Page 1

SERVICE MANUAL

ELECTRONIC CASH REGISTER

QT-6600

(EX-830)

NOV. 2008

QT-6600

Page 2

CONTENTS

QT-6600 PAGE

1. SPECIFICATIONS ...................................................................................1

2. MACHINE INITIALIZATION .....................................................................5

3. DISASSEMBLY .....................................................................................10

4. ASSEMBLY ...........................................................................................24

5. OPTION INSTALLATION ......................................................................36

6. INLINE / ONLINE ...................................................................................38

7. DIAGNOSTIC OPERATION ..................................................................40

8. CIRCUIT EXPLANATION ......................................................................81

9. ERROR CODE LIST ..............................................................................84

10. PCB LAYOUT ........................................................................................95

11. CIRCUIT DIAGRAM ..............................................................................99

12. PARTS LIST ........................................................................................119

To prevent malfunctions caused by the weak batteries, charge the memory

protection batteries for over 12-hours before installation or after a long-time

vacation (over 30 days).

Before installation, initialize the terminal and leave it turn on over 12-hours.

•

After a long-time vacation, initialize the terminal and restore the program

•

data if the terminal is in malfunction, and leave it turn on over 12-hours.

Over 48-hours charging makes the batteries fully charged.

•

Page 3

1. SPECIFICATIONS

1-1. Electrical Specifications

• Power consumption <AC input current at Adaptor>

100V 120V 220V 230V 240V

In operation Max. 1.5A 1.5A 1.5A 1.5A

Display off Max. 0.25A 0.25A 0.25A 0.25A

<DC input current at QT-6600>

In operation Max. 1.3A 1.3A 1.3A 1.3A

Display off Max. 0.5A 0.5A 0.5A 0.5A

• Memory protection Back-up battery

Battery life

Recharge time

• Clock & Calendar Accuracy

Auto calendar

• Clock protection Back-up battery

Battery

Recharge time

1-2. Environmental specifications

• Operating temperature 0 °C ~ 40 °C

• Operating humidity 20 % ~ 85 %

• Storage temperature -20 °C ~ 65 °C

• Storage humidity 10 % ~ 85 %

1-3. Main LSI specifications

• CPU Name

Number of control bit

NiMH (nickel-metal-hydride)

HHR-21HL3G1B (USA only)

HHR-21HL3G1C (Except USA)

Replace the battery every 1 year.

6 hours (full charge)

Within ± 40 sec. Per month (25 °C)

Effective until 2099 A.D.

Manganese dioxide lithium

CR2032/1HF1

Replace the battery every 1 year.

R5S77631AY266BGV

32 bits

• I/O controller Name

• Gate array Name UPD65945GJP16-JEUA

• DDR SDRAM Name

SDRAM Name

• Flash ROM (Back up) Name

• Flash ROM (Program) Name

• Display controller Name MB86276PB-G-ZE1

• Ethernet controller Name LAN9115-MT (10/100BASE)

Number of control bit

Capacity

Capacity

Capacity

Capacity

— 1 —

UPD70F3728GC-8BT-A

16 bits

HYB25DC256163CE-5

256 Mbits

MT48LC4M16A2P-75:G

64 Mbits

S29GL256P90TFCR20

256 Mbits

S29GL256P90TFCR2A*

256 Mbits

Page 4

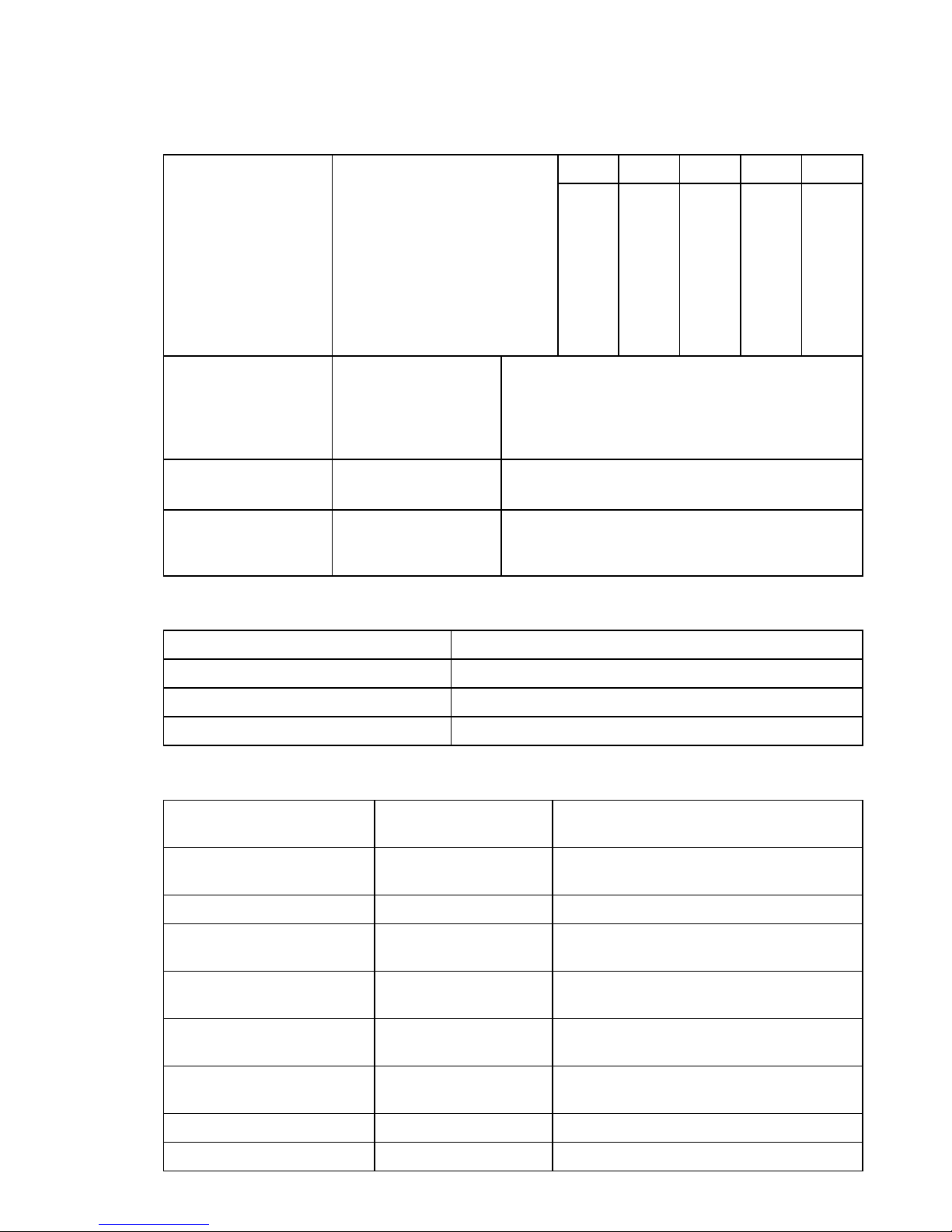

1-4. Devices specifications

DISPLAY

SCANNER

PC/MODEM

COM3

COM6

COM2

COM5

COM1

COM4

SPK

PS/2

KEYBOARD

MIC

LAN

Brightness

COM3 COM6

COM2

COM5

COM1 COM4

Inline (10/100Base-T)

PS/2 Keyboard

AC Adaptor

Drawer 2

Drawer 1

Ext. microphone

Ext. speaker

Bottom side of the terminal

• LCD Display Name

Screen size

Resolution

Interface

Display color

Pixel pitch

Luminance

Contrast ratio

Power supply voltage

Back light

• Touch Panel Name

Size

NL10276BC30-32D

15.0 inch (38cm diagonal)

1024(H) x 768(V) pixels

LVDS (RGB 8 bits each)

16.77 M colors

0.297(H) x 0.297(V) mm

250 cd/m

2

500:1

3.3 V

Top and bottom, 1 CCFL each

N010-0527-T841

15 inch

• Panel brightness control 1 x VR controller

• Power supply External adaptor "SO1330A"

• Cleck key Magnetic ibutton prove "94-J-04"

1-5. I/O Ports

The following optional peripherals can be used by plugging them into the appropriate port.

RS-232C COM 1 port For MODEM, PC direct connection or Order man

RS-232C COM 2 port For Hand held scanner, Slip printer or Scale

RS-232C COM 3 port For Remote customer display or Scale

RS-232C COM 4 port For Remote printer, Slip printer or Scale

RS-232C COM 5 port For Remote printer or Scale

RS-232C COM 6 port For Remote printer or Scale

Inline port. Ethernet

Drawer port x 2 Drawer

CF card slot

(in the card slot cover)

PS-2 keyboard port PS-2 keyboard (Microsoft Wired Keyboard 500)

CF card

— 2 —

Page 5

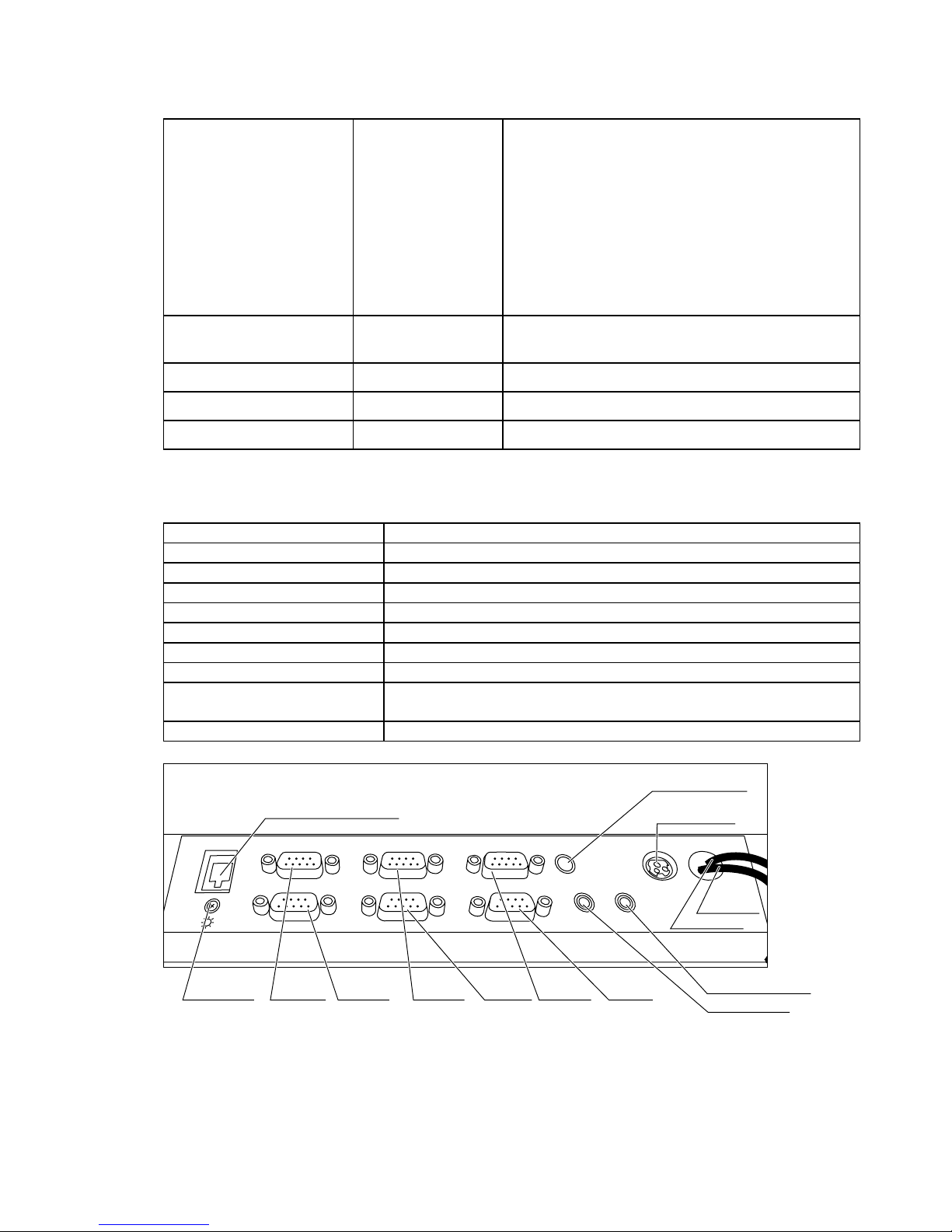

1-6. Option List

CASIO sales options

DEVICE NAME MODEL NOTE

• Magnet i-Button QT-6011DLS

• Display set for customer QT-6060D Connect to Com 3

• Display cable for customer

(for mounting to the base)

• Display 5-meter cable for customer QT-6062CB

• Slip printer SP-1300 Connect to Com 2

• Slip printer cable PRT-CB-8C Length 1.5m

• Remote printer UP-400 Connect to Com 4 ~ 6

• Remote printer UP-360BB Connect to Com 4 ~ 6

• Printer cable PRT-CB-8A Length 3m

• Printer cable PRT-CB-8B Length 5m

• MCR QT-6046MCR

• Drawer extension cable MDL-11

• PC cable PRL-CB-2 Com1 port only

Local purchase options

DEVICE NAME MAKER MODEL NOTE

• Remote printer EPSON TM-T88 IV (Mark 4) Connect to Com 4 ~ 6

• Remote printer EPSON TM-U220 Connect to Com 4 ~ 6

• Remote printer EPSON TM-U230 Connect to Com 4 ~ 6

• Remote printer EPSON TM-J7100 Connect to Com 4 ~ 6

• Remote printer EPSON TM-T88 lll Connect to Com 4 ~ 6

• Printer AC adaptor EPSON PS-180

• Slip printer/AC adaptor Citizen AD31-U or E

• Power cord for power unit EPSON AC-170

• Laser scanner PSC PSC QuickScan6500 Connect to Com 2

• Laser scanner Metrologic Metrologic MS9544 Voyager Connect to Com 2

• Fixation scanner Metrologic Metrologic MS7120 Orbit Connect to Com 2

• Scanner Scale PSC PSC Megellan 8100 Connect to Com 2

• Modem U.S.Robotics 56k V.92 (RS232C) Connect to Com 1

• Modem D-Link DFM-560EL (RS232C) Connect to Com 1

• Orderman Orderman Orderman Don/Max2/

• External speaker ELECOM MS-76CH

• External microphone ELECOM MS-STM55

• Conversion plug OHM

• CF Memory card Sandisk 1GB (Ultra II),

• PS2 keyboard Microsoft Microsoft Wired Keyboard 500

• HUB NETGEAR FS-108

• HUB NETGEAR GS-108

• Ketchen alarm HERALD Kitchen Alarm System

• Video surveillance VHC2-VIDQT6

QT-6061CB

U: 100V / E: 200V

(For SP-1300)

Access Point

AP-2633

ELECTRIC

2/4/8GB (Extreme III)

