Carrier OMNIZONE 50XJ064-104, OMNIZONE 50BV020-064, OMNIZONE 50BV020, OMNIZONE 50BV064, OMNIZONE 50XJ064 Operating And Troubleshooting Manual

...Page 1

50BV020-064, 50XJ064-104

Remote Air-Cooled and Water-Cooled, VAV Systems

18 to 100 Nominal Tons

Controls Operation and

Troubleshooting

OMNIZONE™

Indoor Self-Contained

CONTENTS

SAFETY CONSIDERATIONS...................... 1

GENERAL ........................................1

MAJOR SYSTEM COMPONENTS ...............1-7

Comfort Controller Processor (PCB1) ............1

Comfort Controller I/O Module (PCB2)............2

Comfort Controller I/O Module (PCB3)............2

Local Interface Display ...........................2

PCB Addresses ..................................2

Control Module Communication.................. 2

Carrier Comfort Network Interface................4

Optional and Field-Installed

Accessory Sensors/Devices ...................4

Wiring Control Devices........................... 6

CONTROLS AND FUNCTIONS................. 8-15

Using the Local Interface Display ................ 8

Automatic Run Test ............................. 10

Power Up the LID Display .......................12

Log On to the LID Display ....................... 12

Change the Default Password ................... 12

Set the Clock.................................... 12

Configure Schedules............................13

Program Set Points ............................. 13

Check System Parameters ...................... 14

Display Alarm History ...........................14

Configure Custom Programming Selections .... 14

Set Controller Address ..........................15

Log Off from Controller ......................... 15

OPERATION.................................. 16-26

Occupancy Determination....................... 16

Fan Control .....................................16

Sequence of Operation..........................16

Diagnostic Features .............................18

50XJ Variable Frequency Drive Control..........19

50BV Variable Frequency Drive Control .........22

TROUBLESHOOTING......................... 27-29

Run Test Troubleshooting.......................27

Forcing and Clearing and Input or Output....... 27

Standard Diagnostic Features,

Alarm and Warning Lights .................... 28

APPENDIX A — WIRING DIAGRAMS ......... 30-42

APPENDIX B — CONTROL SCREENS ........ 43-64

Display Screens.................................43

Configuration Screens ..........................45

Maintenance Screens ........................... 58

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be

hazardous due to system pressures, electrical components, and

equipment location. Only trained, qualified installers and

service mechanics should install, start up, and service this

equipment.

When working on this equipment, observe precautions in

the literature; on tags, stickers, and labels attached to the equipment, and any other safety precautions that apply. Follow all

safety codes. Wear safety glasses and work gloves. Use care in

handling, rigging, and setting this equipment, and in handling

all electrical components.

Electrical shock can cause personal injury and death.

Shut off all power to this equipment during installation

and service. There may be more than one disconnect

switch. Tag all disconnect locations to alert others not to

restore power until work is completed.

This unit uses a microprocessor-based electronic control

system. Do not use jumpers or other tools to short out

components, or to bypass or otherwise depart from recommended procedures. Any short-to-ground of the control board or accompanying wiring may destroy the

electronic modules or electrical components.

GENERAL

This publication contains Start-Up, Controls Operation, and

Troubleshooting information for the 50BV,XJ units. These

OMNIZONE™ packaged units are self-contained, watercooled or remote air-cooled indoor units for use in VAV

(variable air volume) applications. Units are equipped with

Comfort Controller 6400 (CC6400) system controls. Refer to

the unit Installation Instructions for unit layout.

MAJOR SYSTEM COMPONENTS

Comfort Controller Processor (PCB1) —

The central processing unit for the OMNIZONE system

control is the Comfort Controller 6400. The Comfort Controller provides general purpose HVAC (heating, ventilation and

air conditioning) control and monitoring capability in a standalone or network environment using closed-loop, direct digital control. The Comfort Controller 6400 has been pre-programmed to work in either stand-alone or CCN (Carrier Comfort Network) system installations.

The CC6400 processor is designed to provide heating and

cooling control, loop control, scheduling, and custom programming. The main processor provides 16 field points (8 input and

8 output). Additional points are provided by the I/O modules

described on page 2. Table 1 lists the control inputs and outputs

for all CC6400 modules.

Specifications for the Comfort Controller 6400 may be

found in the Comfort Controller literature.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 1

Ta b 2 a 2 b

PC 111 Catalog No. 535-00137 Printed in U.S.A. Form 50BV,XJ-2T Pg 1 2-04 Replaces: 50BV,XJ-1T

Page 2

Comfort Controller I/O Module (PCB2) — This

input/output module is factory installed in the 50XJ unit and

allows additional field points (8 inputs and 8 outputs): VFD

(variable frequency drive) Bypass, VAV Terminals Control,

Building Ventilation, and Heating Interlock.

Comfort Controller I/O Module (PCB3) — This

accessory control input/output module can be ordered separately and field-installed in the 50XJ unit. This module allows the

addition of the following field-installed sensors: Tower Sump

Temperature Sensor, Leaving Water Temperature Sensor,

Building Pressure Sensor, CO

Sensor, Indoor Relative

2

Humidity Sensor, and Outdoor Temperature Sensor.

The accessory I/O module provides the following control

outputs (relays): 4-stage heat control, water pump request, tower

request, modulating exhaust fan, and external dehumidification.

Local Interface Display — The Local Interface Display

(LID) is mounted on the front of the 50BV,XJ units. A number

of user-adjustable features are entered/changed using the

display keypad. These features described in detail in the Using

the Local Interface Display section of this manual.

PCB Addresses — Switch 1 (SW1) is used to set each

controller’s address. Individual DIP switches on each board are

used to set the addresses for individual hardware points. PCB1

switches are factory-set for hardware points 1-15, PCB2 DIP

switches are set for points 17-32, and PCB3 for points 33-48.

For more information, refer to Table 1 and the Optional and

Field-Installed Accessory Sensors/Devices section.

Control Module Communication — When power is

applied to the OMNIZONE™ System Control panel, the red

LED (light-emitting diode) on the top front of the processor

module will flash at a rapid pace (about twice a second) for the

first 30 to 60 seconds. See Fig. 1. This rapid flash will then be

replaced by a slower paced flash (about once per second).

The green LED below the red LED will start flashing. This

LED indicates input/output communications for accessory input

output modules and the LID.

The yellow LED (the third LED from the bottom of the controller [PCB1]) will flash when the controller is broadcasting

CCN messages to a laptop or other computer.

2

Page 3

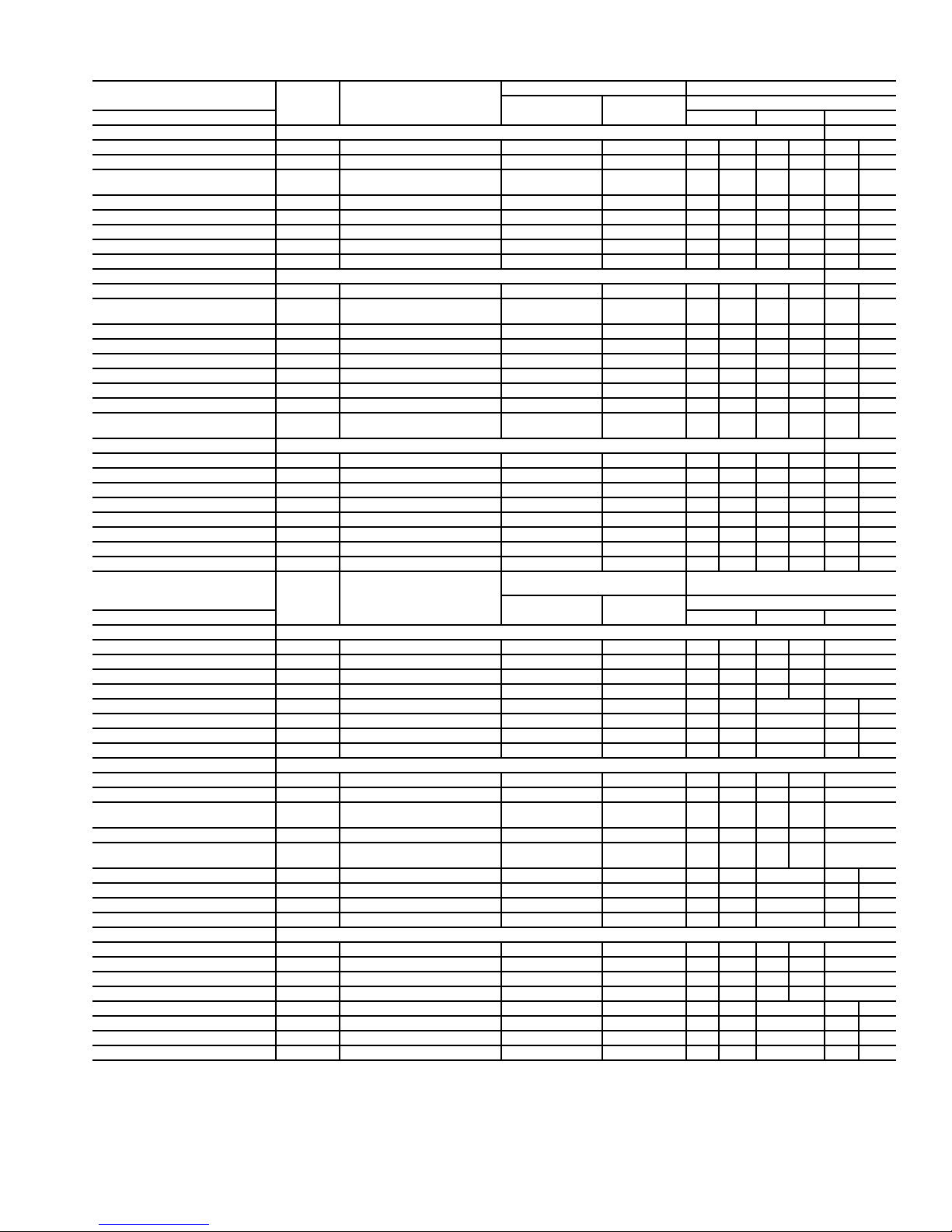

Table 1 — Control Inputs and Outputs

DESCRIPTION

Inputs SW2 SW3 SW1

Main Controller (PCB1) Addr = 1-16

Supply Air Temperature SAT Analog; 10K MCI 1 1 1 Up 1 Down 1 Up

VFD Duct Static Pressure DSP 4-20mA; Internally Powered 2 2 2 Up 2 Up 2 Down

COL/Safeties —

(Comprs.Status; Resister Bd.)

