Page 1

HL1, HL2, HL3 & HL4 Series ALUMINUM HEATED HOLDING

CABINETS & HEATER PROOFERS

OWNERS / OPERATORS MANUAL

HL2-18

MODELS:

HL1 HEATED

CABINETS

(non-insulated)

Models: HL1-5,

HL1-8, HL1-14 &

HL1-18

Formerly models:

HBU5A2GM

HBU8A2GM

HBU14A2GM

HBU18A2GM

HBC10A2GM

HBC16A2GM

HBC28A2GM

HBC36A2GM

HBF5A2GM

HBF8A2GM

HBF14A2GM

HBF18A2GM

Email: technicalservice@carter-hoffmann.com

MODELS:

HL2 HEATER/

PROOFERS

(non-insulated)

Models: HL2-5,

HL2-8, HL2-14 &

HL2-18

Formerly models:

HWU5A2GM

HWU8A2GM

HWU14A2GM

HWU18A2GM

HWC10A2GM

HWC16A2GM

HWC28A2GM

HWC36A2GM

HWF5A2GM

HWF8A2GM

HWF14A2GM

HWF18A2GM

MANUFACTURED BY:

CARTER-HOFFMANN

1551 McCormick Avenue

Mundelein, IL 60060 U.S.A.

Phone: 847-362-5500

Fax: 847-367-8981

Toll Free: 800-323-9793

HL3 HEATED

Models: HL3-5,

HL3-8, HL3-14,

Formerly models:

HBU5A1GM

HBU8A1GM

HBU14A1GM

HBU18A1GM

HBC10A1GM

HBC16A1GM

HBC28A1GM

HBC36A1GM

HBF5A1GM

HBF8A1GM

HBF14A1GM

HBF18A1GM

MODELS:

CABINETS

(insulated)

HL3-18

Formerly models:

HWU5A1GM

HWU8A1GM

HWU14A1GM

HWU18A1GM

HWC10A1GM

HWC16A1GM

HWC28A1GM

HWC36A1GM

HWF5A1GM

HWF8A1GM

HWF14A1GM

HWF18A1GM

MODELS:

HL4 HEATER/

PROOFERS

(insulated)

Models: HL4-5,

HL4-8, HL4-14,

HL4-18

TABLE OF CONTENTS

SAFETY PRECAUTIONS……………………………..…………………. 2

FEATURES & SPECIFICATIONS………..……………..………………. 3-6

UNPACKING, INSPECTION & FREIGHT DAMAGE…………………. 7

INSTALLATION & STARTUP …………………….……………………. 8

DETAILS: CONTROLS AND WATER PANS………………………….. 9

NORMAL OPERATION: HL1 & HL3 HEATED CABINETS………….. 10

NORMAL OPERATION: HL2 & HL4 HEATER PROOFERS ……….. 11

FOOD HOLDING GUIDE………………………………………………... 12

DAILY CLEANING PROCEDURES...………………..………………... 13

CABINET MAINTENANCE………………………………………………. 14

WIRING DIAGRAMS...……………………………………… …………... 15

REPLACEMENT PARTS………………………………………………... 16

TROUBLESHOOTING GUIDE …………………………………………. 17

WARRANTY STATEMENT……….……………….……………………. 18

MANUEL EN FRANÇAIS………………………………………………... 19-36

Part Number: 18400-3130e Printed in The United States of America Rev: KBA120512

Page 2

SAFETY PRECAUTIONS

WARNING: ELECTRIC SHOCK HAZARD

WARNING

All service requiring access to non-insulated components must be performed by

qualified service personnel. Failure to heed this warning may result in severe

electric shock.

CAUTION: ELECTRIC SHOCK HAZARD

Disconnect this appliance from electrical power before performing any

maintenance or service.

CAUTION: BURN HAZARD

Exposed metal surfaces can be hot to the touch and may cause burns.

IMPORTANT SAFETY INSTRUCTIONS

When using electrical appliances basic safety precautions should be followed, including the following:

1) Be familiar with the appliance use, limitations and associated restrictions. Operating instructions must

be read and understood by all persons using or installing this appliance.

2) This appliance must be grounded. Connect only to properly grounded outle t.

3) Use this appliance only for its intended purpose as described in the manual.

a. This equipment is specifically designed to hold pre-cooked food at temperature.

b.

c. This equipment is not designed for industrial or laboratory use.

4) Cleanliness of this appliance and its accessories is essential to good sanitation.

This equipment is intended for use in commercial establishments only.

5) DO NOT submerge this appliance in water. This appliance is not jet stream approved. DO NOT direct

water jet or steam jet at this appliance, or at any control panel or wiring. DO NOT splash or pour

water on, in or over any controls, control panel or wiring. DO NOT use corrosive chemicals or vapors

in this appliance.

6) DO NOT store this appliance outdoors. DO NOT use this product near water – for example,

near a kitchen sink, in a wet basement, or near a swimming pool, and the like.

7) DO NOT operate this appliance if it has a damaged cord or plug, if it is not working properly, or if it has

been damaged or dropped. Do not immerse cord or plug in water, keep cord away from heated

surfaces, and do not let cord hang over edge of table or counter.

8) DO NOT cover or block any openings on the appliance.

9) Only qualified service personnel should service this appliance.

NOTE: The technical content of this manual, including any wiring diagrams, schematics, parts br eakdown

illustrations and/or adjustment procedures, is intended for use by qualified technical personnel and is

subject to change without notice.

2

Page 3

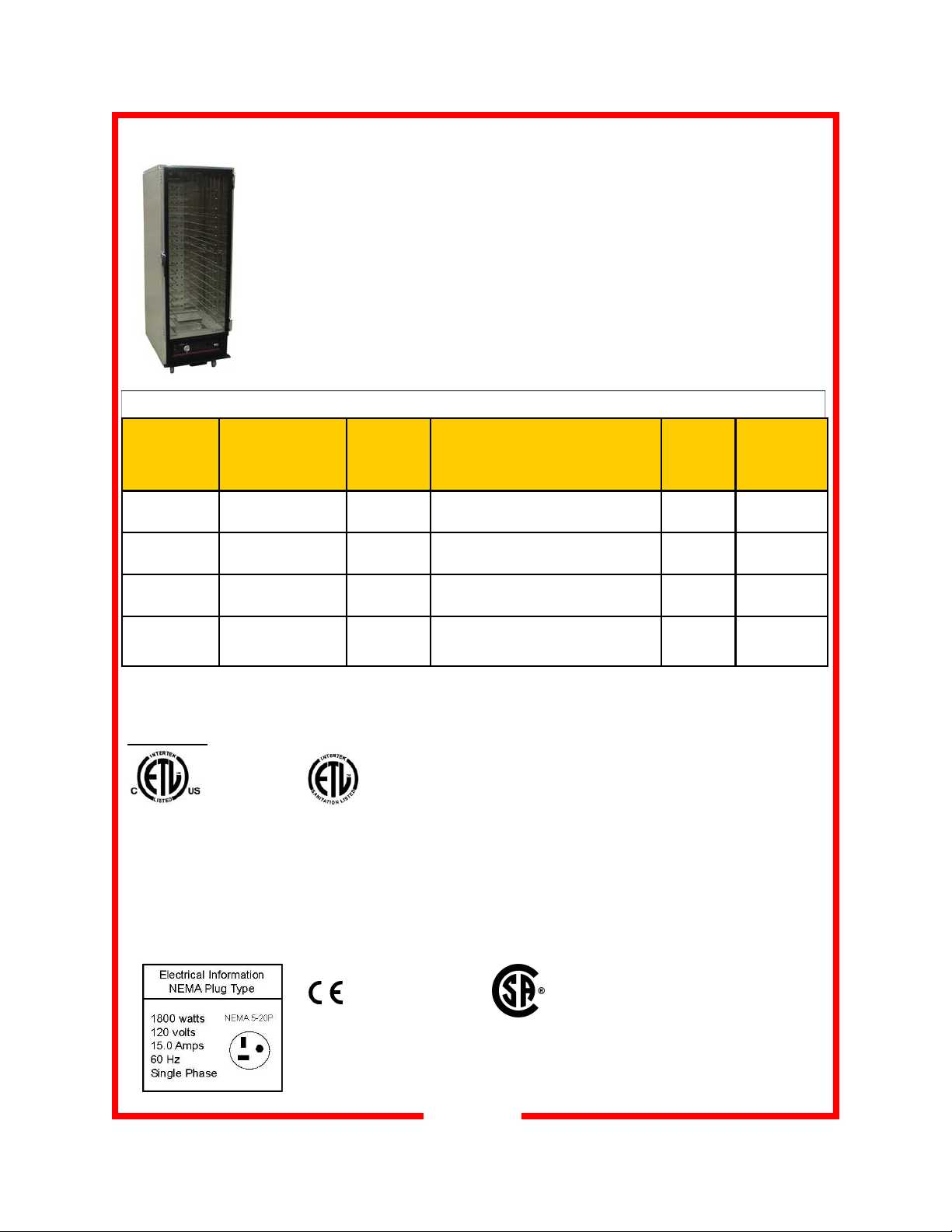

HL1 NON-INSULATED ALUMINUM HEATED CABINET FEATURES & SPECIFICATIONS

HL1 Features & Benefits

Precision-engineered bottom mount heater with superior heat-up and recovery time

Analog heat control. Digital thermometer. Temperature range of 90°- 190°F

Four sizes, available with adjustable universal, fixed universal or adjustable universal slides

All swivel heavy-duty casters, front casters fitted with brakes

Field reversible glass door in heavy-duty extruded aluminum frame is standard, black anodized solid aluminum

door is optional

Fixed wire universal slides for 18”x26” sheet pans and 12”x20”x2.5” steam table pans

Cabinets with Adjustable Universal, Fixed Universal or Angle Slides

Model

Number

Pan/Tray

Capacity*

12”x20” 18”x26”

Slide Pairs

Provided

Overall Dimensions

Height Depth Width

in (mm)

Caster

Diameter

in (mm)

Class 100

Shipping

Weight

lbs (kgs)

HL1-5

(under-counter)

HL1-8

(1/2 size)

HL1-14

(3/4 size)

HL1-18

(full size)

* fixed spacing at 3”

APPROVALS:

3174974

10 5 5 31-1/16 29-1/2 24-11/16

(789) (749) (627)

16 8 8 40-1/16 29-1/2 24-11/16

(1018) (749) (627)

28 14 14 58-1/16 29-1/2 24-11/16

(1474) (749) (627)

36 18 18 70-1/16 29-1/2 24-11/16

(1780) (749) (627)

Conforms to UL Std 197

certified to CAN/CSA Std

C22.2 No. 109

3174974

Conforms to

NSF/ANSI

Std 4

5

(127)

5

(127)

5

(127)

5

(127)

99

(45)

137

(62)

155

(70)

198

(90)

International voltage:

220 volts, 1800 watts,

8.2 Amps, 50 Hz, single

phase, plug cap per

specific country requirements / standards

Canadian Voltage:

