Page 1

RTB Series RETHERMALIZATION CABINETS

MODELS: RTB10, RTB16, RTB34, RTB341, RTB281

OWNERS / OPERATORS MANUAL

MANUFACTURED BY:

CARTER-HOFFMANN

1551 McCormick Avenue

Mundelein, IL 60060 USA

Phone: 847-362-5500

Toll Free: 800-323-9793

Fax: 847-367-8981

Email: service@carter-hoffmann.com

READ THIS MANUAL COMPLETELY

BEFORE OPERATING THIS APPLIANCE

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to

be given to the OWNER, MANAGER, or to the person responsible for training operators of this appliance.

RTB341

RTB281

THIS MANUAL IS TO BE UNDERSTOOD BY ALL PERSONS

USING OR INSTALLING THIS APPLIANCE.

Contact Carter-Hoffmann if you have questions regarding installation, operation or maintenance of this equipment.

SAFETY INSTRUCTIONS…….………………………….. 2

INTRODUCTION AND SPECIFICATIONS…………...… 3

UNPACKING, INSPECTION & INSTALLATION……..… 4

INSTALLATION & START UP……………………………. 5

CONTROLLER FEATURES……………………………… 6-7

DAILY OPERATION……………………….………………. 8

CONTROLLER PROGRAMMING INFORMATIO N…….. 9-10

END-USER PROGRAMMING PATH 1724……………… 11-13

MANAGER PROGRAMMING PATH 3228..…………….. 14-20

DAILY CLEANING PROCEDURE………………………… 21-22

TROUBLESHOOTING GUIDE……………………………. 23

SERVICE EXPECTATIONS………….………….……...... 24

WARRANTY STATEMENT……………………....……….. 25

Printed in

The United States of America

TABLE OF CONTENTS

All Rights Reserved

Part Number: 18400-3155

Rev: KBA040111

Page 2

SAFETY PRECAUTIONS

WARNING: ELECTRIC SHOCK HAZARD

WARNING

All service requiring access to non-insulated components must be performed by

qualified service personnel. Failure to heed this warning may result in severe

electric shock.

CAUTION: ELECTRIC SHOCK HAZARD

Disconnect this appliance from electrical power before performing any

maintenance or service.

CAUTION: BURN HAZARD

Exposed metal surfaces can be hot to the touch and may cause burns.

IMPORTANT SAFETY INSTRUCTIONS

When using electrical appliances basic safety precautions should be followed, including the following:

1) Be familiar with the appliance use, limitations and associated restrictions. Operating instructions must

be read and understood by all persons using or installing this appliance.

2) This appliance must be grounded. Connect only to properly grounded outlet.

3) Use this appliance only for its intended purpose as described in the manual.

a. This equipment is specifically designed to hold pre-cooked food at temperature.

b.

c. This equipment is not designed for industrial or laboratory use.

4) Cleanliness of this appliance and its accessories is essential to good sanitation.

This equipment is intended for use in commercial establishments only.

5) DO NOT submerge this applia nce in water. This appliance is not jet stream approved. DO NOT direct

water jet or steam jet at this appliance, or at any control panel or wiring. DO NOT splash or pour water

on, in or over any controls, control panel or wiring. DO NOT use corrosive chemicals or vapors in this

appliance.

6) DO NOT store this appliance outdoors. DO NOT use this product near water – for example,

near a kitchen sink, in a wet basement, or near a swimming pool, or similar environment.

7) DO NOT operate this appliance if it has a damaged cord or plug, if it is not working properly, or if it has

been damaged or dropped. Do not immerse cord or plug in water, keep cord away from heated

surfaces, and do not let cord hang over edge of table or counter.

8) DO NOT cover or block any openings on the appliance.

9) Only qualified service personnel should service this appliance.

NOTE: This equipment has been designed and manufactured to meet all applicable health and

safety codes and will give years of dependable service if used properly. All cabinets should be

thoroughly cleaned before using.

NOTE:

illustrations and/or adjustment procedures, is intended for use by qualified technical personnel and is

subject to change without notice.

The technical content of this manual, including any wiring diagrams, schem atics, parts breakdown

2

Page 3

Carter-Hoffmann Series RTB Rethermalization cabinets are designed to uniformly rethermal ize individually pre-packaged menu items or individual meal trays in baskets.

INTRODUCTION

This equipment manual will provide you with basic information to safely install and operate this piece

of equipment. Should you encounter any difficulties, have any questions, or require any assistance,

please contact Carter-Hoffmann’s Technical Service department di rectly, at:

Telephone 800-323-9793 (toll-free) 847-362-5500

Fax 847-367-8981

Email service@carter-hoffmann.com.

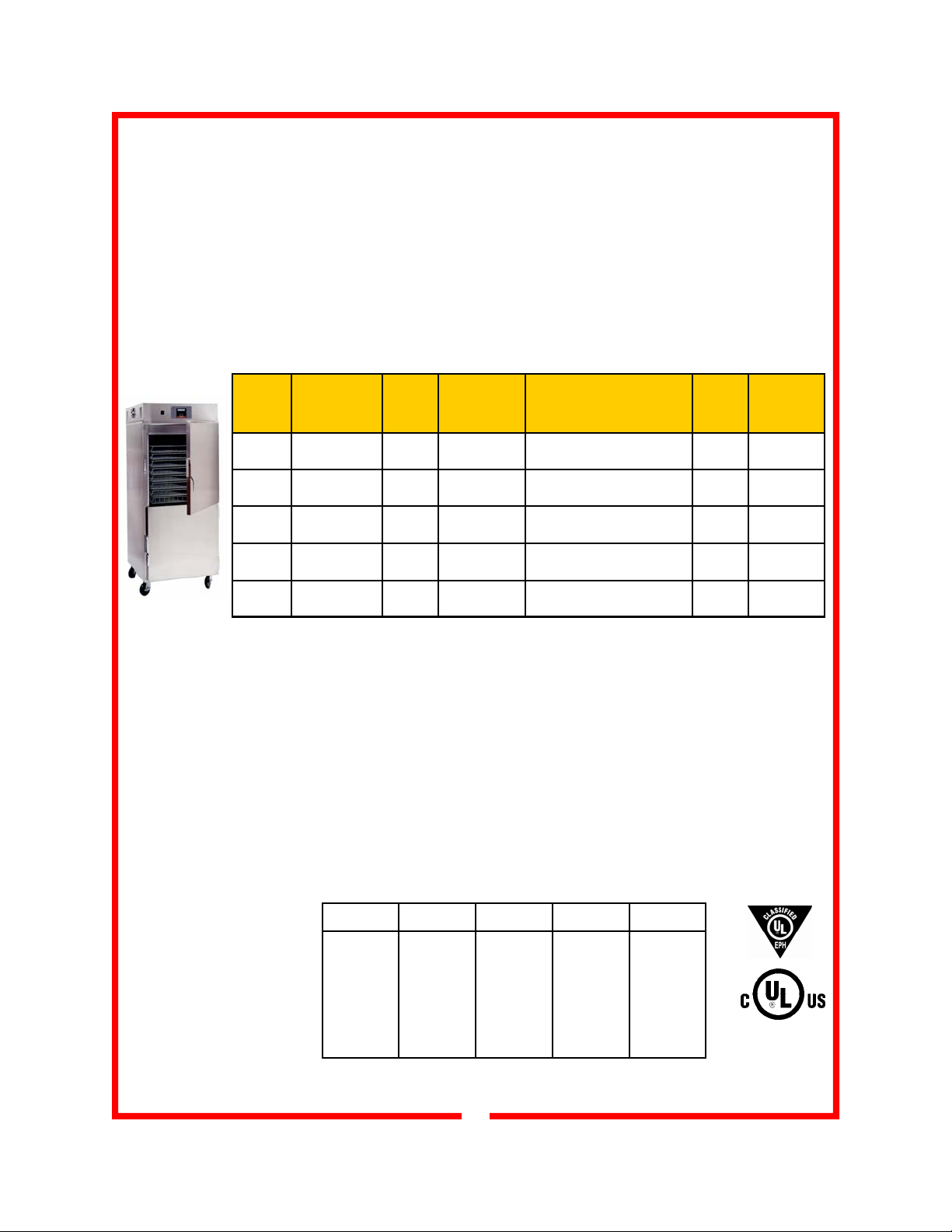

PRODUCT SPECIFICATIONS

RTB34

Model

Number

RTB10

RTB16 16 3

RTB34 34 3

RTB341 32

RTB281 28

Basket

Capacity*

13-3/8” x 25-7/8”

