Page 1

VVVVTT BByyppaassss IIII CCoonnttrroolllleerr

IInnssttaallllaattiioonn aanndd SSttaarrtt--uupp GGuuiiddee

CARRIER CORPORATION ©2019

A member of the United Technologies Corporation family · Stock symbol UTX · Catalog No. 11-808-601-01 · 1/25/2019

Page 2

www.hvacpartners.com

Document revision history

Verify that you have the most current version of this document from

office.

Important changes are listed in

CARRIER CORPORATION ©2019. All rights reserved throughout the world. i-Vu is a registered trademark of Carrier

Corporation. All other trademarks are the property of their respective owners.

at the end of this document.

or your local Carrier

Page 3

Introduction .................................................................................................................................................................. 1

Installing the VVT Bypass II ......................................................................................................................................... 6

Start-up ....................................................................................................................................................................... 22

Sequence of operation .............................................................................................................................................. 26

To adjust the driver properties.................................................................................................................................. 29

Troubleshooting ......................................................................................................................................................... 35

Compliance ................................................................................................................................................................ 39

Contents

What is a VVT Bypass II? ...................................................................................................................................... 1

Specifications ........................................................................................................................................................ 3

Safety Considerations .......................................................................................................................................... 5

Field-supplied hardware ...................................................................................................................................... 6

Mounting the VVT Bypass II ................................................................................................................................. 7

To mount the controller and actuator .................................................................................................. 7

Wiring the VVT Bypass II for power ................................................................................................................. 12

To wire the controller for power .......................................................................................................... 13

Addressing the VVT Bypass II ........................................................................................................................... 14

Wiring for communications .............................................................................................................................. 14

Wiring specifications for BACnet MS/TP and ARC156 ...................................................................... 14

To wire the controller to the BACnet network .................................................................................... 15

Wiring inputs and outputs ................................................................................................................................ 16

Wiring a Duct Air Temperature sensor to an input ............................................................................ 16

Wiring field-supplied actuators to the analog output ........................................................................ 17

Wiring and mounting the Equipment Touch to the Rnet port ........................................................... 20

Wiring the TruVu™ ET Display to the Rnet port ................................................................................. 21

Configuring the VVT Bypass II's properties .................................................................................................... 22

Performing system checkout ........................................................................................................................... 23

Bypass damper .................................................................................................................................... 23

Variable frequency drive (VFD) ........................................................................................................... 24

Duct static pressure control ............................................................................................................................. 26

LAT monitoring and limiting ............................................................................................................................. 26

Equipment fan off detection ............................................................................................................................ 27

Supply Air Temperature Alarm ........................................................................................................................ 27

Airside linkage .................................................................................................................................................... 27

Air source mode determination....................................................................................................................... 28

Driver ................................................................................................................................................................... 29

Device .................................................................................................................................................................. 30

Notification Classes ........................................................................................................................................... 31

Calendars ............................................................................................................................................................ 32

Common Alarms ................................................................................................................................................ 32

Specific Events ................................................................................................................................................... 33

Switches, Jumpers, Options ............................................................................................................................. 33

Flow Calibration Archive ................................................................................................................................... 33

Act Net Network Details ................................................................................................................................... 34

LED's .................................................................................................................................................................... 35

To get the serial number .................................................................................................................................. 36

To restore factory defaults ............................................................................................................................... 36

To replace the battery ....................................................................................................................................... 37

To clean the airflow sensor orifice .................................................................................................................. 37

FCC Compliance ................................................................................................................................................. 39

CE Compliance ................................................................................................................................................... 39

BACnet Compliance........................................................................................................................................... 39

Page 4

Contents

Appendix A: VVT Bypass II Points/Properties ......................................................................................................... 40

Appendix B: BACnet points list ................................................................................................................................ 45

Document revision history ........................................................................................................................................ 46

Status................................................................................................................................................................... 40

Unit Configuration .............................................................................................................................................. 40

Maintenance ....................................................................................................................................................... 42

Alarms ................................................................................................................................................................. 43

Linkage ................................................................................................................................................................ 43

I/O Points ............................................................................................................................................................ 44

Page 5

What is a VVT Bypass II?

NOTE

Introduction

The VVT Bypass II (#OPN-VVTBP-02), a component of the i-Vu® Control System, regulates the supply duct static

pressure by controlling one of the following:

• The system's bypass damper

The controller's damper actuator provides 45 in/lbs (5 Nm) of torque. If the actuator's torque is insufficient,

the VVT Bypass II can be used to drive an external high-torque actuator. Or, the controller can drive multiple

external damper actuators.

• The air source supply fan's variable frequency drive (VFD)

The VVT Bypass II controller is available in both English or Metric units. The metric version has (-M)

appended to the part number. Everything in this document applies to both versions.

The i-Vu Control System uses linkage to exchange data between the zone terminals and their air source to form a

coordinated HVAC system. The system's air source controller, zone controllers, and bypass controller are linked so

that their data exchange can be managed by one zone controller configured as the VVT Master.

You can disconnect the actuator from the controller and mount them separately, connecting them with just the

actuator cable or using an additional extension cable, up to a maximum distance of 300 feet.

The following illustration shows the VVT Bypass II in a typical i-Vu® Control System.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

1

Page 6

Introduction

NOTE

This document gives instructions for field-installation of a VVT Bypass II in an i-Vu® Control System.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

2

Page 7

Introduction

Specifications

CAUTION

Driver drv_bpopn02

Power 24 Vac ±10%, 50–60 Hz

14 VA power consumption

26 Vdc (25 V min, 28.8 V max)

Single Class 2 source only, 100 VA or less

Actuator Belimo brushless DC motor, torque 45 inch-pounds (5 Nm), runtime 154 seconds

Act Net port To connect the actuator cable and the VVT Bypass II

BACnet port

Rnet port You can connect:

Local Access port For system start-up and troubleshooting

Input 1 input for connecting the Duct air temperature sensor (#33ZCSENDAT)

For communication with the controller network using BACnet ARC156 (156 kbps)

or BACnet MS/TP (9600 bps – 76.8 kbps)

One Equipment Touch, using an external 24 Vac power supply

or

One TruVu™ ET Display, using an external 24 Vdc power supply

Input resolution 10 bit A/D

Analog output 1 analog output, 0–10 Vdc (5 mA max).

The controlled device must have a minimum of 2000 Ohms resistance measured

from its input to ground and must share the same ground as the controller.

Output resolution 8 bit D/A

Integral airflow sensor Precision differential pressure sensor 0–2 in. H2O, sensitive down to ±0.001 in.

H2O. Barbed tapered airflow connections accept 3/16 in. (4.75 mm) I.D. tubing.

Allows for readings across the 0–2 in. H2O range, accurate to ±5% of full flow at 2

in. H2O.

Battery 10-year Lithium CR2032 battery retains the following data for a maximum of

10,000 hours during power outages: control programs, editable properties,

schedules, and trends.

Protection Built-in surge and transient protection for power and communications in

compliance with EN61000-6-1.

Incoming power and network connections are protected by non-replaceable

internal solid-state polyswitches that reset themselves when the condition that

causes a fault returns to normal.

The power, network, input, and output connections are also protected against

transient excess voltage/surge events lasting no more than 10 msec.

To protect against large electrical surges on serial EIA-485

networks, place a PROT485 at each place wire enters or exits the building.

