CAS X320 Quick Start Manual

IP69K Washdown Indicator

Quick Start Manual

(800) 223-4227

www.cas-usa.com

U21022050

Quick Start Manual Rev 1.33

003X-608-133 Page 1

Table of Contents

1. INTRODUCTION.............................................................2

1.1. Approvals................................................................2

1.2. Manuals ..................................................................2

2. SHIPPING CONTENTS ..................................................2

3. SPECIFICATIONS ..........................................................3

4. WARNINGS ....................................................................4

4.1. General ...................................................................4

4.2. Configuration Issues...............................................4

5. INSTALLATION ..............................................................5

5.1. Electrical Safety ......................................................5

5.2. opto-LINK................................................................6

6. CONNECTIONS..............................................................7

6.1. Cable Connections .................................................7

6.2. DC Power (DC PWR + , DC PWR –)......................7

6.3. Load Cell Connection .............................................7

6.4. Auxiliary Connections .............................................9

6.5. Connecting Shields...............................................15

6.6. Regulatory Sealing Requirements........................15

7. INSTRUMENT SETUP..................................................17

7.1. Calibration Counter...............................................17

7.2. opto-LINK..............................................................17

7.3. Access Full Setup .................................................18

7.4. Access Safe Setup ...............................................18

7.5. Exit Full or Safe Setup ..........................................18

7.6. Settings.................................................................18

8. ERROR MESSAGES....................................................27

8.1. Weighing Errors ....................................................27

8.2. Setup and Calibration Errors ................................28

8.3. Diagnostic Errors ..................................................29

Quick Start Manual Rev 1.33

Page 2 003X-608-133

1. Introduction

This manual contains information on the installation, calibration

and setup of the instrument.

1.1. Approvals

• C-tick approved and CE approved.

1.1.1. Trade versions

• NSC approval (4000 divisions at 0.8µV/division).

• NMI approval (4000 divisions at 0.8µV/division).

• NTEP approval (10000 divisions at 0.8µV/division).

1.2. Manuals

For more information on this instrument refer to the

Reference Manual, Quick Start Manual or

Communications Manual.

2. Shipping Contents

The following table identifies the items shipped with the

indicator. Please check that your packing box contains the

specified items.

Shipped Items Other Items (Optional)

• Indicator

• Operator Manual

• Quick Start Manual

• Trade Label (plastic)

