Page 1

COMPACT THERMAL PRINTER

COMPACT THERMAL PRINTER

User Manual – Rev.A4

CASCADEMIC Solutions Pvt.Ltd.

Y. Yusup Khan

yusupkhan@cascademic.com

Phone No: +91 80 26583333

1

18-June-2015

Page 2

COMPACT THERMAL PRINTER

Project Name : Compact Thermal Printer

Document Number : CS-P076-UM-1K-Rev.A4

Doc. Description : User Manual

Part Number : CS-STPR-Cxy

Department : Solution - Printer

Contact Details : CASCADEMIC Solutions Pvt. Ltd.

1525/58, 2nd Floor, 28th Main, South End ‘B’ Cross,

9th Block, Jayanagar, Bangalore, India. Pin: 560069

Email: yusupkhan@ cascademic.com, Phone: +91 80 26583333

Document Owner(s) Project Role Signature

Prepared By: Yusup Khan

Approved By: Prabhu . C

Proprietary Notice: This document contains proprietary material for the sole use of the intended

recipient(s). Do not read or print this document if you are not the intended recipient. Any review, use,

distribution or disclosure by others is strictly prohibited. If you are not the intended recipient, you are

hereby notified that any disclosure, copying distribution or use of any of the information contained

within this document is strictly prohibited.

All registered trademarks and product names mentioned in this publication are used for identification

purposes only. The registered trademarks are the property of their respective owners.

CASCADEMIC continuously enhances and update the Solutions. Hence it reserves the right to change

details in this publication including but not limited to any specification without notice.

Revision History

Version Date Author Change Description

A4 06-May-'15 Yusup Khan Document updated

2

Page 3

COMPACT THERMAL PRINTER

Table of Contents

1. PART NUMBER DESCRIPTION.........................................................................................................4

1.1 THERMAL PRINTER SOLUTION – CS-STPR-Cxy...................................................................4

2. PRINTER FEATURES..........................................................................................................................5

3.COMPACT THERMAL PRINTER........................................................................................................6

3.1 TOP VIEW:.....................................................................................................................................6

3.2 POWER SUPPLY:...........................................................................................................................6

3.3 LEDS:..............................................................................................................................................6

3.4 INTERFACE SPECIFICATION:....................................................................................................7

3.4.1. CS-STPR-AA1 (Serial Interface):..........................................................................................7

3.4.2. CS-STPR-AA4 (Bluetooth Interface):....................................................................................7

3.4.3. CS-STPR-AA5 (Wi-Fi Interface):..........................................................................................7

3.5 PROCESS OF LOADING THE THERMAL PAPER....................................................................7

4. COMMAND SPECIFICATIONS..........................................................................................................8

4.1. SELECT FONT TYPE:..................................................................................................................8

4.2. SELECT LINE ALIGNMENT:......................................................................................................9

4.3. LINE SPACING:..........................................................................................................................10

4.4. PRINT AND LINE FEED:...........................................................................................................10

4.5. TEST PRINT:...............................................................................................................................10

4.6. TO CHANGE BAUD RATE:.......................................................................................................11

4.7. PRINT FEED N LINES:..............................................................................................................11

4.8. PRINT REVERSE FEED N LINES:............................................................................................11

4.9. PRINT BAR CODE:....................................................................................................................12

4.10. HINDI PRINT:...........................................................................................................................14

4.11. TO PRINT LOGO:.....................................................................................................................16

4.12. TO PRINT TEST PAGE:............................................................................................................31

4.13. TO PAPER FEED:......................................................................................................................31

5. HANDLING PRECAUTIONS............................................................................................................32

6. HANDLING METHOD......................................................................................................................34

6.1 INSTALLING/UNINSTALLING THE THERMAL PAPER.......................................................34

6.1.1. PROCEDURES FOR INSTALLING/UNINSTALLING THERMAL PAPER...................34

6.1.2. PRECAUTIONS FOR INSTALLING/UNINSTALLING THERMAL PAPER..................34

3

Page 4

COMPACT THERMAL PRINTER

1. PART NUMBER DESCRIPTION

1.1 THERMAL PRINTER SOLUTION – CS-STPR-Cxy

Cxy– Configuration number

C: (Solution Packaging

Configuration)