BT485 connector You attach a BT485 (not included) to a controller at the beginning and end of a

network segment to add bias and to terminate a network segment.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

3

Page 8

Introduction

Status indicators LEDs indicate status of communications, running, errors, power, and digital

outputs

Environmental operating

32 to 130°F (0 to 54.4°C), 10–90% relative humidity, non-condensing

range

Storage temperature range -24 to 140°F (-30 to 60°C), 0 to 90% relative humidity, non-condensing

Physical UL94-5VA plenum rated enclosure for installation in plenum (or other space for

environmental air) in accordance with NEC Section 300.22 (c) and (d)

Controller and actuator

overall dimensions

Width:

Height:

8.9 in. (22.7 cm)

5.9 in. (15.0 cm)

Controller and actuator

mounting dimensions

Controller overall

dimensions

Controller mounting

dimensions

Actuator overall dimensions Width:

Actuator mounting

7.1 in. (18.0 cm) from left side controller mounting hole centerline to actuator

mounting hole centerline

Width:

Height:

Depth:

6.4 in. (16.3 cm)

5.7 in. (14.5 cm)

2.1 in. (5.3 cm)

5.3 in. (13.4 cm) from left side controller mounting hole centerline to right side

controller mounting hole centerline

3.0 in. (7.6 cm)

Height:

Depth:

5.9 in. (15.0 cm)

2.5 in. (6.4 cm)

4.4 in. (11.2 cm) from shaft centerline to actuator mounting hole centerline

dimensions

Panel depth 2.5 in. (6.4 cm) minimum

Shaft dimensions Minimum shaft diameter: .25 in. (.64 cm)

Maximum shaft diameter: .63 in. (1.59 cm)

Minimum shaft length: 1.75 in. (4.45 cm)

Weight 1.8 lbs (0.82 kg)

BACnet support Conforms to the BACnet Advanced Application Controller (B-AAC) Standard Device

Profile as defined in ANSI/ASHRAE Standard 135-2012 (BACnet) Annex L,

Protocol Revision 9

Listed by UL-916 (PAZX), cUL-916 (PAZX7), FCC Part 15-Subpart B, Class B, CE

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

4

Page 9

Introduction

Safety Considerations

CAUTION

WARNING Electrical Shock Hazard

WARNING

Air conditioning equipment will provide safe and reliable service when operated within design specifications. The

equipment should be operated and serviced only by authorized personnel who have a thorough knowledge of

system operation, safety devices, and emergency procedures.

Good judgment should be used in applying any manufacturer's instructions to avoid injury to personnel or damage

to equipment and property.

Failure to follow this warning could cause personal injury, death, and/or equipment damage.

Disconnect all power to the unit before performing maintenance or service. Unit may automatically start if power is

not disconnected.

materials such as mercury contactors.

Follow all local, state, and federal laws regarding disposal of equipment containing hazardous

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

5

Page 10

Installing the VVT Bypass II

Field-supplied hardware

Installing the VVT Bypass II

To install the VVT Bypass II:

1 Mount the controller (page 7).

2 Wire the controller for power (page 12).

3 Set the controller's address (page 14).

4 Wire the controller to the BACnet MS/TP or BACnet ARC156 network (page 14).

5 Wire the inputs and outputs (page 16).

Each VVT Bypass II installation requires the following field-supplied components:

• damper

• damper actuator (if high-torque actuator or slaved dampers are required)

• duct air temperature sensor

• transformer— 24 Vac, 40VA

• wiring

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

6

Page 11

Installing the VVT Bypass II

Mounting the VVT Bypass II

To mount the controller and actuator

Mount the VVT Bypass II on the bypass duct damper actuator shaft. For service access, allow at least 1 foot (.3 m)

of clearance between the front of the controller and adjacent surfaces.

To disconnect and mount the controller and actuator separately

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

7

Page 12

Installing the VVT Bypass II

Act Net

Disconnect the actuator from the controller by inserting a screw driver in the slot on the back of the VVT Bypass II

and pressing the tab. The actuator cable or an attached extension cable must connect to the controller's

port.

1 Turn the damper shaft to fully close the damper.

2 Mount the controller to the VVT terminal by sliding the clamp assembly onto the damper shaft.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

8

Page 13

Installing the VVT Bypass II

NOTE

O-ring Bushing

Anti-rotation slot

NOTES

For service access, allow at least 1 foot (.3 m) of clearance between the front of the controller and

adjacent surfaces.

3 Secure the controller and the actuator by installing the screws, anti-rotation slot's bushings, and o-rings that

are supplied with the VVT Bypass II.

○ Center the bushing in the slot. Failure to do so may cause the actuator to stick or bind.

○ The VVT Bypass II must be secured, but loose enough to allow movement. of the damper shaft.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

9

Page 14

Installing the VVT Bypass II

CAUTIONS

must

○ You

use the screws, anti-rotation slot's bushings, and o-rings that are shipped with the VVT Bypass

II.

○ Overtightening the screws so that the controller and actuator cannot move may damage the unit.

4 Hold down the controller’s damper release button and rotate the actuator clamp in the same direction that

closed the damper. Rotate the clamp until it stops, then rotate it back one notch.

5 Release the button.

6 Tighten the actuator clamp to the damper shaft by tightening the two M5 nuts.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

10

Page 15

Installing the VVT Bypass II

High

NOTE

7 Hold down the actuator damper release button and rotate the damper from fully closed to fully open. If the

damper traveled less than 90 degrees, do the following to set the actuator's fully open position:

a) Loosen the appropriate stop clamp screw. See figure below.

b) Move the stop clamp until it contacts the

edge of the actuator cam.

c) Tighten the screw.

8 Hold down the actuator damper release button, rotate the damper to verify that it fully opens and closes, then

release the button.

9

10 Connect the tube provided to the controller's

connector. Using 1/4" poly tubing, connect the other end

to a duct static pressure probe (for example, Dwyer Instruments part #A-491, or the equivalent, for a 6”

length probe) located in the supply air duct downstream of the bypass damper, but before the first branching

of ductwork.

Tubing should be at least 2 ft. (.61 meters) long for stable airflow measurement. The combined high

and low tubing length should not exceed 16.4 ft. (5 meters) in order to ensure accurate measurements.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

11

Page 16

Installing the VVT Bypass II

Low

Wiring the VVT Bypass II for power

WARNING

CAUTIONS

11 Connect the controller's

return.

connector to open space for plenum return or to a room space if using ducted

• The VVT Bypass II is powered by a Class 2 power source. Take appropriate isolation measures when mounting

it in a control panel where non-Class 2 circuits are present.

• Carrier controllers can share a power supply as long as you:

• Maintain the same polarity.

• Use the power supply only for Carrier controllers.

Do not apply line voltage (mains voltage) to the controller's ports and terminals.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

12

Page 17

Installing the VVT Bypass II

To wire the controller for power

Gnd

24 Vac

Gnd

Power

Run

1 To access the screw terminal connectors, lift up the controller's cover by pulling the tabs located on both

sides of the controller's left mounting bracket.

2 Remove power from the power supply.

3 Pull the screw terminal connector from the controller's power terminals labeled

and

.

4 Connect the transformer wires to the screw terminal connector.

5 Apply power to the power supply.

6 Measure the voltage at the VVT Bypass II’s power input terminals to verify that the voltage is within the

operating range of 21.6–26.4 Vac.

7 Connect a 4-inch (10.2 cm) wire from

to the control panel.