120v, 1400 watts,

12Amps, NEMA 5-15P

3

Page 4

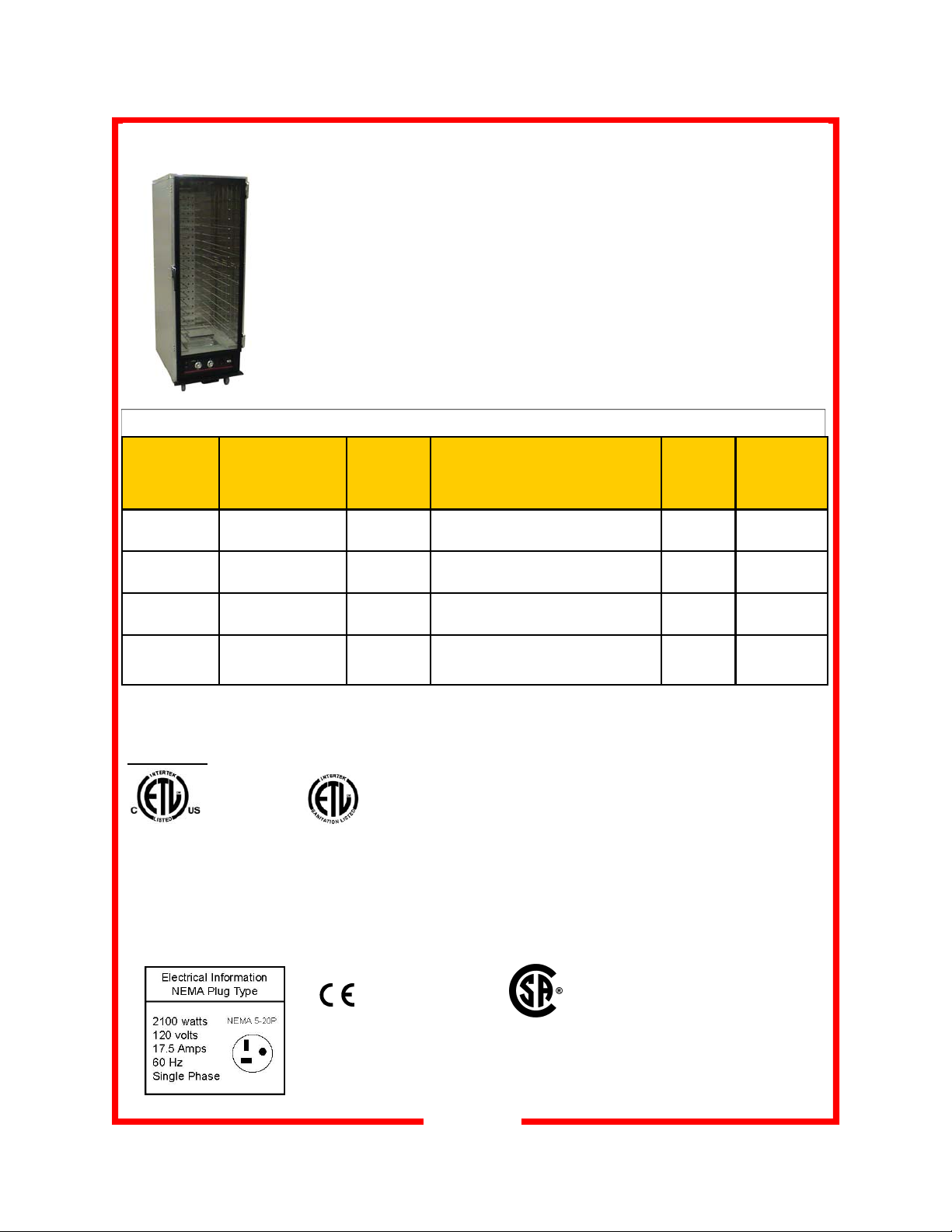

HL2 NON-INSULATED ALUMINUM HEATER/PROOFER FEATURES & SPECIFICATIONS

HL2 Features & Benefits

Precision-engineered bottom mount heater with superior heat-up and recovery time

Analog heat and humidity levels. Digital thermometer. Temperature range of 90°- 190°F

Can be operated with or without humidity. Capable of humidified holding as well as proofing

Four sizes, available with adjustable universal, fixed universal or adjustable universal slides

All swivel heavy-duty casters, front casters fitted with brakes

Field reversible glass door in heavy-duty extruded aluminum frame is standard, black anodized solid aluminum

door is optional

Fixed wire universal slides for 18”x26” sheet pans and 12”x20”x2.5” steam table pans

Cabinets with Adjustable Universal, Fixed Universal or Angle Slides

Model

Number

Pan/Tray

Capacity*

12”x20” 18”x26”

Slide Pairs

Provided

Overall Dimensions

Height Depth Width

in (mm)

Caster

Diameter

in (mm)

Class 100

Shipping

Weight

lbs (kgs)

HL2-5

(under-counter)

HL2-8

(1/2 size)

HL2-14

(3/4 size)

HL2-18

(full size)

* fixed spacing at 3”

APPROVALS:

3174974

10 5 5 31-1/16 29-1/2 24-11/16

(789) (749) (627)

16 8 8 40-1/16 29-1/2 24-11/16

(1018) (749) (627)

28 14 14 58-1/16 29-1/2 24-11/16

(1474) (749) (627)

36 18 18 70-1/16 29-1/2 24-11/16

(1780) (749) (627)

Conforms to UL Std 197

certified to CAN/CSA Std

C22.2 No. 109

3174974

Conforms to

NSF/ANSI

Std 4

5

(127)

5

(127)

5

(127)

5

(127)

99

(45)

137

(62)

155

(70)

198

(90)

International voltage:

220 volts, 2100 watts,

9.5 Amps, 50 Hz, single

phase, plug cap per

specific country requirements / standards

4

Canadian Voltage:

120v, 1400 watts,

12Amps, NEMA 5-15P

Page 5

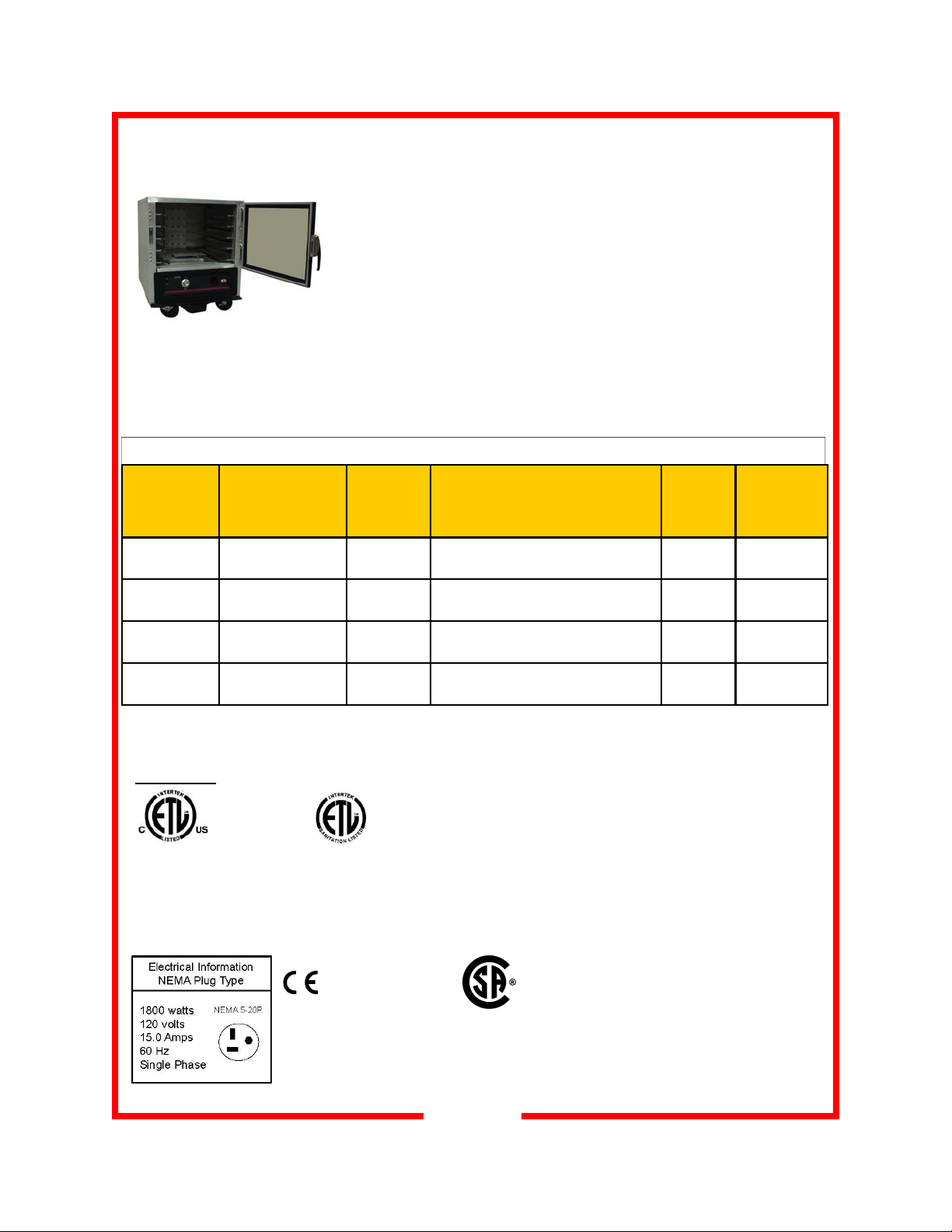

HL3 INSULATED ALUMINUM HEATED CABINET FEATURES & SPECIFICATIONS

HL3 Features & Benefits

Precision-engineered bottom mount heater with superior heat-up and recovery time

Analog heat control. Digital thermometer. Temperature range of 90°- 190°F

Four sizes, available with adjustable universal, fixed universal or adjustable universal slides

All swivel heavy-duty casters, front casters fitted with brakes

Field reversible glass door in heavy-duty extruded aluminum frame is standard, black anodized solid

aluminum door is optional

Fixed wire universal slides for 18”x26” sheet pans and 12”x20”x2.5” steam table pans

Cabinets with Adjustable Universal, Fixed Universal or Angle Slides

Model

Number

Pan/Tray

Capacity*

12”x20” 18”x26”

Slide Pairs

Provided

Overall Dimensions

Height Depth Width

in (mm)

Caster

Diameter

in (mm)

Class 100

Shipping

Weight

lbs (kgs)

HL3-5

(under-counter)

HL3-8

(1/2 size)

HL3-14

(3/4 size)

HL3-18

(full size)

* fixed spacing at 3”

APPROVALS:

3174974

10 5 5 31-5/8 31-1/2 26-1/2

(803) (800) (673)

16 8 8 40-5/8 31-1/2 26-1/2

(1032) (800) (673)

28 14 14 58-5/8 31-1/2 26-1/2

(1489) (800) (673)

36 18 18 70-5/8 31-1/2 26-1/2

(1794) (800) (673)

Conforms to UL Std 197

certified to CAN/CSA Std

C22.2 No. 109

3174974

Conforms to

NSF/ANSI

Std 4

International voltage:

220 volts, 1800 watts,

8.2 Amps, 50 Hz, single

phase, plug cap per

specific country requirements / standards

Canadian Voltage:

120v, 1400 watts,

12Amps, NEMA 5-15P

5

(127)

5

(127)

5

(127)

5

(127)

104

(47)

147

(67)

170

(77)

218

(99)

5

Page 6

HL4 INSULATED ALUMINUM HEATER/PROOFER FEATURES & SPECIFICATIONS

HL4 Features & Benefits

Precision-engineered bottom mount heater with superior heat-up and recovery time

Analog heat and humidity levels. Digital thermometer. Temperature range of 90°- 190°F

Can be operated with or without humidity. Capable of humidified holding as well as proofing

Four sizes, available with adjustable universal, fixed universal or adjustable universal slides

All swivel heavy-duty casters, front casters fitted with brakes

Field reversible glass door in heavy-duty extruded aluminum frame is standard doors are standard, solid

aluminum door is optional

Fixed wire universal slides for 18”x26” sheet pans and 12”x20”x2.5” steam table pans

Cabinets with Adjustable Universal, Fixed Universal or Angle Slides

Model

Number

Pan/Tray

Capacity*

12”x20” 18”x26”

Slide Pairs

Provided

Overall Dimensions

Height Depth Width

in (mm)

Caster

Diameter

in (mm)

Class 100

Shipping

Weight

lbs (kgs)

HL4-5

(under-counter)

HL4-8

(1/2 size)

HL4-14

(3/4 size)

HL4-18

(full size)

* fixed spacing at 3”

APPROVALS:

3174974

10 5 5 31-5/8 31-1/2 26-1/2

(803) (800) (673)

16 8 8 40-5/8 31-1/2 26-1/2

(1032) (800) (673)

28 14 14 58-5/8 31-1/2 26-1/2

(1489) (800) (673)

36 18 18 70-5/8 31-1/2 26-1/2

(1794) (800) (673)

Conforms to UL Std 197

certified to CAN/CSA Std

C22.2 No. 109

3174974

Conforms to

NSF/ANSI

Std 4

International voltage:

220 volts, 2100 watts,

9.5 Amps, 50 Hz, single

phase, plug cap per

specific country requirements / standards

Canadian Voltage:

120v, 1400 watts,

12Amps, NEMA 5-15P

5

(127)

5

(127)

5

(127)

5

(127)

104

(47)

147

(67)

170

(77)

218

(99)

6

Page 7

UNPACKING AND INSPECTION

This appliance

should be

thoroughly

cleaned prior to use.

See the CLEANING

INSTRUCTIONS in

this manual.

NOTE: DO NOT discard

the carton or other

packing materials until

you have inspected the

appliance for hidden

damage and checked it

for proper operation.