• U Bracket

• opto-LINK Cable

• Power Supply

• Battery Pack with Charger

• Captive Security Screws

Quick Start Manual Rev 1.33

003X-608-133 Page 3

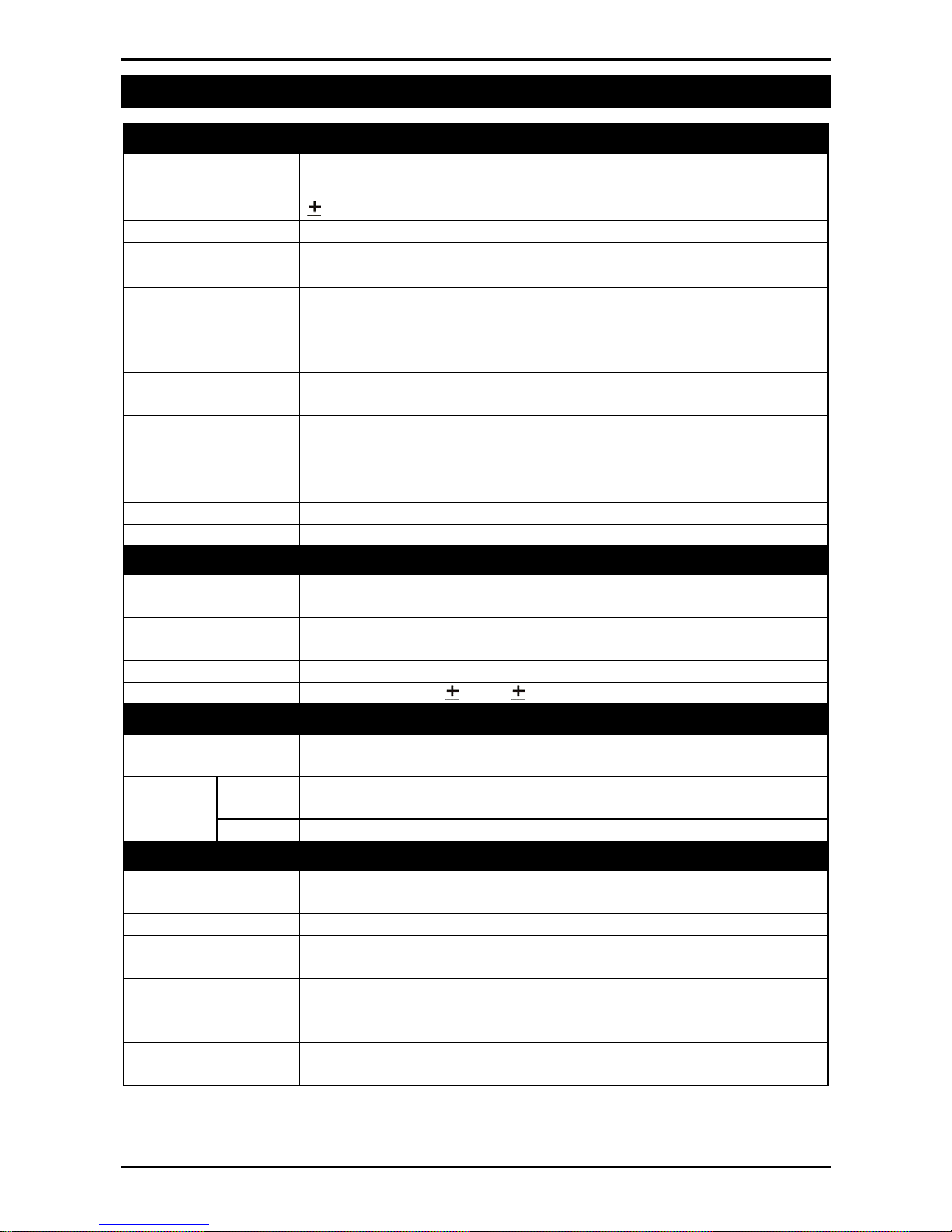

3. Specifications

Performance

Resolution

Up to 30,000 divisions, minimum of 0.25µV/division

(K307 up to 60,000 divisions)

Zero Cancellation

2.0mV/V

Span Adjustment 0.1mV/V to 3.0mV/V full scale

Stability/Drift

Zero: < 0.1µV/°C (+ 8ppm of deadload max)

Span < 8 ppm/°C, Linearity < 20ppm, Noise < 0.2µVp-p

Excitation 5 volts for up to 4 x 350 or 8 x 700 ohm load cells (4-wire or

6-wire plus shield)

Maximum total load cell resistance: 1,000 ohms

A/D Type 24bit Sigma Delta with 8,388,608 internal counts

A/D Conversion

Rate

20Hz with FIR filtering > 80dB

Operating

Environment

Temperature: –10 to +50°C ambient

Humidity: 100%

Storage: –20 to +50°C ambient

IP69K

Case Materials PC+Polyester alloy, PBT, Silicon Rubber, SS304 Stand

Packing Weights Basic Indicator: 2.0kg

Digital

Display LED Backlit LCD with six 20mm high digits with units and

annunciators

Setup and

Calibration

Full digital with visual prompting in plain messages

Digital Filter Sliding window average from 0.1 to 4.0 seconds

Zero Range Adjustable from 2% to 100% of full capacity

Power Input

Standard Power

Input

12 to 24VDC, 9.6, 12 and 24V batteries (2.5 VA max) -

ON/OFF key with memory feature

Variants AC AC Power supply: 110/240VAC 50/60Hz in 24VDC 1.25A

out

Battery 12V battery pack (rechargeable NiMH)

Features

opto-LINK Data

Coupling

Infra-red Connector for optional opto-LINK PC cable (to RS-

232 or USB PC port)

Correction Ten point linearity correction (K304 Only)

Outputs RS-232 automatic transmit, network or printer outputs.