Fire Alarm/Shutdown FSD Switch closure 4 4 4 Up 4 Down 4 Down

Condenser Waterflow Switch CDWF Switch closure 5 5 5 Up 5 Down 5 Down

Remote Occupancy RMTOCC Switch closure 6 6 6 Up 6 Down 6 Down

Duct High Static Limit Switch DHS Switch closure 7 7 7 Up 7 Down 7 Up

Entering Water Temp. Sensor EWT Analog; 5K 8 8 8 Up 8 Down 8 Up

I/O Board (PCB2) Addr = 17-32

Mixed/Return Air Sensor MAT/RAT Analog; 10K MCI 1 1 1 Up 1 Down 1 Up

Filter Status Switch

(Dirty Filter Detect)

PhaseLossMonitor PHASE Switch closure 3 3 3 Up 3 Down 3 Down

External reset RESET 0-10VDC Externally Powered 4 4 4 Up 4 Down 4 Down

Water Econ. FreezeStat FREEZE Switch closure 5 — 5 Up 5 Down 5 Up

Differential Enthalpy ENTH Switch closure — 5 5 Up 5 Down 6 Down

Space Zone Sensor(s) SPT Analog; 10K MCI 6 6 6 Up 6 Down 7 Up

VFD Bypass Enable BYPASS Switch closure 7 7 7 Up 7 Down 8 Up

Refrigerant Pressure

(Compr.#1)

I/O Board (PCB3) Addr = 33-48

Tow e r S um p Te mp . TWRTEMP Analog; 10K MCI 1 1 1 Up 1 Up 1 Up

Building Pressure BSP 4-20mA; Internally Powered 2 2 2 Up 2 Down 2 Down

Leaving Water Temp. LWT Analog; 10K MCI 3 3 3 Up 3 Up 3 Down

Indoor Air Quality IAQ 4-20mA; Internally Powered — 4 4 Up 4 Down 4 Down

Indoor relative Humidity IRH 4-20mA; Internally Powered — 5 5 Up 5 Down 5 Down

Outside Air Temp. OAT Analog; 10K MCI — 6 6 Up 6 Up 6 Up

Unassigned —— ——————7Up

Unassigned —— ——————8Up

DESCRIPTION

Outputs SW4 SW5 SW6

Main Controller (PCB1)

Compressor #1 Relay CMP1 24VDC Discrete 1 1 1 Either 1 DO —

Compressor #2 Relay CMP2 24VDC Discrete 2 2 2 Either 2 DO —

Compressor #3 Relay CMP3 24VDC Discrete 3 3 3 Either 3 DO —

Compressor #4 Relay CMP4 24VDC Discrete 4 4 4 Either 4 DO —

VFD On/Off SF 24VDC Discrete 5 5 5 Either — 1 DO

VFD Speed Control SPEED 4-20mA modulating 6 6 6 Down — 2 AO

Alarm Pending ALARM1 24VDC Discrete 7 7 7 Either — 3 DO

Service Required ALARM2 24VDC Discrete 8 8 8 Either — 4 DO

I/O Board (PCB2)

Ventilation Output VENTOUT 24VDC Discrete 1 1 1 Either 1 DO —

Terminals Occupied OCCTRM 24VDC Discrete 2 2 2 Either 2 DO —

2-Position\

Reverse Operation Valve

Economizer Damper ECONO 4-20mA modulating — 3 3 Down 3 AO —

Modulating Valve Econ./

Head Pressure Control

Hot Water Coil Valve Control HWV 4-20mA modulating 5 5 5 Down — 1 AO

Heat Interlock Relay HIR 24VDC Discrete 6 6 6 Either — 2 DO

VFD Bypass Start BPSS 24VDC Discrete 7 7 7 Either — 3 DO

VAV Terminals Open DAMPERS 24VDC Discrete 8 8 8 Either — 4 DO

I/O Board (PCB3)

Electric Heat Control — Stage #1 HEAT1 24VDC Discrete 1 1 1 Either 1 DO —

Electric Heat Control — Stage #2 HEAT2 24VDC Discrete 2 2 2 Either 2 DO —

Electric Heat Control — Stage #3 HEAT3 24VDC Discrete 3 3 3 Either 3 DO —

Electric Heat Control — Stage #4 HEAT4 24VDC Discrete 4 4 4 Either 4 DO —

Water Pump Request PUMP 24VDC Discrete 5 5 5 Either — 1 DO

Tower Request TOWER 24VDC Discrete 6 6 6 Either — 2 DO

Modulating Exhaust Fan EXH 4-20mA modulating 7 7 7 Down — 3 AO

External Dehumidification DEHUM 24VDC Discrete 8 8 8 Either — 4 DO

LEGEND

AO — Analog Output

DO — Discreet Output

MCI — Precon Type II Thermistor

VAV — Variable Air Volume

VFD — Variable Frequency Drive

ABBREV. TYPE

CMP MUX Analog; 0-10VDC 3 3 3 Up 3 Down 3 Down

FLTS Switch closure 2 2 2 Up 2 Down 2 Down

PRES 4-20mA; Internally Powered 8 8 8 Up 8 Up — —

ABBREV. TYPE

ECONO 4-20mA modulating 3 3 Down 3 AO —

MODVLV 4-20mA modulating 4 4 4 Down 4 AO —

CONTROLLER I/O NO. DIP SWITCH SETTINGS

Water Econ. Units Air Econ.Units

CONTROLLER I/O NO. DIP SWITCH SETTINGS

Water Econ. Units Air Econ.Units

Switch No. and Position

Switch No. and Position

3

Page 4

STATUS

RED

(POWER)

GREEN

(IO BUS

COMMUNICATIONS)

YELLOW

(CNN BUS

COMMUNICATIONS)

Fig. 1 — CC6400 Control Module LEDs

Carrier Comfort Network Interface — The 50BV,XJ

units can be connected to the CCN (Carrier Comfort Network)

if desired. System elements are connected to the communication bus in a daisy chain arrangement. The negative pin of

each system element’s communication connector must be

wired to the respective negative pins, and positive pins on each

component must be connected to respective positive pins. The

controller signal pins must be wired to the signal ground pins.

Wiring connections for CCN must be made at the 3-pin plug.

At any baud rate (9600, 19200, 38400 baud), the number of

controllers is limited to 239 devices maximum. Bus length may

not exceed 4000 ft, with no more than 60 total devices on

any 1000-ft section. Optically isolated RS-485 repeaters are

required every 1000 ft.

NOTE: Carrier device default is 9600 baud.

The CCN Communication Bus wiring is field-supplied and

field-installed. It consists of shielded three-conductor cable

with drain (ground) wire. The cable selected must be identical

to the CCN Communication Bus wire used for the entire

network. See Table 2 for cable recommendations.

NOTE: Conductors and drain wire must be at least 20 AWG

(American Wire Gage), stranded, and tinned copper.

Individual conductors must be insulated with PVC, PVC/

nylon, vinyl, Teflon, or polyethylene. An aluminum/

polyester 100% foil shield and an outer jacket of PVC,

PVC/nylon, chrome vinyl, or Teflon with a minimum

operating temperature range of –20 C to 60 C is required.

The communication bus shields must be tied together at

each system element. If the communication bus is entirely

within one building, the resulting continuous shield must be

connected to ground at only one single point. If the communication bus cable exits from one building and enters another

building, the shields must be connected to the grounds at a

lightning suppressor in each building (one point only).

Optional and Field-Installed Accessory Sensors/

Devices —

accessories that add functionality and control. These options

and accessories are controlled by the CC6400 system as

described below.

NOTE: The CC6400 Control software includes all PCB1

functions, and most of the sensors/devices associated with

those functions are factory installed. However, some PCB1

sensors/devices must be field-connected to the proper terminal.

PCB2 devices are field-installed accessories. The CC6400

software includes these functions, but the actual sensor/device

must be installed and wired in the field. PCB3 is an accessory

control module. All PCB3 sensors/devices and software are

field-installed.

The 50XJ unit can be ordered with options and

Table 2 — Communication Cable Recommendations

MANUFACTURER PART NUMBER

Alpha 2413 or 5463

American A22503

Belden 8772

Columbia 02525

REMOTE OCCUPANCY CONTROL (PCB1) — This control is a field located switch, controller or timer input which,

when activated, tells system when to switch from Unoccupied

to Occupied mode.

When in Occupied mode, the unit turns on the supply fan

and controls supply fan speed to maintain a duct static set point

measured at the Duct Static Pressure Sensor (DSP). The unit

operates to provide conditioning to a set point. When in

Unoccupied mode, the unit provides no cooling/heating, or

controls to a ‘setback’ set point.

FIRE ALARM (PCB1) — The fire alarm is a control voltage

input to the 50XJ unit, which causes the controller to shut the

system down in the event of a fire.

CONDENSER WATER FLOW SWITCH (50XJ

PCB1) — This thermal dispersion type flow switch if factory

installed, is located in the unit waterline to ensure that there is

waterflow before allowing the unit to start the compressor(s). If

no flow is detected, then compressor operation and economizer

cooling is avoided until waterflow is again detected. An

warning light (yellow) is provided during this state.

HEAT INTERLOCK OUTPUT (50XJ PCB2) — This output

is activated whenever heating is activated, commanding the

VAV dampers to operate in heating control mode.

NOTE: In order to this output to function, the Terminal

Occupied output must also be on.

TERMINAL OCCUPIED (50XJ PCB2) — Terminal Occupied is activated to command VAV dampers to control to the

cooling set point. Terminal Occupied must be on along with

Heat Interlock for heating set point control to function.

EXTERNAL RESET INPUT (50XJ PCB2) — This modulating input (0 to 10 vdc) allows remote adjustment (upward) of

the Supply Air Temperature (SAT) sensor set point. The default

External Reset Input setting is 55 F. This variable input can

raise the set point by up to 20 F for a full-range input signal, or

to any point in between.