1. Remove the cabinet from shipping carton, ensuring that all packing materials and protective plastic has been removed from the

unit.

2. Inspect all components for completeness and condition.

3. If any freight damage is present, a freight claim must be filed immediately with the shipping company.

4. Freight damage is not covered under warranty.

5. Check to insure all components are included: cabinet, instruction

packet and additional accessories.

6. Read operation instructions completely.

7. Appliance should be thoroughly cleaned before use. See

CLEANING INSTRUCTIONS in this manual.

Refer to SHIPPING

DAMAGE CLAIM

PROCEDURE on

bottom of this page.

FREIGHT DAMAGE PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully inspected

and packaged by skilled personnel before leaving the factory. Upon acceptance of this shipment,

the transportation company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight

bill or express receipt, and that the note of loss or damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY: Regardless of the extent of damage. Contact

your dealer immediately.

3. CONCEALED DAMAGE: If damage is unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and then file a “CONCEALED DAMAGE” claim

with them. This should be done within fifteen (15) days from the date the delivery was made to

you. Be sure to retain the container for inspection.

Carter-Hoffmann cannot assume liability for damage or loss incurred in transit, freight damage is

not covered under warranty. We will, however, at your request, supply you with the necessary

documents to support your claim.

7

Page 8

INSTALLATION AND STARTUP

WARNING:

Risk of personal injury

Installation procedures must be

performed by a qualified technician

with full knowledge of all applicable

electrical codes. Failure could

result in personal injury and property damage.

IMPORTANT:

Power cord is 8' long

If necessary, contact a licensed

electrician to install an appropriate

20 amp electrical circuit with correct

NEMA receptacle.

DO NOT use an extension cord.

CAUTION:

Electrical Shock Hazard

The ground prong of the power

cord is part of a system designed to

protect you from electric shock in

the event of internal damage.

DO NOT cut off the large round

ground prong or twist a blade to fit

an existing receptacle.

IMPORTANT:

Not under warranty

Damage to unit due to being

connected to the wrong voltage or

phase is NOT covered by warranty.

WARNING:

Risk of personal injury

Unit is not waterproof, to avoid

electrical shock, keep unit from being submerged in water. Do not

operate if unit has been in contact

with water.

LOCATION

For proper operation and maximum performance, locate the

unit in an ambient air temperature of 70ºF (21ºC).

Avoid placement in areas near exhaust fans or where there

are active air movements.

For safe operation and maximum performance, locate the

unit at least 2” from any wall or combustible material.

Unit must be on a solid level surface.

GROUNDING INSTRUCTIONS

This appliance is equipped with a cord having a grounding wire with

a grounding plug which must be plugged into an outlet that is

properly installed and grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current.

WARNING—Improper use of the grounding can result in a risk

of electric shock. Consult a qualified electrician or service agent if

the grounding instructions are not completely understood, or if doubt

exists as to whether the appliance is properly grounded.

START UP

1. Prior to use, thoroughly clean the interior of the unit, per

the instructions in this manual. Familiarize yourself with

the controls.

2. Plug the power cord of the cabinet into a grounded outlet

with a electrical service according to the electrical information provided below. DO NOT MODIFY CORD PLUG.

3. Set POWER switch to the “ON” position.

4. Do not load product into the cabinet. Allow the heat to

remove any residual oils which may adhere to inside metal surfaces. A slight emission of smoke is common during the first few hours of operation.

220 volt CE international versions:

HL1 & HL3 Series: 1800 watts, 220

volts, 8.2 Amps, 50/60 Hz, single

phase

HL2 & HL4 Series: 2100 watts, 220

volts, 9.5 Amps, 50/60 Hz, single

phase

HL1 & HL3 Models HL2 & HL4 Models

Plug cap per specific country requirements / standards

Canada: 1400 watts, 120 volts, 12

Amps, single phase, NEMA 5-15P

8

Page 9

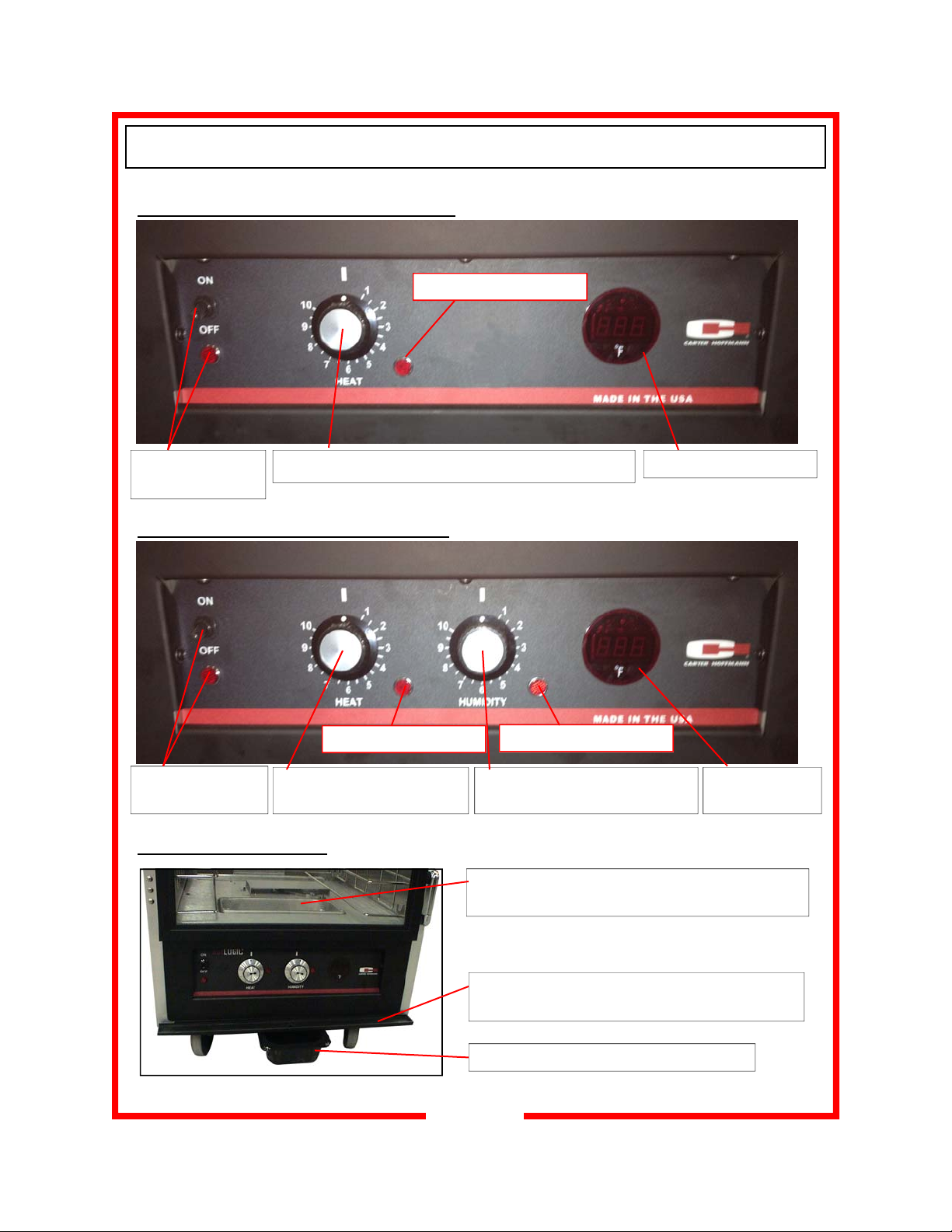

DETAILS: CONTROL PANELS & WATER PANS

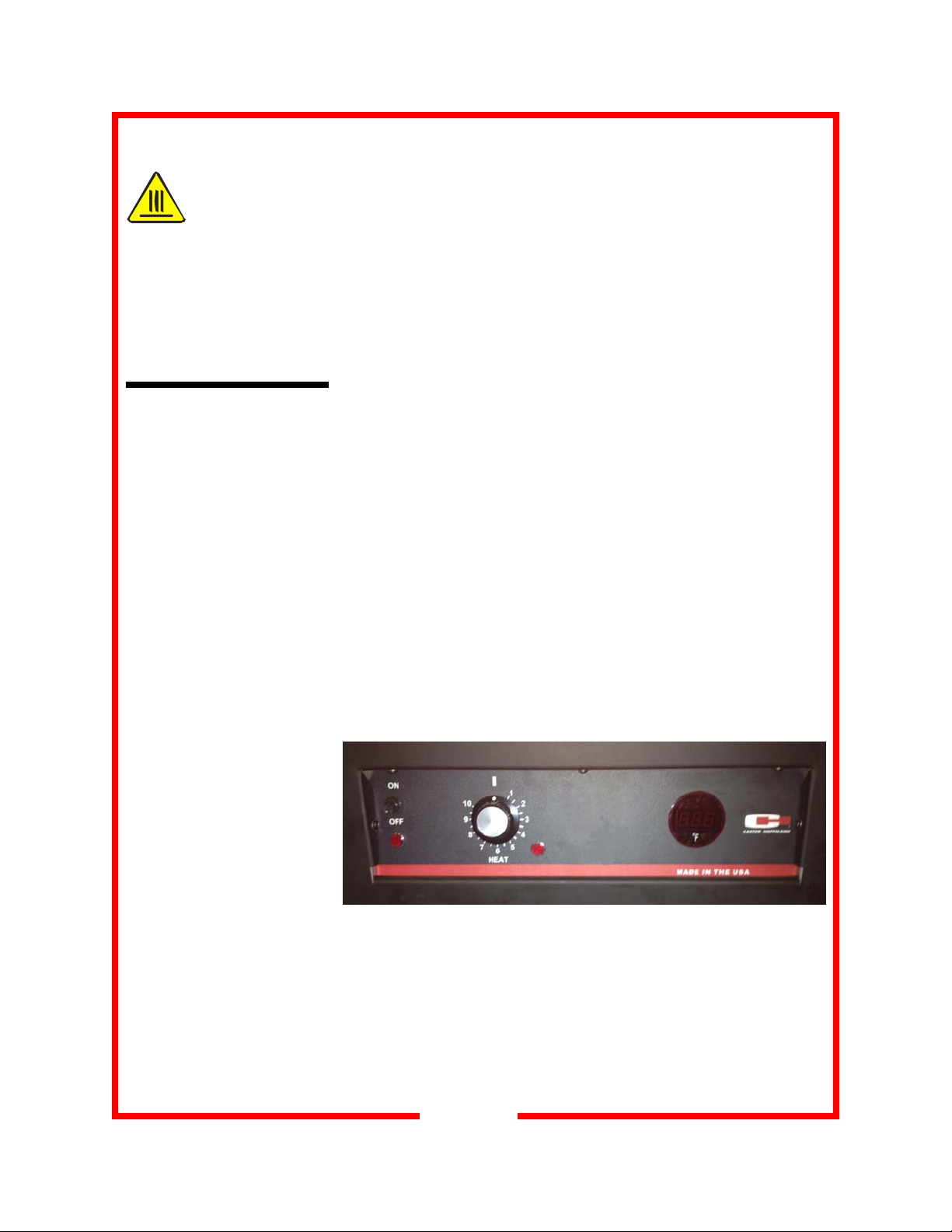

HL1 & HL3 Series Heated Holding Cabinets

Heating element cycle light

ON/OFF power switch

and indicator light

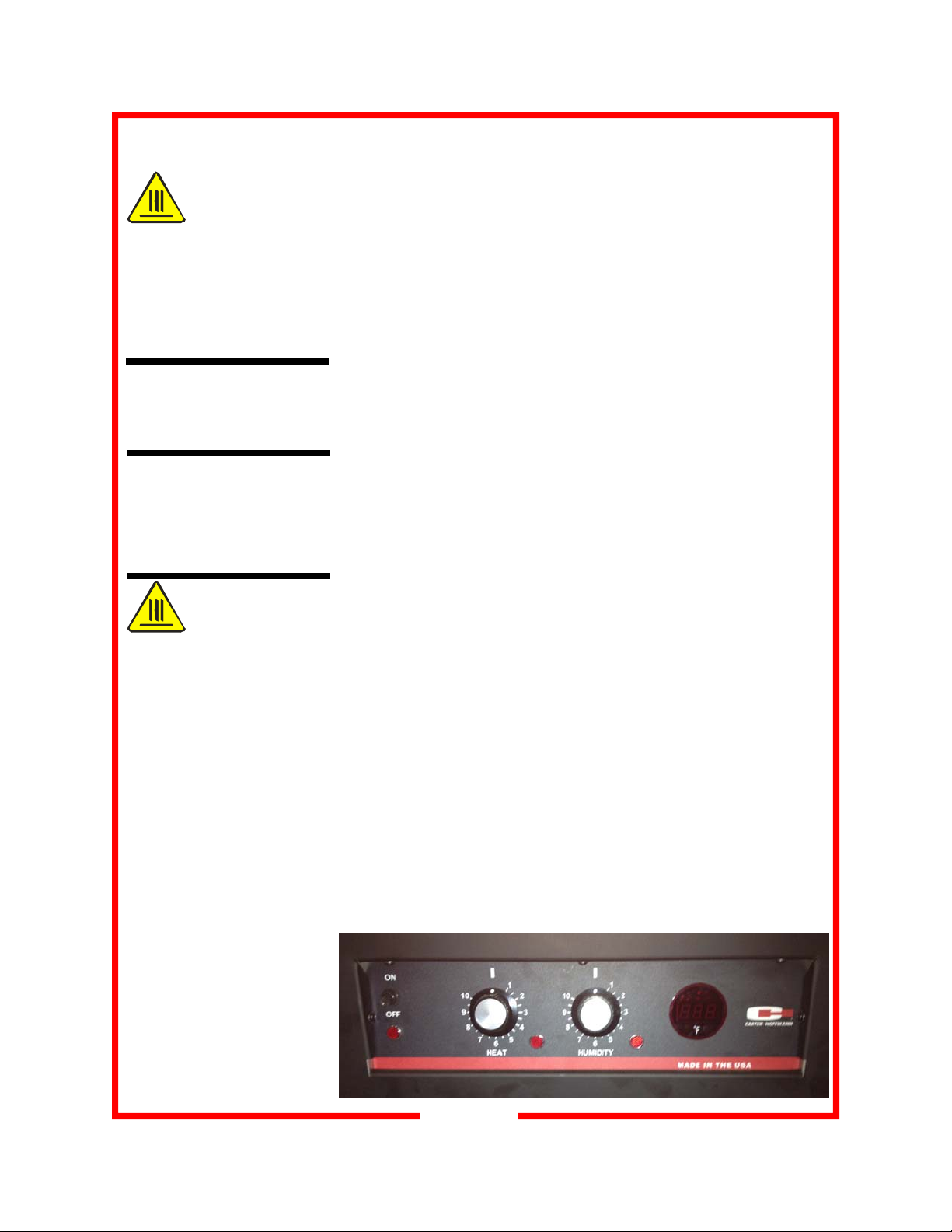

HL2 & HL4 Series Heater/Proofer Cabinets

ON/OFF power switch

and indicator light

WATER PAN LOCATIONS

Heat control knob. Settings from 1 (low heat) to 10 (high heat)

Heating element cycle light

Heat control knob. Settings from

1 (low heat) to 10 (high heat)

Digital temperature read-out

Humidity element cycle light

Humidity control knob. Settings from

1 (low humidity) to 10 (high humidity)

Humidity pan (manual fill): check and fill every 2 hours

when operating cabinet with humidity

Digital temperature

read-out

Water trough for condensation: collects and deposits

condensation into pan below

Condensation pan: check and empty periodically

9

Page 10

NORMAL OPERATION—HL1 & HL3 HB HEATED CABINETS

CAUTION:

HOT SURFACE

Inner and outer surfaces of

the unit will be very hot during and after operation.

Avoid touching the cabinet

when loading or removing

product.

Operating ranges:

- air temp: 90ºF-190ºF

(32°C - 88°C)

*For food safety reasons,

it is recommended that

the holding temperature

be set at 140°F (60°C) or

higher.

FIRST USE

Before using the cabinet, familiarize yourself with the heater controls. See page 9 for details. Plug the cabinet into a proven power

source. See electrical specifications on page 8.

HOLDING

1. Turn the cabinet on using the power switch located on the far left

side of the control panel. Once the switch is turned on, the

power indicator light will illuminate.

2. A water pan is provided in the base of the cabinet to provide a

small amount of passive humidity, if desired. Fill pan with clean

warm water. Check water level every 2 hours and refill as

needed. This step is optional; cabinet be also be operated

without water in the pan.

3. To adjust the temperature setting, rotate the HEAT dial clockwise to increase temperature and counter-clockwise to decrease

temperature to the desired set point. Temperature dial settings

range from 1 to 10, with 1 being the lowest temperature and 10

being the highest temperature. HEAT cycle light will turn on and

off as the heat thermostat cycles.

4. Wait approximately 25 minutes for the cabinet to preheat. Digital

readout dial on right side of control panel will display actual

cabinet temperature*.

5. Load food pans into cabinet. NOTE: Follow all food safety guidelines. Put hot, cooked food into the cabinet. This cabinet is not

intended to reheat food. Food must be cooked and at safe serving temperature prior to being placed in the cabinet.

6. When removing items, start at the bottom and work up. This will

keep food hotter and eliminate spillage onto lower items.

10

Page 11

NORMAL OPERATION—HL2 & HL4 HW HEATER PROOFERS

CAUTION:

HOT SURFACE

Inner and outer surfaces of

the unit will be very hot during and after operation.

Avoid touching the cabinet

when loading or removing

product.

Operating ranges:

- air temp: 90ºF-190ºF

(32°C to 88°C)

- humidity: 0-90%RH

Water reservoir:

When using the water reservoir for humidified holding or

proofing, check water level

every 2 hours and refill if

needed.

CAUTION:

WATER HAZARD

A water trough is located at

the base of the cabinet to

collect and direct condensation into black plastic condensation pan below. Make

sure to periodically check

and empty the pan to avoid

overflow & slip hazard.

*For food safety reasons,

we recommend that the

holding temperature

should be set at or above

140°F (60°C).

FIRST USE

Before using the cabinet, familiarize yourself with the heater controls. See page 9 for details. Plug the cabinet into a proven power

source. See electrical specifications on page 8.

HOLDING

1. If humidity is desired, a water pan is located at the bottom of the

cabinet. This pan will provide active humidification up to 90%RH

(depending on temperature). Fill water pan with clean warm

water. NOTE: Cabinet may also be operated without water.

2. Turn the cabinet on using the power switch located on the far left

side of the control panel. Once the switch is turned on, the

power indicator light will illuminate.

3. To adjust the temperature setting, rotate the HEAT dial clockwise to increase temperature and counter-clockwise to decrease

temperature to the desired set point. Temperature dial settings

range from 1 to 10, with 1 being the lowest temperature and 10

being the highest temperature.

4. To adjust humidity, rotate the humidity dial clockwise to

increase humidity and counter-clockwise to decrease humidity.

If humidity is not required, rotate dial counter-clockwise to the off

position (line up dot on knob with white hash mark on control

panel).

5. Wait approximately 25 minutes for the cabinet to preheat. Digital

readout dial on right side of control panel will display actual

cabinet temperature*.

6. Load food pans into cabinet. NOTE: Follow all food safety guide-

lines. Put hot, cooked food into the cabinet. This cabinet is not

intended to reheat food. Food must be cooked and at safe

serving temperature prior to being placed in the cabinet.

7. When removing items, start at the bottom and work up. This will

keep food hotter and eliminate spillage onto lower items.

PROOFING

1. Follow instructions above for holding. Note: water pan at base

of cabinet must be filled with clean warm water.

2. For proofing settings, rotate HEAT knob clockwise to 5 to 6

(approximately 90°F to 100°F; 32° to 38°C) and rotate HUMIDITY knob clockwise to 10 (90%+ RH).

3. Allow cabinet to preheat for approximately 25 minutes and load

food according to the instructions above.

11

Page 12

FOOD HOLDING GUIDE

CAUTION: SAFE

FOOD HOLDING

PRACTICES

RECOMMENDED

Cooking food to a safe temperature, holding at a temperature of at least 140°F

(60°C) is critical in the prevention of foodborne illness.

Hold only cooked, hot food

at 140°F (60°C) or higher.

This cabinet is not intended

to cook or reheat food.

Food must be at appropriate temperature before being placed into cabinet.

COOK TO AT LEAST

165°F (74°C) Destruc-

165°F

140°F

41°F

NOTE: Times and temperatures

observed in a test kitchen environment. Times and temperatures

may vary, depending on initial food

quality, initial cooked temperature

and user expectations of acceptable food quality.

tion of most bacteria

HOLD at 140°F (60°C) or

higher

DANGER ZONE: 41°F

to 140°F (5° to 60°C)

Bacteria grow

rapidly

PRODUCT SET TEMPERATURE

Bacon, Canadian 180°F / 82°C 30

Bacon, Crisp (uncovered) 180°F / 82°C 30

Baked Potato 180°F / 82°C 60

Biscuits 170°F / 77°C 60

Casseroles 175°F / 79°C 90

Chops, Sliced Meats 160°F / 71°C 60

Chicken, Fried (uncovered) 170°F / 77°C 30

Chicken, Boneless Breasts 175°F / 79°C 60

Chicken Nuggets, Deep Fried (uncovered) 190°F / 88°C 25

Chicken, Pre-Cooked Grilled Boneless Patties 150°F / 66°C 90

Coffee Cakes (uncovered) 170°F / 77°C 60

Cookies (uncovered) 175°F / 79°C 90

Crab Legs 160°F / 71°C 45

Croissants 170°F / 77°C 45

Eggs 160°F / 71°C 45

Fish, Deep-Fried (uncovered) 170°F / 77°C 30

Fish, Baked 155°F / 68°C 45

Fish, Broiled 155°F / 68°C 45

French Toast 165°F / 74°C 60

Gravies / Sauces 170°F / 77°C 45

Hamburgers / Ground Meat Patties 180°F / 82°C 45

Hot Dogs 180°F / 82°C 90

Muffins 170°F / 77°C 60

Omelets 160°F / 71°C 30

Pancakes 180°F / 82°C 30

Pasta 175°F / 79°C 60

Pastries 165°F / 74°C 30

Pizza (uncovered) 180°F / 82°C 15

Pizza (boxed) 180°F / 82°C 60

Poppers, Deep Fried (uncovered) 190°F / 88°C 25

Poultry, Whole, bone-in 175°F / 79°C 60

Poultry, Cut-up, bone-in 175°F / 79°C 60

Ribs 175°F / 79°C 90

Rice 175°F / 79°C 30

Roasts / Bone-in Meats 165°F / 74°C 90

Sausage 180°F / 82°C 90

Shrimp / Shellfish 150°F / 66°C 60

Soups (broth) 185°F / 85°C 90

Tortillas (soft) 180°F / 82°C 60

Vegetables 175°F / 79°C 45

(°F /°C)

MAXIMUM TIME

(MINUTES)

12

Page 13

DAILY CLEANING PROCEDURES

CAUTION:

ELECTRIC SHOCK

HAZARD

Disconnect appliance from

electric power before cleaning.

CAUTION:

HOT SURFACE

Exposed surfaces can

be hot to the touch and may

cause burns. Allow appliance

to cool before cleaning.

IMPORTANT:

DO NOT spill or pour

water into controls,

control panel or wiring.

Water damage is not covered

by warranty.

CAUTION:

Beware of sharp edges with sheet metal

during cleaning process.

1. After all food products have been removed from the cabinet,

turn the power switch to “OFF” and allow the cabinet to cool

completely.

2. Unplug the unit prior to any cleaning.

3. Remove the rack assemblies.

4. Make sure the power cord is not hooked into the cord hook.

Open cabinet door and empty water reservoir. Remove the

heater module by lifting up the front enough to clear its detent,

and then pull the module out of the cabinet. The power cord

will slide through the access hole at the rear of the cabinet.

5. Inspect and clean the areas where there are vents or filters,

making sure no water gets into the internal controls or

electrical areas of the cabinet.

6. Clean the inside of the cabinet as well as the removed parts.

Reinstall when all parts are dry and clean. Empty and clean

black plastic condensation pan.

7. A solution of two tablespoons of baking soda per quart of

warm water is sufficient for most cleaning jobs. Mild soap or

detergent may be used on heavily soiled interiors—follow

manufacturer’s directions.

