CAS WTM Series, WTM-200, WTM-500 Service Manual

Service Manual

– WTM

REV NO

:

V1.1

WTM Series

(Weight Transmitter)

Service Manual

LAST Rev. NO : V1.1

LAST Rev. Date : 2015. 04. 20

Service Manual

– WTM

REV NO

:

V1.1

Table of Contents

1. Cautions for Your Safety ................................................................................................................................... 3

2. User Wanring ...................................................................................................................................................... 6

3. Features .............................................................................................................................................................. 7

4. Overview ............................................................................................................................................................. 9

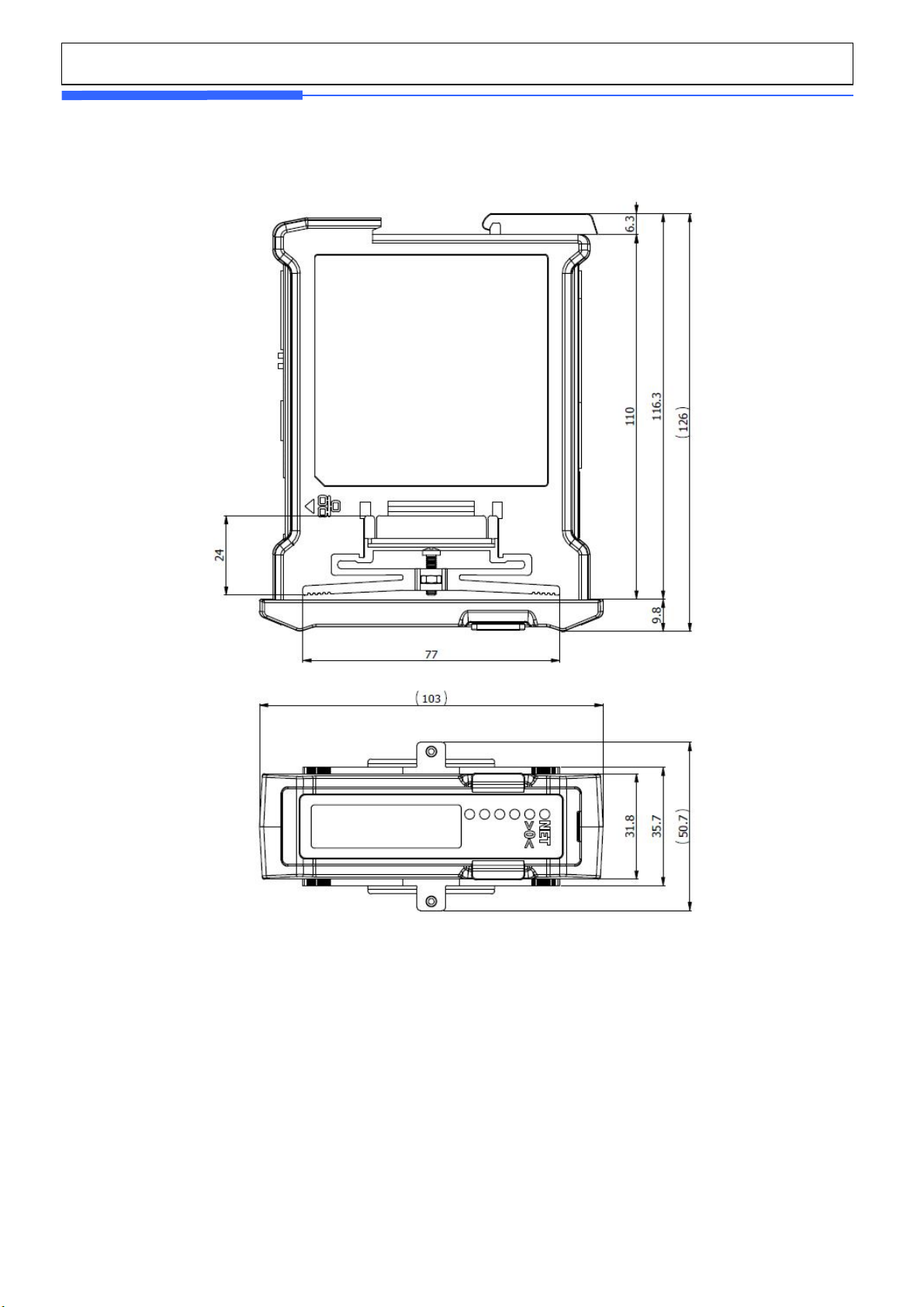

5. External Dimension .......................................................................................................................................... 10

