Carrier OMNIZONE 50XCA06-24, OMNIZONE 50XCA06, OMNIZONE 50XCA08, OMNIZONE 50XCA12, OMNIZONE 50XCA14 Product Data

...

Product

a50-8499

Data

OMNIZONE™

50XCA06-24

Air-Cooled

Indoor Self-Contained Systems

with PURON

®

Refrigerant (R-410A)

5 to 20 Nominal Tons

The 50XCA single-package cooling

units with integral air-cooled condensers

offer:

• Compact, durable, and attractive

cabinet fits any working environment

• Available in ducted or free return with

rear return connections with vertical

supply air discharge

• Provides high-efficiency cooling for

commercial and industrial projects

• Rear condenser inlet and discharge

and belt drive condenser fan permit

condenser air connections to be

ducted through window or wall louver

• Uses Puron

®

refrigerant (R-410A)

Features/Benefits

The Omnizone 50XCA units

provide a practical and

economical approach to

comfort conditioning

requirements for offices,

factories, and other

applications in existing

buildings when indoor aircooled condensers are

required.

Design flexibility

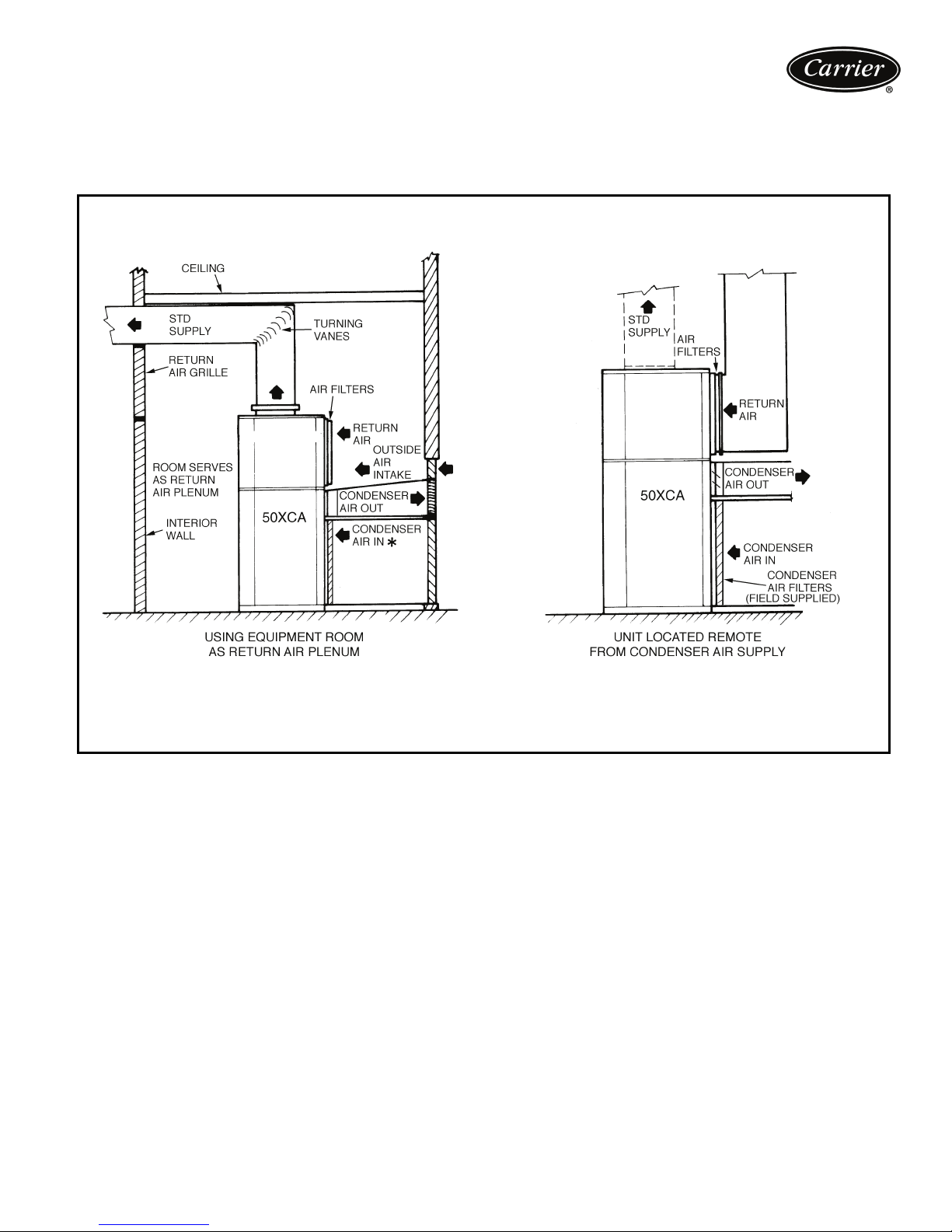

The 50XCA indoor packaged units are

designed to provide the flexibility required in replacement, renovation, and

new construction. Units are available in 6

sizes from 5 tons to 20 tons which meet

the needs for cooling restaurants, retail

stores, warehouses, offices, and building

additions.

Copyright 2010 Carrier Corporation Form 50XCA-1PD

Features/Benefits (cont)

The compact footprint and service

from the front of the units save valuable floor space in equipment rooms.

Belt drive condensers provide adequate

static to overcome ducting and louver

static losses. This allows units to be positioned against an existing window or

wall louver, or ducted to the outside, as

required. These units can be installed

in the equipment room or the conditioned space and used for either ducted

or free return applications. Unit supply

air discharge is vertical.

Easy installation and

maintenance

The units are completely pre-piped

and wired at the factory to ensure time

and money saving installation and service. Exterior access panels are easily

removed to provide speedy inspection,

and service work may be done from

the front of the unit. Precision engineered parts translate to a quality built,

reliable design that will operate efficiently, minimize service calls, and provide years of reliable operation.

Designed for customer

satisfaction

Where space and styling are important

considerations, 50XCA units are designed to exceed expectations. The

high quality baked enamel finish will fit

any environment attractively. These

packaged systems provide the user

with economy and product satisfaction

in cooling, dehumidification, filtering,

and air circulation.

Efficient design to increase

savings

In order to provide an energy efficient

HVAC solution, all 50XCA units have

been designed to exceed the ASHRAE

90.1 (2010) guidelines.

• Space-saver slab type evaporator

and condenser coils use advanced

heat transfer technology and provide peak heat transfer efficiency

with large coil face area. Fins are

mechanically bonded to nonferrous, seamless tubing for efficient

leak-free operation.

• Quiet fan performance moves large

volumes of indoor air. Compact

housing and specially designed discharge air section provide superior

air-handling capacity.

• Convenient front access electrical

control center contains all factory

pre-wired control devices.

• A stainless steel, sloped, condensate

pan is standard. As a result of this

new design, the coil is easily

accessed for cleaning.

• The cabinets are constructed of galvanized steel, bonderized, and

coated on all external surfaces with

a baked enamel finish. The paint

finish is nonchalking and is capable

of withstanding ASTM (American

Society for Testing and Materials)

Standard No. B117 500-hour salt

spray test.

• Choose between a full line of roommounted thermostats.

• Full compressor protection is

assured by several devices, including

current-sensing lockout relay(s), antishort cycle control, and high and

low-pressurestats. These devices

lock out the compressor(s) under

abnormal operating conditions to

prevent compressor damage and

ensure long life.

Table of contents

• The 50XCA units are covered by a

standard limited 5-year warranty on

the compressor and a standard limited one-year warranty on all other

parts.

• Easy to understand and operate

controls provide a virtually mistakeproof control operation.

• All motors are protected against

single-phasing conditions.

• Units are built in an ISO

9001:2000 (International Standards

Organization) certified manufacturing facility, and are fully run-tested.

Environmentally sound

Carrier’s Puron® refrigerant (R-410A)

enables you to make an environmentally responsible decision. Puron

refrigerant (R-410A) is an HFC refrigerant that does not contain chlorine

that is damaging to the stratospheric

ozone layer. Puron refrigerant

(R-410A) is unaffected by the Montreal

Protocol. Puron refrigerant (R-410A) is

a safe, efficient and environmentally

sound refrigerant for the

future.

Special features for outstanding performance

• High-efficiency scroll compressors

deliver quiet, reliable cooling capacity. Compressor motor protection is

assured by quick-acting, internal

sensing elements that prevent trouble before it starts.

2

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AHRI Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26,27

Typical Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28,29

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32,33

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34,35

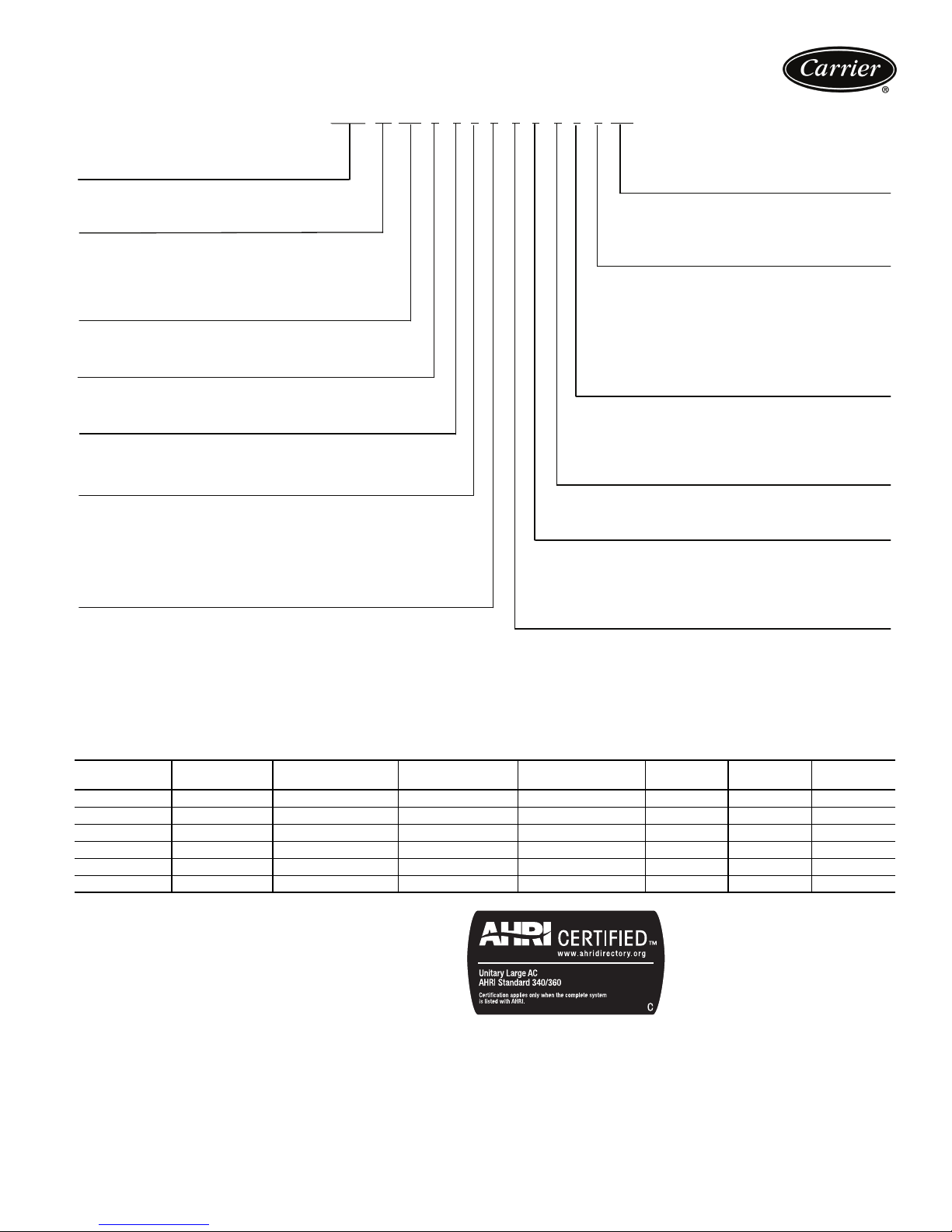

Model number nomenclature

50XC

A24A -

50XC – OMNIZONE™ Indoor Packaged Unit

Condenser Option

A – Air-Cooled

Design Revision Level

0 – Original Release

Voltage Options

1 – 575-3-60

5 – 208/230-3-60

6 – 460-3-60

Unit Size – Nominal Tons

06 – 5 14 – 12

08 – 7 1/2 16 – 15

12 – 10 24 – 20

A

Heating Coil Options

A – No Heating Coil

B

Evaporator Motor Hp Options

B – 1/2 Hp Motor

C – 3/4 Hp Motor

D – 1 Hp Motor

E – 1 1/2 Hp Motor

5A

Control Options

A – Standard Controls

A

Condenser Coil Options

A – 0.0 to 0.2 ESP

B – 0.2 to 0.5 ESP

C – 0.5 to 1.0 ESP

0

Return Air/Discharge Air Options

A – Rear Return, Vertical Discharge, Single Unit, Ducted

Evaporator Fan Speed

See unit price pages.

X – Quote Control

Factory-Installed Options Code

See codes in unit price pages

AA

Condenser Motor Hp Options

D – 1 Hp Motor

E – 1 1/2 Hp Motor

F – 2 Hp Motor

G – 3 Hp Motor

H

H – 5 Hp Motor

J – 7 1/2 Hp Motor

F – 2 Hp Motor

G – 3 Hp Motor

H – 5 Hp Motor

J – 7 1/2 Hp Motor

a50-8500

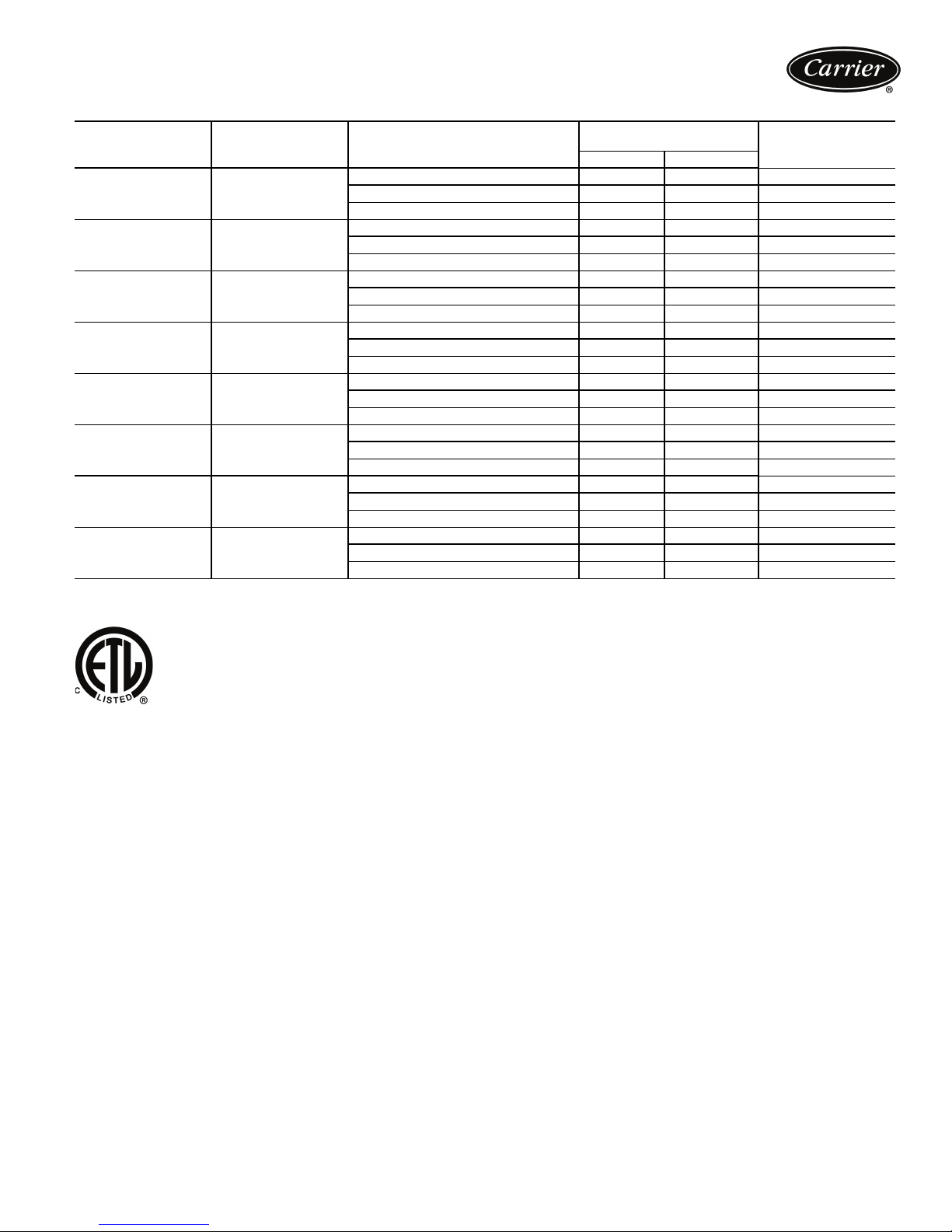

AHRI* capacity ratings

UNIT

50XCA

06 5 1,875 2,800 65,000 5.8 11.2 11.4

08 7

12 10 3,500 5,500 119,000 10.6 11.2 11.4

14 12 4,200 8,000 140,000 12.7 11.0 11.2

16 15 5,250 8,000 162,000 14.7 11.0 11.2

24 20 7,000 11,400 240,000 24.0 10.0 10.1

EER — Energy Efficiency Ratio

IEER — Integrated Energy Efficiency Ratio

*AHRI — Air Conditioning, Heating, and Refrigeration Institute.

NOTE: Unit is tested in accordance with AHRI standard 340/360.

