Page 1

Flotronic™ II Reciprocating Liquid Chillers

Controls, Operation, and

Troubleshooting

with Microprocessor Controls and Electronic Expansion Valves

CONTENTS

Page

SAFETY CONSIDERATIONS ..................2

GENERAL ...................................2

MAJOR SYSTEM COMPONENTS ............2-5

Processor Module ...........................2

Low-Voltage Relay Module ...................4

Electronic Expansion Valve Module ...........4

Options Module .............................4

Keypad and Display Module

(Also Called HSIO or LID) ..................4

Control Switch ..............................4

Electronic Expansion Valve (EXV) ............4

Thermostatic Expansion Valves (TXV) ........4

Sensors .....................................5

Compressor Protection Control

Module (CPCS) ............................5

OPERATION DATA ..........................5-46

Capacity Control ............................5

Head Pressure Control ......................24

• EXV UNITS

• TXV UNITS

Pumpout ...................................24

• EXV UNITS

• TXV UNITS

Keypad and Display Module

(Also Called HSIO or LID) .................24

• ACCESSING FUNCTIONS AND SUBFUNCTIONS

• AUTOMATIC DEFAULT DISPLAY

• AUTOMATIC DISPLAY OPERATION/DEFAULT

DISPLAY

• KEYPAD OPERATING INSTRUCTIONS

• STATUS FUNCTION

• TEST FUNCTION

• HISTORY FUNCTION

• SET POINT FUNCTION

• SERVICE FUNCTION

• SCHEDULE FUNCTION

TROUBLESHOOTING ......................47-64

Checking Display Codes ....................47

30GN040-420

50/60 Hz

Page

Unit Shutoff ................................48

Complete Unit Stoppage ....................48

Single Circuit Stoppage .....................48

Lag Compressor Stoppage ..................48

Restart Procedure ..........................48

• POWER FAILURE EXTERNAL TO THE UNIT

Alarms and Alerts ..........................48

Compressor Alarm/Alert Circuit .............50

Electronic Expansion Valve (EXV) ...........55

• EXV OPERATION

• CHECKOUT PROCEDURE

Thermostatic Expansion Valve (TXV) .........57

Thermistors ................................57

• LOCATION

• THERMISTOR REPLACEMENT (T1, T2, T7, T8)

Pressure Transducers ......................60

• TROUBLESHOOTING

• TRANSDUCER REPLACEMENT

Control Modules ............................63

• PROCESSOR MODULE (PSIO), 4IN/4OUT

MODULE (SIO), LOW-VOLTAGE RELAY

MODULE (DSIO-LV), AND EXV DRIVER

MODULE (DSIO-EXV)

• RED LED

• GREEN LED

• PROCESSOR MODULE (PSIO)

• LOW-VOLTAGE RELAY MODULE (DSIO)

• 4IN/4OUT MODULE (SIO)

ACCESSORY UNLOADER INSTALLATION . . . 64-68

Installation .................................65

• 040-110, 130 (60 Hz) UNITS

(And Associated Modular Units)

• 130 (50 Hz), 150-210 UNITS

(And Associated Modular Units)

FIELD WIRING .............................69,70

REPLACING DEFECTIVE PROCESSOR

MODULE (PSIO) ..........................70

Installation .................................70

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab 5c

PC 903 Catalog No. 563-079 Printed in U.S.A. Form 30GN-3T Pg 1 7-95 Replaces: 30G-1T

Page 2

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can

be hazardous due to system pressures, electrical components, and equipment location (roof, elevatedstructures,etc.).

Only trained, qualified installers and service mechanics should

install, start up, and service this equipment.

When working on this equipment, observe precautions in

the literature, and ontags, stickers, and labelsattached to the

equipment, and any other safety precautions that apply. Follow all safety codes. Wear safety glasses and work gloves.

Use care in handling, rigging, and setting this equipment,

and in handling all electrical components.

Electrical shock can cause personal injury and death.

Shut off all power to this equipment during installation

and service. There may be more than one disconnect

switch. Tag all disconnect locations to alert others not

to restore power until work is completed.

This unit uses a microprocessor-based electronic control system. Do not use jumpers or other tools to short

out components, or to bypass or otherwise depart from

recommended procedures. Any short-to-ground of the

control board or accompanying wiring may destroy the

electronic modules or electrical components.

GENERAL

IMPORTANT: This publication contains controls, operation and troubleshooting data for 30GN040-420

Flotronic™ II chillers.

Circuits are identified as circuitsAand B, and compressors are identified as A1,A2, etc. in circuit A, and

B1, B2, etc. in circuit B.

Use this guide in conjunction with separate Installation Instructions booklet packaged with the unit.

The 30G Series standard Flotronic II chillers feature

microprocessor-based electronic controls and an electronic

expansion valve (EXV) in each refrigeration circuit.

NOTE: The 30GN040 and 045 chillers with a factoryinstalled brine option have thermal expansion valves (TXV)

instead of the EXV.

Unit sizes 230-420 are modular units which are shipped

as separate sections (modulesAand B). Installation instructions specific to these units are shipped inside the individual

modules. See Table 1 for a listing of unit sizes and modular

combinations. For modules 230B-315B, follow all general

instructions as noted for unit sizes 080-110. For all remaining modules, follow instructions for unit sizes 130-210.

