Page 1

TRx3210/TRx3210A

Line Array

Turnkey Systems

Made in USA

User Manual

76-03211A 040214

Page 2

TRx3210/TRx3210A Line Arrays

Table of Contents:

Introduction ............................................................. 3

Unpacking ................................................................3

Concept

.....................................................................3

Specications

- TRx3210 ................................................................. 4

- TRx3210A .............................................................. 5

e Line Array Eect - ...........................................6

Pure Path Horn Lens and MF/LF Drivers

Safety - Stacking and Flying .................................. 7

Ground Stacking ...................................................... 8

SureFly™ Rigging

- Assembling an Array ...................................... 9-12

- T-Bar Hang Points ..............................................13

- Transportation .....................................................14

TRx3210A Wiring & Settings ..............................15

TRx3210 Amplication & Wiring

- Biamp Switch ....................................................... 16

- Pin Flip/Mode Switch ......................................... 17

- H.F. Attenuation Switch

.....................................18

- Processing and tuning ........................................ 19

Amp Rack Packages ..............................................20

Accessories .............................................................21

Warranty

................................................................. 21

System Packages .............................................. 22-23

2

Page 3

Introduction:

Congratulations on purchasing a TRX3000 Series loudspeaker from Carvin Professional Audio Products. e

TRx Series are designed to give you the best in audio quality with many years of reliable, trouble-free operation. e TRx3210/A oers excellent pattern control, easy over-head suspension with safe and practical rigging

hardware, as well as a simple ground stacking design, full technical documentation and the backing of a worldclass company with decades of manufacturing experience, including a comprehensive warranty. Please read

through this user manual carefully before you attempt to operate the loudspeaker system. It contains valuable

information which will enable you to easily and quickly connect the loudspeakers, along with important system set-up, stacking and ying instructions.

Thank You

ere are many options in the market place today for loudspeaker products and we thank you for choosing

Carvin Audio products for your loudspeaker choice.

Carvin Audio products are proudly engineered and manufactured in San Diego, California, USA!

If you would like additional information about this or any other Carvin product, please contact us, or go to

carvinaudio.com (outside USA/Canada: carvinworld.com)

Unpacking

Upon unpacking the unit, please check carefully for damage. If damage has occurred, please notify the delivery

service at once. You, the consignee, must handle any claim. Please retain packaging in case of future re-shipment.

TRx Line Array Concepts

Pulling from our TCS Audio engineering, Carvin has produced a modular line array loudspeaker system that

is very adaptable to a wide rance of perfomance venues. Not every scenario requires a own PA system. So with

that in mind, the TRx3210 Line array loudspeaker can easily be stacked or own.

c

800.854.2235

www.facebook.com/carvinaudio

USA contact: Tony Mirador

Office: 800.403.4484

tonym@carvin.com

12340 World Trade Dr., San Diego, CA 92128 USA

carvinaudio.com (USA) carvinworld.com

International contact: Joel Kiesel

Office: 760.522.5676

export@carvin.com

3

Page 4

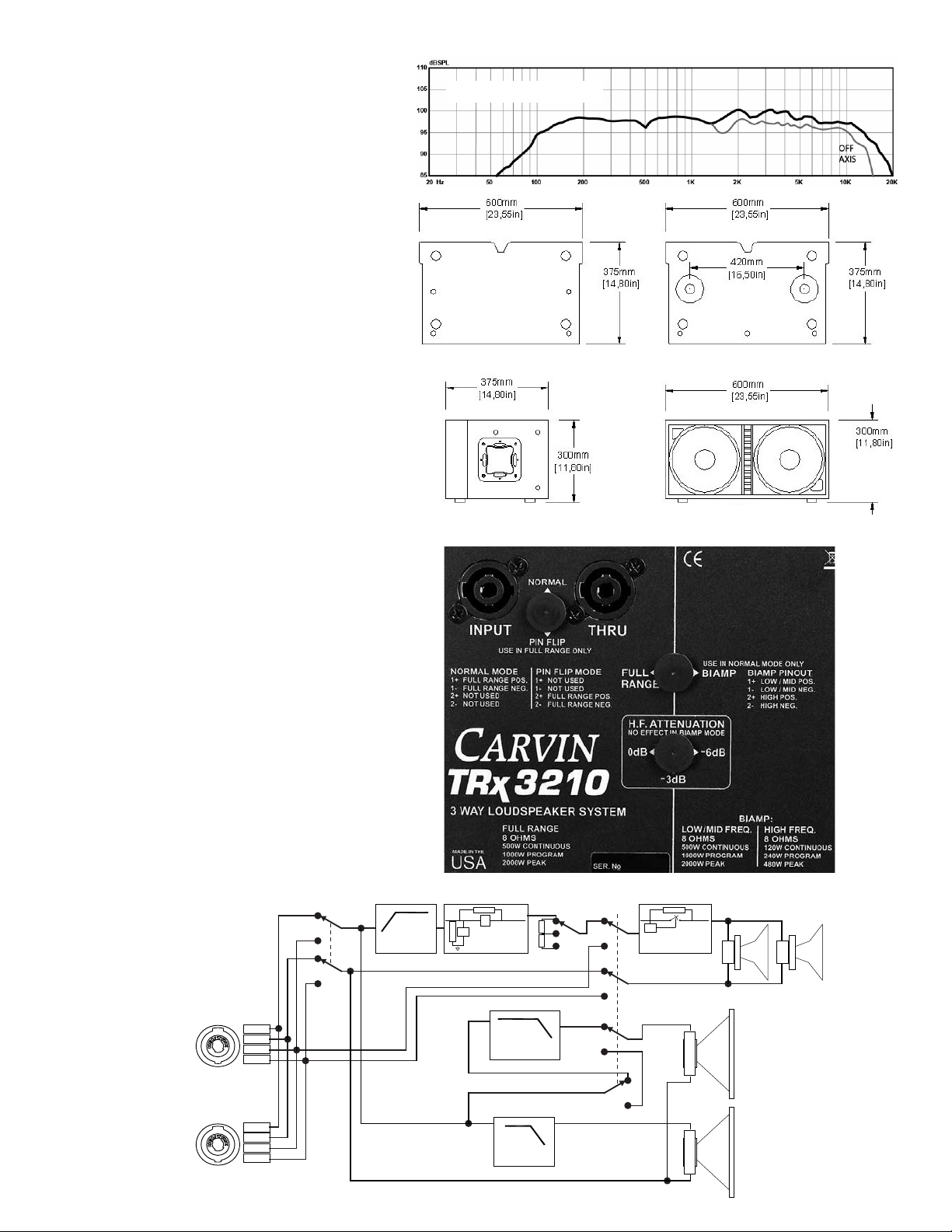

TRx3210 Specifications

TRx3210NF - without SureFly™ hardware

System Type: Dual 10-inch 3-Way, Reflex

Frequency Response: 70 Hz – 18.5 kHz (-10DB)