10 3

(on roll-in dolly) 3 (76)

(on roll-in dolly)

Basket

Spacing

Baskets

(76)

(76)

(76)

nest

Inside Working

Height

in (mm)

14-5/8

(371)

23-5/8

(600)

53-3/8

(1356)

58

(1473)

34-7/16

(875(

Overall Dimensions

Height Depth Width

in (mm)

39-1/4 35 33-1/8

(997) (889) (842) 5 (127)

48-1/4 35 33-1/8

(1226) (889) (842) 5 (127)

77-3/4 35 33-1/8

(1975) (889) (842) 5 (127)

78-1/2 35-5/8 35-3/8

(1994) (905) (899)

53-3/16 36-1/4 35-7/16

(1351) (921) (900)

Caster

Diameter

in (mm)

On legs 500

N/A 450

Class 100

Shipping

Weight

lbs (kg)

270

(123)

400

(181)

525

(238)

(227)

(205)

Construction...All Stainless steel double panel insulated cabinet with tamper resistant fasteners, heavy-duty

strap hinges. Heavy-duty edge-mount latch with magnetic catch. High temperature silicone gasket mounted to

cabinet.

Controller...microprocessor-based controller allows the user to program and store up to ten pre-set retherm

menu cycles. Each menu contains four retherm/hold cycles. Each cycle can be easily programmed for a

unique time and temperature to optimize performance of the heatin g system. Once a menu is programmed,

the cycle is stored in the controller’s memory until a change is made.

Heating System...Heavy-duty stainless steel construction. Secured in-place with tamper resistant fasters;

removable with tools. Inconel-sheathed heating elements, dual cooling fans and thermally protected blower

motor with long-life bearings. Precision engineered interior cabinet baffle system.

Performance… Capable of heating from 70°F (21°C) to 200°F (90C) in 5 minutes with a differential of ± 2.5°F.

Recovery from 120°F (49°C) to 200°F (90°C) in one minute (performance based on empty cabinet)

Electrical Specifications*

Model Volts Phase kW Amps

RTB10 208 1 6 28

RTB16 208 1 9 44

RTB34 208 3 18 60

RTB341 208 3 18 60

RTB281 208 3 27 100

* Electrical specifications shown are typical for standard cabinets. Due to the often customized nature of this product line, i. e. cabinets built to consultant’s/

facility specifications, the electrical specifications on your particular cabinet may be different. Consult serial tag on rear of heating unit for electrical info.

3

Page 4

UNPACKING, INSPECTION & INSTALLATION

This appliance

should be

thoroughly

cleaned prior to use.

See the CLEANING

INSTRUCTIONS in

this manual.

NOTE: DO NOT discard

the carton or other packing materials until you

1. Remove the cabinet from shipping carton, ensuring that all packing

materials and protective plastic has been removed from the unit.

2. Inspect all components for completeness and condition.

3. If any freight damage is present, a freight claim must be filed immediately with the shipping company.

4. Freight damage is not covered under warranty.

5. Check to insure all components are included: cabinet, instruction

packet and additional accessories.

6. Read operation instructions completely.

have inspected the appliance for hidden damage

and checked it for proper

7. Appliance should be thoroughly cleaned before use. See CLEANING INSTRUCTIONS in this manual.

operation. Refer to

FREIGHT DAMAGE

CLAIM PROCEDURE

BELOW

FREIGHT DAMAGE PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully ins pected and packaged

by skilled personnel before leaving the factory. Upon acceptance of this shipment, the transportatio n company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY

immediately.

3. CONCEALED DAMAGE: If damage is unnoticed unti l the merchandis e is unpack ed, notif y the transportation company or carrier immediately, and then file a “CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date the delivery was made to you. Be sure to retain the

container for inspection.

Carter-Hoffmann cannot assume liability for damage or loss incurred in transit, freight damage is not covered

under warranty. We will, however, at your request, supply you with the necessary docu ments to support your

claim.

: Regardless of the extent of damage. Contact your dealer

INSTALLATION LOCATION

For proper operation and maximum performance, locate the unit in an ambient air temperature of

70ºF (21ºC). For safe operation and maximum performance, locate the unit at least 4” from any wall

or combustible material.

Avoid placement in areas near exhaust fans or where there are active air movements.

Do not locate this unit under an overhead ventilation system or close to other cooking equipment.

Fumes and grease particles can be drawn by the cooling fans into the control comp artment of the

heater which should be avoided in order to assure top performance and longer life.

Unit must be on a solid level surface.

4

Page 5

INSTALLATION AND STARTUP

WARNING:

Risk of personal injury

Installation procedures must be

performed by a qualified technician

with full knowledge of all applicable

electrical codes. Failure could

result in personal injury and property damage.

IMPORTANT: See page 3

for power requirements

If necessary, contact a licensed

electrician to install an appropriate

electrical circuit with correct receptacle. Electrical requirements vary

by model number. Consult serial tag

on rear of heating unit for proper

electrical specifications.

DO NOT use an extension cord.

CAUTION:

Electrical Shock Hazard

T

he ground prong of the power

cord is part of a system designed to

protect you from electric shock in

the event of internal damage.

DO NOT cut off the large round

ground prong or twist a blade to fit

an existing receptacle.