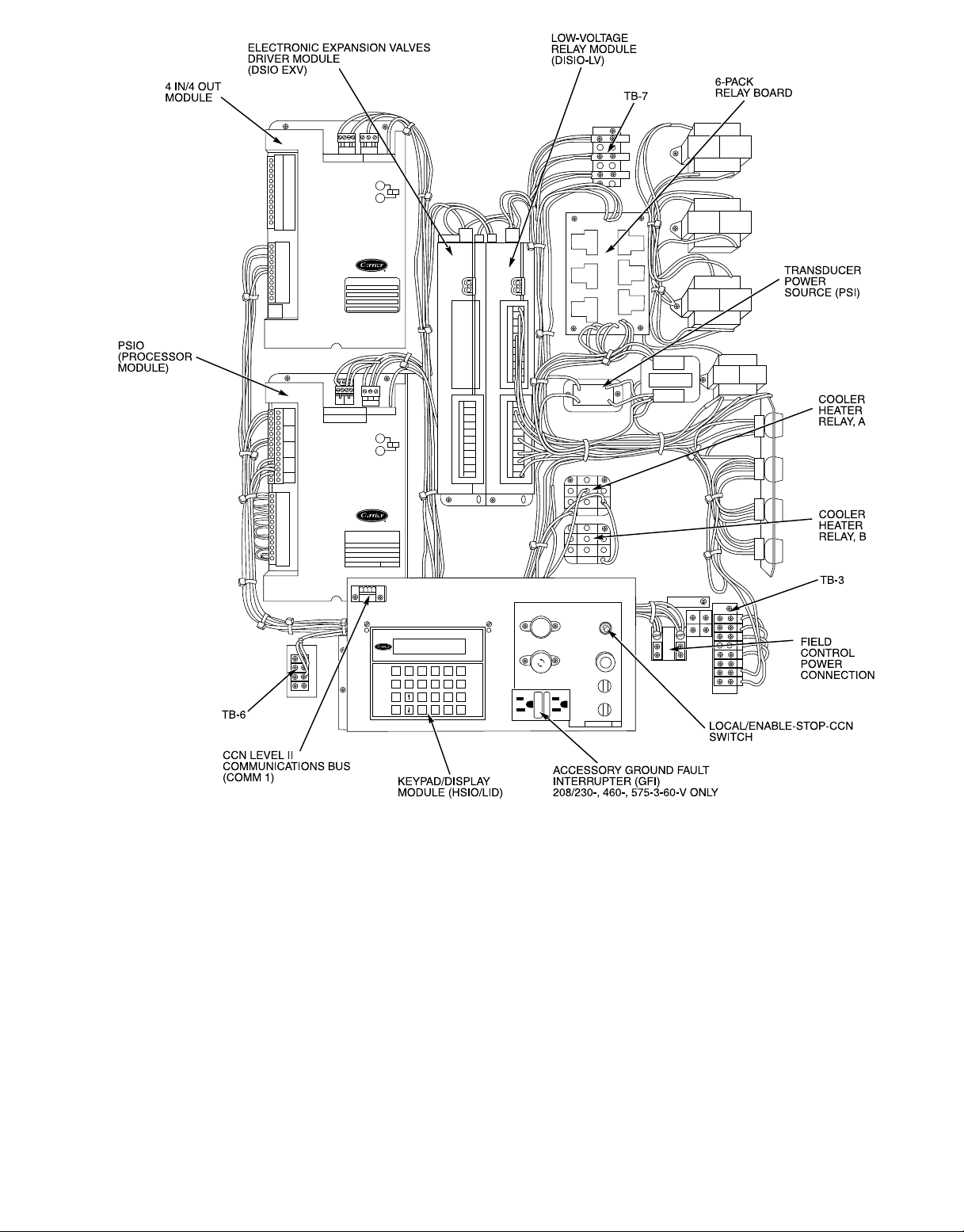

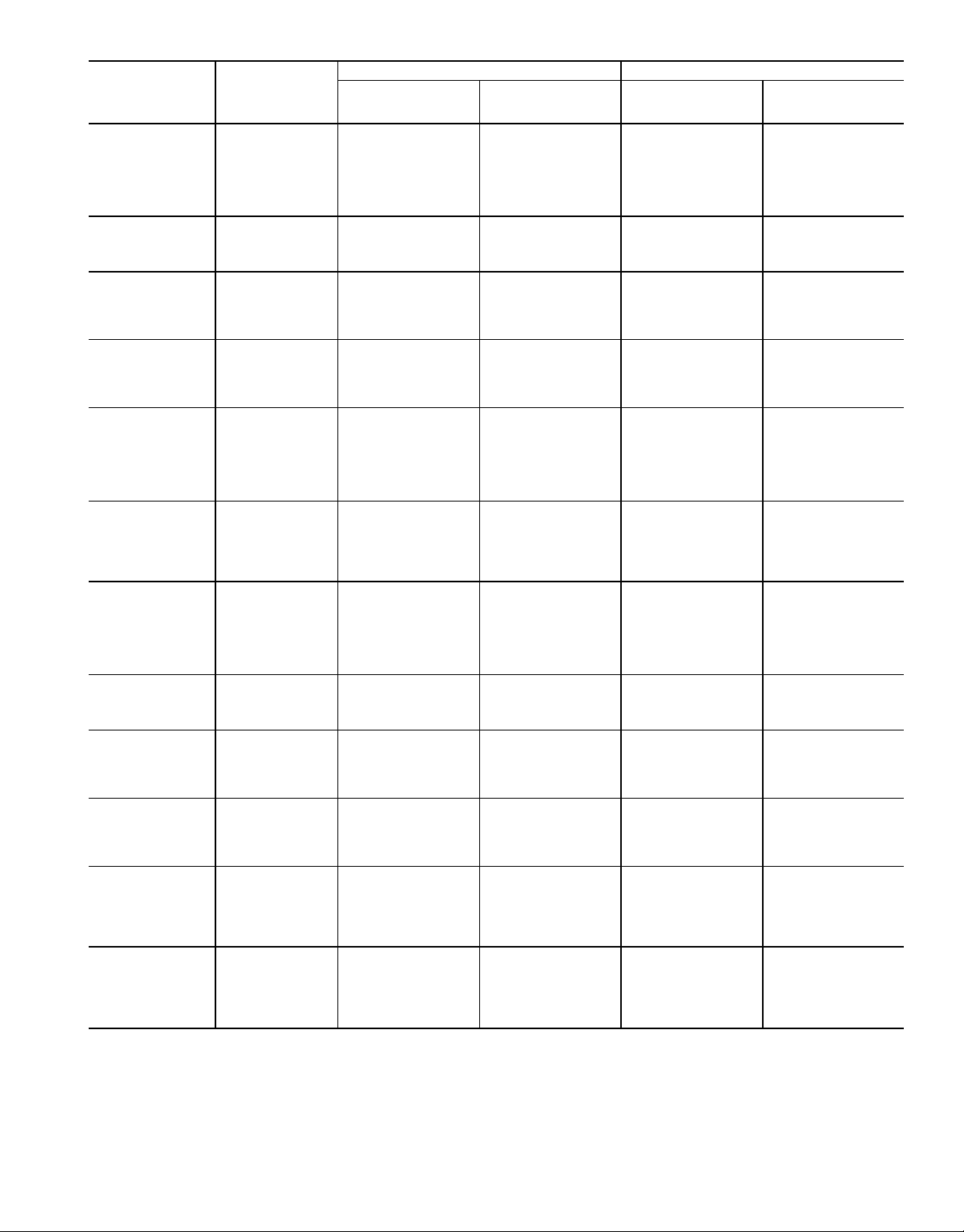

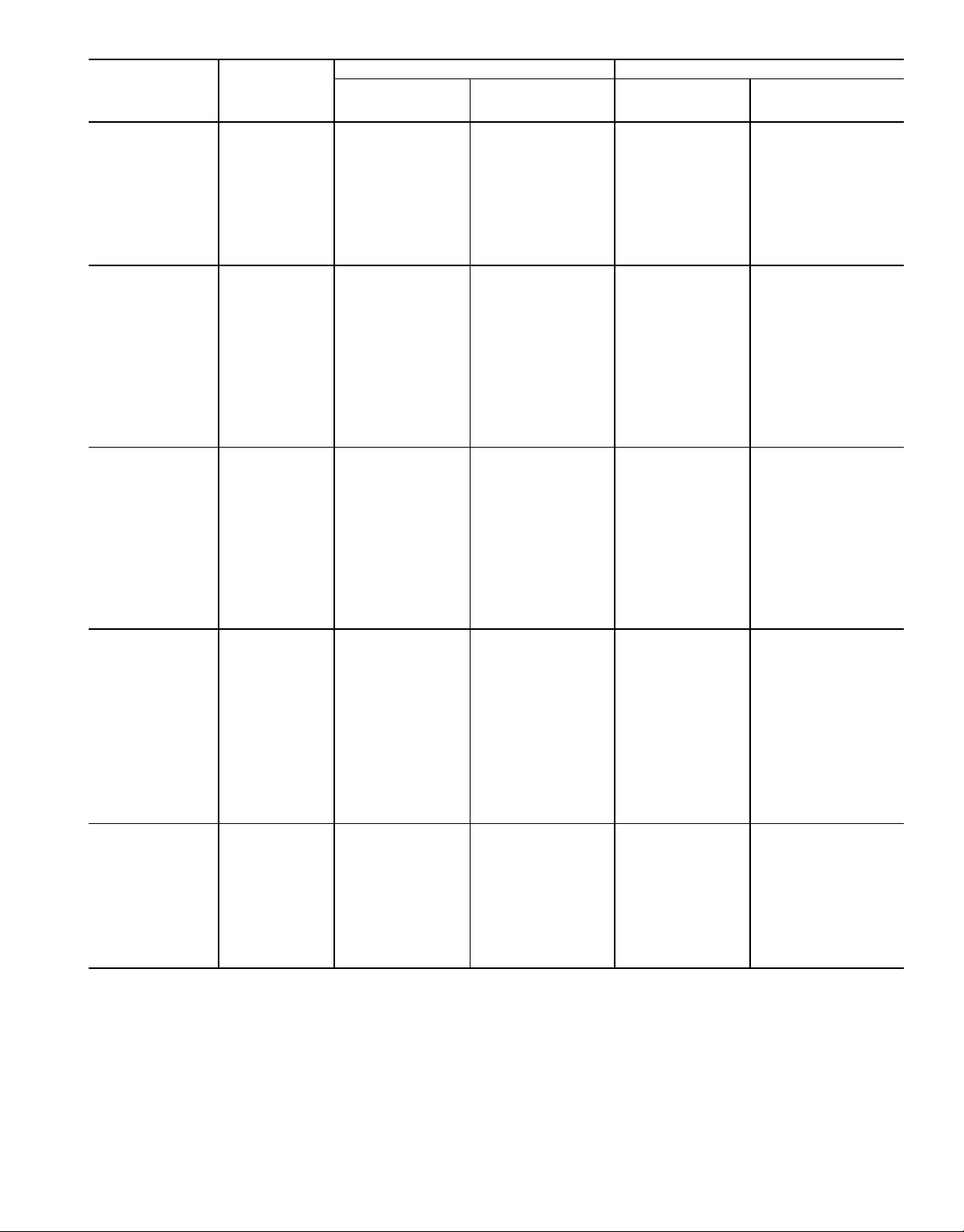

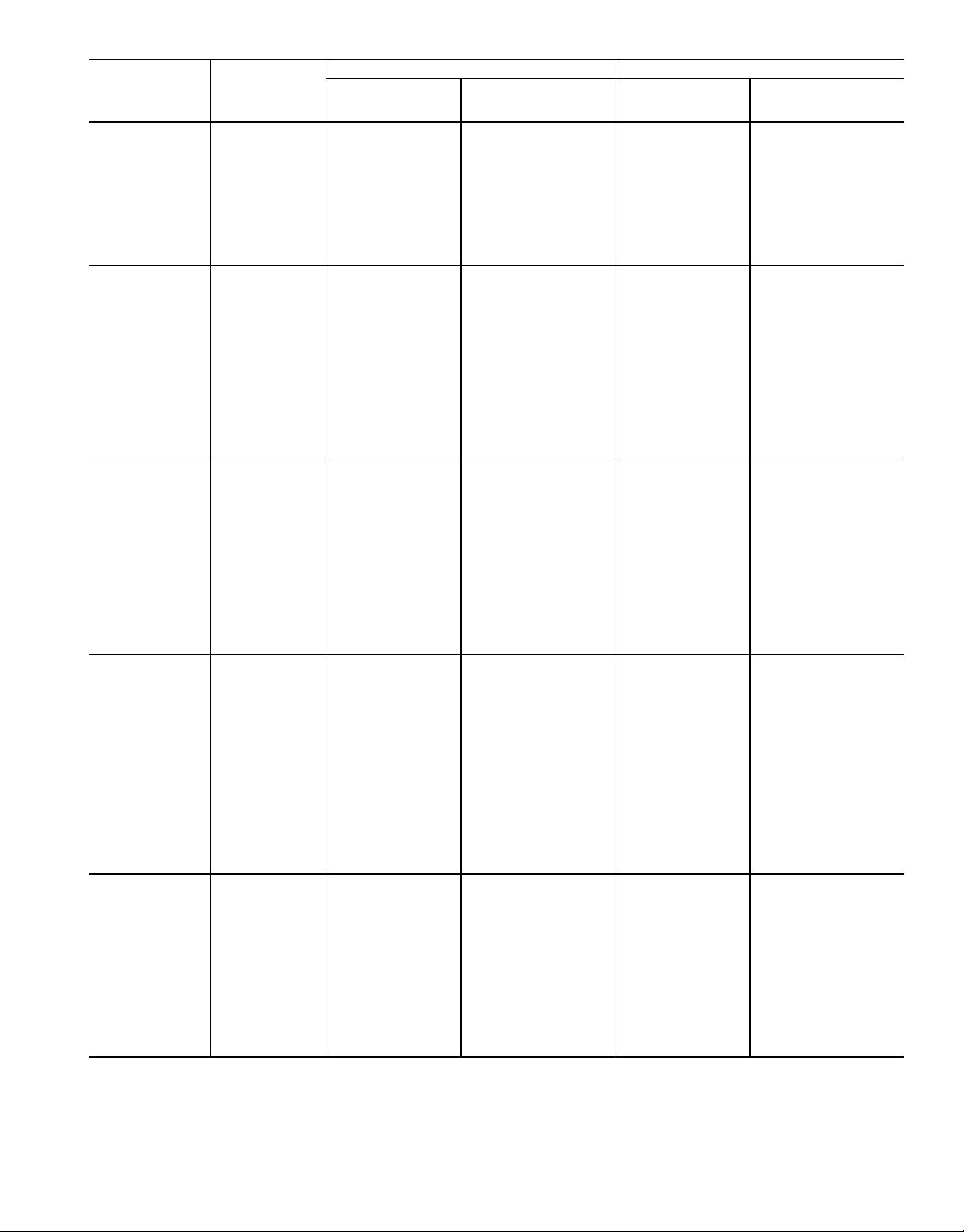

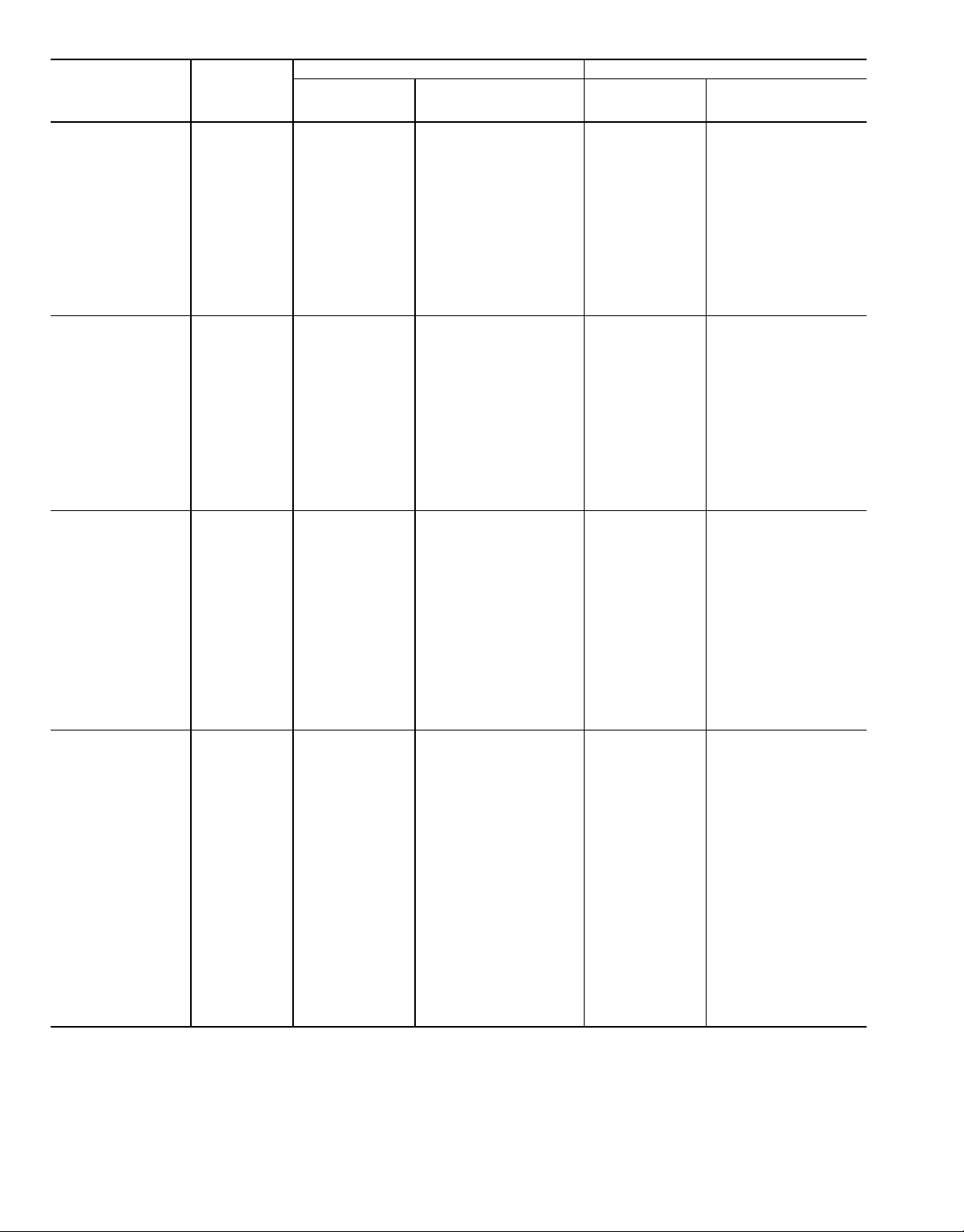

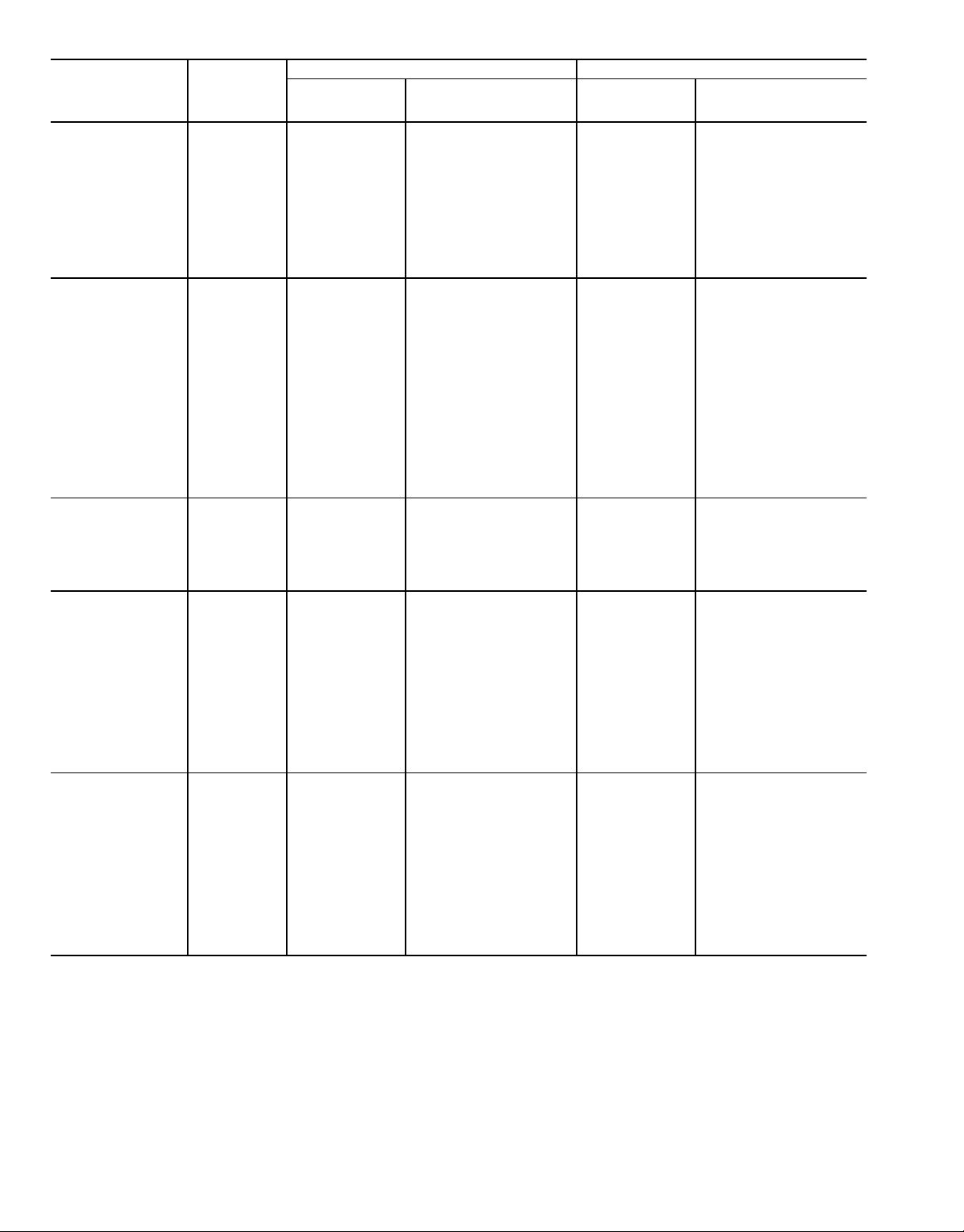

Table 1 — Unit Sizes and Modular Combinations

UNIT MODEL

30GN

040 40 — —

045 45 — —

050 50 — —

060 60 — —

070 70 — —

080 80 — —

090 90 — —

100 100 — —

110 110 — —

130 125 — —

150 145 — —

170 160 — —

190 180 — —

210 200 — —

230 220 150 080

245 230 150 090

255 240 150 100

270 260 170 100

290 280 190 110

315 300 210 110

330 325 170 170

360 350 190 190/170*

390 380 210 190

420 400 210 210

*60 Hz units/50 Hz units.

NOMINAL

TONS

SECTION A

UNIT 30GN

SECTION B

UNIT 30GN

The Flotronic II control system cycles compressor unloaders and/or compressors to maintain the selected leaving

fluid temperature set point. It automatically positions theEXV

to maintain the specified refrigerant superheat entering the

compressor cylinders. It also cycles condenser fans on and

off to maintain suitable head pressure for each circuit. Safeties are continuously monitored to prevent the unit from operating under unsafe conditions. A scheduling function, programmed by the user, controls the unit occupied/unoccupied

schedule. The control also operates a test program that allows the operator to check output signals and ensure components are operable.

