Page 1

KC_141P; KC_183P; KC_223P; KC_233P

KH_123P; KH_233P

Room Air Conditioner

Installation and Operating

Instructions

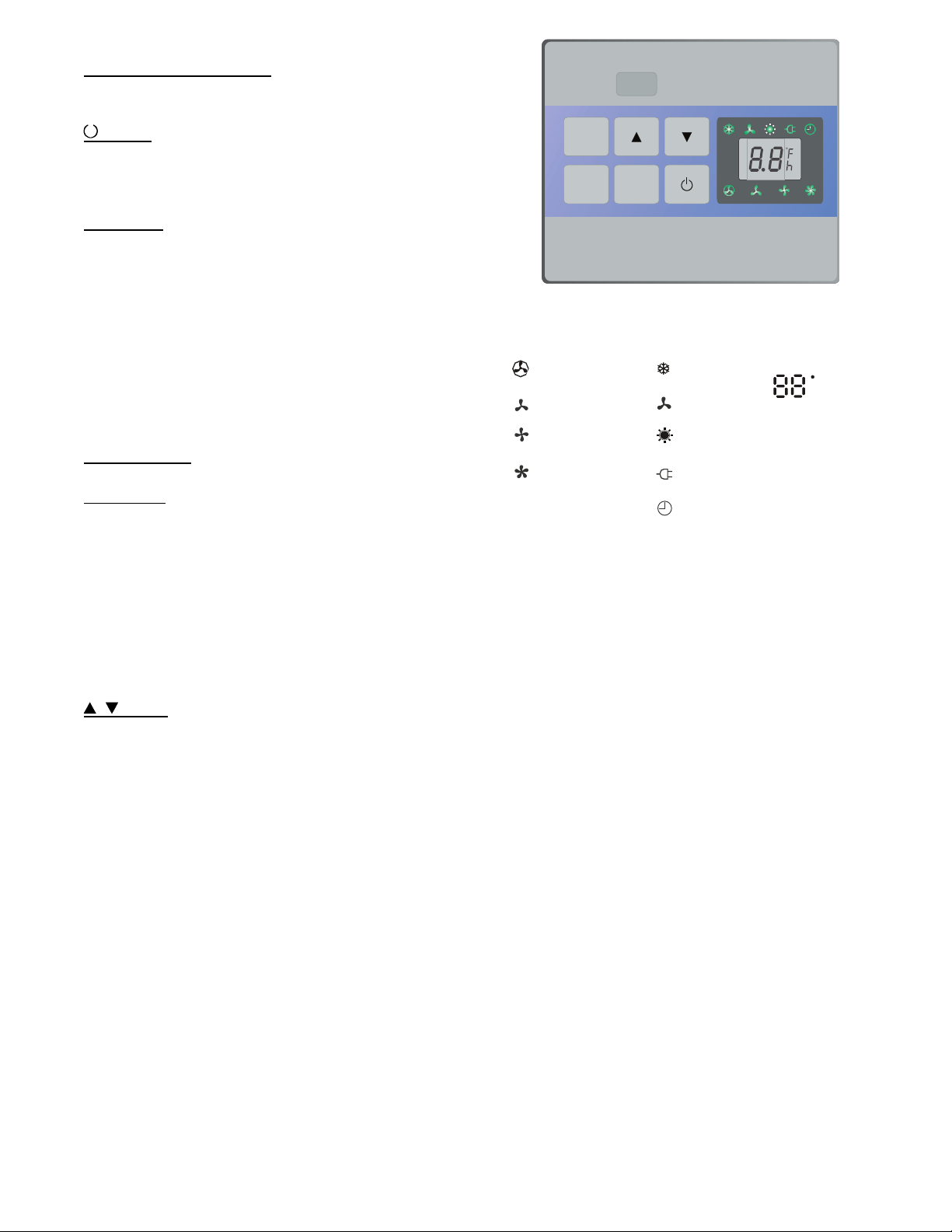

Fig. 1 --- Remote Control Unit

NOTE TO EQUIPMENT OWNER:

Thank you very much for purchasing a Carrier Air conditioner. Please read this Owner’s

Information Manual carefully before installing and using this appliance and keep this manual

for future reference.

For your convenience, please record the model and serial numbers of your new equipment

in the spaces provided. This information, along with the installation data and dealer contact

information, will be helpful should your system require maintenance or service.

UNIT INFORMATION

Model # _____________________________________

Serial # ______________________________________

INSTALLATION INFORMATION

Date Installed ________________________________

DEALERSHIP CONTACT INFORMATION

Company Name_______________________________

Address______________________________________

_____________________________________________

Phone Number _______________________________

Technician Name _____________________________

_____________________________________________

Page 2

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 3...................................................................................

INTRODUCTION 3.............................................................................................

ELECTRICAL SPECIFICATIONS 4................................................................................

TIPS BEFORE INSTALLATION 5.................................................................................

POWER SUPPLY CORD 5.......................................................................................

INSTALLATION INSTRUCTIONS 6--9............................................................................

STORM WINDOW APPLICATIONS 9..............................................................................

WALL INSTALLATIONS 10 -- 11..................................................................................

MASONRY CONSTRUCTION 11..................................................................................

OPERATING INSTRUCTIONS 12 -- 13.............................................................................

CARE AND MAINTENANCE 14..................................................................................

TROUBLESHOOTING GUIDE 14.................................................................................

WARRANTY 15................................................................................................

2

Page 3

SAFETY CONSIDERATIONS

Recognize safety information. This is the safety--alert symbol .

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or d eath. CAUTION is used

to identify unsafe practices which ma y result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

INTRODUCTION

Thank you for choosing this room air conditioner to cool your

home. This Owner’s Information Manual provides information

necessary for the proper care and maintenance of your new room

air conditioner.

If properly maintained, your air conditioner will give you many

years of trouble free operation. To avoid installation difficulties,

read instructions completely before starting. This manual contains

information for the installation and operation of your room air

conditioner.

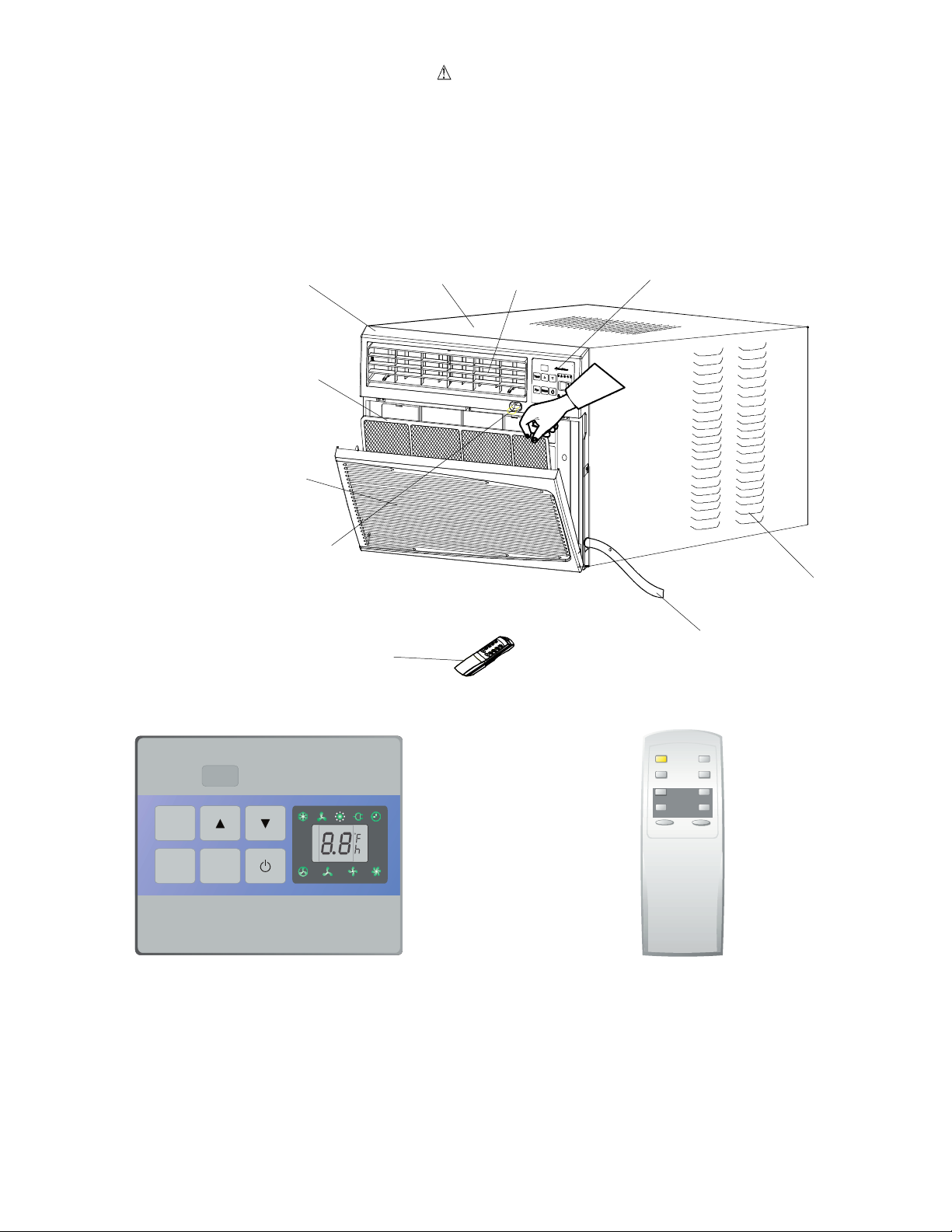

Front Panel

Air Filter

Interior

Air Inlet

Grille

Outdoor Air

Vent Lever

Remote Control

Control Panel

Cabinet

Air Outlet

Control Panel

Exterior

Air Inlet

Power Cord

A06528

Remote Control

Pow e r

Mode

Auto

Fan Spe ed

High Low

_

Te m p/ T i m e

Tim e r

Pow e r Sa ve r

Mid

+

A06529

Ti m e r

Fa n

Sp e e d

Airconditioner

Mode

Fig. 2 --- Air Conditioner Parts Description

NOTE: The figures in this manual are based on the external view of a standard model. Consequently, the shape may differ from that of the

air conditioner you have selected.

3

Page 4

ELECTRICAL SPECIFICATIONS

1. All wiring must comply with local and national electrical

codes and must be installed by a licenced electrician. If you

have any questions regarding the following instructions,

contact a licenced electrician.

2. Check available power supply and resolve any wiring

problems BEFORE installing and operating this unit.

3. For your safety and protection, this unit is grounded

through the power cord when plugged into a matching wall

outlet. If you are not sure whether your wall outlet is

properly grounded, please consult a licenced electrician.

4. The wall outlet (3--pin) must match the plug (3--pin) on the

power cord supplied with the unit. DO NOT use plug

adapters or extension cords. See (Table 1) for receptacle and

fuse information.

5. The rating plate on the unit contains electrical and other

technical data. The rating plate is located on the right side of

the unit. Make sure to use the correct power supply

according to the rating plate of your air conditioner.

RECEPTACLE AND FUSE TYPES

COOLING CAPACITY

RATED VOLTS 125 250 250 250

AMPS 15 15 20 30

10K--- 14K

(Cooling only)

18K(Cooling only)

10K--- 12K(With heating)

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death and/or property damage.

Shut off electrical power to unit before installing or

servicing.

If the air conditioner has a serial plate rating of 115 volts

and up to and including 7.5 amps, the unit maybe on a fuse

or circuit breaker with other devices. However, the

maximum amps on all devices for that fuse or circuit

breaker can not exceed the amps of the fuse for the circuit

breaker.

If the air conditioner has a serial plate rating of 115 volts

and greater than 7.5 amps it must have its own fuse or

circuit breaker, and no other device or unit should be

operated on the fuse or circuit breaker.

If the air conditioner has a serial plate rating of 230 volts, it

must have its own fuse or circuit breaker, and no other

device or unit should be operated on the fuse or circuit

breaker.

!

WARNING

23K

(Cooling only)

18K--- 23K

(With heating)

WALL OUTLET

FUSE SIZE 15 15 20 30

NOTE: 10K--14K (Cooling only) including models

18K (Cooling only) including models

10K--12K (with Heating) including models

NOTE: Check rating plate on your specific model for exact receptacle and fuse type.

23K (Cooling only) including models

18K--23K (with Heating) including models

4

Page 5

TIPS BEFORE INSTALLATION

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in damage to unit

components.

To avoid installation/operating difficulties, read the

instructions thoroughly.

