CAS BW-6, BW Series, BW-30, BW-60, BW-150 Service Manual

...

- 1 -

BATTERY WEIGHING SCALE

BW-SERIES

SERVICE MANUAL

Revision : 2005. 5. 9

- 2 -

Table of Contents

INTRODUCTION 3

TECHNICAL SPECCIFICATION 3

INSTALLATION & CONNECTION 4

TEST MODE 5

CALIBRATION MODE 7

SET MODE 9

SCHEMATIC DIAGRAM 10

P.C.B DIAGRAM 11

CONNECTION DIAGRAM 13

PART LIST 14

EXPLODED VIEW 19

ERROR MESSAGE & TROUBLE SHOOTING 23

- 3 -

INTRODUCTION

The service manual is the specification for the BW-SERIES. They have been

designed with CAS reliability under rigid quality control and with outstanding

performance.

This manual includes basic technical about composition of hardware and program

function.

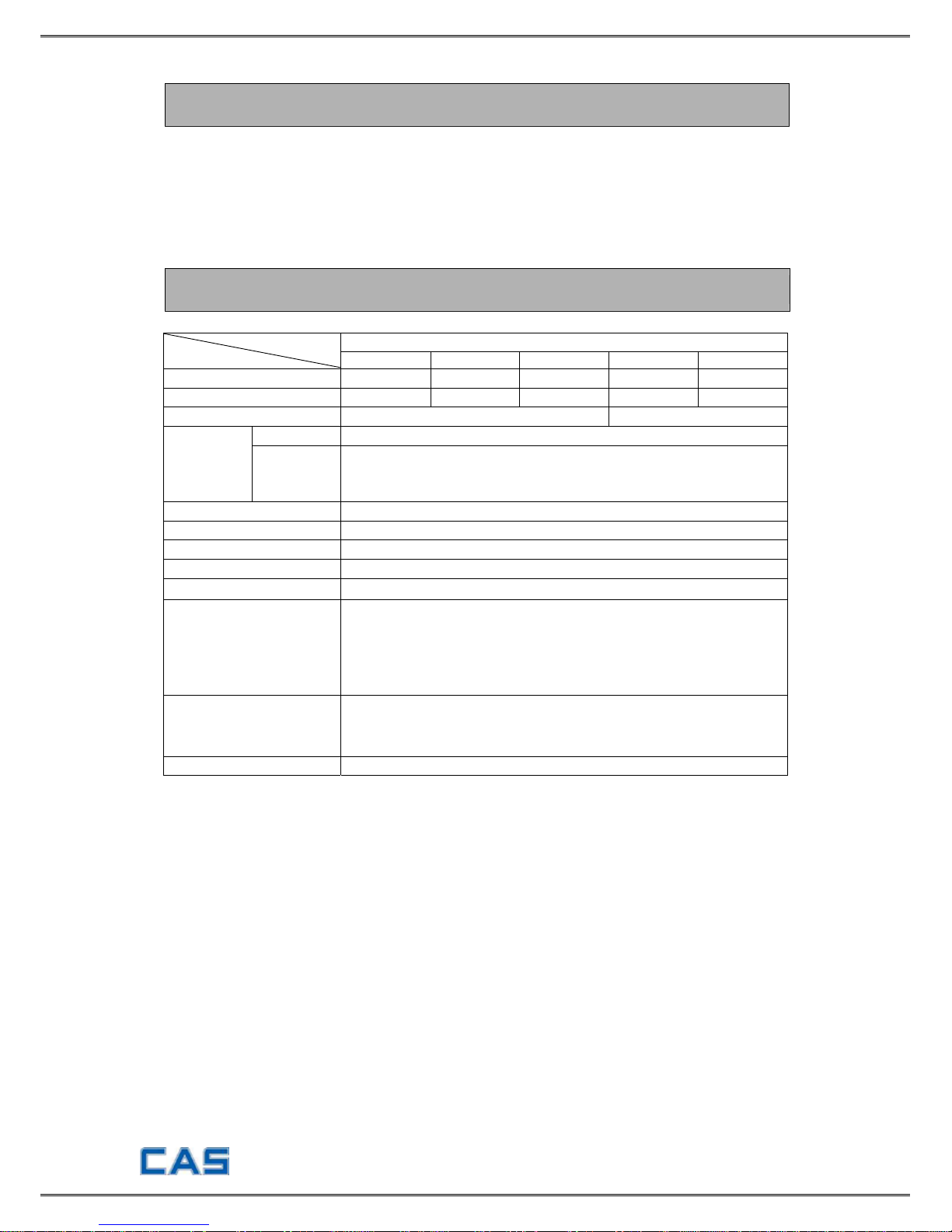

TECHNICAL SPECIFICATION

BW SERIES

Model Item

BW-6 BW-15 BW-30 BW-60 BW-150

Maximum capacity

6kg 15kg 30kg 60kg 150kg

Minimum division

0.002kg 0.05kg 0.01kg 0.02kg 0.05kg

Platform size

280(W) X 280(D) X 80(H)

425(W) X 545(D) X105(H)

Standard ON/OFF, ZERO, TARE, HOLD, COUNT, HIGH/LOW comparing

Function

Option

1. RS-232C

2. BACK LIGHT

3. DC 1.2V(6EA) Recharging Battery, DC 12V Adaptor

Temperature range

-10℃ ~ 40℃

Max. Tare range Max. capacity

Rezero range ±2% of max. capacity

Initial zero range ±10% of max. capacity

Weight display type

5 place LCD(Char. size 23.5 ㎜)

Character display

1. Stable (○)

2. High, Normal, Low (HI, OK, LO)

3. Battery discharge (BAT)

4. quantity unit(PCS)

