Page 1

Number One

AirConditbning

l\Mer

Division of

Carrier Corporation

Carrier Parkway • Syracus

N Y 13221

Weathermaster III Dual-Compressor

Heat Pump

(Outdoor Coil Section; Indoor Compressor Section)

INDEX

Page

SAFETY CONSIDERATIONS

.............................

INSTALLATION.....................................................3

Step 1 — Check Equipment and Jobsite . 3

• UNPACKAGE UNITS

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER SYSTEM

REQUIREMENTS

Step 2 — Install Outdoor Coil

Section.................................................4

• ON THE GROUND

• ON THE ROOF

Step 3 — Install Indoor Compressor

Section.................................................5

Step 4 — Install Indoor Fan-Coil and

Electric Heater

Step 5 — Make Piping Connections

....................................

................

• REPLACE THE ACCURATER™

REFRIGERANT CONTROL PISTON(S)

• CONNECT REFRIGERANT LINES

Step 6 — Install Fan Control Package ... 6

Page

I

Step 7 — Install Outdoor Ambient

Switch...................................................6

Step 8 — Install Room Thermostat,

Outdoor Thermostat(s) and

Emergency Heat Relay

Step 9 — Make Electrical Connections... 8

.......................

8

• INSTALL A BRANCH CIRCUIT

DISCONNECT PER N.E.C.

• ROUTE LINE POWER LEADS INTO

COMPRESSOR SECTION

• CONNECT GROUND LEADS AND

POWER WIRES

• CONNECT POWER LEADS FROM

INDOOR COMPRESSOR SECTION

TO OUTDOOR COIL SECTION

5

5

• CONNECTCONTROL WIRING

INITIAL START-UP................................................9

SEQUENCE OF OPERATION.............................. 9

SERVICE.................................................................. II

MAINTENANCE .................................................... 15

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pressure

and electrical components. Only trained and quali

fied service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainten

ance functions of cleaning coils and filters and re

placing filters. All other operations should be per

formed by trained service personnel. When working

on air conditioning equipment, observe precautions

in the literature, tags and labels attached to the unit

© Carrier Corporation 1979

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for brazing opera

tions. Have fire extinguisher available for all brazing

operations.

Form 38HQ-6SI

Page 2

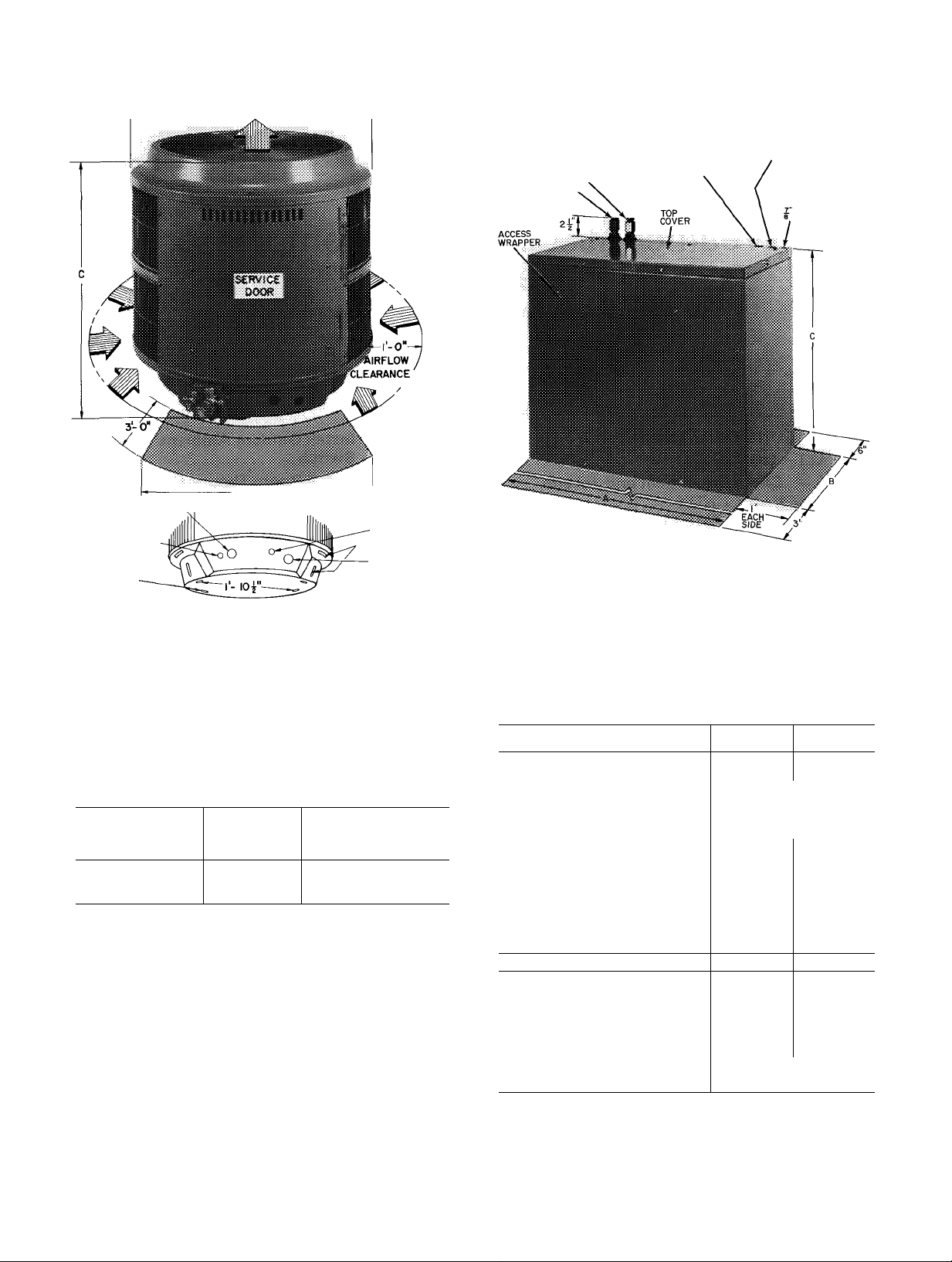

4 -0" OVERHEAD SPACE REQUIRED

FOR SERVICE AND AIRFLOW

VAPOR LINE CONN (ON SERVICE VALVE)

i-b*'-

liquid line

CONN. (ON

SERVICE VALVE)

5" ll“

15’ Is

MTG SLOTS

(USE ANY 2)

^ SPACE REQUIRED FOR SERVICE ^AIRFLOW

Certified dimension drawings available on request

38 HQ

OUTDOOR

COIL

SECTION

i DIAM HOLE

FOR CONTROL

WIRING

DRAINAGE HOLES

I i' DIAM

HOLE FOR

POWER

WIRING

k DIAM HOLE

VAPOR LINE CONN TO

OUTDOOR COIL

VAPOR LINE CONN.

TO INDOOR COIL ‘

38HQ

INDOOR

COMPRESSOR

SECTION

SPACE REQUIRED FOR SERVICE

FOR COMPRESSOR

SECTION LINE POWER

WIRING

Certified dimension drawings available on request

Fig. 2 — Dimensions and Connections, 38HQ

Indoor Compressor Section (Table 2)

DIAM HOLE

FOR OUTDOOR

COIL SECTION

LINE POWER WIRING

(SEE ELECTRICAL

DATA AND WIRING)

DIAM HOLE FOR

CONTROL WIRING

Fig. 1 — Dimensions and Connections, 38HQ

Outdoor Coil Section (Table 2)

Table 1 — Carrier-Approved 38HQ

Weathermaster III Dual-Compressor

Heat Pump Systems

INDOOR

COMPRESSOR

SECTION

38HQ227

38HQ234

OUTDOOR

COIL

SECTION

38HQ940

38HQ960

INDOOR

FAN/COIL

40FS160/28VQ036

40FS200/28VQ042

Table 2 — Physical Data

INDOOR COMPR SECTION

Operating Wt (lbs)

38HQ227

205

Dimensions (ft-in.)

Width

A

Depth B

Height

C

1-11-1/8 (add 3/4-in for

Refrigerant Fittings

Compressor

no. 1

MD2713GM

(46)

(Oil Recharge, oz) no. 2

MD3413GM

(46)

AccuRater Size (in.)

