CARTER-HOFFMANN EVOR208, EVOL208, EVOL240, EVOR240, EVOLTSM208 Owner's And Operator's Manual

...Page 1

FOOD HOLDING STATIONS

MODELS: EVOL208, EVOR208, EVOL240, EVOR240

EVOLTSM208, EVOLTLG208, EVOLTSM240, EVOLTLG240

OWNERS / OPERATORS MANUAL

EVOR208

MANUFACTURED BY:

CARTER-HOFFMANN

1551 McCormick Avenue

Mundelein, IL 60060 U.S.A.

Phone: 847-362-5500

Fax: 847-367-8981

Toll Free: 800-421-3744

Email: TechnicalService@Carter-Hoffmann.com

EVOLTLG208

EVOLTSM208

PAGE

SAFETY PRECAUTIONS 2

FEATURES & SPECIFICATIONS 3

UNPACKING, INSPECTION & FREIGHT DAMAGE 4

INSTALLATION & STARTUP 5

CONTROL PANEL LAYOUT 6

OPERATION 6

CONTROLLER PROGRAMMING INSTRUCTIONS 7

DAILY CLEANING PROCEDURES 8

TIPS FOR CLEANING STAINLESS STEEL 9

WIRING DIAGRAM & REPLACEMENT PARTS LIST 10

TROUBLESHOOTING GUIDE 11-12

WARRANTY STATEMENT 13

Part Number: 18400-3178 Printed in The United States of America Rev4: KBA092413

TABLE OF CONTENTS

Page 2

SAFETY PRECAUTIONS

WARNING: ELECTRIC SHOCK HAZARD

WARNING

All service requiring access to non-insulated components must be performed by

qualified service personnel. Failure to heed this warning may result in severe

electric shock.

CAUTION: ELECTRIC SHOCK HAZARD

Disconnect this appliance from electrical power before performing any

maintenance or service.

CAUTION: BURN HAZARD

Exposed metal surfaces can be hot to the touch and may cause burns.

IMPORTANT SAFETY INSTRUCTIONS

When using electrical appliances basic safety precautions should be adhered to, including the following:

1) Be familiar with the appliance use, limitations and associated restrictions. Operating instructions must

be read and understood by all persons using or installing this appliance.

2) This appliance must be grounded. Connect only to properly grounded outle t.

3) Use this appliance only for its intended purpose as described in the manual.

a. This equipment is specifically designed to hold pre-cooked food at temperature.

b.

c. This equipment is not designed for industrial or laboratory use.

4) Cleanliness of this appliance and its accessories is essential to good sanitation.

This equipment is intended for use in commercial establishments only.

5) DO NOT submerge this appliance in water. This appliance is not jet stream approved. DO NOT direct

water jet or steam jet at this appliance, or at any control panel or wiring. DO NOT splash or pour

water on, in or over any controls, control panel or wiring. DO NOT use corrosive chemicals or vapors

in this appliance.

6) DO NOT store this appliance outdoors. DO NOT use this product near water – for example,

near a kitchen sink, in a wet basement, or near a swimming pool, and the like.

7) DO NOT operate this appliance if it has a damaged cord or plug, if it is not working properly, or if it has

been damaged or dropped. Do not immerse cord or plug in water, keep cord away from heated

surfaces, and do not let cord hang over edge of table or counter.

8) DO NOT cover or block any openings on the appl iance.

9) Only qualified service personnel should service this appliance.

NOTE: The technical content of this manual, including any wiring diagrams, schematics, parts br eakdown

illustrations and/or adjustment procedures, is intended for use by qualified technical personnel and is

subject to change without notice.

