align the pro-

trusion of the core with the hole

of the core base assembly.

(2) Insert the bobbin assembly where

the core has already been fitted

in the core base assembly. At this

time, the lead wires face outside

and there should be no gap be-

tween the bobbin assembly and

the core base assembly.

— 14 —

Page 18

(3) First apply Froil G-311S to the arma-

ture pivot of the bobbin assembly, then

install the armature spring and the ar-

mature assembly. At this time, check

the direction of armature spring.

(4) Secure the armature assembly with

the E-ring and attach the armature

spring to the hole of the armature as-

sembly.

Note:When installing the E-ring and

armature spring, use small radio

pliers or tweezers.

3-3-2 Setting the head assembly

(1) Two tips of FPC are extended from the

head assembly. Bend the two tips at

right angles from the notch line.

— 15 —

Page 19

(2) Place the ribbon mask in the head as-

sembly. At this time, align the holes of

the ribbon mask with the protrusions

of the head assembly.

Note:The ribbon mask is very thin, so

take care not to bend it when installing it.

(3) Install the head return spring in the

head assembly.

3-3-3 Setting the paper feed assembly

(1) Apply Froil G-311S to the two parts of

the paper feed roller shaft where pa-

per feed bracket touches.

(2) Apply Epnoc grease AP to the brake

groove of the paper feed roller.

Note:The paper feed roller must be

free from sticky oil.

(3) Place the paper feed roller in the pa-

per feed bracket. At this time, the

longer shaft should be inserted first.

— 16 —

Page 20

(4) Install the PF bracket bushing in the

bushing groove of the paper feed

bracket and secure the paper feed

roller.

(5) Install the brake spring in the brake

groove of the paper feed roller.

(6) Attach the platen to the paper feed

bracket with two platen spacers and

two screws (M2 × 2.5).

(7) Insert the clutch wheel in the paper

feed roller shaft coming out of the pa-

per feed bracket.

Note:When inserting, push the clutch

wheel until the claws of the

clutch wheel are engaged with

the shaft groove of the paper

feed roller.

(8) Insert the clutch gear in the paper feed

roller shaft.

(9) Apply Froil G-311S to the gear section

of the clutch gear.

— 17 —

Page 21

3-3-4 Setting the main body assembly

(1) Apply Froil G-311S to the gear of the

gear box assembly, the shaft of the

cylinder cam assembly and the teeth,

the opposite of the shaft.

(2) Combine the cylinder cam assembly

with the gear box assembly and install

the cam shaft bushing in the shaft of

the cylinder cam assembly. Then put

block assembled in frame assembly.

Note:

1) When assembling, align the protrusion of the gear box assembly with

the hole on the bend of the frame

assembly.

2) After assembling, align the protrusion, a whirl-stop of the cam shaft

bushing with the notched hole on

the right of the frame assembly.

(3) Bend the notched section on the left

of the frame assembly to secure the

motor of the gear box assembly.

Note:

1) After securing this, check that the

cylinder cam assembly turns

smoothly. If not, reinstall it.

2) Handle the notched section on the

left of the frame assembly carefully

because it may be damaged if it is

bent and turned often.

(4) Insert the paper feed gear in the shaft

of the cylinder cam assembly.

Note:When inserting the gear, push

the claws of the paper feed gear

until they fully engage with the

shaft grooves.

— 18 —

Page 22

(5) Apply Froil G-311S to the pivot of the

PF cam and the cam of the PF cam

gear.

(6) The cam faces inside. Insert the PF

cam gear in the pivot of the PF cam.

Note:

1) When inserting the gear, turn the

cylinder cam assembly beforehand

so that the claws of the paper feed

gear are horizontal. At this time, the

squared notch of the cylinder cam

assembly should face the back.

2) Four-sectored protruding parts of

the PF cam gear should face the

outside.

Engage the center of the protruding part that is horizontal when the

inside cam faces down with the paper feed gear.

(7) Apply Froil G-311S to the two cotter

pin springs and then insert them in

cotter pins.

(8) Put the two cotter pins in the PF cam

gear.

— 19 —

Page 23

(9) Apply Froil G-311S to the upper sur-

face of the PF cam gear.

(10)Install the return ring and the PF6D

cam in the PF cam gear and secure it

with the E-ring.

(11) Apply Froil G-311S to the outside and

surfaces of the PF6D cam.

(12)Insert the pressure roller in the pres-

sure roller shaft and set it in the frame

assembly .

