Casals CTRL-MAX2, CTRL-DPH User Manual

www.casals.com

CV072018-1

CTRL-MAX

2

USER MANUAL AND SETUP INSTRUCTIONS

2

CV072018-1

INDEX

MAIN WINDOW DISPLAY

MANAGEMENT OF FAN SPEED, FLOW OR CONSTANT PRESSURE

BOOSTER FUNCTION

AIR POST-TREATMENT MANAGEMENT

PREHEATING MANAGEMENT

SELECTION MENÚ

STATUS MENÚ: OPERATING STATUS

PROGRAM MENÚ: MANAGEMENT OF THE WEEKLY SCHEDULE

DEFAULT/ PROG. PREDEF.

TIMETABLE

ADJUSTMENT OF SPEED LEVELS

CLOCK MENÚ: CLOCK SETTINGS

ALARMS MENÚ VISUALIZATION OF THE STATUS OF THE ALARMS

INSTALLER MENÚ: CONFIGURATION OF THE INSTALLATION PARAMETERS

WINTER/ SUMMER TEMPERATURE

MODBUS COMMUNICATION

BOARDS

INSTALLATION

WIRING CONTROL PANEL

CONTROL CHARACTERISTICS

WARRANTY CONDITIONS

DIMENSIONS

MOUNTING

p. 3

p. 4

p. 5

p. 5

p. 6

p. 6

p. 7

p. 9

p. 10

p. 11

p. 12

p. 13

p. 13

p. 16

p. 17

p. 24

p. 26

p. 27

p. 31

p. 31

p. 31

p. 31

p. 32

p. 33

3

CV072018-1

VISUALIZATION MAIN SCREEN

The touch screen control panel has been designed to manage units of Mechanically Controlled Ventilation with Heat Recovery (VMC-RC) in

a simple and intuitive way. The user manages the control by means of the icons of the graphic screen making a slight pressure on them; The

direction buttons, which appear after the pressure in a modifiable parameter, allow the user to interact with the unit by going through menu

items and modifying values. Pressing the OK button confirms the modifications or selections made. The color change (green) of an icon after

a press indicates that the parameter represented by that icon can be changed. When an element of the submenus is highlighted, it appears in

background color on a blue background, pressing OK the title changes to green and modifications can be made with the direction buttons.

The main window is a detailed graphic representation of the state of the machine from which all available functions can be activated. To change the window and access the other menus, you have to press the icon to change the menu window. From the other windows you can return

to the previous one by selecting the mentioned icon and pressing OK. To save energy the control is placed in standby mode (paid screen) after

a minute of inactivity, pressing at any point on the screen is automatically reactivated. In the presence of alarms, on the other hand, the screen

lights up for half a second approximately every ten.

Unit without bypass Unit with bypass

*= Modifiable parameter

Exhaust fan

External air temperature

* Fan speed sign Preheating sign (CTRL-MAX

2

)

* Change screen sign

Temperature return air

Temperature air in

Post-heating sign

* Adjustment point temperature

By-pass sign

Expelled air temperature

* Timer

Humidity sign Supply fan

4

CV072018-1

MANAGEMENT OF FAN SPEED, FLOW OR CONSTANT PRESSURE

To modify this parameter, the icon at the top right of the synoptic table must be selected by clicking on it (it will turn green and the direction

buttons will appear). Then press the icon of the address button up to increase or down direction to decrease the value located next to it; Once

the desired one is located, press the OK button to confirm the selection. At first it is possible to turn off the machine directly by pressing the

central button, it disappears automatically by pressing the direction buttons. The variation can be expressed as a percentage for variable speed machines, with a simple 1-2-3 for machines with 3 speeds, in flow (m³ \ h) for machines with constant flow or pressure (Pa) for machines with

constant expression (equipped with the corresponding supplementary kit, see page 29). For these last two models, once the desired value has

been selected, the speed of the fans will automatically vary to keep the flow or the set pressure constant. For machines with a sensor mounted

different from the cop / cav kit, but always with constant pressure or flow rate, enter the percentage value of the pressure or flow scale of the

unit. The regulation it will be carried out in the same way. This also applies to the settings of the weekly programming menu (Program). In

addition to the scale value, the timer element will appear and, if selected, will start the default weekly time program (see Program menu). If an

air quality, relative humidity sensor is present in the unit or if the analog input (0-10V) is activated, we will also have the automatic selection

that allows the automatic regulation of the fan speed in function of CO2, Humidity measured or by an external signal.

