Case IH 1190, 1194, 1290, 1294, 1390 Shop Manual

...

SHOP MANUAL

www.maskinisten.net

CASE INTERNATIONAL

(DAVID BROWN)

MODELS

1190-1194-1290-1294-13901394-1490-1494-1594-1690

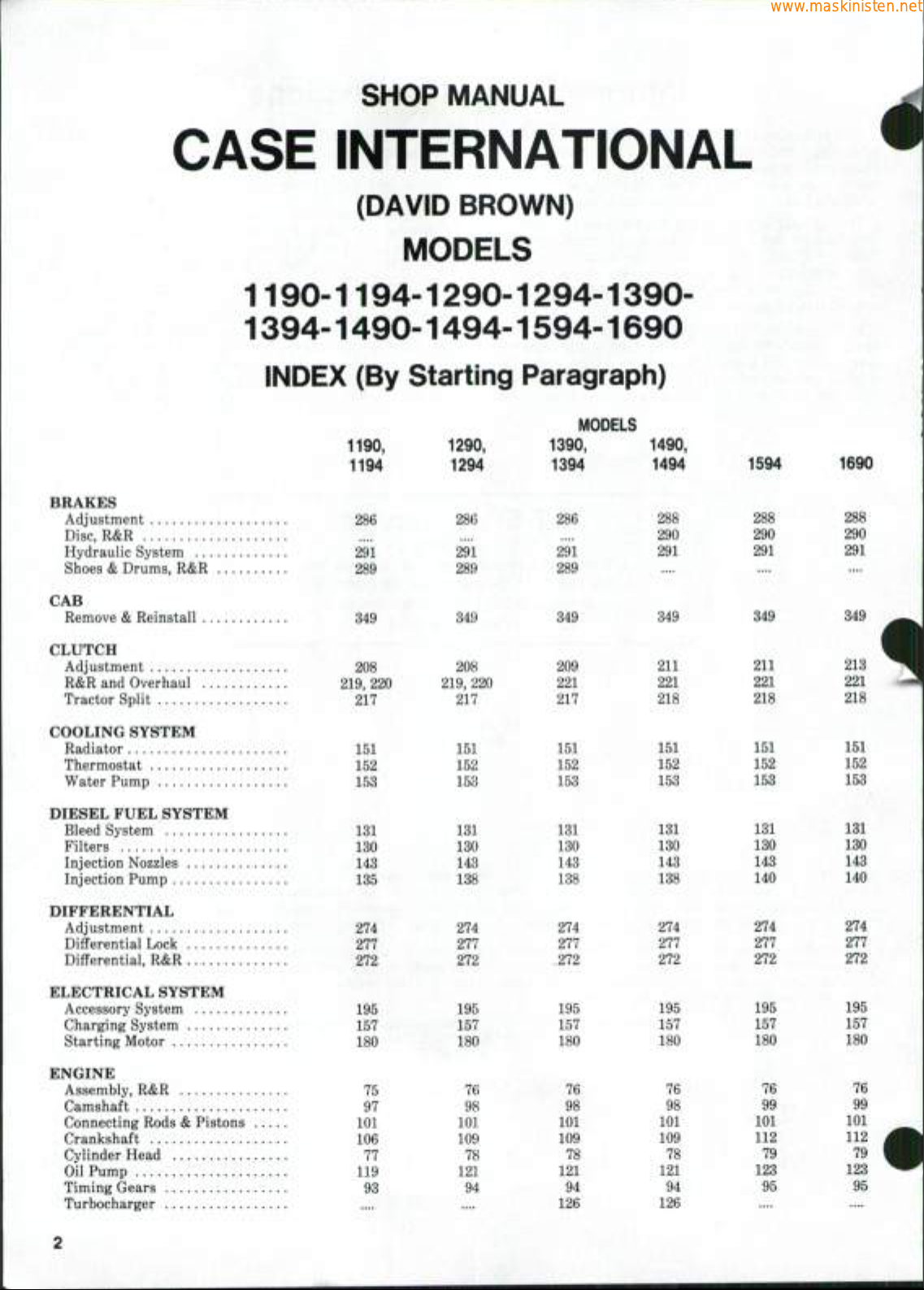

INDEX (By Starting Paragraph)