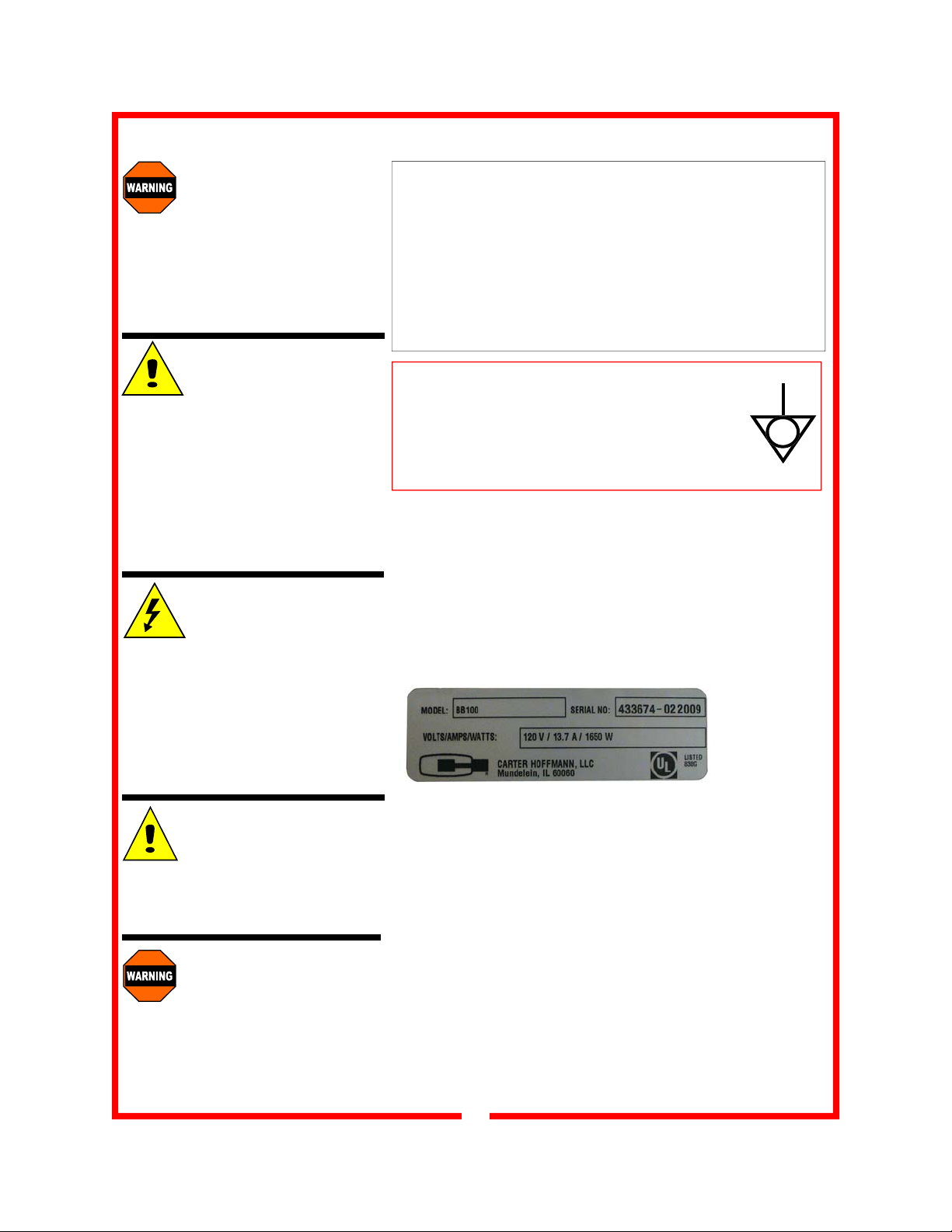

GROUNDING INSTRUCTIONS

This appliance is equipped with a cord having a grounding wire with

a grounding plug which must be plugged into an outlet that is properly installed and grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current.

WARNING—Improper use of the grounding can result in a risk

of electric shock. Consult a qualified electrician or service agent if

the grounding instructions are not completely understood, or if doubt

exists as to whether the appliance is properly grounded.

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in close

vicinity, an equalization-bonding stud is provided. An

equalization bonding lead must be connected to this

stud and the other appliances/metal parts to provide

sufficient protection against potential difference. The

terminal is marked with the following symbol:

START UP

1. Prior to use, thoroughly clean the interior of the cabinet,

according to the instructions in this manual. Familiarize

yourself with the controls.

2. Plug the power cord of the cabinet into a grounded outlet

with a electrical service according to the electrical information provided on the serial tag located on the rear of

the cabinet heating unit. DO NOT MODIFY CORD PLUG.

Sample serial

tag

IMPORTANT:

Not under warranty

Damage to unit due to being

connected to the wrong voltage or

phase is NOT covered by warranty.

WARNING:

Risk of personal injury

Unit is not waterproof, to avoid

electrical shock, keep unit from being submerged in water. Do not

operate if unit has been in contact

with water.

3. Set POWER switch to the “ON” position.

4. Do not load product into the cabinet. Allow the heat to

remove any residual oils which may adhere to inside

metal surfaces. A slight emission of smoke is common

during the first few hours of operation.

5. Heat rethermalizer at 315° F for 35 minutes by pressing

Product Key number ten. The heat will remove any residual oils which may adhere to inside metal surfaces. To

cool down unit, press Product Key #10 again to turn off

cycle and open doors for about 15 minutes. A slight

emission of smoke is normal for the first few hours of operation.

6. Rethermalizer is ready for custom programming, if desired. See pages 9-20 for instructions.

5

Page 6

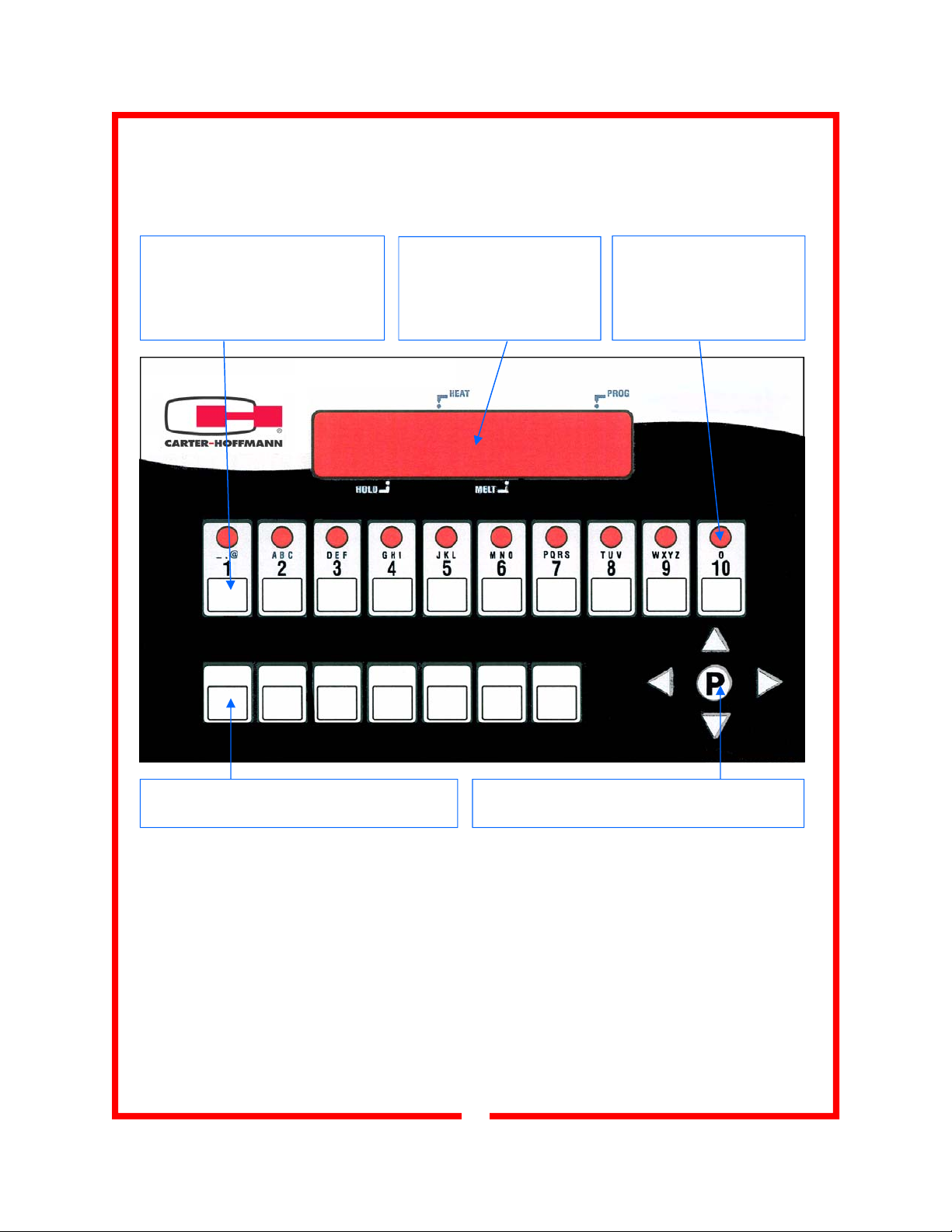

CONTROLLER FEATURES

On/Off rocker switch: located to the left of the control panel (not shown). Switch will illuminate

when cabinet is turned on.