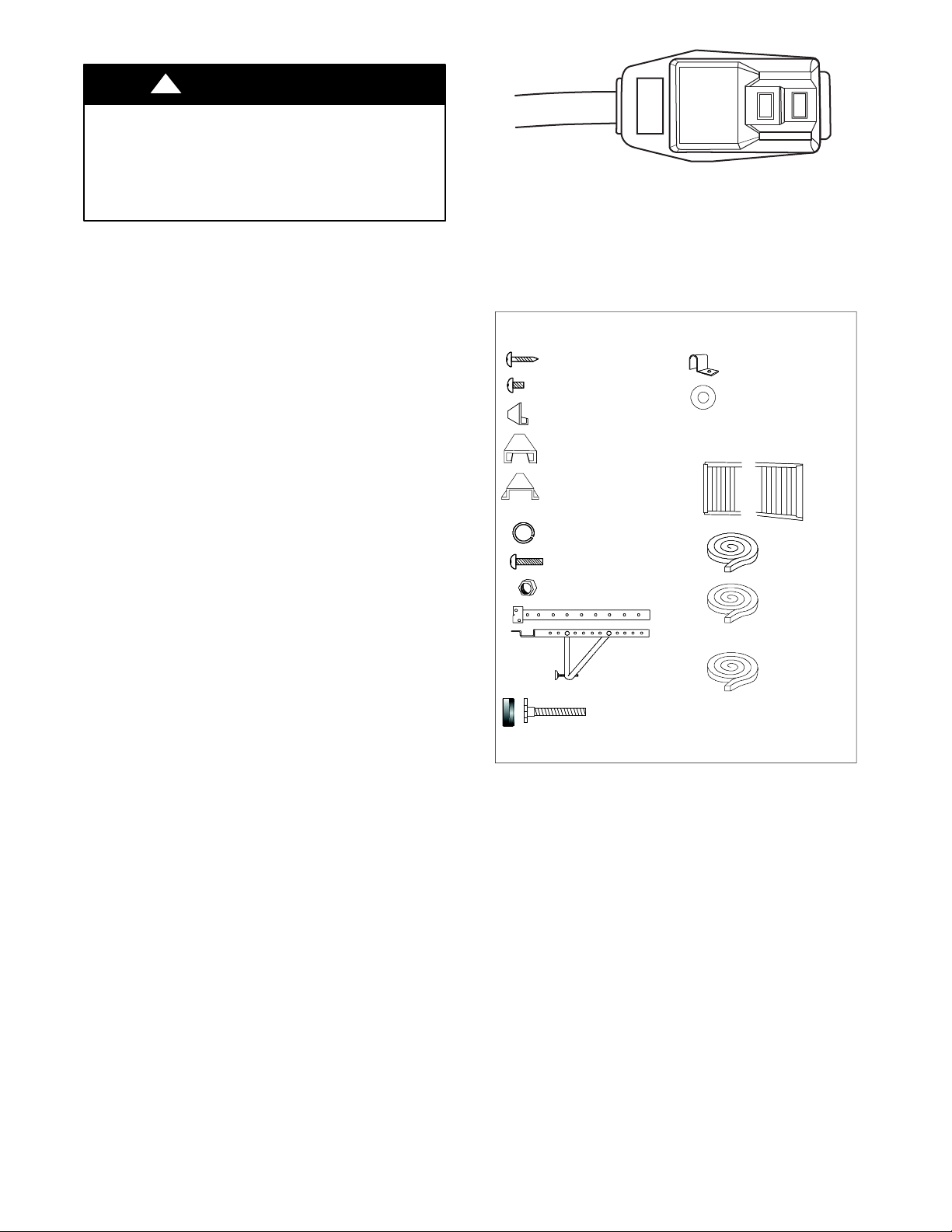

TEST

Fig. 3 --- Power Supply Cord

RESET

A06531

Your Room Air Conditioner unit is designed to be highly efficient

and save energy. Follow these recommendations for greater

efficiency.

1. Select thermostat setting that suits your comfort needs and

leave the thermostat at that chosen setting.

2. The air filter is very efficient in removing airborne particles.

Keep the air filter clean. Typically, the filter should be

cleaned once a month. More frequent cleaning may be

necessary depending on outdoor and indoor air quality.

3. Use drapes, curtains, or shades to keep direct sunlight from

heating your room, but DO NOT obstruct the air

conditioner. Allow air to circulate around the unit without

obstructions.

4. Start your air conditioner before outdoor air becomes

hot/cold and uncomfortable. This avoids an initial period of

discomfort while the unit is cooling or heating off the room.

5. When outdoor temperature is cool enough, use HIGH or

LOW FAN only. This circulates indoor air, providing some

cooling comfort, and utilizes less electricity than when

operating on a cooling setting.

Your Room Air Conditioner was designed for easy installation in a

single or double--hung window.

NOTE: This unit is NOT designed for vertical (slider type)

windows.

POWER SUPPLY CORD

This room air conditioner is equipped with a protective power

supply cord that senses current leakage (see Fig. 3). Unit power is

automatically disconnected when unsafe conditions are detected.

To test the power supply cord:

1. Plug power supply cord into a grounded 3--prong outlet

2. Press RESET.

3. Press TEST (listen for click; RESET button will trip and

pop out).

4. Press and release RESET (listen for click; RESET button

will latch and remain in). The power supply cord is ready

for operation.

The Reset button must be pushed in for proper operation.

The power supply cord must be replaced if the RESET button fails

to trip when the test button is pressed or fails to reset. A damaged

power supply cord must be replaced with a new power supply cord

obtained from the product manufacturer. The damaged cord MUST

NOT be repaired.

Do not use the power supply cord as an off/on switch. The power

supply cord is designed as a protective device.

The power supply cord contains no serviceable parts. Opening the

tamper--resistant case voids all warranty and performance claims.

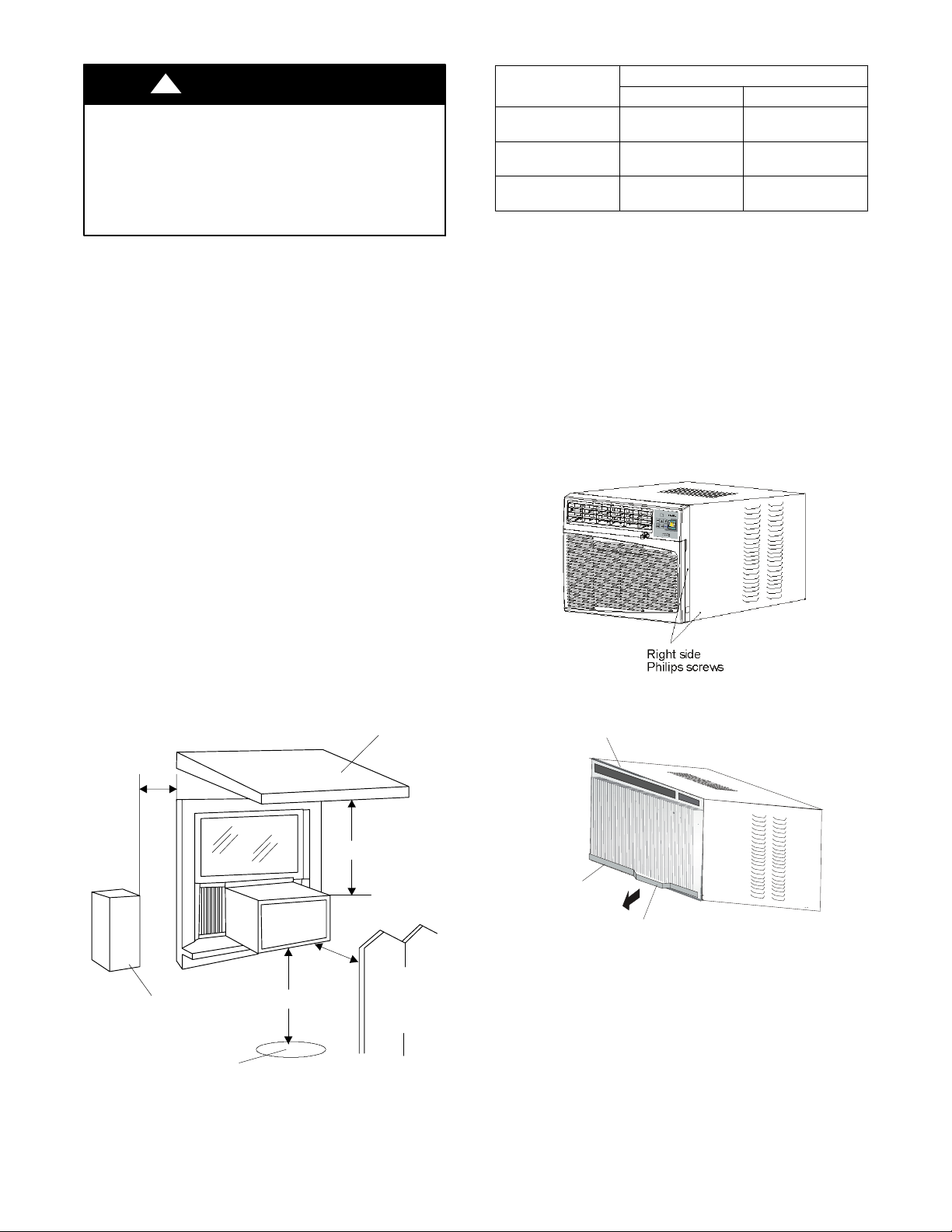

NOTE: Save the shipping carton and packing materials for future

storage or transport of the unit. Please check the contents of the

hardware kit against the corresponding model check list, prior to

installation of the unit. See lists below in Fig. 4.

3/4”Screws (10)

3/4”Screws (10)

1/4”Screws (23)

Top Channel(1)

Top Channel(1)

Bottom Channel(1)

(F

or 10K to 12K models)

Bottom Channel(1)

(For 14K to 23K models)

--- F a c t o r y I n s t a l l e d )

Lock Washers(4)

Lock Washers(4)

1--- 1/2”x1/4 Bolts(4)

1--- 1/2”x1/4 Bolts(4)

1/4” Nuts(4)

1/4” Nuts(4)

Mounting

Mounting

Brackets(2)

Brackets(2)

Angle

Angle

Brackets(2)

Brackets(2)

End Cap &

Leveling Legs(2)

Fig. 4 --- Installation Hardware

NOTE: Surplus screw(s) for spare use.

Tools needed for window installation

Shutter Clamp(2)

Shutter Clamp(2)

Washer(10)

Side Curtain RH(1)

Side Curtain RH(1)

Side Curtain LH(1)

Side Curtain LH(1)

Seal(1)

Foam (1)

Double

Adhering

Seal(1)

A06532

S Screw drivers: both Phillips and flat head

S Power drill: 1/8 inch diameter drill bit

S Pencil

S Measuring tape

S Scissors

S Carpenters level

5

Page 6

INSTALLATION INSTRUCTIONS

!

CAUTION

PERSONAL INJURY/UNIT OPERATION HAZARD

Failure to follow this caution may result in personal injury

and/or damage to unit components.

It is recommended to have someone assist you during the

installation of this unit because the compressor is located on

the controls side of the unit (right side) and this side will be

heavier and more awkward to manipulate.

Step 1 —Select the Best Location

A. Your room air conditioner was designed to fit easily into a

single or double hung window. However, since window

designs vary, it may be necessary to make some modifications

for safe and proper installation.

B. Make sure window and frame is structurally sound and free

from dry and rotted wood.

C. For maximum efficiency, install the air conditioner on side of

the house or building which favors more shade than sunlight.

If the unit is in direct sunlight, it is advisable to provide an

awning over the unit.

D. Provide sufficient clearance around the cabinet to allow for

ample air circulation through the unit (see Fig. 5). The rear of

the unit should be outdoors and not in a garage nor inside of a

building. Keep unit as far away as possible from obstacles and

obstructions and at least 30” above the floor or ground.

Curtains and other objects within a room should be prevented

from blocking the air flow.

E. Be certain the proper electrical outlet is within reach of the

installation. Use only a single outlet circuit rated at proper

current (see table 1 on page 4). All wiring should be in

accordance with local and national electrical codes.

F. Your unit was designed to evaporate condensation under

normal conditions. However, under extreme humidity

conditions, excess condensation may cause the basepan to

overflow to the outside. The unit should be installed where

condensation run--off cannot drip on pedestrians or

neighboring properties.

