Carver Pump 855 Series, 855-CC, 855-OH Safety, Installation, Operation And Maintenance Instructions

855 – Filtrate Pump

Part Number: _______________________________________

Serial Numbers: _____________________________________

These operating instructions contain fundamental information and precautionary notes. Please read the manual

thoroughly prior to installation of unit, electrical connection and commissioning. It is imperative to comply with all

other operating instructions referring to components of individual units.

I-855

855-15.04.EN

SAFETY, INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

This manual shall always be kept close to the unit’s location of operation or directly on the pump set.

I-855

EC Declaration of Conformity

Kurt Doren

Quality/ ISO Manager

www.carverpump.com

Phone: 1-563-263-3410

Email: sales@carverpump.com

855 – Filtrate Pump 855-15.04.EN

MANUFACTURER: CARVER PUMP COMPANY

2415 PARK AVE.

MUSCATINE, IOWA, USA 52761

PRODUCT DESCRIPTION: 855-OH, 855-CC Filtrate Pumps

PART NUMBER:

SERIAL NUMBER:

DATE MANUFACTURED:

APPLICABLE EUROPEAN DIRECTIVES:

Machinery: The designated product complies with the following basic requirements of Directive 2006/42/EC:

Appendix I, section 1.1.2, 1.1.3., 1.1.5., 1.3.1., 1.3.2., 1.3.3., 1.3.4., 1.3.7., 1.3.8., 1.4.1., 1.4.2.1., 1.5.1.,

1.5.8., 1.5.9., 1.5.13., 1.6.1., 1.6.4., 1.6.5., 1.7.

APPLICABLE HARMONIZED STANDARDS:

Machinery: EN ISO 12100:2010 EN ISO 13732-1:2008

EN 626-1:2008 EN ISO 13857:2008

Declaration of Incorporation of Partly Completed Machinery (valid for 855 pumps supplied without a motor)

The product described in this Declaration of Conformity complies with the Applicable European Directives, EHSRs and

relevant sections of the Applicable International Standards "as a Component". The incorporation of this pump with Electric

Motors that are marked to confirm that they comply with the Low Voltage Directive 2006/95/EC and all the necessary guards,

must be declared in conformity by the assembler.

Declaration of Conformity of Completed Machinery (valid for 855 pumps supplied complete with a motor)

The product described in this Declaration of Conformity complies with the Applicable European Directives, EHSRs and

relevant sections of the Applicable International Standards. Motors for CE marked pumps will have motors that are marked to

confirm that they comply with the Low Voltage Directive 2006/95/EC.

The special technical documentation has been complied according to Annex VII Part B of Directive 2006/42/EC, and will be

made available in electronic form to the authorities of the individual states upon justified request.

NOTE: The 855 pumps are NOT supplied or Declared to ATEX Directive 94/9/EC.

Person authorized to compile the technical documentation:

Kurt Doren, Quality/ISO Manager, Carver Pump Company, 2415 Park Ave, Muscatine Iowa, USA 52761

Authorized Signature: Date: March 2015

Important safety information is contained in the installation, operation and service manuals; read and understand this

information prior to installing or using this equipment

This Document applies only to the equipment described above and is invalid if not reproduced in its entirety.

I-855

Installation Date

Location

Application

855 – Filtrate Pump 855-15.04.EN

SERVICE RECORD PAGE

Service No. ______________________ Model _________________________ Size and Type _______________

Customer Order No. ____________________________ Date Installed __________________________________

PUMP RATING

Capacity _____________________________________ Total Head ____________________________________

Suction Pressure ______________________________ Speed (RPM) __________________________________

Liquid pumped ________________________________ Temperature ___________________________________

Specific Gravity _______________________________ Viscosity ______________________________________

Service ______________________________________

PUMP MATERIALS

Casing _________________________ Impeller _______________________ Shaft _______________________

Gaskets _____________________________________ Bearing Frame _________________________________

Mechanical Seal/Packing ________________________

MOTOR DATA

Motor __________________________ Make _________________________ Serial No. ___________________

Type ___________________________ Frame ________________________ AC or DC ___________________

HP _____________________________ RPM _________________________ Volts _______________________

Phase __________________________ Cycles ________________________

I-855

INSPECTION DATE

REPAIR TIME

REPAIRS

COST REMARKS

855 – Filtrate Pump 855-15.04.EN

NOTES ON INSPECTION AND REPAIRS

I-855

855 – Filtrate Pump 855-15.04.EN

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

TABLE OF CONTENTS

SECTION/PARAGRAPH PAGE

SECTION/PARAGRAPH PAGE

I. GENERAL DESCRIPTION ............................... 1

A. General Information ................................... 1

B. Machinery Directive 2006/42/EC ............... 1

C. Disclaimer .................................................. 1

D. Personnel Qualification and Training ......... 1

E. Pump Identification..................................... 2

F. Parts Inventory Guide ................................ 2

G. Parts Ordering ............................................ 2

H. Unauthorized Modification and

Manufacture of Spare Parts ..................... 2

I. Unauthorized Modes of Operation ............. 2

II. SAFETY ............................................................ 2

A. Safety Precautions ..................................... 2

B. Summary of Safety Marking ....................... 2

C. Scope of Compliance ................................. 3

D. Safety Awareness ...................................... 3

E. Safety Instructions for the Operator/User .. 3

F. Safety Instructions for Maintenance

Inspection and Installation Work ............ 3

G. General Safety Instructions ........................ 3

H. Non-Compliance with Safety Instructions .. 4

III. EQUIPMENT DESCRIPTION ........................... 4

A. Pump History .............................................. 4

B. Pump Features ........................................... 4

C. Pump Details .............................................. 4

IV. EFFECTS OF FLUIDS ..................................... 5

A. Net Positive Suction Head (NPSH) ............ 5

B. Changing Pump Speed .............................. 6

C. Effects of Viscosity ..................................... 6

D. Effects of Specific Gravity .......................... 6

V. TECHNICAL DATA ........................................... 6

VI. INSPECTION AND STORAGE ........................ 9

A. Inspection ................................................... 9

B. Packing for Return ..................................... 9

C. Storage of Pump ........................................ 9

VII. INSTALLATION ................................................ 10

A. Location ..................................................... 10

B. Handling ..................................................... 10

C. Pre-Installation Procedures ....................... 11

D. Piping ......................................................... 11

E. Auxiliary Piping Connections

and Gauges ........................................... 11

F. Motor .......................................................... 11

G. Direction of Rotation .................................. 12

VIII. OPERATION .................................................... 12

A. Pre-Start Cautions ..................................... 12

B. Priming ....................................................... 12

C. Starting the Pump ...................................... 12

D. Operating Checks ...................................... 12

E. Stopping the Pump .................................... 13

F. Indefinite Shutdown ................................... 13

IX. TROUBLESHOOTING OPERATING

PROBLEMS ...................................................... 13

X. MAINTENANCE ............................................... 16

A. Lubrication of Pump Bearings .................... 16

B. Lubrication of Motor Bearings .................... 16

C. Torque Values ............................................ 16

XI. SERVICE AND REPAIR ................................... 17

A. Preparations for Disassembly of Pump ..... 17

B. Disassembly of Pump ................................ 18

C. Parts Inspection ......................................... 19

D. Reassembly of Pump ................................. 20

E. Replacement of Packing ............................ 22

F. Replacement of Mechanical Seal .............. 23

G. Belt Installation and Adjustment ................ 24

H. Optional Swing-out Mount Installation ....... 26

I. Motor .......................................................... 27

J. Check Valve ............................................... 27

XII. PARTS LISTS AND DRAWINGS ..................... 27

I-855

855 – Filtrate Pump 855-15.04.EN

TABLE OF CONTENTS - Continued

LIST OF TABLES

NUMBER TITLE PAGE

1. Estimated Noise Characteristics .................. 7

2. Key Component Materials ........................... 8

3. Key Mechanical Data ................................... 8

4. Pumping Unit Troubleshooting .................. 14

5. Recommended Torque Values .................. 16

6. Recommended Tools ................................. 16

7. Belt Tensioning .......................................... 26

8. Parts List .................................................... 28

9. Recommended Spare Parts ...................... 29

LIST OF ILLUSTRATIONS

NUMBER TITLE PAGE

1. Model 855-OH Pump ................................... 4

2. Optional Swing-out ...................................... 5

3. Stuffing Box Dimensions.............................. 7

4. Transport of the Bare Pump ........................ 10

5. Transport of Close-Coupled Pump .............. 10

6. Transport of Complete Unit.......................... 10

7. Removing Packing with Hook ...................... 22

8. Packing Alignment ....................................... 23

9. Mechanical Seal .......................................... 23

10. Belt Tensioning ............................................ 25

11. Swing-out Assembly .................................... 26

12. Drilling Tank Flange for Swing-out .............. 27

13. Adjuster Bolt (Closed position) .................... 27

14. Adjuster Bolt (Open position) ....................... 27

15. Sectional Assembly - Close-Coupled

Pump (Shown with Mechanical Seal) ........ 30

16. Sectional Assembly with Overhead

Drive (Shown with Packing) ....................... 31

17. Optional Swing-out Assembly ...................... 32

18. Model 855 Tank Mounting Flange ............... 33

19. Model 855 Universal Discharge Flange ....... 34

I-855

855 – Filtrate Pump 855-15.04.EN

I. GENERAL DESCRIPTION AND

SAFETY PRECAUTIONS.