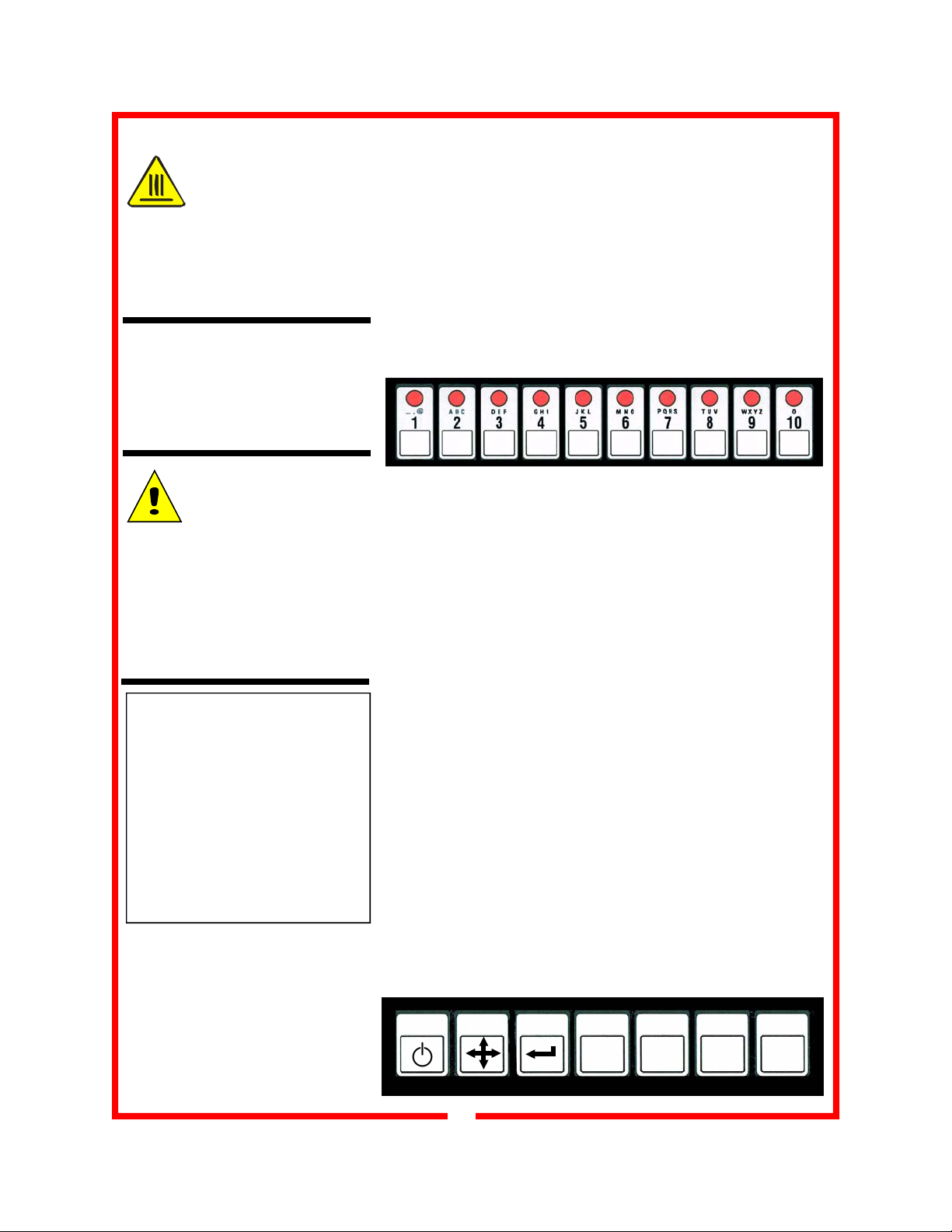

Product Keys: press to start a

cook cycle; also used in program-

ming. Replaceable menu strip to

make menu changes quickly and

easily

8 Character LED Display:

displays programming and

cook cycle information

Indicator Lights: lit when

active cook cycle is in pro-

gramming mode

Feature Keys: used to access programming

functions and controller features

Programming Center: access programming

mode and change cooking parameters

FEATURE DETAILS

Fahrenheit of Celsius Temperature Display: the controller can be configured to display the

temperature in degrees Fahrenheit or Celsius; accessible through the system program mode.

Programmable Hold Times: Product Key hold times can be programmed to track product

quality through a specified holding period. Hold time countdown begins as soon as the cook

cycle is complete. The controller will sound an alarm when the product’s hold time has expired,

alerting the operator to discard the product.

6

Page 7

CONTROLLER FEATURE DETAILS

8 Character LED Display Indicator Lights Product Keys

Programming Center Feature Keys

Four-Stage Programming: each Product Key can be programmed to personalize your cook-

ing system with up to four cooking temperatures and up to ten cook times for a single cook cycle. With each Product Key, you can select a menu, start and stop a menu, scroll through programmed data (in Program Mode).

Programmable Stage Temperatures: cook temperatures for each stage on each Product

Key can be programmed. The temperature range is 200°F to 350°F (93.3°C to 172°C)

Programmable Stage Times: cook times for each Product Key can be programmed.

The controller is programmable in minutes (up to 99) and seconds (up to 59) and allows up

to ten stages per Product Key. Note: multiple cook starts are not allowed if a product key

has more than one stage programmed.

Programmable Fast.Flex™ Timing Mode: flex or straight timing can be configured for each

stage on each Product Key. To insure consistent, high-quality food product, flex time will adjust the actual cook time, taking into consideration the temperature variation due to load size,

initial product temperature, product moisture content, and other factors affecting the cook cycle.

If cooking by straight time, the controller will cook only for the specified time without adjusting

for these variances.

7

Page 8

DAILY OPERATION

WARNING:

HOT SURFACE

Inner surfaces of the unit will be

very hot during and after operation.

Avoid touching the cabinet when

loading or removing product.

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

CONTROLLER

OPERATING

ENVIRONMENT

The solid state components in the

controller are designed to operate

reliably in a temperature range up

to 158°F (70°C). Before installing,

verify that the ambient temperature where this product is located

does not exceed this temperature.

NOTE: To review and/or program

time and temperature settings for

each Product Key, refer to Pro-

gramming Instructions on

pages 10-20.

*NOTE: FAST.FLEX™ Timing

Mode may assist you with variable product features such as

temperature and load; see page

16 for programming instructions.

When cabinet is turned on, controller will default to Product

Key 1, indicated by illuminated indicator light. The display will

read “LOW”.

1) Turn power switch ON.

2) Load Product: For best retherm times, product must be

thawed or slacked prior to loading. Chilled or frozen food will

extend retherm time substantially*. Load baskets of food, beginning at the bottom of the cabinet and working up. If retherming less than a full load, arrange baskets so they are located

on the center shelves; this will ensure best air circulation and

even heating around the food.

3) Start a Cook Cycle: Press desired Product Key (1 through

10 to start a cook cycle. If the key is programmed, the correct

cooking time will be displayed and will immediately start to

count down in minutes and seconds. “DONE” will display

when the cook cycle has ended. Product is ready to be removed, but may stay in the cabinet in Hold Mode until served.

4) Respond to DONE Alarm: DONE alarm will sound at the

end of a completed cycle. Cancel the signal by pressing the

same Product Key used to start the cook cycle.

5) Stop a Cook Cycle: Press and hold an active Product Key

for 3 seconds. Timing will stop.

6) Holding Cycle: If the controller is programmed with holding

times, they will automatically start counting upon expiration of

the cooking cycle. When there are active hold times the HOLD

indicator light will be lit.

To view all active hold times, press and hold the HOLD Key.