6. Installation & Connection ................................................................................................................................ 12

7. Weight Setup (Calibration) Mode .................................................................................................................... 13

8. How to Seal the Indicator (Sealing) ................................................................................................................ 25

9. Installing Options .............................................................................................................................................. 26

10. Interface ......................................................................................................................................................... 27

11. F.W Update Method ....................................................................................................................................... 28

11.1. Enter the F.W update mode(WTM-200) ............................................................................................. 28

11.2. Enter the F.W update mode(WTM-500) ............................................................................................. 28

11.3. F.W update method ............................................................................................................................... 29

12. Exploded Views.............................................................................................................................................. 31

12.1. Exploded view ...................................................................................................................................... 31

13. Partlist ............................................................................................................................................................ 32

13.1. Electronics Parts .................................................................................................................................. 32

13.2. Mechanism Parts .................................................................................................................................. 34

14. Block Diagram ................................................................................................................................................ 35

15. Revision .......................................................................................................................................................... 36

Service Manual

– WTM

REV NO

:

V1.1

1. Cautions for Your Safety

‘ Please comply with 'Cautions for Your Safety', which will lead you to use the product

safely and properly to prevent any dangerous situations.

■ Cautions are divided into 'Warning' and 'Alert', which mean as follows.

■ Keep this manual in a place where product users can find out, after finish reading it.

'Warning' means a great possibility led to the death or heavy injury when instructions are

violated.

'Alert' means a great possibility led to the injury or material damage when instructions

are violated.

Service Manual

– WTM

REV NO

:

V1.1

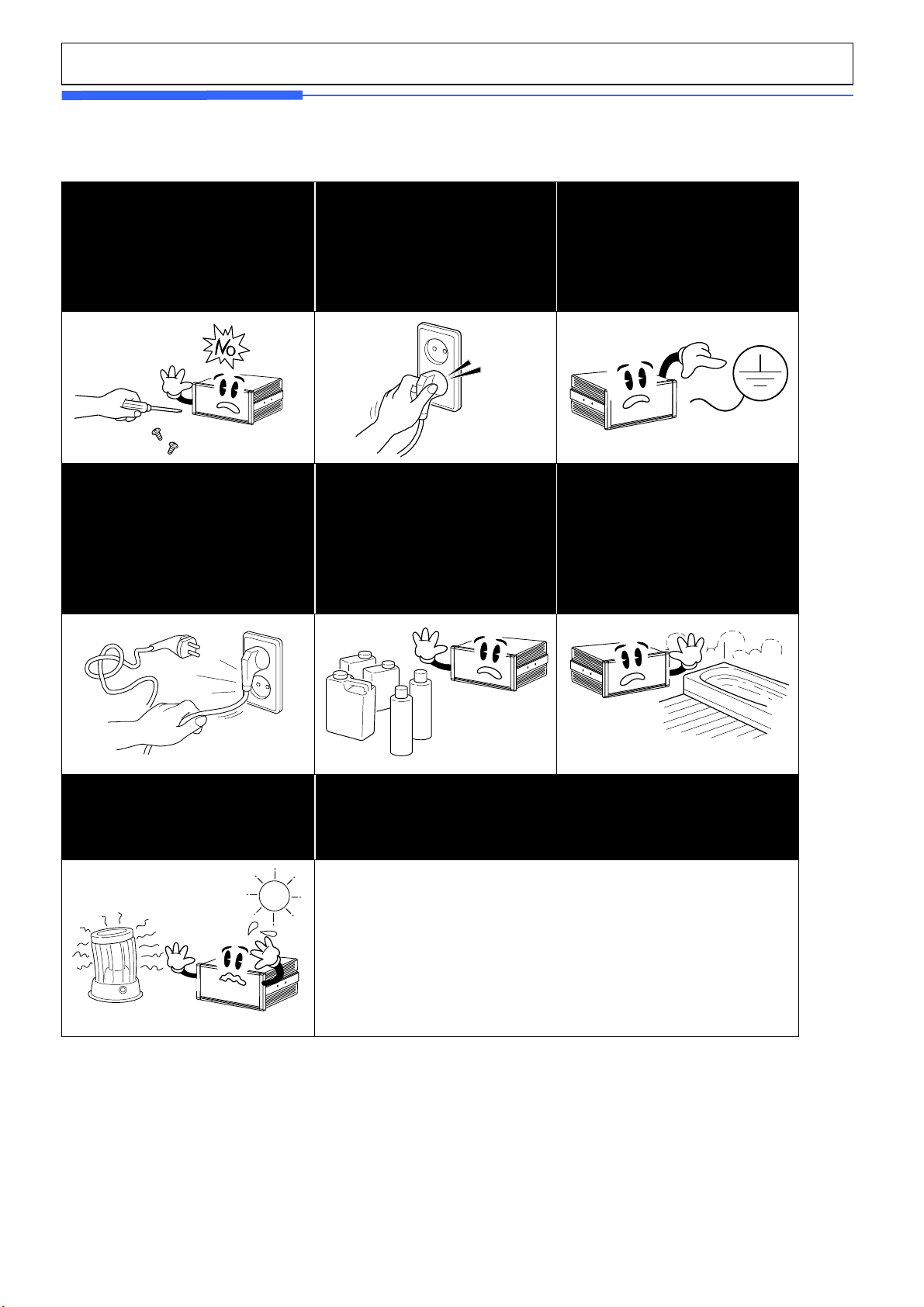

Never disassemble, repair or

from the quality assurance and

cause the damage to devices,

the power plug to be

Any instable connection might

Ensure the grounding of the

Poor grounding might cause

failure or electric shock upon

Keep any combustible spray or

Do not spray water to the outside

It might deteriorate the insulation

electric parts that can cause

retrofit the product.

It might exclude the product

Warning

Ensure

fully

inserted to prevent shaking.

product.

electric shock or fire.

Do not damage, process,

excessively jerk, bend or twist the

power cord.

It might damage the power cord to

cause fire or electric shock.

cause electric sparks to set fire.

fire source away.

It might cause fire.

electric leak.

of the product or use it in any

humid place.

of

the electric shock, fire risk or

weighing errors.

Do not place the product to the

direct sunlight or near any hot

object like a heater.

It might cause fire.

Service Manual

– WTM

REV NO

:

V1.1

Check the weighing error anytime

Any use out of the allowed tolerance

for the careless use or other causes

might not ensure the accurate

Find a proper place to attach the

rubber pad at the bottom of the

indicator, which was shipped

Do not use the product at a place

Do not install the produce at a place with the excessive

Attention

for the accurate weighing.

weighing.

Customer Service:080-022-0022

Avoid any sudden shock to the

product.

It might damage the product to

fail the accurate weighing.

together.

with sudden temperature changes or

severe vibrations.

It might cause the weighing error or

failure.

electromagnetic wave.

It might cause the wrong weighing.

Our Dealers : CAS feels that each of its valued customers should get the best service

available. Whether it’s the initial installation of our product,

maintenance/repair work, or simply answering questions about our

products, CAS Corporation and all of its Authorized Dealers are highly

trained to assist

you with any need regarding CAS products.