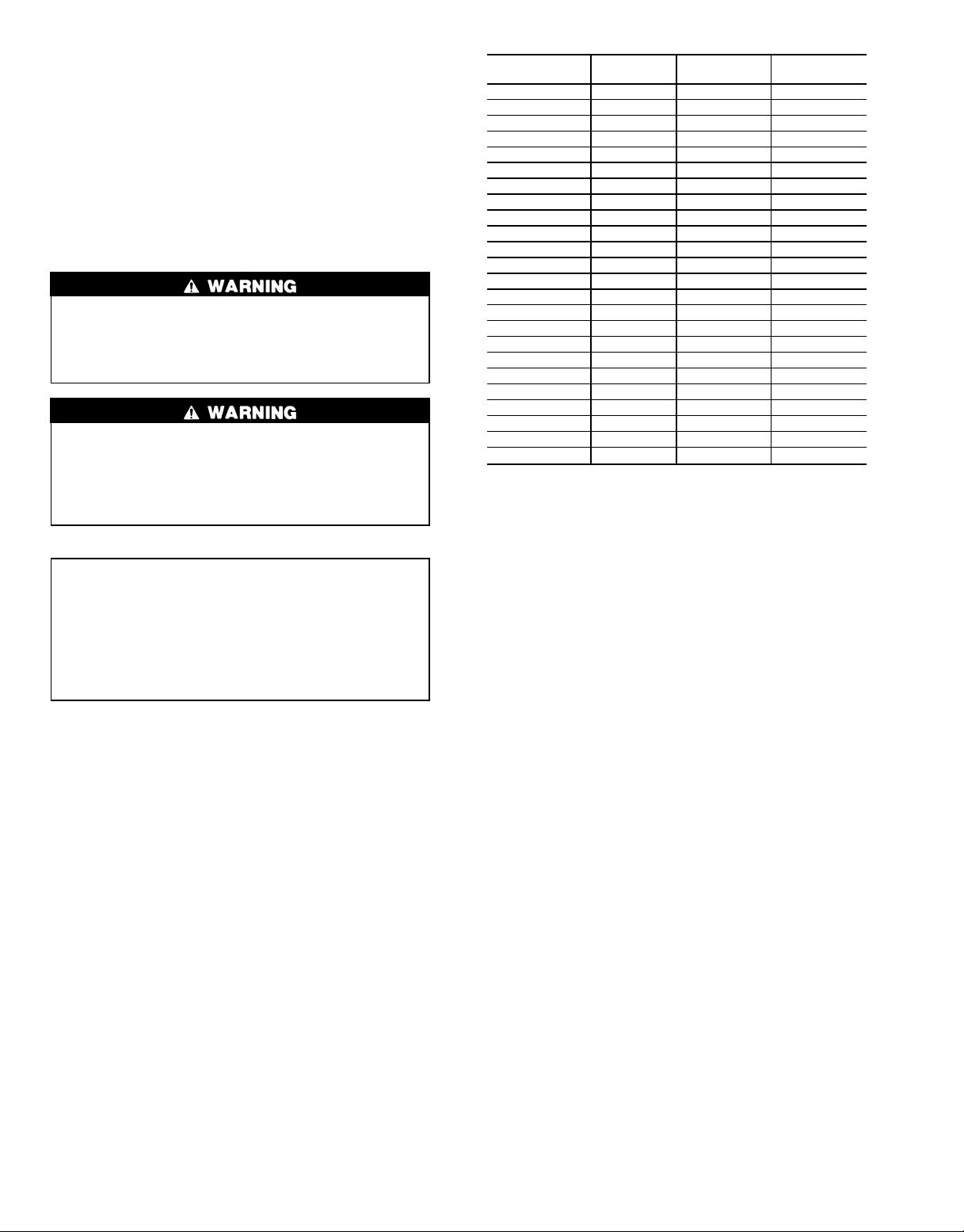

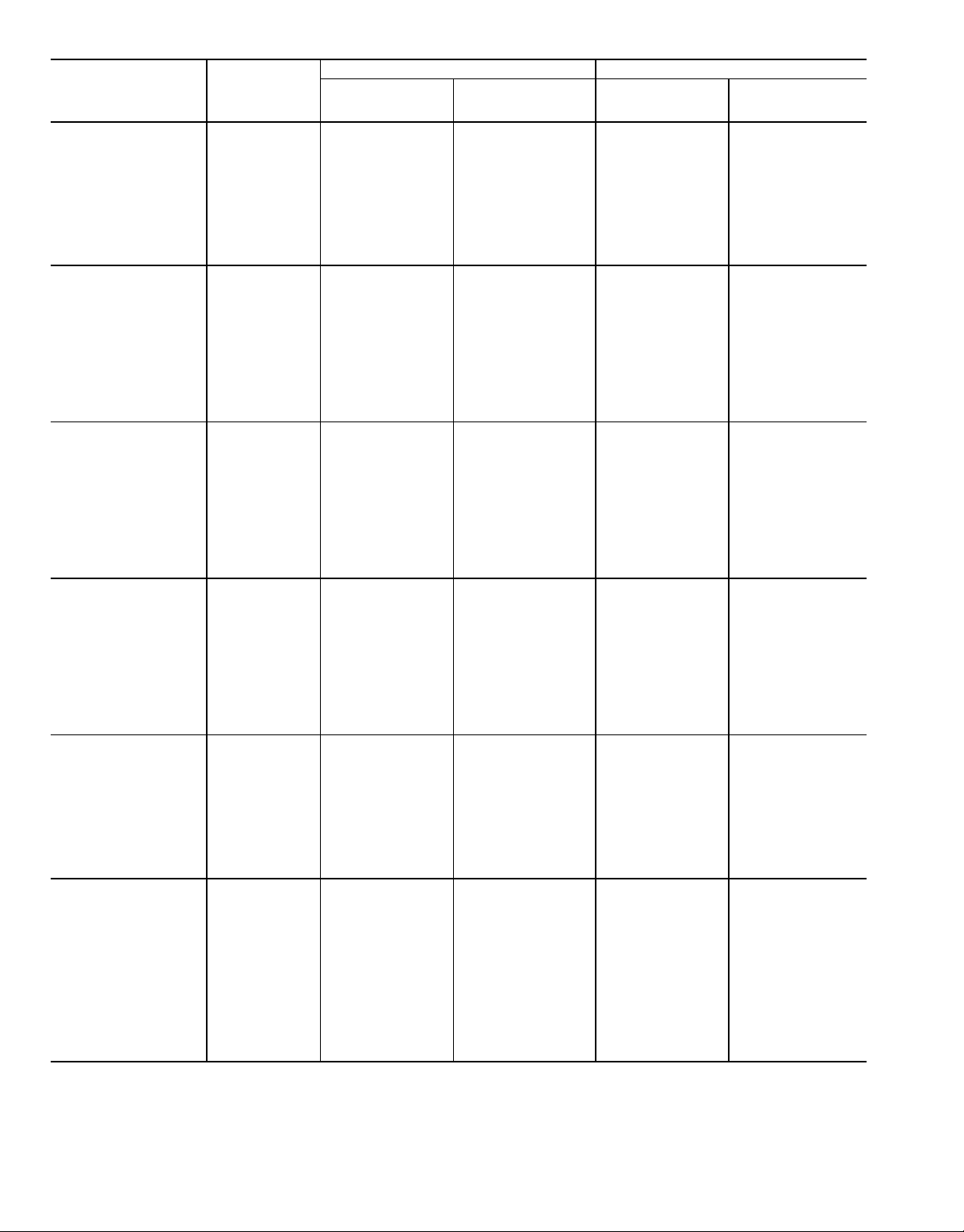

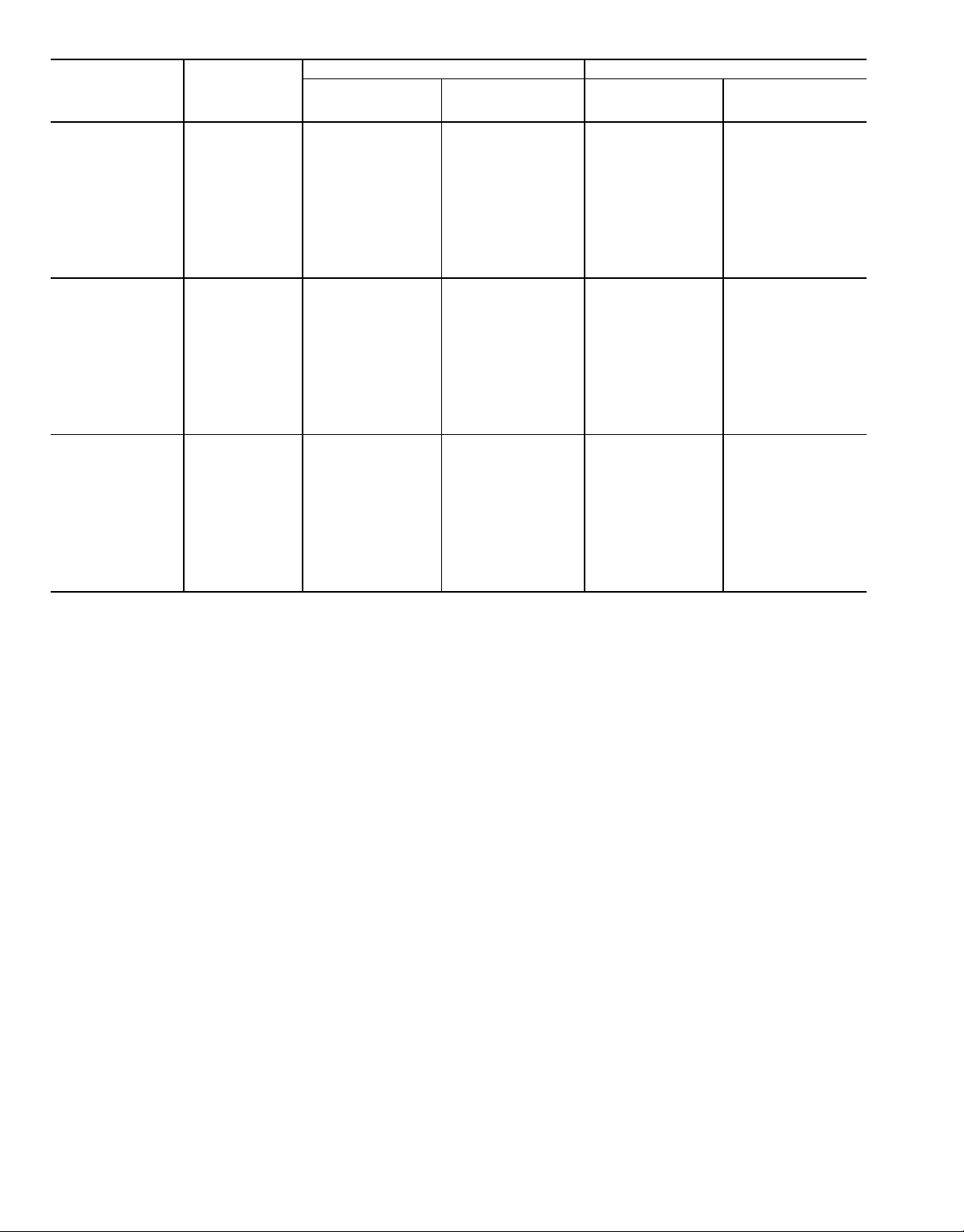

The control system consists ofaprocessor module (PSIO),

a low-voltage relay module (DSIO-LV), 2 EXVs, an EXV

driver module (DSIO-EXV), a 6-pack relay board, a keypad

and display module (also called HSIO or LID), thermistors,

and transducers to provide inputs to the microprocessor. A

standard options module (SIO) is used to provide additional

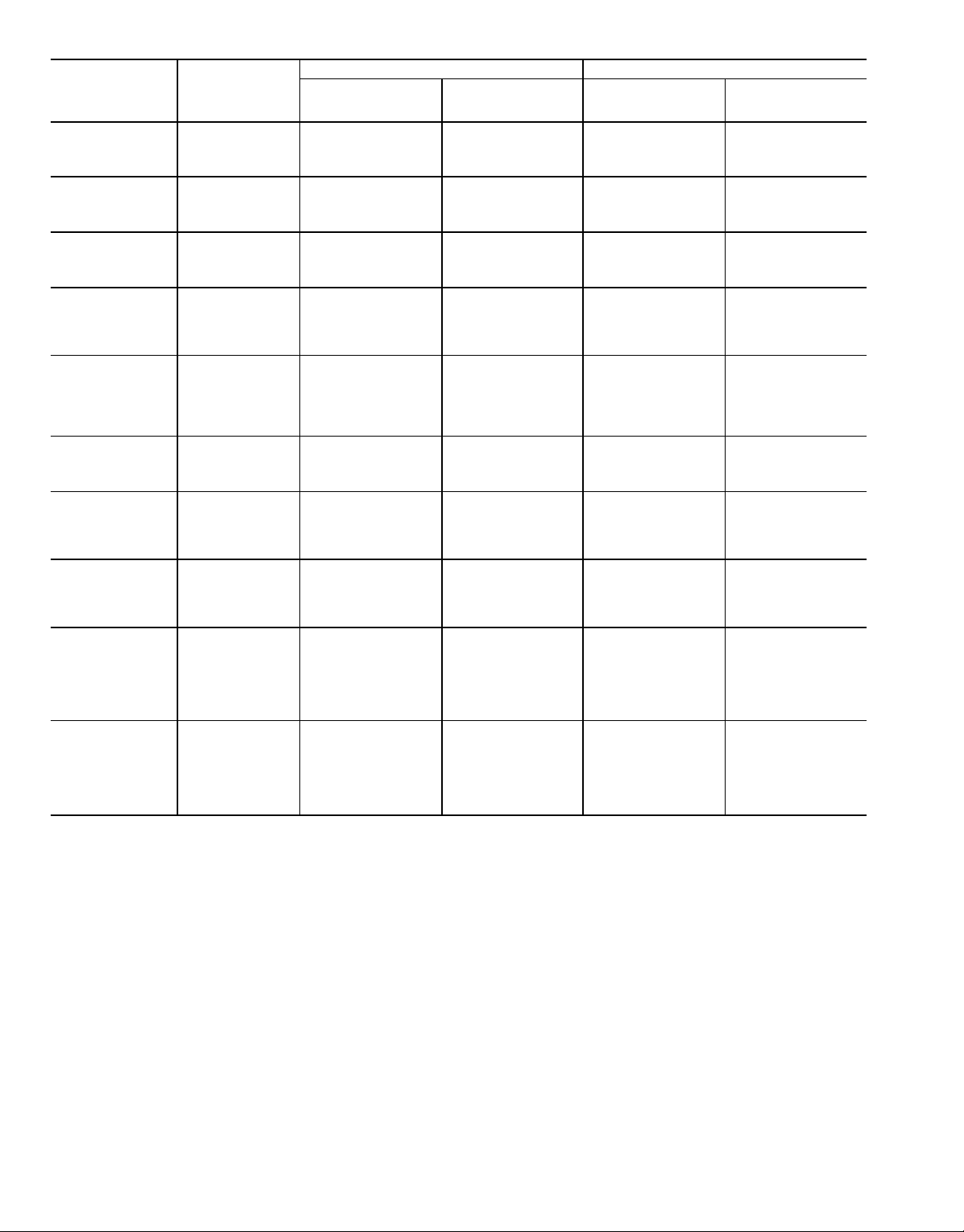

functions. See Fig. 1 for a typical 30GN Control Panel.

MAJOR SYSTEM COMPONENTS

Processor Module —

ating software and controls the operation of the machine. It

continuously monitors information received from the various transducers and thermistors and communicates with the

relay modules and 6-pack relay board to increase or decrease the active stages of capacity. The processor module

This module contains the oper-

2

Page 3

COMM 3 PWR

POINT NUMBER

OF

FIRST CHANNEL

COMM 1

PWR

COMM 3

S1

S2

XX

XX

STAT EXPN

HIST CLR SCHD

SRVC SET

TEST ENTR

STATUS

COMM

J4 J4

789

456

123

–

0•

STATUS

J5

COMM

LVEXV

FUSE 1

S

U

E

F

F

E

U

S

S

U

E

F

FUSE 2

GFI - CO

( 5 AMP MAX )

LOCAL/

ENABLE

STOP

CCN

CB5

CB6

12

3+

5VDC

HK35AA002

Potter & Brumfield

CZ770

SW1

FUSE 3

30GT510568 –

4-

EQUIP GND

99NA505322 D

LEGEND

CCN — Carrier Comfort Network

TB — Terminal Block

Fig. 1 — 30GN Control Panel (040-110 Unit Shown)

3

Page 4

also controls the EXV driver module (as appropriate), commanding it to open or close each EXV in order to maintain

the proper superheat entering thecylinders of each lead compressor.Information istransmittedbetweentheprocessormodule and relay module, the EXV driver module, and the keypad and display module through a 3-wire communications

bus. The options module is also connected to the communications bus.

For the Flotronic™ II chillers,the processor monitors system pressure by means of 6 transducers, 3 in each lead compressor.Compressorsuctionpressure, discharge pressure, and

oil pressure are sensed. If the processor senses high discharge pressure or low suction pressure,it immediately shuts

down all compressors in the affected circuit. During operation, if low oil pressure is sensed for longer than one minute,

all compressors in the affected circuit are shut down. At startup, the oil pressure signal is ignored for 2 minutes. If shutdown occurs due to any of these pressure faults, the circuit

is locked out and the appropriate fault code is displayed.

Low-Voltage Relay Module — This module closes

contacts to energize compressor unloaders and/or compressors. It also senses the status of the safeties for all compressors and transmits this information to the processor.

Electronic Expansion Valve Module (If So

Equipped)—

cessor and operates the electronic expansion valves.

This module receives signals fromthe pro-

Options Module — This module allows the use of Flo-

tronic II features such as dual set point, remote reset, demand limit, hot gas bypass, and accessory unloaders. The

options module also allows for reset and demand limit to be

activated from a remote 4-20 mA signal. The options module is installed at the factory.

Keypad andDisplay Module (Also Called HSIO

or LID) —

tion keys, 5 operative keys, 12 numeric keys, and an alphanumeric 8-character LCD (liquid crystal display). Key usage is explained in Accessing Functions and Subfunctions

section on page 24.

This device consists of a keypad with 6 func-

Control Switch — Control of the chiller is defined by

the position of the LOCAL/ENABLE-STOP-CCN switch.

This is a 3-position manual switch that allows the chiller to

be put under the control of its own FlotronicIIcontrols,manually stopped, or put under the control of a Carrier Comfort

Network (CCN). Switch allows unit operation as shown in

Table 2.

In the LOCAL/ENABLE position, the chiller is under local control and responds to the scheduling configuration and

set point data input at its own local interface device (keypad

and display module).

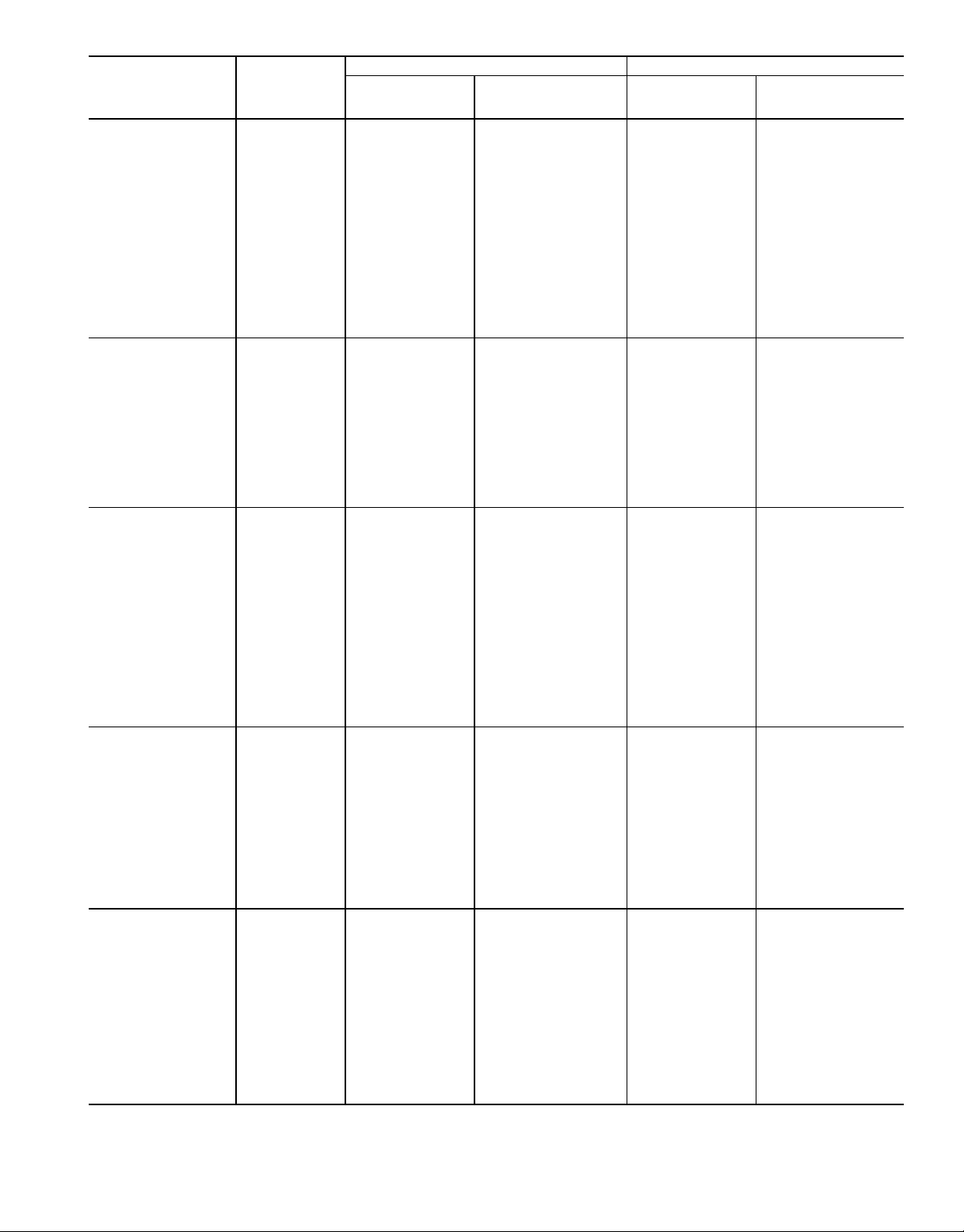

Table 2 — LOCAL/ENABLE-STOP-CCN

Switch Positions and Operation

SWITCH

POSITION

STOP Unit Cannot Run Read/Write Read Only

LOCAL/ENABLE Unit Can Run Read/Limited Write Read Only

CCN Stop — Unit Cannot Run Read Only Read/Write

Run — Unit Can Run Read Only

UNIT

OPERATION

CONFIGURATION AND

SET POINT CONTROL

Keypad Control CCN Control

Read/Limited

Write

In the CCN position, the chiller is under remote control

and responds only to CCN network commands. The occupied/

unoccupied conditions are defined by the network. All keypad and display functions can be read at the chiller regardless of position of the switch.

