Carrier 42HWG007, 42HQG012, 42HQG007, 42HQG009, 42HWG012 Technical Data & Service Manual

...

INDOOR UNIT

42HWG007/009/012/018/024

42HQG007/009/012/018/024

HWG195C/225C/305C/455C/605C

HWG195H/225H/305H/455H/605H

SPLIT SYSTEM AIR CONDITIONER

42HWG-Series, 42HQG-Series, HWG

...

H-Series, HWG

...

C-Series

O

N/O

FF

T

EM

P

SLE

E

P

TECHNICAL DATA & SERVICE MANUAL

1

Contents

11. SPECIFICATIONS........................................................................................................................2

12. OUTLINE AND DIMENSIONS .....................................................................................................6

13. OPERATION ................................................................................................................................7

14. WIRING DIAGRAM ....................................................................................................................29

15. REFRIGERANT CYCLE ............................................................................................................33

16. CONTROL BLOCK DIAGRAM...................................................................................................35

17. ELECTRIC CIRCUIT DIAGRAM ................................................................................................37

18. KEY COMPONENTS OF ELECTRONIC CIRCUIT ...................................................................50

19. CHECKING AND REPAIRING OF ELECTRIC PARTS..............................................................55

10. TROUBLE SHOOTING ..............................................................................................................59

11. DISASSEMBLY INSTRUCTIONS ......................................................................................61

12. EXPLODED DIAGRAM AND PARTS LIST ........................................................................63

13. EXTENDING RATINGS .....................................................................................................71

14. DIP SWITCH CONFIGURATION FOR ETO ......................................................................87

2

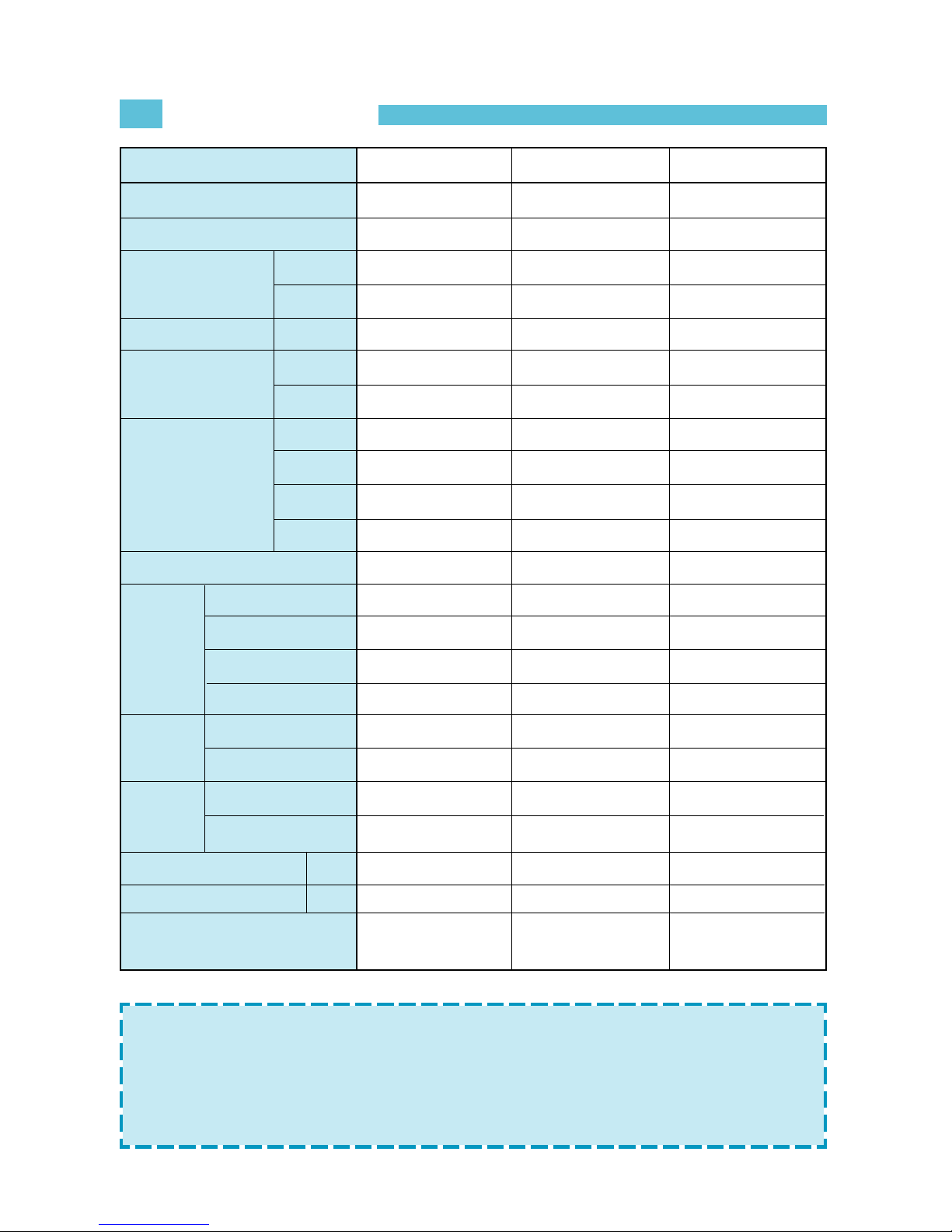

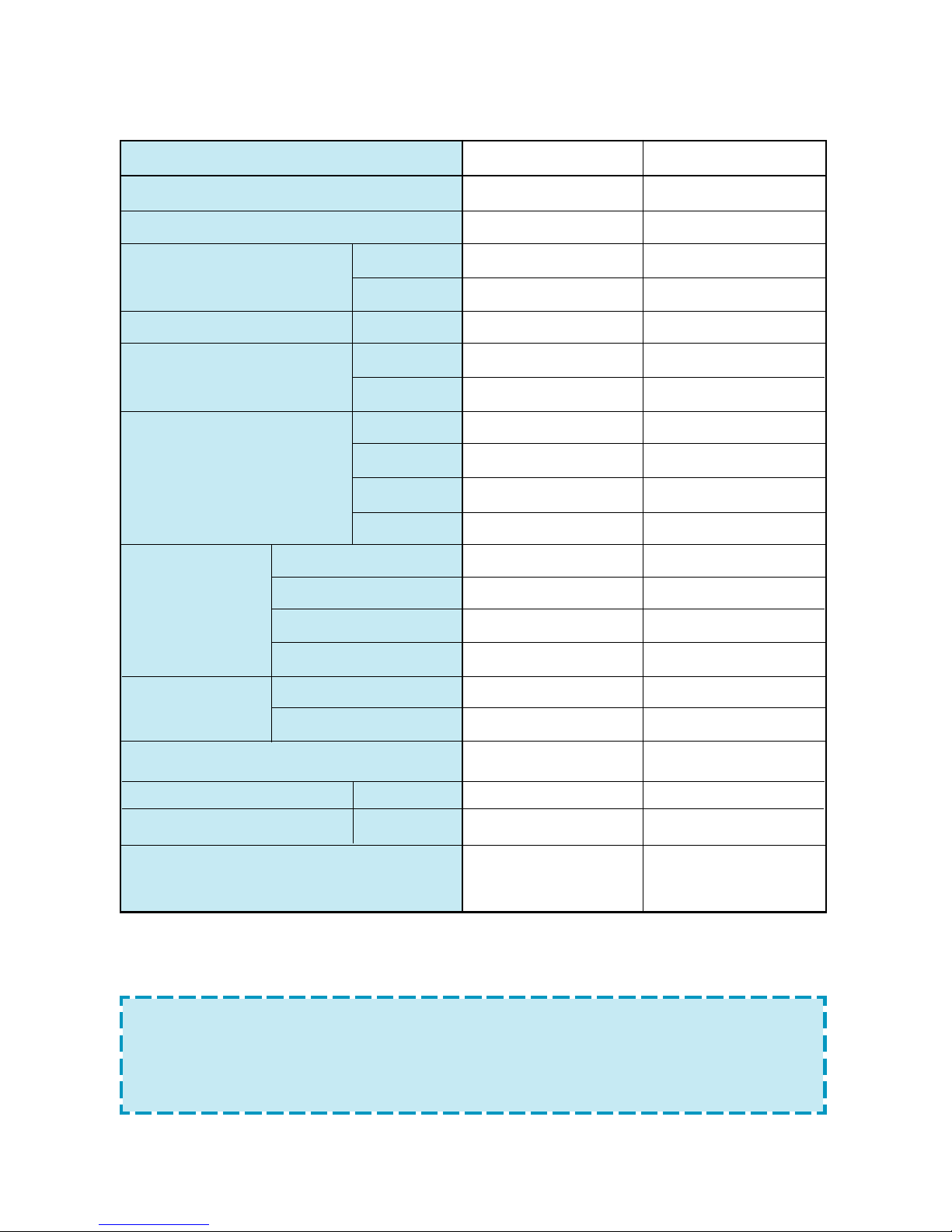

SPECIFICATIONS

1

Model

Function

Power Supply

Capacity

W

Btu/h

Dehumidification L/h

Electrical data A

(ID unit only) W

Electrical data A

(System) W

A

max (*)

W

max (*)

Type

Fan

RPM (Hi/Lo)

Capacitor

Motor Model Number

Connection

Type

OD (Liquid/Suction)

Cord

Power supplied to

connection

indoor unit

conductor

Power supplied to

size

outdoor unit

Dimension (WxHxD) mm

Net Weight Kg

OD MODEL

42HWG007/HWG195C

Cooling

230V-1PH-50Hz

2050

7000

0.8

0.11

25

3.1

700

4.2

890

Indoor unit

Cross flow fan

1000/800

1.0µF, 450V

IC-8415G1KG7A

Flare

1/4”(6.35),3/8”(9.52)

R,C,Y: 2.5mm

2

R,C,Y: 1.0mm

2

780x240x170

8

38GL--07---703EC-40

SKY195C

42HWG009/HWG225C

Cooling

230V-1PH-50Hz

2410

8300

1.0

0.11

25

4.2

930

5.6

1200

Indoor unit

Cross flow fan

1100/900

1.0µF, 450V

IC-8415G1KG7A

Flare

1/4”(6.35),3/8”(9.52)

R,C,Y: 2.5mm

2

R,C,Y: 1.0mm

2

780x240x170

8

38GL--09---703EC-40

SKY225C

42HWG012/HWG305C

Cooling

230V-1PH-50Hz

3140

10700

1.4

0.16

36

5.3

1190

8.0

1700

Indoor unit

Cross flow fan

1050/850

1.0µF, 450V

IC-9420G2KG7A

Flare

1/4”(6.35),1/2”(12.7)

R,C,Y: 2.5mm

2

R,C,Y: 1.0mm

2

815x260x185

9

38GL--12---703EC-40

SKY305C

NOTE: •

Above the datum for running current and power input mean the value

tested in the following conditions.

1) Ambient temperature : Tid=27/19ºC, Tod=35ºC in cooling.

2) (*)Severe operating conditions: Tid=32/23ºC, Tod=43ºC in cooling.

3) Voltage: 198/264V.

•

Specifications can change without notice.

3

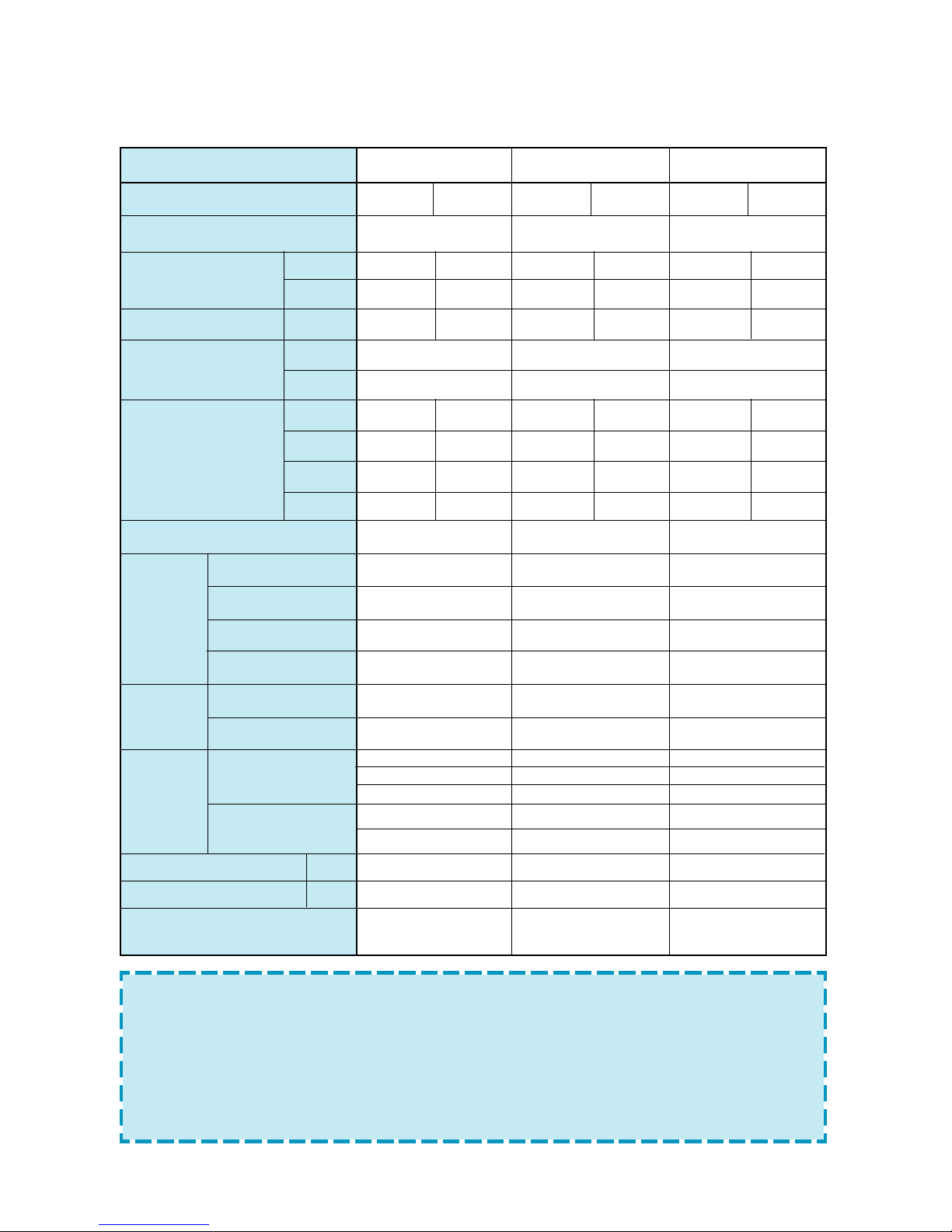

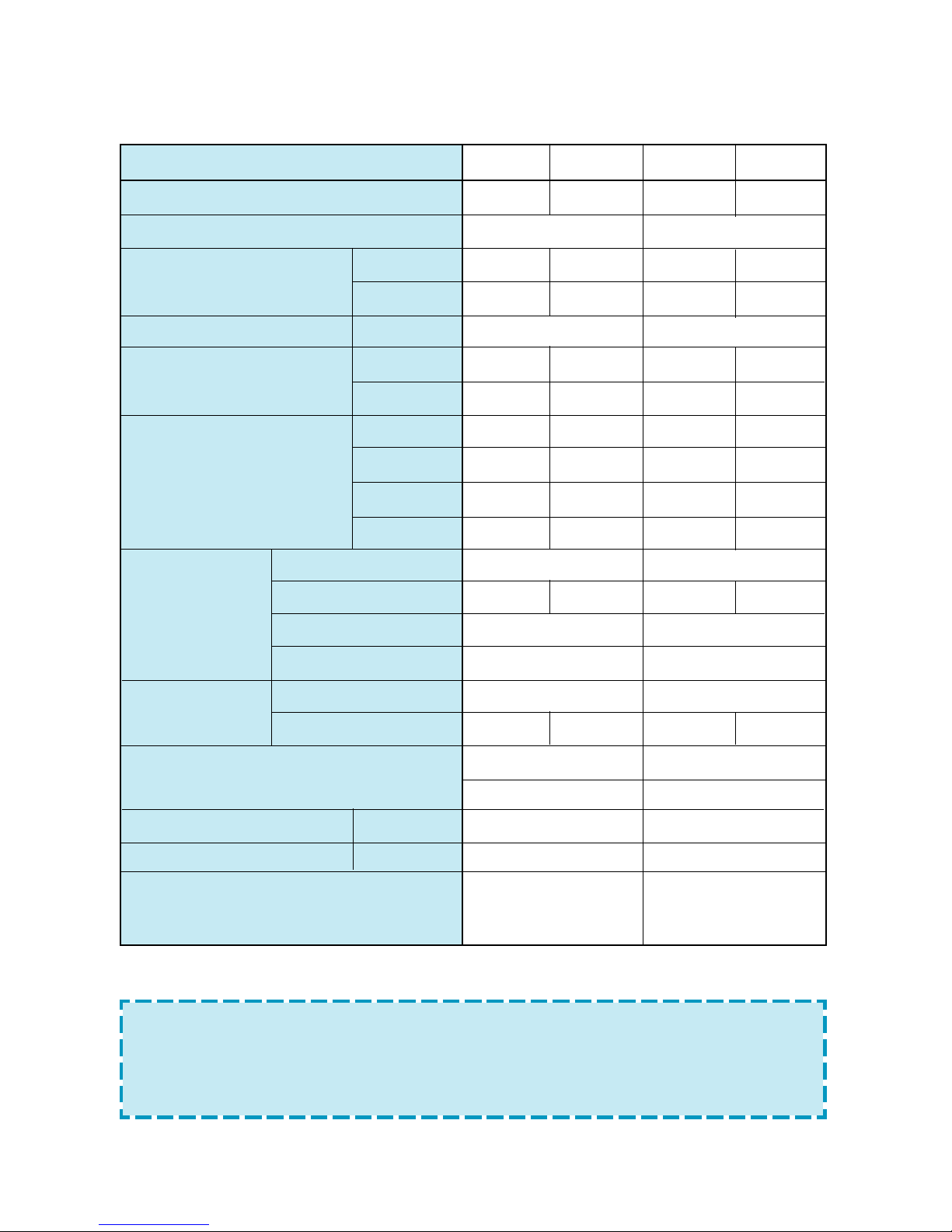

NOTE: •

Above the datum for running current and power input mean the value

tested in the following conditions.

1) Ambient temperature : Tid=27/19ºC, Tod=35ºC in cooling and

Tid=20ºC, Tod=7/6ºC in heating. Voltage 230V.

2) (*)Severe operating conditions: Tid=32/23ºC, Tod=43ºC in cooling and

Tid=27ºC, Tod=24/18ºC in heating. Voltage 198/264V.

•

Specifications can change without notice.

Model

Function

Power Supply

Capacity

W

Btu/h

Dehumidification L/h

Electrical data A

(ID unit only) W

Electrical data A

(System) W

A

max (*)

W max (*)

Type

Fan

RPM (Hi/Lo)

Capacitor

Motor Model Number

Connection

Type

OD (Liquid/Suction)

Power supplied to

Cord

indoor unit

connection

conductor

Power supplied to

size

outdoor unit

Dimension (WxHxD) mm

Net Weight Kg

OD UNIT MODEL

42HQG007/HWG195H-SERIES

Cooling Heating

220/240V-1PH-50Hz

2020 2150

6900 7340

0.8 -

0.11

25

3.24 3.06

730 690

4.5 4.6

920 890

Indoor unit

Cross flow fan

1000/800

1.0µF, 450V

IC-8415G1KG7A

Flare

1/4”(6.35),3/8”(9.52)

R,C,Y : 2.5mm

2

O.W2 : 1.0mm

2

S1,S2 : 0,75mm

2

R,C,Y,O,W2 : 1.0mm

2

S1, S2 : 0,75mm

2

780x240x170

8

38YL--07---703EJ-40

SKY195HJ

42HQG009/HWG225H-SERIES

Cooling Heating

220/240V-1PH-50Hz

2350 2740

8020 9350

1.0 -

0.11

25

4.22 4.17

950 940

5.7 5.8

1230 1230

Indoor unit

Cross flow fan

1100/900

1.0µF, 450V

IC-8415G1KG7A

Flare

1/4”(6.35),3/8”(9.52)

R,C,Y : 2.5mm

2

O.W2 : 1.0mm

2

S1,S2 : 0,75mm

2

R,C,Y,O,W2 : 1.0mm

2

S1, S2 : 0,75mm

2

780x240x170

8

38YL--09---703EJ-40

SKY225HJ

42HQG012/HWG305H-SERIES

Cooling Heating

220/240V-1PH-50Hz

3110 3250

10600 11000

1.4 -

0.16

36

5.4 4.44

1220 1020

8.1 7.0

1700 1300

Indoor unit

Cross flow fan

1050/850

1.0µF, 450V

IC-9420G2KG7A

Flare

1/4”(6.35),1/2”(12.7)

R,C,Y : 2.5mm

2

O.W2 : 1.0mm

2

S1,S2 : 0,75mm

2

R,C,Y,O,W2 : 1.0mm

2

S1, S2 : 0,75mm

2

815x260x185

9

38YL--12---703EJ-40

SKY305HJ

4

Model

Function

Power Supply

Capacity

W

Btu/h

L/h

Electrical data A

(ID unit only) W

Electrical data A

(System) W

A

max (*)

W

max (*)

Type

Fan

RPM (Hi/Lo)

Capacitor

Motor Model Number

Connection

Type

OD (Liquid/Suction)

Cord connection conductor size

(Power supplied to outdoor unit)

Dimension (WxHxD) mm

Net Weight Kg

OD UNIT

42HWG018 / HWG455C

Cooling

230V-1PH-50Hz

4690

16007

1.7

0.19

45

7.9

1780

20

2270

Cross flow fan

1150/950

1.8µF, 450V

IC-9430G4KG7A

Flare

1/4”(6.35) 1/2”(12.7)

R,C,Y: 1.0mm

2

1080x295x185

14

38GL--18---703EC-40

SKY455C

42HWG024 / HWG605C

Cooling

230V-1PH-50Hz

6240

21300

2.5

0.19

45

10.6

2420

17

3300

Cross flow fan

1250/1050

1.8µF, 450V

IC-9430G4KG7A

Flare

1/4”(6.35) 5/8”(15.88)

R,C,Y: 1.0mm

2

1080x295x185

14

38GL--24---703EC-40

SKY605C

NOTE: • Cooling capacity test is performed through temperature condition based

on 27ºC D.B., 19ºC W.B., in indoor and 35ºC D.B., 24ºC W.B. in outdoor.