WATER ECONOMIZER COIL (50XJ PCB2) — This factoryinstalled option contains a water-to-air coil, two (2) electronic

motorized water valves, and related piping. Control of the water

economizer also requires a Mixed/Return Air Temperature

Sensor, a Condenser Water Inlet Temperature Sensor and an

Economizer Freezestat safety switch.

The electronic motorized water valves are each controlled

by the unit controller via separate 4 to 20 mA variable signals

to define variable valve position.

The Mixed/Return Air Sensor (MA_RA) is an air

temperature sensor located in the unit, between economizer

coil and evaporator.

The Condenser Water Inlet Temperature Sensor (CWT) is

located at the unit water inlet connection. This sensor receives

input power from the unit main controller and provides a linear

variable 1 to 5 vdc signal back to the controller. The full

temperature range is 32 to120 F.

The 50XJ units can be connected to two types of building

water systems: variable and fixed or constant flow control. In

either case, the economizer water valves are opened whenever

there is a call for Cooling and the Inlet Water Temperature is

colder than the Econ Start Set Point in the custom configuration.

4

Page 5

Dependencies

— Water Economizer option is enabled, and

Fan is On, and Inlet Water Temperature is below set point; or

from “Remote Scheduler,” or from “Remote Linkage.”

Economizer mode is switched to Off or no start if: there is

no condenser waterflow, Fire Input is On, Fan is not On, or Unoccupied mode is On.

Variable Waterflow Systems

— Whenever water economizer

is off, the economizer flow control valve is fully closed, and the

reverse flow valve directly to the condenser is fully open. Upon

engagement of the water economizer, the economizer flow control valve shall be controlled to maintain the MA_RA located

between the economizer coil and the DX cooling coil, at a temperature near the supply air set point. The the reverse flow valve

will be controlled in reverse of the economizer flow control

valve’s position. The following formula is an example: Reverse/

Head Press Ctrl output = 100 – two-position/Econo output.

When the unit is off, both valves are closed.

Constant Waterflow Systems

— Control of the economizer

flow control valve is same as for variable waterflow systems.

Control of the reverse flow control valve position will inversely

track the economizer flow control valve, such that the total sum

of the two valves open positions always equals 100%. The only

difference between the variable waterflow system and the

constant waterflow system is that for the constant flow system

when the unit is off, the economizer valve will be closed and

the reverse flow control valve will be open.

WATER ECONOMIZER COIL (50BV) — For the 50BV

unit, this factory-installed option contains a water-to-air coil, a

two-position diverting valve, and related piping. The water economizer is controlled by an Aquastat and a return-air thermostat.

HEATING COILS AND VALVE (50XJ PCB2) — Water or

steam heating options are factory installed. Each includes a

motorized, variable control water or steam flow control valve,

which can be factory supplied for field installation outside the

unit. Installed in the water or steam inlet pipe, this valve is

wiredtotheunitmaincontrollerandoperatesona4to20mA

signal. A Heating mode PID control is needed to control the

valve position (i.e., coil heating capacity) variably between 10

and 100%. The PID will control a set point to + 1° F; for VAV

Units this set point is at the Supply Air Temperature Sensor, or

as communicated from a remote thermostat.

HEAD PRESSURE CONTROL (50XJ PCB2) — Head Pressure Control is required for unit installations that will

experience entering condenser water temperatures of 55 F or

lower.

NOTE: Head Pressure Control is not needed or used in

conjunction with a Water Economizer. A refrigerant pressure transducer will monitor head pressure on compressor

circuit 1, allowing the unit main controller to regulate water

flow rate in the main water line entering the unit; i.e., flow

to all condensers. (Water header design to the condensers

will be optimized such as to provide relative flow rates to

each condenser based on its compressor capacity, enabling

successful waterflow control at the main entering pipe.)

There are two possible water valving configurations, as

outlined below.

Pressure transducer input is factory installed in the

discharge line of compressor circuit 1. It is provided 5 vdc by

the unit main controller and returns a signal 1 to 5 vdc linearly.

The sensor’s range is 0 to 550 psig.

Water Valve(s) Control

Variable Building Waterflow Systems — Variable waterflow

configurations use only one water valve in the main water

supply pipe. The factory installed valve is a normally open

motorized variable control type. The valve is controlled by a

4 to 20 mA signal from the main unit controller using the

Reverse/Head Press Ctrl output, which modulates to maintain

the head pressure set point (Setpoint 04).

Constant Building Waterflow Systems — Constant waterflow

configurations use two (2) water valves, only one of which is

in the main water supply pipe. The second valve is located in a

bypass pipe to the main outlet water pipe branched off of the

supply pipe immediately ahead of the first valve. This valve is

same type, but normally closed and is controlled in unison with

the first valve, but opposite position, such that the total opening

of the 2 valves always equals 100%.

VFD BYPASS (50XJ PCB2) — The VFD Bypass option

provides backup for the VFD Drive in VAV units. It uses a

manually operated rotary switch, which includes a series of

high voltage contacts. The bypass is a direct input to the unit

controller, and will be activated via a switch on the unit front

panel. When manually activated, the rotary switch takes the

VFD out of the fan power circuit and provides the 3-phase

power directly to the fan motor, running it at constant speed. A

low voltage control circuit ensures that the unit controller provides a signal to allow all VAV dampers to open fully before

the fan is turned on (at constant/full speed). A blue indicator

light located on the front of the unit indicates that the VFD Bypass is active. A High Duct Static Switch (HDS) shuts the fan

down if duct static exceeds a maximum setting.

VENTILATION OUTPUT (50XJ PCB2) — The ventilation

output is controller output signal (available for field connection)

to a field-supplied ventilation damper(s). This signal is activated

whenever the unit is in the occupied mode.

SPACE TEMPERATURE SENSOR (50XJ PCB2) — A fieldsupplied Carrier space temperature sensor is required to

maintain space temperature in sensor mode.

SUPPLY AIR RESET (50XJ PCB2) — Supply air temperature

set point may be reset using either the SPT or MA_RA.

SUPPLY AIR RESET (50BV) — Reset is provided by a

field-installed temperature sensor.

EXHAUST FAN CONTROL OUTPUT (50XJ PCB2) — This

output is activated whenever the unit is in the Occupied mode.

This is a modulating output that controls based on the Building

Pressure Input set point.

CONDENSER WATER PUMP/WATER TOWER (50XJ

PCB2) — This output (provided for field connection) is used

to control condenser water flow. Either an On/Off signal or a

variable output may be required for this feature.

PHASE LOSS/REVERSAL PROTECTION SWITCH

(50XJ PCB2) — This switch monitors VFD/Fan Motor supply leads to detect phase loss or reversal. If the switch detects

improper phasing, an input is sent to the unit controller, which

shuts the unit down. After a time delay, the controller attempts

to restart the unit.

A phase loss/reversal switch may be installed in the unit to

detect over/under voltage conditions and phase loss or reversal.

When the switch opens, the controller outputs are forced to off

with Safety forces, the alarm output will close and the red

alarm light will be lit. A system alarm will be generated and

displayed on the unit keypad. Unit reset is automatic when the

voltage and power phases have been restored.

FREEZE THERMOSTAT (FREEZSTAT) (50XJ PCB2) — The

Economizer Freezestat, used in conjunction with an optional

water economizer coil or heating coil, is a factory installed

averaging (capillary tube) air temperature sensor positioned in

the unit inlet airstream.

If the freeze protection switch contacts open the ventilation

request output will be closed for 15 minutes and the warning

light will light. If the freeze protection switch contacts are still

open after 15 minutes the supply fan will be stopped, all

compressor cooling will stop, the economizer valve will open

to 100%, the pump request output will remain on, and the

alarm light will light. This will maintain condenser water flow

through the coil to prevent freezing the coil while stopping all

other operations that could have contributed or will be affected

5

Page 6

by the freeze condition. Unit reset is automatic when the

contacts on the freeze protection switch close again. The

contacts on the freeze protection switch open below 37 F.

TOWER SUMP TEMPERATURE SENSOR (50XJ

PCB3) — This sensor is used for monitoring (only) the tower

sump temperature.

LEAVING WATER TEMPERATURE SENSOR (50XJ

PCB3) — This sensor is used for monitoring (only) the leaving water temperature.

BUILDING STATIC PRESSURE SENSOR (50XJ

PCB3) — This sensor is used to control both the speed of the

building exhaust fan and the building static pressure.

INDOOR AIR QUALITY (CO

PCB3) — This sensor monitors CO

)SENSOR(50XJ

2

levels.

2

INDOOR RELATIVE HUMIDITY SENSOR (50XJ

PCB3) — This sensor monitors and controls the humidity

control relay.

OUTDOOR AIR TEMPERATURE SENSOR (50XJ

PCB3) — This sensor is used to monitor outdoor air and

broadcast the value over the Carrier Comfort Network (CCN).

STAGE HEAT RELAYS (50XJ PCB3) — These relays control up to four stages of electric heat, or other heating methods.

PUMP REQUEST RELAY (50XJ PCB3) — This relay turns

on a tower pump when requested.

TOWER REQUEST/CONTROL RELAY (50XJ PCB3) —

This relay is used to activate a tower fan.

BUILDING EXHAUST FAN SPEED CONTROL (50XJ

PCB3) — This output controls building exhaust fan speed.

HUMIDITY CONTROL RELAY (50XJ PCB3) — This relay

controls a humidifier or dehumidification device.

Wiring Control Devices — Standard controls for the

50XJ require no field-wiring. Standard 50XJ controls include:

Supply Air Temperature (SAT), Duct Static Pressure (DSP),

Duct High Static Limit Switch (DHS), Filter Status Switch

(FLTS), Entering Water Temperature (EWT), Compressor Status (CSMUX), Supply Fan Start/Stop (SF), Supply Fan Speed

(SPEED), and Mixed/Air Return/Air sensor (MA_RA).

NOTE: The MA_RA sensor will be located in the return air

steam if the unit does not have a water economizer, and in

the mixed airstream if the unit is equipped with a water

economizer.

For the 50BV unit, standard controls include: Duct Static

Pressure (DSP), Duct High Static Limit Switch (DHS), Compressor Status (CSMUX), Supply Fan Start/Stop (SF), and

Supply Fan Speed (SPEED).

