Cascade Sciences CVO-2, CVO-2-2 Instruction Manual

Benchtop Vacuum Purge Ovens

CVO-2 CVO-2-2

Installation - Operation Manual

cascadesciences.com | Tel. 503 847-9047

Benchtop Vacuum Purge Ovens

CVO-2: 110 – 120 Voltage North America

CVO-2-2: 220 – 240 Voltage

Part Number (Manual): 4861791

Revision: February 22, 2018

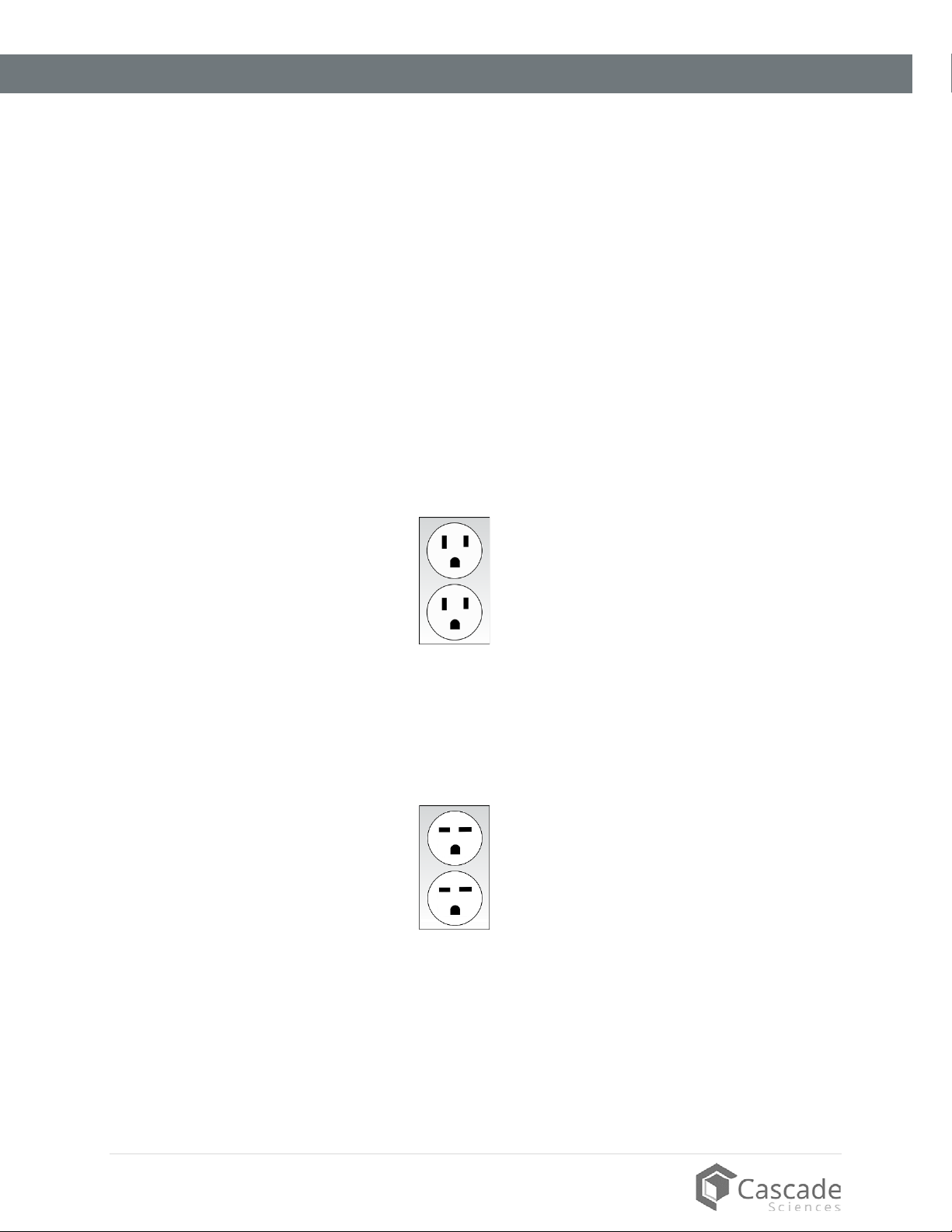

The CVO-2 requires a standard 110 – 120 volt NEMA 5-15 power supply outlet to plug into.