85 Hz – 16 kHz (-3 dB)

Coverage Pattern: 100˚ H x 10˚ V (single enclosure)

LF Driver: 2x 10-inch 2-inch VC

HF Driver: 2x 1-inch exit 1.75-inch VC

Crossover: 3-Way Quasi

Speaker Guard™ HF protection

Crossover Frequencies: 500Hz & 1.5 k Hz

Sensitivity (1w @ 1m): 98dB

Maximum SPL: 131dB Peak single enclosure

137dB Peak four enclosures

140dB Peak eight enclosures

LF Driver: 2x 10-inch 2-inch VC

HF Driver: 2x 1-inch exit 1.75-inch VC

Nominal Impedances (Continuous/Program/Peak)

Full range: 8 ohms 500w /1000w /2000w

Bi-amp LF: 8 ohms 500w /1000w /2000w

Bi-amp HF: 8 ohms 120w /240w /480w

Enclosure: 13-Ply Russian Baltic Birch

Suspension/Mounting: 14 captive 3/8in-16 nut fly pts.

SureFlyTRx™ rigging

Two 1-3/8” pole cups, 16.5” spaced

Finish: Black DuraTec™

UV, water resistant IP2

Transport: 2 Recessed Handles

Grill: Black powder coated steel

Acoustically Transparent Foam Backing

Connectors: T w o 4-pin TwistLoc connectors

Dimensions (H x W x D): 11.8 in x 23.5 in x 14.8 in

300 mm x 600 mm x 376 mm

TRx3210 Net Wt: 60 lb (27 kg) with Flyware

TRx3210NF Net Wt: 52 lb (24 kg) No Flyware

Rigging Accessories:

SureFlyTRx™ rigging kit 6.9 lb (3.1 kg)

SureFlyTBar™ T-bar 19 lb (8.6 kg)

TCSHK58 5/8” Shackle 1.3 lb (0.5 kg)

Maximum Fly Capacity: 16

Frequency Response: One enclosure. Off Axis @ 55deg. horiz.

EASE™ data available

TRx3210

BLOCK DIAGRAM

HF-ATTN BIAMP

HIGH

PIN

FLIP

1+

1-

2+

2-

PASS

EQ AND

MATCHING

MID/LOW

PASS

SPEAKER

GUARD

+

HF DRIVERS

+

-

+

-

MID / LOW

DRIVER

-

1+

1-

2+

2-

4

LOW

PASS

+

LOW

DRIVER

-

Page 5

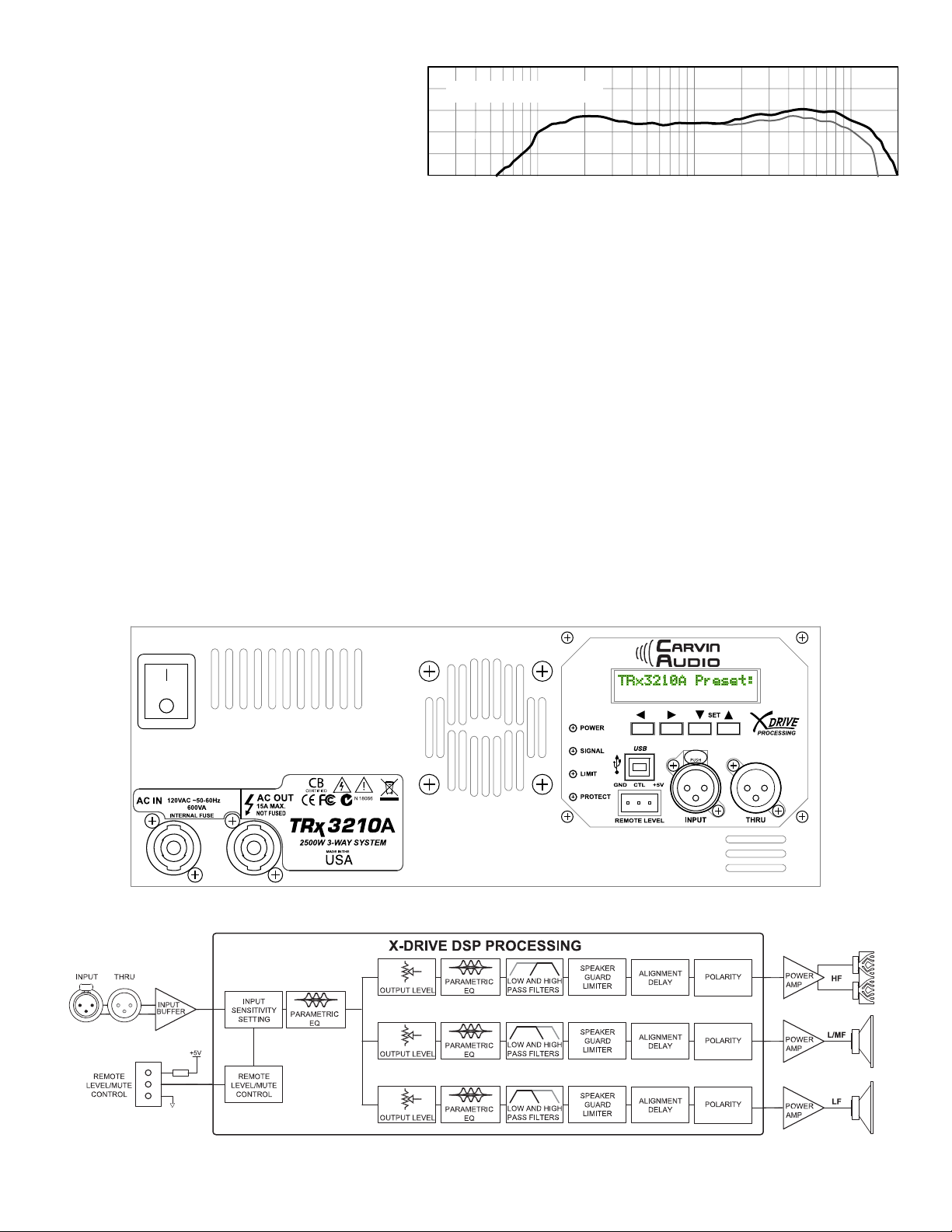

TRx3210A Specifications

20 Hz 50 100 200 500 1K 2K 5K 10K 20K

TRx3210NFA - without SureFly™ hardware

System Type: Active 2500W Tri-Amp, X-Drive™ processed

Dual 10-inch 3-Way, Reflex

Frequency Response: 70 Hz – 18.5 kHz (-10dB)