A – Mobile Compact Printer A – 2 Inch

x: (Major Feature Configuration) y: (Minor Feature Configuration)

1 – Serial

4 – BT

5 – Wi-Fi (802.11b/g/n)

4

Page 5

COMPACT THERMAL PRINTER

2. PRINTER FEATURES

The thermal printer interface card has the following features:-

1. Interface: UART(TTL level-3.3V)/BT/BLE/Wi-Fi.

2. Baud rate can be configured. (Default is 9600)

3. Bar-code printing.

4. Font support (English – Verdana, Courier)

5. Regional language (Marathi, Hindi).

6. Text print support.

7. Image/Logo print.

8. LED indication for Paper and platen detect options.

9. Li-Ion Battery (7.4V/1600mAh)

10. Supported Printer: LTP01-245(SEIKO)

Kit Deliverables

1. Thermal Printer Setup with Enclosure and Battery.

2. Adapter – 12V/2amp (optional)

3. 2 inch Paper Roll – 1 number

5

Page 6

COMPACT THERMAL PRINTER

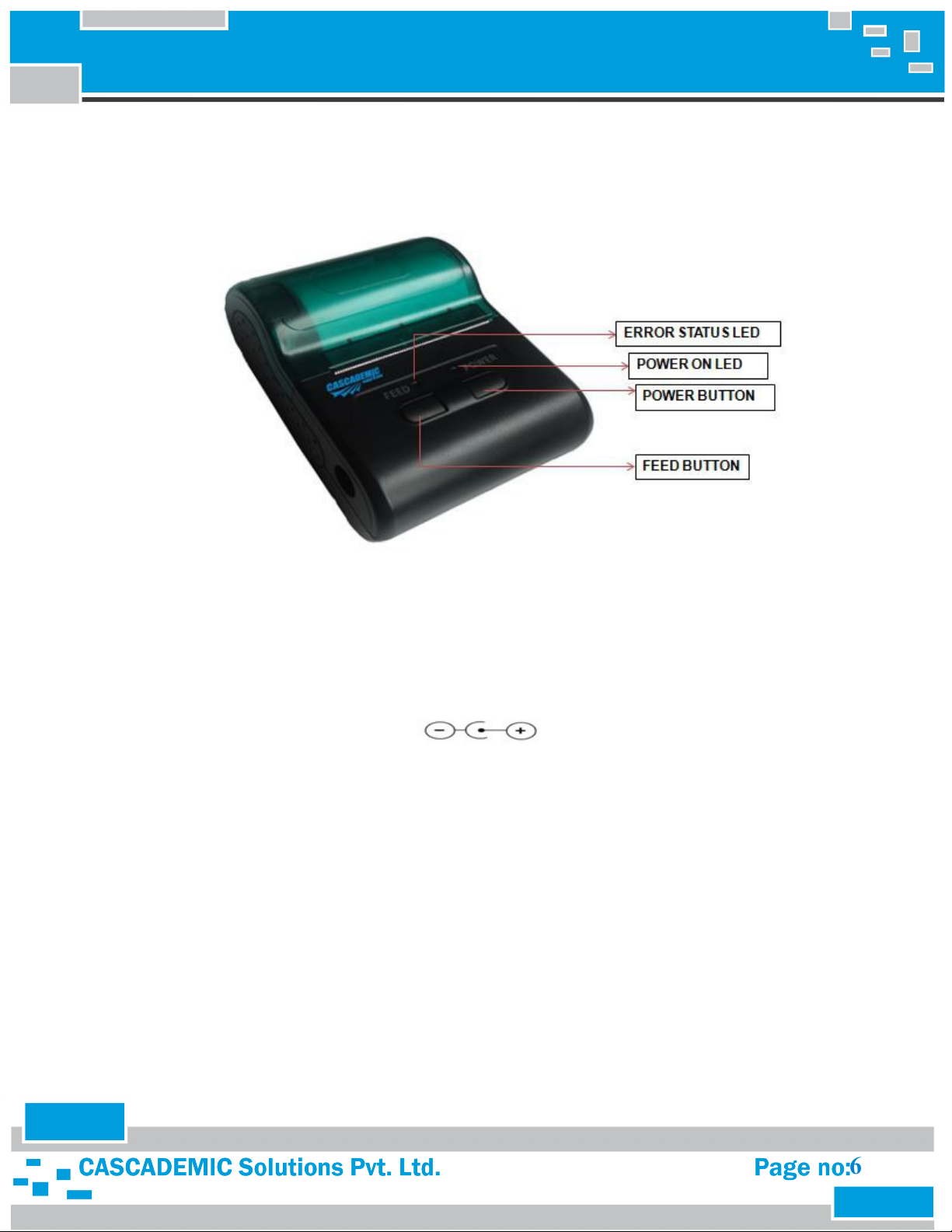

3.COMPACT THERMAL PRINTER

3.1 TOP VIEW:

3.2 POWER SUPPLY:

The Power supply to be used has to be (7.5V-9V / 3A) through an external adapter. Also separate slot is

provided for battery power (7.5V-9V / 3A). Power adapter is of positive polarity.

3.3 LEDS:

Board consists of 2 LED’s as follows:

1. POWER ON LED: This LED will turn RED, when 7.5V / 3A power is applied to the Thermal Printer Card.

