Carver Pump RSA, RS Series, RSB, RSC, RSE Installation, Operation And Maintenance Instructions

...

Part Number: _______________________________________

Serial Numbers: _____________________________________

These operating instructions contain fundamental information and precautionary notes. Please read the manual

thoroughly prior to installation of unit, electrical connection and commissioning. It is imperative to comply with all

other operating instructions referring to components of individual units.

I-280

280 – 16.03.EN

ATEX

Inch Units

For Units Built After December 2015

RS – Multi-Stage, Centrifugal Pump

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

This manual shall always be kept close to the unit’s location of operation or directly on the pump set.

RS – Multi-Stage, I-280

EC Declaration of Conformity

www.carverpump.com

Phone: 1-563-263-3410

Email: sales@carverpump.com

Kurt Doren

Quality/ ISO Manager

Centrifugal Pump 280 – 16.03.EN

MANUFACTURER: CARVER PUMP COMPANY

2415 PARK AVE.

MUSCATINE, IOWA, USA 52761

PRODUCT DESCRIPTION: RS – Multi-Stage, Centrifugal Pump

PART NUMBER:

SERIAL NUMBER:

DATE MANUFACTURED:

APPLICABLE EUROPEAN DIRECTIVES:

Machinery: The designated product complies with the following basic requirements of Directive 2006/42/EC:

Appendix I, section 1.1.2, 1.1.3., 1.1.5., 1.3.1., 1.3.2., 1.3.3., 1.3.4., 1.3.7., 1.3.8., 1.4.1., 1.4.2.1.,

1.5.1., 1.5.8., 1.5.9., 1.5.13., 1.6.1., 1.6.4., 1.6.5., 1.7.

ATEX: 94/9/EC

APPLICABLE INTERNATIONAL STANDARDS:

Machinery: EN ISO 12100:2010 EN ISO 13732-1:2008

EN 626-1:2008 EN ISO 13857:2008

ATEX: EN 1127-1, EN 13463-1, EN 13463-5

NOTIFIED BODY

Det Norske Veritas, ATEX NB 0575 retains a copy of the Technical File

ATEX product marking: II 2 G c T2

The product described in this Declaration of Conformity complies with the Applicable European Directives and

relevant sections of the Applicable International Standards. The signature on this document authorizes the distinctive

European mark to be applied to the equipment described. A Technical Construction File is available for inspection by

designated bodies

Authorized Signature: Date:

Important safety information is contained in the installation, operation and service manuals; read and

understand this information prior to installing or using this equipment

This Document applies only to the equipment described above and is invalid if not reproduced in its entirety.

RS – Multi-Stage, I-280

Installation Date

Location

Application

Centrifugal Pump 280 – 16.03.EN

SERVICE RECORD PAGE

Service No. ______________________ Model _________________________ Size and Type _______________

Customer Order No. ____________________________ Date Installed __________________________________

PUMP RATING

Capacity _____________________________________ Total Head ____________________________________

Suction Pressure ______________________________ Speed (RPM) __________________________________

Liquid pumped ________________________________ Temperature ___________________________________

Specific Gravity _______________________________ Viscosity ______________________________________

Service ______________________________________

PUMP MATERIALS

Casing _________________________ Impeller _______________________ Shaft _______________________

Gaskets _____________________________________ Bearing Frame _________________________________

Mechanical Seal/Packing ________________________

MOTOR DATA

Motor __________________________ Make _________________________ Serial No. ___________________

Type ___________________________ Frame ________________________ AC or DC ___________________

HP _____________________________ RPM _________________________ Volts _______________________

Phase __________________________ Cycles ________________________

RS – Multi-Stage, I-280

INSPECTION DATE

REPAIR TIME

REPAIRS

COST REMARKS

Centrifugal Pump 280 – 16.03.EN

NOTES ON INSPECTION AND REPAIRS

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

TABLE OF CONTENTS

SECTION/PARAGRAPH PAGE

SECTION/PARAGRAPH PAGE

I. GENERAL DESCRIPTION ............................... 1

A. General Information ................................... 1

B. ATEX Directive 94/9/EC ............................. 1

C. Disclaimer .................................................. 1

D. Personnel Qualification and Training ......... 1

E. Pump Identification..................................... 1

F. Parts Inventory Guide ................................ 2

G. Parts Ordering ............................................ 2

II. SAFETY ............................................................ 2

A. Safety Precautions ..................................... 2

B. Summary of Safety Marking ....................... 2

C. Products Used in Potentially Explosive

Atmospheres ......................................... 2

D. Scope of Compliance ................................. 2

E. Safety Awareness ...................................... 3

F. Safety Instructions for the Operator/User .. 3

G. Safety Instructions for Maintenance

Inspection and Installation Work ............ 3

H. Non-Compliance with Safety Instructions .. 3

I. Unauthorized Modification and

Manufacture of Spare Parts ................... 3

J. Unauthorized Modes of Operation ............. 4

K. Explosion Protection .................................. 4

III. EQUIPMENT DESCRIPTION ........................... 7

IV. EFFECTS OF FLUIDS ..................................... 8

A. Net Positive Suction Head (NPSH) ............ 8

B. Changing Pump Speed .............................. 8

C. Effects of Viscosity ..................................... 8

D. Effects of Specific Gravity .......................... 8

V. TECHNICAL DATA ........................................... 8

VI. INSPECTION AND STORAGE ........................ 16

A. Inspection ................................................... 16

B. Packing for Return ..................................... 16

C. Storage of Pump ........................................ 16

VII. INSTALLATION ................................................ 17

A. Location ...................................................... 17

B. Handling ..................................................... 17

C. Foundation ................................................. 17

D. Leveling of Unit .......................................... 18

E. Grouting ..................................................... 18

F. Coupling Alignment .................................... 20

G. Pre-Installation Procedures ....................... 21

H. Piping ......................................................... 21

I. Auxiliary Piping Connection

and Gauges ........................................... 21

J. Motor .......................................................... 21

K. Direction of Rotation .................................. 21

VIII. OPERATION .................................................... 22

A. Pre-Start Cautions ..................................... 22

B. Priming ....................................................... 22

C. Starting the Pump ...................................... 23

D. Turbine Applications .................................. 23

E. Minimum/Maximum Flow Calculations ...... 23

F. Operating Checks ...................................... 23

G. Stopping the Pump .................................... 23

H. Indefinite Shutdown ................................... 24

IX. TROUBLESHOOTING OPERATING

PROBLEMS ...................................................... 24

X. MAINTENANCE ............................................... 26

A. Lubrication of Pump Bearings .................... 26

B. Lubrication of Motor Bearings .................... 27

C. Torque Values ............................................ 27

XI. SERVICE AND REPAIR ................................... 28

A. Preparations for Disassembly of Pump ..... 28

B. Disassembly of Pump with

Standard Sleeve Bearing ....................... 29

C. Disassembly of Pump with

Optional Mechanical Seals .................... 31

D. Parts Inspection ......................................... 33

E. Reassembly of Pump with

Standard Sleeve Bearing ....................... 35

F. Reassembly of Pump with

Optional Mechanical Seals .................... 39

G. Replacement of Wear Ring ........................ 42

H. Motor .......................................................... 44

I. Check Valve ............................................... 44

XII. PARTS LISTS AND DRAWINGS ..................... 44

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

TABLE OF CONTENTS - Continued

LIST OF TABLES

NUMBER TITLE PAGE

1. Fluid Temperature Limits ........................... 5

2. Maximum Allowable Pressures .................. 6

3. Axial Impeller Alignment

Control Dimensions................................ 9

4. Shaft Dimensions ....................................... 12

5. Sleeve Bearing Dimensions ....................... 12

6. Standard Design Pump Mechanical

Seal Settings .......................................... 12

7. Optional Design Pump Mechanical

Seal Settings .......................................... 13

8. Key Mechanical Data ................................. 13

9. Permissible Nozzle Loads ......................... 15

10. Minimum Flow Rates RS-6 and RS-9 ........ 15

11. Pumping Unit Troubleshooting .................. 24

12. Oil Recommendations................................ 27

13. Bearing Cooling Flow Rates

(30 PSIG Max.) ...................................... 27

14. Recommended Torque Values (ft-lbs) ....... 27

15. Recommended Equipment ........................ 27

16. Factory Wear Ring Clearance (Inches) ..... 34

17. New Wear Ring Diametrical

Clearance Limits (Inches) ...................... 43

18. Recommended Spare Parts List ................ 45

LIST OF ILLUSTRATIONS

NUMBER TITLE PAGE

1. Seal Chamber Dimensions .........................11

2. Standard Seal Flush Plans .........................13

3. Bearing Frame Water Cooling ....................14

4. Sling Position for Moving Pump ..................17

5. Sling Position for Moving Pumping Unit .....17

6. Sling Position for Moving

Pumping Unit with Lifting Lugs ...............17

7. Grouting and Foundation Bolting ................19

8. Unit Leveling ...............................................19

9. Coupling Alignment .....................................20

10. Constant Level Oiler ...................................27

11. Bushing Not Torqued Interference .............38

12. Mechanical Seal Not Torqued

Interference .................................................42

13. Sectional Assembly – Standard

Sleeve Bearing .......................................49

14. Sectional Assembly – Optional

Mechanical Seals ....................................51

15. Cooling Options ..........................................52

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

I. GENERAL DESCRIPTION AND

SAFETY PRECAUTIONS.

A. GENERAL INFORMATION. Carver Pump

Company products are carefully engineered and

manufactured and, if properly installed, maintained, and

operated, should provide maintenance-free operation

and a long service life.

CAUTION

These instructions must always be kept close

to the product's operating location or directly

with the product.

This manual is designed to provide sufficient material to

properly maintain the total pumping unit. The information

presented should improve your knowledge and

understanding of the RS Multi-Stage Centrifugal Pump,

thus upgrading the reliability, service life, and quality of

pump maintenance.

These operating instructions are intended to facilitate

familiarization with the product and its permitted use to

help satisfy ATEX safety requirements. These operating

instructions do not take into account local regulations;

the operator must ensure that such regulations are

strictly observed by all, including the personnel called in

for installation. Compliance with such laws relating to

the proper installation and safe operation of the pumping

equipment is the responsibility of the equipment owner

and all necessary steps should be taken by the owner to

assure compliance with such laws before operating the

equipment. These instructions are intended to facilitate

familiarization with the product and its permitted use to

help satisfy safety requirements. Always coordinate

repair activity with operations personnel, and follow all

plant safety requirements and applicable safety and

health laws/regulations.