2

Page 3

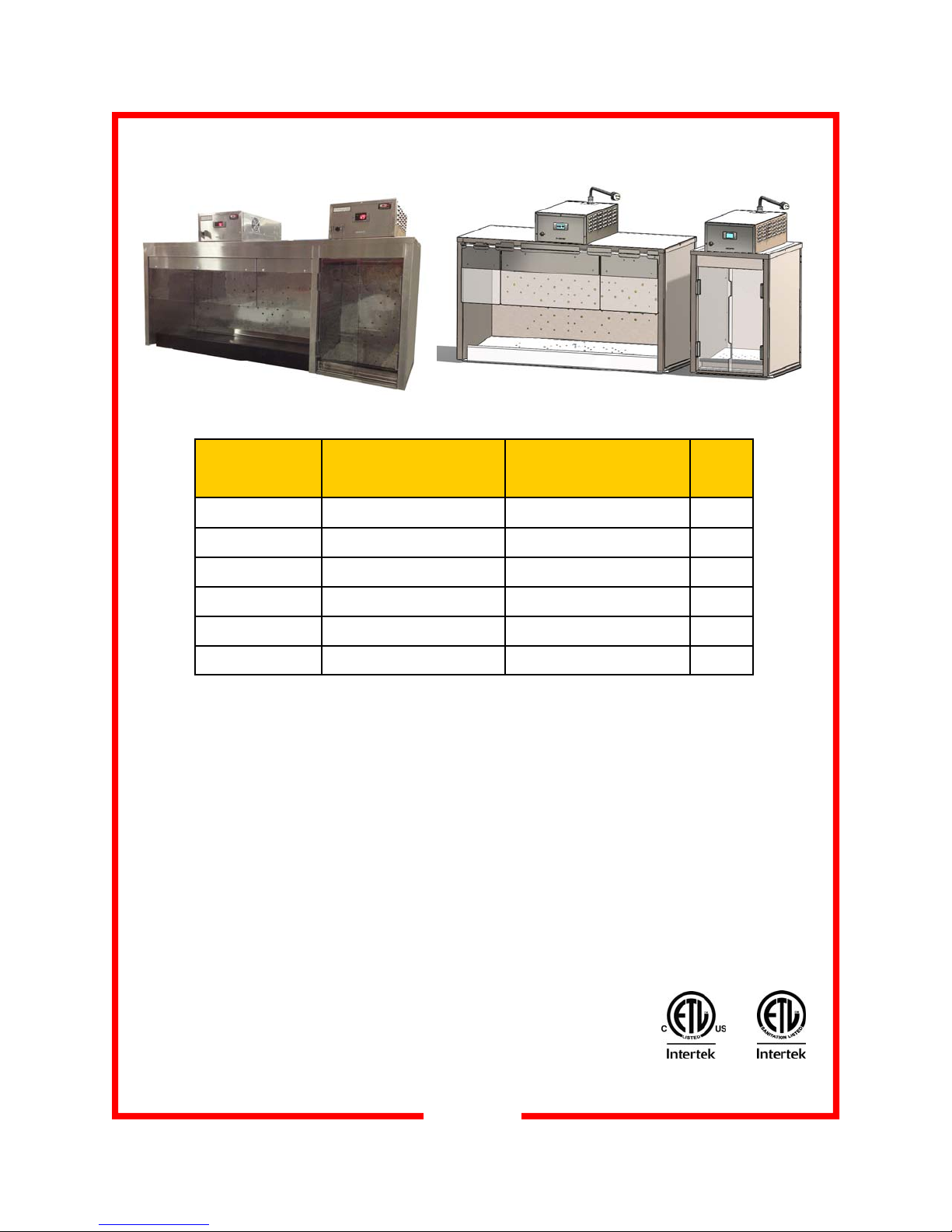

FEATURES & SPECIFICATIONS

EVOR208

Model Overall

Dimensions

EVOLTLG208

Electrical

Information

EVOLTSM208

Shipping

Weight

(each heater)

EVOL240 & EVOR240 32.38”H x 19.83”D x 62.25W 240V, 2400W, 10.5A, 50/60Hz, 1Ph 250 lbs

EVOL208 & EVOR208 32.38”H x 19.83”D x 62.25W 208V, 2400W, 12A, 50/60Hz, 1Ph 250 lbs

