Page 1

HEAT RETENTION TRANSPORT CART

MODELS: SR188 & SR1820

OWNER / OPERATOR’S MANUAL

MANUFACTURED BY:

CARTER-HOFFMANN

1551 McCormick Avenue

Mundelein, IL 60060

Phone: 847-362-5500

Fax: 847-367-8981

Toll Free: 800-323-9793

Email: Service@Carter-Hoffmann.com

PATENTED HEAT RETENTION TECHNOLOGY

SR1820

TABLE OF CONTENTS

US Patent Numbers

7,102,103B2 & 7,394,042

INTRODUCTION…………………………………………….…. 2

SAFETY PRECAUTIONS & GENERAL INFORMATION….. 3

FEATURES & SPECIFICATIONS……………………………. 4

UNPACKING, INSPECTION & FREIGHT DAMAGE……….. 5

INSTALLATION & STARTUP ………………….… ………….. 6

OPERATION & CONTROLS ……………….………………... 7

CLEANING & CABINET MAINTENANCE…………………… 8

WIRING DIAGRAM ……………………………………………. 9

REPLACEMENT PARTS LIST……………………………….. 10

TROUBLESHOOTING GUIDE …………………………........ 11

SERVICE EXPECTATIONS…………………………………… 12

OWNER INFORMATION………………………………………. 13

WARRANTY STATEMENT……………………………………. 14

Part Number: 18400-3136 Printed in the United States of America 060112KBA

Page 2

INTRODUCTION

Thank you for purchasing this Carter-Hoffmann appliance. Proper installation, professional

operation and consistent maintenance of this appliance will ensure that it gives you the very

best performance together with a reliable, long lasting and economical life. This manual

contains information needed to properly install, operate and maintain this appliance

This product is the result of extensive research and field testing. The materials used were

selected to provide optimum performance, maximum durability and an attractive appearance. At Carter-Hoffmann, every single unit is thoroughly inspected and functionally tested

prior to shipment.

This Carter-Hoffmann cabinet provides the best environment for food products in bulk pans

by regulating consistent the air temperature. This model uses hot circulating air (no moisture) and heat retention technology. EnduraHeat® heat retention technology enables

heated transport of bulk food to remote locations, while maintaining serve safe holding temperatures for two hours, unplugged and without the use of canned fuel.

Due to the retention capabilities of the heating module, this unit eliminates the need for any

type of canned fuel or “Sterno™” type heat. This is the major benefit of this unit, which will

pay for itself over a short period of time.

The major benefits of

EnduraHeat®

technology are:

Safety: elimination of po-

tential fire hazards from

fuel use reduces the likelihood of employee burns

Cost: eliminate expense of canned fuel; no

more scorched carpeting or other decor

Productivity: eliminate the extra labor involved to put cans into carts as well as

monitor canned heat use

Sanitation: no open flames to scorch pans,

burn food or scorch the cabinet interior;

eliminate messy residue from canned fuel

Food Quality: no transfer of fuel fumes to

ruin the flavor of food; food is maintained

serving temperature

Extended Unplugged Hold Time: Cabinet

temperature remains above 140°F for 2

hours, unplugged.

CAUTION: SAFE FOOD

HOLDING PRACTICES

RECOMMENDED

Cooking food to a safe temperature,

holding at a temperature of at least 140°

F is critical in the prevention of foodborne

illness. Hold only cooked, hot food at

140°F or higher. This cabinet is not intended to cook or reheat food. Food

must be at appropriate temperature before being placed into cabinet.

COOK TO AT LEAST

165°F Destruction of

165°F

140°F

41°F

most bacteria

HOLD at 140°F or higher

DANGER ZONE: 41°F

to 140°F Bacteria

grow rapidly

2

Page 3

SAFETY PRECAUTIONS & GENERAL INFORMATION

CAUTION: Electric Shock Hazard

All servicing requiring access to non-insulated components must be performed by qualified service

personnel. Do not open any access panels which require the use of tools. Failure to heed this warning can result in electrical shock. Disconnect this appliance from electrical power before performing

any maintenance or servicing.

WARNING: Injury Hazard

All installation procedures must be performed by qualified personnel with full knowledge of all applicable electrical codes. Failure could result in property damage and personal injur y.