In detail the possible selections are:

- off: with this selection, the fans are stopped. Be careful because in any case the unit is electrically powered; this value is obtained by descending below the minimum adjustable speed.

-xxx%: if the unit has modulating fans it is possible to adjust a percentage value of the speed, flow rate or full-scale pressure (for units not

equipped with the corresponding kit but always in a cop / cav version with a different sensor), starting from a minimum (factory adjusted) to

100% with steps of 5% (1% on request).

-1, 2 or 3: if the unit is equipped with 3-speed fans, it is possible to select one of the available ones: speed 1, speed 2 or speed 3.

-watch: with this selection the speed of the fans is controlled according to what is established by the weekly chronoprogram (see Program

menu), this indication is obtained by selecting a value higher than the maximum speed (100% or 3).

- auto: this mode is available only if a sensor (CO2, CO2-COV, relative humidity HR) or an external signal (0-10V) is present. It is obtained by

selecting a value higher than clock.

- xxx m³ \ h: if the unit is a constant flow (CAV) version with a kit, the desired value can be set in m3 \ h of flow. The fans will be regulated automatically to keep it constant depending on the changes in the load.

Speed fan controller (%)

Airflow control

Pressure control

Direction buttons

Direction buttons

on/off

5

CV072018-1

BOOSTER FUNCTION

By selecting the icon on the lower left you access the booster function. Through this you can select a time interval (from a minimum of 1 minute to a maximum of 4 hours) in which to operate the unit at maximum power. The booster function is a priority with respect to other modes

of fan speed management.

After the selection a digital chronometer (hours.minutos.seconds) predetermined to a value of 10 minutes can be modified with the direction

buttons on the right of the screen: up to increase the booster time and down to decrease this time. Pressing the OK button starts the function:

the remaining time for the end of the process is shown on the screen.

When the value 00.00.00 is reached, the fans are controlled again in the previous way. If it is desired to stop the process, it is sufficient to repeat

the adjustment operations of the booster by selecting a time of 0 minutes and pressing OK.