— 3 —

Page 6

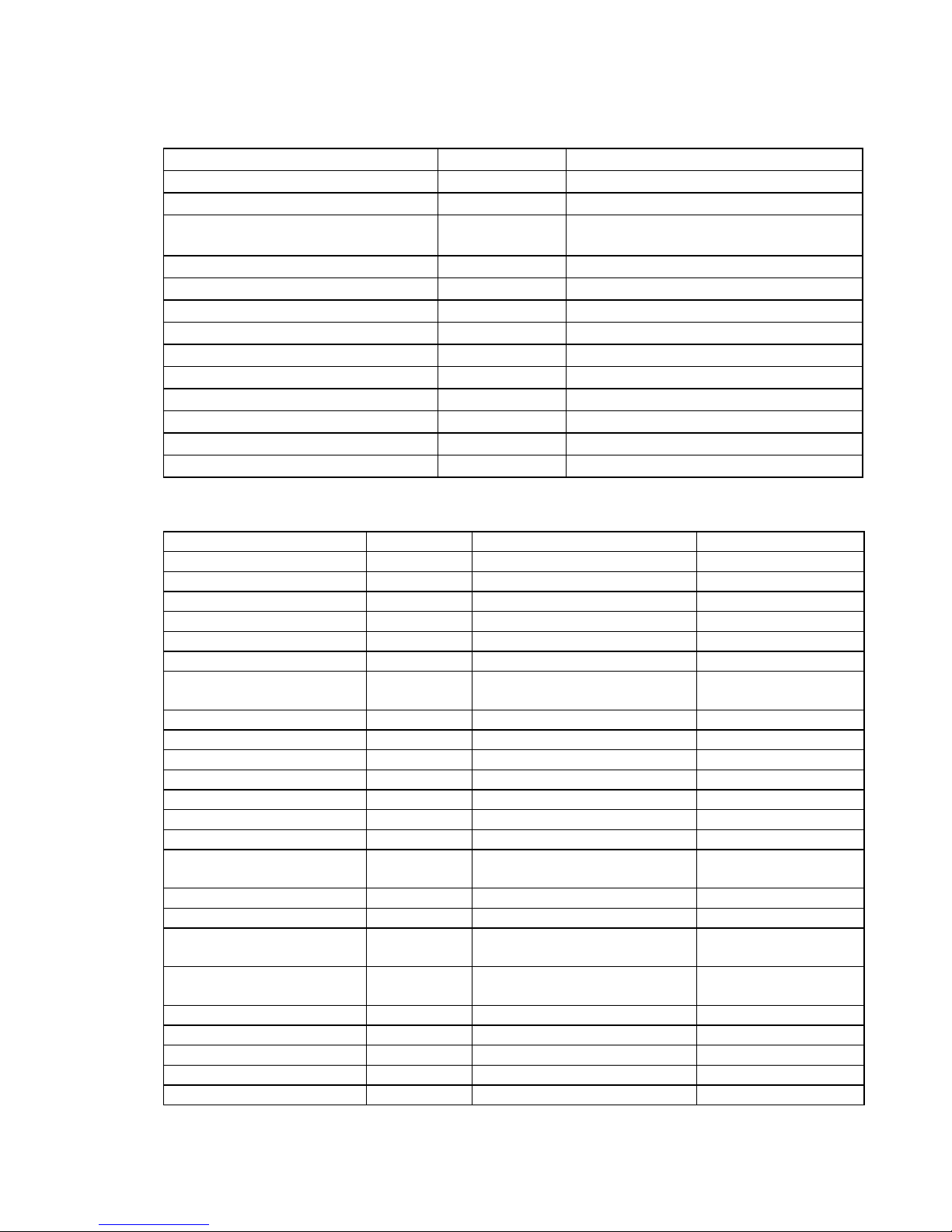

1-7. Drawer

Type Drawer Name Specification USA/Canada Other Countries

M DL-2808 D-24BC-B84M-4 X

M DL-2809 D-24BC-B84-SM-4 X

M DL-2434 D-24BC-B55SM-4 X

M DL-2810 D-24BC-A84SM-4 X

L DL-3622 D-11BH-B65SS-4 X

L DL-3623 D-11BH-B65-4 X

1-8. Duration of Life

TFT LCD (Main) 30,000 hours

STN LCD (Rear) 20,000 hours

Touch Panel (number of touch times) one million times

Battery 1 year

AC adaptor 5 year

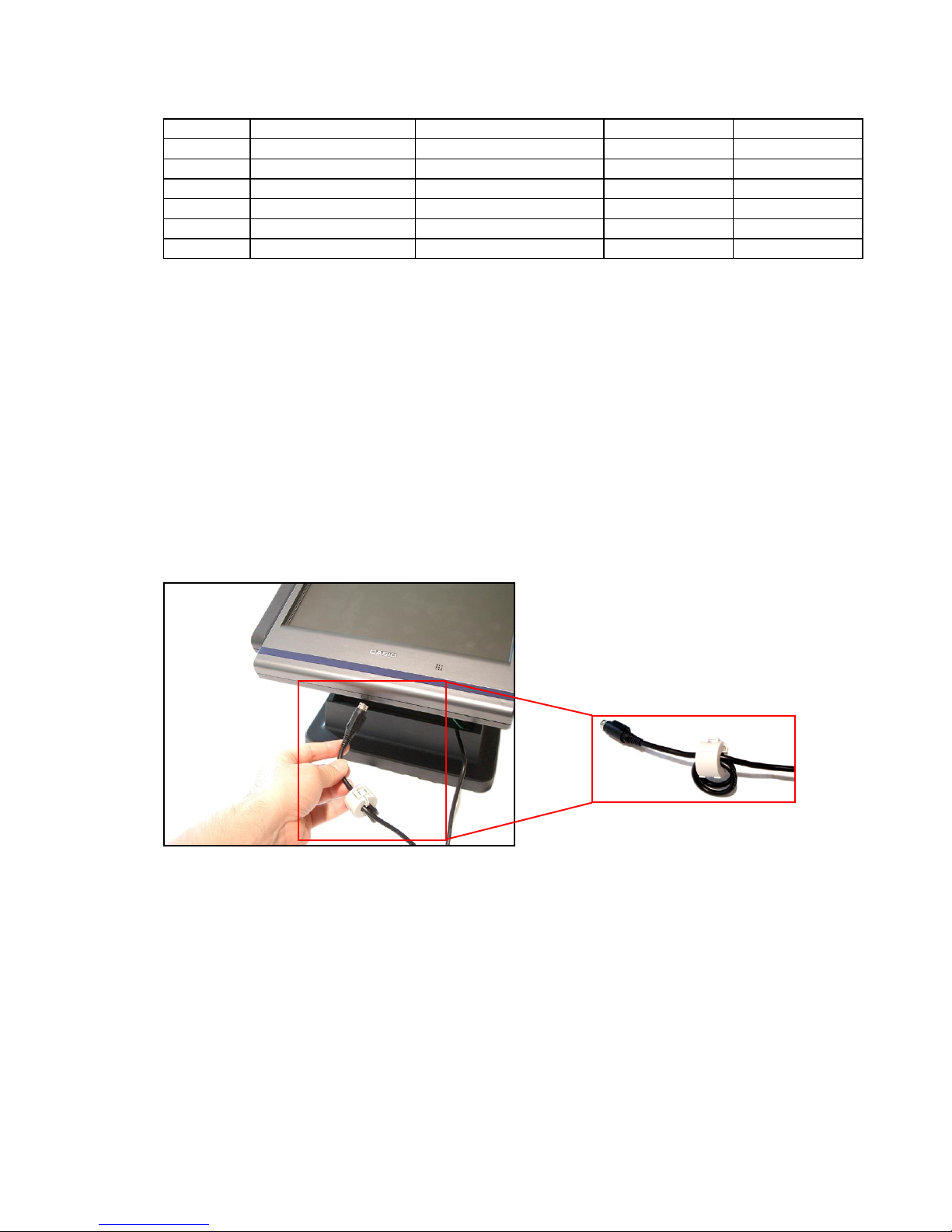

Installing Precautions

■

When installing QT-6600, attach the ferrite core to the QT-6600 side. Wind the

AC adaptor cable around the ferrite core two times.

The ferrite core is packed with QT-6600.

RISK OF EXPLOSION IF BATTERY IS REPLACED

DISPOSE OF USED BATTERIES ACCORDING

CAUTION

BY AN INCORRECT TYPE.

TO THE INSTRUCTIONS

— 4 —

Page 7

Copyright(C) 2008

CASIO COMPUTER CO.,LTD.

All rights reserved.

ROM VER. xxxxxx xxxx

CREATE xxxx-xx-xx xx:xx

QT-6600 x.xx

APL VER. xxxxxx xxxx

Version

INIT

C

7 8 9

4 5 6

1 2 3

0

OK

2. MACHINE INITIALIZATION

Init Sw

ID & IP ADDRESS

Terminal ID

ENTER ID

IP ADDRESS

AUTO

FTP Server

OK?

———

Terminal ID: 0,1 ~ 32

———

Press <YES> to continue.

Yes

Yes

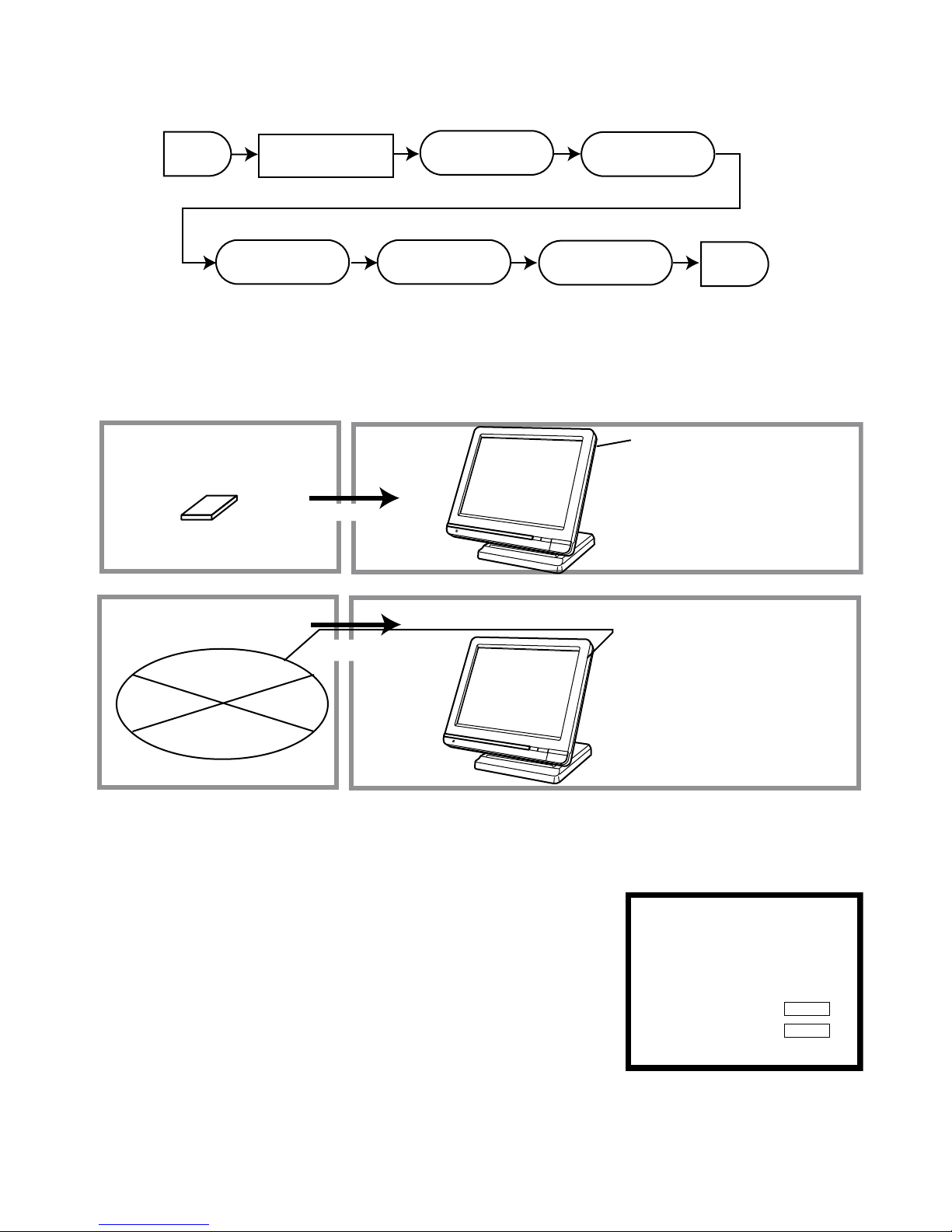

2-1. How to initialize the terminal

Preparation:

1. All peripheral devices and terminals of this cluster should be turned off.

2. Connect all of the peripheral devices (such as printer, display etc.) to terminal.

3. Connect all terminals by inline.

Operation:

4. Turn on all peripheral devices of a terminal.

5. Turn on this terminal with pressing the initialize switch and release after beep sound.

6. After releasing the key, enter “20000” (U.S.), “10000” (other area: English), “40000” (other area:

German), “50000” (other area: French), “60000” (other area: Spanish) and press the <OK> key.

Enter terminal ID and IP address

— 5 —

Page 8

• Case 1: If your system has no LAN device = “0”

OK?

———

Press <YES> to continue.

Yes

——— Press <YES> to continue.

———

Select <YES>, if you want to use this terminal as an FTP server.

———

Select “CLIENT”, if you want to use this terminal as a DHCP client.

——— Enter IP address if you want to change.

IP AD D R E S S

FTP S e r v e r

DHCP SE R V E R

192. 1 6 8 . 0 .

1

MANUA L

OK?

Yes

Yes

——— Press <YES> to continue.

———

Select “MANUAL”, if you want to enter IP address manually.

(IP address setting line will appear on the screen.)

IP AD D R E S S AUTO

OK? Y e s

——— Enter cluster No. “1” ~ “ 9” , if using check cluster system.

——— Select the appropriate printer.

——— Select the appropriate printer.

——— Press <YES> to continue.

———

Master / Backup master / Satellite / Self master

———

Enter time if it is wrong.

———

Within 12 characters

——— Enter date if it is wrong.

OK?

Slip P r i n t e r

No

R/J/O r d e r P r i n t e r 3

No

R/J/O r d e r P r i n t e r 2

No

R/J/O r d e r P r i n t e r 1

No

Check C l u s t e r I D

0

Check S y s t e m

Maste r

ID C h a r a c t e r

MC #0 1

Time

12:34 0 0

Date

01-10 - 1 0

YES

• Case 2: Terminal ID = “1”

* The IP address of each terminal should be the unique number from 192.168. 0. 1 to

192.168.255.255.

• Case 3: Terminal ID = “2” ~ “32”

Declare terminal configuration

— 6 —

Page 9

Program restoration

INIT 1 0 - 1 0 - 0 1 12:34 0 0 00 01

AUTO PG

M

1.No R e s t o r e / Receive

2.PGM R e s t o r e ( CF Card)

3.PGM R e c e i v e ( Inline)

———

Select, if no need to download any data.

———

Select to download a program data from CF card.

———

Select to download a program data from other terminal.

INIT 1 0 - 1 0 - 0 1 12:34 0 0 0 0 0 1

Receive Data

PGM Receive from

OK

?

All PG

M

MC #05

YES

——— All Data (including totalizer) / All PGM (program only)

——— Select the machine to send the data.

• Restore from CF card.

Insert the CF card into the slot and select the appropriate file and press the <YES> key.

• Program receive from other terminal.

2-2. How to initialize the terminal (add / replace one terminal)

Preparation:

1. All peripheral devices and terminals of this cluster should be turned off.

2. Connect all of the peripheral devices (such as printer, display etc.) to this terminal.

3. Connect the added / replaced terminal to inline.

Operation:

Follow the steps shown on the page 5 to 7.

— 7 —

Page 10

2-3. How to flag clear the terminal (or INIT2)

FC

OK

Copyright(C) 2008

CASIO COMPUTER CO.,LTD.

All rights reserved.

ROM VER. xxxxxx xxxx

CREATE xxxx-xx-xx xx:xx

QT-6600 x.xx

APL VER. xxxxxx xxxx

Version

Start

Continue

to INIT

ROM check

Store the receiving

data to Flash

Preparation:

1. All peripheral devices and this terminal should be turned off.

2. Check the connection of all peripheral devices (such as printer, display etc.) of this terminal.

3. Check the connection of this terminal to inline.

Operation:

4. Turn on all peripheral devices of this terminal.

5. Turn on this terminal with pressing the <DISP ON/OFF> key.

6. Press <OK> key.

2-4. IPL (Initial Program Loading)

IPL should be made before initializing when the application software has been modified.

2-4-1. IPL

IPL via CF card or COM1 port

Initial program loading process is as follows: IPL code = 44449999

7. Select “1. Flag Clear” and press <YES> key to flag clear.

or select “2.Init2” and press <YES> key and enter “8888888888” and <YES> key to Init 2.

— 8 —

Page 11

IPL via LAN port

Start

END

Restore

all data

IPL from

CF card

Store IPL data

to CF card

Backup all data

to CF card

Clear IPL data

in the CF card

Insert more than

128MB CF card

CF card

IPL source

IPL target

IPL Data

CF card slot is located

on the leftside of the terminal.

IPL source

LAN port

defined as FTP server

IPL target

IPL Data

xxxxxxx

xxxxxxx

xxxxxxx

xxxxxxx

xxxxxxx

CANCEL

START

2-4-2. System configuration before IPL operation

Connect source terminal (cash register terminal) and target terminals or insert the IPL CF card to the

terminal.

2-4-3. IPL operation

Insert the CF card into the slot before this step.

1. Press the <START> key to proceed, in case of downloading

via inline, automatic ID definition is made by this timing. So

press the <YES> key terminal by terminal.

2. After finishing IPL, machine initialization is necessary.

— 9 —

Page 12

3. DISASSEMBLY

NOTE:

* Please make a back-up copy of the clients’ data before disassembling.

* When the power is turned off, the internal battery enables the hibernate function.

* There are several kinds of screws. Be sure to use the

correct type of screws when reassembling.

It is advisable to sort the screws as shown in the right

after removing them.

* When assembling/disassembling the Stand, be careful not to get the fingers caught.

* Use caution when handling the LCD unit and the inverter for the backlight as there is the risk of

high-voltage electrical shock.

* Internal battery:

• Do not disassemble or short-circuit the battery.

• Do not place the battery near a heat source or expose it to direct flame or heat.

• Place the battery with its (+) and (-) terminals in the correct orientation.

• Do not recharge the battery. (Primary battery)

* When assembling, be sure that it is free of dust and other foreign matters.

Pay special attention when replacing the touch panel and LCD

* Do not tangle the cables in principle.