Transmission rate: 2400, 4800 or 9600 baud

Assignable

Function Key

Unit switching, counting, manual hold, peak hold, live weight,

totalising

Drive Outputs 3 isolated high side drive outputs (400mA each 12-24VDC)

Battery Backed

Clock Calendar

Battery life 10 years minimum

Quick Start Manual Rev 1.33

Page 4 003X-608-133

4. Warnings

4.1. General

• Indicator not to be subject to shock, excessive vibration or

extremes of temperature (before or after installation).

• Inputs are protected against electrical interference, but

excessive levels of electro-magnetic radiation and RFI may

affect the accuracy and stability.

• For full EMC or for RFI immunity, termination of cable shields

and correct earthing of the instrument is essential.

• Indicator and load cell cable are sensitive to excessive

electrical noise. Install well away from any power or

switching circuits.

4.2. Configuration Issues

• Configuration and calibration can be performed from the front

panel, using digital setup. When Full Setup is used, all menu

items are accessible and care must be taken to ensure no

accidental changes are made to calibration and trade

settings.

• Enter a passcode to prevent unauthorised or accidental

tampering. If the passcode is lost, the manufacturer should

be contacted for further advice.

Quick Start Manual Rev 1.33

003X-608-133 Page 5

5. Installation

The following steps are required to set up the indicator.

• Inspect indicator to ensure good condition.

• Use connection diagrams to wire up load cell, power and

auxiliary cables as required.

• Connect Power to indicator and press <POWER> key to turn

the instrument On.

• Refer to the Instrument Setup section page 17 for information

on configuring and calibrating the instrument.

• To turn instrument Off press and hold <POWER> key for

three seconds (until display blanks).

5.1. Electrical Safety

• For your protection all mains electrical hardware must be

rated for environmental conditions of use.

• Pluggable equipment must be installed near an easily

accessible power socket outlet.

• To avoid the possibility of electric shock or damage to the

instrument, always switch off or isolate the instrument from

the power supply before maintenance is carried out.

Quick Start Manual Rev 1.33

Page 6 003X-608-133

5.2. opto-LINK

The optional opto-LINK cable

can be used to transfer setup

and calibration information

from a PC (eg. to be stored for

later use and/or transferred to

other instruments). It can also

be used to download software

upgrades to the instrument

from a PC.

• Attach the opto-LINK cable to the PC using the DB9 or USB

connector.

• Attach the opto-LINK head to the left side of the instrument

display using the permanent magnet located within the head of

the opto-LINK.

WARNING: The opto-LINK head contains a strong magnet and care

should be taken with its proximity to electronic media (eg. credit

cards, floppy disks, etc.) and/or other electronic instrumentation.

5.2.1. opto-LINK Activation

A long press of the <GROSS/NET> key will toggle the opto-LINK

infrared communications On/Off.

When the opto-LINK has been (enabled) the following will occur:

• The instrument briefly displays the prompt opto-L.

• The editing annunciators (ie. GRP, ITM, etc.) will flash for up to

five minutes while the instrument searches for activity. During

this period, the instrument also disables the RS-232

communications.

• After a 5 minute period of no activity, the opto-LINK will be

disabled and the editing annunciators will stop flashing. The

instrument will revert back to the normal RS-232

communications (ie. The SERIAL:TYPE setting will be reactivated).