Awning

Window Opening Requirements

SIZE

Cabinet Size

(W/H/D)

Window Opening

Width

Window Opening

Height

12K 14K--- 23K

22.8”/15.7”/24.1” 26.5”/18.5”/26.9”

27” --- 41” 30” --- 44”

16” 18.5”

MODEL

Step 2 —Preparation to Remove the Air Conditioner

Slide--Out Chassis

A. Remove total of (4) Philips screws securing the chassis to the

cabinet. There are (2) screws on each side. The set of screws

closest to the front of the unit secure the front panel to the

cabinet. The set of screw closest to the rear of the unit secure

the cabinet to the chassis (see Fig. 6).

B. Remove the front panel assembly from the cabinet by gently

pulling it.

C. Grasp the pull handle at the front of the slide--out chassis and

carefully slide the air conditioner out of the cabinet (see Fig. 7).

NOTE: Screws must be reinstalled upon completion of the

window installation to secure slide--out chassis.

IMPORTANT: Please seek assistance for this procedure.

A06535

Fig. 6 --- Screw Removal

Coil

20”

Min.

Side

30” Min.

obstruction

Ground

Fig. 5 --- Air Conditioner Clearances

12” Min.

20”

Min.

Fence,

wall, or

other

obstacle.

A06534

Chassis

Pull Handle

A06536

Fig. 7 --- Air Conditioner Removal

Step 3 —Assembly of the upper & lower channels to the

cabinet

A. ” L” Shaped Top Channel: Stick the double adhering seal to

the ” L” shaped top channel, and then Install the ”L” shaped

top channel to the cabinet as shown in Fig. 8 using (5) 1/4”

screws.

B. ”n” Shaped Bottom Channel installed as shown in Fig.8 using

(4) 1/4” screws.

6

Page 7

NOTE: For 14K to 23K models, the bottom channel has been

y

r

factory--installed, and their shapes may differ from the others, but

their functions are similar.

Step 4 —Assembly of the side shutters (curtains) to the cabinet.

A. Slide the shutters into the top and bottom channels as shown in

Fig. 9. The shutters are identified (on each frame) as ”left” &

”right”. Attach the shutters to the cabinet using (4) 1/4” screws

on each side.

V-slot

Leveling Screw

Bracket Assembly

Bracket Bolts

(TOP VIEW)

90 Angle

Support Brackets

Double

Adhering seal

1/4" Screw

Channel

For 10K to 12K models

For 14K to 23K models,

( Factor

-Installed)

A06537

Fig. 8 --- Channel Assembly

Shutter Frame

1/4" screw

Right Shutte

A06538

Fig. 9 --- Shutter Assembly

Step 5 —Installation of Mounting Brackets and First Sealing

Strip

NOTE: Windows come in a variety of different styles. Therefore,

it may be necessary to modify or improve your particular

installation.

A. Attach the bracket assembly to 90 angle support brackets (Fig.

10) using (2) 1 1/2” bolts, two bolts per bracket. Secure with

the (2) 1/4” lock washers and (2) 1/4”nuts. DO NOT

immediately tighten these bolts as it may be necessary to adjust

the depth of the bracket assembly, depending on the depth of

your window sill. See (Fig. 12).Install the two leveling screws

into the 90 support brackets. Test the bracket assembly in the

window before cabinet installation. If the leveling screws are

distanced too far away from the wall to provide stability, it may

be necessary for you to fill this area with a solid piece of wood.

See (Fig. 13).

B. Measure the inside window sill width and find the center as

shown in (Fig. 11). Align the V--slot in each bracket on these

marks and mount the brackets to the sill using 3/4” screws

provided. Brackets should be perpendicular to the inside

window sill. See (Fig. 11).

A06539

Fig. 10 --- Bracket Assembly

V-slot

Center

9.6"

9.6"

10.3"

12.6"

10.3"

Window sill

A06540

12.6"

Measurement for Model 10K =9.6"

Measurement for Model 12K = 10.3"

Measurement for Model 14K to 23K = 12.6"

Fig. 11 --- Bracket Mounting

C. For proper condensation run-- off it will be necessary to adjust

the angle/pitch of the window brackets. This is accomplished

by adjusting the distance of the leveling screw on the outer

wall. The maximum angle/pitch should not exceed more than

3/16”. See (Fig.12).

D. Cut the seal strip to fit the underside of the bottom window

sash. Remove the peel--off backing on the seal and attach it to

this sash. See (Fig. 14).

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

Use a solid piece of wood to provide stability. This will be

required when sills are extra deep (see Fig. 13).

(2) 3/4" screws per bracket

3/16" Maximum

Bracket Assembly

Leveling Screw

Outer Wall Construction

A06541

Fig. 12 --- Depth/Angle Illustration

7

Page 8

Solid Piece Wood

(If required)

A06542

Fig. 13 --- Solid Piece of Wood Placement

Window Sash

Window Sash

Sealing Strip

A06543

Fig. 14 --- Seal Strip Adhesion

Step 6 —Installation of the cabinet

A. Align one hole in the bottom of the cabinet with one hole in

the bracket assembly. Secure the cabinet to the bracket using

(3) 1/4” screws provided. Repeat the same procedure on the

opposite side of the cabinet. See (Fig. 15).

B. Ensure the ”L” shaped mounting channel is positioned in front

of the sash. The bottom channel of the cabinet should be

positioned in the track provided on the bracket assembly. Pull

the window down until it rests just behind the front of the ”L”

shaped mounting channel. See (Fig. 16).

C. Check to make sure that the cabinet is slanted slightly

downward on the outside. If necessary, re-- adjust support

bracket as shown in (Fig. 12).

Step 7 —Secure Shutters

A. Carefully slide the air conditioner back into the cabinet.

(Please seek assistance for this procedure).

B. Reinstall the slide--out--chassis security screws (removed

earlier) on both sides of the cabinet (see Fig. 12). Secure the

top of the frames to the window sash with (2) 3/4” screws.

C. Now, secure bottom frame of shutters using one shutter clamp

and one 3/4” screw on each side (see Fig. 12).

Step 8 —Reinstalling Front Panel Assembly

A. Position the front panel on the cabinet starting at the top. The

front panel lock tabs must be inserted into the retaining slots in

the cabinet. Repeat this procedure on all sides.

B. Secure the front grille to the cabinet using the Philips screws

removed earlier (see Fig. 6).

Step 9 —Complete the installation

A. Cut the foam to fit the opening between the top of the inside

and outside window (see Fig. 18).

B. Some installations may require additional sealing around

the window and air conditioner. Check for any air leaks and

seal where necessary.

C. In very humid areas, the water removal may be excessive

enough to overflow the unit or increase the noise of the air

conditioner. If this occurs, you may wish to attach a drain hose

(not included) to the drain plug allowing condensations to run

off conveniently (see Fig. 19).

NOTE: Fresh Air ventilation is usually kept in the closed

position. Use only when clearing smoke and/or odors from the

room. Pull to open (see Fig. 20).

1/4" Screws

A06544

Fig. 15 --- Secure the Cabinet

Window Sash

"L"Shaped

Mounting

Channel

Seal

A06545

Fig. 16 --- Mounting Channel

3/4" screws

A

i

r

c

o

n

d

i

t

i

o

n

e

r

TI

M

E

R

F

H

R

F

A

N

M

O

D

O

E

N

O

F

F

/

S

P

E

E

D

W

I

A

T

T

H

R

E

E

MI

N

T

U

E

S

B

E

O

F

E

R

R

E

S

A

T

R

T

I

G

Coil

N

"L"Shaped

Mounting

Channel

Seal

Security Screw

A06546

Fig. 17 --- Security Screw Detail

Foam

A06547

Fig. 18 --- Foam Fitting

8

Page 9

OUTDOOR AIR VENT LEVER

Drain Hose

(not included)

Fig. 19 --- Drain Hose

A06548

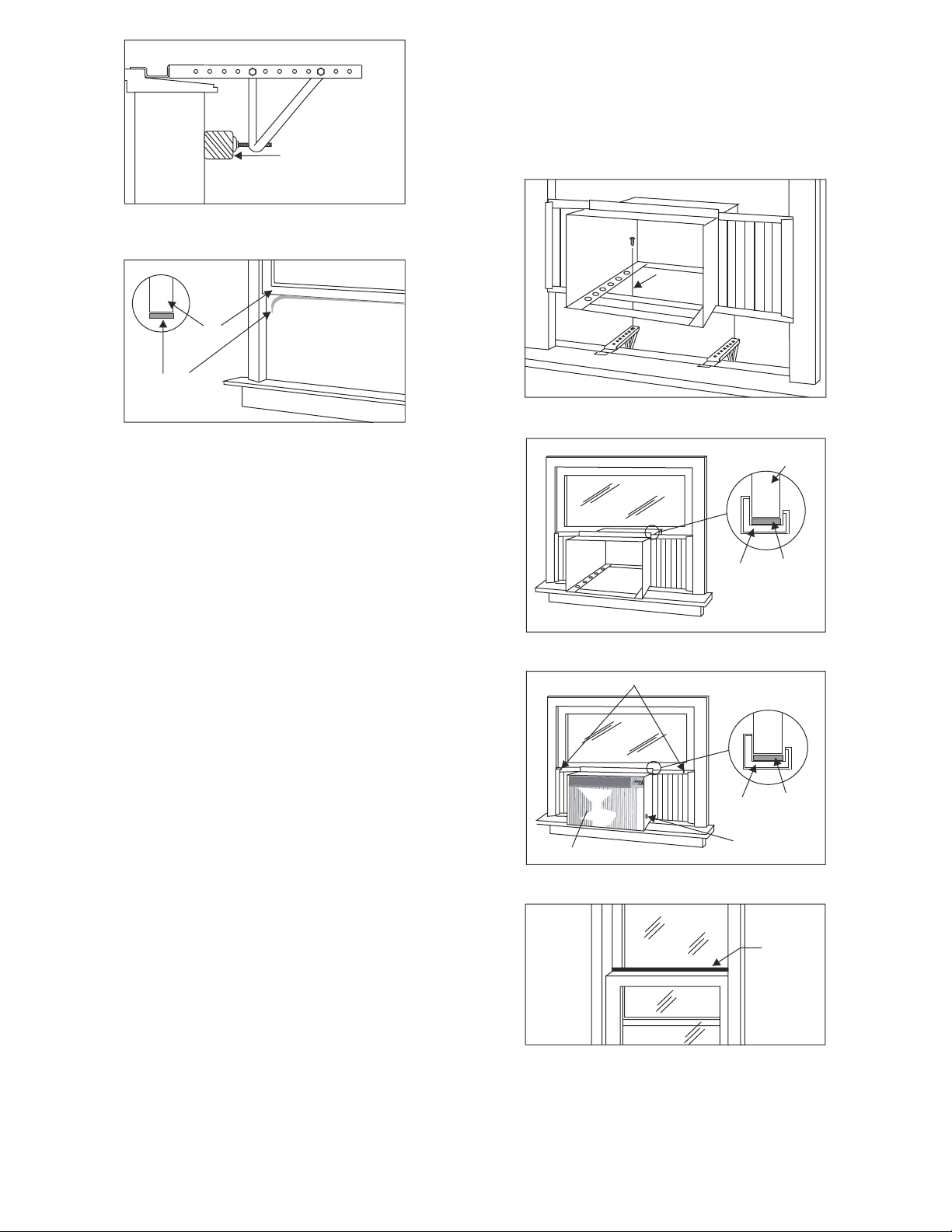

STORM WINDOW APPLICATIONS

If the window is blocked by a storm window and the storm

window cannot be removed, a mounting board (field provided)

will need to be added to the window sash. The air conditioner

needs to be pitched downward to the back in order for condensate

to drain properly.

The frame of the storm window (or any other obstruction) must be

at least 1/2“. lower than the window sill. If the storm window

frame is not at least 1/2“. below the window sill, then a mounting

board will need to be added to raise the height of the window sill

(see Fig. 21). The board will need to be provided and cut by the

installer.

1. The wood mounting board should be a minimum of 1--1/2”

wide and should run the length of the window. The

thickness of the mounting board is dependent on the height

of the storm window frame. The mounting board should

raise the front of the air conditioner high enough so that the

unit will be pitched downward at least 5/8” when the back

of the unit is resting on the storm window frame. See Fig.

21.

2. Cut the wood mounting board to fit the window.

3. Install the wood mounting board on the window using 2

field-- provided nails or screws.

4. Drain holes or slots in storm window frame must not be

caulked or painted shut. Holes are needed to drain rain

water and condensate. Ensure that trapped water can drain

out.

Fig. 20 --- Outdoor Air Vent Lever

A06533

Fig. 21 --- Storm Window Applications

9

Page 10

WALL INSTALLATION

To install the room air conditioner in the wall, perform the

following procedure:

1. Remove air conditioner from shipping box. Do not install

window installation parts.