MODELS

1190,

1194

1290,

1294

1390,

1394

1490,

1494

1594

1690

BRAKES

Adjustment

Disc,

R&R

Hydraulic System

Shoes & Drums, R&R

CAB

Remove & Reinstall

CLUTCH

Adjustment

R&R and Overhaul

Tractor Split

COOLING SYSTEM

Radiator

Thermostat

Water Pump

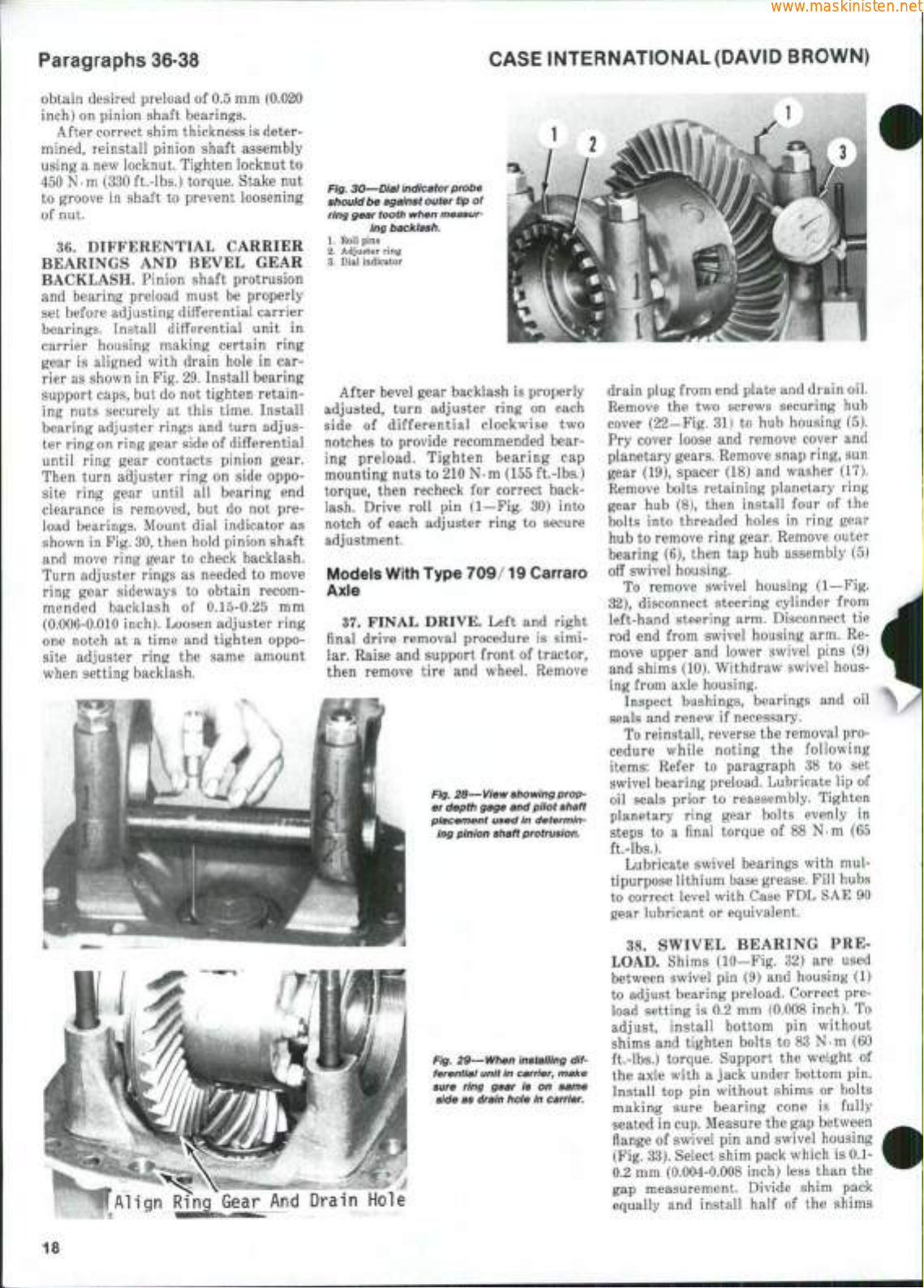

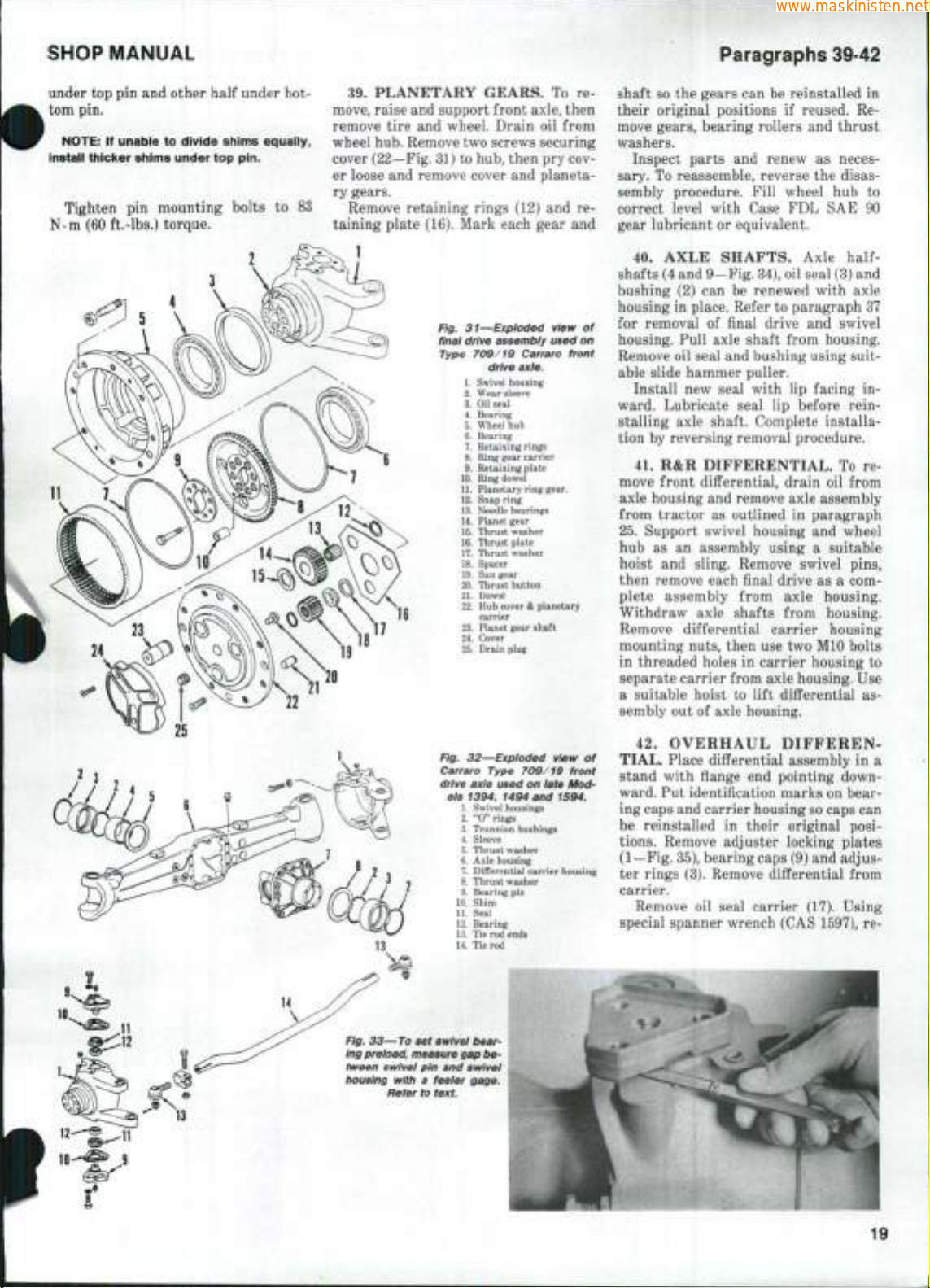

DIESEL FUEL SYSTEM

Bleed System

Filters

Injection Nozzles

Injection Pump

DIFFERENTIAL

Adjustment

Differential Lock

Differential, R&R

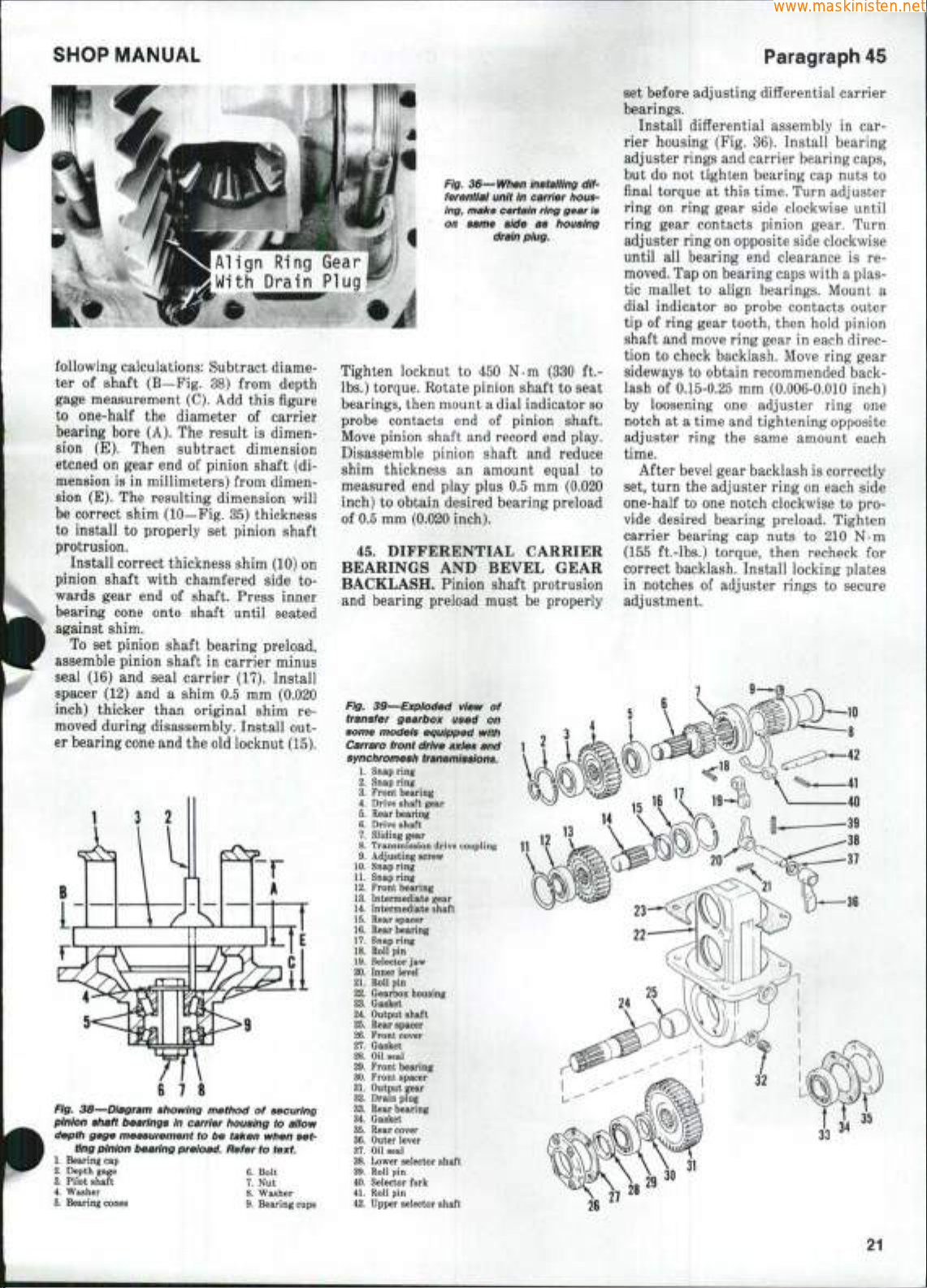

291

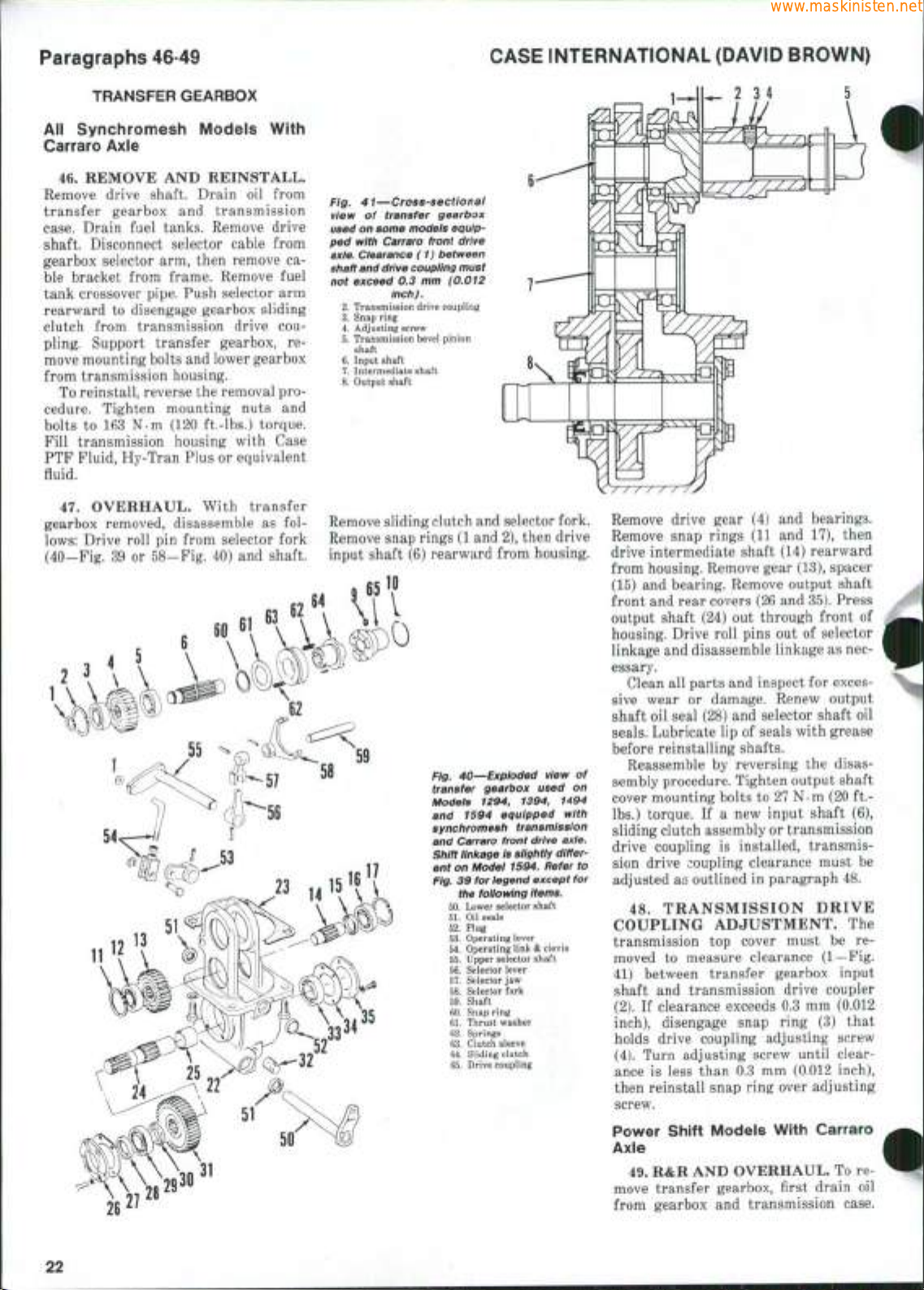

289

34S

208

219,

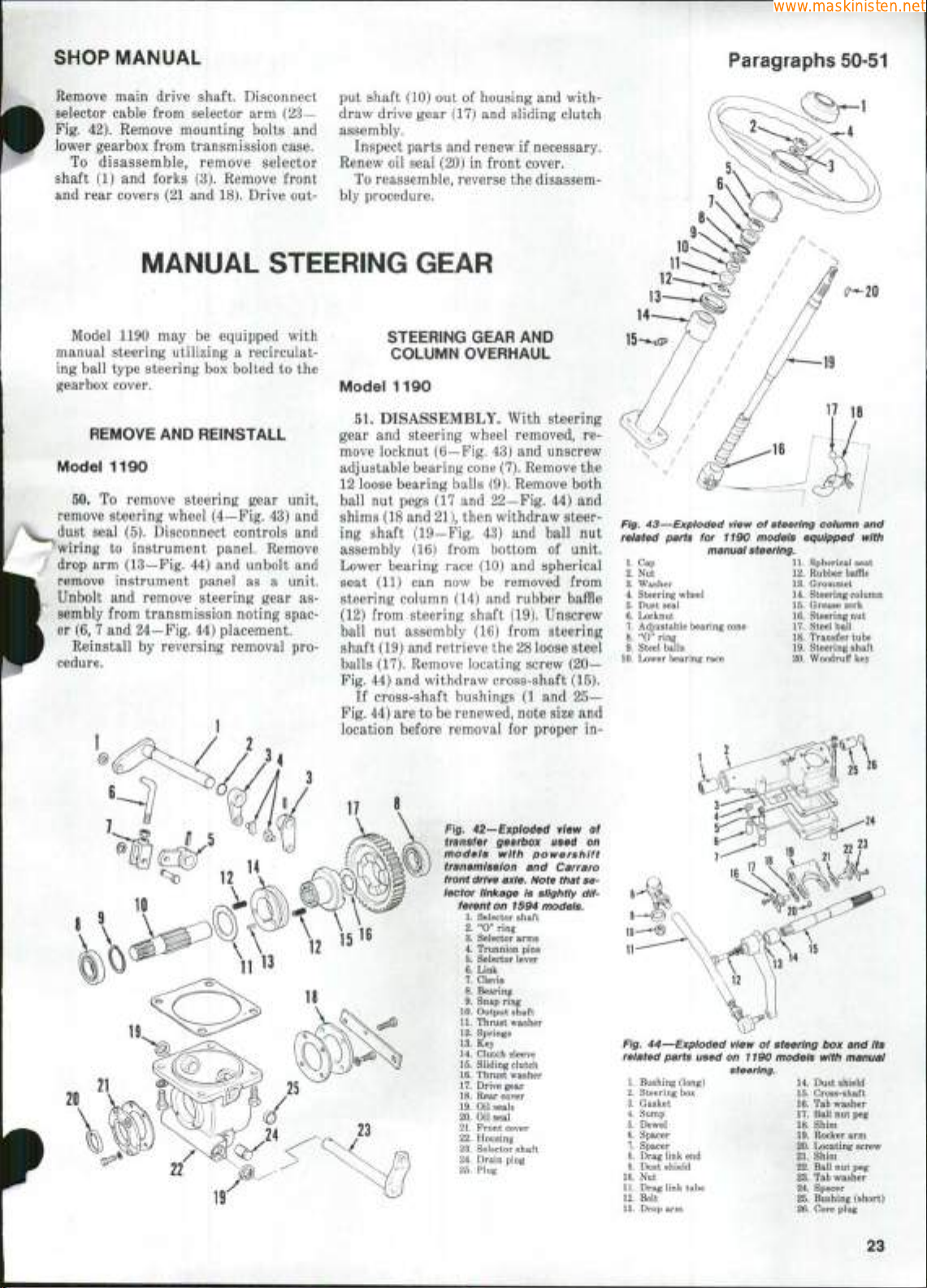

217

151

m

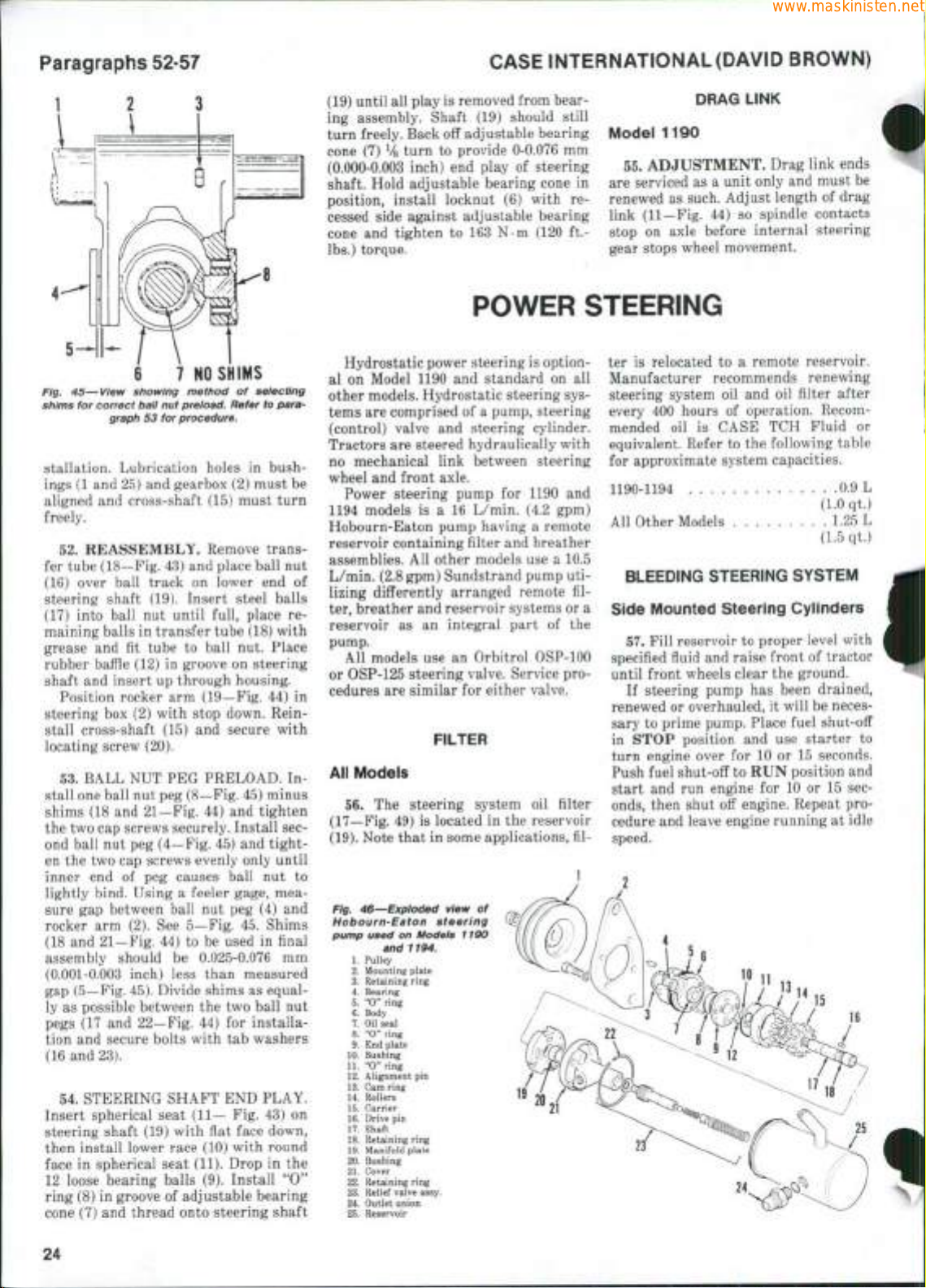

15S

m

ISO

148

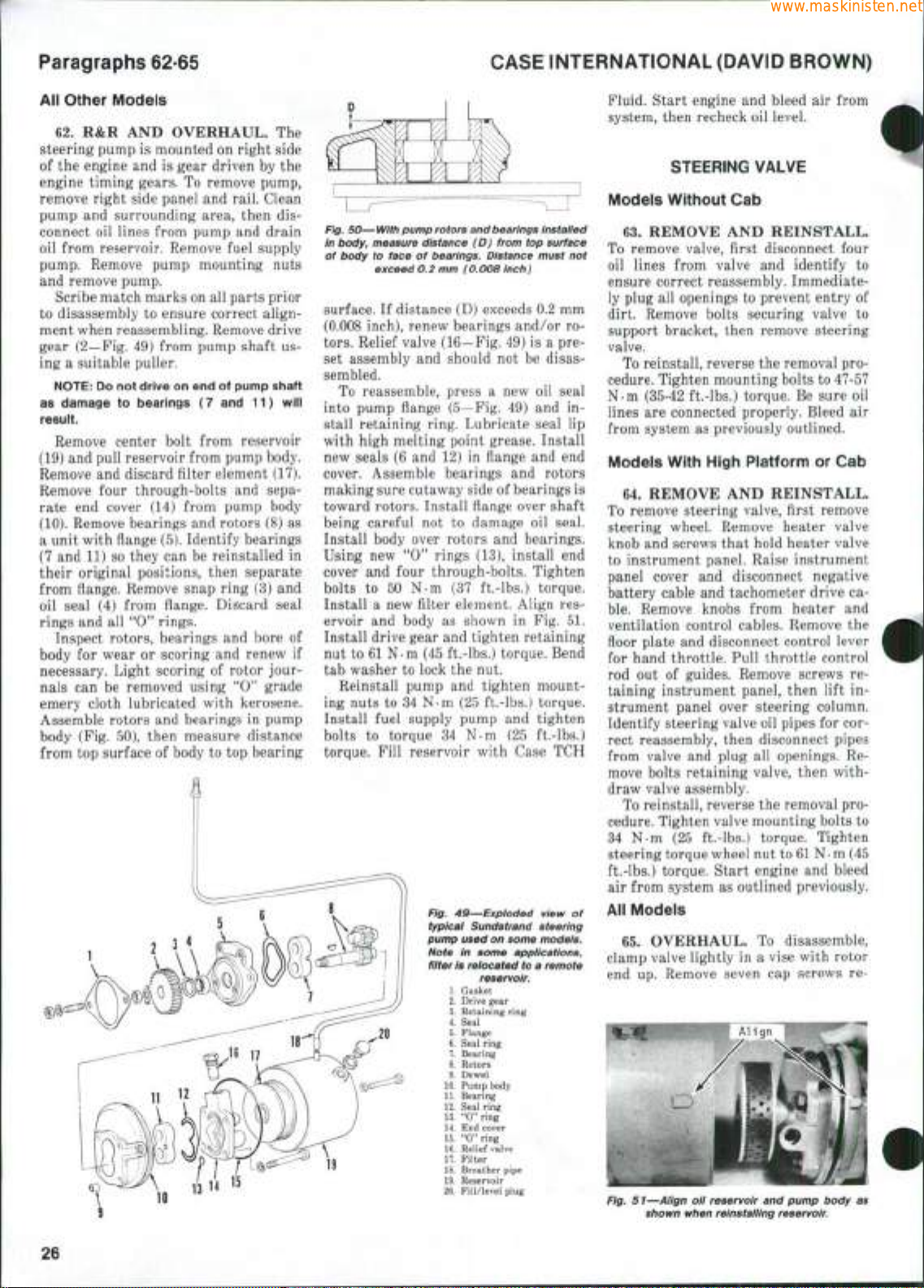

274

277

272

220

^^^ •

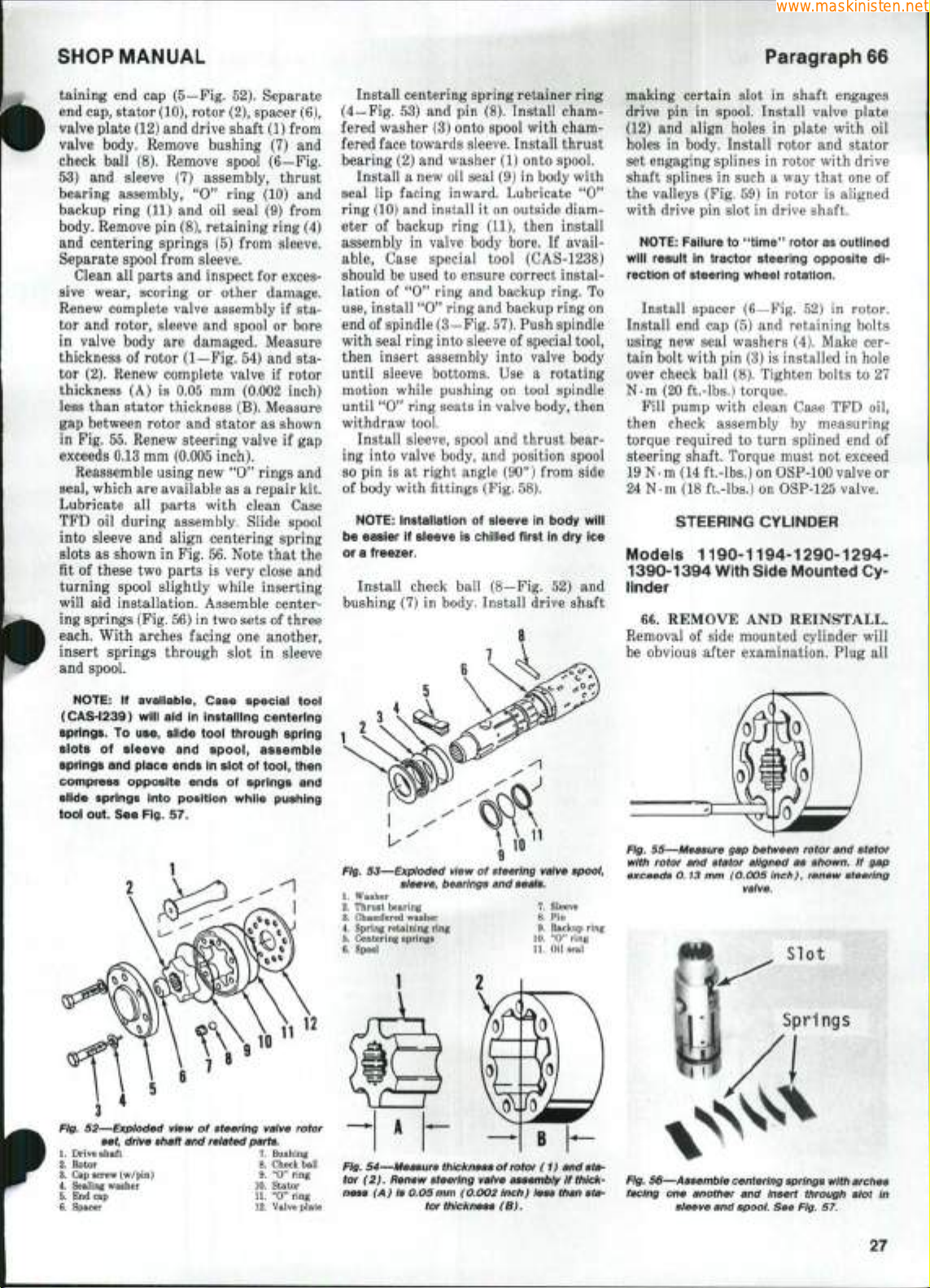

286

291

289

349

208

219,

217

151

152

153

131

130

143

138

274

277

272

220

286

291

289

349

209

221

217

151

152

153

131

130

143

138

274

277

.272

291

349

211

2ZL

218

%$l

162

IM

181

180

148

1%

274

277

272

288

290

291

349

211

221

218

151

152

153

131

130

143

140

274

277

272

288

290

291

349

213

221

218

151

152

153

131

130

143

140

274

277

272

ELECTRICAL SYSTEM

Accessory System

Charging System

Starting Motor

ENGINE

Assembly, R&R

Camshaft

Connecting Rods & Pistons

Crankshaft

Cylinder Head

Oil Pump

Timing Gears

Turbocharger

195

157

180

75

97

101

106

77

119

98

195

157

180

76

98

101

109

78

121

94

195

157

180

76

98

101

109

78

121

94

126

195

157

180

76

98

101

109

78

m

94

126

195

157

180

76

99

101

112

79

123

95

195

157

180

76

99

101

112

79

123

95

••*•

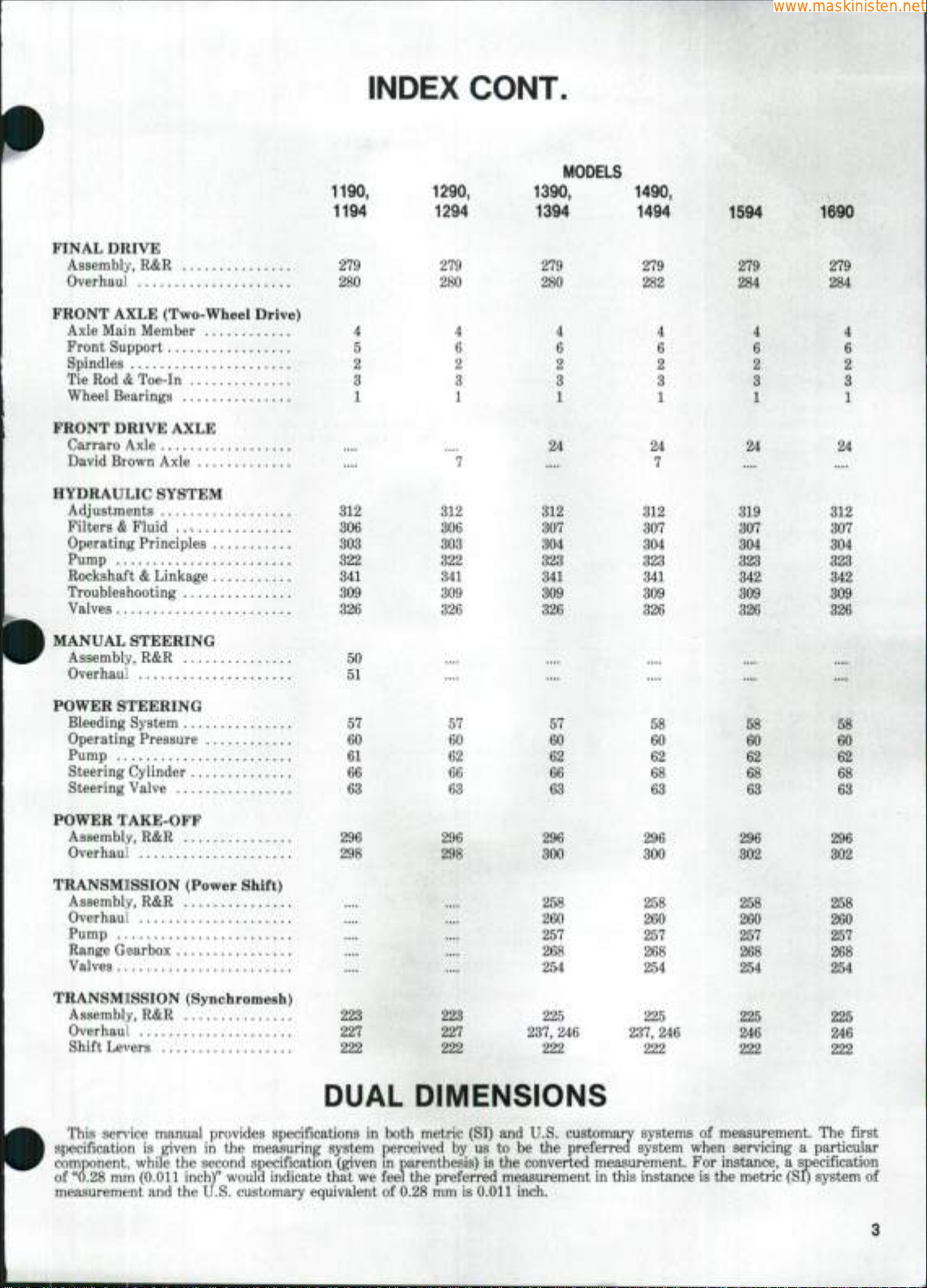

FINAL DRIVE

www.maskinisten.net

Assembly, R&R 2*79

Overhaul

280

FRONT AXLE (Two-Wheel Drive)

Axle Main Member 4

Front Support 5

Spindles 2

Tie Rod & Toe-in 3

Wheel Bearings 1

FRONT DRIVE AXLE

Carraro Axle

David Brown Axle

HYDRAULIC SYSTEM

Adjustments 312

Filters & Fluid 306

Operating Principles 303

Pump 322

Rockshai't & Linkage 341

Troubleshooting 309

Valves 326

INDEX CONT.