CCN run or stop condition is established by a command

from the CCN network. It is not possible to force outputs

from the CCN network, except that an emergency stop command shuts down the chiller immediately and causes ‘ ‘ALARM

52’’ to be displayed.

Electronic Expansion Valve (EXV) — The micro-

processor controls the EXV (if so equipped) throughtheEXV

driver module. Inside the expansion valve is a linear actuator stepper motor.

The lead compressor in each circuit has a thermistor and

a pressure transducer located in the suction manifold after

the compressor motor. The thermistor measures the temperature of the superheated gas entering the compressor cylinders.Thepressuretransducermeasurestherefrigerant pressure

in the suction manifold. The microprocessor converts the pressure reading to a saturated temperature. The difference between the temperature of the superheated gas and the saturation temperature is the superheat.Themicroprocessorcontrols

the position of the electronic expansion valve stepper motor

to maintain 30 F (17 C) superheat.

At initial unit start-up, the EXV position is at zero. After

that, the microprocessor keeps accurate track of the valve

position in order to usethis information as input for theother

control functions. The control monitors the superheat and

the rate of change of superheat to control the position of the

valve. The valve stroke is very large, which results in very

accurate control of the superheat.

Thermostatic Expansion Valves(TXV) — Model

30GN040 and 045 units with factory-installed brine option

are equipped with conventional thermostatic expansion valves

with liquid line solenoids. The liquid line solenoid valves

are not intended to be a mechanical shut-off. When service

is required, use the liquid line service valve to pump down

the system.

4

Page 5

The TXV is set at the factory to maintain approximately

8 to 12° F (4.4to6.7° C) suction superheat leaving thecooler

by monitoring the proper amount of refrigerant intothecooler.

All TXVs are adjustable, but should not be adjusted unless

absolutely necessary.When TXVis used,thermistorsT7 and

T8 are not required.

The TXV is designed to limit the cooler saturated suction

temperature to 55 F (12.8 C). This makes it possible for unit

to start at high cooler fluid temperatures without overloading the compressor.

Sensors— The Flotronic™ II chillercontrolsystemgath-

ers information from sensors to control the operation of the

chiller. The units use 6 standard pressure transducers and

4 standard thermistors to monitor system pressures and temperatures at various points within the chiller. Sensors are listed

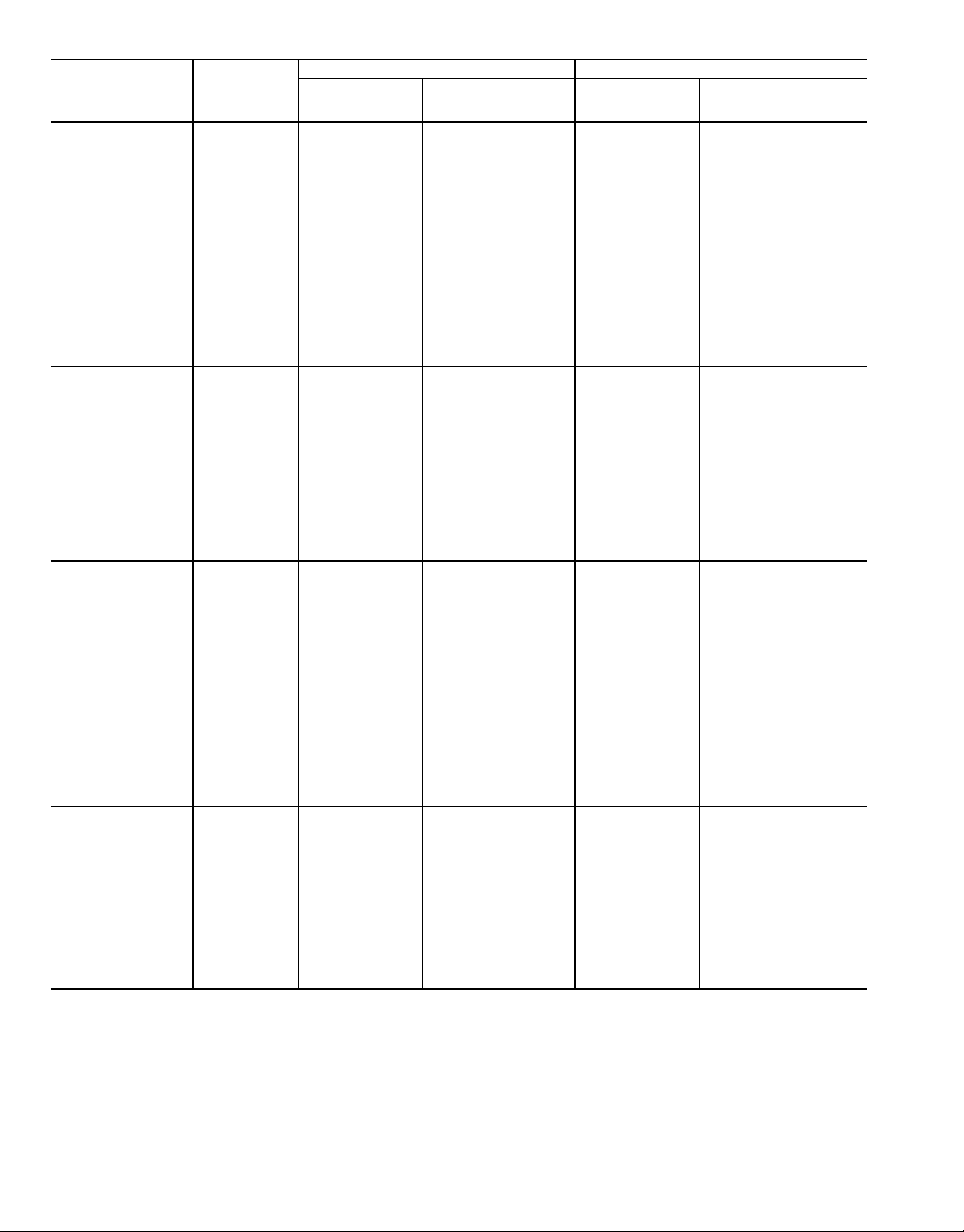

in Table 3.

Table 3 — Thermistor and Transducer Locations

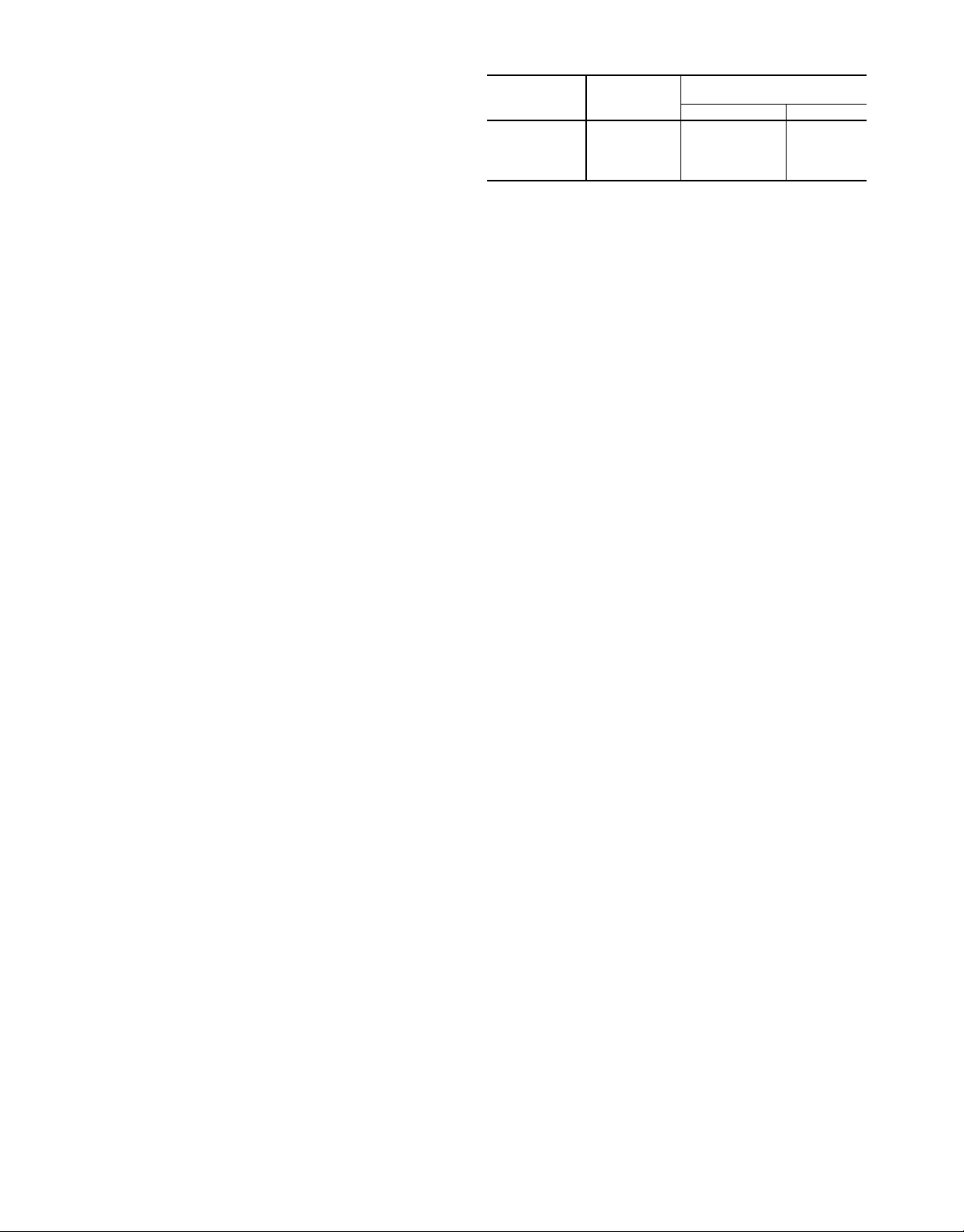

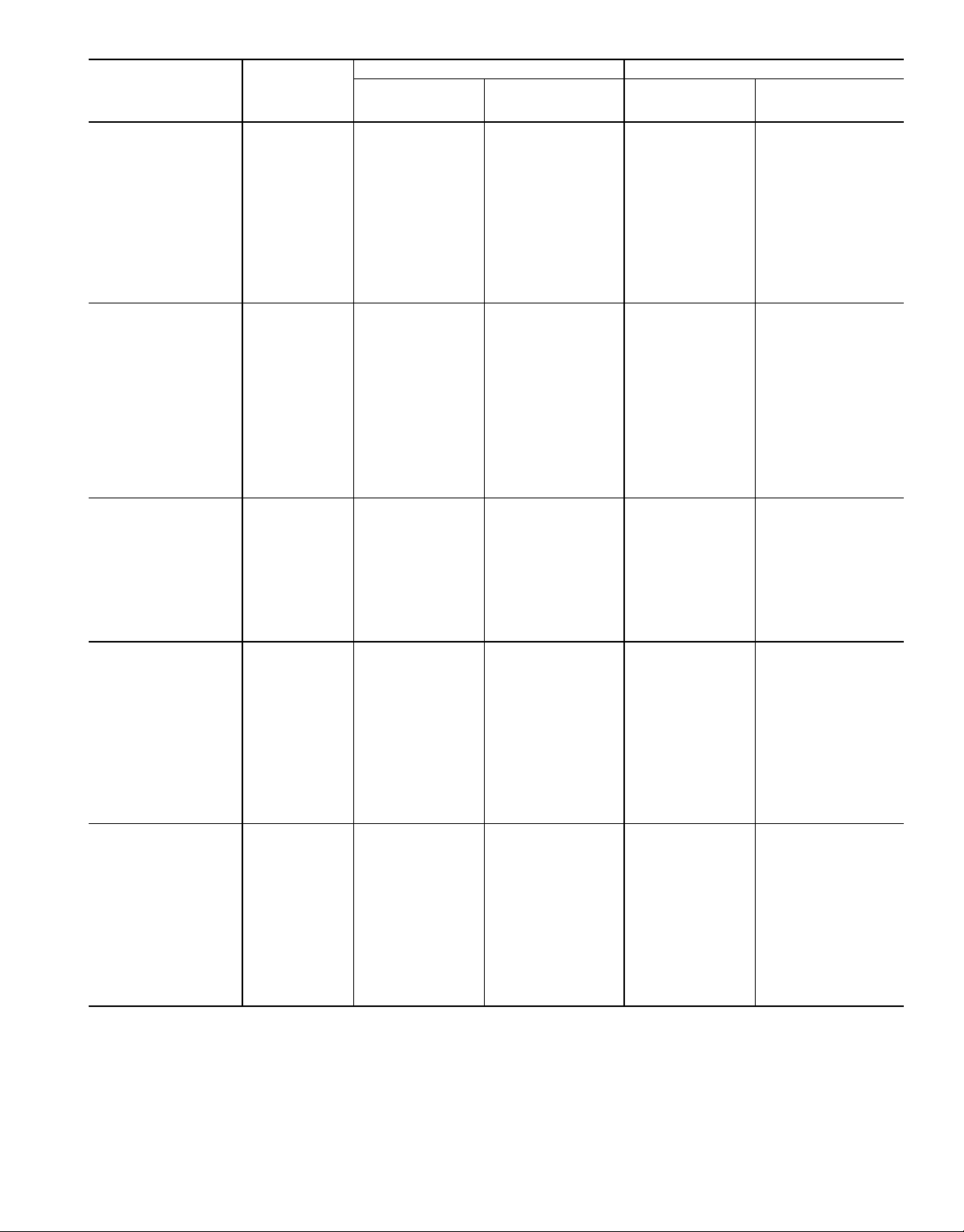

Fig. 2 — Compressor Protection Control Module

Sensor Location

T1 Cooler Leaving Fluid Temp

T2 Cooler Entering Fluid Temp

T7 Compressor Suction Gas Temp Circuit A

T8 Compressor Suction Gas Temp Circuit B

T10 Remote Temperature Sensor (Accessory)

Sensor Location

DPT-A Compressor A1 Discharge Pressure

SPT-A Compressor A1 Suction Pressure

OPT-A Compressor A1 Oil Pressure

DPT-B Compressor B1 Discharge Pressure

SPT-B Compressor B1 Suction Pressure

OPT-B Compressor B1 Oil Pressure

THERMISTORS

PRESSURE TRANSDUCERS

Compressor Protection ControlModule(CPCS)

Each compressor on models 30GN070 (50 Hz), 080-

—

110, and 230B-315B, has its own CPCS as standard equipment. See Fig. 2. All 30GN040-060 and 070 (60 Hz) units

feature the CPCS as an accessory, and CR (control relay) as

standard equipment. The 30GN130-210 and associated modular units havea CR as standard equipment. The CPCS or CR

is used tocontrol and protect the compressors and crankcase

heaters. The CPCS provides the following functions:

• compressor contactor control

• crankcase heater control

• compressor ground current protection

• status communication to processor board

• high-pressure protection

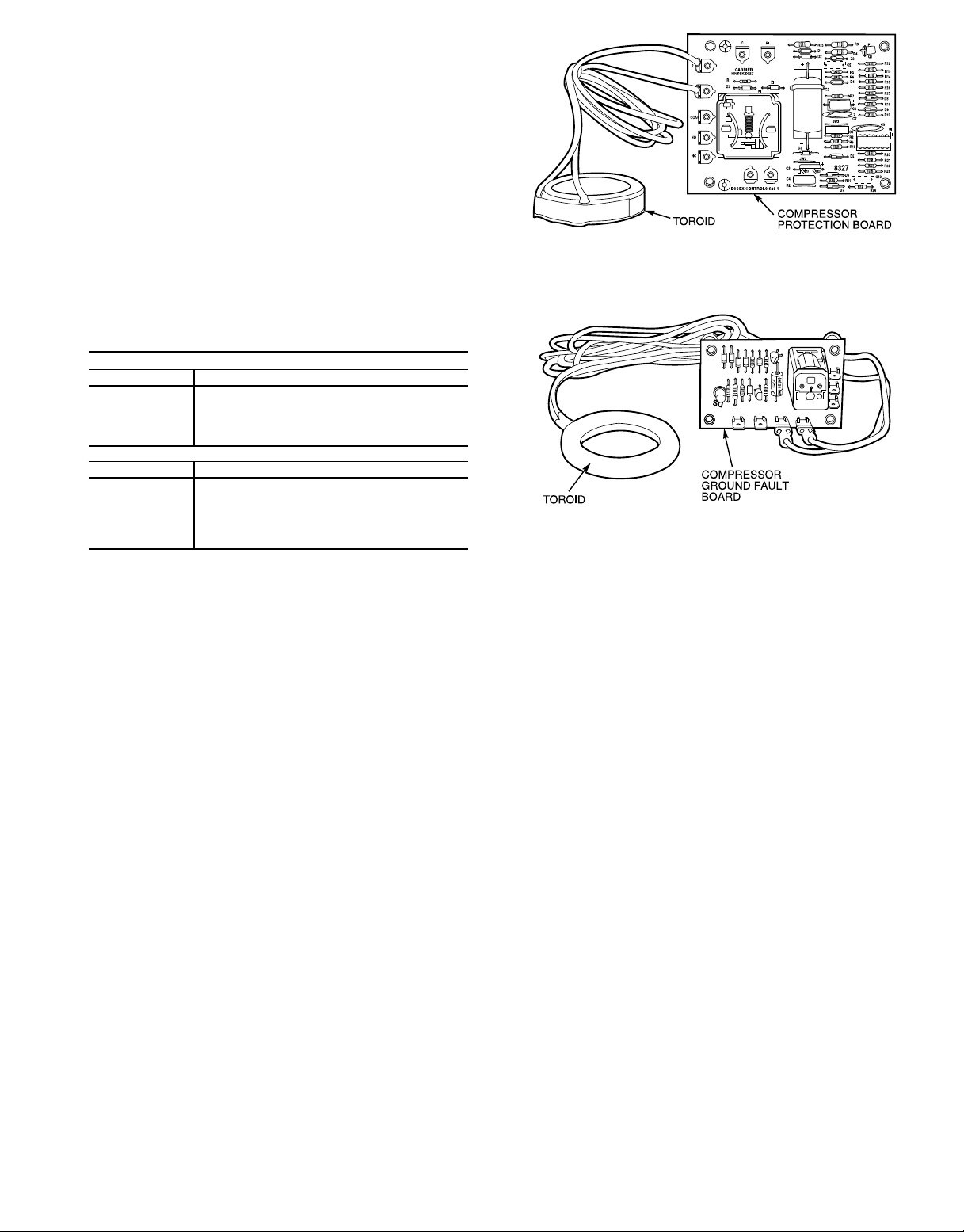

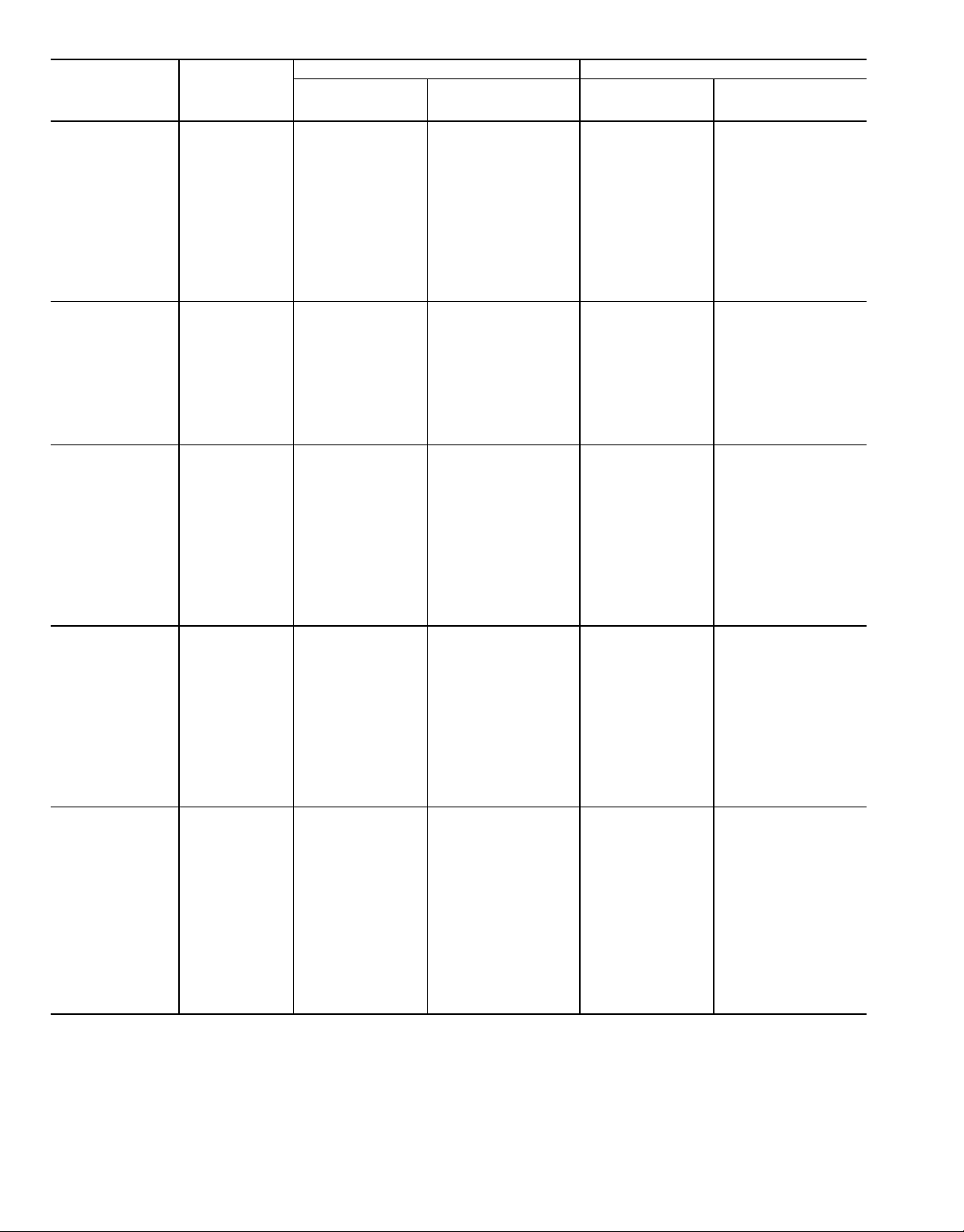

The CR provides all of the same functions as the CPCS

with the exception of compressor ground current protection.

Ground current protection is accomplished by using a CGF

(compressor ground fault module) in conjunction with the

CR. The CGF (See Fig. 3) provides the same ground fault

function as the CPCS for units where the CPCS is not

utilized.

One large relay is located on the CPCS board. This relay

(or CR) controls the crankcase heater and compressor

contactor. The CPCS also provides a set of signal contacts

that the microprocessor monitors to determine the operating

status of the compressor. If the processor board determines

that the compressor is notoperatingproperly through the signal contacts, it will lock the compressor off by deenergizing

the proper 24-v control relay on the relay board. The

CPCS board contains logic that can detect if the current-to-

Fig. 3 — Compressor Ground Fault Module

ground of any compressor winding exceeds 2.5 amps. If this

condition occurs, the CPCS module shuts down the

compressor.

A high-pressure switch with a trip pressure of 426

± 7 psig (2936 ± 48 kPa), is wired in series with the CPCS.

If this switch opens during operation, the compressor stops

and the failure is detected by the processor when the signal

contacts open. The compressor islocked off. If the leadcompressor in either circuit is shut down by the high-pressure

switch or ground current protector, all compressors in the

circuit are locked off.

OPERATION DATA

Capacity Control —

compressor to give capacity control steps as shown in

Tables 4A-4C. The unit controls leaving chilled fluid temperature. Entering fluid temperature is used by the microprocessor in determining the optimum time to add or subtract steps of capacity, but is not a control set point.

The chilled fluid temperature set point can be automatically reset by the return temperature reset or space and

outdoor-air temperature reset features. It can also be reset

from an external 4 to 20 mA signal, or from a network

signal.

The operating sequences shown are some of many possible loading sequences for the control of the leaving fluid

temperature. If a circuit has more unloaders than another,

that circuit will always be the lead circuit.

The control system cycles

5

Page 6

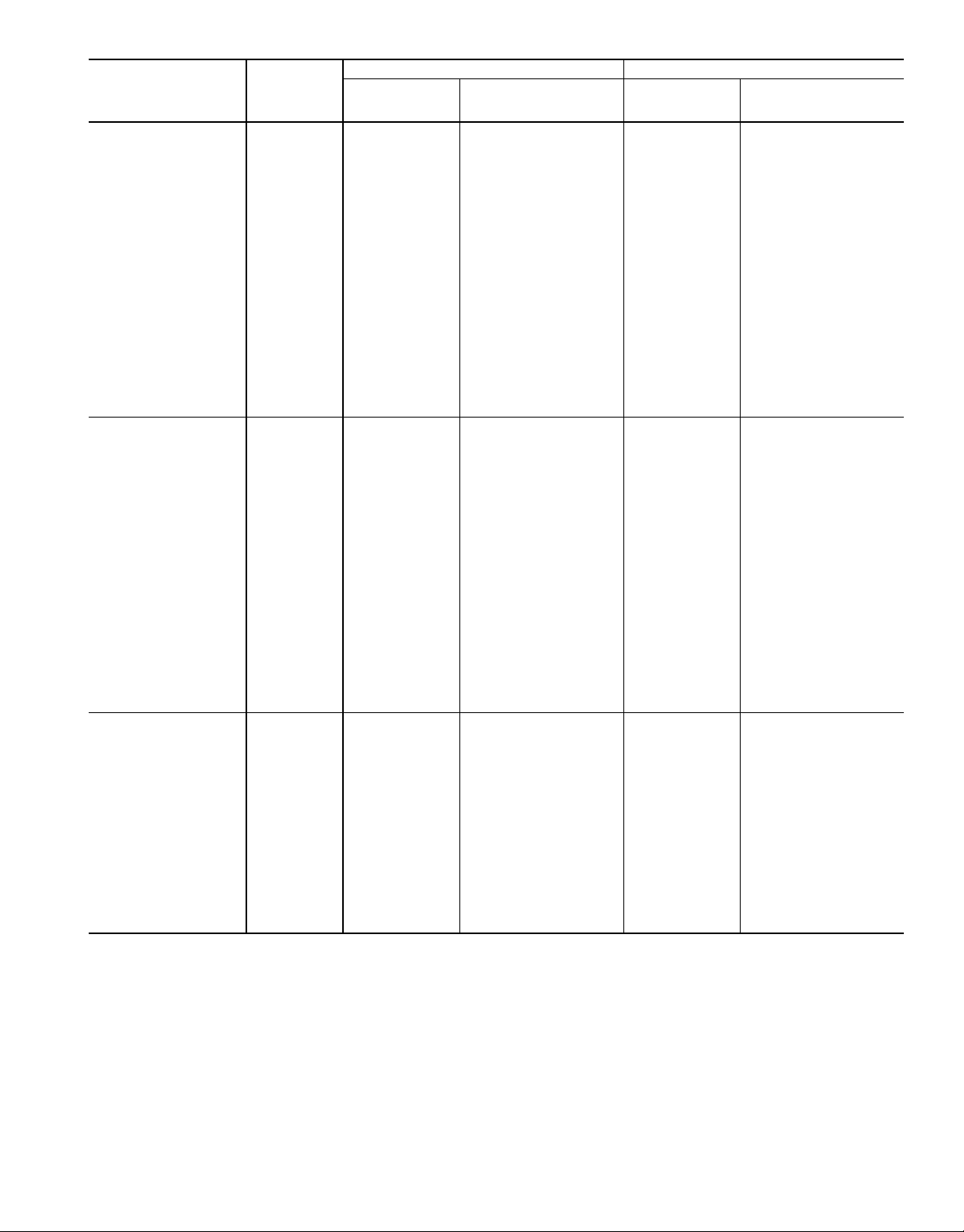

Table 4A — Capacity Control Steps, 040-070

UNIT

30GN

040 (60 Hz)

A1†,B1

040 (60 Hz)

A1†,B1**

040 (50 Hz)

045 (60 Hz)

A1†,B1

040 (50 Hz)

045 (60 Hz)

A1†,B1**

040 (50 Hz)

045 (60 Hz)

A1†,B1**

045 (50 Hz)

050 (60 Hz)

A1†,B1

045 (50 Hz)

050 (60 Hz)

A1†,B1**

045 (50 Hz)

050 (60 Hz)

A1†**,B1

045 (50 Hz)

050 (60 Hz)

A1†**,B1**

045 (50 Hz)

050 (60 Hz)

A1†,B1**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader(s), accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

1 25 A1* — —

250A1— —

3 75 A1*, B1 — —

4 100 A1,B1 — —

1 25 A1* 25 B1*

250A1 50B1

3 75 A1*,B1 75 A1,B1*

4 100 A1,B1 100 A1,B1

1 24 A1* — —

247A1— —

3 76 A1*,B1 — —

4 100 A1,B1 — —

1 24 A1* 37 B1*

247A1 53B1

3 61 A1*,B1* 61 A1*,B1*

4 76 A1*,B1 84 A1,B1*

5 100 A1,B1 100 A1,B1

1 — — 21 B1††

2 — — 37 B1*

3— — 53B1

4 — — 68 A1,B1††

5 — — 84 A1,B1*

6 — — 100 A1,B1

1 31 A1* — —

244A1— —

3 87 A1*,B1 — —

4 100 A1,B1 — —

1 31 A1* 38 B1*

244A1 56B1

3 69 A1*,B1* 69 A1*,B1*

4 87 A1*,B1 82 A1,B1*

5 100 A1,B1 100 A1,B1

1 18 A1†† — —

2 31 A1* — —

3 73 A1††,B1 — —

4 87 A1*,B1 — —

5 100 A1,B1 — —

1 18 A1†† — —

2 31 A1* — —

344A1— —

4 56 A1††,B1* — —

5 73 A1††,B1 — —

6 87 A1*,B1 — —

7 100 A1,B1 — —

1 — — 20 B1††

2 — — 38 B1*

3— — 56B1

4 — — 51 A1*,B1††

5 — — 64 A1,B1††

6 — — 82 A1,B1*

7 — — 100 A1,B1

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

Compressors

%

CompressorsDisplacement Displacement

6

Page 7

Table 4A — Capacity Control Steps, 040-070 (cont)

UNIT

30GN

045 (50 Hz)

050 (60 Hz)

A1†**,B1**

050 (50 Hz)

060 (60 Hz)

A1†,B1

050 (50 Hz)

060 (60 Hz)

A1†,B1**

050 (50 Hz)

060 (60 Hz)

A1†**,B1

050 (50 Hz)

060 (60 Hz)

A1†**,B1**

050 (50 Hz)

060 (60 Hz)

A1†,B1**

050 (50 Hz)

060 (60 Hz)

A1†**,B1**

060 (50 Hz)

070 (60 Hz)

A1†,B1

060 (50 Hz)

070 (60 Hz)

A1†,B1**

060 (50 Hz)

070 (60 Hz)

A1†**,B1

060 (50 Hz)

070 (60 Hz)

A1†**,B1**

060 (50 Hz)

070 (60 Hz)

A1†,B1**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader(s), accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

1 18 A1†† 20 B1††

2 31 A1* 38 B1*

344A1 56B1

4 56 A1††,B1* 64 A1,B1††

5 73 A1††,B1 82 A1,B1*

6 87 A1*,B1 100 A1,B1

7 100 A1,B1 — —

1 28 A1* — —

242A1— —

3 87 A1*,B1 — —

4 100 A1,B1 — —

1 28 A1* 38 B1*

242A1 58B1

3 67 A1*,B1* 67 A1*,B1*

4 87 A1*,B1 80 A1,B1*

5 100 A1,B1 100 A1,B1

1 15 A1†† — —

2 28 A1* — —

3 73 A1††,B1 — —

4 87 A1*,B1 — —

5 100 A1,B1 — —

1 15 A1†† — —

2 28 A1* — —

342A1— —

4 53 A1,B1* — —

5 73 A1††,B1 — —

6 87 A1*,B1 — —

7 100 A1,B1 — —

1 — — 18 B1††

2 — — 38 B1*

3— — 58B1

4 — — 60 A1,B1††

5 — — 80 A1,B1*

6 — — 100 A1,B1

1 15 A1†† 18 B1††

2 28 A1* 38 B1*

342A1 58B1

4 53 A1††,B1* 60 A1,B1††

5 73 A1††,B1 80 A1,B1*

6 87 A1*,B1 100 A1,B1

7 100 A1,B1 — —

1 33 A1* — —

250A1— —

3 83 A1*,B1 — —

4 100 A1,B1 — —

1 33 A1* 33 B1*

250A1 50B1

3 67 A1*,B1* 66 A1*,B1*

4 83 A1*,B1 83 A1,B1*

5 100 A1,B1 100 A1,B1

1 16 A1†† — —

2 33 A1* — —

3 66 A1††,B1 — —

4 83 A1* — —

5 100 A1,B1 — —

1 16 A1†† — —

2 33 A1* — —

350A1— —

4 66 A1††,B1 — —

5 83 A1*,B1 — —

6 100 A1,B1 — —

1 — — 16 B1††

2 — — 33 B1*

3— — 50B1

4 — — 66 A1,B1††

5 — — 83 A1,B1*

6 — — 100 A1,B1

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

Compressors

%

CompressorsDisplacement Displacement

7

Page 8

Table 4A — Capacity Control Steps, 040-070 (cont)

UNIT

30GN

060 (50 Hz)

070 (60 Hz)

A1†**,B1|

070 (50 Hz)

A1†,B1

070 (50 Hz)

A1†,B1**

070 (50 Hz)

A1†**,B1

070 (50 Hz)

A1†**,B1**

070 (50 Hz)

A1†,B1|

070 (50 Hz)

A1†**,B1|

*Unloaded compressor.