Service Manual

– WTM

REV NO

:

V1.1

2. User Wanring

Recommendations for the proper use of weighing instruments

- Keep away from heat sources and direct sunlight

- Repair the instrument from rain(except special IP versions)

- Do not wash with water jet(except special IP versions)

- Do not dip in water

- Do not spill liquid on the instrument

- Do not use solvents to clean the instrument

- Do not install in areas subject to explosion hazard(except special Atex versions)

Recommendations for correct installation of weighing instruments

The terminals indicated on the instrument’s wiring diagram to be connected to earth

must have the same potential as the weighed structure (same earthing pit or earthing

system). If you are unable to ensure this condition, connect with an earthing wire the

terminals of the instrument (including the terminal 0VDC) to the weighed structure.

The cell cable must be individually led to its panel input and not share a conduit with other

cables; connect it directly to the instrument terminal strip without breaking its route with

support terminal strips.

Use “RC” filters on the instrument-driven solenoid valve and remote control switch coils.

Avoid inverters in the instrument panel; if inevitable, use special filters for the inverters

and separate them with sheet metal partitions.

The panel installer must provide electric protections for the instruments (fuses, door lock

switch etc.).

It is advisable to leave the equipment always switched on to prevent the formation of

condensation.

MAXIMUM CABLE LENGTHS

- RS485: 1000 metres with AWG24, shielded and twisted cables

- RS232: 15 metres for baud rates up to 19200

Service Manual

– WTM

REV NO

:

V1.1

3. Features

Power supply voltage 10 ~ 24 V

Max consumption 70 with 350 Ω mA

Power supply Unit

Temperature range

Storage temperature -25 ~ 85

Operating temperature -10 ~ 40

Loadcell

Impedance(complete bridge) > 80 Ω

Connection 4 or 6 wires

Loadcell power supply

Communication

RS485 Half duplex

Baud rate 9600 ~ 115200 BPS

Logical inputs

Numbers 2

type Optocoupler

5 ± 5 %

℃

℃

Vdc

Low level voltage 0 ~ 3 Vdc

Higi level voltage 9 ~ 24 Vdc

Current at high level 10 mA @ 24 V mA

Insulation voltage 2500 Vrms

Logical outputs

Numbers 4

type

Max current @ 40℃

Max voltage in open state 2 Ω

Insulation voltage 2500 Vrms

Legal for use metrological characteristics

Class III or IIII

Service Manual

– WTM

REV NO

:

V1.1

Minimum voltage division per

verification scale division

Maximum voltage for weighing range

Programmable functions

Acquisition of zero, taring, zero tracking

Physical or theoretical calibration

Non-linearity polynomial correction

Low pass, band-stop and self-adaptive digital filters

Set points managements

Checkweigher functioning mode

Peak detection functioning mode

Display 7 Segment LED, 4 key

0.5 uV

39 mV

Slope correction

Option

A-Out V-out, I-out

Relay I/O 2input, 4output

Alibi memory

Ethernet 10/100 M

Fieldbus Profibus

50,000개 Save

Real time clock

-10 V~10 V

0~24 mA

Service Manual

– WTM

REV NO

:

V1.1

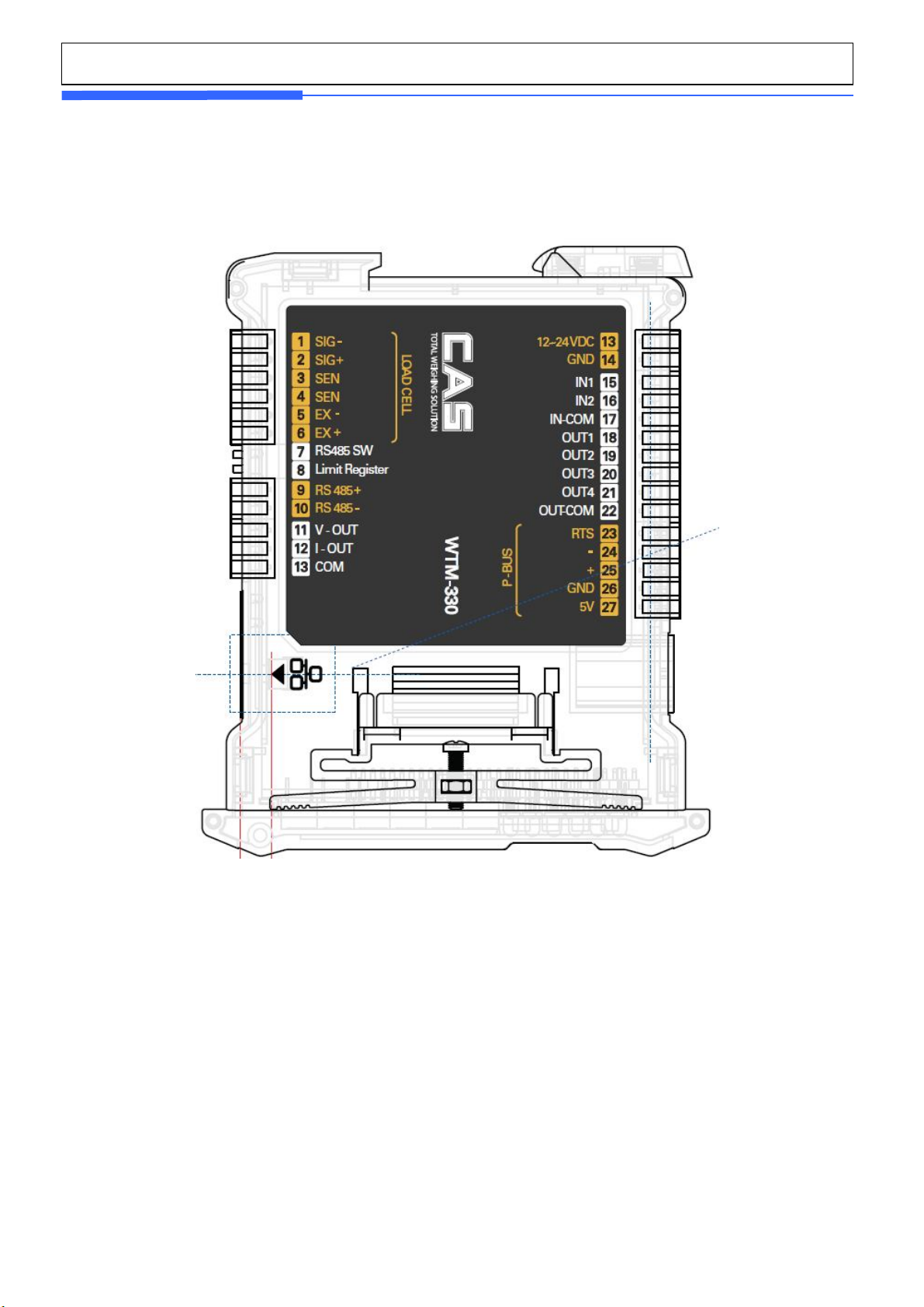

4. Overview

Service Manual

– WTM

REV NO

:

V1.1

5. External Dimension

1. Weight : 6Digits, Decimal point, sign

2. Unit : ton, kg, lb

3. Message : Displayed of indicator’s status

Ext Output are 4

Ext Inputs are 2

Service Manual

– WTM

REV NO

:

V1.1

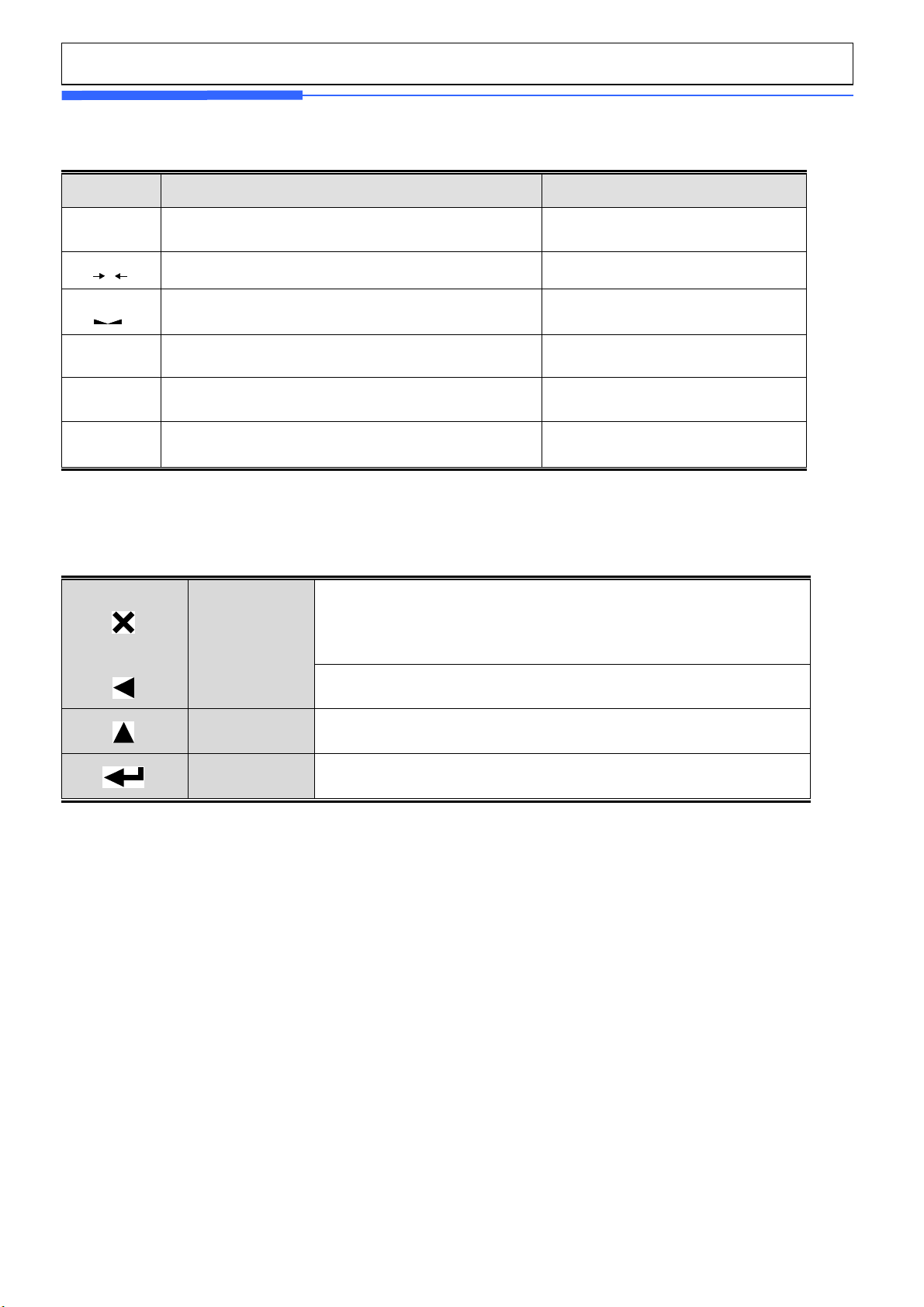

0

Zero

LED

LED

ON : output 3 Closed

■ Display

LED Main function Sub function

NET

On = Net , Off = Gross LED ON : output 4 Closed

Stable LED LED ON : output 2 Closed

t

kg

L

Unit : ton LED ON : output 1 Closed

Unit : kg LED ON : input 2 Closed

Unit : lb LED ON : input 1 Closed

■ Key function

ESC

* It sets the weight display near zero point to 0.

( A range of 2%, 5%, 10%, 20% and 100% can be

selected.)

LEFT

HI

ENTER

* Use it change to item number

* Some functions can be defined to the needs.

* Use it enter to menu mode.

Loading...

Loading...