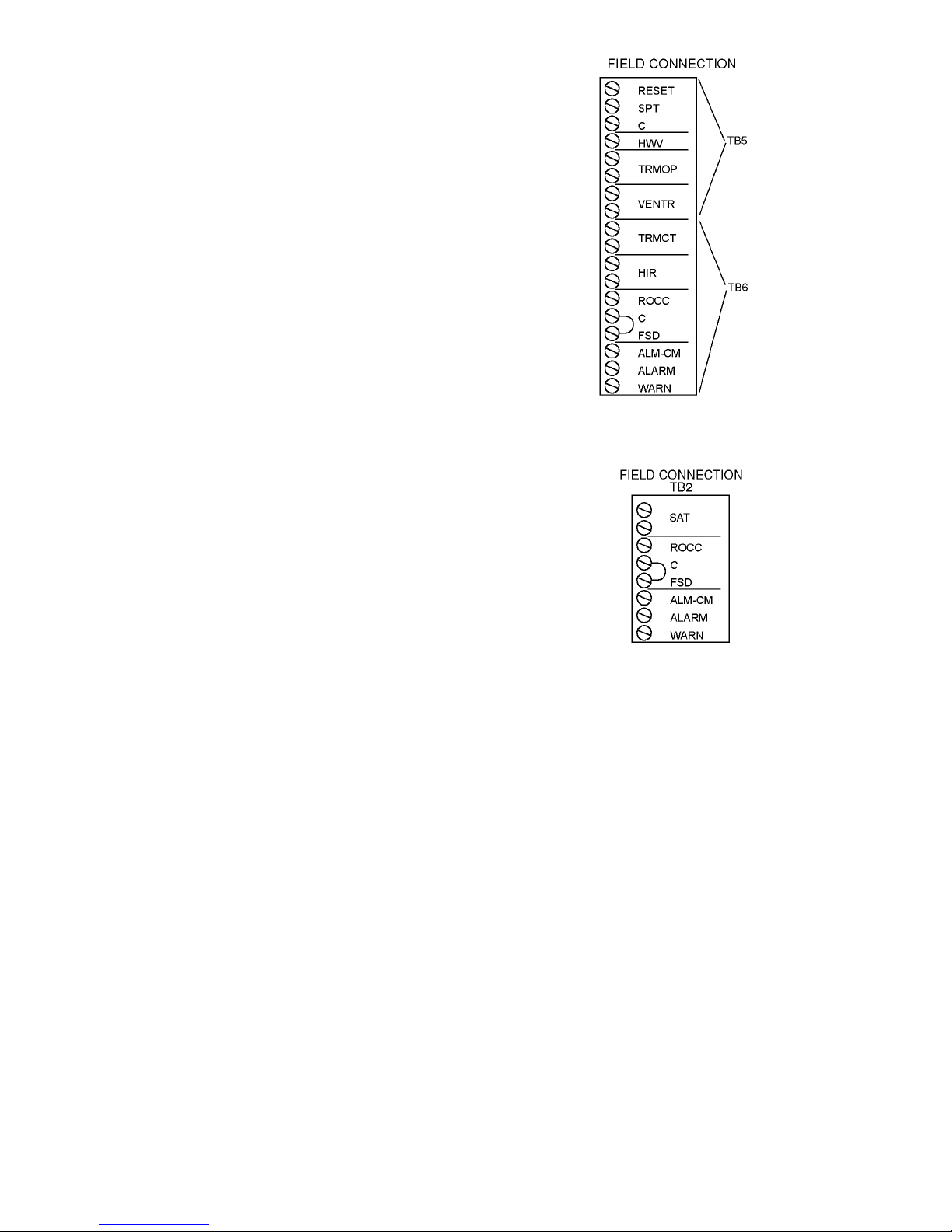

For the 50XJ unit, optional controls will be wired to the

field terminal blocks (TB5 and TB6) provided. Refer to

Fig. 2A and the descriptions below.

For the 50BV unit, optional controls are wired to field

terminal block TB2 as shown in Fig. 2B.

EXTERNAL 0 TO 10 VOLT DC RESET SIGNAL (RESET)

(50XJ PCB2) — This field-supplied 0 to 10 vdc signal is used

to reset the 50XJ supply-air temperature. The controller will

scale the signal to provide 0 reset at 0 volts and 20 degrees of

reset at 10 volts. Wire the positive of the signal to the RESET

terminal and the negative to the C or common terminal.

SUPPLY AIR RESET (50BV) — Use a 5k ohm sensor

installed at the Entering Water Temperature sensor (EWT)

location on PCB1. For space temperature averaging, two 10k

ohm Space Temperature Sensors (SPT) can be wired in parallel.

SPACE TEMPERATURE SENSOR (50XJ PCB2) — The

space temperature sensor (33ZCT55SPT) is used in the following cases:

• When using the optional water economizer and not using

Carrier’s ComfortID™ System.

Fig. 2A — Field Terminal Blocks for 50XJ Unit

Fig. 2B — Field Terminal Block for 50BV Unit

• To determine the average temperature of the space being

served.

• To determine supply-air temperature reset, occupied

heating, unoccupied heating and cooling (refer to

Sequence of Operation in the Start-Up section.).

To wire the sensor, perform the following (see Fig. 3).

Identify which cable is for the sensor wiring.

1. Strip back the jacket from the cable for at least

3 inches. Strip

1

/4-in. of insulation from each conductor. Cut the shield and drain wire from the sensor end

of the cable.

2. Wire the sensor to the SPT and C terminals on the field

terminal block (TB5). A typical 10K thermistor such

as the 33ZCT55SPT sensor may be used. If the SPT

sensor is not installed and the MA_RA (mixed air/

return air) sensor is configured for return air, the 50XJ

unit will use this sensor to control supply air reset,

occupied heat, and unoccupied heating and cooling

See Fig. 4 for space temperature sensor averaging.

HOT WATER OR STEAM VALVE (HWV) (50XJ

PCB2) — The HWV terminal supplies the positive signal to

control a 4 to 20 mA hot water or steam valve for occupied and

unoccupied heat. Connect the common side of the valve to the

C terminal or an equipment ground.

6

Page 7

AIR TERMINALS AND FRESH AIR DAMPER (50XJ

PCB2) — The VAV Terminal Open (TRMOP), Ventilation

Output (VENTR), VAV Terminals Control (TRMCT), and

Heat Interlock Relay (HIR) terminals provide dry contacts to

command the VAV terminals open; a ventilation damper open;

VAV terminals to control to their cooling set points; and VAV

terminals to control to their heat set points, respectively.

REMOTE OCCUPANCY (ROCC) (TB2 50BV, TB6

50XJ) — The 50XJ,BV unit may be commanded by a remote

control system or a twist timer to become occupied and run

when a set of dry contacts close. In order for this to occur, wire

the contacts to ROCC and C.

SMOKE DETECTOR/FIRE ALARM SHUTDOWN (FSD)

(TB2 50BV, TB6 50XJ) — To allow a smoke detector to shut

the 50XJ,BV unit down, remove the jumper from FSD to C

and wire these terminals to a set of normally closed contacts on

the smoke detector.

ALARM (ALARM) AND WARNING (WARN) OUTPUTS

(TB2 50BV, TB6 50XJ) — Two dry contacts output a discrete signal when the alarm and warning lights on the display

are lit. To pick up the alarm output signal, wire between the

ALARM and ALM-CM terminals. To pick up the warning

output signal, wire between the WARN and ALM-CM

terminals.

45

61

RED(+)

WHT(GND)

BLK(-)

BRN (GND)

BLU (SPT)

CCN COM

SENSOR WIRING

SW1

2

3

SEN

Fig. 3 — Space Temperature Sensor

Typical Wiring (33ZCT55SPT)