2. PLATEN DETECTION LED: This LED will turn GREEN when Platen is not connected to the printer.

6

Page 7

COMPACT THERMAL PRINTER

3.4 INTERFACE SPECIFICATION:

3.4.1. CS-STPR-AA1 (Serial Interface):

COM Port Settings:

1. Bits per Second : 9600

2. Data Bits : 8

3. Parity : None

4. Stop Bits : 1

5. Flow Control : None

3.4.2. CS-STPR-AA4 (Bluetooth Interface):

1. Name of the Blue-tooth device is “CAS BT PRINTER” and Password is “1234”.

2. Searching won’t stop until the device is found. Configure the connection between the

master and slave(CAS BT PRINTER). Master can send data to slave and request from slave as

well.

3. You are allowed to transmit and receive data through Blue Term+

Bluetooth Specification:

1. Blue-tooth protocol : Blue-tooth Specification v2.0 + EDR

2. Frequency : 2.4GHz ISM band

3. Profiles : Blue-tooth serial port

4. Power supply : Built-in Chip antenna power supply + 3.3VDC 50mA

5. Dimension : 26.9mm x 13mm x 2.2 mm

3.4.3. CS-STPR-AA5 (Wi-Fi Interface):

1. Name of the Wi-Fi device is “CAS Wi-Fi PRINTER” and Password is “12345678”.

2. Searching won’t stop until the device is found. Configure the connection between the

master and slave device (CAS Wi-Fi PRINTER). Master can send data to slave and request

from slave as well.