EVOLTSM208 32.38 x 19.83 x 17.5 208v, 2400W, 12A, 50/60Hz, 1 Ph 85

EVOLTLG208 32.38 x 19.83 x 46 208v, 2400W, 12A, 50/60Hz, 1 Ph 168

EVOLTSM240 32.38 x 19.83 x 17.5 240V, 2400W, 10.5A, 50/60Hz, 1Ph 85

EVOLTLG240 32.38 x 19.83 x 46 240V, 2400W, 10.5A, 50/60Hz, 1Ph 168

Features & Benefits

EVOL208, EVOR208, EVOL240, EVOR240. EVOR models have the small heating cabinet on the right side.

EVOL models have the small heating cabinet on the left side.

EVOLT models have separate small and large side cabinets.

Precision-engineered heat ducts with blower fan for even heat distribution throughout cabinet.

Each side individually heated with separate, removable heating units. Digitally controlled and monitored tem-

perature, with digital temperature read-out; pre-set factory temperatures of 208°F for small warming box and

158°F for large warming box. On/Off toggle switch on each heater.

Designed for over-counter use with angled interior floor.

Rod-type wire rack holders (NOT INCLUDED) are removable for cleaning.

Rear and bottom duct assemblies are removable for cleaning.

Polycarbonate shields over top of opening with flip up feature on large warming box and sliding doors on

small warming box enhance heating operation.

Supplied with 14/3 HSJO power cord and NEMA L6-15 plug.

3

3194974

Conforms with

UL STD 197

3194974

Conforms with

NSF/ANSI

STD 4

Page 4

UNPACKING AND INSPECTION

This appliance

should be

thoroughly

cleaned prior to use.

See the CLEANING

INSTRUCTIONS in

this manual.

NOTE: DO NOT discard

the carton or other

packing materials until

you have inspected the

appliance for hidden

damage and checked it

for proper operation.

Refer to FREIGHT

DAMAGE CLAIM

PROCEDURE on

bottom of this page.

1. Remove the cabinet from shipping carton, ensuring that all packing

materials and protective plastic has been removed from the unit.

2. Inspect all components for completeness and condition.

3. If any freight damage is present, a freight claim must be filed immediately with the shipping company.

4. Freight damage is not covered under warranty.

5. Check to insure all components are included: cabinet, instruction

packet, mounting brackets and additional accessories, where applicable.

6. Read operation instructions completely.

7. Appliance should be thoroughly cleaned before use. See CLEANING INSTRUCTIONS in this manual (page 8).

FREIGHT DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully inspected

and packaged by skilled personnel before leaving the factory. Upon acceptance of this shipment,

the transportation company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight

bill or express receipt, and that the note of loss or damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY: Regardless of the extent of damage. Contact

your dealer immediately.

3. CONCEALED DAMAGE: If damage is unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and then file a “CONCEALED DAMAGE” claim

with them. This should be done within fifteen (15) days from the date the delivery was made to

you. Be sure to retain the container for inspection.

Carter-Hoffmann cannot assume liability for damage or loss incurred in transit, freight damage is

not covered under warranty. We will, however, at your request, supply you with the necessary

documents to support your claim.

4

Page 5

INSTALLATION and START-UP

WARNING:

Risk of personal injury

Installation procedures must be

performed by a qualified technician

with full knowledge of all applicable

electrical codes and with proper

load-bearing hardware. Failure

could result in personal injury and

property damage.

IMPORTANT:

Each power cord is 6' long

If necessary, contact a licensed

electrician to install an appropriate

15 amp electrical circuit with correct

NEMA receptacle for each heater.

DO NOT use an extension cord.

CAUTION:

Electrical Shock Hazard

The ground prong of the power

cord is part of a system designed to

protect you from electric shock in

the event of internal damage.

DO NOT cut off the large round

ground prong or twist a blade to fit

an existing receptacle.