8 Insert the screw terminal connector into the VVT Bypass II's power terminals.

9 Verify that the

LED is on and the

LED is blinking.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

13

Page 18

Installing the VVT Bypass II

Addressing the VVT Bypass II

Gnd

24 Vac

Tens (10's

Ones (1's

EXAMPLE

Tens (10's

Ones (1's

10's 1's

1

3

4

5

2

7

8

9

6

0

1

3

4

5

2

7

8

9

6

0

CAUTION

Wiring for communications

NOTE

Wiring specifications for BACnet MS/TP and ARC156

WARNING

You must give the VVT Bypass II an address that is unique on the network. You can address the VVT Bypass II

before or after you wire it for power.

1 If the VVT Bypass II has been wired for power, pull the screw terminal connector from the controller's power

terminals labeled

2 Using the rotary switches, set the controller's address. Set the

address, and set the

the

If the controller’s address is 25, point the arrow on the

and

) switch to 5.

. The controller reads the address each time you apply power to it.

) switch to the tens digit of the

) switch to the ones digit.

) switch to 2 and the arrow on

The factory default setting is 00 and must be changed to successfully install your VVT Bypass

II.

The VVT Bypass II communicates using BACnet on the following types of network segments:

• MS/TP communicating at 9600 bps, 19.2 kbps, 38.4 kbps, or 76.8 kbps

• ARC156 communicating at 156 kbps

For more networking details, see the Open Controller Network Wiring Installation Guide.

Cable: 22 AWG or 24 AWG, low-capacitance, twisted, stranded, shielded copper wire

Maximum length: 2000 feet (610 meters)

Do not apply line voltage (mains voltage) to the controller's ports and terminals.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

14

Page 19

Installing the VVT Bypass II

To wire the controller to the BACnet network

WARNING

Act Net

Gnd

24 Vac

Net +, Net -

Shield

NOTE

For...

Set BACnet ARC156 or MS/TP

jumper to...

Set DIP switches 1 and 2 to...

ARC156

MS/TP

MS/TP Baud

NOTE

terminating resistors on that network.

1 Pull the screw terminal connector from the controller's power terminals labeled

2 Check the communications wiring for shorts and grounds.

3 Connect the communications wiring to the controller’s screw terminals labeled

4 Set the communication type and baud rate.

Attaching any ARCNET or MS/TP network to the

Use the same polarity throughout the network segment.

port damages BT485s, DIAG485s, or

and

.

, and

.

ARC156

MS/TP

Use the same baud rate for all controllers on the network segment.

5 If the VVT Bypass II is at either end of a network segment, connect a BT485 to the VVT Bypass II.

6 Insert the power screw terminal connector into the VVT Bypass II's power terminals.

7 Verify communication with the network by viewing a Module Status report in the i-Vu® interface.

N/A. Baud rate will be 156 kbps regardless of the

The appropriate baud rate. See the

DIP switch settings.

diagram on the controller.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

15

Page 20

Wiring inputs and outputs

WARNING

CAUTION

Wiring a Duct Air Temperature sensor to an input

NOTE

warning could cause electrical shock, personal injury, or damage to the controller.

Disconnect electrical power to the VVT Bypass II before wiring it. Failure to follow this

• Do not run sensor or relay wires in the same conduit or raceway with Class 1 AC or DC service wiring.

• Do not abrade, cut, or nick the outer jacket of the cable.

• Do not pull or draw cable with a force that may harm the physical or electrical properties.

• Avoid splices in any control wiring.

Part #33ZCSENDAT

The VVT Bypass II must be connected to a Duct Air Temperature (DAT) sensor that monitors the temperature

of the air delivered by the air source.

This document gives instructions for wiring the sensor to the VVT Bypass II. For mounting and wiring

the sensor, see the Carrier Sensors Installation Guide.

Wiring specifications

Cable from sensor to controller: If <100 ft (30.5 meters) 22 AWG, unshielded

If >100 ft (30.5 meters) 22 AWG, shielded

Maximum length: 500 feet (152 meters)

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

16

Page 21

Installing the VVT Bypass II

NOTE

Wiring field-supplied actuators to the analog output

NOTE

To wire and mount the DAT sensor

1 Wire the sensor to the controller. See diagram below.

Sensor wiring does not have polarity. The wires can be connected to either terminal.

2 Using electrical tape, insulate any exposed wire to prevent shorting.

You can wire a high-torque actuator or parallel actuators to the controller's 0–10 Vdc analog output.

You cannot use the VVT Bypass II's actuator if wiring external actuator(s) to the analog output.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

17

Page 22

Installing the VVT Bypass II

NOTE

High-torque actuators

You can wire one of the following Belimo actuators to the VVT Bypass II's analog output instead of using the

controller's 45 in.-lb (5 Nm) actuator.

NMX24-MFT P-10028 90 in.-lb (10 Nm) actuator with 0–10 Vdc control and 0–10 Vdc

feedback

AMX24-MFT P-10028 180 in.-lb (20 Nm) actuator with 0–10 Vdc control and 0–10 Vdc

feedback

1 Install the actuator according to the manufacturer's instructions.

2 Wire the actuator to the controller using the diagram below.

For proper operation and to prevent damage to the devices, use the same polarity for the actuator's

power and the VVT Bypass II's power.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

18

Page 23

Installing the VVT Bypass II

NOTE

Linked actuators

You can wire up to 4 of the following Belimo actuators to the VVT Bypass II's analog output. Link actuators

whose travel times and other parameters coincide.

LMX24-MFT P-10028 45 in.-lb (5 Nm) actuator with 0–10 Vdc control

NMX24-MFT P-10028 90 in.-lb (10 Nm) actuator with 0–10 Vdc control

AMX24-MFT P-10028 180 in.-lb (20 Nm) actuator with 0–10 Vdc control

1 Install the actuators according to the manufacturer's instructions.

2 Wire the actuators to the controller using the diagram below.

3 Set the direction rotation switch on each actuator to CW.

Maintain polarity if using the same power supply for more than one actuator.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

19

Page 24

Installing the VVT Bypass II

Wiring and mounting the Equipment Touch to the Rnet port

CAUTION

CAUTION

Rnet+

Rnet-

NOTE

Gnd

NOTE

provided by the equipment may be impaired.

For complete Equipment Touch installation instructions including wiring diagrams, see the Equipment Touch

Installation and Setup Guide.

Mounting

The Equipment Touch must be mounted within the building interior. You can mount the Equipment Touch:

• In a panel with the controller or on the panel door

• On a wall up to 500 feet from the controller

Wiring

• The Equipment Touch requires a 24 Vac power supply. It is not powered by the Rnet.

you:

○ Maintain the same polarity.

○ User the power supply only for Carrier controllers.

• You can also wire an external 10 kOhm, Type II thermistor (Carrier part# 33ZCT55SPT) to the Equipment

Touch.

Only one Equipment Touch can be connected to the Rnet, using a 2-conductor cable instead of the standard

4-conductor Rnet cable and follow the instructions below.

1 Turn off the VVT Bypass II's power.

2 Partially cut, then bend and pull off the outer jacket of the cable. Do not nick the inner insulation.

If the equipment is used in a manner not specified by the manufacturer, the protection

The Equipment Touch can share a power source with the Carrier controller as long as

1 Strip about .25 inch (.6 cm) of the inner insulation from each wire.

2 Wire the VVT Bypass II's

Touch's connector.