• Cooling capacity test is performed at high voltage.

• Specification can change without notice.

5

Model

Function

Power Supply

Capacity

W

Btu/h

L/h

Electrical data A

(ID unit only) W

Electrical data A

(System) W

A

max (*)

W

max (*)

Type

Fan

RPM (Hi/Lo)

Capacitor

Motor Model Number

Connection

Type

OD (Liquid/Suction)

Cord connection conductor size

(Power supplied to outdoor unit)

Dimension (WxHxD) mm

Net Weight Kg

OD UNIT

42HQG018 HWG455H

Cooling Heating

230V-1PH-50Hz

4790 5100

16360 17420

1.7

0.19 0.19

45 45

7.3 6.7

1630 1490

x 8.0

2270 1800

Cross flow fan

1150 950

1.8µF, 450V

IC-9430G4KG7A

Flare

1/4”(6.35) 1/2”(12.7)

R,C,Y,O,W2 : 1.0mm

2

S1, S2 : 0.75mm

2

1080x295x185

14

38YL--18---703EC-40

SKY455HJ

42HQG024 HWG605H

Cooling Heating

230V-1PH-50Hz

6110 7170

20886 24486

2.5

0.19 0.19

45 45

10.7 11

2430 2480

17.0 14.6

3300 2900

Cross flow fan

1250 1050

1.8µF, 450V

IC-9430G4KG7A

Flare

1/4”(6.35) 5/8”(15.88)

R,C,Y,O,W2 : 1.0mm

2

S1, S2 : 0.75mm

2

1080x295x185

14

38YL--24---703EC-40

SKY605HJ

NOTE: • Cooling capacity test is performed through temperature condition based

on 27ºC D.B., 19ºC W.B., in indoor and 35ºC D.B., 24ºC W.B. in outdoor.

• Cooling capacity test is performed at high voltage.

• Specification can change without notice.

6

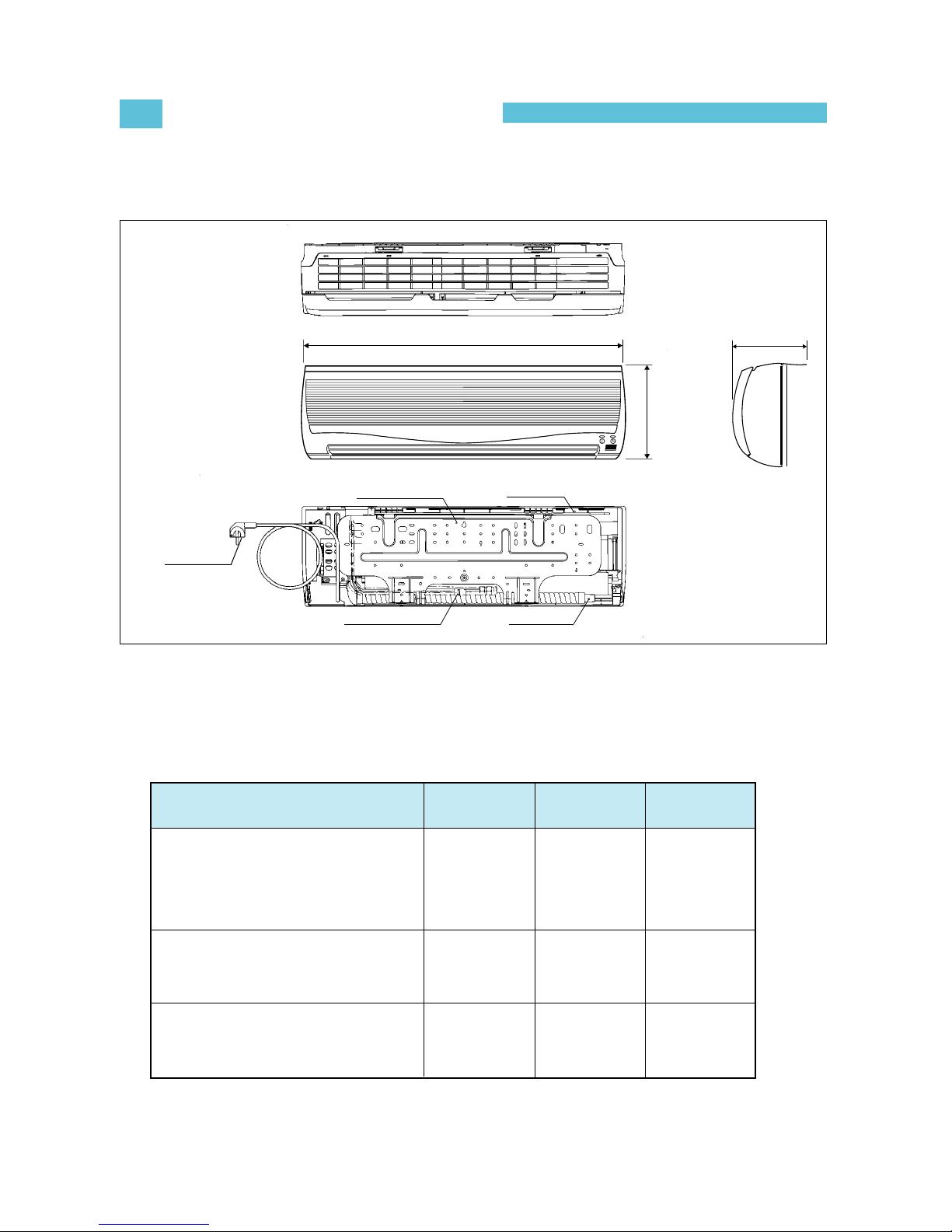

OUTLINE AND DIMENSIONS

2

INDOOR UNIT

MODEL

42HWG007/009

42HQG007/009

HWG195C/195H/225C/225H

42HWG012,42HQG012,

HWG305C/305H

42HWG018/024, 42HQG018/024,

HWG455C/455H/605C/605H

A

780

815

1080

B

240

260

295

C

170

185

185

C

A

B

MOUNTING PLATE

MAIN BODY

POWER PLUG

DRAIN HOSE

CONNECTION TUBE

7

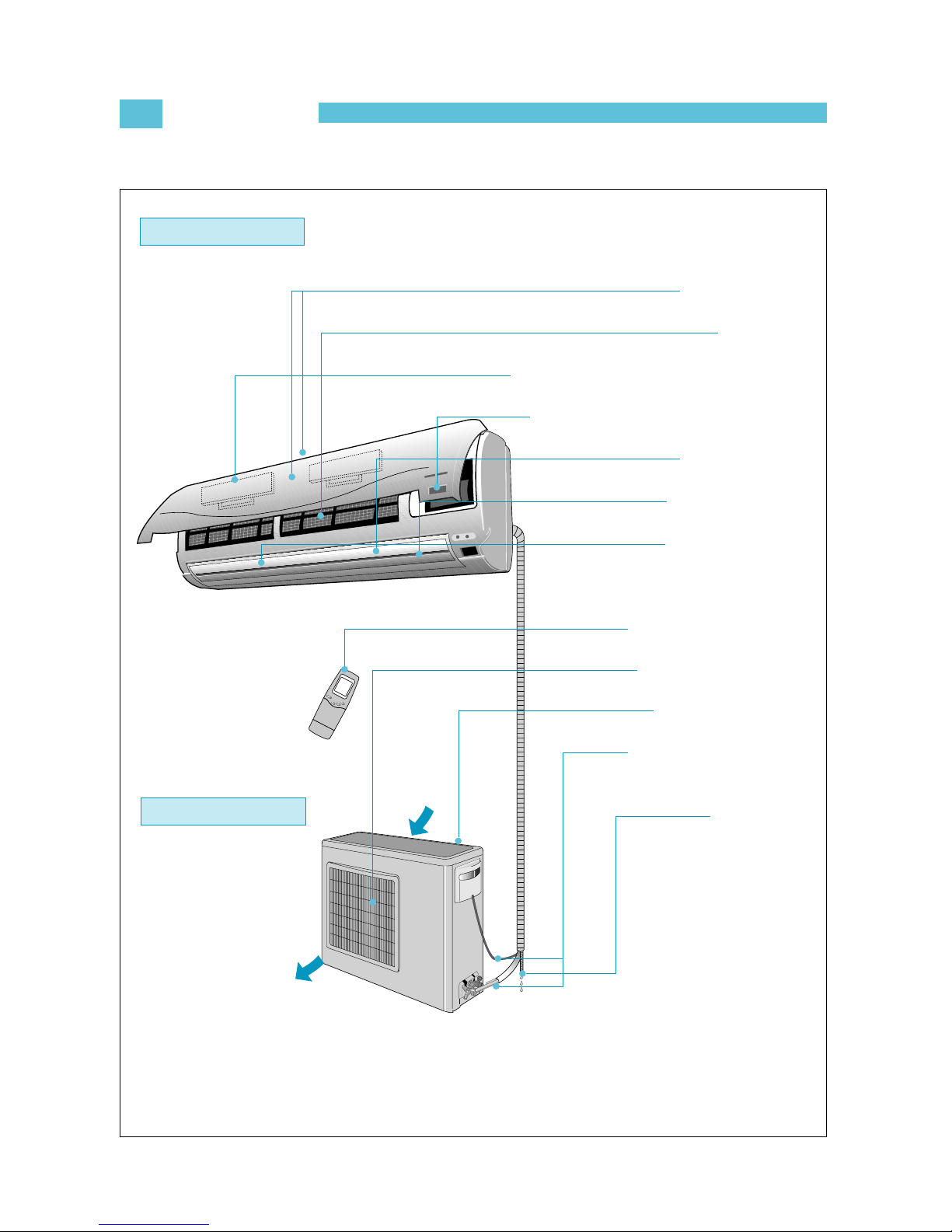

OPERATION

3

1) SYSTEM DIAGRAM

Indoor Unit

O

N

/O

F

F

T

E

M

P

S

L

E

E

P

ROOM AIR INLET

AIR FILTER

ELECTROSTATIC/ACTIVE CARBON FILTER

REMOTE CONTROL SIGNAL RECEIVER

AIR SWING FLAP

VERTICAL LOUVER

ROOM AIR OUTLET

LCD REMOTE CONTROL

OUTDOOR AIR OUTLET

OUTDOOR AIR INLET

INDOOR AND OUTDOOR

CONNECTION

DRAIN HOSE

Outdoor Unit

8

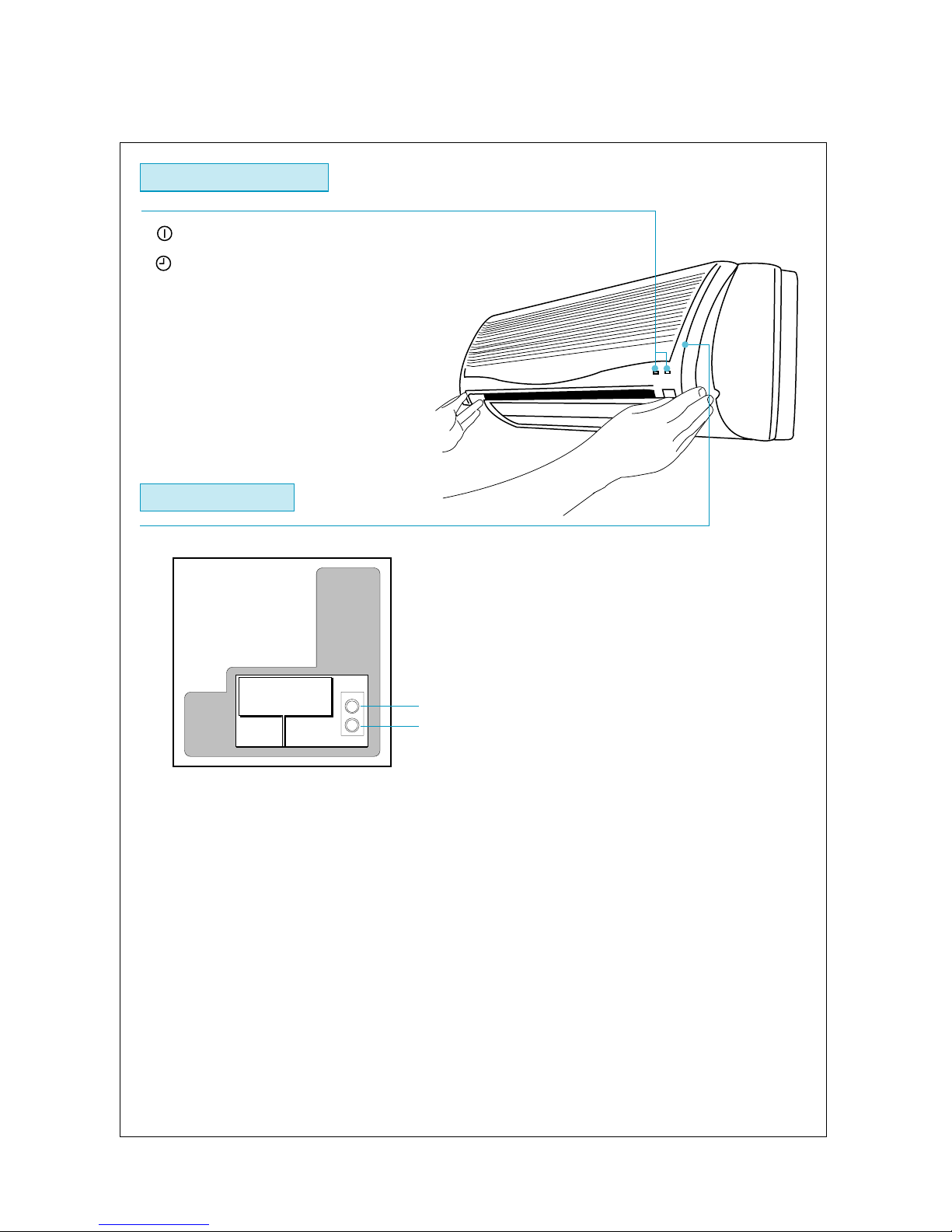

2) INDOOR UNIT DISPLAY AND SWITCH PANEL

.

(Green) : Lights during the operation.

.

(Orange) : Lights during timer mode.

Indoor Unit Display

Switches Panel

EMERG.

TEST

.

EMERG. button :

Can be used when the remote control is missed or inoperative.

.

TEST button :

Is only used by service men to test the unit operation.

.

For the usage of EMERG. and TEST buttons, refer to page 24.

“(8) Emergency and Test Operation.”

9

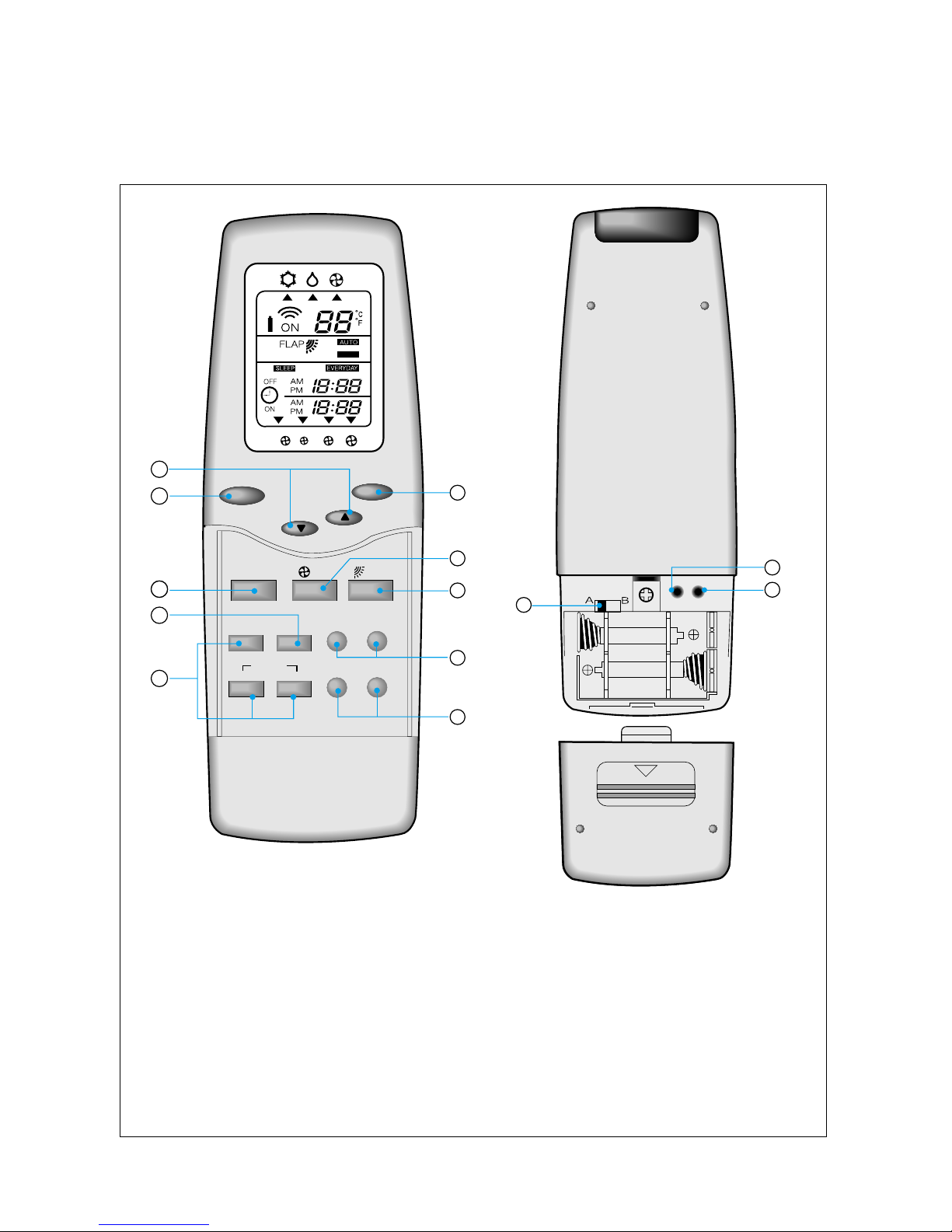

3) NAMES AND FUNCTIONS OF REMOTE CONTROLLER

• 42HWG007/009/012/018/024

HWG195C/225C/305C/455C/605C

RST TA

3

5

6

8

9

I / O

TEMP

.