Upon expiration, the timer will display “HOLD” and pulse with

an audible tone.

To cancel, press the HOLD Key.

ON/OFF SCAN

8

TEMP

TOGL CLEAR

HOLD

Page 9

CONTROLLER PROGRAMMING INSTRUCTIONS

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

CONTROLLER

OPERATING

ENVIRONMENT

The solid state components in the

controller are designed to operate

reliably in a temperature range up

to 158°F (70°C). Before installing,

verify that the ambient temperature where this product is located

does not exceed this temperature.

Operation Mode: When the power is turned “ON”, the controller will read LOW and the temperature of the cabinet displayed

in °F or °C. From the operation mode, a menu can be started

by pressing the appropriate Product Key. Note: the fan will be

ON in the operation mode.

NOTE: To view actual cabinet temperature, press the TEMP

TOGL CLEAR button. Press the button again to exit.

Controller Programming: Retherm cabinets may or may not

have been pre-programmed by the factory to end user specifications. If the factory has pre-programmed the controller, it

should be reviewed to ensure proper set-points prior to use.

If the controller has not been pre-programmed by the factory, it

will be programmed to the default menu settings listed on the

chart below.

If programming is needed, follow the Controller Programming

Instructions on pages 10 through 20. Use the programming

worksheet provided below to aid your controller programming.

Pre-Programmed Default Menu Settings

Control

Display

Time 0 Preheat Time 20 25 30 35 20 25 30 35 20 25

Preheat Preheat Set Point 200 210 220 230 240 250 265 285 300 315

Product Key

Description

Product

Key 1

Product

Key 2

Product

Key 3

Product

Key 4

Product

Key 5

Product

Key 6

Product

Key 7

Product

Key 8

Product

Key 9

Product

Key 10

Time 1 Cook 1 Time 20 15 10 5 20 15 10 5 20 15

Temp 1 Cook 1 Set Point 180 185 190 195 200 215 230 250 275 300

Time 2 Cook 2 Time 20 15 10 5 20 15 10 5 20 15

Temp 2 Cook 2 Set Point 190 200 210 220 230 240 250 280 285 305

Time 3 Hold Time 30 30 30 30 30 30 30 30 30 30

Hold Hold Set Point 170 170 170 170 170 170 170 170 170 170

Controller Programming Worksheet

Control

Display

Time 0 Preheat Time

Preheat Preheat Set Point

Time 1 Cook 1 Time

Temp 1 Cook 1 Set Point

Time 2 Cook 2 Time

Temp 2 Cook 2 Set Point

Time 3 Hold Time

Hold Hold Set Point

Product Key

Description

Product 1 Product 2 Product 3 Product 4 Product 5 Product 6 Product 7 Product 8 Product 9 Product

9

10

Page 10

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Product Keys: press to start

a cook cycle; also used in

programming. Replaceable

menu strip to make menu

changes quickly and easily

Programming Levels The controller is equipped with two levels of programming access:

End User Programming Path 1724 allows the end user to

program Menu Settings. Daily users of this cabinet should be

familiar with all aspects of Program Mode 1724. See pages

11-13 for Program Mode 1724 instructions.

Manager Programming Path 3228 allows the user to program parameters such as Machine Type, Duct Temperature,

Fahrenheit/Celcius, Temperature Minimum and Maximum and

Set Point Differential. It is advised that access to Program

Mode 3228 be known only to owners/operators and not daily

users of the product. See pages 14-20 for Program Mode

3228 instructions.

8 Character LED

Display:

displays programming & cook cycle

information

Indicator Lights:

lit when active cook

cycle is in program-

ming mode

Feature Keys: used to access

programming functions and

controller features

10

Programming Center: access

programming mode and change

cooking parameters

Page 11

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

PROGRAMMING NOTES

Pressing the DOWN ARROW will

scroll through the entire sequence. If you wish to go back to

a particular parameter, press the

UP ARROW until the desired setting is reached.

To EXIT the Programming

Mode, scroll through the pro-

gramming choices until the display reads “SYSTEM”. Press UP

ARROW. The display will read

“EXIT”. Press “P” and you will

return to the Operating Mode.

If you discontinue programming

and leave the controller idle, it will

automatically exit the Programming Mode after two minutes.

END-USER PROGRAMMING PATH 1724

Program Path 1724 allows the end user to program up to ten

Menu Settings, one for each Product Key. Each Product Key

can be programmed for 4 stages in the Cook Cycle. This allows the user to vary the time and temperature in each stage

throughout the cooking cycle to achieve best product quality.

Stage 1: Pre-heat time

Pre-heat setpoint (Temperature setting)

Stage 2: Cook 1 Time

Cook 1 Setpoint (Temperature setting)

Stage 3: Cook 2 Time

Cook 2 Setpoint (Temperature setting)

Stage 4: Hold Time

Hold Setpoint (Temperature setting)

When scrolling through the Program Mode, the sequence of

programming will take you through programming all four program TIMES and then through all four program TEMPERATURES for the Product Key. The programming order scrolls as

such:

TIME 0 (Pre-heat time)

TIME 1 (Cook 1 time)

TIME 2 (Cook 2 time)

TIME 3 (Hold time)

PREHEAT (Pre-heat temperature)

COOK 1 (Cook 1 temperature setpoint)

COOK 2 (Cook 2 temperature setpoint)

HOLD (Hold temperature setpoint)

Pressing the DOWN ARROW will scroll through the entire sequence. If you wish to go back to a particular time or temperature, press the UP ARROW until the desired setting is

reached.

To access Program Mode 1724

press and hold “P”.

The display will read: “COUNTS”

Press the DOWN ARROW

11

Continued on next page

Page 12

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

LED Display

The display will read: “PROGRAM”

Enter code “1724” using the Product Keys. As you type in

the numbers, they will appear as asterisks on the display.

Then, press “P”

The display will read: “RECIPE”

Press “P”

The display will read: “PRODUCT”

Select the Product Key (1 through 10) you wish to program

by pressing the product key.

TIME

PROGRAMMING

INSTRUCTIONS

Press “P”

The display will read: “ALL”

Press the DOWN ARROW button

The display will read: “TIME 0” (this is the PreHeat Time

setting) and then it will display the current time that has been

programmed.

Press the “TEMP TOGL CLEAR” key to clear the display; it

will revert to “:00”

TEMP

ON/OFF SCAN

TOGL CLEAR

HOLD

Continued on next page

12

Page 13

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

LED Display

TEMPERATURE

PROGRAMMING

INSTRUCTIONS

Using the Product Keys, type in the time desired for the PREHEAT time in minutes and seconds, for example 25:30 is 25

minutes and 30 seconds. Use the #10 product key for the

number 0.

Press the DOWN ARROW button to scroll

through and repeat the above procedure for

TIME 1, TIME 2 and TIME 3

After scrolling through the TIME settings

and programming in your desired times,

continue to scroll by pressing DOWN AR-

ROW to enter programming for each of the

four TEMPERATURE settings

The display will read “TEMP”

Press “P”

The display will read “PREHEAT” and then the currently programmed temperature for the preheat cycle (for example 250°

F). Type in the desired temperature for the preheat cycle. Use

the #10 product key for the number 0.

Press the arrow DOWN ARROW button to

scroll through and repeat the procedure to

program temperatures for TEMP 1, TEMP 2

and HOLD cycles.

Display will read “TEMP 1”, “TEMP 2”, and “HOLD” followed

by the currently programmed temperature for each cycle.

Type in the desired temperature for each cycle as you scroll

through them.

After programming the “HOLD” temperature,

press the arrow down button twice (scrolling

past the “ALRMTIME” to get to the EXIT

display).

When the display reads “EXIT”, press “P” to

exit the Programming Mode.