If using shielded wire, connect the shield wire and the ground wire to the

3 Connect the Equipment Touch to an external 24 Vac power source.

4 Turn on the VVT Bypass II's power.

5 Turn on the Equipment Touch.

You do not need to set an address for the Equipment Touch.

and

terminals to the terminals of the same name on the Equipment

terminal.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

20

Page 25

Installing the VVT Bypass II

Wiring the TruVu™ ET Display to the Rnet port

WARNING

24V DC

CAUTION

NOTE

RS485

Rnet

Gnd

Gnd, +

Rnet

+, -

Rnet -

Wiring power

Do not apply line voltage (main) - 24 Vdc power only.

Wire the TruVu™ ET Display

connector to the 24 Vdc power supply using 2-conductor 18 AWG wire.

Maximum distance 100 feet (30 meters).

The TruVu™ ET Display can share a power supply with the Carrier controller as long as:

• The power supply is DC power.

• You maintain the same polarity.

• You use the power source only for Carrier controllers.

Purchase a power supply from a third-party manufacturer.

Wiring communication

1 Turn off the VVT Bypass II's power.

2 Wire the TruVu™ ET Display's

to

using 2-conductor 22 AWG wire with a maximum distance of 500 feet (152 meters).

connector to the <ALCProduct>'s

port,

to

to

3 Turn on the VVT Bypass II's power.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

21

Page 26

Start-up

This interface...

Provides a...

Field Assistant

Equipment Touch

i-Vu®

System Touch

CAUTION

Configuring the VVT Bypass II's properties

NOTE

Start-up

Use one of the following interfaces to start up, access information, read sensor values, and test the controller.

application -

Runs on a laptop that connects to controller's Local Access port

device -

2

Connects to controller's Rnet port

application

Available for BACnet systems only

device

Available only for BACnet MS/TP systems.

1

Temporary or permanent

interface

Permanent interface

Temporary or permanent

interface

Temporary interface

Wire to a BACnet MS/TP network connector and a 24 Vac power supply 3

1

Requires a USB Link (Part #USB-L).

2

See the Equipment Touch Installation and Setup Guide for detailed instructions.

3

See the System Touch Installation and Setup Guide for detailed instructions.

If multiple controllers share power but polarity was not maintained when they were wired,

the difference between the controller's ground and the computer's AC power ground could damage the USB

Link and the controller. If you are not sure of the wiring polarity, use a USB isolator between the computer

and the USB Link. Purchase a USB isolator online from a third-party manufacturer.

To start up the VVT Bypass II, you must configure certain points and properties. Appendix A (page 40) is a

complete list of all the points and properties, with descriptions, defaults, and ranges. These properties affect

the unit operation and/or control. Review and understand the meaning and purpose of each property before

changing it.

See Appendix A (page 40) for a complete list of the controller's points/properties.

Engineering units shown in this document in the defaults and ranges are strictly for reference. You

must enter an integer only.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

22

Page 27

Start-up

Performing system checkout

Bypass damper

Properties

Control Program > Configuration > Service Configuration

Service Test

Service Test

Service Test

Properties

Control Program > Unit

Configuration

Bypass Control

Details

Damper Full Close

Damper Full Open

Zero Cal

Done

Apply

Properties > Control

Program

Configuration > Service Configuration > Service Test

Fan Test

Service Test

Properties

Control Program > Unit

Configuration

Bypass Control

Details

Target Damper Position

Duct Static

Pressure

Target Damper Position

Duct Static Pressure Setpoint

High

Duct

Static Pressure

Pressure Sensor Cal

Apply

High

Automatic Control

1 Verify the VVT Bypass II is securely fastened to the bypass damper shaft and duct work.

2 Verify duct air temperature sensor is installed at the inlet of the damper or in the air source supply duct

upstream of the bypass damper connection.

3 Verify that the high pressure tubing from the controller's airflow (pressure) sensor is connected to the

duct static pressure probe downstream of the bypass damper. Then verify that the low pressure

connector is not blocked.

4 Calibrate damper and pressure sensor:

a) Disable the air source heating, cooling, and fan outputs using one of the following methods:

• Physically disconnect the air source controller’s output wiring to the unit.

• In the i-Vu® or Field Assistant navigation tree, select the RTU Open controller. Go to

Make sure all

other outputs under

b) Select the Bypass controller in the tree, then go to

c) Click

d) Click

e) Click

f) Enable the air source fan output using one of the following methods:

g) Select the Bypass controller in the tree, then go to

h) After the static pressure has stabilized, make sure that

i) Using a branch-tee, connect a magnehelic gauge to the

j) Remove the magnehelic gauge from the

k) Click

.

• Physically connect the air source controller’s fan enable wiring at the unit.

• In the i-Vu® or Field Assistant tree, select the RTU Open controller. Go to

other outputs under

adjust the

sensor, then measure the static pressure. If the measured static pressure is different from the

the button, then click

>

to close the bypass damper and zero the pressure sensor. When

>

>

are not locked and that

, then verify that the damper is fully closed.

, then verify that the damper is fully open.

by ±.05 in. (+.012 kPa), click

to return the bypass to normal control.

are disabled.

>

tab.

are disabled.

>

tab.

slightly to get the damper within this range.

.

connector, then reinsert the pressure tubing.

>

>

, then enable

>

is >0% and <100%. You may have to

connector on the controller's airflow

, then enable

, enter the measured value next to

. Make sure all

appears, click

and

>

.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

23

Page 28

Start-up

Properties > Control

Program > Configuration > Service Configuration > Service Test

Service Test

Fan

Test

Service Test

CAUTION

Variable frequency drive (VFD)

VFD/ACT

Properties > Control Program

Unit Configuration

Control Device Type

VFD

Properties

Control Program > Configuration > Service Configuration

Service Test

Service Test

Service Test

Properties

Control Program > Unit

Configuration

Bypass Control

Details

Damper Full Open

VFD/ACT

Gnd

Damper Full Close

VFD/ACT

Gnd

Zero Cal

Done

Apply

Properties > Control

Program

Configuration > Service Configuration > Service Test

Fan Test

Service Test

Properties

Control Program > Unit

Configuration

Bypass Control

Details

Target Damper Position

Duct Static

Pressure

Target Damper Position

Duct Static Pressure Setpoint

l) Enable the air source’s heating and cooling outputs using one of the following methods:

• Reconnect the air source controller’s output wiring at the unit.

• In the i-Vu® or Field Assistant tree, select the RTU Open controller. Go to

. Make sure all other outputs under

are disabled.

, then disable

and

Pressing the actuator release button and moving the damper or disconnecting the actuator

ribbon connector while the bypass controller is powered will cause the damper position to be out of

calibration. To recalibrate the damper position, you must perform steps 4c and 4d above or power cycle the

controller.

1 Verify that the controller's

configured for a 0-10 Vdc control signal.

2 In the i-Vu® or Field Assistant tree, select the Bypass controller. Go to

3 Verify duct air temperature sensor is installed in the air source supply duct.

4 Verify that the high pressure tubing from the controller's airflow (pressure) sensor is connected to the

duct static pressure probe downstream of the bypass damper. Then verify that the low pressure

connector is not blocked.

5 Calibrate the VFD and pressure sensor:

a) Disable the air source heating, cooling, and fan outputs using one of the following methods:

• Physically disconnect the air source controller’s output wiring to the unit.