5. Weight unit(㎏)

Power

1. DC7.2V(6EA SIZE "C") 2200 ㎃ h Recharging battery

2. DC9V (6EA SIZE “C”) Mn, Alkaline battery

3. DC12V 850 ㎃ AC Adapter

Consumption Approx. 0.15W

- 4 -

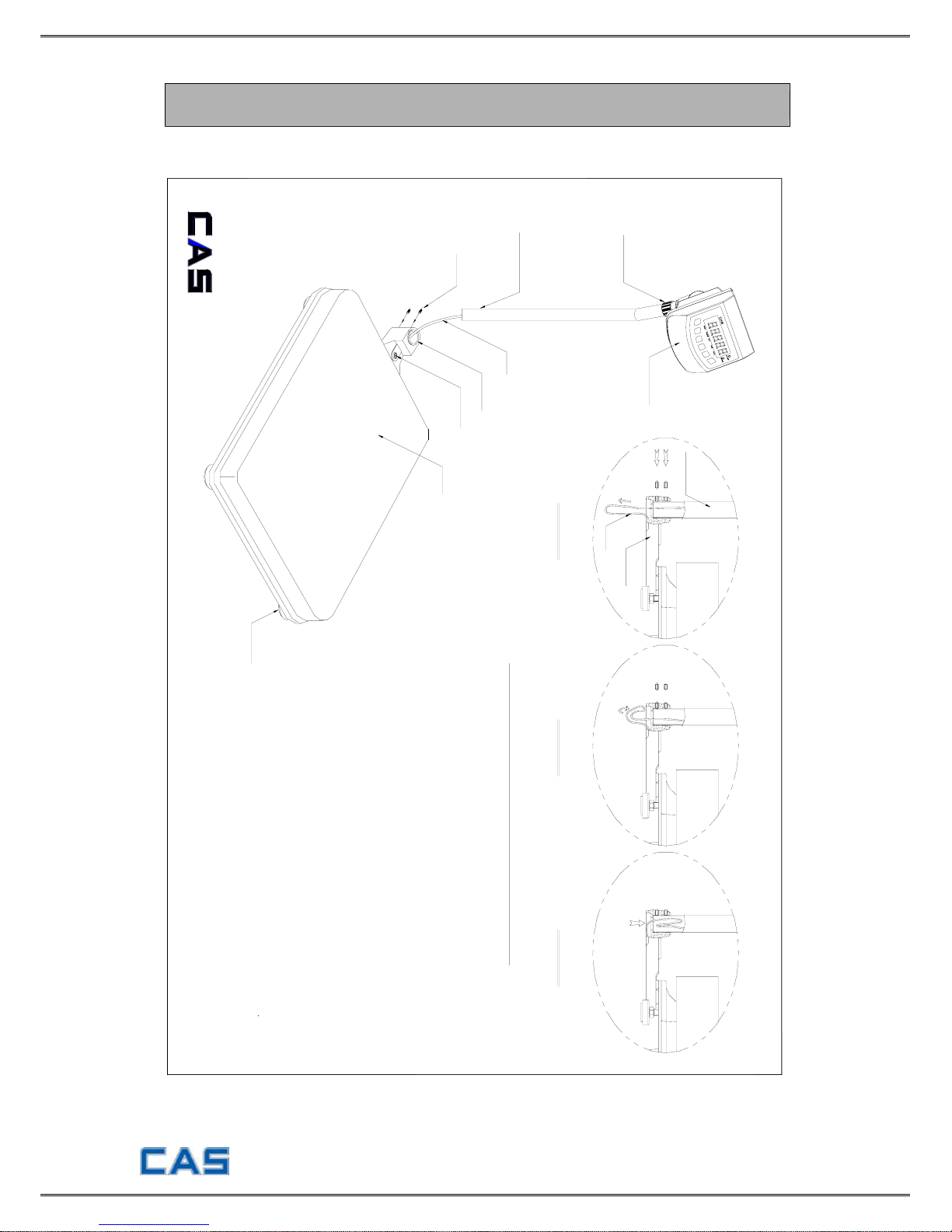

INSTALLATION & CONNECTION

Installation

INDICATOR

LEVELING GAUGE

How to install the BW-series

1. Open the box with care because indicator is

connected to the scale with load cell wire.

2. Turn the post knob so as to fix indicator.

3. Pull down the wire out of post pipe and insert

the post pipe to the post bracket. (Refer to fig. 1)

4. Fasten the post pipe with two bolts. (Refer to fig. 1)

A long bolt should be connected to the upper side.

5. Insert the wire to the post pipe. (Refer to fig. 2.3)

6. If the scale is not properly level, please adjust

4 leg(adjusting bolt) at the bottom of the scale

so as to center the bubble of the leveling gauge

Note: Place the scale on a flat and stable surface.

inside the indicated circle.

FIG. 3

ADJUST

FIG. 2

WIRE

FIG. 1

POST BRACKET

PLATFORM

POST KNOB

POST PIPE

POST BRACKET

LOAD CELL WIRE

BOLT

POST PIPE

- 5 -

Serial Interface (RS-232C)

■ Connecting with PC

RXD 1ㅇ

---------------------------