A. GENERAL INFORMATION. Carver Pump

Company products are carefully engineered and

manufactured and, if properly installed, maintained, and

operated, should provide maintenance-free operation

and a long service life.

CAUTION

B. MACHINERY DIRECTIVE 2006/42/EC. This

product is designed to Conform with Machinery Directive

2006/42/EC, Safety of Machinery EN ISO 12100:2010,

EN ISO 13732-1:2008, EN 626-1:2008, EN ISO

13857:2008, and the EHSRs.

Complete Machinery for use in EU and EAA will have

CE mark and Declaration of Conformity. Motors for CE

marked pumps will have motors that are marked to

confirm that they comply with the Low Voltage Directive

2006/95/EC.

These instructions must always be kept close

to the product's operating location or directly

with the product.

This manual is designed to provide sufficient material to

properly maintain the total pumping unit. The information

presented should improve your knowledge and

understanding of the Filtrate Pump, thus upgrading the

reliability, service life, and quality of pump maintenance.

These operating instructions are intended to facilitate

familiarization with the product. These operating

instructions do not take into account local regulations;

the operator must ensure that such regulations are

strictly observed by all, including the personnel called in

for installation. Compliance with such laws relating to

the proper installation and safe operation of the pumping

equipment is the responsibility of the equipment owner

and all necessary steps should be taken by the owner to

assure compliance with such laws before operating the

equipment. These instructions are intended to facilitate

familiarization with the product and its permitted use to

help satisfy safety requirements. Always coordinate

repair activity with operations personnel, and follow all

plant safety requirements and applicable safety and

health laws/regulations.

Refer to Figures 15 and 16 to locate the pump parts by

item number. Variations do exist between

configurations, not all parts described in the text may be

on your configuration.

CAUTION

These instructions should be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide and in

conjunction with the main user instructions

provided. The equipment must not be put into

service until all the conditions relating to safety

instructions have been met.

CAUTION

Pumps assembled without a motor will have a

Declaration of Incorporation and will not have a

CE mark. When a motor is added, all guards

must be installed, the motor must be CE

marked and the completed machine reviewed

for compliance for applicable EHSRs before a

CE mark is attached.

NOTE

Since 29 December 2009 Directive 2006/42/EC

has regulated the placing on the market, and

the putting into service, of machinery in the

EEA, replacing Directive 98/37/EC.

C. DISCLAIMER. Information in these User

Instructions is believed to be reliable. In spite of all the

efforts of Carver Pump Company to provide sound and

all necessary information the content of this manual may

appear insufficient and is not guaranteed by Carver

Pump Company as to its completeness or accuracy.

D. PERSONNEL QUALIFICATION AND TRAINING.

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be qualified

to carry out the work involved. If the personnel in

question do not already possess the necessary

knowledge and skill, appropriate training and instruction

must be provided. If required the operator may

commission the manufacturer/supplier to provide

applicable training.

Follow instructions in this manual carefully. Factory

warranty applies only when pump operates under

conditions as specified on order acknowledgment, and if

pump is properly installed and maintained as

recommended herein. A copy of this manual should be

available to operating personnel. Additional copies of

this manual are available upon request from Carver

Pump Company and your local distributor. For

comments and/or questions about information provided,

please contact Carver Pump Company or your local

distributor.

1

I-855

855 – Filtrate Pump 855-15.04.EN

E. PUMP IDENTIFICATION. The type of pump, pump

size, operating data, and serial number are all stamped

on the nameplate attached to the pump. Pump

specifications should be recorded upon receipt of the

pumping unit. Record all necessary information on the

pump service record page and inspection and repair

I. UNAUTHORIZED MODES OF OPERATION. The

warranty relating to operating reliability and safety of the

unit supplied is only valid if the pumping unit is used in

accordance with its designated use as described in the

following sections. The limits stated on the nameplate

must not be exceeded under any circumstances.

record provided at the front of this manual. This

information must be included in all correspondence

II. SAFETY.

regarding the unit. This will ensure that the correct pump

and/or parts are ordered in a timely manner.

A. SAFETY PRECAUTIONS. The manual is designed

to provide adequate instructions for the safe and

F. PARTS INVENTORY GUIDE. To avoid

unnecessary delays for maintenance, spare parts

should be readily available, purchase before and keep in

stock, for normal service. Most conditions will be

covered if this manual is followed. For every one to

three pumps, stock one spare set consisting of items

listed in Table 9, Recommended Spare Parts. Part

numbers correspond to Figures 15 and 16.

efficient installation, operation, or maintenance of the

pump. Failure or neglect to properly install, operate, or

maintain the pump may result in personal injury,

property damage, or unnecessary damage to the pump.

This manual must be read and understood both by the

installing personnel and the responsible trained

personnel/operators prior to installation and operation,

and it must always be kept close to the location of the

pumping unit for easy access.

G. PARTS ORDERING. When ordering replacement

parts, please specify:

B. SUMMARY OF SAFETY MARKING. The safety

instructions contained in this manual where non-

Model of pump (located on nameplate)

Serial number of pump (located on nameplate)

observance of the instruction will cause a hazard is

specially marked with the symbol:

Part name (located on parts list)

Quantity of parts needed

Carver Pump Company may ship an interchangeable

part that is not identical in appearance or symbol. This is

done only if the part has been improved. Examine parts

carefully upon delivery before questioning factory or

company representative. Never return parts to the

factory without authorization from Carver Pump

Company.

If an impeller is ordered, specify diameter across blade

tips. Be sure diameter was NOT trimmed further than

diameter shown on Carver Pump Company records.

If a driver or driver parts are ordered, specify name of

manufacturer and all other data found on the driver

nameplate.

H. UNAUTHORIZED MODIFICATION AND

MANUFACTURE OF SPARE PARTS. Modifications or

alterations of the pumping unit supplied are only

permitted after consultation with Carver Pump and to the

extent permitted by Carver Pump. Original spare parts

and accessories authorized by Carver Pump ensure

safety. The use of other parts can invalidate any liability

of Carver Pump for consequential damage and/or

warranty.

General hazard sign to ISO 7000 - 0434.

Notes highlight an operating or maintenance procedure,

condition, or statement which is essential, but is not of

known hazardous nature as indicated by DANGERS,

WARNINGS and CAUTIONS.

The word "CAUTION" is used to introduce safety

instructions whose non-observance may lead to damage

to the machine and its functions.

The word "WARNING" is used to introduce safety

instructions whose non-observance may lead to a

potential hazard exists, capable of producing injury to

personnel, if approved procedures are not followed.

The word “DANGER” indicates a location, equipment, or

system where imminent hazards exist, capable of

producing immediate injury or death to personnel, if

approved procedures are not followed.

Instructions attached directly to the machine, e.g.

Arrow indicating the direction of rotation

Markings for fluid connections must always be

complied with and be kept in a perfectly legible

condition at all times.

Observe all notes, caution or danger tags attached to

the equipment or included in this manual.

2

I-855

855 – Filtrate Pump 855-15.04.EN

C. SCOPE OF COMPLIANCE.

described in the manual for taking the unit out of service

must be adhered to.

Where Carver Pump has supplied only the bare shaft

pump, the rating applies only to the pump. The party

responsible for assembling the pump set shall select the

coupling, driver, seal and any additional equipment, with

the necessary EC Certificate/Declaration of Conformity

establishing it is suitable for the area in which it is to be

installed.

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor and so, for

pump sets with a VFD, the Certification for the motor

must state that it covers the situation where electrical

supply is from the VFD. This is particular requirement

still applies even if the VFD is in a safe area.

D. SAFETY AWARENESS. It is imperative to comply

with the safety instructions contained in this manual, the

relevant national and international explosion protection

regulations, health and safety regulations and the

operator’s own internal work, operation and safety

regulations.

E. SAFETY INSTRUCTIONS FOR THE OPERATOR

/USER.

Pumps handling fluids that are hazardous to personnel

must be decontaminated prior to being worked on.

Immediately following completion of the work, all safety

relevant and protective devices must be reinstalled

and/or reactivated. Please observe all instructions set

out in the Section VIII on start up before returning the

pumping unit to service.