1190,

1194

1290,

1294

279

280

8

1

312

306

303

322

341

309

326

1390,

1394

279

280

4

6

2

3

1

24

312

307

304

323

341

309

326

MODELS

1490,

1494

279

282

24

7

312

307

304

323

341

309

326

1594

279

284

24

319

307

304

323

342

309

326

1690

279

284

4

6

2

3

1

4

6

2

a

1

24

312

307

304

323

342

309

326

MANUAL STEERING

Assembly, R&R 50

Overhaul 51

POWER STEERING

Bleeding System 57

Operating Pressure 60

Pump 61

Steering Cylinder 66

Steering Valve 63

POWER TAKE-OFF

Assembly, R&R 296

Overhaul 298

TRANSM][SSION (Power Shift)

Assembly, R&R

Overhaul

Pump

Range Gearbox

Valves

TRANSMISSION (Synchromesh)

Assembly, R&R 223

Overhaul 227

Shift Levers 222

57

60

62

66

63

296

298

57

60

62

66

63

296

300

258

260

257

268

....

223

227

222

254

225

237,

222

246

DUAL DIMENSIONS

296

300

258

260

257

268

254

225

237,

222

58

60

62

68

63

246

58

60

62

68

63

296

302

258

260

257

268

254

225

246

222

58

60

62

68

63

296

302

258

260

257

268

254

22S

246

222

This sendee manual provides specifications in both metric (SI) and U.S. customary systems of measurement. The first

specification is given in the measuring system perceived b^ us to be the preferred system when servicing a particular

component, while the second specification (given in parenthesis) is the converted measurement. For instance, a specification

of "0.28 mm (0.011 inch)" would indicate that we feel the preferred measurement in this instance is the metric (SI) system of

measuremtsnt and the IJ.S. customary equivalent of 0.28 mm is 0.011 inch.

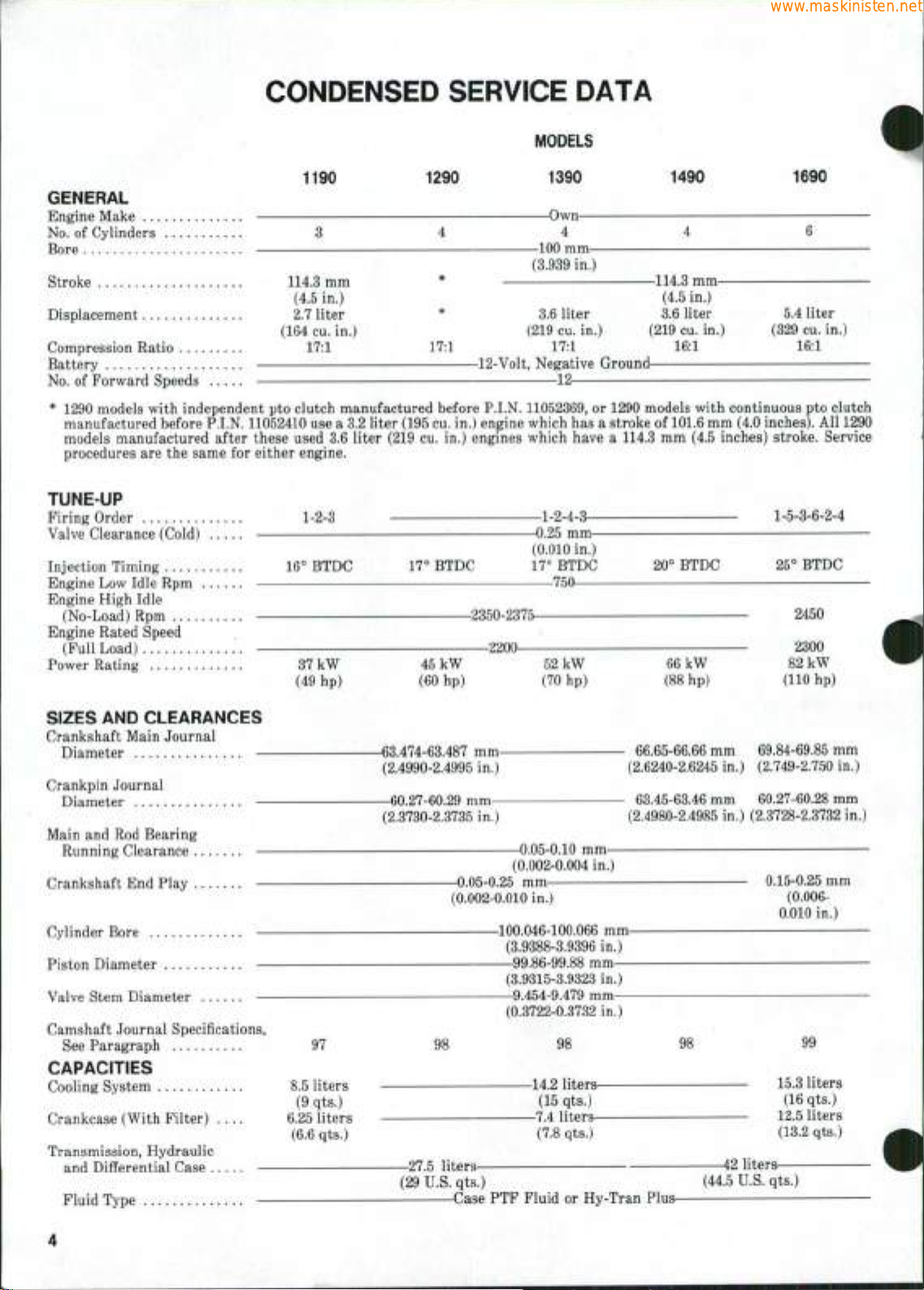

CONDENSED SERVICE DATA

www.maskinisten.net

MODELS

1190 1290 1390 1490 1690

GENERAL

Engine Make Own

No.

of Cylinders 3 4 4 4 6

Bore 100 mm

(3.939 in.)

Stroke 114.3 mm * 114.3 mm

Displacement 2.7 liter * 3.6 liter 3.6 liter 5.4 liter

Compression Ratio 17:1 17:1 17:1 16:1 16:1

Battery 12-Volt, Negative Ground

No.

of Forward Speeds 12

* 1290 models with independent pto clutch manufactured before P.I.N. 11052369, or 1290 models with continuous pto clutch

manufactured before P.I.N. 11052410 use a 3.2 liter (195 cu. in.) engine which has a stroke of 101.6 mm (4.0 inches). All 1290

models manufactured after these used 3.6 liter (219 cu. in.) engines which have a 114.3 mm (4.5 inches) stroke. Service

procedures are the same for either engine.

(4.5 in.) (4.5 in.)

(164 cu. in.) (219 cu. in.) (219 cu. in.) (329 cu. in.)

TUNE-UP

Firing Order

Valve Clearance (Cold)

Injection Timing

Engine Low Idle Rpm .

Engine High Idle

(No-Load) Rpm

Engine Rated Speed

(Full Load)

Power Rating

SIZES AND CLEARANCES

Crankshaft Main Journal

Diameter —

Crankpin Journal

Diameter —

Main and Rod Bearing

Running Clearance —

Crankshaft End Play —

Cylinder Bore —

Piston Diameter —

Valve Stem Diameter —

Camshaft Journal Specifications,

See Paragraph

CAPACITIES

Cooling System ........

Crankcase (With Filter) ....

1-2-3

16° BTDC

37 kW

(49 hp)

97

8.5 liters

(9 qts.)

6.25 liters

(6.6 qts.)

17° BTDC

-2350-23752200—

45 kW

(60 hp)

-63.474-63.487 mm(2.4990-2.4995 in.)

—60.27-60.29 mm—

(2.3730-2.3735 in.)

—0.05-0.25 mm

(0.002-0.010 in.)

-100.046-100.066 mm—99.86-99.88 mm—

—9.454-9.479 mm—

98

-0.25 mm—

(0.010 in.)

17*^

BTDC

750

52 kW

(70 hp)

-0.05-0.10 mm(0.002-0.004 in.)

(3.9388-3.9396 in.)

(3.9315-3.9323 in.)

(0.3722-0.3732 in.)

98

-14.2 liters-

(15 qts.)

-7.4 liters-

(7.8 qts.)

1-5-3-6-2-4

20° BTDC 25° BTDC

2450

2300

66 kW

(88 hp)

- 66.65-66.66 mm 69.84-69.85 mm

(2.6240-2.6245 in.) (2.749-2.750 in.)

- 63.45-63.46 mm 60.27-60.28 mm

(2.4980-2.4985 in.) (2.3728-2.3732 in.)

98

82 kW

(110 hp)

0.15-0.25

(0.006-

0.010 in.)

99

15.3 liters

(16 qts.)

12.5 liters

(13.2 qts.)

mm

Transmission, Hydraulic

and Differential Case —

Fluid Type

-27.5 liters-

(29 U.S. qts.) (44.5 U.S. qts.)

Case PTF Fluid or Hy-Tran Plus

-42 liters-

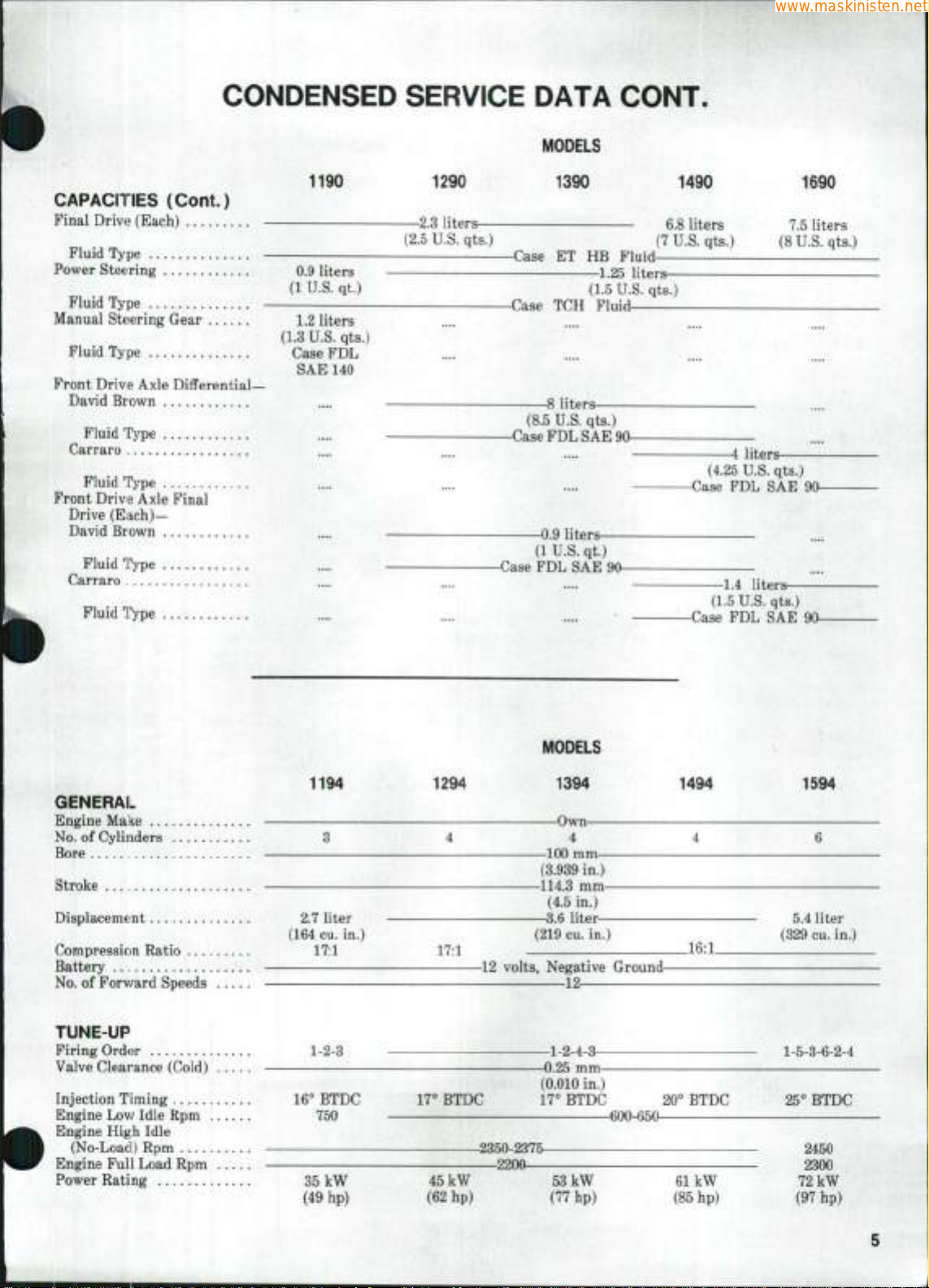

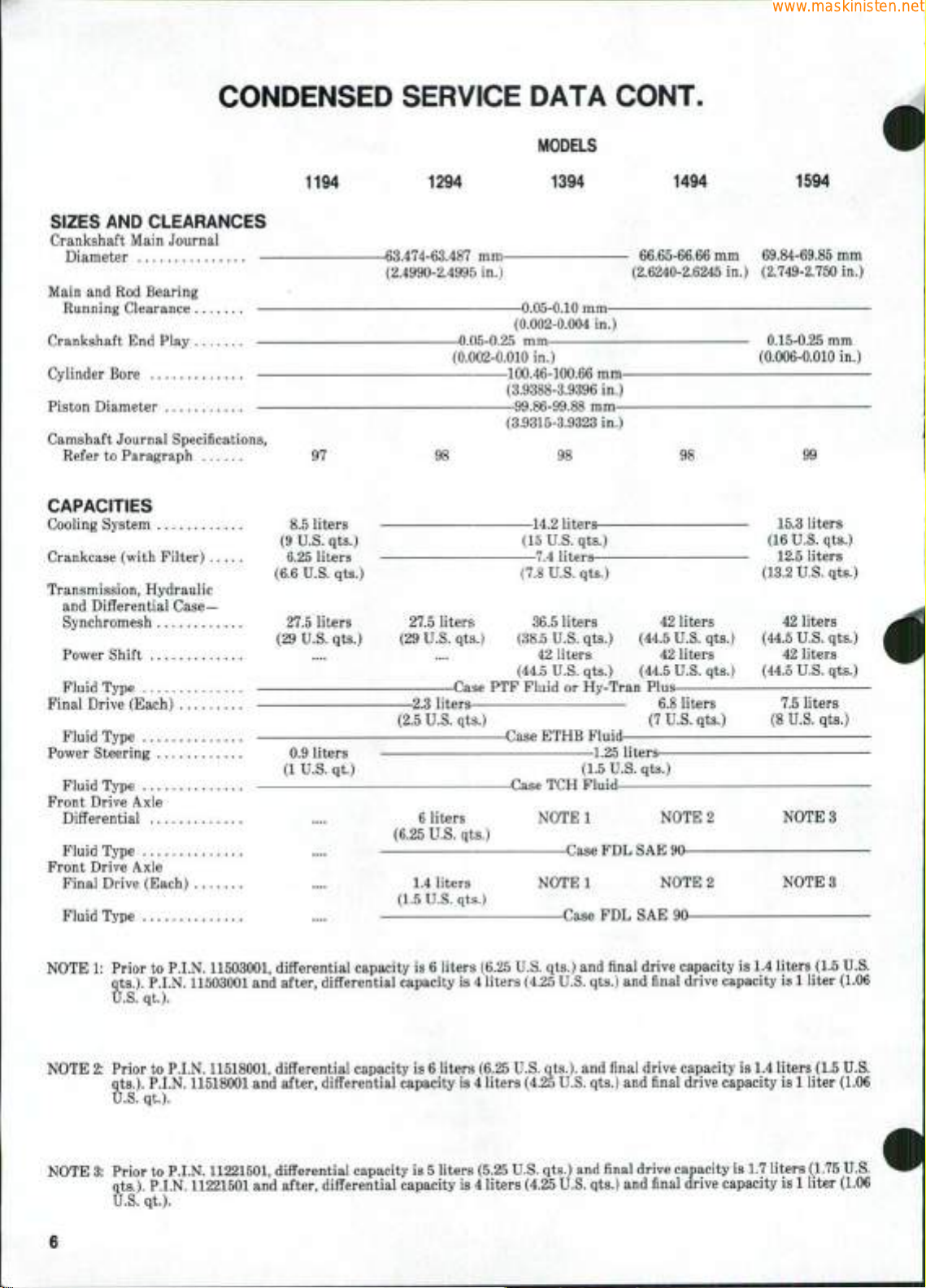

CONDENSED SERVICE DATA CONT.

www.maskinisten.net

MODELS

1190

CAPACITIES (Cont)

Final Drive (Each)

Fluid Type

Power Ste€Ting 0.9 liters

(1 U.S. qt.)

Fluid Type

Manual Steering Gear 1.2 liters

(1.3 U.S. qts.)

Fluid Type Case FDL

SAE 140

Front Drive Axle Differential-

David Brown

Fluid Type

Carraro

Fluid Type

Front Drive Axle Final

Drive (Each)—

David Brown

Fluid Type

Carraro

Fluid Type

1290

-2.3 liters-

(2.5 U.S. qts.)

1390

ET HB Fiuid-

1.25 liters—

-Case

(8.5 U.S. qts.)

-Case FDL SAE 90-

-0.9 liters^

(1 U.S. qt.)

-Case FDL SAE 90-

(1.5 U.S. qts.)

TCH Fluid

-8 liters-

1490

6.8 liters

(7

U.S.

qts.)

-4 liters-

(4.25 U.S. qts.)

-Case FDL SAE 90-

-1.4 liters-

(1.5 U.S. qts.)

-Case FDL SAE 90-

1690

7.5 liters

(8 U.S. qts.)

1194 1294

GENERAL

Engine Make

No.

of Cylinders 3 4

Bore

Stroke

Displacement 2.7 liter

Compression Ratio 17:1

Battery

No.

of Forv/ard Speeds

TUNE-UP

Firing Order : . 1-2-3

Valve Clearance (Cold)

Injection Timing 16° BTDC 17° BTDC

Engine Lov/ Idle Rpm 750

Engine High Idle

(No-Load) Rpm

Engine Full Load Rpm

Power Rating 35 kW 45 kW

(164 cu. in.)

(49 hp) (62 hp)

17:1

MODELS

1394

Own

4

—100 mm—

(3.939 in.)

—114.3 mm—

(4.5 in.)

—3.6 liter—

(219 cu. in.)

-12 volts, Negative Ground12

—1-2-4-3

-0.25 mm

(0.010 in.)