2. Determine the location for air conditioner. Make sure there

is adequate clearance on the inside and outside of the wall.

Ensure that the power cord will reach the available socket

without an extension cord. Air conditioner can be installed

in walls up to 7” thick. Side louvers must never be blocked.

Select a wall surface that:

S Does not support major structural loads such as the frame

construction at ends of windows and under truss--bearing

points

S Does not have plumbing or wiring routed inside

S Is near existing electrical outlets ornear where a newoutlet

can be installed

S Faces the area to be cooled and is not blocked by

obstructions

S Allows unblocked airflow from rear (outside) of installed

air conditioner

3. The following parts will need to be provided by the

installer:

S wood frame

S wood shims

S wood screws (no. 10, 1” long)

4. Working from the inside of the room, find a wall stud

nearest the center of the area where the air conditioner will

be installed. This can be determined by sounding walls or

using a stud finder.

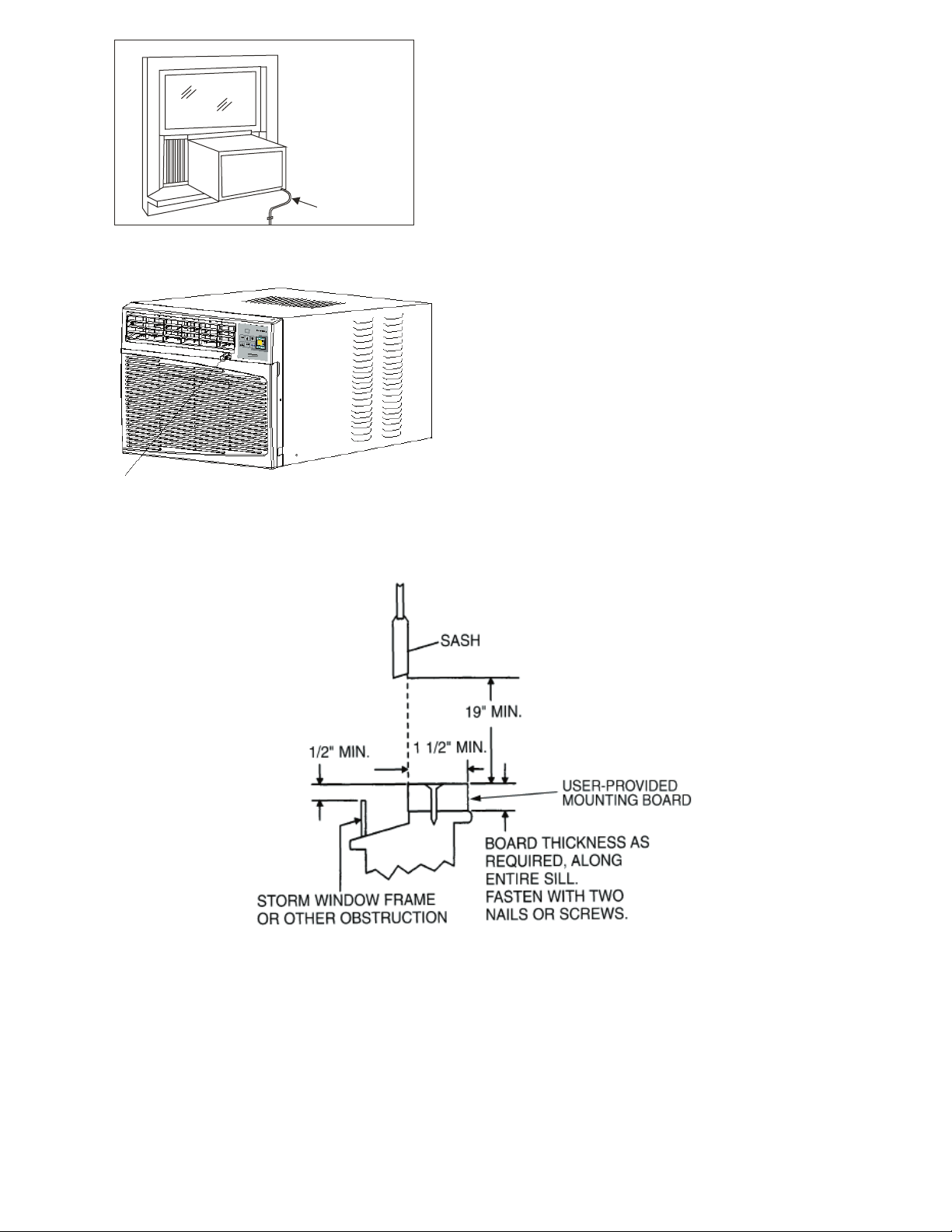

5. Cut or knock out a hole on each side of the center stud. (See

Fig. 22.)

IMPORTANT: Read entire instructions before cutting hole in

wall.

6. Measure between the inside edges of every other stud as

showninFig.22

7. Follow all local building codes when building and installing

frame. Build a wooden frame that will be placed around the

unit in the wall. The frame will reinforce the hole in the wall

where the air conditioner is installed and is used to secure

the air conditioner to the wall. The depth of the frame

should approximately match the depth of the wall. The

thickness of the frame will need to be added to the

dimensions to determine the size of the hole in the wall.

IMPORTANT: Be sure to measure air conditioner to check size

before constructing frame.

For example, if using 3/4” thick wood for the frame, the hole

would need to be: 20-- 1/2” + 3/4” + 3/4” = 22” wide.

IMPORTANT: If thickness of the wall covers top and side vents

of the air conditioner when it is installed, the outer portion of the

wall opening must be widened. The top and side vents must be

clear and uncovered.

8. After the frame has been constructed, check to make sure

that the air conditioner fits correctly inside it. If the frame is

too tight or too loose, adjust the size or re--construct.

9. Measure the outer dimensions of the frame and use those

dimensions to cut the hole in the wall. Make sure the hole is

level or condensate will not drain properly.

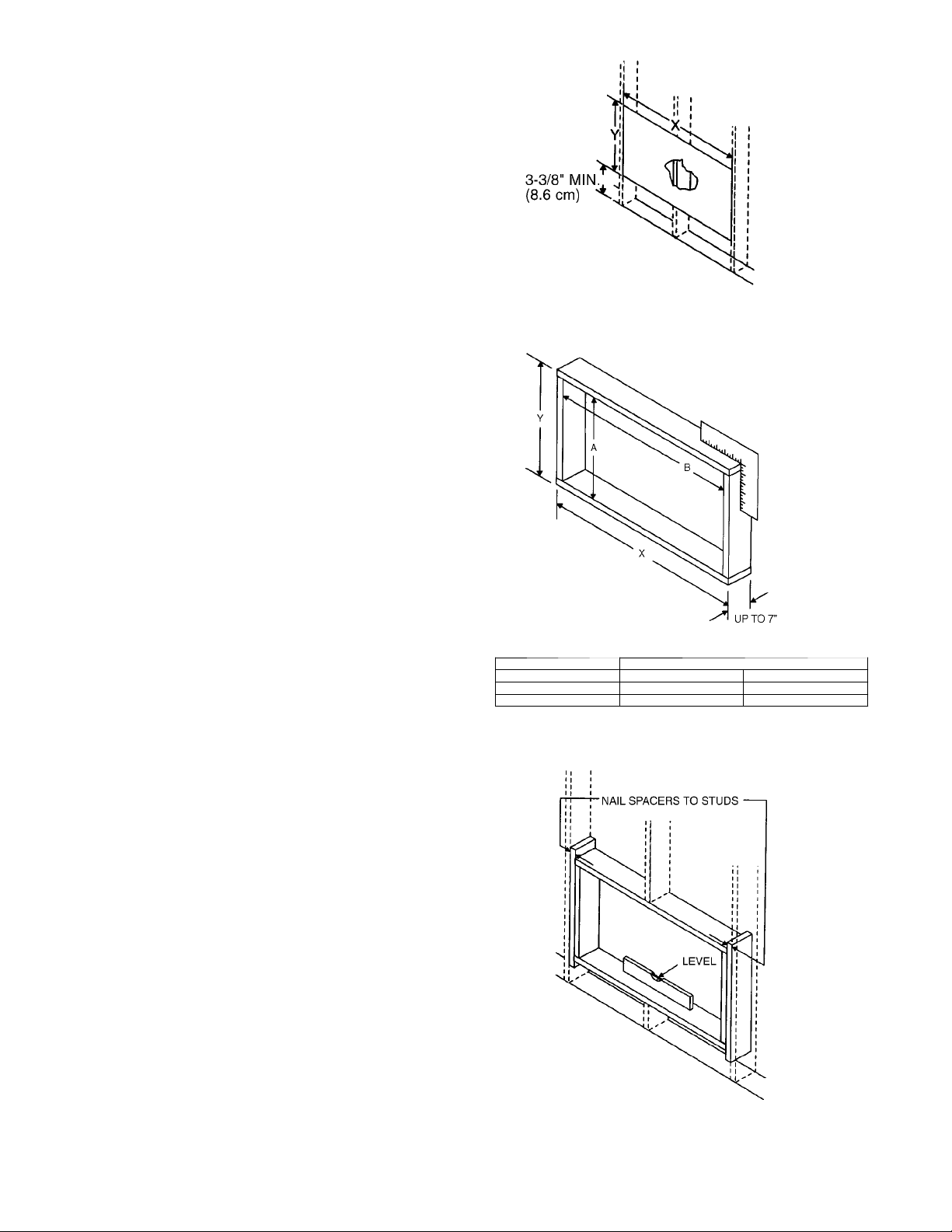

10. Install wooden frame into hole in wall. Make sure frame is

properly secured. Fill in the space between the frame and

the studs with wood shims (spacers). Nails spacers to studs.

If required, provide studs around entire frame to reinforce

stability of wall (see Fig. 24).

Fig. 22 --- Wall Installation Location

UNIT Dimensions

KC o r KH A B

123P 15.75 22.8

141P --- 233P 18.25 26.4

Fig. 23 --- Frame Construction

Fig. 24 --- Frame Installation

A06739

A06740

A06741

10

Page 11

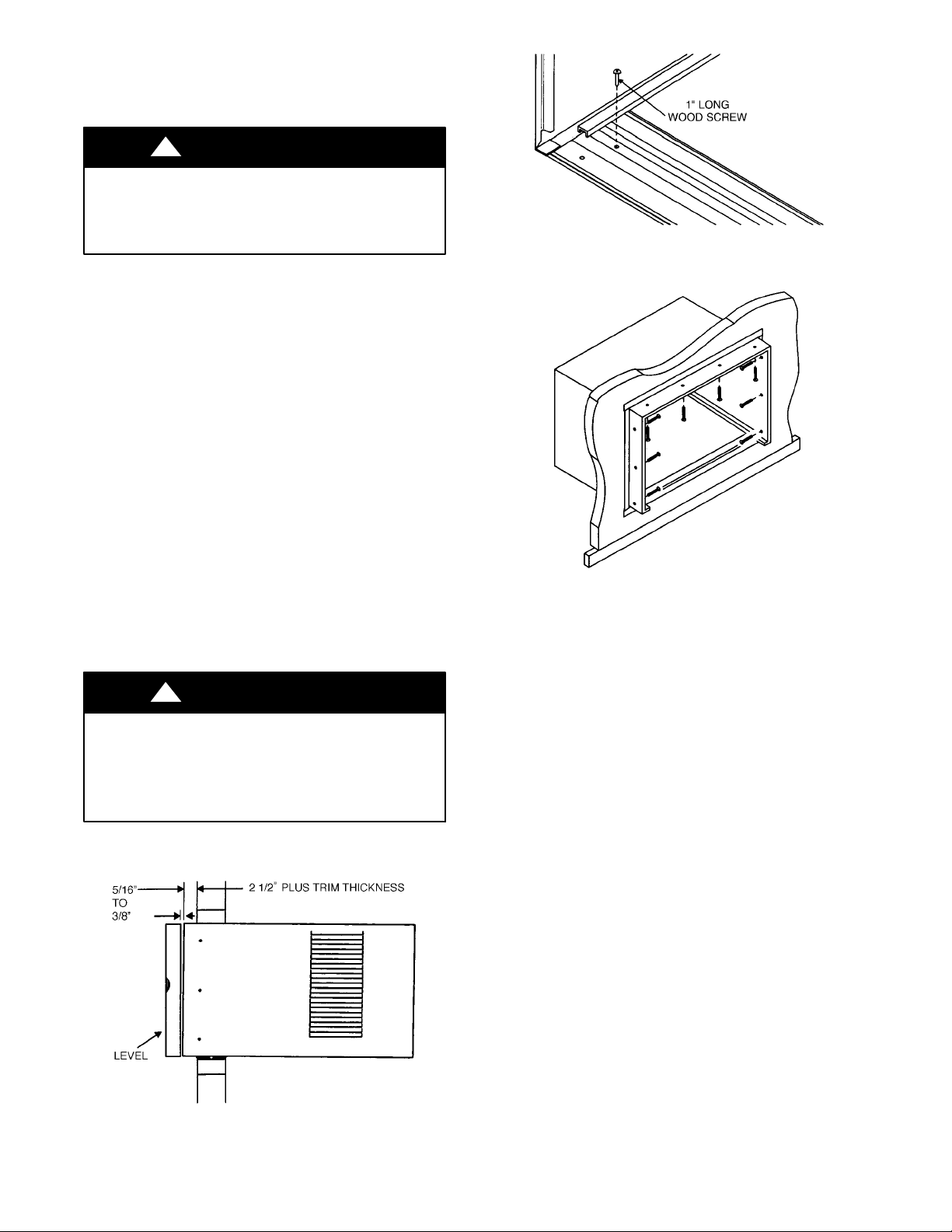

11. Caulk joints in wood frame as required. If wall thickness is

7” or more, add aluminum flashing over bottom of frame

opening to ensure no water can enter area between inner and

outer wall.

