This guide describes the visual inspection process for used Pyramid Probe cores. A Pyramid Probe core is considered

Quick Reference Guide

Pyramid Probes: Used Core Inspection

“Used” once it has touched down on a wafer. Visual inspection should be performed first visually, and then with a

microscope. The recommended procedure employs two microscopes:

This guide describes the visual inspection process for new Pyramid Probe cores. Inspection should be performed first

visually, and then with a microscope. The recommended procedure employs two microscopes:

Low-magnification microscope

(with a large working space)

• Commonly used for PCB inspection and

soldering stations

• Used for inspecting the entire probe, core

window, components and membrane wing

• Magnification range should be approximately

7x to 90x

High-magnification microscopes

• Used for inspecting the probe face, probe tips

and beams

• Recommended microscope objectives include

5x, 20x, and 50x

When saving photos, be sure to include the serial number in the file name.

Use the Pyramid Probes Certificate of Conformance to verify the following:

• The serial number on the core frame matches the Pyramid Probes Certificate of Conformance.

• The product name on the Pyramid Probes Certificate of Conformance matches the product to be tested.

Step 1: Edge Sense Inspection

Pyramid Probes used on manual probe stations have an edge sense type mechanical switch installed. This step applies

only to manual probe stations.

Pyramid Probes used on manual probe stations have an edge sense-type mechanical switch installed. The edge sense

needle contacts a glass pad on the spring in some Pyramid Probes. When installed on larger frame cores, the edge sense

needle contacts the core spring directly. This step applies only to manual probe stations.

Inspection Area Criteria

Edge Sense

(if glass pad is

installed)

Are there cracks in the glass pad?

Contact local support for instructions.

Is the glass pad securely in place?

Contact local support for instructions.

Is the needle touching the glass pad, and roughly centered?

Contact local support for instructions.

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 1

Step 2: Low Magnification Microscope Inspection

Tes t er S i d e

Wafer Side

Pyramid Probes: Used Core Inspection

Inspection Area Criteria

Membrane

Plungers

Are there any tears noted anywhere on the membrane?

A membrane tear is defined as a torn membrane caused by mishandling or equipment malfunction. Tears on a

new core that have been repaired by the factory are acceptable, as long as the repaired patch does not exceed

1000μm.

Tears resulting in signal damage to a critical trace cannot be repaired.

Cores with tears that do not include critical traces should be returned for repair to prevent propagation.

A torn trace can be waived by Engineering if it is not critical to the test program.

Has the membrane come off the alignment pin?

WARNING: Do not install in a box or board until repaired.

Contact local support for instructions.

Is there any damage to the membrane?

Escalate to a higher magnification inspection to determine if there is a failure.

Is the probe face clean of any debris?

Follow the procedure in Pyramid Probe Core Off-line Cleaning With Brush to clean the face after incoming

inspection is complete.

Are there any cracks noted in the plunger beams from the tester side?

If cracks are noted, contact local support for instructions.

Are there any cracks in the plunger beams from the wafer side?

Skip this step if the core is installed in a PCB.

If cracks are noted, contact local support for instructions.