WARNING Electric Shock Hazard

Appliance must be plugged into a properly grounded receptacle to prevent possible shock hazard.

Electrical shock will cause death or serious Injury.

CAUTION: Burn Hazard

Interior surfaces of the appliance may be HOT to the touch, and can cause serious burns.

GENERAL INFORMATION

•

This appliance is intended for use in commercial establishments,

where all operators are familiar with the appliance use, limitations

and associated hazards.

•

Operating instructions and warnings must be read and understood

by all operators and users.

•

This appliance is intended for use to holding pre-plated, covered,

pre-cooked foods for human consumption. No other use is recommended or authorized by the manufacturer or its agents.

•

Cleanliness of this appliance is essential to good sanitation. Read

and follow all included cleaning instructions and schedules to ensure the safety of the food product.

•

All included trouble shooting guides, component views and parts

lists are included for general reference, and are intended for use

by qualified service personnel.

•

Knowledge of proper installation, operation and maintenance procedures is essential to ensure the safe operation of this oven.

•

Always have dry hands prior to using this piece of equipment.

•

Turn OFF the unit (not all units have power switches) anytime the cabinet is not in use.

•

If an electrical shock is felt when touching the cabinet, disconnect the power immediately and call CarterHoffmann Technical Service for assistance or service.

•

If the power cord is frayed or the plug damaged, DO NOT plug into the electrical power receptacle. If it is

already plugged in, turn off the main circuit breaker, usually located in the building’s breaker box, then disconnect the plug.

•

Disconnect the power cord before attempting any repairs to the cabinet or heating unit.

•

Repairs to this unit must be by qualified personnel.

•

DO NOT SPRAY WITH WATER OR CLEANING SOLUTIONS, or submerge the heating unit. Components

and wiring present a high shock hazard when wet.

•

Disconnect heating unit when cleaning cabinet or heating unit.

•

Both the interior and exterior surfaces of this appliance can be hot to the touch and may cause burns.

SERVICE / SAFETY

CAUTION: Equipment

Electrical Damage

DO NOT plug in or use this appliance

until all Installation Instructions are

read and followed. Damage to the

appliance may occur if these instructions are not followed.

This manual is considered to be a

permanent part of this appliance.

This manual must remain with the

appliance if it is sold or moved to

another location

.

