Page 1

Carter-Hoffmann

Since

1947,

Foodservice Equipment That Delivers!

NOTE:

SEPTEMBER

1997

Equipment Manual

1551 McCormick Ave. Mundelein, IL

60060 Phone: (847) 362-5500

Fax: (847) 367-8981

Toll Free Service:1 (800) 323-9793

This equipment has been

designed and manufactured to

meet all applicable health and

safety codes and will give years

of dependable service if used

properly. All carts should be

thoroughly cleaned before using.

for Quick Serve™

Models FSH50, FSH63, FSHM54,

FSC50, FSC63, FSFI35

Printed in U.S.A.

18400-3034

SN/97P0842

TABLE OF CONTENTS

CLEANING PROCEDURES 2

ELECTRICAL REQUIREMENTS,

OPERATING INSTRUCTIONS,

REPLACEMENT PARTS

FOR FSC50, FSC63 3

FOR FSFI35 4

FOR FSHM54 5

FOR FSH50, FSH63 6

CABINET MAINTENANCE 7

WARRANTY 8

Page 2

Turn off power, unplug cabinet and allow to reach room temperature

Cleaning

Procedures

WARNING damage to the electrical components will result.

1. After all food products and containers have been removed from the cabinet, turn the power switch to "OFF" and allow the

cabinet to reach room temperature.

2. If applicable, vinyl trim or laminate should be washed with a chlorine-free detergent and water. Rinse thoroughly with clear

water and allow to dry. Never use abrasive cleaners, waxes, car polish, or substances containing strong aromatic solvents or

alcohol. Caution: When using solvents, it is essential that proper precautionary measures be observed. Refer to solvent

manufacturer's instructions. Use of direct steam/hot water cleaning at temperatures above 190°F may result in "bubbling" or

loosening of vinyl adhesive.

3. To clean stainless steel surfaces use only cleansers, detergents, degreasers, or sanitizers that are certified to be "chloridefree" and "phosphate-free," and cleansers, degreasers, or sanitizers only in the recommended concentrations. DO NOT

exceed recommended concentrations or mixing ratios. After cleaning and sanitizing, rinse all exposed surfaces thoroughly

with large amounts of clean, clear water. Wipe off any standing liquid or residue from all surfaces, corners, or near edges.

CAUTION

metal finish. Water with high chloride content can also damage stainless steel. If unsure

of your water quality, we recommend you have it tested. THIS DAMAGE IS PERMANENT,

COSTLY TO REPAIR, AND IS NOT COVERED BY THE WARRANTY.

before cleaning. The built-in heater/cooling systems should not be

exposed to direct contact with water or cleaning sprays. Permanent

Cleansers, detergents, degreasers, sanitizers, or bleaching agents that

contain chlorides or phosphates will cause permanent damage to

stainless steel products. The damage appears as pits, eruptions,

voids, small holes, cracks, severe discoloration, or dulling of the

RECOMMENDED "TIPS" FOR CLEANING STAINLESS STEEL

Purpose Frequency Cleaning Agent Method of Application

Routine Daily Soap, ammonia detergent Sponge with cloth, rinse with clear water and wipe dry.

cleaning

Smears/ As Needed Stainless steel cleaner Rub with cloth as directed on package. Rub in direction

fingerprints

Stubborn Daily Any chloride-free Apply with damp sponge or cloth. Rub in direction of polish

spots and As Needed or phosphate-free lines. Rinse thoroughly after use, especially if cleaner

stains

Hard water Daily Vinegar Swab with cloth. Rinse with water and wipe dry.

spots As Needed

CAUTION: Do not use steel wool pads as they will result in rusting from the ferrous metal in the pads.

and water

or similar products of grain of stainless steel. Do not use on vinyl trim.

cleaner contains chlorine bleach. Do not use on vinyl trim.