8. If cabinet has a clear glass door, clean with window cleaner,

taking care not to get any of the solution on the aluminum cabinet walls. Stubborn deposits may be cleaned with a mild

soap and water and then rinsed with clean water. Use a soft,

non-abrasive cloth to avoid scratching the door.

9. Control panel should be washed with a clean, damp, nonabrasive cloth and chlorine-free detergent. Rinse thoroughly

with clean damp cloth and allow to dry. Do not use abrasive

cleaners, waxes, car polish, or substances containing strong

aromatic solvents or alcohol. If the control knob(s) need to be

removed for cleaning, simply pull the knob out, clean the control panel and knob, and then replace the knob.

CAUTION:

Do not use strong detergents, alkalis, ammonia solutions or

abrasive cleaners. Use only cleaning agents approved for aluminum and only in the recommended manufacturer’s concentration. Do

not use steel wool pads—ferrous deposits will cause rusting.

Use of cleaning agents that are not recommended for aluminum may

cause permanent damage to the cabinet. THIS DAMAGE IS PERMA-

NENT, COSTLY TO REPAIR AND IS NOT COVERED BY THE

WARRANTY.

13

Page 14

CABINET MAINTENANCE

WARNING:

DO NOT perform

these procedures

while the cabinet is turned on

or heated. Turn off the power

and wait for the cabinet to cool

to room temperature.

CAUTION:

Do not move cabinet

unless door is securely closed. Serious damage to

hinges and door may result if

bumped into tables, walls, or

other equipment when the

doors are open.

CASTERS

Some cabinets may have caster bearings that are equipped with

Zerk grease fittings so that they may be easily lubricated with a

grease gun. Lubricate bearings at least once every six months.

HINGE MAINTENANCE

Make sure all joints remain sealed and door latches do not stick. If

necessary, use WD-40 to keep door latches from sticking. Do not

use oil.

REVERSING THE DOOR

Reversing the door takes about 30 minutes & requires two people.

1. Using a small screwdriver, pry off the hinge covers and set

aside. Removing the covers will allow access to the inside

hinge screws. Remove the three screws that hold each hinge

to the cabinet. DO NOT REMOVE THE SCREWS THAT

HOLD THE HINGES TO THE DOOR. Remove the door, taking care not to let it fall.

2. Remove the door strike plate and screws adjacent to the door

opening on the cabinet. Reinstall door strike plate and screws

on opposite side of the cabinet.

3. Screw hinges onto opposite side of the door.

4. With the help of another person, hold door up to the cabinet

and attach with the screws removed in step one. Before tightening the screws, be sure the door is flush, level and square.

Replace the hinge covers.

14

Page 15

WIRING DIAGRAMS

HL1 & HL3 HB SERIES

Standard US Electric: 120 VOLT, 1800 WATT, 15AMP, 1 PH, 60 HZ

International Electric: 220 VOLT, 1800 WATT, 8.2AM P , 1 PH, 50/60 HZ

HL2 & HL4 HW SERIES

Standard US Electric: 120 VOLT, 2100 WATT, 17.5 AMP, 1 PH

International Electric: 220 VOLT, 2100 WATT, 9.5AM P , 1 PH, 50/60 HZ

15

Page 16

REPLACEMENT PARTS

Use only (OEM) original equipment manufacturer replacement parts. Using unauthorized parts may

cause serious injury or damage to the cabinet. Replacement parts should be installed by a qualified

service technician.

Contact Carter-Hoffmann with your model and serial number for replacement parts.

Call: 800-323-9793 or

Email: Service@Carter-Hoffmann.com

Part Number HL1 & HL Series Description

18600-0046 Hi limit—open at 300°F, close at 250°F

18602-0083 On/Off switch 20 Amp

18602-0031 Switch boot

18608-0010 Knob—heat

18605-0022 Power cord-8’

18606-0221 5-20P plug

18612-0131 Heat element 1700 watt, 120v (Standard US cabinets)

18613-0136 Heat element 1700 watt, 220v (International cabinets)

18616-0071 Transformer (Standard US cabinets)

18616-0074 Transformer (International 220v cabinets)

18614-0360 Fan motor

18614-0321 Fan motor blower wheel

18314-0019 1.8 qt. black condensation pan

18600-0017 Thermostat

18614-0322 Muffin fan

18616-0073 Digital thermometer

18616-0071 Transformer for digital thermometer

18601-1171 Red indicator light, power and heat

Part Number HL2 & HL4 Series Description

18600-0046 Hi limit—open at 300°F, close at 250°F

18602-0083 On/Off switch 20 Amp

18602-0031 Switch boot

18608-0010 Knob—heat or humidity

18605-0022 Power cord—8’

18606-0221 5-20P plug

18612-0131 Heat element 1700 watt, 120v (Standard US cabinets)

18613-0136 Heat element 1700 watt, 220v (International cabinets)

18612-0132 Water pan element 350 watt, 120v (Standard US cabinets)

18612-0137 Water pan element 350 watt, 220v (International cabinets)

18616-0071 Transformer (Standard US cabinets)

18616-0074 Transformer (International 220v cabinets)

18614-0322 Muffin fan

18614-0360 Fan motor

18614-0321 Fan motor blower wheel

18314-0019 1.8 qt. black condensation pan

18600-0017 Thermostat—heat element

18600-0016 Thermostat—humidity element

18616-0073 Digital thermometer

18616-0071 Transformer for digital thermometer

18601-1171 Red indicator light, power, heat & humidity

16

Page 17

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

No power on display Not plugged in or circuit breaker

tripped

Power cord damaged Check - replace if required

Circuit breaker tripped Check circuit breaker

Power switch damaged or defective Check - replace if required

Food dries out too

quickly

Unit is on, motors

are running but no

heat

Takes too long to

get to temperature

Unit is hot

but low or no airflow

Operation where product temp is too

high; food pans should be covered

Control incorrectly set or defective Check proper operation or calibration

Internal wiring error

Element hi-limit trip / defective Call service technician

Improper voltage Call service technician to verify

Internal wiring error Call service technician

Circulation motor has quit Call service technician

Improper voltage Call service technician to verify

Check or reset circuit breaker

Connect to proper receptacle

Check product temps going into

holding cabinet; cover food pans

of control

Call service technician

incoming voltage matches cabinet

specifications.

incoming voltage matches cabinet

specifications.

NOTE:

The technical content of this manual,

including any wiring diagrams, schematics, parts breakdown illustrations and /

or adjustment procedures, is intended

NOTE:

For warranty service, call Carter-Hoffmann

direct at 800-323-9793 for authorization,

we will dispatch the nearest authorized

service agency.

for use ONLY by qualified technical

personnel

.

17

Page 18

3-YEAR WARRANTY on HOTLOGIX HOLDING CABINETS

Carter-Hoffmann Warranty:

Carter-Hoffmann (“CARTER-HOFFMANN”) warrants to the initial purchaser of its standard Carter

Line Products that CARTER-HOFFMANN will, at its option, repair or replace, during the warranty

period set forth below, any part of such products made necessary due to a defect in material or workmanship which is present when the product leaves its factory and which manifests itself d ur ing th e warranty period under normal use and service.

This warranty applies only to original equipment owned and possessed by the initial purchaser and the

warranty period begins on the date of original shipment from the CARTER-HOFFMANN factory and

extends as follows: to component parts and labor for 12 months (36 months on hotLOGIX holding

cabinets, levels HL3 through HL10, and cook & hold cabinets); to refrigeration compressor unit for

one year (limited to replacement only - not to include labor for removal, repair or replacement).

Repair or replacements under this warranty will be performed, unless otherwise authorized in writing

by CARTER-HOFFMANN, at its factory. All parts or components to be repaired or replaced under this

warranty are to be shipped prepaid to CARTER-HOFFMANN, with reimbursement credit for such part

or component to be given if found by CARTER-HOFFMANN to be defective.

CARTER-HOFFMANN neither makes nor assumes and does not authorize any other person to make or

assume any obligation or liability in connection with its pro ducts other than that covered in this warranty. This warranty applies only within the continental United States and Canada. In Alaska and Hawaii, this warranty applies only to and is limited to the supply of replacement parts.

Warranty Exclusions and Limitations:

Any implied warranty of merchantability or fitness for a particular purpose is hereby specifically dis-

claimed by CARTER-HOFFMANN. There are no warranties, expressed or implied, which extend be-

yond the description on the face hereof. This warranty does not cover and CARTER-HOFFMANN shall

not under any circumstances be liable for any incidental, consequential or other damages (such as in-

jury to persons or property, loss of time, inconvenience, loss of business or profits, or other matters not

specifically covered) arising in connection with the use of, inability to use, or failure of these products.

Specifications subject to change through product improvement and innovation.

Carter-Hoffmann

1551 McCormick Ave.

Mundelein, Illinois, 60060 USA

Phone: 847-362-5500 Toll free: 800-323-9793 Fax: 847-367-8981

Sales and Marketing E-mail: sales@carter-hoffmann.com

Service E-mail: technicalservice@carter-hoffmann.com

Company Website: www.carter-hoffmann.com

18

Page 19

CABINETS RÉCHAUDS & RÉCHAUDS ÉTUVES EN ALUMINIUM

Séries HL1, HL2, HL3 & HL4

MANUEL D’INSTRUCTION

HL2-18

MODÈLES:

HL1 CABINETS

RÉCHAUDS

(non isolés)

Modèles: HL1-5,

HL1-8, HL1-14 &

HL1-18

Anciens modèles:

HBU5A2GM

HBU8A2GM

HBU14A2GM

HBU18A2GM

HBC10A2GM

HBC16A2GM

HBC28A2GM

HBC36A2GM

HBF5A2GM

HBF8A2GM

HBF14A2GM

HBF18A2GM

Courriel: technicalservice@carter-hoffmann.com

MODÈLES:

HL2 RÉCHAUDS/

ÉTUVES

(non isolés)

Modèles: HL2-5,

HL2-8, HL2-14 &

HL2-18

Anciens modèles:

HWU5A2GM

HWU8A2GM

HWU14A2GM

HWU18A2GM

HWC10A2GM

HWC16A2GM

HWC28A2GM

HWC36A2GM

HWF5A2GM

HWF8A2GM

HWF14A2GM

HWF18A2GM

FABRIQUÉ PAR:

CARTER-HOFFMANN

1551 McCormick Avenue

Mundelein, IL 60060 U.S.A.

Téléphone: 847-362-5500

Fax: 847-367-8981

Sans-frais: 800-323-9793

HL3 CABINETS

Modèles: HL3-5,

HL3-8, HL3-14,

Anciens modèles:

HBU5A1GM

HBU8A1GM

HBU14A1GM

HBU18A1GM

HBC10A1GM

HBC16A1GM

HBC28A1GM

HBC36A1GM

HBF5A1GM

HBF8A1GM

HBF14A1GM

HBF18A1GM

MODÈLES:

HL4 RÉCHAUDS/

RÉCHAUDS

(isolés)

HL3-18

Anciens modèles:

HWU5A1GM

HWU8A1GM

HWU14A1GM

HWU18A1GM

HWC10A1GM

HWC16A1GM

HWC28A1GM

HWC36A1GM

HWF5A1GM

HWF8A1GM

HWF14A1GM

HWF18A1GM

MODÈLES:

ÉTUVES

(isolés)

Modèles: HL4-5,

HL4-8, HL4-14,

HL4-18

TABLE DES MATIÈRES

MESURES DE SÉCURITÉ……………………………..…………………….. 20

CARACTÉRISTIQUES ET SPÉCIFICATIONS..…………..……………….. 21-24

RÉCEPTION, INSPECTION & DOMMAGES DUS AU TRANSPORT…... 25

INSTALLATION & DÉMARRAGE …………………….……………………. 26

DÉTAILS: CONTRÔLES ET RÉSERVOIRS D’EAU………..……………… 27

OPÉRATION: HL1 & HL3 CABINETS RÉCHAUDS…………….……........ 28

OPÉRATION: HL2 & HL4 RÉCHAUDS/ÉTUVES …………………..…...... 29

GUIDE DE CONSERVATION DES ALIMENTS DANS UN RÉCHAUD.... 30

PROCÉDURES DE NETTOYAGE QUOTIDIEN...…..……...…………...… 31

ENTRETIEN…………….……………………………………………...…….... 32

SCHÉMA ÉLECTRIQUE...………………………………………………….… 33

PIÈCES ET COMPOSANTES……………………………………………...... 34

GUIDE DE DÉPANNAGE………..……………………………………........... 35

GARANTIE……….……………….…………………….…………………….... 36

Numéro: 18400-3130e Imprimé aux États-Unis d’Amérique Rev: KBA090413

Page 20

MESURES DE SÉCURITÉ

AVERTISSEMENT: RISQUE D’ÉLECTROCUTION

WARNING

Tous les manipulations/ajustements nécessitants l'accès à des composante s électriques non isolées doivent être effectués par un professionnel qualifié. Le nonrespect de cet avertissement peut entraîner un choc électrique sévère.