Indoor no 6 ( 0670) no 7(0760)

Outdoor no 3 (.0550)*

Refrig Conn (in.)

OUTDOOR COIL SECTION

Operating Wt (lb)

3/4 3/4

38HQ940 38HQ960

107

Dimensions (ft-in.)

Diameter

Unit Height B

Coil Height

A

C

2-5-1/4

2- 8 3- 8

1-11 2-11

Refrig Conn

Vapor (in., ODF)

Liquid (in., ODF)

3/4, Compatible Fitting

3/8, Flare Fitting

*Piston size shown is shipped with section Remove factory-

installed piston: replace with size shown per text

38HQ234

2-2-3/32

1-4-3/16

MD3413GM

MD3413GM

no 5 ( 0635)

2-5-1/4

225

(46)

(46)

125

©

Page 3

Table 3 — Heater Airflow Data

COMPRESSOR

PART NO.

38CQ900102

38CQ900122

38CQ900132

38CQ900152

38CQ900172

38HQ900011

38HQ900002

38RQ900012

38CQ900072

38RQ900072

TUBING

PACKAGE

38GC900071 10

38GC900081 18

38GC900091

38GC900101 35

38GC900111 50

_ ___ TUBING

INDOOR

SECTION

38HQ227

38HQ234

HEATER MINIMUM ALLOWABLE

SIZE

8 thru 20 kw

(40FQ91 6010 thru 090)

10 thru 25 kw

(40FQ920060 thru 1 50)

Airflow (cfm)

1150

1550

Fan Speed

Low

Low

Table 4 — Accessories

DESCRIPTION

Six 38CQ900081 Low-voltage Honeywell Thermostat (HH07AT071) and Thermostat Subbase (HH93AZ073)

with automatic changeover

Six 38CQ900111 Low-voltage Honeywell Thermostat (HH07AT071) and Thermostat Subbase (HH93AZ075)

with manual changeover

Six 38CQ900091 Liquid Line Filter-Drier

Six 38CQ900141 Solid State Time Guard (24 v)

SixHH22AG110 Optimizer Control

Hot Shot Heat Reclaim Device

Six 38HQ900001 Outdoor Thermostat

Six 38RQ900001 Emergency Heat Relay

Six 38C0900061 two-packs. Flare (3/8-in ) to compatible (3/8-in ) couplings

Six 38RQ900061 Heat Pump Stand for Outdoor Coil Section

Suction*

Tube End

Evap

3/4

3/4

O D. (in )

Cond

3/4

3/4

3/4

3/4

COMPR

SECTION

38HQ227

38HQ234

Length

(ft)

25

Liquid

O.D

(in.)

3/8

3/8

3/8

3/8

3/8 3/8

1-1/8 in OD Suction Tube, Field Supplied

Tube End

OD (in )

3/8

3/8

3/8

3/8

0 D.

(in.)

3/4 3/4 3/4

3/4 3/4

3/4 3/4

3/4

3/4

‘Suction line is insulated and has a 90° bend at one end

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACKAGE UNITS — Move units to final loca

tion. Slide units from cartons taking special care

not to damage service valves, compatible fittings

or grilles. Check unit model numbers. Use only

Carrier-approved unit combinations in system. See

Table 1.

INSPECT EQUIPMENT — File claim with ship

ping company if shipment is damaged or incomplete.

COMPLETE OR CONSIDER SYSTEM RE

QUIREMENTS before installing the 38HQ units.

Consult local building codes and National Elec

trical Code (NEC) for special installation

requirements.

When installing units, allow sufficient space for

airflow clearance (outdoor unit), wiring, refrigerant

piping and servicing unit. Position outdoor unit so

water or ice from roof cannot drop directly on top

of unit. Maximum allowable vertical distance be

tween indoor and outdoor sections is 50 feet. It is

strongly recommended that 38HQ units be used

with only Carrier-approved indoor sections (see

Table 1).

Outdoor Coil Section — Make provision for con

densate drainage and defrost water disposal whether

unit is installed on ground, roof or off-the-wall

platform. Outdoor unit must be elevated 12 in. to

18 in. in areas of heavy snowfall. (Ensure unit base-

pan drainage holes are not blocked. See Fig. 1.) See

Step 2, Install Outdoor Coil Section for details.

Roof installation method for 38HQ depends on

building construction and special requirements of

local codes. Make sure roof can support unit weight.

Indoor Compressor Section — Locate unit in base

ment, garage or utility room. Indoor locations with

in the living space are not recommended. Basement

installations also require careful planning to avoid

areas directly under bedrooms, living rooms, etc.

Page 4

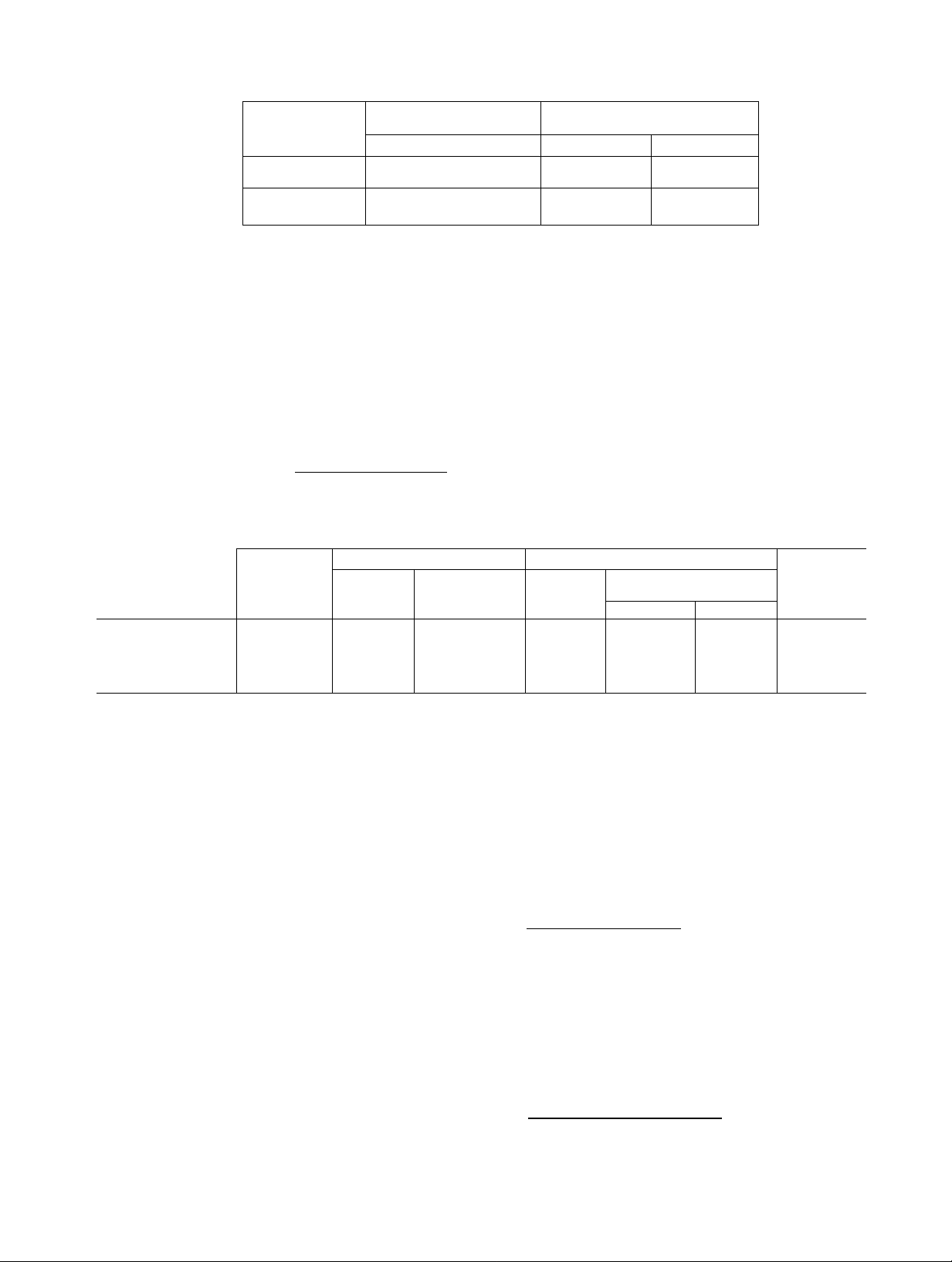

Insert felt isolation pad (factory supplied) be

tween unit and a level rigid mounting base to absorb

vibration. Isolate interconnecting tubing from

framing and ductwork or where tubing runs thru

stud spaces, enclosed ceilings or pipe chases. Use

isolation type hanger, Fig. 3, since rigid fastening

will transmit pulsation to structure creating ob

jectionable sound.