85 Hz – 16 kHz (-3dB)

Coverage Pattern: 100H x 10V (single enclosure)

Crossover: Activ e DSP Tri-amp

Crossover Frequency: 1.2 kHz (750Hz LP one 10-inch)

Power: 3500W two cycle pulse peak

2500W 20ms burst (1000W, 1000W, 500W)

LF Driver: 2x 10-inch 2-inch VC

HF Driver: 2x 1-inch exit 1.75-inch VC

Input Sensitivity: 1.0, 1.2, 1.4, or 2.0 Vrms settings

Maximum Input signal: +12dBu

Maximum SPL: 131dB Peak single enclosure

Connectors: Signal In/Thru: XLR female/XLR male

Remote Level/Mute: Terminal block

AC IN/OUT: Locking Neutrik™ PowerCon™

AC Power Requirement: 600VA

TRx3210A: 120VAC 50/60Hz 15A

TRx3210A-E: 230VAC 50/60Hz 10A

Frequency Response: One enclosure. Off Axis @ 55deg. horiz.

dBSPL

110

105

EASE™ data available

100

95

90

85

Enclosure: 13-Ply Russian Baltic Birch

Suspension/Mounting: 14 captive 3/8in-16 nut fly pts.

SureFlyTRx™ rigging

Two 1-3/8” pole cups, 16.5” spaced

Finish: Black Duratec™

UV, water resistant IP2

Transport: 2 Recessed Handles

Grill: Black powder coated steel

Acoustically Transparent Foam Backing

Dimensions (H x W x D): 11.8 in x 23.5 in x 14.8 in

300 mm x 600 mm x 376 mm

TRx3210A Net Wt: 60 lb (27 kg) with Flyware

TRx3210NFA Net Wt: 52 lb (24 kg) No Flyware

Rigging Accessories:

SureFlyTRx™ rigging kit 6.9 lb (3.1 kg)

SureFlyTBar™ T-bar 19 lb (8.6 kg)

TCSHK58 5/8” Shackle 1.3 lb (0.5 kg)

Maximum Fly Capacity: 16

OFF

AXIS

TRx3210A REAR PANEL

TRx3210A BLOCK DIAGRAM

5

Page 6

The Line Array Effect

The line-array effect is achiev ed by the 0 degree coupling of the

enclosures in the array. The inherent advantage of a line array

design allows the rear audience to hea r n e a r l y t he s a m e l ev e l s a s

the front. The PurePath™ horn produces a tight 10 degree vertical

x 100 degree horizontal pattern on a single cabinet. Conventional

enclosures drop 6dB when doubling the distance to the listener.

Howev er , when coupled in a line array this pattern narrows further

to produce the line array effect, which drops only 3dB when doubling the distance to the listener.

When the straight line of the line array is broken as in the case of

a “J” curve, the elements curved at the bottom of the array behave

more as a “point source” loudspeaker producing normal output to

the closer listeners.

The TRx3210 can be deployed in a full curvilinear array with 10

degrees of angle between elements. This produces a smooth “point

source” array covering 40 degrees of vertical and 100 degrees of

horizontal coverage with only four enclosures.

Line Array with

J curve

Linear Curve

Array

The PurePath™ Horn Lens and dual 10” Drivers

e PurePath™ Horn Lens is CNC machined in-house from acoustically non-resonant Eastern Maple hardwood,

providing a very smooth, equal path length wave guide for pure, natural and cylindrically projected highs. e two

HF Mylar compression drivers feature a 1-inch exit and a 1.75” voice coil. e PurePath™ Horn Lens places the HF

drivers in proper phase alignment with the 10-inch drivers.

PurePath Horn Lens

dual 10” 1000W peak drivers

IP2 UV & Water Resistant

Two 10-inch MF/LF drivers feature 2-inch voice coils and power handling of 1000W peak per driver. ey

are treated for IP2 UV approval, which is also water resistant. ese drivers are front loaded and eld replaceable. e front steel grills are foam backed for added protection from the elements, and are easily removed for

service access.

6

Page 7

Stacking and Flying

Overview

To take full advantage of the extremely exible features of the TRx3210 system, two modes of rigging systems have been developed. e

rst mode utilizes the interlocking feet and pole mounts and the second mode uses the SureFly™ hardware. e two rigging systems allow

either line arrays or virtual point source clusters to be assembled – intuitively, quickly and easily, and with an absolute minimum of additional external parts to suit the coverage requirements of a variety of professional sound reinforcement situations.

e second mode using the SureFly™ hardware is inherently safe, exible, self-contained and simple to use. e load is taken entirely

through the SureFly™ hardware and not through the cabinet’s woodwork. e rigging design allows the creation of clusters and arrays that

can be assembled quickly and with a minimum crew.

Safety Notes on Rigging - Important Please Read!

e Carvin SureFly™ rigging system has been designed and constructed to a high standard of safety and tested in the most demanding

conditions. As a rst concern to ensure the highest safety standards, the information following on the assembly and safe use of rigging

accessories must be carefully understood and followed. Every user that operates, suspends or lis a TRx3210 loudspeaker system needs

to be properly trained before ever constructing and deploying the system in a working situation.

Only use Carvin recommended rigging accessories, which are specically designed for their intended purpose. Do not use Carvin SureFly™ rigging with other types or brands of loudspeakers. is practice may compromise safety standards and Carvin will not be responsible for damage or injury as a result.

Do not modify the rigging accessories or use them in any other way than described in this user manual. Rigging components supplied

as part of a complete assembly are non-interchangeable and must not be exchanged with the component parts of any other assembly.

e component parts of the Carvin SureFly™ rigging accessory must only be assembled using the fasteners and methods of assembly

recommended in this manual. e use of fasteners and methods of assembly not specied or approved by Carvin may result in an unsafe

rigging assembly. Welding, or any other means of permanently xing rigging components to each other or to cabinet xing points should

never be done.

Rigging assemblies must only be assembled using the appropriate parts and xings as specied in this manual using the specic mounting instructions. Rigging components or assemblies must only be xed to Carvin loudspeaker cabinets using the cabinet xing points.