2

Page 3

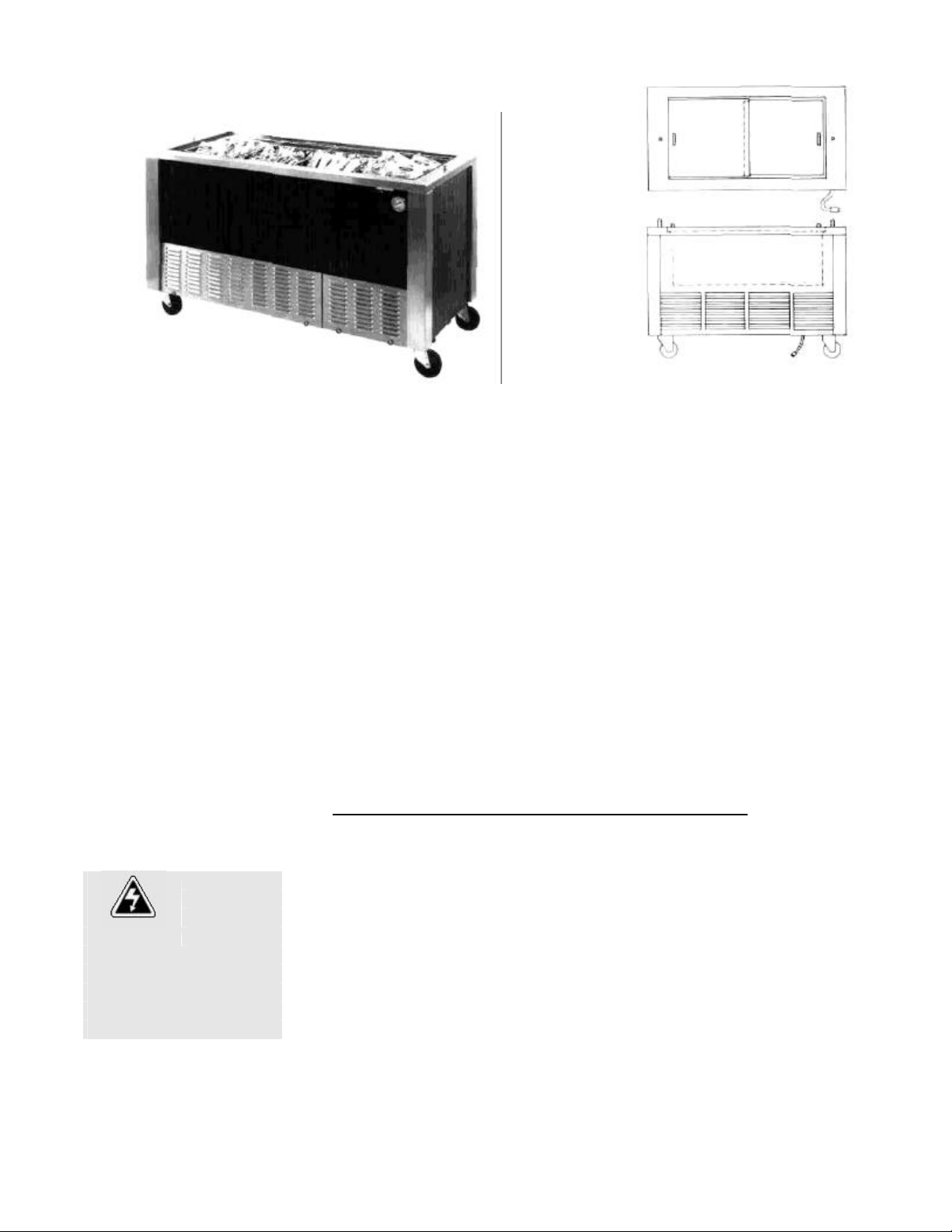

For Model FSC50 and FSC63

Electrical

Operating

Replacement Pa

rts

Operates on 15 AMP, 120 volts, 60 HZ, 1 PH, requires NEMA 5-15R receptacle.

Requirements

Instructions

Contact factory with your model and

serial number for replacement cabinet

components.

Use only

(OEM)

original

WARNING equipment

manufacturer replacement parts.

Using unauthorized parts may

cause serious injury. Replacement

parts should be installed by a

qualified service technician.

The Carter-Hoffmann Quick Serve™ Refrigerated Server is designed to hold

prepackaged food and beverages at or below serving temperatures of 40°F.

The unit will continue to chill the contents, with the top lids removed, during

serving.

1. To access On/Off switch, remove the shorter bottom louvered panel by

twisting screws 1/4 turn, and pivoting up panel. The reverse is followed

for reinstallation.

2. Turn unit on. The thermostat, also located in this area, is pre-set at the

factory. Replace louvered panel and let unit pre-cool for 60 minutes.

3. After pre-cool, open lids and stack loaded baskets of prepackaged food

or beverage in unit.

4. Close lids until serving.

Part Number

16090-0880 Securing Locking Assembly (FSC50)

16090-0849 Securing Locking Assembly (FSC63)

18606-0647 NEMA 5-15 Plug

18616-0083 Dial Thermometer

16002-0004 Complete Slide-In Refrigeration Assembly

18600-0080 Thermostat

18612-5000 Condensing Unit

18614-0050 Accumulator

18614-0062 Filter Drier

18602-0101 Double Pole On/Off Switch

18602-0102 Single Pole On/Off Switch

11000-0881 Wiring Diagram

Description

3

Page 4

For Model FSFI35

Electrical

Operating

4

Requirements

Operates on 15AMP, 120 volts, 60 HZ, 1 PH, requires NEMA5-15R receptacle.

Instructions

Replacement Parts

Contact factory with your model and

serial number for replacement cabinet

components.