†Compressor unloader, standard.

**One compressor unloader, accessory.

††Two unloaders, both unloaded.

\ Two compressor unloaders, accessory.

CONTROL

STEPS

1 16 A1†† 16 B1††

2 33 A1* 33 B1*

350A1 50B1

4 66 A1††,B1 66 A1,B1††

5 83 A1*,B1 83 A1,B1*

6 100 A1,B1 100 A1,B1

1 19 A1* — —

227A1 — —

3 65 A1*,B1 — —

4 73 A1,B1 — —

5 92 A1*,A2,B1 — —

6 100 A1,A2,B1 — —

1 19 A1* 31 B1*

227A1 47B1

3 49 A1*,B1* 49 A1*,B1*

4 65 A1*,B1 57 A1,B1*

5 73 A1,B1 73 A1,B1

6 76 A1*,A2,B1* 76 A1*,A2,B1*

7 92 A1*,A2,B1 84 A1,A2,B1*

8 100 A1,A2,B1 100 A1,A2,B1

1 11 A1†† — —

2 19 A1* — —

3 57 A1††,B1 — —

4 65 A1*,B1 — —

5 73 A1,B1 — —

6 84 A1††,A2,B1 — —

7 92 A1*,A2,B1 — —

8 100 A1,A2,B1 — —

1 11 A1†† — —

2 19 A1* — —

327A1 — —

4 41 A1††,B1* — —

5 57 A1††,B1 — —

6 65 A1*,B1 — —

7 73 A1,B1 — —

8 84 A1††,A2,B1 — —

9 92 A1*,A2,B1 — —

10 100 A1,A2,B1 — —

1 — — 15 B1††

2 — — 31 B1*

3— — 47 B1

4 — — 57 A1*,B1*

5 — — 73 A1,B1

6 — — 84 A1,A2,B1*

7 — — 100 A1,A2,B1

1 11 A1†† 15 B1††

2 19 A1* 31 B1*

327A1 47B1

4 41 A1††,B1* 54 A1*,B1*

5 57 A1††,B1 73 A1,B1

6 65 A1*,B1 84 A1,A2,B1*

7 73 A1,B1 100 A1,A2,B1

8 84 A1††,A2,B1 — —

9 92 A1*,A2,B1 — —

10 100 A1,A2,B1 — —

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

Compressors

%

CompressorsDisplacement Displacement

8

Page 9

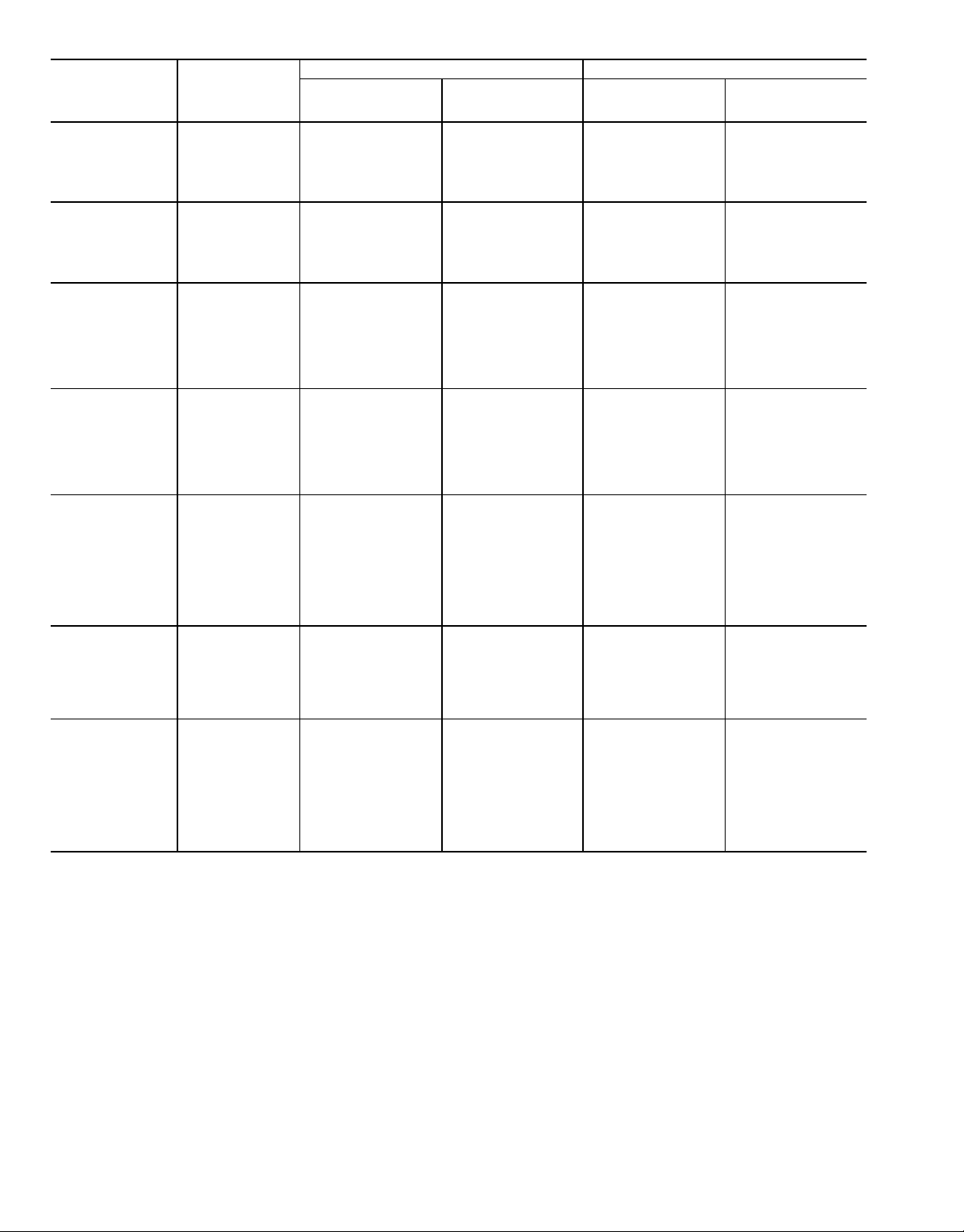

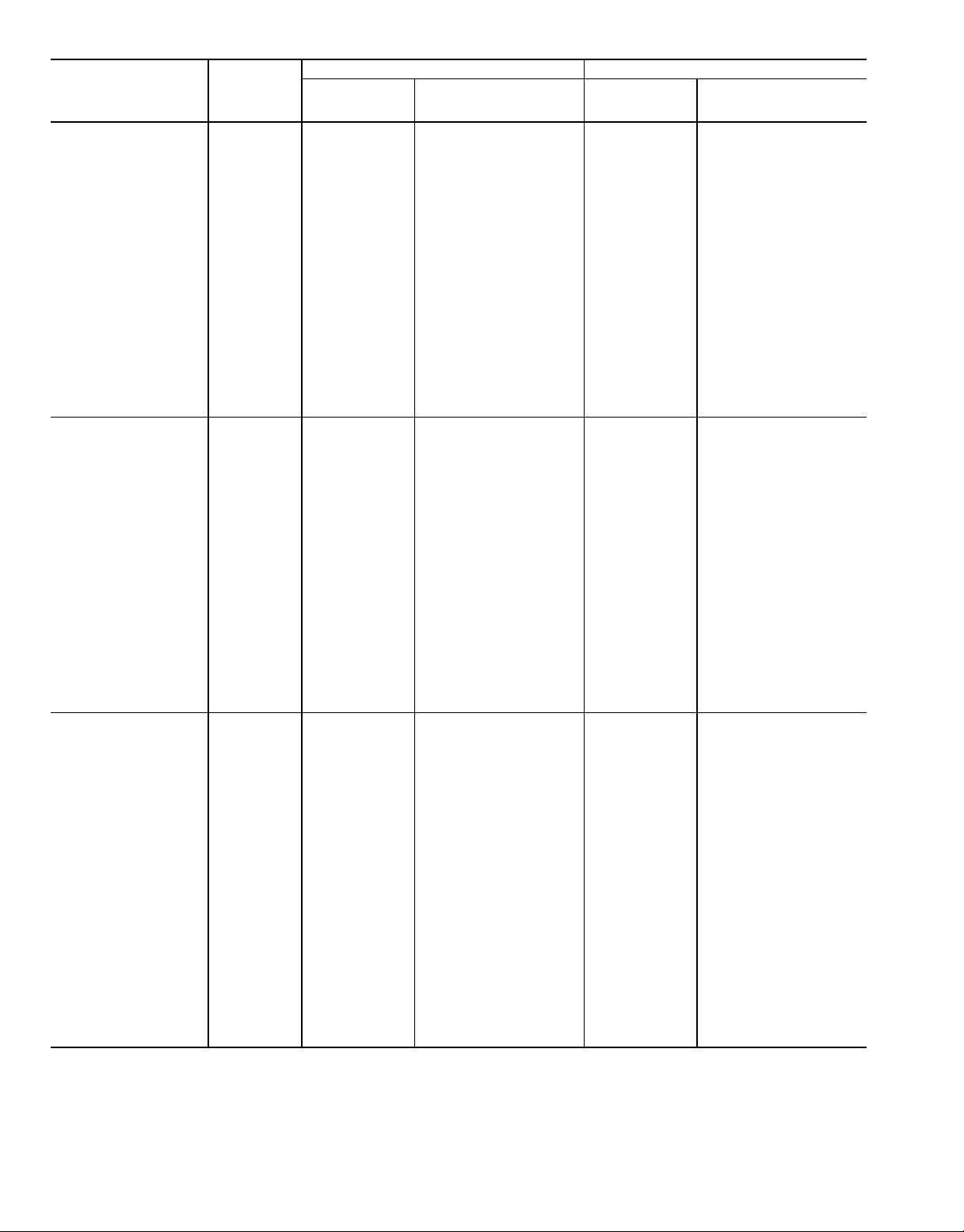

Table 4B — Capacity Control Steps, 080-110 and Associated Modular Units

UNIT

30GN

080, 230B (60 Hz)

A1†,B1†

080, 230B (60 Hz)

A1†**, B1†

080, 230B (60 Hz)

A1†,B1†**

080, 230B (60 Hz)

A1†**,B1†**

080, 230B (50 Hz)

A1†,B1†

080, 230B (50 Hz)

A1†**,B1†

080, 230B (50 Hz)

A1†,B1†**

080, 230B (50 Hz)

A1†**,B1†**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

1 22 A1* 30 B1*

234A1 44B1

3 52 A1*,B1* 52 A1*,B1*

4 67 A1*,B1 63 A1,B1*

5 78 A1,B1 78 A1,B1

6 89 A1*,A2,B1 85 A1,A2,B1*

7 100 A1,A2,B1 100 A1,A2,B1

1 11 A1†† — —

2 22 A1* — —

334A1 — —

4 41 A1††,B1* — —

5 55 A1††,B1 — —

6 67 A1*,B1 — —

7 78 A1,B1 — —

8 89 A1*,A2,B1 — —

9 100 A1,A2,B1 — —

1 — — 15 B1††

2 — — 30 B1*

3— — 44 B1

4 — — 48 A1,B1††

5 — — 63 A1,B1*

6 — — 78 A1,B1

7 — — 85 A1,A2,B1*

8 — — 100 A1,A2,B1

1 11 A1†† 15 B1††

2 22 A1* 30 B1*

334A1 44B1

4 41 A1††,B1* 48 A1,B1††

5 55 A1††,B1 63 A1,B1*

6 67 A1*,B1 78 A1,B1

7 78 A1,B1 85 A1,A2,B1*

8 89 A1*,A2,B1 100 A1,A2,B1

9 100 A1,A2,B1 — —

1 17 A1* 25 B1*

225A1 38B1

3 42 A1*,B1* 42 A1*,B1*

4 54 A1*,B1 50 A1, B1*

5 62 A1,B1 62 A1,B1

6 79 A1*,A2,B1* 79 A1*,A2,B1*

7 92 A1*,A2,B1 88 A1,A2,B1*

8 100 A1,A2,B1 100 A1,A2,B1

1 8 A1†† — —

2 17 A1* — —

325A1 — —

4 33 A1††,B1* — —

5 46 A1††,B1 — —

6 54 A1*,B1 — —

7 62 A1,B1 — —

8 71 A1††,A2,B1* — —

9 84 A1††,A2,B1 — —

10 92 A1*,A2,B1 — —

11 100 A1,A2,B1 — —

1 — — 13 B1††

2 — — 25 B1*

3— — 38 B1

4 — — 50 A1,B1*

5 — — 62 A1,B1

6 — — 67 A1*,A2,B1††

7 — — 75 A1,A2,B1††

8 — — 88 A1,A2,B1*

9 — — 100 A1,A2,B1

1 8 A1†† 13 B1††

2 17 A1* 25 B1*

325A1 38B1

4 33 A1††,B1* 50 A1,B1*

5 46 A1††,B1 62 A1,B1

6 54 A1*,B1 67 A1*,A2,B1††

7 62 A1,B1 75 A1,A2,B1††

8 71 A1††,A2,B1* 88 A1,A2,B1*

9 84 A1††,A2,B1 100 A1,A2,B1

10 92 A1*,A2,B1 — —

11 100 A1,A2,B1 — —

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

Compressors

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

CompressorsDisplacement Displacement

9

Page 10

Table 4B — Capacity Control Steps, 080-110 and Associated Modular Units (cont)

UNIT

30GN

090, 245B (60 Hz)

A1†,B1†

090, 245B (60 Hz)

A1†**,B1†

090, 245B (60 Hz)

A1†,B1†**

090, 245B (60 Hz)

A1†**,B1†**

090, 245B (50 Hz)

A1†,B1†

090, 245B (50 Hz)

A1†**,B1†

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

LOADING SEQUENCE A LOADING SEQUENCE B

STEPS

1 18 A1* 18 B1*

227 A1 27 B1

3 35 A1*,B1* 35 A1*,B1*

4 44 A1*,B1 44 A1,B1*

5 53 A1,B1 53 A1,B1

6 56 A1*,A2,B1* 62 A1*,B1*,B2

7 65 A1*,A2,B1 71 A1,B1*,B2

8 74 A1,A2,B1 80 A1,B1,B2

9 82 A1*,A2,B1*,B2 82 A1*,A2,B1*,B2

10 91 A1*,A2,B1,B2 91 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 9 A1†† — —

2 18 A1* — —

327 A1 — —

4 35 A1††,B1 — —

5 44 A1*,B1 — —

6 53 A1,B1 — —

7 56 A1††,A2,B1 — —

8 65 A1*,A2,B1 — —

9 74 A1,A2,B1 — —

10 82 A1††,A2,B1,B2 — —

11 91 A1*,A2,B1,B2 — —

12 100 A1,A2,B1,B2 — —

1 — — 9 B1††

2 — — 18 B1*

3— — 27 B1

4 — — 35 A1,B1††

5 — — 44 A1,B1*

6 — — 53 A1,B1

7 — — 62 A1,B1††,B2

8 — — 71 A1,B1*,B2

9 — — 80 A1,B1,B2

10 — — 82 A1,A2,B1††,B2

11 — — 91 A1,A2,B1*,B2

12 — — 100 A1,A2,B1,B2

1 9 A1†† 9 B1††

2 18 A1* 18 B1*

327 A1 27 B1

4 35 A1††,B1 35 A1,B1††

5 44 A1*,B1 44 A1,B1*

6 53 A1,B1 53 A1,B1

7 56 A1††,A2,B1 62 A1,B1††,B2

8 65 A1*,A2,B1 71 A1,B1*,B2

9 74 A1,A2,B1 80 A1,B1,B2

10 82 A1††,A2,B1,B2 82 A1,A2,B1††,B2

11 91 A1*,A2,B1,B2 91 A1,A2,B1*,B2

12 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 14 A1* 14 B1*

221 A1 21 B1

3 29 A1*,B1* 29 A1*,B1*

4 36 A1*,B1 36 A1,B1*

5 43 A1,B1 43 A1,B1

6 61 A1*,A2,B1* 53 A1*,B1*,B2

7 68 A1*,A2,B1 60 A1,B1*,B2

8 75 A1,A2,B1 67 A1,B1,B2

9 86 A1*,A2,B1*,B2 86 A1*,A2,B1*,B2

10 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 7 A1†† — —

2 14 A1* — —

321 A1 — —

4 29 A1††,B1 — —

5 36 A1*,B1 — —

6 43 A1,B1 — —

7 54 A1††,A2,B1* — —

8 61 A1††,A2,B1 — —

9 68 A1*,A2,B1 — —

10 75 A1,A2,B1 — —

11 79 A1††,A2,B1*,B2 — —

12 86 A1††,A2,B1,B2 — —

13 93 A1*,A2,B1,B2 — —

14 100 A1,A2,B1,B2 — —

%

(Approx) (Approx)