G. GENERAL SAFETY INSTRUCTIONS.

Various federal, state, and local laws affect

installation, use, and operation of pumping

equipment. Compliance with such laws relating

to proper installation and safe operation of

pumping equipment is the responsibility of the

equipment owner.

Prior to working on pump or driver, ensure all

switches and circuit breakers have been locked

in the open (off) position and tagged, “Out of

Service.”

All circuits NOT known to be dead must be

considered live at all times.

Any hot or cold components that could pose a

hazard must be equipped with a guard by the

operator.

Guards which are fitted to prevent accidental

contact with moving parts (e.g. coupling) must

not be removed whilst the unit is operating.

Do NOT wear loose or torn clothing around

rotating machines.

While working near electricity, do NOT use

metal rules, flashlights, metallic pencils, or any

other objects having exposed conducting

material.

Leakages (e.g. at the shaft seal) of hazardous

fluids (e.g. explosive, toxic, hot) must be

contained so as to avoid any danger to persons

or the environment. Pertinent legal provisions

must be adhered to.

Electrical hazards must be eliminated. (In this

respect refer to the relevant safety regulations

applicable to different countries and/or the local

energy supply companies.)

Make sure you are NOT grounded while

adjusting electrical equipment or using

measuring equipment.

In general, use only one hand when servicing

live electrical equipment.

Make sure to de-energize all electrical

equipment before connecting or disconnecting

meters or test leads.

F. SAFETY INSTRUCTIONS FOR MAINTENANCE,

INSPECTION AND INSTALLATION WORK. The

operator is responsible for ensuring that all

maintenance, inspection and installation work be

performed by authorized, qualified personnel who are

thoroughly familiar with the manual and pumping unit.

The pumping unit must have cooled down to ambient

temperature, pump pressure must have been released

and the pump must have been drained before working

on any pumping unit. Work on the pumping unit must be

carried out during shutdown. The shutdown procedure

For connecting a meter to terminals for

measurement, use a range higher than the

expected voltage.

Check to make sure that the frame of the driver

and starter panel are securely grounded before

operating pumping unit or performing any tests

or measurements.

If a test meter must be held or adjusted while

voltage is applied, ground case of meter before

starting measurement. Do NOT touch live

equipment while holding the meter. Some

3

I-855

855 – Filtrate Pump 855-15.04.EN

moving vane-type meters should not be

grounded nor held during measurements.

Do NOT use test equipment known to be

damaged or in poor condition.

H. NON-COMPLIANCE WITH SAFETY

INSTRUCTIONS. Non-compliance with safety

instructions may result in personal injury, property

damage, or unnecessary damage to the pumping unit.

Non-compliance with these safety instructions will also

lead to forfeiture of any and all rights to claims for

damages. Non-compliance, can for example, result in:

Failure of important pumping unit functions.

Failure of prescribed maintenance and servicing

practices.

Hazard to personnel by electrical, mechanical,

and chemical effects.

III. EQUIPMENT DESCRIPTION.

A. PUMP HISTORY.

The Filtrate Pump line was designed in the late 1950’s

at the request of a large Original Equipment

Manufacturer (OEM) of vacuum filtration equipment.

The company had found that the typical centrifugal

pump would not operate against the high vacuum in a

filtrate receiver tank without the inclusion of a

hydrostatic leg in order to provide enough Net Positive

Suction Head Available (NPSHA) to prevent the pump

from cavitating and destroying itself.

The receiver tank flange-mounted Filtrate Pump was

designed to solve the OEM's problem and they have

been used in pumping liquids under vacuum or with very

low suction pressures ever since.

B. PUMP FEATURES.

Hazard to the environment due to leakage of

hazardous substances.

Avoid Possible Non-Compliance. The following

specific safety precautions apply to the pumping unit:

Do NOT exceed maximum discharge pressure

on discharge case (100 psig/ 690 kpa).

Do NOT operate pump without fluid to seal or

packing.

Do NOT run pump dry for extended periods of

time (longer than 1/2 hour)

Do NOT run pump against a closed discharge

valve.

Do NOT exceed the Maximum rated speed

(2400 rpm).

A check valve should be installed in the

discharge line.

Pumps assembled by Carver without a motor

will have a Declaration of Incorporation and will

not have a CE mark. When a motor is added, all

guards must be installed, the motor must be CE

marked and the completed machine reviewed

for compliance for applicable EHSRs before a

CE mark is attached.

The Filtrate Pumps do not require a hydrostatic leg, will

operate against vacuums up to 660 mm Hg (26” Hg) on

the suction side and if, on occasion, it pumps the

receiver tank dry, or the inflow of process liquid into the

tank is interrupted, it will continue to run, will maintain

the vacuum in the system, and when the suction again

becomes flooded it will prime itself and resume pumping

the process liquid. An important aspect of the pump’s

operation is that it accomplishes all of the foregoing

without the use of mechanical or electrical level

controls on the receiver tank, thereby simplifying and

enhancing the reliability of the entire system.

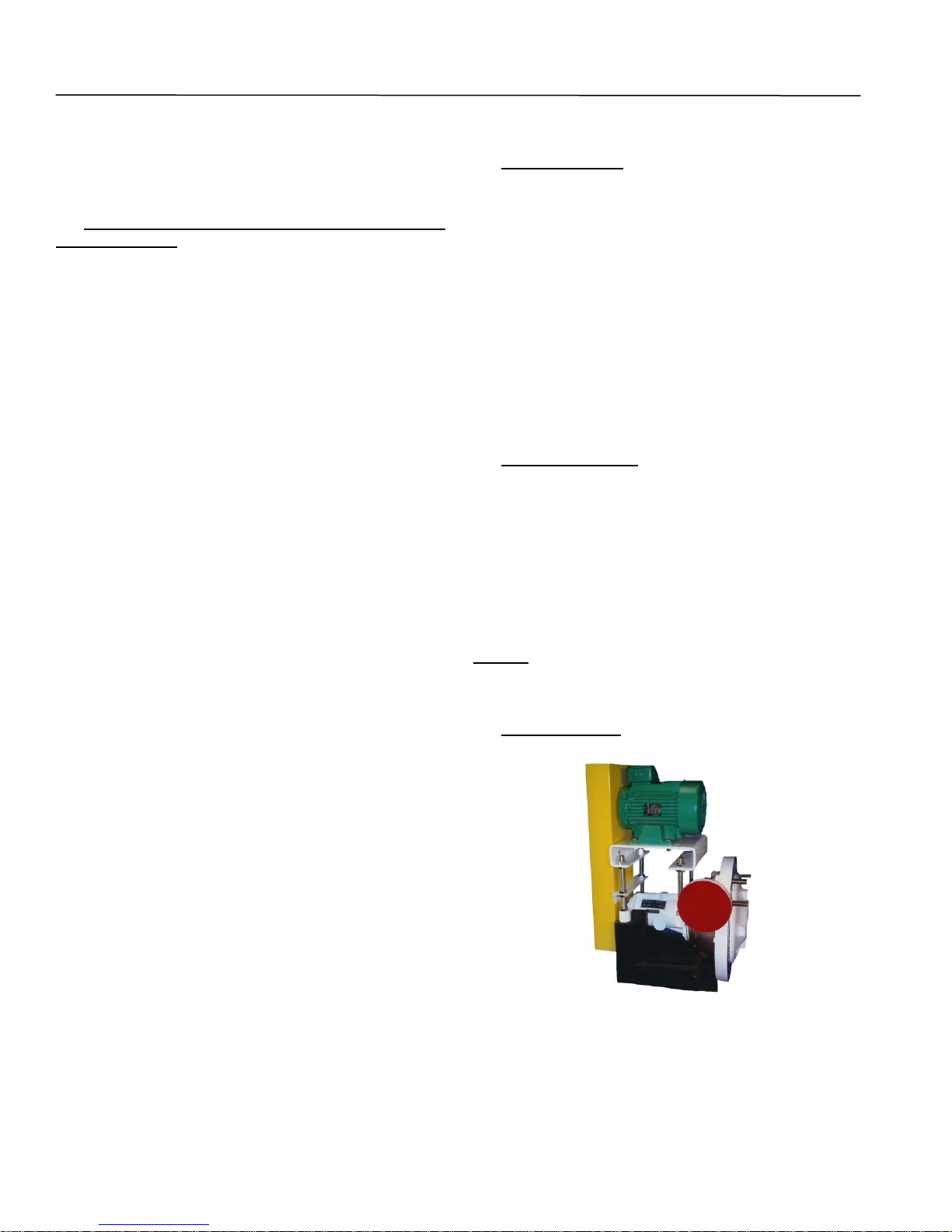

C. PUMP DETAILS.

4

Figure 1. Model 855-OH Pump

The line has two variations. The standard is the flange

mounted Model 855-OH which features an overhead vbelt drive arrangement for varying the pump speed and

I-855

855 – Filtrate Pump 855-15.04.EN

thereby the head/flow conditions delivered by the pump.