IT BTDC 20^ BTDC 25° BTDC

-2350-2375-

-2200-

1-5-3-6-2-4

600-650

53 kW

(77 hp)

1494 1594

5.4 liter

(329 cu. in.)

2450

61 kW

(85 hp)

2300

72 kW

(97 hp)

CONDENSED SERVICE DATA

www.maskinisten.net

MODELS

CONT.

1194

SIZES

Crankshaft Main Journal

Main and Rod Bearing

Crankshaft End Play

Cylinder Bore

Piston Diameter

Camshaft Journal Specifications,

AND

CLEARANCES

Diameter

Running Clearance

Refer to Paragraph 97

CAPACITIES

Cooling System 8.5 liters

(9 U.S. qts.)

Crankcase (with Filter) 6.25 liters

(6.6 U.S. qts.)

Transmission, Hydraulic

and Differential Case—

Synchromesh 27.5 liters

(29 U.S. qts.)

Power Shift

Fluid Type

Final Drive (Each)

Fluid Type

Power Steering 0.9 liters

(1 U.S. qt.)

Fluid Type

Front Drive Axle

Differential .... :

Fluid Type

Front Drive Axle

Final Drive (Each)

Fluid Type

1294

-63.474-63.487 mm(2.4990-2.4995 in.)

-0.05-0.25 mm

(0.002-0.010 in.)

98

27.5 liters 36.5 liters 42 liters 42 liters

(29 U.S. qts.) (38.5 U.S. qts.) (44.5 U.S. qts.) (44.5 U.S. qts.)

Case PTF Fluid or Hy-Tran Plus-

-2.3 liters-

(2.5 U.S. qts.)

-Case ETHB Fluid-

6 liters

(6.25 U.S. qts.)

1.4 liters

(1.5 U.S. qts.)

1394

-0.05-0.10 mm-

(0.002-0.004 in.)

100.46-100.66 mm-

(3.9388-3.9396 in.)

99.86-99.88 mm—

(3.9315-3.9323 in.)

98

—14.2 liters—

(15 U.S. qts.)

—7.4 liters—

(7.8 U.S. qts.)

42 liters 42 liters 42 liters

(44.5 U.S. qts.) (44.5 U.S. qts.) (44.5 U.S. qts.)

1.25 liters—

(1.5 U.S. qts.)

-Case TCH Fluid

NOTE 1 NOTE 2

Case FDL SAE 90

NOTE 1 NOTE 2 NOTE 3

Case FDL SAE 90

1494 1594

- 66.65-66.66 mm

(2.6240-2.6245 in.)

98

6.8 liters

(7

U.S.

qts.)

69.84-69.85 mm

(2.749-2.750 in.)

0.15-0.25 mm

(0.006-0.010 in.)

15.3 liters

(16 U.S. qts.)

12.5 liters

(13.2

U.S.

7.5 liters

(8 U.S. qts.)

NOTE 3

qts.)

NOTE 1: Prior to P.I.N. 11503001, diflFerential capacity is 6 liters (6.25 U.S. qts.) and final drive capacity is 1.4 liters (1.5 U.S.

NOTE 2: Prior to P.I.N. 11518001, differential capacity is 6 liters (6.25 U.S. qts.). and final drive capacity is 1.4 liters (1.5 U.S.

NOTE

qts.).

P.I.N. 11503001 and after, differential capacity is 4 liters (4.25 U.S. qts.) and final drive capacity is 1 liter (1.06

U.S.

qt).

3ts.).

P.I.N. 11518001 and after, differential capacity is 4 liters (4.25 U.S. qts.) and final drive capacity is 1 liter (1.06

qts

•J.S.

qt.).

U.I

3:

Prior to P.I.N. 11221501, differential capacity is 5 liters (5.25 U.S. qts.) and final drive capacity is 1.7 liters (1.75 U.S.

:s.).

P.I.N. 11221501 and after, differential capacity is 4 liters (4.25 U.S. qts.) and final drive capacity is 1 liter (1.06

qts..

U.S.

qt).

FRONT AXLE

www.maskinisten.net

(TWO-WHEEL DRIVE)

Paragraphs

1-4

FRONT WHEEL BEARINGS

All Models

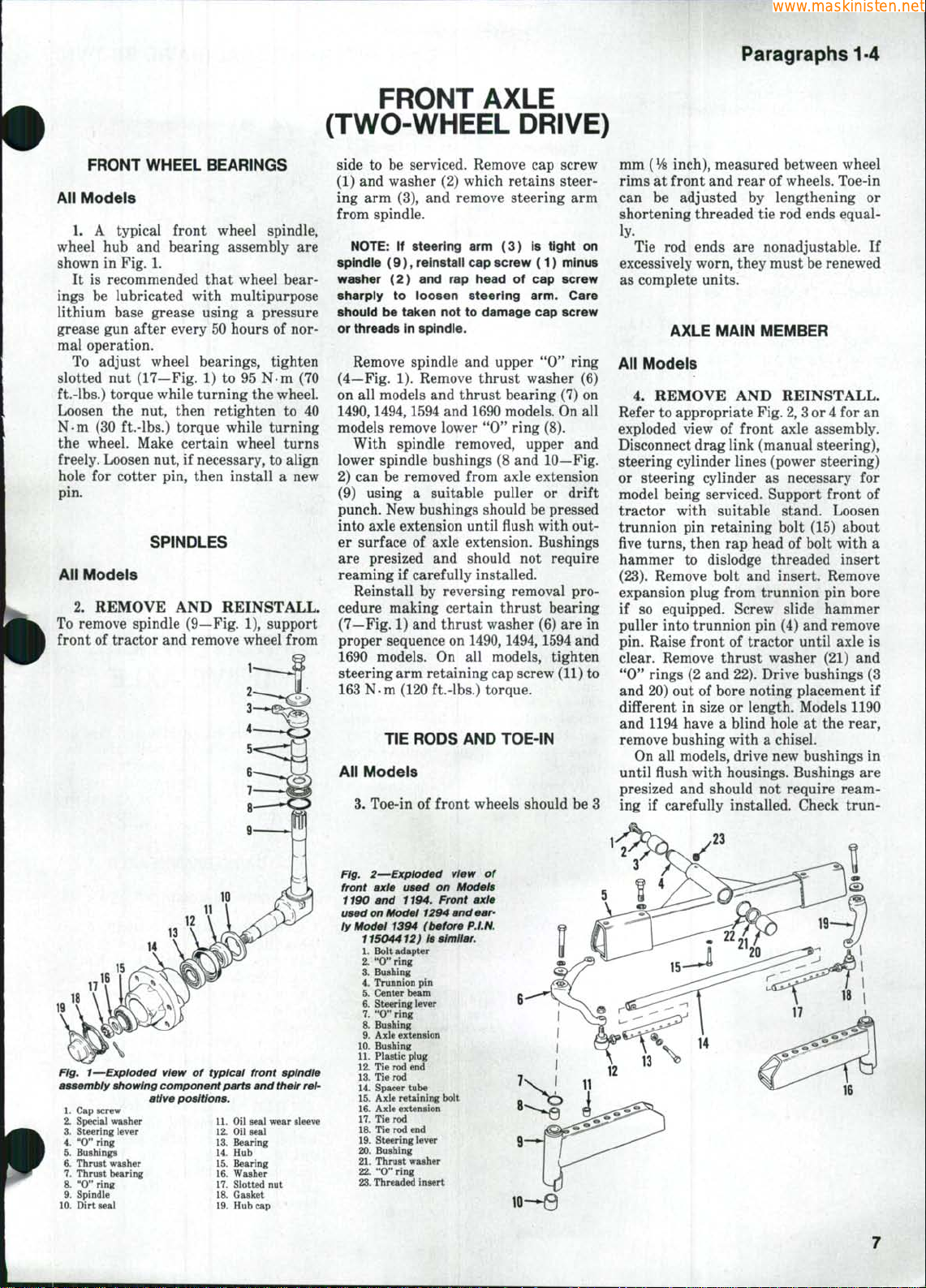

1. A typical front wheel spindle,

wheel

hub and

shown

in

It

is

recommended that wheel bear-

ings

be

lubricated with multipurpose

bearing assembly

Fig.

1.

are

lithium base grease using a pressure

grease gun after every 50 hours

of

nor-

mal operation.

To adjust wheel bearings, tighten

slotted

nut

(17—Fig.

1) to 95 N-m (70

ft.-lbs.) torque while turning the wheel.

Loosen

N-m

the nut,

(30

ft.-lbs.) torque while turning

then retighten

to 40

the wheel. Make certain wheel turns

freely. Loosen nut,

hole

for

cotter pin, then install

if

necessary, to align

a new

pin.

SPINDLES

All Models

2.

REMOVE

To remove spindle (9—Fig.

front

of

tractor and remove wheel from

AND

REINSTALL.

1),

support

side

to be

serviced. Remove

cap

screw

(1) and washer (2) which retains steering

arm

(3),

and

remove steering

from spindle.

NOTE:

spindie (9), reinstall cap screw (1) minus

washer (2) and rap head of cap screw

sharply to loosen steering arm. Care

should be taken not to damage cap screw

or threads in spindie.

Remove spindle

(4—Fig.

on

all

. •

If steering arm (3) is tight on

and

upper "0'^ ring

1).

Remove thrust washer

models and thrust bearing (7)

1490,1494,1594 and 1690 models. On

arm

(6)

on

all

models remove lower "0" ring (8).

With spindle removed, upper

lower spindle bushings

2)

can be

removed from axle extension

(8 and

(9) using a suitable puller

and

10—Fig.

or

drift

punch. New bushings should be pressed

into axle extension until flush with outer surface

are presized

reaming

Reinstall

of

axle extension. Bushings

and

should

if

carefully installed.

by

reversing removal

not

require

procedure making certain thrust bearing

(7—Fig. 1) and thrust washer (6)

are in

proper sequence on 1490,1494,1594 and

1690 models.

steering arm retaining cap screw (11)

On all

models, tighten

to

163 N-m (120 ft.-lbs.) torque.

TIE RODS AND TOE-IN

Alt Models

3,

Toe-in

of

front wheels should be

mm ( VB

rims

can

inch), measured between wheel

at

front and rear

be

adjusted

of

by

lengthening

wheels. Toe-in

shortening threaded tie rod ends equally.

Tie

rod

ends

are

nonadjustable.

excessively worn, they must be renewed

as complete units.

AXLE MAIN MEMBER

All Models

4.

REMOVE

AND

REINSTALL.

Refer to appropriate Fig. 2, 3 or 4 for

exploded view

of

front axle assembly.

Disconnect drag link (manual steering),

steering cylinder lines (power steering)

or steering cylinder

as

necessary

model being serviced. Support front

tractor with suitable stand. Loosen

trunnion

five

hammer

(23).

pin

retaining bolt (15) about

turns,

then

to

dislodge threaded insert

Remove bolt

rap

head

of

and

insert. Remove

bolt with

expansion plug from trunnion

if

so

equipped. Screw slide hammer

puller into trunnion pin (4) and remove

pin. Raise front

of

tractor until axle

clear. Remove thrust washer

"0"

rings (2 and 22). Drive bushings

and 20) out

different

and 1194 have a blind hole

of

bore noting placement

in

size

or

length. Models 1190

at the

remove bushing with a chisel.

On

all

models, drive new bushings

until flush with housings. Bushings

3

presized

ing

and

should

not

require ream-

if

carefully installed. Check trun-

or

If

an

for

of

a

pin

bore

is

(21) and

(3

if

rear,

in

are

Fig. 1—Exploded view of typical front spindle

assembly showing component parts and

1.

Cap screw

2.

Special washer

3.

Steering lever

4.

"0" ring

5.

Bushings

6. Thrust washer

7.

Thrust bearing

8. "0" ring

9. Spindle

10.

Dirt seal

ative positions.

^ 14.

'

16.

their

11.

Oil seat wear sleeve

12.

Oil seal

13.

Bearing

Hub

15.

Bearing

Washer

17.

Slotted nut

18.

Gasket

19.

Hubcap

Flg. 2—Exploded view

front axle used

i190

and

used on Model 1294 and early Model

rel-

if94. Front axle

1394

11504412) is

1.

Bolt adapter

2.

"0" ring

3.

Bushing

4.

Trunnion pin

5.

Center beam

6. Steering lever

7.

"0" ring

8. Bushing

9. Axle extension

10.

Bushing

U. Plastic plug

12.

Tie

rod end

13.

Tie

rod

14.

Spacer tube

15.

Axle retaining bolt

16.

Axle extension

17.

Tie

rod

18.

Tie

rod end

19.

Steering lever

20.

Bushing

21.

Thrust washer

22.

"O" ring

23.

Threaded insert

on

(before

similar.

of

Models

P.I.N.

Paragraphs 5-8

www.maskinisten.net

CASE INTERNATIONAL (DAVID BROWN)

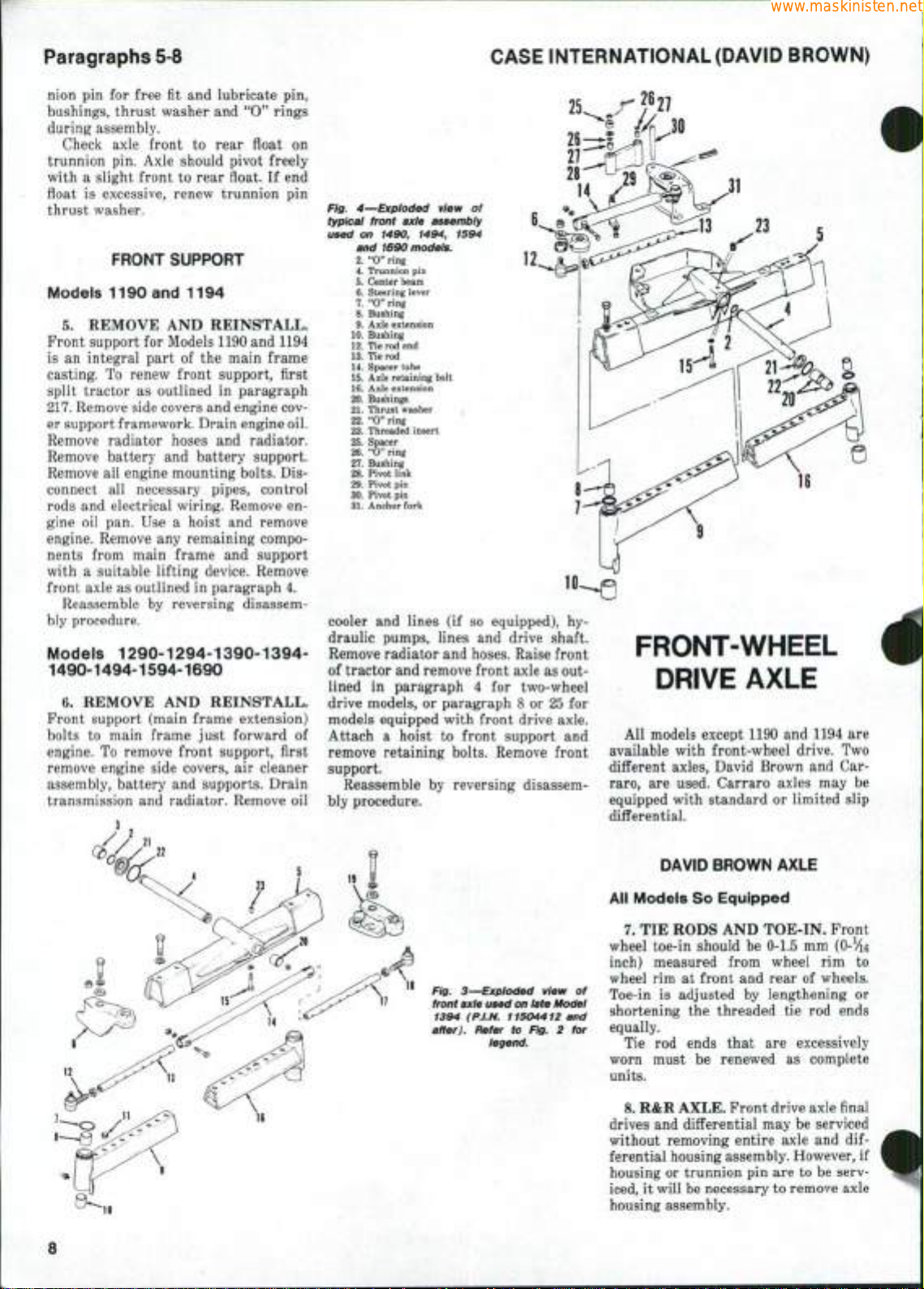

nion pin for free fit and lubricate pin,

bushings, thrust washer and "0" rings

during assembly.

Check axle front to rear fioat on

trunnion pin. Axle should pivot freely

with a slight front to rear float. If end

float is excessive, renew trunnion pin

thrust washer.

•

.

FRONT SUPPORT

Models 1190 and 1194

5.

REMOVE AND REINSTALL.

Front support for Models 1190 and 1194

is an integral part of the main frame

casting. To renew front support, first

split tractor as outlined in paragraph

217.

Remove side covers and engine cov-

er support framework. Drain engine oil.

Remove radiator hoses and radiator.

Remove battery and battery support.

Remove all engine mounting bolts. Disconnect all necessary pipes, control

rods and electrical wiring. Remove engine oil pan. Use a hoist and remove

engine. Remove any remaining components from main frame and support

with a suitable lifting device. Remove

front axle as outlined in paragraph 4.

Reassemble by reversing disassem-

bly procedure.

Models 1290-1294-1390-1394-

1490-1494-1594-1690

6. REMOVE AND REINSTALL.

Front support (main frame extension)

bolts to main frame just forward of

engine. To remove front support, first

remove engine side covers, air cleaner

assembly, battery and supports. Drain

transmission and radiator. Remove oil

25

Fig. 4—Exploded view of

typical front axle aBsembly

used on 1490, 1494, 1594

and 1690 models.

2.

"0"

ring

4.

Trunnion

5.

6.

7.

8.

9.

10.

12.

13.

14.

15.

16.

20.

21.

22.

23.

25.

26.

27.

2&.

29.

30.

31.

cooler and lines (if so equipped), hydraulic pumps, lines and drive shaft.

Remove radiator and hoses. Raise front

of tractor and remove front axle as outlined in paragraph 4 for two-wheel

drive models, or paragraph 8 or 25 for

models equipped with front drive axle.

Attach a hoist to front support and

remove retaining bolts. Remove front

support.

Reassemble by reversing disassem-

bly procedure.

pin

Center beam

Steering lever

"0"

Bushing

Axle extension

Bushing

Tie rod end

Tie rod

Spacer tube

Axle retaining bolt

Axle extension

Bushings

Thrust washer

"0"

Threaded insert

Spacer

"0"

Bushing

Pivot link

Pivot

Pivot

Anchor fork

ring

ring

ring

pin

pin

'

i

FRONT-WHEEL

DRIVE AXLE

All models except 1190 and 1194 are

available with front-wheel drive. Two

different axles, David Brown and Carraro,

are used. Carraro axles may be

equipped with standard or limited slip

differential.

4

Fig. 3—Exploded view of

front axle used on late Model

1394 (P.I.N. 11504412 and

after),

Refer to Fig. 2 for

legend.

DAVID BROWN AXLE

All Models So Equipped

7. TIE RODS AND TOE-IN. Front

wheel toe-in should be 0-1.5 mm

(0-We

inch) measured from wheel rim to

wheel rim at front and rear of wheels.

Toe-in is adjusted by lengthening or

shortening the threaded tie rod ends

equally.

Tie rod ends that are excessively

worn must be renewed as complete

units.