The CVO-2-2 requires a NEMA 6-15R 220 – 240-volt power supply outlet to plug into.

2 | Page

cascadesciences.com | Tel. 503 847-9047

TABLE OF CONTENTS

CERTIFICATIONS ...................................................................................................................................................... 5

UNIT SPECIFICATIONS ............................................................................................................................................. 7

Temperature ............................................................................................................................................................................ 7

Power ......................................................................................................................................................................................... 7

Vacuum ..................................................................................................................................................................................... 7

Weight ........................................................................................................................................................................................ 8

Dimensions ............................................................................................................................................................................... 8

Capacity .................................................................................................................................................................................... 8

INTRODUCTION ........................................................................................................................................................ 9

Read this Manual .................................................................................................................................................................... 9

Contacting Assistance .......................................................................................................................................................... 9

Engineering Improvements.................................................................................................................................................. 9

Vacuum Supply Required .................................................................................................................................................. 10

Gaskets ................................................................................................................................................................................... 10

RECEIVING YOUR OVEN .........................................................................................................................................11

Inspect the Shipment ............................................................................................................................................................ 11

Orientation.............................................................................................................................................................................. 12

Record Data Plate Information ......................................................................................................................................... 14

INSTALLATION ......................................................................................................................................................... 15

Installation Checklist ........................................................................................................................................................... 15

Required Ambient Conditions ........................................................................................................................................... 16

Environmental Disruption Sources .................................................................................................................................. 16

Power Source Requirements ............................................................................................................................................. 17

General Power Safety .......................................................................................................................................................... 17

Lifting and Handling ............................................................................................................................................................ 18

Leveling ................................................................................................................................................................................... 18

Install the Oven ..................................................................................................................................................................... 18

Installation Cleaning ............................................................................................................................................................ 18

Shelving Installation............................................................................................................................................................. 19

Connect to the Vacuum Supply ...................................................................................................................................... 20

Connect to a Gas Backfill Supply .................................................................................................................................... 21

GRAPHIC SYMBOLS ............................................................................................................................................... 23

CONTROL OVERVIEW ............................................................................................................................................ 25

OPERATION.............................................................................................................................................................. 27

Safety Guidelines .................................................................................................................................................................27

Operating Precautions ....................................................................................................................................................... 28

Theory of Operation ........................................................................................................................................................... 29

Put the Oven into Operation ............................................................................................................................................. 31

Put the Chamber Under Vacuum ................................................................................................................................... 33

Set the Temperature Set Point ........................................................................................................................................ 34

Over Temperature Activation .......................................................................................................................................... 35

Vacuum Gauge Operations ............................................................................................................................................. 36

Maximum Obtainable Vacuum ......................................................................................................................................... 37

Pressure Units Conversion Chart ..................................................................................................................................... 37

Data Port ................................................................................................................................................................................ 38

USER MAINTENANCE ............................................................................................................................................. 39

Cleaning and Disinfecting ................................................................................................................................................. 39

Maintaining Atmospheric Integrity ................................................................................................................................. 40

Electrical Components ....................................................................................................................................................... 40

Vacuum Pump Maintenance ............................................................................................................................................. 41

Calibrate the Temperature display ................................................................................................................................ 42

3 | Page

cascadesciences.com | Tel. 503 847-9047

REPLACEMENT PARTS LIST.................................................................................................................................. 47

Replacement Gaskets ........................................................................................................................................................ 48

4 | Page

cascadesciences.com | Tel. 503 847-9047

CERTIFICATIONS

This certificate satisfies NRTL safety requirements

TÜV SÜD CUE

Certificate Number: U8 17 04 64872 077

These units are CUE listed by TÜV SÜD as forced air ovens for appropriate professional, industrial,

or educational use. TÜV SÜD America Inc. is an OSHA recognized NRTL and a Standards Council of

Canada accredited certification body.