This pump is also built in a close coupled (direct drive)

configuration, the Model 855-CC, for use when the vdrive feature is not required.

The bearing frame (19) is connected to the motor plate

with threaded rods (632) and jam nuts (616). The motor

is bolted to the motor plate with bolts (604) and hex nuts

(618).

Each of the models is built in six sizes: 1”, 1 ½”, 2”, 2

½”, 3” and 4” discharges. The complete pumps are built

with a CE stamp indicating compliance with European

Common Market specifications.

Standard materials of construction are cast iron and

CD4MCu. Other metallurgies are available, such as

hard iron, monel, hastelloy, etc... Also available is a fully

rubber lined version for abrasive and extremely

corrosive application including the Flue Gas Desulfurization (FGD) process with high chlorides.

The bare pump consists of following major parts and

options. Please refer to Figures 15, 16 and 17,

assembly drawings, for the location of parts identified by

item numbers.

Item 1 - Casing. The casing houses the impeller (3)

and consists of the discharge volute, and a tangent

discharge nozzle, discharge flange, back cover, stuffing

box and mounting bracket. The casing is fastened to the

bearing frame (19) or motor (200) with capscrews (601).

The casing bolts to the suction cover (10) and to the

discharge piping with special flanges as shown in Figure

19.

Item 3 - Impeller. The filtrate pumps are equipped with

semi-open impellers. The impeller is keyed to the shaft

(6) by the impeller key (32) and is locked in place by the

impeller bolt (26) and impeller washer (28).

Item 6 - Shaft. The shaft of the 855-OH pump is

designed to provide stabilization to the rotor system

when pump operates away from the best efficiency

point. Drive belt(s) connect the pump shaft to the driver

shaft.

Item 16 and 18 – Ball Bearings. Deep groove Conrad

type, C-3 internal fit ball bearings (8"pumps) or doublerow angular contact C-3 internal fit ball bearings

(9"pumps) are housed in the bearing frame (19). The

ball bearings are sealed and lubricated for life.

Item 19 - Bearing Frame. The principal function of the

bearing frame is to carry the loads from the liquid end of

the pump to the base and to transport power from the

motor (200) to the impeller (3). The bearing frame has

an outboard ball bearing (16) and an inboard ball

bearing (18). This bearing frame is designed to be belt

driven by an overhead (OH) mounted motor

Item 23 - Motor Plate. An adjustable motor plate is

designed to provide adequate support for the pump and

motor (200) so the pump can be operated without

excessive deflection, excessive vibration, or resonance.

Item 53 – Optional Swing-out. Pumps may be

equipped with an optional swing-out to facilitate

servicing the pump and to aid in inspecting for debris.

Figure 2. Optional Swing-out

Item 90 – Mechanical Seal. A mechanical seal may be

supplied in place of a packed stuffing box when

specified by the customer. Many variations of types and

materials are available.

Item 180 - Packing. Pumps equipped with packing

have a lantern ring (29) which is located inside the flush

water connection on the stuffing box.

Item 276 – Belt Drive. The Model 855-OH is supplied

with belts (276) and sheaves (277). The belts and

shaeves should be sized to obtain the desired pump

shaft speed for the given motor.

IV. EFFECTS OF FLUIDS.

A. NET POSITIVE SUCTION HEAD (NPSH). Any

liquid, hot or cold, must be pushed into the impeller of

the pump by some absolute pressure, such as the

atmosphere or the vessel pressure from which the pump

takes its action.

The head in feet of liquid necessary to maintain the

required flow into the pump is called the Net Positive

Suction Head (NPSH). This value is measured above

the vapor pressure of the liquid at the pumping

temperature.

NPSH is commonly expressed in two ways: the NPSH

required by the pump, and shown on the pump curve, is

the head needed to cover the losses in the pump

suction and the energy required to enable the liquid to

climb onboard the leading edge of the impeller vane.

The NPSH available is that inherent in the system,

taking into account friction losses in suction piping,

valves, fittings, etc. In all cases, the NPSH available,

5

I-855

855 – Filtrate Pump 855-15.04.EN

measured above vapor pressure, must exceed the

NPSH required in order to push the liquid into the pump.

B. CHANGING PUMP SPEED. Changing the speed of

a centrifugal pump affects the capacity, total head,

NPSH required and the brake horsepower. In general

the capacity will vary in a direct ratio with the speed,

whereas the total head and NPSH required will vary as

the ratio of the speed squared. The brake horsepower

will vary as the ratio of the speed cubed.

NOTE

Pump speeds for close coupled (Model 855)

units are generally limited to 1750 RPM. Pump

speeds for belt driven (Model 855-OH) units are

limited to 2400 RPM.

V. TECHNICAL DATA.

Specifications and operating limits should be recorded

on a Service Record Page; an example is located in the

front matter of this manual. Record the necessary

information upon receipt of the pumping unit. See

Figures 18 and 19 for mating flange information and

weights.

Sound Characteristics. Table 1 shows the estimated

Sound Pressure levels for the Filtrate Pump. These

values are typical, actual values will vary with motor

used, pump size, condition of service, belt adjustment,

bearing condition, etc. Actual values for specific units

must be determined by testing.

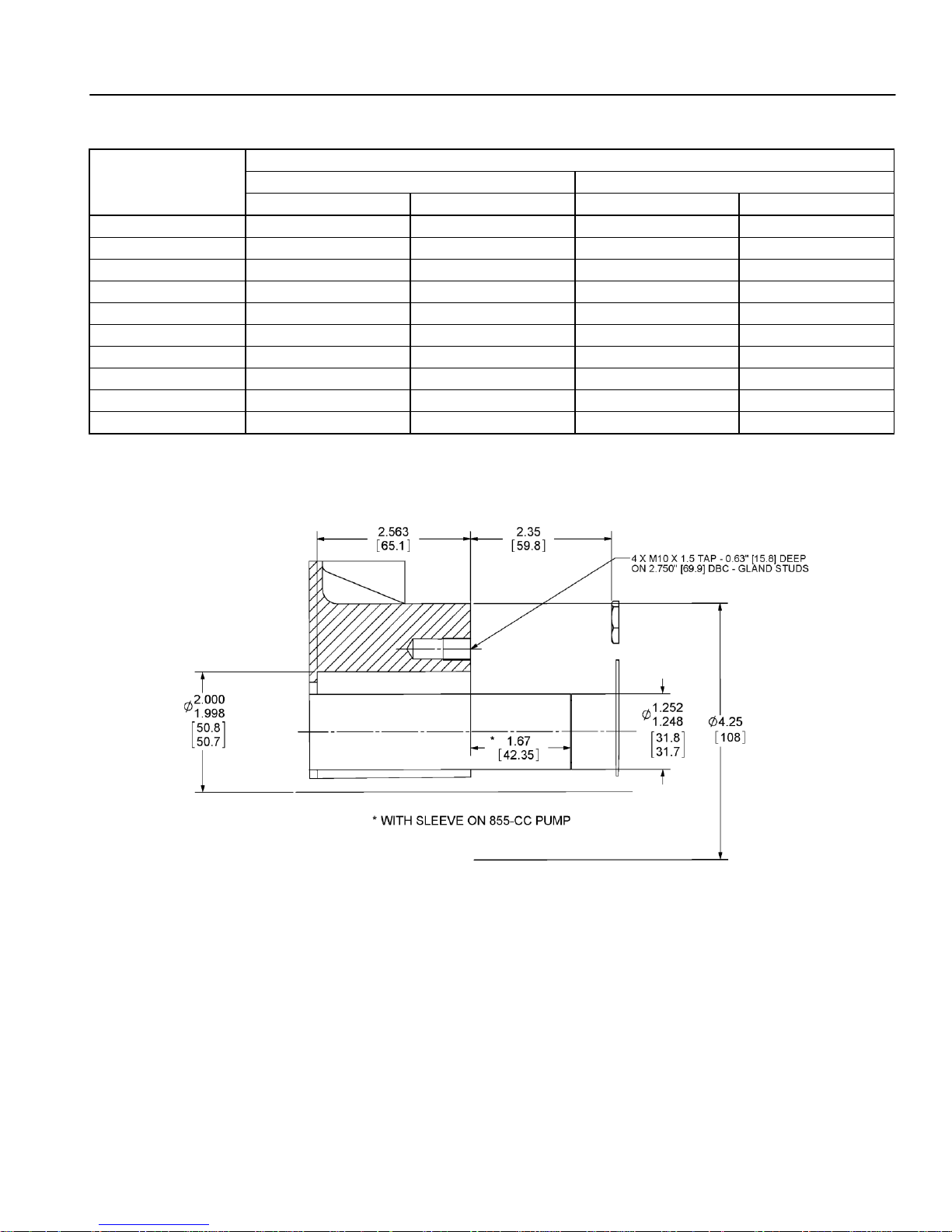

Stuffing Box. The stuffing box, Figure 3, is where the

packing or mechanical seal is located.