ㅇ 2 Transmit Data

TXD 2ㅇ

---------------------------

ㅇ 3 Receive D ata

GND 5ㅇ

---------------------------

ㅇ 7 Signal Ground

┌─

ㅇ 4 Request to Send

├─

ㅇ 5 Clear to Send

├─

ㅇ 6 Data Set Ready

├─

ㅇ 8 Carrier Detect

└─

ㅇ 20 Data Terminal Ready

9 pin port (Male) 25 pin port of PC (Female)

RS-232C port of BW-SERIES

RXD 1ㅇ

---------------------------

ㅇ 3 Transmit Data

TXD 2ㅇ

---------------------------

ㅇ 2 Receive D ata

GND 5ㅇ

---------------------------

ㅇ 5 Signal Ground

┌─

ㅇ 1 Carrier Detect

├─

ㅇ 4 Data Terminal Ready

├─

ㅇ 6 Data Set Ready

├─

ㅇ 7 Request to Send

└─

ㅇ 8 Clear to Send

9 pin port (Male) 25 pin port of PC (Female)

RS-232C port of BW-SERIES

■

Connecting with Sub-display (CD-SERIES)

RXD 1ㅇ

---------------------------

ㅇ 2 Transmit Data

TXD 2ㅇ

---------------------------

ㅇ 3 Receive D ata

GND 5ㅇ

---------------------------

ㅇ 7 Signal Ground

9 pin port (Male) 9 pin port of Sub-display

(Male)

RS-232C port of BW-SERIES

TEST MODE

Moving method

Open the top cover of indicator and power on with pressing CAL switch in the left

top. At that time, LCD screen shows “ZEro=tESt tArE=CAL” message and pressing

‘Zero’ key moves to Test 1.