. -.-.A ■ ■

System Refrigerant Control consists of factoryinstalled bypass-type AccuRater™ devices located

as shown in Fig. 15. These metering devices include a

replaceable orifice piston that is calibrated to

regulate refrigerant flow. Piston data is given in

Table 2. In some instances, the factory-installed

piston must be replaced by a factory-supplied re

placement piston. Where required, substitute

pistons as described in Step 5 and as indicated on

tags attached to system AccuRater devices.

Step 2 — Install Outdoor Coil Section

ON THE GROUND — Use a solid, level concrete

pad as shown in Fig. 4. Position unit so that coil

drainage holes in basepan overhang the pad. (See

Fig. 1 for drainage hole locations.) Be sure pad does

not obstruct drainage holes (water drains from holes

during heating and defrost cycles). Attach unit to

pad with 1 / 4-in. mounting bolts. Any 2 holes in unit

basepan may be used to fasten unit to pad.

Construct round, 24-in. diameter 6-in. thick pad a

minimum of 6 in. above grade to provide clearance

under holes for drainage and ice build-up. In areas

where prolonged subfreezing temperatures or snows

occur: increase clearance by using accessory heat

pump stand to support unit 12 to 18 in. off concrete

base. See Fig. 4. Be sure stand does not obstruct coil

drainage holes. Avoid mounting unit in prevailing

winds to minimize effect on defrost performance.

Construct wind break if necessary. Extend a 12-in.

gravel apron around pad for condensate and defrost

water drainage field.

Provide support bracket from structure or other

solid support to outdoor unit to give stability. Since

it is lightweight, the outdoor section may be

Fig. 4 — Unit Support Details

mounted on a platform attached to or built out from

structure. Construct platform using drainage and

clearance recommendations above. Locate and con

struct platform to avoid possible transfer of unit

vibration to structure. See Table 2 for unit weight.

ON THE ROOF: Install a level platform or frame to

support unit. Elevate unit for proper clearance as

previously described for on-the-ground installation.

Plan roof design and water drainage to prevent unit

from sitting in water. Flash all roof openings to

prevent leaks.

Page 5

Step 3 — Install Indoor Compressor Section on

a level, rigid, solid platform or concrete floor. Do

not install in a living area.

Insert 1/4-in. asphalt-impregnated felt pad

(supplied) between unit basepan and mounting

surface to provide full unit support and vibration

attenuation. (Do not use vibration isolators under

corners of basepan.)

Step 4 — Install Indoor Fan-Coil and Electric

Heater as described in Installation Instructions

supplied with this equipment. Install and connect

thermostats and other controls as described in the

steps that follow.

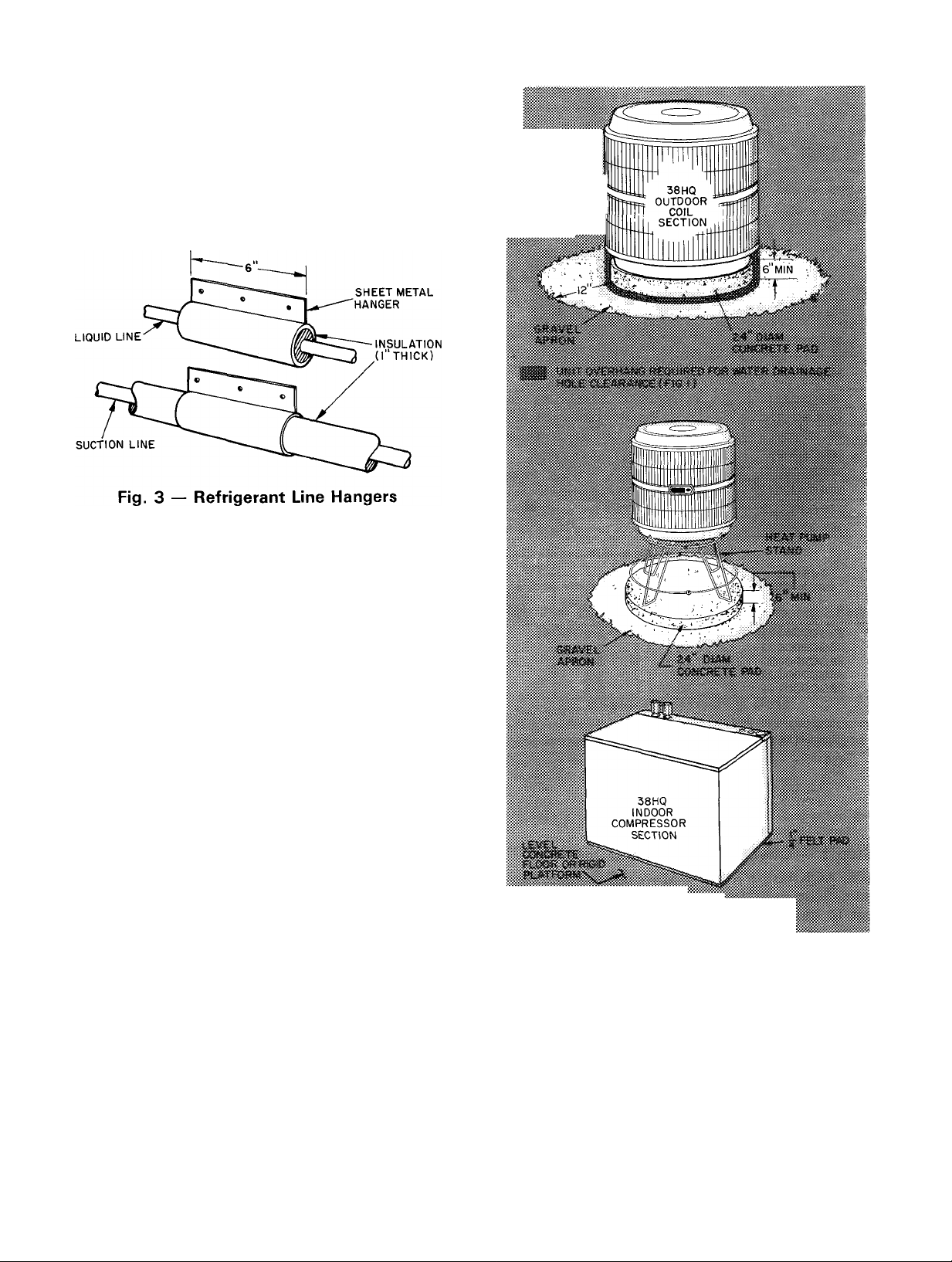

Step 5 — Make Piping Connections — The

38HQ sections may be connected to indoor fan-coil

using Carrier accessory tubing packages or fieldsupplied tubing of refrigerant grade. See Table 2 for

unit piping connection types, sizes and line size

recommendations and Table 4 for accessory tubing

sizes. Maximum allowable system liquid line length

is 100 feet. Maximum vapor line length from com

pressor section to indoor coil is 50 feet. Maximum

vapor line length from compressor section to out

door coil is 50 feet.

When other than 25 ft of interconnecting piping

is used, follow special requirements described in

Refrigerant Charging. Do not use less than 10 ft of

vapor or liquid line.

Do not use damaged or contaminated tubing.

Always evacuate or purge indoor coil, compressor

section and tubing system. When purging, use fieldsupplied refrigerant, not unit refrigerant.

When making tubing connections, be sure to

provide clearance at unit for electrical connections.

Follow tubing isolation recommendations described

previously.

REPLACE THE ACCURATER™ REFRIG

ERANT CONTROL PISTON(S) before connect

ing refrigerant lines as applicable. Refer to tags

attached to AccuRater device. Replacement pistons

are shipped with compressor section and are to be

installed as directed on tag. Replacement procedure,

briefly described below, is detailed on tag. Also, see

AccuRater Servicing for additional information.