NOMINAL

TONS

LEGEND

EVAPORATOR

1

/

2

2,625 3,500 80,000 7.1 11.2 11.4

CFM

CONDENSER

CFM

NET COOLING

(Btuh)

TOTAL

kW

EER IEER

3

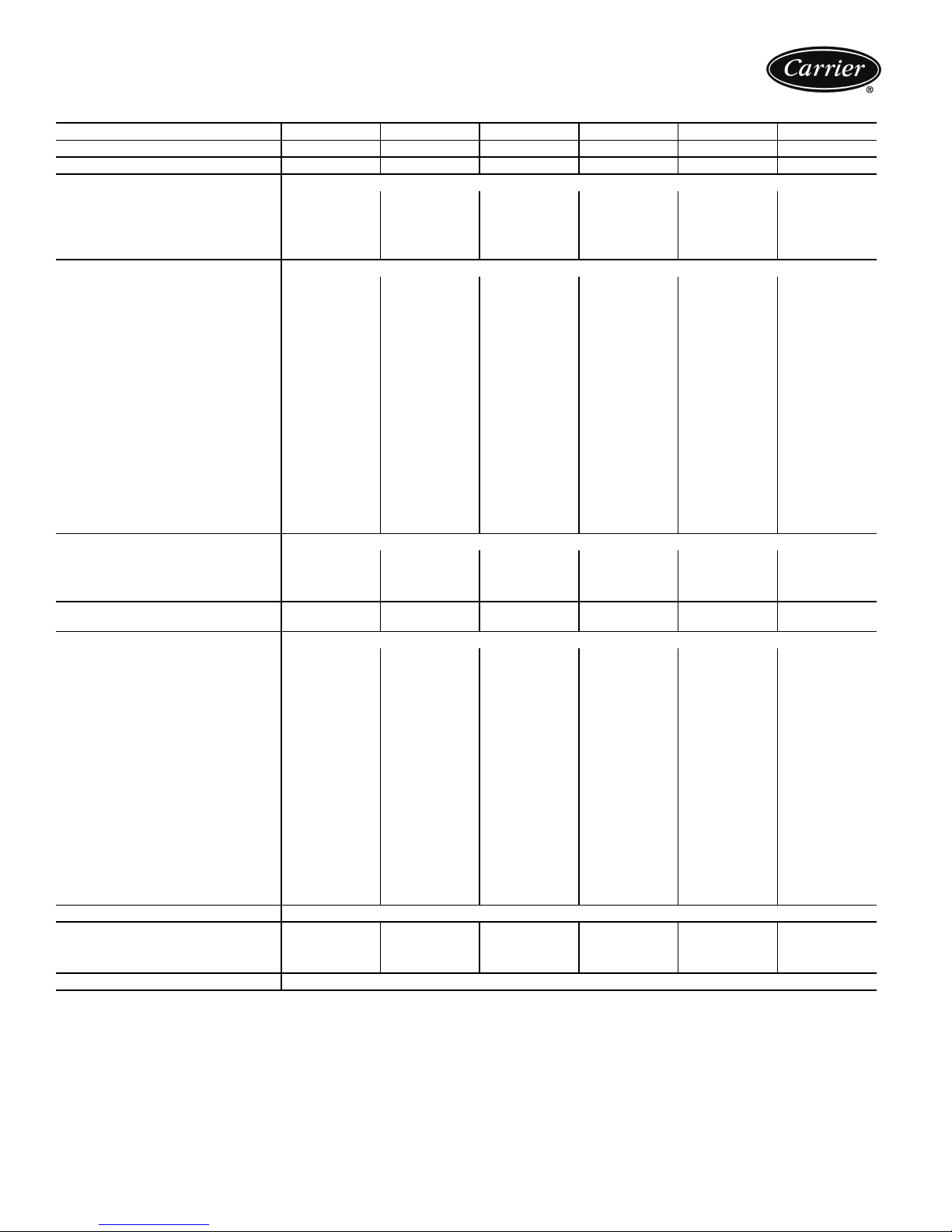

Physical data

UNIT 50XCA 06 08 12 14 16 24

NOMINAL CAPACITY (tons) 57

UNIT OPERATING WEIGHT (lb) 891 1144 1269 1298 1575 2000

COMPRESSOR Copeland Scroll

Compressor Model ZP57 ZP67 ZP51 ZP57 ZP72 ZP103

Qty 112222

Steps of Control 112222

Operating Charge R-410A (lb) 17.4 21.4 15.5 / 14.6 22.1 / 20.8 26.1 / 19.1 26.6 / 19.5

EVAPORATOR FAN Adjustable, Belt-Drive, Centrifugal

Nominal Cfm 1750 2625 3500 4375 5250 7500

Cfm Range 1500 to 2500 2250 to 3750 3000 to 5000 3600 to 6000 4500 to 7500 6000 to 10000

Available Static (in. wg) 0 - 1.6 0 - 1.6 0 - 1.6 0 - 1.6 0 - 1.6 0 - 1.6

Evaporator Fan Size 110-10R 110-10R 120-9R 120-9R 120-9R 120-11R

Number of Evaporator Fans 122233

Standard Speed Range (Rpm) 576 - 782 712 - 949 656 - 750 801 - 832 689 - 918 889 - 913

Max. Allowable Rpm 1600 1700 1700 1700 1700 1700

Belt Quantity ... Type 1...A50 1...BX42 1...BX48 1...BX46 1...BX48 1...BX56

Fan Pulley (Type) AK89 BK65 BK70 BK100 BK67 BK67

Motor Pulley (Type) 1VP44 1VP34 1VP34 1VP56 1VP34 1VP44

Std HP 0.51 11.51.53

HP Range 0.5 - 1.5 1 - 2 1 - 3 1.5 - 5 1.5 - 5 3 - 7.5

Fan Shaft Size (in.) 0.75 1 1 1.1875 1.1875 1.1875

Motor Shaft Size (in.) 0.625 0.875 0.875 0.875 0.875 1.125

Center Distance (in.) 15.3 15.3 17.1 16.5 17.1 21.1

EVAPORATOR COIL

Quantity Rows ... Fin/in. 4...12 4...12 5...12 5...12 5...12 5...12

Fin Block Size (H x L) (in.) 28 x 34 28 x 46 32 x 60 32 x 60 32 x 80 36 x 80

Face Area (sq ft) 6.6 8.9 13.3 13.3 17.8 20.0

RETURN AIR FILTERS (Std 1 in.,

throwaway)

CONDENSER FAN Adjustable, Belt-Drive, Centrifugal

Nominal Cfm 2800 3500 6400 8000 8500 11400

Cfm Range 2100 - 3000 2625 - 4300 4800 - 7600 6000 - 9500 6375 - 9700 8550 - 12700

Available Static 0 - 1.0 0 - 1.0 0 - 1.0 0 - 1.0 0 - 1.0 0 - 1.0

Condenser Fan Size 110-10R 110-10R 150-12R 150-15R 150-15R 150-11R

Number of Condenser Fans 222223

Standard Speed Range (Rpm) 656 - 875 712 - 949 712 - 949 764 - 1011 764 - 1011 820 - 1041

Max. Allowable Rpm 1700 1700 1700 1600 1600 1700

Belt Quantity ... Type 1...BX66 1...BX65 1...BX75 1...BX75 1...BX75 1...BX90

Fan Pulley (Type) BK70 BK65 BK90 BK77 BK77 BK85

Motor Pulley (Type) 1VP34 1VP34 1VP34 1VP44 1VP44 1VP50

Std HP 1.01.52235

HP Range 1 - 1.5 1 - 2 2 - 3 2 - 3 3 - 5 3 - 7.5

Fan Shaft Size (in.) 1 1 1 1.1875 1.1875 1.4375

Motor Shaft Size (in.) 0.875 0.875 0.875 1.125 1.125 1.125

Center Distance (in.) 26 26 29 29 29 35

CONDENSER COIL

Quantity Rows ... Fin/in. 6...16 6...16 6...16 6...16 6...16 6...16

Fin Block Size (H x L) 30 x 46 30 x 46 34 x 60 34 x 80 34 x 80 40 x 80

Face Area (sq ft) 9.6 9.6 14.2 18.9 18.9 22.2

CONDENSATE DRAIN LINE (in.) 1 at

LEGEND

FPT — Female Pipe Thread

(2) 25X25 (2) 25X25 (8) 16X16

1

/

2

3

/8-in. OD, Enhanced Copper Tube, Aluminum Fins

3

/8-in. OD, Enhanced Copper Tube, Aluminum Fins

10 12 15 20

(8) 16x16

(2) 16x20

3

/4 FPT

(8) 16x16

(2) 16x20

(4) 18X18

(4) 18X24

4

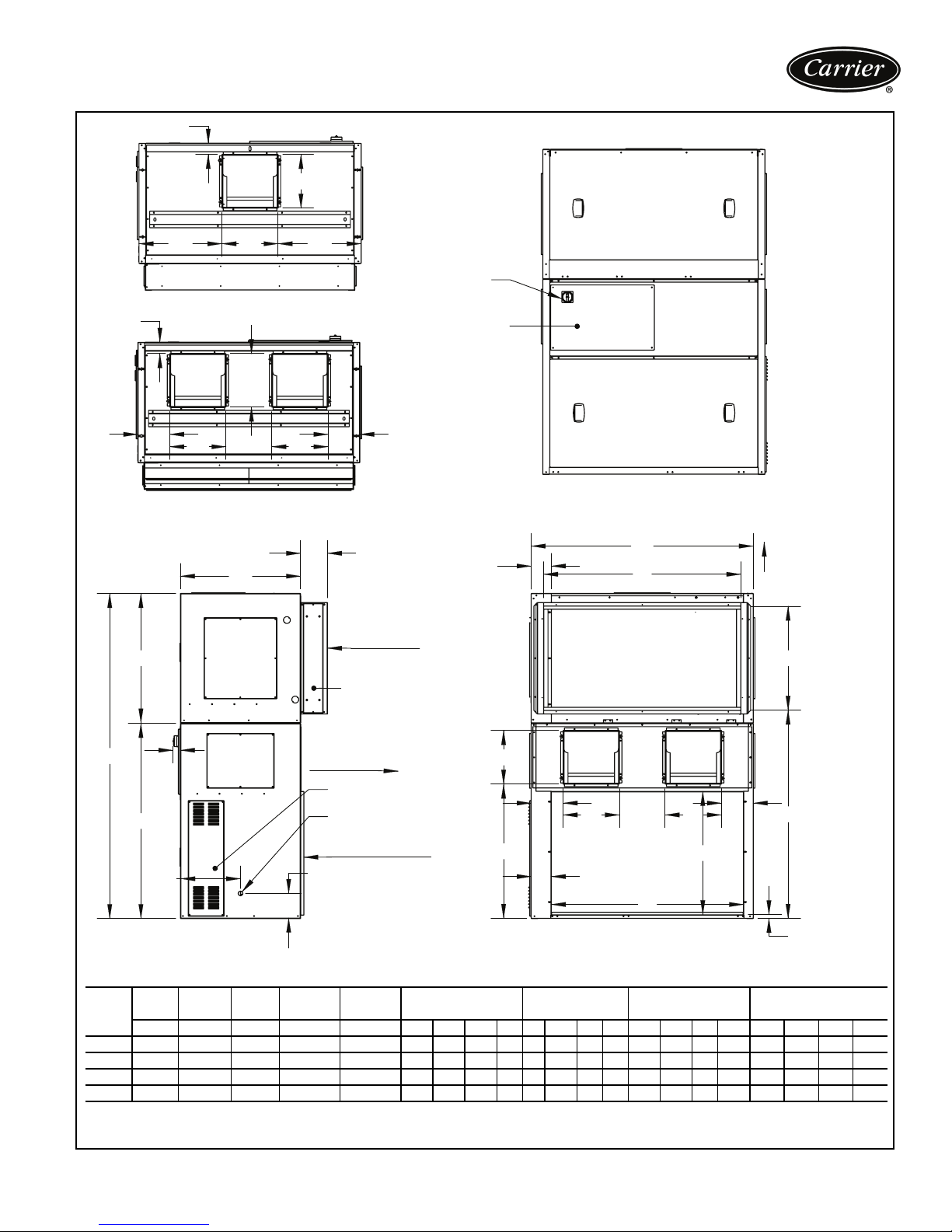

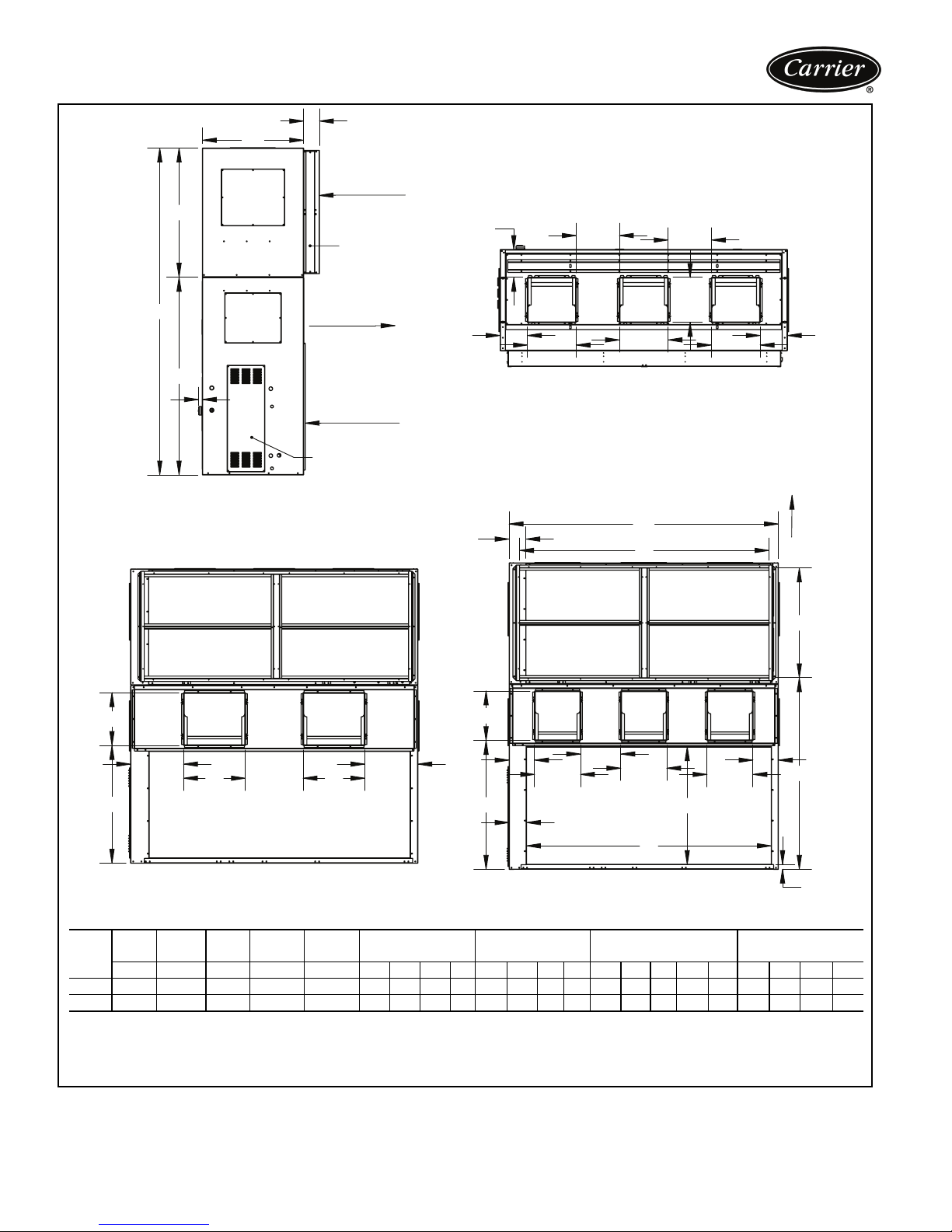

50XCA06

Q

P

O

NQ

50XCA08,12,14

Q

N

P

N

O

Q

RIGHT VIEW

TOP VIEW

REAR VIEW

EVAP ACCESS

TOP VIEW

PANEL

CONDENSER

ACCESS

PANEL

INDOOR SUPPLY

AIR FLOW

R

G

F

K

J

H

R

U

M

A

I

T

S

U

L

FRONT VIEW

CONTROL BOX

DISCONNECT

(OPT)

AIR FLOW

(BOTH SIDES)

OUTDOOR RTN

AIR FLOW

FILTER ACCESS

INDOOR RTN

CONDENSER

DISCHARGE

COND VFD

(OPT)

C

B

E

D

6.4 (1"-2" FLTR)

1.8

5.9

14.3

3/4" FPT DRAIN

NOTE: Dimensions are in inches.

UNIT

50XCA

WIDTH HEIGHT DEPTH

COND

SECTION

EVAP

SECTION

EVAP RETURN

DUCT

EVAP RETURN

DUCT

EVAP SUPPLY DUCT

(Blower Opening)

COND DISCHARGE

DUCT (Blower Opening)

ABC D EFGHIJKLMNOPQRSTU

06 53.1 77.1 30.0 46.6 31.0 47.2 24.8 49.8 4.8 46 29.4 0.9 4.8 13.4 12.8 2.7 19.8 13.4 12.8 32.1 7.6

08 53.1 77.1 30.0 46.6 31.0 47.2 24.8 49.8 4.8 46 29.4 0.9 4.8 13.4 12.8 2.7 7.6 13.4 12.8 32.1 7.6

12 68.0 90.1 31.2 54.5 35.5 61.1 31.8 56.7 5.5 60 32.8 1.5 5.7 12.5 13.8 8.5 13.6 16.4 16.2 36.5 11.5

14 88.0 90.1 31.2 54.5 35.5 81.0 31.8 56.7 2.5 80 32.8 1.5 5.7 12.5 13.8 8.9 23.6 18.9 16.2 36.6 17.2

a50-8501

Dimensions — 50XCA06-14

5

C

4.9

(1"-2" FLTR)

E

D

B

1.2

OUTDOOR RTN

AIR FLOW

INDOOR RTN

AIR FLOW

FILTER ACCESS

(BOTH SIDES)

COND VFD

(OPT)

A

F

I

G

H

T

U

V

S

S

S

V

K

J

M

L

13.2

N

N

N

QQ

O

R

R

P

SS

VV

T

U

TOP VIEW

RIGHT VIEW

REAR VIEW

INDOOR

SUPPLY

AIR FLOW

CONDENSER

DISCHARGE

REAR VIEW

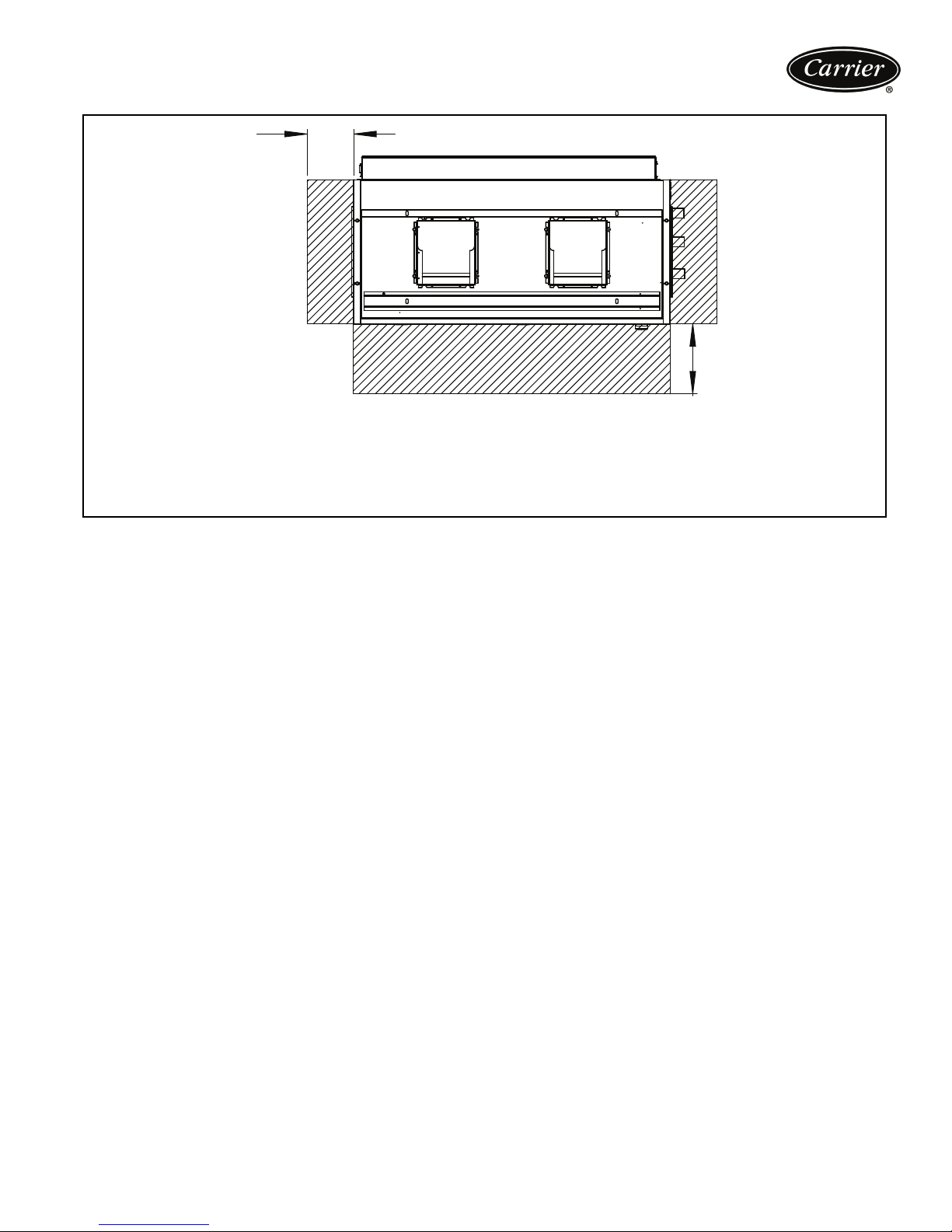

50XCA2450XCA16

NOTE: Dimensions are in inches.