C. EFFECTS OF VISCOSITY. The pump is designed

to deliver rated capacity at rated head for a liquid with a

particular viscosity. When pump is handling heavy

viscous liquid, the viscosity of the liquid must allow it to

be pumped easily. The liquid may have to be heated

prior to starting the pump. When contemplating

operation at some viscosity other than that for which the

pump was originally designed, check with Carver Pump

Company.

D. EFFECTS OF SPECIFIC GRAVITY. The capacity

and total head in feet of liquid developed by a centrifugal

pump are fixed for every point on the curve and are

always the same for the same speed. Neither capacity

nor total head will be affected by a change in the

specific gravity of the liquid pumped. However, since the

discharge pressure in Pounds per Square Inch (PSI)

and the brake horsepower required driving the pump are

functions of the specific gravity of the liquid, both will be

affected in direct proportion by any change in specific

gravity. Therefore, an increase in specific gravity will

raise the discharge pressure and is dangerous as it

might overload the pump's driver, or exceed the pump

casing allowable pressure.

Materials of Construction. The listed material

specifications in Table 2 are referenced for standard

catalog options.

Mechanical Data. The Key Mechanical data in Table 3

lists the maximum allowable horsepower at the

maximum allowable pump shaft speed (2400 rpm).

Dimensions and diameters are reference and given in

inches.

6

I-855

Rated Power Input

PN (kw)

Estimated Sound Pressure Level L pA (dB)*

Pump with Motor

Pump Only

1750

1450

1750

1450

1.5

61.5

58.5

52

52

2.2

63.5

60.5

53

53

3.0

65.5

62.5

55

55

4.0

67

64

57

57

5.5

68.5

65.5

57.5

57.5

7.5

70

67

58.5

58.5

11.0

72

69

60.5

60.5

15.0

73

70

61.5

61.5

18.5

73.5

70.5

62.5

62.5

22.0

74

71

63.5

63.5

* Measured at a distance of 1 m from the pump outline. Room and foundation influences have not been included.

The tolerance for these factors is 1 to 2 dB.

855 – Filtrate Pump 855-15.04.EN

Table 1. Estimated Noise Characteristics

Figure 3. Stuffing Box Dimensions

7

I-855

Component

Material

Specification

Bearing Frame

Ductile Iron

ASTM A536

Casing

Rubber

Lined C.I.

Natural Rubber

ASTM A48, Class 30

CD4MCu

ASTM A890

Cast Iron

ASTM A48, Class 30

Impeller

Cast Iron

ASTM A48, Class 30

CD4MCu

ASTM A890

Shaft

17-4PH

ASTM A564

Duplex

ASTM A276

Item

Bearing Frame

KFA

KFB

KFC

Max power (BHP) @ 2400 RPM

20

30

33

Maximum Speed - RPM

2400

2400

2400

Pump Size(s)

1"

1-1/2, 2" & 2-1/2"

3"& 4"

Maximum Discharge Pressure

100 psig / 690 kPa

Bearing type - radial bearing

6307

5307

5308

- thrust bearing

6307

5307

5308

Lubrication method (standard)

Sealed for life (Grease)

L10 bearing life (hrs) - radial

50,000

50,000

50,000

- thrust

100,000

100,000

100,000

Radial to thrust bearing C/L (in.)

5.83

5.83

5.83

Shaft diameters (in.) @ sheave

1.26

1.26

1.26

@ impeller hub

0.875

0.875

0.875

@ radial bearing

1.378

1.378

1.378

@ thrust bearing

1.378

1.378

1.378

@ stuffing box

1.250

1.250

1.250

Rotor WR2 (lb. - in.)

31.81

31.81

31.81

855 – Filtrate Pump 855-15.04.EN

Table 2. Key Component Materials

Table 3. Key Mechanical Data

8

I-855

855 – Filtrate Pump 855-15.04.EN

VI. INSPECTION AND STORAGE.

CAUTION

A. INSPECTION. Upon receipt of the shipment,

unpack and inspect the pumping unit and individual

parts to insure none are missing or damaged. Carefully

inspect all boxes and packing material for loose parts

before discarding them. Check to make sure the

shipment complies with the purchase order. Immediately

report any missing parts or damage incurred during

shipment to the factory and to the Transportation

Company and file your “damage and/or lost in shipment”

claim with the carrier.

B. PACKING FOR RETURN. If the pumping unit is

sent back to Carver Pump Company for repair, drain the

unit, and re-seal all flanges and connections that were

covered or plugged. Ship the pump(s) in an assembled

condition to prevent damage to sealing faces of

individual components. A Return Goods Authorization

(RGA) and a Material Safety Data Sheet (MSDS) is

required on all returned pumps. Copies of MSDS

records should be kept and maintained by the customer.

The customer is responsible for cleaning and flushing

the pump before it is returned to the factory. Make sure

to specify the fluid used in the service.

C. STORAGE OF PUMP. If the equipment is not to be

immediately installed and operated, store it in a clean,

dry, well ventilated place, free from vibrations, moisture

and rapid or wide variations in temperature.

NOTE

A pump which is made of iron or steel that sits

in extreme heat, high humidity, or full or

partially full water over 30 days will rust and will

most likely seize. If the pump rusts and/or

seizes, a complete overhaul and repair may be

necessary to refurbish the pump.

Consider a unit to be in storage when:

1. It has been delivered to the job site and is

waiting to be installed.

2. It has been installed but operation is delayed

pending completion of construction.

3. There are long (30 days or more) periods

between operating cycles.

4. The plant (or department) is shut down for

periods of longer than 30 days.

Measures to be taken for prolonged shutdown of

installed pumping unit. If the pumping unit remains

installed a periodic check of operation is in order to

make sure that the pump is always ready for instant

start-up and to prevent the formation of deposits within

the pump and the pump intake area. Start up the

pumping unit regularly once a month or once every 3

months for a short time (approximately 5 minutes)

during prolonged shutdown periods. Prior to operation

check run ensure that there is sufficient liquid available

for operating the pump.

Storage requirements vary depending on

climatic environment, length of storage and

equipment. For storage periods of three months

or longer, contact manufacturer for specific

instructions. Improper storage could damage

equipment and would result in non-warranty

covered restoration of non-warranty covered

product failures.

When storing the pump up to three months rotate the

shaft for several revolutions at least once per month to

coat the bearings with lubricant, retard oxidation and

corrosion, and prevent possible false brinelling.

The motor bearings should be prepared for storage

according to the motor manufacturer’s instructions, in

the motor manufacturer’s maintenance manual, which

should come with the motor.

Interim Storage (Indoors)/Preservation. When the

unit is temporarily put into storage, only the wetted low

alloy must be preserved. Commercially available

preservatives can be used for this purpose. Please

observe the manufacturer’s instructions for

application/removal.

The unit/pump should be stored in a dry room where the

atmospheric humidity is as constant as possible.

If stored outdoors, the unit and crates must be covered

by waterproof material to avoid any contact with

humidity.

Protect all stored goods against humidity, dirt, vermin

and unauthorized access!

All openings of the assembled unit components are

closed and must only be opened when required during

installation.

All blank parts and surfaces of the pump are oiled or

greased (silicone-free oil and grease) to protect them

against corrosion.

9

I-855

855 – Filtrate Pump 855-15.04.EN

VII. INSTALLATION.

A. LOCATION. The pump assembly should be

located in an area that will permit periodic inspection

and maintenance. Head room and access should be

provided and all units should be installed in a dry

location with adequate drainage. The discharge piping

should be direct with as few elbows and fittings as

possible.

The pump assembly should be installed as close to the

fluid as possible. A short, direct suction pipe can be

used to keep suction losses at a minimum. If possible,

locate the pump so fluid will flow by gravity to the

suction opening. The discharge piping should be direct

with as few elbows and fittings as possible. The total

NPSHA, which includes the suction lift and pipe friction

losses, must be greater than the Net Positive Suction

Head Required (NPSHR) by the pump.

B. HANDLING.

Figure 4. Transport of the bare pump

CAUTION

Use a hoist with adequate lifting capacity. See

pump nameplate for weights.

Do not pick up the complete unit by the motor

or the pump shafts or motor lifting eyes.

If the pumping unit slips out of the sling

arrangement, it may cause injury to personnel

and/or damage to the pumping unit.

Moving the unit requires proper preparation and

handling. Always make sure that the pump or the

pumping unit while being moved cannot slip out of the

transport suspension arrangement. Use a sling for

pumps without baseplates, refer to Figures 4 and 5. To

lift a complete unit, a hoist or suitable lifting device

should be attached to the motor plate, refer to Figure 6.