8. R&R AXLE. Front drive axle final

drives and differential may be serviced

without removing entire axle and differential housing assembly. However, if

housing or trunnion pin are to be serviced, it will be necessary to remove axle

housing assembly.

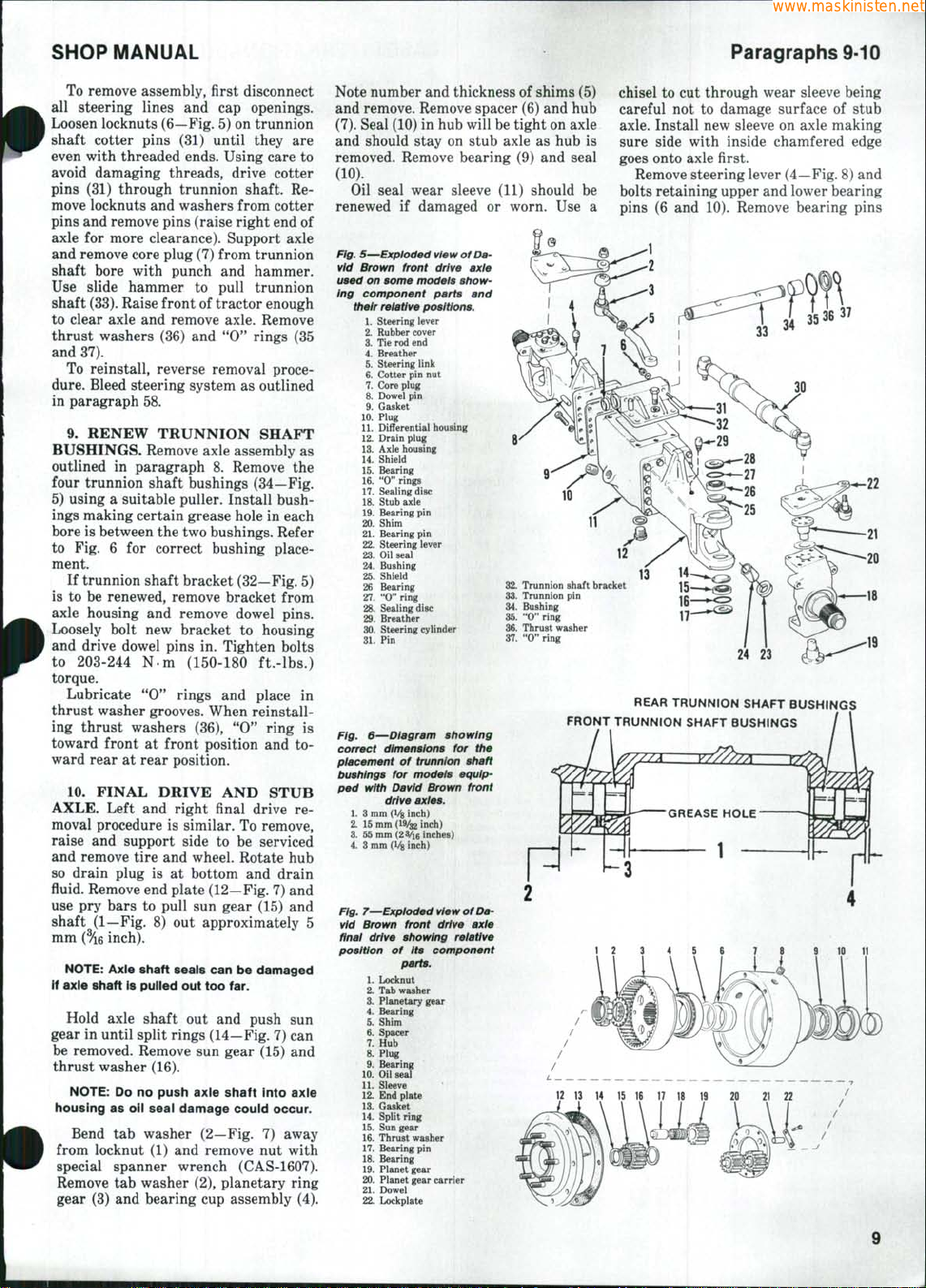

SHOP MANUAL

www.maskinisten.net

Paragraphs 9-10

To remove assembly, first disconnect

all steering lines and cap openings.

Loosen locknuts (6—Fig. 5) on trunnion

shaft cotter pins (31) until they are

even with threaded ends. Using care to

avoid damaging threads, drive cotter

pins (31) through trunnion shaft. Re-

move locknuts and washers from cotter

pins and remove pins (raise right end of

axle for more clearance). Support axle

and remove core plug (7) from trunnion

shaft bore with punch and hammer.

Use slide hammer to pull trunnion

shaft

(33).

Raise front of tractor enough

to clear axle and remove axle. Remove

thrust washers (36) and "0" rings (35

and 37).

To reinstall, reverse removal proce-

dure.

Bleed steering system as outlined

in paragraph 58.

9. RENEW TRUNNION SHAFT

BUSHINGS. Remove axle assembly as

outlined in paragraph 8. Remove the

four trunnion shaft bushings (34—Fig.

5) using a suitable puller. Install bushings making certain grease hole in each

bore is between the two bushings. Refer

to Fig. 6 for correct bushing placement.

If trunnion shaft bracket (32—Fig. 5)

is to be renewed, remove bracket from

axle housing and remove dowel pins.

Loosely bolt new bracket to housing

and drive dowel pins in. Tighten bolts

to 203-244 N-m (150-180 ft.-lbs.)

torque.

Lubricate "0** rings and place in

thrust washer grooves. When reinstalling thrust washers (36), "0" ring is

toward front at front position and toward rear at rear position.

10.

FINAL DRIVE AND STUB

AXLE.

Left and right final drive removal procedure is similar. To remove,

raise and support side to be serviced

and remove tire and wheel. Rotate hub

so drain plug is at bottom and drain

fluid. Remove end plate (12—Fig. 7) and

use pry bars to pull sun gear (15) and

shaft (1—Fig. 8) out approximately 5

mm

{%B

inch).

NOTE:

If axle shaft is pulled out too far.

Axle shaft seals can be damaged

Hold axle shaft out and push sun

gear in until split rings (14—Fig. 7) can

be removed. Remove sun gear (15) and

thrust washer (16).

NOTE:

housing as oil seal damage could occur.

Do no push axle shaft into axle

Bend tab washer (2—Fig. 7) away

from locknut (1) and remove nut with

special spanner wrench (CAS-1607).

Remove tab washer (2), planetary ring

gear (3) and bearing cup assembly (4).

Note number and thickness of shims (5)

and remove. Remove spacer (6) and hub

(7).

Seal (10) in hub will be tight on axle

and should stay on stub axle as hub is

removed. Remove bearing (9) and seal

(10).

Oil seal wear sleeve (11) should be

renewed if damaged or worn. Use a

Fig. 5—Expioded view of

vid Brown front drive axie

used on some models showing component parts and

their relative positions.

1.

Steering lever

2.

Rubber cover

3.

Tie

rod end

4.

Breather

5.

Steering link

6. Cotter pin nut

7.

Core plug

8. Dowel pin

9. Gasket

10.

Plug

11.

Differential housing

12.

Drain plug

13.

Axle housing

14.

Shield

15.

Bearing

16.

"0" rings

17.

Sealing disc

18.

Stub axle

19.

Bearing pin

20.

Shim

21.

Bearing pin

22.

Steering lever

23.

Oil seal

24.

Bushing

25.

Shield

26 Bearing

27.

"O" ring

28.

Sealing disc

29.

Breather

30.

Steering cylinder

31.

Pin

Fig. 6—Diagram showing

correct dimensions for the

placement of trunnion shaft

bushings for models equipped with David Brown front

drive axies.

1.

3 mm (l/g inch)

2.

15 mm (19/32 inch)

3.

55 mm {2 Vie inches)

4.

3 mm (Vg inch)

Fig. 7^Exploded view of

vid Brown front drive axie

finai drive showing reiative

position of its component

parts.

1.

Locknut

2.

Tab washer

3.

Planetary gear

4.

Bearing

5.

Shim

6. Spacer

7.

Hub

8. Plug

9. Bearing

10.

Oil seal

11.

Sleeve

12.

End plate

13.

Gasket

14.

Split ring

15.

Sun gear

16.

Thrust washer

17.

Bearing pin

18.

Bearing

19.

Planet gear

20.

Planet gear carrier

21.

Dowel

22.

Lockplate

Da-

Da-

2&.

Trunnion shaft bracket

33.

Trunnion pin

34.

Bushing

35.

"O"ring

36.

Thrust washer

37.

"0" ring

FRONT TRUNNION SHAFT BUSHINGS

12

13 14 15 16 17 18 19 20 21 22

chisel to cut through wear sleeve being

careful not to damage surface of stub

axle.

Install new sleeve on axle making

sure side with inside chamfered edge

goes onto axle first.

Remove steering lever (4—Fig. 8) and

bolts retaining upper and lower bearing

pins (6 and 10). Remove bearing pins

17

24

23

REAR TRUNNION SHAFT BUSHINGS

12

3 4 5 6 7 8 10 11

Paragraphs 11-14

www.maskinisten.net

CASE INTERNATIONAL (DAVID BROWN)

using jack screws

bearing pins. Retain shims (7)

reassembly. Hold axle shaft

while removing stub axle assembly

prevent damage

in

threaded hole

to oil

seals. Remove

for

in

of

use in

place

to

axle shaft from housing.

Remove upper

discs (28

and 16)

and

and

and

lower sealing

17-Fig. 5), "0" rings

bearings

(26 and

15) from

(27

axle housing (13). Use a suitable puller

to remove upper and lower bearing cups

from axle housing. Remove upper

and

lower shields (25 and 14).

Remove seal (2—Fig.

8)

from inside

stub axle (8). Using a suitable bushing

driver, drive bushing (3) out oil seal end

of stub axle. Install new bushing from

seal

end

until

it

seats

in

stub axle.

Install

new oil

seal with

lip of

seal

entering bore first.

To reassemble, reverse disassembly

procedure using care

not to let

axle

shafts damage oil seals and noting preload must

ings

To

be set on

and

stub axle bearings.

set

bearing pfin preload, reassem-

bearing

pin

bear-

ble unit minus shims (7—Fig. 8). Tighten lower bearing pin mounting bolts

68

N-m (50

bearing

ft.-lbs.) torque

pin

mounting bolts

and

to 20 N-m

(15 ft.-lbs.) torque. Push stub axle

tight against bottom

and

use a

feeler gage

between upper bearing

stub axle.

bearing

See Fig. 9.

pin,

then assemble shims

total thickness

of

axle housing

to

measure

pin

flange

Remove upper

is

0.381 mm (0.015 inch)

to

upper

up

gap

and

so

less than feeler gage measurement.

This will correctly preload bearings

0.10-0.15

mm

(0.004-0.006 inch) when

to

full load is on axle. Tighten upper bearing

pin

bolts

torque. Refer

to 68 N-m (50

to

paragraph

ft.-lbs.)

11 to set

stub axle bearing preload.

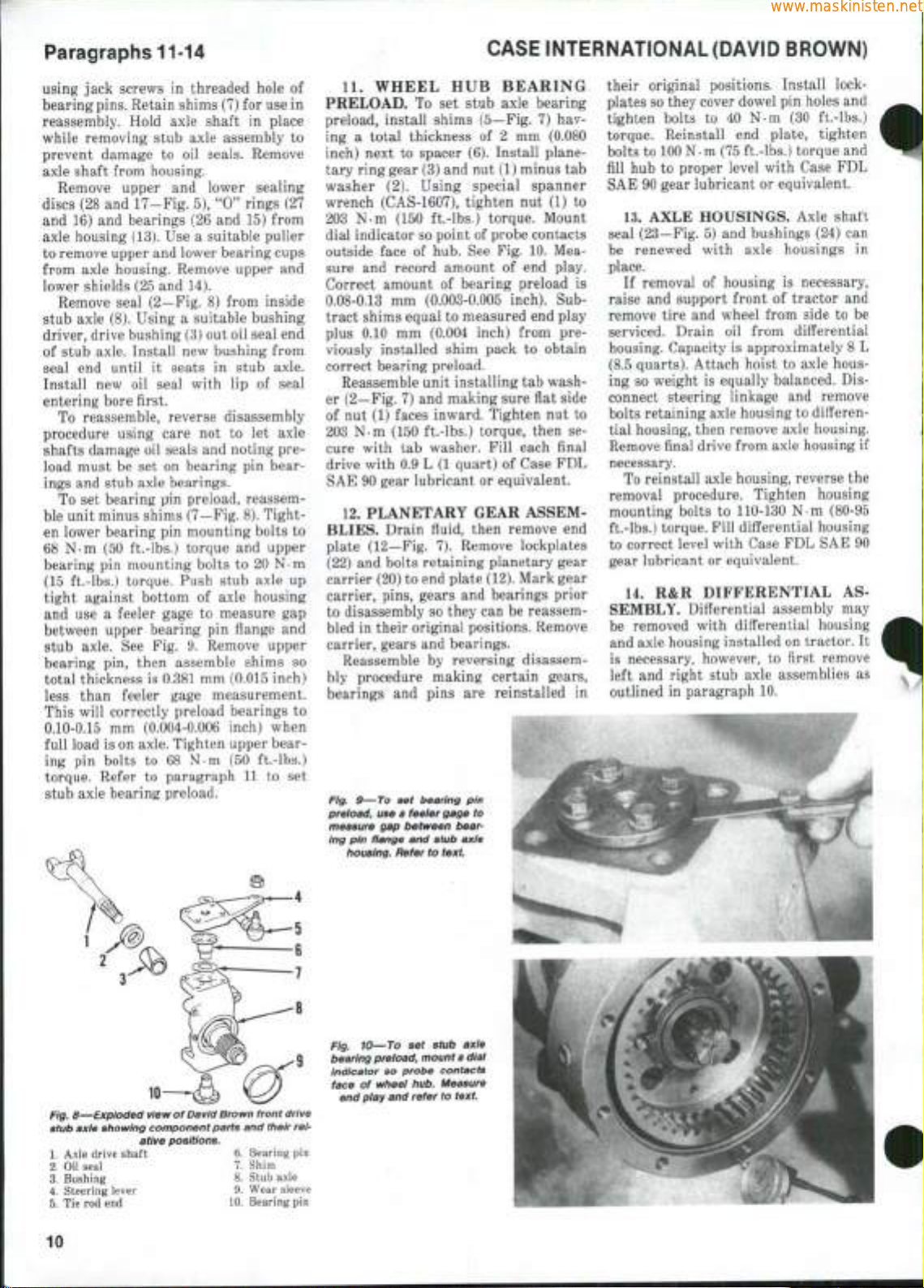

11.

WHEEL

PRELOAD.

preload, install shims (5—Fig.

ing a total thickness

inch) next

HUB

To set

BEARING

stub axle bearing

of 2 mm

to

spacer (6). Install plane-

7) hav (0.080

tary ring gear (3) and nut (1) minus tab

washer

(2).

Using special spanner

wrench (CAS-1607), tighten

203

N.m (150

ft.-lbs.) torque. Mount

dial indicator so point

outside face

sure

and

Correct amount

0.08-0.13

tract shims equal

plus

0.10 mm

of

hub.

See Fig. 10. Mea-

record amount

of

bearing preload

mm

(0.003-0.005 inch).

to

measured end play

(0.004 inch) from

viously installed shim pack

nut (1) to

of

probe contacts

of end

to

play.

is

Sub-

pre-

obtain

correct bearing preload.

Reassemble unit installing tab washer (2—Fig.

of

nut (1)

203

cure with

drive with 0.9 L (1 quart)

SAE 90 gear lubricant

12.

BLIES. Drain fluid, then remove

plate (12—Fig.

(22)

7)

and making sure flat side

faces inward. Tighten

N-m

(150 ft.-lbs.) torque, then

tab

washer. Fill each final

or

equivalent.

of

Case FDL

nut to

PLANETARY GEAR ASSEM-

7).

and

bolts retaining planetary gear

Remove lockplates

se-

end

carrier (20) to end plate (12). Mark gear

carrier, pins, gears

and

bearings prior

to disassembly so they can be reassembled

in

their original positions. Remove

carrier, gears and bearings.

Reassemble

by

reversing disassembly procedure making certain gears,

bearings

Fig.

preioad, use a feeier gage

measure gap between

ing pin fiange

and

pins

9—To

set

bearing

housing. Refer to

and

are

pin

to

bear-

stub axie

text.

reinstalled

in

their original positions. Install lockplates so they cover dowel pin holes and

tighten bolts

torque. Reinstall

bolts

to

fill hub

SAE 90 gear lubricant

13.

AXLE HOUSINGS, Axle shaft

seal (23—Fig.

be renewed with axle housings

to 40 N-m (30

end

plate, tighten

ft.-lbs.)

100 N m (75 ft.-lbs.) torque and

to

proper level with Case

or

equivalent.

5) and

bushings (24)

FDL

can

in

place.

If removal

raise

and

remove tire

serviced. Drain

housing. Capacity

(8.5 quarts). Attach hoist

ing

so

connect steering linkage

of

support front

and

weight

is

housing

wheel from side

oil

is

is

necessary,

of

tractor

and

to be

from differential

approximately 8

to

axle hous-

equally balanced. Dis-

and

remove

bolts retaining axle housing to differential housing, then remove axle housing.

Remove final drive from axle housing if

necessary.

To reinstall axle housing, reverse

the

removal procedure. Tighten housing

mounting bolts

to

110-130

N-m

(80-95

ft.-lbs.) torque. Fill differential housing

to correct level with Case FDL SAE

gear lubricant

14.

R&R

or

equivalent.

DIFFERENTIAL

SEMBLY. Differential assembly

90

AS-

may

be removed with differential housing

and axle housing installed on tractor.

is necessary, however,

left

and

right stub axle assemblies

outlined

in

paragraph 10.

to

first remove

It

as

L

flg^ S—Exploded view of

stub axle showing component parts and their rel-

1.

Axle drive shaft

2.

Oil seal

3.

Bushing

4.

Steering lever

5.

Tie rod end

10

10-

_ _

David Brown

ative positions.

front drive

6. Bearing pin

7.

Shim

8. Stub axle

9. Wear sleeve

10.