Refer to Figures 13, 14, and 15 to locate the pump parts

by item number. Variations do exist between

configurations, not all parts described in the text may be

on your configuration.

CAUTION

These instructions should be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide and in

conjunction with the main user instructions

provided. The equipment must not be put into

service until all the conditions relating to safety

instructions have been met.

B. ATEX DIRECTIVE 94/9/EC. It is a legal

requirement that machinery and equipment put into

service within certain regions of the world shall conform

to the applicable CE Marking Directives for Equipment

for Potentially Explosive Atmospheres (ATEX).

Where applicable the Directive covers important safety

aspects relating to the equipment, its use and the

satisfactory provision of technical documents. Where

applicable this document incorporates information

relevant to these Directives. To establish if the product

itself is CE marked for a Potentially Explosive

Atmosphere check the nameplate and the Certification

provided.

C. DISCLAIMER. Information in these User

Instructions is believed to be reliable. In spite of all the

efforts of Carver Pump Company to provide sound and

all necessary information the content of this manual may

appear insufficient and is not guaranteed by Carver

Pump Company as to its completeness or accuracy.

D. PERSONNEL QUALIFICATION AND TRAINING.

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be qualified

to carry out the work involved. If the personnel in

question do not already possess the necessary

knowledge and skill, appropriate training and instruction

must be provided. If required the operator may

commission the manufacturer/supplier to provide

applicable training.

Follow instructions in this manual carefully. Factory

warranty applies only when pump operates under

conditions as specified on order acknowledgment, and if

pump is properly installed and maintained as

recommended herein. A copy of this manual should be

available to operating personnel. Additional copies of

this manual are available upon request from Carver

Pump Company and your local distributor. For

comments and/or questions about information provided,

please contact Carver Pump Company or your local

distributor.

E. PUMP IDENTIFICATION. The type of pump, pump

size, operating data, and serial number are all stamped

on the nameplate attached to the pump. Pump

specifications should be recorded upon receipt of the

pumping unit. Record all necessary information on the

pump service record page and inspection and repair

record provided at the front of this manual. This

information must be included in all correspondence

regarding the unit. This will ensure that the correct pump

and/or parts are ordered in a timely manner.

1

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

F. PARTS INVENTORY GUIDE. To avoid

unnecessary delays for maintenance, spare parts

should be readily available, purchase before and keep in

used in safety instructions where noncompliance in the hazardous area would cause

the risk of an explosion.

stock, for normal service. Most conditions will be

covered if this manual is followed. For every one to

three pumps, stock one spare set consisting of items

listed in Table 19, Recommended Spare Parts. Part

General hazard sign to ISO 7000 - 0434.

numbers correspond to Figures 11, 12 and 13.

The word "Caution" is used to introduce safety

G. PARTS ORDERING. When ordering replacement

parts, please specify:

instructions whose non-observance may lead to damage

to the machine and its functions.

Instructions attached directly to the machine, e.g.

Serial number of pump (located on nameplate)

Part name (located on parts list)

Quantity of parts needed

Carver Pump Company may ship an interchangeable

part that is not identical in appearance or symbol. This is

done only if the part has been improved. Examine parts

carefully upon delivery before questioning factory or

Arrow indicating the direction of rotation

Markings for fluid connections must always be

complied with and be kept in a perfectly legible

condition at all times.

Observe all notes, caution or danger tags attached to

the equipment or included in this manual.

company representative. Never return parts to the

factory without authorization from Carver Pump

Company.

C. PRODUCTS USED IN POTENTIALLY EXPLOSIVE

ATMOSPHERES

If an impeller is ordered, specify diameter across blade

tips. Be sure diameter was NOT trimmed further than

diameter shown on Carver Pump Company records.

If a driver or driver parts are ordered, specify name of

manufacturer and all other data found on the driver

nameplate.

II. SAFETY.

A. SAFETY PRECAUTIONS. The manual is designed

to provide adequate instructions for the safe and

efficient installation, operation, or maintenance of the

pump. Failure or neglect to properly install, operate, or

maintain the pump may result in personal injury,

property damage, or unnecessary damage to the pump.

This manual must be read and understood both by the

installing personnel and the responsible trained

personnel/operators prior to installation and operation,

and it must always be kept close to the location of the

pumping unit for easy access.

B. SUMMARY OF SAFETY MARKING. The safety

instructions contained in this manual follow specific

ATEX safety marking where non-observance of the

instruction will cause a hazard is specially marked with

the symbol:

Measures are required to:

Avoid excess temperature

Prevent buildup of explosive mixtures

Prevent the generation of sparks

Prevent leakages

Maintain the pump to avoid hazard

The following instructions for pumps and pump units

when installed in potentially explosive atmospheres

must be followed to help ensure explosion protection.

Both electrical and non-electrical equipment must meet

the requirements of European Directive 94/9/EC.

D. SCOPE OF COMPLIANCE.

Use equipment only in the zone for which

it is appropriate. Always check that the driver,

drive coupling assembly, seal and pump

equipment are suitably rated and/or certified for

the classification of the specific atmosphere in

which they are to be installed.

This symbol indicates explosive

atmosphere marking according to ATEX. It is

2

Where Carver Pump has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The party

responsible for assembling the pump set shall select the

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

coupling, driver, seal and any additional equipment, with

the necessary CE Certificate/Declaration of Conformity

establishing it is suitable for the area in which it is to be

installed.

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor and so, for

G. SAFETY INSTRUCTIONS FOR MAINTENANCE,

INSPECTION AND INSTALLATION WORK. The

operator is responsible for ensuring that all

maintenance, inspection and installation work be

performed by authorized, qualified personnel who are

thoroughly familiar with the manual and pumping unit.

pump sets with a VFD, the ATEX Certification for the

motor must state that it covers the situation where

electrical supply is from the VFD. This is particular

requirement still applies even if the VFD is in a safe

area.

To ensure safe operation the ball

bearings must be replaced at 20000 hours of

service or whenever the mechanical seal is

inspected or serviced.

E. SAFETY AWARENESS. It is imperative to comply

with the safety instructions contained in this manual, the

relevant national and international explosion protection

regulations, health and safety regulations and the

operator’s own internal work, operation and safety

regulations.

Ex symbol relates to additional

requirements which must be adhered to when

the pump is operated in potentially explosive

atmospheres.

F. SAFETY INSTRUCTIONS FOR THE OPERATOR

/USER.

Any hot or cold components that could pose a

hazard must be equipped with a guard by the

operator.

Guards which are fitted to prevent accidental

contact with moving parts (e.g. coupling) must

not be removed whilst the unit is operating.

Leakages (e.g. at the shaft seal) of hazardous

fluids (e.g. explosive, toxic, hot) must be

contained so as to avoid any danger to persons

or the environment. Pertinent legal provisions

must be adhered to.

The pumping unit must have cooled down to ambient

temperature, pump pressure must have been released

and the pump must have been drained before working

on any pumping unit. Work on the pumping unit must be

carried out during shutdown. The shutdown procedure

described in the manual for taking the unit out of service

must be adhered to.

Pumps handling fluids that are hazardous to personnel

must be decontaminated prior to being worked on.

Immediately following completion of the work, all safety

relevant and protective devices must be reinstalled

and/or reactivated. Please observe all instructions set

out in the Section VIII on start up before returning the

pumping unit to service.

H. NON-COMPLIANCE WITH SAFETY

INSTRUCTIONS. Non-compliance with safety

instructions may result in personal injury, property

damage, or unnecessary damage to the pumping unit.

Non-compliance with these safety instructions will also

lead to forfeiture of any and all rights to claims for

damages. Non-compliance, can for example, result in:

Failure of important pumping unit functions.

Failure of prescribed maintenance and servicing

practices.

Electrical hazards must be eliminated. (In this

respect refer to the relevant safety regulations

applicable to different countries and/or the local

energy supply companies.)

If the pumps/units are located in

potentially explosive atmospheres, it is

imperative to make sure that unauthorized

modes of operation are prevented. Noncompliance may result in the specified

temperature limits being exceeded.

Hazard to personnel by electrical, mechanical,

and chemical effects as well as explosion.

Hazard to the environment due to leakage of

hazardous substances.

I. UNAUTHORIZED MODIFICATION AND

MANUFACTURE OF SPARE PARTS. Modifications or

alterations of the pumping unit supplied are only

permitted after consultation with Carver Pump and to the

extent permitted by Carver Pump. Original spare parts

and accessories authorized by Carver Pump ensure

safety. The use of other parts can invalidate any liability

of Carver Pump for consequential damage and/or

warranty.

3

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

J. UNAUTHORIZED MODES OF OPERATION. The

warranty relating to operating reliability and safety of the

unit supplied is only valid if the pumping unit is used in

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

accordance with its designated use as described in the

following sections. The limits stated on the nameplate

must not be exceeded under any circumstances.

K. EXPLOSION PROTECTION. If the pumps/units are

installed in potentially explosive atmospheres, the

measures and instructions given in the following

sections K.1 to K.6 must be adhered to without fail, to

ensure explosion protection.

K.1 Unit Fill.

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

II 2 GD c IIC 135 ºC (T4)

Gas and/or dust

It is assumed that the system of suction

and discharge lines and thus the wetted pump

G = Gas

D = Dust

internals are completely filled with the fluid to

be handled at all times during pump operation,

so that an explosive atmosphere is prevented.

c = Constructional safety

(in accordance with EN13463-5)

Gas Group (Equipment Category 2 only)

If the operator cannot warrant this

condition, appropriate monitoring devices must

be used.

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

CAUTION

In addition, it is imperative to make sure that

the seal chambers, auxiliary systems of the

shaft seal and the heating and cooling systems

are properly filled.

K.2 Marking.

The marking on the pump only refers to

the pump, i.e. the coupling and driver must be

regarded separately. The coupling must have

an EC manufacturer’s declaration. The driver

must be regarded separately.

Maximum surface temperature (Temperature Class)

(Refer to Section II, Paragraph K.5)

K.3 Checking the Direction of Rotation.