— 10 —

Page 13

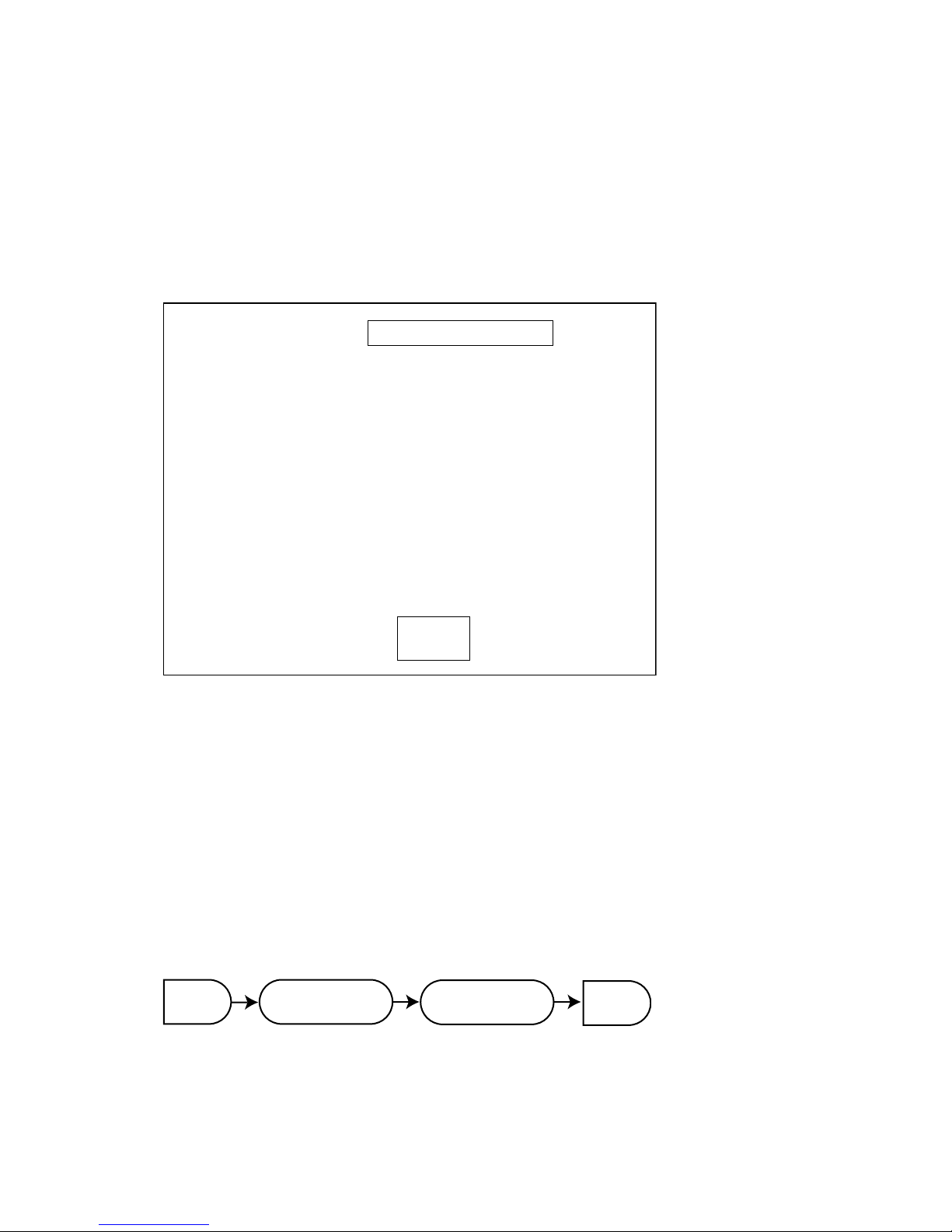

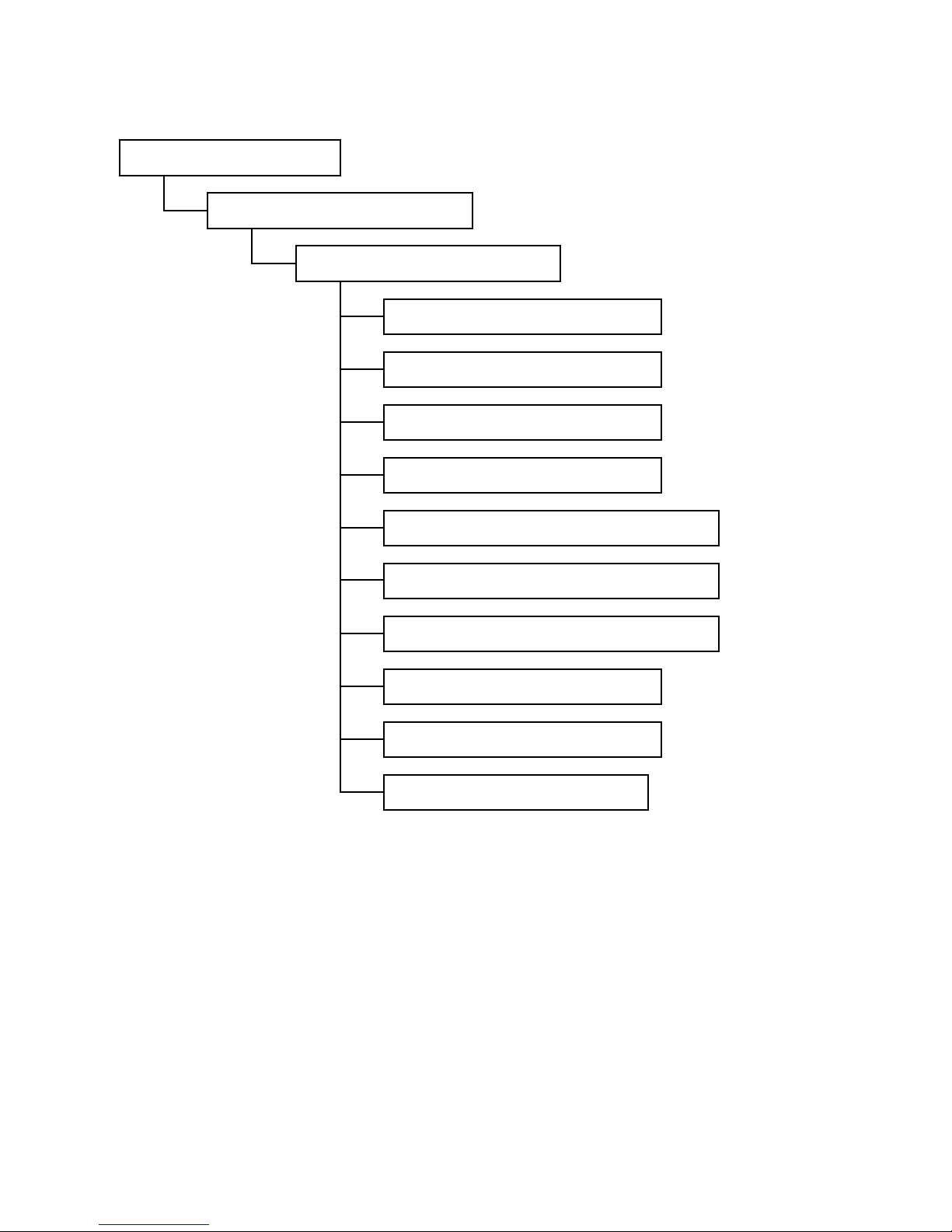

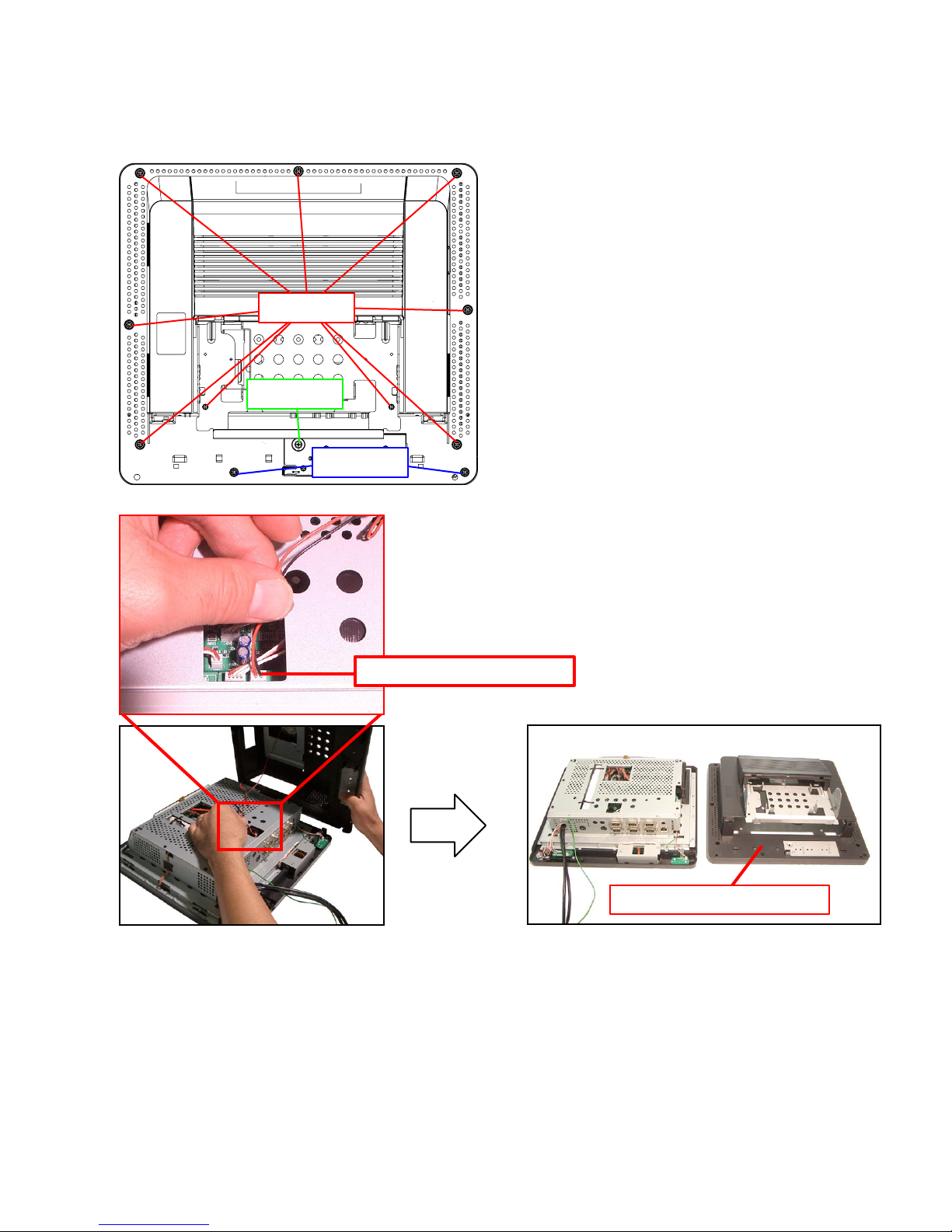

Disassembling

A.

Removing the Stand

B.Removing the B-case Assy Block

C.Removing the Rear Display Block

D.Disassembling the Rear Display

E.Removing the Mic PCB (E830-MIC)

F.Removing the LED PCB (E830-E6)

G.Removing the Inverter Unit

H.Removing the Touch Panel PCB (E830-TP)

I.

Removing the Power Supply PCB (E830-INLET)

J.Removing the COM PCB (E830-COM)

K.Removing the Main PCB (E830-1)

L.Removing the MCR

M.Removing the LCD/Touch Panel

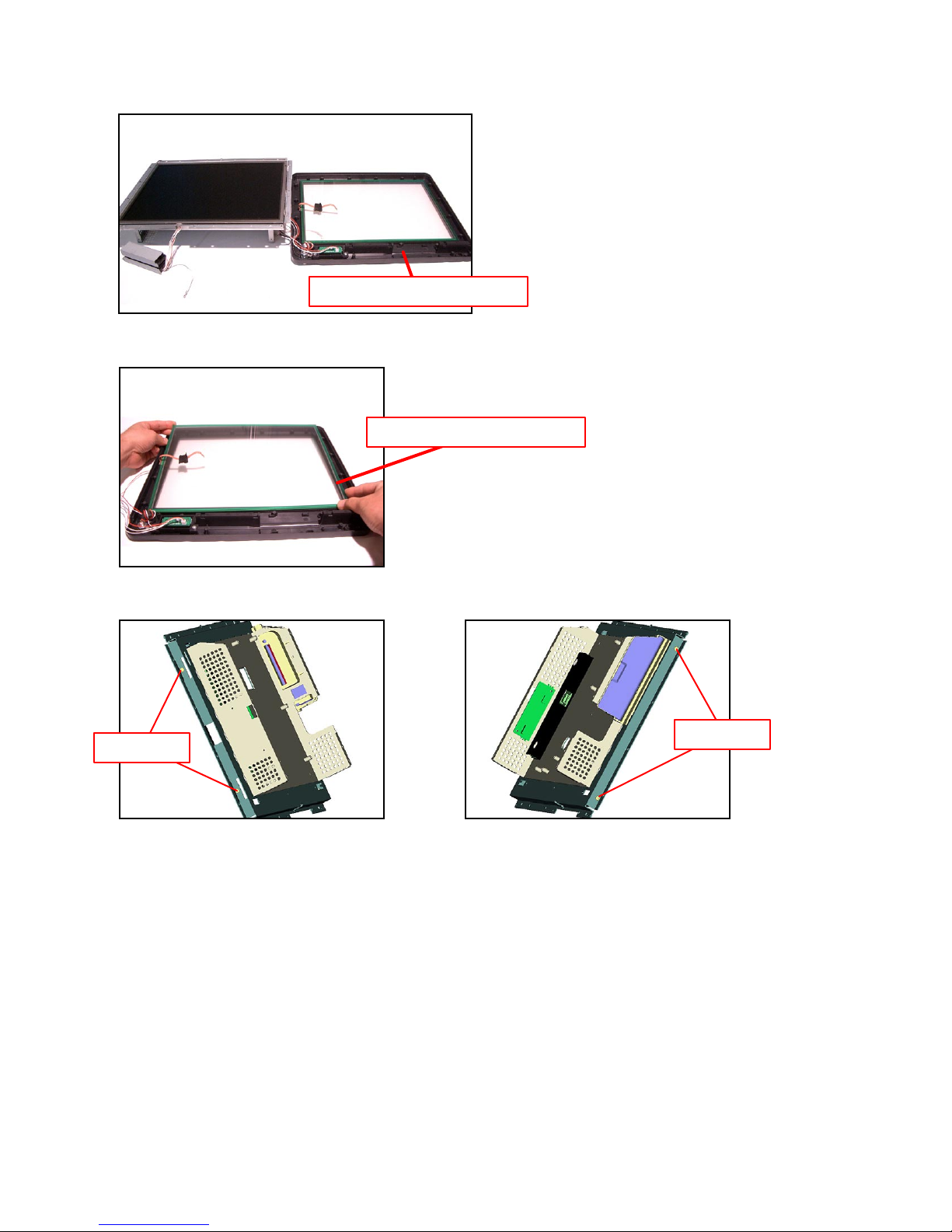

■

See the flowchart below for the order of disassembling main parts.

— 11 —

Page 14

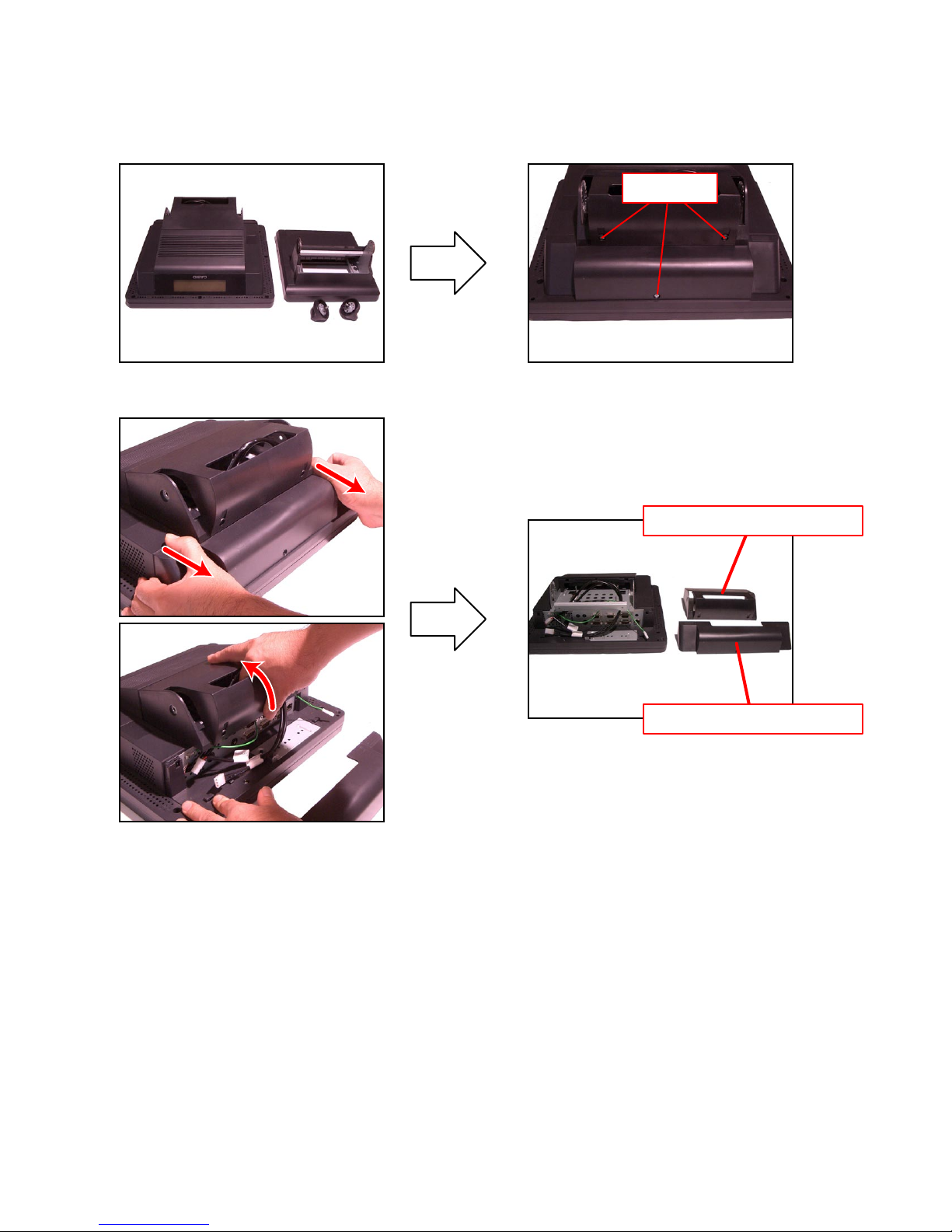

A. Disengage and remove the Main Unit from the Stand.

B. Removing the B-case Assy Block

B-1. Remove three screws.

B-2. Remove two covers.

Screws (S4)

HNG COVER

CONNECTOR COVER

— 12 —

Page 15

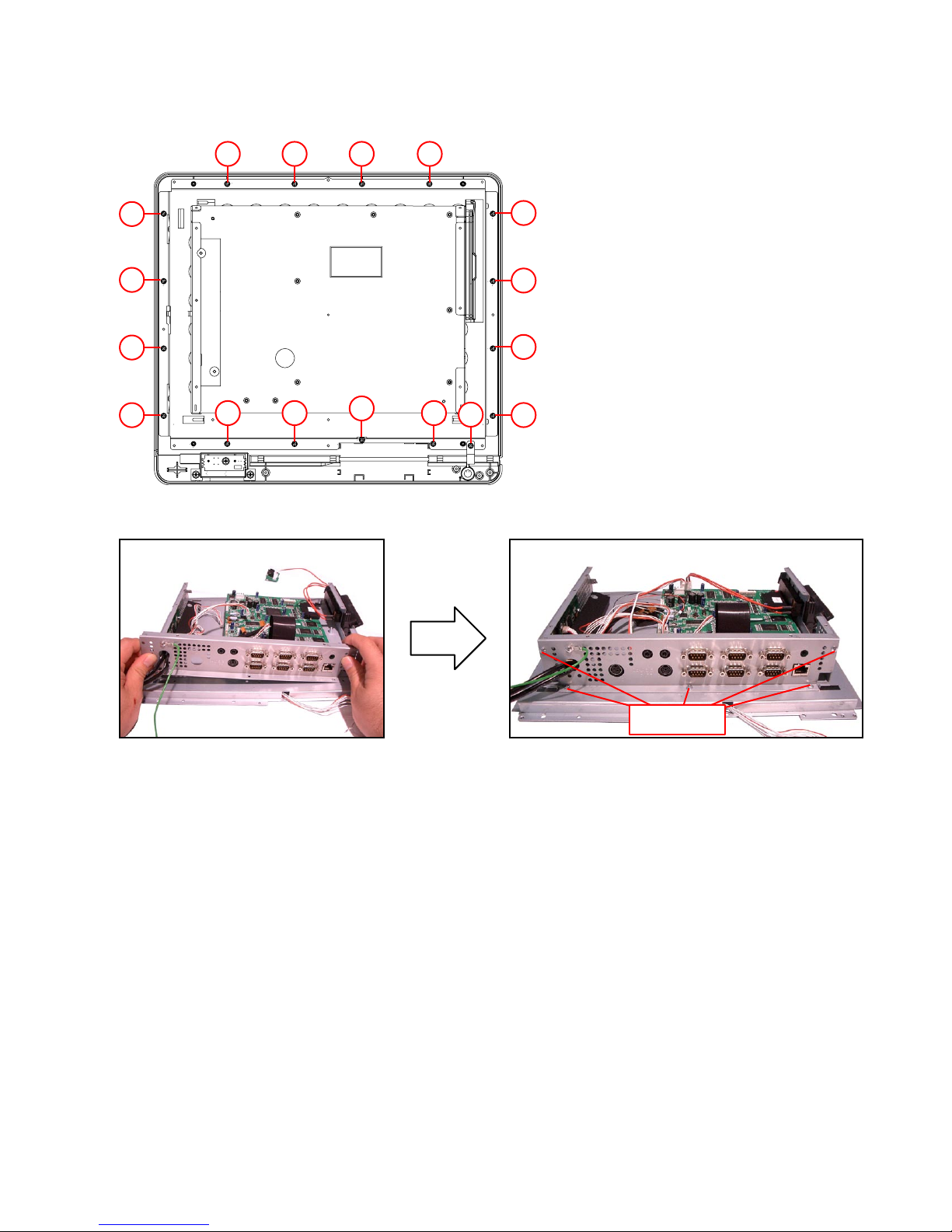

B-3. Remove 12 screws.