Bearing pin

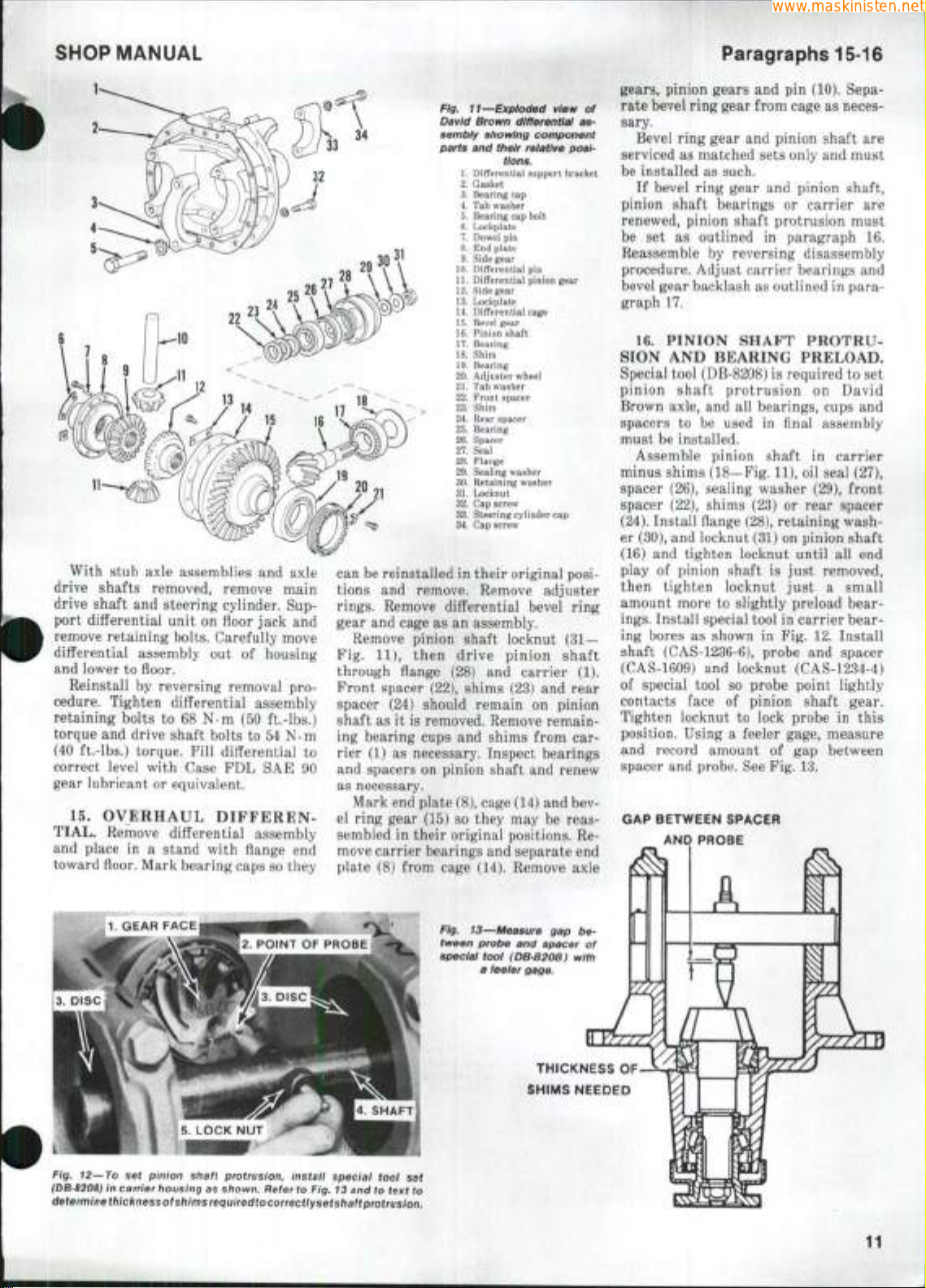

Fig. 10—To

bearing preload, mount a dlai

indicator

face

end play and refer to

set

stub axle

so

probe contacts

of

wheel hub. Measure

text.

SHOP MANUAL

www.maskinisten.net

With stub axle assemblies

drive shafts removed, remove main

drive shaft

port diflferential unit

and

steering cylinder. Sup-

on

remove retaining bolts. Carefully move

differential assembly

and lower

Reinstall

to

by

floor.

out of

reversing removal

cedure. Tighten differential assembly

retaining bolts

torque

and

to 68 N m (50

drive shaft bolts

(40 ft.-lbs.) torque. Fill differential

correct level with Case

gear lubricant

15.

OVERHAUL DIFFEREN-

or

equivalent.

TIAL. Remove differential assembly

and place

in a

stand with flange

toward floor. Mark bearing caps so they

and

axle

floor jack

and

housing

pro-

ft.-lbs.)

to

54

N m

to

FDL SAE 90

end

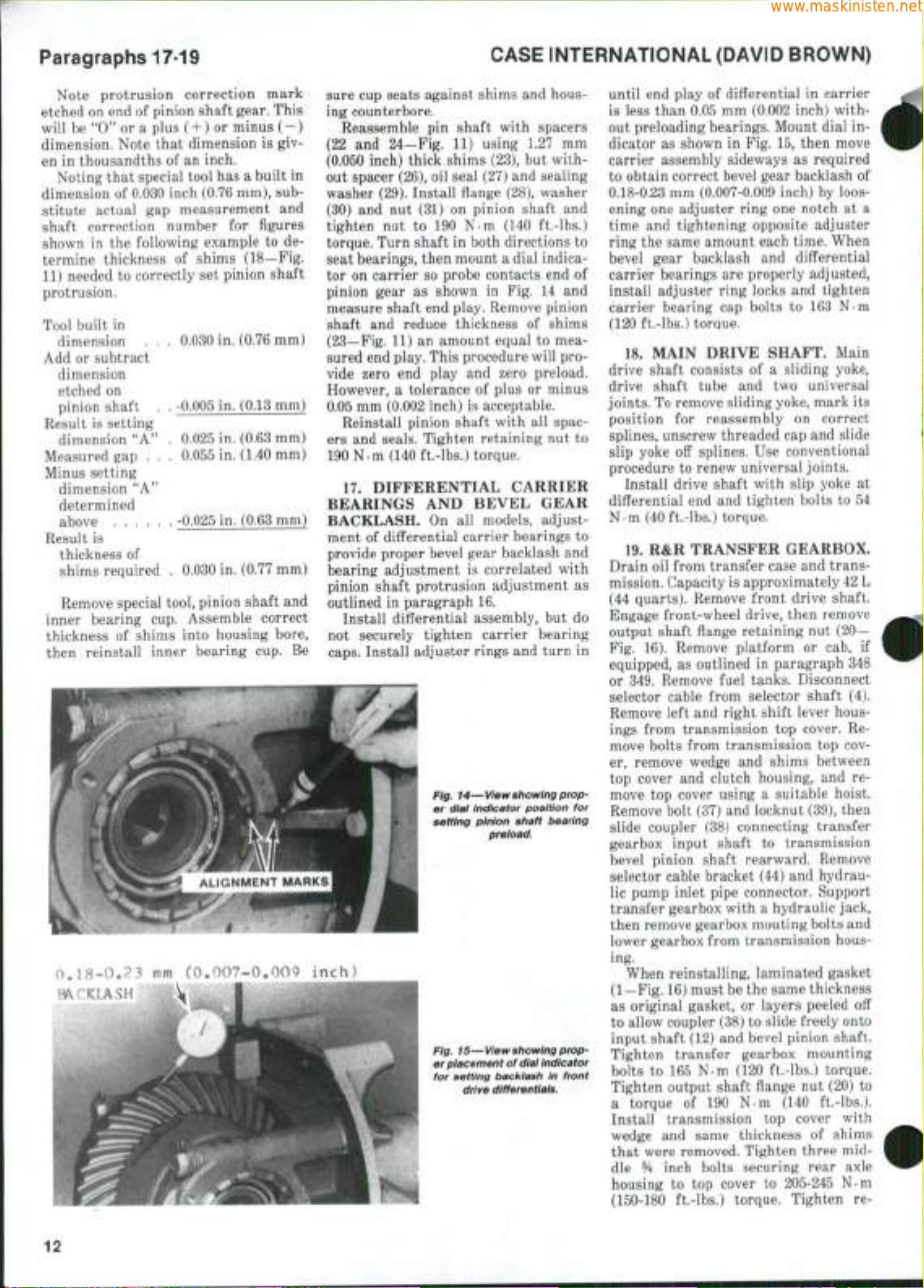

Fig. 11—Exploded view

David Brown differentiai

sembiy showing component

parts

and

their relative

tions.

1.

Differential support bracket

2.

Gasket

3.

Bearing

cap

4.

Tab

washer

5.

Bearing

cap

pin

plate

washer

screw

screw

bolt

pin

6.

Lockplate

7.

Dowel

8.

End

9.

Side gear

10.

Differential

11.

Differential pinion gear

12.

Side gear

13.

Lockplate

14.

Differential cage

15.

Bevel gear

16.

Pinion shaft

17.

Bearing

18.

Shim

19.

Bearing

20.

Adjuster wheel

21.

Tab

22.

Front spacer

23.

Shim

24.

Rear spacer

25.

Bearing

26.

Spacer

27.

Seal

28.

Flange

29.

Sealing washer

30.

Retaining washer

31.

Locknut

32.

Cap

33.

Steering cylinder

34.

Cap

cap

of

as-

posi-

can be reinstalled in their original positions

and

rings.

gear and cage

Remove pinion shaft locknut

Fig.

through flange

Front spacer (22), shims (23)

spacer

shaft

ing bearing cups

rier

and spacers

remove. Remove adjuster

Remove differential bevel ring

as an

assembly.

(31 —

11),

then drive pinion shaft

(28) and

carrier

and

(24)

as it is

removed. Remove remain-

and

(1) as

necessary. Inspect bearings

on

pinion shaft

should remain

on

pinion

shims from

and

renew

(1).

rear

car-

as necessary.

Mark end plate (8), cage (14) and bevel ring gear (15)

sembled

in

so

they

may be

reas-

their original positions. Remove carrier bearings and separate end

plate

(8)

from cage (14). Remove axle

Paragraphs 15-16

gears,

pinion gears

rate bevel ring gear from cage as neces-

sary.

Bevel ring gear

serviced

be installed

as

matched sets only and must

as

If bevel ring gear

pinion shaft bearings

renewed, pinion shaft protrusion must

be

set as

Reassemble

outlined

by

procedure. Adjust carrier bearings

bevel gear backlash as outlined in paragraph 17.

16.

PINION SHAFT PROTRU-

SION

AND

Special tool (DB-8208)

pinion shaft protrusion

Brown axle,

spacers

and all

to be

must be installed.

Assemble pinion shaft

minus shims (18—Fig. 11), oil seal (27),

spacer (26), sealing washer (29), front

spacer (22), shims

(24).

Install flange (28), retaining washer (30), and locknut (31) on pinion shaft

(16)

and

play

tighten locknut until

of

pinion shaft

then tighten locknut just a small

amount more

ings.

Install special tool

ing bores

as

shaft (CAS-1236-6), probe

(CAS-1609)

and

of special tool

contacts face

Tighten locknut

position. Using a feeler gage, measure

and record amount

spacer and probe. See Fig. 13.

GAP BETWEEN SPACER

AND PROBE

and pin

and

(10). Sepa-

pinion shaft

are

such.

and

pinion shaft,

or

in

paragraph

carrier

are

16.

reversing disassembly

and

BEARING PRELOAD.

is

required to set

on

bearings, cups

used

in

(23) or

final assembly

David

and

in

carrier

rear spacer

all end

is

just removed,

to

slightly preload bear-

in

shown

carrier bear-

in Fig. 12.

and

Install

spacer

locknut (CAS-1234-4)

so

probe point lightly

of

pinion shaft gear.

to

lock probe

of gap

in

this

between

Fig. 12—To set pinion shaft protrusion, install special tool set

iDB'8208)

determlnethicknessofshimsrequiredtocorrectlysetshaftprotrusion.

in carrier housing as

shown.

Refer

to Fig.

13

and to text to

Fig. 13—Measure

tween probe

special tool (DB-8208) with

a feeier gage.

gap be-

and

spacer

of

THICKNESS

SHIMS HEEDED

OF

11

Paragraphs 17-19

www.maskinisten.net

CASE INTERNATIONAL (DAVID BROWN)

Note protrusion correction mark

etched on end of pinion shaft gear. This

will be

*'O'*

or a plus ( + ) or minus

( —)

dimension. Note that dimension is given in thousandths of an inch.

Noting that special tool has a built in

dimension of 0.030 inch (0.76 mm), sub-

stitute actual gap measurement and

shaft correction number for figures

shown in the following example to determine thickness of shims (18—Fig.

11) needed to correctly set pinion shaft

protrusion.

Tool built in

dimension . .

0.030 in. (0.76 mm)

Add or subtract

dimension

etched on

pinion shaft .

-0.005 in. (0.13 mm)

Result is setting

dimension **A"

Measured gap . .

0.025 in.

0,055 in.

(0.63 mm)

(1.40 mm)

Minus setting

dimension "A"

determined

above -0.025 in. (0.63 mm)

Result is

thickness of

shims required . 0.030 in. (0.77 mm)

Remove special tool, pinion shaft and

inner bearing cup. Assemble correct

thickness of shims into housing bore,

then reinstall inner bearing cup. Be

0.18-0.23 mm (0.0()7-.O.OOQ inch)

sure cup seats against shims and housing counterbore.

Reassemble pin shaft with spacers

(22 and 24—Fig. 11) using 1.27 mm

(0.050 inch) thick shims (23), but without spacer (26), oil seal (27) and sealing

washer (29). Install flange (28), washer

(30) and nut (31) on pinion shaft and

tighten nut to 190 N m (140 ft-lbs.)

torque. Turn shaft in both directions to

seat bearings, then mount a dial indicator on carrier so probe contacts end of

pinion gear as shown in Fig. 14 and

measure shaft end play. Remove pinion

shaft and reduce thickness of shims

(23—Fig. 11) an amount equal to measured end play. This procedure will provide zero end play and zero preload.

However, a tolerance of plus or minus

0.05 mm (0.002 inch) is acceptable.

Reinstall pinion shaft with all spac-

ers and seals. Tighten retaining nut to

190 N-m (140 ft.-lbs.) torque.

17.

DIFFERENTIAL CARRIER

BEARINGS AND BEVEL GEAR

BACKLASH. On all models, adjust-

ment of differential carrier bearings to

provide proper bevel gear backlash and

bearing adjustment is correlated with

pinion shaft protrusion adjustment as

outlined in paragraph 16.

Install differential assembly, but do

not securely tighten carrier bearing

caps.

Install adjuster rings and turn in

Fig. 14—View

er dial indicator position for

setting pinion shaft bearing

Fig. 15—

er placement of dial

for setting

showing

preload.

View showing

drive differentials.

baciciash

indicator

prop-

prop-

in front

until end play of differential in carrier

is less than 0.05 mm (0.002 inch) without preloading bearings. Mount dial indicator as shown in Fig. 15, then move

carrier assembly sideways as required

to obtain correct bevel gear backlash of

0.18-0.23 mm (0.007-0.009 inch) by loosening one adjuster ring one notch at a

time and tightening opposite adjuster

ring the same amount each time. When

bevel gear backlash and differential

carrier bearings are properly adjusted,

install adjuster ring locks and tighten

carrier bearing cap bolts to 163 N-m

(120 ft.-lbs.) torque.

18.

MAIN DRIVE SHAFT. Main

drive shaft consists of a sliding yoke,

drive shaft tube and two universal

joints.

To remove sliding yoke, mark its

position for reassembly on correct

splines, unscrew threaded cap and slide

slip yoke off splines. Use conventional

procedure to renew universal joints.

Install drive shaft with slip yoke at

differential end and tighten bolts to 54

N-m (40 ft.-lbs.) torque.

19.

R&R TRANSFER GEARBOX.

Drain oil from transfer case and transmission. Capacity is approximately

42

(44 quarts). Remove front drive shaft.

Engage front-wheel drive, then remove

output shaft flange retaining nut (20—

Fig. 16). Remove platform or cab, if

equipped, as outlined in paragraph 348

or 349. Remove fuel tanks. Disconnect

selector cable from selector shaft (4).

Remove left and right shift lever housings from transmission top cover. Remove bolts from transmission top cov-

er, remove wedge and shims between

top cover and clutch housing, and remove top cover using a suitable hoist.

Remove bolt (37) and locknut (39), then

slide coupler (38) connecting transfer

gearbox input shaft to transmission

bevel pinion shaft rearward. Remove

selector cable bracket (44) and hydraulic pump inlet pipe connector. Support

transfer gearbox with a hydraulic jack,

then remove gearbox mouting bolts and

lower gearbox from transmission housing.

When reinstalling, laminated gasket

(1—Fig. 16) must be the same thickness

as original gasket, or layers peeled off

to allow coupler (38) to slide freely onto

input shaft (12) and bevel pinion shaft.

Tighten transfer gearbox mounting

bolts to 165 N-m (120 ft.-lbs.) torque.

Tighten output shaft flange nut (20) to

a torque of 190 N m (140 ft.-lbs.).

Install transmission top cover with

wedge and same thickness of shims

that were removed. Tighten three middle % inch bolts securing rear axle

housing to top cover to 205-245 N-m

(150-180 ft.-lbs.) torque. Tighten re-

L

12

SHOP MANUAL

www.maskinisten.net

Paragraphs 20-23

mainder of top cover mounting bolts to

110-130 N-m (80-95 ft.-lbs.) torque.

Tighten drive shaft flange bolts to 54

N-m (40 ft-lbs.) torque. Complete installation by reversing removal procedure.

20.

OVERHAUL TRANSFER

GEARBOX. With transfer gearbox re-

moved, disassemble as follows: Remove

end plates (3 and 46—Fig. 16) and

shims (36). Note position and thickness

of shims

(36).

Drive input shaft (12) and

idler shaft (34) out of housing (2).

Remove input gear (13). Remove front

bearing and cup (16). Remove output

flange

(23),

(21).

cork seal (22) and washer

Remove oil seal housing (26) and

output shaft end cover (43). Note thick-

ness of shims (33). Drive output shaft

(19) out of housing (2), remove the six

bearing pads (18) and bearing and cup

(27).

Remove bottom cover (9) and drive

roll pin (7) out of selector fork (6) and

remove selector shaft (4). Remove se-

lector fork, fixed gear (30) and sliding

gear (29). Remove output gear (17) and

idler gear (15). Remove selector shaft

oil seal (5) and core plug (41).

Clean and inspect all parts for exces-

sive wear or damage. Lubricate all

parts during reassembly.

21.

Install idler gear (15-Fig. 16)

into bottom of transfer gearbox housing (2). Install output gear (17) into

housing with hub for sliding gear engagement towards front of housing.

Place fixed gear (30) inside sliding gear

(29) and install output shaft (19) into

rearward side of bottom hole in housing, pushing it through output gear (17)

and partially through fixed gear (30).

Oil slots on side of fixed gear (30) go

against output gear (17). Spacer (31)

and bearing (32) must already be assembled on output shaft

(19).

Install six

bearing pads in output shaft, concave

side against shaft, as it is pushed

through output gear (17) and fixed gear

(30).

Install rear bearing cup (32), gasket (42), rear cover (43) and cable

bracket (44) minus shims (^33). Tighten

bolts to 27 N.m (20 ft.-lbs.) torque.

Install front bearing (27) and bushing

(28) on output shaft and drive front

bearing cup (27) into housing (2). Install oil seal (25) in oil seal housing (26)

and install oil seal housing on transfer

gearbox housing. Tighten bolts to 27

N-m (20 ft.-lbs.) torque. Hit end of output shaft (19) with a plastic hammer to

seat bearings and cups.

Mount dial indicator on transfer gear

box housing (2) so probe end contacts

end of output shaft (19). Measure and

record end play of output shaft. End

play tolerance is 0-0.05 mm (0-0.002

inch) for new bearings and 0.05-0.10

mm (0.002-0.004 inch) for used bearings.

To determine proper shim (33—Fig.

16) thickness, subtract 0.025 mm (0.001

inch) from dial indicator measurement

if new bearings were installed, or subtract 0.076 mm (0.003 inch) from dial

indicator measurement if original bearings are reused. The result is the re-

quired shim thickness to provide rec-

ommended end play.

Remove rear bearing cover (43) and

install correct thickness of shims (33).

Reinstall cover and tighten bolts to 27

N-m (20 ft.-lbs.) torque. Recheck end

play and adjust shim thickness, if necessary, if not withint tolerance.

Install oil seal (5—Fig. 16) into housing (2) and place trunnion pins (40) in

selector fork (6). Install selector fork in

housing, making certain trunnion pins

engage slot in sliding gear (29). Install

selector shaft (4) through oil seal (5)

and selector fork. Align roll pin holes in

selector fork and shaft and install roll

pin (7). Install core plug (41), bottom

cover gasket (8) and bottom cover (9).