• In the i-Vu® or Field Assistant navigation tree, select the RTU Open controller. Go to

Make sure all

other outputs under

b) Select the Bypass controller in the tree, then go to

c) Click

d) Click

e) Click

>

to zero the pressure sensor. When

f) Enable the air source fan output using one of the following methods:

• Physically connect the air source controller’s fan enable wiring at the unit.

• In the i-Vu® or Field Assistant tree, select the RTU Open controller. Go to

>

other outputs under

g) Select the Bypass controller in the tree, then go to

>

h) After the static pressure has stabilized, make sure that

adjust the

are not locked and that

, then verify that

, then verify the voltage at

, then verify the voltage at

output wiring is correctly connected to the VFD and that the VFD is

is set to

.

>

, then enable

are disabled.

>

tab.

>

and

and

appears, click

is 0 Vdc.

is 10 Vdc.

.

, then enable

. Make sure all

are disabled.

>

tab.

>

and

is >0% and <100%. You may have to

slightly to get the damper within this range.

>

>

.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

24

Page 29

Start-up

High

Duct

Static Pressure

Pressure Sensor Cal

Apply

High

Automatic Control

Properties > Control

Program > Configuration > Service Configuration > Service Test

Service Test

Fan

Test

Service Test

i) Using a branch-tee, connect a magnehelic gauge to the

connector on the controller's airflow

sensor, then measure the static pressure. If the measured static pressure is different from the

the button, then click

j) Remove the magnehelic gauge from the

k) Click

by ±.05 in. (+.012 kPa), click

.

to return the bypass to normal control.

, enter the measured value next to

connector, then reinsert the pressure tubing.

l) Enable the air source’s heating and cooling outputs using one of the following methods:

• Reconnect the air source controller’s output wiring at the unit.

• In the i-Vu® or Field Assistant tree, select the RTU Open controller. Go to

. Make sure all other outputs under

are disabled.

, then disable

and

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

25

Page 30

Sequence of operation

Duct static pressure control

NOTE

NOTE

NOTE

LAT monitoring and limiting

Minimum Cooling SAT

Maximum Heating SAT

LAT Duct Static Pressure

Setpoint

LAT Duct Static Pressure Setpoint

Maximum Heating SAT

Minimum Cooling SAT

Controlling Pressure Setpoint

LAT Airflow Increase

Sequence of operation

The VVT Bypass II maintains supply duct static pressure under all system operating conditions and can

operate as part of a linked VVT system or as a stand-alone controller.

The VVT Bypass II modulates a bypass damper or VFD to maintain the static pressure in the supply duct of the

pressure-dependent VVT system. The VVT Bypass II has a damper actuator that provides 45 in./lbs (5 Nm) of

torque.

You can use the controller's 0–10 Vdc output to:

• Drive a larger actuator if the VVT Bypass II's actuator's torque is insufficient. The actuator must be

installed so that 0 volts causes the bypass damper to fully open. See

actuator.

below and High-torque

• Drive multiple damper actuators from a single bypass controller. See

• Control a VFD

You cannot use the VVT Bypass II's actuator if external actuator(s) are wired to the analog output.

If linkage is active, normal duct static pressure control is overridden if the linked air source is in either of the

following modes:

• Fire shutdown or evacuation mode – The bypass damper will be fully open. If controlling a VFD, the VFD

output will be at 0%.

• Pressurization mode – The bypass damper will be fully closed. If controlling a VFD, the VFD output will be

at 100%.

To protect the air source from excessive supply air temperature conditions, the VVT Bypass II monitors the

supply air temperature. If the temperature reaches either the

the

which increases airflow through the air source.

The amount of increase in airflow is related to the square root of the pressure increase. For example, a 25%

increase in airflow at 1 in. (.249 kPa) of static pressure would require a 56% increase in duct static pressure

[1 in.H2O (.249 kPa) * 1.252 = 1.56 in. H2O (.388 kPa)]. The default

in.H

O (.199 kPa) provides a maximum 25% increase in airflow over the default Duct Static Pressure Setpoint

2

of .5 in.H

the

O (.125 kPa). [.5 in.H2O (.125 kPa)* 1.252 = .75 [~.8] in.H2O (.199 kPa)]. When the LAT exceeds

2

condition and displays the

[120° F (48.9°C) default], the Bypass controls to the

or

below and Linked actuators.

[45°F (7.2°C) default] or

of 0.8

, the controller detects and indicates the excessive LAT

and the associated

(%).

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

26

Page 31

Sequence of operation

Supply Air Temperature Alarm

Equipment fan off detection

Supply Air Temperature Alarm

Maximum

Heating SAT

Minimum Cooling SAT

Airside linkage

The Bypass does not resume normal control to the Duct Static Pressure Setpoint until the SAT drops 15 °F

(8.3

°C) below the Maximum Heating Sat or rises 7 °F (3.9 °C) above the Minimum Cooing Setpoint.

If the supply air temperature exceeds the configured limits, a

is generated. If

Linkage is active, the controller monitors the supply air temperature from the equipment rather than its own

temperature input for faster response.

The VVT Bypass II continuously monitors its damper's position and the supply duct static pressure. If the

pressure drops below 10% of the nominal setpoint and the bypass damper is fully closed (or VFD is

commanded to maximum speed), after 1 minute the controller assumes that the equipment fan turned off.

The bypass damper then modulates to 65% open and the VFD speed is commanded to 35% (3.5 volts) to

facilitate a fan restart. The controller monitors the static pressure to determine when the equipment fan

restarts. If it rises above 10% of the nominal pressure setpoint, the controller assumes the fan restarted and

controls to maintain the duct static pressure setpoint. If Linkage is active, the air source mode is provided to

the VVT Bypass II.

The VVT Bypass II generates an alarm if the supply air temperature remains above the configured

or below the configured

When the VVT Bypass II is part of a linked system, it uses data received through Linkage (equipment SAT and

mode) to detect excessive leaving air temperature (LAT) conditions at the equipment and equipment

operating mode.

for more than 5 minutes.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

27

Page 32

Sequence of operation

Air source mode determination

Linked air source modes

OFF

WARMUP

HEAT

FREECOOL

COOL

PRESSURIZATION

EVACUATION

VENT

– In a linked system, the air source determines its operating mode and qualifies

that mode based on its own SAT. The following modes can be sent by the air source depending on its

capability and configuration:

Air source fan is off. Terminal damper is positioned approximately 70%

open to allow for system restart.

Air source fan is on and providing first cycle of heat when changing from

unoccupied to occupied. It may also be used as an equipment safety to

increase system airflow. The terminal’s heating setpoint temporarily

increases to the midpoint between the configured occupied heating and

occupied cooling setpoints.

Air source fan is on and providing heat. The terminal modulates its primary

air damper to maintain the current heating setpoint.

Air source fan is on and providing cooling using only the economizer and

usually during an unoccupied period. The terminal modulates its primary air

damper to maintain the midpoint between the configured occupied heating

and occupied cooling setpoints.

Air source fan is on and providing cooling. The terminal modulates its

primary air damper to maintain the current cooling setpoint.

Air source supply fan is on usually as a result of a fire-life safety input being

active. It may also be used as an equipment safety to increase system

airflow. The terminal modulates its primary air damper to provide the

configured maximum cooling airflow.

Evacuation is usually the result of a fire-life safety input at the air source

being active. The terminal fully closes its primary air damper and disables

its terminal fan, if equipped.