Walls, oors or ceilings must be capable of load bearing capacity. When mounting rigging components on walls, oors or ceilings, ensure

that all xings and fasteners used are of an appropriate size and load rating. Wall and ceiling claddings and the construction and composition of walls and ceilings all need to be taken into account when determining whether a particular xing arrangement can be safely

employed for a particular load. Cavity plugs or other specialist xings, if required, must be of an appropriate type and must be tted and

used in accordance with the makers instructions. Use only the rigging accessory xing holes indicated in this manual and the specic

mounting instructions to x Carvin SureFly™ rigging accessories to walls, oors or ceilings.

Where specied, the recommended maximum torque settings for screw fasteners must be strictly complied with.

Secondary Safeties

Best practice dictates in addition to the principle load bearing means of suspension, that all loudspeakers own in theaters, studios or

other places of work and entertainment should (and where local laws apply) be provided with an independent, properly rated and securely attached secondary means of safety. Only steel wire ropes or steel chains of an approved construction and load rating may be used as

secondary safeties. Plastic covered steel wire ropes are not permitted for use as secondary safeties.

Safety Inspections

Carefully inspect rigging components and cabinets for defects or signs of damage before proceeding to assemble a own array. If any

parts are damaged or suspect, DO NOT USE.

Safety legislation and test and inspection requirements will vary from country to country. In most cases, annual independent test and

inspection by a suitably approved and qualied inspector will be required. Carvin recommends regular safety inspections and further

recommends keeping a logbook detailing the test and inspection history of each Carvin rigging component. Always wear protective

headwear, footwear and eye protection in accordance with local regulations. Anyone involved in ying ANY sound system, especially in

a touring capacity, should take note of the following advice:

“e rigging of a own sound system may be dangerous unless undertaken by qualied personnel with the required

experience and certication to perform the necessary tasks. For ground suspension verify that the Genie™ li or similar

li is level in both directions, or the array will not hang properly. Fixing of hanging points in a roof should always be

carried out by a professional rigging specialist and in accordance with the local rules of the venue. e house rigger and/

or building manager must always be consulted.”

7

Page 8

Stacking Array without SureFly™ Hardware

Each TRx3210NF features durable feet and align to interlock without the need for yware. is is ideal for

stacking on top of a ground-stacked subwoofer or elevated using two SS4 poles.

Stacking with SureFly™ hardware

e SureFly™ hardware can also be utilized for

ground stacking. e SureFly™ T-bar can be used as

a base for a ground stacked array.

8

TRx3210

TRx3210

e TRx3118 is an 18”

subwoofer featuring 3

top pole mounts and

SureFly™ hardware.

TRx3118

Page 9

Assembling an Array

Assembly and deployment of TRx3210 arrays are carried out one array module at a time or in pre assembled

groups of array modules. With the SureFly™ hardware kit installed on each enclosure, attach the T-bar to the top

array enclosure. Each subsequent enclosure can be pinned at dierent angles to accomplish wide vertical coverage

angles and focus sound energy where needed.

Tighten bolts to 20 ft lbs

Step 1 (skip with TRX3210 Flyware Model)

Installing the SureFlyTRx rigging kit on TRx3210NF.

Each TRx3210NF will require one SureFlyTRx rigging kit. e kit

includes all mounting hardware and quick release pins. Drilling into

the TRx3210NF enclosure is not required. All mounting points on

the TRx3210NF enclosure have threaded inserts.

Set all quick release pins aside. As shown in the diagrams, assemble

the side panels of the SureFlyTRx kit using the included bolts and

washers. Insert the adjustment plate in-between the two mounting

plates. e lower bolt will function as a hinge. Hand tighten the bolts

and insert the quick release pins as shown. Once the side plates are

aligned by installing the Quick Release Pins into the positions shown,

use a torque wrench to tighten the bolts to 20. lbs. Repeat this proceedure on the other side of the enclosure. Aer the SureFlyTRx

hardware has been installed on all enclosures, they may be stacked

4 high by making sure both side adjustment plates slide in-between

the mounting plates of the enclosure below. Store pins in the handle

area aer installation.

Step 2

Installing the T-Bar

Attach assembled T-Bar to the top array enclosure. At

the same time lower side plates of the T-Bar evenly into the SureFly hardware. Attach the T-Bar side

plates using the bolts, washers and nuts supplied.

Using a torque wrench, tighten the bolts to 50 lbs.

e T-bar side plates must insert between the two

plates of the array module hardware. Align holes and

secure with the included four (2 per side) quick release pins into both (A) and (B) holes.

T-Bar Side Plate

Tighten bolts to 50 ft lbs

Washer

2.

1.

1.

2.

2.

1.

T-Bar

Mounting

Plate

Adjustment

Plate

Quick

Release Pins

Side Plate

1.

1.

2.

9

Page 10

Step 3

Attach to motor hoist

Straight Vertical Hang

Installing the Shackle

Attach rated 5/8” shackle to lug #4. Note:

this position sets a basic starting point for a

straight vertical hang.

straight vertical hang

Lug #4

1 2 3

Shackle

Finger tighten

shackle only.

Do not use a

5/8” Shackle

# TCSHK58

tool to tighten

TRx3118 subwoofer

When suspending the TRx3118 with SureFly™ hardware, place the subwoofer at the top of the array.

en attach the TRx3210 boxes below.

Step 4

Adding additional enclosures

Attach a rated chain motor or hoist hook to the

shackle. Using the chain motor or hoist, li assembly up to clear another array module. Place

an array module underneath the rst array

module assembly and lower suspended array

module. As you are lowering, align so feet mate

with foot receptacles on top of lower array module. Side adjustment plates must insert between

the two plates of the array module hardware.

See Step 5 for adjustment plate.

GROUND

TRx3118

TRx3210

TRx3210

Attach to motor hoist

Quick Release Pin

Press the button on the top of the pin with thumb to

insert and remove pin.

10

GROUND

Page 11

Pin Storage

Attach to motor hoist

GROUND

Attach to motor hoist

GROUND

Attach to motor hoist

e quick-release pins

can be stored in the

handles on the inside

of the SureFly hardware

plates on each side of

the array module. is

keeps them from being

misplaced or damaged

during transport and

holds the inner adjustment plate from swinging down.

Step 5

Remove the lower quick-release pin from the handle storage location to release the adjustment plate.