When connecting indoor compressor section

38HQ227 to outdoor coil section 38HQ940, remove

no. 4 piston from outdoor coil AccuRater device;

replace with no. 3 piston. Attach AccuRater identi

fication sticker to unit (replacing existing sticker, if

any).

CONNECT REFRIGERANT LINES to fittings on

indoor and outdoor sections. Fig. 1, 2 and 5. Indoor

compressor section has 2 Compatible Fitting vapor

line connections. Outdoor and indoor fan-coil

sections have Compatible Fitting vapor line connec

tion and liquid line flare connection.

Flare and connect liquid line from outdoor coil

section to indoor fan-coil unit. It is not necessary

to flare system liquid line if an accessory flare-to-

Fig. 5 — Refrigerant Piping Connections

5

Page 6

Compatible Fitting coupler is used for liquid line

connection. See accessory coupler, Fig. 6.

Connect vapor line from outdoor coil section to

indoor compressor section, and from compressor

section to indoor fan-coil. Section vapor line as

required (Fig. 5). Use correct compressor section

vapor line connection to indoor and outdoor coils.

Unit Compatible Fittings permit mechanical or

sweat connection as described below.

When a 1-1/8 in. field-supplied vapor line is used

on 38HQ234, four field-supplied 3/4-in. to 1-1 / 8 in.

vapor line adapters must be provided.

Insulate Refrigerant Lines — After making tubing

connections, the compressor section fittings must be

insulated. Butt the Armaflex tubing insulation (pro

vided in tubing package) against the Compatible

Fittings. Secure the insulation with Prestito or an

equivalent material which provides both adhesion

and insulation. Also wrap the Compatible Fittings

with Prestito to prevent sweating.

Mechanical Connection-to-Compatible Fitting

(Mate one set of connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure 0-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length.

4. Insert tube into Compatible Fitting until it

bottoms.

5. Tighten nut until it bottoms on back coupler

flange. Keep tube bottomed in Compatible

Fitting while tightening nut.

Sweat Connection-to-Compatible Fitting (Use

refrigerant grade tubing.)

1. Remove locking nut, rubber O-ring and Schrader

core from valve.

2. Cut tubing to correct length.

3. Insert tube into Compatible Fitting. Wrap top

and bottom of service valves in wet cloth to pre

vent damage by heat. Solder with low tempera

ture (430 F) silver alloy solder.

4. Replace Schrader core.

5. Evaeuate or purge system with field-supplied

refrigerant.

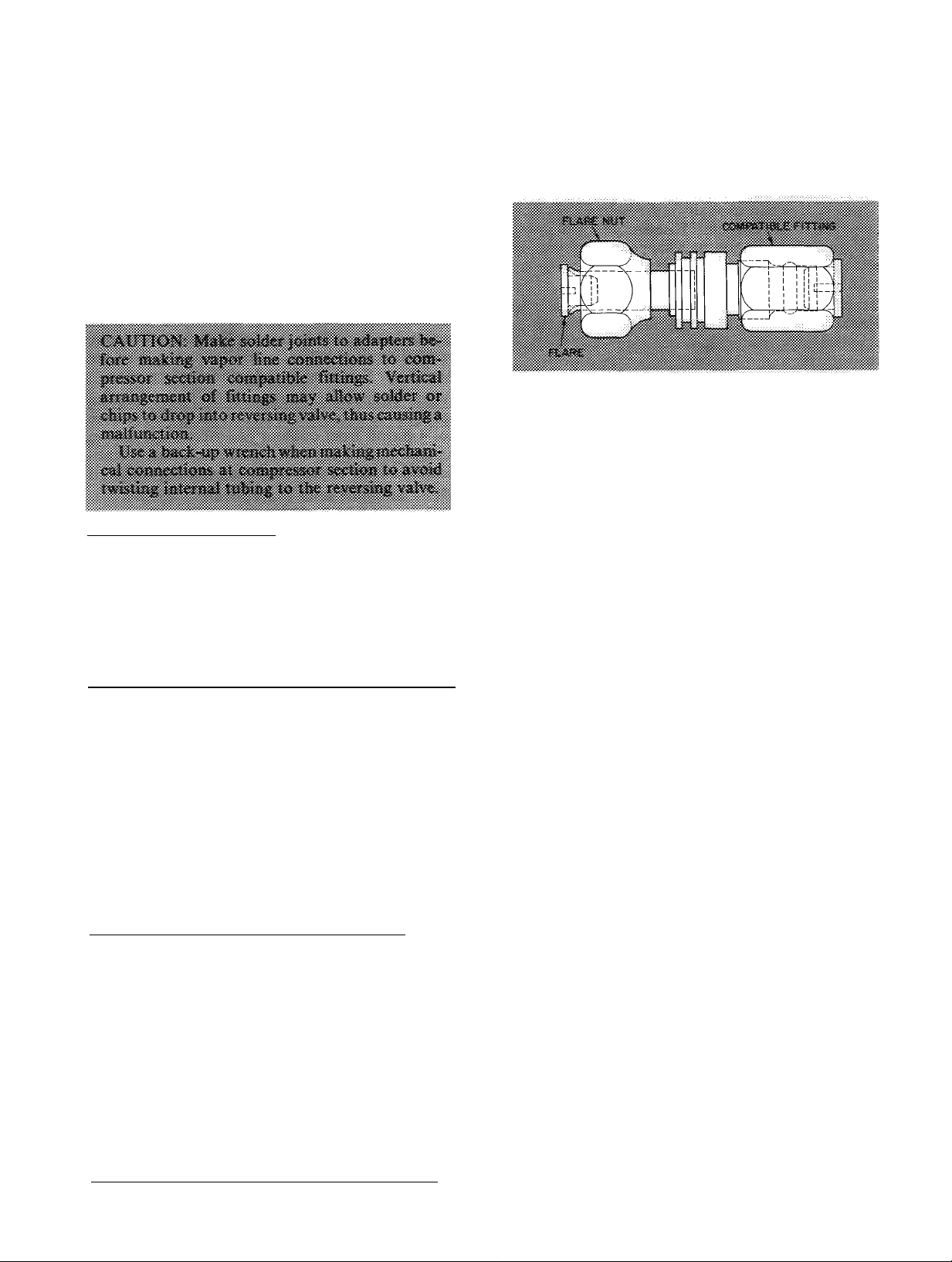

Accessory Flare-to-Compatible Fitting Coupler is

shown in Fig. 6. Attach flare nut on coupler to flare

fitting on unit liquid line connection. Connect liquid

line to Compatible Fitting using mechanical or

sweat connection. When mechanical connection is

made, use 2 wrenches to tighten Compatible Fitting

nut — one to hold coupler and one to tighten nut.

Fig. 6 — Accessory Coupler

Step 6 — Install Fan Control Package (factory

supplied; packaged separately inside indoor com

pressor section) — This control, consisting of a

transformer and a relay, provides high-speed fan

operation when both compressors are energized.

Refer to connection diagram in Fig. 7 for wiring

details. Install control as follows:

1. Remove factory-installed transformer from

indoor fan-coil unit electric heater package.

Refer to 40FS service instructions as required.

2. Install fan control package in upper right-hand

corner of the 40FS.

3. Route wires from controls to heater package thru

knockouts provided. Restore transformer wiring

connections including ground wire.

4. Connect black wire from indoor fan relay (IFR)

terminal no. 4 (or no. 6) to black wire from

indoor fan relay no. 2 (IFR-2) terminal no. 3.

(Cut off male connector from IFR wire; supply

wire nut to splice wires.)

5. Connect black wire from IFR-2 terminal no. 6 to

fan speed selector block terminal no. 1 (high

speed).

6. Connect blue wire from IFR-2 terminal no. 1 to

fan speed selector block terminal no. 3 (low

speed).

7. Connect low-voltage field control wires between

indoor compressor section and indoor fan relay

(IFR-2) orange pigtails (TB OA to OFR-2, ter

minal no. 4; contactor C-2, terminal C to IFR-2,

terminal no. 5). Field-supplied, 24-gage, NEC

Class 2 thermostat wire may be used.

Step 7 — Install Outdoor Ambient Switch

(OA) (factory-supplied; packaged separately inside

indoor compressor section) — This switch activates

compressor no. 2 when the first heating thermal

balance point is reached. The switch is installed in

the same manner as the outdoor thermostat (step 8),

except refer to Fig. 7 for correct wiring.