Install flange (23), cork washer (22),

washer (21) and locknut (20). Tighten

locknut to 190 N-m (140 ft.-lbs.)

torque.

22.

Install idler shaft (34—Fig. 16)

and bearing assembly through rear of

housing and drive it through idler gear

(15).

Install rear bearing cup (35) and

end plate (46). Tighten bolts to 27 N-m

(20 ft.-lbs.) torque. Drive front bearing

(16) onto idler shaft (34) until seated.

Install bearing cup (16) and end plate

(3).

Tighten bolts to 27 N-m (20 ft.-lbs.)

torque and hit idler shaft (34) to seat

bearings.

Mount dial indicator so end of probe

contacts end of idler shaft (34—Fig. 16).

Measure and record amount of end

play. End play tolerance is 0-0.05 mm

(0-0.002 inch) for new bearings and

0.05-0.10 mm (0.002-0.004 inch) for used

bearings.

To determine correct shim (36—Fig.

16) thickness, subtract 0.025 mm (0.001

inch) from dial indicator measurement

if new bearings are used, or subtract

0.076 mm (0.003 inch) from dial indicator measurement if original bearings

are reused. The result is the required

thickness of shims needed to obtain

desired end play.

Remove rear end plate (46—Fig. 16)

and install correct shim (36) thickness.

Reinstall end plate (46) and tighten

bolts to 27 N-m (20 ft.-lbs.) torque.

Recheck end play and adjust shim

thickness, if necessary, if not within

required tolerance.

23.

Install input shaft (12—Fig. 16)

and bearing assembly through front of

housing (2) and input gear (13). Install

bearing cup (14) and end plate (3).

Tighten bolts to 27 N-m (10 ft.-lbs.)

torque. Drive rear bearing (11) onto

input shaft (12) until seated. Install

bearing cup (11) and end plate (46).

Tighten bolts to 27 N-m (20 ft.-lbs.)

torque. Set end play in the same manner as outlined in paragraph 22.

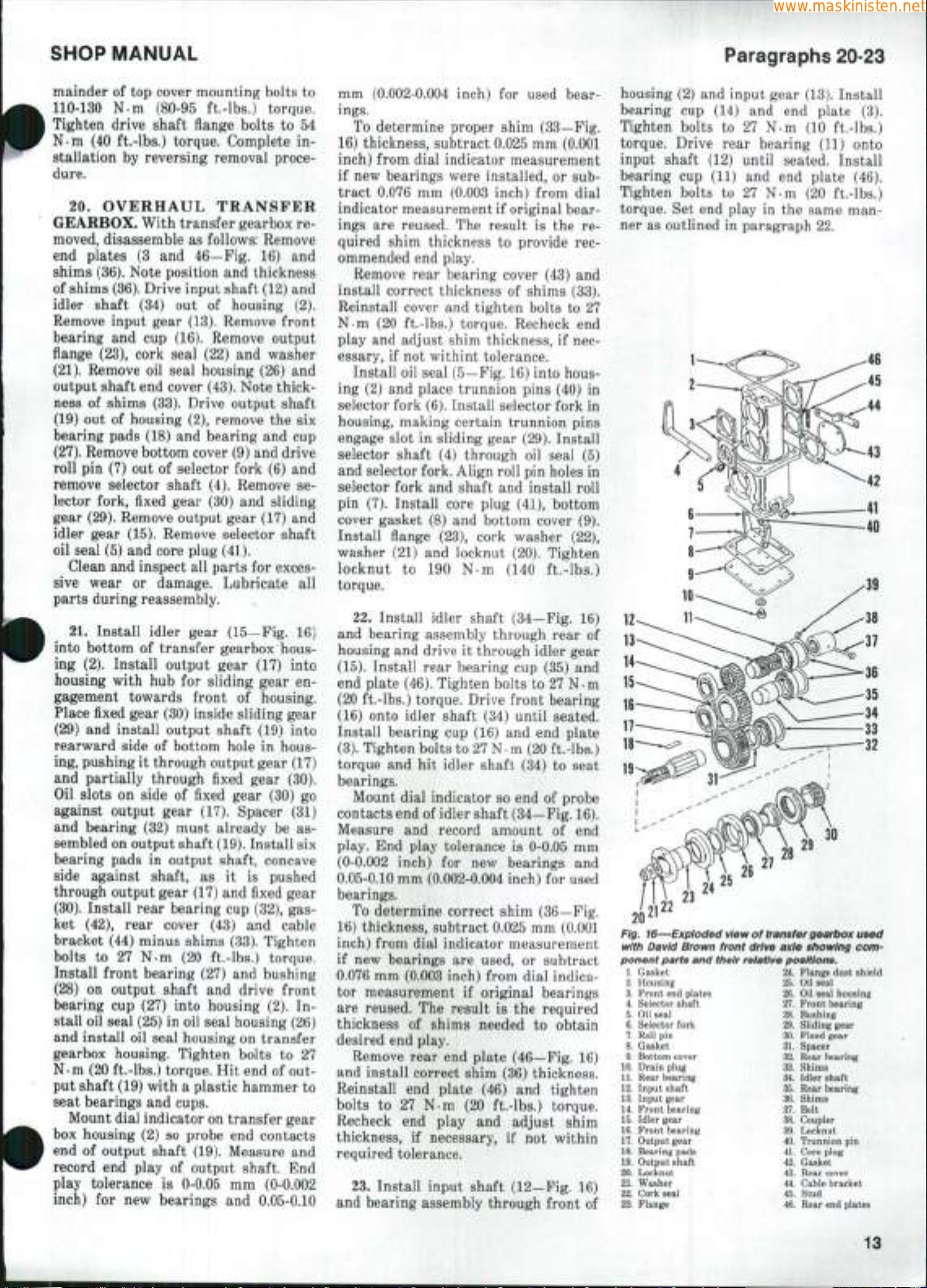

Fig. 16—Exploded view of transfer gearbox used

with David Brown front drive axle showing com-

ponent parts and their relative positions.

1.

Gasket

2.

Housing

3.

Front

end

4.

Selector shaft

5.

Oil

seal

6.

Selector fork

7.

Roll

pin

8.

Gasket

9.

Bottom cover

10.

Drain plug

11.

Rear bearing

12.

Input shaft

13.

Input gear

14.

Front bearing

15.

Idler gear

16.

Front bearing

17.

Output gear

18.

Bearing pads

19.

Output shaft

20.

Locknut

21.

Washer

22.

Cork seal

23.

Flange

\

plates

1

24.

Flange dust shield

25.

Oil

seal

26.

Oil

seal housing

27.

Front bearing

28.

Bushing

29.

Sliding gear

30.

Fixed gear

31.

Spacer

32.

Rear bearing

33.

Shims

34.

Idler shaft

35.

Rear bearing

36.

Shims

37.

Bolt

38.

Coupler

39.

Locknut

40.

Trunnion

41.

42.

Gasket

43.

44.

Cable bracket

45.

46.

Core plug

Rear cover

Stud

Rear

end

pin

plates

13

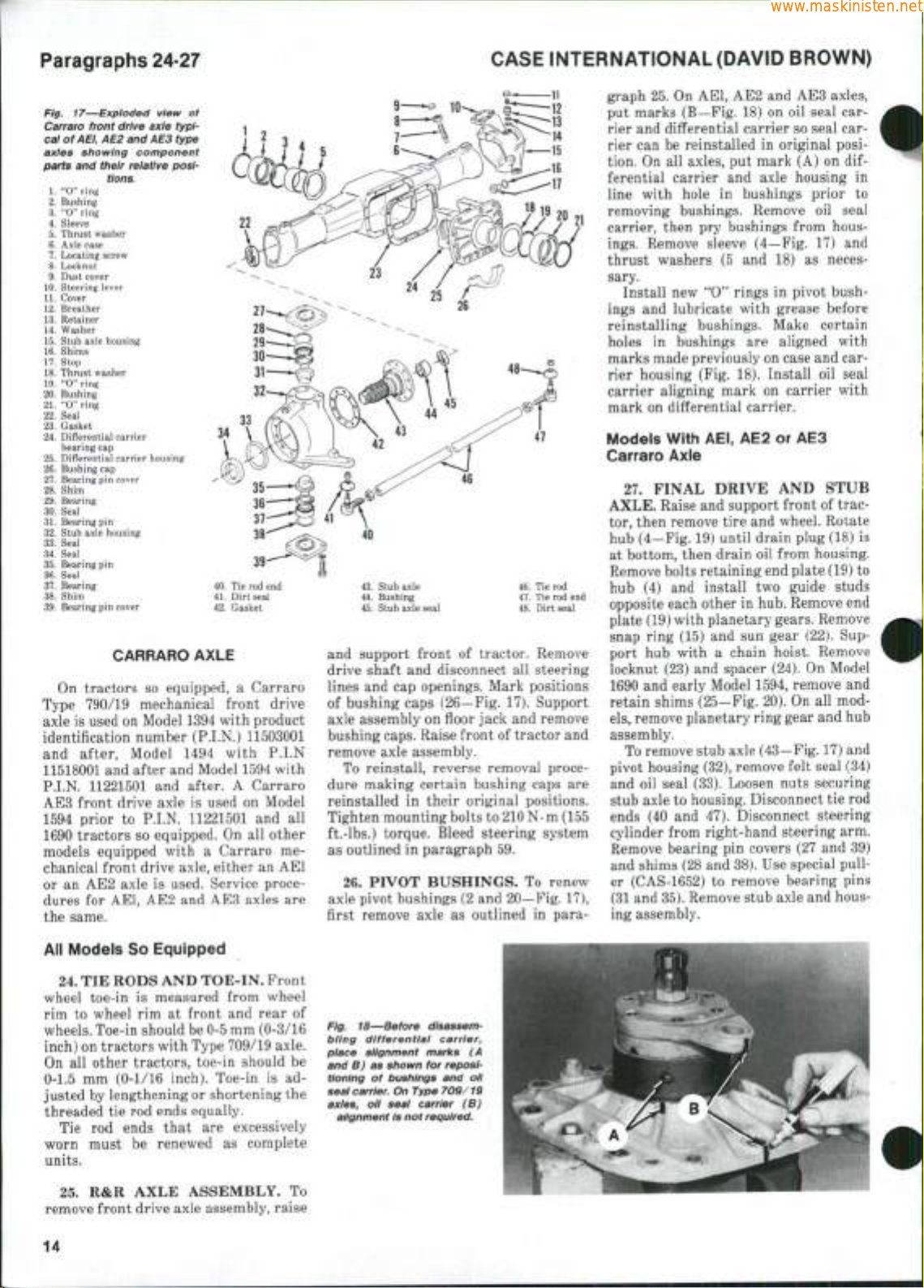

Paragraphs 24-27

www.maskinisten.net

CASE INTERNATIONAL (DAVID BROWN)

Fig. 17—Exploded view of

Carraro front drive axle typicai of

AEi,

AE2

and

AE3

,

type

40.

Tie rod end

41.

Dirt seal

42.

Gasket

axies showing component

parts and their reiative posi-

1.

"0"

2.

Bushing

3.

"0"

4.

Sleeve

5.

Thrust washer

6.

Axle case

7.

Locating screw

8.

Locknut

9.

Dust cover

10.

Steering lever

11.

Cover

12.

Breather

13.

Retainer

14.

Washer

15.

Stub axle housing

16.

Shims

17.

Stop

18.

Thrust washer

19.

"0"

20.

Bushing

21.

"0"

22.

Seal

23.

Gasket

24.

Differential carrier

25.

Differential carrier housing

26.

Bushing

27.

Bearing

28.

Shim

29.

Bearing

30.

Seal

31.

Bearing

32.

Stub axle housing

33.

Seal

34.

Seal

35.

Bearing

36.

Seal

37.

Bearing

38.

Shim

39.

Bearing

ring

ring

ring

ring

bearing

cap

cap

pin

pin

pin

pin

tions.

cover

cover

CARRARO AXLE

On tractors

so

equipped, a Carraro

Type 790/19 mechanical front drive

axle is used on Model 1394 with product

identification number (P.I.N.) 11503001

and after, Model

1494

with

P.I.N

11518001 and after and Model 1594 with

P.I.N. 11221501

AE3 front drive axle

1594 prior

1690 tractors

models equipped with a Carraro

chanical front drive axle, either

or

an

AE2 axle

dures

for

and

to

P.I.N. 11221501

so

equipped.

is

AEI, AE2

used. Service proce-

and

after. A Carraro

is

used

on

Model

and all

On all

other

me-

an

AEI

AE3 axles

are

the same.

43.

Stub axle

44.

Bushing

45.

Stub axle seal

and support front

drive shaft

lines

and

and

disconnect

cap openings. Mark positions

of

46.

Tie rod

47.

Tie rod end

48.

Dirt seal

tractor. Remove

all

steering

of bushing caps (26—Fig. 17). Support

axle assembly on floor jack and remove

bushing caps. Raise front of tractor and

remove axle assembly.

To reinstall, reverse removal procedure making certain bushing caps

reinstalled

Tighten mounting bolts to

in

their original positions.

210 N • m

are

(155

ft.-lbs.) torque. Bleed steering system

as outlined

26.

in

paragraph 59.

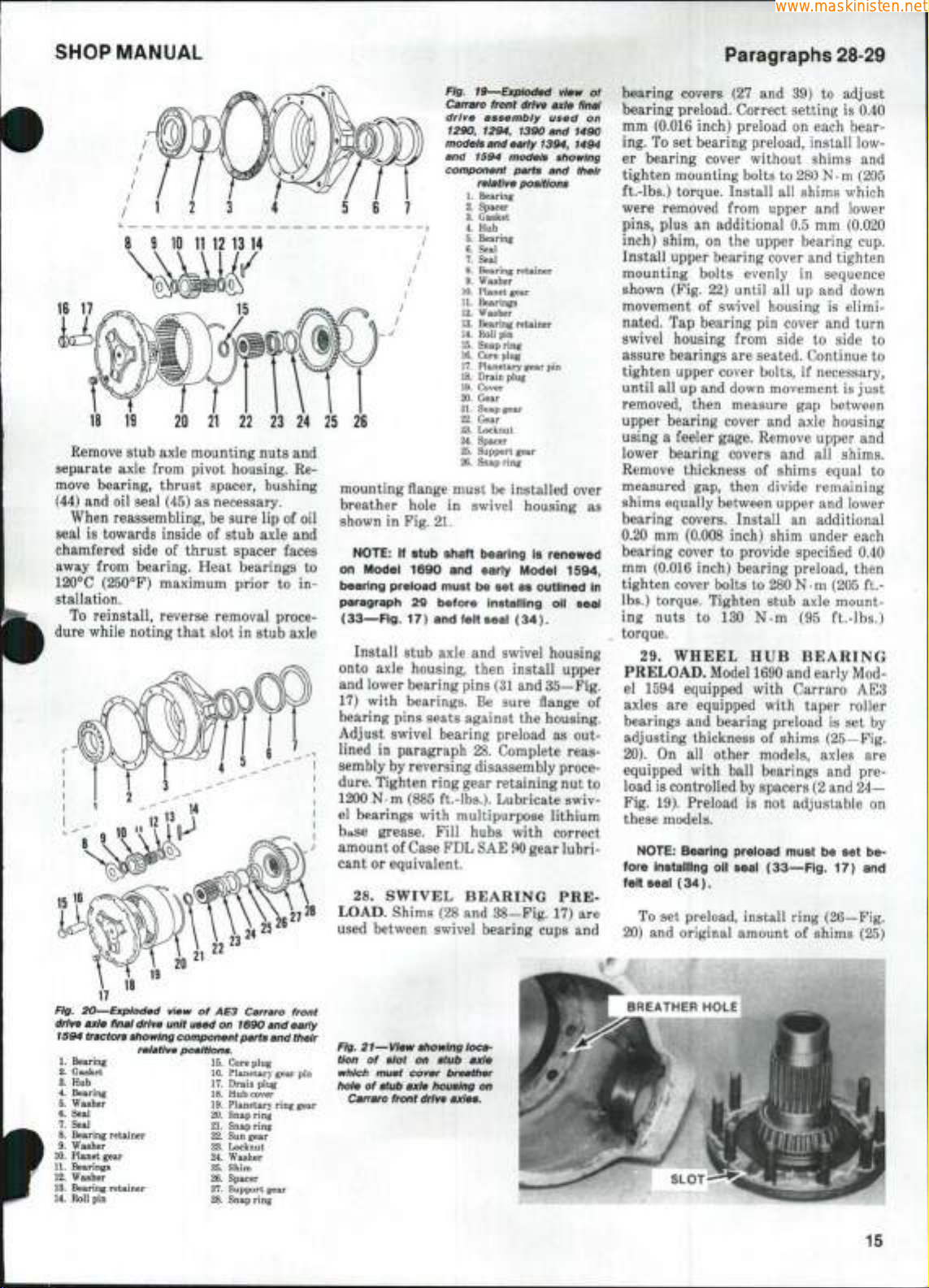

PIVOT BUSHINGS.

To

renew

axle pivot bushings (2 and 20—Fig. 17),

first remove axle

as

outlined

in

para-

graph 25.

put marks (B—Fig. 18)

On

AEI, AE2

and

on oil

AE3 axles,

seal

carrier and differential carrier so seal carrier can

tion. On

ferential carrier

line with hole

removing bushings. Remove

carrier, then

ings.

thrust washers

be

reinstalled

all

axles,

pry

in

original posi-

put

mark (A)

and

axle housing

in

bushings prior

bushings from hous-

Remove sleeve (4—Fig.

(5 and 18) as

on dif-

in

to

oil

seal

17) and

neces-

sary.

Install

new

ings

"0" rings

and

lubricate with grease before

in

pivot bush-

reinstalling bushings. Make certain

holes

in

bushings

are

aligned with

marks made previously on case and carrier housing (Fig.

carrier aligning mark

18).

Install

on

carrier with

oil

seal

mark on differential carrier.

Models With AEI, AE2

or

AE3

Carraro Axle

27.

FINAL DRIVE

AXLE.

Raise and support front

AND

STUB

of

tractor, then remove tire and wheel. Rotate

hub (4—Fig. 19) until drain plug (18)

is

at bottom, then drain oil from housing.

Remove bolts retaining end plate (19)

hub

(4) and

opposite each other

install

two

guide studs

in

hub. Remove end

to

plate (19) with planetary gears. Remove

snap ring (15)

port

hub

locknut (23)

1690

and

retain shims (25—Fig. 20). On

els,

remove planetary ring gear and hub

and sun

gear (22).

Sup-

with a chain hoist. Remove

and

spacer (24).

early Model 1594, remove

On

all

Model

and

mod-

assembly.

To remove stub axle (43—Fig. 17) and

pivot housing (32), remove felt seal (34)

and

oil

seal (33). Loosen nuts securing

stub axle

ends

to

(40 and

housing. Disconnect tie rod

47). Disconnect steering

cylinder from right-hand steering arm.

Remove bearing

pin

covers (27

and 39)

and shims (28 and 38). Use special puller (CAS-1652)

(31 and

35).

to

remove bearing pins

Remove stub axle and hous-

ing assembly.

All Models So Equipped

24.

TIE RODS AND TOE-IN. Front

wheel toe-in

rim

to

wheel

is

measured from wheel

rim at

front

wheels. Toe-in should be 0-5 mm (0-3/16

inch) on tractors with Type 709/19 axle.

On

all

other tractors, toe-in should

0-1.5

mm

(0-1/16 inch). Toe-in

justed by lengthening or shortening the

threaded

worn must

Tie

tie

rod ends equally.

rod

ends that

be

are

renewed

units.

25.