If the explosion hazard also exists during

the installation phase, the direction of rotation

must never be checked by starting up the

unfilled pump unit, even for a short period, to

prevent temperature increases resulting from

contact between rotating and stationary

components.

K.4 Pump Operating Mode.

Make sure that the pump is always started up with the

suction-side shut-off valve fully open and the dischargeside shut-off valve slightly open. However, the pump can

also be started up against a closed swing check valve.

The discharge-side shut-off valve shall be adjusted to

comply with the duty point immediately following the runup process.

4

RS – Multi-Stage, I-280

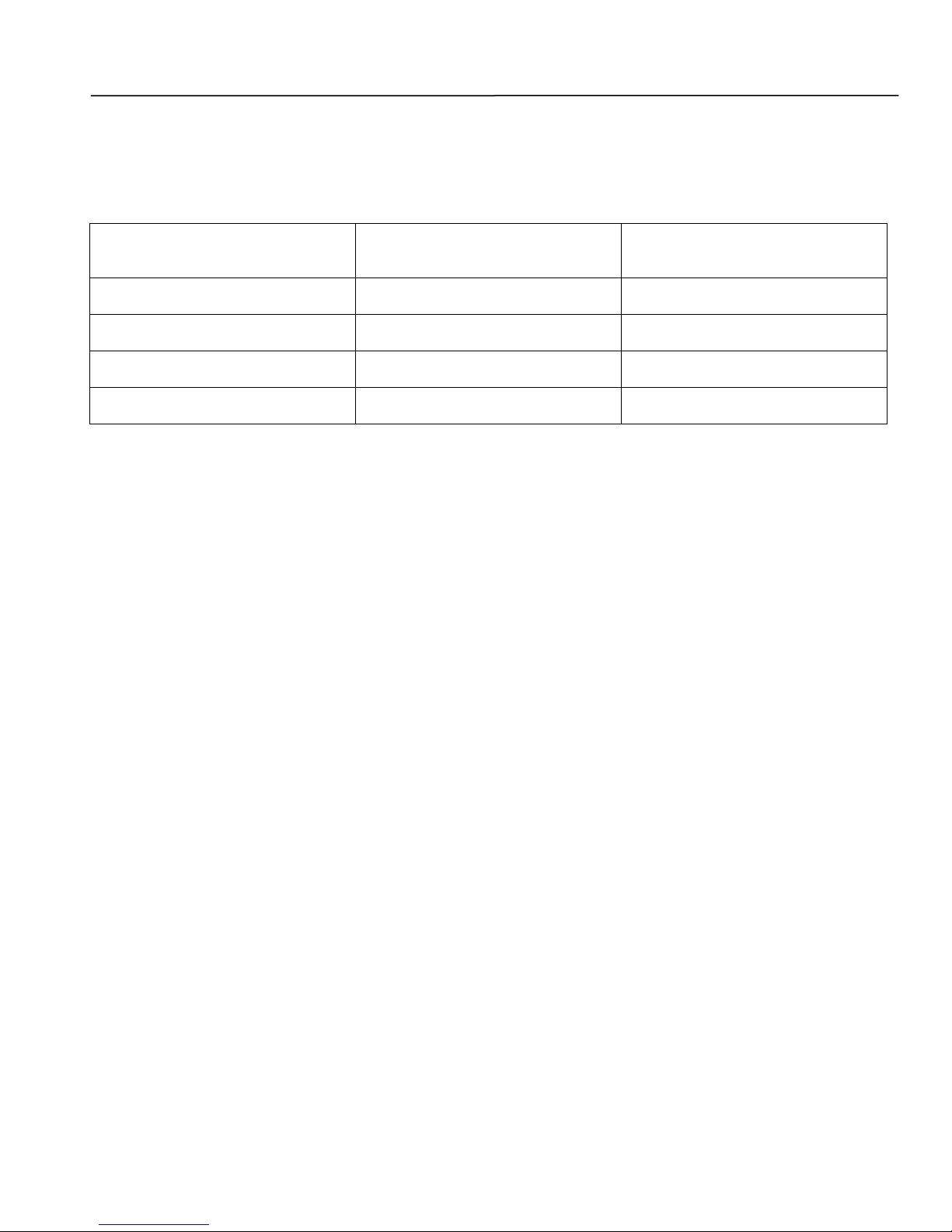

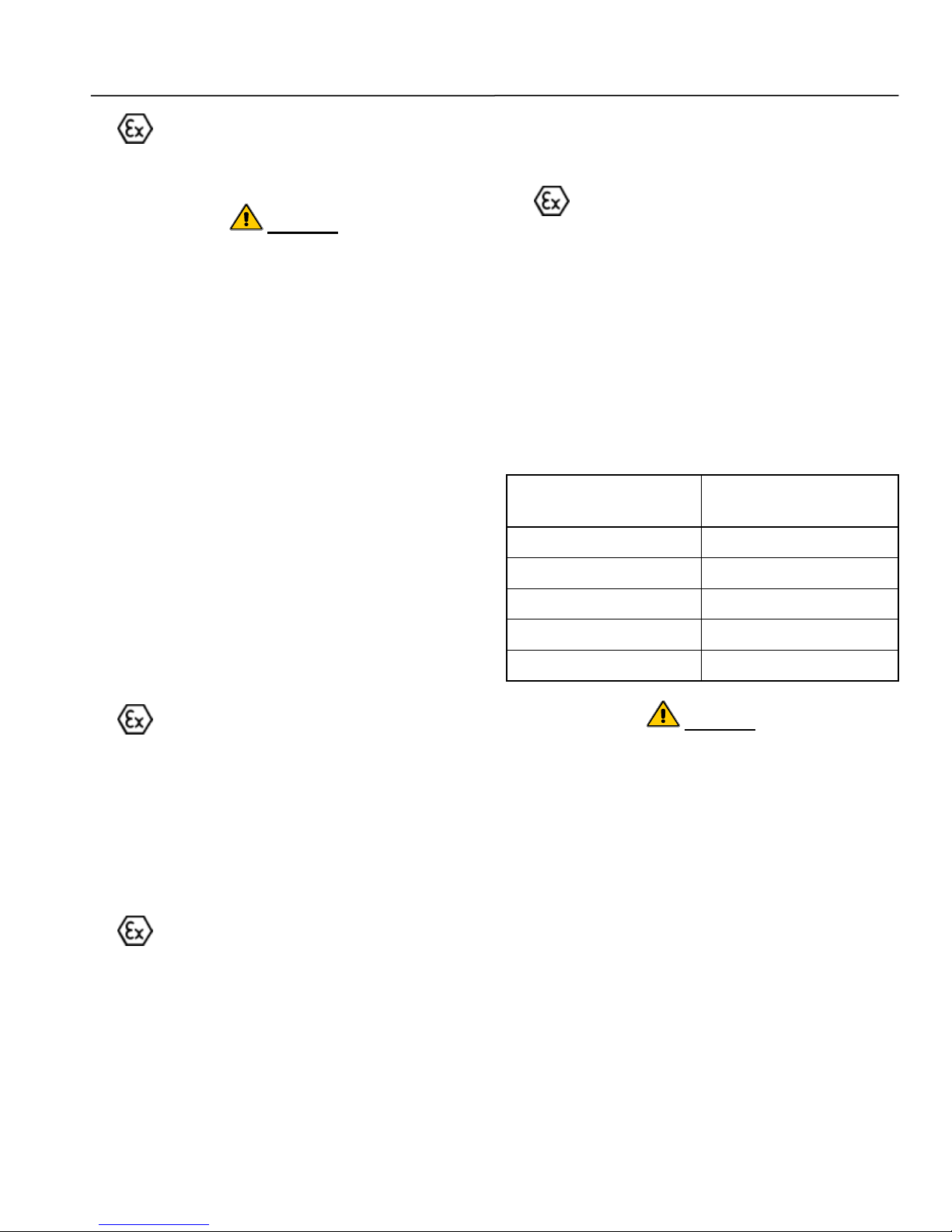

Temperature class

to EN 13463-1:

Temperature limit of

fluid handled

T5

185 °F (85 °C)

T4

284 °F (120 °C)

T3

365 °F (185 °C)

T2

536 °F (280 °C)

T1

662 °F (350 °C)

Centrifugal Pump 280 – 16.03.EN

In the ball bearing bracket area, the unit surfaces must

Pump operation with the shut-off valves in

the suction and/or discharge pipes closed is not

be freely exposed to the atmosphere and the fan inlet

flow must be unimpeded.

permitted.

CAUTION

In this condition, there is a risk of the pump

casing taking on high surface temperatures

after a very short time, due to a rapid

temperature rise in the pumped fluid inside the

pump. Additionally, the resulting rapid pressure

build-up inside the pump may cause excessive

stresses on the pump materials or even

bursting.

The minimum flows calculated in Section VIII,

Paragraph E, refer to water and water-like liquids.

Longer operating periods with these liquids and at the

flow rates indicated will not cause an additional increase

in the temperatures on the pump surface. However, if

the physical properties of the fluids handled are different

from water, it is essential to check if an additional heat

build-up may occur and if the minimum flow rate must

therefore be increased.

To check, proceed as described in Section VIII,

Paragraph E.

In addition, the instructions given in Section VIII of this

operating manual must be observed.

In any case, responsibility for compliance

with the specified fluid temperature (operating

temperature) lies with the plant operator. The

maximum permissible fluid temperature

depends on the temperature class to be

complied with.

Table 1 below lists the temperature classes to EN

13463-1 and the resulting theoretical temperature limits

of the fluid handled. In stipulating these temperatures,

any temperature rise in the shaft seal area has already

been taken into account.

Table 1. Fluid Temperature Limits

Mechanical seals may exceed the

specified temperature limits if run dry. Dry

running may not only result from an

inadequately filled seal chamber, but also from

excessive gas content in the fluid handled.

Pump operation outside its specified operating range

may also result in dry running.

K.5 Temperature Limits.

In normal pump operation, the highest

temperatures are to be expected on the surface

of the pump casing, at the shaft seal and in the

ball bearing areas. The surface temperature at

the pump casing corresponds to the

temperature of the fluid handled.

If the pump is heated, it must be ensured that the

temperature classes stipulated for the plant are

observed.