Allow the adjustment plate to swing down between

the two side plates on the lower enclosure. Adjust

enclosures to allow adjustment plate to capture the

lower enclosure with hook on adjustment plate.

n

w

o

d

s

g

n

i

w

s

e

t

a

l

p

t

n

e

m

t

s

u

j

d

A

When the adjustment plate is fully in place, the “A”

location pin can be inserted. Repeat on opposite

side of array enclosure.

close up view

Step 6

Push the second quick-release pin into forward

hole labeled (A 0˚) on the upper enclosure. Repeat

on opposite side of array enclosure. This 0 degree

position is used for a straight Line-Array. This is

also storage and transport position when using the

DB3210 dolly board.

Adjustment plate

hook captures

lower enclosure

11

Page 12

Step 6 continued

If you require a J curve at the bottom of a long array or a curve array, adjust the pins on the lower enclosures to

create the desired curve. There are 6 different angles that can be achieved between each enclosure by changing

both pin positions. With the lower enclosure in the “A” position, the upper enclosure’s pin positions/angles are:

0, 2.5 and 5 degrees. When adjusting angle pin, lower the front of the bottom cabinet to the desired angle.

0 degree Pin position

2.5 degree Pin position

5 degree Pin position

With the lower cabinet in the “B” position the upper enclosure’s angle pin positions/angles are: 7.5 and10 degrees. Caution when adjusting pin “A” or “B”. Support the weight of the lower enclosure. Do not adjust pin “ A”

or “B” with additional enclosures attached below. This pin locks the adjustment plate to the lower enclosure.

7.5 degree Pin position 10 degree Pin position

12

Page 13

T-Bar Hang Points

8˚

12˚

16˚

20˚

8˚

1-POINT

HANG

(4 CABS)

0˚

23˚

26˚

29˚

To change the angle of the array, attach the shackle to the dierent lug holes as shown in the below diagram. e

further back from center, a larger degree of forward tilt is achieved.

By using two hang points and two chain motor hoists, the angle of the array can be changed by raising or lowering the front or back of the array by adjusting the chain motors. is requires the use of a second shackle as

shown in the diagram below.

For ground suspension verify that the Genie™ li or similar is level in both directions, or the array will not hang

properly.

To chain

8˚

8˚

1-POINT

HANG

(4 CABS)

motor hoist

0˚

12˚

16˚

20˚

23˚

26˚

29˚

motor hoist

To chain

2-POINT

To chain

motor hoist

HANG

13

Page 14

DB3210 Transport Dolly Board (optional)

e optional Baltic Birch/Duratec™ DB3210 transport Dolly Board allows a block of up to four TRx3210 speaker

cabinets to be conveniently transported in a pre-rigged conguration and is recommended as the most ecient

way to truck and handle the cabinets. e transport dolly board is wide enough to allow the lock pins to be inserted in the SureFly™ hardware while on the dolly board, which makes it possible to li the block of four cabinets

together while still being dimensioned to t up to ve-across for a standard truck pack.

strap slots

14

Page 15

TRx3210A Active Module and Settings

L

The active TRx3210A triamp module is driven by X-Drive™ DSP processing with optimized presets for arrays and ground stacks.

Crossover filters, Parametric EQ, Alignment Delay and Amp Limiters are factory tuned to maximize performance output.

POWER SWITCH

Push the upper portion of the power switch to turn the system on. If the

blue POWER indicator is on but there is no sound check the Protect LED.

POWER LED

The POWER LED indicates the unit is turned on and functioning properly.

SIGNAL LED

The SIGNAL LED indicates there is a signal present at the INPUT XLR.

LIMIT LED

The LIMIT LED indicates maximum output of the system is being

reached. A flashing LIMIT LED is acceptable. The DSP will reduce peaks

to prevent amp clipping. If the LIMIT LED is continuously ON, reduce

the level going in to the INPUT XLR. As with any system, reduce the

volume if distortion is heard.

PROTECT LED

The PROTECT LED indicates one of the protection circuits has activated.

To reset the amp, turn the power off for about 10 seconds, then turn it

back ON. If the PROTECT LED stays lit for more than 5 seconds, check

for a blocked fan intake.

DIGITAL DISPLAY

The bright green LED DIGITAL DISPLAY will display various information

about the system and its settings. When you first turn on the unit, the

display will indicate which preset is loaded.

SETTING BUTTONS: UP/DOWN (SET) & LEFT/RIGHT

Use the UP and DOWN (SET) buttons to load presets for different

speaker configurations, based on the number of TRx3210A and the

array angle set by the SureFly™TRx quick release pins.

1-4 boxes 0-2.5 deg (straight)

1-4 boxes 5-7.5 deg

1-4 boxes 10 deg

5-8 boxes 0-2.5 deg (straight)

9-12 boxes 0-2.5 deg (straight)

13-16 boxes 0-2.5 deg (straight)

Use the LEFT/RIGHT buttons to access the Input Sensitivity setting and

set with the UP/DOWN for 1.0 Vrms, 1.2Vrms, 1.4Vrms or 2.0 Vrms.

The factory setting is 1.4Vrms. Increase the setting to lower the output.

USB PORT

The USB port is for updating system firmware such as additional presets.

REMOTE LEVEL (MUTE) CONNECTOR

This is a terminal block connector with 5 volt control of volume, typically

used in permanent installations. Short the CTL and GND pins to MUTE.

INPUT/THRU XLR CONNECTORS

Connect the INPUT XLR to a signal source such as the output of a mixer.

The THRU XLR can be connected to more TRx3210A’s or other units.

FAN INTAKE/EXHAUST VENTS

The TRx3210A features a variable speed fan, which runs silent at low

speeds. Make sure the fan intake and exhaust vents are free from

blockage at all times.

AC IN JACK (BLUE PowerCon™ A-type)

The AC IN connector accepts the blue Neutrik™ PowerCon™ “A-type”

connector (part# NAC3FCA). One NAC3FCA connector is supplied,

attached to a short length of 3-conductor wire. You can use a longer

wire if it is properly rated for the application. Attach a proper 3-prong

connector for your voltage type to the other end of the wire, with

careful attention to follow the correct pinouts and safety standards.

No attempt should ever be made to use the unit without the ground

connected. Plug into the proper voltage for your unit.

Alternately, you can attach the grey Neutrik™ PowerCon™ “B-type”

connector (part# NAC3FCB) for an A-B jumper cable between two

TRx3210’s. Pay careful attention

to follow the correct pinouts and

safety standards. With the connector attached, plug into the AC

OUT jack of another TRx3210A, or

into a PowerCon™ “B-type” outlet

with the proper voltage.