IMPORTANT:

Not under warranty

Damage to unit due to being

connected to the wrong voltage or

phase is NOT covered by warranty.

WARNING:

Risk of personal injury

Unit is not waterproof, to avoid

electrical shock, keep unit and

counter from being submerged in

water. Do not operate if unit has

been in contact with water.

LOCATION

Read equipment manual completely before installing and operating the cabinet.

Unit must be installed by qualified service personnel only. Unit must be installed in such a fashion to bear the weight

of the cabinet when fully loaded; minimum 350 pounds.

The power connection for each heater is a grounded plug.

Electrical information for each heater is provided on the heat-

er serial tag on the front of each heater. Verify that the proper

electrical service required for this cabinet is available prior to

installation. Plug the power cords into grounded outlets with a

electrical service according to the electrical information provided on page 3.

Heater serial tag locations

Cabinet serial tag (Note

serial number if calling

for service)

GROUNDING INSTRUCTIONS

This appliance is equipped with cords having a grounding wire with

a grounding plug which must be plugged into an outlet that is

properly installed and grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current.

WARNING—Improper use of the grounding can result in a risk

of electric shock. Consult a qualified electrician or service agent if

the grounding instructions are not completely understood, or if doubt

exists as to whether the appliance is properly grounded.

START-UP

1. Prior to use, thoroughly clean the interior of the unit, per

the instructions in this manual (page 8).

2. Plug the power cord of the cabinet into grounded outlets

with a electrical service according to the electrical information provided on page 3. Set POWER switches to the

“ON” position.

3. Do not load product into the cabinet. Allow the heat to

remove any residual oils which may adhere to inside metal surfaces. A slight emission of smoke is common during the first few hours of operation.

5

Page 6

EVOR208

CONTROL PANEL LAYOUT

Controllers

On/Off Toggle

Switches

OPERATION

AUX Key

(inoperable)

aux

Set Key

Press and release

to display temperature set point

CAUTION:

HOT SURFACE

Inner surfaces of the unit

will be very hot during and

after operation. Avoid

touching the cabinet when

loading or removing

product.

Up Arrow Key

Press to increase temperature set point

Digital Display

(1° increments)

Readout

Down Arrow Key

Press to decrease temperature set point

(1° increments)

1. Turn the power switches ON and let cabinet preheat for 30

minutes. When the cabinet is turned on, the air heater will operate until the cabinet reaches the air temperature setpoint. Each

display will read the actual temperature.

The temp icon will be illuminated when the cabinet temperature

is below the air temperature setpoint.

2. To view the temperature setpoint, press and release the SET

key.

3. After preheat, load cabinet with food product. Food is held in

various pan sizes as indicated by the spacing of the wire racks

inside the cabinet.

4. When cabinet is not in use, turn power off.

5. Cabinet must be cleaned daily. See cleaning instructions on

page 8.

6

Page 7

CONTROLLER PROGRAMMING INSTRUCTIONS

AUX Key

(inoperable)

aux

Up Arrow Key

Press to increase temperature set point

(1° increments)

Set Key

Press and release

to display temperature set point

Down Arrow Key

Press to decrease temperature set point

(1° increments)

Each controller has been factory pre-set for an air temperature set point and a low temperature alarm set point.

In most cases, these set points will not need to be changed. However, if changes are necessary, the controller is

programmable.

Factory Preset Set Points Large Side Heater Small Side Heater

Air Temperature

Low Temperature Alarm*

Air Temperature Operating Range

*Note: If Air Temperature is programmed to another setting, the Low Temperature Alarm Setting will automatically be reset 25 degrees below the Air Temperature setting.

To Lock or Unlock the Controller: Press and hold both Arrow Keys at the same time for at least three seconds. “oF” will display when the controller is locked; “oN” will display when the controller is unlocked.