B-4. Remove the B-case Assy Block.

B-5. Unplug the connector to the speaker.

Screws (S1)

Screws (S2)

Screws (S3)

Connector (Speaker)

B-CASE ASSY BLOCK

— 13 —

Page 16

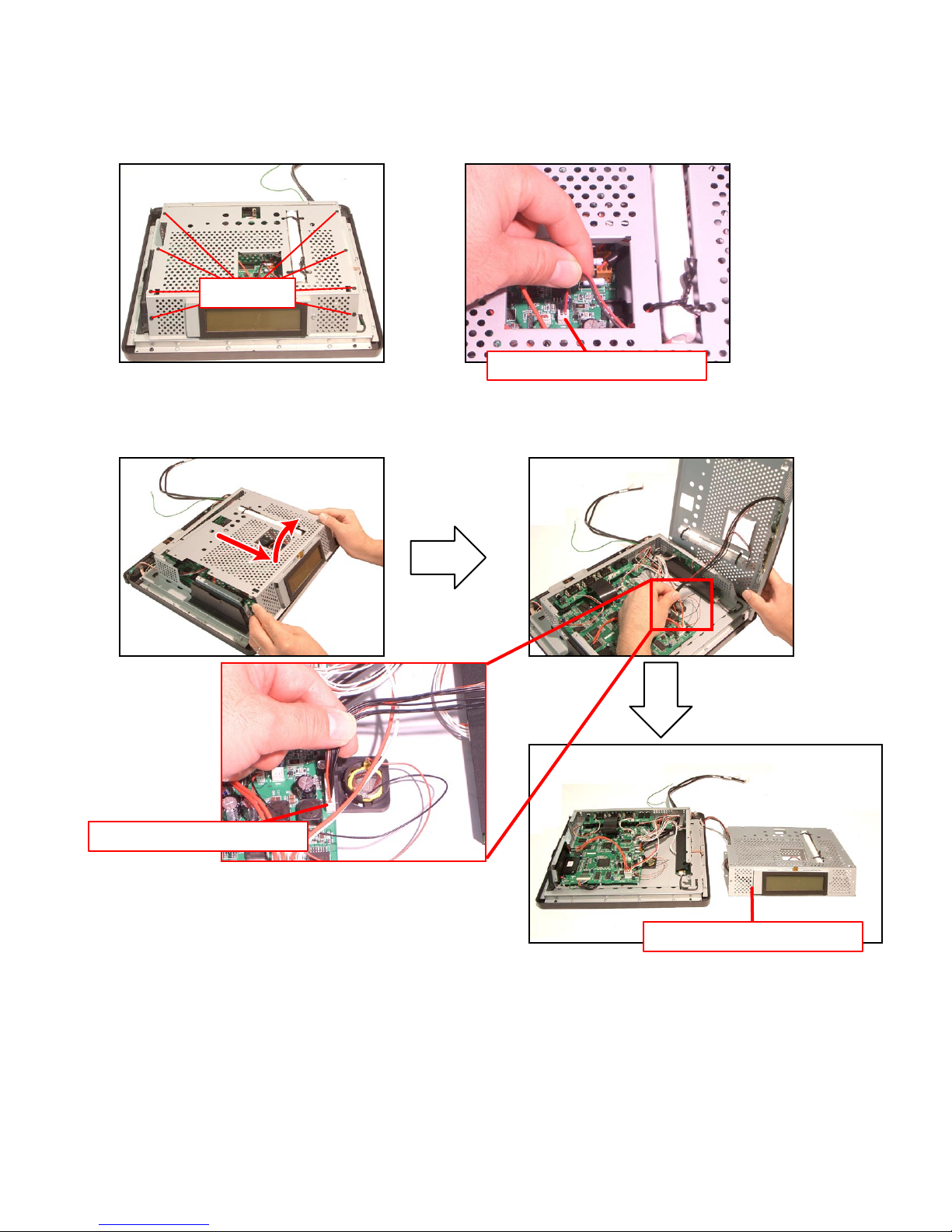

C. Removing the Rear Display Block

C-1. Remove eight screws.

C-2. Remove the connector to the battery.

Screws (S6)

C-3. Remove the Rear Display Block.

C-4. Unplug the connector to the Rear Display.

Connector (Battery)

Connector (REAR DISPLAY)

REAR DISPLAY BLOCK

— 14 —

Page 17

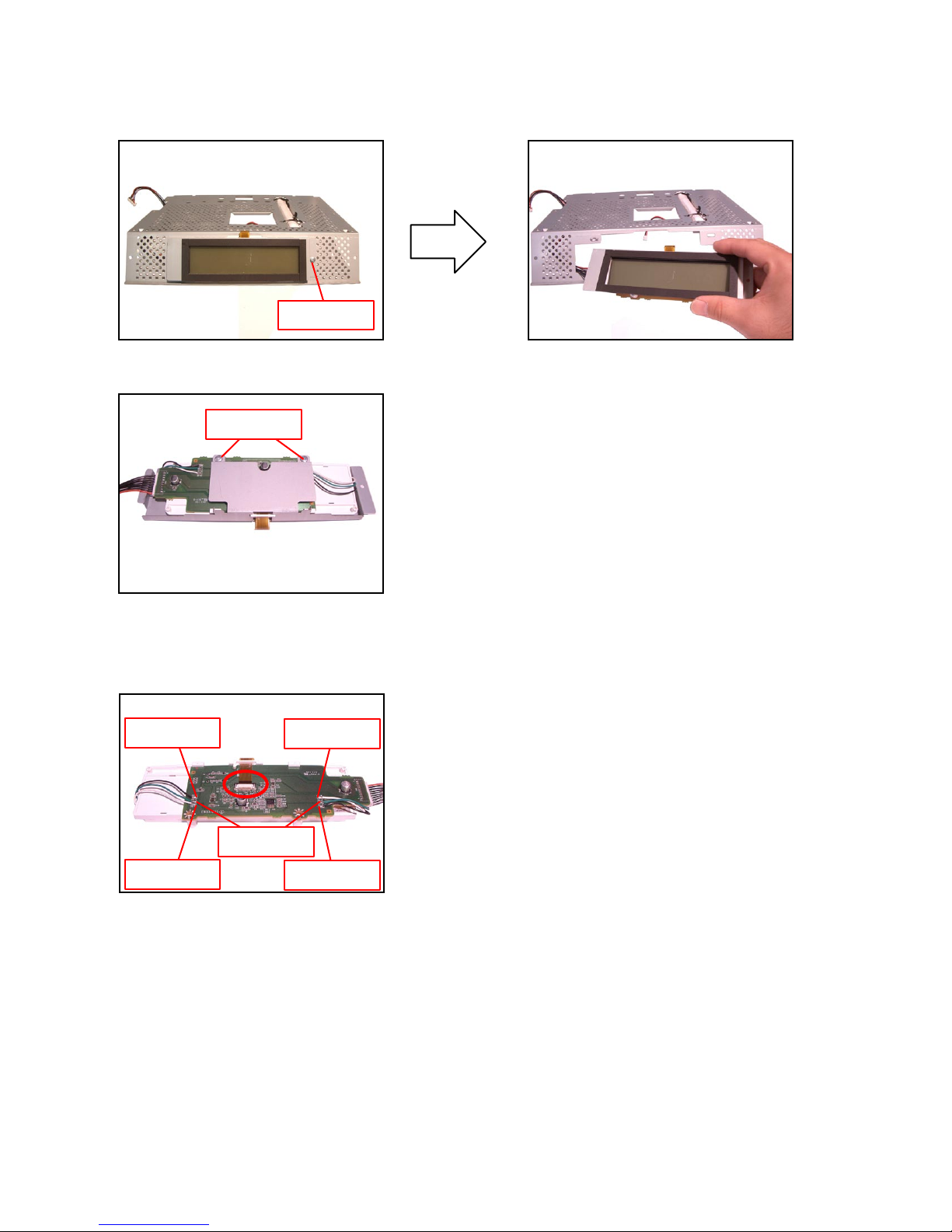

D. Disassembling the Rear Display

D-1. Remove the screw and remove the Rear Display Unit.

Screws (S5)

D-2. Remove two screws and remove the LCD Frame.

Screws (S7)

D-3. Use a solder to remove six lead wires.

D-4. Release the connector lock and disconnect the FPC.

D-5. Remove the Rear LCD PCB (E830-E22).

Black

White

Green

White

Black

— 15 —

Page 18

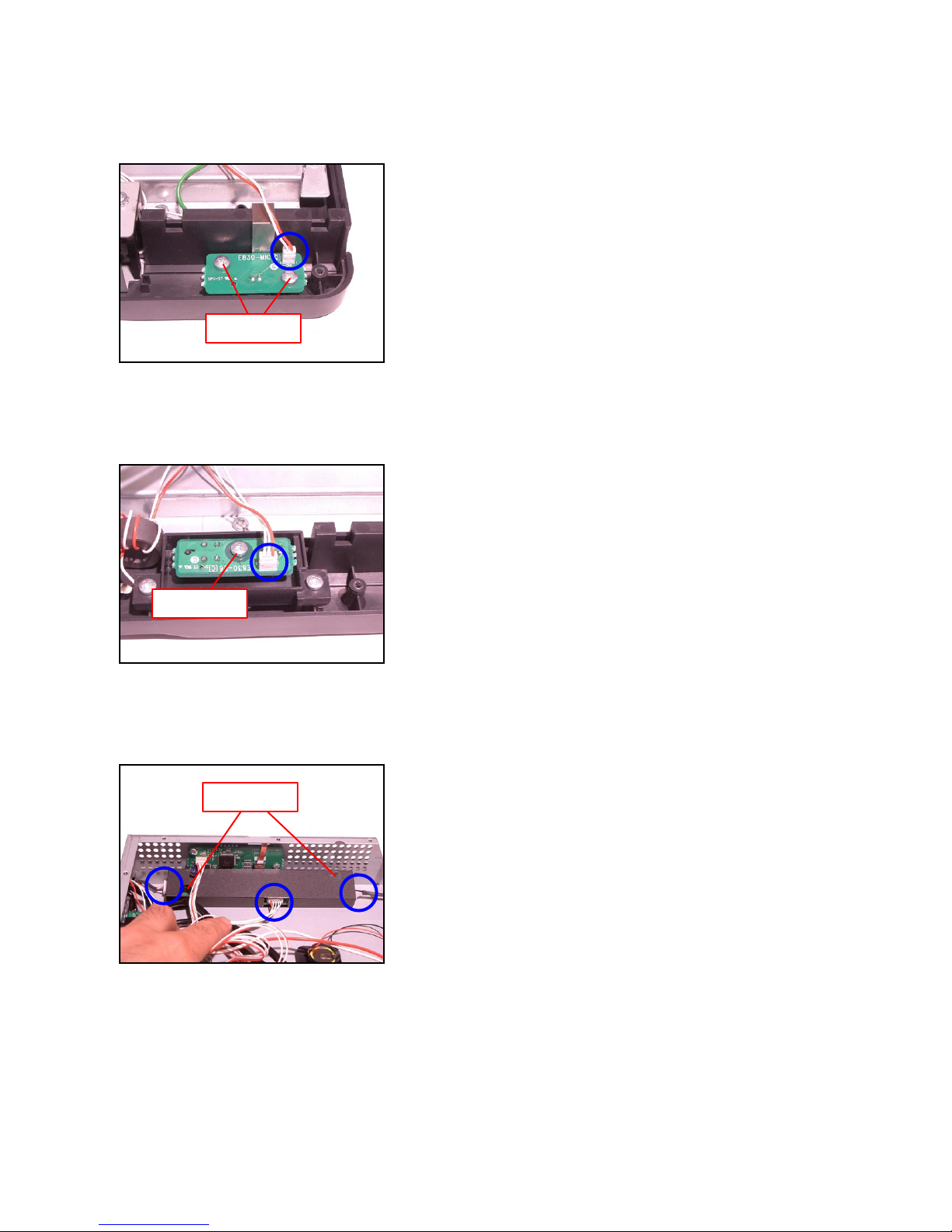

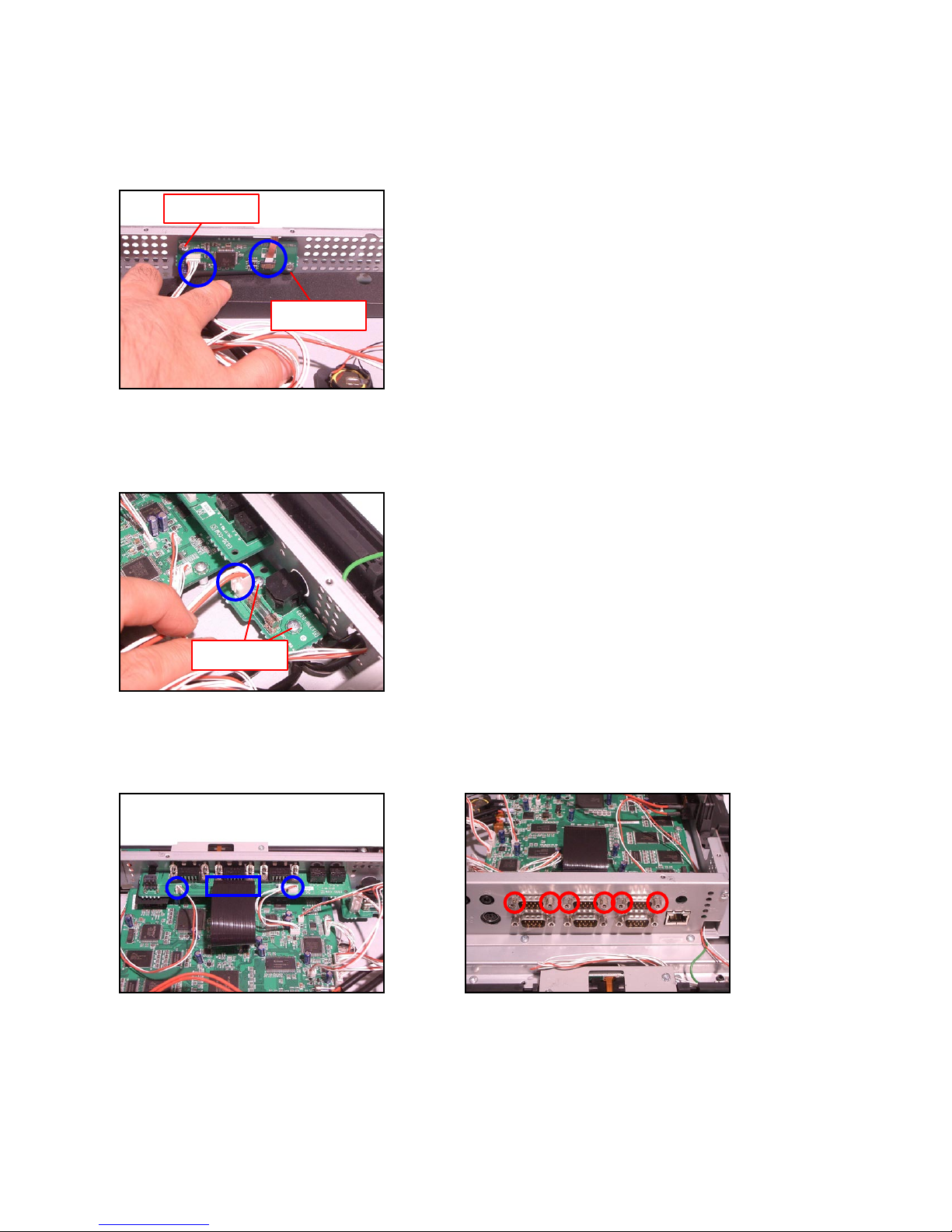

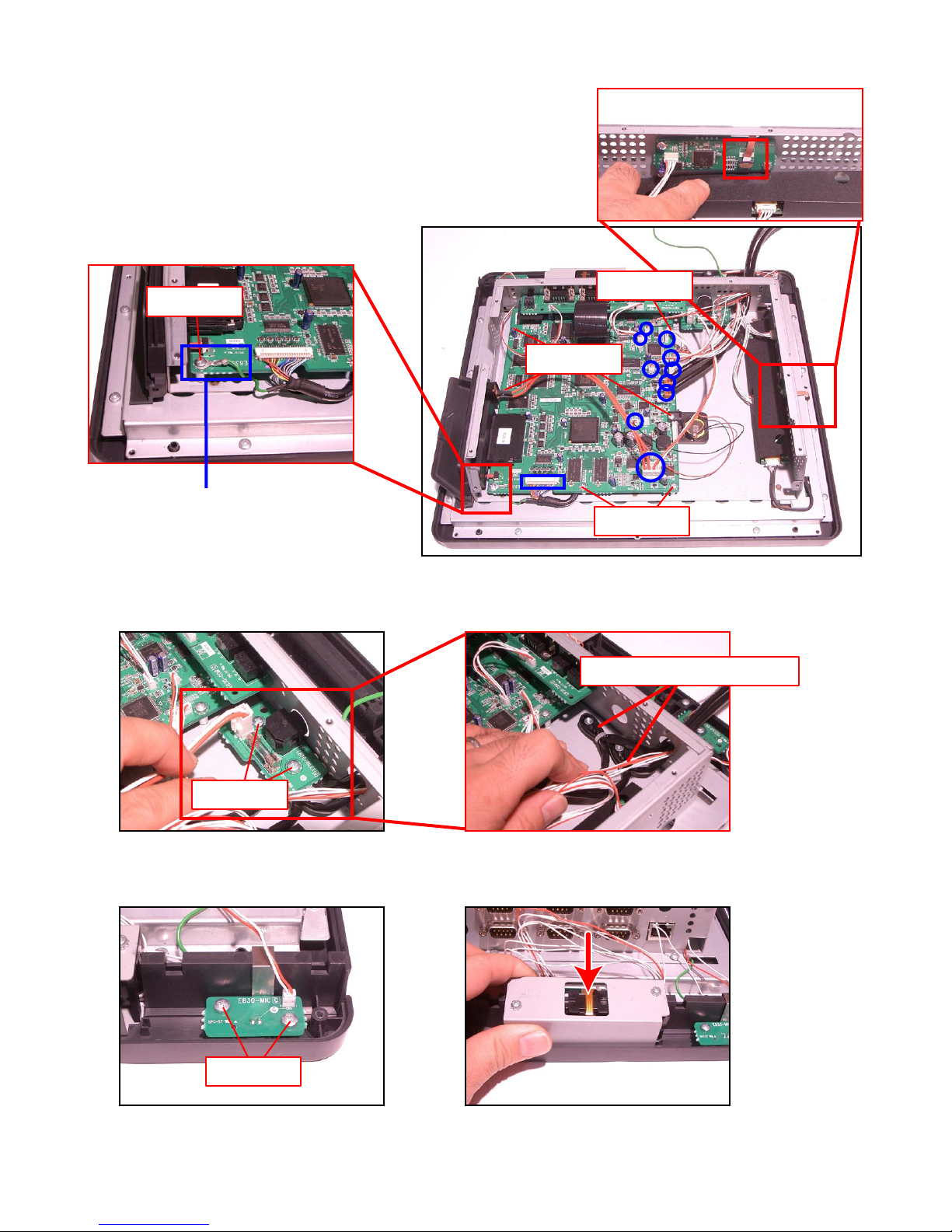

Mic PCB (E830-MIC)

COM PCB (E830-COM)

LED PCB (E830-E6)

LCD

i-Button key

MCR

Touch panel PCB(E830-TP)

Inverter unit

Power switch/code

Drawer 2

Drawer 1

PCBs and the Connectors to the Main PCB

LED PCB

(E830-E6)

Power supply PCB

(E830-INLET)

Inverter unit

Touch panel PCB

(E830-TP)

Main PCB

(E830-1)

COM PCB

(E830-COM)

Mic PCB

(E830-MIC)

■

PCBs and the Connectors to the Main PCB

■

— 16 —

Page 19

E. Removing the Mic PCB (E830-MIC)

E-1. Unplug the connector.