The individual motor may be lifted using proper eyebolts

provided by the manufacturer, but these should not be

used to lift the assembled unit.

Figure 5. Transport of close-coupled pump

10

Figure 6. Transport of the complete unit

I-855

855 – Filtrate Pump 855-15.04.EN

C. PRE-INSTALLATION PROCEDURES.

CAUTION

CAUTION

Use a hoist with adequate lifting capacity. See

pump nameplate for weights.

1. The Filtrate Pumps are design for the suction

side of the pump to mount directly to a flange on

a receiver tank, refer to Figure 18.

NOTE

The pump is shipped with flange covers to

protect flange face and to prevent foreign

matter from entering pump. Flange covers

should remain intact until suction and discharge

piping are connected to pump flanges.

2. Remove the flange covers from the flange

faces.

3. Connect the piping.

D. PIPING. All piping should be independently

supported near the pump so that pipe strain will not be

transmitted to the pumping unit.

The Filtrate Pump tank-mounted pumps are designed to

operate under vacuum conditions up to 660 mm Hg (26”

Hg). These units are used on tanks equipped with a

special mounting flange and require no suction piping.

Refer to Figure 18 for mounting flange dimensions.

Discharge Position: The pumps are built for top

horizontal/bottom horizontal discharge position, provided

the small hole (vent port) in the suction cover (10) is

always located at the 12 o’clock position, i.e. at the very

top. Refer to Figure 18 for mounting flange dimensions.

All piping connections must be made with the

pipe in a freely supported state. Do not apply

vertical or side pressure to align the piping with

the pump flange.

Before connecting the suction, discharge and

auxiliary piping, check to see that the piping is

absolutely clean internally. Any debris in the

piping will be drawn into the pump

passageways and can cause extreme damage.

The internal diameters of the suction and

discharge lines must be equal to the internal

diameters of the pump suction and discharge

nozzles.

NOTE

The discharge flanges are designed to mate

with both ANSI Class 125/150 flanges and DIN

PN10 flanges without adapters while meeting

the discharge pressure requirements of the

pump. Refer to Figure 19 for the discharge

flange dimensions.

The pump is shipped with flange covers to

protect flange faces and to prevent foreign

matter from entering the pump. Flange covers

should remain intact until suction and discharge

piping are connected to pump flanges.

E. AUXILIARY PIPING CONNECTIONS AND

GAUGES. In addition to primary piping connections, the

pump may require other connections such as gauges or

drains. All these lines and gauges should now be

installed. Refer to vendor mechanical seal drawing for

seal line connections to the mechanical seal.

Discharge Piping: Discharge piping may be installed

with an increaser to reduce pipe friction losses. A check

valve is to be installed in the discharge line to prevent

reverse flow and loss of vacuum when the pump loses

prime. Lack of a check valve can allow the tank to

overfill. A shut-off valve is recommended after the check

valve to isolate the pump. Horizontal discharge lines

should be installed with a continuous upward slope

away from the pump. Refer to Figure 19 for the

discharge flange dimensions.

F. MOTOR. Refer to motor vendor’s manual for motor

information and information on connecting to the power

supply.

DANGER

Connection to the power supply must be

effected by a trained electrician only. Check

available main voltage against the data on the

motor rating plate and select appropriate startup method.

11

I-855

855 – Filtrate Pump 855-15.04.EN

G. DIRECTION OF ROTATION. Direction of rotation

for 855OH pumps is clockwise as viewed from belt end

of pump shaft. Direction of rotation for 855CC pumps is

clockwise as viewed from fan end of motor.

B. PRIMING. Dry running a centrifugal pump can

result in extensive damage and possible seizing. It is,

therefore, imperative that the pump be primed prior to

initial start-up and that prime must be maintained

through subsequent start-stop cycles.

VIII. OPERATION.

Follow the procedure listed below:

A. PRE-START CAUTIONS.

DANGER

Before activating the pumping unit, check to

make sure there are no personnel working on

the unit. Serious injury or death to personnel

could result if the unit is activated while being

worked on.

1. Before starting or operating the pump, read this

entire manual, especially the following

instructions.

2. Observe all caution or danger tags attached to

the equipment.

3. Rotate both the pump and driver shafts by hand

to assure all moving parts are free.

4. Check motor for correct rotation before

connecting the belts.

5. If necessary, recheck belt tension and

alignment.

6. Before starting the pump, install closed guards

around all exposed rotating parts.

7. Check to make sure that fluid in the pump is

free of debris.

WARNING

Never run the pump dry. Close running fits

within the pump are liquid lubricated. Dry

running will result in pump seizure or damage.

8. Before starting a mechanical seal pump

equipped with external flush lines, turn on

mechanical seal water, and confirm the

mechanical seal water is at sufficient pressure.

Running without fluid in the stuffing box may

result in packing/mechanical seal failure.

9. Pumps are shipped with Lube-For-Life bearings

and no additional oil or grease is required in the

bearing frame.

10. If excessive vibration or noise occurs during

operation, shut the pump down and rotate shaft

by hand. If excessive vibration or noise

continues, consult a Carver representative.

1. Check the level in the tank to see that the pump

is submerged in liquid.

2. Completely open system to pump and fill pump

with fluid.

3. The pump is now primed.

C. STARTING THE PUMP.

CAUTION

DO NOT operate pumping unit against a closed

discharge system. If pump has any chance of

seeing operation against a closed system, a

bypass system allowing a minimum design flow

should be installed. This bypass will be

satisfactory for short periods of operation. For

extended periods of operation the bypass

should be sized for the minimum continuous

flow required by the pump.

1. Confirm pumping unit is ready to start.

Complete Section VIII, Paragraphs A and B.

2. If unit is equipped with mechanical seal cooling

lines, confirm that the mechanical seal cooling

water is turned on.

3. Open discharge valves slightly, about 1 to 1 ½

turns if pump is being started for the first time or

from being turned off for overhaul.

4. Open valves to pressure gauges in the system.

5. Start electrical power supply to driver. Start the

pump.

6. Slowly open system valves in discharge line and

adjust pressure and flow to the appropriate

operating conditions. Refer to pump nameplate

and system operating procedures for design

point condition.

D. OPERATING CHECKS.

1. Check for undue vibration or noise. If any

occurs and does not stop within a short period

of time, turn off the pump. For determination of

the cause and its remedy refer to

Troubleshooting in Section IX or consult Carver

Pump Company.

12

I-855

855 – Filtrate Pump 855-15.04.EN

2. Check mechanical seals or packing rings for

leakage.

3. Check for adequate lubricating liquid flow to the

seal or packing.

4. Check that pump is operating within design

criteria and perimeters. Check and record flow

and pressure readings. The flow and pressure

readings should be within the operating system

guidelines and similar to number stamped on

the pump nameplate.

5. Check and record bearing temperature. It

should not exceed 70ºC (160º F). Both inboard

(18) and outboard (16) ball bearing

temperatures should be measured and recorded

at a minimum of 15 minute intervals until the ball

bearing temperatures stabilize. Stabilization of

ball bearing temperature can be defined as the

results of three consecutive readings at

approximately 15 minute intervals with no

temperature rise.

6. Check and record power input to the motor.

7. Check and record vibration.

F. INDEFINITE SHUTDOWN.

Stop the pumping unit per Section VIII, Paragraph E.

Remove casing plug to drain casing. Drain all piping if

there is a possibility of liquid freezing. Provide pump and

driver with a protective cover.

IX. TROUBLESHOOTING OPERATING

PROBLEMS.

If you have followed the installation and starting

procedures outlined in this manual, the pump should

provide reliable service and long life. However, if

operating problems do occur; significant time and

expense can be saved if you refer to Table 4 to

eliminate the most common causes of those problems.

NOTE

Immediate action to be taken before

proceeding with corrective actions in Table 4 is

to stop the pump, refer to Section VIII,

Paragraph E.

E. STOPPING THE PUMP.

WARNING

When pump is handling hazardous fluid,

extreme care must be taken to ensure safety of

personnel when attempting to drain pump.

Suitable protection devices should be used

and/or protective clothing should be worn.

1. Stop the pumping unit in accordance with the

directions on the electrical power supply.

2. Tagout and lockout power to motor according to

OSHA Standard 1910.147.

3. Close discharge and suction valves and any

auxiliary fluid lines.

4. The pumping unit is now off.

13

I-855

SYMPTOM

IMMEDIATE ACTION

PROBABLE CAUSE

CORRECTIVE ACTION

Pump does not deliver

rated capacity or rated

head.

1. Stop the pump, refer to

Section VIII, Paragraph

E.

1. Excessive system

pressure.

1. Check GPM and head

against design

conditions; Consult

local distributor or

Carver Pump

Company.