To View the Temperature Set Point: Press and release the SET button

To Change the Temperature Set Point: Turn power ON. Press and hold the SET button for 3 seconds. The

current set point will display and “°F” will flash. Push the up or down arrow buttons to raise or lower the temperature set point in 1° increments. Push SET to store the new setting; the new temperate setting will flash 3 times

and then the display will revert back to the actual temperature. (If set button is not pushed within 13 seconds, the

new setting will be automatically set and the display will revert back to the actual temperatur e).

To Change from °F to °C, contact factory.

158°F 208°F

25°F below set point 25°F below set point

145° to 185°F 165° to 220°F

7

Page 8

DAILY CLEANING PROCEDURES

CAUTION:

ELECTRIC SHOCK

HAZARD

Disconnect appliance from

electric power before cleaning.

CAUTION:

HOT SURFACE

Exposed surfaces can

be hot to the touch

and may cause burns. Allow

appliance to cool before cleaning.

IMPORTANT:

DO NOT spill or pour

water into controls,

control panel or wiring. Water

damage is not covered by the

warranty.

CAUTION:

Beware of sharp edges with sheet metal

during cleaning process.

CAUTION:

Do not use steel wool

pads to clean cabinet.

Ferrous deposits will cause

rusting; roughness of the pad

will scratch the black powder

coating on the front door frame.

1. After all food products have been removed from the cabinet,

turn the power switches to “OFF” and allow the cabinet to

cool. If cabinet is supplied with a plug, disconnect from power prior to cleaning.

2. Remove the pan rack assemblies and clean according to

manufacturer’s directions.

3. Remove the doors from the large cabinet by flipping up and

lifting off. To remove the doors from the smaller cabinet, first

remove the front door by lifting the door up and out of the

track. Then remove metal track divider that is located between the doors. Lastly, lift the rear door up and out of the

track. Doors should be washed with a clean damp cloth and

chlorine-free detergent. Rinse thoroughly with clean damp

cloth and allow to dry. Do not use abrasive cleaners, waxes,

car polish, or substances containing strong aromatic solvents or alcohol. Do not use scratch pads or steel wool on

the plastic doors. Do not use stainless steel cleaner.

4. Remove bottom heat duct and then remove the rear heat

duct in each cabinet. Using a clean damp cloth with appropriate cleaner (see page 9), clean the inside of the unit and

the removed parts. Wipe any residue with clean damp cloth.

Reinstall all parts when they are dry and clean.

5. Inspect and clean the areas where there are vents or filters,

making sure no water gets into the internal controls or electrical areas of the cabinet.

6. Plastic control panel should be washed with a clean damp

cloth and chlorine-free detergent. Rinse thoroughly with

clean damp cloth and allow to dry. Do not use abrasive

cleaners, waxes, car polish, or substances containing strong

aromatic solvents or alcohol. Do not use stainless steel

cleaner.

8

Page 9

TIPS FOR CLEANING STAINLESS STEEL

RECOMMENDED TIPS FOR CLEANING STAINLESS STEEL

Purpose Frequency Cleaning Agent Method of Application

Routine Daily Soap, ammonia Sponge with cloth, rinse with clear water

cleaning detergent and water and wipe dry.

Smears/ As Stainless steel cleaner Rub with soft cloth as directed on package.

Fingerprints needed or similar products Rub in direction of grain of stainless steel.

Do not use on vinyl trim.

Stubborn Daily Any chloride-free Apply with damp sponge or cloth. Rub in

spots and as or direction of grain of stainless steel. Rinse

stains needed phosphate-free thoroughly, especially if cleaner contains

cleaner chlorine bleach, do not use on vinyl trim.

Hard water Daily Vinegar Swab with cloth.

spots as needed Rinse with water and wipe dry.

CAUTION:

Cleansers, detergents, degreasers, sanitizers, or bleaching agents that contain chlorides or phosphates will

cause permanent damage to stainless steel products. The damage appears as pits, eruptions, voids, small

holes, severe discoloration or dulling of the metal finish.