Note:The pressure roller must be set

in the notched hole of the frame

assembly .

— 20 —

Page 24

(13)Mount the paper pressure guide on the

back of the frame assembly.

(14)Set the PF clutch spring and the clutch

spacer in the clutch gear of the paper

feed and then put it in the frame assembly from over the paper pressure

guide.

Note:

1) The clutch spacer must be set from

the right of the frame assembly to

the inside.

Therefore, set it while the PF clutch

spring is shortened.

2) When assembling, align the protrusions on the bottom of the paper

feed bracket with the holes of the

frame assembly.

(15)Secure both the paper feed and the

paper pressure guide to the frame assembly with two screws (M2 × 2.5).

(16)Apply Froil G-311S to the pivot of the

ribbon drive and the teeth of the sector gear assembly.

(17)Insert the sector gear assembly in the

pivot of the ribbon drive.

Note: When inserting the assembly,

engage the bottom teeth of the

sector gear assembly with the

final gear of the clutch gear.

— 21 —

Page 25

(18)Apply Froil G-311S to the bushing of

the sector gear assembly and then insert the worm and secure it with the

E-ring.

(19)Set the sector gear spring between the

sector gear assembly and the frame

assembly.

(20)Apply Froil G-311S to the fitting hole

of the ribbon drive and then insert the

ribbon drive pin from under the bottom of the frame assembly.

(21)Insert the worm gear in the ribbon drive

pin.

— 22 —

Page 26

(22)Apply Froil G-311S to the upper sur-

face of the worm gear and then install

the ribbon drive latch and the latch

spacer and secure them with the push

nut.

Note:When installing these, check the

direction of ribbon drive latch.

(23)Secure the solenoid assembly to the

right of the frame assembly with a

single screw.

(24)Install the reset pulse sensor assem-

bly to the right of the frame assembly

and secure it by bending the notched

section of the right of the frame assembly .

Note:Handle the notched section of

the right of the frame assembly

carefully because it may be damaged if it is bent or turned often.

(25)Secure the PCB terminal assembly to

the front of the frame assembly with

two screws (M2 × 2.5).

— 23 —

Page 27

(26)Apply Froil G-311S to the tip of the re-

set arm and the two shaft bushings of

the head assembly.

(27)Set the shaft pin in the head assem-

bly.

(28)Hang one end of the head return

spring, which is set in the head assembly, on the notched section of the right

of the head assembly.

(29)Insert the tip of the shaft pin, which is

set in the head assembly, in the groove

of the cylinder cam assembly.

Note:Before insertion, the squared

notch of the cylinder cam assembly should face the back and

the head assembly should touch

the right of the frame assembly.

— 24 —

Page 28

(30) Insert the two carriage guide shafts

from the left of the frame assembly and

pass them through the head assembly and secure them with the E-rings.

(31) Apply Froil G-31 1S to the groove of the

cylinder cam assembly.

(32) Solder the following terminals on the

PCB terminal assembly:

FPC terminals (ten) to the head assembly, terminals (two) of the paper

feed solenoid assembly and terminals

(two) of the reset pulse sensor assembly .

Note:When soldering the terminals of

the reset pulse sensor assembly, two terminal leaves are

pressed back but the leaf tips

should not protrude from the

case.

(33) Pass the curl of the grounding spring

through the hole in the near side right

of the frame and then hang the V -section at the end of the opposite side of

the frame on the groove of the paper

feed roller shaft.