UNIT

50XCA

WIDTH HEIGHT DEPTH

COND

SECTION

EVAP

SECTION

EVAP RETURN DUCT EVAP RETURN DUCT

EVAP SUPPLY DUCT

(Blower Opening)

COND DISCHARGE

DUCT (Blower Opening)

ABC D EFGHIJKLMNOPQRSTUV

16 88.0 90.1 31.0 54.5 35.5 81.0 31.8 56.7 5.5 80.0 32.8 1.5 5.7 12.5 13.8 8.5 13.5 11.7 18.9 16.2 36.5 16.2

24 88.0 100.1 31.0 60.5 39.5 81.5 35.8 62.6 5.5 80.0 38.5 1.5 5.7 14.9 13.8 8.6 8.3 13.2 15.0 16.2 42.0 8.3

a50-8502

Dimensions — 50XCA16,24

6

Selection procedure (50XCA08 unit example)

36

24

(TYP)

SERVICE CLEARANCE

NOTE: Dimensions are in inches.

a50-8502

I Determine design conditions.

Given:

Cooling Requirements

Total Cooling Capacity (TC) . . . . . . . . .82,000 Btuh

Sensible Cooling Capacity (SHC) . . . . .65,000 Btuh

Evaporator Air Quantity. . . . . . . . . . . . . 3,000 Cfm

Condenser Air Quantity . . . . . . . . . . . . . 3,500 Cfm

Summer Entering-Air Conditions:

Entering dry bulb (edb) . . . . . . . . . . . . . . . . .80 F

Entering wet bulb (ewb) . . . . . . . . . . . . . . . .67 F

Entering Condenser Air Temp (EAT) . . . . . . .95 F

Unit Voltage . . . . . . . . . . . . . . . . . . . . . . . . 460 V

Fan Requirements

External Static Pressure Required

ESP (in. wg) . . . . . . . . . . . . . . . . . . . . . . . . . .0.75

II Select unit based on cooling requirements.

Enter Gross Cooling Capacities table for 50XCA08

unit at 3000 cfm and required wet bulb of 67 F and

read down to the section displaying capacities with

95 F entering-air temperature. The 50XCA08 provides a total capacity closest to design requirements.

For example:

Unit selection — 50XCA08

Selected at 3000 cfm of 80 F edb, 67 F ewb entering air.

TC = 83,800 Btuh

SHC = 66,500 Btuh

(See correction factor table, below the cooling

capacity tables.)

Compressor — Power Input = 5.85 kW

Leaving Air db

= 59.9 F

Leaving Air wb at 67 F wb

= 58.3 F

III Fan requirements.

External static pressure (ESP) required 0.75 in. wg

Enter Evaporator Fan Performance table for cfm, and

static pressure required to obtain the following data:

For 3000 cfm and 0.75 ESP, by interpolation the

fan operates at 877 rpm and requires 0.98 brake

horsepower.

Since standard motor horsepower is 1.0, it will produce the necessary cfm and ESP for this job.

7

Performance data

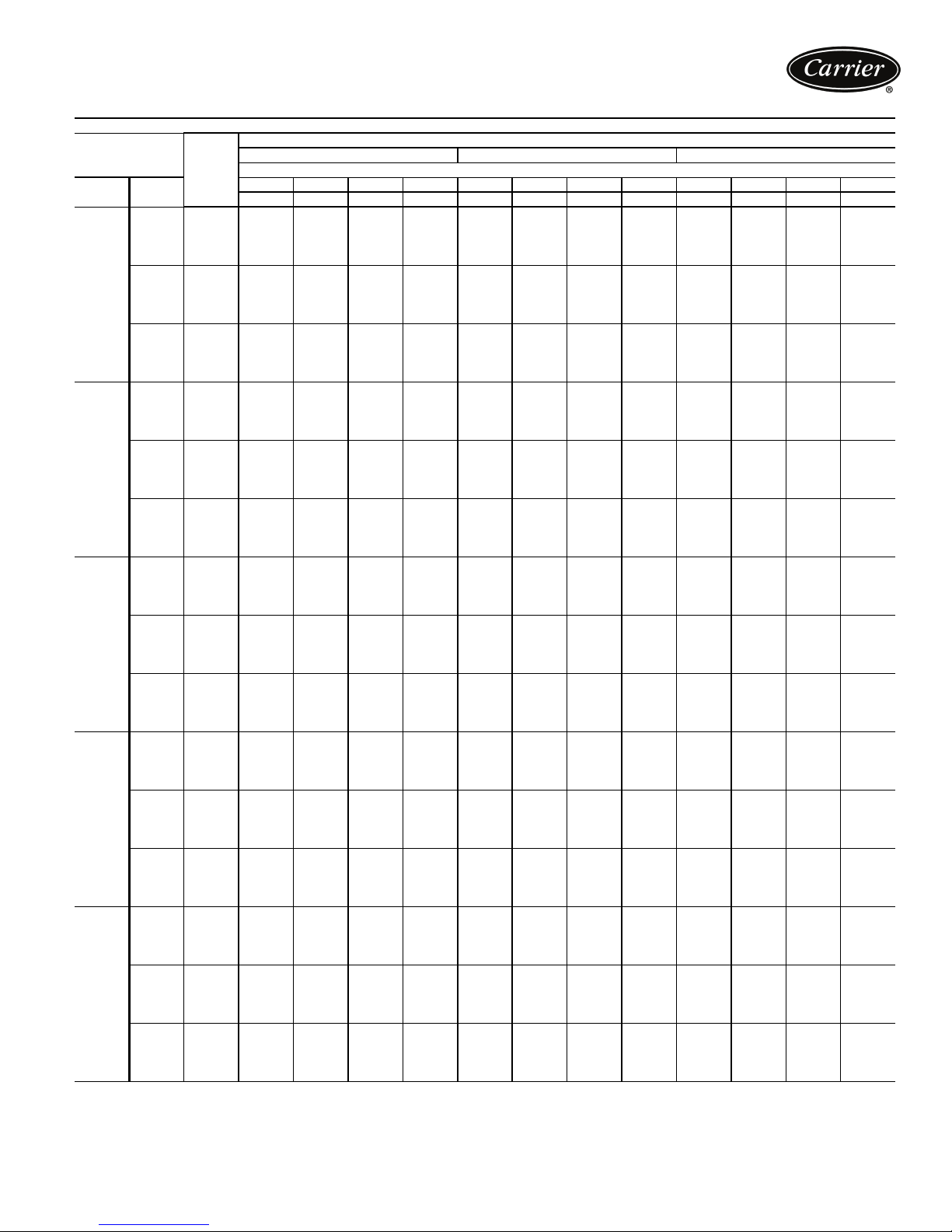

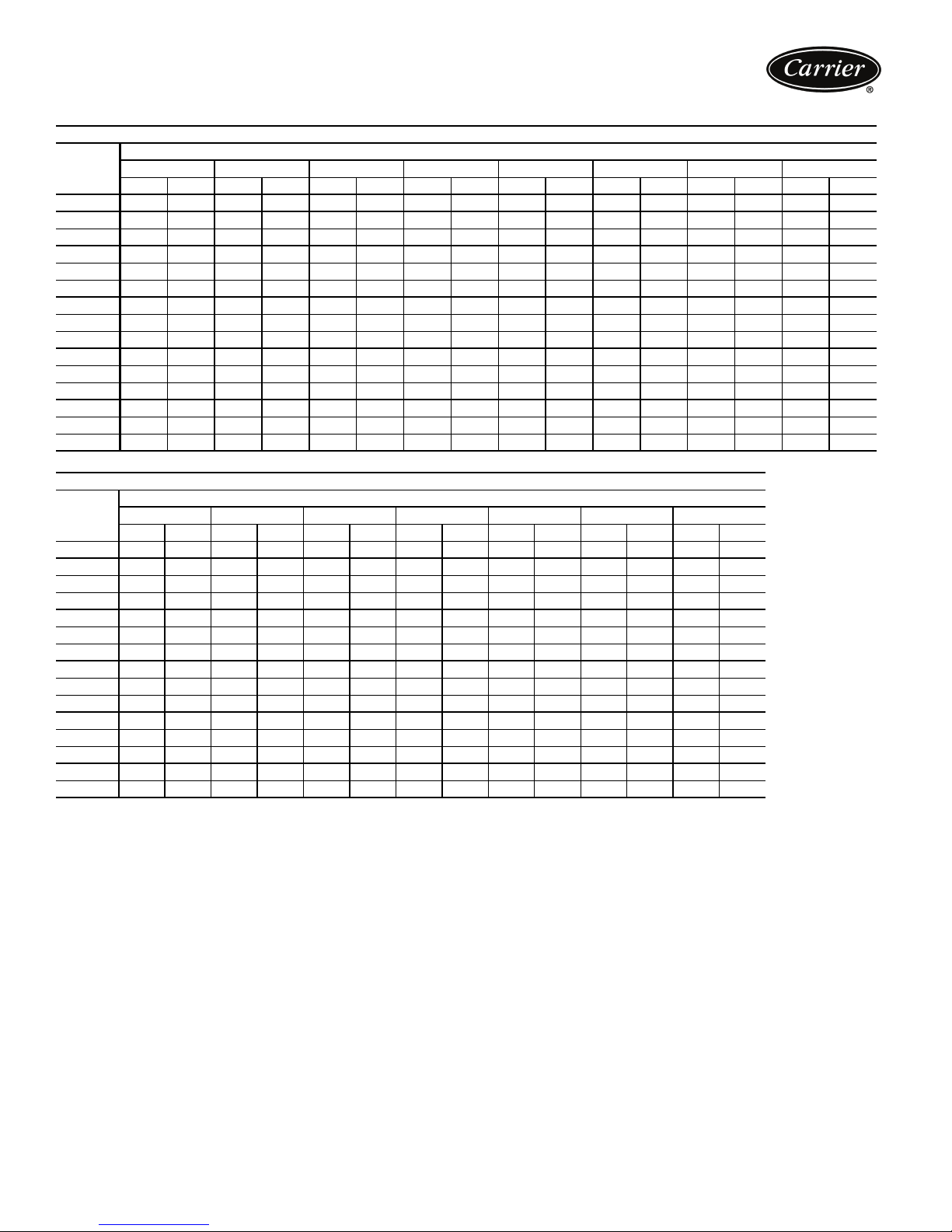

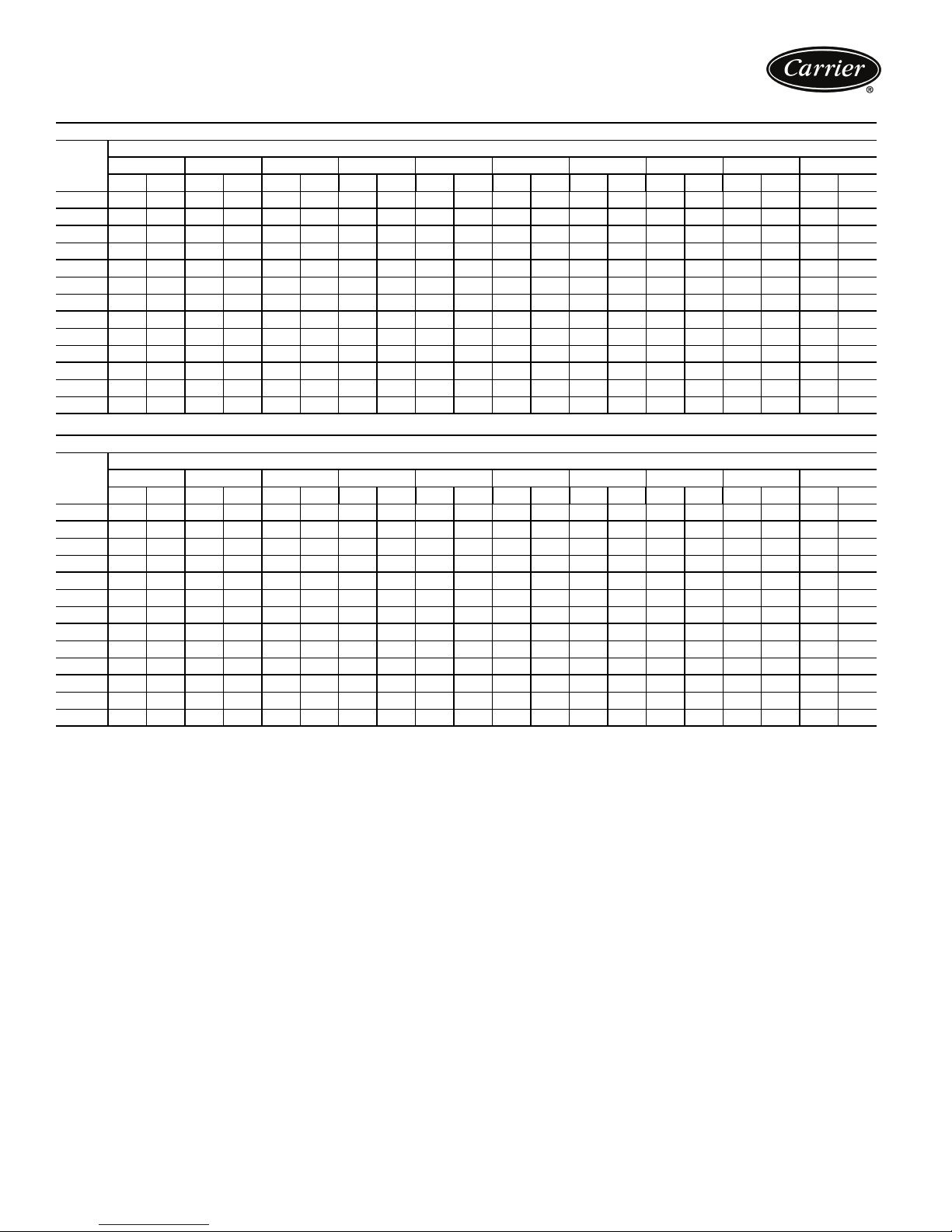

GROSS COOLING CAPACITIES

50XCA06 (5 TONS)

Entering

Condenser Air

ECT (F) CFM

2100

55

75

95

105

115

BF — Bypass Factor EWB — Entering Wet Bulb (F) SHC — Sensible Capacity (1000 Btu/hr)

ECT — Entering Condenser Temperature (F) LDB — Leaving Dry Bulb (F) TC — Total Capacity (1000 Btu/hr)

EDB — Entering Dry Bulb (F) LWB — Leaving Wet Bulb (F) kW — Compressor Motor Power Input (kilowatts)