3

Page 4

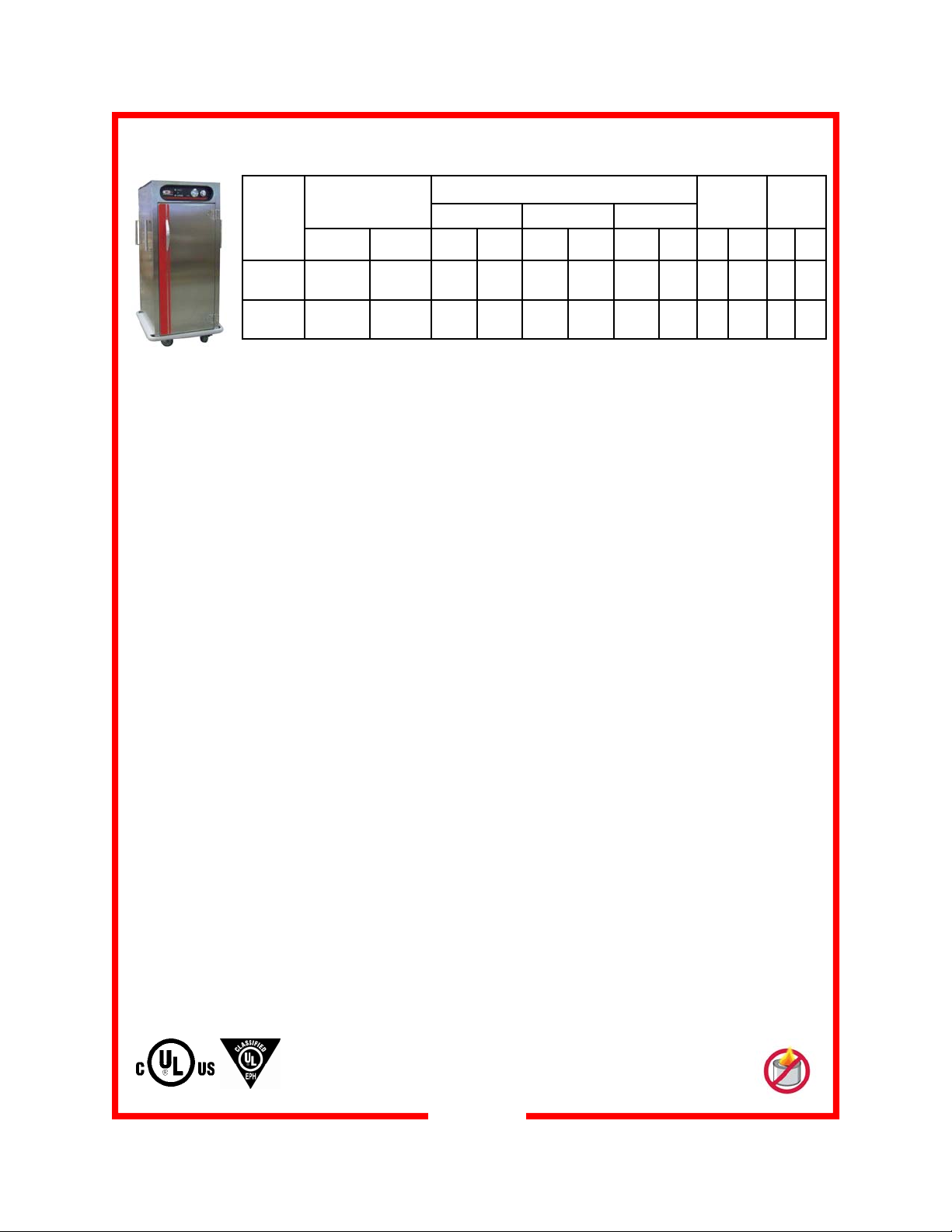

PRODUCT SPECIFICATIONS AND OPERATING FEATURES

PAN CAPACITY*

12”x20”x2.5” 18”x26” in mm in mm in mm in mm lbs kgs

SR1820

MODEL

NUMBER

SR188 12 6 45 1/2 597 35 889 31 3/4 806 6 152 285 130

SR1820 24 12 67 1/2 1715 35 889 31 3/4 806 6 152 440 200

*Standard tray slide spacing at 3.5”. Tray slides are adjustable at 1.5” spacing to accommodate varying pan depths.

CONSTRUCTION...Completely welded

double wall cabinet construction with

outer cabinet formed and welded to

base. All seams turned in to eliminate

raw edges.

CABINET MATERIAL...All stainless

steel; polished exterior.

BASE FRAME...12 gauge stainless

steel full depth caster bolsters.

CASTERS...6” diameter, industrial

grade balloon casters. Plate mounted

and bolted to base in offset, wheelahead pattern. Delrin sleeve axle bearings and double ball bearing swivel.

Zerk grease fittings. Two casters fitted

with brakes.

BUMPER...Non-marking gray vinyl

bumper set in heavy-duty 3/16” thick

extruded aluminum frame with reinforced corner cutouts.

INSULATION...2” thick, high density

continuous wrap-around type fiberglass

insulation.

THERMOMETER...Dial type with remote sensing bulb and sensing bulb

protector.

OVERALL DIMENSIONS

HEIGHT DEPTH WIDTH

DOOR...Recessed within cart walls, top

and base. Welded double panel

stainless steel pocket door. Filled with

2” thick high density fiberglass insulation. Large curved door handle for easy

grasp.

HINGES...12 gauge stainless steel

strap hinges with 3/8” diameter stainless

steel pins, fully welded to cabinet and

doors.

DOOR CLOSURE... Pocket style door

with magnetic closure. Gasketless design with side-mounted transport latch

with padlock provision.

HANDLE...SR188: Two horizontal full

width stainless steel tubular handles,

mounted to sides of cabinet on top

edge. SR1820: Four 1” stainless steel

tubular handles. Two vertically mounted

and bolted with backup plates to each

side of cabinet.

RACK ASSEMBLIES… Removable

solid stainless steel universal slides

placed into removable stainless steel

baffles. Tray slides fully adjustable at 13/4” spacing. Standard spacing at 3-1/2”

centers.