RED

BLK

J6

6

7

RED

BLK

RED

BLK

SENSOR 1 SENSOR 2 SENSOR 3 SENSOR 4

RED

BLK

RED

BLK

SPACE TEMPERATURE AVERAGING — 4 SENSOR APPLICATION

J6

6

7

RED

BLK

BLK

SENSOR 1

RED

RED

BLK

RED

BLK

SENSOR 2

RED

BLK

SENSOR 3

RED

BLK

LEGEND

Field Wiring

SPACE TEMPERATURE AVERAGING — 9 SENSOR APPLICATION

BLK

SENSOR 4

RED

RED

BLK

SENSOR 7

SENSOR 5

SENSOR 8

Fig. 4 — Space Temperature Averaging

7

SENSOR 6

RED

BLK

SENSOR 9

Page 8

CONTROLS AND FUNCTIONS

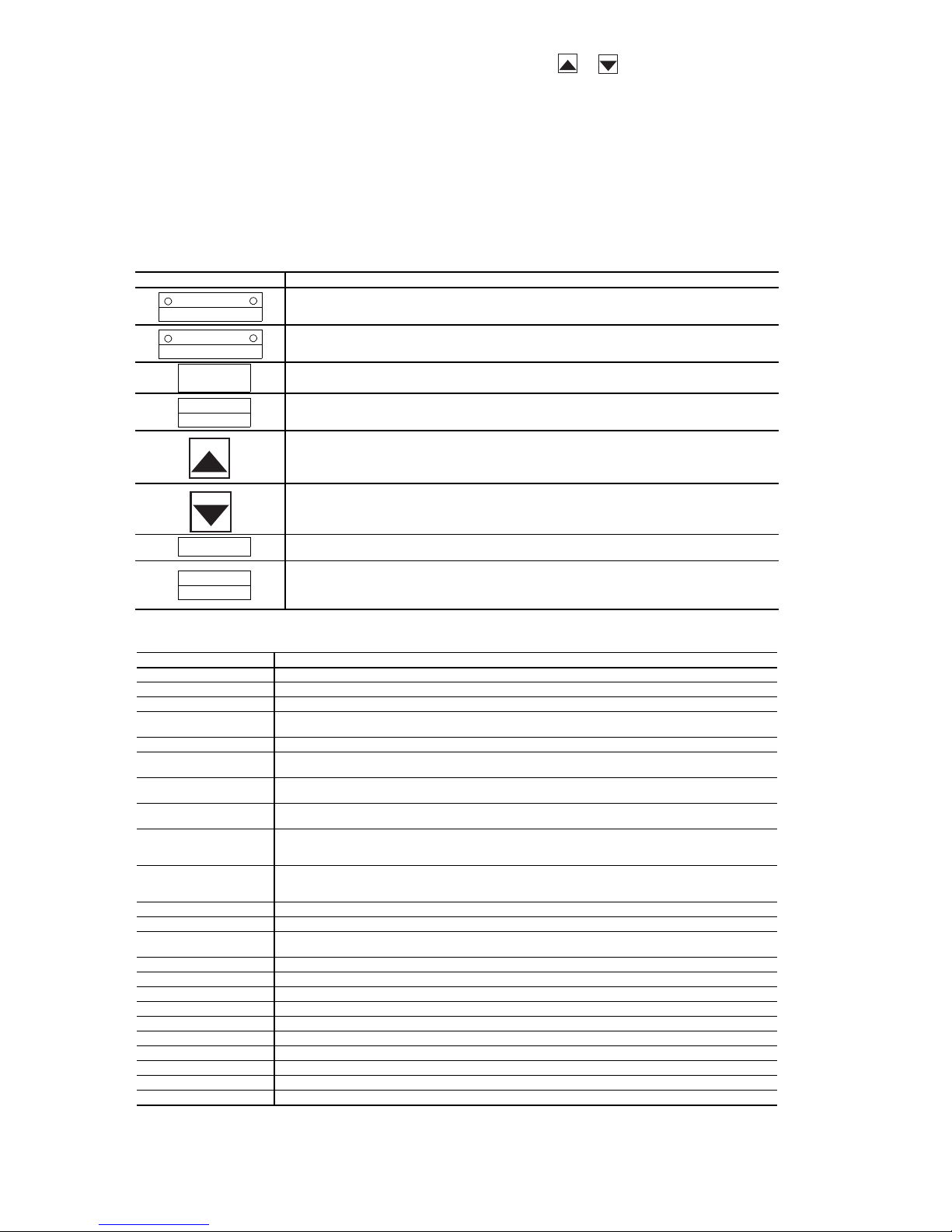

Table 4 — Operative Keys

Using the Local Interface Display —

The Local

Interface Device (LID) is a CCN operator interface that gives

the user the capability to view and modify all configuration and

service data for the CC6400 control system. The LID also

allows the user to override all point display and maintenance

data.

MENU STRUCTURE — The LID operates on a hierarchy of

four levels (menus).

The top level contains the LID’s major functions. Each

function has a corresponding key on the LID. For an explanation of each function key, refer to Table 3.

The second level separates the major functions (items) into

types with corresponding type numbers that can be used for

quick access.

The third level gives the user the capability to access each

occurrence of an item. For example, the application may

require two DO (Discreet Output) — Analog Comparison

algorithms. Thus, the CC6400 Controller would have two

occurrences of the DO — Analog Comparison algorithm.

The fourth level gives the user the capability to access maintenance and configuration data associated with the selected

occurrence of the item.

DEFAULT SCREEN — Figure 5 shows the LID. The LID’s

screen provides the user with the 24-character controller name

and the controller’s current time, date, and alarm status. This

screen appears when the LID is powered up and communicating with the controller or there is no keyboard activity for

10 minutes.

KEYPAD AND DISPLAY — The LID consists of a keypad

with 8 function keys, 4 operative keys, 12 numeric keys (0 to

9,., and -) and a two-line, alphanumeric liquid crystal display

(LCD). Each line on the LCD can display up to 24 characters.

See Fig. 5. Table 4 defines the purpose of the LID’s operative

keys. Table 5 defines the purpose of the LID’s numeric keys.

Table 3 — LID Function Keys

OPERATIVE

KEYS

Status — gives access to maintenance

values and configuration data for points.

Alarm — gives access to maintenance

and configuration data for alarms.

History — gives access to maintenance

and configuration data for history system

functions.

Service — gives access to maintenance

and configuration data for service system

functions.

Setup — gives access to configuration

data for setup system functions.

Schedule — gives access to maintenance

and configuration data for schedules.

Algorithm — gives access to maintenance

and configuration data for AO, DO, and global

algorithms. It also gives access to BEST

custom programs.

Edit — gives the capability to switch from

Status mode to Edit (configuration) mode for

the selected item.

LEGEND

AO — Analog Output

DO — Digital/Discreet Output

USE

++™

OPERATIVE

KEYS

CLEAR

ENTER

Clear — performs three operations:

• Cancels a data entry before the user

presses Enter, thus leaving the current

value unchanged.

• Returns a forced point to automatic

control.

• Redisplays the previous menu level.

Enter — performs two operations:

• Selects the displayed item, thus displaying

either its maintenance or configuration

data, depending on whether the user is in

the Status mode or the Edit mode.

• Accepts the value entered in a configuration

decision as new configuration data or as a

force.

Down arrow — displays the next configured

item or decision. When the last configured

item or decision is displayed, the LID

re-displays the first configured item or

decision. For example, when the user presses

the down arrow key while viewing the last

configuration decision of an algorithm, the LID

re-displays the first configuration decision.

Up arrow — Displays the previous configured

item or decision.

USE

Table 5 — Numeric Keys

OPERATIVE

KEYS

-

Numeric keys

Performs two operations:

• Separates items, such as an algorithm from

its occurrence or hours from minutes.

• Serves as a decimal point in numeric values.

Performs two operations:

• Negates the value of numeric keys.

• Clears current data entry value any time it is

not the first key pressed during the data

entry sequence.

USE

VIEWING MODES — The user can view items in either the

Status (maintenance) mode or the Edit (configuration) mode.

Status Mode

— When the user first powers up the LID, it

displays the CC6400 controller items in Status (maintenance)

mode. The user may view the current value or status of an item

in Status mode without actually logging on to the Controller.

Knowing the current values or status of items can be useful

when troubleshooting. For example, the user could determine

if a point was forced.

NOTE: Not all items have maintenance data. If the item you

select does not have maintenance data, the LID will display

“No maintenance.”

Accessing Items in Status Mode

— The user can access

maintenance data in Status mode in two ways:

• Pressing the appropriate function key (i.e., )

ALRM

once to access a category (i.e., alarms) and then continuing to press that key ( ) to scroll through all the

ALRM

items in that category (i.e., Limit Alarm, Set point

Alarm, Discrete Alarm, First Out Alarm, Runtime

Alarm, and Number of Starts Alarm). Press to

ENTER

display the first maintenance decision.

NOTE: Scrolling by repeatedly pressing the function key

displays the name of all the items in that category, whether

or not they are actually configured. Scrolling by pressing

the up or down arrow displays only the configured items

within that category.

8

Page 9

• Pressing the appropriate LID numeric key (i.e., 2) and

the appropriate function key (i.e., ) to directly

ALRM

access an item without having to scroll through all the

items in that category. Press to display the first

ENTER

maintenance decision.

Edit Mode

— Because the LID first displays items in Status

mode when it is powered up, the user must log on to the connected CC6400 Controller and press the key to

EXPN/EDIT

switch to Edit mode.

While in Edit mode, the user can change the configuration

of items. For example, the user could change the value of an algorithm’s configuration decision.

NOTE: Not all items have configuration data. If the item

selected does not have configuration data, pressing the

EXPN/EDIT

key will have no effect. The LID will display

“No configuration.”

Accessing Items in Edit Mode

— The two ways to access

items in Edit mode are the same as in Status mode, except for

an additional step — pressing the key.

EXPN/EDIT

The user can access configuration data in Edit mode in two

ways:

• Pressing the appropriate function key (i.e., ) once

to access a category (i.e., alarms), pressing

and then continuing to press that key ( ) to scroll

ALRM

EXPN/EDIT

ALRM

through all the items in that category (i.e., Limit Alarm,

Set point Alarm, Discrete Alarm, First Out Alarm,

Runtime Alarm, and Number of Starts Alarm).

NOTE: Scrolling by repeatedly pressing the function key

displays the name of all the items in that category, whether

or not they are actually configured. Scrolling by pressing

the up or down arrow displays only the configured items

within that category.

• Pressing the appropriate LID numeric key (i.e., 2),

the appropriate function key (i.e., ), and

EXPN/EDIT

to directly access an item without having

ALRM

to scroll through all the items in that category.

QUICK ACCESS IN EITHER STATUS OR EDIT

MODE — Use Table 6 as a reference to directly access

CC6400 Controller items using a LID in either Status or Edit

mods. For example, to access maintenance data for the AO —

Heating VAV algorithm, press , , and . To

6 ALGO ENTER

access configuration data for the AO (Analog Output) —

Heating VAV algorithm, press , , ,

and . If the database consisted of two AO — Heating

ENTER

VAV algorithms, to access the second one, press , (decimal), ,, ,and .

2 ALGO EXPN/EDIT ENTER

6 ALGO EXPN/EDIT

6 .

FUNCTION

KEYS

OPERATIVE

KEYS

OMNIZONE VPAC

12:00 02-06-04

EXPN

STAT

SET

EDIT

SCHD

1

4

7

–

NUMERIC KEYS

Fig. 5 — Local Interface Display (LID)

3

2

5

6

8

9

.

0

TEST

SRVC

ALRM

HIST ALGO

CLEAR

ENTER

FUNCTION

KEYS

OPERATIVE

KEYS

9

Page 10

Table 6 — Quick Access Chart

LID

NUM.