12. Remove the chassis from the unit cabinet.

!

CAUTION

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

Be careful when handling chassis. Sharp edges on coil fins

can cause personal injury.

13. Slide the empty cabinet into the wall opening and into

wooden frame. Approximately 2--1/2“ of the cabinet should

be in the room. The rest of the cabinet should be positioned

through and outside the wall. (See Fig. 25.) Maintain proper

slope for condensate drain operation. Bottom rail should be

resting firmly on bottom board of wooden frame.

14. Secure bottom rail to wood frame with two large wood

screws (1” long) using the two holes in the bottom of the

channel. (See Fig. 26.)

15. There are screw holes in the cabinet (4 each side, 4 top)

which are used to secure the cabinet to the wooden frame.

With the cabinet in its final position, drill holes in the

wooden frame using the screw holes in the cabinet as a

guide. After the holes have been drilled, secure the cabinet

to the wooden frame using field--supplied screws. See Fig.

27.

16. Caulk around wood frame and wall opening on outside wall

for a water--tight seal.

17. Optional caulking between the cabinet and the wooden

frame may be done on inside wall. Caulking provides an air

seal around the cabinet. Decorative wood trim may be

added to provide a more pleasing appearance.

18. Lift chassis and carefully slide it into the cabinet. Be sure

that it is firmly seated towards the rear of the cabinet.

!

CAUTION

PERSONAL INJURY/UNIT OPERATION HAZARD

Failure to follow this caution may result in personal injury

and/or damage to unit.

Do not push on the controls or the coil when installing

chassis. Personal injury and/or unit damage could result.

19. Install the front panel

20. Plug in the unit.

A06743

Fig. 26 --- Securing Bottom Rail of Cabinet

A06744

Fig. 27 --- Securing Cabinet to Frame

MASONRY CONSTRUCTION

The air conditioner is installed the same way as the Wall

Installation section with a few exceptions. Follow all local and

national building codes.

The cabinet can be secured to the masonry by using masonry nail

or masonry anchor screws.

Another installation technique would be to construct a frame of

2 x 4s and install the frame between the wall opening and the

cabinet. The frame must be securely anchored to the masonry wall

opening.

Use a lintel to support masonry above wall opening. Install exterior

cabinet support brackets.

Fig. 25 --- Cabinet Location in Wall

A06742

11

Page 12

OPERATING INSTRUCTIONS

Electronic Control Panel Model

You can easily operate this air conditioner by pressing relevant

button on the control panel as well as the remote control

|

Button

The air conditioner will be started when it is energized or will be

stopped when it is in operation, if you press this button. When the

air conditioner is heating, allow 3 minutes after you press this

button.

Button

Mode

Each time MODE button is pressed, the operation mode is changed

in sequence:

COOL: COOLING -- FAN ONLY -- ENERGY SAVING --

COOLING

HEAT: COOLING -- FAN ONLY -- HEATING --

ENERGY SAVING -- COOLING

NOTE: After setting the mode, allow 3 minutes before switching

to another mode.

In the FAN ONLY Mode, room temperature display range is from

0_C(32_F) to 38_C(99_F).

Room temperature below 32_F, the temperature display L0.

Room temperature above 99_F, the temperature display H1.

Fan Speed

Used to select fan speed in sequence auto, low, medium, and high.

Timer

Used to set or cancel timer operation.

When the unit is in operation, you can set OFF TIMER.

When the unit is off, you can set ON TIMER.

Timer setting range is 0 to 24 hours.

If the OFF TIMER is set, the timer LED displays the remaining

time to turn off the unit for only 12 seconds, then LED shifts to

display set temperature. If you press TiMER button within the 12

seconds, OFF TIMER will be canceled.

If the ON TIMER is set, the timer LED displays the remaining time

to turn on the unit. If you want to cancel ON TIMER, press

TIMER button.

Used to set room temperature in COOLING mode or used to set

time in TIMER mode. If the two keys are pressed at the same time,

the temperature LED display will alternate between _Cand_F.

NOTE: Temperature setting range is from 19_C(66_F) to

31_C(88_F).

Button

Button

Button

Airconditioner

Ti m e r

Fa n

Sp e e d

Mode

Indication symbols of LED on control panel:

Auto fan speed Cooling

Low fan speed

Medium fan speed

High fan speed

Above LED lights on when the relevant mode is in used.

Fan only

Heating

Energy-saving

Timer

Display set temp

Display set timer

Fig. 28 --- Control Panel

F

h

12

Page 13

Remote Control

1

2

7

4

3

Power

Mode

Auto

Fan Spee d

Timer

Powe r Saver

Mid

High Low

_

+

Temp/Time

Power BUTTON

1

The appliance will be started when it is

energized or will be stopped when it is

8

9

BUTTONS

5

6

in operation, if you press this button.

Mode BUTTON

2

Used to select the operation mode.

3

Used to set room temperature in Cooling

mode or used to set time in Timer mode.

High BUTTON

4

Used to select the mode.high fan speed

Mid BUTTON

5

Used to select the Mid mode.fan speed

Low BUTTON

6

Used to select the Low mode.fan speed

Auto BUTTON

7

Used to select the Auto mode. fan speed

Fig. 29 --- Remote Control

How to Insert

Batteries

Step 1 —Remove battery cover according to arrow direction.

Step 2 —Insert new batteries making sure that the (+) and (--)

of battery are matched correctly.

Step 3 —Reattach the cover by sliding it back into position.

NOTE:

-- Use 2 LR06 AA (1.5 volt) batteries. Do not use rechargeable

batteries. Replace batteries with new ones of the same type when

the display becomes dim.

-- If the replacement is done within 1 minute, the remote control

will keep original presetting. (This function only for LCD remote

control).

How to

Use

To operate the room air conditioner, aim the remote control to the

signal receptor. The remote control will operate the air conditioner

at a distance of up to 23 ft. when pointing at signal receptor of unit.

Timer BUTTON

8

Used to set or cancel timer operation.

Power Saver BUTTON

9

Used to select the mode.Energy-saving

A

i

r

co

n

dit

i

o

ne

r

T

I

M

E

R

F

F

A

N

H

R

M

O

D

E

S

P

E

O

E

N

D

/

O

FF

W

A

I

T

T

H

R

E

E

M

I

N

U

T

E

S

BE

F

O

R

E

R

E

ST

A

R

T

IN

G

13

Signal receptor

Page 14

CARE AND MAINTENANCE

When servicing the air conditioner, be sure to turn the mode switch

to the “OFF” position and disconnect the power cord from the

electrical outlet.

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

DO NOT use gasoline, benzine, thinner or other chemicals

on the air conditioner as these substances may cause

damage to the paint finish and deformation of plastic parts.

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

Never attempt to pour water directly in front of the unit as

this will cause deterioration of the electrical insulation.

If the air filter becomes clogged with dust, air--flow is obstructed

and reduces efficiency. The air filter should be cleaned once a

month. More frequent cleaning may be necessary depending on

outdoor and indoor air quality.

Air Filter

The air filter is located behind the air intake front grill.

To remove the air filter, open the air inlet grille and take out the air

filter.

To reinstall the air filter, reverse the above procedure.

Removal

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage

and/or improper operation.

DO NOT forget to install the air filter. If the air conditioner

is left to operate without the air filter, dust is not removed

from the room and may cause your air conditioner to fail.

When the air filter inlet grille and cabinet are dirty, wipe

with lukewarm water (below 40_C/104_F). Use of mild

detergent is recommended

Cleaning the Air Filter

1. Remove dust clogged in the filter by tapping it or

vacuuming clean it.

2. Wash the filter well with lukewarm water below 40_C

(104_F) while rubbing lightly: To get better results, wash it

with soapy water or a neutral cleaning agent.

3. Rinse the filter well using clean water then dry completely.

End--of--Season Car

1. Operate the fan alone for half a day to dry out the inside of

the unit.

2. Turn off power and remove plug from all socket.

3. Clean filter.

4. Store in a dry location.

e

TROUBLESHOOTING GUIDE

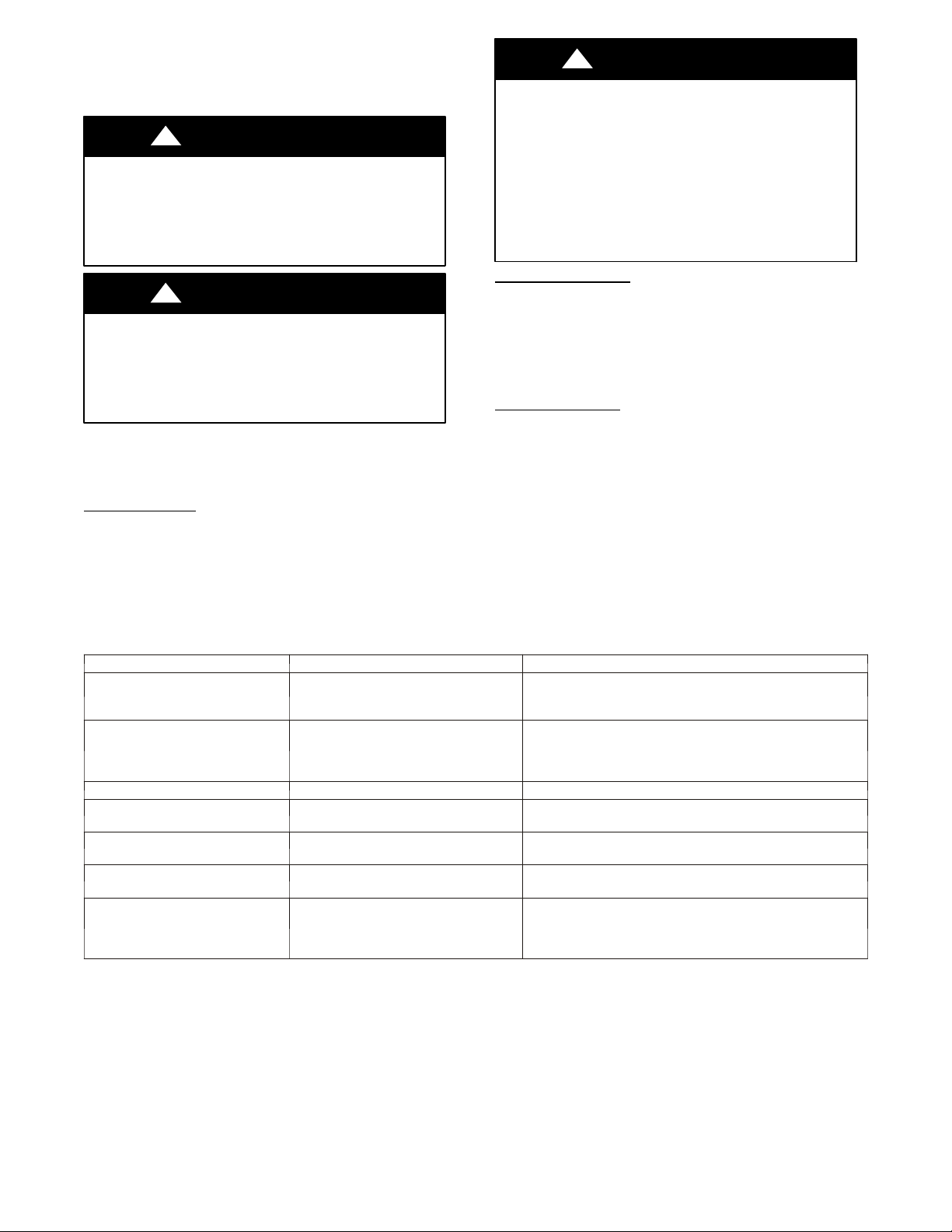

Frequently, a problem is minor and a service call may not be necessary, use this troubleshooting guide for a possible solution.