CASTER

DIAMETER

SHIPPING

WEIGHT

HEATING SYSTEM...1500 watt blower

heater located in top of cabinet. Patented solid-to-solid phase change heat

retention material heated by 950 watt

tubular element, located in bottom of

cabinet. High impedence protected,

internally cooled fan motor. Auto reset

high-limit switch to protect all internal

electrical components. Recessed control panel. Two position toggle switch

with convection and EnduraHeat settings. Power indicating light, EnduraHeat charge ready light, full range thermostat control knob.

ELECTRICAL CHARACTERISTICS...

Operates on 120 volts, 60 cycle, single

phase, 1500 watts, 12.8 amps. Ten foot

power cord with 3 prong grounding plug.

NEMA 5-20P.

PERFORMANCE...Capable of heating

F (94C°). Convection preheat to

to 200°

F (71°C) in approximately 30 min-

160°

utes. EnduraHeat mode charge time

and preheat in approximately one hour.

Preheat in standard convection mode is

20 minutes.

ACCESSORIES/OPTIONS...

-Alternate caster sizes and types

-Four wheel brakes

-Menu card holder (5”x7” or 8.5”x11”)

-6” extended width tray slides

-Alternate electrical configuration

NOTE: Specifications subject to change through product improvement & innovation.

US Patent Nos. 7,102,103 B2 & 7,394,042 B2

4

Page 5

UNPACKING, INSPECTION & FREIGHT DAMAGE

This appliance

should be

thoroughly

cleaned prior to use.

See the CLEANING

INSTRUCTIONS ON

PAGE 8 in this manual.

NOTE: DO NOT discard

the carton or other

packing materials until

you have inspected the

appliance for hidden

damage and checked it

for proper operation.

Refer to FREIGHT

DAMAGE CLAIM

PROCEDURE below.

1. Remove the cabinet from shipping carton, ensuring that all packing materials and protective plastic has been removed from the

unit.

2. Inspect all components for completeness and condition.

3. If any freight damage is present, a freight claim must be filed immediately with the shipping company.

4. Freight damage is not covered under warranty.

5. Check to insure all components are included: cabinet, instruction

packet and additional accessories.

6. Read operation instructions completely.

7. Appliance should be thoroughly cleaned before use. See

CLEANING INSTRUCTIONS ON PAGE 8 in this manual.

FREIGHT DAMAGE PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully inspected

and packaged by skilled personnel before leaving the factory. Upon acceptance of this shipment,

the transportation company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight

bill or express receipt, and that the note of loss or damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY

your dealer immediately.

3. CONCEALED DAMAGE: If damage is unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and then file a “CONCEALED DAMAGE” claim

with them. This should be done within fifteen (15) days from the date the delivery was made to

you. Be sure to retain the container for inspection.

Carter-Hoffmann cannot assume liability for damage or loss incurred in transit, freight damage is

not covered under warranty. We will, however, at your request, supply you with the necessary

documents to support your claim.

: Regardless of the extent of damage. Contact

5

Page 6

INSTALLATION & STARTUP

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it for

proper operation.

Refer to FREIGHT DAMAGE

CLAIM PROCEDURE on PAGE 5

of this manual.

WARNING:

Risk of

Installation procedures must

be performed by a qualified

technician with full knowledge of

all applicable electrical codes.

Failure can result in personal

injury and property damage.

personal injury

CAUTION:

Electrical Shock Hazard

The ground prong of the

power cord is part of a system

designed to protect you from electric shock in the event of internal

damage. DO NOT cut off the large

round ground prong or twist a

blade to fit an existing receptacle.

IMPORTANT:

Power cord is 10' long.

If necessary, contact a licensed

electrician to install an appropriate

20 amp electrical circuit with

NEMA 5-20R receptacle. DO

NOT use an extension cord.

IMPORTANT:

Damage to unit due to being connected to the wrong voltage or

phase is NOT covered by warranty.

Unpack the cabinet. Ensure that all packing materials and

protective plastic has been removed from the unit. Inspect all

components for completeness and condition.

For safe operation and maximum performance, located the

unit at least 2” from any wall or combustible material.

Install tray slides at 3.5” spacing (every other notch). Tabs on

each end of the slides will fit into notches on side wall baffles.

Simply angle the slide so that the top of each tab slides into

the notch; then turn the slide to level position.