SLEEP

MODE FLAP

CLOCK EVERYDAYHOUR MINUTE

SETTIMER

ON OFF

CANCEL

10

10

2

1

4

7

SWING

LR03(AM4)1.5V

LR03(AM4)1.5V

11

12

13

A

FAN

I/O BUTTON

TEMPERATURE SETTING BUTTONS

SLEEP TIMER BUTTON

OPERATION MODE SELECTING

BUTTON

FAN SPEED SELECTING BUTTON

FLAP CONTROL BUTTON

ON/OFF TIMER AND CURRENT

TIME BUTTONS

HOUR/MINUTE SETTING BUTTONS

SET AND CANCEL

BUTTONS

EVERYDAY TIMER BUTTON

CURRENT TIME ADJUSTING

BUTTON

RESET BUTTON

ADDRESS SWITCH

10

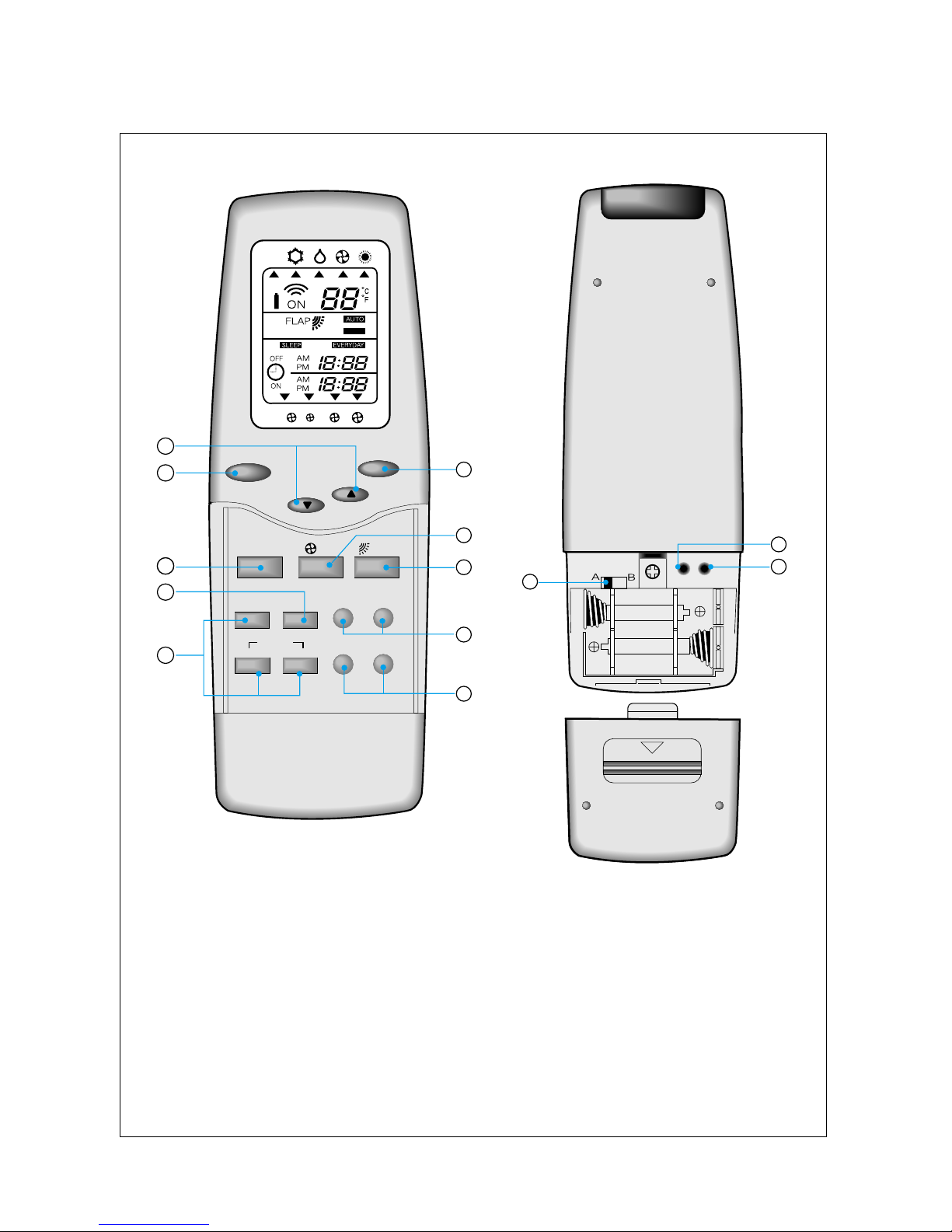

• 42HQG007/009/012/018/024 & HWG195H/225H/305H/455H/605H

I/O BUTTON

TEMPERATURE SETTING BUTTONS

SLEEP TIMER BUTTON

OPERATION MODE SELECTING

BUTTON

FAN SPEED SELECTING BUTTON

FLAP CONTROL BUTTON

ON/OFF TIMER AND CURRENT

TIME BUTTONS

HOUR/MINUTE SETTING BUTTONS

SET AND CANCEL

BUTTONS

EVERYDAY TIMER BUTTON

CURRENT TIME ADJUSTING

BUTTON

RESET BUTTON

ADDRESS SWITCH

RST TA

3

5

6

8

9

I / O

TEMP

.

SLEEP

MODE

CLOCK EVERYDAYHOUR MINUTE

SETTIMER

ON OFF

CANCEL

10

10

2

1

4

7

LR03(AM4)1.5V

LR03(AM4)1.5V

11

12

13

SWING

A

FLAPFAN

A

11

I/O BUTTON

Press this button to start operation. (A receiving beep is heard).

Press this button again to stop operation. (A receiving beep is heard).

When pressing the I/O button immediately after turning the unit off, the compressor

will not operate for 3 minutes to keep it from overloading.

TEMPERATURE SETTING BUTTON

Set the temperature to a desired room temperature, then unit will keep the tempera-ture to

the set temperature.

• In cooling mode, when the room temperature is higher than the setting, the com-

pressor is automatically turned on to provide a cooling effect. When the room temperature is lower than the setting, the compressor is automatically turned off to stop cooling

operation.

• In heating mode, when the room temperature is lower than the setting, the

compressor is automatically turned on to provide a heating effect. When the

room temperature is higher than the setting, the compressor is automatically

turned off to stop heating operation.

(42HQG007/009/012/018/024 & HWG195H/225H/305H/455H/605H)

However the indoor fan will run to circulate the indoor air even during turning off the

compressor.

SLEEP TIMER BUTTON

Press this button to set the sleep timer.

OPERATION MODE SELECTING BUTTON

Press this button to set the desired modes.

• DRY mode

In DRY mode, the microcomputer of the unit controls the indoor fan motor and makes

the outdoor unit automatically turn on and off according to the room tempera-

ture, and the room moisture will be removed more effectively.

• COOL mode

In COOL mode, the unit will run in normal cooling mode.

• FAN mode

In FAN mode, only the indoor fan will operate at the selected speed and circulate the room

air.

• HEAT mode (42HQG007/009/012/018/024 & HWG195H/225H/305H/455H/605H)

In HEAT mode, the unit will run in the normal heating mode.

• AUTO mode (42HQG007/009/012/018/024 & HWG195H/225H/305H/455H/605H)

In AUTO mode, the unit will operate automatically by selecting Cool or Heat mode and

Fan speed according to the room temperature.

12

FAN SPEED SELECTING BUTTON

Press this button to select the desired fan speed.

The indoor fan will operate at the selected fan speed. (AUTO, LOW, MED, HIGH)

When you select “AUTO”, the fan speed is controlled by microcomputer of the unit.

FLAP CONTROL BUTTON

Controls the discharge air flow direction up and down.

• In the beginning, the flaps open properly according to the operating mode.

• If you press this button, the flap will move stepwise and the position will be dis-

played.

• If you press this button again, the unit will operate at “SWING”. The flap will swing up

and down continuously at “SWING”.

ON/OFF TIMER AND CURRENT TIME BUTTONS

• Set the desired time for the unit control with these buttons.

• If you set ON and OFF time, the unit will be automatically turned on and off at the set

time.

• Press current time button when you want to know the current time, and the current

time is indicated.

SET AND CANCEL BUTTONS

Press SET button to reserve ON/OFF timer and if you want to cancel the reserved

time, use CANCEL button.

EVERYDAY TIMER BUTTON

Press this button at the reserved condition of the combined ON and OFF timer in

order to repeat the combined ON and OFF timer reservation everyday until the

reservation is canceled.

CURRENT TIME ADJUSTING BUTTON

Press this button to adjust the current time.

RESET BUTTON

Press this button when the remote control is not operating properly or after replacing

batteries.

ADDRESS SWITCH

If there are two indoor units in the same room, link one remote control with one indoor

unit, and link the other remote control with the other indoor unit.

HOUR/MINUTE SETTING BUTTONS

Adjust current time and ON/OFF timer with these buttons.

13

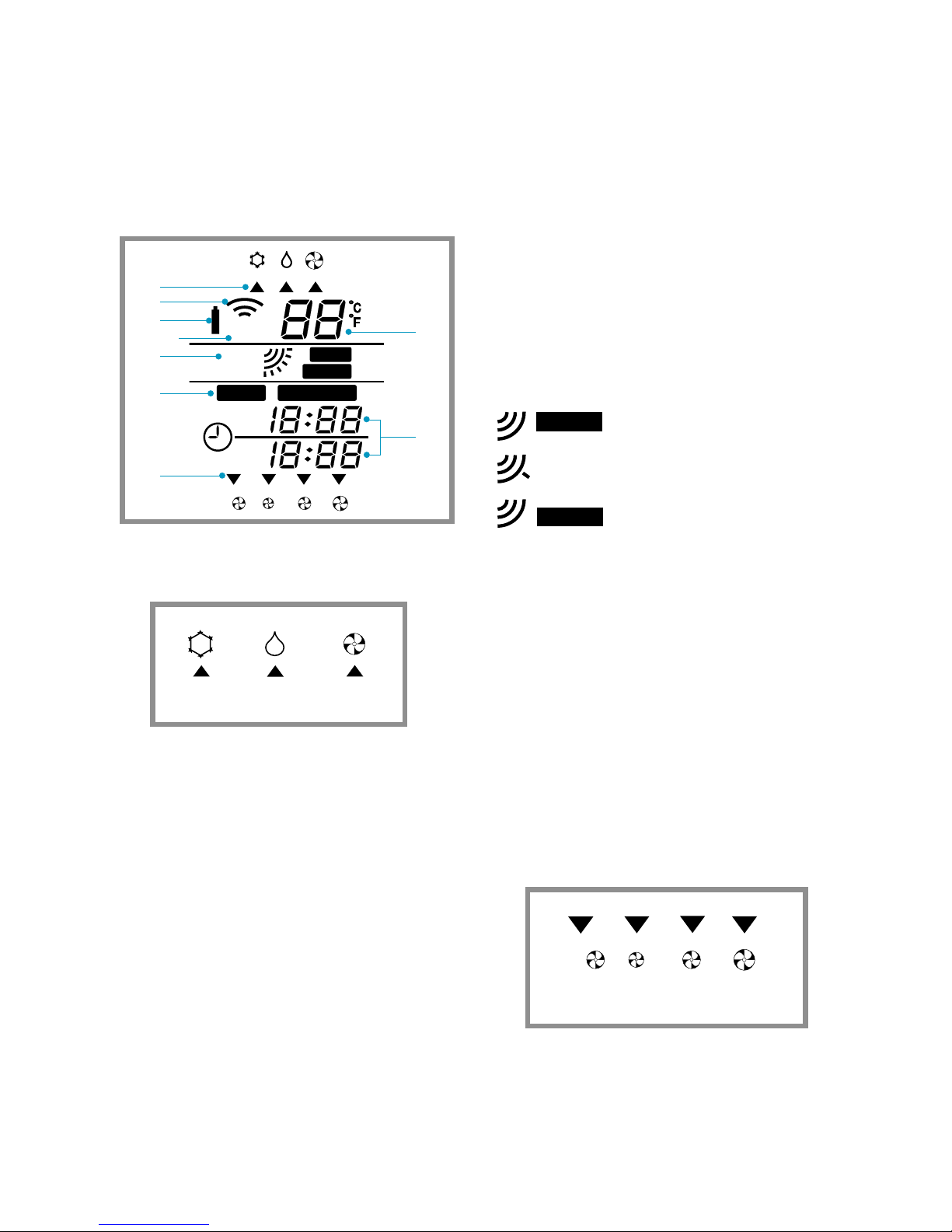

4) REMOTE CONTROLLER DISPLAY

• 42HWG007/009/012/018/024 & HWG195C/225C/305C/455C/605C

1

Indicates the selected operating mode.

2

Lights up when the signal from the remote

control is transmitted.

A receiving beep is heard from the unit.

3

Lights up when the batteries must be

replaced with new ones. When this mark

appears, replace the batteries within a week.

4

Lights up when the unit is operating.

5

Indicates the selected temperature.

6

Indicates flap modes

AUTO

SWING

Automatic position

User selected position

Swing up and down

7

Indicates the reserved status of SLEEP timer

or EVERYDAY timer.

8

Indicates the reserved time of ON timer

and OFF timer or the current time.

9

Indicates the selected fan speed.

OFF

OFF

ON

ON

AM

AM

PM

PM

AM

AM

PM

PM

FLAP

ON

AUTO

SLEEP

SLEEP

EVERYDAY

EVERYDAY

SWING

A

COOL DRY FAN

AUTO LOW MED HIGH

A

14

A

OFF

OFF

ON

ON

AM

AM

PM

PM

AM

AM

PM

PM

FLAP

FLAP

ON

AUTO

AUTO

SLEEP

SLEEP

EVERYDAY

EVERYDAY

SWING

SWING

A

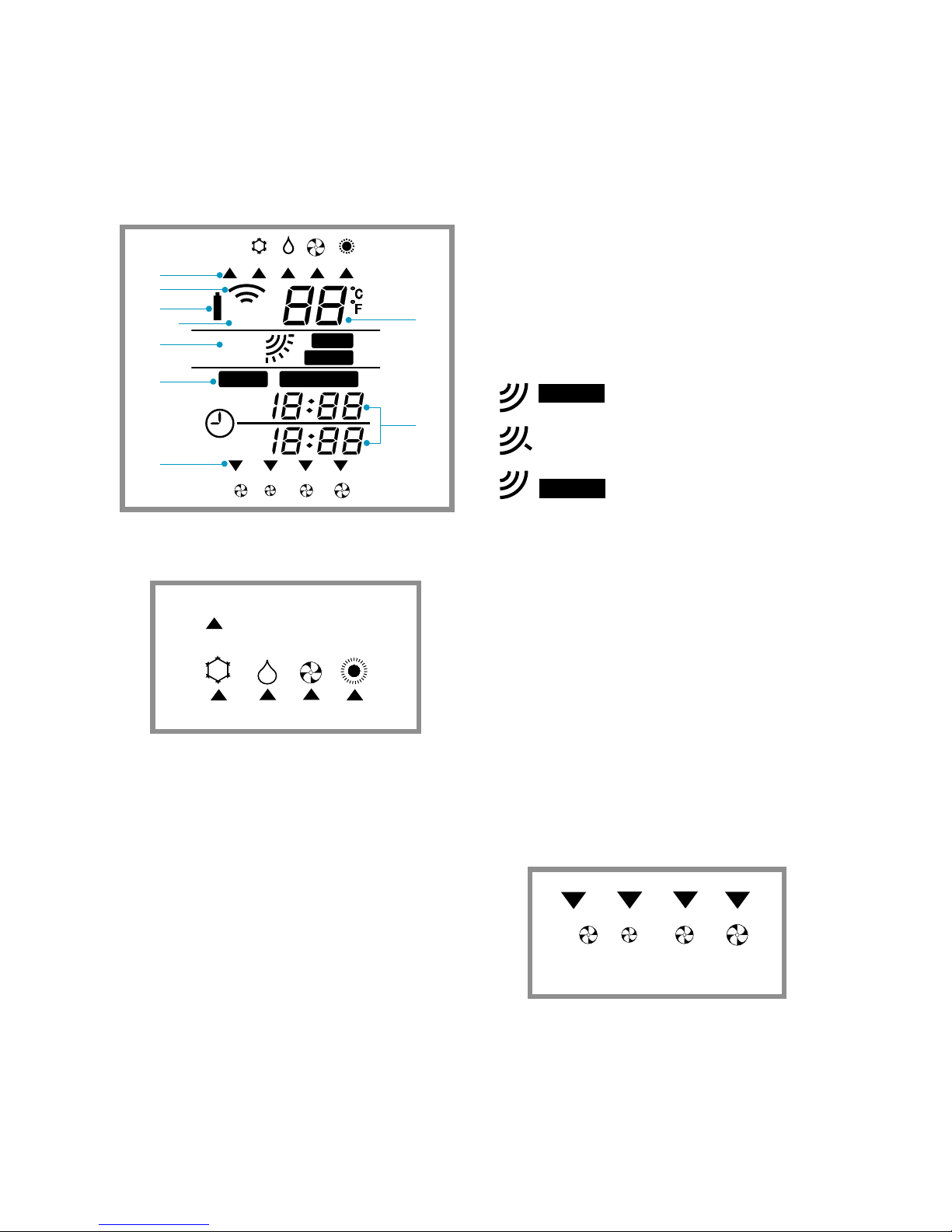

• 42HQG007/009/012/018/024 & HWG195/225/305H/455H/605H

1

Indicates the selected operating mode.

2

Lights up when the signal from the remote

control is transmitted.

A receiving beep is heard from the unit.

3

Lights up when the batteries must be

replaced with new ones. When this mark

appears, replace the batteries within a week.

4

Lights up when the unit is operating.

COOL DRY FAN

A

HEAT

AUTOMATIC CHANGEOVER

5

Indicates the selected temperature.

6

Indicates flap modes

Automatic position

User selected position

Swing up and down

7

Indicates the reserved status of SLEEP timer

or EVERYDAY timer.

8

Indicates the reserved time of ON timer

and OFF timer or the current time.

9

Indicates the selected fan speed.

AUTO

SWING

AUTO LOW MED HIGH

A

15

5) DESCRIPTION OF FUNCTIONS

(1) Timer Mode

General features

– If user changes time of ON/OFF timer during timer function execution, the timer will be

changed according to the new set time.

– The other mode changes are enabled during timer function execution.

– The maximum timer range is twenty-four hours according to the remote controller.

– If user pushes the TEST or EMERG. button during timer function execution, timer function

will be canceled.

– If unit receives the timer function signal in Test or Emergency operation, these operations

will be canceled and timer function will be operated.

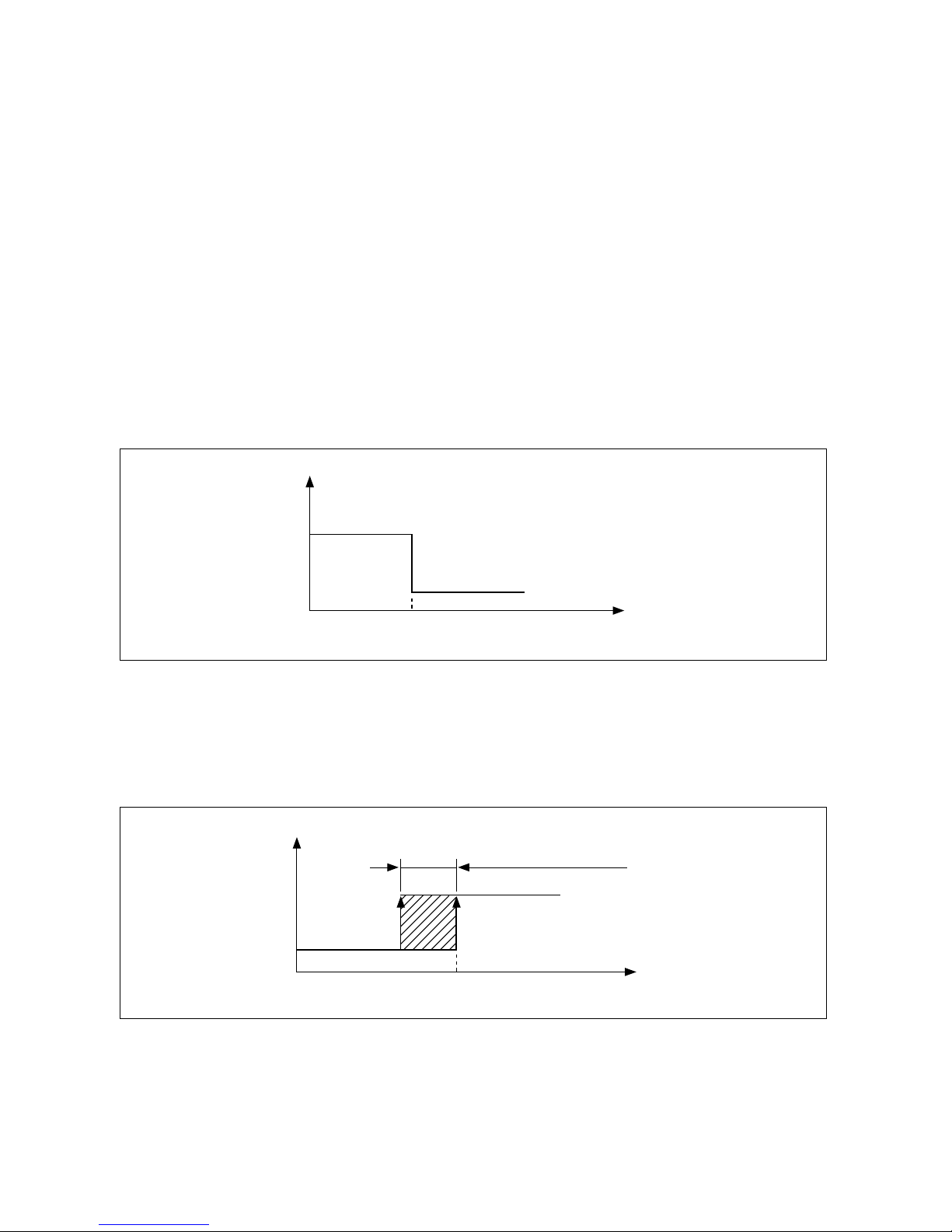

OFF-Timer

– If user sets time with OFF timer, the unit will stop at the set time.