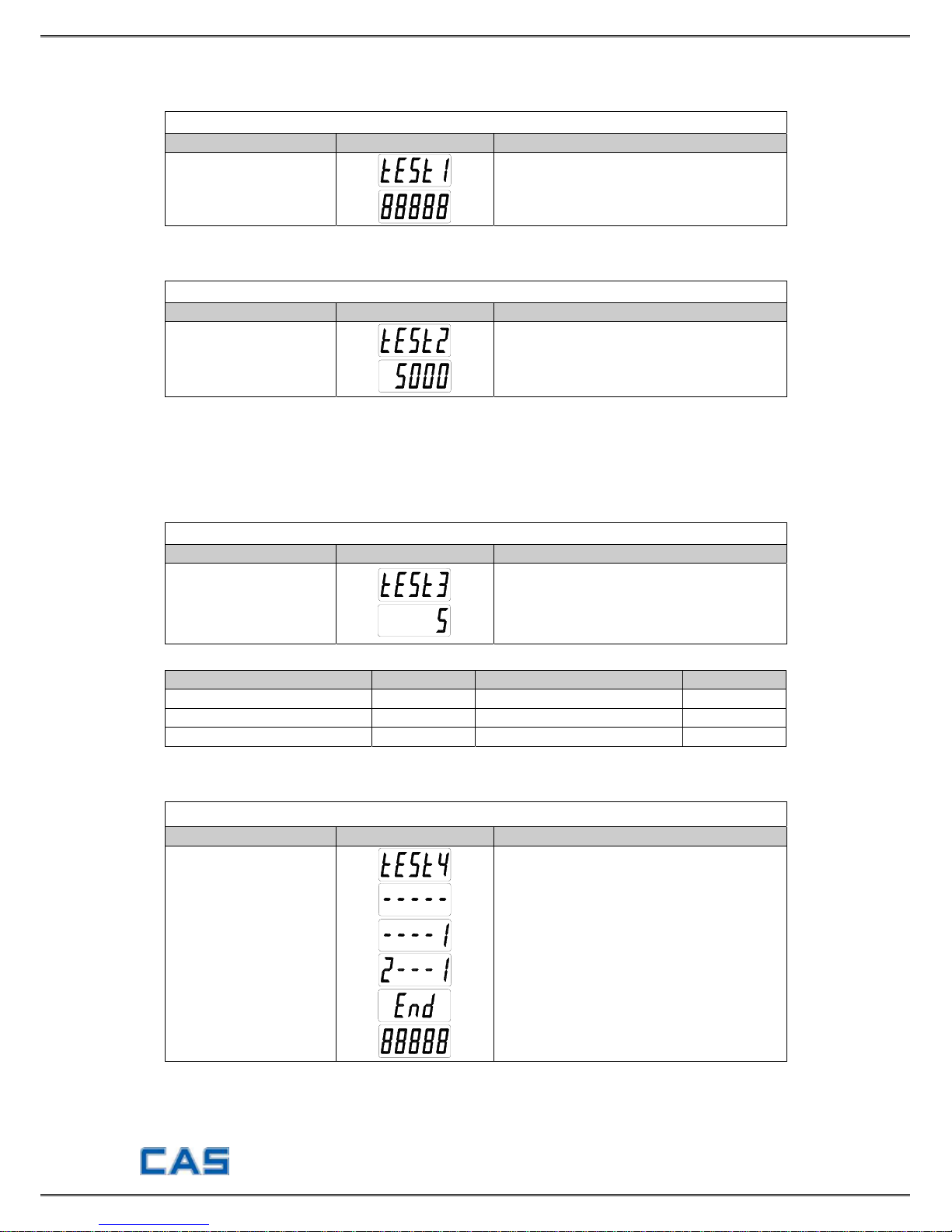

Test menu (tESt 1 ~ tESt 4)

TEST 1: Liquid crystal display test

TEST 2: A/D conversion test

TEST 3: Key test

TEST 4: RS-232C communication test

- 6 -

TEST 1 (Enter ‘TEST’ mode to start TEST 1.)