CAUTION

The permissible operating temperature of the

pump in question is indicated on the data

sheet. If the pump is to be operated at a higher

temperature, the data sheet is missing or if the

pump is part of a pool of pumps, the maximum

permissible operating temperature must be

enquired from the pump manufacturer.

Based on an ambient temperature of 104˚ Fahrenheit

(F) [40˚ Celsius (C)] and proper maintenance and

operation, compliance with temperature class T4 is

warranted in the area of the rolling element ball

bearings. A special design is required for compliance

with temperature class T6 in the ball bearing area. In

such cases, and if ambient temperature exceeds 104˚F

(40˚C), contact the manufacturer.

5

RS – Multi-Stage, I-280

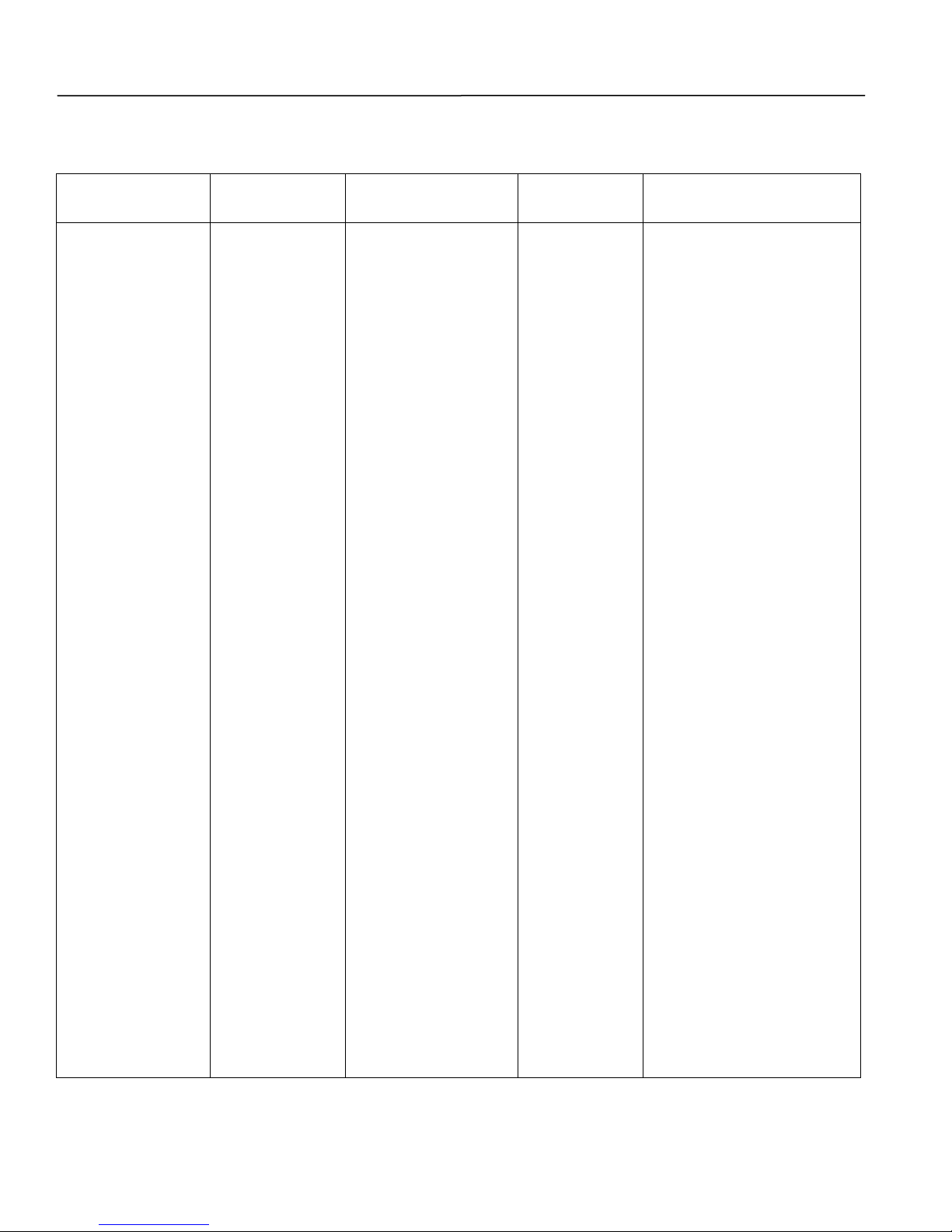

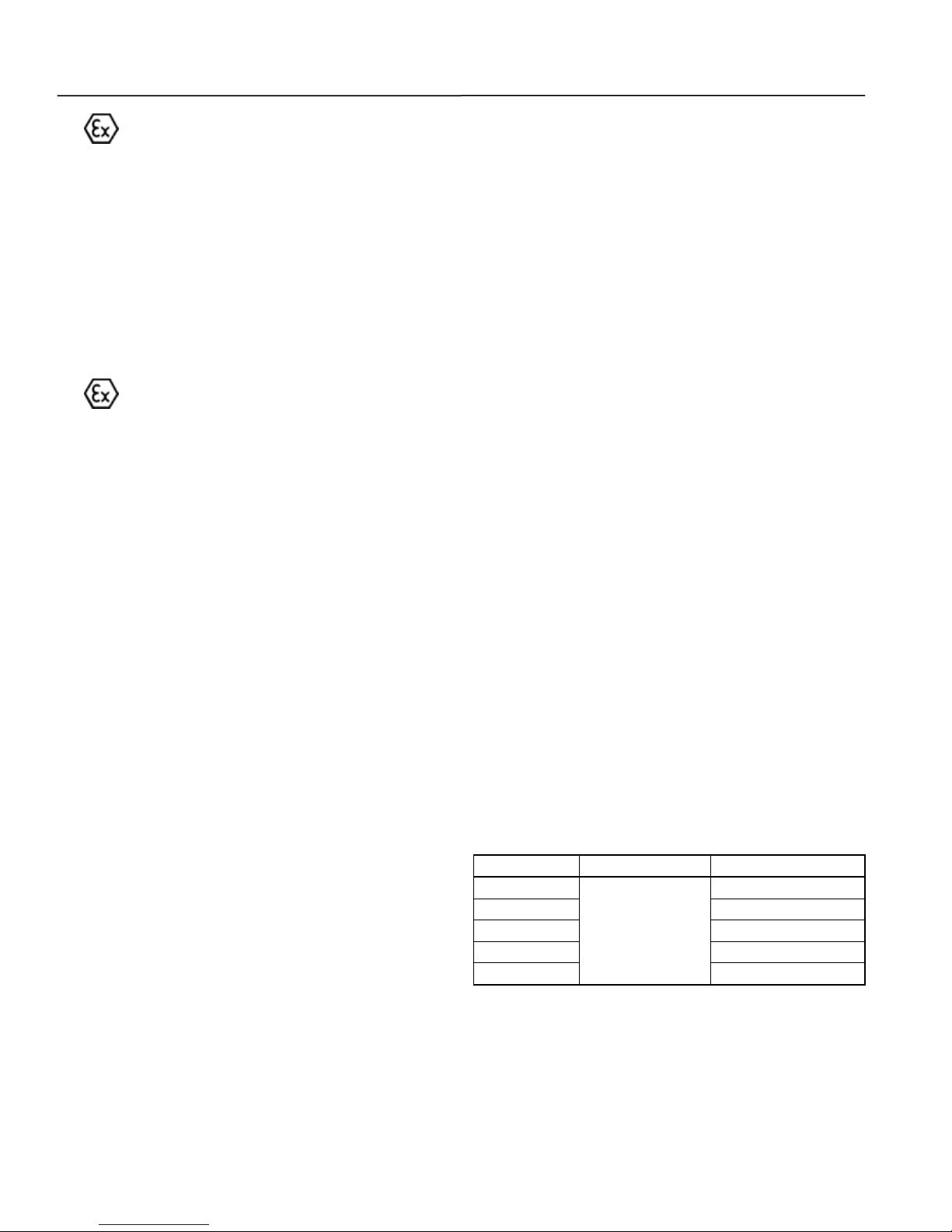

Size

Suction

Discharge

A

415 PSIG*

1,475 PSIG

B

1,475 PSIG

C

1,475 PSIG

D

1,810 PSIG

E

1,460 PSIG

*Unless otherwise rated.

Centrifugal Pump 280 – 16.03.EN

Make sure you are NOT grounded while

Pump liquids over 225˚F (107˚C); pumps

must be equipped with auxiliary cooling.

adjusting electrical equipment or using

measuring equipment.

Pumps of high temperature construction are provided

with cooled ball bearings for a unit operating in

temperature range between 225˚ F and 300˚ F (107˚ C

and 149˚ C). Cooling water flows through cavities of the

bearing frame and keeps temperature of the ball

bearings within acceptable limits. Refer to Table 13 for

cooling flow rates of water temperature of 60˚ F (140˚C)

for ball bearings.

K.6 Maintenance.

Only a pumping unit which is properly

serviced and maintained in perfect technical

condition will give safe and reliable operation.

This also applies to the reliable function of the thrust or

radial ball bearings whose actual lifetime largely

depends on the operating mode and operating

conditions. Regular checks of the lubricant and the

running noises will prevent the risk of excessive

temperatures as a result of the thrust or radial ball

bearings running hot or defective bearing isolators.

The correct function of the bearing isolators must be

checked regularly. Any auxiliary systems installed must

be monitored, as necessary, to make sure that they

function correctly.

In general, use only one hand when servicing

live electrical equipment.

Make sure to de-energize all electrical

equipment before connecting or disconnecting

meters or test leads.

For connecting a meter to terminals for

measurement, use a range higher than the

expected voltage.

Check to make sure that the frame of the driver

and starter panel are securely grounded before

operating pumping unit or performing any tests

or measurements.

If a test meter must be held or adjusted while

voltage is applied, ground case of meter before

starting measurement. DO NOT touch live

equipment while holding the meter. Some

moving vane-type meters should not be

grounded nor held during measurements.

DO NOT use test equipment known to be

damaged or in poor condition.

The following specific safety precautions apply to the

pumping unit:

Hydro suction case separately on RS-9 units.

K.7 General Safety Instructions.