2800

3500

2100

2800

3500

2100

2800

3500

2100

2800

3500

2100

2800

3500

BF 0.20 0.10 0.10 0.03 0..34 0.15 0.14 0.10 0.44 0.22 0.18 0.15

TC 73.4 74.8 80.4 90.4 68.8 71.9 77.8 87.8 62.9 67.9 73.7 83.7

SHC 73.4 70.2 58.6 38.9 68.8 63.2 53.4 36.9 62.1 55.2 47.5 34.5

LDB 53.08 54.40 58.75 65.92 48.48 51.18 55.83 63.36 42.07 46.49 51.34 59.30

LWB 45.41 51.41 56.79 65.43 43.16 48.97 54.36 63.10 39.61 45.04 50.43 59.29

kW 3.25 3.27 3.34 3.48 3.20 3.23 3.31 3.45 3.13 3.18 3.26 3.39

TC

SHC 74.0 70.7 59.0 39.5 69.3 63.6 53.7 37.4 62.4 55.4 47.8 35.0

LDB 52.85 54.22 58.60 65.71 48.23 51.03 55.66 63.11 41.87 46.35 51.15 59.01

LWB 45.30 51.28 56.63 65.22 43.03 48.84 54.18 62.86 39.46 44.88 50.23 59.00

kW 2.85 2.86 2.90 2.98 2.82 2.84 2.88 2.96 2.79 2.82 2.85 2.93

TC 74.5 76.1 82.2 93.1 69.6 73.0 79.4 90.2 63.5 68.8 75.0 85.6

SHC 74.5 70.9 59.3 39.9 69.6 63.8 54.0 37.7 62.5 55.6 48.0 35.2

LDB 52.70 54.13 58.49 65.59 48.09 50.95 55.54 62.97 41.79 46.23 51.01 58.88

LWB 45.22 51.21 56.54 65.11 42.96 48.76 54.08 62.73 39.39 44.77 50.11 58.87

kW 2.63 2.63 2.65 2.70 2.61 2.62 2.64 2.69 2.60 2.61 2.63 2.67

TC 68.7 69.3 74.4 83.5 64.6 66.7 72.1 81.3 59.0 63.2 68.6 77.8

SHC 68.7 67.3 56.1 36.5 64.6 60.6 50.9 34.5 59.0 52.8 45.1 32.2

LDB 54.80 55.46 59.67 66.79 50.37 52.37 56.96 64.42 43.96 47.94 52.76 60.63

LWB 46.22 52.26 57.64 66.23 44.09 50.05 55.40 64.09 40.86 46.40 51.77 60.58

kW 4.29 4.29 4.37 4.52 4.23 4.26 4.34 4.48 4.15 4.21 4.28 4.43

TC 69.5 70.3 75.5 85.2 65.2 67.6 73.1 82.8 59.5 63.8 69.5 79.1

SHC 69.5 67.8 56.5 37.1 65.2 61.1 51.3 35.0 59.5 53.1 45.5 32.7

LDB 54.52 55.26 59.51 66.59 50.10 52.17 56.76 64.18 43.66 47.76 52.54 60.36

LWB 46.09 52.11 57.48 66.04 43.96 49.87 55.21 63.86 40.70 46.22 51.55 60.31

kW 3.83 3.84 3.88 3.96 3.80 3.82 3.86 3.94 3.76 3.79 3.83 3.91

TC 70.0 70.9 76.3 86.2 65.6 68.0 73.8 83.8 59.7 64.2 70.0 79.8

SHC 70.0 68.1 56.8 37.5 65.6 61.3 51.6 35.4 59.7 53.3 45.7 33.0

LDB 54.34 55.15 59.39 66.45 49.93 52.09 56.63 64.03 43.50 47.63 52.39 60.18

LWB 46.01 52.03 57.37 65.92 43.87 49.79 55.10 63.72 40.62 46.10 51.42 60.14

kW 3.57 3.58 3.60 3.64 3.56 3.56 3.59 3.63 3.54 3.55 3.57 3.61

TC 63.4 63.5 67.6 75.8 59.8 60.9 65.7 74.0 54.9 57.8 62.8 71.1

SHC 63.4 63.5 53.3 33.9 59.8 57.7 48.2 31.9 54.9 50.2 42.5 29.7

LDB 56.74 56.84 60.66 67.73 52.58 53.68 58.16 65.57 46.46 49.52 54.32 62.13

LWB 47.14 53.16 58.57 67.11 45.16 51.21 56.55 65.18 42.14 47.93 53.26 62.00

kW 5.48 5.48 5.55 5.70 5.42 5.43 5.52 5.67 5.28 5.38 5.47 5.62

TC 64.3 64.5 68.8 77.5 60.5 61.9 66.8 75.5 55.3 58.5 63.7 72.4

SHC 64.3 64.5 53.7 34.4 60.5 58.1 48.6 32.4 55.3 50.4 42.9 30.2

LDB 56.44 56.48 60.53 67.54 52.26 53.49 57.99 65.34 46.21 49.36 54.11 61.85

LWB 46.99 53.01 58.41 66.92 45.01 51.02 56.36 64.96 42.01 47.73 53.03 61.73

kW 4.99 4.99 5.03 5.11 4.95 4.97 5.01 5.09 4.91 4.94 4.98 5.06

TC 64.8 65.0 69.6 78.6 61.0 62.4 67.5 76.5 55.7 59.0 64.3 73.3

SHC 64.8 65.0 54.1 34.8 61.0 58.4 48.9 32.8 55.7 50.7 43.2 30.5

LDB 56.23 56.29 60.39 67.40 52.05 53.36 57.84 65.18 45.99 49.20 53.93 61.66

LWB 46.90 52.93 58.30 66.80 44.91 50.91 56.23 64.81 41.90 47.59 52.88 61.55

kW 4.70 4.71 4.73 4.77 4.69 4.70 4.72 4.76 4.66 4.68 4.70 4.75

TC 60.4 60.5 63.8 71.6 57.1 57.7 62.2 70.0 52.4 54.8 59.5 67.4

SHC 60.4 60.5 51.8 32.5 57.1 56.0 46.7 30.5 52.4 48.7 41.1 28.3

LDB 57.84 57.93 61.22 68.24 53.82 54.46 58.84 66.20 47.96 50.43 55.18 62.95

LWB 47.64 53.62 59.08 67.59 45.76 51.83 57.17 65.77 42.90 48.76 54.07 62.78

kW 6.11 6.11 6.17 6.32 6.05 6.06 6.14 6.29 5.96 6.01 6.10 6.24

TC 61.3 61.4 65.0 73.3 57.8 58.7 63.2 71.5 53.0 55.6 60.4 68.7

SHC 61.3 61.4 52.1 33.0 57.8 56.5 47.1 31.0 53.0 49.1 41.4 28.8

LDB 57.52 57.61 61.09 68.06 53.49 54.26 58.67 65.98 47.63 50.19 54.97 62.67

LWB 47.50 53.48 58.92 67.40 45.61 51.63 56.99 65.55 42.73 48.52 53.85 62.51

kW 5.62 5.62 5.66 5.75 5.59 5.60 5.64 5.73 5.54 5.57 5.62 5.70

TC 61.9 62.0 65.9 74.4 58.3 59.3 64.0 72.6 53.4 56.0 61.1 69.6

SHC 61.9 62.0 52.5 33.4 58.3 56.8 47.4 31.4 53.4 49.3 41.8 29.2

LDB 57.29 57.39 60.94 67.91 53.26 54.11 58.50 65.80 47.38 50.08 54.78 62.46

LWB 47.39 53.39 58.80 67.27 45.49 51.53 56.85 65.40 42.61 48.42 53.68 62.32

kW 5.34 5.34 5.36 5.41 5.32 5.33 5.35 5.40 5.29 5.31 5.33 5.38

TC 57.3 57.3 59.9 67.3 54.2 54.3 58.4 65.8 49.9 51.5 56.1 63.6

SHC 57.3 57.3 50.2 31.0 54.2 54.3 45.1 29.1 49.9 47.1 39.6 27.0

LDB 59.00 59.09 61.79 68.77 55.15 55.22 59.53 66.84 49.53 51.38 56.07 63.77

LWB 48.18 54.09 59.60 68.07 46.39 52.48 57.82 66.37 43.68 49.64 54.92 63.57

kW 6.76 6.76 6.81 6.95 6.70 6.70 6.78 6.93 6.61 6.64 6.74 6.88

TC 58.3 58.3 61.2 68.9 55.1 55.4 59.6 67.4 50.6 52.4 57.1 64.9

SHC 58.3 58.3 50.7 31.6 55.1 54.5 45.6 29.6 50.6 47.5 40.0 27.4

LDB 58.63 58.72 61.62 68.58 54.76 55.16 59.33 66.61 49.11 51.15 55.82 63.49

LWB 48.01 53.94 59.43 67.89 46.21 52.28 57.62 66.15 43.47 49.40 54.67 63.29

kW 6.28 6.28 6.32 6.40 6.25 6.25 6.30 6.38 6.19 6.22 6.27 6.36

TC 58.8 58.8 62.0 69.9 55.5 55.9 60.2 68.3 50.9 52.8 57.6 65.7

SHC 58.8 58.8 51.0 31.9 55.5 54.9 45.9 29.9 50.9 47.7 40.2 27.7

LDB 58.45 58.54 61.49 68.46 54.58 54.99 59.21 66.47 48.92 51.03 55.69 63.32

LWB 47.92 53.87 59.32 67.78 46.12 52.17 57.51 66.02 43.38 49.29 54.54 63.14

kW 6.00 6.00 6.02 6.06 5.99 5.99 6.01 6.06 5.95 5.97 6.00 6.04

57 62 67 75 57 62 67 75 57 62 67 75

74.0 75.7 81.5 92.2 69.3 72.7 78.8 89.4 63.3 68.5 74.5 85.0

2500 2000 1500

AIR ENTERING EVAPORATOR — 80 F Edb (F) - CFM

Air Entering Evaporator — Ewb (F)

LEGEND

8

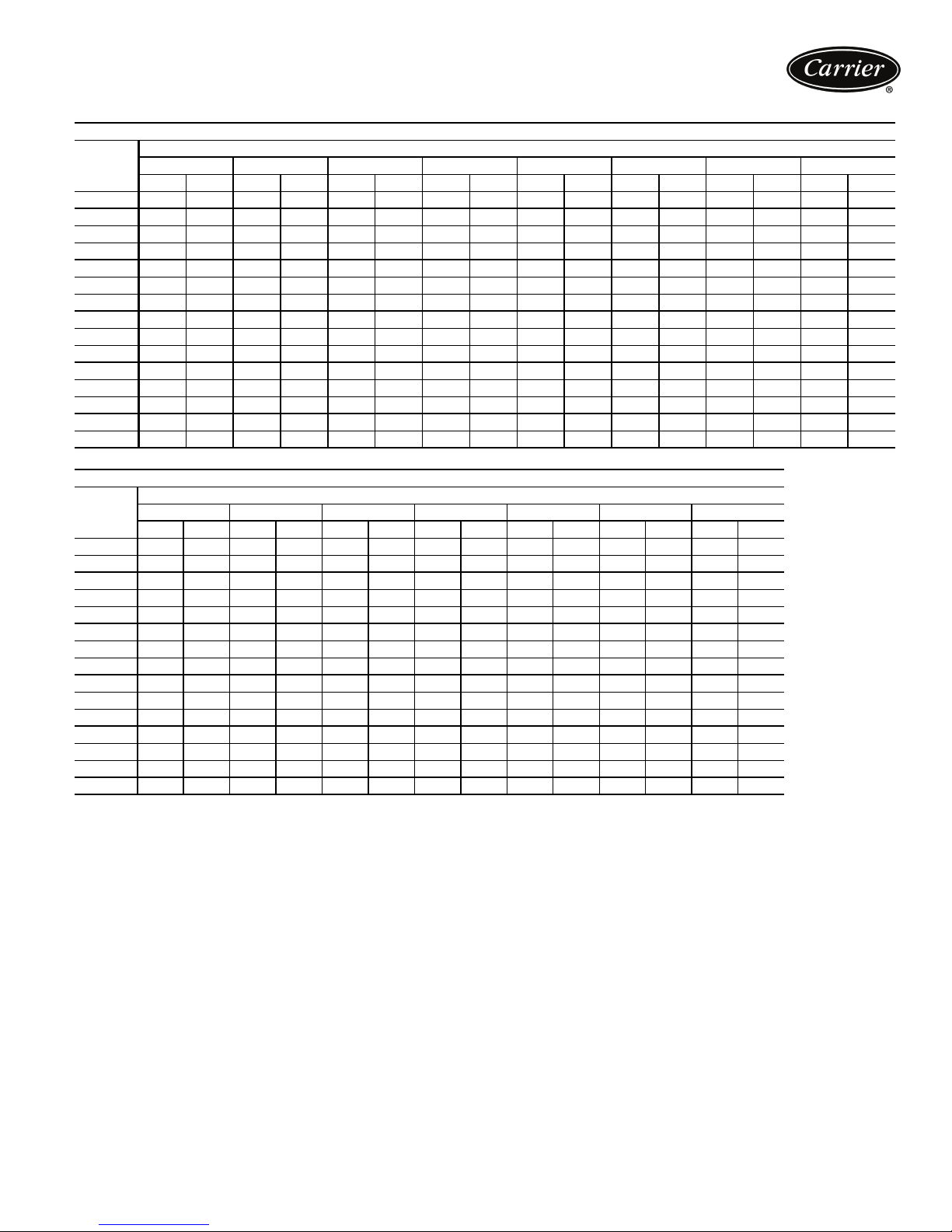

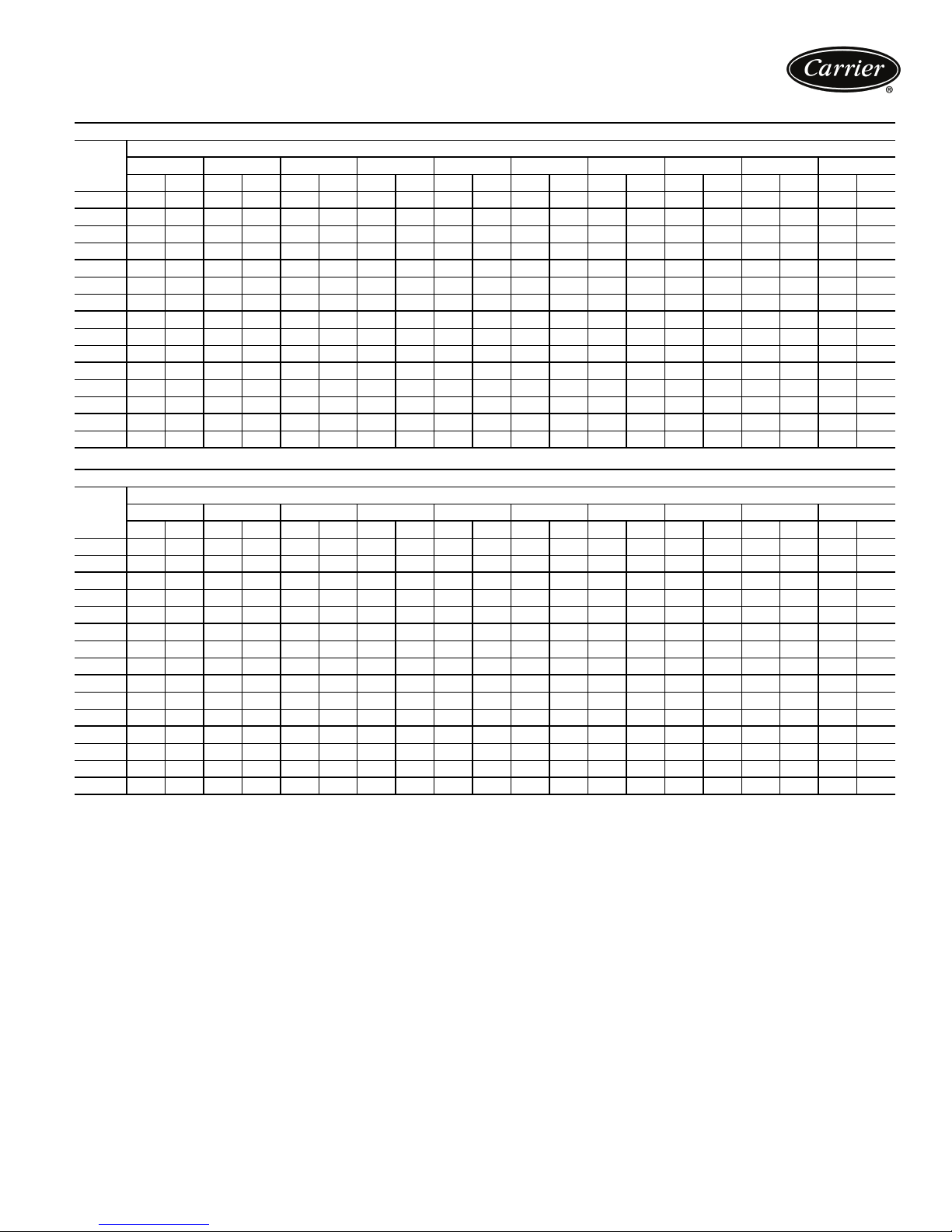

GROSS COOLING CAPACITIES (cont)

1

Entering

55

75

95

/2 Tons)

2625

3500

4300

2625

3500

4300

2625

3500

4300

2625

3500

4300

2625

3500

4300

3750 3000 2250

BF 0.30 0.11 0.10 0.06 0.43 0.20 0.13 0.12 0.52 0.31 0.17 0.16

TC 95.1 95.4 100.9 113.5 89.6 91.1 98.1 110.8 82.1 86.4 93.8 106.4

SHC 95.1 95.3 80.3 50.9 89.6 86.8 72.4 47.9 82.1 75.4 63.8 44.5

LDB 56.76 56.81 60.59 67.72 52.61 53.61 58.11 65.58 46.56 49.48 54.30 62.17

LWB 47.15 53.14 58.61 67.13 45.18 51.24 56.60 65.20 42.19 47.98 53.32 62.05

kW 3.95 3.97 4.07 4.32 3.85 3.88 4.01 4.26 3.71 3.79 3.93 4.18

TC 96.1 96.2 102.4 115.5 90.4 92.1 99.5 112.7 82.7 87.1 94.9 108.1

SHC 96.1 96.2 80.9 51.5 90.4 87.3 73.0 48.5 82.7 75.7 64.3 45.0

LDB 56.51 56.61 60.44 67.57 52.37 53.47 57.94 65.40 46.31 49.36 54.11 61.94

LWB 47.03 53.06 58.48 66.98 45.06 51.11 56.44 65.02 42.07 47.85 53.14 61.81

kW 3.53 3.53 3.61 3.80 3.45 3.47 3.57 3.76 3.35 3.41 3.51 3.70

TC 96.5 96.7 103.1 116.6 90.8 92.5 100.0 113.6 83.0 87.5 95.3 108.8

SHC 96.5 96.7 81.2 51.9 90.8 87.6 73.2 48.8 83.0 75.9 64.5 45.3

LDB 56.41 56.49 60.37 67.49 52.24 53.39 57.88 65.30 46.19 49.26 54.04 61.83

LWB 46.98 53.02 58.42 66.90 45.00 51.06 56.38 64.93 42.01 47.77 53.07 61.71

kW 3.30 3.31 3.37 3.53 3.24 3.26 3.34 3.49 3.16 3.21 3.29 3.44

TC 88.9 89.0 93.2 105.0 84.0 84.5 90.8 102.6 77.2 80.1 87.0 98.8

SHC 88.9 89.0 77.1 48.0 84.0 83.2 69.4 45.0 77.2 72.3 60.9 41.7

LDB 58.27 58.36 61.34 68.43 54.32 54.72 59.01 66.44 48.53 50.72 55.49 63.28

LWB 47.84 53.79 59.30 67.77 46.00 52.10 57.46 66.00 43.18 49.13 54.44 63.09

kW 5.06 5.06 5.16 5.44 4.96 4.97 5.11 5.38 4.81 4.87 5.02 5.29

TC 89.9 89.9 94.7 106.8 84.8 85.5 92.0 104.3 77.8 81.0 88.0 100.3

SHC 89.9 89.9 77.8 48.6 84.8 83.7 69.9 45.6 77.8 72.7 61.3 42.2

LDB 58.04 58.13 61.18 68.29 54.08 54.56 58.89 66.27 48.30 50.54 55.32 63.08

LWB 47.74 53.70 59.17 67.64 45.88 51.97 57.32 65.84 43.07 48.98 54.28 62.89

kW 4.58 4.58 4.66 4.85 4.50 4.51 4.61 4.81 4.39 4.44 4.55 4.74

TC 90.4 90.5 95.4 107.9 85.3 86.0 92.7 105.3 78.1 81.3 88.6 101.1

SHC 90.4 90.5 78.1 48.9 85.3 84.0 70.2 45.9 78.1 72.9 61.6 42.5

LDB 57.90 58.00 61.11 68.19 53.94 54.47 58.79 66.17 48.17 50.48 55.21 62.95

LWB 47.67 53.64 59.11 67.55 45.82 51.90 57.24 65.74 43.00 48.91 54.18 62.78

kW 4.32 4.32 4.38 4.54 4.26 4.27 4.35 4.51 4.17 4.21 4.30 4.46

TC 82.1 82.2 84.7 95.4 77.8 77.9 82.6 93.4 71.8 73.4 79.7 90.3

SHC 82.1 82.2 73.8 44.8 77.8 77.9 66.2 41.9 71.8 68.9 57.7 38.6

LDB 59.93 60.01 62.15 69.19 56.21 56.31 60.00 67.37 50.75 52.08 56.74 64.49

LWB 48.60 54.47 60.06 68.48 46.89 52.94 58.39 66.89 44.28 50.34 55.63 64.25

kW 6.36 6.37 6.43 6.72 6.25 6.26 6.38 6.67 6.10 6.14 6.30 6.58

TC 82.9 83.0 86.1 97.1 78.5 78.5 83.8 95.0 72.2 74.1 80.4 91.7

SHC 82.9 83.0 74.3 45.4 78.5 78.5 66.5 42.4 72.2 69.3 58.1 39.1

LDB 59.73 59.82 62.02 69.06 56.03 56.13 59.89 67.21 50.58 51.93 56.61 64.30

LWB 48.51 54.39 59.93 68.35 46.80 52.86 58.26 66.73 44.19 50.22 55.51 64.06

kW 5.83 5.83 5.89 6.10 5.75 5.75 5.85 6.06 5.64 5.67 5.79 6.00

TC 83.5 83.6 86.9 98.2 79.0 79.1 84.5 96.0 72.6 74.5 81.1 92.6

SHC 83.5 83.6 74.6 45.8 79.0 79.1 66.9 42.8 72.6 69.4 58.3 39.4

LDB 59.59 59.67 61.95 68.96 55.87 55.97 59.79 67.11 50.42 51.86 56.49 64.17

LWB 48.45 54.33 59.87 68.27 46.73 52.80 58.18 66.63 44.12 50.16 55.41 63.94

kW 5.55 5.55 5.60 5.77 5.48 5.49 5.56 5.73 5.39 5.42 5.52 5.68

TC 78.3 78.3 80.2 90.2 74.4 74.4 78.2 88.6 68.7 69.5 75.6 85.8

SHC 78.3 78.3 71.9 43.1 74.4 74.4 64.4 40.3 68.7 67.0 56.1 37.1

LDB 60.86 60.95 62.61 69.60 57.28 57.38 60.54 67.84 52.00 52.86 57.39 65.10

LWB 49.02 54.85 60.46 68.86 47.39 53.39 58.90 67.34 44.89 51.04 56.29 64.84

kW 7.07 7.08 7.13 7.41 6.97 6.97 7.08 7.37 6.81 6.83 7.00 7.29

TC 79.1 79.1 81.6 91.9 75.0 75.1 79.5 90.0 69.2 70.4 76.3 87.0

SHC 79.1 79.1 72.4 43.6 75.0 75.1 64.9 40.7 69.2 67.4 56.3 37.5

LDB 60.67 60.75 62.49 69.47 57.09 57.18 60.39 67.72 51.82 52.71 57.31 64.95

LWB 48.94 54.77 60.34 68.74 47.30 53.30 58.75 67.21 44.80 50.88 56.18 64.69

kW 6.54 6.54 6.58 6.79 6.45 6.46 6.54 6.76 6.34 6.36 6.48 6.70

TC 79.7 79.8 82.3 93.0 75.5 75.6 80.0 91.0 69.6 70.8 76.9 87.9

SHC 79.7 79.8 72.8 44.0 75.5 75.6 65.1 41.1 69.6 67.6 56.6 37.8

LDB 60.52 60.60 62.41 69.38 56.93 57.02 60.33 67.61 51.66 52.60 57.18 64.82

LWB 48.87 54.71 60.27 68.66 47.22 53.24 58.69 67.11 44.72 50.80 56.07 64.57

kW 6.24 6.24 6.28 6.45 6.18 6.18 6.25 6.42 6.09 6.10 6.20 6.37

TC 74.1 74.1 75.4 84.8 70.5 70.5 73.6 83.2 65.3 65.6 71.0 80.7

SHC 74.1 74.1 69.8 41.4 70.5 70.5 62.5 38.5 65.3 64.9 54.2 35.3

LDB 61.90 61.98 63.11 70.03 58.47 58.56 61.10 68.39 53.40 53.68 58.15 65.81

LWB 49.49 55.26 60.87 69.25 47.94 53.87 59.41 67.84 45.56 51.71 57.01 65.51

kW 7.82 7.82 7.86 8.14 7.71 7.71 7.81 8.10 7.56 7.57 7.73 8.02

TC 75.0 75.1 76.7 86.3 71.2 71.3 74.8 84.7 65.9 66.5 71.9 82.0

SHC 75.0 75.1 70.3 41.8 71.2 71.3 63.0 39.0 65.9 65.2 54.5 35.7

LDB 61.66 61.74 62.99 69.91 58.24 58.33 60.96 68.25 53.17 53.57 58.03 65.64

LWB 49.38 55.17 60.76 69.14 47.83 53.78 59.28 67.70 45.45 51.55 56.87 65.34

kW 7.28 7.28 7.32 7.52 7.20 7.20 7.28 7.49 7.09 7.10 7.22 7.43

TC 75.7 75.7 77.4 87.4 71.8 71.8 75.5 85.7 66.3 66.9 72.5 82.9

SHC 75.7 75.7 70.7 42.2 71.8 71.8 63.3 39.3 66.3 65.5 54.8 36.1

LDB 61.51 61.59 62.91 69.82 58.07 58.16 60.88 68.15 53.00 53.46 57.91 65.51

LWB 49.31 55.10 60.70 69.06 47.75 53.71 59.20 67.61 45.37 51.48 56.76 65.22

kW 6.99 6.99 7.02 7.19 6.93 6.93 6.99 7.16 6.83 6.84 6.94 7.11

57 62 67 75 57 62 67 75 57 62 67 75

AIR ENTERING EVAPORATOR — 80 F Edb (F) - CFM

Air Entering Evaporator — Ewb (F)