ATTENTION: RISQUE D’ÉLECTROCUTION

Débranchez cet appareil de l'alimentation électrique avant toute opération de

maintenance ou de service.

ATTENTION: RISQUE DE BRÛLURE

Les surfaces métalliques exposées peuvent être chaudes au toucher et peuvent

causer des brûlures.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Lorsque vous utilisez des appareils électriques, des précautions élémentaires doivent être observées, y com-

pris ce qui suit:

1) Familiarisez-vous avec l'utilisation de l'appareil, les limitations et restrictions qui s'y rattachent. Les

instructions de fonctionnement doivent être lues et comprises par toutes les personnes qui utilisent ou

installent cet appareil.

2) Cet appareil doit être mis à la terre. Raccordez l'appareil uniquement à une prise correctement mise à

la terre.

3) Utilisez cet appareil uniquement pour l'usage prévu, comme décrit dans le manuel.

a. Cet équipement est spécialement conçu pour maintenir des aliments précuits à une

certaine température.

b. Cet équipement est destiné à être utilisé dans des établissements commerciaux seulement.

c. Cet équipement n'est pas conçu pour un usage industriel ou de laboratoire.

4) La propreté de cet appareil et de ses accessoires est indispensable à une bonne salubrité.

5) NE PAS immerger l'appareil dans l'eau. Cet appareil n'est pas étanche. NE PAS diriger de jet d’eau ou

câblage. NE PAS utiliser de produits corrosifs dans cet appareil.

6) NE PAS entreposer cet appareil à l'extérieur. NE PAS utiliser ce produit près de l'eau - par exemple,

7) NE PAS utiliser cet appareil si le cordon ou la fiche est endommagé, s'il ne fonctionne pas correcte-

8) NE PAS couvrir ni obstruer les ouvertures de l'appareil.

9) Seul un professionnel qualifié doit réparer cet appareil.

de vapeur en direction de l’appareil, ou du panneau de commande ou le câblage. NE PAS

éclabousser ou verser de l'eau sur, dans ou au-dessus de tout contrôle, panneau de contrôle ou le

près d'un évier, dans un sous-sol humide ou près d'une piscine, etc.

ment ou s'il a été endommagé ou est tombé. Ne pas immerger le cordon ou la fiche dans l'eau, garder

le cordon éloigné des surfaces chaudes, et ne laissez pas le cordon pendre de la table ou du comptoir.

NOTE: Le contenu technique de ce manuel, y compris les schémas électriques, schémas, illustrations, pro-

cédures d'ajustement, est destiné à être utilisé par un profession nel qualifié et sont sujets à modific ation sans

préavis.

20

Page 21

HL1 CABINET RÉCHAUD NON ISOLÉ CARACTÉRISTIQUES & SPÉCIFICATIONS

HL1 Caractéristiques et avantages

Système de chauffage de précision au bas de l’appareil. Offre une chaleur constante et une récupération rapide

Contrôle électromécanique de la température. Thermomètre digital. Atteint des températures de 90° à 190°F

Quatre dimensions disponibles avec supports universels ajustables, fixes ou à angles

Roulettes pivotantes, roulettes avant équipées de freins

Porte vitrée dans un cadre robuste en aluminium extrudé réversible. Porte pleine en aluminium anodisé noire en

option

Supports universels fixes pour plaques de 18”x26” et bacs 12”x20”x2.5”

Cabinets avec Supports Universels Ajustables, Universels Fixes ou à Angles

Modèle

Capacité

bacs/plaques*

12”x20” 18”x26”

Supports

inclus

(paire)

Dimensions extérieures

Hauteur Profondeur Largeur

pouce

des roues

(mm)

HL1-5

(sous le comptoir)

HL1-8

(1/2)

HL1-14

(3/4)

HL1-18

(pleine grandeur)

10 5 5 31-1/16 29-1/2 24-11/16

(789) (749) (627)

16 8 8 40-1/16 29-1/2 24-11/16

(1018) (749) (627)

28 14 14 58-1/16 29-1/2 24-11/16

(1474) (749) (627)

36 18 18 70-1/16 29-1/2 24-11/16

(1780) (749) (627)

Diamètre

pouce

(mm)

5

(127)

5

(127)

5

(127)

5

(127)

Poids

d’expédition

(classe 100)

lbs (kgs)

99

(45)

137

(62)

155

(70)

198

(90)

* Espace fixe de 3”

LISTÉS:

3174974

Système électrique

Monophasé

Conformes à UL Std 197

certifiés CAN/CSA Std

C22.2 No. 109

NEMA

3174974

Conformes à

NSF/ANSI

Std 4

Voltage international:

220 volts, 1800 watts, 8.2

Amps, 50 Hz, monophasé,

fiche respectant les exigences / normes du pays

spécifié

21

Voltage canadien:

120v, 1400 watts,

12Amps, NEMA 5-15P

Page 22

HL2 RÉCHAUD/ÉTUVE NON ISOLÉ EN ALUMINIUM CARACTÉRISTIQUES & SPÉCIFICATIONS

HL2 Caractéristiques et avantages

Système de chauffage de précision au bas de l’appareil. Offre une chaleur constante et une récupération

rapide

Contrôle électromécanique de la température et de l’humidité. Thermomètre digital. Atteint des températures

de 90° à 190°F

Peut être utilisé avec ou sans humidité en mode réchaud et en mode étuve

Quatre dimensions disponibles avec supports universels ajustables, fixes ou à angles

Roulettes pivotantes, roulettes avant équipées de freins

Porte vitrée dans un cadre robuste en aluminium extrudé réversible. Porte pleine en aluminium anodisé noire

en option

Supports universels fixes pour plaques de 18”x26” et bacs 12”x20”x2.5”

Cabinets avec Supports Universels Ajustables, Universels Fixes ou à Angles

Modèle

Capacité

bacs/plaques*

12”x20” 18”x26”

Supports

inclus

(paire)

Dimensions extérieures

Hauteur Profondeur Largeur

pouce

(mm)

Diamètre

des roues

pouce

(mm)

Poids

d’expédition

(classe 100)

lbs (kgs)

HL2-5

(sous le comptoir)

HL2-8

(1/2)

HL2-14

(3/4)

HL2-18

(pleine grandeur)

* Espace fixe de 3”

LISTÉS:

3174974

10 5 5 31-1/16 29-1/2 24-11/16

(789) (749) (627)

16 8 8 40-1/16 29-1/2 24-11/16

(1018) (749) (627)

28 14 14 58-1/16 29-1/2 24-11/16

(1474) (749) (627)

36 18 18 70-1/16 29-1/2 24-11/16

(1780) (749) (627)

Conformes à UL Std 197

certifiés CAN/CSA Std

C22.2 No. 109

3174974

Conformes à

NSF/ANSI

Std 4

5

(127)

5

(127)

5

(127)

5

(127)

99

(45)

137

(62)

155

(70)

198

(90)

Système électrique

NEMA

Monophasé

Voltage international:

220 volts, 2100 watts, 9.5

Amps, 50 Hz, monophasé,

fiche respectant les exigences / normes du pays

spécifié

22

Voltage canadien: 120v,

1400 watts, 12Amps,

NEMA 5-15P

Page 23

HL3 CABINET RÉCHAUD ISOLÉ EN ALUMINIUM CARACTÉRISTIQUES & SPÉCIFICATIONS

HL3 Caractéristiques et avantages

Système de chauffage de précision au bas de l’appareil. Offre une chaleur constante et une récupé-

ration rapide

Contrôle électromécanique de la température. Thermomètre digital. Atteint des températures de 90°

à 190°F

Quatre dimensions disponibles avec supports universels ajustables, fixes ou à angles

Roulettes pivotantes, roulettes avant équipées de freins

Porte vitrée dans un cadre robuste en aluminium extrudé réversible. Porte pleine en aluminium

anodisé noire en option

Supports universels fixes pour plaques de 18”x26” et bacs 12”x20”x2.5”

Cabinets avec Supports Universels Ajustables, Universels Fixes ou à Angles

Modèle

Capacité

bacs/plaques*

12”x20” 18”x26”

Supports

inclus

(paire)

Dimensions extérieures

Hauteur Profondeur Largeur

pouce

(mm)

Diamètre

des roues

pouce

(mm)

Poids

d’expédition

(classe 100)

lbs (kgs)

HL3-5

(sous le comptoir)

HL3-8

(1/2)

HL3-14

(3/4)

HL3-18

(pleine grandeur)

* Espace fixe de 3”

LISTÉS:

3174974

Système électrique

NEMA

Monophasé

10 5 5 31-5/8 31-1/2 26-1/2

(803) (800) (673)

16 8 8 40-5/8 31-1/2 26-1/2

(1032) (800) (673)

28 14 14 58-5/8 31-1/2 26-1/2

(1489) (800) (673)

36 18 18 70-5/8 31-1/2 26-1/2

(1794) (800) (673)

Conformes à UL Std 197

certifiés CAN/CSA Std

C22.2 No. 109

3174974

Conformes à

NSF/ANSI

Std 4

Voltage international:

220 volts, 1800 watts,

8.2 Amps, 50 Hz, monophasé, fiche respectant les exigences /

normes du pays spéci-

Voltage canadien: 120v,

1400 watts, 12Amps,

NEMA 5-15P

5

(127)

5

(127)

5

(127)

5

(127)

104

(47)

147

(67)

170

(77)

218

(99)

23

Page 24

HL4 RÉCHAUD/ÉTUVE ISOLÉ EN ALUMINIUM CARACTÉRISTIQUES & SPÉCIFICATIONS

HL4 Caractéristiques et avantages

Système de chauffage de précision au bas de l’appareil. Offre une chaleur constante et une récupération

rapide

Contrôle électromécanique de la température et de l’humidité. Thermomètre digital. Atteint des tempéra-

tures de 90° à 190°F

Peut être utilisé avec ou sans humidité en mode réchaud et en mode étuve

Quatre dimensions disponibles avec supports universels ajustables, fixes ou à angles

Roulettes pivotantes, roulettes avant équipées de freins

Porte vitrée dans un cadre robuste en aluminium extrudé réversible. Porte pleine en aluminium en op-

tion.

Supports universels fixes pour plaques de 18”x26” et bacs 12”x20”x2.5”

Cabinets avec Supports Universels Ajustables, Universels Fixes ou à Angles

Modèle

Capacité

bacs/plaques*

12”x20” 18”x26”

Supports

inclus

(paire)

Dimensions extérieures

Hauteur Profondeur Largeur

pouce

(mm)

Diamètre

des roues

pouce

(mm)

Poids

d’expédition

(classe 100)

lbs (kgs)

HL4-5

(sous le comptoir)

HL4-8

(1/2)

HL4-14

(3/4)

HL4-18

(pleine grandeur)

* Espace fixe de 3”

LISTÉS:

3174974

Système électrique

NEMA

Monophasé

10 5 5 31-5/8 31-1/2 26-1/2

(803) (800) (673)

16 8 8 40-5/8 31-1/2 26-1/2

(1032) (800) (673)

28 14 14 58-5/8 31-1/2 26-1/2

(1489) (800) (673)

36 18 18 70-5/8 31-1/2 26-1/2

(1794) (800) (673)

Conformes à UL Std 197

certifiés CAN/CSA Std

C22.2 No. 109

3174974

Conformes à

NSF/ANSI

Std 4

Voltage international:

220 volts, 2100 watts,

9.5 Amps, 50 Hz, monophasé, fiche respectant les exigences /

normes du pays spéci-

Voltage canadien: 120v,

1400 watts, 12Amps,

NEMA 5-15P

5

(127)

5

(127)

5

(127)

5

(127)

104

(47)

147

(67)

170

(77)

218

(99)

24

Page 25

DÉBALLAGE ET INSPECTION

Cet appareil

doit être

nettoyé à fond

avant de l’utiliser.

Voir PROCÉDURES DE

NETTOYAGE dans ce

manuel.