AC OUT JACK (GREY PowerCon™ B-type)

The AC OUT connector accepts the grey Neutrik™ PowerCon™

“B-type” connector (part# NAC3FCB), and is used to power other

units.

Use the VA rating on other devices to determine how many can be

connected to the AC OUT. The maximum limit on the AC OUT connector is 15A. Other limiting factors include the breaker rating for the AC

line you are plugging into, wire type and (if used) generator capacity.

FUSE

The FUSE is located internally near the AC input. To check or replace,

first remove the power cord and then remove the amp module from

the speaker enclosure then remove the front panel to access the fuse.

The fuse type is a 250V Slow Blow rated at 10A.

PowerCon™ wiring

N

15

Page 16

TRx3210 Bi-Amp Configuration (Passive Systems)

AB

TRx3210 enclosures can be congured either in full range/passive mode or bi-amped 3-way mode. ey ship

from the factory as standard in full range/passive mode with the H.F. Attenuation switch set to 0. Changing the

TRx3210 from Full Range to Bi-Amp is as simple as ipping a concealed switch on the connection panel.

AMP SET FOR BIAMP MODE

THRU INPUT INPUT THRU

Bi Amp Operation:

Remove rubber plug marked FULL RANGE/

BIAMP from connection panel. Using a small athead screw driver, carefully insert screwdriver into

opening and slide switch to the right for Bi-Amp

operation.

Note: Mode switch must always be in the UP

(normal) position for Bi-Amp operation and H.F.

Attenuation switch must be in the 0 position.

Replace rubber plug aer change.

DCM3800Lx

NORMAL, BIAMP

NORM

INPUT

OUTPUT

BRIDGE

1

All four pins are used:

(1+, 1-) LOW

(2+, 2-) HIGH

BIAMP

ONLY

2

NORMAL, BIAMP

NORM

BIAMP

CONNECT UP TO

2 MORE TRx3210’s

16

Page 17

TRx3210 Pin Flip Switch (Full Range Operation)

Carvin TRx3210 loudspeakers come with a speaker pin ip switch. In full range/passive mode, this switch

allows the user to select operation from either pins 1+ & 1- (standard) or pins 2+ & 2-. is can signicantly

simplify speaker cable runs by half with 4-pin TwistLoc cables. Below is an example of how the pin ip switch

is used.

Remove rubber plug marked NORMAL/ PIN FLIP from connection panel. Using a small at-head screw

driver, carefully insert screwdriver into opening and slide switch to the down position for Pin Flip operation.

is will enable use of pin 2+ & 2- to drive this speaker module. Note: pins 1+ & 1- will be no longer used in

this cabinet. Replace rubber plug aer change.

When using the PIN FLIP feature, you must switch to

FULL RANGE mode.

Four TRx3210 Full-Range Passive Hook-up: 2 cabs in Pin Flip Mode, 2 cabs in Normal pin Mode

USE PARALLEL INPUTS (ARRAYS), or STEREO (LEFT/RIGHT)

THRU INPUT INPUT THRU

AB

DCM3800Lx

All four pins are used:

(1+,1-) amp OUTPUT 1

(2+,2-) amp OUTPUT 2

AMP CH.1: PINS 1+, 1-

(NORMAL, FULL RANGE)

AMP CH.1: PINS 1+, 1-

(NORMAL, FULL RANGE)

INPUT

OUTPUT

BRIDGE

1 2

ONLY

AMP CH.2: PINS 2+, 2-

(PIN FLIP, FULLRANGE)

AMP CH.2: PINS 2+, 2-

(PIN FLIP, FULLRANGE)

17

Page 18

TRx3210 High Frequency Attenuation Switch

Each Carvin TRx3210 Line Array loudspeaker contains a

high-frequency section that is designed for extremely high

sound pressure level (SPL). When the TRx3210 is used in

large multi-box arrays, the mid and low frequency speakers

mutually couple and produce higher SPL’s. e more speakers used, the more output and coverage is accomplished. In

smaller congurations of less than four units, it is recommended that the high frequency section of each box be lower

in output volume (attenuation). Depending on the amount

of boxes used, room acoustics, and application, dierent levels of attenuation will be needed to match the volume of the

mid/low frequency drivers.

Another use of the attenuation switch is to control shading

in multiple-box arrays. In larger congurations, it may be

specied to have the upper boxes produce full output of the

HF frequencies to project longer distances to the rear of the

venue, while the lower boxes are attenuated for the near-eld

listeners.

e HF Attenuation switch has three user selectable positions 0dB, -3dB, and -6dB. Since every room is dierent, the

level of attenuation should be selected accordingly.

Note: is switch is only functional in FULL RANGE passive

mode. is switch has no eect in BIAMP mode.

Remove rubber plug marked H.F. ATTENUATION from

the connection panel. Using a small at-head screw driver,

carefully insert screwdriver into opening and slide switch

to the desired attenuation setting. Replace rubber plug aer

change.

18

Page 19

TRx3210 Passive Full Range w/Sub TRx3210 Bi-Amp w/Sub

Main SUB High Low-Mid SUB

Output Gain -3 dB 0.0 dB Output Gain -15 dB 0.0 dB 0.0 dB

Output Limit 00 Output Limit 000

Output Dela

y

0.0 mS 0.0 mS Output Dela

y

84 uS 0.0 mS 0.0 mS

Polarit

y

IN IN Polarit

y

OUT IN IN

LPF 20 kHz 80 Hz LPF 20 kHz 1.5 kHz 80 Hz

Q OFF Linkwz 24 Q OFF Butter 48 Linkwz 24

HPF 80 Hz 31.5 Hz HPF 1.5 kHz 80 Hz 31.5 Hz

Q Linkwz 24 Butter 12 Q Butter 48 Linkwz 24 Butter 12

PEQ1 GAIN 6 dB PEQ1 GAIN 6 dB -12 dB

PEQ1 FREQ 630 Hz PEQ1 FREQ 2 kHz 315 Hz

PEQ1 BW 0.16 PEQ1 BW 1 0.3

PEQ2 GAIN -9 dB PEQ2 GAIN 12 dB 9 dB

PEQ2 FREQ 2.7 kHz PEQ2 FREQ 12 kHz 400Hz

PEQ2 BW 0.12 PEQ2 BW 3 0.12

TRx3210 passive 4 unit curve array

TRx3210 Bi-Amp 4+ Arrays: Straight, lower 4 J-curve (J), and Sub

Main SUB High Low-Mid

High (J) Low-Mid (J)

