Objective

Figure 1. P800-S mounted on a PCB.

i

Quick Reference Guide

Pyramid Probe Card: P800-S Online Cleaning

Particulate contamination can build up on the probe face and tips during probing. In some cases, particulate contamination

may go unnoticed by the user, while in others it can cause persistent open channels. Large, hard particles can crush probe

tips and are a leading cause of premature, catastrophic probe card failure. This application note describes the recommended

online cleaning methods for Pyramid Probes with a steel plunger stack, for example the P800-S (see Figure 1), when probing

solder balls.

This application note starts with some general information regarding contaminants that may be found in probing

environments. It then describes Cascade Microtech’s recommendations for online cleaning methods and a proposed

cleaning recipe. Finally, a procedure for determining the optimum value of online cleaning parameters is described.

N

OTE

For details on cleaning Pyramid Probes with a plastic plungers, see the application note titled

“Online Cleaning Methods for Pyramid Probe Cards”.

Contaminants

Contaminants on Pyramid Probes can be divided into two general classes:

• Particulate contaminants

• Resistive-buildup contaminants

Particulate Contaminants

Particulate contamination can build up on the probe face and tips during probing. In some cases, particulate contamination

may go unnoticed by the user, while in others it can cause persistent open channels. Though unlikely in solder ball probing

applications, large, hard particles can crush probe tips and are a leading cause of premature, catastrophic probe card

failure.

Once particles have been transferred to the membrane, they are best removed by using the offline cleaning brush supplied

with your core. This procedure is described in the application note titled Pyramid Probe Cores Off-line Cleaning With Brush.

The best solution for particulate contamination, however, is removal of the particles at their source. A few simple

precautions can protect Pyramid Probes from particulate damage. To avoid accidental damage to the probe core:

• Probe in a cleanroom environment.

• Use extreme caution when probing correlation wafers.

• Do not load or unload probe cards with the wafer on the chuck.

• Do not share brushes between Pyramid Probes and other probe card technologies.

• Do not touch the membrane, even with gloved hands.

• Do regular preventative maintenance to clean the wafer area of the prober.