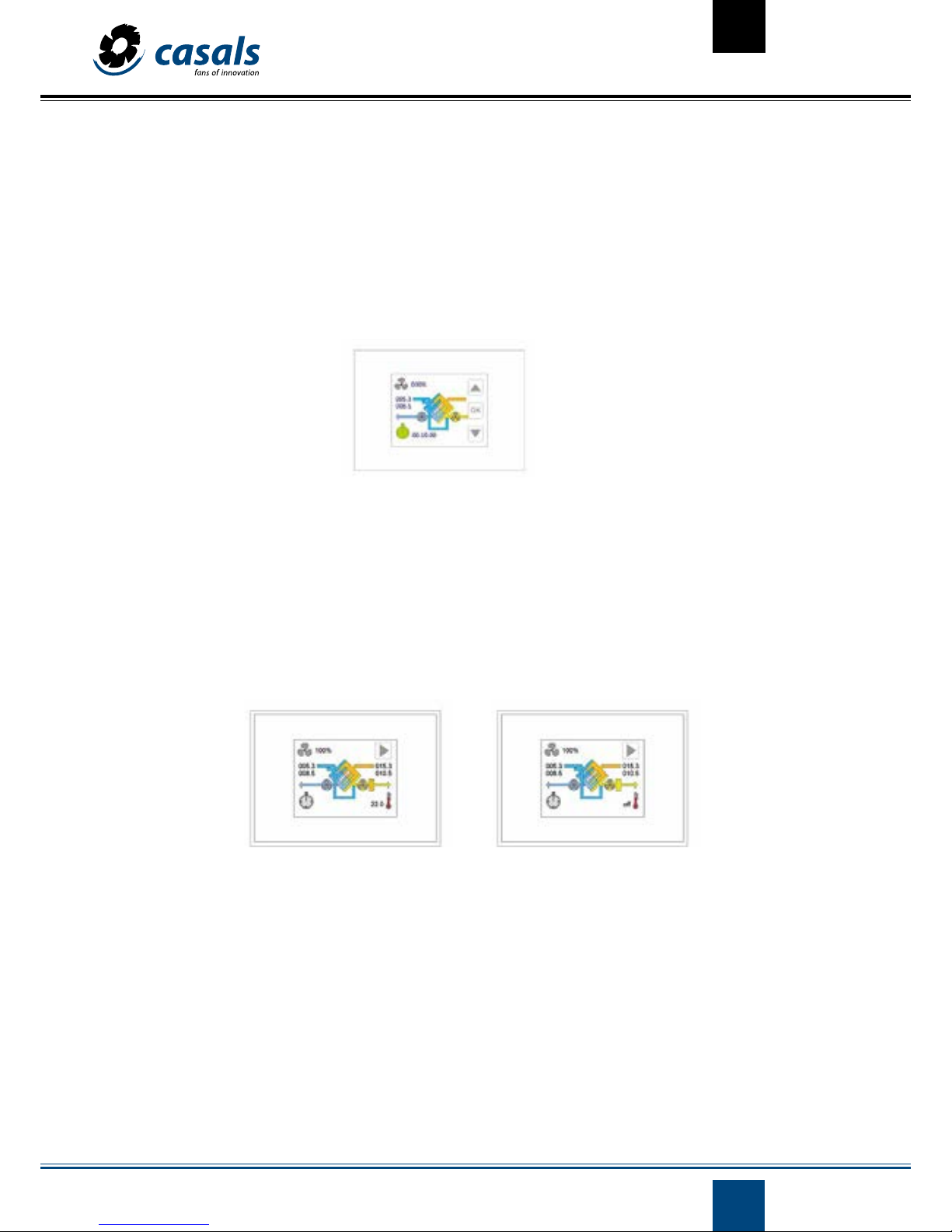

MANAGEMENT OF AIR POSTGRADING

The control is capable of managing an air after-treatment system with both water coil and electrical resistance.

The first is regulated by the control of a 3-point solenoid valve 230V or 24AC-DC \ 0-10V, while the resistance through the corresponding relay.

If after-treatment management is established, the main screen is modified: an icon - thermometer with a temperature value appears in the

lower right corner. On its side and on the flow of the driving air, a picture of post-heating / cooling appears.

Selecting the icon in the bottom right corner establishes the desired temperature set point (TS) inside: the user can increase the value of TS

with the direction arrow up or, on the contrary, decrease it with the Direction arrow below. Once the desired value has been reached, the selection is confirmed by pressing the OK button. With the central button, which appears at first, the post-treatment can be switched off directly.

TS can assume values between 05.0 ° C and 30.0 ° C with steps of 0.1 ° C; if the user selects a TS value lower than 05.0 ° C, the control considers

the post-heating deactivated and the display appears next to the corresponding icon on the screen. It is possible to combine electric afterheating for winter and water cooling in summer, or under the same conditions, control two separate cold-hot coil (cold only with 0-10V valve).

TS becomes the reference for heating or cooling depending on whether or not these are enabled in the corresponding station of the installer

menu (exclusive to each other) and depending on the one selected in the parameter menu. The post-heating status is shown in the main

window: It is also possible to manage a dehumidification system made by the two separate coil (hot-cold) or by a cold coils with an electrical

resistance underneath.

Active post-heating

Postheating off

6

CV072018-1

PREHEATING MANAGEMENT

In addition to the post-heating, the CTRL-MAX2 control is able to manage an electric preheating system (operated by a PWM signal or on-off)

to prevent the formation of ice inside the heat exchanger. The control automatically activates the anti-frost procedure when the temperature

measured by the expulsion probe (Tx) drops below the value of 3 °C. Here the heater is powered at the minimum power. If the temperature Tx

continues to decrease and falls below 1 °C, the feed of the preheater is progressively increased until it reaches 100%. When Tx returns above

3 °C the procedure is interrupted. The temperature values 3C° and 1C° are set at the factory and can be modified on request. The preheating

status is shown in the main window.

MENU SELECTION

From the main window you access the menu window by touching the corresponding icon (window change icon). You have to scroll with the

up arrow key and then press OK on the desired item. When selecting, you access the diverse detailed information about the installation. When

the last menu item is reached, the arrow below disappears.

On the other hand, when you go beyond the first one, the window change icon appears with the arrow to the left. To return to the previous

menu, click on the latter.

In the menu window you can access the following functions:

- Status

- Program

- Clock

- Alarms

- Installer

- Factory (protected by password, accessible only by factory).

From the Menu window, you access the main window by pressing the up arrow button until the window change icon appears and pressing OK.