SUB

Output Gain -3 dB 0.0 dB Output Gain -9 dB 0.0 dB -15 dB 0.0 dB 0.0 dB

Output Limit 00 Output Limit -3dB 0 -3dB 0 0

Output Dela

y

0.0 mS 0.0 mS Output Dela

y

84 uS 0.0 mS 84 uS 0.0 mS 0.0 mS

Polarit

y

IN IN Polarit

y

OUT IN OUT IN IN

LPF 20 kHz 80 Hz LPF 20 kHz 1.5 kHz 20 kHz 1.5 kHz 80 Hz

Q OFF Linkwz 24 Q OFF Butter 48 OFF Butter 48 Linkwz 24

HPF 80 Hz 32 Hz HPF 1.5 kHz 80 Hz 1.5 kHz 80 Hz 32 Hz

Q Linkwz 24 Butter 12 Q Butter 48 Linkwz 24 Butter 48 Linkwz 24 Butter 12

PEQ1 GAIN 6 dB PEQ1 GAIN -6 dB -12 dB -6 dB -12 dB

PEQ1 FREQ 630 Hz PEQ1 FREQ 2 kHz 315 Hz 2 kHz 315 Hz

PEQ1 BW 0.16 PEQ1 BW 1 0.3 1 0.3

PEQ2 GAIN -9 dB PEQ2 GAIN 12 dB 9 dB 12 dB 9 dB

PEQ2 FREQ 2.7 kHz PEQ2 FREQ 12 kHz 400Hz 12 kHz 400Hz

PEQ2 BW 0.12 PEQ2 BW 3 0.12 3 0.12

Audio Processing (Passive Systems)

Processor Settings for DCMLx, XD360 or other speaker management systems

For optimum performance, a loudspeaker management processor is recommended. Carvin oers the DCMLx

power amps which include on-board X-Drive™ processing, as well as the XD360 X-Drive™ outboard processor to

manage ampliers without on-board processing. Carvin’s DCMLx power amps and XD360 will have TRx3210

crossover settings as a preset. e following charts provide a variety of settings that cover both full-range and

bi-amping.

e settings below apply to all speaker management systems.

19

Page 20

Turnkey Factory Assembled Amp Racks

SUB Amp Rack (15,200 Watts)

Main Amp Rack (6,600 Watts)

ARX AMP RACKS

DCM-LX DSP AMPS (No XD360 required)

ARX-S

(4)DCM3800LX (bridged)

(1)IP340

(1)USB-HUB

(4)USB-CBL

(4)C3XLR

(1)4U Vented Panel

(1) AR1 Amp Rack

(1) ASSM-AR

(1)AC3PH120*

* Delete Option Available

ARX-MAIN

(1)DCM2004LX

(2)DCM3800LX

(1)IP340

(1)USB-HUB

(3)USB-CBL

(4)C3XLR

(1)2U Panel

(1)4U Vented Panel

(1) AR1 Amp Rack

(1) ASSM-AR

(1)AC3PH120*

ARx AMP RACKS

DCM-Lx DSP Amps

Configured for minimum of 4 ohm operation per amplifier channel

IP840

Interconnect Panel

ARx4 Amp Rack

(4) DCM3800Lx (15,200w)

(1) IP840 Connect Panel

(1) USB6HUB

(4) C2U USB 2ft cable

(6) C1XLR 8” cable

(2) C3XLR 3ft cable

(1) 4UVP Vented Panel 4U

(1) 2UP Blank Panel 2U

(1) SR8 8U Shock Rack Case

(1) AR-ASSM Assembled/Tested

RearFront

Option: AC3PH120 AC Panel

3 phase 208v distributor. Amps

prewired when ordered with rack

ARx2 Amp Rack (not shown)

(2) DCM3800Lx (7,200w)

(1) IP840 Connect Panel

(1) USB6HUB

(2) C2U USB 2ft cable

(2) C1XLR 8” cable

(2) C3XLR 3ft cable

(1) 4UVP Vented Panel 4U

(1) 2UP Blank Panel 2U

(1) SR8 8U Shock Rack Case

(1) AR-ASSM Assembled/Tested

• IP840 2U Interconnect XLR inputs and TwistLoc outputs • Fast multi-pin for easy connections to rack gear

• Built-in rear TwistLoc cables connect to power amps • Front USB to computer, rear to USB hub

AC3PH120

• AC3PH120 2U AC power panel for 100-130VAC 50-60Hz • Saftey approvals ETL listed to UL standards.

• 3 phase 120VAC/208VAC • Each phase (leg) supports one 20 amp breaker (3rd & 4th breaker on leg 3)

20

3 Phase Power Splitter

Page 21

Components

TRx3210A Active 2500w dual 10” Line Array with SureFly™ hardware.

TRx3210NFA Active 2500w dual 10” Line Array without SureFly™ hardware

TRx3210 Dual 10” Line Array with SureFly™ hardware.

TRx3210NF Dual 10” Line Array without SureFly™ hardware

TRx3018A Active 2500w 18” subwoofer, non-flyable

TRx3118A Active 2500w 18” subwoofer with SureFly™ hardware

TRx3118NFA Active 2500w 18” subwoofer without SureFly™ hardware

TRx3118 4000w 18” subwoofer with SureFly™ hardware

TRx3118NF 4000w 18” subwoofer without SureFly™ hardware

TRx2218B 1600w dual 18” subwoofer

TRx3218 2000w dual 18” subwoofer

SUREFLYTBAR Optional T-Bar suspension kit. One required per array. Hang up to 16 array modules. Includes 4 Quick Release Pins

SUREFLYTRx Optional upgrade kit to fly TRx3210NFA or TRx3210NF

SF3118 Optional upgrade kit to fly TRx3118NF

Accessories

SureFlyPin Extra Quick Release Pins

TCSHK58 Rated 5/8” Anchor Pin Shackle

IP840 XLR/TwistLoc 2U interconnect panel with 37-pin DT12 interconnects and TwistLoc cables

AC3PH120 120V, 3-phase AC distribution panel

NAC3FCA PowerCon™ power IN cable (120VAC, US version) for TRx3210A or TRx3118A

NAC3FCB PowerCon™ power OUT jumper cable for TRx3210A or TRx3118A

DB3210 Baltic Birch/Duratec™ transport dolly for up to four TRx3210 array modules

DB3118 Baltic Birch/Duratec™ transport dolly with locking latches for TRx3118 subwoofers

CTS44 4” Swivel Caster for subwoofer - set of 4

C2U 2 ft. USB cable

C1XLR 8” XLR cable

C3XLR 3 ft. XLR cable

PRO1TL 18” NL4 Speaker jumper cable 12 gauge

PRO25TL 25 ft NL4 Speaker Cable 12 Gauge

PRO50TL 50 ft NL4 Speaker Cable 12 Gauge

PR050TL-8 50 ft. NL8 Speaker cable 12 gauge

PRO100TL-8 100 ft. NL8 Speaker cable 12 gauge

AD48 NL8 to (2) NL4 Y breakout

NL8MM NL8 male to male barrel connector

Warranty

The Carvin warranty on the professional TRx3000 series loudspeaker products remains in effect for five years from the date of the first

consumer purchase. Carvin DCM series power amplifiers are warranted for three years from the date of original purchase. All other

Carvin products are warranted for one year from the date of original purchase.