NOTE: NE PAS jeter le

carton ou autres matériaux d'emballage avant

d'avoir vérifié si l'appareil

comporte des dommages

cachés et d’avoir vérifier

le bon fonctionnement de

celui-ci.

1. Retirez le carton d'emballage, assurez-vous que tous les matériaux d'emballage et de protection en plastique ont été retirés de

l'appareil.

2. Inspectez toutes les composantes.

3. En cas de dommages dus au transport, une demande de réclamation doit être déposée immédiatement auprès du transporteur.

4. Les dommages dus au transport ne sont pas couverts par la

garantie.

5. Vérifiez afin de vous assurer que toutes les composantes sont

incluses: cabinet, manuel d’instruction et autres accessoires.

6. Lisez les instructions de fonctionnement.

7. L’appareil doit être nettoyé à fond avant de l'utiliser. Voir PROCÉDURES DE NETTOYAGE dans ce manuel.

Si votre appareil a été

endommagé durant le

transport, reportez-vous à

la PROCÉDURE DE RÉCLAMATION au bas de

cette page.

PROCÉDURE DE RÉCLAMATION POUR COLIS ENDOMMAGÉ

NOTE: Pour votre protection, notez que l'équipement dans cette expédition a été minutieusement

inspecté et emballé par un professionnel qualifié avant de quitter l'usine. Sur acceptation de cette

expédition, la compagnie de transport assume l'entière responsabilité de sa livraison en bon état.

SI LE COLIS EST ENDOMMAGÉ:

1. PERTE OU DOMMAGES VISIBLES: Notez les pertes ou dommages sur le bon de transport ou

le reçu, et faites signer le livreur.

2. COMPLÉTEZ LE FORMULAIRE DE RÉCLAMATION IMMÉDIATEMENT: Quelle que soit

l'ampleur des dégâts, contactez immédiatement votre vendeur.

3. DOMMAGES CACHÉS: Si les dommages sont inaperçus jusqu'à ce que la marchandise soit

déballée, avisez la compagnie de transport ou le transporteur immédiatement, puis déposez

une réclamation avec eux. Cela devrait être fait dans les quinze (15) jours à compter de la d ate

de la réception du colis. Veillez à conserver l’emballage pour l'inspection.

Carter-Hoffmann ne peut pas assumer la responsabilité des dommages ou des pertes subies en

transit, les dégâts dus au transport ne sont pas couverts par la garantie. Nous allons, cependant, à

votre demande, vous fournir les documents nécessaires pour appuyer votre demande de réclamation.

25

Page 26

INSTALLATION & DÉMARRAGE

MISE EN GARDE:

Risque de blessures

L’installation doit être effectuée par

un technicien qualifié en pleine connaissance de tous les codes électriques en vigueurs. Une mauvaise

installation pourrait entraîner des

blessures et des dommages matériels.

IMPORTANT:

Le cordon d'alimentation

est d’une longueur de 8’

Si nécessaire, contactez un électricien agréé pour installer un circuit

électrique de 20 ampères et la prise

NEMA appropriée.

NE PAS utiliser de rallonge.

ATTENTION:

Risque d’électrocution

EMPLACEMENT

Pour un bon fonctionnement et une performance maximale,

localisez l'appareil dans une pièce ou la température ambiante est de 70ºF (21ºC).

Évitez de placer près d’une hotte ou dans une zone avec

beaucoup de courants d’air.

Pour une utilisation sécuritaire et une performance maximale,

placez l'unité à au moins 2 " du mur ou de matières combustibles.

L'unité doit être sur une surface plane et stable.

INSTRUCTIONS DE MISE À LA TERRE

Cet appareil est équipé d'un cordon muni d'un fil de mise à la terre

avec une fiche de mise à la terre qui doit être branchée dans une

prise de courant correctement installée et mise à la terre. Dans le

cas d'un court-circuit, la mise à la terre réduit le risque de choc électrique en fournissant un circuit de fuite au courant électrique.

AVERTISSEMENT- L'utilisation incorrecte de la mise à la terre

peut entraîner un risque d’électrocution. Consultez un électricien

qualifié ou un agent de service si les instructions de mise à la terre

ne sont pas complètement comprises ou s'il existe un doute quant à

savoir si l'appareil est correctement mis à la terre.

La mise à la terre du cordon d'alimentation fait partie d'un système

conçu pour vous protéger contre les

chocs électriques en cas de dommages internes.

NE PAS couper la grande broche

ronde ou forcer une lame pour

s'adapter à une prise existante.

IMPORTANT:

Pas sous garantie

Les dommages causés par une

connexion à une mauvaise tension

ou phase ne sont PAS couverts par

la garantie.

MISE EN GARDE:

Risque de blessures

Cet appareil n'est pas étanche, pour

éviter un choc électrique, gardez

l'unité au sec. Ne pas faire fonctionner si l'appareil a été en contact

avec de l'eau.

DÉMARRAGE

1. Avant utilisation, bien netto yer l'intérieur de l'appareil, conformément aux instructions de ce manuel. Familiarisez-vous avec les

commandes.

2. Branchez le cordon d'alimentation dans une prise mise à la

terre avec une tension électrique selon l'information fournie cidessous. NE PAS MODIFIER LE CORDON.

3. Réglez le commutateur POWER sur la position "ON".

4. Ne pas mettre de produit dans le cabinet. Permettre à la cha-

leur d’éliminer les huiles résiduelles qui peuvent adhérer au x

surfaces métalliques à l'intérieur. Une légère émission de fumée est courante pendant les premières heures de fonctionnement.

Système électrique

NEMA

monophasé

Modèles HL1 & HL3 Modèles HL2 & HL4

Système électrique

NEMA

monophasé

220 volt CE version internationale:

Séries HL1 & HL3: 1800 watts, 220

volts, 8.2 Amps, 50/60 Hz, monophasé

Séries HL2 & HL4: 2100 watts, 220

volts, 9.5 Amps, 50/60 Hz, monophasé

Fiche respectant les exigences /

normes du pays spécifié

Canada: 1400 watts, 120 volts, 12

Amps, monophasé, NEMA 5-15P

26

Page 27

DÉTAILS: CONTRÔLES ET RÉSERVOIRS D’EAU

Cabinets réchauds des séries HL1 & HL3

Élément chauffant en fonction

Interrupteur

MARCHE/ARRÊT

avec témoin lumineux

Réchauds/étuves des séries HL2 & HL4

Interrupteur

MARCHE/ARRÊT

avec témoin lumineux

BACS D’EAU

Contrôle de la chaleur. Niveau 1 (basse température) à 10

(haute température)

Élément chauffant

en fonction

Contrôle de la chaleur. Niveau 1

(basse température) à 10 (haute

température)

Thermomètre digital

Élément d’immersion en

fonction

Contrôle de l’humidité. Niveau 1

(faible taux d'humidité) à 10 (haut

taux d'humidité)

Bassin d’eau (remplissage manuel): vérifiez et remplissez

toutes les 2 heures si vous utilisez l’humidité

Thermomètre digital

Gouttière: récupère et dépose la condensation dans le

bac sous l’appareil

Bac de condensation: surveillez et videz régulièrement

27

Page 28

OPÉRATION—HL1 & HL3 HB CABINETS RÉCHAUDS

ATTENTION:

SURFACES

CHAUDES

Les surfaces intérieures et

extérieures de l'appareil

sont très chaudes pendant

et après l'utilisation.

Évitez de toucher à l'armoire lors du chargement

ou déchargement de produits.

Plage de température de

fonctionnement :

90ºF-190ºF

*Pour des raisons de sécurité alimentaire, il est

recommandé que le maintien de la température soit

fixée à 140°F (60°C) ou

plus.

PREMIÈRE UTILISATION

Avant d'utiliser l'appareil, familiarisez-vous avec les commandes de

température. Voir page 9 pour plus de détails. Branchez le boîtier

sur une source d'alimentation sûre. Voir les spécifications électriques à la page 8.

RÉCHAUD

1. Démarrez l’appareil en utilisant l'interrupteur d'alimentation situé

à l'extrême gauche du panneau de commande. Une fois que le

commutateur est activé, le voyant d'alimentation s'allume.

2. Un bassin d’eau est installé dans le fond de l’appareil pour fournir une petite quantité d'humidité passive, si on le souhaite.

Remplissez le bac avec de l'eau propre et chaude. Vérifiez le

niveau d'eau toutes les 2 heures et remplir si nécessaire. Cette

étape est facultative; le réchaud peut être également utilisé sans

eau dans le bassin.

3. Pour ajuster la température, tournez la molette dans le sens horaire pour augmenter la CHALEUR et dans le sens antihoraire

pour diminuer la température. Les paramètres de numérotation

varient de 1 à 10, 1 étant la température la plus basse et 10

étant la température la plus élevée. Un témoin lumineux s’allume lorsque l’élément chauffant est en fonction et s’éteint lorsque celui-ci à atteint la température.

4. Attendez environ 25 minutes pour le préchauffage. Le thermomètre numérique sur le côté droit du panneau de commande

affiche la température* réelle à l’intérieur de l’appareil.

5. Chargez les aliments dans le réchaud. REMARQUE: Suivez

toutes les consignes de sécurité alimentaire. Mettre des aliments chauds cuits dans l'appareil. Ce cabinet n'est pas destiné

à réchauffer les aliments. Les aliments doivent être cuits et à

une température sécuritaire avant d'être placé dans le réchaud.

6. Lorsque vous retirez des aliments, commencez par le bas et

travaillez vers le haut. Cela permet de garder la nourriture

chaude et d’éliminer les risque de déversements sur les articles

situés en-dessous.

28

Page 29

OPÉRATION—HL2 & HL4 HW RÉCHAUDS/ÉTUVES

ATTENTION:

SURFACES

CHAUDES

Les surfaces intérieures et

extérieures de l'appareil

sont très chaudes pendant

et après l'utilisation.

Évitez de toucher à l'armoire lors du chargement

ou déchargement de pro-

Plage de fonctionnement:

- Température:

90ºF-190ºF (32°C to 88°C)

- Humidité: 0-90%RH

Bassin d’eau:

Lorsque vous utilisez le bassin d'eau, vérifiez le niveau

de l'eau toutes les 2 heures

et remplir si nécessaire.

ATTENTION:

RISQUES LIÉS À

L’EAU

Une gouttière est situé au

bas de l’appareil pour recueillir et diriger la condensation dans un bac en plastique noir. Assurez-vous de

vérifier périodiquement et de

vider le plat pour éviter un

débordement.

*Pour des raisons de sécurité alimentaire, il est recommandé que le maintien

de la température soit

fixée à 140°F (60°C) ou

plus.

PREMIÈRE UTILISATION

Avant d'utiliser l'appareil, familiarisez-vous avec les commandes de

température. Voir page 9 pour plus de détails. Branchez le boîtier

sur une source d'alimentation sûre. Voir les spécifications électriques à la page 8.

RÉCHAUD

1. Si l'humidité est souhaitée, un bac à eau est situé en bas de

l'appareil. Ce bac procure une humidification active jusqu'à 90%

HR (selon la température). Remplissez le bac avec de l'eau

propre et chaude. REMARQUE: Le cabinet peut également être

utilisé sans eau.

2. Démarrez l’appareil en utilisant l'interrupteur d'alimentation situé

à l'extrême gauche du panneau de commande. Une fois que le

commutateur est activé, le voyant d'alimentation s'allume.

3. Pour ajuster la température, tournez la molette dans le sens horaire pour augmenter la CHALEUR et dans le sens antihoraire

pour diminuer la température. Les paramètres de numérotation

varient de 1 à 10, 1 étant la température la plus basse et 10

étant la température la plus élevée. Un témoin lumineux s’allume lorsque l’élément chauffant est en fonction et s’éteint lorsque celui-ci à atteint la température.

4. Pour ajuster l'humidité, tournez la molette dans le sens horaire

pour augmenter l'humidité et antihoraire pour la diminuer. Si aucune humidité est nécessaire, laissez le cadran à ARRÊT.

5. Attendez environ 25 minutes pour le préchauffage. Le thermomètre numérique sur le côté droit du panneau de commande

affiche la température* réelle à l’intérieur de l’appareil.

6. Chargez les aliments dans le réchaud. REMARQUE: Suivez

toutes les consignes de sécurité alimentaire. Mettre des aliments chauds et cuits dans l'appareil. Ce cabinet n'est pas destiné à réchauffer les aliments. Ceux-ci doivent être cuits et à une

température sécuritaire avant d'être placé dans le réchaud.