The units have been tested to the following requirements:

CAN/CSA-C22.2 No. 61010-1:2012 + U2:2016-04

CAN/CSA-C22.2 No. 61010-2-010:2015

UL 61010-1:2012/R:2016-04

UL 61010-2-010:2015

EN 61010-1:2010

EN 61010-2-010:2014

5 | Page

cascadesciences.com | Tel. 503 847-9047

CERTIFICATIONS

6 | Page

cascadesciences.com | Tel. 503 847-9047

UNIT SPECIFICATIONS

Please refer to the oven data plate for individual electrical specifications.

Technical data specified applies to units with standard equipment at an ambient temperature of 25°C

±3° (77°F ±5.4°) and at nominal voltage. The temperatures specified are determined in accordance to

factory standard following DIN 12880 respecting the recommended wall clearances of 10% of the

height, width, and depth of the inner chamber. All indications are average values, typical for units

produced in the series. We reserve the right to alter technical specifications at all times.

TEMPERATURE

Model Range Uniformity Stability

CVO-2 Ambient +26°F to 250°F ±1.5° @105°F

CVO-2-2 Ambient +26°F to 250°F ±1.5° @105°F

POWER

Model AC Voltage Amperage Frequency

CVO-2

CVO-2-2

110 – 120 6.0 50/60 Hz

220 – 240 4.0 50/60 Hz

VACUUM

Operational Vacuum Range - All Ovens

inHg mmHg kPa bar

-3.0 to -29.9 -76 to -760 -10 to -101

± 0.4°F @ 105°F

± 0.4°F @ 105°F

-0.1016 to -1.0125

Vacuum Display Range – All Ovens

inHg mmHg kPa bar

0.0 to -29.9 37.5 to - 757

5 to -101

0.05 to -1.013

7 | Page

cascadesciences.com | Tel. 503 847-9047

UNIT SPECIFICATIONS

WEIGHT

Model Shipping Weight Unit Weight

CVO-2

CVO-2-2

DIMENSIONS

Inches

Model Exterior W × D × H Interior W × D × H

CVO-2 18.8 x 24.5 x 24.5 in 12.0 x 20.0 x 12.0 in

CVO-2-2 18.8 x 24.5 x 24.5 in 12.0 x 20.0 x 12.0 in

Millimeters

Model Exterior W × D × H Interior W × D × H

CVO-2 478 x 622 x 622 305 x 508 x 305

CVO-2-2 478 x 622 x 622 305 x 508 x 305

183 lb / 83.0 kg 148 lb / 67.1 kg

183 lb / 83.0 kg 148 lb / 67.1 kg

CAPACITY

Model Cubic Feet Liters

CVO-2

CVO-2-2

8 | Page

1.67 47.2

1.67 47.2

cascadesciences.com | Tel. 503 847-9047

INTRODUCTION

READ THIS MANUAL

Failure to follow the guidelines and instructions in this user manual may create a protection

impairment by disabling or interfering with the unit safety features. This can result in injury or death.

Before using the unit, read the manual in its entirety to understand how to install, operate, and

maintain the unit in a safe manner. Keep this manual available for use by all operators. Ensure all

operators are given appropriate training before the unit begins service.

Intended Applications and Locations

CVO vacuum ovens are engineered for drying, curing, and baking applications under vacuum in

professional, industrial, and educational environments. The ovens are not intended for use at

hazardous or household locations.

CONTACTING ASSISTANCE

Phone hours for Technical Support are 6 am – 4:30 pm Pacific Coast Time (west coast of the United States,

UTC -8) Monday - Friday. Please have the following information ready when calling or emailing Technical

Support: the model number and the serial number (see page 14).

PHONE: 866-466-7511 or 503-847-9047

Cascade Sciences

5285 NE Elam Young Parkway

Unit B100

Hillsboro OR, 97124

ENGINEERING IMPROVEMENTS

Cascade Sciences continually improves all of its products. As a result, engineering changes and

improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit’s operating characteristics or

appearance differs from those described in this manual, please contact your oven dealer or

customer service representative for assistance.