Use only

(OEM)

original

WARNING equipment

manufacturer replacement parts.

Using unauthorized parts may

cause serious injury. Replacement

parts should be installed by a

qualified service technician.

The Carter-Hoffmann Quick Serve™ Freezer Server is designed to hold

prepackaged food at serving temperatures to 0°F.

1. Plug unit in.

2. Turn unit on through access door in louvered panel and let pre-cool for

60 minutes.

3. After pre-cool, open lids and stack frozen food in unit. Close lids until

serving. NOTE: Be sure tub drain plug is in place before loading.

4. To access thermostat, remove bottom louvered panel by removing two

(2) lower screws, pulling out, and dropping panel (the reverse is

followed for reinstallation). The thermostat is pre-set at the factory.

Part Number

16090-0842 Security Locking Assembly

18602-0025 On/Off Toggle Switch

18606-0647 NEMA 5-15P Plug

Description

Page 5

For Model

FSHM54

Electrical

Part Number

Description

Requirements

Operating

Instructions

Replacement Parts

Contact factory with your model and

serial number for replacement cabinet

components.

Use only

(OEM)

original

WARNING equipment

manufacturer replacement parts.

Using unauthorized parts may

cause serious injury. Replacement

parts should be installed by a

qualified service technician.

Individual branch circuit 30 AMP, 120 volts, 60 HZ, 1 PH, requires NEMA 530R receptacle.

The Carter-Hoffmann Quick Serve™ Heated Display Merchandiser is designed

to provide a heated display environment for prepackaged and/or wrapped

foods. The lower base unit provides storage space for top sliding lids used on

the FSH and FSC series cabinets.

1. Temperature setting and On/Off switches are located in the lower unit

behind the right door.

2. Adjust temperature setting to 3.

3. Use the convection heat lower unit to warm display area. Turn on switch

labeled "BASE"

4. For french fries or similar unwrapped foods, load unit and turn on infrared

lamps (switch labeled "LAMPS").

NOTE: Be sure to turn off the convection (BASE) heat when lamps are in use

to prevent overheating of food. In most applications, the infrared lamps

18600-0046

18606-0648

18614-0320

18614-0321

18600-0010

18608-0010

18602-0030

18606-0579

18612-0109

18601-0042

18616-0084

18602-0101

11000-0874

should be on food only 45 minutes to an hour.

N/C 300°F Hi Limit (Auto Reset)

NEMA 5-30P Plug

Motor

Motor Fan Blade

Thermostat

Thermostat Knob

On/Off Switch

NEMA L5-15P Plug

Box Element (120 Volt, 900 Watt)

Porcelain Socket

Hot Food Thermometer

On/Off Switch for Display

Wiring Diagram

5

Page 6

For Model FSH50, FSH63

Electrical

Individual branch circuit 30AMP,

120

volts,

60

HZ, 1 PH, requires NEMA 5

-

30R

NOTE:

Replacement Parts

Part Number

Description

receptacle.

Requirements

Operating

Instructions

Product must be in a single layer within

each basket. Stack baskets to the tot) of

the unit.

Contact factory with your model and

serial number for replacement cabinet

components.

Use Only

(OEM)

original

WARNING equipment

manufacturer replacement parts.

Using unauthorized parts may

cause serious injury. Replacement

parts should be installed by a

qualified service technician.

The Carter-Hoffmann Quick Serve™ Heated Server is designed to rethermalize

and hold prepackaged food from 40°F to 150°F in VA to 2 hours and retain an

elevated temperature for 30 minutes with top lids open or removed during

serving

Due to various conditions such as extremely low cafeteria room temperatures,

concentration and placement of food, and high frequency of lid opening, the

retherm period may be extended.

1. Open top lids and place one layer of 2" baskets inverted (upside down) on

the bottom to obtain optimum air flow during rethermalization. Close lids for

preheat.

2. To access controls, remove shorter bottom louvered panel by twisting

screws 1/4 turn, and pivoting up panel. The reverse is followed for

reinstallation of panel.

3. Set temperature knob at "5" and turn "ON" unit. Replace louvered panel and

let unit preheat for 20 minutes.

4. After preheat, open lids and stack loaded baskets of prepackaged food in a

single layer on inverted empty baskets. Close lids.

5. Allow approximately 1 1/2 to 2 hours to retherm chilled contents to a serving

temperature of 150°F.

6. Remove or open lids just prior to serving.

16090-0880 Security Locking Assembly (FSH50)

16090-0849 Security Locking Assembly (FSH63)

18606-0648 NEMA 5-30P Plug

18616-0010 Dial Thermometer

27080-1025 Complete Slide-In Heater

18600-0010 Thermostat

18602-0102 On/Off Switch

18608-0010 Thermostat Knob

18600-0046 N/C 300°F Hi-Limit (Auto Reset)

18612-0084 Finstrip Heater

18614-0320 Motor

18614-0321 Motor Fan Blade

18601-1150 Pilot Light

11000-0880 Wiring Diagram

6

Page 7

Cabinet

Maintenance

WARNING

Never move cart unless all

doors are securely closed,

serious damage to hinges

and doors may result if

bumped into tables, walls,

or other equipment when

doors are open.

