Page 1

48/50HG014-028

Single-Package Rooftop Units

Accessory Return and Supply

Smoke Detectors

Installation Instructions

Part No. CRSMKDET001C00 and CRSMKSUP001A00

CONTENTS

GENERAL

SAFETY CONSIDERATIONS

INSTALLATION

Check Package Contents

Return Air Smoke Detector Installation

Supply Air Smoke Detector Installation

Configuring the

OPERATION

MAINTENANCE

Cleaning Procedure

Filter Replacement

Board Replacement

TROUBLESHOOTING

Smoke Entry Tests

• AIRFLOW TEST

• SMOKE RESPONSE TEST

Standby, Alarm and Sensitivity Tests

• STANDBY AND TROUBLE TEST

• ALARM TESTS

• SENSITIVITY TEST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Comfort

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5,6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . 2

. . . . . . . . . . 5

Link™ Controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . .7,8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . 5

. . . . . . . . . . . . . 8

GENERAL

An HVAC (heating, ventilation and air-conditioning) system supplies conditioned air to virtually every area of a

building. Smoke introduced into this air duct system will be

distributed throughout the entire building. Smoke detectors

designed for use inside the unit are used to sense the presence

of smoke passing through the unit.

The smoke detector utilizes photoelectric technology for the

detection of smoke. This detection method, when combined

with an efficient ducting design, samples air passing through

the unit. If sufficient smoke is sensed, an alarm signal is initiated and the ComfortLink controls will shut down the unit. With

the unit shut down, the unit will not blow toxic smoke and fire

gases throughout the areas served by the duct system.

The return air smoke detector is part number

CRSMKDET001C00. The supply air smoke detector is part

number CRSMKSUP001A00.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service personnel. When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to the unit,

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use care when handling and installing the accessory.

Before performing service or maintenance operations on

unit, turn off main power swit ch to unit. Electrical shock

could cause personal injury.

The National Fire Protection Association has established

that DUCT DETECTORS MUST NOT BE USED AS A

SUBSTITUTE FOR OPEN AREA DETECTOR PROTECTION as a means of providing life safety. Nor are they

a substitute for early warning in a building’s regular fire

detection system. Carrier supports this positi on and strongly

recommends that the user read NFPA Standards 90A, 72,

and 101. This smoke detector is listed per UL 2 68A.

This device will not operate without electrical power.

Fire situations may cause an interruption of power. The

system safeguards should be discussed with your local fire

protection specialist.

This device will not sense smoke unless the ventilation system is operating and the cover is installed.

For this detector to function properly, it MUST be installed

according to the instructions in this manual. Furthermore,

the detector MUST be operated within ALL e lectrical and

environmental specifications listed in this manual. Failure

to comply with these requirements may prevent the detector from activating when smoke is present in the air duct.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1144

Tab 1a1b6a6b

PC 111 Catalog No. 534-80096 Printed in U.S.A. Form 48/50HG-19SI Pg 1 2-02 Replaces: 48/50HG-17SI

Page 2

INSTALLATION

When installing the smoke detector in the unit, follow all

local codes. Damage to unit may result.

Check Package Contents —

Remove accessory packaging and inspect shipment for damage. If any damage is

found, file a claim with the shipping agent immediately. If any

item is missing or any part does not assemble properly, notify

your Carrier distributor.

Tables 1A and B list the accessory package contents.