GROUNDING INSTRUCTIONS

This appliance is equipped with a cord having a grounding

wire with a grounding plug which must be plugged into an

outlet that is properly installed and grounded. In the event of

an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current.

WARNING—Improper use of the grounding can result in

a risk of electric shock. Consult a qualified electrician or

service agent if the grounding instructions are not completely

understood, or if doubt exists as to whether the appliance is

properly grounded.

START UP

Appliance should be thoroughly cleaned before use. See

CLEANING INSTRUCTIONS, page 8.

1. Familiarize yourself with the controls. Plug the power

cord of the cabinet into a properly grounded NEMA 5-20R

electrical receptacle according to the electrical information provided below. DO NOT MODIFY CORD PLUG.

Volts : 120

Watts: 1500

Amps: 12.5

2. Set POWER switch to the “ON” position.

3. Do not load product into the cabinet. Allow the heat to

remove any residual oils which may adhere to inside

metal surfaces. A slight emission of smoke is common

during the first few hours of operation.

6

Page 7

OPERATION & CONTROLS

Before using,

familiarize yourself with

the heater controls.

Read entire manual

before using unit.

ATTENTION:

Whenever

possible,

heating unit

should remain running to

ensure maximum product

temperatures, especially

after finishing the food

loading stage.

DO NOT USE

ANY CANNED

FUEL IN THIS

CABINET!

This cabinet is designed

to eliminate the need for

canned fuel.

USE OF CANNED FUEL

IN ENDURAHEAT

CABINETS WILL VOID

THE WARRANTY!

CAUTION: SAFE

FOOD HOLDING

PRACTICES

RECOMMENDED

Cooking food to a safe temperature, holding at a temperature of at least 140°F is

critical in the prevention of

foodborne illness. Hold only

cooked, hot food at 140°F

or higher. This cabinet is

not intended to cook or reheat food. Food must be at

appropriate temperature

before being placed into

cabinet.

EnduraHeat® Mode:

1. One hour bef ore loading food, turn the temperature dial to 200º F. Flip the

toggle switch on heating unit down to “EnduraHeat”. The white indicator

lamp will illuminate.

2. Allow one hour for EnduraHeat® charging and cabinet pre-heat to approximately 180°F. Do not open cabinet doors during preheat phase. The green

“Ready” light will illuminate when system is fully charged.

3. Load pans as quickly as possible and close doors. The cabinet temperature will drop. Keep heating unit plugged in during loading to keep food

warm.

4. Once pans are loaded, unplug heating unit, wrap cord around cord wrap

bracket .

5. Transport food to serving area. Do not open cabinet doors until re ady to

serve. Food will remain at serving temperatures for approximately two

hours.

6. If holding time is extended beyond two hours and cabinet temperature

drops below 145º F, move cart to location where 20 Amp electricity is available and plug in heater. Flip toggle switch to “Conv ection” mode and op erate heater until food are served.

7. When removing items, start at the bottom of the cabinet and work to the top

shelf position. This will keep food warmer and reduce spillage onto items

on lower shelves.

Convection Heat Mode:

1. At least 30 minutes before loading pans, turn the temperature dial to 200ºF.

Flip toggle switch on heating unit up to “Convection” mode. White indicator

lamp will illuminate.

2. Allow at least 20 minutes for cabinet to preheat to approximately 180ºF.

3. Load pans and close doors. During loading, the cabinet temperature will

drop. Keep unit plugged in to electrical source to keep meals warm. Try

not to move the cart right away; wait 10-15 minutes until the cabinet

recovers air temperature.

4. To transport to serving location, unplug heater, wrap cord around cord

wrap bracket and transport food to serving area.

5. Upon reaching the serving area, unwind the power cord and reconnect the

heater to a 20 Amp outlet as quickly as possible.

6. When removing items, start at the bottom of the cabinet and work to the top

shelf position. This will keep food warmer and reduce spillage onto items

on lower shelves.

ATTENTION:

Whenever possible, heating unit should remain running to

ensure maximum product temperatures, especially after

finishing the food loading stage.

7

Page 8

CLEANING & CABINET MAINTENANCE

WARNING: ELECTRIC

SHOCK HAZARD

Unplug the unit from

electric power before

performing cleaning or maintenance.