E-2. Remove two screws and remove the Mic PCB (E830-MIC).

Screws (S7)

F. Removing the LED PCB (E830-E6)

F-1. Unplug the connector.

F-2. Remove the screw and remove the LED PCB (E830-E6).

Screws (S7)

G. Removing the Inverter Unit

G-1. Unplug three connectors.

G-2. Remove two screws and remove the Inverter Unit.

Screws (S5)

— 17 —

Page 20

H. Removing the Touch Panel PCB (E830-TP)

H-1.Unplug the connector.

H-2. Release the connector lock and disconnect the FPC.

H-3. Remove two screws and remove the Touch Panel PCB (E830-TP).

Screws (S5)

Screws (S5)

I. Removing the Power Supply PCB (E830-INLET)

I-1. Unplug the connector.

I-2. Remove two screws and remove the Power Supply PCB (E830-INLET).

Screws (S5)

J. Removing COM PCB (E830-COM)

J-1. Unplug two connectors and 1 FPC.

J-2. Remove six nuts and remove the COM PCB (E830-COM).

— 18 —

Page 21

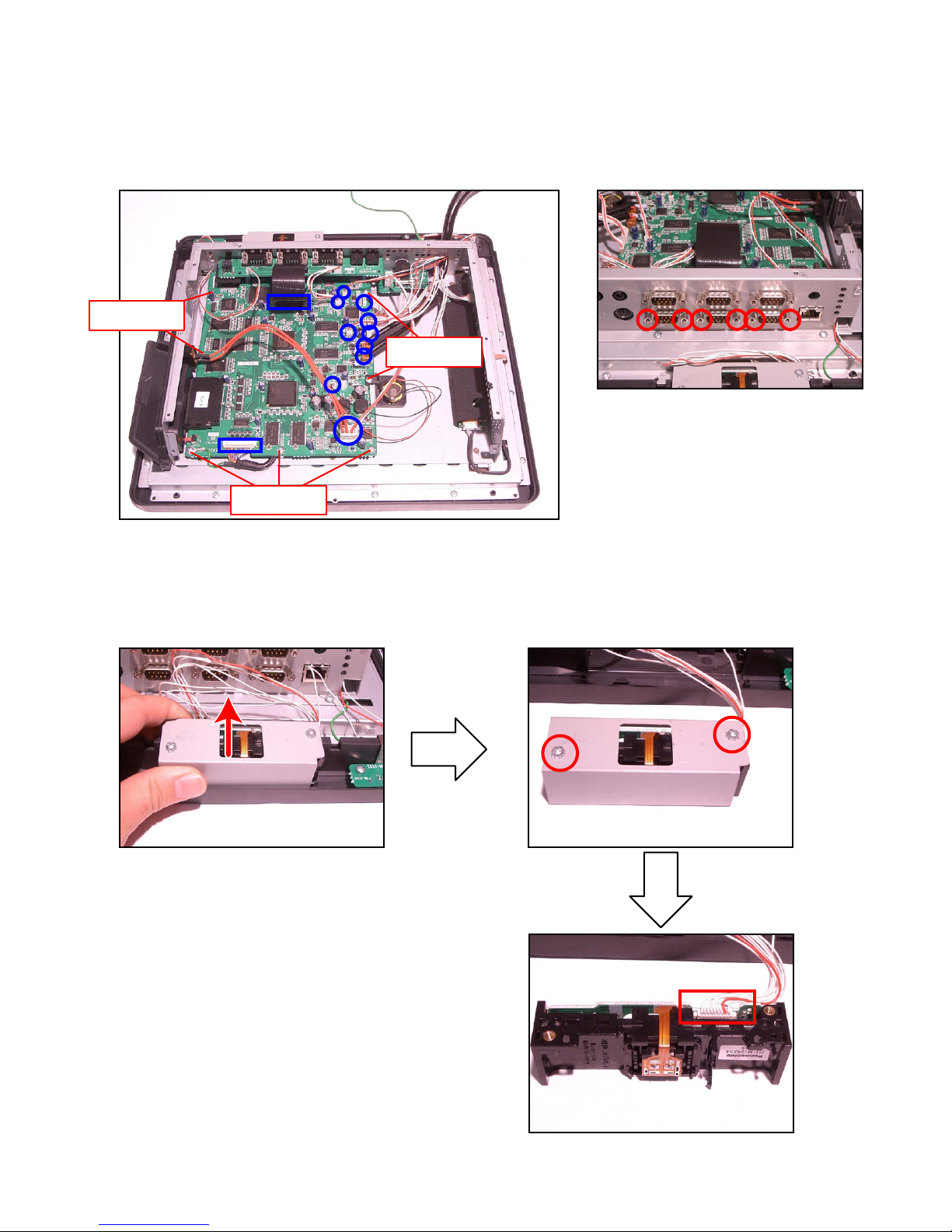

K. Removing the Main PCB (E830-1)

K-1. Unplug 10 connectors and 2 FPCs.

K-2. Remove six nuts.

K-3. Remove seven screws and remove the Main PCB (E830-1).

Screws (S9)

Screws (S9)

Screws (S9)

L. Removing the MCR

L-1. Disengage and remove the MCR Unit from the Main Unit.

L-2. Remove two screws and remove the MCR Unit.

L-3. Unplug the connector.

— 19 —

Page 22

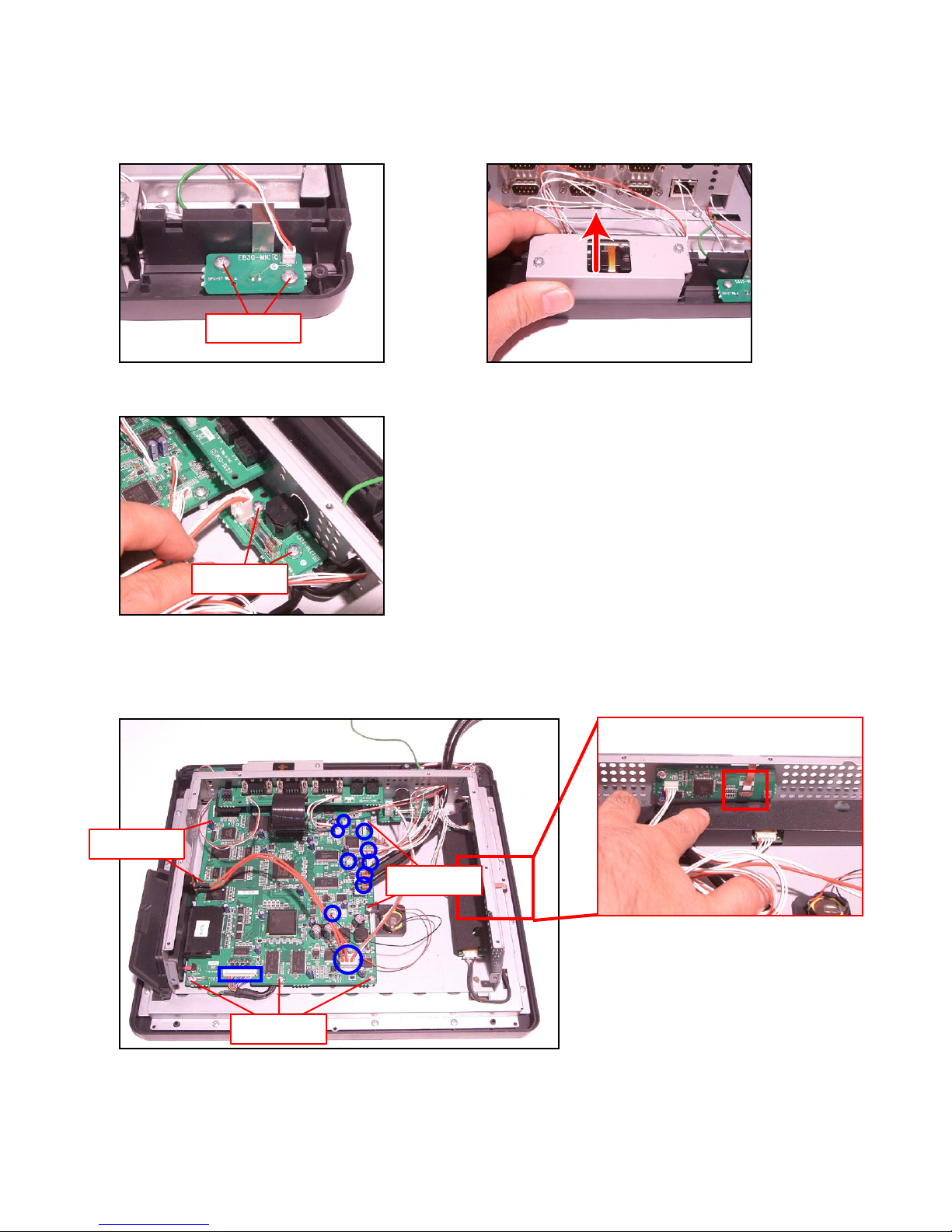

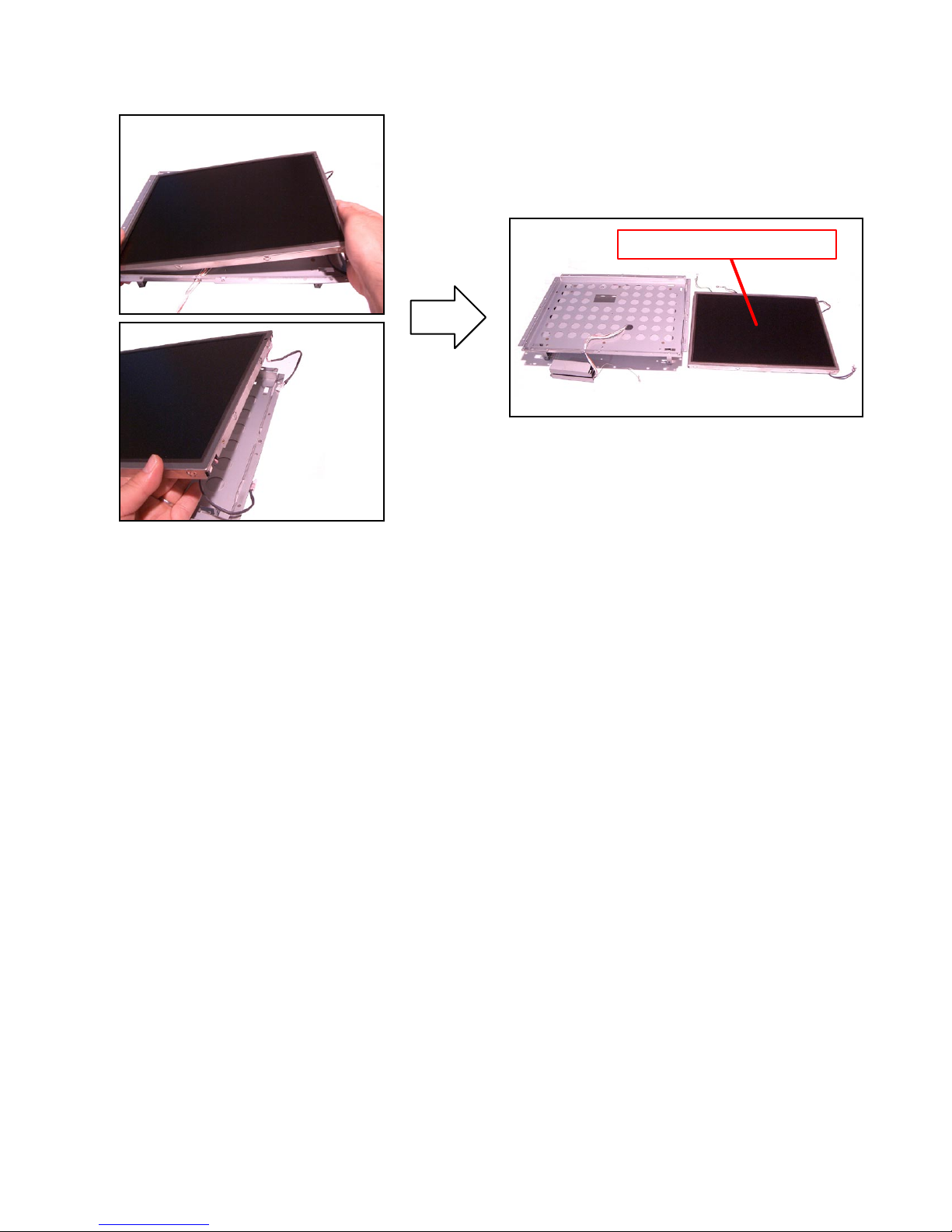

M. Removing the LCD/Touch Panel

M-1. Remove two screws and remove Mic PCB (E830-MIC).

M-2. Disengage and remove the MCR unit from the Main Unit.

Screws (S7)

M-3. Remove two screws and remove the Power Supply PCB (E830-INLET).

Screws (S5)

M-4. Unplug 10 connectors and disconnect 1 FPC.

M-5. Remove seven screws.

M-6. Release the Touch Panel PCB (E830-TP) connector lock and disconnect the FPC.

Screws (S9)

Screws (S9)

Screws (S9)

— 20 —

Page 23

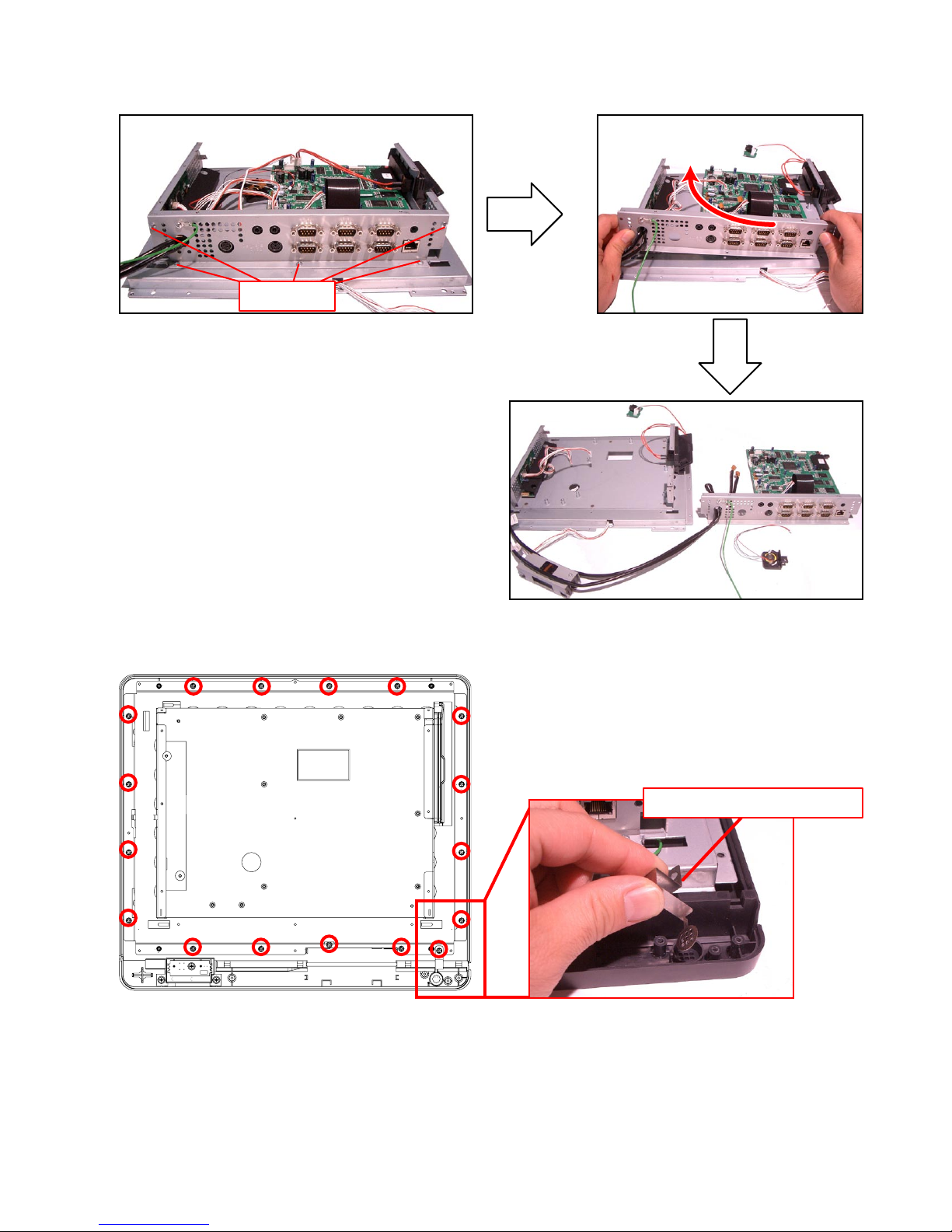

M-7. Remove five screws and remove the COM Chassis and the Main PCB.

Screws (S5)

M-8. Remove 17 screws.

M-9. Disconnect the earth wire for the Mic.

Mic earth

— 21 —

Page 24

M-10. Remove the U-Case Assy Block.

U-CASE ASSY BLOCK

M-11. Remove the Touch Panel.

Touch panel

M-12. Remove four screws.

Screws (S10)

Screws (S10)

— 22 —

Page 25

M-13. Disengage and remove the LCD Unit.