PROBLEM POSSIBLE CAUSE SUGGESTED SOLUTION

Check connection of power cord to power source. Check

Air conditioner will not operate No power to the unit.

Dirty air filter. Inappropriate capacity for

Inefficient or no cooling

Noisy unit Loose parts. Inadequate support. Tighten loose parts. Provide additional support to unit.

Odors

Water dripping outside

Water dripping inside

I c e o r f r o s t b u i l d --- u p

NOTE: If circuit breaker is tripped repeatedly, or fuse is blown more than once, contact a licensed technician.

application. Blocked air flow. Power

interruption, settings change too quickly, or compressor overload tripped.

Formation of mold, mildew, or algae on

wet surfaces.

Condensation run --- off is normal during hot and humid weather

Unit is not properly angled to allow water to drain outside.

Low outside temperature. Unit air filter

is dirty.

fuse or circuit breaker. Set FAN CONTROL to position other

than ”OFF”.

Clean or replace air filter. Check with dealer to determine

proper unit capacity for application. Remove obstruction

from grill or outdoor louvers. Let fan run to restart compressor (in approximately 10 minutes).

Drain plug and drain base pan. Replace drain plug. Clean

unit thoroughly. Remove

Add flexible tubing to redirect water flow.

Unit must be installed on an angle for proper condensation run---off. Check the unit and make adjustments.

When outdoor temperature is approximately 65 F or below, frost may form when unit is in cooling mode. Switch

unit to FAN (only) operation until frost melts. Remove and

clean filter.

14

Page 15

CARRIER ROOM AIR CONDITIONER FULL WARRANTY

ONE YEAR WARRANTY -- CARRIER warrants to the user that this product will be free from defects of workmanship under normal use

and maintenance for a period of one year from the date of original purchase. CARRIER, through its authorized independent servicing dealers

or service stations, will either repair or replace a defective product (as decided solely by CARRIER) free of charge to the user.* CARRIER

may replace any defective part with either a new or remanufactured part, at CARRIER’s sole option.

EXTENDED FOUR YEAR WARRANTY ON SEALED REFRIGERATION SYSTEM ONLY -- During the second through fifth years

after date of original purchase, CARRIER further warrants to the user that the compressor, condenser, evaporator, and connecting tubing will

be free from defects in material or workmanship under normal use and maintenance. CARRIER will either repair or replace (as decided solely

by CARRIER) any defective compressor, condenser, evaporator or connecting tubing free of charge to the user, including a recharge of

refrigerant for the system if necessary. However, THIS LIMITED WARRANTY DOES NOT INCLUDE costs incurred for diagnosing,

removing, installing, shipping or transporting the product or any parts. User is responsible for these costs; however, SUCH COSTS MAY BE

COVERED by a separate warranty or service agreement provided by the seller or another third party, such agreement being separate and

distinct from this factory warranty.

LIMITATION OF WARRANTIES -- ALL IMPLIED WARRANTIES (INCLUDING IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE) ARE HEREBY LIMITED IN DURATION TO THE PERIOD

FOR WHICH THE APPLICABLE PRODUCT COMPONENT IS EXPRESSLY WARRANTED HEREIN. Some states or provinces do not

allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. THE EXPRESS WARRANTIES

MADE IN THIS WARRANTY ARE EXCLUSIVE AND MAY NOT BE ALTERED, ENLARGED OR CHANGED BY ANY

DISTRIBUTOR, DEALER, OR OTHER PERSON WHATSOEVER. CARRIER WILL NOT BE RESPONSIBLE FOR ANY SPECIAL,

INCIDENTAL OR CONSEQUENTIAL PROPERTY OR COMMERCIAL DAMAGES OF ANY NATURE WHATSOEVER. Some states

or provinces do not allow the exclusion of incidental or consequential damages, so the above limitation may not apply to you. All work

provided for by this warranty shall be performed during normal working hours. All replacement parts, whether new or remanufactured,

assume as their warranty period only the remaining time period for which the applicable component is expressly warranted herein.

*Authorized independent dealers or service stations are registered with CARRIER through its distributor organization.

CARRIER WILL NOT BE RESPONSIBLE FOR:

1. Damage due to failure to perform normal maintenance outlined in the Owner’s Guide.

2. Instruction on methods of control and use of air conditioning unit after initial installation.

3. Damage or repairs needed as a consequence of faulty installation or application. This is the responsibility of the installer.

4. Failure to start due to voltage conditions, blown fuses, open circuit breakers, or any other damages due to the inadequacy or interruption of

electrical service.

5. Damage or repairs needed as a consequence of any misapplication, abuse, unauthorized alteration, improper servicing or operation.

6. Damage as a result of floods, winds, fires, lightning, accidents, corrosive environments, or other conditions beyond the control of

CARRIER.

7. Any parts not supplied or designated by CARRIER.

8. CARRIER products installed outside the continental U.S.A., Alaska, Hawaii, and Canada.

9. Shipping damage or damage as a result of storing or transporting the unit. This warranty gives you specific rights, and you may also have

other rights which vary from state to state or province to province.

IF YOUR UNIT DOES NOT WORK, FOLLOW THESE STEPS IN ORDER:

1. Check the things you can do yourself. These include being sure the air conditioner is plugged in an appropriate receptacle, checking the

fuse or circuit breaker and ensuring its replacement or resetting, if necessary, and rereading the instruction book to ensure all controls are set

properly. By doing this you can save money. Many unnecessary calls result in the serviceman doing what the owner can do for himself.

2. CONTACT YOUR DEALER ON THE CARRIER AUTHORIZED SERVICE CENTER. You may find this name printed on the product,

on your invoice, or in your Homeowner’s Packet.

3. CONTACT THE NEAREST CARRIER DISTRIBUTOR SERVING YOUR AREA. (See Telephone Yellow Pages.)

4. CONTACT CARRIER IF A S ATISFACTORY SOLUTION IS NOT REACHED IN STEPS 2 AND 3.

Carrier Air Conditioning Consumer Relations Department, P.O. Box 4808, Carrier Parkway, Syracuse, New York 13221

Telephone: 1--800--CARRIER From Canada: (315) 432--7885

FOR FUTURE REFERENCE, FILL IN DETAILS OF YOUR PURCHASE. KEEP YOUR SALES RECEIPT.

Model/Catalog No. ________________________________ Installed By: _________________________________

Service/Discrete No. _______________________________ Name of Owner ______________________________

Unit Serial No. ____________________________________ Address of Installation _________________________

Date of Installation ________________________________

15

Page 16

Copyright 2007 Carrier Corp. S 7310 W. Morris St. S Indianapolis, IN 46231

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

Printed in China. Edition Date: 01/07

16

C at al og N o : O M KC K H --- 2

R e p la c es : O M KC K H --- 1

Page 17

KC_141P; KC_183P; KC_223P; KC_233P

KH_123P; KH_233P

Acondicionador de aire tipo ventana

Instrucciones de

instalación y funcionamiento

Fig. 1 -- Unidad con control remoto

NOTA PARA EL PROPIETARIO:

Gracias por comprar un acondicionador de aire Carrier. Lea el manual del propietario con atención antes de instalar y utilizar este

electrodoméstico, y conserve esta información como referencia.

Es conveniente que apunte el número de modelo y serie de la unidad en el espacio facilitado para este fin. Esta información, junto

con la información de instalación y los datos de contacto del distribuidor, le será útil si necesita mantener o reparar la unidad.

INFORMACIÓN DE LA UNIDAD

N.º de modelo _____________________________________

N.º de serie ______________________________________

INFORMACIÓN DE INSTALACIÓN

Fecha de instalación ________________________________

INFORMACIÓN DE CONTACTO DEL DISTRIBUIDOR

Nombre de la compañía_______________________________

Dirección__________________________________________

__________________________________________________

Teléfono __________________________________________

Nombre del técnico _________________________________

_________________________________________________

Page 18

CONTENIDO

Página

PRECAUCIONES DE SEGURIDAD 3..............................................................................

INTRODUCCIÓN 3.............................................................................................

ESPECIFICACIONES ELÉCTRICAS 4.............................................................................

CONSEJOS PARA ANTES DE LA INSTALACIÓN 4..................................................................

CABLE ELÉCTRICO 5..........................................................................................

INSTRUCCIONES DE INSTALACIÓN 6--9.........................................................................

INSTALACIÓNENLAPARED 10.................................................................................

CONSTRUCCIÓN EN MAMPOSTERÍA 12..........................................................................

INSTRUCCIONES DE FUNCIONAMIENTO 12 -- 13..................................................................

CUIDADO Y MANTENIMIENTO 14...............................................................................

SOLUCIÓN DE PROBLEMAS 14..................................................................................

GARANTÍA 15.................................................................................................

2

Page 19

PRECAUCIONES DE SEGURIDAD

Aprendaaidentificarlainformación de seguridad.Estesímboloindicaque debe estar alerta

.Cuando veaestesímboloen las instrucciones,en ladocumentación o en launidad misma esté alertaanteun posible accidente.

Las indicaciones de advertencia: PELIGRO, ADVERTENCIA y

PRECAUCIÓN. Estas palabras vienen acompañadas por el símbolo

de alerta. La indicación de PELIGRO denota los riesgos máspeligrosos que resultarán en lesiones personales graves o en la muerte. La

indicación de ADVERTENCIA denota los riesgos que podrían re-

sultar en lesiones personales graves o en la muerte. La indicación de

PRECAUCIÓN se usaparaadvertircontraprácticas que comprome-

ten la seguridady que podrían resultaren lesionespersonales menoreso desperfectosen el producto o lapropiedad.La NOTA se usapara

destacar recomendaciones que tendrán como resultado una mejor

instalación, rendimiento o funcionamiento.

INTRODUCCIÓN

Gracias por elegireste acondicionador deaire tipo ventana para aclimatar suvivienda.El manual del propietario contiene la información

necesaria para cuidar y mantener el nuevo acondicionador.

Siempre que se mantenga correctamente, la unidad le dará muchos

años de funcionamiento sin problemas. Para evitar dificultades durante la instalación, lea las instrucciones en su totalidad antes de empezar.Este manual contiene información sobre la instalación y elfuncionamiento del acondicionador de aire tipo ventana.

Panel frontal Caja Salida de aire

Filtro de aire

Rejilla interior

de admisión

de aire

Palanca de ventilación

de aire fresco

Mando a distancia

Panel de control

Admisión de aire exterior

Cable eléctrico

A06528

Panel de control

Ti m e r

Fa n

Mode

Sp e e d

Acondicionador de aire

Mando a distancia

Pow e r

Tim e r

Mode

Pow er Sa v e r

Mid

Auto

Fan Sp ee d

High Low

_

+

Tem p / T i m e

A06529

Fig. 2 -- Descripción de las partes del acondicionador de aire

Nota: Las ilustraciones que aparecen en estemanual se basan en una vista exterior del modelo estándar. Por lo tanto la forma de su unidad puede

ser distinta.

3

Page 20

ESPECIFICACIONES ELÉCTRICAS

1. Todaslasconexiones tienenque cumplircon loscódigoseléctricos locales y nacionales, y las debe efectuar un electricista

autorizado.Si tienealgunapregunta,póngaseen contactocon

un electricista autorizado.

!

ADVERTENCIA

RIESGO DE DESCARGA ELÉCTRICA

Si no se tiene en cuenta esta advertencia podría ocurrir un

accidente o una fatalidad.

2. Determine la ubicación de las fuentes de alimentación disponibles y resuelva cualquier problema de cableado eléctrico

ANTES de instalar y poner en funcionamiento la unidad.

3. Para la protección del usuario, esta unidad dispone de unatoma atierra enel enchufe del cable eléctricocuando está conectado a un tomacorriente compatible. Si no sabe si el tomacorriente lleva una toma a tierra, póngase en contacto con un

electricista autorizado.

Desenchufe la unidad antes de instalarla o repararla.

Si el acondicionador de aire tiene una clasificación de 115

voltios y 7,5 amperios como máximo, la unidad puede

encontrarse en el mismo fusible o disyuntor (cortacircuito)

conotrosaparatos. Sin embargo,elamperajemáximodetodos

losaparatosjuntos no puedesuperar el amperaje de ese fusible

o disyuntor.