All terminals treat VENT mode the same as the COOL mode. For VVT

terminals, VENT modes allows for an increase in airflow. VVT terminals use

the greater of the configured Vent Damper Position or the Minimum Cooling

Damper Position as the minimum during the VENT mode.

See the air source’s installation manual for more specific operation.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

28

Page 33

To adjust the driver properties

Driver Properties

Properties

Driver

Driver

Driver

Settings

TouchScreen Control

TouchScreen Schedule Edit

Enable

Module Clock

Clock Fail Date and Time

TIP

Time Synch Sensitivity

(seconds)

Network Microblocks

Number of poll retries before

Network Input Microblocks

indicate failure

Periodic rebinding interval

To adjust the driver properties

Use the following if you want to change the driver's properties in the i-Vu® interface.

1 On the i-Vu® navigation tree, right-click the VVT Bypass II and select

2 Make changes as needed on the

page for

and any of its children.

.

On the

page >

below.

tab, you can change the Module clock synchronization and failure. See table

This field is checked automatically to allow a user to edit this controller's

schedules from an Equipment Touch's Schedules screen. Uncheck to disable.

Date and time the control program uses when controller's time is invalid.

Use an occupied date and time (such as a Tuesday at 10 a.m.) so the

equipment does not operate in unoccupied mode if the controller loses power

during occupancy.

When the controller receives a time sync request, if the difference between the

controller's time and the time sync's time is greater than this field's value, the

controller's time is immediately changed. If the difference is less than this field's

value, the controller's time is slowly adjusted until the time is correct.

The maximum number of retries after the initial attempt that a Network

microblock will attempt to communicate with its target device. If unsuccessful, the

point will transition to an idle state for 30 seconds before attempting to

communicate again. Change this field only if directed by Technical Support.

If a microblock uses a wildcard in its address, this timer determines how often the

microblock will attempt to find the nearest instance of its target. For example, if

an outside air temperature address uses a wildcard, a VAV application will look for

the outside air temperature on the same network segment or on the nearest

device containing that object.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

29

Page 34

To adjust the driver properties

BACnet COV Throttling

Enable COV Throttling

Excessive COV

Common Alarms

Trend Sampling

Collect a daily midnight

sample for all points in this

controller that are sampling

on COV

Device

Device

Configuration

NOTE

Max Masters and Max Info

Frames

Under normal circumstances, COV Throttling should be enabled to prevent

excessive network traffic if an object's COV Increment is set too low. See

EXCEPTION below.

When enabled, if an object generates excessive COV broadcasts (5 updates in 3

seconds), the driver automatically throttles the broadcasts to 1 per second. Also,

if the object's value updates excessively for 30 seconds, an alarm is sent to the iVu® application listing all objects that are updating excessively. A Return-tonormal alarm is sent only after all objects have stopped updating excessively.

EXCEPTION: In rare circumstances, such as process control, a subscribing object

may require COV updates more frequently than once per second. For these

situations, clear this checkbox, but make sure that your network can support the

increased traffic. You will also need to disable the

the driver's

.

alarms under

For values that change infrequently, select to verify at midnight daily that the

point is still able to communicate trend values.

On the

• BACnet device object properties for the VVT Bypass II

• VVT Bypass II network communication

page, you can view the following properties:

The three APDU fields refer to all networks over which the VVT Bypass II

communicates.

Apply only if the VVT Bypass II is on an MS/TP network.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

30

Page 35

To adjust the driver properties

Notification Classes

Priorities

NOTE

Priority range

Network message priority

Priority of Off-Normal

Priority of Fault

Priority of Normal

Ack Required for Off-Normal,

Fault, and Normal

TIP

Alarm

Enable/Disable

Recipient List

Recipients

Add

Recipient Description

Recipients

Recipient Type

Address

Issue Confirmed

Notifications). This use is rare.

Recipient Device Object

Identifier

Device Instance

#

Process Identifier

Issue Confirmed

Notifications

Transitions to Send

Alarms in the i-Vu® application use Notification Class #1. A BACnet alarm's Notification Class defines:

• Alarm priority for Alarm, Fault, and Return to Normal states

• Options for BACnet alarm acknowledgment

• Where alarms should be sent (recipients)

00–63 Life Safety

64–127 Critical Equipment

128–191 Urgent

192–255 Normal

BACnet priority for Alarms.

BACnet priority for Fault messages.

BACnet priority for Return-to-normal messages.

BACnet defines the following Network message priorities for Alarms and

Events.

Specifies whether alarms associated with this Notification Class require a BACnet

Acknowledgment for Off-Normal, Fault, or Normal alarms.

You can require operator acknowledgment for an Alarm or Return-to-

normal message (stored in the i-Vu® database). In the i-Vu® interface on the

>

source or an alarm category.

tab, change the acknowledgment settings for an alarm

The first row in this list is from the i-Vu® application. Do not delete this row. Click

if you want other BACnet devices to receive alarms associated with this

Notification Class.

Name that appears in the

Use

table.

(static binding) for either of the following:

• Third-party BACnet device recipients that do not support dynamic binding

When you want alarms to be broadcast (you must uncheck

•

Days and times The days and times during which the recipient will receive alarms.

Type the

the

field.

from the network administrator for third-party devices in

Change for third-party devices that use a BACnet Process Identifier other than 1.

The i-Vu® application processes alarms for any 32-bit Process Identifier.

Select to have a device continue sending an alarm message until it receives

delivery confirmation from the recipient.

Uncheck the types of alarms you do not want the recipient to get.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

31

Page 36

To adjust the driver properties

Calendars

Schedules

Common Alarms

Common alarms:

• Module Halted

Excessive COV

Module Generated Alarm

Description

Alarms

Events

Alarm Category and Alarm

Template

Enable

Notification Class

Calendars are provided in the driver for BACnet compatibility only. Instead, use the

Vu® interface.

On these pages, you can enable/disable, change BACnet alarm properties, or set delays for the following

BACnet alarms:

• All Programs Stopped

• Duplicate Address

• Locked I/O

• Control Program

• Program Stopped

•

Short message shown on the i-Vu®

type of alarm is generated.

feature in the i-

page or in an alarm action when this

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

32

See Alarms in i-Vu® Help.

Clear these checkboxes to disable Alarm or Return to normal messages of this

type from this controller.

Do not change this field.

Page 37

To adjust the driver properties

Specific Events

Specific alarms:

NOTES

Module Generated Alarm

Description

Alarms

Events

Alarm Category and Alarm

Template

Enable

Notification Class

Switches, Jumpers, Options

Switches, Jumpers, Options

Flow Calibration Archive

Flow Calibration Archive

On these pages, you can enable/disable, change BACnet alarm properties, or set delays for the following

BACnet alarms:

• Flow Control Alarm

• Reheat Valve Alarm (future use)

• To set up alarm actions for controller generated alarms, see See Alarms in i-Vu® Help.

• Reheat Valve Alarms are for future use.

Short message shown on the i-Vu®

Clear these checkboxes to disable Alarm or Return to normal messages of this

Do not change this field.

The

page shows the current physical settings on the VVT Bypass II.

type of alarm is generated.