FUNCTION : Liquid crystal display Test

KEY LC DISPLAY DESCRIPTION

ENTER Key : Next menu

Display TEST 1 state.

TEST 2

FUNCTION : A/D conversion test

KEY LC DISPLAY DESCRIPTION

ENTER Key : Next menu

ZERO Key :

Use to set the current

value to “0”

Display TEST 2 state.

Display the digital value corresponding to

current weight.

Note 1. ▶ Check whether the digital value is changing whenever you load or unload

the weight on the platter. If the digital value is fixed or zero is

displayed,

please check the connection of loadcell.

TEST 3

FUNCTION : Key test

KEY LC DISPLAY DESCRIPTION

ENTER key : Next menu

Other key : Test execution

Display TEST 3 state.

Press the key to be tested and the No. of

key mode should be identifying with code

of key as the follows.

<KEY CODE>

KEY CODE KEY CODE

* 1 GROSS /NET 4

ZERO 2 HOLD or kg/lb 5

TARE 3

TEST 4

FUNCTION : RS-232C communication test

KEY LC DISPLAY DESCRIPTION

ENTER key :

Move to weighing mode.

Other key :

Execute data transmission

to a computer.

Display TEST 4 state.

Waiting for transmission and reception.

Received : None, Transmitted : 1

Received : 2, Transmitted : 1

Press ENTER key.

When this test is completed, it is

automatically moved to NORMAL MODE.

▶ Note 1. Connect the computer COM port with RS232C connector of indicator before

running this test.

▶ Note 2. Send No. 2 in computer keyboard and check if indicator receives No.2 send No. 1

in indicator keyboard and check if computer receives No.1

- 7 -

CALIBRATION MODE

Moving method

Open the top cover of indicator and power on with pressing CAL switch in the left

top. At that time, LCD screen shows “ZEro=tESt tArE=CAL” message and pressing

‘TARE’ key moves to CAL 1.

Calibration menu (CAL 1 ~ CAL 5)

CAL 1 : Maximum Capacity Set

CAL 2 : Minimum Division Set

CAL 3 : Setting Weight in Span Calibration

CAL 4 : Zero Calibration

CAL 5 : Span Calibration

Digit input method

NET/GROSS Key : Increase the first place value by 1.

TARE Key : Move to the left by 1 place.

ZERO/MODE Key : Set the inputted value to “0”.

ENTER Key : Move to the next menu.