LEGEND

50XCA08 (7

Condenser Air

ECT (F) CFM

105

115

BF — Bypass Factor EWB — Entering Wet Bulb (F) SHC — Sensible Capacity (1000 Btu/hr)

ECT — Entering Condenser Temperature (F) LDB — Leaving Dry Bulb (F) TC — Total Capacity (1000 Btu/hr)

EDB — Entering Dry Bulb (F) LWB — Leaving Wet Bulb (F) kW — Compressor Motor Power Input (kilowatts)

9

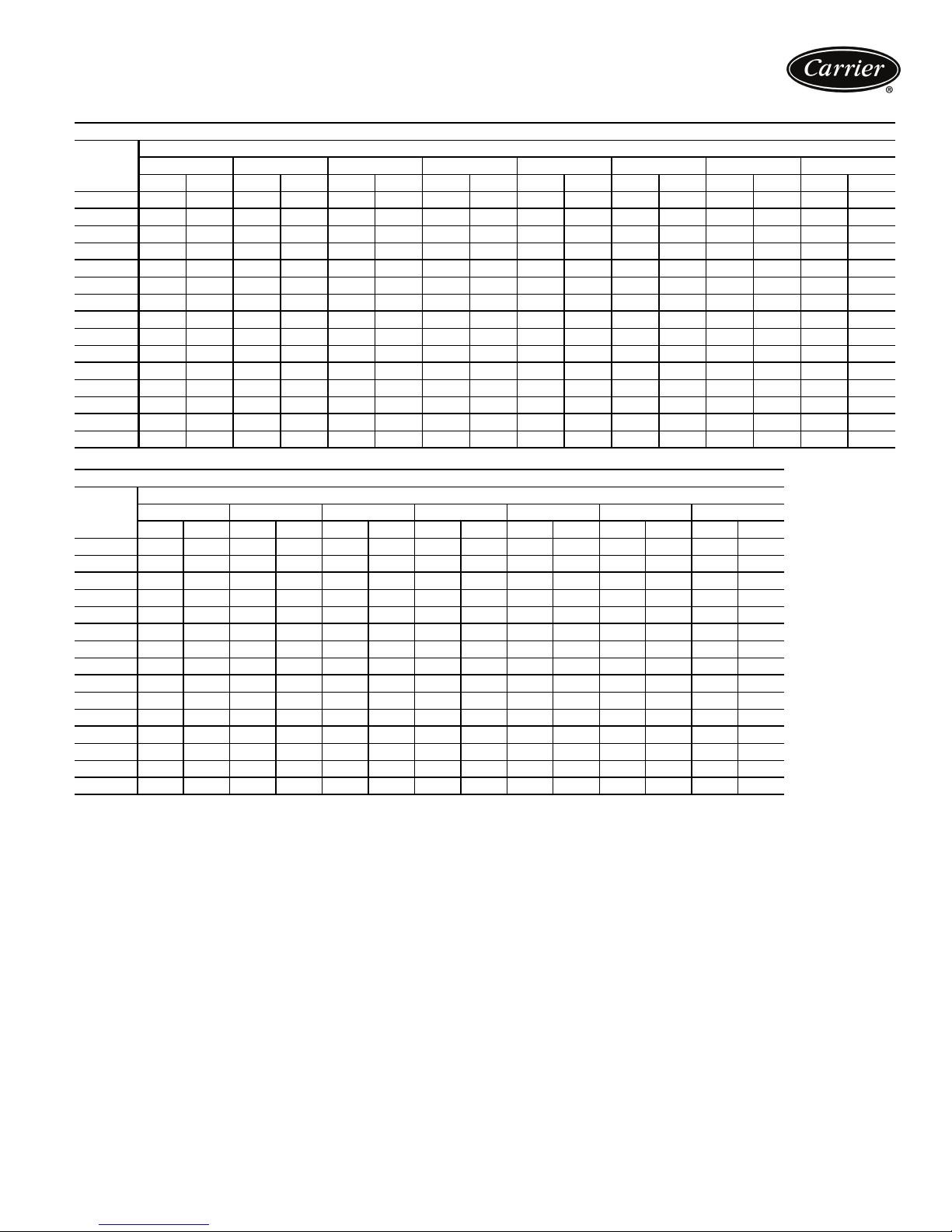

Performance data (cont)

GROSS COOLING CAPACITIES (cont)

50XCA12 (10 TONS)

Entering

Condenser Air

ECT (F) CFM

4800

55

75

95

105

115

BF — Bypass Factor EWB — Entering Wet Bulb (F) SHC — Sensible Capacity (1000 Btu/hr)

ECT — Entering Condenser Temperature (F) LDB — Leaving Dry Bulb (F) TC — Total Capacity (1000 Btu/hr)

EDB — Entering Dry Bulb (F) LWB — Leaving Wet Bulb (F) kW — Compressor Motor Power Input (kilowatts)

6000

7600

4800

6000

7600

4800

6000

7600

4800

6000

7600

4800

6000

7600

BF 0.23 0.06 0.05 0.03 0.37 0.13 0.08 0.06 0.46 0.23 0.11 0.10

TC 140.7 140.9 151.0 171.6 131.8 135.1 146.3 166.9 119.7 127.4 139.0 159.3

SHC 140.7 140.9 117.2 75.7 131.8 125.6 105.3 71.0 119.7 108.2 92.4 65.8

LDB 54.21 54.30 58.75 66.32 49.79 51.37 56.13 63.98 43.44 47.13 52.10 60.24

LWB 45.94 52.09 57.48 65.97 43.81 49.88 55.21 63.77 40.59 46.26 51.54 60.18

kW 5.93 5.93 6.09 6.42 5.80 5.85 6.02 6.34 5.62 5.74 5.91 6.22

TC 141.6 141.8 152.6 173.7 132.5 136.0 147.7 168.7 120.2 128.2 140.0 160.8

SHC 141.6 141.8 117.9 76.4 132.5 126.1 105.9 71.6 120.2 108.6 92.9 66.4

LDB 54.03 54.13 58.62 66.19 49.62 51.26 56.00 63.83 43.27 47.01 51.96 60.07

LWB 45.86 52.02 57.37 65.85 43.72 49.79 55.08 63.63 40.50 46.14 51.41 60.02

kW 5.31 5.31 5.42 5.64 5.22 5.26 5.37 5.59 5.11 5.18 5.30 5.50

TC 142.1 142.6 153.3 174.8 132.9 136.5 148.3 169.6 120.5 128.6 140.5 161.5

SHC 142.1 141.3 118.1 76.7 132.9 126.3 106.2 71.9 120.5 108.8 93.1 66.6

LDB 53.95 54.23 58.57 66.13 49.54 51.21 55.94 63.76 43.18 46.95 51.89 59.99

LWB 45.82 51.96 57.32 65.78 43.68 49.74 55.03 63.56 40.46 46.08 51.34 59.94

kW 4.97 4.96 5.05 5.21 4.90 4.93 5.01 5.17 4.82 4.87 4.96 5.11

TC 131.8 132.0 140.0 159.5 123.7 125.4 135.8 155.2 112.6 118.3 129.3 148.5

SHC 131.8 132.0 112.8 71.6 123.7 120.7 101.0 66.9 112.6 103.8 88.1 61.7

LDB 55.83 55.93 59.54 67.05 51.65 52.50 57.11 64.88 45.59 48.47 53.38 61.44

LWB 46.71 52.78 58.24 66.66 44.71 50.85 56.16 64.65 41.70 47.54 52.79 61.35

kW 7.65 7.65 7.80 8.16 7.51 7.53 7.72 8.08 7.31 7.41 7.60 7.95

TC 132.7 132.9 141.2 161.3 124.5 126.2 136.9 156.8 113.2 119.1 130.2 149.8

SHC 132.7 132.9 113.3 72.2 124.5 121.1 101.4 67.5 113.2 104.2 88.5 62.2

LDB 55.67 55.77 59.44 66.94 51.48 52.39 57.00 64.76 45.41 48.35 53.26 61.29

LWB 46.63 52.71 58.15 66.56 44.63 50.77 56.06 64.53 41.61 47.43 52.67 61.21

kW 6.94 6.94 7.03 7.28 6.84 6.86 6.98 7.22 6.72 6.78 6.91 7.14

TC 133.2 133.3 141.9 162.1 124.9 126.7 137.5 157.6 113.5 119.5 130.7 150.5

SHC 133.2 133.3 113.6 72.5 124.9 121.4 101.7 67.7 113.5 104.4 88.8 62.5

LDB 55.58 55.68 59.40 66.89 51.39 52.34 56.95 64.70 45.32 48.29 53.19 61.21

LWB 46.59 52.68 58.11 66.52 44.59 50.72 56.01 64.47 41.56 47.38 52.61 61.14

kW 6.53 6.54 6.60 6.78 6.47 6.48 6.57 6.74 6.38 6.43 6.51 6.68

TC 121.9 122.0 127.6 145.4 114.7 114.9 123.9 141.9 104.7 108.3 118.3 136.2

SHC 121.9 122.0 107.9 67.0 114.7 114.9 96.2 62.4 104.7 98.9 83.5 57.3

LDB 57.65 57.75 60.43 67.88 53.72 53.81 58.19 65.90 48.02 49.95 54.78 62.76

LWB 47.56 53.54 59.08 67.46 45.71 51.89 57.21 65.63 42.92 48.94 54.16 62.64

kW 9.68 9.68 9.80 10.18 9.53 9.53 9.72 10.10 9.32 9.39 9.60 9.98

TC 122.8 122.9 128.7 147.1 115.4 115.6 124.9 143.3 105.3 109.1 119.2 137.4

SHC 122.8 122.9 108.3 67.5 115.4 115.6 96.6 62.9 105.3 99.3 83.8 57.7

LDB 57.49 57.59 60.36 67.78 53.55 53.65 58.10 65.79 47.83 49.83 54.67 62.63

LWB 47.49 53.47 59.01 67.37 45.63 51.81 57.12 65.53 42.83 48.83 54.05 62.51

kW 8.89 8.90 8.97 9.23 8.80 8.80 8.92 9.18 8.66 8.71 8.85 9.09

TC 123.2 123.3 129.3 147.9 115.8 116.0 125.5 144.1 105.6 109.4 119.7 138.0

SHC 123.2 123.3 108.5 67.8 115.8 116.0 96.8 63.1 105.6 99.5 84.0 58.0

LDB 57.42 57.51 60.31 67.73 53.47 53.56 58.06 65.74 47.74 49.77 54.61 62.56

LWB 47.45 53.44 58.97 67.33 45.59 51.78 57.07 65.47 42.79 48.78 53.99 62.45

kW 8.45 8.45 8.51 8.69 8.38 8.38 8.47 8.65 8.29 8.32 8.42 8.59

TC 116.5 116.6 120.9 137.9 109.8 109.9 117.5 134.6 100.4 102.9 112.5 129.4

SHC 116.5 116.6 105.2 64.6 109.8 109.9 93.6 59.9 100.4 96.3 81.0 54.9

LDB 58.64 58.73 60.93 68.32 54.84 54.94 58.78 66.45 49.32 50.73 55.53 63.47

LWB 48.01 53.94 59.53 67.89 46.25 52.37 57.76 66.16 43.57 49.66 54.88 63.33

kW 10.81 10.82 10.91 11.29 10.66 10.66 10.84 11.22 10.45 10.51 10.72 11.10

TC 117.3 117.4 121.9 139.4 110.5 110.6 118.5 136.0 101.0 103.7 113.3 130.6

SHC 117.3 117.4 105.6 65.1 110.5 110.6 94.0 60.4 101.0 96.6 81.3 55.3

LDB 58.49 58.58 60.85 68.23 54.68 54.78 58.69 66.34 49.14 50.63 55.42 63.34

LWB 47.95 53.88 59.46 67.80 46.17 52.30 57.68 66.06 43.48 49.56 54.78 63.21

kW 10.00 10.00 10.07 10.33 9.90 9.91 10.02 10.28 9.77 9.81 9.95 10.20

TC 117.7 117.8 122.5 140.1 110.8 111.0 119.0 136.7 101.3 104.0 113.7 131.2

SHC 117.7 117.8 105.8 65.3 110.8 111.0 94.2 60.6 101.3 96.8 81.5 55.5

LDB 58.42 58.51 60.81 68.19 54.60 54.71 58.64 66.29 49.06 50.58 55.37 63.28

LWB 47.91 53.85 59.42 67.76 46.13 52.26 57.64 66.01 43.44 49.52 54.73 63.15

kW 9.54 9.54 9.59 9.77 9.47 9.47 9.55 9.74 9.37 9.40 9.50 9.68

TC 110.8 110.9 114.0 129.9 104.5 104.7 110.8 127.0 95.9 97.3 106.2 122.3

SHC 110.8 110.9 102.3 62.0 104.5 104.7 90.9 57.4 95.9 93.5 78.4 52.4

LDB 59.69 59.78 61.44 68.78 56.04 56.14 59.38 67.02 50.71 51.57 56.30 64.21

LWB 48.49 54.37 59.99 68.33 46.81 52.87 58.34 66.71 44.26 50.42 55.64 64.05

kW 12.01 12.01 12.08 12.47 11.86 11.87 12.01 12.40 11.66 11.70 11.90 12.29

TC 111.6 111.7 114.9 131.3 105.2 105.3 111.7 128.2 96.3 97.9 107.0 123.4

SHC 111.6 111.7 102.7 62.5 105.2 105.3 91.3 57.8 96.3 93.8 78.7 52.8

LDB 59.55 59.63 61.38 68.70 55.90 56.00 59.31 66.92 50.58 51.50 56.21 64.10

LWB 48.43 54.31 59.93 68.25 46.74 52.81 58.26 66.62 44.19 50.34 55.54 63.95

kW 11.20 11.20 11.25 11.50 11.09 11.10 11.20 11.46 10.96 10.98 11.13 11.38

TC 111.9 112.0 115.4 132.0 105.5 105.7 112.1 128.9 96.6 98.3 107.4 124.0

SHC 111.9 112.0 102.9 62.7 105.5 105.7 91.5 58.1 96.6 94.0 78.9 53.0

LDB 59.48 59.56 61.34 68.66 55.82 55.91 59.26 66.88 50.48 51.44 56.15 64.04

LWB 48.40 54.28 59.90 68.22 46.70 52.77 58.23 66.57 44.14 50.29 55.49 63.89

kW 10.73 10.73 10.77 10.95 10.66 10.66 10.73 10.91 10.56 10.58 10.68 10.86

57 62 67 75 57 62 67 75 57 62 67 75

5000 4000 3000

AIR ENTERING EVAPORATOR — 80 F Edb (F) - CFM

Air Entering Evaporator — Ewb (F)

LEGEND

10

GROSS COOLING CAPACITIES (cont)

50XCA14 (12 TONS)

Entering

Condenser Air

ECT (F) CFM

6000

55

75

95

105

115

BF — Bypass Factor EWB — Entering Wet Bulb (F) SHC — Sensible Capacity (1000 Btu/hr)

ECT — Entering Condenser Temperature (F) LDB — Leaving Dry Bulb (F) TC — Total Capacity (1000 Btu/hr)

EDB — Entering Dry Bulb (F) LWB — Leaving Wet Bulb (F) kW — Compressor Motor Power Input (kilowatts)