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 1

Resistive-Buildup Contaminants From Solder

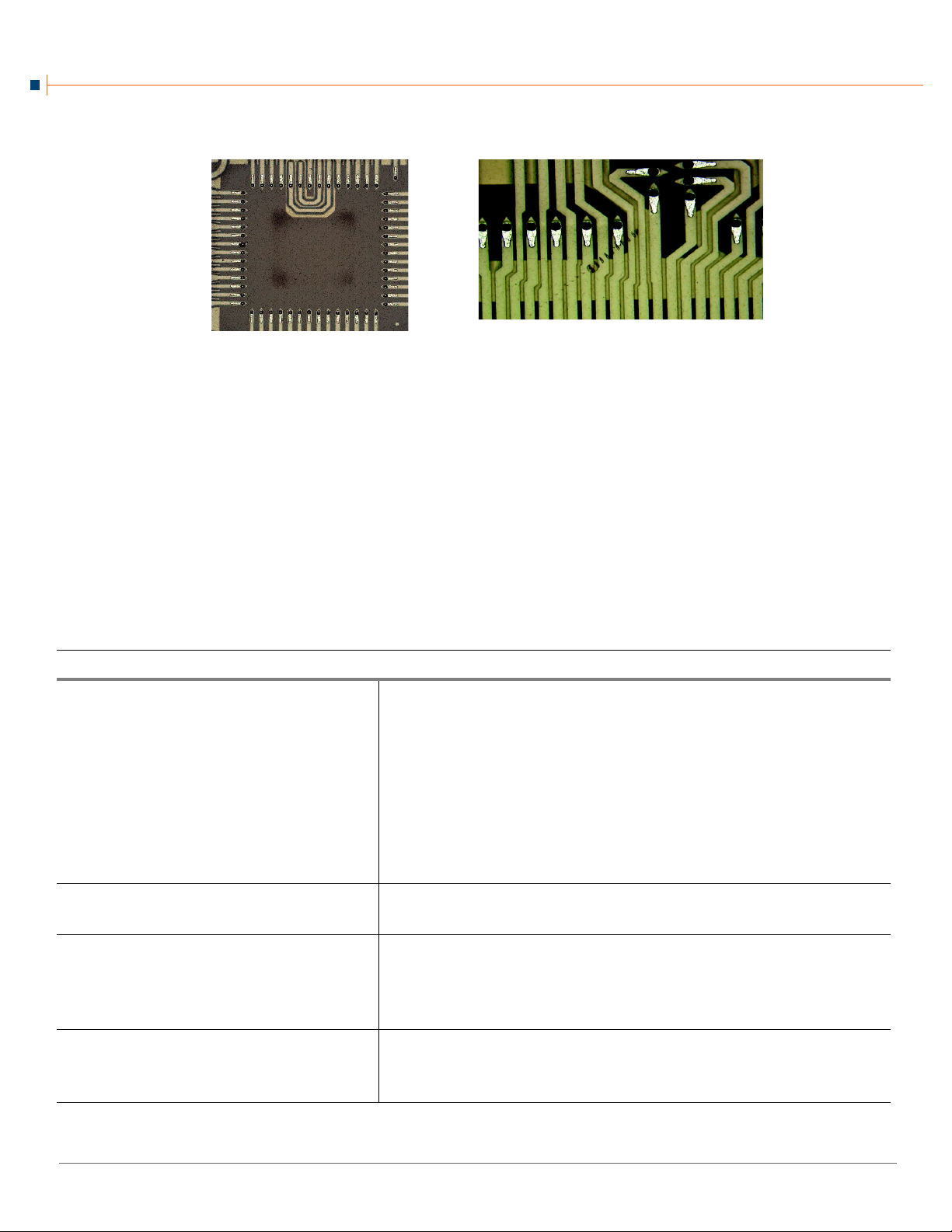

Figure 3. Solder buildup.Figure 2. Clean probe tip.

Online Cleaning Instructions

Resistive buildup contaminants such as organics and oxides can accumulate on the probe tips during probing (see Figure 2,

Figure 3). To maintain high yield, these contaminants must be removed by abrasive cleaning. For best results, this

contamination should be removed preventively. Resistive buildup contaminants do not usually damage probe tips directly.

However, in response to the increasing contact resistance caused by this buildup, users may choose to increase overtravel

— which stresses the probe tips and can cause premature probe failure.

Probe tips for solder-ball probing are much more susceptible to accumulation of resistive-buildup contaminants. Under

normal probing, the soft solder material sticks to the probe tip surface. This buildup typically appears as a dark-colored

mass that covers the entire tip surface and occurs with all types of solder alloys. Often, the mass will include areas that are

green, blue, brown, or black. Yield will suffer if this buildup is not removed preemptively with aggressive online cleaning.

Online Cleaning Materials

C

AUTION

!

Excessive use of abrasive substrates may cause premature failure of Pyramid Probes.

The most effective method for controlling contact resistance (Rc) and cleaning resistive buildup from Pyramid Probe tips is

online cleaning by touching down on an abrasive. Abrasive cleaning media can be divided into four categories:

• Abrasive coated foams

• Abrasive loaded elastomers

• Lapping films

• Soft-backed lapping films

The only recommended media for cleaning the P800-S is an abrasive coated foam.

The results of a cleaning study performed at Cascade Microtech were presented at the at the 18th Annual IEEE

Semiconductor Wafer Test Workshop in June 2008 in a paper by Eric Hill and Josh Smith, Probe Card Cleaning Media

Survey. The presentation can be viewed at: http://www.swtest.org/swtw_library/2008proc/PDF/

S07_01_Hill_SWTW2008.pdf.

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 2

Table 1. Recommended, acceptable and unacceptable online cleaning materials and methods.

(Drawing courtesy of MIPOX)

Thickness approx.

450 µm

Resin

Abrasive

PET Film

Polyurethane

Adhesive

Online Cleaning Instructions

Recommended Abrasive

Coated

Foams

The most common source for abrasive coated foams is MIPOX International. Abrasivecoated foams consist of a layer of abrasive particles in a resin binder. Instead of being

bonded to a polyester film carrier like a lapping film, the particles are coated onto a soft,

open-celled foam. These films are typically 450-500 µm thick. Abrasive-coated foams are

the only recommended cleaning media for P800-S type Pyramid Probes.

Figure 4. Abrasive coated foam architecture.

MIPOX International Corporation offers probe card cleaning sheets with foam backing

materials in a variety of abrasives and grit sizes. Contact MIPOX directly for applicationspecific recommendations and product support (http://www.mipox.co.jp/en/contact/

index.html).