WARNING:

BURN HAZARD

Allow the unit to cool

before performing any

cleaning or maintenance procedures.

WARNING: ELECTRIC

SHOCK HAZARD

DO NOT spray or

splash water on the

heater, control panel, timer or

wiring.

CAUTION: Heating unit

weighs approximately

50 lbs.

Two people are required

to remove the heater assembly

from the cabinet.

Turn the main power switch OFF, unplug and allow the unit to

cool completely before cleaning. DO NOT spray or splash water

on the heater, control panel, timer or wiring.

1. Tray slides are easily removed without tools for cleaning,

Simply lift up and pull out. The tray slides may be hand

washed or run through an automatic washer.

2. Before cleaning, unplug the heating assembly. Remove the

heater by grasping handles on each side of the heater. Pull

up and lift out. Disconnect power cord from heater assembly

before removing completely.

3. To clean stainless steel surfaces use only cleansers,

detergents, degreasers, or sanitizers that are certified to be

"chloride-free" and "phosphate-free," and cleansers,

degreasers, or sanitizers only in the recommended

concentrations. DO NOT exceed recommended concentrations or mixing ratios. After cleaning and sanitizing, rinse all

exposed surfaces thoroughly with large amounts of clean,

clear water. Wipe off any standing liquid or residue from all

surfaces, corners and rear edges.

4. Vinyl trim should be washed with a chlorine-free detergent

and water. Rinse thoroughly with clear water and allow to

dry. Never use abrasive cleaners, waxes, car polish, or

substances containing strong aromatic solvents or alcohol.

Use of direct steam / hot water cleaning at temperatures

above 190°F may result in “bubbling” or loosening of vinyl

adhesive.

IMPORTANT: Cleansers, detergents, degreasers, sanitizers or bleaching agents that contain chlorides or

phosphates will cause permanent damage to stainless steel products. This damage appears as pits,

eruptions, voids, small holes, cracks, severe discolorations or dulling of the metal finish. Water with a high

chlorine content can also damage stainless steel. If unsure of your water quality, we recommend you have it

tested. THIS DAMAGE IS PERMANENT, COSTLY TO REPAIR, AND IS NOT COVERED BY WARRANTY.

RECOMMENDED TIPS FOR CLEANING STAINLESS STEEL

PURPOSE FREQUENCY CLEANING AGENT METHOD OF APPLICATION

Routine

cleaning

Smears

and

fingerprints

Stubborn spots

and

stains

Hard

water spots

Daily Soap or ammonia or

detergent and water

As needed Stainless steel cleaner

or similar products

Daily or as needed Any chloride-free or

phosphate-free

cleanser

Daily or as needed Vinegar Swab with cloth.

Swab with cloth.

Rinse with clear water, wipe dry.

Rub with cloth as directed on package.

Rub in direction of grain of stainless steel.

Do not use on vinyl trim or control panel.

Apply with damp sponge or cloth.

Rub in direction of grain. Rinse thoroughly.

Do not use on vinyl trim or control panel.

Rinse with clear water, wipe dry.

8

Page 9

WIRING DIAGRAM

120 VOLT, 1500 WATT, 12.5 AMP, 1 PH

NOTE:

The technical content of this manual,

including wiring diagrams, schematics,

parts breakdown illustrations and/or

adjustment procedures, is intended

for use ONLY by qualified technical

personnel.

9

Page 10

REPLACEMENT PARTS

Use only (OEM) original equipment manufacturer replacement parts. Using unauthorized parts may

cause serious injury or damage to the cabinet. Replacement parts should be installed by a qualified

service technician.

Contact Carter-Hoffmann with your model and serial number for replacement parts.

Call: 800-323-9793 or

Email: Service@Carter-Hoffmann.com

Part Number Description

Top Convection Heater

18600-0046 Hi limit—open at 300°F, close at 250°F

18602-0238 Time relay—recycler

18602-0239 Time relay-delay on make

18602-0240 Relay

18605-0017 14/3 HJSO cord w/ 5-20 plug

18607-0010 Terminal block—6 POS #306

18612-0096 Box element-120 volt, 1500 watt

18614-0316 Blower housing #C1281-1

18614-0316 Cord set x 40”, #4C552

18614-0321 Blower wheel

18614-0322 Muffin fan

18614-0360 Convection motor-120/208/220/230/240

18602-0016 Toggle switch

18602-0031 Rubber switch boot

18601-1176 Convection heat indicator light (white)