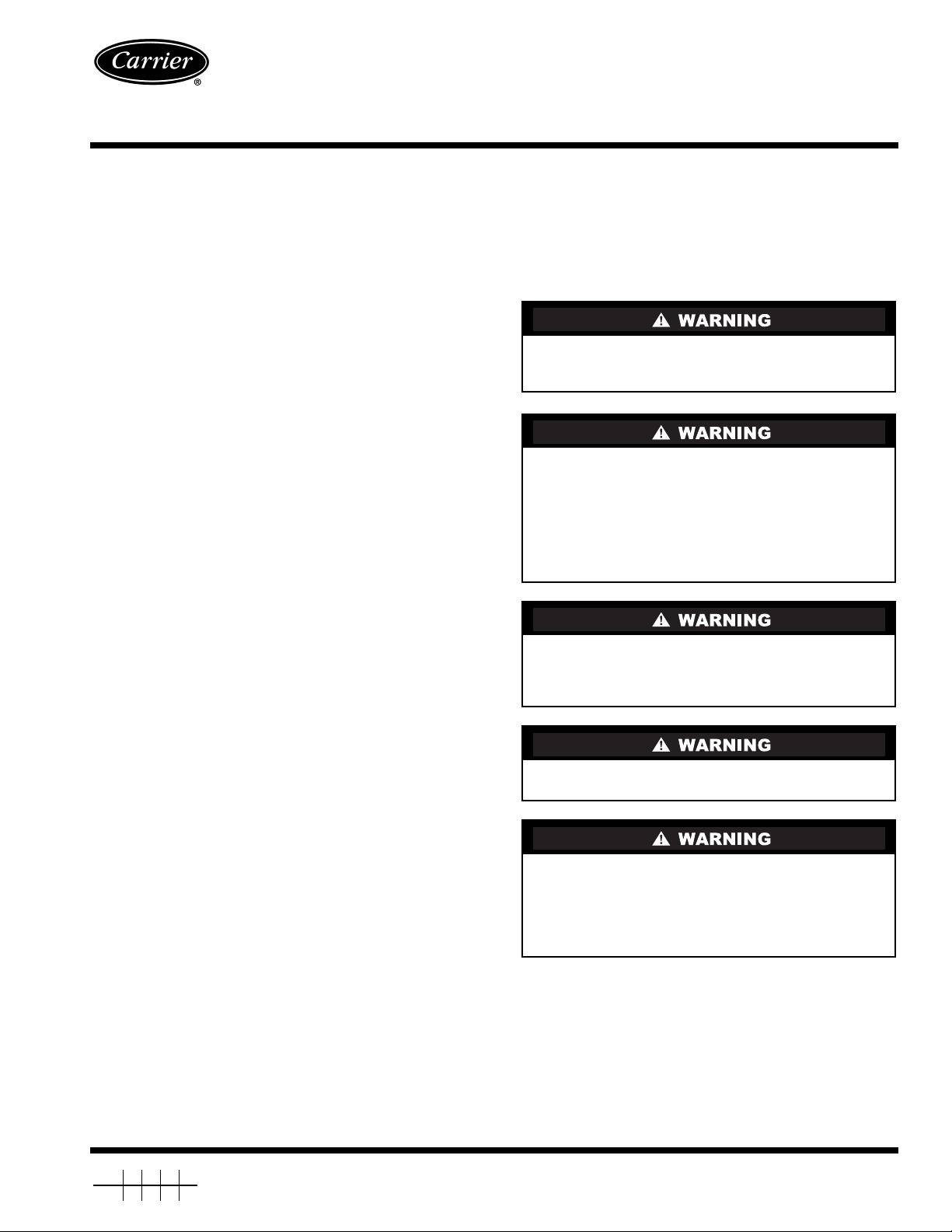

Figure 1 shows the smoke detector.

Table 1A — Accessory Package Contents —

Return Air Smoke Detector (CRSMKDET001C00)

ITEM QUANTITY

Smoke Detector with Cover

Sampling Tube (long)

Sampling Tube Filters

Test Magnet

Foam Gaskets

Screw, no. 6 Self Tapping

Tube End Plug (large)

Sampling Tube Support Bracket

Screw, 8-18

Screw,

Small Snap Bushing

Large Snap Bushing

Harness Assembly (4-Wires, short)

Wire Tie, Screw Mounted

3

/4-in. Pan Head

1

/4AB-14 5/8-in.

1

1

2

1

2

2

1

1

2

2

1

1

1

1

Table 1B — Accessory Package Contents —

Supply Air Smoke Detector (CRSMKSUP001A00)

ITEM QUANTITY

Smoke Detector with Cover

Sampling Tube (short)

Sampling Tube Filters

Test Magnet

Foam Gaskets

Tube End Plug (small)

Screw, 8-18

Small Snap Bushing

Harness Assembly (4-Wires, long)