9 | Page

cascadesciences.com | Tel. 503 847-9047

Vacuum Pump

Building

INTRODUCTION

VACUUM SUPPLY REQUIRED

CVO ovens require a vacuum supply source, which must be purchased separately from

the oven. Please see the Cascade Sciences website for pumps and vacuum system

accessories suitable for your application.

cascadesciences.com/vacuum-pumps

Minimum Vacuum Draw

In order to seal completely, the oven chamber must be under a minimum vacuum draw of:

Vacuum Supply

inHg mmHg kPa bar

-3.0 -76

-10

-0.1016

GASKETS

Gaskets are high-wear items, subject to compression forces, heat, and outgassed

byproducts. Keeping a spare gasket on hand during operations is strongly recommended.

Each CVO-2 oven comes with a replaceable Buna silicon gasket installed on the chamber

liner. This gasket seals against the chamber door to maintain the vacuum integrity of the

chamber. The gasket must be replaced periodically and is rated to 221°F (105°C). It is

resistant to solvents but not acids. See page 48 for more information on gasket type

suitability for baking applications.

10 | Page

cascadesciences.com | Tel. 503 847-9047

RECEIVING YOUR OVEN

INSPECT THE SHIPMENT

• When a unit leaves the factory, safe delivery becomes the responsibility of the carrier.

• Damage sustained during transit is not covered by the manufacturing defect warranty.

• Save the shipping carton until you are certain that the unit and its accessories function

properly.

When you receive your unit, inspect it for concealed loss or damage to its interior and exterior. If you

find any damage to the unit, follow the carrier’s procedure for claiming damage or loss.

1. Carefully inspect the shipping carton for damage. Save the shipping carton until you are

certain that the unit and its accessories function properly

2. Report any damage to the carrier service that delivered the unit.

3. If the carton is not damaged, open the carton and remove the contents.

4. The unit should come with an end-user Installation and Operation Manual.

5. Verify that the correct number of accessories have been included.

6. Carefully check all packaging for loose accessory items before discarding.

Included Accessories:

Tall Shelves Medium Shelves Short Shelf w/ Clip Power Cord Leveling Feet

2 2 1 1 4

11 | Page

cascadesciences.com | Tel. 503 847-9047

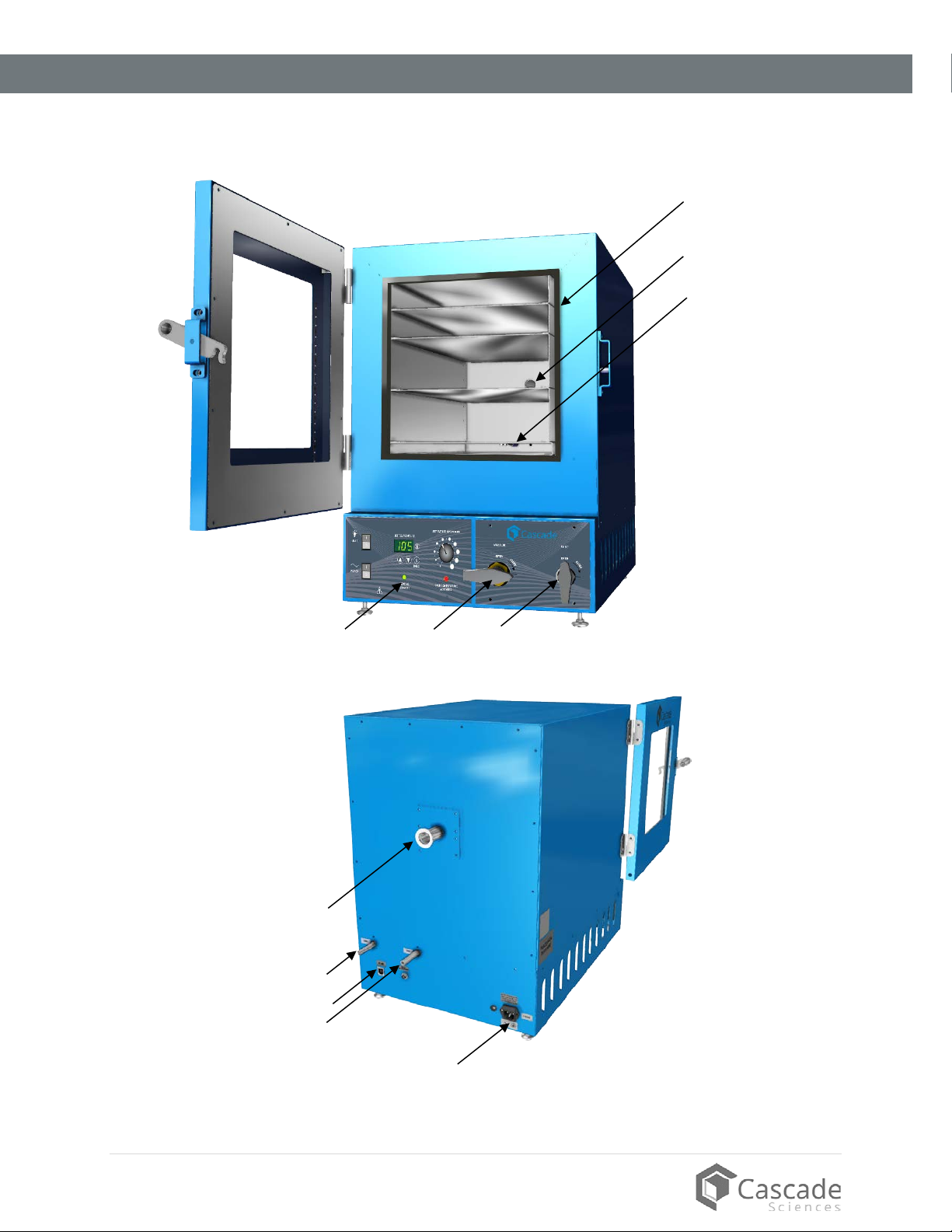

Control Panel

Intake Vent Control (allows

the oven chamber)