– The unit will be turned off automatically when the set time of OFF timer is reached.

UNIT ON

UNIT OFF

HOURT.S.

T.S.=USER SET TIME

ON-Timer

– When the ON timer is set, unit monitors the room temperature before 1 hour from set time to

make the room as set condition at reserved set time.

– The actual on time of unit is decided at 0 to 40 minutes earlier than reserved on time accord-

ing to the room temperature and size.

UNIT OFF

HOUR

UNIT ON

T.S.

ACTUAL ON TIME(0~40MIN)

16

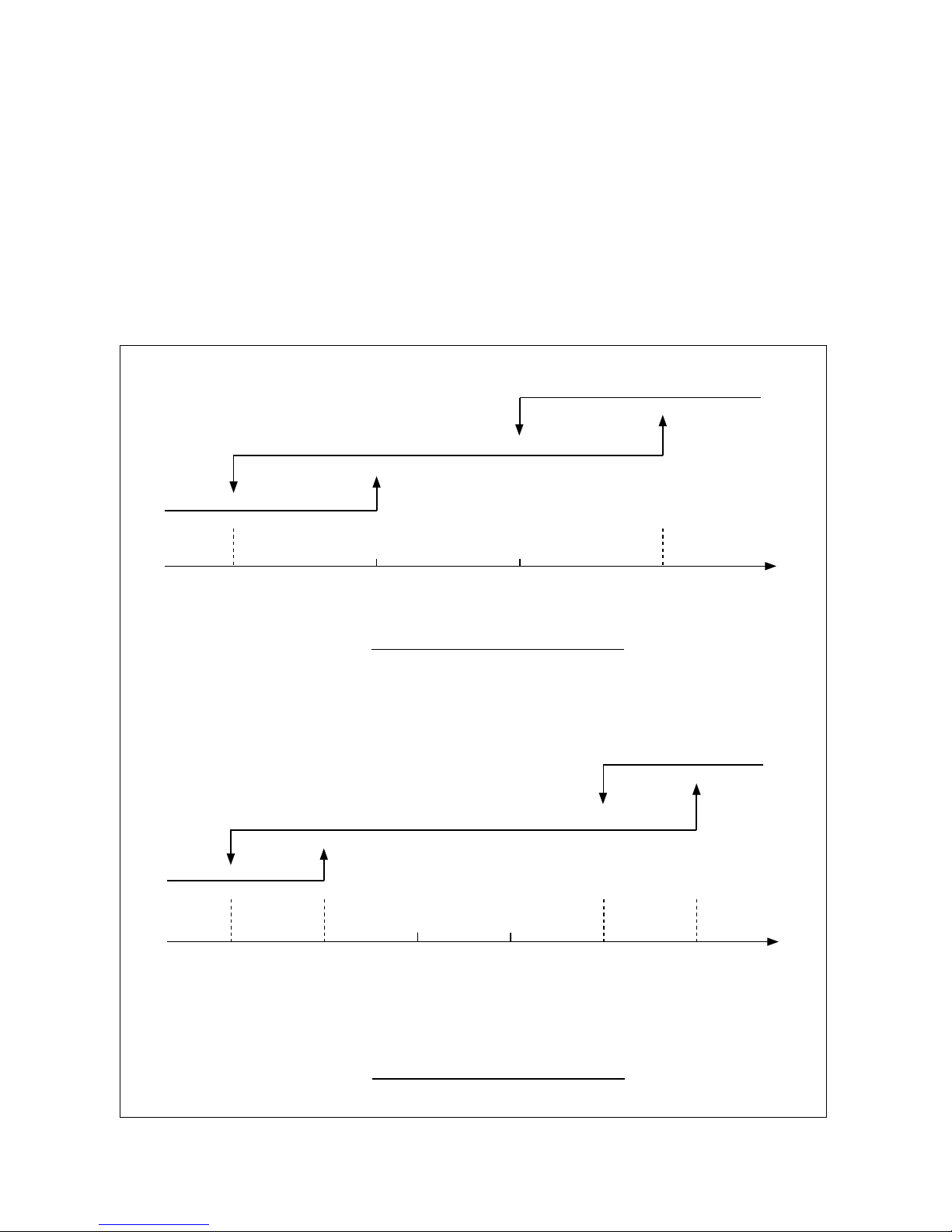

Combination of ON and OFF Timer

– If user sets time with ON/OFF timer, the unit will start and stop at the set time.

SLEEP-Timer

– When the SLEEP timer is set, the unit will control the setting temperature to avoid

overcooling in Cool operation or overheating in Heat operation.

– When the SLEEP timer is set, the luminosity of unit lamps will be dimly not to interrupt the

sleeping.

– The SLEEP timer can be combined with ON timer.

– Reserved time: 1hr, 2hr, 3hr, 7hr, 9hr

– Indoor fan will operate at low speed.

UNIT ON

UNIT OFF

HOUR

UNIT ON

ON TIMEOFF TIME

NOTE :

• The current time is not indicated during the reservation of ON/OFF timer.

• If user wants to know the current time, press the CLOCK button and the

current time will be displayed for 5 seconds.

• If user reserves the ON timer during operation, the unit will operate

continuously.

• In ON/OFF timer operation, the earlier setting compared to the current time

will operate first.

TIME (MIN.)

FOR COOLING MODE

SET TIME

30 70 110 150

SET

TEMP.

°C

+0.5°C

+0.5°C

+0.5°C

+0.5°C

TIME (MIN.)

FOR HEATING MODE

SET TIME

90 150

SET

TEMP.

°C

–1°C

–1°C

–1°C

30

17

EVERYDAY-Timer

– The EVERYDAY timer can be set in case of reserved condition of the combined ON and

OFF timer or the combined ON and SLEEP timer.

– If user sets time with EVERYDAY timer, the unit will repeat the combined ON and OFF timer

reservation everyday.

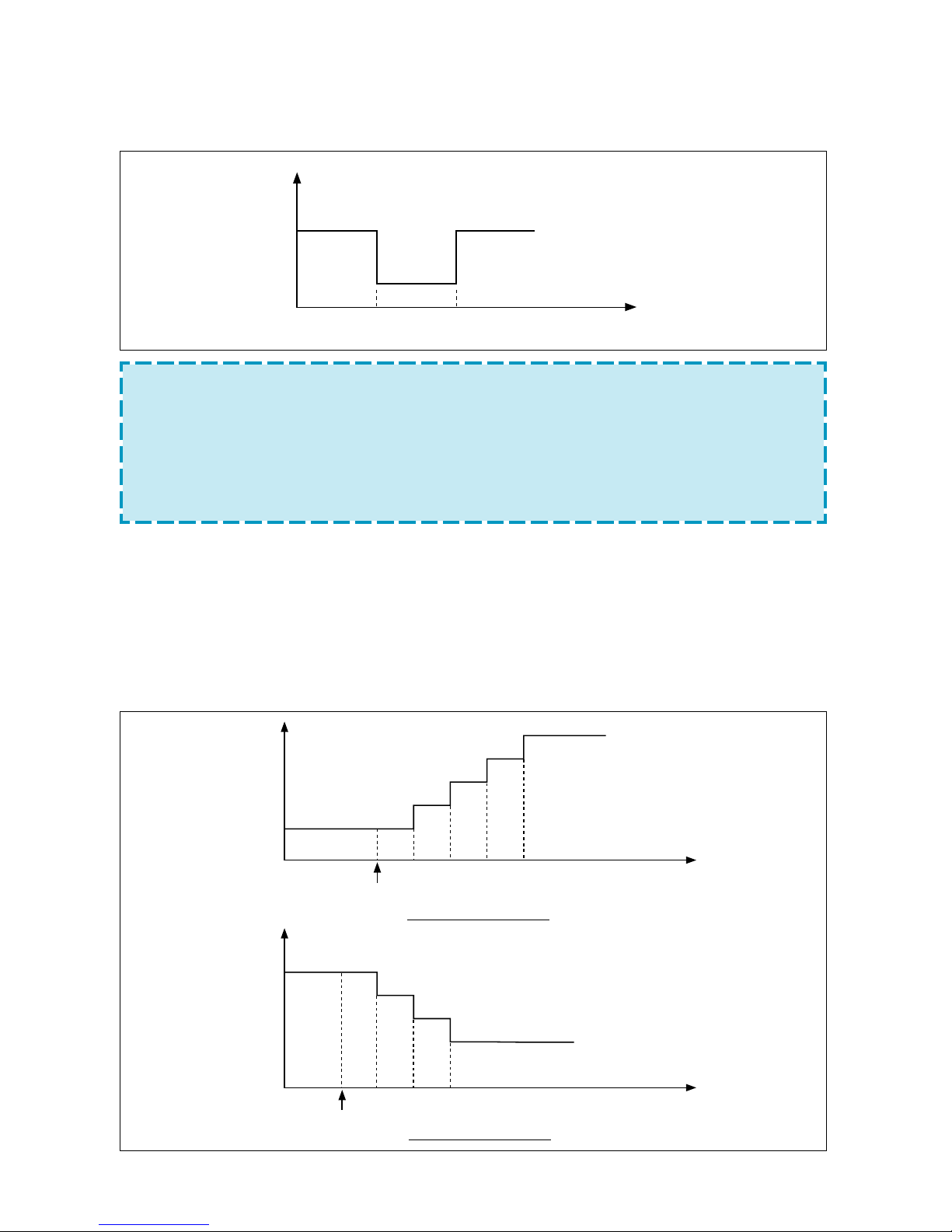

(2) Fan Speed

• User can select the fan speed of AUTO, LOW, MED and HIGH by the remote controller.

• If user selects 'AUTO' fan speed, the speed is automatically controlled according to the

room temperature. (See following figure).

(R.T-T.S)° C

LOW

MED

HIGH

0123

FAN SPEED IN AUTO COOL MODE

(T.S- R.T)° C

LOW

MED

HIGH

0 1 2 3 4 5

* R.T= ROOM TEMPERATURE

T. S= USER SET TEMPERATURE

FAN SPEED IN AUTO HEAT MODE

18

(3) Dry Mode

– This operation eliminates moisture effectively by operating the compressor, indoor and

outdoor fan motor intermittently, so that the room temperature is maintained at set

temperature.

– Determination of dry mode BLOCK based on Room temp. and Set temp.

(Set temp. : Ts)

1) Initial determination of dry mode BLOCK

CBA

Ts–2 Ts+1

2) Redetermination of dry mode BLOCK

C

B

A

Ts–2Ts–1 Ts+1 Ts+2

– Operating state according to the each BLOCK

1) BLOCK A

COMP & ODF : “ON”

IDF : operate at LOW speed

2) BLOCK B

COMP & ODF : repeat “ON” for 5 min. and “OFF” for 5 min.

IDF : operate at ULO speed

3) BLOCK C

COMP & ODF : “OFF”

IDF : operate at ULO speed

NOTE :

1. Unit determines again the dry mode BLOCK by sensing Room temp.

every 5 min.

2. 3 min. minimum operation of compressor is not applied.

19

(4) Automatic Operation

(42HQG007/009/012/018/024 & HWG195H/225H/305H/455H/605H)

– If the unit is set to ‘AUTO’ mode, the unit operates automatically by selecting COOL

or HEAT mode according to the room temperature to keep the room temperature

comfortable.

ROOM TEMPERATURE

T.S+1° C

T.S

T.S-1° C

COOLING MODE

HOLD CURRENT MODE

HEATING MODE

– When the room temperature is lower than 21°C or is higher than 29°C, the unit

operates Heating or Cooling operation regardless of the user set temperature.

This Automatic operation is not suitable for the application to the computer

room or some food/wine stock storage

21° C

COOL/HEAT TRANSITION

HEATING

ONLY

COOLING

ONLY

SENSED

ROOM TEMP.

29° C

20

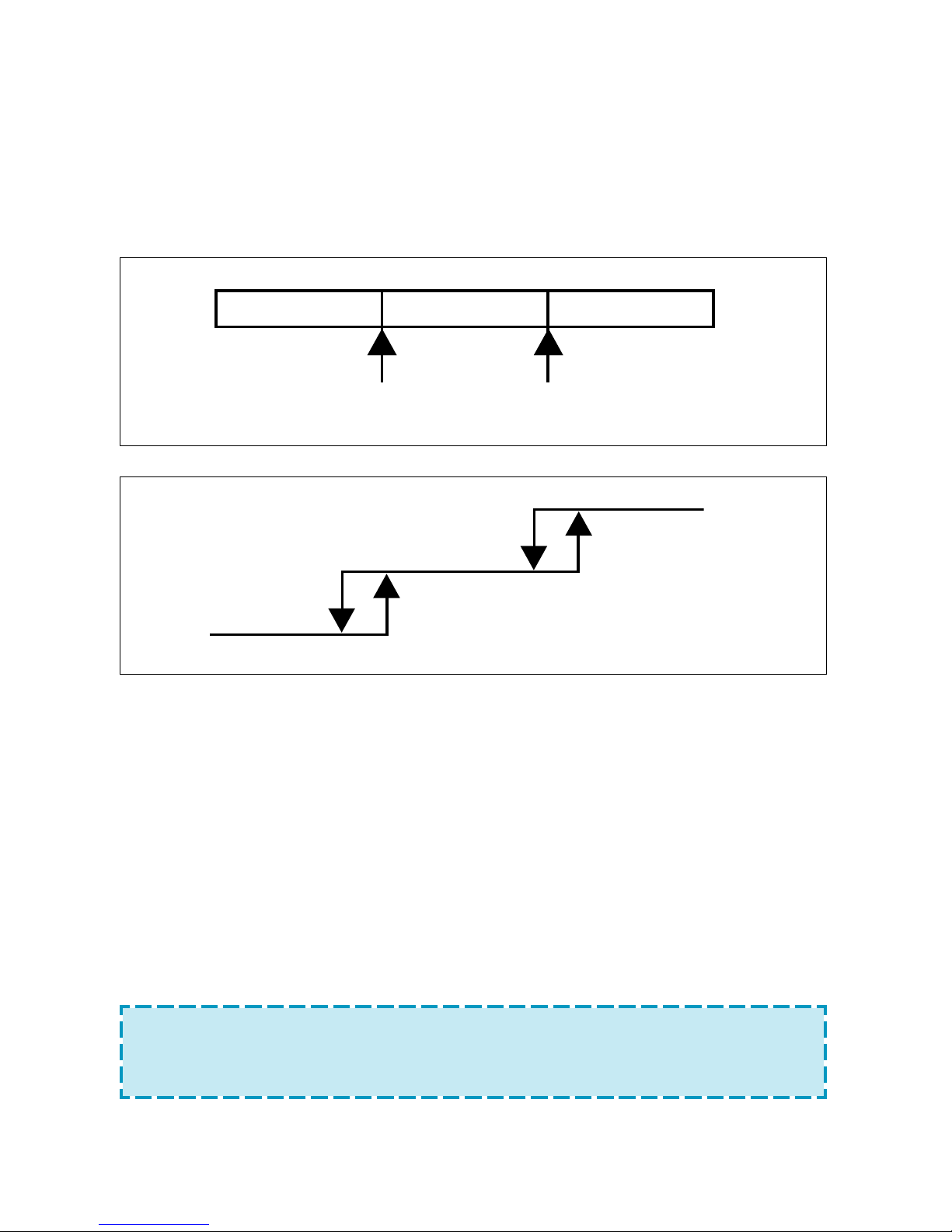

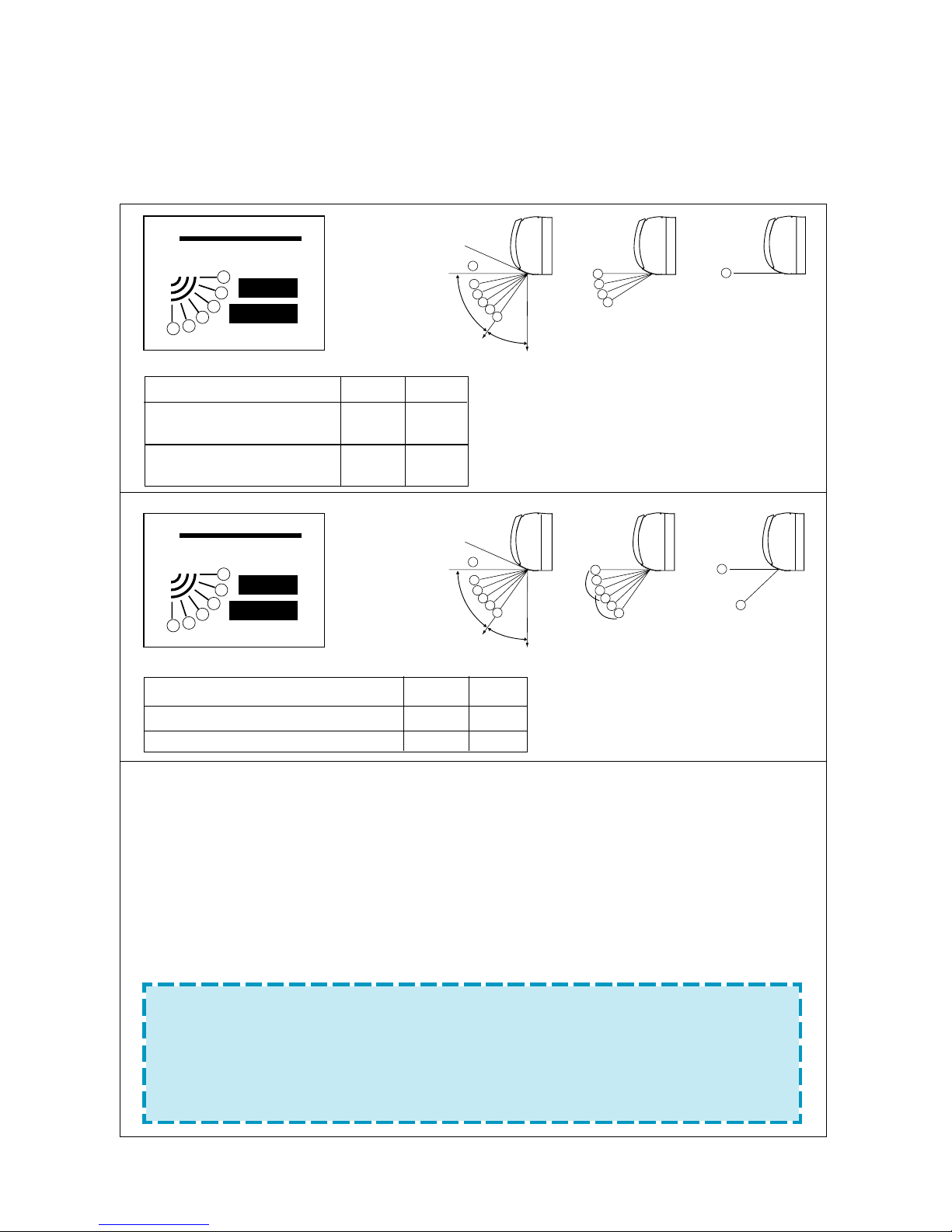

(5) Discharge Air Louver Control

Up and Down Control

The air discharge direction can be controlled to swing up and down and can be fixed at

preferred position or automatic position by the remote control.

• If you select the Flap position using the FLAP button in the remote control, the flap in

the unit will move to that position automatically. Once you select the position, the unit

remembers that position and whenever you turn on the unit, the flap will be positioned

to that position.

• If you select SWING, the flap will swing up and down. In the COOL, DRY and FAN

mode, the flap will swing in the cool range. In the HEAT mode, the flap will swing in the

heat range.

• If you select AUTO, the flap will position itself to the preset position according to the

operation mode.

NOTE

• Always use the remote control to adjust the flap position, otherwise it may cause

abnormal operation. Please turn off the unit and turn it on again when you manually adjust the flap out of range.

• The unit can have maximum capacity when the flap is located at position

.