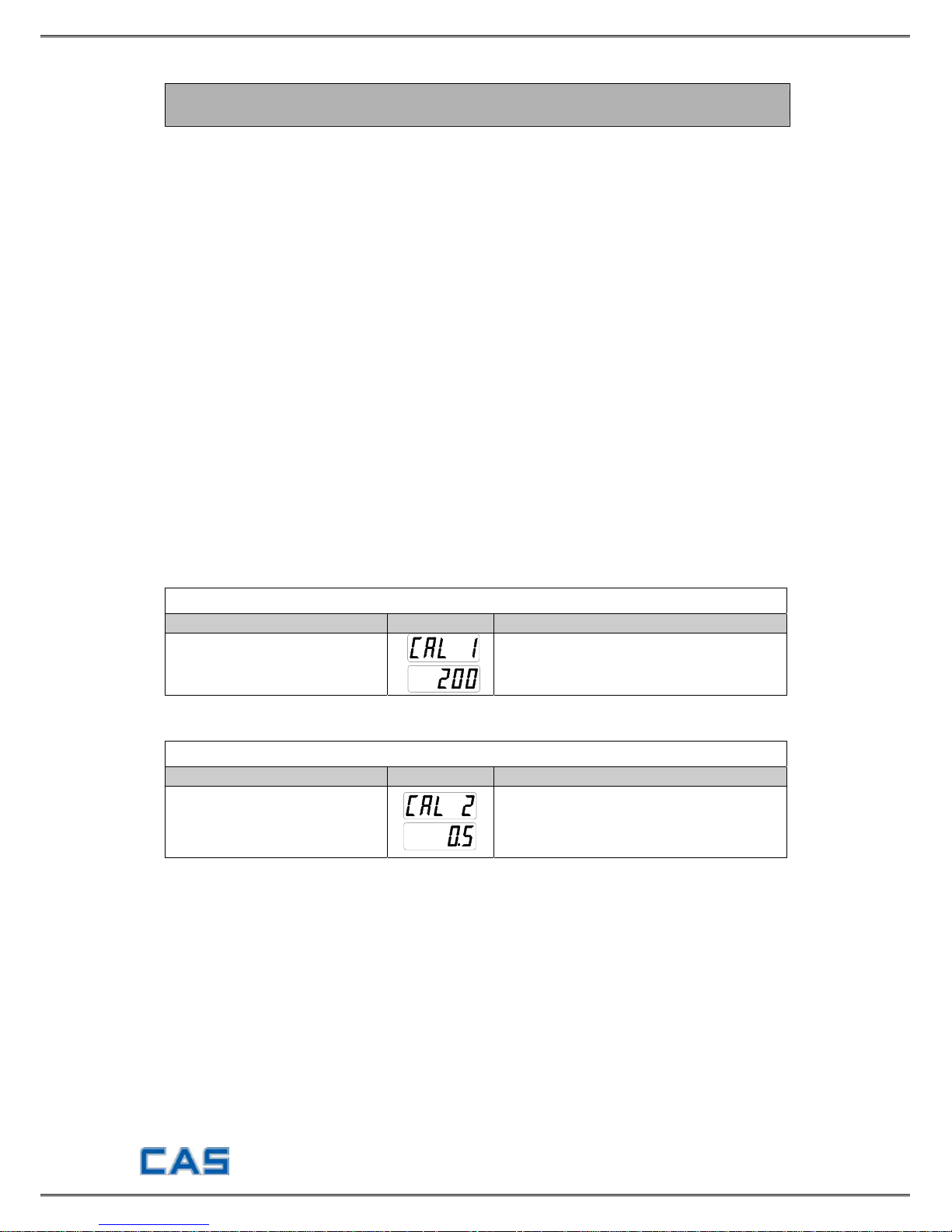

CAL 1

FUNCTION : Maximum Capacity Set (Range : 1 ~ 99,999)

KEY LC DISPLAY

DESCRIPTION

Input by digit input method.

ENTER : save and go to next menu

CAL 1 condition

200 Kg

CAL 2

FUNCTION : Minimum Division Set (Range : 0.001 ~ 50)

KEY LC DISPLAY

DESCRIPTION

NET/GROSS key:

Input the next division

TARE key:

Input the previous division

ENTER key: Move to the next menu

CAL 2 condition

0.5 Kg

▶ Note 1. The minimum division means the value of one division.

▶ Note 2. External resolution is obtained by dividing the min. division by the

maximum capacity. Set the resolution to be within 1/10,000.

▶ Note 3. The maximum capacity/minimum division is over 10,000, error message

“CH 11” will occur.