Water with high chloride content can also damage stainless steel. If unsure of your water quality, we recommend you have it tested. THIS DAMAGE IS PERMANENT, COSTLY TO REPAIR, AND IS NOT COVERED BY THE WARRANTY.

9

Page 10

WIRING DIAGRAM

REPLACEMENT PARTS LIST

PART NUMBER DESCRIPTION

18600-0042 Hi Limit 120°F Snap Disc

18600-0046 Hi Limit 350°F Auto

18602-0031 Switch Boot

18602-0083 DPDT Toggle Switch

18612-0135 Heat Element 240V/2400W

18612-0149 Heat Element 208V/2400W

18614-0275 Fan Grill

18614-0323 Muffin Fan, 230V

18614-0360 Motor, 115/230V

18616-9996 Cord Grip

18614-0321 Blower Wheel

18616-0035

PART NUMBER DESCRIPTION

18600-0117 Fan Safety Hi Limit 160°F w/Reset Snap Disc

18616-0366 Dixell 208V/16A 208°F Set-point Controller

18616-0367 Dixell 208V/16A 158°F Set-point Controller

16090-3594 HSJO 14/3 Cord with L6-16P Plug

18616-0035 20” Probe for EVO Heater

16095-3480 Sliding doors for small warming cavity (one

front and one back door)

16095-3532 Three-door flip up assembly (left)

16095-3531 Three-door flip up assembly (right)

10

Page 11

TROUBLESHOOTING GUIDE

EVO Heater: 208VAC and 240VAC. Reference connections on wiring diagram (previous page)

WARNING: All operations must be performed to requirements of NFPA-70E (Standard for

Electrical Safety in the Workplace) by a qualified electrician. CALL FOR SERVICE.

Symptom Possible Cause Remedy

No power; Dixell temperature controller display is

Switch is not in ON position

Turn the switch ON

not lit

Unit is not plugged in Plug in the power cord

Circuit breaker tripped Reset the circuit breaker. If it trips again, disconnect the EVO heater

and reset once more. When it trips, call an electrician to replace the

breaker or replace the feeder.

Otherwise, investigate for a short in the heater. Test:

1. Heating element

A. 208V - 18 Ω

B. 240V - 24Ω

Replace if the difference is significant.

2. Bower motor—replace if necessary.

Advice: When testing the motor, please pay attention to: body temperature (may be very hot!), rotor side wobbling, jammed rotor, partial or

complete winding shortage.

Power cord or plug is de-

Replace or repair

fective

Main switch is defective Replace it

Dixell temperature controller display is not lit,

but cooling fan is running

Defective thermostat Dixell Check wires for crimping or looseness—correct if necessary

Check wire connection on thermostat terminals #5 and #6—correct

connection or replace the thermostat

Dixell temperature con-

Cooling fan is not running 1. Check the fan’s cable connection-correct if necessary

troller display is not lit

Dixell Temperature con-

Heating element is cold 1. Check wires for crimping or loose connection—correct if necestroller display is lit, but

the food chamber is not

heated

Heating element is hot.

CAUTION: Heating ele-

ment may reach tempera-

ture as hot as 650°F.

2. Cooling fan is defective—replace if necessary

sary

2. Check wire connections on Dixell temperature controller terminals

#8 and #9—correct loose connection

3. Check Dixell temperature controller—replace if necessary

4. Check Hi Limit 350°F—correct connection or replace Hi Limit if

necessary

5. Check heating element (see above) - replace the element if defective

6. Check Hi Limit 160°F. If the Hi Limit reset button has popped up,

figure out reason, repair and reset.

1. Blower fan is loose—tighten set screw or replace

2. Check blower motor:

A. Motor is very hot: overheat protection activated; figure out why

motor has overheated, correct it, cool down motor. Replace if the

motor is faulty.

B. Motor is cold: correct connections or replace motor or

capacitor if necessary.

11

Page 12

TROUBLESHOOTING GUIDE - Continued

Symptom Possible Cause Remedy

Dixell temperature controller display is lit up

and food chamber is

overheated

Cooling fan does not

operate

No heat Heater blower not running,

Heating element is hot.