6

1

2

3

4

5

6

3

4

5

6

CLOSE

A

B

Fixed

Swing Range

Auto Position

Cooling Only Model

AUTO

SWING

FLAP

6

5

4

3

2

1

Remote control

6

3

4

5

6

Fixed Swing Range Auto Position

Heat Pump Model

2

1

COOL

HEAT

2

COOL

HEAT

1

2

3

4

5

6

CLOSE

A

B

AUTO

SWING

FLAP

6

5

4

3

2

1

Remote control

MODEL A B

42HWG007/009/012

HWG195C/225C/305C 54° 36°

42HWG018/024

HWG455C/605C 66° 24°

MODEL A B

42HQG007/009/012, HWG195H/225H/305H 54° 36°

42HQG018/024, HWG455H/605H 66° 24°

21

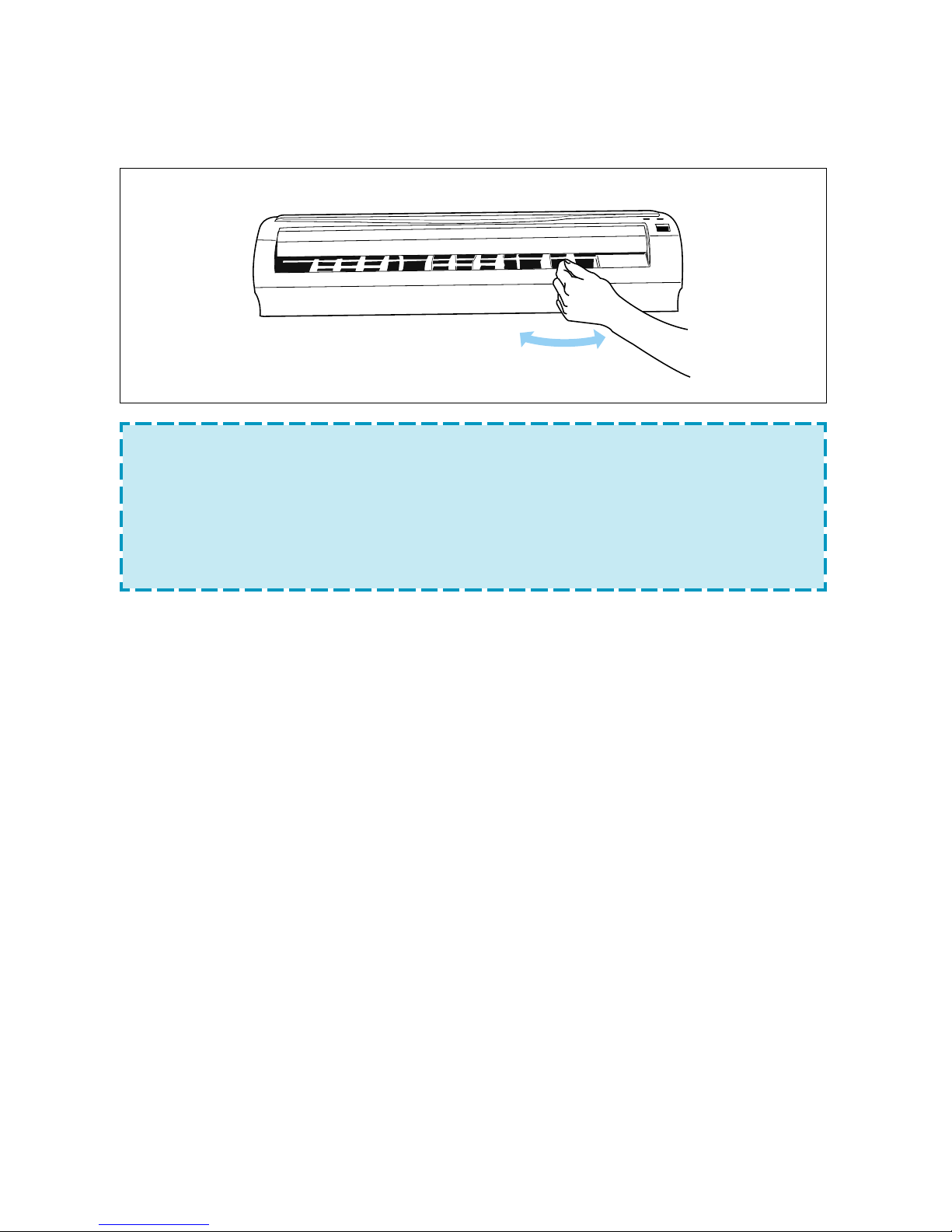

Left and Right Control

If you want to adjust the direction of the discharge air to left or right, adjust the vertical

louver with the handle after opening the flap.

HANDLE

NOTE

•

Please do not fix the flap at position for a long time, as this position minimizes air

circulation resulting in uneven room temperature.

• Please avoid the discharge air being directed towards the occupants for a long period

of time.

• Do not adjust the flap by the hand during SWING operation because it may damage

the air swing function.

(6) Unit Protection Devices

3 min. Time Delay and 3 min. minimum operation time of compressor

– In normal operation, there is a time delay of three minutes (42HQG024/HWG605H : 5

minutes during heating mode) between compressor turning off and turning back on including initial power up.

– After compressor turns on, it will operate for 3 minutes independent of temperature condi-

tion.

Time Delay When changing the operation mode

– The unit operates immediately when changing mode from ON to OFF or from OFF to ON,

or indoor fan speed without the change of operation mode.

– The unit operates after 10-second time delay when changing operating mode.

– The unit operates after 3-second time delay when changing the set temp. without the

change of operation mode.

Frost Prevention of Indoor Unit.

– When the unit operates at low ambient temperature, frost may appear on the evapo-

rator. When the indoor coil temperature is less than 0ºC for 10 minutes of continuous compressor operation from the start, microcomputer of the unit stops the compressor to protect the unit from the frost.

– The system performs this function only in COOL and DRY mode.

– The control procedure for indoor coil freeze protection.

1) The compressor and outdoor fan turn off.

2) Indoor fan operates according to user set speed.

3) The normal operation returns when the indoor coil temperature is greater than or equal

to 7ºC.

22

Indoor Coil High Temperature Protection

– The system performs this function only in HEAT mode.

– If the indoor coil temperature is greater than or equal to 57°C, the outdoor fan turns off and

does not turn on until the indoor coil temperature is less than or equal to 49°C.

– If the indoor coil temperature is greater than or equal to 62°C, the compressor turns off

until the indoor coil temperature is less than or equal to 42°C. The 3 min. time delay of

compressor is applied in this case.

INDOOR COIL TEMP.

ON

42° C 49° C 57° C 62° C

ON

OFF

OFF

OUTDOOR FAN

COMPRESSOR

Defrost

– In HEAT mode, outdoor coil may be frosted, which cause decrease of the unit perfor-

mance. Therefore the microcomputer of the unit turns on or off the compressor to remove the frost.

– The defrost operation is performed as follows:

• Defrost initiation

1) On the basis of the demand condition considering the difference between indoor

coil temperature and indoor room temperature, controller decides defrost initiation

after satisfying two steps of preceding condition.

23

2) Preceding condition is

a) The first step is “the accumulated compressor on time is greater than 30

minutes.”

b) Second step is the one of below two

-The first condition ; If Real-Delta>Defrost-Delta for 60 continuous seconds and

the following conditions are all true then defrost initiates.

)The outdoor coil temperature<-2°C

)The compressor has been on continuously for 15 minutes.

OR

-The second condition ; If the outdoor coil temperature is less than -20°C and

the following conditions are all true then defrost initiates.

)The outdoor fan has been on continuously for 60 seconds.

)The compressor has been on continuously for 3 minutes.

•

Defrost mode

The normal system operations are stopped and the system operates as follows.

a) The indoor fan, outdoor fan will be de-energized.

b) The compressor and R.V.S. will be energized.

•

Defrost termination

The defrost cycle will terminate in one of the following cases.

a) The outdoor coil temperature is greater than or equal to +25°C.

b) 10 minutes after the start of defrost cycle.

•

Auto refresh

During normal heating operation, if the unit becomes OFF mode condition, then

defrost mode will be performed at the OFF mode state of louver and display when

the second step of preceding conditions is satisfied regardless of first step.

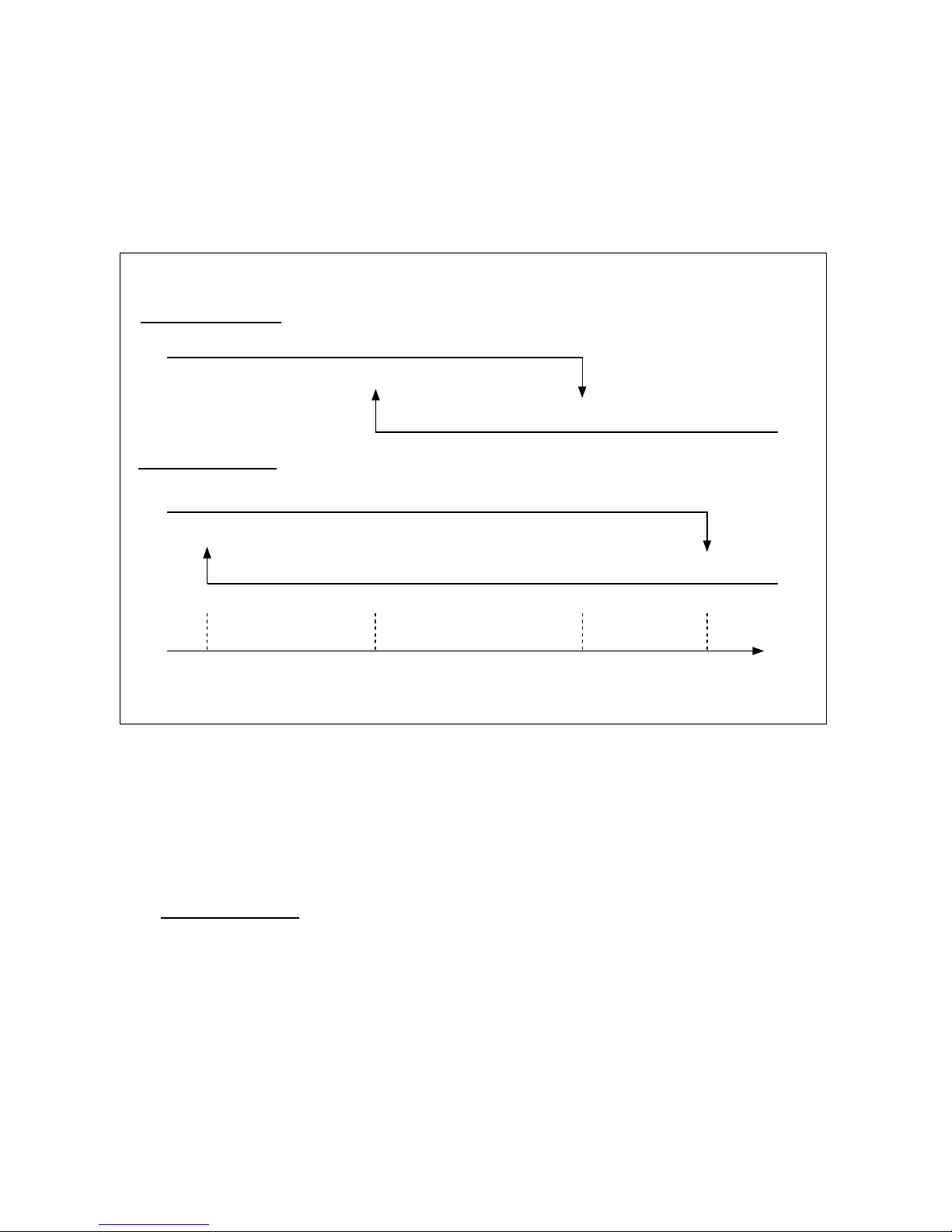

Self-Diagnostic Function

The control will contain diagnostic test to verify the integrity of the system.

Once a malfunction is detected, the diagnostic control section will force the system mode

to OFF for 3 minutes. After the OFF delay, system mode is released and allowed to return

to its normal state. The system will be allowed to restart on its own. The diagnostic control

section will allow the system to fail 5 consecutive times before shutting down the system.

The lamp is scanned every half second and the error codes are displayed by the

flashing frequency of lamp. The error codes are displayed during SHUT-OFF (3

minutes off and after the 5th retry failure) as follows.

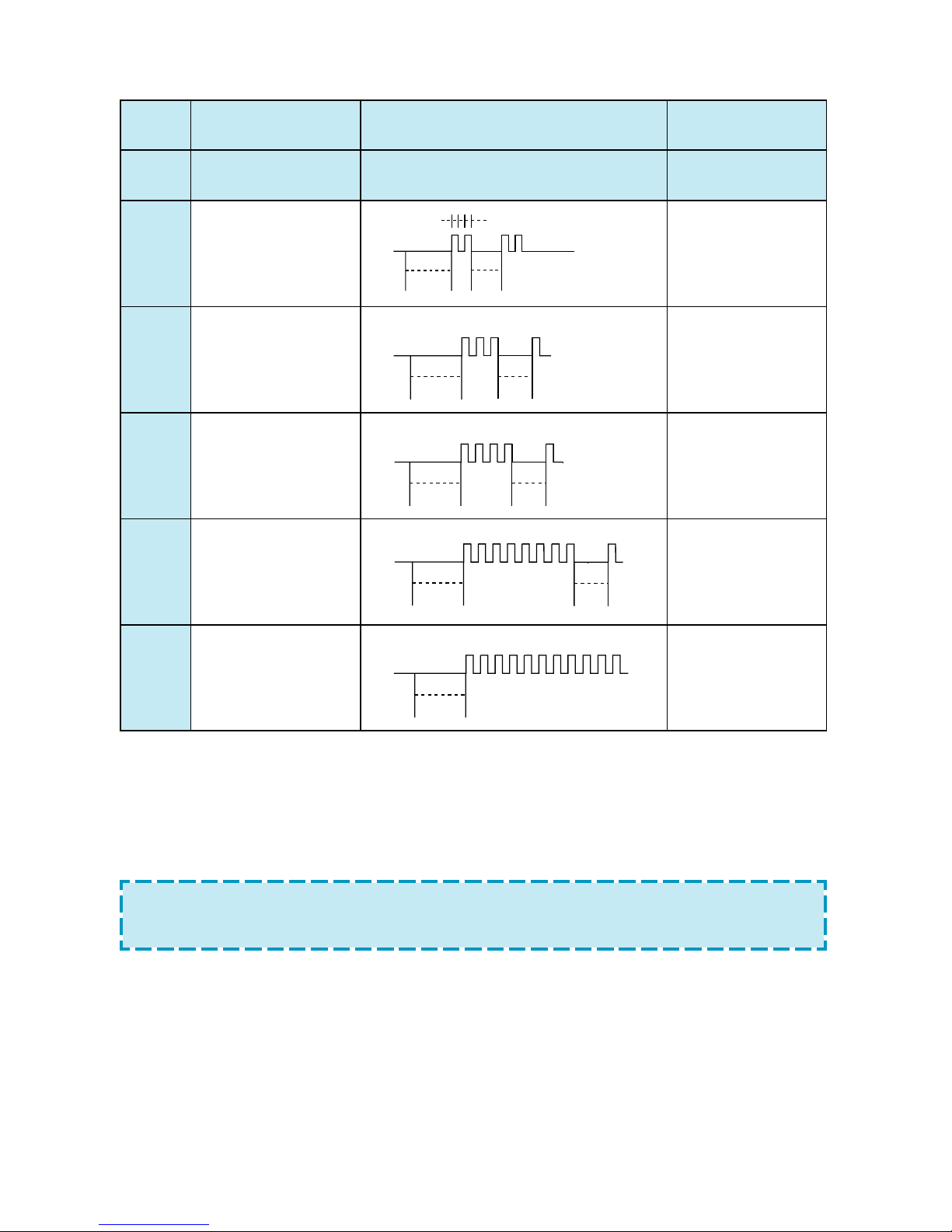

24

NOTE :

If more than two errors occur, the highest item are displayed.

If the highest item is cleared, the next item codes are displayed.

NO ERROR DISPLAY ALLOWED

(RANK)

CONTENTS PATTERN MODES

1 MICOM MEMORY NOTHING SYSTEM RESET

2 ROOM AIR FAN ONLY

THERMISTOR MODE

MALFUNCTION

3 INDOOR COIL FAN ONLY

THERMISTOR MODE

MALFUNCTION

4 OUTDOOR COIL FAN ONLY

THERMISTOR MODE

MALFUNCTION

5 INDOOR FAN

MOTOR

MALFUNCTION

6 THERMISTOR ALL

WRONG WIRING MODE

(ONLY IN TEST

MODE)

3 sec

3 sec

0.5 sec (2 times)

3 sec

3 sec

0.5 sec (3 times)

0.5 sec (4 times)

3 sec

3 sec

3 sec3 sec

0.5 sec (8 times)

3 sec

0.5 sec (continue)

25

Auto restart Mode

– When the power failure is happened during the system operating, the micro will memo-

rize the operation mode and the unit operates automatically according to the previous

operating mode after the power is recovered.

– Whenever the unit receives remote signal, the micom will memorize the following opera-