8000

9500

6000

8000

9500

6000

8000

9500

6000

8000

9500

6000

8000

9500

BF 0.24 0.09 0.08 0.05 0.38 0.15 0.12 0.10 0.47 0.25 0.15 0.13

TC 165.3 166.3 178.4 202.5 155.0 159.4 172.8 196.7 141.0 150.5 164.0 187.6

SHC 165.3 163.1 136.5 88.8 155.0 146.7 123.2 83.4 141.0 127.1 108.6 77.5

LDB 54.74 55.21 59.37 66.62 50.40 52.14 56.73 64.30 44.09 47.82 52.68 60.60

LWB 46.20 52.28 57.65 66.14 44.11 50.11 55.43 64.00 40.93 46.54 51.85 60.51

kW 6.11 6.13 6.21 6.39 6.05 6.08 6.17 6.34 5.97 6.02 6.11 6.27

TC 165.8 166.9 179.2 204.0 155.5 159.9 173.5 197.8 141.3 150.8 164.6 188.6

SHC 165.8 163.7 136.8 89.3 155.5 147.0 123.5 83.8 141.3 127.2 108.8 77.8

LDB 54.66 55.13 59.33 66.54 50.31 52.08 56.69 64.23 44.01 47.81 52.63 60.51

LWB 46.17 52.24 57.60 66.07 44.07 50.07 55.38 63.93 40.89 46.51 51.79 60.42

kW 5.51 5.51 5.54 5.62 5.48 5.49 5.53 5.60 5.45 5.47 5.50 5.57

TC 166.2 167.2 179.7 204.6 155.8 160.2 174.0 198.5 141.6 151.2 165.0 189.2

SHC 166.2 163.8 137.0 89.5 155.8 147.1 123.7 84.1 141.6 127.4 109.0 78.1

LDB 54.61 55.10 59.29 66.51 50.25 52.06 56.64 64.18 43.95 47.76 52.58 60.46

LWB 46.14 52.22 57.57 66.04 44.04 50.05 55.34 63.88 40.86 46.47 51.75 60.37

kW 5.24 5.24 5.26 5.32 5.23 5.24 5.25 5.30 5.22 5.22 5.24 5.28

TC 155.1 155.3 165.2 187.7 145.8 148.1 160.3 182.7 133.1 140.1 152.7 174.9

SHC 155.1 155.3 131.2 83.8 145.8 141.1 118.0 78.5 133.1 122.0 103.6 72.7

LDB 56.31 56.40 60.17 67.37 52.15 53.20 57.71 65.22 46.11 49.13 53.94 61.79

LWB 46.94 52.99 58.41 66.85 44.96 51.05 56.36 64.88 41.97 47.77 53.05 61.65

kW 8.16 8.16 8.24 8.44 8.09 8.11 8.21 8.39 8.00 8.05 8.14 8.33

TC 155.7 155.9 166.0 189.0 146.3 148.9 161.0 183.8 133.4 140.6 153.3 175.8

SHC 155.7 155.9 131.5 84.2 146.3 141.4 118.3 78.9 133.4 122.2 103.8 73.0

LDB 56.22 56.30 60.13 67.30 52.06 53.15 57.66 65.14 46.02 49.08 53.87 61.70

LWB 46.90 52.94 58.36 66.79 44.92 50.99 56.31 64.80 41.92 47.71 52.99 61.56

kW 7.45 7.46 7.49 7.58 7.43 7.44 7.47 7.56 7.39 7.41 7.45 7.53

TC 156.1 156.2 166.6 189.8 146.7 149.2 161.6 184.6 133.7 141.0 153.8 176.4

SHC 156.1 156.2 131.8 84.5 146.7 141.5 118.5 79.2 133.7 122.4 104.0 73.3

LDB 56.15 56.26 60.09 67.26 51.99 53.12 57.61 65.09 45.95 49.02 53.82 61.64

LWB 46.87 52.92 58.33 66.75 44.89 50.97 56.27 64.76 41.89 47.67 52.94 61.51

kW 7.14 7.14 7.15 7.20 7.13 7.13 7.15 7.19 7.12 7.12 7.14 7.17

TC 143.5 143.6 150.6 171.0 135.3 135.9 146.4 166.9 124.1 127.8 140.0 160.6

SHC 143.5 143.6 125.4 78.3 135.3 134.3 112.3 73.1 124.1 115.9 98.1 67.5

LDB 58.08 58.17 61.05 68.19 54.17 54.48 58.78 66.22 48.39 50.65 55.31 63.08

LWB 47.76 53.72 59.23 67.63 45.93 52.05 57.38 65.84 43.12 49.19 54.37 62.89

kW 10.55 10.55 10.61 10.80 10.48 10.48 10.57 10.77 10.39 10.27 10.52 10.71

TC 144.1 144.3 151.6 172.4 135.8 136.7 147.1 168.1 124.3 129.2 140.6 161.3

SHC 144.1 144.3 125.8 78.7 135.8 134.6 112.6 73.5 124.3 116.6 98.3 67.7

LDB 57.98 58.07 60.98 68.13 54.07 54.44 58.73 66.15 48.35 50.48 55.25 63.01

LWB 47.71 53.68 59.17 67.57 45.88 51.98 57.33 65.77 43.10 49.02 54.31 62.83

kW 9.79 9.79 9.82 9.90 9.76 9.77 9.80 9.88 9.73 9.74 9.78 9.85

TC 144.6 144.8 152.1 173.3 136.2 137.0 147.7 168.9 124.7 129.4 141.2 162.0

SHC 144.6 144.8 126.0 79.1 136.2 134.8 112.9 73.8 124.7 116.7 98.6 68.0

LDB 57.90 58.00 60.96 68.08 53.98 54.40 58.68 66.10 48.26 50.44 55.18 62.95

LWB 47.68 53.65 59.15 67.53 45.84 51.96 57.28 65.72 43.05 49.00 54.25 62.77

kW 9.44 9.44 9.45 9.49 9.43 9.43 9.44 9.48 9.43 9.43 9.44 9.47

TC 137.3 137.4 142.6 162.4 129.7 129.6 138.8 158.6 119.0 122.1 133.3 152.6

SHC 137.3 137.4 122.2 75.6 129.7 129.6 109.3 70.4 119.0 113.2 95.4 64.7

LDB 59.03 59.12 61.53 68.60 55.24 55.38 59.36 66.74 49.70 51.34 55.99 63.77

LWB 48.20 54.11 59.68 68.04 46.44 52.56 57.93 66.34 43.77 49.83 55.05 63.57

kW 11.85 11.85 11.90 12.09 11.78 11.78 11.87 12.05 11.68 11.71 11.82 12.00

TC 137.7 137.8 143.7 163.6 130.0 130.3 139.5 159.4 119.2 122.8 133.6 153.3

SHC 137.7 137.8 122.6 75.9 130.0 130.3 109.5 70.6 119.2 113.5 95.4 64.9

LDB 58.96 59.05 61.47 68.56 55.18 55.24 59.31 66.70 49.65 51.27 55.99 63.72

LWB 48.17 54.08 59.62 67.98 46.41 52.50 57.88 66.29 43.74 49.75 55.02 63.51

kW 11.08 11.08 11.11 11.19 11.06 11.06 11.09 11.17 11.02 11.03 11.07 11.15

TC 138.2 138.4 144.1 164.3 130.5 130.6 140.2 160.2 119.6 123.1 134.2 154.0

SHC 138.2 138.4 122.8 76.1 130.5 130.6 109.8 70.9 119.6 113.6 95.6 65.1

LDB 58.88 58.97 61.44 68.52 55.09 55.19 59.25 66.65 49.54 51.23 55.92 63.66

LWB 48.13 54.05 59.59 67.95 46.37 52.47 57.83 66.25 43.69 49.72 54.96 63.46

kW 10.73 10.73 10.74 10.77 10.72 10.72 10.73 10.76 10.71 10.72 10.73 10.75

TC 130.4 130.5 134.2 152.8 123.4 123.5 130.6 149.5 113.4 115.2 125.4 144.1

SHC 130.4 130.5 118.8 72.5 123.4 123.5 106.0 67.4 113.4 109.7 92.0 61.7

LDB 60.08 60.16 62.04 69.07 56.44 56.54 59.97 67.31 51.12 52.21 56.84 64.51

LWB 48.67 54.53 60.14 68.48 47.00 53.04 58.51 66.89 44.46 50.60 55.85 64.28

kW 13.18 13.18 13.22 13.39 13.12 13.12 13.18 13.36 13.02 13.04 13.14 13.31

TC 130.8 130.9 135.3 154.0 123.7 123.8 131.6 150.2 113.6 116.0 126.1 144.8

SHC 130.8 130.9 119.2 72.8 123.7 123.8 106.4 67.5 113.6 110.0 92.2 61.9

LDB 60.02 60.10 61.98 69.03 56.39 56.48 59.89 67.28 51.07 52.13 56.78 64.47

LWB 48.65 54.51 60.08 68.43 46.98 53.02 58.44 66.85 44.44 50.51 55.78 64.23

kW 12.45 12.45 12.47 12.54 12.42 12.42 12.45 12.52 12.38 12.39 12.43 12.50

TC 131.4 131.5 135.8 154.5 124.2 124.3 132.1 151.0 114.0 116.3 126.7 145.4

SHC 131.4 131.5 119.4 73.0 124.2 124.3 106.6 67.8 114.0 110.2 92.5 62.1

LDB 59.93 60.01 61.95 69.00 56.29 56.39 59.86 67.23 50.96 52.09 56.70 64.41

LWB 48.61 54.47 60.05 68.40 46.93 52.98 58.41 66.80 44.39 50.48 55.72 64.18

kW 12.10 12.10 12.11 12.13 12.10 12.10 12.11 12.13 12.08 12.09 12.10 12.12

57 62 67 75 57 62 67 75 57 62 67 75

6000 4800 3600

AIR ENTERING EVAPORATOR — 80 F Edb (F) - CFM

Air Entering Evaporator — Ewb (F)

LEGEND

11

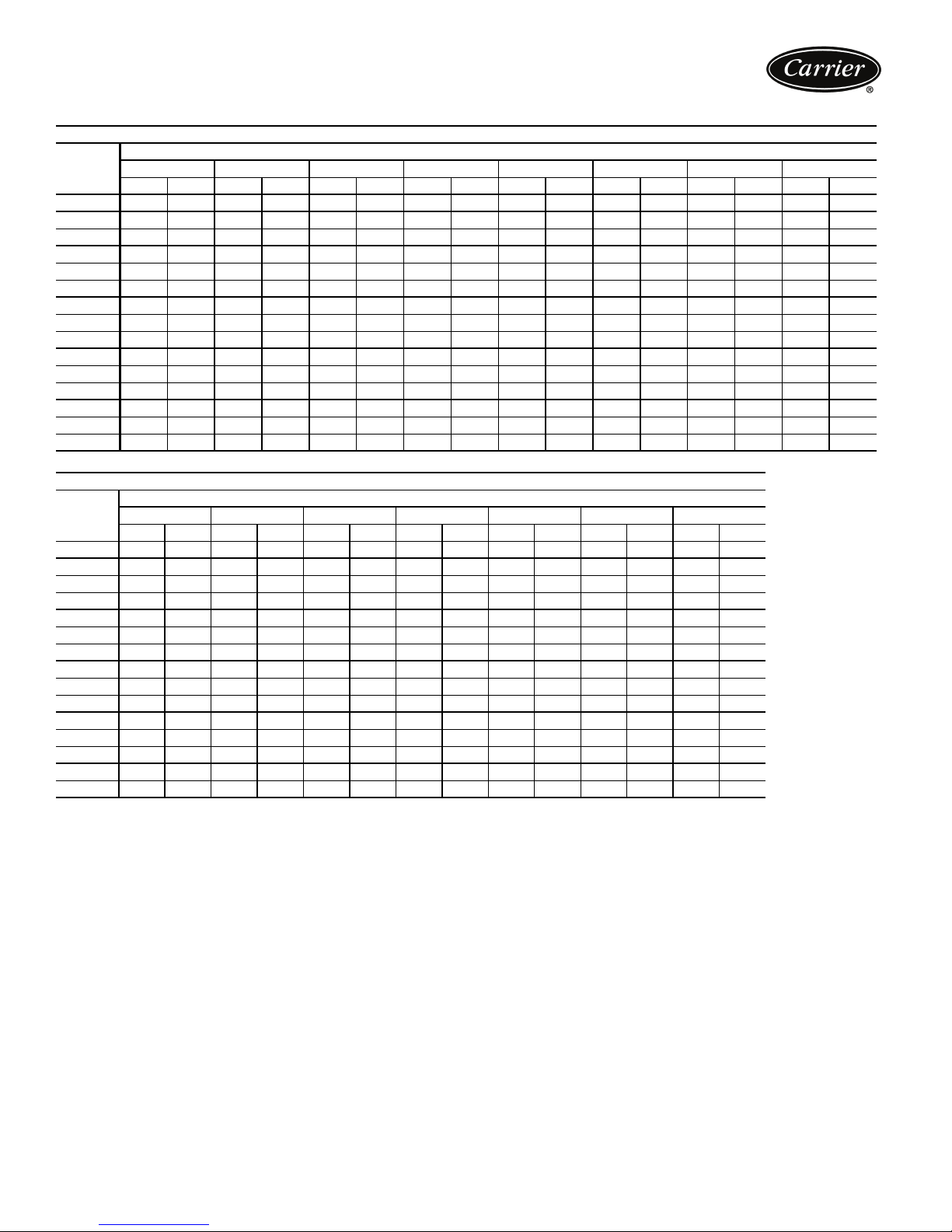

Performance data (cont)

GROSS COOLING CAPACITIES (cont)

50XCA16 (15 TONS)

Entering

Condenser Air

ECT (F) CFM

6000

55

75

95

105

115

BF — Bypass Factor EWB — Entering Wet Bulb (F) SHC — Sensible Capacity (1000 Btu/hr)

ECT — Entering Condenser Temperature (F) LDB — Leaving Dry Bulb (F) TC — Total Capacity (1000 Btu/hr)

EDB — Entering Dry Bulb (F) LWB — Leaving Wet Bulb (F) kW — Compressor Motor Power Input (kilowatts)

8000

9500

6000

8000

9500

6000

8000

9500

6000

8000

9500

6000

8000

9500

BF 0.26 0.06 0.05 0.03 0.39 0.15 0.08 0.06 0.48 0.26 0.11 0.09

TC 203.8 204.2 216.8 245.4 191.2 194.5 210.3 239.1 173.8 183.8 200.2 228.8

SHC 203.8 204.1 172.7 109.9 191.2 185.0 154.6 102.7 173.8 159.1 135.2 94.9

LDB 55.09 55.18 59.12 66.76 50.79 51.89 56.64 64.53 44.59 47.79 52.78 60.98

LWB 46.37 52.47 57.93 66.44 44.30 50.43 55.77 64.34 41.19 46.96 52.26 60.92

kW 8.70 8.72 8.96 9.57 8.43 8.50 8.83 9.44 8.09 8.28 8.63 9.22

TC 205.2 205.4 219.2 249.0 192.4 196.1 212.5 242.3 174.8 184.8 201.7 231.5

SHC 205.2 205.4 173.6 111.0 192.4 185.8 155.5 103.8 174.8 159.5 135.8 95.9

LDB 54.92 55.02 59.01 66.62 50.60 51.77 56.50 64.37 44.40 47.70 52.67 60.78

LWB 46.29 52.40 57.82 66.30 44.21 50.32 55.64 64.18 41.09 46.86 52.13 60.73

kW 7.91 7.92 8.14 8.64 7.72 7.77 8.04 8.53 7.44 7.60 7.86 8.35

TC 206.2 206.4 220.2 250.6 193.2 196.8 213.4 243.6 175.4 185.6 202.7 232.6

SHC 206.2 206.4 174.0 111.5 193.2 186.1 155.9 104.3 175.4 160.0 136.3 96.3

LDB 54.80 54.91 58.96 66.55 50.49 51.72 56.44 64.30 44.27 47.61 52.57 60.70

LWB 46.23 52.36 57.77 66.24 44.15 50.28 55.58 64.11 41.02 46.79 52.05 60.65

kW 7.61 7.61 7.82 8.25 7.42 7.48 7.72 8.17 7.18 7.32 7.56 8.00

TC 190.2 190.4 199.8 226.8 179.0 180.0 194.2 221.2 163.3 169.9 185.3 212.2

SHC 190.2 190.4 165.9 103.7 179.0 177.2 148.1 96.6 163.3 152.4 128.7 88.8

LDB 56.75 56.85 59.94 67.50 52.66 53.06 57.62 65.45 46.74 49.14 54.08 62.18

LWB 47.15 53.17 58.71 67.15 45.21 51.39 56.73 65.23 42.29 48.25 53.51 62.09

kW 10.80 10.80 11.03 11.69 10.54 10.56 10.89 11.55 10.18 10.33 10.69 11.33

TC 191.6 191.8 202.1 229.7 180.1 181.6 195.9 223.8 164.1 171.3 186.8 214.4

SHC 191.6 191.8 166.8 104.6 180.1 178.0 148.7 97.4 164.1 153.0 129.3 89.7

LDB 56.58 56.67 59.83 67.39 52.48 52.95 57.53 65.32 46.57 49.01 53.96 62.02

LWB 47.07 53.10 58.60 67.04 45.12 51.28 56.63 65.10 42.20 48.12 53.39 61.94

kW 9.93 9.93 10.12 10.63 9.72 9.75 10.01 10.52 9.44 9.57 9.84 10.35

TC 192.6 192.8 203.1 231.5 180.9 182.3 197.1 225.5 164.7 171.9 187.8 215.9

SHC 192.6 192.8 167.2 105.2 180.9 178.4 149.2 98.0 164.7 153.3 129.8 90.2

LDB 56.46 56.56 59.78 67.31 52.36 52.88 57.45 65.23 46.44 48.95 53.86 61.92

LWB 47.01 53.05 58.56 66.97 45.07 51.24 56.56 65.02 42.14 48.07 53.31 61.84

kW 9.55 9.55 9.72 10.19 9.37 9.39 9.62 10.09 9.12 9.23 9.48 9.93

TC 175.5 175.6 181.6 205.9 165.6 165.8 176.7 201.3 151.6 155.4 169.3 194.0

SHC 175.5 175.6 158.6 96.9 165.6 165.8 141.0 89.9 151.6 145.3 122.0 82.4

LDB 58.55 58.65 60.82 68.31 54.70 54.80 58.68 66.45 49.11 50.56 55.43 63.47

LWB 47.98 53.91 59.52 67.93 46.18 52.31 57.74 66.20 43.47 49.58 54.84 63.35

kW 13.24 13.25 13.41 14.07 12.98 12.99 13.28 13.94 12.62 12.72 13.08 13.74

TC 176.7 176.8 183.6 208.6 166.5 166.7 178.4 203.8 152.3 156.5 170.4 195.9

SHC 176.7 176.8 159.4 97.7 166.5 166.7 141.8 90.7 152.3 145.8 122.4 83.0

LDB 58.41 58.50 60.72 68.21 54.56 54.66 58.57 66.33 48.97 50.46 55.34 63.34

LWB 47.91 53.85 59.44 67.83 46.12 52.25 57.65 66.08 43.41 49.48 54.74 63.22

kW 12.31 12.31 12.45 12.97 12.11 12.11 12.35 12.87 11.82 11.90 12.19 12.71

TC 177.6 177.8 184.5 210.3 167.3 167.5 179.2 205.3 152.9 157.0 171.4 197.3

SHC 177.6 177.8 159.8 98.4 167.3 167.5 142.1 91.3 152.9 146.1 122.9 83.5

LDB 58.29 58.38 60.68 68.14 54.44 54.54 58.52 66.25 48.85 50.40 55.24 63.24

LWB 47.86 53.81 59.40 67.76 46.06 52.20 57.60 66.00 43.35 49.43 54.66 63.13

kW 11.89 11.90 12.02 12.49 11.71 11.72 11.92 12.39 11.46 11.53 11.79 12.25

TC 167.5 167.7 171.7 194.9 158.3 158.5 167.1 190.6 145.3 147.3 160.4 184.2

SHC 167.5 167.7 154.6 93.4 158.3 158.5 137.3 86.4 145.3 141.4 118.3 79.1

LDB 59.52 59.61 61.30 68.74 55.81 55.91 59.24 66.98 50.39 51.35 56.15 64.13

LWB 48.42 54.31 59.96 68.34 46.71 52.78 58.29 66.71 44.11 50.30 55.55 64.01

kW 14.57 14.57 14.69 15.33 14.32 14.33 14.57 15.21 13.97 14.03 14.38 15.04

TC 168.6 168.8 173.7 197.8 159.1 159.3 169.0 193.0 145.9 148.6 161.7 185.9

SHC 168.6 168.8 155.4 94.3 159.1 159.3 138.0 87.1 145.9 141.9 118.8 79.5

LDB 59.39 59.48 61.21 68.63 55.69 55.79 59.14 66.87 50.28 51.25 56.06 64.03

LWB 48.36 54.26 59.88 68.23 46.65 52.73 58.19 66.60 44.05 50.19 55.45 63.90

kW 13.64 13.64 13.75 14.28 13.44 13.44 13.65 14.17 13.15 13.21 13.49 14.02

TC 169.5 169.7 174.6 199.0 159.8 160.0 169.7 194.5 146.5 149.1 162.5 187.2

SHC 169.5 169.7 155.8 94.7 159.8 160.0 138.4 87.7 146.5 142.2 119.2 80.0

LDB 59.28 59.37 61.16 68.58 55.59 55.69 59.09 66.78 50.16 51.19 55.99 63.93

LWB 48.31 54.21 59.84 68.18 46.60 52.68 58.14 66.52 43.99 50.15 55.39 63.81

kW 13.21 13.21 13.31 13.78 13.03 13.03 13.22 13.69 12.78 12.83 13.08 13.55

TC 159.0 159.2 161.6 183.2 150.6 150.8 157.3 179.9 138.6 139.3 151.3 173.9

SHC 159.0 159.2 150.4 89.7 150.6 150.8 133.5 83.0 138.6 137.1 114.6 75.5

LDB 60.56 60.65 61.82 69.18 56.99 57.08 59.83 67.49 51.77 52.22 56.90 64.84

LWB 48.89 54.73 60.41 68.76 47.26 53.27 58.85 67.22 44.78 51.01 56.28 64.70

kW 15.94 15.94 16.02 16.64 15.70 15.71 15.90 16.54 15.36 15.39 15.73 16.37

TC 160.0 160.2 163.5 186.0 151.4 151.5 159.1 181.7 139.1 140.4 152.4 175.4

SHC 160.0 160.2 151.1 90.6 151.4 151.5 134.1 83.5 139.1 137.6 115.1 75.9

LDB 60.44 60.53 61.73 69.08 56.88 56.97 59.73 67.42 51.66 52.11 56.82 64.75

LWB 48.84 54.68 60.32 68.66 47.20 53.22 58.75 67.13 44.73 50.91 56.19 64.60

kW 15.04 15.04 15.11 15.62 14.85 14.85 15.01 15.52 14.57 14.60 14.87 15.38

TC 160.9 161.1 164.3 187.2 152.0 152.2 159.8 183.0 139.7 140.9 153.4 176.6

SHC 160.9 161.1 151.5 91.0 152.0 152.2 134.4 83.9 139.7 137.9 115.5 76.4

LDB 60.33 60.42 61.68 69.03 56.77 56.87 59.68 67.35 51.55 52.05 56.73 64.66

LWB 48.79 54.64 60.29 68.62 47.16 53.18 58.71 67.07 44.67 50.88 56.12 64.52

kW 14.62 14.62 14.68 15.13 14.44 14.44 14.60 15.05 14.20 14.23 14.47 14.93

57 62 67 75 57 62 67 75 57 62 67 75

7500 6000 4500

AIR ENTERING EVAPORATOR — 80 F Edb (F) - CFM

Air Entering Evaporator — Ewb (F)

LEGEND

12

GROSS COOLING CAPACITIES (cont)

50XCA024 (20 TONS)

Entering

Condenser Air

ECT (F) CFM

8,550

55

11,400

12,700

8,550

75

11,400

12,700

8,550

95

11,400

12,700

8,550

105

115

BF — Bypass Factor EWB — Entering Wet Bulb (F) SHC — Sensible Capacity (1000 Btu/hr)