1. Casters...Caster bearings are equipped with Zerk grease fittings so that they may

be easily lubricated with a grease gun. Lubricate bearings at least once every six

months. Lubrication will be required more frequently if carts are cleaned with hot

water or steam cleaning system. (Casters with special Delrin™ bearings are

recommended for frequent cart wash with steam cleaning systems or high pressure

hose.)

2. Latches...Check frequently to insure that all door latches are secure. Latches may

become "sticky" due to residue buildup from daily use and cleaning procedures.

Lubricate latches once every six (6) months or when needed with WD40, silicone

spray, graphite or other commercial lubricant for stainless steel products. Do not

use oil.

3. Doors...Never tip carts forward on open doors to drain water during or after

washing. This can cause serious damage to hinges, doors, and latches.

Calibrations

forFSHM54, FSH50, and FSH63

A] THERMOSTAT CALIBRATION_____________

If additional heat range is required in the heating unit , unplug unit, remove

thermostat knob, insert small straight blade screwdriver into opening and turn limit

control set screw counterclockwise (not clockwise) one full turn. Replace

thermostat knob and turn clockwise to reach new maximum temperature. Repeat

this until desired temperature is reached. Each 1/4 turn of the calibration set screw

will raise the element heating capacity by approximately 25T -35T.

If a reduction of heat is desired, turn limit control set screw clockwise one full turn.

Hold the door open allowing unit to cool until inside temperature is below the

temperature desired. Close the door and allow unit to rise to new maximum

temperature. Repeat this until desired temperature is reached.

B] THERMOMETER CALIBRATION___________

Place an oven thermometer in the center of the cabinet. Turn heater on; turn

thermostat to maximum setting and wait approximately 45 minutes. Open the door

and check inside thermometer temperature. If recalibration is required, pry the

plastic cover off the dial body and with a small flat blade screwdriver insert into the

pointer as shown. Carefully turn the pointer with your finger to the correct setting.

Be careful not to bend the pointer, it is very fragile.

7

Page 8

Carter-Hoffmann

Carter

-

Hoffmann Corporation ("CARTER

-

HOFFMANN") warrants to the initial

Since 1947

,

Foodservice Equipment Th

at Delivers

!

Corporation

Warranty:

purchaser of its standard Carter line Products that CAKTEK-HOFFMANN will, at its

option, repair or replace, during the warranty period set forth below, any part of such

products made necessary due to a defect in material or workmanship which is present

when the product leaves its factory and which manifests itself during the warranty period

under normal use and service.

This warranty applies only to original equipment owned and possessed by the initial

purchaser and the warranty period begins on the date of original shipment from the

CAKTEK-HOPFMANN factory and extends as follows: to electrical and refrigeration

components/or one year; to electrical and refrigeration labor for 120 days;

to refrigeration compressor unit for 1 year (limited to replacement of the unit only—not

to include labor for removal, repair or replacement), and to all other component parts

and labor for 12 months.

Repair or replacements under this warranty will he performed, unless otherwise

authorized in writing by CARTER-HOFFMANN, at its factory. All parts or components

to he repaired or replaced under this warranty are to he shipped prepaid to CAKTEKHOFFMANN, with reimbursement credit for such part or component to he given if found

by CARTER-HOPFMANN to he defective.

CAKTEK-HOFFMANN neither makes nor assumes and does not authorize any other

person to make or assume any obligation or liability in connection with its products other

than that covered in this warranty. This warranty applies only within the continental

United States and Canada. In Alaska and Hawaii, this w'arranty applies only to and is

limited to the supply of replacement parts.

Warranty

Exclusions And

Limitations:

Any implied warranty of merchantability or fitness for a particular purpose is hereby

specifically disclaimed by Carter-Hoffmann Corporation. There are no warranties,

expressed or implied, which extend beyond the description on the face hereof.

This warranty does not cover and CARTER-HOFFMANN shall not under any circumstances he liable for any incidental, consequential or other damages (such as injury to

persons or property, loss of time, inconvenience, loss of use, loss of business or profits, or

other matters not specifically covered) arising in connection with the use of, inability to

use, or failure of these products.

Specifications subject to change through product improvement and innovation.

Printed in U.S.A.

1551 McCormick Avenue, Mundelein, Illinois 60060 SEPTEMBER 1997

Tel. 1-800-323-9793 • Fax No. (847) 367-8981 18400-3034

SN/97P0842

Loading...

Loading...