tion

• Power ON/OFF

• Operation mode

• Temperature setpoint

• Louver position

• Fan speed

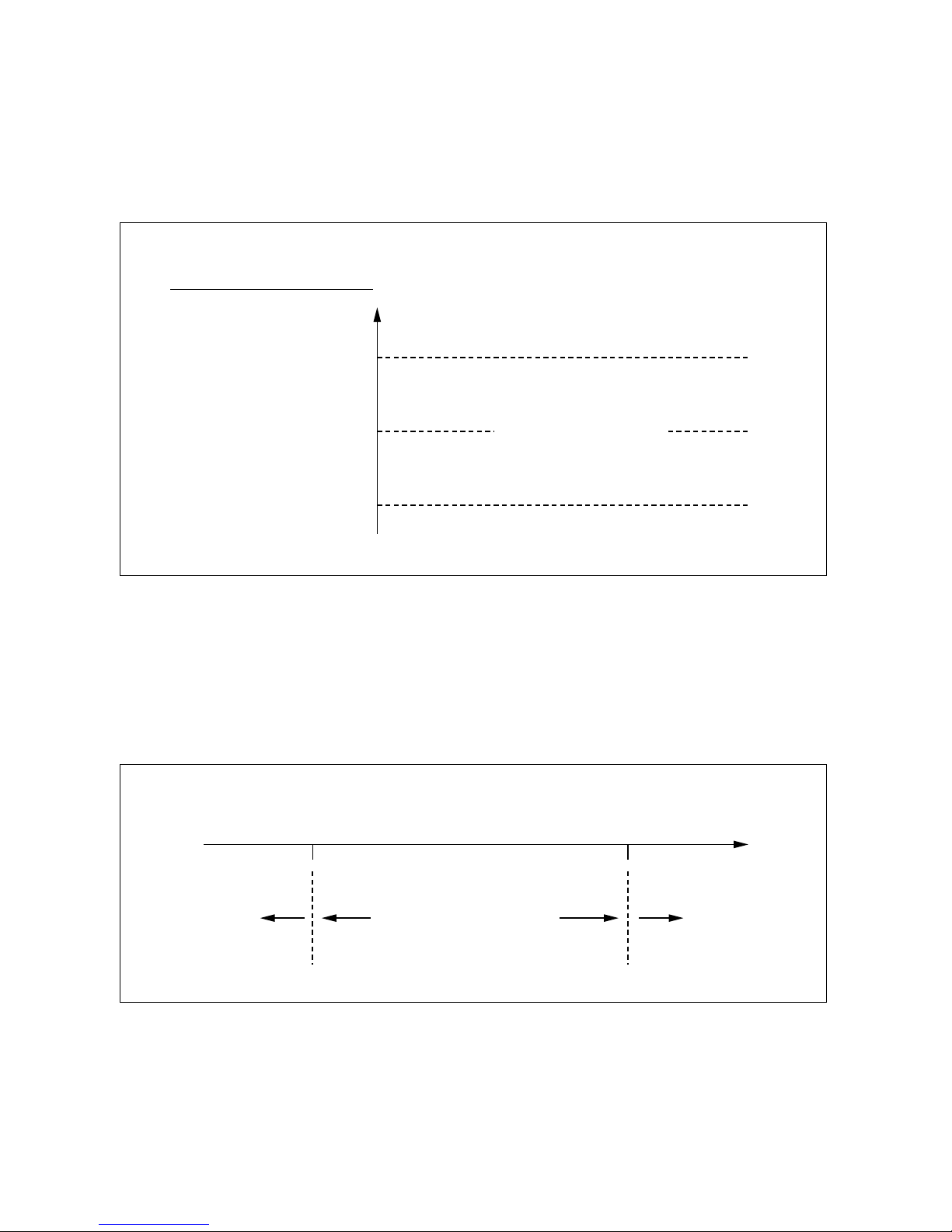

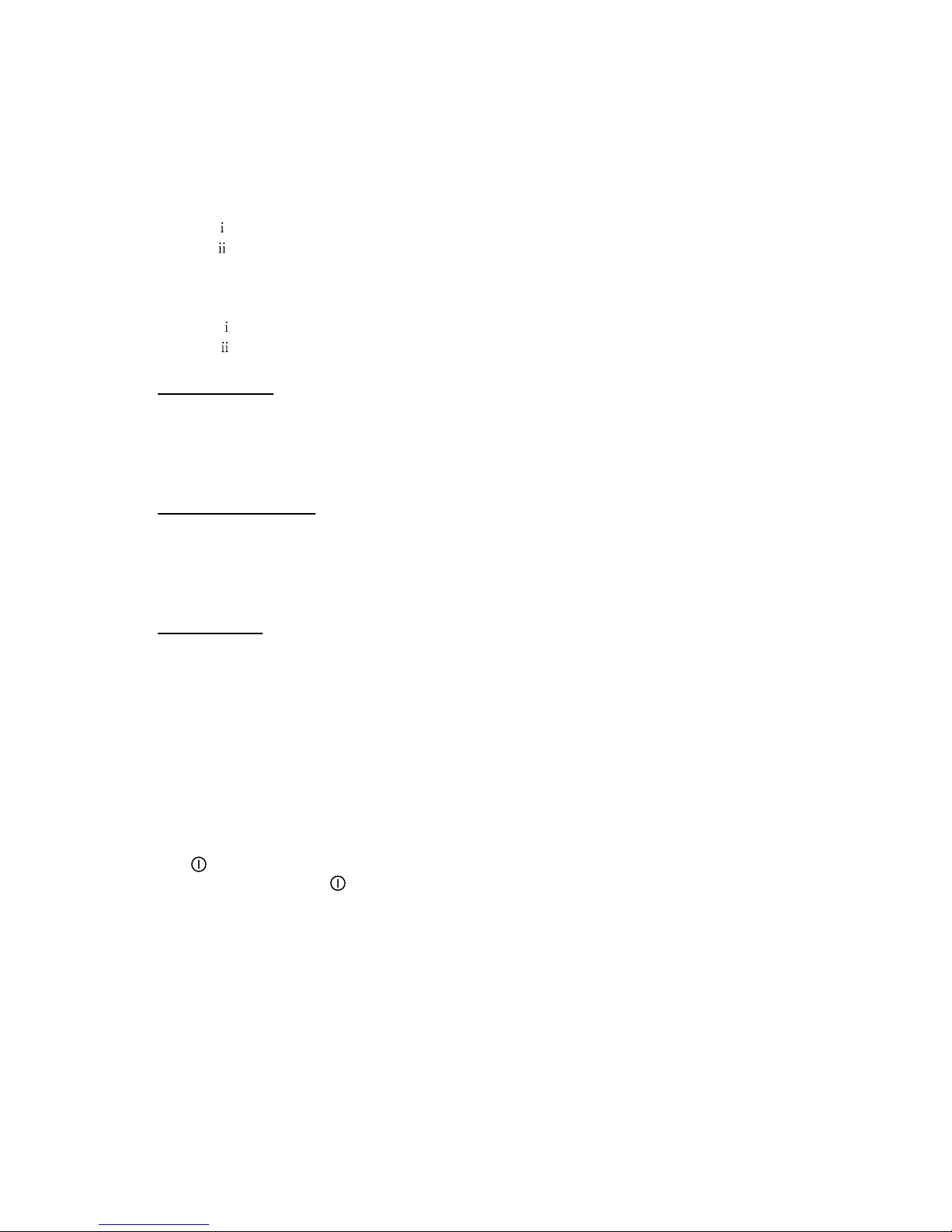

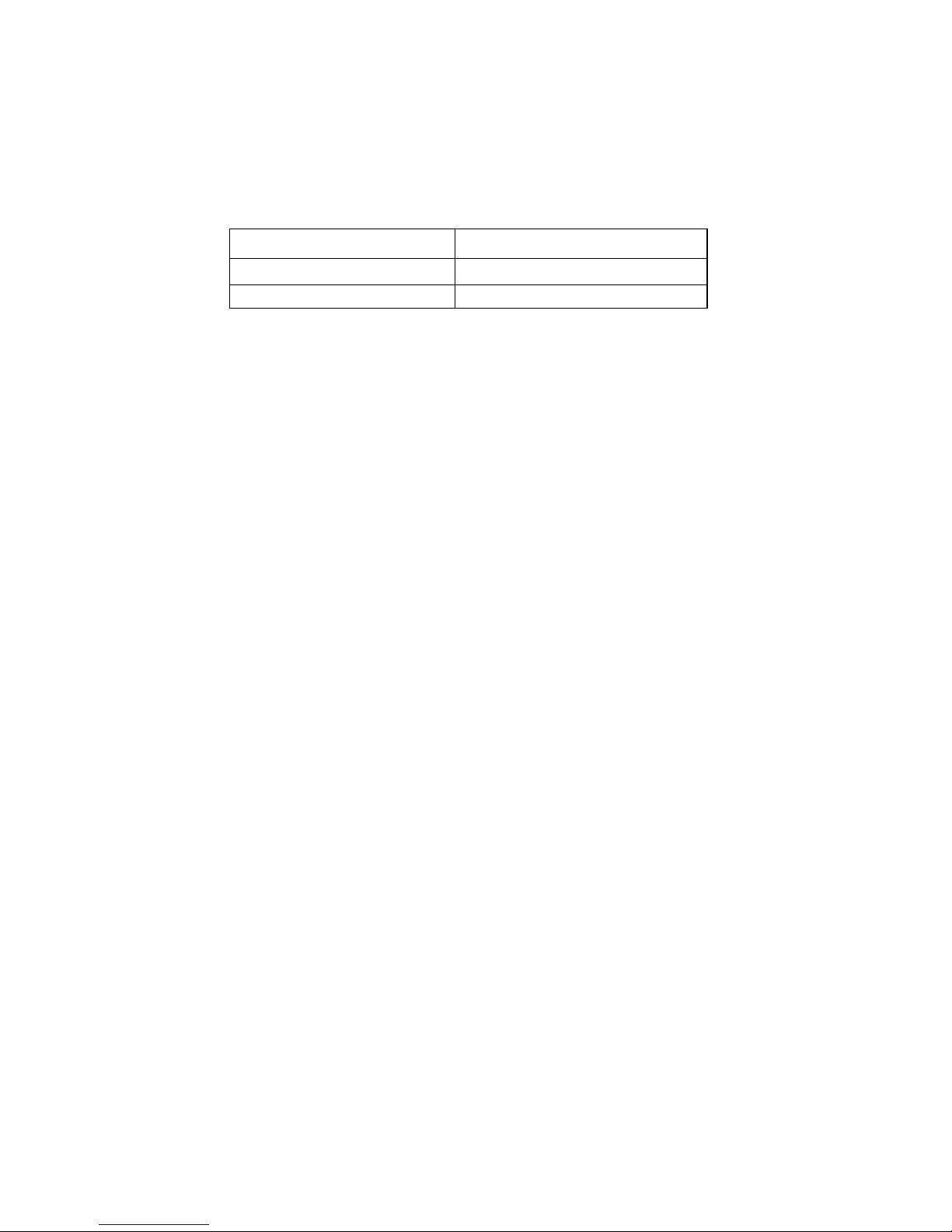

Cold draft function

– The system performs this function only in HEAT mode.

– If the indoor coil temperature is lower than

a certain level, then indoor fan motor runs at slow

speed regardless of user setting speed.

1) When the compressor stops,

Indoor fan moter runs at monitoring speed only.

2) When the compressor runs,

Indoor fan motor runs as follows.

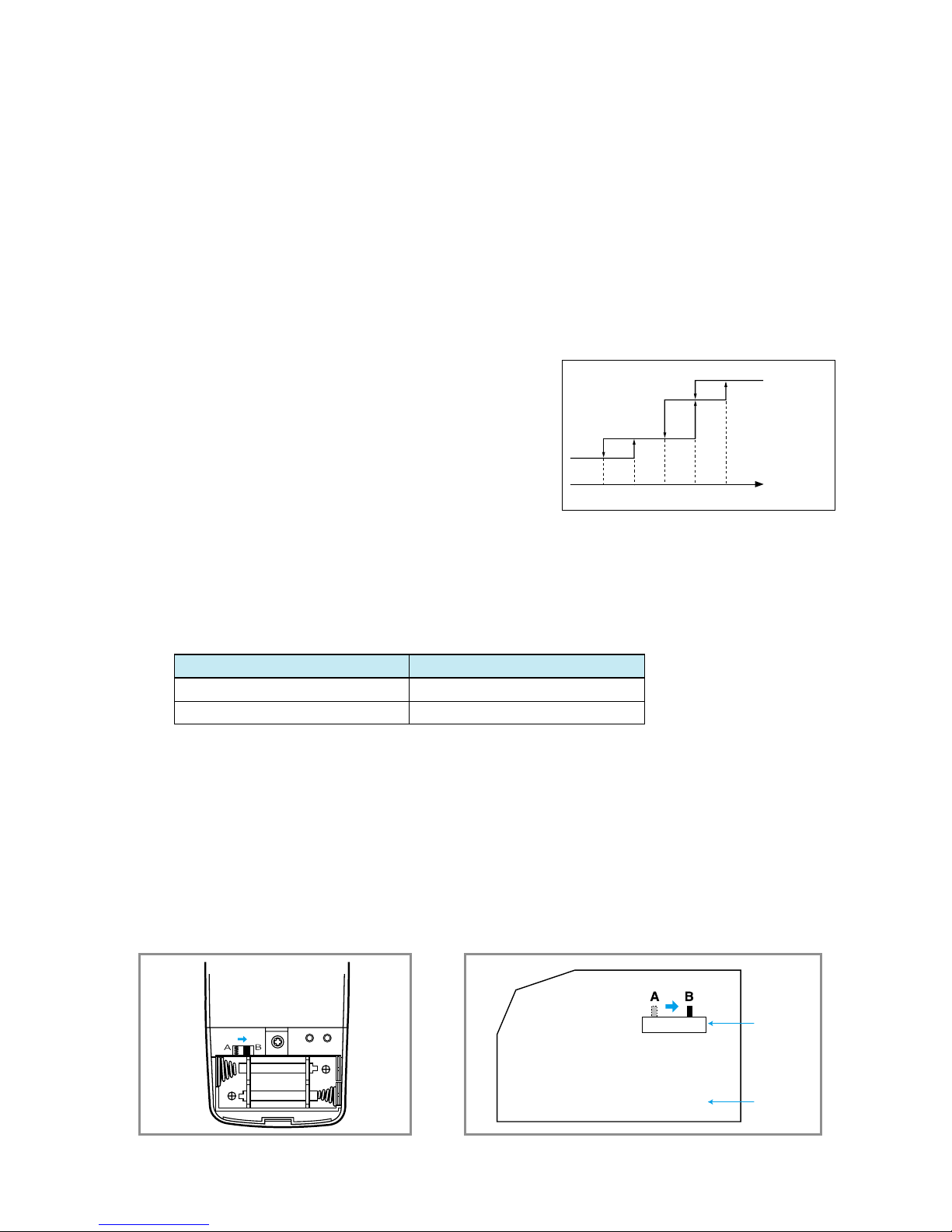

(7) Address configuration

– According to input of selecting address configuration, this function configures custom

code of transmitted remote signal and processes it as input.

– Processable custom codes are displayed as follows.

Address configuration Processable custom code

A DCCA

B DCCB

–

If user wants to use “B” address, adjust the slide switch to “B” in control PCB and

remote.

ADDRESS

PCB

RST TA

LR03(AM4)1.5V

LR03(AM4)1.5V

•

Remote control

• Remove the lid of battery case.

• Assign the address switch of one remote

control as B.

• Press the RST button with a sharp object.

•

Indoor unit

• Turn off the unit and pull out the power plug.

• Remove the front panel, terminal block cover and

frame grille.

• Pull out the PCB.

• Assign the address switch of one indoor unit as B.

Indoor Coil

temperature(

ϒC

)

0

ϒC

-3

ϒC

30ϒC37ϒC43

ϒC

OFF

Monitoring Speed

Setted Speed

Low

26

(9) Emergency and T est Operation.

Emergency operation

– When the remote control is lost, damaged or the battery is discharged, the

Emergency operation can be able to run the unit.

– lf user wants Emergency operation, push the EMERG. button on the T/B cover of

the indoor unit.

– The unit is operated automatically by selecting Cooling or Heating Mode according

to the room temperature.

– lf user wants to stop the Emergency operation, push the EMERG. button again or

operate remote control.

– The setting conditions of Emergency operation are as follows.

• Operation mode :

AUTO (42HQG007/009/012/018/024, HWG195H/225H/305H/455H/605H)

COOL (42HWG007/009/012/018/024, HWG195C/225C/305C/455C/605C)

• Preset temperature:

25ºC (42HQG007/009/012/018/024, HWG195H/225H/305H/455H/605H)

24C (42HWG007/009/012/018/024, HWG195C/225C/305C/455C/605C)

(8) DST Interface

–

According to input of selecting address configuration of indoor unit PCB, the one of

below functions is assigned.

– The applicable connector for these functions is CN18 of indoor unit PCB.

DST Interface

1) The DST(Dealer Service Tool) is an application program used to verify a defec-

tive control board in Air Conditioner

2) It can also be used to diagnose the fault before the board replacement.

3) To use DST function, first of all, following preparations are required.

– DST interface converter

– G-DST interconnection wire

– IBM PC 386DX-33 processor with MS Windows OS 3.1

( Minimum system requirement )

4) If there are any problems or questions relating to the operation or installation of

the DST please consult the ‘Installation Guide and User’s Manual’

Address configuration Functions

A DST Interface available

B DST Interface not available

27

• Fan Speed: AUTO

• Timer mode: Disable

• Discharge Air Direction: Preset location according to 'COOL' or 'HEAT' mode.

Test operation

– Perform TEST operation after the units have been installed in position and gas

leak test has been completed.

– lf installer wants TEST operation, push the TEST button on the T/B cover of the

indoor unit.

– After TEST operation, push the TEST button again or operate remote control.

– Do not perform TEST operation in normal operation.

– The setting conditions of TEST operation are as follows.

• Operation Mode: COOL

• Fan Speed: HIGH

• Timer mode: Disable

• Discharge Air Direction: SWING

Air cleaning operation

• Filters Air filter

Option 1: Active carbon filter/Photo-catalyst filter

Option 2: Active carbon filter/Electrostatic filter

• Air filters eliminate dust and lint

• Optional Active carbon filter/Photo-catalyst filter effectively eliminates

odor and cigarette smoke in the room air.

• Optional Active carbon filter/Electrostatic filter is particularly effective in

eliminating odor and microscopic dust.

• The life of active carbon filter & electrostatic filter

– The life of above filters varies according to the amount of cigarette smoke, room size

and the operating time.

– Air filters can be cleaned with a vacuum cleaner or rinsed under running water after

using a month.

ACTIVE CARBON FILTER

(Black Color, OPTIONAL)

ELECTROSTATIC FILTER

(White Color, OPTIONAL)

or

PHOTO-CATALIST FILTER

(Blue Color, OPTIONAL)

STANDARD AIR FILTER

28

– The life time of optional Active carbon filter is about 2 years and that of optional

Electrostatic filter is about 3 months.(In case of electrostatic filter, refer to color

sample sticker indicating pollution level.)

These filters cannot be recycled.

– The life time of optional Photo-catalyst filter is about 2 years. This filter can be

washed under running water and can be refreshed by exposing under direct sun

light. Exposed time is 6 hours after using 3 months.

– When you need new filters, call your distributor.

Time to replace

• STEP 1

• STEP 3

• STEP 2

• STEP 4

– Remove the two air filters

– Pull out the two collectors.

– Insert active carbon and electrostatic filter

(or photo-catalyst filter) into each other

frame collector.

– Refix the air filters and close the insert grille.

hook holder

four hooks

Electrostatic filter

or

photo-catalyst filter

Active carbon filter

NOTE

• Do not keep the filters unpacked, before inserted into the unit. The life of the filters may be reduced.

• Do not splash water into the active carbon filter, as the life and capability of the filters may be reduced.

• The operation with filter may reduce a little air flow and capacity of the unit.

• The active carbon filter should be inserted into left.

29

WIRING DIAGRAM

4

1) 42HWG007/009/012 & HWG195/225/305C-SERIES INDOOR UNIT

LEGEND

K: RELAY IDFM: INDOOR FAN MOTOR MSW: MAIN SWITCH

TB: TERMINAL BLOCK FCU: FAN COIL UNIT HS: HALL (RPM) SENSOR

TP: THERMAL PROTECTOR CDU: CONDENSING UNIT TRANS: TRANSFORMER

CN: CONNECTOR RA Th: ROOM AIR THERMISTOR COMP: COMPRESSOR

EC1: FAN MOTOR CAPACITOR MOV: METAL OXIDE VARISTOR STM: STEP MOTOR

IDC Th: INDOOR COIL THERMISTOR CB: TIME DELAY FUSE or CIRCUIT BREAKER

30

2) 42HQG007/009/012 & HWG195/225/305H-SERIES INDOOR UNIT

LEGEND

K: RELAY IDFM: INDOOR FAN MOTOR MSW: MAIN SWITCH

TB: TERMINAL BLOCK FCU: FAN COIL UNIT HS: HALL (RPM) SENSOR

TP: THERMAL PROTECTOR CDU: CONDENSING UNIT ODFM: OUTDOOR FAN MOTOR

CN: CONNECTOR RA Th: ROOM AIR THERMISTOR COMP: COMPRESSOR

EC1: FAN MOTOR CAPACITOR MOV: METAL OXIDE VARISTOR TRANS: TRANSFORMER

IDC Th: INDOOR COIL THERMISTOR

ODC Th: OUTDOOR COIL THERMISTOR

RVS: REVERSING VALVE COIL

STM: STEP MOTOR CB: TIME DELAY FUSE or CIRCUIT BREAKER

31

3) 42HWG018/024 & HWG455C/605C-SERIES INDOOR UNIT

LEGEND

K: RELAY IDFM: INDOOR FAN MOTOR MSW: MAIN SWITCH

TB: TERMINAL BLOCK FCU: FAN COIL UNIT HS: HALL (RPM) SENSOR

TP: THERMAL PROTECTOR CDU: CONDENSING UNIT TRANS: TRANSFORMER

CN: CONNECTOR RA Th: ROOM AIR THERMISTOR COMP: COMPRESSOR

EC1: FAN MOTOR CAPACITOR MOV: METAL OXIDE VARISTOR STM: STEP MOTOR

IDC Th: INDOOR COIL THERMISTOR CB: TIME DELAY FUSE or CIRCUIT BREAKER

32

4) 42HQG018/024 & HWG455H/605H-SERIES INDOOR UNIT

LEGEND

K: RELAY IDFM: INDOOR FAN MOTOR MSW: MAIN SWITCH

TB: TERMINAL BLOCK FCU: FAN COIL UNIT HS: HALL (RPM) SENSOR

TP: THERMAL PROTECTOR CDU: CONDENSING UNIT ODFM: OUTDOOR FAN MOTOR

CN: CONNECTOR RA Th: ROOM AIR THERMISTOR COMP: COMPRESSOR

EC1: FAN MOTOR CAPACITOR MOV: METAL OXIDE VARISTOR TRANS: TRANSFORMER

IDC Th: INDOOR COIL THERMISTOR

ODC Th: OUTDOOR COIL THERMISTOR

RVS: REVERSING VALVE COIL

STM: STEP MOTOR CB: TIME DELAY FUSE or CIRCUIT BREAKER

33

REFRIGERANT CYCLE

5

1) 42HWG007/009/012/018/024 & HWG195C/225C/305C/455C/605C

INDOOR UNIT

Evaporator

Cross flow fan

Service

valve

Expansion

device

Condenser

Propeller fan

OUTDOOR UNIT

Compressor

Accumulator

Service valve

Refrigerant flow

Connecting pipe

34

2) 42HQG007/009/012/018/024 & HWG195H/225H/305H/455H/605H

INDOOR UNIT

Cross flow fan

Service

valve

Propeller fan

OUTDOOR UNIT

Service valve

Reversing

valve

outdoor heat exchanger

Accumulator

Compressor

Accurater

lndoor heat exchanger

Connecting pipe

Refrigerant flow (cooling)

Refrigerant flow (heating)

35

CONTROL BLOCK DIAGRAM

6

1) 42HWG007/009/012/018/024 & HWG195C/225C/305C/455C/605C

2) 42HQG007/009/012/018/024 & HWG195/225/305/455/605H-SERIES

36

37

ELECTRIC CIRCUIT DIAGRAM

7

1) FUNCTIONAL CIRCUIT DIAGRAM

a 42HWG007/009/012 & HWG195/225/305C-SERIES

• After the power I/O button is pressed once, the Power-relay and AC SWITCH are turned

on or off per the remote control setpoint.

– AC SWITCH U9 is controlled per the fan speed selection.

– Power-relay K1 is controlled per the operation mode selection.

• If the power I/O button is pressed once more, the Power-relay and AC SWITCH are turned

off and the unit stops operation.

• The unit turns on or off according to the temperature setpoint by sensing the room air

temperature through thermistor.

• If the fan speed selection is set to the auto position, the fan speed is automatically con-

trolled according to the temperature difference between room temperature and temperature setpoint.

38

b 42HQG007/009/012 & HWG195/225/305H-SERIES

• After the power I/O button is pressed once, the Power-relay, relays and AC SWITCH are

turned on or off per the remote control setpoint.

– AC SWITCH U9 is controlled per the fan speed selection.

– Power-relay K1, relay K2, K3 are controlled per the operation mode selection.

• If the power I/O button is pressed once more, Power-relay, relays and AC SWITCH are

turned off and the unit stops operation.

• The unit turns on or off according to the temperature setpoint by sensing the room air

temperature through thermistor.

• If the fan speed selection is set to the auto position, the fan speed is automatically

controlled according to the temperature difference between room temperature and

temperature setpoint.

c 42HWG018/024 & HWG455/605C-SERIES

• After the power I/O button is pressed once, the relay and AC SWITCH are turned on or

off per the remote control setpoint.