Si el acondicionador de aire tiene una clasificación de 115

voltios y más de 7,5 amperios tendrá que tener su propio

4. El tomacorriente de la pared (tres patas) deberá corresponder

con el enchufe (3 patas) del cable eléctrico de la unidad. NO

use adaptadores de enchufe ni cables de extensión. Consulte

la tabla 1 para ver los tipos de tomacorrientes y fusibles.

fusible o disyuntor, sin ningún otro aparato en ese mismo

fusible o disyuntor.

Si el acondicionador de aire tiene una clasificación de 230

voltios, también tendrá que tener su propio fusible o

disyuntor, sin ningún otro aparato en ese mismo fusible o

5. La placa de especificaciones contiene los datos eléctricos y

disyuntor.

técnicos. La placa de especificaciones se encuentra en el lado

derecho de la unidad. Utilice el suministro de potencia correcto según las indicaciones de esta placa.

TIPOS DE TOMACORRIENTES Y FUSIBLES

CAPACIDAD DE

ENFRIAMIENTO

TENSIÓN NOMINAL 125 250 250 250

AMPS 15 15 20 30

10K--- 14K

(Sólo enfriamiento)

18K (Sólo enfriamiento)

10K--- 12K (Con calefacción)

23K

(Sólo enfriamiento)

18K--- 23K

(Con calefacción)

TOMACORRIENTE

TAMAÑO DE

FUSIBLE

Nota: 10K--14K modelos sólo con enfriamiento

18K modelos sólo con enfriamiento

15 15 20 30

23K modelos sólo con enfriamiento

18K--23K modelos sólo con calefacción

10K--12K modelos sólo con calefacción

Nota: En la placa de especificaciones de su modelo encontrará la información correcta sobre el tipo de tomacorrientes y fusible.

4

Page 21

CONSEJOS PARA ANTES DE LA INSTALACIÓN

!

PRECAUCIÓN

RIESGO DE OPERACIÓN ERRÁTICA DE LA

UNIDAD

No tener en cuenta esta advertencia podría provocar

desperfectos a la unidad.

Lea las instrucciones con atención para evitar problemas de

instalación y funcionamiento.

El acondicionador deaire tipo ventanaha sido diseñado para funcionarcon la máximaeficienciay ahorrarenergía.Sigaestasrecomendaciones para conseguir un rendimiento óptimo.

1. Seleccione la temperatura que le resulte más cómoda y deje el

termostato programado a esa temperatura.

2. El filtro esmuy efectivo en laretención de partículas presentes

en elaire. Manténgalo siempre limpio. Como norma general,

sedebelimpiar el filtro una vez al mes. Dependiendo dela calidad del aire interior y exterior, puede que necesite limpiarlo

más a menudo.

3. Use cortinas o persianas para evitar que la luz del sol caliente

lahabitación,pero NO obstruyael acondicionadorde aire.Deje que el aire circule libremente a su alrededor.

4. Encienda el acondicionador de aireantesde quelatemperaturaexteriorsubao baje lo suficientecomopararesultarmolesta.

Asíse ahorra la incomodidad de tener que esperara que la habitación se enfríe o caliente.

5. Cuando latemperaturaafueraseaagradable,usesólo la modalidad HIGH FAN (ventilador rápido) o LOW FAN (ventilador

lento). Esta modalidadhacecircularelairede lahabitación,refresca y usamenos electricidad que lasmodalidades de enfriamiento.

Su acondicionador deaireCarrier hasido diseñado para ser instalado

con facilidad en una ventana de una o dos hojas.

Nota: Esta unidad NO se debe instalar en ventanas verticales

(deslizantes).

CABLE ELÉCTRICO

El acondicionador de aire tipo ventanalleva un cable eléctrico deseguridad que detecta las pérdidasde corriente(Figura 3). Si sedetecta

una situación peligrosa, la electricidad que llega a la unidad queda

cortada automáticamente.

Para comprobar el funcionamiento del cable eléctrico:

1. Enchufe el cable en un tomacorriente de tres patas.

2. Apriete RESET (restablecer).

3. Apriete TEST (prueba) (escuchará un chasquido y el botón

RESET saltará).

4. Apriete y suelte RESET (escuchará un chasquido y el botón

RESET se quedará metido). El cable eléctrico está listo para

usar.

El botón Reset tiene que quedar metido para que la unidad funcione

correctamente.

Siel botón RESETno saltacuandose aprietael botón Testo no serestablece, cambie el cable eléctrico. Compre el cable nuevo del fabricante del producto. Si el cable está dañado, NO lo repare.

No utilice el cable para encender y apagar elacondicionador. Elcable

funciona como dispositivo de seguridad.

El cableno contiene ninguna pieza quese puedareparar. Sise abrela

funda resistente a la manipulación, quedarán anuladas todas las garantías y reclamaciones de rendimiento.

RESET

TEST

A06531

Fig. 3 -- Cable eléctrico

Nota: Guarde la caja y el material de empaquetado por si necesita

guardar la unidad o transportarla. Compare el contenido de la bolsa

de piezas con la lista de verificación del modelo que corresponda

antes de instalar la unidad. Vea la lista en la figura 4.

Tornillos de 3/4 plg. (10)

Tornillos de 3/4 plg. (10)

Tornillos de 1/4 plg. (23)

Canal superior (1)

Canal superior (1)

Canal inferior (1)

modelos de 10K a 12K)

(Para

Canal inferior (1)

(Para modelos 14K a 23K

---instalado de fábrica)

Arandelas de seguridad (4)

Arandelas de seguridad (4)

Pernos de 1---1/2 x 1/4 plg. (4)

Pernos de 1---1/2 x 1/4 plg. (4)

Tue rcas de 1/4 plg. (4)

Tue rcas de 1/4 plg. (4)

Soportes

Soportes

(2)

(2)

Escuadras

Escuadras

(2)

(2)

Ta pó n y

patas niveladoras (2)

Cortina lateral derecha (1)

Cortina lateral izquierda (1)

Fijador (2)

Fijador (2)

Arandela (10)

Sello (1)

Espuma (1)

Cinta

adherente

de dos caras (1)

A06532

Fig. 4 -- Piezas de instalación

Nota: Se incluyen tornillos extra como repuesto.

Herramientas necesarias para la instalación en la ventana:

S Destornilladores: Phillips y plano

S Taladro: broca de 1/8 de pulgada de diámetro

S Lápiz

S Cinta métrica

S Tijeras

S Nivel de carpintero (burbuja)

5

Page 22

INSTRUCCIONES DE INSTALACIÓN

!

PRECAUCIÓN

RIESGO DE OPERACIÓN ERRÁTICA DE LA

UNIDAD Y LESIONES

No tener en cuenta esta advertencia podría provocar

desperfectos a la unidad y lesiones personales.

Se recomienda que pida ayuda a alguien durante la

instalación, yaqueel compresor seencuentra enel mismo lado

que los controles (en el lado derecho) y este lado pesa más y

es difícil de manejar.

Paso 1—Seleccione la mejor ubicación posible

A. El acondicionador de aire ha sido diseñado para que quepa con

facilidad en ventanas de una o de dos hojas. No obstante, debido

a que hay distintos diseños de ventanas, esprobable que sea necesario efectuar algunas modificaciones para instalarlo apropiadamente y sin peligro.

B. Compruebe que la ventanay el marco estén en buenascondicio-

nes y que no haya madera reseca ni podrida.

C. Paraconseguirla máximaeficiencia,instaleel acondicionadorde

aire en el lado de la casa o edificio donde haya más sombra que

sol. Si le da el sol directamente,es conveniente instalar un toldo

encima.

D. Deje espaciosuficientealrededorde la unidad para que elairecir-

cule con libertad a su alrededor (Figura 5). La parte trasera de la

unidaddebequedaralairelibre,no dentro de ungarajeo deledificio.Alejeel acondicionadorlo másposiblede obstáculos y otras

obstrucciones, y a 30 pulgadas como mínimo delsuelo. No deje

que la libre circulación del aire se vea impedida por cortinas y

otros objetos.

E. Asegúrese de que haya un tomacorriente cerca del lugar donde

vaya a instalar la unidad. Utilice un circuito de un sólo tomacorriente con la clasificación correcta(Tabla 1en lapágina 4). Todas

lasconexionesdeben cumplir con los códigos localesy nacionales.

F. La unidad ha sido diseñada para evaporar la condensación en

condiciones normales.No obstante, en días extremadamentehúmedos,el excesode condensaciónpuede rebosarse dela bandeja

y salirse dela unidad. Instalela unidad de forma queel excesode

condensación no le caiga encima a los peatones o a sus vecinos.

To ld o

20 plg.

mín.

12 plg. mín.

20 plg.

mín.

Valla,

muro u

otros

obstáculos

Obstrucción

lateral

30 plg. mín.

Suelo

A06534

Fig. 5 -- Distancias de seguridad del acondicionador de

aire

Aperturas de la ventana

TAMAÑO

Tamaño de la caja

(L/H/A)

Largo de la apertura

de la ventana

Alto de la apertura

de la ventana

22,8/15,7/24,1 plg. 26,5/18,5/26,9 plg.

27 -- 41 plg. 30 -- 44 plg.

16 plg. 18,5 plg.

Paso 2—Preparación para desmontar el chasis deslizante del

acondicionador de aire

A. Quite los cuatro tornillos Phillips que sujetan el chasis a la caja.

Hay dos (2)tornillos acada lado.Los tornillos situados haciaadelante sujetan el panel frontal a la caja. Los tornillos situados hacia

atrás sujetan la caja al chasis (Figura 6).

B. Tire con cuidado del panel frontal para desmontarlo.

C. Agarre eltirador en la parte delantera del chasisdeslizante y saque

el acondicionador de aire dela caja con cuidado (Figura 7). NO-

TA.Vuelva ainstalar los tornillos cuando acabe deinstalar la uni-

dad en la ventana para que el chasis quede fijo.

IMPORTANTE: Pida ayuda para completar este procedimiento.

MODELO

12K 14--23K

6

Page 23

Marco de la persiana

Air

c

o

n

d

ition

e

r

T

I

MER

F

F

A

N

H

R

M

O

D

E

S

P

E

O

E

N

D

/

O

FF

W

A

I

T

T

H

R

E

E

M

IN

U

TE

S

B

EFO

R

E

R

E

S

TA

R

T

I

N

G

Tornillo de ¼ de plg.

Persiana derecha

Tornillos Phillips (lado derecho)

A06535

Fig. 6 -- Modo de retirar los tornillos

Serpentín

Chasis

Tirador

A06536

Fig. 7 -- Modo de desmontar el acondicionador de aire

Paso 3—Montaje del canal inferior y superior en la caja

A. Canal superioren formade L:Pegue la cinta adherentede dos ca-

ras en el canal superior en forma de L y luego instale el canal en

la caja con loscinco (5) tornillosde 1/4 depulgada como semuestraenlafigura8.

B. Canal inferior en forma de N instalado con loscuatro (4) tornillos

de 1/4 de pulgada como se muestra en la figura 8.

Nota: Enlos modelos 14K a 23K,el canalinferiorya vieneinstalado

de fábricay puede tener una forma distinta, pero sufunción essimilar.

Paso 4—Montaje de las persianas (cortinas) lateralesen la caja.

A. Deslice las persianas en el canal superior y el inferior como se

muestra en la figura 9. Las persianas están marcadas como derecha e izquierda. Instalelas persianas en lacaja concuatro (4)tornillos de 1/4 de pulgadas en cada lado.

A06538

Fig. 9 -- Montaje de las persianas

Paso5—Instalación de lossoportes de montaje y laprimera cinta

selladora

Nota: Las ventanas vienen en muchos estilos diferentes. Por lo tanto,

puede que haga falta modificar de algún modo su instalación en

particular.

A. Conecteel ensamblaje de soportesalasescuadras (Figura10) con

dos (2) pernos de 1 pulgada y media (dos pernos por soporte).

Asegúreloscon dos (2) arandelas deseguridad de1/4 depulgada

ydos (2) tuercasde 1/4 de pulgada.NO aprietelos pernostodavía,

ya que podríahacer falta ajustar el ancho del soporte, dependiendo del ancho de la repisa de la ventana. Vea la figura 12. Instale

dos tornillos niveladores en las escuadras. Ensaye el ensamblaje

de soportes en la ventana antes deinstalar lacaja. Si los tornillos

niveladores estándemasiado alejados de la pared y no ofrecen estabilidad, es conveniente llenar el área con una pieza de madera

sólida. Vea la figura 13.

B. Mida el ancho de la repisa interior de la ventana y determine el

centro como seindica en la figura 11. Alinee laranura en V encada soporte con estasmarcasy montelos soportes en la repisa con

los tornillos de 3/4 de pulgada. Los soportes deben quedar perpendiculares al interior de la repisa. Vea la figura 11.