Various federal, state, and local laws affect

installation, use, and operation of pumping

equipment. Compliance with such laws relating

to proper installation and safe operation of

pumping equipment is the responsibility of the

equipment owner.

Prior to working on pump or driver, ensure all

switches and circuit breakers have been locked

in the open (off) position and tagged, “Out of

Service.”

All circuits NOT known to be dead must be

considered live at all times.

DO NOT wear loose or torn clothing around

rotating machines.

While working near electricity, DO NOT use

metal rules, flashlights, metallic pencils, or any

other objects having exposed conducting

material.

Isolate pump for system hydro.

DO NOT exceed maximum rated suction

pressure unless otherwise rated.

DO NOT exceed maximum rated discharge

pressure.

Table 2. Maximum Allowable Pressures

6

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

III. EQUIPMENT DESCRIPTION.

RS high-pressure pumps are multi-stage, centrifugal

pumps with radially split casings. The pump consists of

a suction case, a discharge case, plus a number of

interstage casings, all secured with tie bolts. Suction

casing, interstage casings and diffusers are provided

with wear rings. Diffusers are provided with bushings.

Due to prolonged operation, wear rings and bushings

may become worn and/or damaged. Replace all worn

and/or damaged parts with new.

RS high-pressure pumps incorporate special design

refinements, which help to absorb the appreciable axial

thrust generated by their high head operation. Residual

axial thrust is absorbed by the thrust bearings.

CAUTION

Be careful not to mix RS6 and RS9 parts

since RS6 parts are not rated for the pressure

of the RS9.

ATEX and CE require bearing isolators

and metal splash guards to meet requirements.

Other customers may use oil seals and plastic

splash guards.

The bare pump consists of following major parts and

options. Refer to Figures 11 and 12, for the location of

parts identified by item numbers.

Item 1 – Discharge Case. The Discharge Case (1)

houses the impeller (2A or 2X) and diffuser (5A or 5X).

The discharge case is fastened to the suction case with

tie bolts (173) and tie bolt nuts (616) with tie bolt

washers (645).

Item 2A – Impeller, 1st Stage. RS pumps are

equipped with enclosed impellers. The impeller (2A) is

keyed to the shaft (6) by the impeller key (32A) and

located by sleeves and shims. If the RS pump is only a

one stage pump then only the 1st stage impeller is used.

All impellers face the same direction on the shaft.

Item 2X – Impeller. RS pumps are equipped with

enclosed impellers. The impeller (2X) is keyed to the

shaft (6) by the impeller key (32A) and located by

interstage sleeves (58) and shims. All impellers face the

same direction on the shaft.

Item 5A – Diffuser. Diffusers (5A) are inserted in

individual interstage casings. Diffusers are provided with

diffuser bushings (63) and hold wear rings (7X).

Item 5X – Last Stage Diffuser. The last stage diffuser

is located in the discharge case (1). Holds wear ring

(7X) and sits on sleeve bearing (63X).

Item 6 – Shaft. The pump shaft is protected against

wear by interstage sleeves, spacer sleeves, and shaft

sleeves. The shaft (6) of the RS pump is designed for

maximum deflection of 0.002 inch at the face of the

mechanical seal (90). The shaft is also designed to

provide stabilization to the rotor system when pump

operates away from the best efficiency point. A coupling

connects the shaft to the driver shaft. The pump

coupling key (46) holds the coupling in place, causing it

to rotate with the shaft.

Item 16 and 18 – Ball Bearings. A deep-groove

Conrad-type, C3 internal fit radial ball bearing and a

back-to-back mounted ball bearing are housed in the

bearing frame (99) depending on design. The ball

bearings will be designated as 7000 series. Ball

bearings designated in the 7000 series will be duplex

40° angular contact ball bearings. The ball bearing is

held in place by the bearing jam nuts (22). The bearings

are oil lubricated by oil bath.

Item 99 – Bearing Frame. The principal function of the

bearing frame (99) is to carry the loads from the liquid

end of the pump to the base and to transport power from

the power unit to the impeller (2A or 2X). The bearing

frame has a pair of back-to-back mounted angular

contact thrust ball bearings (16). This bearing frame is

designed to be oil lubricated. The bearing frame is

attached to the suction case (9) and discharge case (1)

by tie bolts.

The use of a sight glass constant level oiler (143)

maintains the oil level high enough on the higher of the

two ball bearings so that the ball bearings themselves

provide the motivation for the oil to be moved through

the races of the ball bearings. In addition to the oil lube,

the bearing frame contains the bearing isolator (169).

Item 23 – Base. A grout-able base (23) is designed to

provide adequate support for the pump and motor so

pump can be operated without base deflection,

excessive vibration, or resonance. The pump is attached

to the base with stud (634) and hex nut (614). Grouting

of this type of base is required by Carver Pump

Company.

Item 90 and 91 – Mechanical Seal. Mechanical seals

(90 and 91) are to be used. Complete mechanical seal

instructions should be obtained from the seal

manufacturer. The standard seal chamber dimensions

are shown in Figure 1.

Item 111 – Interstage Case. The interstage case

houses the impeller (2A or 2X) and diffuser (5A). The

interstage casings are all secured with tie bolts to the

7

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

suction (9) and discharge (1) casings. Interstage

casings are provided with wear rings (7X). O-rings (89D)

seal the individual interstage casings. A one stage pump

does not have an interstage case.

IV. EFFECTS OF FLUIDS.

Solids in the fluid pumped may cause

internal damage to pump casing and damage

to the seal faces with resulting Hazardous

conditions. Care is to be taken to ensure that

the process fluid is clear of solids and debris.

A. NET POSITIVE SUCTION HEAD (NPSH). Any

liquid, hot or cold, must be pushed into the impeller of

the pump by some absolute pressure, such as the

atmosphere or the vessel pressure from which the pump

takes its action.

The head in feet of liquid necessary to maintain the

required flow into the pump is called the Net Positive

Suction Head (NPSH). This value is measured above

the vapor pressure of the liquid at the pumping

temperature.

NPSH is commonly expressed in two ways: the NPSH

required by the pump, and shown on the pump curve, is

the head needed to cover the losses in the pump

suction and the energy required to enable the liquid to

climb onboard the leading edge of the impeller vane.

The NPSH available is that inherent in the system,

taking into account friction losses in suction piping,

valves, fittings, etc. In all cases, the NPSH available,

measured above vapor pressure, must exceed the

NPSH required in order to push the liquid into the pump.

B. CHANGING PUMP SPEED. Changing the speed of

a centrifugal pump affects the capacity, total head,

NPSH required and the brake horsepower. In general

the capacity will vary in a direct ratio with the speed,

whereas the total head and NPSH required will vary as

the ratio of the speed squared. The brake horsepower

will vary as the ratio of the speed cubed.

C. EFFECTS OF VISCOSITY. The pump is designed

to deliver rated capacity at rated head for a liquid with a

particular viscosity. When pump is handling heavy

viscous liquid, the viscosity of the liquid must allow it to

be pumped easily. The liquid may have to be heated

prior to starting the pump. When contemplating

operation at some viscosity other than that for which the

pump was originally designed, check with Carver Pump

Company.

D. EFFECTS OF SPECIFIC GRAVITY. The capacity

and total head in feet of liquid developed by a centrifugal

pump are fixed for every point on the curve and are

always the same for the same speed. Neither capacity

nor total head will be affected by a change in the

specific gravity of the liquid pumped. However, since the

discharge pressure in Pounds per Square Inch (PSI)

and the brake horsepower required driving the pump are

functions of the specific gravity of the liquid, both will be

affected in direct proportion by any change in specific

gravity. Therefore, an increase in specific gravity will

raise the discharge pressure and is dangerous as it

might overload the pump's driver, or exceed the pump

casing allowable pressure.

V. TECHNICAL DATA.

Specifications and operating limits should be recorded

on a Service Record Page; an example is located in the

front matter of this manual. Record the necessary

information upon receipt of the pumping unit.

Noise Levels. Noise levels may exceed 85dBa at 1

meter during operation. Ear protection must be worn

whenever working in high noise locations.