3. You are allowed to transmit and receive data through TCP Client.

4. IP Settings : 192.168.16.254

5. Port Settings : 8080

3.5 PROCESS OF LOADING THE THERMAL PAPER

1. Remove the platen slowly.

2. Replace the paper and Load the platen back to its position.

3. Make sure that the platen is placed properly. If not placed properly it is indicated by LED .

7

Page 8

COMPACT THERMAL PRINTER

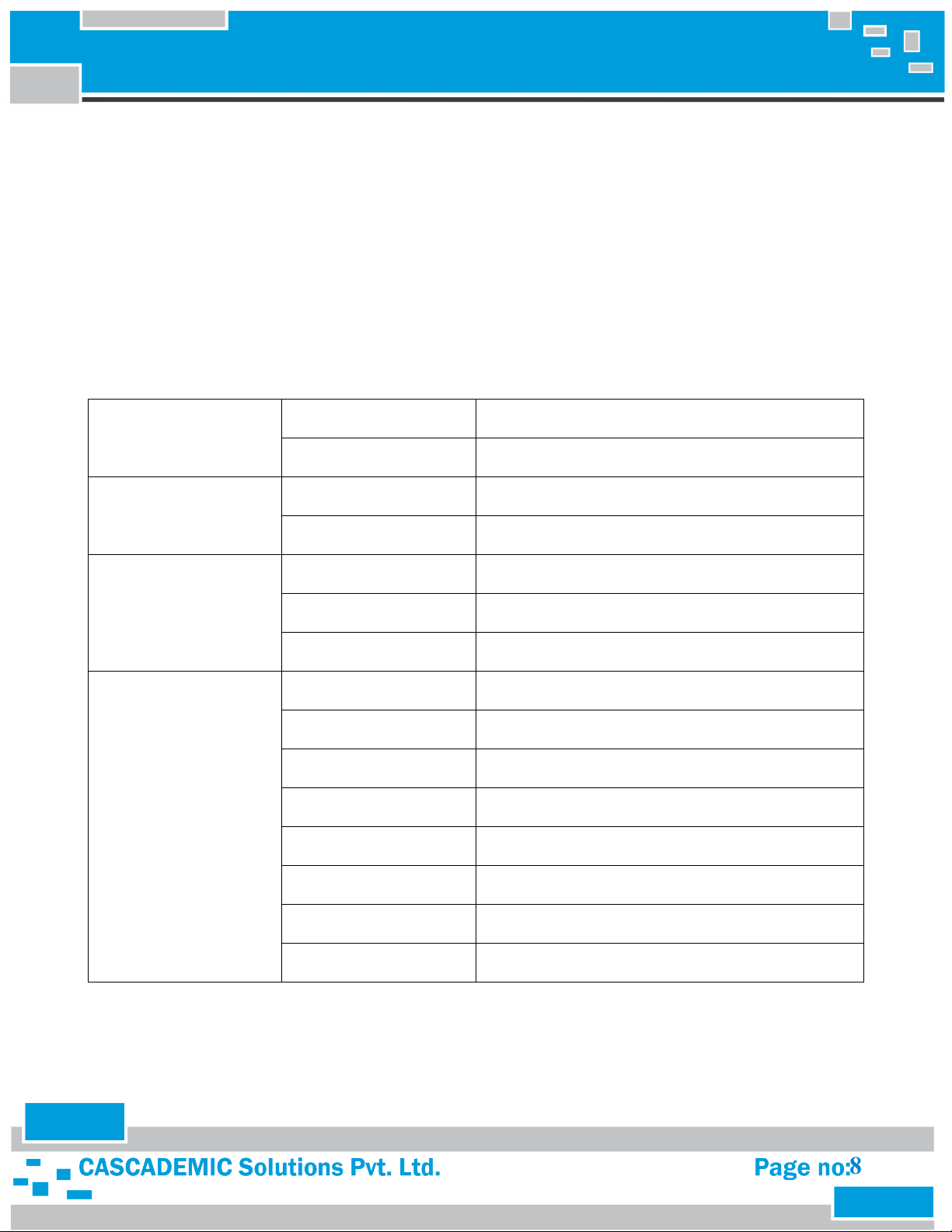

4. COMMAND SPECIFICATIONS

4.1. SELECT FONT TYPE:

[Command] : $1Bwxyz<Space>

[Range] : 0 ≤ w ≤ 1

x = 'N' or 'B'

0 ≤ y ≤ 2

0 ≤ z ≤ 7

Font (w) 0 Courier font

1 Calibri font

Style (x) N Normal

B Bold

Characters per line (y) 0 24

1 32

2 48

Size (z) 0 Width=1,Height=1

1 Width=1,Height=2

2 Width=1,Height=3

3 Width=1,Height=4

4 Width=2,Height=1

5 Width=2,Height=2

6 Width=2,Height=3

7 Width=2,Height=4

Example:

If we want bold courier font at 32 chars per line and the height at 3 and width at 1, the command is $1B0B12

8

Page 9

COMPACT THERMAL PRINTER

4.2. SELECT LINE ALIGNMENT:

[Command] : $1B61mn

[Range] : m=30 for Left alignment

m=31 for Center alignment

m=32 for Right alignment

[Range] : n < Characters per line. (Range between from 0 to Characters per line)

[Description] : Selects the type of alignment using m.

Characters to align = n. n should be less than characters per line.

$1B6130n - Left alignment

$1B6131n - Center alignment

$1B6132n - Right alignment

[Notes] : In alignment, if you want to change font, you can send font command followed

by alignment command.