LCD unit

— 23 —

Page 26

4. ASSEMBLY

M. Assembling the Stand

L. Assembling the B-case Assy Block

K. Assembling the Rear Display Block

I. Assembling the Mic PCB (E830-MIC)

H. Assembling the LED PCB (E830-E6)

G. Assembling the Inverter Unit

F. Assembling the Touch Panel PCB (E830-TP)

E. Assembling the Power Supply PCB (E830-INLET)

D. Assembling the COM PCB (E830-COM)

C. Assembling the Main PCB (E830-1)

B. Assembling the MCR

A. Assembling the LCD/Touch Panel

J. Assembling the Rear Display

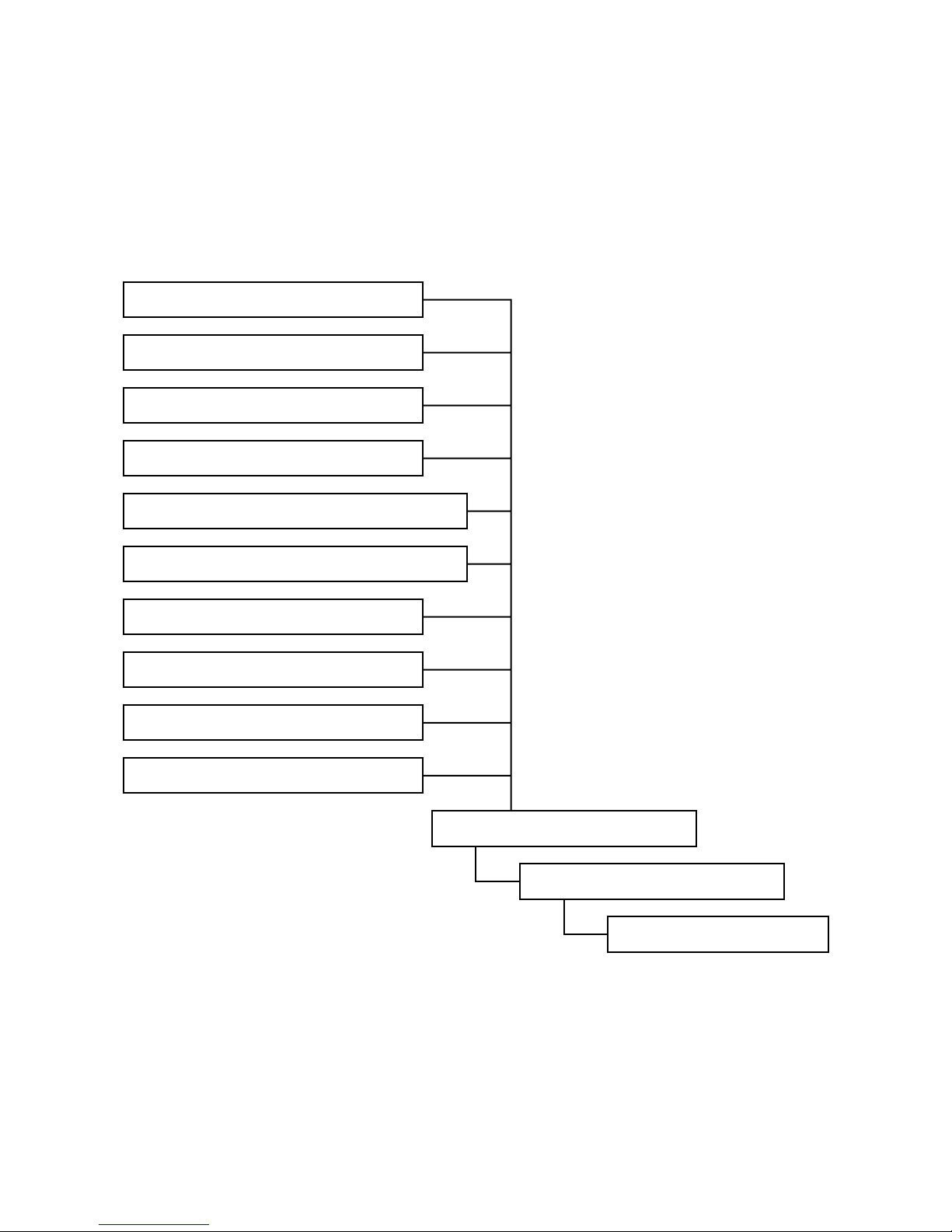

Assembling

■

See the flowchart below for the order of re-assembling major units.

— 24 —

Page 27

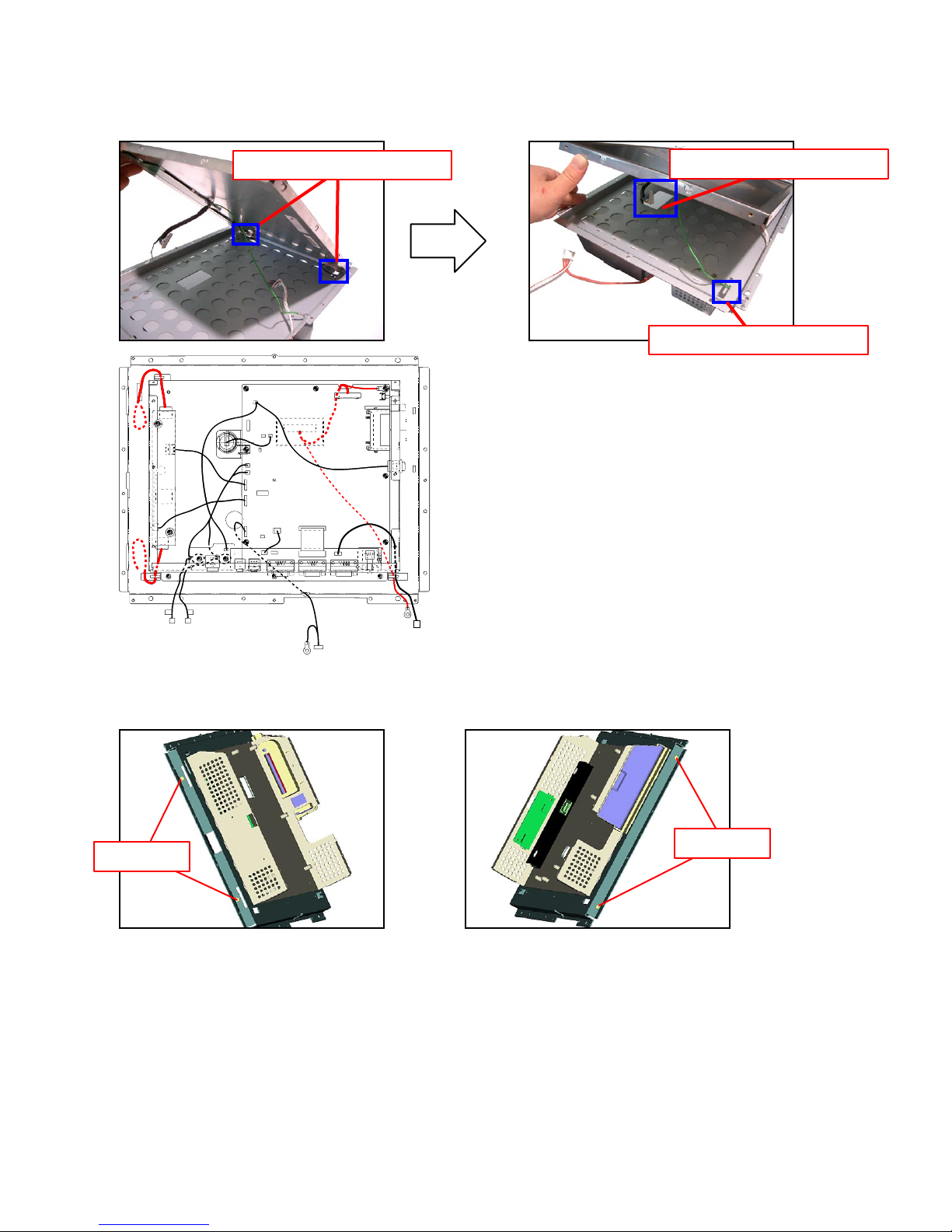

A. Assembling the LCD/Touch Panel

A-1. Lay four cables in the appropriate groove.

Backlight cables

LCD cable

Earth cable

A-2. Engage the LCD Unit and secure it with four screws.

NOTE: Do not tighten the screws excessively. (Reference torque value: 0.34N•m or less)

Screws (S10)

Screws (S10)

— 25 —

Page 28

A-3. Engage the Touch Panel.

Guide Guide

Guide Guide

NOTE: Place the Touch Panel evenly inside the guides of the U-case.

Touch panel

A-4. Engage the U-Case Assy Block.

NOTE: Before engaging the U-case Assy Block, be sure that the LCD and the Touch Panel are clean and

free of dust, dirt, or any foreign matter.

NOTE: Pull out the FPC of the Touch Panel through the opening of the chassis.

A-5. Engage the Mic Earth.

U-CASE ASSY BLOCK

Mic earth

Touch panel FPC

— 26 —

Page 29

A-6. Secure it with 17 screws.

11 1 3 9

15

8

6

14

13

5

7

16

10 4

2

12

17

NOTE: Tighten the screws in the order of the numbers indicated in the illustration below.

A-7. Engage the COM Chassis and the Main PCB, and then secure them with five screws.

Screws (S5)

— 27 —

Page 30

A-8. Plug 10 connectors and 1 FPC.

NOTE: Do not tangle the wires.

A-9. Secure it with seven screws.

A-10. Connect the Touch Panel PCB (E830-TP) to the FPC.

Screws (S9)

NOTE: Position it so that the earth terminal

is in the correct orientation.

Screws (S9)

Screws (S9)

Screws (S9)

A-11. Engage the Power Supply PCB (E830-INLET) and secure it with two screws.

NOTE: Two Drawer Cables are arranged under the PCB.

Drawer cables

Screws (S5)

A-12. Engage the Mic PCB (E830-MIC) and secure it with two screws.

A-13. Engage the MCR Unit.

Screws (S7)

— 28 —

Page 31

B. Assembling the MCR

B-1. Connect the cables to the MCR Unit.

B-2. Engage the MCR Unit and secure it with two screws.

B-3. Engage the MCR Unit in the Main Unit.

C. Assembling the Main PCB (E830-1)

C-1. Engage the Main PCB and secure it with seven screws.

C-2. Install three COM Ports and secure them with two nuts each.

C-3. Plug 10 connectors and two FPCs.

Screws (S9)

Screws (S9)

Screws (S9)

NOTE: Position it so that the earth terminal is in the correct orientation.

— 29 —

Page 32

D. Assembling COM PCB (E830-COM)

D-1. Install three COM PCBs (E830-COM) and secure them with two nuts each.

D-2. Plug two connectors and the FPC.

E. Assembling the Power Supply PCB (E830-INLET)

E-1. Engage the Power Supply PCB (E830-INLET) and secure it with two screws.

NOTE: two Drawer Cables are arranged under the PCB.

E-2. Plug the connector.

Drawer cables

Screws (S5)

F. Assembling the Touch Panel PCB (E830-TP)

F-1. Engage the Touch Panel PCB (E830-TP) and secure it with two screws.

F-2. Plug the connector and 1 FPC.

NOTE: Engage the FPC securely until it locks in.

Screws (S5)

Screws (S5)

— 30 —

Page 33

G. Assembling the Inverter Unit

G-1. Engage the Inverter Unit and secure it with two screws.

G-2. Connect three connectors.

Screws (S5)

H. Assembling the LED PCB (E830-E6)

H-1. Engage the LEC PCB (E830-E6) and secure it with the screw.

H-2. Plug the connector.

Screws (S7)

I. Assembling the Mic PCB (E830-MIC)

I-1. Engage the Mic PCB (E830-MIC) and secure it with two screws.

I-2. Plug the connector.

Screws (S7)

— 31 —

Page 34

J. Assembling the Rear Display

J-1. Engage the Rear LCD PCD (E830-E22).

J-2. Use solder to connect six lead wires.

J-3. Connect the FPC.

NOTE: Engage the FPC securely until it locks in.

Black

White

Green

White

Black

J-4. Engage the LCD Frame and secure it with two screws.

Screws (S7)

J-5. Engage the Rear Display Unit and secure it with the screw.

NOTE: When assembling, use caution so that the wires are not caught in chassis.

Screws (S5)

— 32 —

Page 35

K. Assembling the Rear Display Block

NOTE:

Check that the cables for the i-Button key receiver and the LED PCB (E830-E6) are contained in the tube.

K-1. Plug the connector to the Rear Display and engage the Rear Display Block.

Connector (REAR DISPLAY)

K-2. Secure it with eight screws.

K-3. Plug the connector to the Battery.

Screws (S6)

Connector (Battery)

— 33 —

Page 36

L. Assembling the B-case Assy Block

L-1. Plug the connector to the Speaker and engage the B-case Assy Block.

NOTE: Insert the B-case in the groove of the Card Cover.

Card cover

Connector (Speaker)

L-2. Secure it with 12 screws.

Screws (S1)

Screws (S2)

Screws (S3)

— 34 —

Page 37

L-3. Engage two covers.

CONNECTOR COVER

HNG COVER

L-4. Secure them with three screws.

Screws (S4)

M. Engage the Main Unit to the Stand.

— 35 —

Page 38

5. OPTION INSTALLATION

210mm

Coil

Wind two turns of cable around the coil.

DISPLAY

SCANNER

PC/MODEM

COM3

COM6

COM2

COM5

COM1

COM4

SPK

PS/2

KEYBOARD

M

IC

LAN

COM6

COM3 COM2 COM1

COM5 COM4

5-1. To install the I-Button

5-2. REMOTE PRINTER / SLIP PRINTER

Connect the following peripherals to the COM ports respectively.

REMOTE PRINTER: COM 4, 5 or 6

SLIP PRINTER: COM 2

— 36 —

Page 39

5-3. To install the DRAWER

In case of connecting drawer, follow the procedure below.

1. Connect drawer connector (three color lead on drawer) to the terminal.

2. Connect frame drawer connector (green lead on drawer) to the terminal.

Mount the cash register.

1. Screw in 2 fixing screws bottom side of the terminal.

2. Mount the terminal on the top of the drawer, ensuring that the feet on the bottom of the terminal

go into the holes on the drawer.

— 37 —

Page 40

6. IN LINE / ON LINE

PC

Via COM 1 port of the master terminal

or Inline (wire or wireless)

Maximum 32 terminals

PC

on-line (Public / Private Telephone line)

Maximum 32 terminals

6-1. Inline collection/consolidation system

• Inline collection/consolidation and auto-programming for up to 32 terminals.

6-2. Online collection / consolidation system

• Online collection / consolidation and auto-programming for up to 32 terminals.

— 38 —

Page 41

6-3. Online collection / consolidation system (use FTP feature)

PC

Maximum 32 terminals

ADSL/FTTH

MODEM

ADSL/FTTH

MODEM

VPN roote

r

VPN rooter

Internet

• Online collection / consolidation and auto-programming for up to 32 terminals.

— 39 —

Page 42

7. DIAGNOSTIC PROGRAM

DALLAS

DRW 1CLOSE 2CLOSE

MAC ADRS XX-XX-XX-XX-XX-XX

TEMP 0 VOLTAGE 0 CHARGE-MODE 359M

DISP ON/OFF OFF CF NON

Ioc Ver : xxxxxx xxxx

Boot Ver : xxxxxx xxxx

TOUCH START

221

Enter the Calibration mode

==>> Push Disp on/off ke

y

Skip the Calibration mode

==>> Touch the pane

l

0000 00000221

PANEL SIZE 15"

Copyright(C)2008

CASIO COMPUTER CO.,LT D.

All rights reserved.

ROM VER. xxxxxx xxxx

C

1

0

4

7

2

5

8

3

6

9

CREATE

xxxx-xx-xx xx:xx

QT-6600 Version x.xx

APL VER. xxxxxx xxxx

OK

Display on/off key

7-1. Starting the Program

Init switch

(1) Check that the power is turned OFF.

(2) While holding down the INIT switch, turn on the power.

Power switch

(3) Release the switch when the screen below appears.

* If the switch is released before this screen appears, either of the following modes is launched.

• Power-failure recovery reboot

• INIT boot-up

(4) Enter “99990000” and press [OK].

(5) When the program is launched, the software version information is printed out as shown below.

• BOOTER

• IOC

| IOC Ver : xxxx xxxxxx | IOC

| Boot Ver : xxxx xxxxxx | BOOTER

(6) After the version information is displayed and printed out, a

message appears prompting for an action to take as the next

step.

To proceed with the calibration settings, press the ON/OFF

key on the display. For detailed procedures, see “[15] LCD

CALIBRATION SETTING”. If you wish to skip the calibration

settings, press anywhere on the touch panel.

— 40 —

Page 43

7-2. General Notes on the Diagnostic Program

X X X X X X n a g d

XXXXXX : additional action

n : number of times

a : action

g : group

d : device number

• The test result is printed out through an external printer.

Baud rate :9600 bps

Connection : COM1

• A scanner must be connected to COM2.

• You may select “single test” or “repeat indefinitely” for the number of retries.To repeat the test

indefinitely, enter any number except for 0 in the command specifying the number of retries.

• When you press [ESC] while the test is repeated indefinitely, the following message is displayed

and printed out, then the test is terminated.

| ESC |

• Cut the receipt after the test result is printed out.

[Pass(OK)/fail(NG) Determination of Test Result by Operator]

• After the message below appears, the operator may decide pass(OK) or fail(NG) of the result by

pressing 1 or 9, respectively.

| Please Hit Key OK-> 1 NG-> 9 |

[Other]

• Hibernation memory

In this program, the automatic clear of the hibernation memory is executed or stopped in the following

situations:

<Execute>

• When INIT/FC is launched

• When a power-failure recovery is detected while idling (waiting for an input of a command)

<Stop>

• When the hibernation memory test is being executed

7-3. Command Input System

Follow the code below to enter a command.

— 41 —

Page 44

7-4. Status Information

DALLAS

DRW 1CLOSE 2CLOSE PANEL SIZE 15

"

MAC ADRS XX-XX-XX-XX-XX-XX

TEMP 20 VOLTAGE XX CHARGE-MODE 360M

DISP ON/OFF ON CF INSERT

Diag Ver : XXXXXX XXXX

0000 1234

Status information is displayed continuously

(in ordinary characters). However,

when performing a test, the status at

completion of a test is displayed

following completion of that test.

Counter display

Shows a screen as shown below on the LCD (XGA).

(In this chapter, the area for entries and the area for test results are illustrated separately.)

[Function]

Displays the status of each device.

DALLAS Indicates DALLAS key No. in a hexadecimal value

DRW 1/DRW 2 Indicates open/close status of the drawer.

CHARGE-MODE Indicates the remaining amount of the battery in minutes.

TEMP/VOLTAGE TEMP/VOLTAGE Indicates the A/D value of the battery.

PANEL SIZE PANEL SIZE: Indicates the panel size.

CF CF: Indicates whether a CF Card is inserted.

MAC ADRS MAC ADRS: MAC address written on FLASH ROM is indicated in a

DISP ON/OFF The default is set to ON.