KEY

1 AO—Adaptive Control Hardware Points Alarm History Function Definition Limit Set Clock Occupancy

2 AO—Cooling CV Software Points Analog Point Trace Channel Definition Setpoint Real Time Clock Setpoint

3 AO—Cooling VAV Temperature Input Discrete Point Trace System Definition Discrete Controller Password Holiday

4 AO—Fan Tracking Milliamp Input Consumable Channel Setpoint Definition First out N/A S/W Setpoint

5 AO—Heating CV Custom Milliamp Input Internal Consumable Database Control Runtime N/A Network Time

6 AO—Heating VAV Voltage Input Runtime Channel Comfort Controller # of starts N/A N/A

7 AO—Humidity Control Custom Voltage Input N/A CCN Control N/A N/A N/A

8 AO—Mixed Air CV w/IAQ Sensed Discrete Input N/A LID Preferences N/A N/A N/A

9 AO—Mixed Air VAV w/IAQ Latched Discrete Input N/A N/A N/A N/A N/A

10 AO—Permissive Interlock Pulsed Discrete Input N/A N/A N/A N/A N/A

11 AO—Reset Milliamp Output N/A N/A N/A N/A N/A

12 AO—Shared Transducer Custom Milliamp Output N/A N/A N/A N/A N/A

13 AO—Static Pressure Voltage Output N/A N/A N/A N/A N/A

14 DO—Analog Custom Voltage Output N/A N/A N/A N/A N/A

15 DO—DX-Staging VAV Discrete Output N/A N/A N/A N/A N/A

16 DO—Electric Heat CV Stepper Motor Output N/A N/A N/A N/A N/A

17 DO—Electric Heat VAV Discrete Software Point N/A N/A N/A N/A N/A

18 DO—Enthalpy Comparison Analog Software Point N/A N/A N/A N/A N/A

19 DO—Interlock Network Data Out N/A N/A N/A N/A N/A

20 DO—Lighting Control Network Data In N/A N/A N/A N/A N/A

21 DO—Permissive Interlock N/A N/A N/A N/A N/A N/A

22 DO—Pump Control N/A N/A N/A N/A N/A N/A

23 DO—Prop Ther mo N/A N/A N/A N/A N/A N/A

24 DO—Prop Thermo 2 Pipe N/A N/A N/A N/A N/A N/A

25 DO—Prop Thermo 4 Pipe N/A N/A N/A N/A N/A N/A

26 DO—Staged Thermostat N/A N/A N/A N/A N/A N/A

27 DO—Staging Control N/A N/A N/A N/A N/A N/A

28 DO—Time Clock N/A N/A N/A N/A N/A N/A

29 DO—Time Clock w/Check N/A N/A N/A N/A N/A N/A

30 AOSS Schedule N/A N/A N/A N/A N/A N/A

31 Network Broadcast N/A N/A N/A N/A N/A N/A

32 Linkage/AOSS Schedule N/A N/A N/A N/A N/A N/A

33 NTFC w/Enthalpy Check N/A N/A N/A N/A N/A N/A

34 Sensor Group N/A N/A N/A N/A N/A N/A

35 WSM Air Source N/A N/A N/A N/A N/A N/A

36 WSM Cool Source N/A N/A N/A N/A N/A N/A

37 Custom Program N/A N/A N/A N/A N/A N/A

AO — Analog Output

AOS S — Adaptive Optimal Star t/Stop

CV — Constant Volume

DO — Digital Output

IAQ — Indoor Air Quality

N/A — Not Available

NTFC — Nighttime Free Cooling

VAV — Variable Air Volume

WSM — Water System Manager

Algorithms

(ALGO)

LEGEND NOTES:

Status

(STAT)

LID FUNCTION KEYS

History

(HIST)

1. To change from Edit mode to Status mode, press or press

EXPN/EDIT

2. Not all available selections will have items to select in sublevels.

Service

(SRVC)

again.

Alarm

(ALRM)

Setup

(SET)

Schedules

CLEAR

(SCHD)

Automatic Run Test — The 50BV,XJ unit controls are

programmed with an automatic run test that checks connection

and operation of major components. To perform the run test:

Verify that the control display (LID device/System Monitor)

interface cable is connected to internal jack on main controller;

that the fire alarm/shutdown switch input (FSD) has a factory

jumper or field input; that Bypass (if installed) is set in the

DRIVE position; and that the Local/Off/Remote switch is set to

the REMOTE position.

NOTE: When the Local/Off/Remote switch is in the

REMOTE position, the controller time schedule is pre-set

(from the factory) as unoccupied. This means that the unit

will not turn on until the run test is enabled. However, if the

controller schedule has already been modified in the field,

and the current time of day is occupied, then the supply fan

will start. The run test will shut the fan down when it

begins. The run test will complete and then the supply will

automatically restart.

NOTE: If the Local/Off/Remote switch is in the OFF position, it is normal for the red alarm light on the display panel

to be lit, indicating that the unit is disabled.

NOTE: If the red light stays on when the switch is moved to

REMOTE, or if any other problems occur during the run

test, refer to the Troubleshooting section of this manual.

To perform the Run Test:

1. Turn unit power on.

The LID display will show the controller identification, time and date (Fig. 5):

OMNIZONE VPAC

hh:mm mm-dd-yy

10

Page 11

2. Press 3 and then . The LID display will show:

SET

Controller Password

3. Press . The LID display will show:

ENTER

LogintoController

Enter Password

NOTE: The LID display has two modes: Edit mode and

Status/Maintenance mode. If the LID display is in Edit

mode, then the display will only show the word “password.” Press the key to toggle to the Status

EXPN/EDIT

mode.

Press the to display:

EXPN/EDIT

LogintoController

Enter Password

4. Key in the password and press .

ENTER

NOTE: The default password is 1111.

5. The LID display will show:

LogintoController

Logged In

NOTE: At this point, for the 50BV unit only, the run

test will follow these steps:

a. Press 37 . The display will show:

ALGO

Custom Program

b. Press . The display will show:

ENTER

2.0 Global Dictionary

OMNIZONE

c. Press (NOTE: Display will flash,

EXPN/EDIT

indicating that the device is now in edit mode.)

The display will show:

2.0 Global Dictionary

OMNIZONE

d. Press . The display will show:

ENTER

Compressor Stages

4.00

NOTE: A 50BV unit with only 2 compressors will

display 2.00. Skip to Step 6.

e. Input 2.00 and Press . The display will show:

ENTER

Compressor Stages

2.00

6. Press . The LID display will show:

STAT

Hardware Points

7. Press again. The LID display will show:

STAT

Software Points

8. Press . The LID display will show:

ENTER

Compressor 1 Status

9. Press 6 times. The LID display will show:

Factory/Field Test

Stop

10. Press 1 then , The LID display will show:

ENTER

Factory/Field Test

Start

NOTE: At this point, the yellow warning light on the

display panel will be lit and will stay on throughout the

run test. After each successful step, the red alarm light

will blink once.

11. The control module will now check if there is input from

BYPAS(50XJ),DHS,FSD,SAT,DSP,andCSMUX.

If the control does not receive open/open/closed/

in range/in range/in range, the red alarm LED will go

on and the test will stop.

If the inputs are OK, the red alarm LED blinks once

and the test continues.

12. Next, the control forces the Supply Fan (SF) and all of the

Compressors (COMP) off, and waits 15 seconds.

For the 50XJ unit, if the REMOTE LED and AUTO

LED on the VFD display are on, the red LED blinks

once and the test continues.

NOTE: For the 50XJ unit, if the controller is configured with a water Economizer, the delay is 2 min. and

both valves are commanded to 0%. Both water valves

will close.

13. The control forces SF on and SPEED to 20 percent and

then waits 30 seconds.

If the VFD display shows “10.6 Hz,” the Remote and

Auto LEDs blink, and the fan goes on, then the red LED

on the control module blinks once and the test continues.

NOTE: For the 50XJ unit, if the controller is configured with a water Economizer the delay is 2 min. and

Econo valve is commanded to 100%. The economizer

valve will open and the RVS/HD (reverse/head

pressure) valve will remain closed.

14. The control forces SF on and SPEED to 35 percent and

then waits 30 seconds.

If the VFD display shows “20.0 Hz,” the Remote and

Auto LEDs blink, and the fan goes on, then the red LED

on the control module blinks once and the test continues.

NOTE: For the 50XJ unit, if the controller is configured

with a water Economizer the delay is 2 min. and RVS/

HD valve is commanded to 100%. The economizer valve

is commanded to 0% and the RVS/HD valve will open.

15. The control forces SF off then waits 15 seconds.

If the VFD display shows “Off,” the Remote and Auto

LEDs are off, and the fan goes off, then the red LED on

the control module blinks once and the test continues.

NOTE: For the 50XJ unit, if the controller is configured

with a water Economizer both valves are commanded

to 0%. The economizer valve and RVS/HD will close.

NOTE: For the 50BV unit, the steps below (16-24)

will be completed for the number of compressors

configured.

16. The control forces CMP1 (compressor 1) on then waits

5 seconds.

If CSMUX is not in range the red LED will go on and

the test will stop.

If CSMUX is in range, the red LED blinks once and

the test continues.

17. The control forces CMP1 off.

18. The control forces CMP2 (compressor 2) on then waits

5 seconds.

If CSMUX is not in range the red LED will go on and

the test will stop.

If CSMUX is in range, the red LED blinks once and

the test continues.

19. The control forces CMP2 off.

20. The control forces CMP3 (compressor 3) on, if configured, then waits 5 seconds.

If CSMUX is not in range the red LED will go on and

the test will stop.

If CSMUX is in range, the red LED blinks once and

the test continues.

21. The control forces CMP3 off.

11

Page 12

22. The control forces CMP4 (compressor 4) on, if configured, then waits 5 seconds.

The LID display shows:

Factory/Field Test

Stop

The yellow LED will go off, and the red LED will go

off.

23. The control forces CMP4 off.

24. The run test is complete.

Power Up the LID Display — After completing the

automatic run test, perform the following procedures to change

the controller password, set the controller clock, configure

schedules, set parameters, view settings, and view alarm

history.

1. Set the Remote/Local/Off switch on the front of the unit to

the OFF position. This prevents operation of the fan and

compressors while still providing power to the unit controls.

NOTE: When the switch is in the OFF position, the red

alarm LED will be lit; this is normal. The bypass point

will also indicate OK.

2. If the unit access panel (for power and controls) is still on

the unit, remove it in order to view the control modules

during start-up.

3. Switch the main unit power disconnect to ON.

When power is applied to the OMNIZONE™ System

Control panel, the red LED on the top front of the processor

module will flash at a rapid pace (about twice a second) for the

first 30 to 60 seconds. This rapid flash will then be replaced by

a slower paced flash (about once per second).

The green LED below the red LED will start flashing. This

LED indicates input/output communications for accessory

input output modules and the LID display.

The yellow LED will flash when the controller is broadcasting CCN messages to a laptop or other computer.

The third LED from the bottom of the controller (PCB1)

will light.

The LID display will show the controller identification,

time and date as shown below.

OMNIZONE VPAC

hh:mm mm-dd-yy

Log On to the LID Display — ToLogOntotheLID

display, perform the following procedure:

1. Press 3 and then . The LID display will show:

Controller Password

2. Press . The LID display will show:

3. Key in the password and press .

ENTER

LogintoController

Enter Password

NOTE: The LID display has two modes: Edit mode and

Status/Maintenance mode. Edit mode allows the user to

change settings on the configurations screens. Status/

Maintenance mode only allows the user to look at the

settings.