Sample Text

$1B613012<Space>ABCDEFGHIJKLMNOPQRSTUVWXYZ

Here m = 30 and n = 12

Sample Text

$1B613108<Space>ABCDEFGHIJKLMNOPQRSTUVWXYZ

Here m = 31 and n = 08

Sample Text

$1B613205<Space>ABCDEFGHIJKLMNOPQRSTUVWXYZ

Here m = 32 and n = 05

9

Page 10

COMPACT THERMAL PRINTER

4.3. LINE SPACING:

Line Space On:

[Command] : $1B32

Line Space Off:

[Command] : $1B30

[Range] : None

[Description] : $1B32 Prints the data with line space. This command setting is effective until

feeding $1B30, reset or Power-off.

Sample Text

$1B32<Space>ABCDEFGHIJKLMNOPQRSTUVWXYZABCDEFGHIJKLMNOPQRSTUVWXYZABCDEFGHIJKLMNOPQR

STUVWXYZABCDEFGHIJKLMNOPQRSTUVWXYZ

Sample Text

$1B30<Space>ABCDEFGHIJKLMNOPQRSTUVWXYZABCDEFGHIJKLMNOPQRSTUVWXYZABCDEFGHIJKLMNOPQR

STUVWXYZABCDEFGHIJKLMNOPQRSTUVWXYZ

4.4. PRINT AND LINE FEED:

[Command : $0A

[Range] : None

[Description] : Prints the data and feed one line (‘\n’), based on current line spacing.

Sample Text

ABCDEFGH$0A<Space>IJKLMNOPQRS$0A<Space>TUVWXYZ

4.5. TEST PRINT:

[Command] : $1D41

[Description] : Executes the test print.

10

Page 11

COMPACT THERMAL PRINTER

4.6. TO CHANGE BAUD RATE:

[Command] : $1D44

[Range] : 2400 to 230400. Default baud rate is 9600

[Description] : Sets the baud rate for data communication.

[Notes] : Once new baud rate is set, similar configuration has to be made in

Hyper Terminal.

E.g. To configure baud rate 57600 (use command $1D44 57600)

4.7. PRINT FEED N LINES:

[Command] : $14$0$n

[Range] : 00 ≤ n ≤ 99 (n in millimeter)

[Description] : Prints data and feed “n” millimeter line spacing.

[Notes] : This command is used to feed a specific line without changing the line spacing

set by other commands.

4.8. PRINT REVERSE FEED N LINES:

[Command] : $14$1$n

[Range] : 00 ≤ n ≤ 99 (n in millimeter)

[Description] : Prints data and feed “n” millimeter line spacing in reverse direction.

[Notes] : This command is used to feed a specific line without changing the line spacing

set by other commands.

Sample Text

ABCDEFGHIJKLMNOPQRSTUVWX$14$0$08<Space>YZABCDEFGHIJKLMNOPQRSTUV$14$1$50<Space>WXYZAB

CDEFGHIJKLMNOPQRST

Here 08 = 8mm and 50 = 50mm line spacing

11

Page 12

COMPACT THERMAL PRINTER

4.9. PRINT BAR CODE:

[Command] : $1D68m<Space>d1…..d12

[Range] : 01 ≤ m ≤ 03

[Description] : Prints the bar code using the bar code height in m.

‘d’ specifies the character code data of the bar code to be printed.

The length of data ‘d’ should be 12 digits only.

[Notes] : Bar Code will be printed in EAN-13 format. Other formats will be implemented

based on customer request.