See Alarms in i-Vu® Help.

type from this controller.

page or in an alarm action when this

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

33

The

Test and Balance tool.

page shows measured flow and sensor readings that were entered in the i-Vu®

Page 38

To adjust the driver properties

Act Net Network Details

NOTE

Act Net

CAUTION

Duplicate address on network

No communication with device

Device

Status

Act Net Address Setting

Act Net Statistics

The actuator serial numbers are automatically read and filled in by the i-Vu® application. Only those devices

that are physically connected or in the control program will show in the table.

See To get the Carrier VVT Bypass II serial number (page 36) for the controller serial number.

The

network shows the VVT Bypass II’s actuator has Address 1.

, contact Carrier Control Systems Support. Do not use

If you see

Carrier Control Systems Support.

or

under

unless directed by

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

34

Page 39

Troubleshooting

NOTE

LED's

If this LED is on...

Status is...

Power

Rx

Tx

CW

CCW

Run

Error

If Run LED shows...

And Error LED shows...

Status is...

Run

Run

Run

Troubleshooting

If you have problems mounting, wiring, or addressing the VVT Bypass II, contact Carrier Control Systems

Support.

To help you troubleshoot, obtain a Module Status (Modstat) from the controller and review the System

Error and Warning details.

The LED's on the VVT Bypass II show the status of certain functions. Verify the LED patterns by cycling power

to the controller and noting the lights and flashes.

The VVT Bypass II has power.

The VVT Bypass II is receiving data from the network segment

The VVT Bypass II is transmitting data over the network segment

The actuator motor is turning clockwise

The actuator motor is turning counterclockwise

The

and

LED's indicate controller and network status.

2 flashes per second Off Normal

2 flashes per second 2 flashes,

alternating with

2 flashes per second 3 flashes,

then off

2 flashes per second 1 flash per second The controller is alone on the network

2 flashes per second On Exec halted after frequent system errors or

5 flashes per second On Exec start-up aborted, Boot is running

5 flashes per second Off Firmware transfer in progress, Boot is running

Five minute auto-restart delay after system error

LED

The controller has just been formatted

control programs halted

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

35

7 flashes per second 7 flashes per second,

alternating with

14 flashes per second 14 flashes per second,

alternating with

Ten second recovery period after brownout

LED

Brownout

LED

Page 40

Troubleshooting

If Run LED shows...

And Error LED shows...

Status is...

Replace the VVT Bypass II.

To get the serial number

Core

Main) board hardware

Module Status

To restore factory defaults

CAUTION

Gnd

24 Vac

Format Short pins

Error

Run

On On Failure. Try the following solutions:

If you need the VVT Bypass II's serial number when troubleshooting, the number is on a Module Status report

(Modstat) under

To obtain a modstat in the i-Vu® interface:

1 Select the VVT Bypass II in the navigation tree.

2 Right-click and select

(or

• Turn the VVT Bypass II off, then on.

• Format the VVT Bypass II.

• Download memory to the VVT Bypass II.

•

.

reconfigure all custom settings. It is recommended to restore the factory defaults only under the guidance of

Carrier Control Systems Support.

To erase volatile memory data and restore factory default configuration settings:

1 Pull the screw terminal connector from the controller's power terminals labeled

sure the address switches are not set to 0, 0.

2 Short the

3 Insert the power screw terminal connector into the VVT Bypass II's power terminals.

4 Continue to short the jumper until the

5 Remove the short.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

36

This erases all archived information and user-configuration settings. You will have to

and

jumper’s pins and maintain the short for steps 3 and 4.

LED flashes three times in sync with the

LED.

. Make

Page 41

Troubleshooting

To replace the battery

CAUTION

To clean the airflow sensor orifice

High

Low

If the VVT Bypass II experiences a power outage and the control program stops functioning, replace the

battery.

You need to replace the battery if the voltage measures below 2.9 volts when the controller is not powered.

1 Verify that the VVT Bypass II's power is on.

data will be lost.

2 Remove the VVT Bypass II's cover.

3 Remove the battery from the controller, making note of the battery's polarity.

4 Insert the new battery, matching the battery's polarity with the polarity indicated on the controller's cover.

5 Replace the VVT Bypass II's cover.

6 Download the VVT Bypass II.

If the controller's power is not on when replacing the battery, your date, time, and trend

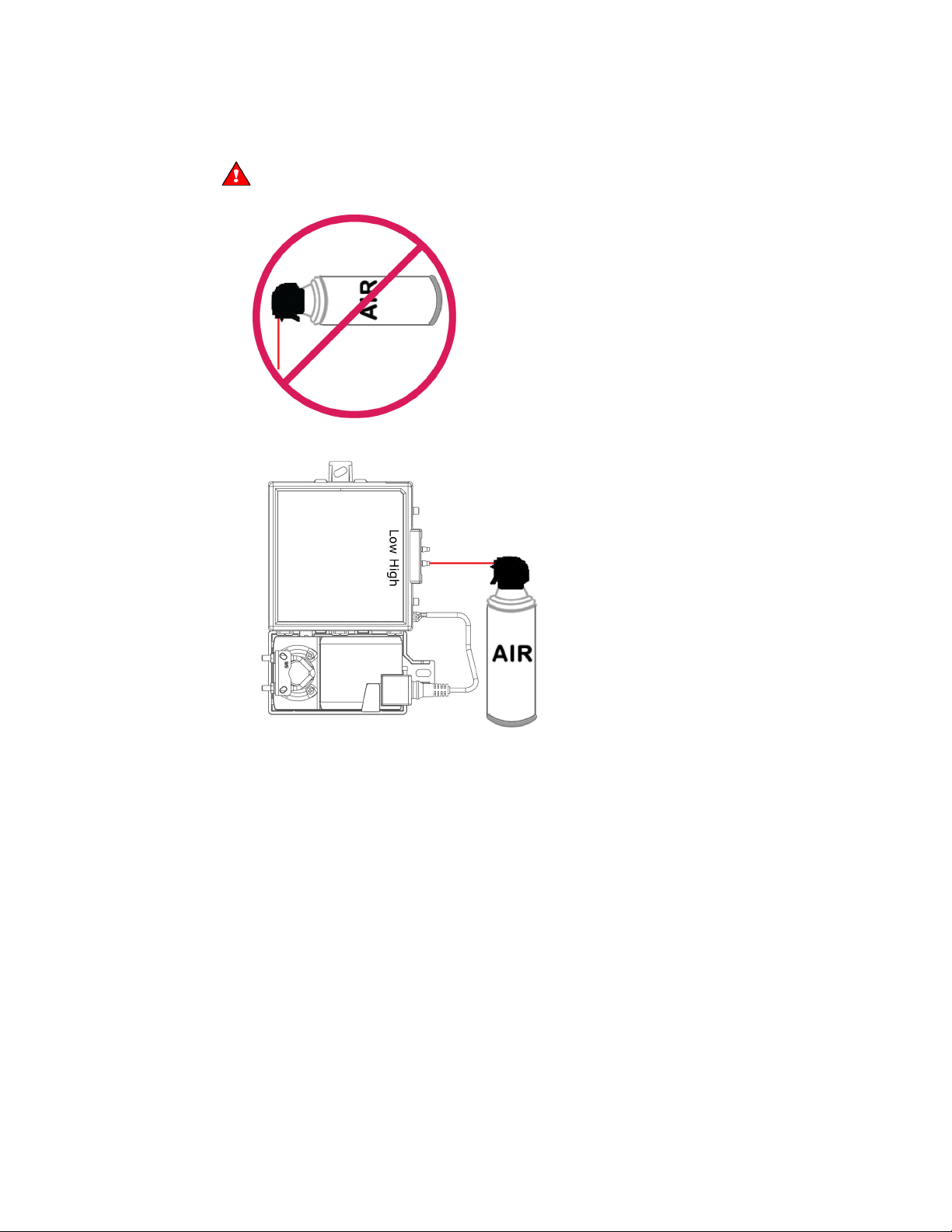

In less than .02% of installations, small particulates (micron/submicron-level) can build up in the airflow

sensor's internal orifice causing airflow restriction. Symptoms of airflow restriction are:

• Diffuser noise increases over time

• Space overcools at minimum airflow

• Frequency of dampers opening to maintain flow setpoint increases over time

• AHU fan speed increases over time

To check for these symptoms, set up trending of:

• Damper position to look for long term increase

• AHU fan speed for maintaining static pressure

If you see these symptoms, you should clean the flow sensor.