— 25 —

Page 29

4 Parts list

N Item Code No. Parts Name Specification Q R

1-1 1904 7581 Frame NC44701-07 1 X

2-1 1904 7582 Gear box sub ass'y NC10701-00 1 A

2-10, 5-6 1906 2087 E-Ring,2 E60320-00 3 X

2-2 1904 7583 Cylinder cam NC19701-00 1 X

2-3 1904 7584 Bushing for cam shaft NC21201-01 1 X

2-4 1904 7585 Paper feeding gear NC20201-02 1 B

2-5 1904 7586 Gear for paper feed cam NC20202-03 1 B

2-6 1904 7587 Spring for cutter pin NC23602-01 2 X

2-7 1904 7588 Pin for cotter(PLS) NC29202-02 2 X

2-8 1904 7589 Ring for return NC29203-01 1 X

2-9 1904 7590 Cam NC29201-03 1 X

3-1 1904 7591 Sector gear NC20701-01 1 X

3-2 1904 7592 Worm NC30201-01 1 X

3-3 1904 7593 E-Ring, 1.2 E60312-00 1 X

3-4 1904 7594 Spring for sector gear NC23603-03 1 X

3-5 1904 7595 Pin for ribbon drive NC32201-01 1 X

3-6 1904 7596 Gear for worm NC30202-00 1 B

3-7 1904 7597 Latch for ribbon drive NC33101-01 1 X

3-8 1904 7598 Spacer for latch NC39101-01 1 X

3-9 1904 7599 Nut E40520-00 1 X

4-1 1904 7600 PF solenoid NC25704-00 1 B

4-2 1904 7601 Core base NC25702-02 1 X

4-3 1904 7602 Core for PF solenoid NC25102-01 1 X

4-4 1904 7603 Bobbin NC25701-00 1 X

4-5 1904 7604 Spring for armature NC25601-02 1 X

4-6 1904 7605 Armature NC25703-00 1 X

4-7 1904 7593 E-Ring, 1.2 E60312-00 1 X

4-8, 9-2 1904 7607 Screw M2x2.5 E01420-025 2 X

5-1 1904 7608 Head NC09701-05 1 A

5-2 1904 7609 Ribbon mask NC14102-05 1 A

5-3 1904 7610 Spring for head return NC13601-01 1 B

5-4 1904 7611 Pin for shaft NC12001-02 1 X

5-5 1904 7612 Shaft for carrige guide NC02001-03 2 X

6-1 1904 7613 Shaft for pressure roller NC22003-01 1 X

6-10 1904 7614 Spring for brake NC23102-02 1 X

6-11 1904 7615 Damper for platen NC04102-03 1 X

6-2 1904 7616 Pressure roller NC22201-03 1 B

6-3 1904 7617 Guide for paper pressure NC23101-02 1 C

6-4 1904 7618 Bracket for paper feed NC24201-06 1 X

6-5 1904 7619 Paper feed roller NC22501-09 1 C

6-6 1904 7620 Platen NC04101-02 1 C

6-7 1904 7621 Spacer for platen (0.10) NC04103-00 2 X

6-7 1904 7622 Spacer for platen (0.05) NC04103-10 2 X

6-8 1904 7607 Screw M2x2.5 E01420-025 2 X

6-9 1904 7624 Bushing for PF bracket NC21101-05 1 X

7-1 1904 7625 Wheel for clutch NC20204-03 1 B

7-2 1904 7626 Gear for clutch NC20203-04 1 B

7-3 1904 7627 Spring for PF clutch NC23601-02 1 B

7-4 1904 7628 Spacer for clutch NC29102-00 1 X

7-5, 11-7 1904 7607 Screw M2x2.5 E01420-025 2 X

8-1 1904 7630 RP switch NC68701-00 1 A

9-1 1904 7631 PCB terminal NC66702-00 1 C

10-1 1904 7632 Cover NC44102-01 1 C

11-1 1904 7633 Vertical manual knob NC29701-00 1 C

11-2 1904 7634 Bracket (V) NC29702-01 1 X

— 26 —

Page 30

N Item Code No. Parts Name Specification Q R

11-3 1904 7635 Knob NC20208-01 1 X

11-4 1904 7636 Gear for PF drive NC20209-01 1 B

11-5 1904 7637 Gear for idler NC20210-00 1 B

11-6 1906 2087 E-Ring, 2 E60320-00 1 X

12-1 1904 7638 Gear A for knob NC20205-01 1 B

12-2 1904 7639 Gear B for knob NC20206-03 1 B

12-3 1904 7640 Knob NC20901-05 1 B

12-4 1904 7641 Screw M1.4x3.5 E12714-035 1 X

— 27 —

Page 31

5 Exploded view

4-4

9-2

9-1

5-5

2-1

2-2

3-9

3-7

5-4

5-4

5-1

3-8

5-2

2-3

3-6

2-4

1-1

8-1

4-2

4-1

4-3

4-6

4-5

4-8

2-5

3-5

3-4

4-7

2-6

2-7

3-2

3-1

2-9

3-3

11-2

2-6

11-5

2-8

2-7

11-3

2-10

11-1

11-6

11-4

11-7

5-6

5-6

10-1

5-5

5-3

6-2

6-6

6-5

6-7

6-9

12-4

6-4

6-7

6-10

6-1

7-5

12-2

6-11

12-3

7-1

7-2

6-8

7-4

7-3

12-1

6-3

— 28 —

Page 32

Page 33

MA0201571A

Loading...

Loading...