Page 7

LEGEND

C-2

IFR

PL

SEQ

TB

Tran

NOTES;

1

2

Contactor

Indoor Fan Relay

Plug, Fan

Sequencer

Terminal Board

Transformer

Junction

Component Connection (Marked)

o

Field Splice

Field Power Wiring

Field Ground Wiring

Field Control Wiring

Use copper conductors only.

May be terminal board or fuse block depending

on heater model used

Will be terminal no 4 on 40FQ916 models,

and terminal no 6 on 40FQ920 models

FAN CONTROL PACKAGE

THERMOSTAT 40FQ

SUBBASE ELECTRIC HEATER

HH93AZ0730R TERMINAL

HH93AZ075 BOARD

THERMOSTAT

SUBBASE

HH93AZ073 OR

HH93AZ075

40FQ

ELECTRIC HEATER

TERMINAL

BOARD

COOLING AND TWO-STAGE HEATING

(38H0 WITH 40FS/28H0.V0

EOUIPPED WITH ELECTRIC HEATER;

EMERGENCY HEAT, NO OUTDOOR THERMOSTATS)

DFT — Defrost Thermostat

EHR — Emergency Fleet Relay

OA — Outdoor Ambient Switch

ODT — Outdoor Thermostat

_______ Factory Wiring

_______

Field Wiring

38HQ

COMPRESSOR

SECTION

TERMINAL BOARD

38H0

COMPRESSOR

SECTION

TERMINAL BOARD

THERMOSTAT

SUBBASE

HH93AZ073 OR

HH93AZ075

THERMOSTAT 40FQ 38HQ

SUBBASE ELECTRIC HEATER COMPRESSOR

HH93AZ0730R TERMINAL SECTION

HH93AZ075 BOARD TERMINAL BOARD

(38HQWITH 40FS/28HQ/VQ

EQUIPPED WITH ELECTRIC HEATER;

EMERGENCY HEAT, TWO OUTDOOR THERMOSTATS)

40 FQ

ELECTRIC HEATER

TERMINAL

BOARD

EOUIPPEDWITH ELECTRIC HEATER;

EMERGENCY HEAT, ONE OUTDOOR THERMOSTAT)

38H0

COMPRESSOR

SECTION

TERMINAL BOARD

"Transformer (75 va) located in fan control package

fTerminal L is identified as terminal X on some former thermostats (Required for system

malfunction warning indicator on compressor section )

fRemove 1 or both factory-installed jumpers (connection B) when installing outdoor ther

mostats (ODT) shown in connections C and D

Fig. 7 — Control Circuit Connections

Page 8

Attach one lead to compressor terminal board

connection OA. Connect other lead to line side of

defrost thermostat.

Set switch at temperature of first thermal balance

point (heating). This balance point is provided by

CLIC load estimating program. Further adjust

ments can be made following operating experience.

Step 8 — Install Room Thermostat, Outdoor

Thermostat(s) and Emergency Heat Relay —

Follow Installation Instructions shipped with these

accessories plus the instructions in the sections that

follow. Connect as described in step 9.

INDOOR THERMOSTAT — Use only Carrier

indoor thermostat and subbase as shown in Table 4.

Set heat anticipator settings according to Table 5.

These settings may be changed slightly to provide

a greater degree of comfort for certain installations.

section of outdoor coil section junction box. Fasten

in place with sheet metal screws.

EMERGENCY HEAT RELAY — This accessory is

required when 2 or more outdoor thermostats are

used. It is automatically energized by the manuallyoperated emergency heat switch in the indoor ther

mostat subbase. The indoor thermostat locks out

the compressor and the relay bypasses the outdoor

thermostats for electric heater operation during heat

pump shutdown. When one outdoor thermostat is

used, an emergency heat relay is not required. The

emergency heat switch in the indoor thermostat

subbase bypasses the outdoor thermostat, locks out

the compressor and activates the electric heater.

Install emergency heat relay in a convenient loca

tion on indoor unit. Attach with sheet metal screw.

Connect relay as shown in Fig. 7.

Table 5 — Thermostat Heat Anticipator

Settings

INDOOR

COMPR

SECTION

38HQ227 38HQ940

38HQ234 38HQ960

OUTDOOR

COIL

SECTION

INDOOR

UNIT WITH

ELECTRIC

HTR

40FS160 with

40FQ916010

thru 090

40FS200 with

40FQ920060

thru 150

HTR

KW

8 thru

20

10 thru

25

ANTICIPATOR

SETTINGS

Second

First

Stage

Fixed 16

Fixed 49

Stage

OUTDOOR THERMOSTAT ACCESSORY pro

vides adjustable outdoor control of accessory

electric heater (used on indoor fan-coil). This ther

mostat closes on a drop in outdoor temperature.

It energizes a stage of electric heat when the out

door temperature setting is reached, provided the

room thermostat is on the second stage of heating.

One outdoor thermostat is recommended for each

stage of electric heat after the first stage. Connect

as described in Step 9. Set the outdoor thermostats

progressively lower for each stage. Refer to heat

load of building and unit capacity to determine the

correct outdoor thermostat settings. Locate maxi

mum of 2 outdoor thermostats in control voltage

Step 9 — Make Electrical Connections — In

stall field wiring in accordance with local and

national fire, safety and electrical codes. Be sure

voltage to units is within ± 10% of voltage indi

cated on nameplate. Contact local power company

for correction of improper line voltage.

When making electrical connections, provide

clearance at unit for refrigerant piping connections.

See Table 6 for recommended wire and fuse sizes.

Line power connections and control circuit connec

tions are shown in Fig. 7 and 8.

Route line and control power wiring for 38HQ

outdoor coil from connections in the 38HQ in

door compressor section. Use 14-ga (minimum) line

power wire size to outdoor coil section when total

wire length connecting compressor section to coil is

under 25 feet. If over 25 ft, use same wire size as

compressor section branch circuit.

Table 6 — Electrical Data

VOLTAGE

INDOOR

COMPR

SECTION

38HQ227 38HQ940 230

38HQ234 38HQ960

FLA — Full Load Amps

ICS — Indoor Compressor Section

LRA — Locked Rotor Amps

OCS — Outdoor Coil Section

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

‘Permissible limits of the voltage range (for limited period of time)

at which the units will operate satisfactorily

fOutdoor coil section wiring — for 25 ft wire run or less, use

OUTDOOR

COIL

SECTION

Nom

1-Ph

60-Hz

230

Operating*

Max Min LRA

254

254 207

COMPR

1

RLA LRA

207 72 17 88

20

88

COMPR

2

94

BRANCH CIRCUIT

OFM

(FLA)

RLA

1 5 6

17 8

2 3 4

21 2

minimum 14 AWG size wire For longer wire run use same size

as supply to compressor section

^Required when using nonmetallic conduit

“Maximum dual element fuse size

NOTES;

1 All units have 24-v control circuit which requires external

power source

2 Copper wire size table based on 60 C Use copper or copper-clad

aluminum wire to indoor section; copper wire only to outdoor

section Use latest National Electrical Code for wire sizing

Min Size

(AWG)

ICS

Power Wire

OCS

ICS

55

14t

75

14t

Max Ft

OCS

25t

25t

Gnd Wire

Sizet

(AWG)

OCS

ICS

10 14t

10 14t

Min

Ckt

Amps

40 8 50

48 8

Max

Fuse

Amps“

60

Page 9

FACTORY WIRING

Fig. 8 — Line Power Connections

INSTALL A BRANCH CIRCUIT DISCONNECT

PER N.E.C. of adequate size to handle compressor

section starting current. Provide a separate dis

connect switch for outdoor coil section. Provide a

separate disconnect for indoor fan-coil and for each

accessory electric heater circuit as required. (See In

door Unit and Electric Heater Installation, Start-Up

and Service Instructions.) Locate disconnect(s)

within sight of and readily accessible to the units, per

section 440-14 of National Electrical Code (NEC).

ROUTE LINE POWER LEADS INTO COM

PRESSOR SECTION — Extend lead from discon

nect per N.E.C. thru 1-1/8 in. hole provided in com

pressor section top panel (Fig. 2) and into control

box. Extend line power leads for outdoor coil

section thru 7/8-in. hole provided in compressor

section top panel and into control box.