CAUTION: Heating element may reach temperature as hot as 650°F

Cooling fan does not operate

heating element not ener-

gized. WARNING: heater

blower may have failed

1. Hi limit 350°F is always closed: measure temperature on it surface; replace Hi Limit if it is hotter than 325°F. NOTE: When the

cover is open, the wire compartment, including the Hi Limit 350°F

is naturally cooled.

2. Dixell temperature controller is defective; replace controller

1. Check Hi Limit 120°F—replace if necessary

2. Check cooling fan—replace if necessary. NOTE: The fan is con-

trolled by Hi Limit of 120°F and starts when the temperature in

the wire box is higher than 120°F. This can take up to 6 minutes.

Also, the fan might run after turning the switch OFF, until the tem-

perature falls under 120°F.

1. Remove cover, press Hi Limit reset button on “FAN SAFETY” limit

(Part Number: 18600-0117)

2. Check operation of heater blower; replace if necessary. NOTE:

this Hi Limit prevents an “over temp” situation INSIDE the control

unit. Ensures proper air flow throughout heater and cooling fan

operation.

Temperature Controller Alarms—CONTACT SERVICE IF YOU SEE ANY OF

THESE ALARM CODES ON THE DISPLAY

Display Reads Indicates

P1 Air probe failure

HA Maximum temperature alarm

LA Low temperature alarm

EA External alarm

For technical assistance with troubleshooting, call

Carter-Hoffmann at (800)421-3744 or (847)362-5500.

NOTE: Prior to calling for service locate the serial tag on the cabinet. You will need the serial

number of the cabinet for proper identification.

Cabinet serial tag

12

Page 13

WARRANTY

Carter-Hoffmann Warranty:

Carter-Hoffmann (“CARTER-HOFFMANN”) warrants to the initial purchaser of its standard Carter

Line Products that CARTER-HOFFMANN will, at its option, repair or replace, during the warranty

period set forth below, any part of such products made necessary due to a defect in material or workmanship which is present when the product leaves its factory and which manifests itself d ur ing th e warranty period under normal use and service.

This warranty applies only to original equipment owned and possessed by the initial purchaser and the

warranty period begins on the date of installation for three years on parts an d l ab or.

Repair or replacements under this warranty will be performed, unless otherwise authorized in writing

by CARTER-HOFFMANN, at its factory. All parts or components to be repaired or replaced under this

warranty are to be shipped prepaid to CARTER-HOFFMANN, with reimbursement credit for such part

or component to be given if found by CARTER-HOFFMANN to be defective.

CARTER-HOFFMANN neither makes nor assumes and does not authorize any other person to make or

assume any obligation or liability in connection with its pro ducts other than that covered in this warranty. This warranty applies only within the continental United States and Canada. In Alaska and Hawaii, this warranty applies only to and is limited to the supply of replacement parts.

Warranty Exclusions and Limitations:

Any implied warranty of merchantability or fitness for a particular purpose is hereby specifically dis-

claimed by CARTER-HOFFMANN. There are no warranties, expressed or implied, which extend be-

yond the description on the face hereof. This warranty does not cover and CARTER-HOFFMANN shall

not under any circumstances be liable for any incidental, consequential or other damages (such as in-

jury to persons or property, loss of time, inconvenience, loss of business or profits, or other matters not

specifically covered) arising in connection with the use of, inability to use, or failure of these products.

Specifications subject to change through product improvement and innovation.

Phone: 847-362-5500 Toll free: 800-421-3744 Fax: 847-367-8981

Sales and Marketing E-mail: sales@carter-hoffmann.com

Service E-mail: technicalservice@carter-hoffmann.com

Company Website: www.carter-hoffmann.com

Carter-Hoffmann

1551 McCormick Ave.

Mundelein, Illinois, 60060 USA

13

Loading...

Loading...