Compressors

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

CompressorsDisplacement Displacement

10

Page 11

Table 4B — Capacity Control Steps, 080-110 and Associated Modular Units (cont)

UNIT

30GN

090, 245B (50 Hz)

A1†,B1†**

090, 245B (50 Hz)

A1†**,B1†**

100, 255B,

270B (60 Hz)

A1†,B1†

100, 255B,

270B (60 Hz)

A1†**,B1†

100, 255B,

270B (60 Hz)

A1†,B1†**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

LOADING SEQUENCE A LOADING SEQUENCE B

STEPS

1 — — 7 B1††

2 — — 14 B1*

3— — 21 B1

4 — — 29 A1,B1††

5 — — 36 A1,B1*

6 — — 43 A1,B1

7 — — 46 A1*,B1††,B2

8 — — 53 A1,B1††,B2

9 — — 60 A1,B1*,B2

10 — — 67 A1,B1,B2

11 — — 79 A1*,A2,B1††,B1

12 — — 86 A1,A2,B1††,B1

13 — — 93 A1,A2,B1*,B2

14 — — 100 A1,2,B1,B2

1 7 A1†† 7 B1††

2 14 A1* 14 B1*

321 A1 21 B1

4 29 A1††,B1 29 A1,B1††

5 36 A1*,B1 36 A1,B1*

6 43 A1,B1 43 A1,B1

7 49 A1††,A2,B1†† 46 A1*,B1††,B2

8 54 A1††,A2,B1* 53 A1,B1††,B2

9 61 A1††,A2,B1 60 A1,B1*,B2

10 68 A1*,A2,B1 67 A1,B1,B2

11 75 A1,A2,B1 72 A1††,A2,B1††,B2

12 79 A1††,A2,B1*,B2 79 A1*,A2,B1††,B2

13 86 A1††,A2,B1,B2 86 A1,A2,B1††,B2

14 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

15 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 16 A1* 16 A1*

223 A1 23 A1

3 31 A1*,B1* 31 A1*,B1*

4 39 A1*,B1 39 A1*,B1

5 46 A1,B1 46 A1,B1

6 58 A1*,A2,B1* 58 A1*,A2,B1*

7 66 A1*,A2,B1 66 A1*,A2,B1

8 73 A1,A2,B1 73 A1,A2,B1

9 85 A1*,A2,B1*,B2 85 A1*,A2,B1*,B2

10 92 A1*,A2,B1,B2 92 A1*,A2,B1,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 8 A1†† — —

2 16 A1* — —

323 A1 — —

4 31 A1††,B1 — —

5 39 A1*,B1 — —

6 46 A1,B1 — —

7 50 A1††,A2,B1* — —

8 58 A1††,A2,B1 — —

9 66 A1*,A2,B1 — —

10 73 A1,A2,B1 — —

11 77 A1††,A2,B1*,B2 — —

12 85 A1††,A2,B1,B2 — —

13 92 A1*,A2,B1,B2 — —

14 100 A1,A2,B1,B2 — —

1 — — 8 B1††

2 — — 16 B1*

3— — 23 B1

4 — — 31 A1,B1††

5 — — 39 A1,B1*

6 — — 46 A1,B1

7 — — 50 A1*,B1††,B2

8 — — 58 A1,B1††,B2

9 — — 66 A1,B1*,B2

10 — — 73 A1,B1,B2

11 — — 77 A1*,A2,B1††,B2

12 — — 85 A1,A2,B1††,B2

13 — — 92 A1,A2,B1*,B2

14 — — 100 A1,A2,B1,B2

%

(Approx) (Approx)

Compressors

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

CompressorsDisplacement Displacement

11

Page 12

Table 4B — Capacity Control Steps, 080-110 and Associated Modular Units (cont)

UNIT

30GN

100, 255B,

270B (60 Hz)

A1†**,B1†**

100, 255B,

270B (50 Hz)

A1†,B1†

100, 255B,

270B (50 Hz)

A1†**,B1†

100, 255B,

270B (50 Hz)

A1†,B1†**

100, 255B,

270B (50 Hz)

A1†**,B1†**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

10 73 A1,A2,B1 73 A1,B1,B2

11 77 A1††,A2,B1*,B2 77 A1*,A2,B1††,B2

12 85 A1††,A2,B1,B2 85 A1,A2,B1††,B2

13 92 A1*,A2,B1,B2 92 A1,A2,B1*,B2

14 100 A1,A2,B1,B2 100 A1,A2,B1,B2

10 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

10 70 A1,A2,B1 — —

11 80 A1††,A2,B1*,B2 — —

12 87 A1††,A2,B1,B2 — —

13 93 A1*,A2,B1,B2 — —

14 100 A1,A2,B1,B2 — —

10 — — 70 A1,B1,B2

11 — — 80 A1*,A2,B1††,B2

12 — — 87 A1,A2,B1††,B2

13 — — 93 A1,A2,B1*,B2

14 — — 100 A1,A2,B1,B2

10 63 A1*,A2,B1 63 A1,B1*,B2

11 70 A1,A2,B1 70 A1,B1,B2

12 74 A1††,A2,B1††,B2 74 A1††,A2,B1††,B2

13 80 A1††,A2,B1*,B2 80 A1*,A2,B1††,B2

14 89 A1††,A2,B1,B2 87 A1,A2,B1††,B2

15 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

16 100 A1,A2,B1,B2 100 A1,A2,B1,B2

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1 8 A1†† 8 B1††

2 16 A1* 16 B1*

323A1 23B1

4 31 A1††,B1 31 A1,B1††

5 39 A1*,B1 39 A1,B1*

6 46 A1,B1 46 A1,B1

7 50 A1††,A2,B1* 50 A1*,B1††,B2

8 58 A1††,A2,B1 58 A1,B1††,B2

9 66 A1*,A2,B1 66 A1,B1*,B2

1 13 A1* 13 B1*

220A1 20B1

3 26 A1*,B1* 26 A1*,B1*

4 33 A1,B1 33 A1,B1*

5 40 A1,B1 40 A1,B1

6 57 A1*,A2,B1* 57 A1*,B1*,B2

7 63 A1*,A2,B1 63 A1,B1*,B2

8 70 A1,A2,B1 70 A1,B1,B2

9 87 A1*,A2,B1*,B2 87 A1*,A2,B1*,B2

1 7 A1†† — —

2 13 A1* — —

320 A1 — —

4 26 A1††,B1 — —

5 33 A1*,B1 — —

6 40 A1,B1 — —

7 50 A1††,A2,B1* — —

8 57 A1††,A2,B1 — —

9 63 A1*,A2,B1 — —

1 — — 7 B1††

2 — — 13 B1*

3— — 20 B1

4 — — 26 A1,B1††

5 — — 33 A1,B1*

6 — — 40 A1,B1

7 — — 50 A1*,B1††,B2

8 — — 57 A1,B1††,B2

9 — — 63 A1,B1*,B2

1 7 A1†† 7 B1††

2 13 A1* 13 B1*

320A1 20B1

4 26 A1††,B1 26 A1,B1††

5 33 A1*,B1 33 A1,B1*

6 40 A1,B1 40 A1,B1

7 43 A1††,A2,B1†† 43 A1††,B1††,B2

8 50 A1††,A2,B1* 50 A1*,B1††,B2

9 57 A1††,A2,B1 57 A1,B1††,B2

Compressors

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

CompressorsDisplacement Displacement

12

Page 13

Table 4B — Capacity Control Steps, 080-110 and Associated Modular Units (cont)

UNIT

30GN

110, 290B,

315B (60 Hz)

A1†,B1†

110, 290B,

315B (60 Hz)

A1†**,B1†

110, 290B,

315B (60 Hz)

A1†,B1†**

110, 290B,

315B (60 Hz)

A1†**,B1†**

110, 290B,

315B (50 Hz)

A1†,B1†

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

10 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

10 75 A1,A2,B1 — —

11 79 A1††,A2,B1*,B2 — —

12 86 A1††,A2,B1,B2 — —

13 93 A1*,A2,B1,B2 — —

14 100 A1,A2,B1,B2 — —

10 — — 67 A1,B1,B2

11 — — 79 A1*,A2,B1††,B2

12 — — 86 A1,A2,B1††,B2

13 — — 93 A1,A2,B1*,B2

14 — — 100 A1,A2,B1,B2

10 68 A1*,A2,B1 67 A1,B1,B2

11 75 A1,A2,B1 72 A1††,A2,B1††,B2

12 79 A1††,A2,B1*,B2 79 A1*,A2,B1††,B2

13 86 A1††,A2,B1,B2 86 A1,A2,B1††,B2

14 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

15 100 A1,A2,B1,B2 100 A1,A2,B1,B2

10 92 A1*,A2,B1,B2 92 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1 14 A1* 14 B1*

221 A1 21 B1

3 29 A1*,B1* 29 A1*,B1*

4 36 A1*,B1 36 A1,B1*

5 43 A1,B1 43 A1,B1

6 61 A1*,A2,B1* 53 A1*,B1*,B2

7 68 A1*,A2,B1 60 A1,B1*,B2

8 75 A1,A2,B1 67 A1,B1,B2

9 86 A1*,A2,B1*,B2 86 A1*,A2,B1*,B2

1 7 A1†† — —

2 14 A1* — —

321 A1 — —

4 29 A1††,B1 — —

5 36 A1*,B1 — —

6 43 A1,B1 — —

7 54 A1††,A2,B1* — —

8 61 A1††,A2,B1 — —

9 68 A1*,A2,B1 — —

1 — — 7 B1††

2 — — 14 B1*

3— — 21 B1

4 — — 29 A1,B1††

5 — — 36 A1,B1*

6 — — 43 A1,B1

7 — — 46 A1*,B1††,B2

8 — — 53 A1,B1††,B2

9 — — 60 A1,B1*,B2

1 7 A1†† 7 B1††

2 14 A1* 14 B1*

321 A1 21 B1

4 29 A1††,B1 29 A1,B1††

5 36 A1*,B1 36 A1,B1*

6 43 A1,B1 43 A1,B1

7 47 A1††,A2,B1†† 46 A1*,B1††,B2

8 54 A1††,A2,B1* 53 A1,B1††,B2

9 61 A1††,A2,B1 60 A1,B1*,B2

1 17 A1* 17 B1*

225 A1 25 B1

3 33 A1*,B1* 33 A1*,B1*

4 42 A1*,B1 42 A1,B1*

5 50 A1,B1 50 A1,B1

6 58 A1*,A2,B1* 58 A1*,B1*,B2

7 67 A1*,A2,B1 67 A1,B1*,B2

8 75 A1,A2,B1 75 A1,B1,B2

9 83 A1*,A2,B1*,B2 83 A1*,A2,B1*,B2

Compressors

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

CompressorsDisplacement Displacement

13

Page 14

Table 4B — Capacity Control Steps, 080-110 and Associated Modular Units (cont)

UNIT

30GN

110, 290B,

315B (50 Hz)

A1†**,B1†

110, 290B,

315B (50 Hz)

A1†,B1†**

110, 290B,

315B (50 Hz)