CONNECT GROUND LEADS AND POWER

WIRES — Connect ground leads to the ground lug

in control box for safety. Splice compressor section

line power leads to yellow and black pigtails, and

outdoor coil section power leads to brown and blue

pigtails. Use wire nuts and tape at each splice con

nection as shown in Fig. 8.

CONNECT POWER LEADS FROM INDOOR

COMPRESSOR SECTION TO OUTDOOR

COIL SECTION thru secondary disconnect switch.

From this disconnect switch extend leads thru

hole provided in outdoor eoil section basepan

(Fig. 1) and into line voltage seetion of junction

box. Fig. 14. Splice leads to black and blue pigtails

with wire nuts.

CONNECT CONTROL WIRING (24-v) — Extend

wiring thru 7 / 8-in. grommeted hole in compressor

section top panel (Fig. 2), and to control wiring

terminal board on side of control box. Connect

leads to terminal board as shown in Fig. 7. Extend

and connect control wiring from compressor section

to outdoor coil section as required. Make splice

connections in low-voltage section of coil junction

box.

Use indoor fan-eoil transformer as 24-v supply for

system. Be sure fan eontrol package is installed as

described in Step 6. Package contains 75-va trans

former of adequate capacity to handle system

current.

INITIAL START-UP

The compressors in the indoor compressor

section are equipped with crankcase heaters. It is

reeommended that the heaters be energized a

minimum of 24 hours before starting the system. To

energize crankcase heaters only, set the thermostat

at OFF position and turn on main power to

compressor section.

To Start System — (Be sure crankcase heaters

have been energized for 24 hours.) Adjust the ther

mostat as follows;

1. Set selector switch at OFF.

2. Turn on main disconnect switch(es) to indoor

and outdoor units.

3. Set fan switch as desired (ON or AUTO.).

4. Set thermostat dial at desired temperature.

5. Set selector switch at HEAT or COOL.

Check system refrigerant charge. See Service —

Refrigerant Charging.

SEQUENCE OF OPERATION

Fan Switch at AUTO. Position, Thermostat at

ON Position (Crankcase heater is on as soon as the

field power supply is on.)

THERMOSTAT CALLS FOR COOLING

1. First-stage cooling thermostat (Co) closes and

the reversing valve solenoid (RVS) is energized.

The RVS actuates the reversing valve and

switches the system to cooling.

2. Second-stage cooling thermostat (Cl) closes. If

the low-pressure switch (LPS) is closed, com

pressor contactor (C) is energized and compres

Page 10

sor no. 1 starts. At the same time, the outdoor fan

motor (OFM) starts and the defrost timer (DT) is

energized although it is not functional in the

cooling mode; the indoor fan relay (IFR) is

energized and the indoor fan motor (IFM) starts.

Compressor no. 2 does not run in COOL mode.

When the second stage of cooling is satisfied, Cl

opens. The compressor stops; the indoor and out

door fans stop; DT is de-energized. When the con

trolled temperature drops approximately 1 F below

the cooling set point, Co opens. RVS is de-energized

and the reversing valve switches to heating (normal

position). The unit is shut down except for the two

compressor crankcase heaters, which remain on as

long as the field power supply is on.

THERMOSTAT CALLS FOR HEATING (The

reversing valve is de-energized, in heating position.)

1. First stage heating thermostat (HI) closes. Com

pressor contactor no. 1 (Cl) is energized and

compressor starts; outdoor fan motor (OFM)

starts; defrost timer (DT) is energized. Indoor

fan relay (IFR) is energized and indoor fan

motor (IFM) starts. When the outdoor ambient

switch (OA) closes (at first thermal balance

point), compressor contactor no. 2 (C2) is ener

gized and compressor no. 2 starts. Compressor

no. 1 and compressor no. 2 operate simul

taneously as long as OA is closed. The crankcase

heaters are de-energized when both compressors

are running.

2. Second-stage heating thermostat (H2) closes and

activates the first accessory heater element

sequencer thru indoor thermostat terminal W2.

The first-stage electric heater element is energized

immediately and the other heater elements are

energized at regular intervals thru the sequencers.

Separate outdoor thermostats may be used to

energize the second sequencer and bring on addi

tional heater elements if more incremental heat

control is desired.

When the second stage of heating is satisfied, H2

opens and the electric heater(s) shuts off. When the

first stage of heating is satisfied, HI opens and the

unit shuts down, except for the compressor crank

case heater, which remains on as long as the field

power supply is on.

Unit Controls and Safety Devices

HIGH-PRESSURE RELIEF VALVE is located in

compressor. Relief valve opens at a pressure

differential of approximately 500 psi between

suction (low side) and discharge (high side) to allow

pressure equalization.

INTERNAL CURRENT AND TEMPERATURE

SENSITIVE OVERLOAD resets automatically

when internal compressor motor temperature drops

to a safe level (overloads may require up to 45 min

utes to reset). When an internal overload is suspected

of being open, check by using an ohmmeter or con

tinuity tester. If necessary, refer to Carrier Standard

Service Techniques Manual, Chapter 2, Electrical,

for complete instructions.

LOW-PRESSURE SWITCH is located in compres

sor section on suction line between reversing valve

and accumulator. Provides loss-of-charge protec

tion by shutting compressor off if suction pressure

drops below setting. Low-pressure switch settings

are: open, 5 ± 3 psig; close, 20 ± 5 psig.

CRANKCASE HEATERS are activated by a relay.

Heaters derive power from contactor no. 2 and are

energized when compressors are off or when only

one compressor is functioning.

The heater keeps the crankcase warm during the

off cycle and thus prevents dilution of the oil with

the refrigerant, assures good lubrication, and pre

vents loss of oil from crankcase during start-up.

If the electrical disconnect switch to the compres

sor section has been off for an extended period of

time, the crankcase heater should be energizedfor 24

hours before starting the compressor.

SIGNAL-LOC™ SYSTEM MALFUNCTION

WARNING INDICATOR AND LOCKOUT —

Indoor compressor section is equipped with a solid-

state warning logic circuit that protects the system.

In case of a malfunction (compressors do not oper

ate due to safety device cutout), emergency heat light

on thermostat comes on and compressors are pre

vented from restarting. Compressors can be re

started after resetting thermostat (turn thermostat

off then on). If either compressor malfunctions,

both will be locked out (prevented from restarting).

The emergency heat light goes out when com

pressors are restarted or when indoor thermostat is

satisfied. If the light does not stay out after two or

three attempts to restart, check for cause of

malfunction.

DEFROST CONTROL, consisting of a defrost

timer, defrost thermostat and defrost relay, inter

rupts normal system heating operation every 90

minutes to defrost outdoor coil, if the coil saturated

suction temperature indicates freezing tempera

tures. Defrost control simultaneously stops outdoor

fan, energizes reversing valve solenoid to return

system to cooling cycle (outdoor coil as condenser,

indoor fan-coil unit as evaporator), and activates

accessory electric heater.

For the heat pump to defrost, 2 conditions are

necessary;

1. Defrost timer contacts must be closed.

2. Refrigerant temperature from outdoor unit must

be cold enough to cause defrost thermostat

contacts to close. Contacts close at 27 (± 4) F.

Every 90 minutes of elapsed running time, the de

frost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit

defrosts. The defrost timer limits defrosting period

to 10 minutes. Normally the frost is removed and the

10

Page 11

defrost thermostat contacts will open to terminate

defrosting before 10 minutes have elapsed. The

defrost thermostat contacts open at 80 (± 6) F liquid

refrigerant temperature. When defrosting is ter

minated, the outdoor fan motor is energized and the

reversing valve solenoid is de-energized returning

unit to heating cycle.

If the defrost thermostat contacts are open, (no

need for defrost cycle), system operates for another

90-minute interval before attempting another

defrost cycle.

Table 7 — Service Data

SYSTEM

Indoor Compr Section 38HQ227

Outdoor Coil Section 38HQ940

Fan

Cfm

Rpm

Diam (in.)

Motor Hp

Factory Charge (lbs, R-22) 7 1

Total Req'd Charge (lbs, R-22)

Additional Charge Req'd (lbs) 2 1

Propeller, Direct Drive

38HQ234

38HQ960

3100

1015

20 20

1/5 1/4

9 2

3600

1080

100

11 0

1 0

SERVICE

Heat Pump Circuits shown in Fig. 9 are refrigerant

flow diagrams for heating and cooling cycles.