EnduraHeat Module

18605-0027 14/3 cord/L5-20P assembly

18606-0563 Twist lock 20A, 125v receptacle

18610-0010 Handy box: 2x4 4SSL-1/2

18610-0110 Cover plate

18610-0198 3/8” lock nut

18617-0007 Cord grip

18617-0054 Ceramic terminal block

18612-0116 Tubular element, 120v

18612-0347 Heat retention module

18600-0061 Thermostat-225 deg./25A

18601-1176 EnduraHeat indicator light (white)

18601-1175 Enduraheat ready light (green)

Cabinet Parts

18303-0085 Door handle

10

Page 11

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE POSSIBLE REMEDY

No power to unit,

No light on display

Not plugged in or circuit breaker

off or tripped

Motor not running

Main switch damaged Check main power switch,

Damaged power cord Replace cord

Hi-limit safety tripped Allow unit to cool, hi-limit will

Unit does not hold temperature Damaged door gasket (metal

trim strip)

Damaged door latch Replace defective latch

Temp probe damaged Replace probe

Door gap, out of alignment Adjust door hinging and strike

Unit does not heat Cabinet temp above setpoint

(setpoint too low)

Internal wiring error Call service technician

Damaged relay Call service technician

Damaged controller Call service technician

Damaged heating element Perform ohm reading,

Plug into receptacle.

Reset circuit breaker,

check facility circuit breaker

replace if damaged

reset automatically, or replace

Replace gasket

Turn thermostat setpoint up

Check thermometer calibration

Replace element

Unit overheats Setpoint too high Change setpoint

Thermostat damaged Replace thermostat

Defective hi-limit control Call service technician

Blower fan failure Call service technician

Blower motor not running Damaged fan motor Replace motor

Blower fan jammed Find source of fan binding

Relay is “chattering”

Takes too long to get to tem-

perature

Check proper wiring to switch Repair wiring or replace switch

Improper voltage Call service technician to verify

that incoming voltage matches

cabinet specifications

NOTE:

The technical content of this manual, including

wiring diagrams, schematics, parts breakdown

illustrations and/or adjustment procedures, is

intended for use ONLY by qualified technical personnel.

NOTE:

For warranty service, call Carter-Hoffmann

direct at 800-323-9793 for authorization. We

will dispatch the nearest authorized service

agency.

11

Page 12

SERVICE EXPECTATIONS

Service Philosophy

For almost sixty years, Carter-Hoffmann has enjoyed a reputation for manufacturing rugged,

dependable foodservice equipment that permits foodservice professionals serve more food

products to more people, and thus, to grow their business.

Our goal is not only to provide the best food service equipment for the price, but also to back it up

with after-sale service that is responsive, fast, efficient and professional. To ensure a clear understanding of our goals, expectations, and responsibilities, we have prepared this brief document.

Carter-Hoffmann products are innovative and efficient. They are easy to use, easy to clean and easy

to maintain. Although the products are quite reliable they are also designed for easy repair. We

believe that a malfunction to a Carter-Hoffmann product should cause as little inconvenience to

the customer as possible. Our aim is to provide “same day/first time fix” repair service on all of our

products. We are dedicated to making every aspect of our customer service the stand ard by which

others are judged.

End-User Responsibilities

While we all strive to serve our mutual customers as well as possible that does not mean that

the end-user (including his employees) does not share some responsibilities.

1. All shipping damage must be noted on the freight bill when the shipment is received. Any freight

damages must be collected from the Freight Company, NOT Carter-Hoffmann.

2. The end-user should be advised beforehand to carefully unpack and inspect all products when

they are received BEFORE SIGNING THE SHIPPER'S RECEIPT OF DELIVERY.

3. The end-user must provide a safe, dry, level surface for the equipment to be placed upon.

4. The end-user must provide the proper electrical supply. All in-wall electrical modifications are to

be completed by a licensed electrician. All building modifications are the responsibility of the

end-user.

5. The end-user must operate, clean and maintain the equipment in accordance with the

procedures described in the Operation Manual.