R&R

AXLE ASSEMBLY.

remove front drive axle assembly, raise

14

and

rear

is ad-

excessively

as

complete

of

Fig. 18—Before disassembiing differentiai carrier,

piace alignment marks (A

be

and B) as shown for repositioning of bushings and oil

seal

carrier.

axies, oil seal carrier (B)

aiignment is not required.

To

On Type 709/19

SHOP MANUAL

www.maskinisten.net

Paragraphs 28-29

12

3 4

8

9 10

18

19 20 21 22 23 24 25 26

11 12 13 14

Remove stub axle mounting nuts and

separate axle from pivot housing.

Remove bearing, thrust spacer, bushing

(44) and oil seal (45)

When reassembling, be sure lip

seal

is

towards inside

chamfered side

away from bearing. Heat bearings

120°C (25O''F) maximum prior

as

necessary.

of

of

stub axle

thrust spacer faces

of

oil

and

to

to in-

stallation.

To reinstall, reverse removal proce-

dure while noting that slot

in

stub axle

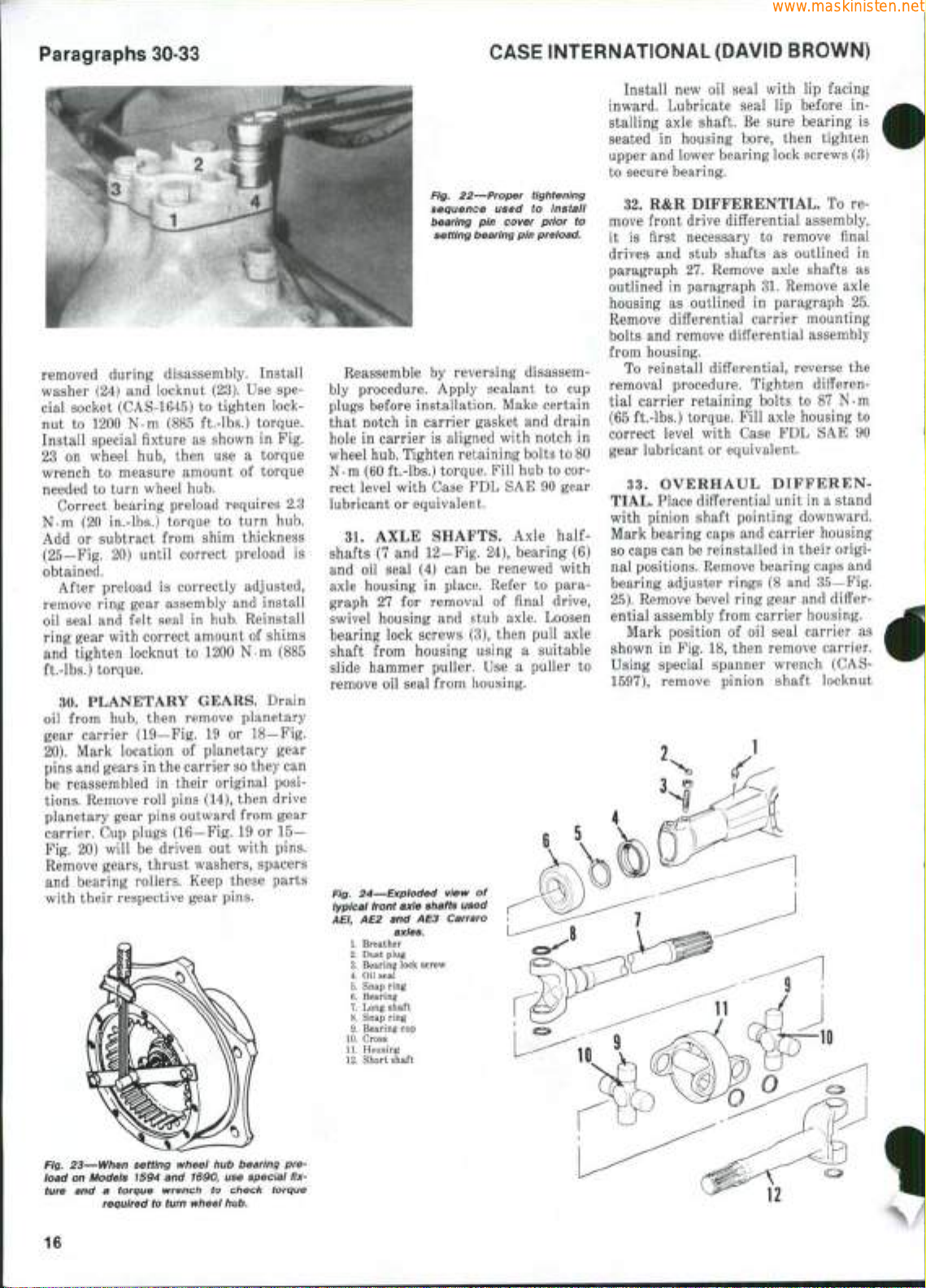

Fig. 19—Expioded view

Carraro front drive axie finai

drive assembiy used

1290, 1294, 1390 and 1490

modeis and eariy 1394,

and

1594

component parts

modeis showing

reiative positions

1.

Bearing

2.

Spacer

3.

Gasket

4.

Hub

5.

Bearing

6.

Seal

7.

Seal

8.

Bearing retainer

9.

Washer

10.

Planet gear

11.

Bearings

12.

Washer

13.

Bearing retainer

14.

Roll pin

15.

Snap ring

16.

Core plug

17.

Planetary gear pin

18.

Drain plug

19.

Cover

20.

Gear

21.

Snap gear

22.

Gear

23.

Locknut

24.

Spacer

25.

Support gear

26.

Snap ring

and

of

on

1494

their

mounting flange must be installed over

breather hole

shown

in

NOTE:

on Model 1690 and eariy Model 1594,

bearing preioad must be set as outlined In

paragraph 29 before instaiiing oil seal

(33-—Fig.

Install stub axle

in

swivel housing

as

Fig. 21.

If stub shaft bearing is renewed

17) and felt seal (34).

and

swivel housing

onto axle housing, then install upper

and lower bearing pins

17) with bearings.

(31

Be

sure flange

and 35—Fig.

of

bearing pins seats against the housing.

Adjust swivel bearing preload

lined

in

paragraph 28. Complete reas-

as out-

sembly by reversing disassembly procedure.

Tighten ring gear retaining nut

to

1200 N.m (885 ft.-lbs.). Lubricate swiv-

el bearings with multipurpose lithium

bttse grease. Fill hubs with correct

amount of Case FDL SAE 90 gear lubricant

or

equivalent.

28.

SWIVEL BEARING

LOAD. Shims (28

used between swivel bearing cups

and

38-Fig. 17)

PRE-

are

and

bearing covers

bearing preload. Correct setting

mm (0.016 inch) preload

ing. To

set

er bearing cover without shims

tighten mounting bolts

ft.-lbs.) torque. Install

were removed from upper

pins,

plus

inch) shim,

(27 and 39) to

on

each bear-

adjust

is

0.40

bearing preload, install low-

and

to

280 N-m (205

all

shims which

and

an

additional

on the

0.5 mm

upper bearing

lower

(0.020

cup.

Install upper bearing cover and tighten

mounting bolts evenly

shown (Fig.

movement

nated.

Tap

22)

until

of

swivel housing

bearing

swivel housing from side

assure bearings are seated. Continue

tighten upper cover bolts,

until

all up

and down movement is just

removed, then measure

upper bearing cover

using a feeler gage. Remove upper

lower bearing covers

Remove thickness

measured

gap,

then divide remaining

in

all up and

pin

cover

if

gap

and

axle housing

and all

of

shims equal

sequence

down

is

elimi-

and

to

turn

side

necessary,

between

shims.

to

to

and

to

shims equally between upper and lower

bearing covers. Install

0.20

mm

bearing cover

(0.008 inch) shim under each

to

an

additional

provide specified

0.40

mm (0.016 inch) bearing preload, then

tighten cover bolts

to

280

Nm

(205

ft.lbs.) torque. Tighten stub axle mounting nuts

to 130 N.m (95

ft.-lbs.)

torque.

29.

WHEEL

HUB

BEARING

PRELOAD. Model 1690 and early Mod-

el

1594

axles

are

bearings

adjusting thickness

20).

equipped with taper roller

and

bearing preload

of

On all

other models, axles

shims (25—Fig.

equipped with ball bearings

load is controlled by spacers (2 and

Fig.

19).

equipped with Carraro

Preload

is not

adjustable

AE3

is set by

are

and pre-

24—

on

these models.

NOTE:

fore instaiiing oil seai (33—Fig. 17) and

felt seal (34).

20)

Bearing preload must be set be-

To

set

preload, install ring (26—Fig.

and

original amount

of

shims

(25)

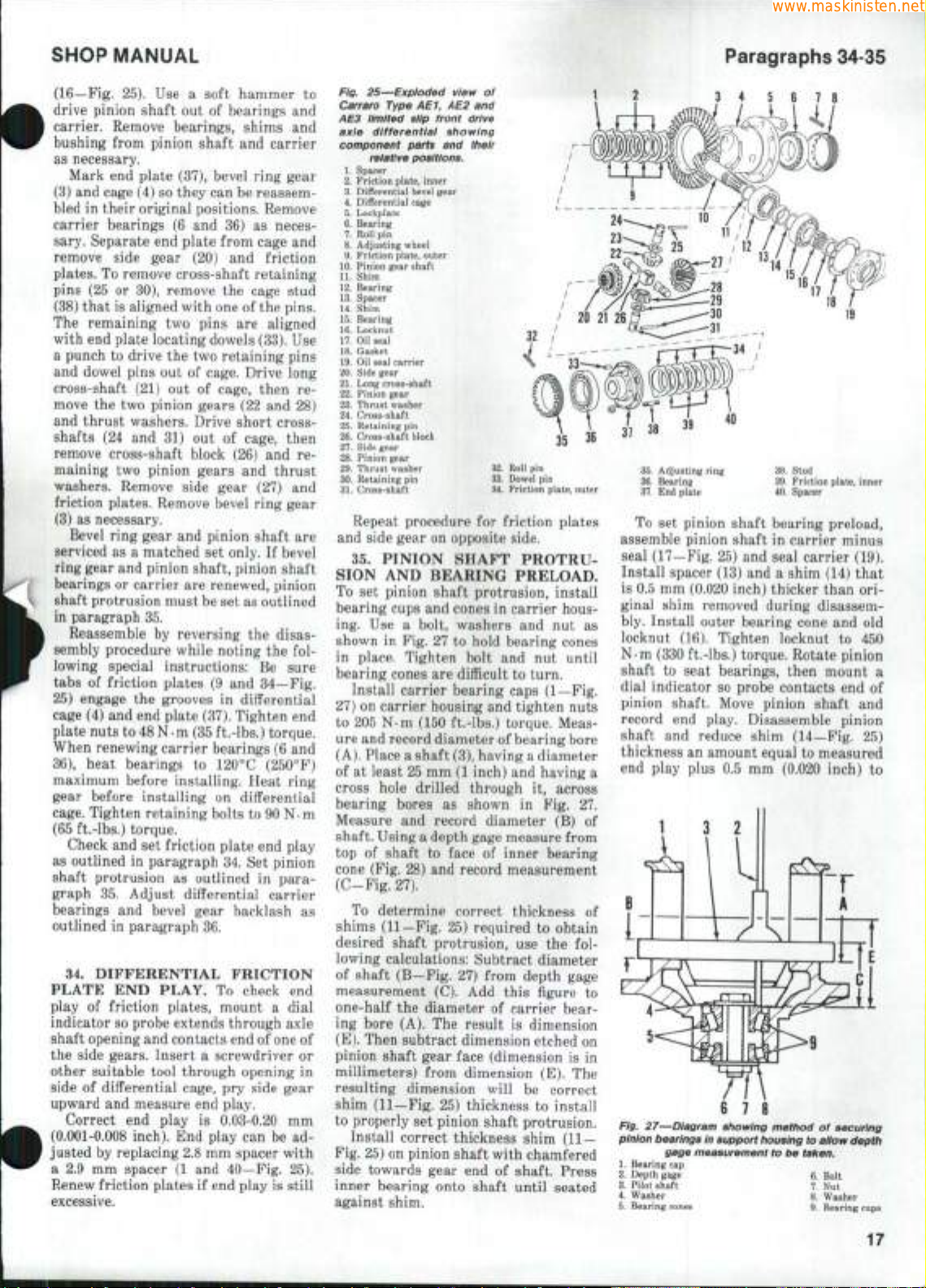

Fig, 20—exploded view

drive axie final drive unit used on 1690 and eariy

1594 tracton showing component parts and

1.

Bearing 15. Core plug

2.

Gasket

16.

3.

Hub 17.

4.

Bearing 18. Hub cover

5.

Washer

19.

6.

Seal

20.

7.

Seal 21. Snap ring

8.

Bearing retainer

9.

Washer 23. Locknut

10.

Planet gear

11.

Bearings 25. Shim

12.

Washer

13.

Bearing retainer

14.

Roll pin

. 24.

26,

28.

of AE3

reiative positions.

22.

27.

Carraro front

their

Planetary gear pin

Drain plug

Planetary ring gear

Snap ring

Sun gear

Washer

Spacer

Support gear

Snap ring

Fig. 21—View showing iocatlon

of

siot

on

which must cover breather

hoie

of

stub axie housing

Carraro front drive axies.

stub axie

on

15

Paragraphs 30-33

www.maskinisten.net

removed during disassembly. Install

washer

(24) and

cial socket (CAS-1645)

nut

to 1200 N-m (885

Install special fixture

23

on

wheel

wrench

to

needed

to

Correct bearing preload requires

N-m

(20

Add

or

subtract from shim thickness

(25—Fig.

obtained.

After preload

remove ring gear assembly

oil seal

and

ring gear with correct amount

and tighten locknut

ft.-lbs.) torque.

30.

PLANETARY GEARS. Drain

oil from

hub,

gear carrier (19—Fig.

20).

Mark location

pins and gears

be reassembled

tions.

Remove roll pins (14), then drive

planetary gear pins outward from gear

carrier.

Cup

Fig.

20)

will

Remove gears, thrust washers, spacers

and bearing rollers. Keep these parts

with their respective gear pins.

locknut (23).

to

tighten lock-

ft.-lbs.) torque.

as

shown

hub,

then

use a

measure amount

turn wheel

in.-lbs.) torque

20)

felt seal

hub.

to

until correct preload

is

correctly adjusted,

in hub.

to 1200 N-m (885

then remove planetary

19 or

of

in

planetary gear

the carrier so they can

in

their original posi-

plugs (16—Fig.

be

driven

out

Use spe-

in Fig.

torque

of

torque

2.3

turn

hub.

is

and

install

Reinstall

of

shims

18—Fig.

19 or

15—

with pins.

CASE INTERNATIONAL (DAVID BROWN)

Fig. 22—Proper tightening

sequence used

bearing

setting bearing pin preioad.

Reassemble

by

reversing disassembly procedure. Apply sealant

plugs before installation. Make certain

that notch

hole

in

in

carrier

carrier gasket

is

aligned with notch

wheel hub. Tighten retaining bolts to 80

N-m (60 ft.-lbs.) torque. Fill hub

rect level with Case

lubricant

shafts

and

or

equivalent.

31.

AXLE SHAFTS. Axle

(7 and

oil

seal

(4) can be

axle housing

graph

27 for

swivel housing

bearing lock screws

FDL SAE 90

12-Fig.

in

place. Refer

removal

and

stub axle. Loosen

(3),

shaft from housing using a suitable

slide hammer puller.

remove

oil

seal from housing.

Fig. 24—Expioded view

typical

front

AEI,

10.

11.

12.

axle shafts used

AE2 and AE3

axles.

1.

Breather

2.

Dust plug

3.

Bearing lock screw

4.

Oil

seat

5.

Snap ring

6. Bearing

7.

Long shaft

8. Snap ring

9. Bearing cup

Cross

Housing

Short shaft

of

Carraro

to

pin

cover prior

to cup

and

24),

bearing

renewed with

to

of

final drive,

then pull axle

Use a

puller

instaii

to

drain

in

to

cor-

gear

half-

(6)

para-

to

Install

new oil

inward. Lubricate seal

stalling axle shaft.

seated

in

housing bore, then tighten

upper

and

lower bearing lock screws

seal with

lip

Be

sure bearing

lip

facing

before

in-

is

(3)

to secure bearing.

32.

R&R

DIFFERENTIAL.

To remove front drive differential assembly,

it

is

first necessary

drives

and

paragraph

outlined

housing

in

as

stub shafts

27.

paragraph 31. Remove axle

outlined

to

remove final

as

outlined

Remove axle shafts

in

paragraph

in

as

25.

Remove differential carrier mounting

bolts

and

remove differential assembly

from housing.

To reinstall differential, reverse

the

removal procedure. Tighten differential carrier retaining bolts

(65 ft.-lbs.) torque. Fill axle housing

correct level with Case

gear lubricant

33.

OVERHAUL DIFFEREN-

or

equivalent.

TIAL. Place differential unit

to 87 N-m

to

FDL SAE 90

in a

stand

with pinion shaft pointing downward.

Mark bearing caps

so caps can be reinstalled

nal positions. Remove bearing caps

bearing adjuster rings

25).

Remove bevel ring gear

and

carrier housing

in

their origi-

(8 and

and

and

35—Fig.

differ-

ential assembly from carrier housing.

Mark position

shown

in Fig. 18,

Using special spanner wrench

1597),

remove pinion shaft locknut

of oil

seal carrier

then remove carrier.

(CAS-

as

Fig. 23—When setting wheel

ioad

on

Modeis 1594

ture

and a

torque wrench

required

16

to

and

turn

hub

1690,

use

to

check torque

wheei hub.

bearing

speciai

pre-

fix-

SHOP MANUAL

www.maskinisten.net

Paragraphs 34-35

(16—Fig. 25). Use a soft hammer to

drive pinion shaft out of bearings and

carrier. Remove bearings, shims and

bushing from pinion shaft and carrier

as necessary.

Mark end plate (37), bevel ring gear

(3) and cage (4) so they can be reassembled in their original positions. Remove

carrier bearings (6 and 36) as neces-

sary. Separate end plate from cage and

remove side gear (20) and friction

plates.

To remove cross-shaft retaining

pins (25 or 30), remove the cage stud

(38) that is aligned with one of the pins.

The remaining two pins are aligned

with end plate locating dowels (33). Use

a punch to drive the two retaining pins

and dowel pins out of cage. Drive long

cross-shaft (21) out of cage, then re-

move the two pinion gears (22 and 28)

and thrust washers. Drive short crossshafts (24 and 31) out of cage, then

remove cross-shaft block (26) and remaining two pinion gears and thrust

washers. Remove side gear (27) and

friction plates. Remove bevel ring gear

(3) as necessary.

Bevel ring gear and pinion shaft are

serviced as a matched set only. If bevel

ring gear and pinion shaft, pinion shaft

bearings or carrier are renewed, pinion

shaft protrusion must be set as outlined

in paragraph 35.

Reassemble by reversing the disassembly procedure while noting the foliowing special instructions: Be sure

tabs of friction plates (9 and 34—Fig.

25) engage the grooves in differential

cage (4) and end plate (37). Tighten end

plate nuts to

48 N • m

(35 ft-lbs.) torque.

When renewing carrier bearings (6 and

36),

heat bearings to 120°C (250°F)

maximum before installing. Heat ring

gear before installing on differential

cage.

Tighten retaining bolts to 90 N-m

(65 ft.-lbs.) torque.

Check and set friction plate end play

as outlined in paragraph 34. Set pinion

shaft protrusion as outlined in para-

graph 35. Adjust differential carrier

bearings and bevel gear backlash as

outlined in paragraph 36.