MIPOX International’s WA6000-SWE is used in the factory for cleaning P800-S Pyramid

Probes. Sheets of 9 x 11 inch MIPOW WA6000-SWE are available directly from MIPOX (p/

n WA6000-SWE FWX w/PSA).

Acceptable Abrasive

Loaded

Elastomers

Abrasive-loaded elastomer media consist of a relatively thick layer of elastomer [such as

silicone, polyurethane, or rubber) with abrasive particles mixed evenly throughout the

polymer. This gel-like film is generally mounted to a polyester backing film or a cleaning

wafer. The most common source of this type of cleaning film is International Test Solutions

(ITS). Abrasive-loaded elastomers are expected to be safe for use.

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 3

Unacceptable

Online Cleaning Instructions

Lapping

Films

The traditional method used for cleaning cantilever probe cards. Lapping film contains

abrasive particles that have been bonded to the backing film with a relatively hard resin

binder. These films are typically 75-125 µm thick.

The preferred method for cleaning Pyramid Probes with a plastic plunger uses Allied High

Tech Products’ 3 µm Diamond Lapping Film, after removing some of the binder. However,

lapping film should NOT be used with the P800-S type Pyramid Probes, as too much

overtravel (force) is required to make contact with all the probe tips.

SoftBacked

Lapping

Films

Other A number of probe cleaning methods common within the industry can cause irreversible

Using soft backed lapping films applies uneven pressure on the probe tips causing uneven

wear, reducing coplanarity, especially at the edges or corners of an array of tips, and

increasing the overtravel requirement over time. In addition, too much overtravel is

required to make contact with all the probe tips. This type of cleaning material should not

be used to clean Pyramid Probes.

Examples of soft-backed lapping films include:

• MIPOX PF3 types, for example, GC6000-PF3 and GC8000-PF3, SI10000-PF3

• 3M Type CL (cushion layer)

• Stacked layers of cleaning films to create the equivalent of a soft-backed lapping film

damage to Pyramid Probe cards. These methods must not be used with Pyramid Probe

cards under any circumstances:

• Tungsten Carbide, Silicon Carbide, Alumina or other Ceramic Plates - even if they are

similar to the Allied 3 µm diamond lapping film in grit size, probing on these surfaces will

quickly grind away Pyramid Probe tips.

• Non-qualified chemicals - many chemicals are incompatible with the materials used in

Pyramid Probe cores. Refer to the Cascade Microtech application note, Pyramid Probe

Core Off-line Cleaning With Brush for a list of qualified chemicals.

• Lapping Films with the abrasive contained in ceramic beads - the large ceramic beads

can damage the probe tips. The beads are also brittle and can shatter, causing contamination on the face of the probe. This type of cleaning material should not be used to

clean Pyramid Probes. Examples of lapping films with ceramic beads containing abrasive include:

— Allied High Tech Products, Type B lapping films

— 3M Type B lapping films

Online Cleaning Parameters

General Precautions

When using a prober or cleaning station, never clean Pyramid Probe cards by moving the cleaning chuck back-and-forth in

the XY-plane when it is in contact with the probe tips. Instead, clean the probe tips contacting the cleaning substrate using

only a Z-axis motion. Many probers and probe card analyzers default to a scrubbing X-Y motion, which must be disabled.

CAUTION

!

When cleaning Pyramid Probe cards, never move the cleaning substrate in the XY-plane

when the substrate and the probe tips are in contact.

When stepping Pyramid Probe cards down on a cleaning substrate, do not exceed 250 µm in overtravel. Overtravel

between 35 and 75 µm is optimal for most cleaning applications. Higher overtravel is more likely to generate particles from

the cleaning film.

Step the cleaning chuck at least 2x the tip diameter in the X and Y directions between touchdowns to ensure the probe tips

always contact fresh material and an even distribution of abrasive particles.

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 4

Cleaning Pyramid Probe cards by contacting a cleaning substrate takes multiple touchdowns to achieve good results. A

Online Cleaning Instructions

ratio of 2.5 probing cycles to the number of cleaning cycles is expected. Experiment to find the cleaning count that works

best in your environment. Eighty cleaning contacts for 200 touchdowns is a good number to start.