ECT — Entering Condenser Temperature (F) LDB — Leaving Dry Bulb (F) TC — Total Capacity (1000 Btu/hr)

EDB — Entering Dry Bulb (F) LWB — Leaving Wet Bulb (F) kW — Compressor Motor Power Input (kilowatts)

11,400

12,700

8,550

11,400

12,700

BF 0.22 0.06 0.05 0.02 0.36 0.12 0.08 0.06 0.46 0.22 0.11 0.09

TC 283.6 283.9 303.4 343.6 266.0 272.2 294.2 334.0 241.5 256.8 279.6 319.2

SHC 283.6 283.9 235.7 152.1 266.0 252.8 211.8 142.4 241.5 217.7 185.8 132.0

LDB 54.01 54.11 58.63 66.25 49.52 51.19 56.00 63.92 43.11 46.94 51.95 60.18

LWB 45.86 52.02 57.44 65.97 43.68 49.79 55.15 63.77 40.42 46.12 51.44 60.16

kW 12.84 12.85 13.26 14.06 12.50 12.62 13.07 13.86 12.04 12.34 12.78 13.56

TC 285.9 286.2 307.0 348.6 267.7 274.4 297.3 338.8 242.7 258.5 282.1 323.0

SHC 285.9 286.2 237.3 153.7 267.7 253.9 213.1 144.0 242.7 218.6 186.9 133.4

LDB 53.79 53.90 58.48 66.10 49.33 51.06 55.85 63.74 42.92 46.80 51.79 59.96

LWB 45.75 51.93 57.31 65.82 43.58 49.68 55.01 63.59 40.33 45.99 51.28 59.95

kW 11.73 11.75 12.06 12.72 11.46 11.56 11.91 12.56 11.10 11.33 11.68 12.31

TC 286.5 287.3 308.0 350.2 268.1 274.9 298.2 340.1 243.0 259.0 282.8 324.1

SHC 286.5 284.4 237.7 154.3 268.1 254.3 213.5 144.5 243.0 218.9 187.2 133.8

LDB 53.74 54.06 58.44 66.05 49.27 51.03 55.81 63.68 42.87 46.77 51.74 59.90

LWB 45.73 51.89 57.28 65.77 43.56 49.65 54.97 63.53 40.30 45.96 51.24 59.89

kW 11.46 11.33 11.60 12.19 11.20 11.30 11.64 12.04 10.85 11.07 11.41 11.82

TC 265.8 266.0 281.2 318.7 249.8 252.9 273.0 310.6 227.4 238.7 260.2 297.4

SHC 265.8 266.0 227.0 143.8 249.8 243.1 203.1 134.2 227.4 209.0 177.2 123.9

LDB 55.64 55.74 59.41 66.99 51.38 52.29 56.98 64.84 45.26 48.26 53.23 61.38

LWB 46.63 52.71 58.20 66.68 44.59 50.76 56.10 64.65 41.53 47.41 52.69 61.33

kW 16.17 16.18 16.52 17.40 15.81 15.88 16.33 17.21 15.33 15.57 16.05 16.90

TC 267.9 268.2 284.7 323.1 251.4 255.2 275.6 314.5 228.6 240.6 262.3 300.7

SHC 267.9 268.2 228.4 145.2 251.4 244.2 204.1 135.6 228.6 209.9 178.1 125.1

LDB 55.44 55.54 59.28 66.87 51.19 52.16 56.87 64.69 45.08 48.13 53.10 61.20

LWB 46.54 52.63 58.09 66.56 44.50 50.64 55.99 64.50 41.44 47.27 52.56 61.15

kW 14.81 14.82 15.11 15.74 14.54 14.62 14.94 15.60 14.18 14.39 14.72 15.36

TC 268.8 269.1 285.5 325.1 252.1 255.7 276.8 316.2 229.1 241.1 263.3 302.2

SHC 268.8 269.1 228.8 145.9 252.1 244.6 204.7 136.2 229.1 210.1 178.6 125.6

LDB 55.36 55.46 59.25 66.80 51.11 52.12 56.80 64.62 44.99 48.09 53.03 61.12

LWB 46.50 52.59 58.06 66.50 44.46 50.61 55.93 64.44 41.40 47.24 52.50 61.08

kW 14.47 14.47 14.72 15.36 14.21 14.27 14.59 15.21 13.87 14.05 14.38 14.98

TC 246.1 246.4 256.8 290.7 232.0 231.9 249.7 284.2 212.0 219.1 238.8 273.1

SHC 246.1 246.4 217.3 134.7 232.0 231.9 193.6 125.3 212.0 199.5 168.1 115.1

LDB 57.44 57.53 60.29 67.82 53.42 53.57 58.05 65.84 47.62 49.70 54.61 62.69

LWB 47.47 53.46 59.04 67.48 45.58 51.79 57.13 65.63 42.73 48.77 54.04 62.61

kW 20.12 20.13 20.40 21.30 19.76 19.76 20.22 21.11 19.25 19.43 19.94 20.83

TC 247.9 248.2 259.7 295.0 233.3 234.0 251.7 287.7 212.8 220.7 240.4 276.1

SHC 247.9 248.2 218.5 136.1 233.3 233.9 194.4 126.5 212.8 200.2 168.7 116.1

LDB 57.27 57.37 60.18 67.70 53.27 53.33 57.97 65.71 47.48 49.59 54.51 62.53

LWB 47.39 53.39 58.94 67.36 45.50 51.69 57.04 65.50 42.66 48.66 53.93 62.46

kW 18.61 18.61 18.83 19.50 18.34 18.35 18.68 19.36 17.97 18.11 18.47 19.14

TC 248.9 249.2 260.6 297.0 234.2 234.7 253.0 289.5 213.5 221.2 241.5 277.6

SHC 248.9 249.2 218.9 136.8 234.2 233.6 195.0 127.1 213.5 200.5 169.3 116.7

LDB 57.18 57.27 60.15 67.63 53.17 53.37 57.89 65.64 47.38 49.54 54.43 62.45

LWB 47.35 53.35 58.91 67.30 45.46 51.65 56.99 65.43 42.61 48.62 53.87 62.38

kW 18.19 18.19 18.39 19.02 17.94 17.95 18.26 18.89 17.59 17.73 18.07 18.68

TC 235.4 235.7 243.1 275.6 222.1 222.4 236.4 269.4 203.4 208.0 226.5 259.4

SHC 235.4 235.7 211.9 129.9 222.1 222.4 188.5 120.4 203.4 194.1 163.0 110.2

LDB 58.42 58.51 60.78 68.26 54.55 54.65 58.63 66.39 48.93 50.50 55.37 63.41

LWB 47.92 53.86 59.50 67.90 46.11 52.25 57.71 66.16 43.39 49.53 54.79 63.32

kW 22.31 22.32 22.52 23.42 21.95 21.96 22.35 23.25 21.44 21.58 22.08 22.98

TC 237.0 237.2 246.4 280.4 223.3 223.6 239.3 273.2 204.1 209.9 228.5 262.6

SHC 237.0 237.2 213.1 131.4 223.3 223.6 189.5 121.6 204.1 195.0 163.7 111.3

LDB 58.27 58.37 60.67 68.12 54.42 54.52 58.51 66.26 48.81 50.38 55.26 63.25

LWB 47.85 53.80 59.39 67.77 46.05 52.19 57.59 66.03 43.33 49.39 54.67 63.15

kW 20.77 20.77 20.95 21.63 20.50 20.50 20.81 21.48 20.11 20.22 20.60 21.27

TC 238.1 238.3 247.2 281.7 224.2 224.5 240.1 274.9 204.8 210.4 229.7 264.1

SHC 238.1 238.3 213.6 131.8 224.2 224.5 189.9 122.2 204.8 195.2 164.3 111.9

LDB 58.17 58.26 60.63 68.08 54.31 54.41 58.47 66.18 48.71 50.34 55.18 63.16

LWB 47.81 53.76 59.36 67.73 46.00 52.15 57.55 65.96 43.28 49.36 54.60 63.07

kW 20.32 20.32 20.48 21.11 20.07 20.07 20.36 20.99 19.72 19.82 20.17 20.79

TC 223.9 224.1 229.1 259.8 211.6 211.8 223.0 254.3 194.2 196.6 213.9 245.2

SHC 223.9 224.1 206.2 124.8 211.6 211.8 183.2 115.4 194.2 188.6 157.8 105.3

LDB 59.48 59.56 61.30 68.71 55.76 55.85 59.23 66.95 50.33 51.34 56.15 64.14

LWB 48.40 54.29 59.96 68.34 46.68 52.76 58.29 66.71 44.08 50.29 55.55 64.03

kW 24.63 24.63 24.78 25.68 24.27 24.28 24.61 25.53 23.76 23.85 24.35 25.26

TC 225.3 225.5 232.2 264.3 212.6 212.9 225.8 257.7 194.8 198.5 215.8 248.3

SHC 225.3 225.5 207.4 126.2 212.6 212.9 184.2 116.5 194.8 189.3 158.5 106.3

LDB 59.35 59.43 61.19 68.58 55.64 55.74 59.12 66.83 50.24 51.24 56.05 63.99

LWB 48.34 54.24 59.86 68.22 46.63 52.71 58.17 66.59 44.03 50.16 55.44 63.88

kW 23.05 23.05 23.19 23.86 22.79 22.79 23.05 23.73 22.41 22.48 22.85 23.53

TC 226.4 226.7 233.1 265.6 213.6 213.9 226.5 259.6 195.6 199.0 217.0 249.9

SHC 226.4 226.7 207.8 126.7 213.6 213.9 184.5 117.2 195.6 189.6 159.1 106.9

LDB 59.24 59.33 61.15 68.54 55.52 55.62 59.08 66.75 50.11 51.19 55.97 63.90

LWB 48.30 54.20 59.83 68.18 46.57 52.66 58.14 66.52 43.97 50.13 55.37 63.80

kW 22.59 22.60 22.72 23.33 22.36 22.36 22.60 23.22 22.01 22.08 22.42 23.04

57 62 67 75 57 62 67 75 57 62 67 75

10,000 8,000 6,000

AIR ENTERING EVAPORATOR — 80 F Edb (F) - CFM

Air Entering Evaporator — Ewb (F)

LEGEND

13

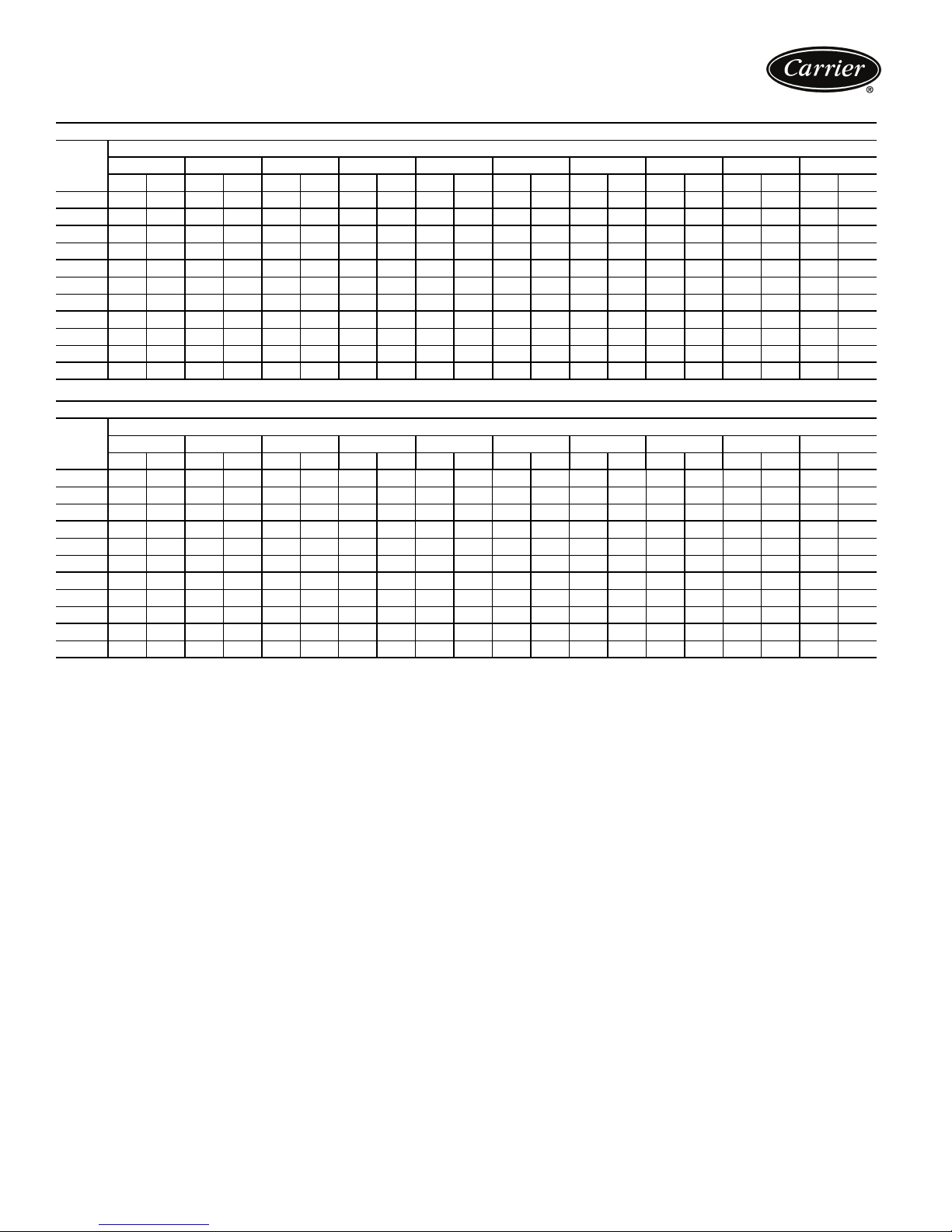

Performance data (cont)

CONDENSER FAN PERFORMANCE

50XCA06 (5 Tons)

ESP (in. wg)

CFM

1800 594 0.19 594 0.19 594 0.19 676 0.25 755 0.33 828 0.42

1900 588 0.19 588 0.19 598 0.20 686 0.27 764 0.35 836 0.44

2000 582 0.19 582 0.19 610 0.21 696 0.29 773 0.37 844 0.46

2100 576 0.19 576 0.19 623 0.23 707 0.31 783 0.40 852 0.49

2200 570 0.20 570 0.20 636 0.25 718 0.33 793 0.42 861 0.51

2300 564 0.20 564 0.20 649 0.27 730 0.36 803 0.44 870 0.54

2400 558 0.20 573 0.22 662 0.29 742 0.38 814 0.47 880 0.57

2500 552 0.21 589 0.24 676 0.32 754 0.41 825 0.50 890 0.60

2600 546 0.21 605 0.26 690 0.34 766 0.43 836 0.53 901 0.63

2600 540 0.21 622 0.28 704 0.37 779 0.46 848 0.56 911 0.66

2800 550 0.23 638 0.31 719 0.40 792 0.49 860 0.59 923 0.70

2900 570 0.26 655 0.34 734 0.43 806 0.53 872 0.63 934 0.74

3000 590 0.29 672 0.37 749 0.46 819 0.56 885 0.67 946 0.78

50XCA06 (5 Tons) (cont)

CFM

1800 896 0.51 960 0.61 1020 0.72 — —————

1900 902 0.54 965 0.64 1025 0.74 1082 0.86 ————

2000 909 0.56 971 0.66 1030 0.77 1086 0.88 1140 1.00 — —

2100 917 0.58 978 0.69 1036 0.80 1091 0.91 1145 1.03 1196 1.16

2200 925 0.61 985 0.72 1042 0.83 1097 0.94 1150 1.06 1201 1.19

2300 933 0.64 993 0.75 1049 0.86 1103 0.98 1155 1.10 1206 1.22

2400 942 0.67 1001 0.78 1057 0.89 1110 1.01 1161 1.13 1211 1.26

2500 951 0.70 1009 0.81 1064 0.93 1117 1.05 1168 1.17 1217 1.30

2600 961 0.74 1018 0.85 1073 0.96 1125 1.09 1175 1.21 1224 1.34

2700 971 0.77 1028 0.89 1081 1.00 1133 1.13 1183 1.25 1231 1.39

2800 982 0.81 1037 0.93 1090 1.05 1141 1.17 1190 1.30 1238 1.43

2900 992 0.85 1047 0.97 1100 1.09 1150 1.21 1199 1.34 1246 1.48

3000 1003 0.89 1057 1.01 1109 1.13 1159 1.26 1207 1.39 — —

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

0.00 0.10 0.20 0.30 0.40 0.50

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

ESP (in. wg)

0.60 0.70 0.80 0.90 1.00 1.10

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

NOTES:

1. Units are available with several motor hp options. Refer to the

physical data table.

2. Static pressure losses must be applied to external static pressure

before entering the fan performance table.

14

3. Interpolation is permitted; extrapolation is not.

4. Fan performance is based on filter, unit casing, and wet coil

losses.

CONDENSER FAN PERFORMANCE (cont)

50XCA08 (7

CFM

2500 594 0.25 594 0.25 662 0.32 738 0.41 807 0.50 872 0.60 932 0.70 988 0.81

2650 588 0.26 600 0.27 682 0.36 757 0.45 824 0.55 887 0.65 946 0.75 1001 0.87

2800 582 0.27 625 0.31 704 0.40 776 0.49 842 0.59 903 0.70 961 0.81 1016 0.93

2950 576 0.28 650 0.35 726 0.45 795 0.54 860 0.65 920 0.76 977 0.87 1030 0.99

3100 597 0.31 675 0.40 748 0.50 816 0.60 879 0.71 938 0.82 993 0.94 1046 1.06

3250 625 0.36 700 0.45 771 0.55 836 0.66 898 0.77 956 0.88 1010 1.00 1062 1.13

3400 654 0.42 726 0.51 794 0.61 858 0.72 918 0.83 974 0.95 1027 1.08 1078 1.21

3550 683 0.47 752 0.57 818 0.68 879 0.79 938 0.91 993 1.03 1045 1.16 1095 1.29

3700 712 0.54 778 0.64 842 0.75 901 0.86 958 0.98 1012 1.11 1064 1.24 1113 1.37

3850 741 0.60 805 0.71 866 0.82 924 0.94 979 1.06 1032 1.19 1083 1.33 1131 1.47

4000 770 0.68 831 0.79 890 0.90 947 1.02 1001 1.15 1053 1.29 1102 1.42 1150 1.56

4150 799 0.75 858 0.87 915 0.99 970 1.11 1023 1.25 1073 1.38 1122 1.52 1168 1.67

4300 828 0.84 885 0.96 940 1.08 994 1.21 1045 1.34 1094 1.49 1142 1.63 1188 1.78

4450 856 0.93 912 1.05 966 1.18 1017 1.31 1068 1.45 1116 1.59 1162 1.74 1207 1.89

4600 885 1.03 939 1.15 991 1.28 1042 1.42 1090 1.56 1138 1.71 1183 1.86 — —

1

/2 Ton s )

ESP (in. wg)

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

50XCA08 (7

1

/2 Tons) (cont)

ESP (in. wg)

CFM

0.80 0.90 1.00 1.10 1.20 1.30 1.40

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

2500 1042 0.93 1094 1.05 1144 1.17 1192 1.30 1238 1.43 1283 1.57 1327 1.72

2650 1054 0.98 1105 1.11 1154 1.23 1201 1.36 1247 1.50 1291 1.64 1334 1.78

2800 1068 1.05 1117 1.17 1166 1.30 1212 1.43 1257 1.57 1301 1.71 1343 1.86

2950 1081 1.11 1131 1.24 1178 1.37 1223 1.50 1268 1.64 1311 1.79 1353 1.94

3100 1096 1.18 1144 1.31 1191 1.44 1236 1.58 1279 1.72 1322 1.87 —

3250 1111 1.26 1159 1.39 1205 1.53 1249 1.67 1292 1.81 1333 1.96 — —

3400 1127 1.34 1174 1.47 1219 1.61 1263 1.75 1305 1.90 — — — —

3550 1143 1.42 1189 1.56 1234 1.70 1277 1.85 1319 2.00 — — — —

3700 11601.5112061.6512491.8012921.95 — — — — — —

3850 11781.6112221.7512651.90 — — — — — — — —

4000 11951.7112391.86——————————

4150 12131.8212571.97——————————

4300 12321.93————————————

4450 ——————————————

4600 ——————————————

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTES:

1. Units are available with several motor hp options. Refer to the

physical data table.