13

Page 14

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

PROGRAMMING NOTES

Once in Programming Path 3228,

pressing “DOWN ARROW” or

“P” will scroll through the entire

sequence of parameters. If you

wish to go back to a particular

parameter, press the UP AR-

ROW until the desired setting is

reached.

To EXIT the Programming

Mode, scroll through the pro-

gramming choices until the display reads “SYSTEM”. Press UP

ARROW. The display will read

“EXIT”. Press “P” and you will

return to the Operating Mode.

If you discontinue programming

and leave the controller idle, it will

automatically exit the Programming Mode after two minutes.

MANAGER PROGRAMMING PATH 3228

Program Path 3288 is a deeper level programming mode that

should be used by the manager only. In most cases, this

mode would be used infrequently, if at all. The sequence of

parameters that may be programmed in Program Path 3228

is:

MACHINE (you will not ever need to change this parameter)

APPLIANC (you will not ever need to change this parameter)

GD BAND Allows changes to the heating duct temperature;

maximum temperature is 400°F

TIMING Allows you program standard or FAST.FLEX™ timing

mode

COOKUNIT Allows you to change the timing to hours and min-

utes, or minutes and seconds

TONE VOL Allows you to change the volume of the controller

alarm

TEMP UNIT Allows you to change the temperature scale to

Fahrenheit or Celsius

RANGE L 1 Allows you to change the lower programmable

menu temperature; minimum 32°F

RANGE L 2 Allows you to change the upper programmable

menu temperature; maximum 350°F

HYS 1 Allows you to set the lower temperature differential; this

tells the machine when the temperature drops a certain number of degrees below the temperature setpoint to turn the

heating element on. Preprogrammed differential is 5°; In most

cases this is sufficient for effective machine performance

HYS 2 Allows you to set the upper temperature differential;

this tells the machine when the temperature goes above the

set point temperature to turn the heating element off. Preprogrammed differential is 5°; In most cases this is sufficient for

effective machine performance

RANGEL 2 (you will not ever need to change this parameter)

RANGEH 2 (you will not ever need to change this parameter)

HYSL 2 (you will not ever need to change this parameter)

HYSH 2 (you will not ever need to change this parameter)

14

Continued on next page

Page 15

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

*PROGRAMMING NOTE

You may also enter Programming Mode 1724 by scrolling to

“RECIPE” from the “SYSTEM”

screen using the DOWN ARROW

button. You may then program

the menu settings for Product

Keys 1 through 10, according to

the instructions on pages 12-13.

Scrolling past “RECIPE” at this

level will take you to

“DIAGNOST”, “OFFSET”, SCK

ADDR” and “EXIT” in that order.

“DIAGNOST” “OFFSET” and

“SCK ADDR” are to be used by

service technicians only. Do not

change any of the settings in

these parameters.

To exit, scroll until the screen

reads “EXIT” by using the UP or

DOWN ARROW buttons, and

then press “P”.

To access Program Mode 3228

press and hold “P”.

The display will read: “COUNTS”

Press the DOWN ARROW

The display will read: “PROGRAM”

Enter code “3228” using the Product Keys. As you type in

the numbers, they will appear as asterisks on the display.

*The display will read: “SYSTEM”

Press “P”

The display will read “MACHINE”

Skip this program by pressing the DOWN ARROW button

Press the DOWN ARROW button

The display will read “APPLIANC”

Skip this program by pressing the DOWN ARROW button

Press the DOWN ARROW button

15

Continued on next page

Page 16

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

TO CHANGE THE HEATER DUCT TEMPERATURE, scroll

using the DOWN ARROW until the display reads “GD BAND”

If you wish to change the heating duct temperature

press “P”.

and the display will read the current duct temperature.

To change the temperature, press the TEMP TOGL

CLEAR button. The display will read 0°F.

TEMP

ON/OFF SCAN

TOGL CLEAR

HOLD

Type in a the desired duct temperature using the Product Keys (use 10 for the number 0). The maximum num-

ber that may be entered is 400°F.

ABOUT FAST.FLEX™ OR

STRAIGHT TIMING MODE

Flex or straight timing can be configured for each stage on each

Product Key. The advantage of the

FAST.FLEX mode is to insure consistent, high-quality food product.

FAST.FLEX will adjust the actual

cook time, taking into consideration the temperature variation due

to load size, initial product temperature, product moisture content, and other factors affecting the

cook cycle. However, using

FAST.FLEX mode may alter the

time expected to finish the cooking

cycle. If cooking by straight time,

the controller will cook only for the

specified time without adjusting for

these variances.

After typing in your desired temperature, press “P” to return

to the main 3228 Program Sequence. The display will read

“TIMING”.

TO CHANGE THE TIMING MODE, scroll by pressing DOWN

ARROW until the display reads “TIMING”

If you wish to change the timing from standard cooking

mode to FAST.FLEX™ mode or vice versa

press RIGHT ARROW or LEFT ARROW

to alternate between ‘FLEX” and

“STRAIGHT”

When your desired timing appears on the display, press

“P” to select and save your choice.

The display will read “COOKUNIT”

Continued on next page

16

Page 17

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

PROGRAMMING NOTES

Once in Programming Path 3228,

pressing “DOWN ARROW” or

“P” will scroll through the entire

sequence of parameters. If you

wish to go back to a particular

parameter, press the UP AR-

ROW until the desired setting is

reached.

To EXIT the Programming

Mode, scroll through the pro-

gramming choices until the display reads “SYSTEM”. Press UP

ARROW. The display will read

“EXIT”. Press “P” and you will

return to the Operating Mode.

If you discontinue programming

and leave the controller idle, it will

automatically exit the Programming Mode after two minutes.

TO CHANGE THE TIMER COUNTDOWN from minutes and

seconds to hours and minutes or vice versa, scroll using the

DOWN ARROW until the display reads “COOKUNIT”

Press LEFT ARROW or RIGHT ARROW

to select “HH:MM” (hours and minutes) or

“MM:SS” (minutes and seconds) for the

timer countdown

press “P”.

The display will read “TONE VOL”

TO CHANGE THE TONE VOLUME of the controller, scroll

using the DOWN ARROW until the display reads “TONE

VOL”

Press LEFT ARROW or RIGHT ARROW

to select your desired volume; tone

ranges from 1 (softest) to 4 (loudest).

When you reach the desired volume

press “P”.

The display will read “TEMP UNIT”

TO CHANGE THE TEMPERATURE SCALE of the controller

from Fahrenheit to Celsius or vice versa, scroll using the

DOWN ARROW until the display reads “TEMP UNIT”

Press LEFT ARROW or RIGHT ARROW

to select your desired scale (controller will

read “F” or “C”). When you reach the

desired scale

press “P”.

The display will read “RANGE L 1”

17

Continued on next page

Page 18

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

PROGRAMMING NOTES

Once in Programming Path 3228,

pressing “DOWN ARROW” or

“P” will scroll through the entire

sequence of parameters. If you

wish to go back to a particular

parameter, press the UP AR-

ROW until the desired setting is

reached.

To EXIT the Programming

Mode, scroll through the pro-

gramming choices until the display reads “SYSTEM”. Press UP

ARROW. The display will read

“EXIT”. Press “P” and you will

return to the Operating Mode.

If you discontinue programming

and leave the controller idle, it will

automatically exit the Programming Mode after two minutes.

TO CHANGE THE LOW TEMPERATURE RANGE of the controller, scroll using the DOWN ARROW until the display reads

“RANGEL 1” and then the currently stored LOW temperature

setting (i.e. 32°F). Press “TEMP TOGL CLEAR” button to

clear the temperature setting. The display will read “0°F”

ON/OFF SCAN

TOGL CLEAR

HOLD

TEMP

Using the Product Keys, type in the new desired LOW temperature setting (Use the number 10 for 0). NOTE: 32°F is the

lowest possible setting that can be used.

press “P”.