Quick Start Manual Rev 1.33

003X-608-133 Page 7

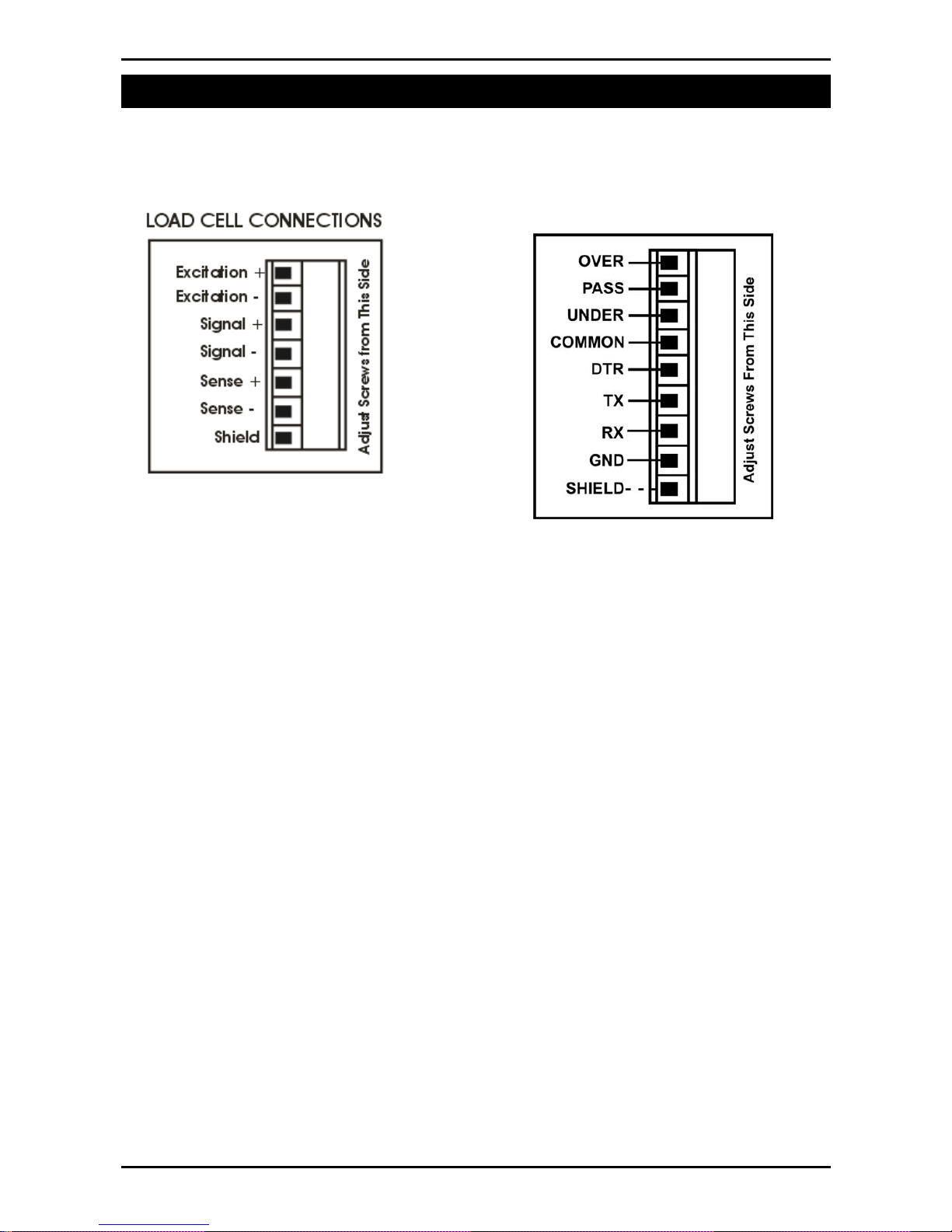

6. Connections

6.1. Cable Connections

• All cable connections are made to the rear of the instrument

using pluggable screw terminals.

6.2. DC Power (DC PWR + , DC PWR –)

• The DC supply need not be regulated, provided that it is free

of excessive electrical noise and sudden transients.

• The instrument can be operated from a high quality plugpack as long as there is sufficient capacity to drive both it

and the load cells.

• If an optional battery pack is fitted, then the supplied

charging system must be used.