- 8 -

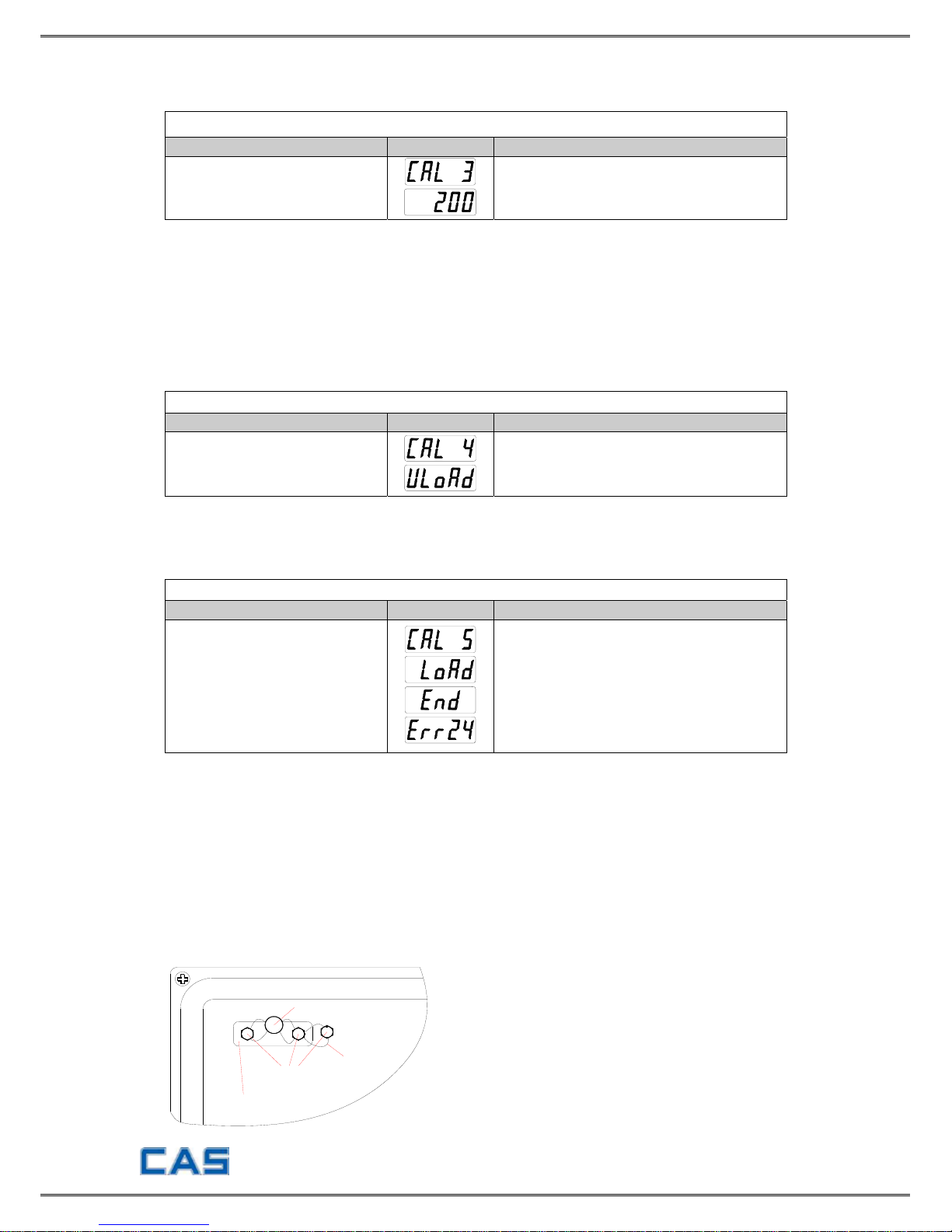

CAL 3

FUNCTION : Setting Weight In Span Calibration

KEY LC DISPLAY

DESCRIPTION

Input by digit input method.

ENTER : save and go to next menu

CAL 3 condition

200 Kg

▶ Note 1. The span weight shall be within 10-100% of maximum capacity.

The initial span weight is 100% of max. capacity but if the current span

weight is different from it, input the desired weig ht again.

▶ Note 2. The span weight shall be above 10% of maximum capacity.

If not so, an error message “ERR22” is shown.

▶ Note 3. Never install the span weight higher than maximum capacity because

an error message “ERR23” is shown.

CAL 4

FUNCTION : Zero Calibration

KEY LC DISPLAY

DESCRIPTION

ENTER key : Move to next menu

after zero calibration

Empty the platform and when LCD screen

shows “ULOAD”, press ‘ENTER’ key.

After completing zero calibration, it will be

automatically moved to CAL 5.

▶ Note 1. Zero calibration is performed automatically by program.

Loadcell output is automatically adjusted within 0.05mV and 5mV.

CAL 5

FUNCTION : Span Calibration

KEY LC DISPLAY

DESCRIPTION

ENTER key : Span calibration

Put the weight set in CAL3 on platform

and press ‘ENTER’ key.

Span calibration is terminated.

Error occurrence.

Move into initial menu automatically.

▶ Note 1. Display “END” message and move into the NORMAL MODE at completion

of span calibration

▶ Note 2. At occurrence of ERR24, reset by lowering the resolution.

Sealing method

Perform the sealing as shown in the below figure after the calibration is completed.

Open the top cover.

Cover CAL switch in the left top of cover with sealin g plate and screw 2 sealing bolt.

Connect the sealing wire as follows and compress the sealing lead.

SEALING WIRE

SEALING PLATE

SEALING BOLT

SEALING SOLDER

Loading...

Loading...