The display will read “RANGEH 1”

TO CHANGE THE HIGH TEMPERATURE RANGE of the

controller, scroll using the DOWN ARROW until the display

reads “RANGEH 1” and then the currently stored HIGH temperature setting (i.e. 350°F). Press “TEMP TOGL CLEAR”

button to clear the temperature setting. The display will read

“0°F”

TEMP

ON/OFF SCAN

TOGL CLEAR

HOLD

Using the Product Keys, type in the new desired HIGH temperature setting (Use the number 10 for 0). NOTE: 350°F is

the highest possible setting that can be used.

press “P”.

The display will read “HYS L 1”

18

Continued on next page

Page 19

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

PROGRAMMING NOTES

Once in Programming Path 3228,

pressing “DOWN ARROW” or

“P” will scroll through the entire

sequence of parameters. If you

wish to go back to a particular

parameter, press the UP AR-

ROW until the desired setting is

reached.

To EXIT the Programming

Mode, scroll through the pro-

gramming choices by pressing

“P” until the display reads

“SYSTEM”. Press UP ARROW.

The display will read “EXIT”.

Press “P” and you will return to

the Operating Mode.

If you discontinue programming

and leave the controller idle, it will

automatically exit the Programming Mode after two minutes.

TO CHANGE THE LOWER TEMPERATURE DIFFERENTIAL

of the controller, scroll using the DOWN ARROW until the display reads “HYSL 1” and then the currently stored lower differential temperature setting (i.e. 5°F). Press “TEMP TOGL

CLEAR” button to clear the temperature setting. The display

will read “0°F”

ON/OFF SCAN

TOGL CLEAR

HOLD

TEMP

Using the Product Keys, type in the new desired low temperature setting (Use the number 10 for 0).

press “P”.

The display will read “HYSH 1”

TO CHANGE THE UPPER TEMPERATURE DIFFERENTIAL

of the controller, scroll using the DOWN ARROW until the display reads “HYSH 1” and then the currently stored upper differential temperature setting (i.e. 5°F). Press “TEMP TOGL

CLEAR” button to clear the temperature setting. The display

will read “0°F”

ON/OFF SCAN

TOGL CLEAR

HOLD

TEMP

Using the Product Keys, type in the new desired upper temperature setting (Use the number 10 for 0).

19

press “P”.

Continued on next page

Page 20

CONTROLLER PROGRAMMING INSTRUCTIONS (Continued)

Operating range:

Temperature: 200ºF-350ºF

(93.3°C to 172°C)

Time: up to 99 minutes, 59

seconds, for each stage on the

Product Key

Programming Center Keys

LED Display

PROGRAMMING NOTES

Once in Programming Path 3228,

pressing “DOWN ARROW” or

“P” will scroll through the entire

sequence of parameters. If you

wish to go back to a particular

parameter, press the UP AR-

ROW until the desired setting is

reached.

To EXIT the Programming

Mode, scroll through the pro-

gramming choices until the display reads “SYSTEM”. Press UP

ARROW. The display will read

“EXIT”. Press “P” and you will

return to the Operating Mode.

If you discontinue programming

and leave the controller idle, it will

automatically exit the Programming Mode after two minutes.

It is not necessary to program the rest of the parameters in

the sequence. They are:

The display will read “RANGEL 2”

Skip this parameter by pressing “P”

The display will read “RANGEH 2”

Skip this parameter by pressing “P”

The display will read “HYSL 2”

Skip this parameter by pressing “P”

The display will read “HYSH 2”

Skip this parameter by pressing “P”

The controller will return to the beginning of the sequence

and the display will read “MACHINE”

To EXIT PROGRAMMING MODE 3228

Scroll through the programming sequence using the DOWN

ARROW or UP ARROW until the display reads “MACHINE”

Press UP ARROW

The display will read “SYSTEM”

Press UP ARROW

The display will read “EXIT”

press “P”.

The controller is now out of Program Mode and in Operating

Mode.

The controller will also exit Programming Mode if left idle for

more than two minutes.

20

Page 21

DAILY CLEANING PROCEDURES

CAUTION:

ELECTRIC SHOCK

HAZARD

Disconnect appliance from

electric power before cleaning.

NOTE: When the power is

turned off, the cooling fans will

continue to operate until the

heater compartment cools

down. DO NOT unplug the

cabinet until the cooling fans

turn off.

CAUTION:

HOT SURFACE

Exposed surfaces can

be hot to the touch and may

cause burns. Allow appliance

to cool before cleaning.

IMPORTANT:

DO NOT spill or pour

water into controls,

control panel or wiring. Water

damage is not covered by warranty.

CAUTION

Beware of sharp

edges with sheet

metal during cleaning process.

:

1. After all food products have been removed from the cabinet,

turn the power switch to “OFF” and allow the cabinet to cool.

2. Unplug the unit prior to any cleaning.

3. Remove the side heat duct and rack assemblies. Simply lift

up and pull out. They may be hand washed or run through an

automatic washer. Clean the inside of the unit as well as the

removed parts. Reinstall when all parts are dry and clean.

4. To clean stainless steel surfaces, use only cleansers, detergents, degreasers or sanitizers that are certified to be

“chloride-free” and “phosphate-free.” Use these products only

in recommended concentrations. DO NOT exceed recommended concentrations or mixing ratios. After cleaning and

sanitizing, rinse all exposed surfaces thoroughly with large

amounts of clean, clear water. Wipe off any standing liquid or

residue from all surfaces, corners and near edges.

5. Inspect and clean the areas where there are vents or filters,

making sure no water gets into the internal controls or electrical areas of the cabinet. CAUTION: When using solvents, it is

essential that proper precautionary measure be observed.

Refer to solvent manufacturer’s instructions. Use of direct

steam/hot water at temperatures above 190°F may result in

bubbling or loosening of the control panel.

6. Plastic control panel should be washed with a clean damp

cloth and chlorine-free detergent. Rinse thoroughly with clean

damp cloth and allow to dry. Do not use abrasive cleaners,

waxes, car polish, or substances containing strong aromatic

solvents or alcohol.

CAUTION: Cleansers, detergents, degreasers, sanitizers, or bleaching agents that contain chlorides or phosphates will cause permanent damage to stainless steel products. The damage appears

as pits, eruptions, voids, small holes, severe discoloration or dulling of the metal finish.

Water with high chloride content can also damage stainless steel. If unsure of your water quality, we recommend you have it tested. THIS DAMAGE IS PERMANENT, COSTLY TO REPAIR, AND IS NOT COVERED

BY THE WARRANTY.

SEE NEXT PAGE FOR RECOMMENDED TIPS FOR CLEANING STAINLESS STEEL

21

Page 22

CABINET MAINTENANCE

CAUTION:

Never move cart

unless all doors are

securely closed. Serious

damage to hinges and doors

may result if bumped into tables, walls, or other equipment when doors are open.

CASTERS

Your cabinet may be equipped with casters or legs. If your cabinet

has casters they may be easily lubricated with a grease gun. Lubricate bearings at least once every six months. Lubrication will be

required every one to two weeks if carts are cleaned with hot water

or steam cleaning system. NOTE: Casters with special DelrinTM

bearings are recommended for frequent cart wash with steam

cleaning systems or high pressure hose.

LATCHES

Check frequently to insure that all door latches are secure.

Latches may become “sticky” due to residue buildup from daily use

and cleaning procedures. Lubricate latches once every six months

or when needed with WD40, silicone spray, graphite or other commercial lubricant for stainless steel products. Do not use oil.