2. Speed to low, motor

speed incorrect, belts

slip, or line voltage to

low.

1. Correct motor speed.

2. Adjust belt tension.

3. Check electrical supply

and correct as

necessary.

4. Incorrect sheave size

or pump and motor

sheaves reversed.

3. Valves are not fully

open or plugged

discharge line.

1. Open valves and if

necessary, lock valves

open to prevent

accidental closure.

2. Inspect and clean

discharge.

4. Clogged impeller.

1. Disassemble pump and

clean impeller, if

necessary

5. Reverse rotation.

1. Direction of rotation for

855OH pumps is

clockwise as viewed

from belt end of pump

shaft. Direction of

rotation for 855CC

pumps is clockwise as

viewed from fan end of

motor.

6. Motor running on two

phases only.

1. Replace defective fuse.

2. Check electrical cable

connections.

7. Excessive wear of

internal parts.

1. Disassemble pump,

inspect and replace

worn parts

8. Liquid level in tank to

low.

1. Increase liquid level in

tank.

9. Vent in suction cover

plugged.

1. Clean vent.

Leakage at case joints.

1. Stop the pump, refer to

Section VIII, Paragraph

E.

1. Gaskets damaged.

1. Disassemble pump and

replace gaskets.

855 – Filtrate Pump 855-15.04.EN

Table 4. Pumping Unit Troubleshooting

14

I-855

SYMPTOM

IMMEDIATE ACTION

PROBABLE CAUSE

CORRECTIVE ACTION

Bearings run hot.

1. Stop the pump, refer to

Section VIII, Paragraph

E.

1. Bearing setting

incorrect.

2. Worn bearings.

1. Correct bearing axial

clearance.

1. Replace bearings.

Pump discharge pressure

excessive.

1. Stop the pump, refer to

Section VIII, Paragraph

E.

1. Excessive speed.

1. Check speed precisely.

Decrease speed.

2. Pump is pumping fluid

with specific gravity in

excess of that

specified. (If

temperature of fluid is

lower, then specified

specific gravity will be

higher.)

1. If prescribed fluid

temperature or specific

gravity cannot be

attained, one or more

of the following

measures can be

taken:

a. Partially close

discharge valve,

reducing pump

capacity to a point

where driver is not

overloaded.

b. Install more powerful

driver. Consult

Carver Pump

Company specifying

exact operating

conditions.

Pump overloads motor.

1. Stop the pump, refer to

Section VIII, Paragraph

E.

1. Speed too high.

1. Check pumps RPM

and determine correct

sheave and belts for

proper speed. Consult

local distributor or

Carver Pump

Company.

2. Pump discharge

pressure is lower than

design point, therefore

pump's volume too high

(check pump

nameplate).

1. Partially close

discharge valve until

pressure at discharge

flange is as specified.

Decrease speed if

driver remains

overloaded.

3. Same as 2 under

“Pump Discharge

Pressure Excessive.”

1. Same as 2 under pump

discharge pressure

excessive.

4. Wrong port width.

1. Consult Carver Pump

Company specifying

exact operating

conditions.

855 – Filtrate Pump 855-15.04.EN

Table 4. Pumping Unit Troubleshooting - Continued

15

I-855

Fastener Size

Torque Value

(Foot Pounds)

Torque Value

(n-M)

M10 x 1.50

18

25

M12 x 1.75

60

85

M20 x 2.50

295

400

Adjusting Jam Nut

(3/4-10UNC)

80

110

Adjusting Jam Nut

(7/8-9UNC)

100

135

Impeller Capscrew

(3/8-16UNC)

18

25

Tools

Materials

Test Equipment

Spanner Wrench

Rawhide or

Wood Mallet

Oil

O-ring

Lubricant

Belt Alignment

Gauges

Volt-Amp Meter

Wooden Wedge

Allen Wrench Set

Rust Solvent

Belt Tension

Gauge

Socket, Open, &

Box Wrench

Set

Vice Grips

Torque Wrench

Bearing Heater

855 – Filtrate Pump 855-15.04.EN

X. MAINTENANCE.

Generally the pump does not need continuous

supervision. The pump should always run quietly and

smoothly, without vibration. Regular checks of the pump

running noises will prevent the risk of excessive

temperatures as a result of bearings running hot or

defective bearing seals. To ensure such operation, the

following maintenance schedule should be applied at

regular intervals during operation of the pump.

Occasional visual checks are recommended. Data

should be recorded periodically for each pump to keep

track of maintenance which has been performed and to

note operational problems. A sample maintenance

record sheet is provided for this purpose at the front of

this manual.

NOTE

Regular inspection and service are essential for

safe operation of the pump. Any auxiliary

systems installed must be monitored, if

necessary, to make sure they function

correctly.

A. LUBRICATION OF PUMP BEARINGS. The ball

bearings are installed "Greased-For-Life". Always

replace the roller bearings when disassembling unit for

seal service.

B. LUBRICATION OF MOTOR BEARINGS. See

motor manufacturer’s instructions to be sure motor ball

bearings are properly lubricated.

C. TORQUE VALUES. Refer to Table 5,

Recommended Torque Values. Clean and properly

lubricate threads and bearing face of the fastener to

obtain the proper fastener loading from these torque

values. Fasteners should be tightened evenly and in

stages. Refer to your torque wrench manual for the

proper use of your wrench.

Table 5. Recommended Torque Values (ft-lbs)

Parts marked with * are options or vary by

pump.

Daily Inspection:

Visually inspect unit.

Check bearing temperatures.

Check for leakage at mechanical seal.

Weekly Inspection:

Check power (amps) readings.

Check pump discharge pressure.

Check vibration on pump and driver bearings.

Vibration should NOT exceed 3.0 of overall

displacement (unfiltered) peak to peak mils

(0.001”) at 1750 RPM.

Monthly Inspection:

Check belt condition and alignments.

Semi-annual Inspection:

If stand-by pumps are installed, it is advisable to

operate pumps on a rotational system to give

each pump a periodic duty. This ensures that

stand-by pumps will have periodic operation and

always be in good condition for instant start-up.

Table 6. Recommended Equipment

12,500 Hours - Overhaul

For pump overhaul, complete Section XI, Service

and Repair.

16

I-855

855 – Filtrate Pump 855-15.04.EN

XI. SERVICE AND REPAIR.

Refer to Figures 15 and 16 to locate the pump parts by

item number and parts list Table 8. If a specific sectional

assembly drawing exists for a particular pumping unit

then that drawing should be referred to for service work.

A. PREPARATIONS FOR DISASSEMBLY OF PUMP.

During disassembly, match mark parts so they can be

replaced in their original position. All parts should be

thoroughly cleaned or replaced with new, if necessary.

Sealing faces should be perfectly clean.

CAUTION

Factory authorized parts must be used to safely

maintain your Carver Pump.

NOTE

To avoid damage to O-rings, check to make

sure all parts are free of sharp edges or burrs.

All O-rings, ball bearings, shims, mechanical

seals, lip seals, packing, and gaskets if

disturbed from position should be replaced.

Variations do exist between configurations, not

all parts described in the text may be on your

configuration. Review what variations your

pumping unit has before starting. Parts marked

with * are options or vary by pump.

Close suction and/or discharge valves. The pump

should be cooled down to ambient temperature. The

casings must be empty and not under pressure.

After prolonged operation, components may not be

easily removed from shaft. In such instances, rust

solvent may be used and suitable extracting tools

applied wherever possible. Do NOT use force under any

circumstances. Refer to Table 6, Recommended

Equipment, for proper tooling during disassembly and

assembly. Refer to appropriate sectional drawing for

location of parts followed by an item number.

Prepare the pumping unit for disassembly using the

following list:

Refer to cartridge seal (90*), refer to vendor

instructions for proper mechanical seal removal

procedure.

3. For cartridge mechanical seals (90*), reinstall

seal clip.

Before attempting to disassemble the pump,

the electrical power supply to the driver must

be locked and tagged in the “OFF” position to

prevent injury or death to personnel servicing

the pumping unit.

When pump is handling hazardous fluid,

extreme care must be taken to ensure safety of

personnel when attempting to drain pump and

piping before disconnecting the pumping unit.

Suitable protection devices should be used

and/or protective clothing should be worn.

Applicable hazardous material procedures must

be followed.

Fluid will remain in lower portion of casing and

care must be taken to trap and dispose of this

fluid in a safe and appropriate manner.

4. Drain pump by removing liquid at suction flange

connection. If necessary, flush pump to remove

corrosive or toxic pumpage. Collect and dispose

of corrosive or toxic material appropriately.

5. Disconnect piping, gauge lines, and auxiliary

connections, as necessary.

Use a hoist with adequate lifting capacity; refer

to Section VII, Paragraph B for handling of the

pump.

For close-coupled units continue with step 9.