A1†**,B1†**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1 8 A1†† — —

2 17 A1* — —

325 A1 — —

4 33 A1††,B1 — —

5 42 A1*,B1 — —

6 50 A1,B1 — —

7 58 A1††,A2,B1 — —

8 67 A1*,A2,B1 — —

9 75 A1,A2,B1 — —

10 83 A1††,A2,B1,B2 — —

11 92 A1*,A2,B1,B2 — —

12 100 A1,A2,B1,B2 — —

1 — — 8 B1††

2 — — 17 B1*

3— — 25 B1

4 — — 33 A1,B1††

5 — — 42 A1,B1*

6 — — 50 A1,B1

7 — — 58 A1,B1††,B2

8 — — 67 A1,B1*,B2

9 — — 75 A1,B1,B2

10 — — 83 A1,A2,B1††,B2

11 — — 92 A1,A2,B1*,B2

12 — — 100 A1,A2,B1,B2

1 8 A1†† 8 B1††

2 17 A1* 17 B1*

325A1 25B1

4 33 A1††,B1 33 A1,B1††

5 42 A1*,B1 42 A1,B1*

6 50 A1,B1 50 A1,B1

7 58 A1††,A2,B1 58 A1,B1††,B2

8 67 A1*,A2,B1 67 A1,B1*,B2

9 75 A1,A2,B1 75 A1,B1,B2

10 83 A1††,A2,B1,B2 83 A1,A2,B1††,B2

11 92 A1*,A2,B1,B2 92 A1,A2,B1*,B2

12 100 A1,A2,B1,B2 100 A1,A2,B1,B2

Compressors

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

CompressorsDisplacement Displacement

14

Page 15

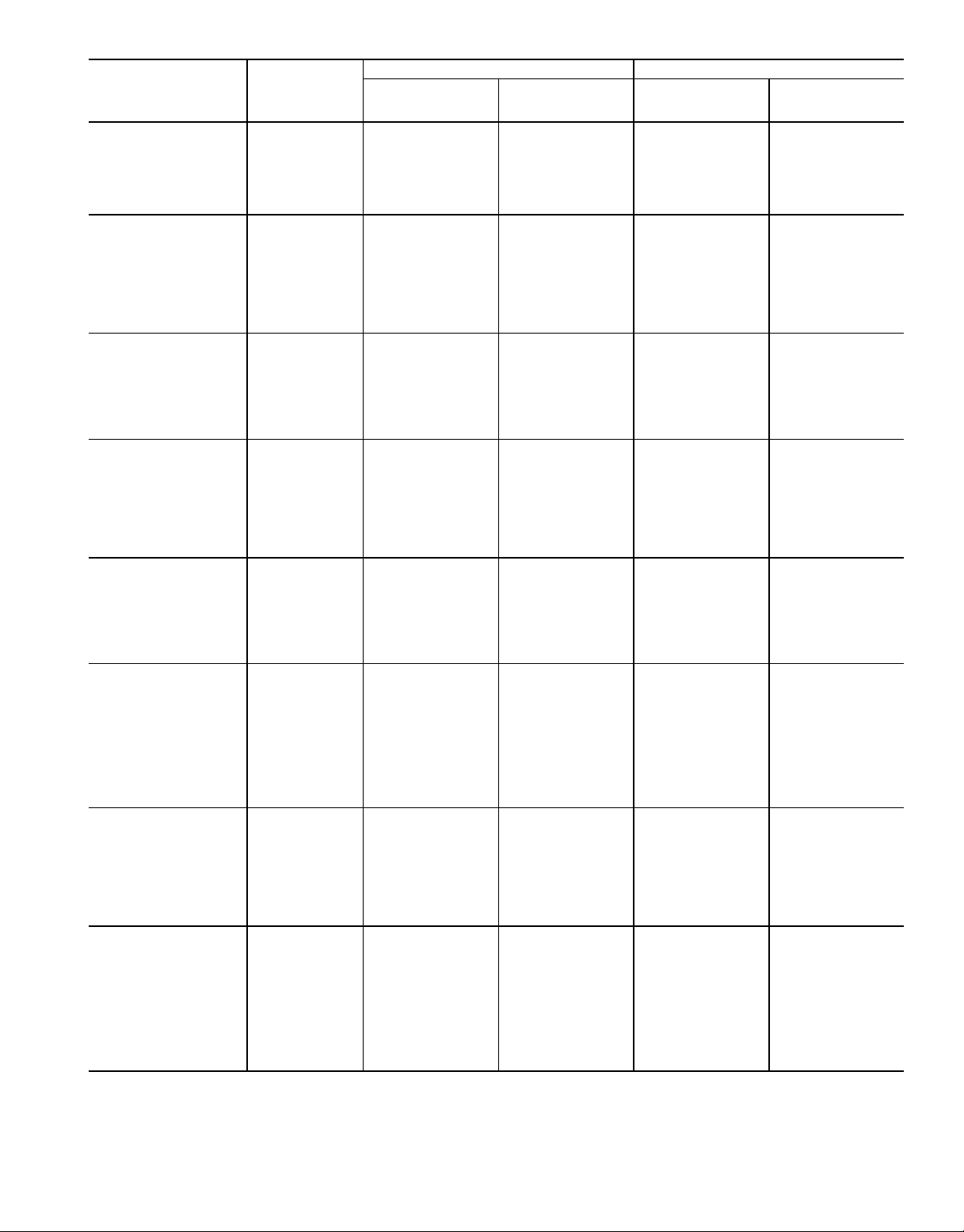

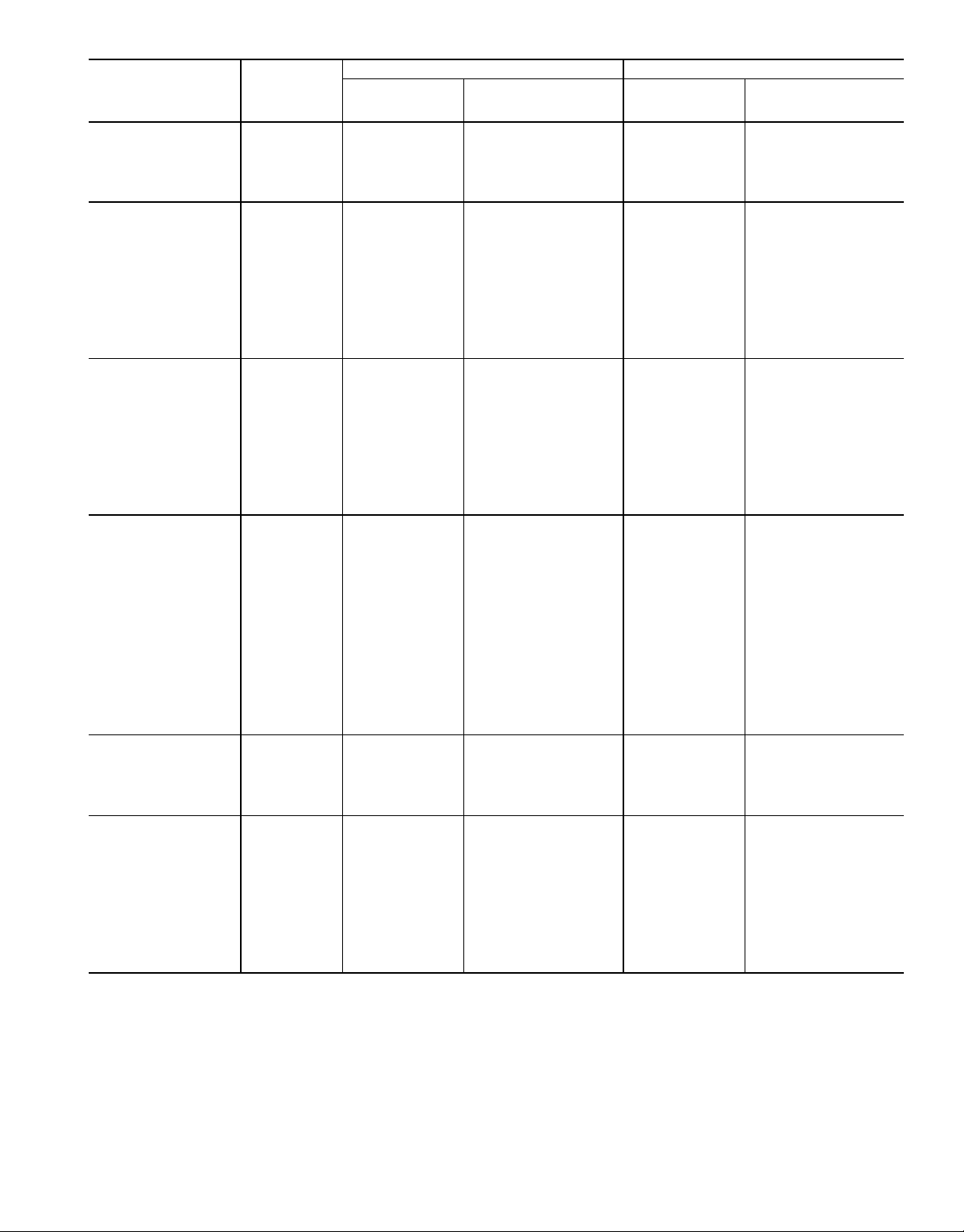

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units

UNIT

30GN

130 (60 Hz)

A1†,B1†

130 (60 Hz)

A1†**,B1†

130 (60 Hz)

A1†,B1†**

130 (60 Hz)

A1†**,B1†**

130 (50 Hz)

A1†,B1†

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

14

21

28

35

42

58

64

71

87

93

100

8

14

21

22

28

35

42

51

58

64

71

80

87

93

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

8

14

21

22

28

35

42

44

51

58

64

71

73

80

87

93

100

10

14

26

35

39

44

53

57

69

78

82

87

96

100

Compressors

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1††

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1††,B2

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

14

21

28

35

42

58

64

71

87

93

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

14

21

22

28

35

42

51

58

64

71

80

87

93

100

14

21

22

28

35

42

44

51

58

64

71

73

80

87

93

100

16

25

26

31

39

51

56

64

69

74

82

87

91

100

8

8

CompressorsDisplacement Displacement

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

B1††

B1*

B1

A1*,B1††

A1,B1††

A1,B1*

A1,B1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1††,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

B1††

B1*

B1

A1*,B1††

A1,B1††

A1,B1*

A1,B1

A1††,B1††,B2

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1††,A2,B1††,B2

A1*,A2,B1††,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

15

Page 16

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units (cont)

UNIT

30GN

130 (50 Hz)

A1†**,B1†

130 (50 Hz)

A1†,B1†**

130 (50 Hz)

A1†**,B1†**

150, 230A, 245A,

255A (60 Hz)

A1†,B1†

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

10

11

12

13

14

15

16

17

18

19

10

11

12

13

14

15

10

11

12

13

14

15

16

17

18

19

10

11

12

13

14

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

14

22

31

35

39

40

49

53

57

65

74

78

82

83

91

96

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

10

14

22

31

35

39

40

49

53

57

65

74

78

82

83

91

96

100

11

15

29

38

42

44

53

58

71

80

85

86

95

100

6

6

Compressors

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1*,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1*,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

16

25

31

39

43

47

56

64

65

74

82

83

91

100

16

25

31

39

43

47

56

64

65

74

82

83

91

100

—

—

—

—

18

27

29

33

42

55

60

69

71

75

85

86

91

100

CompressorsDisplacement Displacement

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

8

8

B1††

B1*

B1

A1,B1*

A1,B1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1††,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

B1††

B1*

B1

A1,B1*

A1,B1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1††,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

—

—

—

—

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

16

Page 17

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units (cont)

UNIT

30GN

150, 230A, 245A,

255A (60 Hz)

A1†**,B1†

150, 230A, 245A,

255A (60 Hz)

A1†,B1†**

150, 230A, 245A,

255A (60 Hz)

A1†**,B1†**

150, 230A, 245A,

255A (50 Hz)

A1†,B1†

150, 230A, 245A,

255A (50 Hz)

A1†**,B1†

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

10

11

12

13

14

15

16

17

10

11

12

13

10

11

12

13

14

15

16

17

10

11

12

13

14

10

11

12

13

14

15

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

11

15

24

33

38

42

49

53

58

66

75

80

85

91

95

100

—

—

—

—

—

—

—

—

—

—

—

—

—

11

15

24

33

38

42

49

53

58

66

75

80

85

91

95

100

13

20

26

33

40

46

53

60

66

73

80

86

93

100

13

20

26

33

40

46

53

60

66

73

80

86

93

100

6

6

6

Compressors

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

—

—

—

—

—

—

—

—

—

—

—

—

—

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1††

A1*

A1

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

18

27

33

42

46

51

60

69

75

85

91

100

18

27

33

42

46

51

60

69

75

86

91

100

—

—

—

—

13

20

26

33

40

46

53

60

66

73

80

86

93

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

CompressorsDisplacement Displacement

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

9

9

B1††

B1*

B1

A1,B1*

A1,B1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

B1††

B1*

B1

A1,B1*

A1,kB1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

—

—

—

—

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

17

Page 18

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units (cont)

UNIT

SIZE

150, 230A, 245A,

255A (50 Hz)

A1†,B1†**

150, 230A, 245A,

255A (50 Hz)

A1†**,B1†**

170, 270A,

330A/B (60 Hz)

A1†,B1†

170, 270A,

330A/B (60 Hz)

A1†**,B1†

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

10

11

12

13

14

15

10

11

12

13

14

15

10

11

12

13

14

15

16

17

10

11

12

13

14

15

16

17

18

19

20

21

22

23

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

13

20

26

33

40

46

53

60

66

73

80

86

93

100

11

17

23

28

33

39

45

50

56

61

67

73

78

83

89

95

100

11

17

17

23

28

33

34

39

45

50

51

56

61

67

67

73

78

83

84

89

95

100

6

6

Compressors

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

A1††

A1*

A1

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1*,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1††,A2,A3,B1*,B2,B3

A1††,A2,A3,B1,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

13

20

26

33

40

46

53

60

66

73

80

86

93

100

13

20

26

33

40

46

53

60

66

73

80

86

93

100

11

17

23

28

33

39

45

50

56

61

67

73

78

83

89

95

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

CompressorsDisplacement Displacement

6

6

B1††

B1*

B1

A1,B1††

A1,B1*

A1,B1

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1††,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

B1††

B1*

B1

A1,B1††

A1,B1*

A1,B1

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1††,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1*,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1*,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

18

Page 19

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units (cont)

UNIT

SIZE

170, 270A,

330A/B (60 Hz)

A1†,B1†**

170, 270A,

330A/B (60 Hz)

A1†**,B1†**

170, 270A,

330A/B,360B (50 Hz)

A1†,B1†

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

6

11

17

17

23

28

33

34

39

45

50

51

56

61

67

67

73

78

83

84

89

95

100

9

14

19

23

28

33

37

42

52

57

61

72

76

81

91

96

100

Compressors

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1*,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1††,A2,A3,B1*,B2,B3

A1††,A2,A3,B1,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

11

17

17

23

28

33

34

39

45

50

51

56

61

67

67

73

78

83

84

89

95

100

11

17

17

23

28

33

34

39

45

50

51

56

61

67

67

73

78

83

84

89

95

100

14

19

23

28

38

43

47

52

57

61

72

76

81

91

96

100

6

6

9

CompressorsDisplacement Displacement

B1††

B1*

B1

A1*,B1††

A1,B1††

A1,B1*

A1,B1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1††,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1††,B2,B3

A1,A2,B1††,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1††,B2,B3

A1,A2,A3,B1††,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

B1††

B1*

B1

A1*,B1††

A1,B1††

A1,B1*

A1,B1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1††,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1††,B2,B3

A1,A2,B1††,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1††,B2,B3

A1,A2,A3,B1††,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1*,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1*,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

19

Page 20

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units (cont)

UNIT

SIZE

170, 270A,

330A/B, 360B (50 Hz)

A1†**,B1†

170, 270A,

330A/B, 360B (50 Hz)

A1†,B1†**

170, 270A,

330A/B, 360B (50 Hz)

A1†**,B1†**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

5

9

14

14

19

23

28

28

33

37

42

48

52

57

61

67

72

76

81

87

91

96

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

5

9

14

14

19

23

28

28

33

37

42

43

48

52

57

61

63

67

72

76

81

82

87

91

96

100

Compressors

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1*,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1††,A2,A3,B1*,B2,B3

A1††,A2,A3,B1,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

A1††

A1*

A1

A1††,B1*

A1††,B1

A1*,B1

A1,B1

A1††,A2,B1*

A1††,A2,B1

A1*,A2,B1

A1,A2,B1

A1††,A2,B1††,B2

A1††,A2,B1*,B2

A1††,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1††,A2,A3,B1††,B2

A1††,A2,A3,B1*,B2

A1††,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1††,A2,A3,B1††,B2,B3

A1††,A2,A3,B1*,B2,B3

A1††,A2,A3,B1,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

14

14

19

23

28

34

38

43

47

48

52

57

61

67

72

76

81

87

91

96

100

14

14

19

23

28

29

34

38

43

47

48

52

57

61

63

67

72

76

81

82

87

91

96

100

5

9

5

9

CompressorsDisplacement Displacement

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

B1††

B1*

B1

A1*,B1††

A1,B1††

A1,B1*

A1,B1

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1††,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1††,B2,B3

A1,A2,B1††,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1††,B2,B3

A1,A2,A3,B1††,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

B1††

B1*

B1

A1*,B1††

A1,B1††

A1,B1*

A1,B1

A1††,B1††,B2

A1*,B1††,B2

A1,B1††,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1††,B2

A1,A2,B1††,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1††,A2,B1††,B2,B3

A1*,A2,B1††,B2,B3

A1,A2,B1††,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1††,A2,A3,B1††,B2,B3

A1*,A2,A3,B1††,B2,B3

A1,A2,A3,B1††,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B3,B3

20

Page 21

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units (cont)

UNIT

SIZE

190, 290A, 360A/B,

390B (60 Hz)

A1,B1

190, 290A, 360A/B,

390B (60 Hz)

A1**,B1

190, 290A, 360A/B,

390B (60 Hz)

A1,B1**

190, 290A, 360A/B,

390B (60 Hz)

A1**,B1**

190, 290A, 360A,

390B (50 Hz)

A1,B1

190, 290A, 360A,

390B (50 Hz)

A1**,B1

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

10

11

12

10

11

12

10

11

12

13

14

15

16

17

10

11

12

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

13

25

41

56

78

100

13

21

25

37

41

53

56

74

78

96

100

—

—

—

—

—

—

—

—

—

—

—

—

13

18

21

25

33

37

41

49

53

56

71

74

78

93

96

100

17

33

50

67

83

100

11

17

28

33

44

50

61

67

78

83

94

100

9

9

Compressors

A1

A1,B1

A1,A2,B1

A1,A2,B1,B2

A1,A2,A3,B1,B2

A1,A2,A3,B1,B2,B3

A1*

A1

A1*,B1

A1,B1

A1*,A2,B1

A1,A2,B1

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

—

—

—

—

—

—

—

—

—

—

—

—

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1

A1,B1

A1,A2,B1

A1,A2,B1,B2

A1,A2,A3,B1,B2

A1,A2,A3,B1,B2,B3

A1*

A1

A1*,B1

A1,B1

A1*,A2,B1

A1,A2,B1

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

13

25

41

56

78

100

—

—

—

—

—

—

—

—

—

—

—

—

13

21

25

37

41

53

56

74

78

96

100

13

18

21

25

33

37

41

49

53

56

71

74

78

93

96

100

17

33

50

67

83

100

—

—

—

—

—

—

—

—

—

—

—

—

CompressorsDisplacement Displacement

B1

A1,B1

A1,B1,B2

A1,A2,B1,B2

A1,A2,B1,B2,B3

A1,A2,A3,B1,B2,B3

—

—

—

—

—

—

—

—

—

—

—

—

9

A1,A2,A3,B1*,B2,B3

9

A1*,A2,A3,B1*,B2,B3

A1,A2,A3,B1*,B2,B3

B1*

B1

A1,B1*

A1,B1

A1,B1*,B2

A1,B1,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1,A2,A3,B1,B2,B3

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1*,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1,A2,A3,B1,B2,B3

B1

A1,B1

A1,B1,B2

A1,A2,B1,B2

A1,A2,B1,B2,B3

A1,A2,A3,B1,B2,B3

—

—

—

—

—

—

—

—

—

—

—

—

21

Page 22

Table 4C — Capacity Control Steps, 130-210 and Associated Modular Units (cont)

UNIT

SIZE

190, 290A, 360A,

390B (50 Hz)

A1,B1**

190, 290A, 360A,

390B (50 Hz)

A1**,B1**

210, 315A, 390A,

420A/B (60 Hz)

A1,B1

210, 315A, 390A,

420A/B (60 Hz)

A1**,B1

210, 315A, 390A,

420A/B (60 Hz)

A1,B1**

*Unloaded compressor.

†Compressor unloader, standard.

**Compressor unloader, accessory.

††Two unloaders, both unloaded.

CONTROL

STEPS

10

11

12

10

11

12

13

14

15

16

17

10

11

12

13

14

10

11

12

13

14

LOADING SEQUENCE A LOADING SEQUENCE B

%

(Approx) (Approx)

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

—

—

—

—

—

—

—

—

—

—

—

—

11

17

22

28

33

39

44

50

55

61

67

72

78

83

89

94

100

11

25

36

56

67

86

100

11

22

25

33

36

52

56

63

67

83

86

97

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

8

Compressors

—

—

—

—

—

—

—

—

—

—

—

—

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1

A1,B1

A1,A2,B1

A1,A2,B1,B2

A1,A2,A3,B1,B2

A1,A2,A3,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

A1*

A1

A1*,B1

A1,B1

A1*,A2,B1

A1,A2,B1

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1*,A2,A3,A4,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

—

—

—

—

—

—

—

—

—

—

—

—

—

—

NOTE: Thesecapacitycontrolsteps may vary due to lag compressor

sequencing.

%

17

28

33

44

50

61

67

78

83

94

100

17

22

28

33

39

44

50

55

61

67

72

78

83

89

94

100

14

25

44

56

75

86

100

—

—

—

—

—

—

—

—

—

—

—

—

—

—

14

21

25

40

44

51

56

71

75

82

86

96

100

CompressorsDisplacement Displacement

11

11

A1*,A2,A3,B1*,B2,B3

A1,A2,A3,A4,B1,B2,B3

9

A1,A2,A3,A4,B1*,B2,B3

A1,A2,A3,A4,B1,B2,B3

B1*

B1

A1,B1*

A1,B1

A1,B1*,B2

A1,B1,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3