HINGES

Your cart doors and hinges have been factory aligned to assure

positive latching and smooth action. If doors are removed for

cleaning, we recommend that they be put back on the same cart to

assure the best

possible alignment and operation.

DOORS

Never tip carts forward on open doors to drain water during or after

washing. This can cause serious damage to hinges, doors and

latches.

RECOMMENDED TIPS FOR CLEANING STAINLESS STEEL

Purpose Frequency Cleaning Agent Method of Application

Routine Daily Soap, ammonia Sponge with cloth, rinse with clear water

detergent and water and wipe dry.

Smears/ As Stainless steel cleaner Rub with soft cloth as directed on package.

Fingerprints needed or similar products Rub in direction of grain of stainless steel.

Do not use on vinyl trim.

Stubborn Daily Any chloride-free Apply with damp sponge or cloth. Rub in

spots and as or direction of grain of stainless steel. Rinse

stains needed phosphate-free thoroughly, especially if cleaner contains

cleaner chlorine bleach, do not use on vinyl trim.

Hard water Daily Vinegar Swab with cloth.

spots as needed Rinse with water and wipe dry.

22

Page 23

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

NO POWER Power cord not plugged in Plug in power cord to proper re-

ceptacle

ON/OFF Switch OFF Turn ON/OFF Switch ON

Main circuit breaker tripped Check and reset breaker

Line fuse blown Correct cause of fuse failure and

replace fuses

Defective 24VAC transformer Replace transformer. Replace

controller

CABINET FAILS TO HEAT

(Start/Stop button pressed. Oven

will not heat. Blower fan runs)

CABINET FAILS TO HEAT

(Heat indicator comes on. All

other displays normal)

CABINET FAILS TO HEAT

(Temperature lamp comes on.

All other displays normal)

OVEN NOT HEATING

NORMALLY

CONTROLLER

INOPERATIVE

OR ERRATIC

AIR TEMP PROBE FAILURE

(Air probe malfunctions)

Door not fully closed Close door again. Retry cooking

cycle.

Incorrect cooking cycle Retry cooking cycle

Inoperable component Identify & replace failed part (s)

RF Interference Verify RF leakage within limits

Faulty controller Replace controller

Hi-limit tripped Reset hi-limit

Faulty heater relay Replace relay

Faulty heat elements Replace elements

Incorrect heating procedure Check time setting

Wattage output too low Check element

Defective capacitor Check & replace if necessary

RF Interference Verify RF leakage within limits

Faulty controller Replace controller

Faulty controller transformer Replace transformer

Loose probe connection Repair connections

Faulty air thermocouple Replace air probe

NO SOUND Inoperable speaker Replace controller

BUTTON PROBLEM Frozen key Unplug controller. Hold down the

TEMP TOGGLE/CLEAR key as

you plug the controller back in

Inoperable key Replace controller

READING WRONG

TEMPERATURE

Display reads “PROBE”

Defective temperature probe Replace temperature probe

Defective temperature probe Replace probe

Probe not plugged in Plug in probe

23

Page 24

SERVICE EXPECTATIONS

For over fifty years, Carter-Hoffmann has enjoyed a reputation for manufacturing rugged, dependable foodservice

equipment that permits foodservice professionals serve more food products to more people, and thus, to grow their

business.

Our goal is not only to provide the best food service equipment for the price, but also to back it up with after-sale service that is

responsive fast, efficient and professional. To ensure a clear understanding of our goals, expectations, and responsibilities,

we have prepared this brief document

Carter-Hoffmann products are innovative and efficient. They are easy to use, easy to clean and easy to maintain. Although

the products are quite reliable, when necessary they are also easy to repair.

We believe that a malfunction to a Carter-Hoffmann product should cause as little inconvenience to the customer as possible.

Our aim is to provide “same day”/first time fix” repair service on all of our products, whether in warranty or not.

We are dedicated to making every aspect of our customer service the standard by which others are judged.

While we all strive to serve our mutual customers as well as possible that does not mean that the end-user (including

his employees) does not share some responsibilities.

1. All shipping damage must be noted on the freight bill when the shipment is received. Any freight damages must be collected from the Freight Company, NOT Carter-Hoffmann.

2. The end-user should be advised beforehand to carefully unpack and inspect all products when they are received BEFORE

SIGNING THE SHIPPER'S RECEIPT OF DELIVERY.

3. The end-user must provide a safe, dry, level surface for the equipment to be placed upon.

4. The end-user must provide the proper electrical supply. All in-wall electrical modifications are to be completed by a licensed electrician. All building modifications are the responsibility of the end-user.

5. The end-user must operate, clean and maintain the equipment in accordance with the procedures described in the Equipment Manual.

6. Carter-Hoffmann is NOT responsible for any loss of the customer’s income, loss of food product, extra labor charges, or

any other incidental or consequential costs as a result of the malfunction of our product.

7. The end-user shall contact our authorized service provider only whenever service or repair to a Carter-Hoffmann product

under warranty is required.

8. The end-user shall allow for on-premises repair of the equipment to be completed at a mutually convenient place and time.

1. Warranty service is to be initiated by authorized Carter-Hoffmann personnel only.

2. The service provider is NOT authorized to change or extend any of the terms or conditions of our warranty.

3. Initial freight damage is NOT covered by the product warranty.

1. The end user and all his employees and sub-agents shall protect and keep confidential Carter-Hoffmann’s proprietary designs, information, and knowledge.

2. All materials provided by Carter-Hoffmann is to be considered confidential; it remains Carter-Hoffmann’s property; and is

not to be reproduced without our prior approval

Service Philosophy

End-User Responsibilities

Warranty Service

Confidentially

24

Page 25

Carter-Hoffmann Warranty:

Carter-Hoffmann (“CARTER-HOFFMANN”) warrants to the initial purchaser of its stan dard Carter Line

Products that CARTER-HOFFMANN will, at its option, repair or replace, during the warranty period set

forth below, any part of such products made necessary due to a defect in material or workmanship which

is present when the product leaves its factory and which manifests itself during the warra nty period under

normal use and service.

This warranty applies only to original equipment owned and possessed by the initial pu rchaser and the

warranty period begins on the date of original shipment from the CARTER-HOFFMANN factory and extends as follows: to component parts and labor for 12 months.

Repair or replacements under this warranty will be performed, unless othe rwise authorized in writing by

CARTER-HOFFMANN, at its factory. All parts or components to be repaired or replaced under this warranty are to be shipped prepaid to CARTER-HOFFMANN, with reimbursement credit for such part or

component to be given if found by CARTER-HOFFMANN to be defective.

CARTER-HOFFMANN neither makes nor assumes and does not authorize any other person to make or

assume any obligation or liability in connection with its products other tha n that covered in this warranty.

This warranty applies only within the continental United States and Canada. In Alaska and Hawaii, th is

warranty applies only to and is limited to the supply of replacement parts.

Warranty Exclusions and Limitations:

Any implied warranty of merchantability or fitness for a particular purpos e is hereby specifically dis-

claimed by CARTER-HOFFMANN. There are no warranties, expressed or implied, which extend beyond

the description on the face hereof. This warranty does not cover and CARTER-HOFFMANN shall not under any circumstances be liable for any incidental, consequential or other damages (such as injury to per-

sons or property, loss of time, inconvenience, loss of business or profits, or other matters not specifically

covered) arising in connection with the use of, inability to use, or failure of these products.

Specifications are subject to change through product improvement and innovation.

Carter-Hoffmann

1551 McCormick Ave.

Mundelein, Illinois, 60060 USA

Phone: 847-362-5500 Toll free: 800-323-9793 Fax: 847-367-8981

Sales and Marketing E-mail: sales@carter-hoffmann.com

Service E-mail: service@carter-hoffmann.com

Company Website: www.carter-hoffmann.com

25

Loading...

Loading...