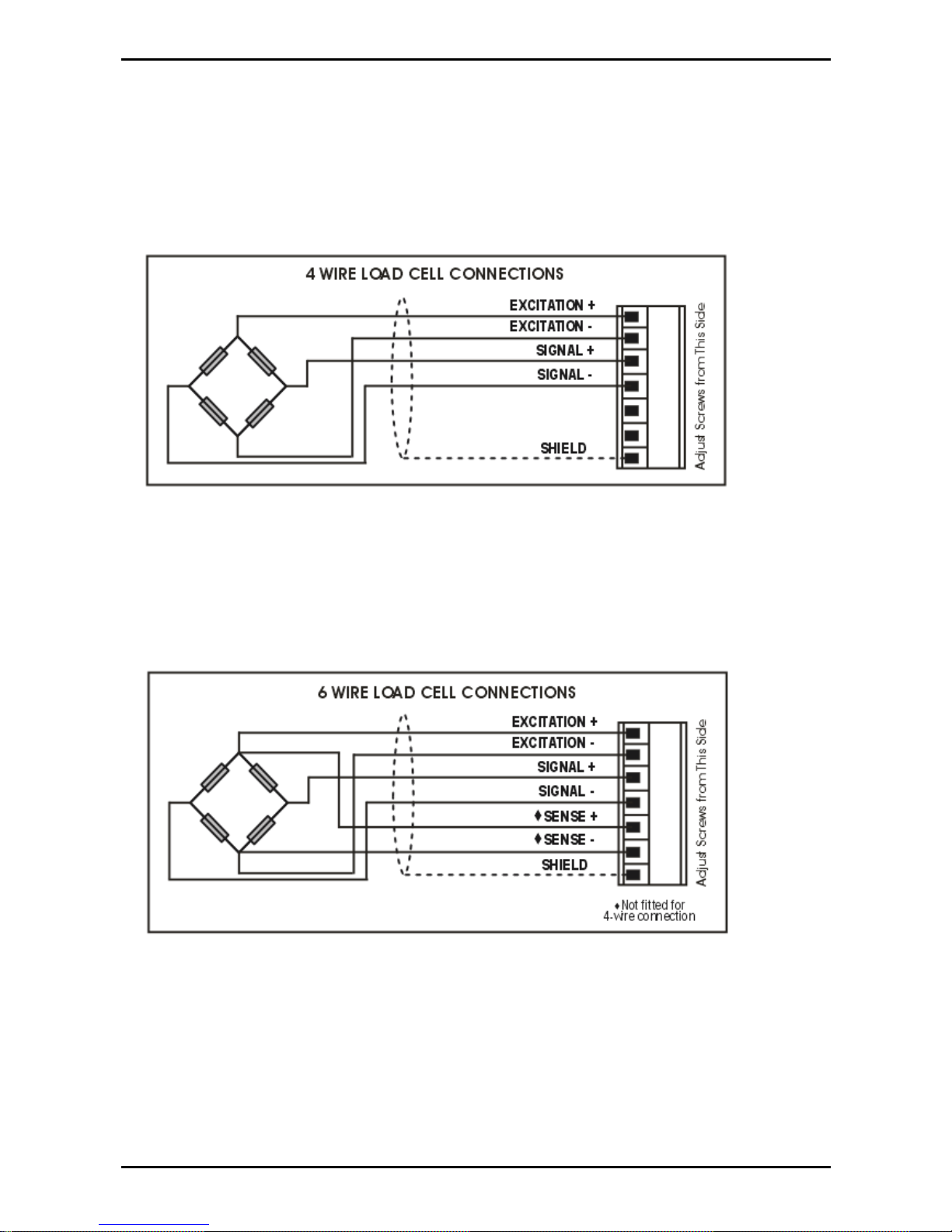

6.3. Load Cell Connection

The instrument may be connected for either 4-wire or 6-wire

operation. For more information, refer to BUILD:CABLE

setting page 19.

Quick Start Manual Rev 1.33

Page 8 003X-608-133

6.3.1. 4-Wire Connection

The minimum connectivity requirements are the connection of

four wires (ie. Excitation + and – along with Signal + and –).

The BUILD:CABLE option must be set to 4 to allow for 4-wire

connection.

6.3.2. 6-Wire Connection

The excitation and signal lines are connected the same as for

a 4-wire installation.

The BUILD:CABLE option must be set to 6 (the default) to

allow for 6-wire connection.