– AC SWITCH U9 is controlled per the fan speed selection.

– Relay K1 is controlled per the operation mode selection.

• If the power I/O button is pressed once more, the relay and AC SWITCH are turned off

and the unit stops operation.

• The unit turns on or off according to the temperature setpoint by sensing the room air

temperature through thermistor.

• If the fan speed selection is set to the auto position, the fan speed is automatically

controlled according to the temperature difference between room temperature and

temperature setpoint.

39

d 42HQG018/024 & HWG455/605H-SERIES

• After the power I/O button is pressed once, relays and AC SWITCH are turned on or off

per the remote control setpoint.

– AC SWITCH U9 is controlled per the fan speed selection.

– Relay K1, K2, K3 are controlled per the operation mode selection.

• If the power I/O button is pressed once more, relays and AC SWITCH are turned off and

the unit stops operation.

• The unit turns on or off according to the temperature setpoint by sensing the room air

temperature through thermistor.

• If the fan speed selection is set to the auto position, the fan speed is automatically

controlled according to the temperature difference between room temperature and

temperature setpoint.

40

41

2) PCB CIRCUIT DIAGRAM

a MAIN CONTROL PART

42HWG007/009/012, 42HQG007/009/012, HWG195/225/305C, HWG195/225/305H

b MAIN CONTROL PART

42HWG018/024, 42HQG018/024, HWG455/605C, HWG455/605H

42

43

INDEX DESCRIPTION

STEPPING MOTOR DRIVING

STEPPING MOTOR

RPM SENSOR INPUT

HALL (RPM) SENSOR

FUNCTION CONFIGURATION

TEMPERATURE SENSING

THERMISTOR

“EMERGENCY” OR “TEST” SIGNAL INPUT

ADDRESS SELECTION INPUT

SIGNAL RECEIVER & INDICATOR LAMP DRIVING

SIGNAL RECEIVER & INDICATOR LAMP

CLOCK GENERATION

DC POWER SUPPLY

DST SIGNAL INTERFACE or H.A COMMUNICATION

RVS & ODF RELAY DRIVING FOR H/P

BUZZER DRIVING

AC SWITCH DRIVING FOR IDF

INDOOR FAN MOTOR

EEPROM DRIVING

AC POWER SUPPLY & RELAYS OUTPUT

RESET CIRCUIT

POWER LINE FREQ. MONITORING INPUT

STATUS LED DRIVING

COMP. RELAY DRIVING

-1 -2 -3

c REMOTE CONTROL PART

44

3) PCB PATTERN DIAGRAM

a CONTROL PCB (SOLDERING SIDE)

42HWG007/009/012, 42HQG007/009/012, HWG095/225/305C, HWG195/225/305H

45

46

b CONTROL PCB (COMPONENTS SIDE)

42HWG007/009/012, 42HQG007/009/012, HWG195/225/305C, HWG195/225/305H

47

c CONTROL PCB (SOLDERING SIDE)

42HWG018/024, 42HQG018/024, HWG455/605C, HWG455/605H

48

d CONTROL PCB (COMPONENTS SIDE)

42HWG018/024, 42HQG018/024, HWG455/605C, HWG455/605H

e Display and Receiver PCB (Component side)

4) LCD PANEL TEST

a

Selecting the test mode

: Press the LCD test key (K15) in remote control PCB during OFF mode

b T

est mode cancellation

– After the test program is completed.

– If the reset button is pressed.

c

LCD panel test flow

When this key is pressed, the LCD segment test is performed to verify the integrity of

LCD panel as described and then reset.

TEST START BLOCK ‘A’ ON/OFF BLOCK ‘B’ ON/OFF

BLOCK ‘C’ ON/OFF BLOCK ‘D’ ON/OFF RESET MODE

A

B

C

D

OFF

ON

AM

PM

AM

PM

FLAP

ON

AUTO

SLEEP

EVERYDAY

SWING

49

KEY COMPONENTS OF ELECTRONIC CIRCUIT

8

1) U1 (MICOM)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P20/SI1

P21/SO1

P22/SCK1

P23/STB

P24/BUSY

P25/SI0/SB0

P26/SO0/SB1

P27/SCK0

P30/TO0

P31/TO1

P32/TO2

P33/TI1

P34/TI2

P35/PCL

P36/BUZ

P37

Vss

P40/AD0

P41/AD1

P42/AD2

P43/AD3

P44/AD4

P45/AD5

P46/AD6

P47/AD7

P50/A8

P51/A9

P52/A10

P53/A11

P54/A12

P55/A13

Vss

AV

AV

P17/AN17

P16/AN16

P15/AN15

P14/AN14

P13/AN13

P12/AN12

P11/AN11

P10/AN10

AV

P04/XT1

XT2

IC

X1

X2

V

P03/INTP3

P02/INTP2

P01/INTP1

P00/INTP0/TI0

RESET

P67/ASTB

P66/WAIT

P65/WR

P64/RD

P63

P62

P61

P60

P57/A15

P56/A14

µPD78012FCW- XXX

REF

DD

DD

SS

50

51

101112131415161718

GND1817161514131211

COMMONO8O7O6O5O4O3O2O1

987654321

PIN CONNECTION (TOP VIEW)

COMMON

GND

OUTPUT

2.7k

7.2k

3k

INPUT

SCHEMATICS (EACH DRIVER)

3) U4 (14584B): SCHUMITT TRIGGER INVERTER

1

2

3

4

5

6

9

8

11

10

I3

12

LOGIC DIAGRAM

V

DD

=PIN14

Vss=PIN7

EQUIVALENT CIRCUIT SCHEMATIC

(1/2 OF CIRCUIT SHOWN)

4) U5 (NM24C02): EEPROM

AO

A1

A2

Vss

1

2

3

45

6

7

8

Vcc

NC

SCL

SDA

NM24CO2L

NM24CO4L

A0,A1,A2

Vss

SDA

SCL

NC

Vcc

Device Address Inputs

Ground

Data I/0

Clock Input

No Connection

+5V

Pin Names

TL/ D/ 11099-2

Top View

See NS Package Number

MO8A(M8) and NO8E(N)

Dual-In-Line Package(N)

and SO Package(M8)

2) U2 (TD62083AP): DARLINGTON ARRAYS

1PB RST

2TD

3TOL

4GND

8 Vcc

7ST

6 RST

5 RST

MAX1232

Vcc

TOL

TD

PB RST

ST

RST

RST

DEBOUNCE

RESET

GENERATOR

5%/10%

TOLERANCE

SELECT

WATCHDOG

TIMEBASE

SELECT

WATCHDOG

TIMER

GND

REF

+

-

+

MAXIM

MAX1232

MAXIM

6) U7 (7812ACT)/U8 (7805CT): VOLTAGE REGULATOR

100K 500

100

100

0.3

10K

6K

500

1K

5K

28K

6K

30pF

2K

5K

200

240

1.4

K

2.7

K

3.3

K

0.19K

INPUT

OUTPUT

GND

SCHEMATIC DIAGRAM

TSUFFIX

PLASTIC PACKAGE

CASE 221A

TO-220TYPE

PIN 1. INPUT

2. GND

3. OUTPUT

1

2

3

5) U6 (MAX 1232EPA): RESET I.C

52

7) U9 (TSA3100J(v)): AC SWITCH

25.2 0.2

10.16 0.6

0.55 0.15

1.1 0.15

1 : AC OUTPUT(MT2)

2 : AC OUTPUT(MT1)

3 : GATE

4 : DC INPUT(+)

5 : DC INPUT(-)

* : RESIN FLASH

7.5 0.5

4.0 0.2

1.2 0.2

0.5 0.15

1.5MAX.

2.3 0.2

9.0 0.2

2.54 0.3

7.62 0.6

8) U10 (TLP621): PHOTO-COUPLER

6.4

12

43

4.58 ±0.25

2.54 ±0.25

1.2

0.5

0.8

3.65

2.5MIN

7.62 ±0.25

0.25

+0.1

-0.05

7.85~8.80

TLP621

Weight : 0.26g

1

2

4

3

TLP621

1 : ANODE

2 : CATHODE

3 : EMITTER

4 : COLLECTOR

53

54

9) RU1: REMOCON MICOM

64

TEST

K13

K12

K11

K10

K03

K02

K01

K00

P03

P02

P01

P00

R20

R13

R12

R11

R10

R03

R02

R01

R00

Vs1

OSC

4

N.C

SEG31

SEG30

SEG29

SEG28

SEG27

SEG26

SEG25

SEG24

SEG23

SEG22

SEG21

SEG20

SEG19

SEG18

SEG17

OSC3

Vss

OSC2

OSC1

N.C.

V

DD

AOUT

AMPM

AMPP

RSTOUT

R33(REM)

V

L1

V

ADJ

RESET

V

L2

V

L3

60 55 50 45

35

30

24

SEG16

SEG15

SEG14

SEG13

SEG12

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

COM3

COM2

COM1

COM0CCCB

CA

2015105

70

75

80

1X

Index

SMC621A

N.C.:No connection

10) LCD (E-30294)

42.0 –0.2

39.5 –0.3

37.5

-0

(33.0)

26.0 +0

4.5 +0

16.0-0

2.5–0.3

36.0 –0.2

36.0 –0.2

3.0 –0.5

0.5 –0.5

4.6 –0.2

SEALING MOLD

0.5 –0.5

0.5 –0.5

29.0 –0.2

POLARIZER

WITH UV FILTER

POLARIZER

WITH REFLECTOR

VIEWING DIRECTION(6H)

1.0 +0

2.0 +0

4.6–0.2

(1.584)

(1.584)

30.0 –0.2

28.0 -0

(26.0)

A

A

2.7 –0.3

29.0 –0.2

1.1–0.1 1.1–0.1

S1S2S3S4S5S6S7S8S9

COM1

COM2

COM3

COM4

S10

S11

S12

S13

(1.8)

(0.3)

(0.4)

*1

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

COM4

COM3

COM2

COM1

S24

S25

S26

4-R1.0 +0

55

CHECKING AND REPAIRING OF ELECTRIC PARTS

9

Operating Procedure Photos

Fig. 1

Fig. 2

1) Measuring insulation resistance of indoor fan

motor

a Remove the fan motor connector from PCB.

b Connect clip to the ground terminal

connecting Green/Yellow line.

c Measure insulation resistance by connecting

terminal of insulation ohmmeter to the arbitrary

fan motor connector. (Refer to fig. 1)

d It is normal that insualtion resistance is over

1MΩ.

2) Checking the winding of compressor motor

a. After removing terminal cover of compressor

motor, set the range of resistance measurement

of multimeter to "x1Ω".

b. Among the terminals, check the disconnection

between two terminals (C R, C S)as shown

in fig. 2.

c. Check the disconnection between two terminals

(1 3) of Overload-protector of compressor motor.

d. It is normal if there is no disconnections.

3) Checking PCB for control by operating voltage

of fan motor

a. Remove the connector between PCB and fan

motor.

b. Assure that other parts are not short before

supplying power to the unit.

c. Operate the unit and change fan speed by remote

controller.

d. It is normal that the voltage between the

connector pin (CN3, ) is measured as

over (line voltage - 50VAC). But, this test has to be

done within 1 minute.

Green/Yellow

Ground terminal

Compressor terminal

OLP

3

1

S

C

R

Multimeter

56

4) Checking power transformer

a. Remove power transformer from control box.

b. Set the range of resistance measurement of

multimeter to "x1Ω"

c. Measure lead line resistance between the yellow

and yellow and between the brown and blue.

d. It is normal that the resistance measured is

accorded with table 1.

5) Checking thermistor

a. Remove thermistor connector from PCB.

b. Check the resistance of thermistor according to

temperature.

Operating Procedure Photos

Table 1.

Lead Line

Resistance

PTC01BU046B PTC01DR008B

Brown-Blue(Pri.) 5 4 6Ω±10 % 427.7Ω±10%

YEL-YEL(Sec.) 2.3 Ω±10% 1.65Ω±10%

57

9) Thermistor temperature vs. resistance table

a Room air thermistor

TEMP(ºC) R(K )

8 1 0.8508

8 2 0.8271

8 3 0.8041

8 4 0.7820

8 5 0.7605

8 6 0.7397

8 7 0.7196

8 8 0.7002

8 9 0.6813

9 0 0.6631

9 1 0.6454

9 2 0.6283

9 3 0.6117

9 4 0.5956

9 5 0.5800

9 6 0.5649

9 7 0.5503

9 8 0.5361

9 9 0.5224

10 0 0.5090

10 1 0.4961

10 2 0.4835

10 3 0.4714

10 4 0.4596

10 5 0.4481

10 6 0.4370

10 7 0.4262

10 8 0.4157

10 9 0.4055

11 0 0.3956

11 1 0.3860

11 2 0.3767

11 3 0.3676

11 4 0.3588

11 5 0.3503

11 6 0.3420

11 7 0.3339

11 8 0.3261

11 9 0.3185

12 0 0.3110

TEMP(ºC) R(K )

4 1 2.993

4 2 2.890

4 3 2.792

4 4 2.698

4 5 2.607

4 6 2.519

4 7 2.435

4 8 2.355

4 9 2.277

5 0 2.203

5 1 2.131

5 2 2.062

5 3 1.995

5 4 1.931

5 5 1.869

5 6 1.810

5 7 1.753

5 8 1.698

5 9 1.645

6 0 1.593

6 1 1.544

6 2 1.496

6 3 1.451

6 4 1.406

6 5 1.364

6 6 1.323

6 7 1.283

6 8 1.245

6 9 1.208

7 0 1.172

7 1 1.137

7 2 1.104

7 3 1.072

7 4 1.041

7 5 1.011

7 6 0.9819

7 7 0.9539

7 8 0.9268

7 9 0.9006

8 0 0.8753

TEMP(ºC) R(K )

1 14.37

2 13.75

3 13.17

4 12.61

5 12.07

6 11.57

7 11.09

8 10.63

9 10.19

1 0 9.771

1 1 9.373

1 2 8.993

1 3 8.631

1 4 8.286

1 5 7.956

1 6 7.641

1 7 7.341

1 8 7.054

1 9 6.779

2 0 6.517

2 1 6.267

2 2 6.027

2 3 5.798

2 4 5.579

2 5 5.369

2 6 5.168

2 7 4.976

2 8 4.792

2 9 4.616

3 0 4.447

3 1 4.286

3 2 4.131

3 3 3.982

3 4 3.840

3 5 3.703

3 6 3.573

3 7 3.447

3 8 3.326

3 9 3.211

4 0 3.100

TEMP(ºC) R(K )

-4 0 113.1

-3 9 106.8

-3 8 100.9

-3 7 95.35

-3 6 90.15

-3 5 85.27

-3 4 80.68

-3 3 76.36

-3 2 72.31

-3 1 68.49

-3 0 64.90

-2 9 61.52

-2 8 58.33

-2 7 55.33

-2 6 52.51

-2 5 49.84

-2 4 47.33

-2 3 44.95

-2 2 42.71

-2 1 40.60

-2 0 38.60

-1 9 36.72

-1 8 34.93

-1 7 33.25

-1 6 31.65

-1 5 30.14

-1 4 28.72

-1 3 27.37

-1 2 26.09

-1 1 24.87

-1 0 23.72

- 9 22.63

- 8 21.60

- 7 20.62

- 6 19.69

- 5 18.81

- 4 17.97

- 3 17.18

- 2 16.42

- 1 15.70

0 15.02

b Indoor coil & Outdoor coil thermistor

TEMP(ºC) R(K )

8 1 1.218

8 2 1.179

8 3 1.142

8 4 1.107

8 5 1.072

8 6 1.039

8 7 1.007

8 8 0.9759

8 9 0.9461

9 0 0.9173

9 1 0.8896

9 2 0.8628

9 3 0.8370

9 4 0.8120

9 5 0.7879

9 6 0.7647

9 7 0.7422

9 8 0.7205

9 9 0.6995

10 0 0.6793

10 1 0.6597

10 2 0.6408

10 3 0.6225

10 4 0.6048

10 5 0.5877

10 6 0.5712

10 7 0.5552

10 8 0.5397

10 9 0.5248

11 0 0.5103

11 1 0.4963

11 2 0.4827

11 3 0.4695

11 4 0.4568

11 5 0.4445

11 6 0.4326

11 7 0.4210

11 8 0.4098

11 9 0.3990

12 0 0.3885

TEMP(ºC) R(K )

4 1 5.118

4 2 4.918

4 3 4.727

4 4 4.544

4 5 4.370

4 6 4.203

4 7 4.043

4 8 3.890

4 9 3.744

5 0 3.604

5 1 3.470

5 2 3.342

5 3 3.219

5 4 3.101

5 5 2.988

5 6 2.880

5 7 2.776

5 8 2.677

5 9 2.581

6 0 2.490

6 1 2.402

6 2 2.318

6 3 2.237

6 4 2.160

6 5 2.085

6 6 2.013

6 7 1.945

6 8 1.879

6 9 1.815

7 0 1.754

7 1 1.695

7 2 1.639

7 3 1.585

7 4 1.532

7 5 1.482

7 6 1.434

7 7 1.387

7 8 1.343

7 9 1.300

8 0 1.258

TEMP(ºC) R(K )

1 31.04

2 29.51

3 28.06

4 26.69

5 25.40

6 24.18

7 23.02

8 21.92

9 20.88

1 0 19.90

1 1 18.97

1 2 18.09

1 3 17.26

1 4 16.46

1 5 15.71

1 6 15.00

1 7 14.32

1 8 13.68

1 9 13.07

2 0 12.49

2 1 11.94

2 2 11.42

2 3 10.92

2 4 10.45

2 5 10.00

2 6 9.572

2 7 9.165

2 8 8.778

2 9 8.409

3 0 8.057

3 1 7.722

3 2 7.403

3 3 7.099

3 4 6.809

3 5 6.532

3 6 6.268

3 7 6.016

3 8 5.776

3 9 5.547

4 0 5.327

TEMP(ºC) R(K )

-4 0 339.9

-3 9 317.9

-3 8 297.5

-3 7 278.6

-3 6 260.9

-3 5 244.5

-3 4 229.3

-3 3 215.1

-3 2 201.8

-3 1 189.5

-3 0 178.0

-2 9 167.2

-2 8 157.2

-2 7 147.9

-2 6 139.1

-2 5 130.9

-2 4 123.3

-2 3 116.2

-2 2 109.5

-2 1 103.2

-2 0 97.34

-1 9 91.85

-1 8 86.70

-1 7 81.87

-1 6 77.34

-1 5 73.08

-1 4 69.09

-1 3 65.34

-1 2 61.82

-1 1 58.50

-1 0 55.39

- 9 52.46

- 8 49.70

- 7 47.10

- 6 44.66

- 5 42.35

- 4 40.18

- 3 38.14

- 2 36.21

- 1 34.38

0 32.67

58

59

TROUBLE SHOOTING

10

Note 1)

a Neither indoor unit nor outdoor unit runs

Check the following point first (There is following case in normal operation).

a. Is the timer mode set to “TIMER-OFF” and the timer had passed?

b Neither outdoor fan nor compresssor runs while indoor fan runs

Check following points first (There are following cases in normal operation).

a. Is the temperature setpoint suitable?

b. Has the 3 minutes time guard for compressor operated?

c. Has the frost prevention function operated? (When the indoor coil temperature is below 0°C)

d. Is the operation mode dry mode?

(In dry mode, the unit stops intermittently according to the difference between room temperature and temperature setpoint)

Note 2) Please refer to page 24, f self Diagnostic function.

60

61

DISASSEMBLY INSTRUCTIONS

11

• INDOOR UNIT

1. INDOOR UNIT

(1) Turn off operation of the air conditioner and

disconnect the power cord from the wall outlet.

2. Removing the Front Panel

(1) Lift insert grille to the top of the unit with both hands

and it will be automatically separated from the unit.

(fig. 1)

(2) After detaching terminal block cover by removing two

screws, remove two screws from frame grille. (fig. 2)

(3) After pulling the triangle marks located at the bottom

of the frame grille, lift frame grille to the top of the

unit. (fig. 3)

3. Removing the drain pan

(1) Detach stepper motor wire from the stepper motor.

(2) Remove two screws from the drain pan.

(3) Detach the drain pan by pulling snap-fits of the body

and remove drain hose if necessary. (fig. 4)

4. Removing the Control Box

(1) Detach air and coil sensor from the coil.

(2) Remove one screw and one toothed washer for

ground wires. (fig. 5)

(3) Disconnect fan motor lead wire and hall sensor wire

from connectors on PCB.

(4) Remove one screw from the control box. (fig. 6)

(5) Detach control box by lifting the lower part.

Fig. 1

Fig. 2

Fig. 3-1

Fig. 3-2

Fig. 4

PROCEDURES PHOTOS

5. Removing the indoor coil.

(1) Turn the unit over and you will find one screw for insert

body.

(2) Remove one screw and detach insert body. (fig. 7)

(3) Turn the unit over again and remove three screws from

the coil.

(4) Detach coil by pulling the snap-fit out from the unit.