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 2

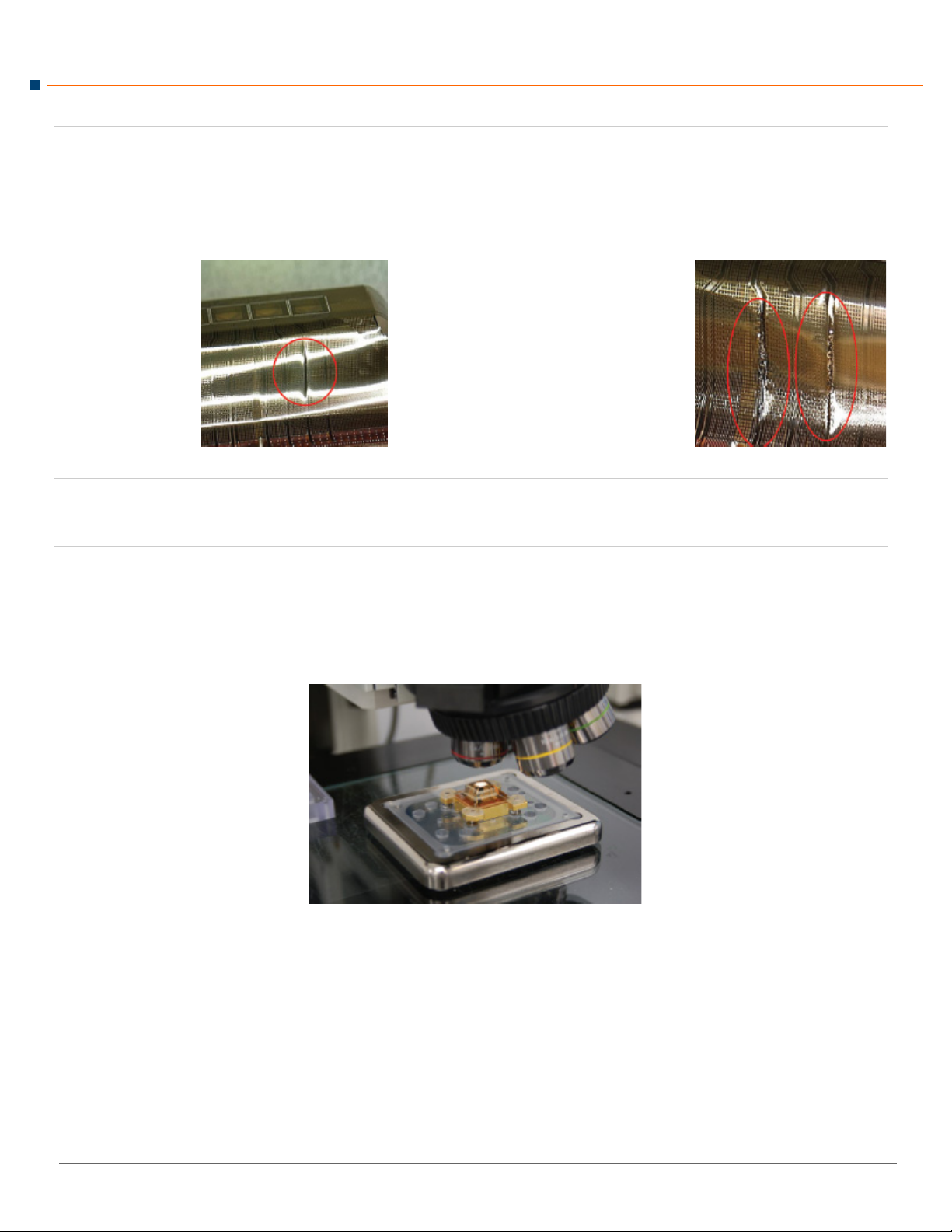

Components

Low-magnification photo of wing

on VLSR core. Burnt trace

verifies test failure for open. It has

been damaged by high current.

Low-magnification photo of wing.

These two traces would fail

electrical test as open circuits. They

were damaged by high current.

Pyramid Probes: Used Core Inspection

Is there any damage to installed components?

Small scratches from the assembly process are acceptable.

Cracked solder joints, cold solder joints or lifted component pads are unacceptable at any time in the core’s life

Damaged components can be waived by Engineering if the electrical signal is not affected.

Note any damage that indicates incorrect handling during installation of the core and provide feedback to

engineeering.

Traces

Is there any high current damage to traces?

The pass/fail criteria is the test program.

Provide feedback to Engineering to check program for current protection on this signal.

Step 3: High Magnification Microscope Inspection

Inspect Core Using the 5x Objective

1. Place the core on a high-magnification fixture with the probe tips up.

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 3

2. Inspect the core using the 5x objective.

Adhesion loss appears near the corner of the membrane.

This is acceptable because there is no large bulge.

Pyramid Probes: Used Core Inspection

Inspection Area Criteria

Probe Face

Membrane

Are there any scratches on the probe face?

Note any scratches on the probe face.

Are any particle hits visible on the membrane?

An indentation in the membrane surface is not a failure. Use the criteria for damage to traces to determine

pass/fail.

Are there any particles embedded in the membrane?

The following criteria describe unacceptable embedded particles:

• Large or deeply embedded particles that cause shorts between traces or layers

• Large embedded particles that cause open traces

• Tall, embedded particles that contact the wafer (maximum particle height is difficult to define; there are

many variables, such as probe tip height, overtravel, membrane design, surface flatness, etc.)

Is there any repeatable diagonal indentation in the membrane?

This is caused by a particle on the cleaning

media.

Follow the pattern of indentations to verify

that a probe tip is not damaged.

Use the pass/fail criteria for scratches to

evaluate the indentations.

Are there any tears in the membrane at the corners of the probe face?

Tears on the probe face cannot be repaired.

Are there any tears along the edges of the wings?

• Fail if a signal is damaged electrically.

• Return for repair to prevent propagation of tears that do not include a signal trace.

Is there any adhesion loss noted on the probe face between the membrane and plunger

stack?

Adhesion loss causing the membrane to

bulge is unacceptable. Focus on the

membrane surface to verify the bulge is not

taller than the probe tips.