If the LID display is in Edit mode, then the display will

only show the word “password.” Press the

EXPN/EDIT

sure the LID display shows:

LogintoController

Enter Password

NOTE: The default password is 1111.

SET

key to toggle to the Status mode. Make

ENTER

4. The LID display will show:

LogintoController

Logged In

NOTE: The user will be automatically logged off after

15 min. of non-use.

Change the Default Password — To change the

default password, perform the following procedure:

NOTE: The password must have already been entered to

perform this procedure.

1. Press 3 and then . The LID display will show:

Controller Password

2. Press . The LID display will show:

3. Press . The LID display will show:

4. Enter the new password (up to 6 digits) and press

5. Press twice to leave the password screen and re-

ENTER

LogintoController

Logged in

EXPN/EDIT

Password

1111 (default password, or previous password entered)

ENTER

Password

(password just entered)

NOTE: Remember this password; write it down.

CLEAR

turn to the default display screen.

SET

. The LID display will show:

Set the Clock — The user must be logged in to set the

clock. To set the clock, perform the following procedure:

1. Press 1 and then . The LID display will show:

Set Clock

2. Press . The LID display will show:

3. Press . The LID display will show:

4. Enter the time. The time is entered in military time (for

5. Enter the day of week. The numbers 1 through 7 corre-

6. Enter the number of the corresponding month (1 through

7. Enter the day of the month. Press then press

ENTER

No Maintenance

NOTE: There is no maintenance information regarding

setting the clock.

EXPN/EDIT

Time

00:00

example 14.59 for 2.59 pm). Press then press

the button. The LID display will show:

Day of Week

1

spond to the days of the week (1 = MON, 2 = TUE,

3 = WED, 4 = THUR, 5 = FRI, 6 = SAT, 7 = SUN). Press

ENTER

Month

1

12). Press then press . The LID display

will show:

Day

1

. The LID display will show:

Ye a r

95

SET

ENTER

then press . The LID display will show:

ENTER

ENTER

12

Page 13

8. Enter the last two digits of the current year. Press

ENTER

then press . The LID display will show:

Update Clock

No

9. Press 1 and then to cause the controller to

ENTER

update the clock. The LID display will flash. Press

CLEAR

twice to view the default display and the clock

should update to the input time and date.

Configure Schedules — Schedules are one method of

starting and stopping the unit at specified intervals. To configure the schedules, perform the following procedure:

1. Press 1 and then . The LID display will show:

SCHD

Occupancy Algorithm

2. Press . The LID display will show:

ENTER

Time Schedule

Enter to select

3. Press . If the LID display shows “MODE 0” then

ENTER

the user is in Maintenance mode and the LID display is

showing the maintenance information for the occupancy

schedule. Press to enter the configuration

EXPN/EDIT

mode. The LID display will show:

Manual Override Hours

0 hours

This is the first configuration for each occupancy

algorithm and is used to put the schedule in or out of

occupancy override for the number of hours entered.

4. Press . The LID display will show:

Period 1: Day of week

00000000

The eight digits represent if this period should apply to

certain days of the week or holidays. The digits representM,Tu,W,Th,F,Sa,Su,andHol,respectively.

Enter a series of 0s or 1s with a 1 corresponding to the

days that this period should apply to and a 0 for the

days that this schedule should not apply to. As an

example, entering 11111000 would make the schedule

apply to days Monday through Friday and not apply to

Saturday, Sunday, or Holidays.

5. Press the button. The LID display will show:

Period 1 occupied from

00:00

6. Input the Occupancy Start time for this period.

NOTE: 12.00 represents 12:00 pm.

7. Press the to input the Occupied To time for period 1.

8. Input the days and times for periods 2 through 8 as

required.

9. Press clear to leave the occupancy programming.

Program Set Points — To program the set points,

perform the following procedure:

1. Press 2 and then . The LID display will show:

Set point Schedule

2. Press . The LID display will show:

ENTER

Supply Fan Status

SETPT01

3. Press .

ENTER

SCHD

4. If “No maintenance” is displayed, press to

EXPN/EDIT

view the set point information. The LID display will

show:

Occupied Lo Set point

0.30 ″ H2O

This is the pressure set point below which the fan is

considered to be off.

5. Press . The LID display will show:

Occupied Hi Set point

0.40 ″ H2O

This is the pressure set point above which the fan is

considered to be on.

The down or up arrow will also display the Unoccu-

pied Low and High Temperature set points. These

values should be kept the same as the occupied values.

6. Setpoint 02 internally coordinates the supply air set point

reset in several of the algorithms and can not be modified.

Setpoint 03 is used for comparison by the unit to return

air, Space temperature or Average space temperature

through linkage to determine when to start reset of the

supply air when occupied, when to turn on heat and

disable cooling when occupied and when to bring the unit

on for unoccupied heating or cooling.

Setpoint 04 is used to set the head pressure set point if

the unit is ordered with the head pressure control

option. Only the Occupied Low set point may be

modified the other values will change to the Occupied

low valued shortly after it is modified so that all the

values remain the same.

Setpoint 05 is used to set the supply air static pressure the

unit should maintain. Only the Occupied Low set point

may be modified the other values will change to the

Occupied low value shortly after it is modified so that all

the values remain the same. The set point in the static

pressure control algorithm will also follow and cannot be

modified in the algorithm configuration screens.

Setpoint 06 is the Supply air temperature set point.

Only the Occupied Low set point may be modified the

other values will change to the Occupied low value

shortly after it is modified so that all the values remain

the same. The set point in DX VAV staging and some

of the other algorithms will also follow and cannot be

modified in the algorithm configuration screens.

Setpoint 07 is the building pressure set point for the

building pressure control of a variable speed exhaust

fan from a field-supplied module. Only the Occupied

Low set point may be modified the other values will

change to the Occupied low value shortly after it is

modified so that all the values remain the same.

Setpoint 08 is the raw milliamp set point for the building pressure control and is tied to Setpoint 07 for the

sensor range selected in the custom programming

configuration. Several choices of building static

pressure sensors may be purchased and supplied for

building pressure control.

Setpoint 09 is used for the humidification/dehumidification

output from a field-supplied module. This set point may be

modified to enable the Humidity output to either humidify

or dehumidify when the indoor relative humidity (IRH)

exceeds the set point.

Table 7 lists the available controller set points and their

default values.

7. Pressing the button will take the user out of the

CLEAR

set point configuration mode.

13

Page 14

Table 7 — Controller Set Points

DESCRIPTION

DISPLAY

SCREENS

OMNIZONE::SETPT01:

Supply fan Status

Occupied Lo Setpoint 0.3 in H2O OccLow

Occupied Hi Setpoint 0.4 in H2O OccHgh

Unoccupied Lo Setpoint 0.3 in H2O UnOccLow

Unoccupied Hi Setpoint 0.4 in H2O UnOccHgh

OMNIZONE::SETPT02:

VAVRESETbaseline

Occupied Lo Setpoint 0 dF OccLow

Occupied Hi Setpoint 0 dF OccHgh

Unoccupied Lo Setpoint 0 dF UnOccLow

Unoccupied Hi Setpoint 0 dF UnOccHgh

OMNIZONE::SETPT03:

Heat\Cool Mode & Reset

Occupied Lo Setpoint 70 dF OccLow

Occupied Hi Setpoint 74 dF OccHgh

Unoccupied Lo Setpoint 55 dF UnOccLow

Unoccupied Hi Setpoint 85 dF UnOccHgh

OMNIZONE::SETPT04:

Head Pressure Control

Occupied Lo Setpoint 225 PSIG OccLow

Occupied Hi Setpoint 225 PSIG OccHgh

Unoccupied Lo Setpoint 225 PSIG UnOccLow

Unoccupied Hi Setpoint 225 PSIG UnOccHgh

OMNIZONE::SETPT05:

Supply Static Pressure

Occupied Lo Setpoint 1.5 in H2O OccLow

Occupied Hi Setpoint 1.5 in H2O OccHgh

Unoccupied Lo Setpoint 1.5 in H2O UnOccLow

Unoccupied Hi Setpoint 1.5 in H2O UnOccHgh

OMNIZONE::SETPT06:

Supply Air Temperature

Occupied Lo Setpoint 55 dF OccLow

Occupied Hi Setpoint 55 dF OccHgh

Unoccupied Lo Setpoint 55 dF UnOccLow

Unoccupied Hi Setpoint 55 dF UnOccHgh

OMNIZONE::SETPT07:

Building Static Pressure

Occupied Lo Setpoint 0.02 in H2O OccLow

Occupied Hi Setpoint 0.02 in H2O OccHgh

Unoccupied Lo Setpoint 0.02 in H2O UnOccLow

Unoccupied Hi Setpoint 0.02 in H2O UnOccHgh

OMNIZONE::SETPT08:

BSP raw control

Occupied Lo Setpoint 12.32 ma OccLow

Occupied Hi Setpoint 12.32 ma OccHgh

Unoccupied Lo Setpoint 12.32 ma UnOccLow

Unoccupied Hi Setpoint 12.32 ma UnOccHgh

OMNIZONE::SETPT09:

Humidity Control

Occupied Lo Setpoint 0 %RH OccLow

Occupied Hi Setpoint 99 %RH OccHgh

Unoccupied Lo Setpoint 0 %RH UnOccLow

Unoccupied Hi Setpoint 99 %RH UnOccHgh

LEGEND

BSP — Building Static Pressure

RH — Relative Humidity

VALUE UNITS STATUS FORCE NAME

Check System Parameters — To check system

parameters, press the button. The LID display will

show: “Hardware Points Table 1.” Press to view the

hardware points. The user can navigate up and down through

the points with the up and down arrows.

Press 2 and to display the software points. The user

STAT

can navigate up and down through the points with the up and

down arrows.

Refer to Tables 8 and 9 for hardware and software points.

STAT

ENTER

Display Alarm History — If the controller is indicating

there are alarms, the user can view the alarm history by

pressing the button. The LID display will show “Alarm

History.” Press . The LID display will show the date

HIST

ENTER

and type of alarm.

As an example, if the LID display shows:

ALARM — 10:55 11-27-02

SFS

That display indicates that on 11/27/02 at 10:55 A.M. the

system Supply Fan was either on when it had not been

commanded on or was off when it was commanded on.