6. Carter-Hoffmann is NOT responsible for any loss of the customer’s income, loss of food product,

extra labor charges, or any other incidental or consequential costs as a result of the malfunction

of our product.

7. The end-user shall allow for on-premises repair of the equipm ent to be completed at a mutually

convenient place and time.

Warranty Service

1. Warranty service is to be initiated by authorized Carter-Hoffmann personnel only.

2. The service provider is NOT authorized to change or extend any of the terms or conditions of our

warranty.

3. Initial freight damage is NOT covered by the product warranty.

Confidentiality

1. The end user and all his employees and sub-agents shall protec t and keep confidential Carter Hoffmann’s proprietary designs, information, and knowledge.

2. All literature and informational materials provided by Carter-Hoffmann are to be considered

confidential; they remain Carter-Hoffmann’s property; and are not to be reproduced without our

prior written consent.

12

Page 13

OWNER INFORMATION

YOUR LOCAL CONTACTS

SERVICE & PARTS DISTRIBUTOR

NAME:

CONTACT:

ADDRESS:

TEL:

FAX:

TOLL FREE:

EMAIL: WEBSITE:

SERVICE LOG

DATE SERVICE AGENT NATURE OF PROBLEM / ACTION TAKEN

FACTORY SALES REPRESENTATIVE

IMPORTANT OWNER INFORMATION

Please take the time to record the model

number and serial number, the identification decal is normally located on the right

hand side of the unit. Also be sure to

record your voltage and purchase date of

your piece of Carter-Hoffmann equipment

in the spaces below.

It is extremely helpful to have this information available when calling CarterHoffmann for service or assistance.

Cabinet Model #:______________________ _______

Cabinet Serial #:______________________ _________

Heater Head Model #:___________________________

Heater Head Serial #:__________________________

Voltage: ____________________

Wattage: ___________________________

Phase: ____________

Date of Installation: _______/___________/_____________

Carter-Hoffmann Invoice / Sales Order #:_______________

Purchase Order #: _________________________

13

Page 14

WARRANTY

Carter-Hoffmann Warranty:

Carter-Hoffmann (“CARTER-HOFFMANN”) warrants to the initial purchaser of its standard Carter

Line Products that CARTER-HOFFMANN will, at its option, repair or replace, during the warran ty

period set forth below, any part of such products made necessary due to a defect in material or workmanship which is present when the product leaves its factory and which man ifests itself du ring th e warranty period under normal use and service.

This warranty applies only to original equipment owned and possessed by the initial purchaser and the

warranty period begins on the date of original shipment from the CARTER-HOFFMANN factory and

extends as follows: to component parts and labor for 12 months; to refrigeration compressor unit for

one year (limited to replacement only - not to include labor for removal, repa ir or replacement).

Repair or replacements under this warranty will be performed, unless otherwise authorized in writing

by CARTER-HOFFMANN, at its factory. All parts or components to be repaired or replaced under this

warranty are to be shipped prepaid to CARTER-HOFFMANN, with reimbursement credit for such part

or component to be given if found by CARTER-HOFFMANN to be defective.

CARTER-HOFFMANN neither makes nor assumes and does not authorize any other person to make or

assume any obligation or liability in connection with its products other than that covered in this wa rranty. This warranty applies only within the continental United States and Canada. In Alaska and Hawaii, this warranty applies only to and is limited to the supply of replacement parts.

Warranty Exclusions and Limitations:

Any implied warranty of merchantability or fitness for a particular purpos e is hereby specifically dis-

claimed by CARTER-HOFFMANN. There are no warranties, expressed or implied, which extend be-

yond the description on the face hereof. This warranty does not cover and CARTER-HOFFMANN shall

not under any circumstances be liable for any incidental, consequential or other damages (such as in-

jury to persons or property, loss of time, inconvenience, loss of business or profits, or other matters not

specifically covered) arising in connection with the use of, inability to use, or failure of these products.

Specifications subject to change through product improvement and innovation.

Carter-Hoffmann

1551 McCormick Ave.

Mundelein, Illinois, 60060 USA

Phone: 847-362-5500 Toll free: 800-323-9793 Fax: 847-367-8981

Sales and Marketing E-mail: sales@carter-hoffmann.com

Service E-mail: service@carter-hoffmann.com

Company Website: www.carter-hoffmann.com

14

Loading...

Loading...