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 4

3. Inspect the core using the 20x objective.

Anomaly examples

Cracks originating from beam Cracks parallel to trace

Pyramid Probes: Used Core Inspection

Inspection Area Criteria

Tips

Do all tips appear uniform in size and shape?

On a used core, missing, tilted or crushed tips can be waived by Engineering if they are a redundant contact

like ground or power, or if they still have electrical continuity.

Is there any high current damage to the signal trace evident around the probe tip?

The pass/fail criteria is the test program.

Provide feedback to Engineering to check

program for current protection on this

signal.

Electrical Traces

Surface Layer

Cracks

Are any anomalies present that affect the electrical trace metal?

An anomaly is something different,

abnormal, peculiar or not easily classified.

Anomalies greater than 50% of an electrical

trace width are acceptable on used cores if

the core passes electrical test.

Anomalies affecting the ground grid are

acceptable.

Are there any cracks in the electrical traces?

Cracks greater than 50% are acceptable on used cores if the core passes electrical test.

Cracks affecting the ground grid are acceptable.

To troubleshoot an electrical open, inspect the trace:

• First, inspect the immediate areas of component connections.

• Inspect the probe tip.

• Inspect the entire length of the trace.

Cracks may be present in the surface layer of the polyimide.

• Cracks originating from the beam are

acceptable

• Cracks parallel to an electrical trace,

but not within 20 µm of the beam are

acceptable.

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 5

Middle Layer

Acceptable

Not acceptable. Membrane is

cracked and has some separation.

Acceptable

Cross section with internal

encapsulated particle

Acceptable

Pyramid Probes: Used Core Inspection

Polyimide

Are there any cracks in the Middle Layer Polyimide that do not come to the surface?

This type of crack is acceptable unless it is

causing other damage to the membrane,

such as separation between the layers or

cracks through the entire membrane.

Stress Cracks

Membrane

Surface

Are there any cracks in the surface layer of the membrane where it bends at the edge of the

face?

These cracks are not in the metal. They

are in the polyimide.

Change the focus of the microscope to

confirm the cracks are in the polyimide.

If cracks also appear in the electrical

traces, refer to the appropriate criteria in

Electrical Traces on page 5.

Were any particles created or formed below the membrane (poly2) surface during the

thinfilm fabrication process?

Internal encapsulated particles are acceptable as long as they pass all other specifications.

Polyimide may appear rough and discolored around the beams, component attachment pads, or any other

plated metal area forming part of the membrane surface:

• On the probe face, this is acceptable up to 200µm radius around the beams or other plated metal area

forming part of the membrane surface.

• On the wings and the interface area, this is acceptable in all areas.

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 6

Beams

Pyramid Probes: Used Core Inspection

Are there any cracked beams?

Cracked beams can be waived by Engineering if they are a

redundant contact such as ground or power, or if they still have

electrical continuity.

Is beam slope greater than 10μm?

The probe tip is near the end of its life. Contact Engineering.

See the Pyramid Probe Core User Guide for more details on measuring beam slope.

Is there beam slope throughout all beams?

Beam slope throughout may indicate one of the following:

• Too much overtravel

•End of life

Is the beam slope isolated?

Isolated beam slope can indicate one of the following:

• Particle hit

• Mishandling

• Stepping off wafer

4. Inspect the core using the 50x objective. The primary goal at this magnification is to inspect the surface of the probe tip.

Inspection Area Criteria

Probe Tips

Is there any organic buildup or fibers on tips?

Fibers are not acceptable on used probe tips.

Used cores will have small amounts of organic contamination from probing or cleaning that might not be

completely removed by off-line cleaning.

To remove contamination, see the procedure in Pyramid Probe Cores Off-line Cleaning With Brush.

Is there any metal present on the probe tips?

Metallic buildup on the tips is acceptable if the core passes electrical test.

If there is aluminum or solder contamination covering more than 25% of the probe tip surface, provide

feedback to Engineering to evaluate the online cleaning parameters and the cleaning film.

Are the probe tips textured?

Probe tips for gold pads do not need texture, but can have a textured tip surface.

Probe tips for probing all other metals, must have texture on 25% of the tip surface.

Do the probe tips meet height and diameter dimensions?

For used cores, the criteria for tip height is to pass functional test.

For used cores, the criteria for tip diameter is device-specific to the passivation opening.

Do adjacent probe tips have a height difference greater than 2μm?

A height difference greater than 2μm on a used core is acceptable if electrical contact is made at production

overtravel.