NOTE

WARNING

CAUTION

CAUTION

NOTE

1. Read this entire section and study the

applicable sectional view drawing and parts list

before disassembling the pump.

2. Stop the pumping unit; refer to Section VIII,

Paragraph E.

6. Relieve tension on belts by loosening

adjustment jam nuts (616).

7. Remove guard cover screw (605) and guard

retaining screw flat washer (642) from belt

guard cover (131E). Remove the belt guard

cover (131E).

17

I-855

855 – Filtrate Pump 855-15.04.EN

NOTE

Bushings are tapered for achieving a kind of

clamp fit between the hub of the sheave and

the shaft. Use of an Allan key is required for

removing bushings.

Use a hoist with adequate lifting capacity; refer

to Section VII, Paragraph B, for lifting the

complete unit.

CAUTION

8. Remove the belt (276), sheave (277) and

bushing (278) from pump and motor. Remove

bushing keys (46 and 46X) from the pump and

motor shafts.

9. Remove bolts (604) and hex nuts (618) from

motor (200). Remove motor.

10. Remove guard bolt (603) and guard hex nuts

(617) to remove guard (131D). The slide guard

(131F) and slide guard screws (607) will remain

attached to the guard.

11. Remove motor plate (23) and adjusting

threaded rods (632). Belt guard bracket (133)

will be removed with threaded rods.

12. Support pump; remove the bolts that hold the

pump to the tank. Remove the pump from the

tank. Refer to Section VII, Paragraph B for

handling of the pump.

13. Move the pump to a suitable work area for

disassembly.

B. DISASSEMBLY OF PUMP. The instructions that

follow are an aid for properly trained personnel to

service your Carver Pump. Refer to Figures 15 and 16

to locate the pump parts by item number and parts list

Table 8. If a specific sectional assembly drawing exists

for a particular pumping unit then that drawing should be

referred to for service work. Read this entire section

before disassembling the pump.

NOTE

Refer to Section II for Safety precautions before

disassembling pump.

Variations do exist between configurations, not

all parts described in the text may be on your

configuration. Review what variations your

pumping unit has before starting. Parts marked

with * are options or vary by pump.

After completion of dismantling, all parts should be

thoroughly cleaned or replaced by new ones if

necessary. All gaskets and sealing faces should be

perfectly clean. When cutting new gaskets, make sure

they are exactly the same thickness as the old ones

unless noted.

When pump is handling hazardous fluid,

extreme care must be taken to ensure safety of

personnel when attempting to drain pump and

piping before disconnecting the pumping unit.

Suitable protection devices should be used

and/or protective clothing should be worn.

Applicable hazardous material procedures must

be followed.

NOTE

Mark or number each component while

dismantling according to sequence.

The individual components should be

unscrewed or removed.

1. Complete Section XI, Paragraph A before

continuing with disassembly.

2. Remove splash guard screw (606) and guard

retaining screw flat washer (642). Remove the

splash guards (131B/C).

NOTE

Refer to cartridge seal (90*), refer to vendor

instructions for proper mechanical seal removal

procedure.

3. Remove gland hex nuts (615) and the gland flat

washers (641*) on studs (630). Slide back gland

(17*) to release tension on mechanical seal

(90*). Slide back and remove gland (17*) halves

from packing rings (180*).

NOTE

If gaskets are disturbed from position replace

with new.

4. Remove capscrew (600) and suction cover (10).

Remove the tank suction gasket (73B) and

suction casing gasket (73A), discard.

5. Remove impeller capscrew (26) and impeller

washer (28). Pull impeller (3) from shaft (6).

Impeller key (32) may come off with impeller, if

not remove impeller key. Remove any impeller

shims (15) that may be present and discard.

18

I-855

855 – Filtrate Pump 855-15.04.EN

NOTE

NOTE

Take special care during disassembly with the

mechanical seal rotary and stationary elements

when removing the casing off the shaft.

6. Remove capscrew (601) from casing (1) and

remove casing from bearing frame (19) or motor

(200) for close-coupled units.

7. Remove old packing (180*), lantern ring (29*)

and packing retaining ring (63*) from casing (1).

8. Remove mechanical seal spacer (68*) from

shaft (6).

NOTE

Refer to mechanical seal (90*) vendor

instructions for proper mechanical seal removal

procedure.

Do NOT remove rotating element of

mechanical seal (90*) from shaft sleeve (14*),

at this point, especially if mechanical seal is

relatively clean and in good working condition.

Model 855 CC will have a shaft sleeve (14*)

upon which the seal operates.

9. If applicable, remove the shaft sleeve (14*) and

rotating element of mechanical seal (90*) from

shaft (6). Inspect rotating element of mechanical

seal before removing from shaft sleeve. If

replacement is required remove rotating

element of mechanical seal from shaft sleeve.

10. If applicable, remove the gland (17*) and

stationary element of mechanical seal (90*)

from shaft (6).

11. Remove O-ring (89*) from shaft (6)

12. If the slinger (40) is damaged and needs

replaced or it is necessary to replace the ball

bearings (18) remove the slinger from the shaft

(6).

NOTE

If lip seals or gaskets are disturbed from

position replace with new.

13. Remove capscrews (602) fastening bearing

caps (35) to bearing frame (19). Remove

bearing caps from bearing frame. Remove lip

seal (169) and gasket (73) from bearing caps.

Do not remove shaft guard (131G) unless

necessary.

14. Remove the shaft (6) (with radial and thrust ball

bearing assemblies) from the bearing frame

(19).

If ball bearings are disturbed from position

replace with new.

15. If desired, pull ball bearing (18) from shaft (6).

16. If desired, pull ball bearing (16) from shaft (6).

C. PARTS INSPECTION.

1. All parts should be thoroughly cleaned with a

suitable solvent or replaced with new ones if

necessary.

2. All sealing faces should be perfectly clean. All

ball bearings, mechanical seals, gaskets, Orings, lip seals, and locking devices with a

nylock feature are to be replaced with new if

disturbed from position.

3. Check shaft for runout, scratches, grooves, or

any possible damage. Touch up scratches and

grooves with a polishing cloth and inspect for

remaining grooves or deep scratches. A bent or

excessively damaged shaft should be replaced.

4. Inspect the casing for pitting, scoring, and

erosion. The inside of the casing should be free

of any pits or grooves. The maximum allowable

depth is 1/8” (3mm). Replace the casing if any

of these defects are present.

5. Inspect mechanical seal. Replace the

mechanical seal that is disturbed from position

or damaged.

6. Inspect the impeller and bushing keys for

distortion and push fit into keyways. The keys

should be square on all four edges. They should

fit without having to be forced. The keys should

not rock in keyway. Replace keys or shaft if

necessary.

7. Check the shaft sleeves and spacer sleeves

visually for score marks, scratches, pits,

grooves or burrs. Touch up sleeves with

polishing cloth and inspect for remaining

grooves or deep scratches. Remove burrs with

a file. Shaft sleeves and spacer sleeves should

be replaced if any marks, pits or grooves are

still visible after touching up.

8. Inspect tubing for kinking. Replace kinked

tubing.

9. If the impeller shows excessive wear due to

erosion or pitting, so that performance cannot

be restored, it must be replaced. If a new

impeller is installed, check to make sure that it is

balanced and of the correct trim. If an impeller is

restored or replaced check the dynamic balance

of the rotor before reassembly of the pump.

19

I-855

855 – Filtrate Pump 855-15.04.EN

D. REASSEMBLY OF PUMP. Read this entire section

before reassembling the pump. The instructions that

CAUTION

follow are an aid for properly trained personnel to

assemble your Carver Pump. Refer to Figures 15 and

16 to locate the pump parts by item number and parts

Handle lip seal (169) with care. Mishandling

could damage faces of the lip seal.

list Table 8. If a specific sectional assembly drawing

exists for a particular job then that drawing should be

referred to for assembly. Refer to Table 5 for

recommended torque values. Assemble the pump in

accordance with accepted rules of engineering practice.

Coat individual components with a suitable lubricant

before assembling. Assembly of unit should be

performed on a clean, flat surface. During reassembly,

install parts as applicable.

2. Install the lip seals (169) in the bearing caps

(35).

3. Install the shaft (6) in the bearing frame (19).

4. Install one paper gasket (73) on the impeller

end bearing cap (35). Install impeller end

bearing cap on bearing frame (19) securing it to

the bearing frame with capscrews (602). Refer

to Table 5 for recommended torque values.

5. For proper shaft endplay clearance to allow for

CAUTION

thermal growth of the shaft, measure and install

gasket(s) (73) on the shaft side of bearing frame

During reassembly, install new O-rings, ball

bearings, lip seals, packing, mechanical seals

and gaskets if disturbed from position. O-rings,

ball bearings, lip seals, packing, mechanical

seals and gaskets may have been damaged

during disassembly.

as follows;