Ranura

en V

Ensamblaje de

Pernos para soportes

Tornillos niveladores

(VISTA SUPERIOR)

soportes

Escuadra de

90 grados

A06539

Fig. 10 -- Ensamblaje de soportes

Ranura en V

Centro

Tornillo de ¼ de plg.

Para modelos de 10K a 12K

Para modelos de 14K a 23K,

(instalado de fábrica)

Fig. 8 -- Montaje de los canales

Cinta adherente de dos caras

Canal

A06537

9,6

plg.

9,6

plg.

12,6

10,3

plg.

plg.

plg.

Repisa

10,3

12,6

Medidas para el modelo de 10K = 9,6 plg.

Medidas para el modelo de 12K = 10,3 plg.

Medidas para los modelos de 14K a 23K = 12,6 plg.

plg.

A06540

Fig. 11 -- Montaje de los soportes

C. Es posibleque haya que ajustarlainclinaciónde los soportespara

que la condensacióndesagüeadecuadamente.Parahacerlo, ajuste ladistancia con el tornillo nivelador en lapared exterior.La inclinación no debe superar los 3/16 de pulgada. Vea la figura 12.

D. Corte una tira selladora para el espacio pordebajodel bastidor in-

ferior.Despegueel papel queprotegela tira ypéguelaen elbastidor. Vea la figura 14.

7

Page 24

!

PRECAUCIÓN

RIESGO DE DAÑO A LA UNIDAD

No tener en cuenta esta advertencia podría provocar

desperfectos a la unidad.

Utilice una pieza de madera sólida para dar estabilidad. Esto

puede ser necesario si la repisa es muy ancha (ver figura 13).

2 tornillos de ¾ de plg. por soporte

Máximo 3/16 de plg.

Ensamblaje

de soportes

Tornillos niveladores

Muro exterior

Fig. 12 -- Ilustración del ancho y el ángulo

Pieza de madera sólida

(si fuera necesario)

A06541

Paso 7—Fije las persianas

A. Introduzca el aire acondicionado en la caja con cuidado. Pida

ayuda para completar este procedimiento.

B. Vuelvaa colocar en ambos lados de lacaja los tornillos de seguri-

dad del chasis que retiró anteriormente. Vea la figura 12. Fije el

marco superior de las persianasal bastidor dela ventana condos

(2) tornillos de 3/4 de pulgada.

C. Ahora, sujete el marco inferior de las persianas con un fijador y

uno de los tornillos de 3/4 de pulgada en cada lado (Fig. 12).

Paso 8—Vuelva a instalar el panel frontal

A. Coloque el panel frontal en la cajaempezandodesde arriba. Las pes-

tañasdel panel frontaldeberánentraren las ranurasrestantesde lacaja. Repita el mismo procedimiento con el resto de los lados.

B. Fije larejilla a lacaja con los tornillos Phillips que quitó anterior-

mente (Figura 6).

Paso 9—Complete la instalación

A. Corte la espuma al tamaño de la apertura entre la parte superior

de la ventana interior y exterior (Figura 18).

B. En algunas instalaciones puede ser necesario usar más mate-

rial de sellado alrededor de la ventana y de la unidad. Compruebe que no haya ninguna fuga de aire y si la hay séllela.

C. En zonas muy húmedas, la cantidad de agua condensada puede re-

bosar la unidad o aumentar el ruido que hace al funcionar. Si esto

ocurre, se puede conectar una manguera (no se incluye) al tapón de

desagüe para que la condensación pueda salir (Figura 19).

Nota: La ventilación de aire fresco se suele mantener cerrada. Sólo

se deberá utilizar para despejar la habitación de humo y olores. Tire

para abrirlo (Figura 20).

A06542

Fig. 13 -- Colocación de la pieza de madera

Bastidor

Tira selladora

del bastidor

A06543

Fig. 14 -- Adhesión de la tira selladora

Paso 6—Instalación de la caja

A. Alineeelagujeroenel fondo delacaja con el agujeroen el ensam-

blaje de soportes. Fije la caja al soporte con tres (3) tornillos de

1/4 depulgada.Repitael mismo procedimiento en elladoopuesto de la caja. Vea la figura 15.

B. El canalde montajeen formade Ltieneque quedar en lapartede-

lantera del bastidor. El canal inferior de la caja deberá quedar en

la guía delensamblajede soportes.Bajela ventanahasta que descanse detrás de la parte delantera del canal en forma de L. Vea la

figura 16.

C. La caja tiene que quedar ligeramente inclinada hacia afuera. Si

fuera necesario, vuelva a ajustar elsoporte como se muestra enla

figura 12.

Tornillo de

¼ de plg.

A06544

Fig. 15 -- Fije la caja

Bastidor

Canal de

montaje en

forma de L

Cinta

selladora

A06545

Fig. 16 -- Canal de montaje

8

Page 25

Bobina

Tornillos de 3/4 de plg.

A

r

i

c

n

o

d

i

t

i

o

n

r

e

T

I

M

E

R

F

H

R

F

A

N

M

O

D

O

E

N

O

F

F

/

S

P

E

E

D

W

A

I

T

T

H

R

E

E

M

I

N

U

T

E

S

B

E

F

O

E

R

R

E

S

T

A

R

T

I

N

G

Canal de

montaje en

forma de L

Cinta

selladora

Tornillo de seguridad

A

ir

c

o

n

ditio

n

e

r

T

I

M

E

R

F

F

AN

H

R

M

O

D

E

S

P

E

O

E

N

D

/

O

F

F

W

A

I

T

T

H

R

E

E

MI

N

U

T

E

S

B

E

F

O

R

E

R

E

S

T

A

R

T

I

N

G

Fig. 17 -- Detalle del tornillo de seguridad

Espuma

Fig. 18 -- Colocación de la espuma

Manguera de desagüe

(no se incluye)

Fig. 19 -- Manguera

A06546

A06547

A06548

Palanca de ventilación de aire exterior

A06533

Fig. 20 -- Palanca de ventilación de aire exterior

INSTALACIONES CON CONTRAVENTANA

Si laventana está bloqueada poruna contraventana queno se puede quitar, hay que poner una tabla de montaje (provista por el instalador) en el

bastidor de laventana.La unidad tiene que estarinclinadahacia atráspara

facilitar el drenaje del agua condensada.

El marco de la contraventana (o cualquier otro tipode estructurapresente) tiene queestar a un nivel de media pulgada como mínimo por

debajo de la repisa de la ventana. Si el marco dela contraventanano

está media pulgada como mínimo por debajo del nivel de la repisa,

habráque usar unatablade montaje parasubir la repisa. Veala figura

21. El instalador tendrá que suministrar y cortar la tabla.

1. La tabla demontajedebemedir como mínimo unapulgaday media de ancho y cubrir el largo entero de la ventana. El grosor dependeráde la altura del marco de la contraventana. La tabla debe

levantar el frente dela unidad lo suficiente como para que la unidad quede inclinada hacia abajo 5/8 de pulgada como mínimo

cuando la parte de atrás de la unidad esté descansando sobre el

marco de la contraventana. Vea la figura 21.

2. Corte la tabla de montaje según el tamaño de la ventana.

3. Instale la tabla en la ventana con dos tornillos o clavos (no incluidos).

4. Los agujeros o ranuras dedrenajeen el marco de lacontraventana

no se deben obstruir con calafateo ni pintura. Estos agujeros son

necesarios para drenar el agua de lluvia y la condensación. Compruebe que el agua acumulada pueda drenarse.

plg. mín

CONTRAVENTANA U OTRAS

OBSTRUCCIONES

Fig. 21 -- Instalaciones con contraventa

BASTIDOR

plg. mín

1 1/2 plg.

mín

PIEZA DE MADERA DEL

GROSOR NECESARIO, A LO

LARGO DE TODA LA REPISA.

FIJAR CON DOS CLAVOS O

TORNILLOS.

9

PIEZA DE MADERA

FACILITADA POR EL

PROPIETARIO

Page 26

INSTALACIÓN EN LA PARED

Parainstalar el acondicionadorde aireen lapared,realiceel siguiente

procedimiento:

1. Saque elacondicionadorde airede lacajade envío.No use los

componentes para la instalación en ventanas.

2. Determineelpunto donde seinstalaráel acondicionadorde aire.Asegúresede que hayasuficienteespaciode instalaciónpor

dentro y por fuera de la pared. Asegúrese de que el cable eléctrico pueda enchufarse en el tomacorriente sin tener que usar

un cable de extensión. El acondicionador deaire puede instalarse en paredes con un grosor máximo de 7 pulg. Las entradas

de aire exterior deben quedar desobstruidas. Seleccione una

área de la pared:

S Que no soporte cargas estructurales mayores como la

construcción de entramado en los extremos de las ventanas y debajo de puntos de apoyo de vigas

S Que no contenga tubos de plomería ni cableado eléctrico

S Que quede cerca de un tomacorriente existente o cerca de

donde podría instalarse otro

S Queestéorientadahaciaeláreaaenfriaryqueestélibre

de obstrucciones

S Que permita un flujo de aire ininterrumpido desde la

parte trasera (exterior) del acondicionador de aire instalado

3. El instalador deberá proporcionar los siguientes componentes:

IMPORTANTE: Si después de instalarel acondicionador de aire el

grosor de la pared cubre las entradas de aire superior y lateral, será

necesario ampliar la parte exterior de la abertura de la pared. Las

entradas de aire superior y lateral deben quedar desobstruidas y

descubiertas.

8. Una vez construido, verifique que el marco esté ajustado correctamente alrededordel acondicionadorde aire.Si el marco

resulta demasiado apretado o flojo, ajuste su tamaño o vuelva

a construirlo.

9. Determine las dimensiones exteriores del marco y utilícelas

para crear laabertura en la pared. Asegúrese de que laabertura

quede nivelada, de lo contrario el condensado no drenará correctamente.

10. Instale el marco de madera dentro de la abertura en la pared.

El marco debe estar correctamente asegurado. Coloque unas

cuñas de madera (espaciadores) entre el marco y los montantes.Use clavos para fijar los espaciadores alos montantes. De

ser necesario, instale montantes alrededor de todo elmarco para reforzar la estabilidad de la pared. Vea la figura 24.

3-3/8 pulg. mín.

(8,6 cm)

S marco de madera

S cuñas de madera

S tornillos para madera (no. 10, 1 pulg.)

4. Desde el interior dela habitación, localice el montante de paredmás cercanoal centrodel puntodonde se instalará el acondicionador de aire. Para hacerlo, golpee ligeramente la pared

o use un localizador de montantes.

5. Corte o haga una abertura enla pared a cada lado del montante

central. Vea la figura 22.

IMPORTANTE: Lea todas las instrucciones antes de crear la

abertura en la pared.

6. Mida la distancia entre los bordes interioresde los montantes

a cadalado del montante centraltal como semuestra enla figura 22.

7. Siga todos loscódigosde construcciónlocalesalconstruir einstalar el marco. Construya un marco de madera que se colocará alrededor de la unidad en la pared. El marco reforzará la abertura en

la pared dondese instalael acondicionador deairey sirvepara fijarlo a la pared. La profundidad del marco deberá corresponder

aproximadamente a la profundidad de la pared. Será necesario

agregar el grosor del marco a las dimensiones para determinar el

tamaño de la abertura en la pared.

IMPORTANTE: Asegúrese de confirmar las dimensiones del

acondicionador de aire antes de construir el marco.

Fig. 22 -- Punto de instalación en la pared

HASTA 7 PULG

UNIDAD Dimensiones

KC o KH A B

123P 15,75 22,8

141P --- 233P 18,25 26,4

A06739

Por ejemplo, si el grosor de la madera del marco es de 3/4 de pulg.,

la abertura deberá tener un ancho de: 20--1/2 + 3/4 + 3/4 = 22 pulg.

A06740

Fig. 23 -- Construcción del marco

10

Page 27

USE CLAVOS PARA FIJAR LOS

ESPACIADORES A LOS

MONTANTES

NIVEL DE

BURBUJA

!

PRECAUCIÓN

RIESGO DE OPERACIÓN ERRÁTICA DE LA

UNIDAD Y LESIONES

No tener en cuenta esta advertencia podría provocar

desperfectos a la unidad o lesiones personales.

Cuandovaya a instalarel chasis,no apliquepresióncontralos

controles ni el serpentín. Podría provocar desperfectos a la

unidad o lesiones personales.

19. Instale el panel frontal

20. Enchufe la unidad.

A06741

Fig. 24 -- Instalación del marco