2. Static pressure losses must be applied to external static pressure

before entering the fan performance table.

3. Interpolation is permitted; extrapolation is not.

4. Fan performance is based on filter, unit casing, and wet coil

losses.

15

Performance data (cont)

CONDENSER FAN PERFORMANCE (cont)

50XCA12 (10 Tons)

ESP (in. wg)

CFM

4800 594 0.86 598 0.87 655 1.00 708 1.14 757 1.29 803 1.44 846 1.59 — —

5000 588 0.91 618 0.97 673 1.11 725 1.25 773 1.40 818 1.56 861 1.72 — —

5200 582 0.95 638 1.08 692 1.23 742 1.37 789 1.53 833 1.68 875 1.85 915 2.02

5400 601 1.06 658 1.20 711 1.35 759 1.50 805 1.66 849 1.82 890 1.99 930 2.16

5600 623 1.18 679 1.33 729 1.48 777 1.64 822 1.80 865 1.97 905 2.14 944 2.32

5800 646 1.31 699 1.46 749 1.62 795 1.78 839 1.95 881 2.12 921 2.30 959 2.48

6000 668 1.45 720 1.61 768 1.77 813 1.94 856 2.11 897 2.29 936 2.47 974 2.65

6200 690 1.60 740 1.76 787 1.93 832 2.10 874 2.28 914 2.46 952 2.64 989 2.83

6400 713 1.76 761 1.93 807 2.10 850 2.28 891 2.46 931 2.64 969 2.83 1005 3.03

6600 735 1.93 782 2.11 827 2.28 869 2.46 909 2.65 948 2.84 985 3.03 1021 3.23

6800 757 2.11 803 2.29 846 2.47 888 2.66 927 2.85 965 3.04 1002 3.24 1037 3.44

7000 779 2.30 824 2.49 866 2.68 907 2.87 946 3.06 983 3.26 1019 3.46 1053 3.67

7200 802 2.51 845 2.70 887 2.89 926 3.09 964 3.29 1001 3.49 1036 3.70 1070 3.91

7400 824 2.72 866 2.92 907 3.12 945 3.32 983 3.52 1019 3.73 1053 3.94 1087 4.15

7600 846 2.95 887 3.15 927 3.35 965 3.56 1001 3.77 1037 3.98 1071 4.20 1104 4.42

50XCA12 (10 Tons) (cont)

CFM

4800 ——————————————

5000 ——————————————

5200 ——————————————

5400 ——————————————

5600 9812.50————————————

5800 9962.6710312.86——————————

6000 10102.8410453.04——————————

6200 10253.0310603.2310933.43 — — — — — — — —

6400 10403.2310743.4311073.6411393.85 — — — — — —

6600 10563.4310893.6411223.8511534.07 — — — — — —

6800 1071 3.65 1104 3.86 1136 4.08 1168 4.30 1198 4.52 — — — —

7000 1087 3.88 1120 4.09 1151 4.31 1182 4.54 1212 4.77 1241 5.00 — —

7200 1103 4.12 1135 4.34 1166 4.56 1197 4.79 1226 5.02 1255 5.26 1284 5.50

7400 1119 4.37 1151 4.60 1182 4.82 1212 5.06 1241 5.29 1270 5.53 1298 5.78

7600 1136 4.64 1167 4.87 1197 5.10 1227 5.33 1256 5.57 1284 5.82 1312 6.06

0.00 0.00 0.10 0.20 0.30 0.40 0.50 0.60

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

ESP (in. wg)

0.70 0.80 0.90 1.00 1.10 1.20 1.30

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTES:

1. Units are available with several motor hp options. Refer to the

physical data table.

2. Static pressure losses must be applied to external static pressure

before entering the fan performance table.

16

3. Interpolation is permitted; extrapolation is not.

4. Fan performance is based on filter, unit casing, and wet coil

losses.

CONDENSER FAN PERFORMANCE (cont)

50XCA14 (12 Tons)

ESP (in. wg)

CFM

6000 494 1.50 494 1.50 494 1.50 494 1.50 494 1.50 521 1.68 554 1.93 586 2.18

6250 488 1.52 488 1.52 488 1.52 488 1.52 494 1.56 528 1.80 561 2.05 592 2.30

6500 482 1.53 482 1.53 482 1.53 482 1.53 502 1.67 536 1.92 568 2.17 599 2.44

6750 476 1.55 476 1.55 476 1.55 477 1.56 511 1.79 544 2.05 576 2.31 606 2.58

7000 470 1.56 470 1.56 470 1.56 488 1.68 520 1.93 552 2.18 583 2.45 613 2.73

7250 464 1.58 464 1.58 466 1.59 498 1.82 530 2.07 561 2.33 591 2.60 621 2.88

7500 458 1.59 458 1.59 477 1.73 509 1.96 540 2.21 570 2.48 600 2.76 628 3.04

7750 452 1.61 459 1.66 489 1.88 519 2.12 549 2.37 579 2.64 608 2.92 636 3.22

8000 446 1.62 472 1.81 501 2.04 530 2.28 560 2.54 588 2.81 617 3.10 644 3.40

8250 458 1.77 485 1.97 513 2.20 542 2.45 570 2.71 598 2.99 626 3.28 653 3.59

8500 472 1.93 498 2.14 526 2.38 553 2.63 580 2.90 608 3.18 635 3.48 661 3.79

8750 486 2.11 512 2.33 538 2.56 564 2.82 591 3.09 618 3.38 644 3.68 670 4.00

9000 500 2.29 525 2.52 550 2.76 576 3.02 602 3.30 628 3.59 654 3.90 679 4.22

9250 514 2.49 538 2.72 563 2.97 588 3.23 613 3.52 638 3.81 663 4.13 688 4.45

9500 528 2.70 551 2.93 575 3.19 600 3.46 624 3.74 649 4.05 673 4.36 697 4.69

50XCA14 (12 Tons) (cont)

CFM

6000 616 2.43 644 2.69 671 2.96 697 3.23 722 3.50 746 3.78 768 4.06

6250 622 2.57 650 2.84 677 3.11 703 3.39 728 3.67 751 3.95 774 4.24

6500 628 2.71 656 2.98 683 3.27 709 3.55 734 3.84 757 4.13 780 4.43

6750 635 2.86 663 3.14 689 3.43 715 3.72 739 4.02 763 4.32 786 4.62

7000 642 3.01 669 3.30 696 3.60 721 3.90 745 4.20 769 4.51 792 4.82

7250 649 3.17 676 3.47 702 3.77 727 4.08 752 4.39 775 4.71 — —

7500 656 3.34 683 3.65 709 3.96 734 4.27 758 4.59 781 4.91 — —

7750 663 3.52 690 3.83 715 4.15 740 4.47 764 4.80 — — — —

8000 671 3.71 697 4.02 722 4.35 747 4.67 — — — — — —

8250 679 3.90 705 4.22 730 4.55 754 4.89 — — — — — —

8500 687 4.11 712 4.44 737 4.77 — — — — — — — —

8750 695 4.32 720 4.66 744 5.00 — — — — — — — —

9000 ——————————————

9250 ——————————————

9500 ——————————————

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

ESP (in. wg)

0.80 0.90 1.00 1.10 1.20 1.30 1.40

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTES:

1. Units are available with several motor hp options. Refer to the

physical data table.

2. Static pressure losses must be applied to external static pressure

before entering the fan performance table.

3. Interpolation is permitted; extrapolation is not.

4. Fan performance is based on filter, unit casing, and wet coil

losses.

17

Performance data (cont)

CONDENSER FAN PERFORMANCE (cont)

50XCA16 (15 Tons)

ESP (in. wg)

CFM

6250 494 1.56 494 1.56 494 1.56 494 1.56 494 1.56 528 1.80 561 2.05 592 2.30

6500 488 1.57 488 1.57 488 1.57 488 1.57 502 1.67 536 1.92 568 2.17 599 2.44

6750 482 1.59 482 1.59 482 1.59 482 1.59 511 1.79 544 2.05 576 2.31 606 2.58

7000 476 1.61 476 1.61 476 1.61 488 1.68 520 1.93 552 2.18 583 2.45 613 2.73

7250 470 1.62 470 1.62 470 1.62 498 1.82 530 2.07 561 2.33 591 2.60 621 2.88

7500 464 1.64 464 1.64 477 1.73 509 1.96 540 2.21 570 2.48 600 2.76 628 3.04

7750 458 1.65 459 1.66 489 1.88 519 2.12 549 2.37 579 2.64 608 2.92 636 3.22

8000 452 1.67 472 1.81 501 2.04 530 2.28 560 2.54 588 2.81 617 3.10 644 3.40

8250 458 1.77 485 1.97 513 2.20 542 2.45 570 2.71 598 2.99 626 3.28 653 3.59

8500 472 1.93 498 2.14 526 2.38 553 2.63 580 2.90 608 3.18 635 3.48 661 3.79

8750 486 2.11 512 2.33 538 2.56 564 2.82 591 3.09 618 3.38 644 3.68 670 4.00

9000 500 2.29 525 2.52 550 2.76 576 3.02 602 3.30 628 3.59 654 3.90 679 4.22

9250 514 2.49 538 2.72 563 2.97 588 3.23 613 3.52 638 3.81 663 4.13 688 4.45

9500 528 2.70 551 2.93 575 3.19 600 3.46 624 3.74 649 4.05 673 4.36 697 4.69

9750 542 2.92 564 3.16 588 3.42 612 3.69 635 3.98 659 4.29 683 4.61 707 4.94

50XCA16 (15 Tons) (cont)

CFM

6250 622 2.57 650 2.84 677 3.11 703 3.39 728 3.67 751 3.95 774 4.24

6500 628 2.71 656 2.98 683 3.27 709 3.55 734 3.84 757 4.13 780 4.43

6750 635 2.86 663 3.14 689 3.43 715 3.72 739 4.02 763 4.32 786 4.62

7000 642 3.01 669 3.30 696 3.60 721 3.90 745 4.20 769 4.51 792 4.82

7250 649 3.17 676 3.47 702 3.77 727 4.08 752 4.39 775 4.71 — —

7500 656 3.34 683 3.65 709 3.96 734 4.27 758 4.59 781 4.91 — —

7750 663 3.52 690 3.83 715 4.15 740 4.47 764 4.80 — — — —

8000 671 3.71 697 4.02 722 4.35 747 4.67 — — — — — —

8250 679 3.90 705 4.22 730 4.55 754 4.89 — — — — — —

8500 687 4.11 712 4.44 737 4.77 — — — — — — — —

8750 695 4.32 720 4.66 744 5.00 — — — — — — — —

9000 7044.557284.89——————————

9250 7124.78————————————

9500 ——————————————

9750 ——————————————

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

ESP (in. wg)

0.80 0.90 1.00 1.10 1.20 1.30 1.40

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTES:

1. Units are available with several motor hp options. Refer to the

physical data table.

2. Static pressure losses must be applied to external static pressure

before entering the fan performance table.

18

3. Interpolation is permitted; extrapolation is not.

4. Fan performance is based on filter, unit casing, and wet coil

losses.

CONDENSER FAN PERFORMANCE (cont)

50XCA24 (20 Tons)

ESP (in. wg)

CFM

8,500 594 1.60 636 1.84 682 2.14 724 2.44 764 2.74 801 3.04 837 3.35 870 3.66

8,800 606 1.72 655 2.02 700 2.33 741 2.64 780 2.95 817 3.27 852 3.58 885 3.90

9,100 626 1.90 674 2.22 718 2.54 758 2.85 797 3.18 833 3.50 867 3.82 900 4.15

9,400 647 2.09 693 2.42 736 2.75 776 3.08 813 3.41 849 3.74 882 4.08 915 4.41

9,700 668 2.30 713 2.64 754 2.98 793 3.32 830 3.66 865 4.00 898 4.35 930 4.69

10,000 688 2.52 732 2.87 773 3.22 811 3.57 847 3.92 881 4.27 914 4.63 945 4.99

10,300 709 2.75 752 3.11 791 3.47 829 3.83 864 4.20 898 4.56 930 4.92 961 5.29

10,600 730 3.00 771 3.37 810 3.74 846 4.11 881 4.49 914 4.86 946 5.23 976 5.61

10,900 750 3.26 791 3.64 829 4.02 864 4.41 898 4.79 931 5.17 962 5.56 992 5.95

11,200 771 3.54 810 3.93 847 4.32 882 4.71 916 5.11 948 5.50 979 5.90 1008 6.29

11,500 792 3.83 830 4.23 866 4.64 901 5.04 933 5.44 965 5.85 995 6.25 1024 6.66

11,800 812 4.14 850 4.55 885 4.96 919 5.38 951 5.79 982 6.21 1012 6.62 1041 7.04

12,100 833 4.46 869 4.88 904 5.31 937 5.73 969 6.16 999 6.58 1029 7.01 1057 7.43

12,400 854 4.80 889 5.24 923 5.67 956 6.10 987 6.54 1017 6.97 1046 7.41 1074 7.85

12,700 874 5.16 909 5.60 942 6.05 974 6.49 1005 6.94 1034 7.38 1063 7.83 1090 8.28

50XCA24 (20 Tons) (cont)

CFM

8,500 902 3.97 933 4.28 963 4.59 992 4.91 1020 5.22 1046 5.54 1073 5.87

8,800 917 4.22 947 4.54 976 4.86 1005 5.19 1032 5.51 1059 5.84 1085 6.17

9,100 931 4.48 961 4.81 990 5.14 1018 5.48 1046 5.81 1072 6.15 1098 6.49

9,400 946 4.75 975 5.09 1004 5.44 1032 5.78 1059 6.13 1085 6.48 1111 6.83

9,700 960 5.04 990 5.39 1018 5.74 1046 6.10 1072 6.45 1098 6.81 1124 7.17

10,000 975 5.34 1004 5.70 1032 6.07 1060 6.43 1086 6.80 1112 7.16 1137 7.53

10,300 990 5.66 1019 6.03 1047 6.40 1074 6.77 1100 7.15 1126 7.53 1150 7.91

10,600 1006 5.99 1034 6.37 1062 6.75 1088 7.13 1114 7.52 1139 7.91 1164 8.29

10,900 1021 6.33 1049 6.72 1076 7.11 1103 7.51 1128 7.90 1153 8.30 1178 8.70

11,200 1037 6.69 1064 7.09 1091 7.49 1117 7.90 1143 8.30 1168 8.71 1192 9.11

11,500 1053 7.07 1080 7.48 1106 7.89 1132 8.30 1157 8.71 1182 9.13 1206 9.55

11,800 1069 7.46 1096 7.88 1122 8.30 1147 8.72 1172 9.15 1196 9.57 1220 10.00

12,100 1085 7.86 1111 8.29 1137 8.73 1162 9.16 1187 9.59 — — — —

12,400 11018.2911278.7311539.1711789.61 — — — — — —

12,700 11178.7311439.1811699.63 — — — — — — — —

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

ESP (in. wg)

0.80 0.90 1.00 1.10 1.20 1.30 1.40

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTES:

1. Units are available with several motor hp options. Refer to the

physical data table.

2. Static pressure losses must be applied to external static pressure

before entering the fan performance table.

3. Interpolation is permitted; extrapolation is not.

4. Fan performance is based on filter, unit casing, and wet coil

losses.

19

Performance data (cont)

EVAPORATOR FAN PERFORMANCE

50XCA06 (5 Tons)

ESP (in. wg)

CFM

1500 594 0.23 594 0.23 594 0.23 612 0.24 670 0.29 727 0.34 785 0.40 842 0.46 897 0.53 950 0.60

1600 588 0.24 588 0.24 588 0.24 630 0.28 684 0.32 738 0.37 793 0.43 847 0.49 900 0.56 952 0.64

1700 582 0.26 582 0.26 596 0.27 650 0.31 701 0.36 752 0.41 803 0.47 854 0.53 905 0.60 955 0.67

1800 576 0.28 576 0.28 618 0.31 670 0.36 719 0.40 767 0.45 815 0.51 863 0.57 911 0.64 959 0.71

1900 570 0.29 586 0.31 641 0.35 691 0.40 738 0.45 784 0.50 829 0.56 875 0.62 920 0.69 966 0.76

2000 564 0.31 612 0.35 664 0.40 712 0.45 757 0.50 801 0.56 845 0.61 888 0.67 931 0.74 975 0.81

2100 593 0.36 637 0.40 687 0.46 734 0.51 778 0.56 820 0.61 862 0.67 903 0.73 944 0.80 985 0.87

2200 621 0.42 663 0.46 710 0.51 756 0.57 799 0.62 840 0.68 879 0.74 919 0.80 958 0.86 997 0.93

2300 649 0.48 689 0.52 734 0.58 779 0.63 820 0.69 860 0.75 898 0.81 936 0.87 974 0.93 1011 1.00

2400 677 0.54 715 0.59 759 0.64 801 0.70 842 0.76 880 0.82 918 0.88 954 0.95 990 1.01 1026 1.08

2500 705 0.61 742 0.66 783 0.72 824 0.78 864 0.84 902 0.90 938 0.97 973 1.03 1008 1.10 1043 1.17

50XCA06 (5 Tons) (cont)

CFM

1500 1000 0.68 1047 0.76 1092 0.84 1134 0.93 1174 1.01 1213 1.10 1249 1.19 1284 1.28 1318 1.36 1351 1.46

1600 1001 0.71 1049 0.80 1094 0.88 1137 0.97 1178 1.06 1218 1.14 1255 1.24 1291 1.33 1326 1.42 1359 1.52

1700 1004 0.75 1051 0.83 1096 0.92 1139 1.01 1181 1.10 1221 1.19 1259 1.28 1296 1.38 1331 1.48 1365 1.57

1800 1007 0.79 1053 0.87 1098 0.96 1141 1.05 1183 1.14 1223 1.24 1262 1.33 1300 1.43 — — — —

1900 1011 0.83 1056 0.92 1100 1.00 1143 1.09 1185 1.19 1225 1.28 1264 1.38 1302 1.48 — — — —

2000 1018 0.89 1061 0.97 1104 1.05 1146 1.14 1187 1.24 1227 1.33 1266 1.43 ——————

2100 1026 0.94 1068 1.02 1109 1.11 1150 1.20 1190 1.29 1230 1.39 1268 1.49 ——————

2200 1037 1.01 1076 1.09 1116 1.17 1155 1.26 1194 1.35 1233 1.45 — ———————

2300 1049 1.08 1087 1.16 1124 1.24 1162 1.33 1200 1.42 — — — ———————

2400 1062 1.16 1098 1.23 1135 1.32 1171 1.40 1207 1.49 — — — ———————

2500 1077 1.24 1112 1.32 1147 1.40 1181 1.48 1216 1.57 — — — ———————

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

ESP (in. wg)

1.00 1.10 1.20 1.30 1.40 1.50 1.60 1.70 1.80 1.90

RpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhpRpmBhp

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTES:

1. Units are available with several motor hp options. Refer to the

physical data table.

2. Static pressure losses must be applied to external static pressure

before entering the fan performance table.

3. Interpolation is permitted; extrapolation is not.

4. Fan performance is based on filter, unit casing, and wet coil

losses.

20

EVAPORATOR FAN PERFORMANCE (cont)

1

50XCA08 (7

CFM

2200 594 0.26 594 0.26 594 0.26 644 0.31 707 0.38 766 0.45 820 0.53 871 0.62 918 0.70 963 0.79

2400 588 0.28 588 0.28 602 0.29 667 0.36 728 0.43 785 0.51 838 0.59 888 0.68 935 0.77 979 0.86

2600 582 0.29 582 0.29 630 0.34 692 0.42 750 0.49 805 0.58 857 0.66 906 0.75 952 0.84 996 0.94

2800 576 0.31 597 0.33 659 0.41 718 0.48 774 0.56 827 0.65 877 0.74 925 0.83 970 0.93 1013 1.03

3000 570 0.33 631 0.40 690 0.48 746 0.55 799 0.64 850 0.73 898 0.82 945 0.92 989 1.02 1032 1.12