Quick Start Manual Rev 1.33

003X-608-133 Page 9

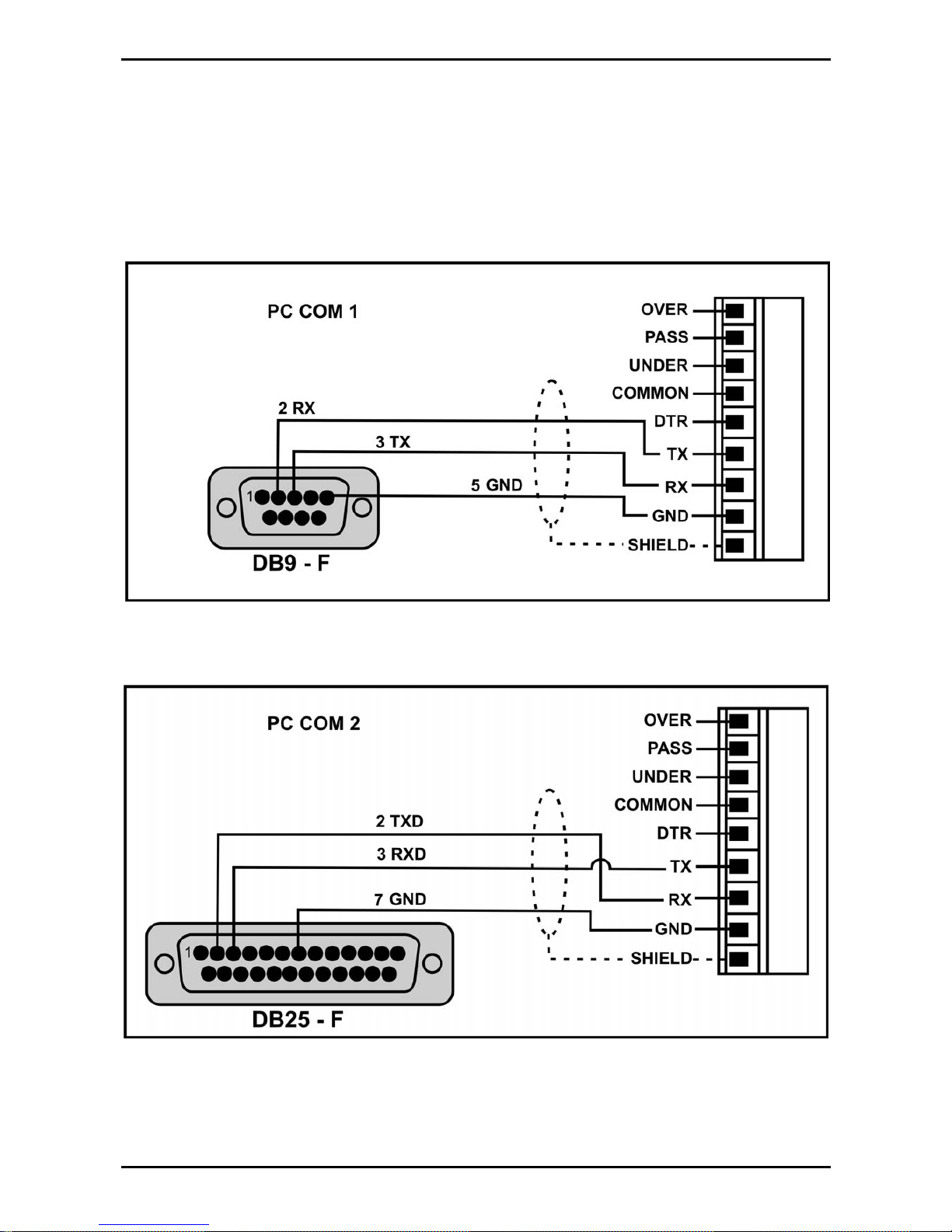

6.4. Auxiliary Connections

This section provides diagrams to illustrate the terminal

connections.

6.4.1. RS-232 Serial to PC

Network: One Instrument to PC (DB9) (RXD, TXD, GND)

Network: One Instrument to PC (DB25) (RXD, TXD, GND)

Loading...

Loading...