Device Status information (description of messages)

OPEN: Drawer is open

CLOSE: Drawer is closed

nM: Remaining battery (minutes) n=0 ~ 360

DISP ON/OFF: The acquisition of TEMP status is prioritized when

the switch is ON.

Be sure to turn off DISP ON/OFF switch before opening other status

information or starting the Test Mode.

15”: Enhanced model (15-inch panel)

12”: Junior model (12-inch panel)

INSERT: CF Card is inserted

NON: CF Card is not yet inserted.

hexadecimal value.

To write in FLASH ROM, use the MAC Address Writing function of

this DIAG.

ON/OFF may be switched in the software setting.

— 42 —

Page 45

7-5. Memory Test Overview

Scope of the test in this range

• Sum check

BOOTER, Protected data area

0x0100000

0x1FFFFFF

0x0000000

FROM 32MByte (128KBytes × 256 blocks)

Program

FILE data

Free area

Scope of the test in this range

• CLEAR&WRITE/READ Test

• READ ONLY Test

• WRITE/READ Test

7-5-1.Types of memory tests

FLASH ROM

(for programming)

WRITE Test

READ ONLY Test

CLEAR Test

CLEAR & WRITE/READ Test

CHECK SUM Test

RAM

7-5-2. Scope of memory tests

[FROM Test]

This program does not back up programs or data. Be sure to perform IPL after performing CLEAR

and/or WRITE READ Test.

The data contained in the area used to perform CLEAR or WRITE Test is not protected.

In order to perform CLEAR or WRITE/READ Test, the program and data are copied as backup

temporarily in an available area of RAM.

Do not turn OFF the power during the test. Doing so may destroy the program and the proper

operation cannot be guaranteed. Should this occur, all operations, starting IPL, must be

performed.

FLASH ROM

(for hibernation)

CF

— 43 —

Page 46

[RAM Test]

The sizes vary according to

the program and system capacities.

Area for BOOTER

0x0030000

0x3FFFFFF

0x3FDFFEF

0x0000000

RAM 64MByte

Program/system area

USER area

Timer

Scope of READ ONLY Test

Scope of WRITE/READ Test

Scope of the test in this rang

e

CLEAR Test

READ ONLY Test

WRITE/READ Test

System area

0x0020000

0x3FFFFFF

0x0000000

FROM 64MByte (128KByte × 512 blocks)

Backup area

RAM Test uses, as the test area, all areas except for the program and system areas. USER area

is not guaranteed after performing the test.

[FROM Test for Hibernation]

FROM test for hibernation tests all areas.

Do not turn off the power during the test. If a power fails during the test, the hibernation function is

launched and this FROM is used.

Therefore the test which was being performed may be unsuccessful.

If the power is turned off without any backup battery, the hibernation function does not operate

— 44 —

Page 47

7-6. Test Items

This program performs the following tests.

No Device to be checked Operation Note Page

RAM, FROM (for programming),

1 Batch Test 1 1

2 Batch Test 2 2

3 RAM WRITE/READ Test n011 35

4 RAM READ ONLY Test n111 35

5 FLASH ROM CLEAR Test cn212 36

6 FLASH ROM WRITE/READ Test cn012 37

7 FLASH ROM CLEAR & WRITE/READ Test cn312 38

8 FLASH ROM CHECK SUM Test n512 39

9 CF-CARD CLEAR Test n213 39

10 CF-CARD WRITE/READ Test n013 40

11 CF-CARD READ ONLY Test n113 40

12 CF-CARD CLEAR & WRITE/READ Test n313 41

13 LCD Test n021 42

14 LCD Backlight OFF Test 121 42

15 LCD Calibration Setting 221 43

16 VRAM CHECK Test n721 44

17 REAR DISPLAY Test n322 45

18 REAR DISPLAY Backlight Test cn122 46

19 REAR DISPLAY Contrast Adjustment 422 47

20 REMOTE DISPLAY Test bn023 48

21 External Printer Output Test x1x2x3nm3d 49

22 Ethernet Printer Output Test x100nm37 51

23 COM(RS232C) Test xn04d 53

24 COM (RS232C) Batch Test 40 54

25 Printing COM (RS232C) Test Result 47 55

26 Ethernet Test: bm0a51 56

27 Setting MAC (Media Access Control Address) x0951 58

28 Date/Time Setting

hhmmss0070

yymmdd0170

29 Date/Time Display 070 60

30 Drawer Test xn091 61

31 Buzzer Test n092 62

32 MCR Test 96 63

33 Sound Test axn097 64

34 Microphone Test 98 64

35 Charge Mode Test 99 65

36 OBR Test 95 65

37 PS/2 Keyboard Test r1n094 66

FROM (for hibernation),

Date/Time, Buzzer, Drawer,

Receipt

LCD,LCD backlight, REAR

DISPLAY, REAR DISPLAY

backlight

33

34

60

— 45 —

Page 48

7-7. Test Procedures

[ 1 ] Batch Test 1

[Function]

Performs the following tests in sequence.

(1) RAM Test:

RAM WRITE/READ Test

(2) FROM (for program) Test

Check Sum test for the program code area.

(3) FROM (for hibernation) Test

Displays/prints out the sum of the FLASH headers for hibernation.

Calculates the sum of each byte and displays/prints out the lowest 8 bits.

(4) Date/Time Setting:

Sets the preset test data.

Test data: 01 year/ 12 month/ 31 day/ 23 hours/ 59 minutes /30 Seconds

(5) Buzzer Test:

Sounds single one-shot buzzer. There is no display/print-out for this test.

Select the test result "1" (OK) or "9" (NG) by touching the panel.

(6) Drawer Test:

Opens all drawers.

(7) Receipt Test:

Issues a receipt.

[Operation]

Operation : 1 ST

[LCD] [PRINT]

BATCH 1

RAM WR OK

FLASH CHK SUM OK

FLASH hib SUM XX

DATE 01/12/31

TIME 23:59-30

Please Hit Key OK−>1 NG−>9

FLASH CHK SUM OK

BATCH 1

RAM WR OK

FLASH CHK SUM OK

FLASH hib SUM XX

DATE 01/12/31

TIME 23:59-30

DRW OK

END 1

FLASH hib SUM XX

DATE 01/12/31

TIME 23:59-30

Please Hit Key OK−>1 NG−>9

DRW ALL OK

END 1

— 46 —

Page 49

[ 2 ] Batch Test 2

Green Blue

Reverse

check

RedWhiteBlack

Check (black

and white)

ABCDEFGHIJKLMNOPQRST

UVWXYZabcdefghijklm

n

ABCDEFGHIJKLMNOPQRST

UVWXYZabcdefghijklm

n

Back light

OFF

Back light OFF

White

Green

Emerald green

[Function]

Performs the following tests in sequence.

(1) LCD Test: Performs the LCD Display Test.

To change the screen, touch any part of the panel.

Select the test result "1" (OK) or "9" (NG) by touching the panel.

(2) LCD Backlight Test: Performs the OFF test of the LCD Backlight.

To change the screen, touch any part of the panel.

Select the test result "1" (OK) or "9" (NG) by touching the panel.

(3) REAR DISPLAY Test: Performs the REAR DISPLAY Test.

To change the screen, touch any part of the panel.

Select the test result "1" (OK) or "9" (NG) by touching the panel.

(4) REAR DISPLAY Backlight Test: Performs the OFF test of the Rear LCD Backlight.

To change the screen, touch any part of the panel.

Select the test result "1" (OK) or "9" (NG) by touching the panel.

[Operation]

Operation : 2 ST

[LCD] [PRINT]

BATCH 2

Please Hit Key OK−>1 NG−>9

LCD OK

Please Hit Key OK−>1 NG−>9

LCD BACKLIGHT OK

Please Hit Key OK−>1 NG−>9

BATCH 2

LCD OK

LCD BACKLIGHT OK

REAR DISP OK

REAR BACKLIGHT OK

END 2

REAR DISP OK

Please Hit Key OK−>1 NG−>9

REAR BACK LIGHT OK

END 2

— 47 —

Page 50

[ 3 ] RAM WRITE/READ Test

[Function]

Tests whether writing in/reading RAM is correctly performed.

Test data is written on the RAM, and tests are performed to check if the data has been written

properly.

The areas where performing this test affects the operation are excluded from the test.

[Operation]

Operation : n 0 1 1 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

RAM 11

RAM WR OK

END 11

RAM 11

RAM WR OK

END 11

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

[ 4 ] RAM READ ONLY Test

[Function]

Tests whether reading on RAM is correctly performed.

Be sure to perform “[3] RAM WRITE/READ Test” before this test.

[Operation]

Operation : n 1 1 1 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

RAM 111

RAM RD OK

END 111

RAM 111

RAM RD OK

END 111

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

— 48 —

Page 51

[ 5 ] FLASH ROM CLEAR Test

[Function]

Tests whether FLASH ROM Clear erases the memory correctly.

After this test, be sure to perform “[6] FLASH ROM WRITE/READ Test” before conducting other

tests. If other tests are performed without having conducted FLASH ROM WRITE/READ Test, the

program may be damaged and may not operate properly. Should this occur, perform all operations

starting from IPL.

[Operation]

Operation : c n 2 1 2 ST

c: Specifying FLASH ROM

0 FLASH ROM (for programming)

1 FLASH ROM (for hibernation)

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

FLASH ROM (for programming)

FLASH 0n212

FLASH CLR OK

END 0n212

FLASH 0n212

FLASH CLR OK

END 0n212

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

FLASH ROM (for hibernation)

FLASH hib 1n212

FLASH hib CLR OK

END 1n212

FLASH hib 1n212

FLASH hib CLR OK

END 1n212

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

— 49 —

Page 52

[ 6 ] FLASH ROM WRITE/READ Test

[Function]

Tests whether writing/reading to FLASH ROM is correctly performed.

This test targets all areas except for the data protection areas.

Be sure to perform “[5] FLASH ROM CLEAR Test” before this test. If other tests are performed

without having conducted FLASH ROM CLEAR test, this program may be damaged and may not

operate properly. Should this occur, perform all operations starting from IPL.

[Operation]

Operation : c n 0 1 2 ST

c: Specifying FLASH ROM

0 FLASH ROM (for programming)

1 FLASH ROM (for hibernation)

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

FLASH ROM (for programming)

FLASH 0n012

FLASH WR OK

END 0n012

FLASH ROM (for hibernation)

FLASH hib 1n012

FLASH hib WR OK

END 1n012

FLASH 0n012

FLASH WR OK

END 0n012

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

FLASH hib 1n012

FLASH hib WR OK

END 1n012

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

— 50 —

Page 53

[ 7 ] FLASH ROM CLEAR & WRITE/READ Test

[Function]

Clears FLASH ROM memory and tests whether writing/reading is correctly performed.

[Operation]

Operation : c n 3 1 2 ST

c: Specifying FLASH ROM

0 FLASH ROM (for programming)

1 FLASH ROM (for hibernation)

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

FLASH ROM (for programming)

FLASH 0n312

FLASH CLR&WR OK

END 0n312

FLASH ROM (for hibernation)

FLASH hib 1n312

FLASH hib CLR&WR OK

END 1n312

FLASH 0n312

FLASH CLR&WR OK

END 0n312

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

FLASH hib 1n312

FLASH hib CLR&WR OK

END 1n312

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

— 51 —

Page 54

[ 8 ] FLASH ROM CHECK SUM Test

[Function]

Performs CHECK SUM of FLASH ROM.

This test is exclusively for FLASH ROM for programming.

[Operation]

Operation : n 5 1 2 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

FLASH n512

FLASH CHK SUM OK

END n512

FLASH n512

FLASH CHK SUM OK

END n512

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

[ 9 ] CF-CARD CLEAR Test

[Function]

Tests whether CF card is clears properly.

The data contained and the operation of the CF card used for this test cannot be guaranteed.

[Operation]

Operation : n 2 1 3 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

CF-CARD n213

CF CLR OK

END n213

CF-CARD n213

CF CLR OK

END n213

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

— 52 —

Page 55

[ 10 ] CF-CARD WRITE/READ Test

[Function]

Tests whether writing in /reading CF Card is correctly performed.

Be sure to perform “[9] CF-CARD CLEAR Test” before this test.

After a CF Card is used for this test, the data contained in it and its operation cannot be

guaranteed.

[Operation]

Operation : n 0 1 3 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

CF-CARD n013

CF WR OK

END n013

CF-CARD n013

CF WR OK

END n013

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

[ 11 ] CF-CARD READ ONLY Test

[Function]

Tests whether reading on CF Card is correctly performed.

Be sure to perform “[10] CF-CARD WRITE/READ Test” before this test.

After a CF Card is used for this test, the data contained in it and its operation cannot be

guaranteed.

[Operation]

Operation : n 1 1 3 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

CF-CARD 113

CF RD OK

END 113

CF-CARD 113

CF RD OK

END 113

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

— 53 —

Page 56

[ 12 ] CF-CARD CLEAR&WRITE/READ Test

[Function]

Clears CF Card memory and tests whether writing/reading is correctly performed.

After a CF Card is used for this test, the data contained in it and its operation cannot be

guaranteed.

[Operation]

Operation : n 3 1 3 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

CF-CARD n313

CF CLR&WR OK

END n313

CF-CARD n313

CF CLR&WR OK

END n313

* If the test ends with errors, the line number

and the address are printed instead of OK

message.

— 54 —

Page 57

[ 13 ] LCD Test

Green Blue

Reverse

check

RedWhiteBlack

Check (black

and white)

[Function]

Tests whether LCD operates correctly.

When performing a single test:

To change the screen, touch any part of the panel.

In order to complete the test, the operator must determine pass(OK)/fail(NG) of the result.

When performing test infinitely:

The screens change automatically.

Press ESC to end the test.

[Operation]

Operation : n 0 2 1 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

LCD n021

Please Hit Key OK−>1 NG−>9

LCD OK

LCD n021

LCD OK

END n021

END n021

[ 14 ] LCD Backlight OFF Test

[Function]

Tests whether LCD Backlight turns OFF properly.

In order to complete the test, the operator must determine pass(OK)/fail(NG) of the result.

The backlight is set to OFF after the test. Touch any part of the Touch Panel and determine

pass(OK)/fail(NG) of the result.

(1) LCD Backlight turns OFF

(2) Touch any part of the panel

(3) LCD Backlight turns ON

(4) The operator determines pass(OK)/fail(NG) of the test result

[Operation]

Operation : 1 2 1 ST

[LCD] [PRINT]

LCD BACK LIGHT 121

Please Hit Key OK−>1 NG−>9

LCD BACK LIGHT OK

END 121

— 55 —

LCD BACK LIGHT 121

LCD BACK LIGHT OK

END 121

Page 58

[ 15 ] LCD Calibration Setting

Display on/off key

[Function]

Configures the calibration settings of the LCD (Touch Panel).

When touching the cross marks on the LCD, 10 coordinates shown below are indicated in

sequence.

(X,Y) =

[Operation]

Operation : 2 2 1 ST

<To skip the calibration setting]>

The screen below appears after entering a command and before the cross marks appear on

the screen.

You may skip the calibration mode by following the instruction on the screen.

Enter the Caribration mode

==>> Push Disp on/off key

Skip the Caribration mode

==>> Touch the panel

(25,19)

(999,19)

(487,19)

(25,749)

(999,749)

➉

(487,19)

(25,365)

(999,365)

(487,749)

(487,365)

Enter the Calibration mode: Press DISP ON/

OFF switch

Skip: Touch any part of the panel

<To enter the Calibration Mode>

Once the Calibration Mode is launched, cross marks appear on the LCD one by one.

When you touch the cross marks appear in sequence, the data of 9 coordinates on the LCD panel

and Touch Panel are obtained and any discrepancies are calculated. After the position of the 10th

coordinate is calculated and displayed, the offset value is to be confirmed. If the position of the

10th coordinate you touched differ that of the displayed coordinate only within a margin of errors,

it is determined as OK. If not, it is determined as NG. The offset values are written on EEPROM of

the panel controller when the operator touches the 9th coordinate.

<Calibration Test Results>

If the position data of the 10th coordinate falls within the values shown below after the

calibration offset, the precision is determined to be acceptable and OK is displayed and

printed out before ending the test. If the values exceed the range below, the result fails and

the test ends.

• X10: within 487±12

• Y10: within 365±12

— 56 —

Page 59

[LCD]

TOUCH START 221

Enter the Caribration mode

==>> Push Disp on/off key

Skip the Caribration mode

==>> Touch the panel

(X1,Y1) : (XXX,XXX)

(X2,Y2) : (XXX,XXX)

:

(X9,Y9) : (XXX,XXX)

(X10,Y10) : (XXX,XXX)

TOUCH OK

END 221

[PRINT]

TOUCH START 221

(X1,Y1) : (XXX,XXX)

(X2,Y2) : (XXX,XXX)

:

(X9,Y9) : (XXX,XXX)

(X10,Y10) : (XXX,XXX)

TOUCH OK

END 221

LCD display only

Displays data 1 for calibration

Displays data 2 for calibration

:

Displays data 9 for calibration (Performs offset)

Displays the position of the 10th coordinate (performs

calibration) (Checks offset errors)

Result of the offset value check

— 57 —

Page 60

[ 16 ] VRAM CHECK Test

VRAM

16MB

Display Area

(3Mbyte)

Te

stArea

LIME

Register Area * LIME : Internal Memory Area

00FFFFFFh

00300000h

00FFFFFFh

01FC0000h

01FFFFFFh

00000000h

[Function]

Checks VRAM of the LCD.

All areas except for the GDC system area are subjected to this test.

VRAM is not backed up by the battery. A power failure during the test results in an error.

This test uses the same test data as RAM Test to write on VRAM.

[Operation Overview]

(1) Write the test data from the beginning to the end of VRAM Test area.

(2) Verifies the written data from the beginning to the end of VRAM Test area.

(3) Displays and prints out the test result.

* If an error occurs, the test is immediately terminated and the result is displayed and printed out.

If the test is set to repeat indefinitely, the operation returns to Step (1) and continues the test.

* When the test is set to repeat indefinitely, Steps (1) through (3) repeat as a set until [ESC] is

pressed.

[Test area]

This test targets the free areas of VRAM (TestArea).

[Operation]

Operation : n 7 2 1 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

LCD VRAM 721

LCD VRAM OK

LCD VRAM NG address

END 721

* If an NG occurs, the address of the error is displayed /printed out.

* The counter is displayed on the LCD during the test.

— 58 —

LCD VRAM 721

LCD VRAM OK

LCD VRAM NG address

END 721

Page 61

[ 17 ] REAR DISPLAY Test

ABCDEFGHIJKLMNOPQRST

UVWXYZabcdefghijklmn

Pattern 1

ABCDEFGHIJKLMNOPQRST

UVWXYZabcdefghijklmn

Pattern

2

Pattern 3Pattern 4

Command

input

END

[Function]

Tests whether REAR DISPLAY operates correctly.

The backlight turns emerald green (white and green) during the test and turns off when the test

ends.