Online Cleaning Frequency – Yield vs. Wear

Each time a probe card is cleaned abrasively, a small amount of probe tip material may be removed in addition to the

contaminant. When developing a cleaning strategy for probe cards, a trade-off is made between the lifetime of the probe

card and the test yield. Yield suffers if the probing-to-cleaning ratio is set too high. Alternatively, probe card lifetime and test

equipment utilization suffer if the probing-to-cleaning ratio is set too low. When developing the cleaning strategy, the

objective is to determine a probing-to-cleaning ratio low enough to minimize probe tip wear, but high enough to maximize

yield.

Figure 5. Probing-to-cleaning touchdown ratio.

Overtravel

If all the tips are in contact, increasing cleaning overtravel on Pyramid Probe tips does not increase the foreign material

removal rate. In fact, higher cleaning overtravel may accelerate the accumulation of particles from the cleaning substrate.

The tips on a Pyramid Probe range from 20-55 µm tall. The foam on abrasive coated foams is soft, enabling the probe tips

to push into it relatively easily. Therefore, increasing overtravel values far beyond the tip length does not increase the

cleaning action because the tips are buried and the probe face is simply compressing the foam.

It is best to set the overtravel high enough to ensure that all tips contact the film, but low enough to minimize particle

generation from the film. Typical cleaning overtravel used in the Cascade Microtech factory environment is 35 to 75 μm.

Cleaning Recipe, Initial Settings

Experiments were performed in the factory on solder covered wafers to establish a cleaning recipe to use as a starting

point for customers probing solder balls with P800-S Pyramid Probes. Contact resistance was monitored while the number

of cleaning touches was varied. Cleaning cycles were made after every 200 contact resistance measurements. A ratio of

probing contacts to cleaning contacts was calculated for each recipe. The tested ratios were 1:1, 2.5:1, 5:1, and 10:1. The

results showed that the highest ratio of probing to cleaning that maintained less than 0.5 ohms increase in contact

resistance was 2.5:1; or 80 cleaning cycles for every 200 measurements. A cleaning recipe can be created using the

process described in this document, or by starting with these values and refining them based on yield.

Die between cleaning cycles 200

Cleaning TD per cycle 80

Cleaning overtravel: 50 µm

Cleaning material MIPOX WA6000-SWE

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 5

Procedure: Determining Cleaning Parameters

i

Online Cleaning Instructions

N

OTE

Cleaning parameters quoted here are guidelines only. Optimized cleaning parameters for

the best yield and lifetime must be developed in your unique probing environment.

Use the following procedure to determine cleaning parameters (cleaning interval, touchdowns per clean, and cleaning

overtravel).

1. Ensure that the proper cleaning medium is installed on the cleaning chuck or wafer.

2. Verify that the prober is set for the correct height offset or will detect the height of the cleaning surface optically. MIPOX

International’s WA6000-SWE film thickness varies from 470 to 500 µm.

3. Before installing the card in the prober, examine the probe tips under a microscope. Magnification levels of 500 to 1000x

and bright-field lighting are optimal. Typical probe-tip dimensions are:

• 18 µm nominal for fine-pitch solder balls

• 25 µm nominal for wide-pitch solder balls

4. Verify the prober cleaning settings.

• Cleaning Type set to Z-only

• The XY increment between cleaning touchdowns is at least 2 times the tip diameter

5. Choose initial cleaning overtravel in the range of 35 to 75 µm. 50 µm is the recommended.

CAUTION

!

Difficulty auto-focusing on the probe tips can cause actual and programmed overtravel to be

different. This can lead to poor cleaning performance.

6. Determine the cleaning interval.

a. Probe until a yield drop occurs.

b. Clean the probe tips very well with 150-200 cleaning cycles.

c. Repeat steps a and b enough times until you can predict the number of die probed before a yield drop.

d. Set the cleaning interval to be about 75 or 80% of the average number of touchdowns before yield drops.

7. Determine the number of touchdowns per cleaning cycle.

a. Choose an initial value. Traditionally, this has been a small number like 10 to 20. Recent experiments show that

more cleaning touchdowns may increase the number of die between cleaning. Consider starting with 150 to 200

cleaning touchdowns, especially for solder ball probing.

b. Probe several cleaning cycles to validate a stable process.

c. Reduce the number of cleaning touchdowns by about 20%.

d. Repeat steps b and c until the yield can not be maintained for the entire probing cycle.

e. Increase the number of cleaning touchdowns to the previous, larger, number.

8. Remove the probe card and examine the probe tips under a microscope for signs of contamination buildup. See

Contaminants on page 1 for information on contamination type, if any, building up on the probe tips.