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 7

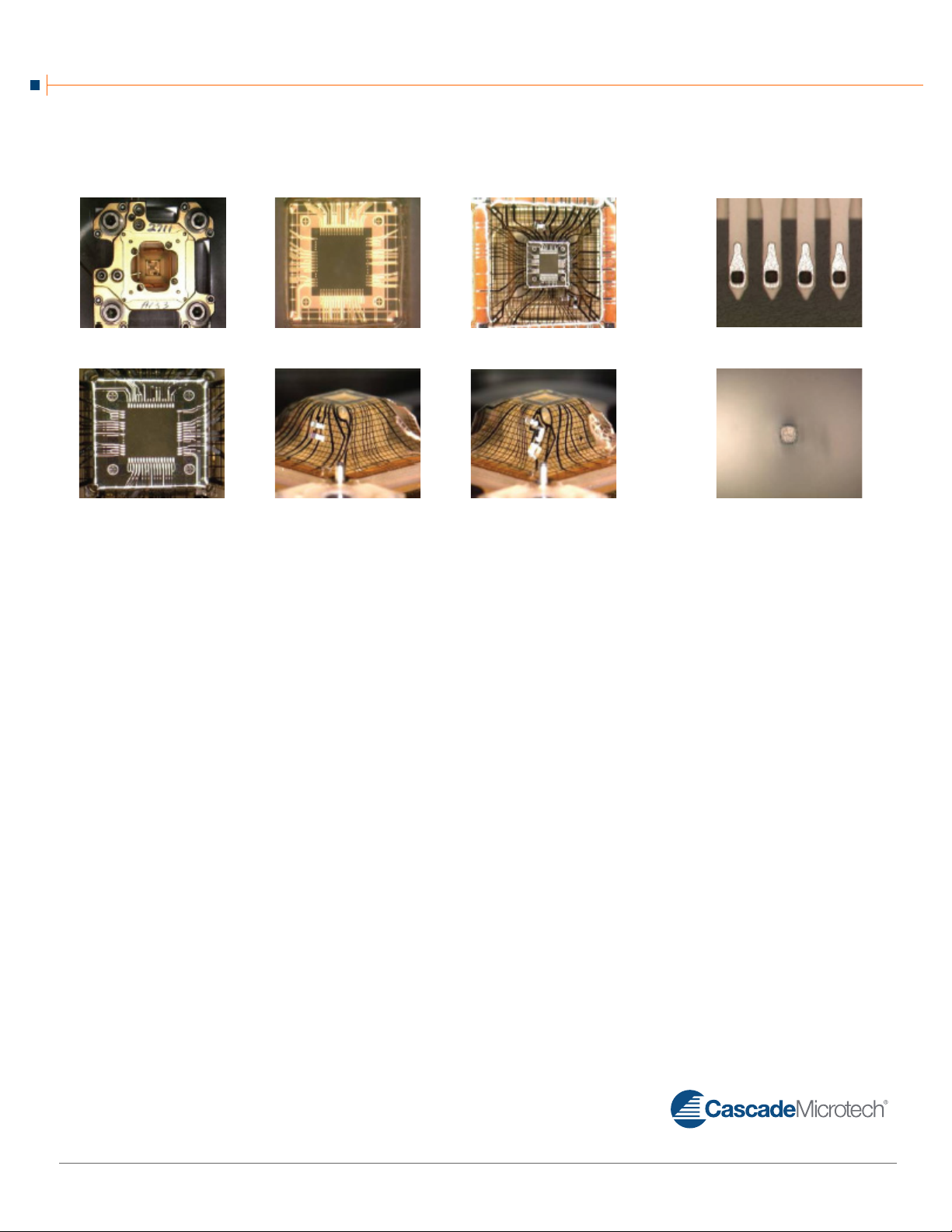

Example Images

© Copyright 2011 Cascade Microtech, Inc.

All rights reserved. Cascade Microtech is

a registered trademark of Cascade Microtech, Inc. All other trademarks are the

property of their respective owners.

Data subject to change without notice.

Pyramid Probes: Used Core Inspection

Entire Probe Core Window Entire Membrane Beams @ 50x

Probe Face Wing North and East Wing South and West Probe Tips@ 50x

Low Magnification Scope High Magnification Scope

Cascade Microtech, Inc.

Corporate Headquar

toll free: +1-800-550-3279

phone: +1-503-601-1000

email: cmi_sales@cmicro.com

ters

PN 153-691-2 www.cascademicrotech.comI Pyramid Probes: Used Core Inspection• 8

Germany

phone: +49-89-9090195-0

email: cmg_sales@ cmicro.com

Japan

phone: +81- 3-5615-5150

email: cmj_sales@ cmicro.com

China

phone: +86-21-3330-3188

email: cmc_sales@ cmicro.com

eSingapor

phone:

+65-6873-7482

email: cms_sales@ cmicro.com

Tai wa n

phone: +886-3-5722810

email: cmt_sales@cmicro.com

Loading...

Loading...