Refrigerant Charging — Each indoor compressor

section is shipped with a vapor holding charge; out

door coil section contains partial system charge

as shown in Table 7. Add refrigerant to system so

that total required charge is attained as described

below. Refer to Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants for additional

information.

Adjust system charge for refrigerant line lengths

and diameters that differ from 25 ft and 3 / 8-in. O.D.

(liquid line), respectively, using refrigerant weights

shown in table below. (Twenty-five feet of 3/8-in.

O.D. tubing contains 14.4 oz of R-22.) Add R-22

charge to system if liquid line is over 25 ft; remove

charge if liquid line is shorter than 25 feet.

LIQUID LINE OUNCES OF R-22/FT LENGTH

DIAM (in.) OF LIQUID LINE

3/8

5/16 36

1/4 21

58

When recharging is necessary during heating or

cooling season, weigh in total charge indicated in

Table 7. (Charge must be weighed in during heating

season.) Remove any refrigerant remaining in sys

tem before recharging. If system has lost complete

f.

Fig. 9 — Refrigerant Flow Diagrams

11

Page 12

charge, evacuate system to 500 microns (29.7 in.

vacuum) before recharging. Service port connec

tions are provided on indoor compressor unit

suction and discharge lines for evacuation and

charging. (See Fig. 14 for service port location.)

Dial-a-charge charging cylinder is an accurate de

vice used to recharge systems by weight. The

cylinders are available at refrigeration supply

firms.

TO CHECK AND/ OR ADJUST CHARGE DUR

ING COOLING SEASON — Use correct Cooling

Cycle Charging Chart (Fig. 10 and 11) and follow

charging chart usage method below.

TO CHECK SYSTEM OPERATION DURING

HEATING CYCLE — Use correct Heating Cycle

Operation Check Chart (Fig. 12 and 13). These

charts indicate whether a correct relationship

exists between system operating pressures and air

temperatures entering indoor and outdoor units. If

pressure and temperature lines do not intersect on

chart, the system refrigerant charge may not be

correct or other system abnormalities may exist.

Do not use Operation Check Charts to adjust

refrigerant charge. Weigh charge into system.

USING COOLING CYCLE CHARGING

CHARTS

1. Operate unit a minimum of 10 minutes before

checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

indoor unit suction service port. (See Fig. 14 for

correct service port location.)

3. Measure outdoor air dry-bulb temperature enter

ing outdoor coil. Use a service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor fan-coil

unit.

5. Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor air

wet-bulb temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart pres

sure, add refrigerant to system until chart pres

sure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

Temporary Capacitance Boost — If necessary, see

Carrier Standard Service Techniques Manual,

Chapter 2, Electrical, for details.

SUCTION PRESSURE {PSIG) AT SERVICE PORT

Fig. 10 — 38HQ227/38HQ940 with

28VQ036/40FS160 Cooling Cycle

Charging Chart

t

Fig. 11 — 38HQ234/38HQ960 with

28VQ042/40FS200 Cooling Cycle

Charging Chart

12

Page 13

if-

Fig. 12 — 38HQ227/38HQ940 with 28VQ036/40FS160 Heating Cycle

Operation Check Charts

Fig. 13 — 38HQ234/38HQ960 with 28VQ042/40FS200 Heating Cycle

Operation Check Charts

13

Page 14

Compressor Removal — See Table 2 for com

pressor information; Fig. 14 for component loca

tion. Shut off power to unit. Remove refrigerant

from system using refrigerant removal methods

described in Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants.

Follow safety codes, and wear safety glasses and

work gloves. Have quenching cloth available.

Pumpdown Procedure (Cooling Cycle) — The

38HQ units may be pumped down in order to make

repairs on low side of system without losing com

plete refrigerant charge.

SUCTION LINE

VAPOR LINE

CONNECTIONS

ACCUMULATOR

RUN, CAPACITOR

CONTROL WIRE

TERMINAL BOARD

If either compressor fails due to motor burnout,

it is necessary to replace both compressors. Since

both compressors use common oil, one compressor

burnout contaminates both compressors.

1. Remove unit top cover and front access

wrapper.

2. Remove compressor terminal box cover, dis

connect and remove compressor power leads.

3. Using a tubing cutter, cut suction and discharge

lines at convenient place near compressor for

easy reassembly to new compressor with copper

slip couplings.

4. Disconnect equalizer tube from compressor

shell.

5. Remove crankcase heater from compressor

base.

6. Remove compressor hold-down bolts. Lift out

compressor.

7. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

LOW

PRESSURE

SWITCH

.CONTROL

BOX

8. Braze piping stubs (removed in step 1) onto new

compressor.

9. Clean system. Add new liquid line heat pump

filter-drier as described below.

10. Install new compressor in unit. Braze suction

and discharge lines to compressor piping stubs

(at points where cut, step 3) using field-supplied

copper couplings. Reconnect equalizer tube.

Teflon O-ring in fitting is reusable. Torque

fitting to 30-40 ft-lb. Ensure compressor hold

down bolts are in place. Connect wiring.

11. Evacuate and recharge system.

Lubrication — Compressor contains factory oil

charge. Replace oil when lost. See Table 2 for oil

recharge. If necessary, refer to Carrier Standard

Service Techniques Manual, Chapter 1, Refrig

erants, pages 1-21, for oil recharging procedure.

Use Carrier PP33-1, Texaco Capella B or Suniso

3G oil.

Filter-Drier — Install accessory heat pump filter-

drier (Table 4) in system liquid line when refrig

erant system is opened for service as described under

Compressor Removal. Position drier in liquid line at

convenient location.

N0.1 N0.2

INDOOR COMPRESSOR SECTION-TOP VIEW

ACCESSORY

OUTDOOR

THERMOSTAT

LOCATION

CONTROL

VOLTAGE

SECTION

DEFROST

THERMOSTAT'

LIQUID LINE SERVICE'

VALVE(WITH SERVICE PORT)

VAPOR LINE SERVICE VALVI

(WITH SERVICE PORT) 38HQ OUTDOOR COIL SECTION

'CONTACTOR

Fig. 14 — Component Location

SIGNAL-LOG"’

N01

N0 2

14

Page 15

1. Attach pressure gage to suction service port.

2. Frontseat the liquid line valve on the outdoor

coil section.

3. Start system and run until suction pressure

reaches 5 psig (see Caution) or low-pressure

switch opens.

4. Shut off system. Frontseat vapor line valve on

outdoor coil section.

5. Vent remaining pressure.

AccuRater™ (Bypass Type) Servicing — See

Fig. 15 for bypass-type AccuRater components. The

piston has a refrigerant metering orifice thru it.

The retainer forms a stop for the piston in the

refrigerant bypass mode, and a sealing surface for

liquid line flare connection. To check, clean or

replace piston:

1. Shut off power to unit.

2. Pump unit down using Pumpdown Procedure

described previously.

3. Remove liquid line flare connection from

AccuRater.

4. Pull retainer out of body being careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use locking pliers to

remove retainer.

5. Slide piston out by inserting a small, soft wire

thru metering orifice (18-gage thermostat wire).

See that metering orifice, sealing surface around

piston cones and fluted portion of piston are not

damaged.

6. Clean piston refrigerant metering orifice.

Fig. 15 — AccuRater™ (Bypass Type)

Components

7. Replace retainer O-ring before reassembling

bypass-type AccuRater. Carrier O-ring part no.

is 99CC501052.

Liquid Line Strainer (protects AccuRater) made

of wire mesh is located in the liquid line inside

indoor fan-coil unit behind liquid line service

valve (Fig. 9). Liquid line is belled and sweat con

nected where strainer is located. If strainer is

plugged, unsweat belied liquid line connection and

replace strainer.

Compatible Fitting Repair

LEAKING MECHANICAL CONNECTION —

Frontseat outdoor section service valves and relieve

refrigerant pressure in tubing and compressor

section. Back off locknut from Carrier Compatible

Fitting onto tube. Cut fitting between threads and

seal ring bead as shown in Fig. 17. Remove tubing

section remaining in threaded portion of fitting.

Discard locknut.

Clean, flux and insert new tube end into remain

ing portion of Carrier Compatible Fitting. Wrap

valve base (outdoor unit) in wet cloth. Heat and

apply low-temperature solder (430 F).