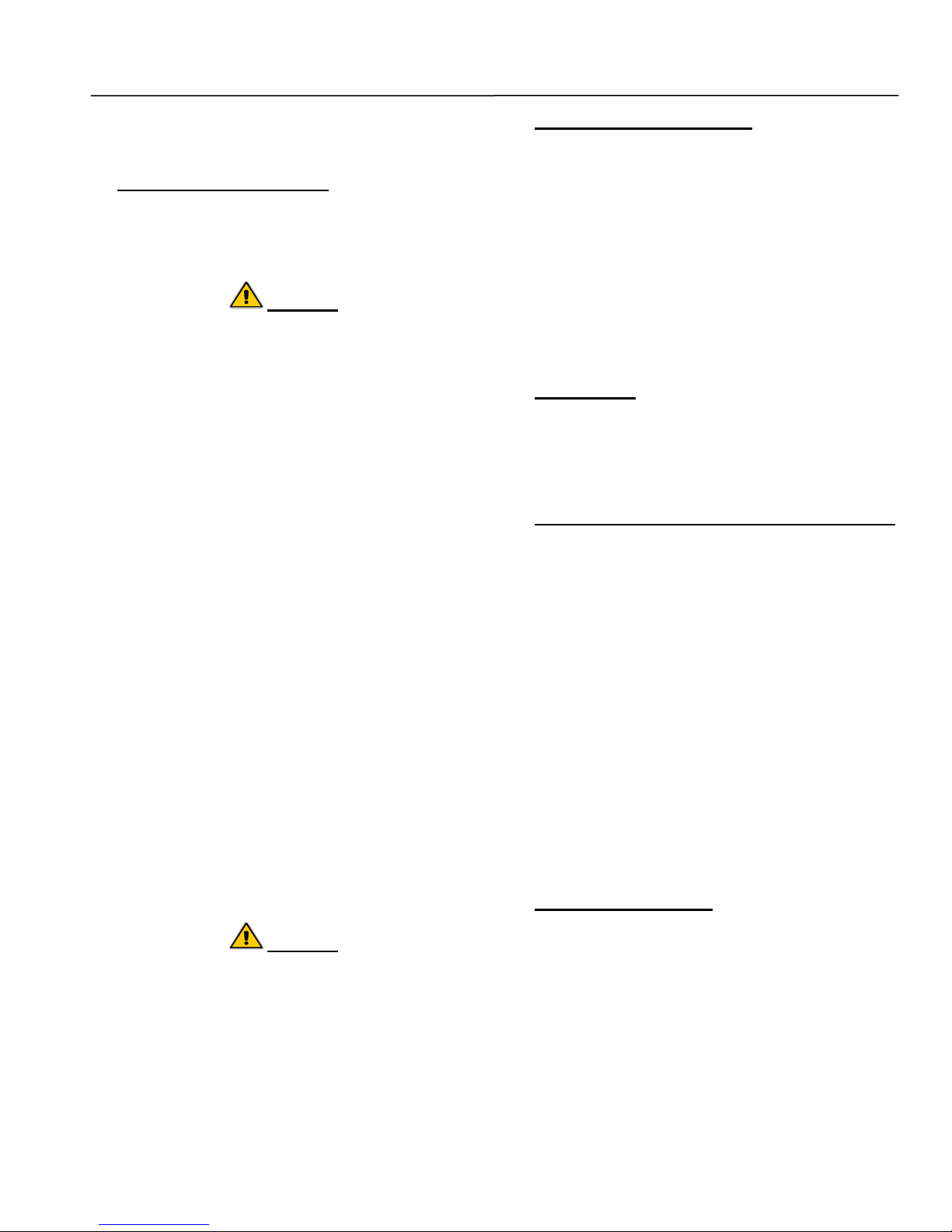

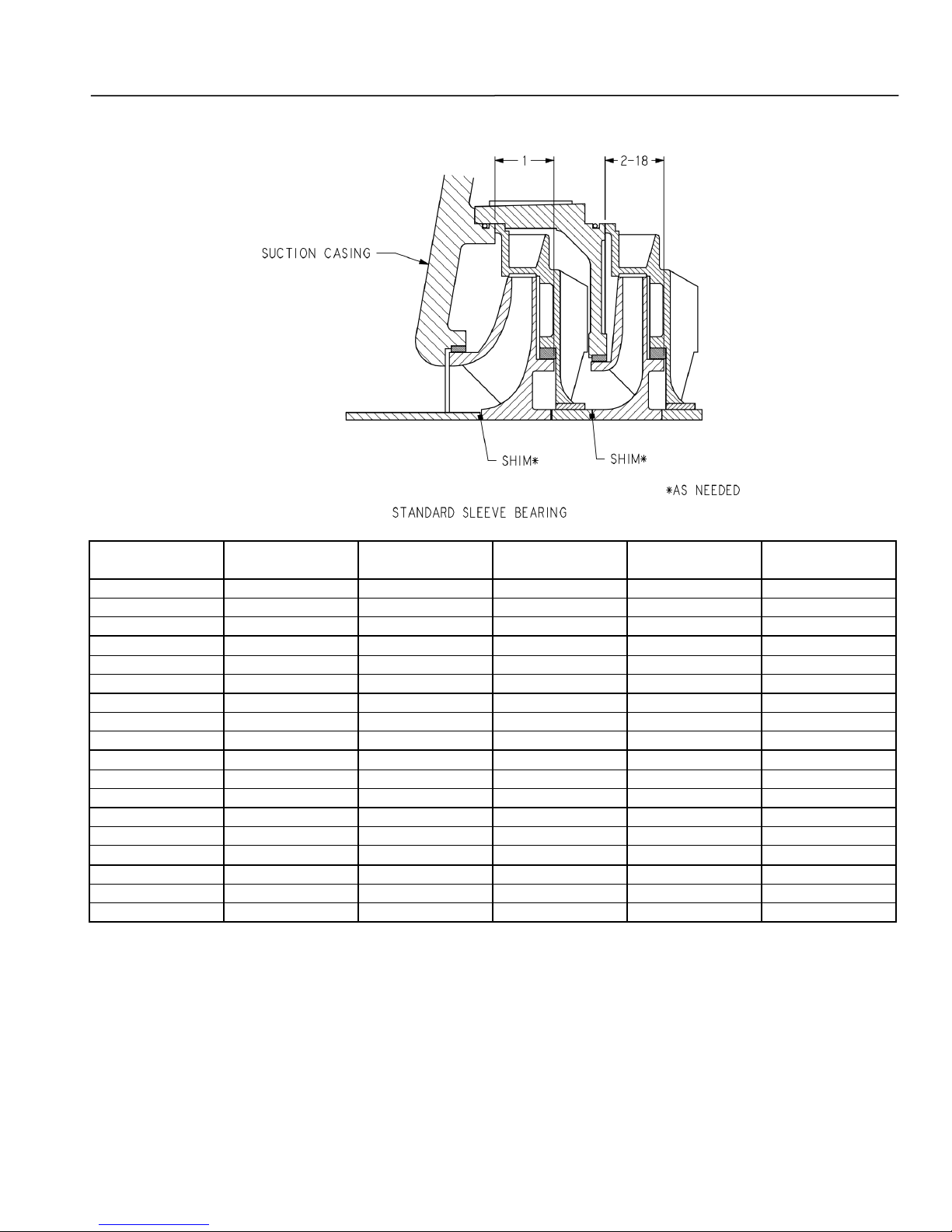

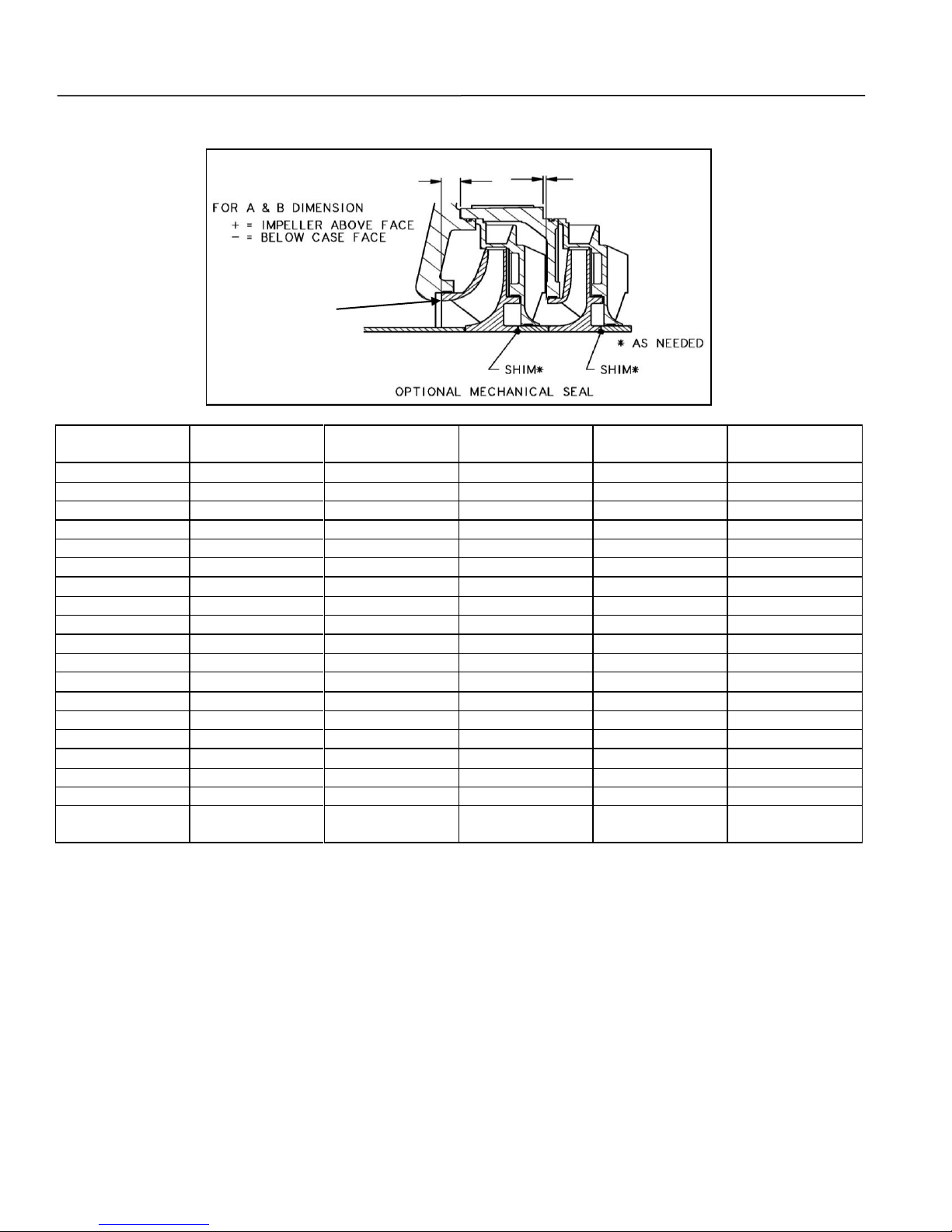

Axial Impeller Alignment Control Dimensions. Axial

impeller alignment control dimension are located in

Table 3 and are arranged by pump size.