WHO IS PROTECTED BY THIS WARRANTY?

Your Carvin TRx3210 and TRx3210A warranty protects the original owner for five years so long as: A) Your product has been purchased

from Carvin. B) The original dated sales invoice is presented whenever warranty service is required.

WHO PAYS FOR WHAT?

Carvin pays for all material expenses related to defective workmanship including drivers and crossovers. However, Carvin does not pay

for any driver with an open voice coil, rubbing voice coil or drivers, which in all cases is an indication that excessive power has been

used.

WHAT DOES THE CARVIN WARRANTY COVER?

Except as specified, your Carvin Warranty covers all defects in material and workmanship. The following are not covered: Damage

caused by accident, misuse, abuse, product modification or neglect; damage occurring during shipment; damage resulting from failure to

follow instructions contained in your Instruction Manual; damage resulting from the performance of repairs by someone not authorized

by Carvin; claims based upon any misrepresentations by the seller; any Carvin product on which the serial number has been defaced,

modified or removed.

WARRANTY INFORMATION

If your Carvin product needs service, email service@carvin.com or export@carvin.com for international customers. Please do not ship

your Carvin product to the factory without prior authorization. You are responsible for shipping charges.

21

Page 22

Turnkey Systems

500+ Person System Package

TRS500A (Active TRx3018A subs, Passive TRx3210)

Subwoofer powered full range system (10,000w)

(4) TRx3210NF Array Enclosures

(2) TRx3018A Active Subwoofers w/Ext. Amp

(2) PRO1TL

(2) PRO5TL

(4) SS4 Poles

(1) DB35 Dolly Board

(1) DB3210 Dolly Board

1500+ Person System Packages

FLYING SUBS PACKAGE

TRx3118A-4 (Active TRx3118A subs)

Active Flyable Subwoofer System (10,000w)

Mounts Inline on the SureFlyTBar in array systems

(4) TRx3118A Active Flyable Subwoofer

TRS1500A (Active TRx3210A)

Active Line Array System (20,000w)

(8) TRx3210A Active Array Enclosures

(2) SureFlyTBar

(4) TCSHK58 shackles

(2) DB3210 Dolly Boards (8 TRx3210)

TRS1500P (Passive TRx3210)

Biamp Passive Line Array System (15,200w)

(8) TRx3210 Array Enclosures

(1) ARx4 Amp Rack

(2) SureFlyTBar

(4) TCSHK58 shackles

(2) DB3210 Dolly Boards (8 TRx3210)

SUBWOOFER PACKAGE

TRS1500S (TRx2218B subs)

Passive Subwoofer System (15,200w)

(4) TRx2218B Dual 18” Subwoofer

(1) ARx4 Amp Rack

(4) CTS44 Caster Set

4000+ Person System Packages

TRS4000A (Active TRx3210A)

Active Line Array System

(16) TRx3210A Active Array Enclosure

(2) SureFlyTBar

(4) TCSHK58 shackle

(4) DB3210 Dolly Board (16 TRx3210)

SUBWOOFER PACKAGE

(40,000w)

TRS4000S (TRx2218B subs)

Passive Subwoofer System (30,400w)

(8) TRx2218B Dual 18” Subwoofer

(2) ARx4 Amp Rack

(8) CTS44 Caster Set

TRS4000P (Passive TRx3210)

Biamp Passive Line Array System (30,400w)

(16) TRx3210 Array Enclosure

(2) ARx4 Amp Rack

(2) SureFlyTBar

(4) TCSHK58 shackle

(4) DB3210 Dolly Board (16 TRx3210)

22

Page 23

CARVIN

CARVIN

CARVIN

CARVIN

7000+ Person

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

CARVIN

System Packages

TRS7000A (Active TRx3210A)

Active Line Array System (60,000w)

(24) TRx3210A Active Array Enclosure

(2) SureFlyTBar

(4) TCSHK58 shackle

(6) DB3210 Dolly Board (24 TRx3210)

SUBWOOFER PACKAGE

TRS7000S (Passive TRx3218 subs)

Passive Subwoofer System (60,800w)

(16) TRx3218 Dual 18” Subwoofer

(4) ARx4 Amp Rack

(16) CTS44 Caster Set

TRS7000P (Passive TRx3210)

Biamp Passive Line Array System (30,400w)

(24) TRx3210 Array Enclosure

(2) ARx4 Amp Rack

(2) SureFlyTBar

(4) TCSHK58 shackle

(6) DB3210 Dolly Board (24 TRx3210)

9000+ Person

System Packages

TRS9000A (Active TRx3210A)

Active Line Array System (80,000w)

(32) TRx3210A Active Array Enclosure

(2) SureFlyTBar

(4) TCSHK58 shackle

(8) DB3210 Dolly Board (32 TRx3210)

SUBWOOFER PACKAGE

TRS9000S (Passive TRx3218 subs)

Passive Subwoofer System (91,200w)

(24) TRx3218 Dual 18” Subwoofer

(6) ARx4 Amp Rack

(24) CTS44 Caster Set

TRS9000P (Passive TRx3210)

Biamp Passive Line Array System (60,800w)

(32) TRx3210 Array Enclosure

(4) ARx4 Amp Rack

(2) SureFlyTBar

(4) TCSHK58 shackle

(8) DB3210 Dolly Boards (32 TRx3210)

23

Page 24

Made in USA

c

800.854.2235 carvinaudio.com carvinworld.com

www.facebook.com/carvinaudio

USA contact: Tony Mirador

Office: 800.403.4484

tonym@carvin.com

12340 World Trade Dr., San Diego, CA 92128

24

International contact: Joel Kiesel

Office: 760.522.5676

export@carvin.com

Loading...

Loading...