Menu selection window

Active post-heating

Postheating off

Central window change icon

7

CV072018-1

STATUS MENU: OPERATING STATUS

If the remote control panel is used to manage several units (master-slave mode), a screen with the list of available machines (max 4) will appear

in the menu:

To view the status of an individual unit, select it (move with the arrows and confirm the selection with OK). If the control is configured to manage an individual unit, when accessing this menu, the status of the unit is displayed directly, displaying the values taken by the parameters

that characterize it; using the direction buttons (up-down) it is possible to scroll through all of them. The pressure, flow parameters refer to

machines with cop / cav kit (see instructions):

Te (exter.) Renewal air temperature in °C

Tr (return) Return air temperature in °C

Tx

(expelled)

Expelled air temperature in °C

Ti (input) Air temperature introduced in °C

Tw(water) It is active if the after-heating is present by means of a water coil, it indicates the temperature of the water flowing

out of the coil, it is expressed in ° C

Wat.nofrost It is active when the after-heating is established by a water coil and indicates whether the anti-freeze / no-frost

mode is in progress.

The no-frost function relative to the coil is activated when the temperature measured by the Tw probe falls below

3 ° C and then deactivates when it returns above 5 ° C (3 + 2). When a temperature below 3 ° is detected, the control

valve (hot water) is completely opened in order to prevent the formation of ice inside the elements. If Tw falls below

1C ° the fans stop and at the same time an alarm is signaled (see ALARMS menu). The two temperature values of 3

° C and 1 ° C can be changed (menu FACTORY -factory-).

Anti-frost Antifrost function (antifreeze) exchanger. It is activated when the temperature measured by the Tx probe falls be-

low 1 ° C and then deactivated when it returns above 3 ° C.

The purpose is to avoid the formation of ice inside the exchanger.

It can be managed by a preheating resistor, by unbalancing the air flow rates or by regulating the by-pass.

Fan supply Admission fan speed, this value is expressed in:

- Revolutions per minute (RPM) if fans with tachometer signal are installed.

- Percentage if variable speed fans are installed without tachometer signal (Off with fan off).

- Off, 1, 2 or 3 for three-speed fans.

Fans. remote Only Evo-d. If on, it indicates the independent regulation of the drive fan from Modbus.

Flow supply Only for units of constant flow with control over two flows. Value in m³ \ h of flow of the driving fan.

Display menu statusSelection of unit to control configuration menu status

8

CV072018-1

Dp Supply Only for units of constant pressure with control over two flows. Pressure value in pascals below the driving fan.

Fan exhau. Exhaust fan speed, see vent. Entr.

FanE

. Remote

Only Evo-d. If on, it indicates the independent regulation of the return fan from Modbus.

FlowExhau

.

Only for units of constant flow with control over two flows or with flow sensors. Value in m³ \ h of the return flow.

DpExhau Only for units of constant pressure with control over the two flows. Pressure value in pascals above the return fan.

Flow Only for units of constant flow with control over a flow. Value in m3 \ h of flow of the fan of impulsion.

Dp Only for units of constant pressure with control over a flow. Pressure value in pascals below the driving fan.

Fan hours Hours of operation of the unit.

Bypass It is active if the bypass is configured:

- On open bypass.

- Off bypass closed.

- Bypass Mod Modulation (if set from the factory menu).

Heating/Cooling/On\

Off

It is active if air or water after-treatment is configured:

- Heat On \ Off active afterheating \ inactive.

- Refriger. On \ Off after cooling active inactive.

CO

2

/VOC ppm It is active if a CO2 or VOC / VOC probe is present: it indicates the concentration of CO2 or CO2 / VOC in parts per

million (ppm) measured by the air quality probe, it can take values between 0 and 2000.

Humidity % It is active if a relative humidity probe is present: it indicates the relative humidity value in percentage measured by

the probe, it can take values between 0 and 100.

Auto est .% It is active if the automatic operation of the fans is configured by an external 0-10V signal. Indicates the percentage

value of the external signal (10V corresponds to 100%).

Remote It is active if a digital input (DI) is configured as remote (parameter adjustable in the factory):

- On if DI closed (the fans operate at the speed set on the remote panel).

- Off if DI open (fans stopped).

Boost It is active if a digital input (DI) is configured as a booster (parameter adjustable in the factory):

- end DI open and a time exceeding Boost min. since the last impulse, therefore inactive booster (fans at the speed

established by the control).

- Max. the time has not yet elapsed Boost min. (1 -> 240 minutes) since the DI has received the impulse, active

booster (fans at maximum speed).