(fig. 8)

6. Removing blower and fan motor.

(1) Detach bearing bracket by removing one screw from

the body. (fig. 9)

(2) Loosen a set-screw inside the blower with hex key

wrench(M3). (fig. 10)

(3) Pull the blower out.

(4) Detach motor bracket L and R by removing two

screws from the body. (fig. 11)

(5) Pull the motor out.

Fig. 5

Fig. 9

Fig. 10

PROCEDURES PHOTOS

Fig. 6

Fig. 7 Fig. 8

Fig. 11

62

EXPLODED DIAGRAM AND PARTS LIST

12

63

64

• 42HWG007/009, HWG195C/225C

COOL COOL COOL COOL

N O . PART NAME

42HWG007 42HWG009 HWG195C HWG225C

REMARK

1 BOX AS, CONTROL 1 1

11

1- 1 TRANSFORMER 1 1 1 1

1-2 BOX, CONTROL 1 1 1 1

1- 3 PCB AS, T/B 1 1 1 1

1- 4 PCB AS, DISPLAY 1 1 1 1

1- 5 BRACKET, LED 1 1 1 1

1- 6 PCB AS 1, CONTROL 1 1

11

1- 7 THERMISTOR AS 1 1 1 1

2 BRACKET, MTG 1 1 1 1

3 BODY ASSY 1 1 1 1

4 BLOWER AS 1 1 1 1

5 PLA, BEARING AS 1 1 1 1

6 CUSHION, L BRG 1 1 1 1

7 BRACKET, BEARING 1 1 1 1

8 CYCLE AS, FCU 1 1 1 1

2ROW-2CIRCUIT

9 GUARD, EVAP 1 1 1 1

1 0 GUARD, TOP EVAP 1 1 1 1

1 1 INSU AS, DRN PAN 1 1 1 1

1 2 BLADE 1, VERTICAL 2 2 2 2

1 3 BLADE 2, VERTICAL 1 1 1 1

14 SUPPORT, FLAP 2 2 2 2

1 5 LINK, FLAP 1 1 1 1

16 BUSHING 3 3 3 3

1 7 FLAP 1 1 1 1 1

1 8 FLAP 2 1 1 1 1

19 STEPPING MOTOR 1 1 1 1

2 0 HOSE ASSY, DRAIN 1 1 1 1

21 INSERT, BODY 1 1 1 1

22 MOTOR, FAN 1 1 1 1 IC-8415G1KG7A

23 CUSHION, MOTOR 2 2 2 2

2 4 BRACKET R, MOTOR 1 1 1 1

2 5 BRACKET L, MOTOR 1 1 1 1

2 6 INSU, TUBE EVAP 1 1 1 1

27 HOLDER, SENSOR 1 1 1 1

2 8 CLIP, SENSOR 1 1 1 1

2 9 COVER, T/B 1 1 1 1

3 0 GRILLE AS, FRAME 1 1 1 1

3 1 GRILLE AS, INSERT 1 1 G-Grille

1 1 N-Grille

3 2 FILTER AS 2 2 2 2

33 BRACKET, SENSOR 1 1 1 1

34 DISPLAY, LED 1 1 1 1

35 REMOCON ASSY 1 1

11

36 CASE AS, REMOCON 1 1 1 1

37 COLLECTOR 2 2 2 2 OPTION

3 8 FILTER AS, ELEC 1 1 1 1 OPTION

3 9 FILTER AS CARBON 1 1 1 1 OPTION

65

• 42HQG007/009, HWG195H/225H

HEATPUMP HEATPUMP HEATPUMP HEATPUMP

N O . PART NAME

42HQG007 42HQG009 HWG195H HWG225H

REMARK

1 BOX AS, CONTROL 1 1

11

1- 1 TRANSFORMER 1 1 1 1

1-2 BOX, CONTROL 1 1 1 1

1- 3 PCB AS, T/B 1 1 1 1

1- 4 PCB AS, DISPLAY 1 1 1 1

1- 5 BRACKET, LED 1 1 1 1

1- 6 PCB AS 1, CONTROL 1 1

11

1- 7 THERMISTOR AS 1 1 1 1

2 BRACKET, MTG 1 1 1 1

3 BODY ASSY 1 1 1 1

4 BLOWER AS 1 1 1 1

5 PLA, BEARING AS 1 1 1 1

6 CUSHION, L BRG 1 1 1 1

7 BRACKET, BEARING 1 1 1 1

8 CYCLE AS, FCU 1 1 1 1

9 GUARD, EVAP 1 1 1 1

1 0 GUARD, TOP EVAP 1 1 1 1

1 1 INSU AS, DRN PAN 1 1 1 1

1 2 BLADE 1, VERTICAL 2 2 2 2

1 3 BLADE 2, VERTICAL 1 1 1 1

14 SUPPORT, FLAP 2 2 2 2

1 5 LINK, FLAP 1 1 1 1

16 BUSHING 3 3 3 3

1 7 FLAP 1 1 1 1 1

1 8 FLAP 2 1 1 1 1

19 STEPPING MOTOR 1 1 1 1

2 0 HOSE ASSY, DRAIN 1 1 1 1

21 INSERT, BODY 1 1 1 1

22 MOTOR, FAN 1 1 1 1

IC-8415G1KG7A

23 CUSHION, MOTOR 2 2 2 2

2 4 BRACKET R, MOTOR 1 1 1 1

2 5 BRACKET L, MOTOR 1 1 1 1

2 6 INSU, TUBE EVAP 1 1 1 1

27 HOLDER, SENSOR 1 1 1 1

2 8 CLIP, SENSOR 1 1 1 1

2 9 COVER, T/B 1 1 1 1

3 0 GRILLE AS, FRAME 1 1 1 1

3 1 GRILLE AS, INSERT 1 1 G-Grille

1 1 N-Grille

3 2 FILTER AS 2 2 2 2

33 BRACKET, SENSOR 1 1 1 1

34 DISPLAY, LED 1 1 1 1

35 REMOCON ASSY 1 1

11

36 CASE AS, REMOCON 1 1 1 1

66

• 42HWG012, HWG305C, 42HQG012, HQG305H

1 BOX AS, CONTROL 1 1

11

1- 1 TRANSFORMER 1 1 1 1

1-2 BOX, CONTROL 1 1 1 1

1- 3 PCB AS, T/B 1 1

11

1- 4 PCB AS, DISPLAY 1 1 1 1

1- 5 BRACKET, LED 1 1 1 1

1- 6 PCB AS 1, CONTROL 1 1

11

1- 7 THERMISTOR AS 1 1 1 1

2 BRACKET, MTG 1 1 1 1

3 BODY ASSY 1 1 1 1

4 BLOWER AS 1 1 1 1

5 PLA, BEARING AS 1 1 1 1

6 CUSHION, L BRG 1 1 1 1

7 BRACKET, BEARING 1 1 1 1

8 CYCLE AS, FCU 1 1 1 1 16FPI

9 GUARD, EVAP 1 1 1 1

1 0 GUARD, TOP EVAP 1 1 1 1

1 1 INSU AS, DRN PAN 1 1 1 1

1 2 BLADE 1, VERTICAL 2 2 2 2

1 3 BLADE 2, VERTICAL 1 1 1 1

14 SUPPORT, FLAP 2 2 2 2

1 5 LINK, FLAP 1 1 1 1

16 BUSHING 3 3 3 3

1 7 FLAP 1 1 1 1 1

1 8 FLAP 2 1 1 1 1

19 STEPPING MOTOR 1 1 1 1

2 0 HOSE ASSY, DRAIN 1 1 1 1

21 INSERT, BODY 1 1 1 1

22 MOTOR, FAN 1 1 1 1 IC-9420G2KG7A

23 CUSHION, MOTOR 2 2 2 2

2 4 BRACKET R, MOTOR 1 1 1 1

2 5 BRACKET L, MOTOR 1 1 1 1

2 6 INSU, TUBE EVAP 1 1 1 1

27 HOLDER, SENSOR 1 1 1 1

2 8 CLIP, SENSOR 1 1 1 1

2 9 COVER, T/B 1 1 1 1

3 0 GRILLE AS, FRAME 1 1 1 1

3 1 GRILLE AS, INSERT 1 1 G-Grille

1 1 N-Grille

3 2 FILTER AS 2 2 2 2

33 BRACKET, SENSOR 1 1 1 1

34 DISPLAY, LED 1 1 1 1

35 REMOCON ASSY 1

1

1

1

36 CASE AS, REMOCON 1 1 1 1

37 COLLECTOR 1 1 1 1 OPTION

3 8 FILTER DEODOR

1 1 1 1 OPTION

FILTER ELECTRO

39 FILTER CARBON 1 1 1 1 OPTION

COOL COOL HE ATPUMP HEATPUMP

N O. PART NAME

42HWG012 HWG305C 42HQG012 42HQG305H

REMARK

67

• 42HWG018/024, HWG455C/605C

1 BOX AS, CONTROL 1 1

11

1- 1 TRANSFORMER 1 1 1 1

1-2 BOX, CONTROL 1 1 1 1

1- 3 PCB AS, T/B 1 1 1 1

1- 4 PCB AS, DISPLAY 1 1 1 1

1- 6 BRACKET, LED 1 1 1 1

1- 7 PCB AS 1, CONTROL 1 1

11

1- 8 THERMISTOR AS 1 1 1 1

2 BRACKET, MTG 1 1 1 1

3 BODY ASSY 1 1 1 1

4 BLOWER AS 1 1 1 1

5 PLA, BEARING AS 1 1 1 1

6 CUSHION, L BRG 1 1 1 1

7 BRACKET, BEARING 1 1 1 1

8 CYCLE AS, FCU 1 1 1/4”, 1/2”

1 1 1/4”, 5/8”

9 GUARD, EVAP 1 1 1 1

1 0 GUARD, TOP EVAP 1 1 1 1

1 1 INSU AS, DRN PAN 1 1 1 1

1 2 BLADE 1, VERTICAL 2 2 2 2

1 3 BLADE 2, VERTICAL 1 1 1 1

14 SUPPORT, FLAP 2 2 2 2

1 5 LINK, FLAP 1 1 1 1

16 BUSHING 3 3 3 3

1 7 FLAP 1 1 1 1 1

1 8 FLAP 2 2 2 2 2

19 STEPPING MOTOR 1 1 1 1

2 0 HOSE ASSY, DRAIN 1 1 1 1

21 INSERT, BODY 1 1 1 1

22 MOTOR, FAN 1 1 1 1

IC-9430G4KG7A

23 CUSHION, MOTOR 2 2 2 2

2 4 BRACKET R, MOTOR 1 1 1 1

2 5 BRACKET L, MOTOR 1 1 1 1

2 6 INSU, TUBE EVAP 1 1 1 1

27 HOLDER, SENSOR 1 1 1 1

2 8 CLIP, SENSOR 1 1 1 1

2 9 COVER, T/B 1 1 1 1

3 0 GRILLE AS, FRAME 1 1 1 1

3 1 GRILLE AS, INSERT 1 1 G-Grille

1 1 N-Grille

3 2 FILTER AS 2 2 2 2

33 BRACKET, SENSOR 1 1 1 1

34 DISPLAY, LED 1 1 1 1

35 REMOCON ASSY 1 1

11

36 CASE AS, REMOCON 1 1 1 1

COOL COOL COOL COOL

N O . PART NAME

42HWG018 42HWG024 HWG455C HWG605C

REMARK

68

• 42HQG018/024, HQG455H/605H

1 BOX AS, CONTROL 1 1

11

1- 1 TRANSFORMER 1 1 1 1

1-2 BOX, CONTROL 1 1 1 1

1- 3 PCB AS, T/B 1 1 1 1

1- 4 PCB AS, DISPLAY 1 1 1 1

1- 5 BRACKET, LED 1 1 1 1

1- 6 PCB AS 1, CONTROL 1 1

11

1- 7 THERMISTOR AS 1 1 1 1

2 BRACKET, MTG 1 1 1 1

3 BODY ASSY 1 1 1 1

4 BLOWER AS 1 1 1 1

5 PLA, BEARING AS 1 1 1 1

6 CUSHION, L BRG 1 1 1 1

7 BRACKET, BEARING 1 1 1 1

8 CYCLE AS, FCU 1 1 1/4”, 1/2”

1 1 1/4”, 5/8”

9 GUARD, EVAP 1 1 1 1

1 0 GUARD, TOP EVAP NOT USED

1 1 INSU AS, DRN PAN 1 1 1 1

1 2 BLADE 1, VERTICAL 2 2 2 2

1 3 BLADE 2, VERTICAL 1 1 1 1

14 SUPPORT, FLAP 2 2 2 2

1 5 LINK, FLAP 1 1 1 1

16 BUSHING 3 3 3 3

1 7 FLAP 1 1 1 1 1

1 8 FLAP 2 1 1 1 1

19 STEPPING MOTOR 1 1 1 1

2 0 HOSE ASSY, DRAIN 1 1 1 1

21 INSERT, BODY 1 1 1 1

22 MOTOR, FAN 1 1 1 1 IC-9430G4KG7A

23 CUSHION, MOTOR 2 2 2 2

2 4 BRACKET R, MOTOR 1 1 1 1

2 5 BRACKET L, MOTOR 1 1 1 1

2 6 INSU, TUBE EVAP 1 1 1 1

27 HOLDER, SENSOR 1 1 1 1

2 8 CLIP, SENSOR 1 1 1 1

2 9 COVER, T/B 1 1 1 1

3 0 GRILLE AS, FRAME 1 1 1 1

3 1 GRILLE AS, INSERT 1 1 G-Grille

1 1 N-Grille

3 2 FILTER AS 2 2 2 2

33 BRACKET, SENSOR 1 1 1 1

34 DISPLAY, LED 1 1 1 1

35 REMOCON ASSY 1 1

11

36 CASE AS, REMOCON 1 1 1 1

37 COLLECTOR 1 1 1 1 OPTION

3 8 FILTER DEODOR

FILTER ELECTRO

1 1 1 1 OPTION

39 FILTER CARBON 1 1 1 1 OPTION

HEATPUMP HEATPUMP HEATPUMP HEATPUMP

N O. PART NAME

42HQG018 42HQG024 HQG455H HQG605H

REMARK

69

• REMOTE CONTROL

42HWG007/009/012/018/024, 42HQG007/009/012/018/024,

HWG195/225/305/455/605C, HWG195/225/305/455/605H

COOL COOL HEATPUMP HEATPUMP

N O . PART NAME 42HWG007/009/ HWG195/225/305/ 42HQG007/009/ HWG195/225/305/ REMARK

012/018/024 455/605C 012/018/024 455/605H

1 BOX 1, REMOCON 1 1 1 1

2 DISPLAY, LCD 1 1

11

3 BOX 2, REMOCON 1 1

11

4 RUBBER 1, SWITCH 1 1 1 1

5 PCB AS, REMOCON 1 1

11

6 LCD DISPLAY 1 1 1 1

7 ZEBRA CONTACT 2 2 2 2

8 BRACKET, LCD 1 1 1 1

9 SPRING, BATTERY 1 1 1 1

1 0 RUBBER 2, SWITCH 1 1 1 1

11 SCREEN 1 1 1 1

12 COVER, REMOCON 1 1 1 1

13 DOOR, REMOCON 1 1 1 1

1 4 DOOR, BATTERY 1 1 1 1

70

General notes

1. Shown performances are valid under the following conditions:

a) indoor / outdoor tubing length 6 m

b) indoor / outdoor unit level difference O m

c) indoor fan running at high speed

2. Correction factors for different tubing length and / or different indoor fan speed

are shown in Table 1, Table 2a and 2b.

Please see the installation manual of the outdoor unit for the maximum

allowed tubing length.

3. Interpolation of shown data is allowed.

4. Extrapolation of shown data is not allowed.

5. Shown Total Sensible Capacity SHC are based on indoor coil entering air dry bulb

temperature 27 °C, as per ISO 5151.

6. Correction factors for different air temperature are shown in Table 3.

7. Cooling and heating capacities include the heat generated by the indoor fan motor.

Legend

BF = Bypass factor

EWB = Indoor air wet bulb temperature (indoor coil inlet) °C

KW = Total input power kW

SHC = Total sensiblecapacity kW

TC = Total cooling capacity kW

TH = Total heating capacity kW

THI = Integrated heating capacity kW

71

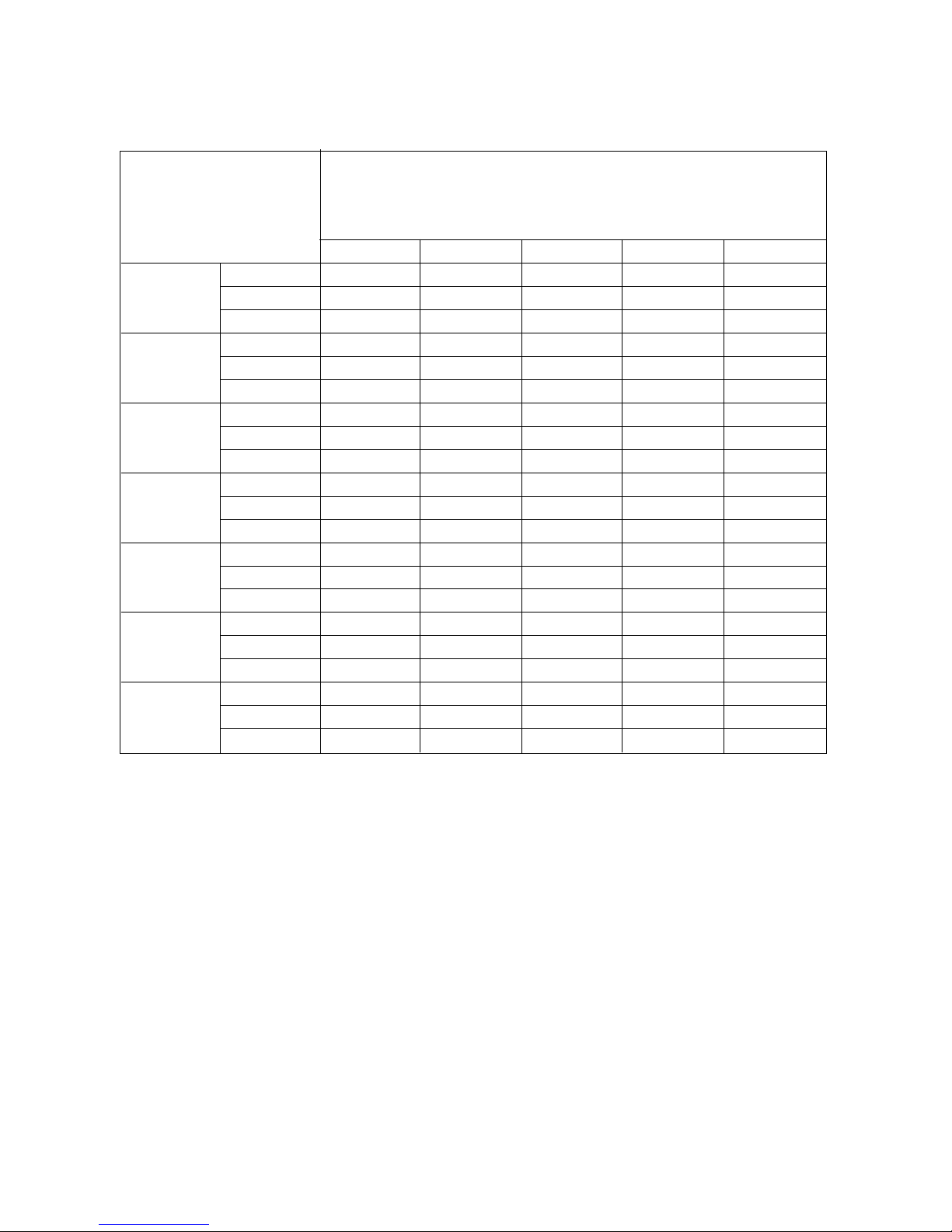

CORRECTION FACTOR OF COOLING AND HEATING

SYSTEM PERFORMANCES DUE TO

INDOOR / OUTDOOR PIPING LENGTH

UNIT PIPING LENGTH

SIZE 3 6 10 15 25

07 1.02 1 0.97 0.93 ==

09 1.02 1 0.97 0.93 ==

12 1.02 1 0.97 0.93 ==

18 1.01 1 0.99 0.97 0.95

24 1.01 1 0.97 0.95 0.93

EXTENDING RATINGS

13

1) TABLE 1

72

2) TABLE 2

CORRECTION FACTORS OF SYSTEM PERFORMANCES

DUE TO INDOOR UNIT FAN SPEED

2A - COOLING MODE

UNIT FAN COOLING CAPACITY POWER

SIZE SPEED TOTAL SENSIBLE INPUT

Hi 1.00 1.00 1.00

07 Me 0.98 0.93 0.99

Lo 0.96 0.87 0.98

Hi 1.00 1.00 1.00

09 Me 0.98 0.93 0.99

Lo 0.96 0.87 0.99

Hi 1.00 1.00 1.00

12 Me 0.98 0.96 0.99

Lo 0.96 0.93 0.98