7. Lorsque vous retirez des aliments, commencez par le bas et

travaillez vers le haut. Cela permet de garder la nourriture

chaude et d’éliminer les risque de déversements sur les articles

situés en-dessous.

ÉTUVE

1. Suivez les étapes ci-dessus. Remarque: le bassin d’eau doit

contenir de l'eau propre et chaude.

2. Pour étuver, ajuster la température à 5-6 (environ 90°F à 100°F,

32 °C à 38 °C) et l’humidité à 10 (90%+ RH).

3. Attendez environ 25 minutes pour le préchauffage.

29

Page 30

GUIDE DE CONSERVATION DES ALIMENTS DANS UN RÉCHAUD

ATTENTION:

BONNE CONSERVATION DES ALI-

MENTS RECOMMANDÉE

La cuisson des aliments à

une température sécuritaire

et le maintien à une température d'au moins 140°F

(60°C) est essentiel dans la

prévention des maladies

d'origine alimentaire. Ne

gardez que des aliments

cuits dans le réchaud. Ce

cabinet n'est pas destiné à

cuire ou réchauffer des aliments. Les aliments doivent

être à la température appropriée avant d'être placé

dans le réchaud.

RÉCHAUD à 140°F (60°C)

ou plus

165°F

140°F

41°F

NOTE: Les temps et les températures ont été observés dans un

environnement de cuisine d'essai.

Les temps et les températures

peuvent varier en fonction de la

qualité des aliments initiale, la température initiale et les attentes des

utilisateurs.

CUIRE AU MOINS À

ZONE DE DANGER:

41°F à 140°F (5°C

à 60°C) Les bacté-

ries se multiplient

rapidement

PRODUIT TEMPÉRATURE

Bacon, Canadien 180°F / 82°C 30

Bacon, Croustillant (à découvert) 180°F / 82°C 30

Pomme de terre cuite au four 180°F / 82°C 60

Biscuit de campagne 170°F / 77°C 60

Casseroles 175°F / 79°C 90

Côtelettes, viandes tranchées 160°F / 71°C 60

Poulet frit (à découvert) 170°F / 77°C 30

Poitrines de poulet désossées 175°F / 79°C 60

Croquettes de poulet (à découvert) 190°F / 88°C 25

Galettes de poulet précuites 150°F / 66°C 90

Gâteau pause-café (à découvert) 170°F / 77°C 60

Biscuits (à découvert) 175°F / 79°C 90

Pattes de crabe 160°F / 71°C 45

Croissants 170°F / 77°C 45

Oeuf 160°F / 71°C 45

Poisson frit (à découvert) 170°F / 77°C 30

Poisson cuit 155°F / 68°C 45

Poisson grillé 155°F / 68°C 45

Pain perdu 165°F / 74°C 60

Sauces 170°F / 77°C 45

Hamburgers / Galettes de viande hachée 180°F / 82°C 45

Hot Dogs 180°F / 82°C 90

Muffins 170°F / 77°C 60

Omelettes 160°F / 71°C 30

Crêpes 180°F / 82°C 30

Pâtes 175°F / 79°C 60

Pâtisserie 165°F / 74°C 30

Pizza (à découvert) 180°F / 82°C 15

Pizza (dans sa boîte) 180°F / 82°C 60

Piment jalapenos frit (à découvert) 190°F / 88°C 25

Poulet entier 175°F / 79°C 60

Poulet avec os (cuisse/poitrine) 175°F / 79°C 60

Côtes levées 175°F / 79°C 90

Riz 175°F / 79°C 30

Rôti / Viande avec os 165°F / 74°C 90

Saucisses 180°F / 82°C 90

Crevette / fruits de mer 150°F / 66°C 60

Soupes (bouillon) 185°F / 85°C 90

Tortillas (souple) 180°F / 82°C 60

Légumes 175°F / 79°C 45

(°F/°C)

TEMPS MAXIMUM

(MINUTES)

30

Page 31

PROCÉDURES DE NETTOYAGE QUOTIDIEN

ATTENTION:

RISQUE D’ÉLECTROCUTION

Coupez l 'alimentation électrique avant de nettoyer l’appareil.

ATTENTION:

SURFACE CHAUDE

Les surfaces peuvent

être chaudes et peuvent causer des brûlures. Laissez l’appareil refroidir avant de le nettoyer.

IMPORTANT:

NE PAS renverser ou

verser d'eau dans les

contrôles, panneau de contrôle

ou le câblage.

Les dommages causés par

l'eau ne sont pas couverts par

la garantie.

ATTENTION:

Méfiez-vous des

bords coupants pen-

dant le nettoyage .

1. Après que tous les produits alimentaires ont été retirés du réchaud, mettez l'interrupteur d'alimentation sur "ARRÊT" et laissez le cabinet refroidir complètement.

2. Débranchez l'appareil avant toute opération de nettoyage.

3. Retirez les supports.

4. Assurez-vous que le cordon d'alimentation n'est pas sur le

crochet. Ouvrez la porte du cabinet et videz le réservoir d'eau.

Retirez le module de chauffage en soulevant l'avant suffisamment pour dégager son cran, puis tirez le module hors de la

chambre. Le câble d'alimentation se glissera à travers le trou

d'accès à l'arrière du réchaud.

5. Inspectez et nettoyer les zones où il ya des évents ou des

filtres en veillant à ce que l’eau ne pénètre pas dans les contrôles internes ou les zones électriques.

6. Nettoyez l'intérieur du réchaud ainsi que les pièces démontées. Réinstallez lorsque toutes les pièces sont propres et

sèches. Videz et nettoyez le bac de condensation en plastique

noir.

7. Une solution de deux cuillères à soupe de bicarbonate de

soude par litre d'eau chaude est suffisant pour la plupart des

tâches de nettoyage. Du savon ou un détergent doux peut être

utilisé sur les endroits très sales: suivre les recommandations

du fabricant.

8. Si le réchaud a une porte en verre, nettoyez avec un nettoyant

pour fenêtre, en prenant soin de ne pas en mettre sur les parois en aluminium. Les dépôts tenaces peuvent être nettoyées

avec un savon doux et de l'eau, puis rincer à l'eau claire. Utilisez un chiffon doux, non abrasif pour éviter de rayer la porte.

9. Le panneau de contrôle doit être lavé avec un chiffon propre,

humide et non abrasif et un détergent non-chloré. Rincez soigneusement avec un chiffon propre humide et laissez sécher.

Ne pas utiliser de nettoyants abrasifs, de cires ou des substances contenant des solvants ou de l'alcool. Si les boutons de

commandes doivent être retirés pour le nettoyage, il suffit de

tirer la poignée, nettoyez le panneau de contrôle et le bouton,

puis replacez le bouton .

ATTENTION:

Ne pas utiliser de détergents forts, des alcalis, des solutions

d'ammoniac ou de nettoyants abrasifs. Utilisez uniquement des produits

de nettoyage approuvés pour l'aluminium. Ne pas utiliser de laine d'acier,

les dépôts ferreux provoqueront de la rouille.

L’utilisation d’agents de nettoyage qui ne sont pas recommandés pour

l'aluminium peut causer des dommages permanents à l'appareil. CES

DOMMAGES SONT PERMANENTS, COÛTEUX À RÉPARER

ET NE SONT PAS COUVERTS PAR LA GARANTIE.

31

Page 32

ENTRETIEN

AVERTISSEMENT:

NE PAS effectuer ces

procédures alors que

le réchaud est en marche.

Coupez l'alimentation et attendez que le cabinet refroidisse à

température ambiante.

ATTENTION:

Déplacez l’appareil

que si la porte est

bien fermée. Les

charnières et la porte peuvent

subir de graves dommages si

la porte est ouverte lors de la

manipulation du réchaud.

NON!

NON!

ROULETTES

Certains réchauds peuvent être équipés de roulettes av ec roulement à billes comprenant un raccord de graissage afin qu'il puisse

être facilement lubrifié avec un pistolet à graisse. Lubrifiez les roulements au moins une fois tous les six mois.

CHARNIÈRES

Assurez-vous que tous les joints sont scellées et que les charnières ne collent pas. Si nécessaire, utilisez du WD-40 pour empêcher les charnières de coller. Ne pas utiliser d'huile.

INVERSION DE LA PORTE

L’inversion de la porte prend environ 30 minutes et nécessite deux

personnes.

1. Avec un petit tournevis, retirez les couvercles de charnières et

mettre de côté. Le retrait des capots permettra l'accès aux vis

de la charnière à l'intérieur. Retirez les trois vis qui maintiennent chaque charnière au cabinet. NE PAS RETIRER les vis

qui retiennent les charnières à LA PORTE. Retirez la porte, en

prenant soin de ne pas la laisser tomber.

2. Retirez la plaque de gâche et les vis adjacentes à l'ouverture

de la porte du cabinet. Réinstallez la gâche de porte et les vis

sur le côté opposé de l'appareil.

3. Vissez les charnières du côté opposé de la porte.

4. Avec l'aide d'une autre personne, tenir la porte au cabinet et

fixez-la avec les vis retirées à l'étape un. Avant de serrer les

vis, assurez-vous que la porte est encastrée, au niveau et

d'équerre. Replacez les couvre-charnières.

32

Page 33

SCHÉMA ÉLECTRIQUE

SÉRIES HL1 & HL3 HB

Voltage américain: 120 VOLT, 1800 WATT, 15AMP, 1 PH, 60 HZ

Voltage international: 220 VOLT, 1800 WATT, 8.2AMP, 1 PH, 50/60 HZ

SÉRIES HL2 & HL4 HW

Voltage américain: 120 VOLT, 2100 WATT, 17.5 AMP, 1 PH

Voltage international: 220 VOLT, 2100 WATT, 9.5AMP, 1 PH, 50/60 HZ

33

Page 34

PIÈCES ET COMPOSANTES

Utilisez seulement des pièces d'origine du fabricant. L'utilisation de pièces non autorisées peut causer des blessures graves ou des dommages à l'appareil. Les pièces de rechange doivent être installés par un technicien qualifié.

Contactez Carter-Hoffmann avec le modèle et le numéro de série de votre appareil pour obtenir de s

pièces de rechange.

Téléphone: 800-323-9793

Courriel: Service@Carter-Hoffmann.com

Numéro de pièce Séries HL1 & HL Description

18600-0046 Thermostat limite haute température 300°F, arrêt à 250°F

18602-0083 Interrupteur Marche/Arrêt 20 Amp

18602-0031 Couvert d’interrupteur

18608-0010 Bouton - Chaleur

18605-0022 Cordon d’alimentation-8’

18606-0221 Fiche 5-20P

18612-0131 Élément 1700 watt, 120v (Américain)

18613-0136 Élément 1700 watt, 220v (International)

18616-0071 Transformateur (Américain)

18616-0074 Transformateur (International 220v)

18614-0360 Moteur du ventilateur

18614-0321 Ventilateur

18314-0019 Bac de condensation noir de 1.8 qt.

18600-0017 Thermostat

18614-0322 Ventilateur axial

18616-0073 Thermomètre digital

18616-0071 Transformateur pour thermomètre digital

18601-1171 Lampe témoin rouge

Numéro de pièce Séries HL2 & HL4 Description

18600-0046 Thermostat limite haute température 300°F, arrêt à 250°F

18602-0083 Interrupteur Marche/Arrêt 20 Amp

18602-0031 Couvert d’interrupteur

18608-0010 Bouton - Chaleur et Humidité

18605-0022 Cordon d’alimentation—8’

18606-0221 Fiche 5-20P

18612-0131 Élément 1700 watt, 120v (Américain)

18613-0136 Élément 1700 watt, 220v (International)

18612-0132 Élément immersion 350 watt, 120v (Américain)

18612-0137 Élément immersion 350 watt, 220v (International)

18616-0071 Transformateur (Américain)

18616-0074 Transformateur (International 220v)

18614-0322 Ventilateur axial

18614-0360 Moteur du ventilateur

18614-0321 Ventilateur

18314-0019 Bac de condensation noir de 1.8 qt.

18600-0017 Thermostat - chaleur

18600-0016 Thermostat - humidité

18616-0073 Thermomètre digital

18616-0071 Transformateur pour thermomètre digital

18601-1171 Lampe témoin rouge

34

Page 35