PIR It is active if a digital input (DI) is configured as PIR (parameter adjustable in the factory).

- min Open DI (fans at minimum speed).

- max. DI closed (fans at maximum speed) and the minimum PIR time has not yet elapsed.

(1 -> 240 minutes) fixed in the installer menu.

- off DI closed (fans at the speed set by the user in the control) and has

after the time PIR min. from the moment of closing the DI entry.

Summer It is active if a remote digital input (factory default) is set as summer / summer.

- Yes / yes DI open, the summer station is established.

- No DI closed, the winter season is established.

Humidity I t is active if a remote digital input (factory default) is set as humidity / humidity.

- Yes / yes DI open, the humidity threshold of the humidistat has been exceeded.

- No DI closed, the humidity threshold of the humidistat has not been exceeded

Fire It is active if a remote digital input (factory) is configured as fire / fire.

- Yes / yes DI open (exhaust fan at maximum speed and blower fan off).

- No DI closed (fans at the speed set by the control).

PFanSupply It is active if the fan alarm is set to 2Press (factory default).

- off open alarm contact, drive fan stopped or broken

- on closed alarm contact, running fan in operation.

PFanExhau It is active if the fan alarm is set to 2Press (factory default).

- off contact of open alarm, return fan stopped or faulty

- on closed alarm contact, return fan in operation.

Recircul.Req. Off/On It is active if it is set to Recircul. one of the digital inputs (at the factory, when recirculation gates are installed).

- open contact off, standard recirculation management.

- on closed contact, maximum active recirculation.

9

CV072018-1

Dehumidif.On/Off It is active if the control is configured to manage the dehumidification system

- on dehumidification enabled

- off dehumidification disabled.

DWat. NoFrost Off\On It is active if the control is configured to manage the dehumidification system Air temperature after the cold coil

in ° C.

It is active if after treatment is established by water coil. Indicates whether anti-freeze / - nofrost mode measured

by on-off thermostat (directed at 1 ° C and connected to a digital input) is in progress. In this case, the control valve

opens completely and both fans stop. At the same moment an alarm appears in the corresponding menu.

Td(Dehum.) It is active if the control is configured to manage the dehumidification system Air temperature after the cold coil

in ° C.

The digital inputs / outputs can be programmed from the factory menu by asking the manufacturer for passwords and instructions on the

available functions.