Sample Text

$1D6801<Space>890244221790

Here m= 01

Sample Text

$1D6802<Space>890244221790

Here m= 02

12

Page 13

COMPACT THERMAL PRINTER

Sample Text

$1D6803<Space>890244221790

Here m= 03

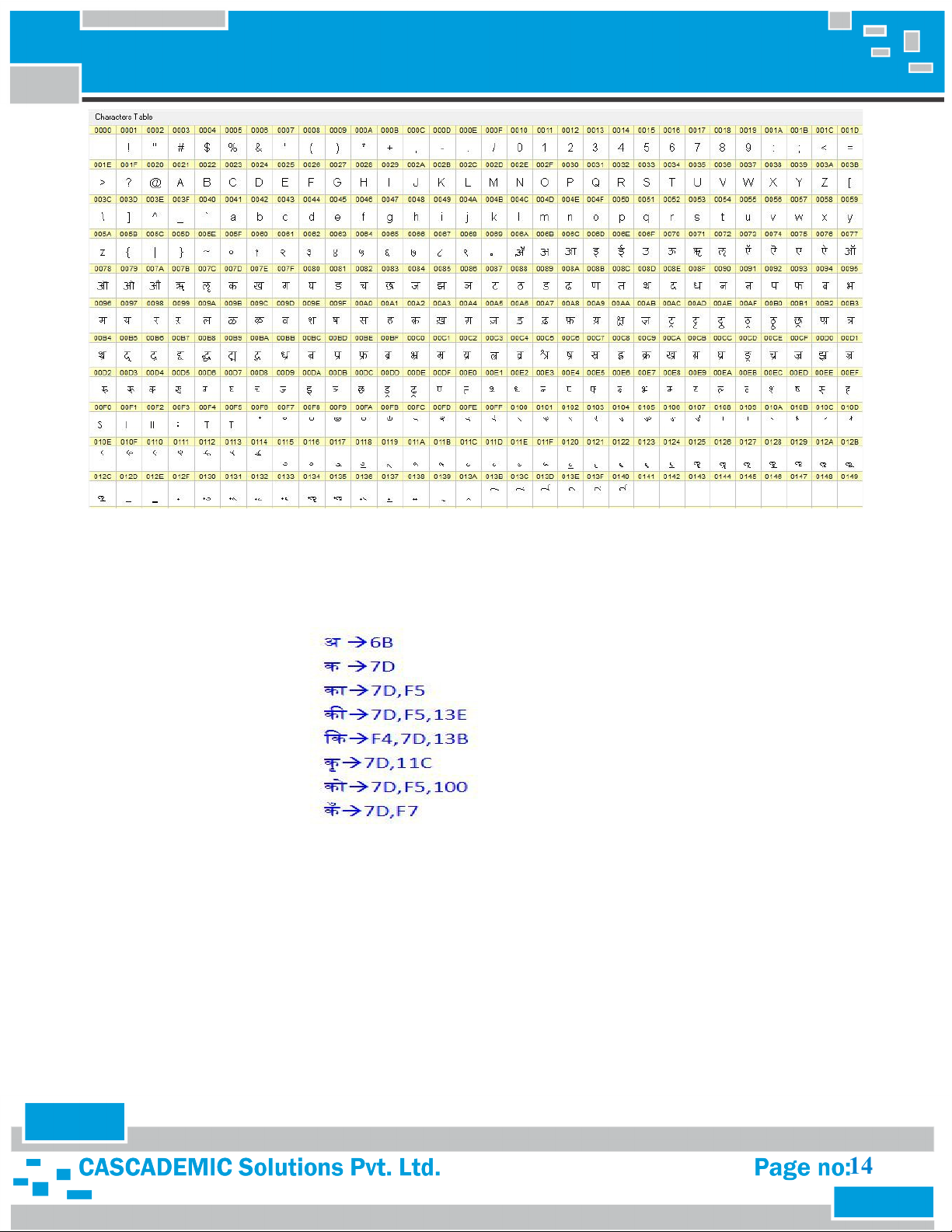

4.10. HINDI PRINT:

[Command] : $1551mn<Space>

[Range] : 01 ≤ n ≤ 04 (n for Height of font)

m=0 for Normal font

m=1 for Bold font

13

Page 14

COMPACT THERMAL PRINTER

Hindi Font Table

[Description] : Print normal Hindi font using $15510n and print bold Hindi font using $15511n.

Commands that need to be sent shall be based on the Hindi font table given above. For e.g:

14

Page 15

COMPACT THERMAL PRINTER

6B is a value as required to print as given in the above image

To print above character give command $1551mn<Space>6B

This letter () requires combination of two values and this letter () requires combination of three values.

Each Unicode separated by a comma (,). For e.g:

$1551mn<Space>F4,7D,13B,

You can send various combinations based on Hindi text that you want to print.

Note: Make sure you have sent the Hindi Font selection command before sending the data and also you can

print English with Hindi using this command ($1550<Space>English). Bar code and line alignment commands

are not supported in Hindi print. Updated Hindi Font table attached as a separate document. Refer the

document for Hindi Print.