Intake Vent Port ¼ inch OD

USB Data Port

Power Cord Inlet

Chamber Door

Latch

CVO-2s

Vacuum Valve

Vacuum Port 3/8 inch OD

KF-25 Vacuum Port

Temperature Sensor

Access Port

Chamber Gasket

RECEIVING YOUR OVEN

ORIENTATION

Probe

Control

external atmosphere into

12 | Page

cascadesciences.com | Tel. 503 847-9047

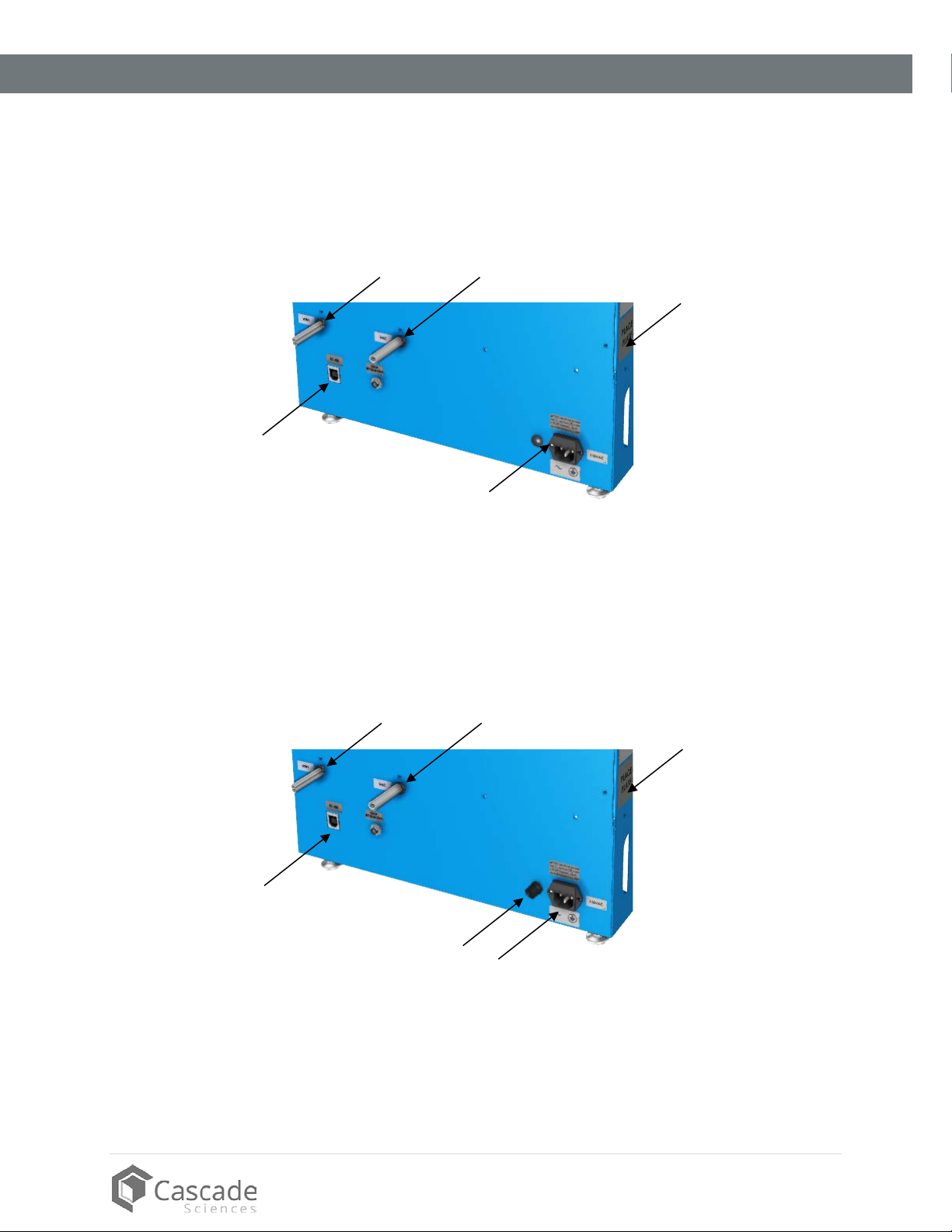

Power Cord Inlet with fuse

USB Data Port

Intake Vent – To the oven

chamber ¼ in (6.35mm) OD

CVO-2

Data Plate

Vacuum Inlet 3/8in (9.52mm) OD -

Power Cord Inlet with fuse

USB Data Port

Intake Vent – To the oven

chamber ¼ in (6.35mm) OD

Data Plate

Vacuum Inlet 3/8in (9.52mm) OD -

Fuse Holder, 2nd Fuse

CVO-2-2

RECEIVING YOUR OVEN

Power Panels

Located on the back of each unit

Connect the vacuum pump or supply

Connect the vacuum pump or supply

13 | Page

cascadesciences.com | Tel. 503 847-9047

Model Number

RECEIVING YOUR OVEN

RECORD DATA PLATE INFORMATION

Locate the data plate on the left side of the oven near the back. The data plate contains the oven

model number and serial number. Enter this information below for future reference.

Data Plate Information

Serial Number

14 | Page

cascadesciences.com | Tel. 503 847-9047

INSTALLATION

INSTALLATION CHECKLIST

Carry out the procedures and steps listed below to install the oven in a new workspace location and

prepare it for use. All procedures are found in the Installation section of this manual.

Pre-Installation

Verify that a vacuum supply source (stand-alone pump or in-house system) suitable for

your application is available and can be connected to the oven. See page

oven gas and vacuum port locations.

Check that the required ambient conditions, ventilation, and spacing for the oven are

met, page

• Unit dimensions may be found on page 8.

16.

20 for the

Check for performance-disrupting heat and cold sources in the environment, page 16.

Check that a suitable electrical outlet and power supply for the oven is present, page 17.

Check that a suitable electrical outlet and power supply for the vacuum pump is present. Please

see the pump operator manual for electrical requirements.

Install the Oven in a suitable workspace location

Review the lifting and handling instructions, page 18.

Install the oven in its workspace location, page 18.

Make sure the oven is level, page 18.

Set up the Oven for use

Clean the oven shelving. Clean the chamber if needed, page 18.

Install the shelving in the oven chamber, page 19.

Connect the oven to its vacuum supply source, page 20.

Optional: Connect the oven to a neutral purging gas. See page 21.

15 | Page

Loading...

Loading...