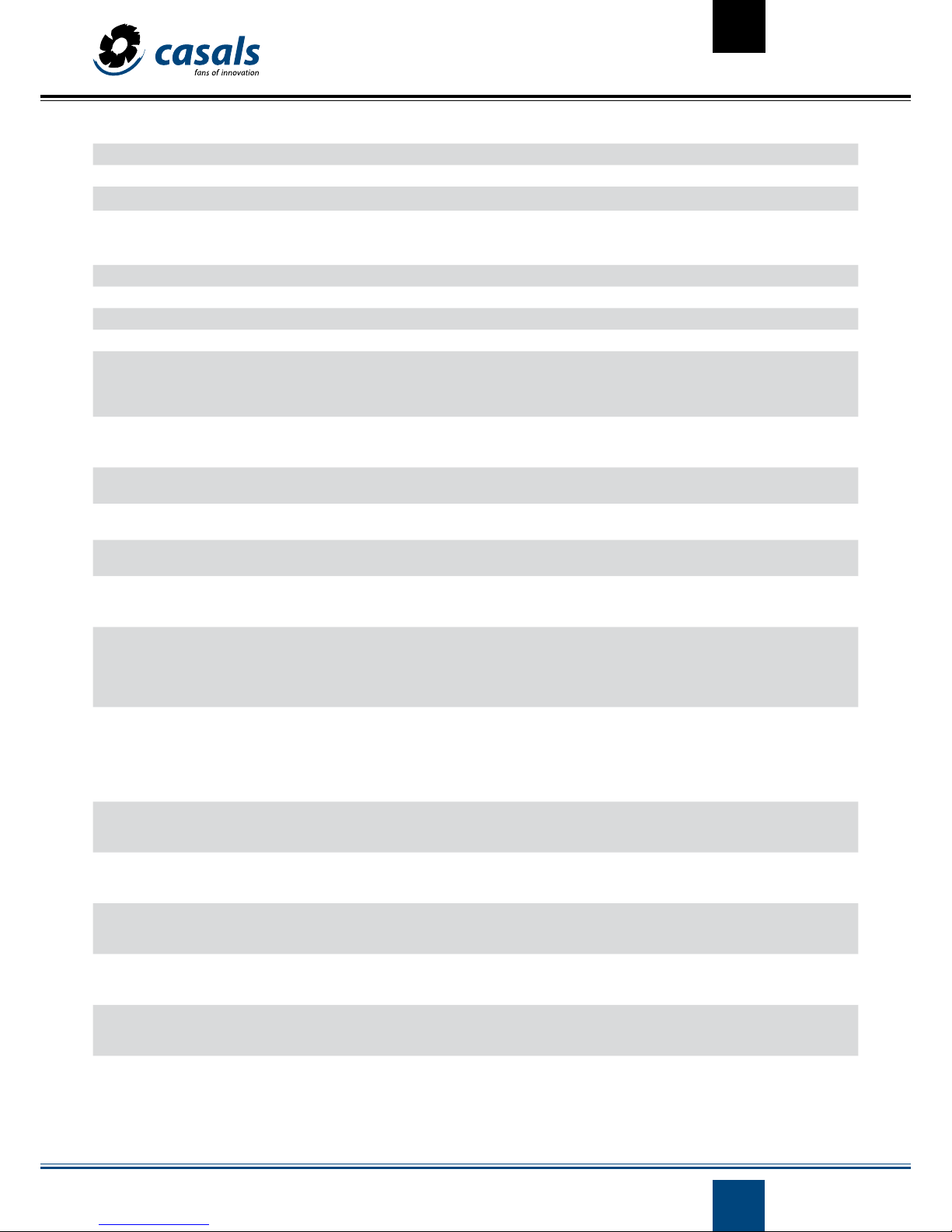

PROGRAM MENU: WEEKLY PROGRAMMING MANAGEMENT

This menu allows to manage the speed of the fans (in three levels) that are expressed in percentage for machines of variable speed, in pascals

for machines of constant pressure and in m3 / h for machines of constant flow. It is also possible to enable / inhibit air after-treatment (if present) in a different way for each day of the week.

Everything can be adjusted for different time slots (from 1 to 8 definable by the user with a resolution of 30 minutes). To access the programming management functions, select Program with the direction buttons pointing to it and press OK.

Program menu display with fan speed Program menu display with air low Program menu display with pressure

10

CV072018-1

DEFAULT

By selecting this menu item and pressing the OK button, the parameters for the management of the unit are automatically assigned the

preset values:

Program valid from Monday to Friday:

Program valid from Saturday to Sunday:

TIME TABLE

Time table Speed fans/ air flow/ pressure Air after-treatment condition: (ON enabled, OFF inhibited)

C1 00:00 -> 06:29 medium OFF

C2 06:30 -> 07:59 medium ON

C3 08:00 -> 11:29 low ON

C4 11:30 -> 12:59 High ON

C5 13:00 -> 17:59 low ON

C6 18:00 -> 21:59 high ON

C7 22:00 -> 00:00 medium OFF

C8 not used - -

TIME TABLE

Time table Speed fans/ air flow/ pressure Air after-treatment condition: (ON enabled, OFF inhibited)

C1 00:00 -> 07:29 medium OFF

C2 07:30 -> 07:59 medium ON

C3 08:00 -> 11:29 medium ON

C4 11:30 -> 12:59 high ON

C5 13:00 -> 17:59 medium ON

C6 18:00 -> 21:59 high ON

C7 22:00 -> 00:00 medium OFF

C8 not used - -

SPEED LEVELS

Low: Medium sp. OFF

Medium sp.: 030% if the unit is equipped with adjustable speed fans; 1 if the unit is equipped with three-

speed fans; auto if the unit has a CO2 sensor, relative humidity or if it is managed by an external

0-10V signal.

0200m s\h if the unit is of constant flow with cop \ cav kit. This value also depends on the factory

menu settings based on the performance of the unit.

010Pa if the unit is constant pressure with cop \ cav kit. This value also depends on the factory

menu settings based on the performance of the unit.

High speed: 065% if the unit is equipped with adjustable speed fans; 2 if the unit is equipped with three-

speed fans; auto if the unit has a CO2 sensor, relative humidity or if it is managed by an external

0-10V signal.

20000m s\h if the unit is of constant flow with kit cop\ cav. This value also depends on the factory menu settings based on the performance of the unit.

Loading...

Loading...