15

Page 16

COMPACT THERMAL PRINTER

4.11. TO PRINT LOGO:

PROCEDURE TO CONVERT A PICTURE TO PRINT ON 2” THERMAL

PRINTER:

Step 1) Select the image that you would need to print

16

Page 17

COMPACT THERMAL PRINTER

Step 2) Right click and open with paint

Step 3) Select and crop the exact image that you would need to print without extra white space

17

Page 18

Step 4) Image after cropping

COMPACT THERMAL PRINTER

Step 5)

i. Click Resize option

ii. Under Resize, Select Pixels

18

Page 19

COMPACT THERMAL PRINTER

Step 6)

i. Under Resize and Skew, Uncheck Maintain aspect ratio

ii. Reduce the Image size by using stretch/skew option

iii. Image width (Horizontal) should be equal to 192 pixels

iv. Image Height (Vertical) should be less than or equal to 48 pixels

Step 7)

i. Click OK

ii. In our example the Width is 192 (equal to 192) and Height is 48( less than or equal to 48) as shown

above.

19

Page 20

COMPACT THERMAL PRINTER

Step 8) Select Save as type “Monochrome Bitmap” and Save the image.

Step 9) Click on OK option, it will ask confirmation for the changes and select yes option, your Image will change

to Black and white as shown below.

20

Page 21

Step 10) Black and white Image.

COMPACT THERMAL PRINTER

Step 11)

i. Again select Save as type “JPEG”

ii. Change the File Name and Save the image.

21

Page 22

COMPACT THERMAL PRINTER

Step 12) From Left Side,

i. Image (1) is bmp image

ii. Image (2) is Original image in JPEG format

iii. Image (3) is Black and White image in JPEG format.

Step 13) Go to the following link

http://www.digole.com/tools/PicturetoC_Hex_converter.php

22

Page 23

COMPACT THERMAL PRINTER

Step 14)

i. Upload image(3)

ii. Enter the value of width of Image(192) in the box of Width

iii. Submit

23

Page 24

COMPACT THERMAL PRINTER

Step 15) Image data in bytes(Hexadecimal Values)

24

Page 25

COMPACT THERMAL PRINTER

Step 16)

i. Copy the image data and paste in word document

ii. Remove 0x from all bytes

25

Page 26

COMPACT THERMAL PRINTER

Step 17) Convert from 00 to 0 in all bytes

26

Page 27

Step 18)

COMPACT THERMAL PRINTER

Count the number of characters in the remaining text. In the example, the total number of characters is

2768. The total number of words is 48.

27

Page 28

COMPACT THERMAL PRINTER

Step 19) Merge all the characters without any space to reduce the number of words to 1. Make sure

that the number of characters is not reduced than before.

In the example now, the total number of characters is 2768. The total number of words is 1.

Final Image data should be less than or equal to 3K characters

28

Page 29

COMPACT THERMAL PRINTER

Step 20) Now convert the lower case characters to upper case. This can be done by pressing

“Shift+Caps Lock+F3” twice.

29

Page 30

COMPACT THERMAL PRINTER

Step 21) The printing of this image can be achieved by sending Image print command followed by

image data as shown in the below image.

i. Image print command is $1B5E$n<Space>

ii. n is Alignment of Image print

if n = 0, Left Align

if n = 1, Centre Align

if n = 2, Right Align

30

Page 31

COMPACT THERMAL PRINTER

4.12. TO PRINT TEST PAGE:

Press Switch SW3 to print test page.

4.13. TO PAPER FEED:

Press Switch SW5 to feed the paper for 5cm.

Note:

1. All commands should start from the beginning of the line.

2. But line feed command ($0A) can be used anywhere in the text.

3. Every command should be followed by a single space then text.

31

Page 32

COMPACT THERMAL PRINTER

5. HANDLING PRECAUTIONS

The following are examples of issues arising in the printer:

(1) Poor printing quality due to low thermal sensitivity

(2) Abrasion of the thermal head due to the thermal paper surface roughness

(3) Printing stuck and unusual noise due to sticking the thermal layer of the thermal paper to the thermal head

(4) Printing fades due to low preservability of the thermal paper

(5) Electrolytic corrosion of the thermal head due to inferior paper

The precautions to be taken are:

1. Do not leave the printer on for a long period of time, the platen could be deformed and resulted in

print quality deteriorated. In this case, feed the thermal paper for a while to recover deformation of the

platen. If the thermal head is remained in contact with the platen without thermal paper for a long

time, the platen and the thermal head may be stuck together and cause paper feed difficulty. If facing

this problem, release the platen unit, and set it back again before starting printing.