The user can view other stored alarms by pressing the up

and down arrows. The twenty-four most recent alarms are

stored.

Configure Custom Programming Selections —

To configure the custom programming selections, perform the

following procedure:

1. Press 37 . The LID display will show:

Custom Program

2. Press . The LID display will show:

2.0 Global Dictionary

OMNIZONE

3. Press . The display indicates “No Data.”

Press then press . Press

ENTER

Compressor Stages

4.00

4. Press 4 and then to indicate that 4 compressors

are installed.

5. Use the down and up arrows to select the other configuration parameters as required. See Table 10 for a list of configuration parameters.

6. A field-supplied 0 to 10 vdc signal to the 50XJ unit may

be used to reset the supply-air temperature.

The reset will be taken off the supply air set point

configured in the controller. The reset range can be

changed by adjusting the High Conversion Endpoint

value of the custom voltage input to a value other than

20. For example for 10 degrees of reset change the Hi

input value to 10. This may be found by pressing 7

STAT

custom voltage input point in the controller. The first

will be CSMUX, which is the compressor status multiplexed input. Press to see the following in the

LID display:

Ext. Supply Air Reset

RESET

Press . If the LID display shows:

System Value

Press . The LID display will show:

Low Input Endpoint

2.0 Volts

Press three times to get to the High Conversion

Endpoint. The user must be logged in to be able to change this

otherwise you can only view it. See the start up section for how

to log into the controller.

Configuration parameters are shown in Table 10.

ALGO

ENTER

ENTER

CLEAR

EXPN/EDIT

again. The LID display should now show:

ENTER

from the Keypad. RESET will be the second

ENTER

EXPN/EDIT

14

Page 15

Table 8 — Controller Hardware Points Table 9 — Software Points

DESCRIPTION

DISPLAY

SCREENS

OMNIZONE::HWP01-32:

Hardware points Table 1

Supply Air Temperature 67 dF SAT

Duct Static Pressure 0.2 in H2O DSP

Comp. Status MUX 1.86 Volts CSMUX

Fire Alarm/ShutDown Enable FSD

Cond. Water Flow Switch Ye s C DW F

Remote Occupancy Disable ROCC

Duct High Press. Switch Normal DHS

Entering Water Temp. 69.9 dF EWT

Compressor 1 Relay Stop CMP1

Compressor 2 Relay Stop CMP2

Compressor 3 Relay Stop CMP3

Compressor 4 Relay Stop CMP4

Supply Fan/VFD Stop SF

VFD Speed Signal 0 % SPEED

Non Critical Fault Off WARN

Critical Fault Off ALARM

Mixed/Return Air Temp 77.2 dF MA_RA

Dirty Filter Status Clean FLTS

Phase Loss Protection Normal PHASE

Ext. Supply Air Reset 0 dF RESET

Water Econ. FreezeStat Normal FREEZ

Space_Reset Sensor 79.2 dF SPT

VFD Bypass Enable Disable BYPAS

Head Pressure(Comp1) 118.76 PSIG PRES

Ventilation Request Close VENTR

VAV Termi nals Co ntro l No TRMCT

2-position/Econo Valve 0% ECONO

Reverse/Head Press Ctrl 100 % Control MVLV

Hot Water Valve 0% HWV

Heat Interlock Relay Off HIR

Bypass Start_Stop Stop BPS_S

VAV Terminals Open MAX Close TRMOP

OMNIZONE::HWP33-64:

Hardware points table 2

Cooling Tower Sump Temp. 57.5 dF TWR

Building Static Milliamp 12.51 ma BSP

Condenser Leaving Water 70.3 dF LWT

Indoor Air Quality 587.21 IAQ

Indoor Relative Humidity 49.7 % IRH

Outdoor Air Temp. 76.1 dF OAT

Heat Stage 1 Off HEAT1

Heat Stage 2 Off HEAT2

Heat Stage 3 Off HEAT3

Heat Stage 4 Off HEAT4

Pump Request Off PUMP

Cooling Tower Request Off TOWER

Exhaust Fan 0% EXH

Ext. Dehumidification Stop DEHUM

VALUE UNITS STATUS FORCE NAME

DESCRIPTION

DISPLAY

SCREENS

OMNIZONE::SWP65-96:

Software Points

Compressor 1 Status Off CLO1

Compressor 2 Status Off CLO2

Compressor 3 Status Off CLO3

Compressor 4 Status Off CLO4

Bypass Acc Panel Secure No BP_SAFE

DX VAVRESET control 0 dF VAVRESET

Factory/Field Test Stop FLDTST

Building Static Pressure 0.03 in H2O BSP_IN

Time Clock Off TIMCLOCK

Cooling Disable COOLOK

Supply Fan Status Off Control SFS

Ok to run Fan No OKFAN

OK Fan + Sup. Fan Stat FA L SE S F_ SF S

Fan + Cond. Water Flow FA LS E FAN _C DW F

Equipment Mode Cool Control MODE

Activate Evacuation Mode Disable EVAC

Space Control Point 74 dF CTRLPT

Mod. Econ Enabled No Control ECON_OK

Head Pressure Control Disable Control HEAD

Economizer Control Temp. 77.22 dF ECONPT

Compressor Cooling Disable COMPRES

Duct Static Failure Normal DSP_ALM

Compressor 1 Alarm Normal C1_ALM

Compressor 2 Alarm Normal C2_ALM

Compressor 3 Alarm Normal C3_ALM

Compressor 4 Alarm Normal C4_ALM

Cond. Flow Alarm Status Disable Control CDWF_ST

VALUE UNITS STATUS FORCE NAME

Table 10 — Configuration Parameters

DESCRIPTION VALUE UNITS NAME

Compressor Stages 2.00 NUM_CMP

Reset Ratio 3.00 dF RSET_RTO

CDWF 0=NO,1=YES 0.00 CDFW_SWT

ECON 0=NO,1=YES 0.00 EWT_SNS

EWT Reset 0=NO,1=YES 1.00 EWT_RST

MOD.VLV 0=NO,1=YES 0.00 MOD_ECON

0=CONST.,1=VARIABLE 0.00 FLOW_TYP

0=RAT,1=MAT 2=NONE 2.00 MARA_SNS

PHASE 0=NO,1=YES 0.00 PHAS_SWT

FREEZ 0=NO,1=YES 0.00 FREZ_SWT

ENABLE ECON. 68.00 dF ECON_SET

SPT 0=NO,1=YES 0.00 SPT_SNS

PRES 0=NO,1=YES 0.00 PRES_SNS

TWR 0=NO,1=YES 0.00 TWR_SNS

LWT 0 =N O,1 =YE S 0.00 LWT_SNS

IAQ 0=NO,1=YES 0.00 IAQ_SNS

IRH 0=NO,1=YES 0.00 IRH_SNS

BSP 0=NO,1=YES 0.00 BSP_SNS

BSP Range 1.00 in H2O BSP_RNG

BSP LOW VALUE –0.50 in H2O BSP_LOW

LEGEND

BSP — Building Static Pressure

CDWF — Condenser Water Flow

ECON — Economizer

EWT — Entering Water Temperature

IAQ — Indoor Air Quality

IRH — Indoor Relative Humidity

LW T — Leaving Water Temperature

MAT — Mixed Air Temperature

RAT — Return Air Temperature

SPT — Space Temperature

Set Controller Address — To set the address of the

OMNIZONE™ System Control panel controller, perform the

following procedure:

1. Press 7 and then . Press and then

EXPN/EDIT

SRVC ENTER

.

2. Type in the CCN element number and press .

3. Press the button. Type in the CCN bus number and

press .

ENTER

Log Off from Controller — To log off from the

OMNIZONE System controller Press 3 and then . The

controller password will be displayed.

ENTER

SET

15

1. Press . The display should show:

ENTER

Log in to Controller

Logged in

If this is not displayed, Press until it is

EXPN/EDIT

displayed.

2. Press the button. The LID display will show:

Log out of Controller

Press 1. Press to log off.

ENTER

Page 16

OPERATION

Occupancy Determination —

controller can determine occupancy in many ways. Local occupancy is determined by either a local schedule contained in the

CC6400 controller, the use of the ROCC discrete input point or

by setting the Local/Off/Remote switch to Local. In order for

the CC6400 schedule or ROCC point to function the Local/

Off/Remote switch must be set to Remote.

When the OMNIZONE unit is connected to a Carrier

Comfort Network and the Local/Off/Remote switch is set to

Remote, the controller occupancy can be determined by a

Network Group schedule, a Network Global schedule, or via

Linkage from a linkage device such as a ComfortID™ linkage

master.

The OMNIZONE™

Fan Control — All Variable Air Volume (VAV) units have

a Variable Frequency Drive (VFD) to provide variable fan

motor speed and thus variable airflow. Fan control turns the fan

on and off based on unit operating mode, and controls fan

speed to maintain a particular duct static pressure at a Duct

Static Pressure Sensor (DSP). The objective is to maintain a

reasonably constant supply-air exit velocity at VAV system

outlet grilles, regardless of damper opening positions. The duct

static pressure sensor is field-installed about

2

/3of the way

toward the “far end” of the ductwork. A High Duct Static

Switch (HDS) provides protection by shutting the fan down if

the duct static pressure exceeds a maximum setting.

For the 50XJ unit, a VFD interface display is mounted in

the front of the unit. A number of user-adjustable features can

be entered/changed using the keypad on the display. These

features described in detail in the Variable Frequency Drive

Control section.

Sequence of Operation — The following control

sequence of operation for the 50XJ,BV unit describes the

various sequences that occur depending upon the way an

operation is triggered and which software control points are

involved.

SUPPLY FAN — The Supply fan can be activated in any of

the following ways:

• Unoccupied space or return air temperature demand.

• Unoccupied Linkage demand.

• Local Time Schedule (TIMCLOCK software point).

• Remote Occupancy (ROCC software point).

• By placing the remote-off-local switch in the local

mode.

• Enabled by Schedule.

Once one of the above conditions exists, either TIMECLOCK or ROCC indicates ON or Enable. The software point

OKFAN will turn on followed by the points TRMCT for air

terminal control and PUMP and TOWER to request condenser

water flow and temperature control. Approximately 20 to

30 seconds later the supply fan (SF) point will turn ON and the

VFD output SPEED will increase. The SPEED point will