To clean the flow sensor

You can use a can of compressed air to clean the sensors while the controller is installed or on a repair

bench.

1 Disconnect the

and

flow sensor tubes.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

37

Page 42

Troubleshooting

High

WARNING

High

Low

2 Insert the compressed air straw 1/4" into the controller's

The compressed air can MUST be upright. It will damage the flow sensors by producing

ice crystals if the can is on its side.

connector.

3 Press the air can's trigger twice for no more than 2 seconds each time.

4 Reconnect tubing to the

and

flow sensor tubes.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

38

Page 43

Compliance

FCC Compliance

IMPORTANT

NOTE

CE Compliance

WARNING

BACnet Compliance

Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1 This device may not cause harmful interference.

2 This device must accept any interference received, including interference that may cause undesired

operation.

user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy, and if it is not installed and used in accordance with this

document, it may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

Any changes or modifications not expressly approved by manufacturer could void the

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This is a Class B product. In a light industrial environment, this product may cause radio

interference in which case the user may be required to take adequate measures.

Compliance of listed products to requirements of ASHRAE Standard 135 is the responsibility of BACnet

International. BTL

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

39

®

is a registered trademark of BACnet International.

Page 44

Appendix A: VVT Bypass II Points/Properties

NOTE

Status

Navigation:

i-Vu® / Field Assistant:

Properties > Control Program > Status

Point Name/Description

Range

Static Pressure - Prime Variable

Supply Air Temperature

Airside Linkage Status

Active

Airside Linkage Status

Not Active

Damper Position

Control Device Type

Actuator

VFD output

Control Device Type

VFD

LAT Control

LAT Airflow Increase

LAT Control

LAT Duct Static Pressure Setpoint

Controlling Pressure Setpoint

Unit Configuration

Navigation:

i-Vu® / Field Assistant:

Properties > Control Program > Unit Configuration

Point Name/Description

Default/Range

Control Device Type

Power Fail Restart Delay

Automatic Deadband Adjustment

Appendix A: VVT Bypass II Points/Properties

Engineering units shown in this document in the defaults and ranges are strictly for reference. You

must enter an integer only.

– The current supply duct static pressure. This value is

shown on the default area graphic in i-Vu or Field Assistant.

– If

is

current supply air temperature. If

the local SAT sensor.

position.

– If

– If

is

is

, this is the current VFD speed capacity. R: 0 to 100%

, this is the current open damper

– The status of LAT Limit duct static pressure override control of the

bypass.

– If

is On, this is the percent of increase in supply

airflow that the overriding

normal

.

, this is the air source’s

is

, this value is from

will provide above the

R:

0 to 2.0 in. H2O

(0 to .498 kPa

R: -56 to 245°F

(-48.9 to 118.3°C)

R: 0 to 100%

R: On/Off

R: 0 to 100%

– The device the controller uses to control static pressure. D:

– How long the controller delays normal operation after the

power is restored.

– If using an actuator, set to Enable to automatically

adjust the damper for full travel to correctly scale the damper position. If using a VFD

drive, set to Disable.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

40

Actuator

R:

Actuator/VFD drive

D:

60 seconds

R:

0 to 600 secs

D:

Enable

R:

Enable/Disable

Page 45

Appendix A: VVT Bypass II Points/Properties

Point Name/Description

Default/Range

Maximum Heating SAT

LAT Duct Static Pressure Setpoint

Supply Air Temperature Alarm

Minimum Cooling SAT

Supply Air Temperature Alarm

Pressure Control Deadband

CAUTION

Bypass Control

Direction Clockwise

Duct Static Pressure Setpoint

LAT Duct Static Pressure Setpoint

Maximum Heating SAT

Minimum Cooling SAT

Duct Static Pressure Setpoint

Locks

CAUTION

Duct Static Pressure

Target damper position

– The value that the SAT must exceed to cause the static

pressure setpoint to be set to the

. This is also the

's high limit.

– The minimum low limit value that the SAT must exceed to

cause the static pressure setpoint to be set to the LAT Duct Static Pressure Setpoint.

This is also the

's low limit.

– The amount that is added to and subtracted from the

bypass controlling setpoint (Duct Static Pressure Setpoint or LAT Duct Static Pressure

Setpoint). When the static pressure is within the controlling setpoint +/- this value, the

output to the actuator or VFD drive maintains at its current position. When the static

pressure is greater than the controlling setpoint +/- this value, the output modulates

accordingly.

If this value is too low, the damper may oscillate to maintain the static

pressure. This could cause the actuator to fail prematurely.

clockwise.

(Only in the i-Vu®/Field Assistant applications)

controller will maintain.

controller will maintain if the SAT exceeds the

– Set this field to the damper's position when it rotates

– The normal static pressure setpoint the

– The static pressure setpoint that the

or

value. To disable this function, set this value less than

or equal to the

.

D:

120°F (48.9°C)

R:

40 to 180°F

(4.4 to 82.2°C)

D:

45°F (7.2°C)

R:

40 to 180°F

(4.4 to 82.2°C)

D:

.05 in H

R:

0 to 2.0 in. H2O

2

(0 to .498 kPa

D:

Close

R:

Open/Close

D:

.5 in. H2O (.125 kPa)

R:

.1 to 2.0 in. H2O

(.025 to .498 kPa)

D:

.8 in. H

R:

.1 to 2.0 in. H

O (.199 kPa)

2

(.025 to .498 kPa)

O (.012 kPa)

O

2

ductwork.

testing and troubleshooting.

damper/VFD for the purpose of testing and troubleshooting.

VVT Bypass II Controller CARRIER CORPORATION ©2019

Installation and Start-up Guide All rights reserved

41

–

Overriding these values may damage equipment or

– Lets you override the static pressure sensor input for

– Allows you to override the normal control of the

R:

0 to 2.0 in. H

O

2

(0 to .498 kPa

R: 0 to 100%

Page 46

Appendix A: VVT Bypass II Points/Properties

Point Name/Description

Default/Range

Test and Balance

Zero Cal

Pressure Sensor Cal

Damper Full Open

Automatic Control

This

must be activated when you finish using any of the other Test and Balance

commands.

Damper Full Close

Local Sensor Calibration

Supply Air Temperature

Supply Air Temp Calibration

Maintenance

Navigation:

i-Vu® / Field Assistant:

Properties > Control Program > Maintenance

Point Name/Description

Range

Static Pressure

Controlling Pressure Setpoint

Maximum Duct Pressure Setpoint

Minimum Duct Pressure Setpoint