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 6

9. Determine the optimum overtravel using the same strategy. Start with a larger value and decrease until yield suffers.

Figure 7. Repeating particle indent, near miss.

Figure 6. Lapping film abrasion on membrane.

Online Cleaning Instructions

Troubleshooting

Troubleshooting your cleaning process depends on the device yield, and the type and amount of contamination found.

Refer to Tab le 2 for a summary of the actions to take based on the results.

After setting the initial parameters, allow the system to run for a period, perhaps 10 probing/cleaning cycles. When you

have collected enough data to spot trends, review the device yield.

• If the yield decreases over time, varies cyclically with the cleaning interval, or is lower than expected, refer to Tab le 2

to increase the cleaning efficiency.

• If the yield is stable and acceptable, consider reducing the cleaning touchdowns per cycle or increasing the interval

between cleanings to verify the settings and optimize the process. See Tab le 2 below for guidance.

Table 2. Troubleshooting.

Issue Possible Actions

Contamination on tips:

• Metal

•Organic

•Oxide

• Or yield does not recover after cleaning

Yield drops off between cleanings • Decrease cleaning interval

Particles around the tips • Brush clean

Abrasion on membrane (see Figure 6) • Reduce cleaning overtravel

• Run cleaning cycle 1 or 2 times (100-200 touchdowns)

• Check probe tip height

• Check cleaning media height and planarity

• Check XY step between cleaning touchdowns

• Visually inspect probe marks on cleaning media

• Increase cleaning overtravel if contamination limited to some areas of probe

• Increase touchdowns per cleaning

• Decrease cleaning interval

• Monitor yield closely

• Double Z touchdown

• Reduce cleaning overtravel

• Clean cleaning media

• Change to a different type of cleaning media

• Check probe tip height

• Check cleaning medium height and planarity

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 7

Issue Possible Actions

Corporate Headquar

Cascade Microtech, Inc.

Germany

phone: +49-89-9090195-0

email: cmg_sales@ cmicro.com

Japan

phone: +81- 3-5615-5150

email: cmj_sales@ cmicro.com

China

phone: +86-21-3330-3188

email: cmc_sales@ cmicro.com

eSingapor

phone:

email: cms_sales@ cmicro.com

Tai wa n

phone: +886-3-5722810

email: cmt_sales@cmicro.com

toll free: +1-800-550-3279

phone: +1-503-601-1000

email: cmi_sales@ cmicro.com

+65-6873-7482

ters

© Copyright 2010 Cascade Microtech, Inc.

All rights reserved. Cascade Microtech

and Pyramid Probe are registered trademarks of Cascade Microtech, Inc. All

other trademarks are the property of their

respective owners.

Data subject to change without notice.

Online Cleaning Instructions

Repeating indents on probe face (see Figure 7) • Clean cleaning media

• Change cleaning media

None • Return to service

• Increase cleaning interval

• Reduce touchdowns per cleaning

Recommended Offline Cleaning Methods and Materials

Brush Cleaning

Refer to the Cascade Microtech Application Note, Pyramid Probe Core Off-line Cleaning With a Brush for a complete

brush-cleaning procedure.

Abrasive Cleaning

CAUTION

!

Offline abrasive cleaning can reduce the lifetime of your Pyramid Probe card. Use this procedure only after other possibilities have been exhausted.

Extreme resistive-buildup contamination can be removed by abrasively cleaning the probe tips. This cleaning process is

identical to the online process described above, except that the number of touchdowns is higher.

In most cases resistive tips can be cleaned up with only 150-200 touchdowns on the cleaning film. However, sometimes

more aggressive cleaning is required. In these instances, up to 1000 touchdowns may be necessary to remove the

contamination. Accumulation of contamination this tenacious usually indicates other problems in the probing environment.

High current, residue on bond pads, insufficient online cleaning, and hot probing (making or breaking contact with power

applied) can all contribute to abnormal accumulation of resistive films on Pyramid Probe tips.

Service

To remove the most severe contamination, return the probe card to Cascade Microtech for cleaning. Before shipping a part

to Cascade Microtech, obtain a Return Material Authorization number (RMA #). Contact Cascade Microtech customer

service at (800) 550-3279 or (503) 601-1000.

PN 151-853-A www.cascademicrotech.com Pyramid Probe Card: P800-S Online Cleaning• 8

Loading...

Loading...