LEAKING SWEAT CONNECTION — Frontseat

service valves and relieve refrigerant pressure in

tubing. Clean and flux area around leak and apply

low-temperature solder (430 F).

Evacuate or purge indoor fan-coil, compressor

section and tubing system. Add refrigerant charge

as described in Service, Refrigerant Charging.

LEAKING FLARE CONNECTION — Cut and

reflare 3/8-in. system liquid line.

MAINTENANCE

CAUTION: Eefo/® pedbrmstj^

OUTDOOR FAN MOTOR BEARINGS are pre

lubricated for 3 years heavy duty or 5 years normal

duty. When lubrication is necessary, it should be

lubricated in a motor repair shop.

Outdoor Coil Cleaning — Ensure power to unit is

shut off. Clean the outdoor unit coil with water at

the beginning of every cooling season or more often

if required. Use ordinary garden hose at a pressure

high enough to clean efficiently. For best results,

unscrew and remove unit top cover (grille).

Insert hose nozzle between fan blades and spray

coil fins from inside-to-outside the unit. If unit has

a double-row coil, loosen screws to separate coils,

carefully pull outer row of coils away slightly from

inner row. Do not strain coil tubing connections.

Flush dirt toward outside of both coils. Flush dirt

from basepan by spraying water thru top of unit.

Avoid splashing mud on coil or water on fan motor.

Make sure that water drainage holes under outdoor

coil are not obstructed.

15

Page 16

Outdoor Fan Adjustment — Required fan posi

tion is shown in Fig. 16. Adjust fan by loosening set

screws and moving fan blades up or down.

Fig. 16 — Condenser Fan Position

FAN MOTOR REMOVAL

1. Shut off power to outdoor coil.

2. Remove top cover (grille). Open or remove

service door. Remove junction box cover.

3. Disconnect fan motor leads in line-voltage sec

tion of junction box. See Fig. 14.

4. Remove fan from motor shaft by loosening

setscrews and pulling upward on fan hub.

5. Remove bolt holding fan motor to motor mount

ing bracket. Remove motor with wiring thru

top of unit.

To replace motor: place motor on motor mount

ing bracket and retighten bolt.

Before replacing metal fan, be sure rain shield

(Fig. 16) is in place on motor shaft.

Fig. 17 — Carrier Compatible Fitting

16

Page 17

TROUBLESHOOTING GUIDE — COOLING

r

/■

\

SYMPTOM AND PROBABLE CAUSE

COMPRESSOR WILL NOT RUN OR SHUTS

OFF — WILL NOT RESTART

Contactor open

1. Burned out transformer, open thermostat

circuit, open overload.

2. Power supply interrupted.

3. Power circuit is open due to loose electrical

connection, open compressor safety device.

Contactor or coil defective.

4. Signal-Loc™ malfunction.

Contactor Closed, or Closes then Opens

1. Compressor power is out, compressor motor is

burned out or internal overloads are open.

Timer circuit (clock or switch) is faulty.

2. Compressor stuck.

3. Control circuit open due to faulty low-voltage

transformer or defective control circuit

compartment.

PROBABLE REMEDY

1. Check control circuit component and wiring. Refer

to unit label diagram, check all safety devices.

Refer to Standard Service Techniques Manual,

Chapter 2, Electrical.

2. Check for blown fuses or tripped circuit breakers.

3. Check power wire connection for tightness. Check

compressor internal thermostat, overloads (see

label diagram). Check contactor, replace if

defective.

4. Check wire connections. Check continuity thru

terminals 2 and 3. Check to see if power wire has

been routed thru current loop.

1. Check main power supply and wiring. Refer to

Electrical Data table and label diagram. Check

defrost timer circuit relay. Check defrost control

contacts. Replace defective controls.

2. Check start capacitor. Check compressor motor

windings.

3. Review label diagrams. Check control power

wires, connections. Check control transformer

power output (24 v). Check remote control center

contacts and temperature settings.

COMPRESSOR RUNS BUT COOLING IS

INSUFFICIENT

1. Low suction pressure or incorrect superheat.

2. Restricted airflow due to dirty filters, duct

obstruction or indoor coil icing. Refrigerant

system obstructed. Filter-drier obstructed or

refrigerant flow is insufficient.

3. High suction pressure/low head pressure due

to open internal pressure relief, defective com

pressor valves or faulty reversing valve.

4. High suction pressure/low superheat (com

pressor may be flooding).

COMPRESSOR CYCLES ON AND OFF

1. Internal overloads are opening or refrigerant

system is dirty. High or low pressure switch is

opening.

2. Faulty timer or defrost control operation.

Run capacitor faulty.

3. Fan motors operate intermittently.

4. Reversing valve in mid-position.

1 Check Refrigerant Charging procedure, charging

charts. Check AccuRater™ for proper piston.

2. Check indoor air system for obstructions — dirty

filters, ductwork debris, improper fan speed.

Expansion valve or AccuRater improperly sized.

3. Check Carrier Compressor Service Manual for

compressor repair procedures. See Compressor

Removal. Check reversing valve solenoid opera

tion and valve seats.

4. Check refrigerant flow device Check that maxi

mum elevation between indoor and outdoor units

is not too great Check refrigerant charge

1. Check refrigerant system for noncondensables, or

improper charge. See Refrigerant Charging.

Check for airflow obstructions See Coil Cleaning.

2. Check timer or defrost control relays and con

tacts. Replace fun capacitor.

3. Check motor leads and overloads.

4. Check reversing valve solenoid. See label diagram.

Check that dirt in refrigerant system does not

cause valve to "hang up."

17

Page 18

TROUBLESHOOTING GUIDE — HEATING

SYMPTOM AND PROBABLE CAUSE

NO HEATING (Compressor Will Not Run)

1. Main power circuit open due to faulty power

supply.

2. Control power circuit open or faulty.

3. Defrost control malfunctioning.

4. Signal-Loc™ malfunction.

INSUFFICIENT HEATING (Compressor Runs or

Cycles)

1. Low suction and low head pressure due to

coil obstruction in airflow or refrigerant circuit.

2. High suction, low superheat.

PROBABLE REMEDY

Check power supply, main power wire connec

1.

tions, fuses. See Electrical Data.

2. Check low voltage transformer, remote control

center, control relay and contacts, timer relay and

motor, compressor overloads and pressurestats

for faulty operation. Review component headings

in Service section. Check unit label diagram(s).

3. Check Defrost control procedure to be sure defrost

thermostat and relay are operational.

4. Check wire connections. Check continuity thru

terminals 2 and 3 Check to see if power wire has

been routed thru current loop.

1 Check coil for obstruction (dirt, debris). Check that

outdoor air fan is correctly positioned and turns

freely. Review fan clearance requirements and

coil cleaning procedure. Check liquid line drier,

AccuRater.

2. Check refrigerant flow device Check refrigerant

charge.

3. Frozen outdoor coil.

4. Accessory electric resistance heaters not

operating.

5. High suction, low head pressures (caused by

refrigerant system or indoor fan problem).

6. Low suction, high head pressures (may be

accompanied by low airflow at air outlets).

7. Compressor no. 2 fails to start due to failure of

outdoor thermostat.

3. Check fan operation, coil cleanliness. Check

defrost control circuit. Check refrigerant charge

(use Charging Charts and/or Operational Check

Charts).

4. Check heater power supply, outdoor thermostats

and their settings Check that heater elements are

not broken.

5. Reversing valve may be leaking or "hung-up "

Check valve and its solenoid for correct operation

Replace if suspect

Indoor fan motor capacitor may be defective

Replace capacitor Fan may be cycling on over

loads. Check overloads, loose terminal connec

tions Fan motor may be burned out. Check and

replace or lubricate See Fan Adjustment. Replace

or repair motor or fan as necessary.

6. Check for restricted refrigerant system com

ponent. Check Heating Operational Check charts

to detect even charge. Check system for non

condensables. Refer to Standard Service Tech

niques Manual, Chapter 1, Refrigerants.

7 Check outdoor ambient switch. Switch should be

closed when ambient is below switch set point.

18

Page 19

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book14

Tab

5a

5a

Form 38HQ-6SI New Printed in U S A 8-79

PC 101 Catalog No 533-892

Loading...

Loading...