When performing a single test:

To change the screen, touch any part of the panel.

In order to complete the test, the operator must determine pass(OK)/fail(NG) of the result.

When performing test infinitely:

The screens change automatically.

Press ESC to end the test.

[Operation]

Operation : n 3 2 2 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

REAR DISP n322

Please Hit Key OK−>1 NG−>9

REAR DISP OK

REAR DISP n322

REAR DISP OK

END n322

END n322

— 59 —

Page 62

[ 18 ] REAR DISPLAY Backlight Test

Back light OFF

White

Green

Emerald green

[Function]

Tests whether REAR DISPLAY backlight operates correctly.

In order to complete the test, the operator must determine Pass(OK)/fail(NG) of the result. (When

performing a single test)

The specified backlight turns on while performing the test and turns off when the test ends.

[Operation]

Operation : c n 1 2 2 ST

c: Specifying the backlight color

0 Batch test (batch-test the specified colors 1 through 4)

1 OFF (green OFF/white OFF)

2 White (green OFF/white ON)

3 Green (green ON/white OFF)

4 Emerald green (green ON/ white OFF)

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[Batch Test]

Touching any part of the panel changes the color in the following sequence.

[LCD] [PRINT]

REAR DISP 122

Please Hit Key OK−>1 NG−>9

REAR BACK LIGHT OK

REAR DISP 122

REAR BACK LIGHT OK

END 122

END 122

— 60 —

Page 63

[ 19 ] REAR DISPLAY Contrast Adjustment

ABCDEFGHIJKLMNOP

QRSTUVWXYZabcdef

[Function]

Adjusts the contrast of REAR DISPLAY and writes the adjustment values on FLASH.

FLASH may be written up to 16 times. Writing more than 16 times results in an error. When such

an error occurs, you may follow the procedure “Clearing the contrast area” to re-initialize FLASH.

The contrast setting at the restart is the value written in the previous adjustment (“128” when

no value has been written). You may write the adjustment values by entering [ST] after an

adjustment. The contrast may be set at 256 increments within the range of 0 – 255.

[Operation]

Operation : 4 2 2 ST

When you launch the mode by using the above command, use the following keys to operate.

• Numeric key [1]: DARK key Current contract +1

• Numeric key [9]: LIGHT key Current contract -1

• ST: Finalize the entry (writes on FLASH and complete the sequence)

• ESC: Cancel adjustment (ends the mode)

[REAR DISPLAY]

[LCD]

REAR DISP 422

CONTRAST XXX

LED display only. XXX indicates the contrast value.

REAR CONTRAST Set value

REAR CONTRAST NG

REAR CONTRAST OVER

REAR CONTRAST ESC

REAR CONTRAST ERASE

An error is printed

The maximum times of writing is exceeded

When leaving the sequence without setting the contrast

When the contrast area is cleared

END 422

[PRINT]

REAR DISP 422

REAR CONTRAST Set value

REAR CONTRAST NG

REAR CONTRAST OVER

REAR CONTRAST ESC

REAR CONTRAST ERASE

END 422

[Clearing the Contrast Area]

FLASH may be written up to 16 times. If you wish to write more than 16 times, execute the

following command to clear the area and initialize FLASH.

1 0 4 2 2 ST

— 61 —

Page 64

[ 20 ] REMOTE DISPLAY Test:

ABCDEFGHIJKLMNOP

QRSTUVWXYZabcdef

0,1,2,3,4,5,6,7,8,9,

[Function]

Tests whether the data is correctly displayed on REMOTE DISPLAY.

Be sure to connect REMOTE DISPLAY to COM3. When changing the baud rate, be sure to also

change the settings on REMOTE DISPLAY. The backlight turns on in pastel green (green + white)

when performing the test and turns off when the test ends.

When performing a single test:

In order to complete the test, the operator must determine pass(OK)/fail(NG) of the result.

After the operator determines pass(OK)/fail(NG), the display and the backlight turn off.

When repeating the test infinitely:

Repeats transmitting the same test text at a set interval.

Press [ESC] to terminate the test, clear the display, and turn off the backlight.

[Operation]

Operation : b n 0 2 3 ST

b:Specifying the baud rate

0 19.2 Kbps

1 9600 bps

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD]

REMOTE DISP bn023

Please Hit Key OK−>1 NG−>9

REMOTE DISP OK

END bn023

[PRINT] [REMOTE DISPLAY]

REMOTE DISP bn023

REMOTE DISP OK

END bn023

— 62 —

Page 65

[ 21 ] External Printer Output Test

[Function]

Connects a printer with a RS232C interface and tests whether the printer operates and prints

properly. The external printer must be connected to COM.

[Operation]

Operation : x1 x2 x3 n m 3 d ST

x1: Printout format

0 Pattern A

1 Pattern B

x2: Specify COM port

1 COM1

2 COM2

3 COM3

4 COM4

5 COM5

6 COM6

x3: Specify the baud rate

1 4800 bps

2 9600 bps

3 19.2 kbps

< Printer baud rate table >

When changing the baud rate, be sure to also change the baud rate of the printer.

19.2 kbps 9600 bps 4800 bps

SLIP SP1300

RJ UP360/UP400

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

m: Operation pattern

1 Print one line

2 Feed 5 lines + full cut

3 Print 10 lines + feed 5 lines + full cut

4 Feed 5 lines + partial cut

5 Print 10 lines + Insert 5 lines + partial cut

— 63 —

Page 66

d: Specifying a printer

1 External printer RJ

2 External printer SLIP

[LCD]

RJ is connected Error display (when a printer is disconnected)

PRT xxxn03d

NON PRINTER ERR

END xxxn03d

[PRINT]

There are two formats to print out to the external printer.

RJ is set at 40 lines and SLIP at 35 lines.

Pattern A Pattern B

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBB *8,888,88

— 64 —

Page 67

[ 22 ] Ethernet Printer Output Test

HUB

PRINTER

UP-400

QT-6600

[Function]

Tests whether the Ethernet printer operates and prints out properly.

The illustration below shows how QT-6600 and the printer are connected.

< Printer settings >

The printer settings are fixed. Please configure the printer to be used before the test.

IP address: 192.168.0.100

Subnet mask: 255.255.255.0

Default gateway: 192.168.0.200

TCP port number: 9100

Baud rate: AutoNegotiation

QT-6600 operates with IP address 192.168.0.1 at the fixed baud rate of 100M.

* Ethernet does not operate without setting a MAC address. Be sure to set a unique MAC address

before use.

* If Ethernet has already been tested, run all operations starting from INIT boot-up.

[Operation]

x1: Printout format

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

m: Operation pattern

Operation : x1 0 0 n m 3 7 ST

0 Pattern A

1 Pattern B

1 Print one line

2 Feed 5 lines + full cut

3 Print 10 lines + feed 5 lines + full cut

4 Feed 5 lines + partial cut

5 Print 10 lines + Insert 5 lines + partial cut

— 65 —

Page 68

[LCD]

PRT xxxn03d

EtherPrt OK

EtherPrt NG

When it is NG (communication error, etc.)

END xxxn03d

[PRINT]

There are two formats to print out to the external printer.

Pattern A Pattern B

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBB *8,888,88

— 66 —

Page 69

[ 23 ] COM (RS232C) Test

[Function]

Performs a loop back test on RS232C port.

This test does not generate a printout of the result.

To generate a printout, see “[25] Printing COM(RS232C) Test Result.”

Please refer to the illustration in "[24] COM(RS232C) Batch Test” for wiring.

[Operation]

Operation : x n 0 4 d ST

x: Specify the baud rate

0 2400 bps

1 4800 bps

2 9600 bps

3 19200 bps

4 38400 bps

5 57600 bps

6 115200 bps

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

d: Specify COM port

0 Batch

1 COM1

2 COM2

3 COM3

4 COM4

5 COM5

6 COM6

[LCD]

COM1 xn04d

RTSx=1 → CTSx=1 OK

DTRx=1 → DSRx=1 OK

DTRx=1 → CDx=1 OK

DTRx=1 → CIx=1 OK

RTSx=0 → CTSx=0 OK

DTRx=0 → DSRx=0 OK

DTRx=0 → CDx=0 OK

DTRx=0 → CIx=0 OK

TxD → RxD OK

END xn04d

Displays only COM1

Displays only COM1

Displays only COM1

Displays only COM1

x: COM number

— 67 —

Page 70

[ 24 ] COM (RS232C) Batch Test

T x D

R x D

C T S

R T

S

D T R

DS R

C D

C I

T x D

R x D

C T

S

R T

S

D T R

DS R

COM1 COM2~COM6

∗ ∗

∗

∗

: output “1” � “0” from the output terminal and checks the input terminal.

∗

Figure : RS232C port connection

[Function]

Performs a loop back batch test on RS232C port.

When performing this test, attach the loop back connecters to all COM ports.

Please see below for how to wire.

[Operation]

Operation : 4 0 ST

Baud rate: COM1: 115 kbps, COM2-6: 19.2 kbps

Number of test: once (fixed)

[LCD]

COM BATCH 40

.

.

.

END 40

Refer to the previous paragraph "COM Test."

— 68 —

Page 71

[ 25 ] Printing COM (RS232C) Test Result

[Function]

Prints out COM (RS232C) test results.

The printer must be connected to COM1 port at 9600 bps.

[Operation]

Operation : 4 7 ST

[PRINT]

COM1 47

RTSx=1 → CTSx=1 OK

DTRx=1 → DSRx=1 OK

DTRx=1 → CDx=1 OK

DTRx=1 → CIx=1 OK

RTSx=0 → CTSx=0 OK

DTRx=0 → DSRx=0 OK

DTRx=0 → CDx=0 OK

DTRx=0 → CIx=0 OK

TxD → RxD OK

END 47

x: COM number

Prints only COM1

Prints only COM1

Prints only COM1

Prints only COM1

When no test has been performed after IPL or INIT

COM* NO TEST

* In case of "NO TEST", the printout shows TxD RxD as failed (NG) and the rest as successful (OK).

— 69 —

Page 72

[ 26 ] Ethernet Test

CNT(2BYTE) DATA 00h~FFh,00h~FFh,00h~FFh,...(1444BYTE)

Lowest 8 bits of

the test counter

Highest 8 bits of

the test counter

[Function]

Tests the Ethernet counter communication.

QT-6600 in the reception mode becomes on standby and, then, QT-6600 in the transmitting mode

sends data.

Once the communication opens properly, the number of successful/failed communication to LCD

is displayed on the counter, which will be printed out when the test ends.

* Ethernet does not operate without setting a MAC address. Be sure to set a unique MAC address

before use.

* When testing the Ethernet counter communication without a HUB, the AutoNagotiation function

is disabled. Set the baud rate at 100base to run a test.

* If an Ethernet printer test has been performed beforehand, run all operations stating from INIT

boot-up.

< Transmitting/receiving data >

Test counter: counts up from 1 through INT Max. and returns to 1.

The test data length (CNT + DATA) is 1446 bytes in total, excluding the Ethernet header, the IP

header, the TP header, etc.

<TCP Mode>

A counter communication test by TCP protocol with an error control.

When the receiving end (command below a=2) receives the data properly, the data is checked

and returned (FBh – 01h, 00h, FFh-00h) to the transmitting end, which checks the data returned

(repeats the operations).

[Operation]

When an ID is set, perform the test with that ID. When you change the ID, run all operations

starting from INIT boot-up. The same applies to the baud rate.

Operation : b m 0 a 5 1 ST

b: Baud rate

0 Any number except for 1 (or not specified) → AutoNegotiation

1 100BASE

m: ID

<ID>

1 through 9 are valid numbers for the ID. If an invalid value is assigned, number 1 is automatically

set and IDs are converted as shown in the example below.

The upper values of the IP address are fixed at 192.168.0 and the lowest number corresponds to

the ID.

e.g. ID=1 → IP address = 192.168.0.1, ID=9 →IP address = 192.168.0.9

Note that the address is 192.168.0.10 in the receiving mode regardless of the ID. In the

transmitting mode, the data is sent to a fixed address of 192.168.0.10.

— 70 —

Page 73

a: Transmitting/receiving mode

0 TCP transmitting mode

1 TCP receiving mode

5 Ping transmission

Transmitting and receiving continue unless an error occurs.

Press ESC to terminate the test. (To terminate the test, operate at the transmitting end.)

<Ping transmission>

Ping is sent to 192.168.0.10. When a ping is transmitted, the counter adds a value. After

terminating it with ESC key, the number of successful/failed communication is displayed.

[LCD]

ETHERNET bm0a51

TCP MODE

OK xxxx NG xxxx

END bm0a51

[PRINT]

ETHERNET bm0a51

TCP MODE

OK xxxx NG xxxx

END bm0a51

Prints the number of successful and failed communicationupon the end of the test

— 71 —

Page 74

[ 27 ] Setting MAC (Media Access Control Address

[Function]

Configures MAC address

[Operation]

When an ID is set, perform the test with that ID. When you change the ID, run all operations

starting from INIT boot-up.

Operation : x 0 9 5 1 ST

x: Specifying how to write the address

Writes a continual address based on MAC address on CF Card.

<e.g.>

0

When ASCII data “080074FF0300” is on MACADR.TXT file in a CF Card,

080074FF0301, the value to which 1 is added to the aforementioned address, is to

be written on MAC address area. Then the same value is written in the CF Card.

Writes MAC address manually.

In the manual mode, MAC address will be on standby.

An address may be entered by 8 bits. Enter 3 decimal values + press [ST] to confirm

8 bits.

By repeating this step 6 times (48 bits), a 48-bit address is entered and, upon pressing [ST] for the 6th time, written. Each time an 8-bit value is entered, the address

1

entered is displayed in hexadecimal value.

Performing CLEAR resets the address. Or pressing ESC terminates the step without

writing an address.

<e.g.>

To write a MAC address 080074FF0300

After entering the manual writing mode, entering a numeric value 008 + [ST] → 000 + [ST]

→ 116 + [ST] → 255 + [ST] → 003 + [ST] → 000 + [ST] writes the address.

[LCD]

When configuring using a CF Card

MAC ADDRESS x0951

Write EEPROM : ******

END x0951

When configuring manually

MAC ADDRESS x0951

1 : 008

2 : 000

3 : 116

4 : 255

5 : 003

6 : 000

Write EEPROM : ******

END x0951

Written MAC address (in hexadecimal)

In the above example

Written MAC address (in hexadecimal)

— 72 —

Page 75

[PRINT]

When configuring using a CF Card

MAC ADDRESS x0951

Write EEPROM : ******

END x0951

When configuring manually

MAC ADDRESS x0951

1 : 008

2 : 000

3 : 116

4 : 255

5 : 003

6 : 000

Write EEPROM : ******

END x0951

— 73 —

Page 76

[ 28 ] Date/Time Setting [ 29 ] Date/Time Display

[Function]

Configures or displays the date and time.

If [ST] is pressed without an entry while Date/Time Setting, the Date/Time is displayed.

[Operation]

Date/Time Setting

Operation : h h m m s s 0 0 7 0 ST

hh: Hour, mm: minute, ss: second

Operation : y y m m d d 0 1 7 0 ST

yy: Year, mm: month, dd: day

Date/Time Display

Operation : 0 7 0 ST

Press ESC to terminate the mode.

[LCD]

When setting the date/time When displaying the date/time

DATE/TIME YYMMDD****

DATE/TIME YY/MM/DD

END YYMMDD****

****: Command

[PRINT]

When setting the date/time

DATE/TIME YYMMDD****

DATE/TIME YY/MM/DD

END YYMMDD****

When displaying the date/time

DATE/TIME 70

DATE/TIME YY/MM/DDHH:MM-SS

END 70

DATE/TIME 70

DATE/TIME YY/MM/DDHH:MM-SS

END 70

Each data will be printed only when setting the

date and time.

This line is not printed out

— 74 —

Page 77

[ 30 ] Drawer Test

[Function]

Tests whether drawers operate properly.

In order to complete the test, the operator must determine pass(OK)/fail(NG) of the result.

[Operation]

Operation : x n 0 9 1 ST

x: Drawer No.

0 Opens all drawers.

1 Opens Drawer 1

2 Opens Drawer 2

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD]

When all drawers are open When Drawer No. is specified

DRW 0n091

DRW ALL OK

END 0n091

DRW xn091

DRW n OK

END xn091

n: Drawer number

[PRINT]

When all drawers are open When Drawer No. is specified

DRW 0n091

DRW ALL OK

END 0n091

DRW xn091

DRW n OK

END xn091

— 75 —

Page 78

[ 31 ] Buzzer Test

[Function]

Tests whether the buzzer operates properly.

When performing a single test, one-shot buzzer sounds once.

When repeating a test infinitely, the buzzer sounds intermittently for 500 msec.

Press ESC key to terminate the buzzer.

[Operation]

Operation : n 0 9 2 ST

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

BUZZ n092

END n092

BUZZ n092

END n092

— 76 —

Page 79

[ 32 ] MCR Test

[Function]

Tests whether the card reader (MCR) operates properly.

The data read out is compared against the preset data to determine pass(OK)/fail(NG).

Track 1:

1234567890123456789012345678901234567890123456789012345678901234567890123456

Track 2:

1234567890123456789012345678901234567

[Operation]

Operation : 9 6 ST

[LCD]

MCR 96

MCR1 OK

MCR2 OK

MCR1 ******************

**************************************

MCR2 OK

MCR1 OK

MCR2 ******************

********************

END 96

When it is operating properly

When MCR1 data does not match the test data

When MCR2 data does not match the test data

[PRINT]

MCR 96

MCR1 OK

MCR2 OK

MCR1 ******************

**************************************

MCR2 OK

MCR1 OK

MCR2 ******************

********************

END 96

— 77 —

Page 80

[ 33 ] Sound Test

[Function]

Tests whether sound is replayed properly through the internal or external speaker.

In order to complete the test, the operator must determine pass(OK)/fail(NG) of the result. (when

performing a single test)

[Operation]

Operation : a x n 0 9 7 ST

a: Volume

0 Max. volume

The volume may be set at 7 increments (including 0)

1 ~ 7 When 8 or 9 is entered, the volume is set at level 7

The larger the value, the lower the volume.

x: Selecting sound data

0 Replay the data recorded in Command 98

1 ~ 9 Replay specific sound data

n: Number of times

0 or no value To perform a single test

A value other than 0 (1 ~ 9) Tests repeat infinitely (press ESC to terminate)

[LCD] [PRINT]

SOUND axn097

SOUND OK

SOUND axn097

SOUND axn097

SOUND OK

SOUND axn097

[ 34 ] Microphone Test

[Function]

Tests whether sound is replayed properly through the internal or external microphone.

Sound is recorded for 3 seconds and, then, replayed at the maximum volume.

In order to complete the test, the operator must determine pass(OK)/fail(NG) of the result.

[Operation]

Operation : 9 8 ST