2. Never loosen the screws that fasten respective parts of the printer. Loosened screws may reduce the

efficiency of the performance of the printer mechanism.

3. Do not release the platen unit during printing; otherwise this may reduce the efficiency of the printer

and may cause damage.

4. Do not apply stress to the platen unit during printing. The print defect may occur.

5. When setting the platen unit, the reduction gear may interfere with the platen gear and may cause the

platen unit to not be set. In such a case, release the platen unit and set it again.

6. Never pull out the thermal paper while the platen unit is set. The printer mechanism may become

damaged.

7. When handling the printer, make sure to use antistatic clothing and to ground yourself to prevent the

electronic parts such as thermal head, out-of-paper sensor, motor, and platen detection switch from

damaged by static electricity. Especially take care of the thermal head heat element and the connecting

terminal.

8. Do not hit or scratch the surface of the thermal head with any sharp or hard object. This could damage

the thermal head.

9. When printing at a high print ratio in a low temperature or high humidity environment, the vapor from

the thermal paper during printing may cause condensation to form on the printer and soil the thermal

paper itself. Prevent the thermal head from a drop of water. It may cause electrolytic corrosion of the

thermal head. If condensed, do not activate electricity until dried.

10. Connect or disconnect the connecting terminal after turn off the power.

11. Do not apply stress to the FPC while connecting and disconnecting them. Otherwise the FPC may

become damaged.

32

Page 33

COMPACT THERMAL PRINTER

12. Warn users not to pull the thermal paper and not to change the paper eject angle during printing.

Otherwise, the paper jam or the cut failure may occur.

13. In order to prevent the electronic parts such as thermal head, out-of-paper sensor, motor, and platen

detection switch from damage and to avoid the print defect, warn users not to touch the thermal head

and the sensor directly when handling the printer like replacing the thermal paper.

14. Do not use the paper roll with glued end or folded end. In case of using such paper roll, replace to a

new one before the end of the paper roll is shown up.

15. The printer is not waterproof and drip proof. Prevent contact with water and do not operate with wet

hands as it may damage the printer or may cause a short circuit or fire.

16. The printer is not dust proof. Never use the printer in a dusty place, as it may damage the thermal head

and paper drive system.

33

Page 34

COMPACT THERMAL PRINTER

6. HANDLING METHOD

6.1 INSTALLING/UNINSTALLING THE THERMAL PAPER

6.1.1. PROCEDURES FOR INSTALLING/UNINSTALLING THERMAL PAPER

Procedures for installing the thermal paper by the easy operation (setting and releasing the

platen block)

1. Installing the thermal paper

• Install the thermal paper with the platen unit released.

• Set the thermal paper straight to the printer and set the thermal paper until its

edge is ejected for 5 cm and more from the top surface of the printer mechanism.

2. Uninstall the thermal paper

• Uninstall the thermal paper in the same manner for installing the thermal paper.

3. Clearing a paper jam

• Uninstall the thermal paper in the same manner for installing the thermal paper.

6.1.2. PRECAUTIONS FOR INSTALLING/UNINSTALLING THERMAL PAPER

1. Install the thermal paper with the platen unit released. Auto-loading is not allowed.

2. Set the thermal paper straight to the printer and set the thermal paper until its edge is

ejected for 5 cm and more from the top surface of the printer mechanism.

3. When setting the platen unit, the reduction gear may interfere with the platen gear and

may cause the platen unit to not be set. In such a case, release the platen unit and set it

again.

4. If the thermal paper is skewed, feed the thermal paper until the thermal paper

becomes straight or install the thermal paper again.

5. Remove the jamming paper with the platen unit released. Do not pull the thermal

paper by force because severe damages may occur.

6. If the thermal head is remained in contact with the platen without the thermal paper

for a long time, the platen and the thermal head may be stuck together and cause the

auto-loading difficulty. If facing this problem, release the platen block and set it back

again before starting printing.

34

Loading...

Loading...