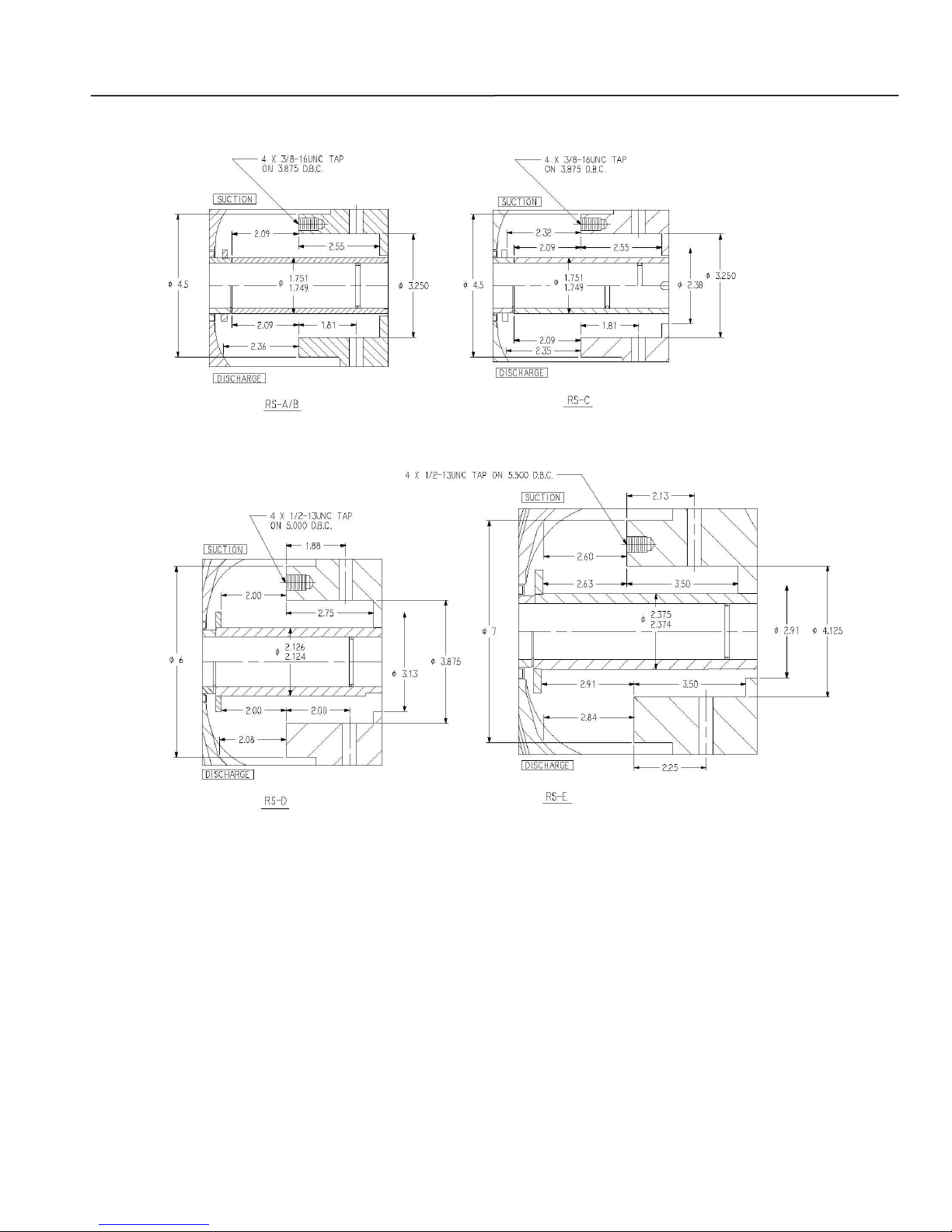

Seal Chamber Dimensions. Standard seal chamber

dimensions are located in Figure 1 and are arranged by

pump size.

Basic Design Features. Basic design features of the

pump are located in Tables 3, 4, 5, 6, 7, 10, and Figures

2 and 3 and are arranged by pump model.

Key Mechanical Data. Key mechanical data for the

pump is located in Table 8 and is arranged by pump

model.

Permissible Nozzle Loads. The forces and moments

in Table 9 are to be understood as the limit for a single

acting force or moment along the particular coordinate

axes or any resultant of two or more forces and

moment.

8

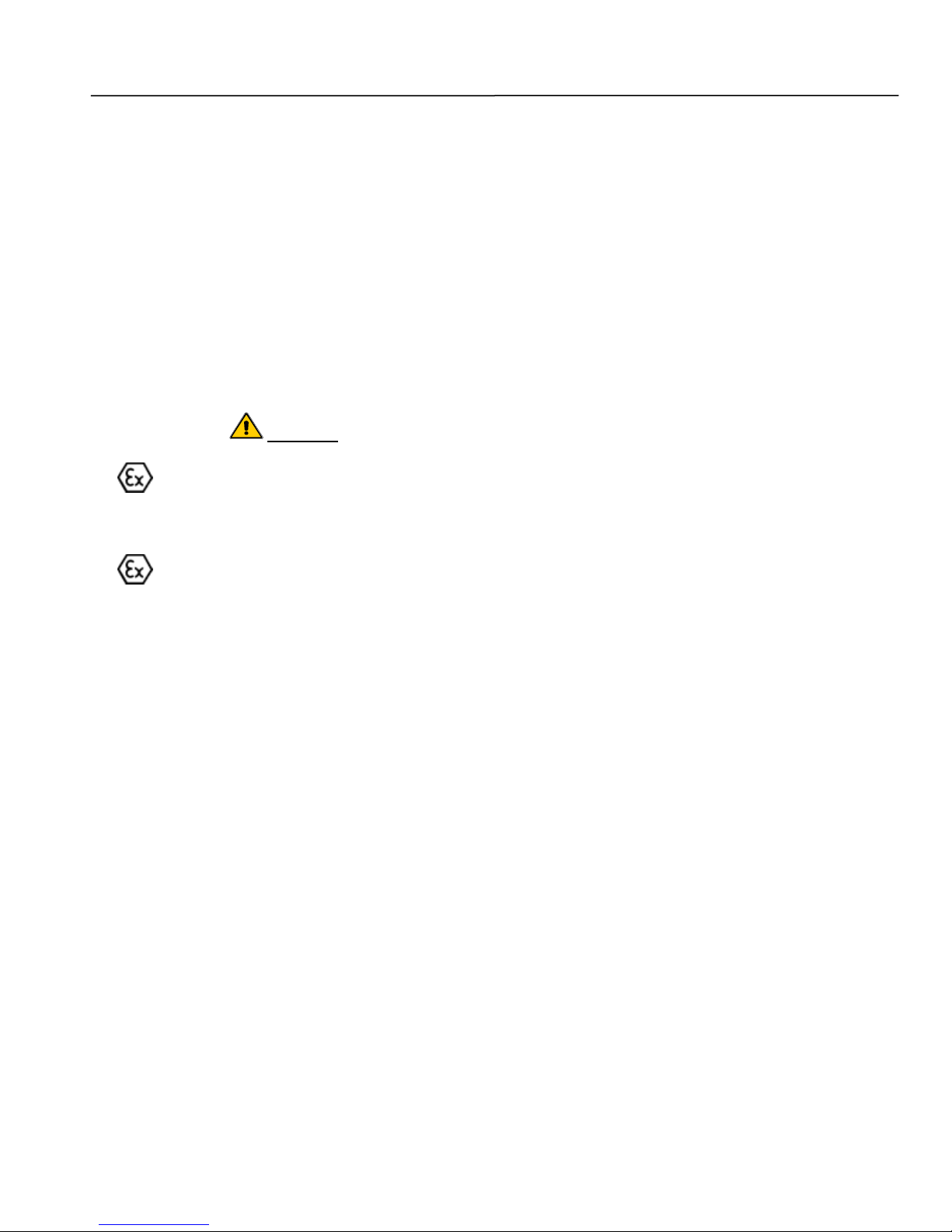

RS – Multi-Stage, I-280

Stages

Pump Size A

(Inches)

Pump Size B

(Inches)

Pump Size C

(Inches)

Pump Size D

(Inches)

Pump Size E

(Inches)

1

1.147

1.150

1.267

1.580

2.093

2

1.144

1.143

1.263

1.635

1.998

3

1.141

1.140

1.260

1.632

1.995

4

1.138

1.137

1.257

1.629

1.992

5

1.135

1.134

1.254

1.626

1.989

6

1.132

1.131

1.251

1.623

1.986

7

1.129

1.128

1.248

1.620

1.983

8

1.126

1.125

1.245

1.617

1.980

9

1.123

1.122

1.242

1.614

N/A

10

1.12

1.119

1.239

1.611

N/A

11

1.117

1.116

1.236

1.608

N/A

12

1.114

1.113

1.233

1.605

N/A

13

1.111

1.110

N/A

N/A

N/A

14

1.108

1.107

N/A

N/A

N/A

15

1.105

1.104

N/A

N/A

N/A

16

1.102

1.101

N/A

N/A

N/A

17

1.099

1.098

N/A

N/A

N/A

18

1.096

1.095

N/A

N/A

N/A

Centrifugal Pump 280 – 16.03.EN

Table 3. Axial Impeller Alignment Control Dimensions

*Additional stages will require compensation for interstage compression, on average .003 inch per stage. Use .010

inch shim as needed. Refer to Section XI, Paragraphs E.

9

RS – Multi-Stage, I-280

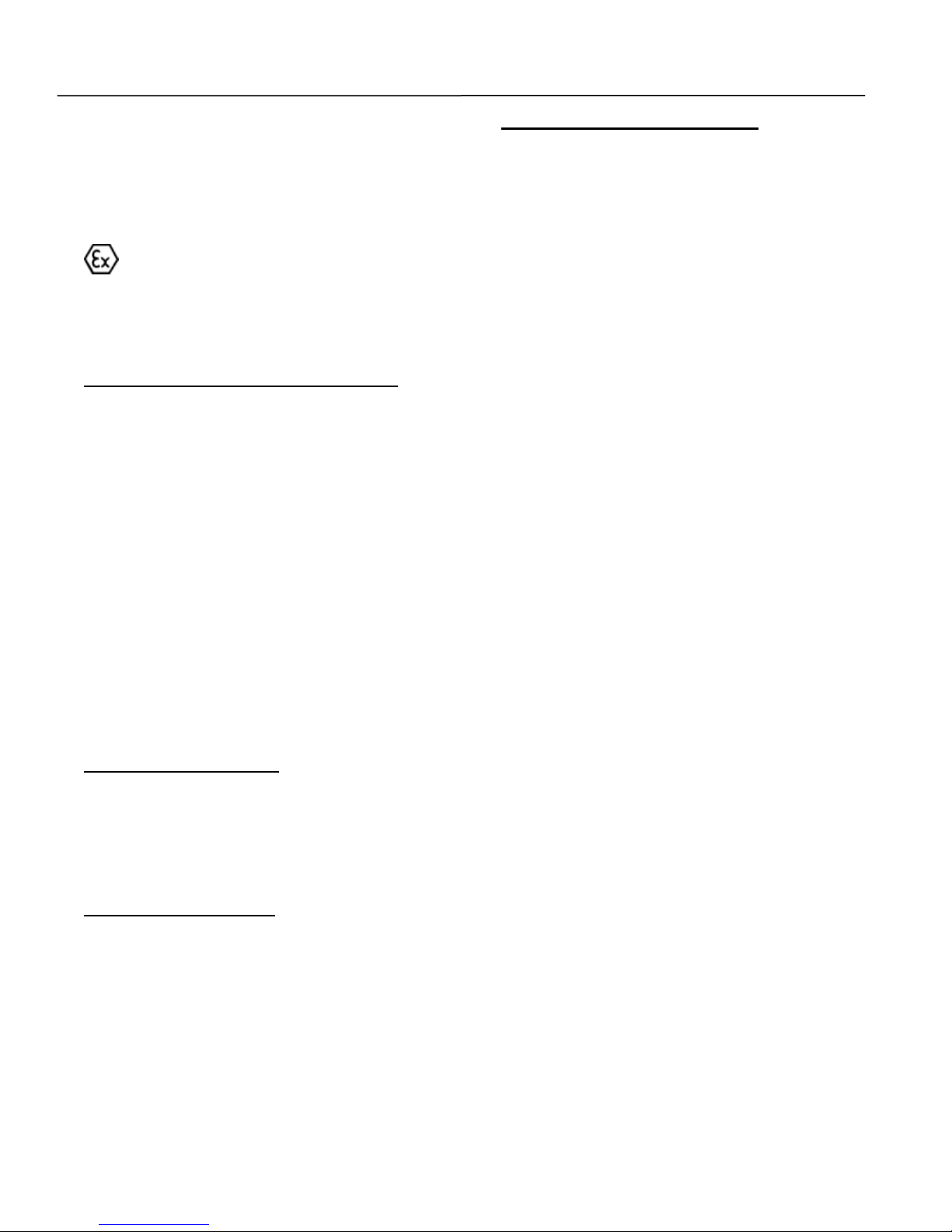

Stages

Pump Size A

(Inches)

Pump Size B

(Inches)

Pump Size C

(Inches)

Pump Size D

(Inches)

Pump Size E

(Inches)

1

-.110

-.110

-.125

.137

.185

2

-.113

-.113

-.128

.134

.182

3

-.116

-.116

-.131

.131

.179

4

-.119

-.119

-.134

.128

.176

5

-.122

-.122

-.137

.125

.173

6

-.125

-.125

-.140

.122

.170

7

-.128

-.128

-.143

.119

.167

8

-.131

-.131

-.146

.116

.164

9

-.134

-.134

-.149

.113

N/A

10

-.137

-.137

-.152

.110

N/A

11

-.140

-.140

-.155

.107

N/A

12

-.143

-.143

-.158

.104

N/A

13

-.146

-.146

N/A

N/A

N/A

14

-.149

-.149

N/A

N/A

N/A

15

-.152

-.152

N/A

N/A

N/A

16

-.155

-.155

N/A

N/A

N/A

17

-.158

-.158

N/A

N/A

N/A

18

-.161

-.161

N/A

N/A

N/A

Low NPSH

Impeller

See note below

See note below

See note below

See note below

See note below

2 - 18

1 (Discharge Side)

Low NPSH Impeller

(Suction)

Centrifugal Pump 280 – 16.03.EN

Table 3. Axial Impeller Alignment Control Dimensions - Continued

*Additional stages will require compensation for interstage compression, on average .003 inch per stage. Use .010

inch shim as needed. Refer to Section XI, Paragraphs F.

RSA No NPSH Impeller

RSB .210 – [#of stages X (.003) - Gaps] = NPSH Impeller Setting

RSC .538 – [#of stages X (.003) - Gaps] = NPSH Impeller Setting

RSD .792 – [#of stages X (.003) - Gaps]= NPSH Impeller Setting

RSE .210 – [#of stages X (.003) - Gaps] = NPSH Impeller Setting

10

RS – Multi-Stage, I-280

Centrifugal Pump 280 – 16.03.EN

Figure 1. Seal Chamber Dimensions

11

RS – Multi-Stage, I-280

Pump Model

At Impeller (Inches)

At Coupling (Inches)

A

1.437

1.250

B

1.437

1.250

C

1.437

1.250

D

1.574

1.500

E

1.771

1.625

Pump Model

Sleeve Bearing New

(Inches)

Sleeve Bearing

Replacement Limits

(Inches)

Sleeve

(Ø = Diameter Measured)

New (Inches)

Replace (Inches)

A

1.758/1.760

Ø > 1.762

1.751/1.749

Ø < 1.746

B

1.758/1.760

Ø > 1.762

1.751/1.749

Ø < 1.746

C

1.758/1.760

Ø > 1.762

1.751/1.749

Ø < 1.746

D

1.972/1.974

Ø >1.976

1.965/1.963

Ø < 1.961

E

2.382/2.384

Ø >2.386

2.375/2.373

Ø < 2.371

Pump Model

Suction End (Inches)

(from end of sleeve to face of collar)

A

3.100

B

3.100

C

3.100

D

4.322

E

4.500

Centrifugal Pump 280 – 16.03.EN

Table 4. Shaft Dimensions

Table 5. Sleeve Bearing Dimensions

Table 6. Standard Design Pump Mechanical Seal Settings

12

RS – Multi-Stage, I-280

Pump

Model

Discharge End (Seal Type 1)

(for reference only) – Inches

(from face of box to face of

collar)

Discharge End (Seal Type

8B1) (for reference only) –

Inches

(from face of box to face of

collar)

Suction end (Seal Type 1 or

21)

- Inches

(from face of box to face of

collar)

A

.750

1.375

1.000

B

.750

1.375

1.000

C

.750

1.375

1.000

D

2.062

1.750

1.312

E

1.792

1.812

1.594

Item

Pump Model

A, B C D

E

Maximum Speed

3500 RPM

Max HP – (17-4 PH shaft)

370

370

603

900

Max HP – (416 SS Shaft)

308

308

500

690

WR2 of Rotor – 1st Stage (lb-In2)

14.6

30.8

36.7

106.5

WR2 of Rotor –

each Stage (lb-In2)

10.2

26.7

31.1

94.4

Lubrication Method (Standard)

Oil – ISO Grade 68

L10 Bearing Life (hrs) - Thrust

50,000

L10 Bearing Life (hrs) - Radial

50,000

Radial Bearing Type

307

307

308

309

Thrust Bearing Type

7307

7307

7308

7309

Plan 13

Plan 11

Plan 13

Plan 23

Plan 21

Centrifugal Pump 280 – 16.03.EN

Table 7. Optional Design Pump Mechanical Seal Settings

Table 8. Key Mechanical Data

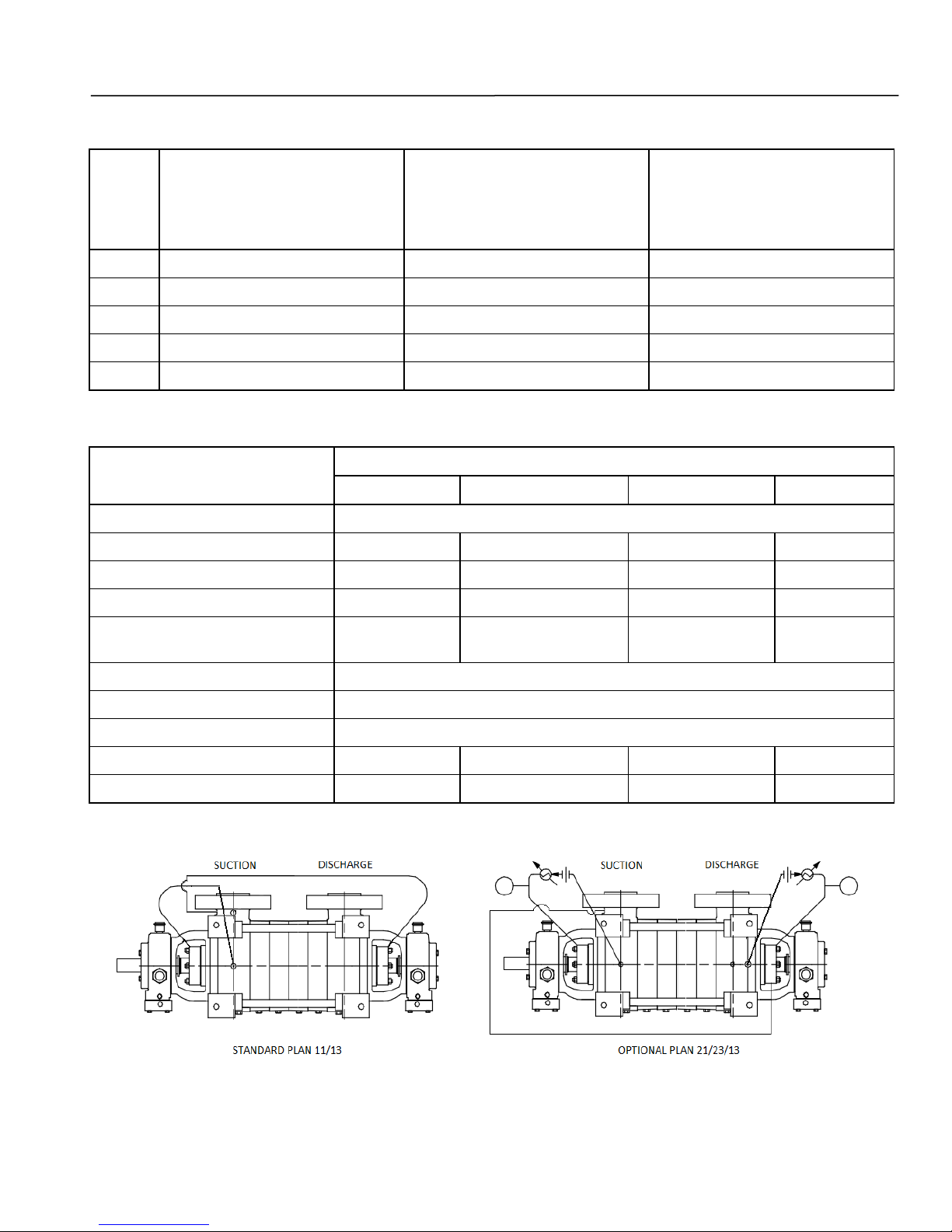

The standard seal flush plans provided with the optional outboard mechanical seal are shown below.

Recirculation from Suction Point to Seal Recirculation from Discharge Point thru a TI

and Heat Exchanger to Seal

Figure 2. Standard Seal Flush Plans

13

Loading...

Loading...