Wire Tie, Screw Mounted

Wire Tie

Screw, no. 8 Self Tapping

Screw, no. 10

3

/4-in. Pan Head

1

1

2

1

2

1

2

1

1

5

1

1

2

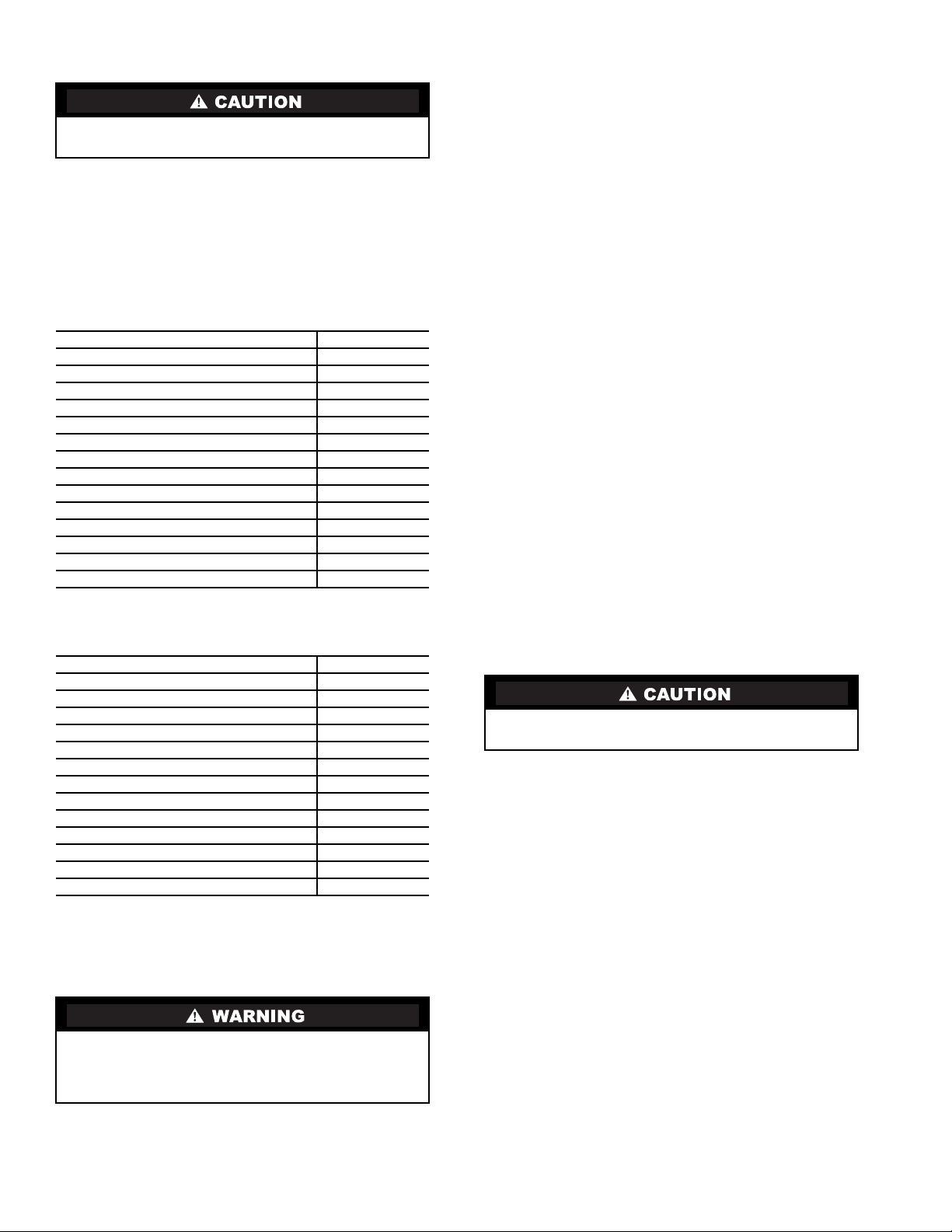

Return Air Smoke Detector Installation —

The return air smoke detector is to be installed in the predrilled

holes located above compressor B1 in the electrical/

compressor section (Fig. 2).

Prior to instal lation of this access ory, make sure all power

is disconnected to the unit and locked out. Failure to disconnect power supply prior to servicing may result in serious injury.

NOTE: For horizontal applications it is easiest to install the

smoke detector prior to making duct connections.

1. Open the hinged electrical/compressor access door and

secure.

2. Find the 2 plugs located above compressor B1, remove

and discard. Cut holes in the insulation located behind the

partition.

3. Remove cover from smoke detector. The screws will

remain captured in the cover.

4. Place foam gaskets over each sampling tube on smoke

detector. (See Fig. 1.)

5. Remove one knockout from top of smoke detector.

6. Insert stripped ends of wire harness through knockout and

wire to smoke detector as shown in Fig. 3.

7. Provide strain relief for wires by attaching wire tie to

ground screw located next to the knockout in the smoke

detector. Ti ghten the wire tie.

8. Slide smoke detector into holes in partition with the

terminal block to the right. Do not secure at this time.

9. Slide sampling tube into left-hand hole of smoke detector.

It might be necessary to tilt the smoke detector upw ards

in order properly align the sampling tube.

10. Remove the unit side panel at the return end of the unit.

Save screws for use later.

11. Mount the sampling tube support bracket to the cross

member with two

1

/4AB-14 5/8-in. screws as shown

in Fig. 4. Insert large snap bushing into hole in bracket.

12. Slide sampling tube into bracket, making sure that the

sampling holes point down. Pull the sampling tube so that

it is flush with the smoke detector.

13. Return to Electrical/Compressor section and secure sampling tube to smoke detector with two no. 6 self-tapping

screws.

3

14. Attach smoke detector to partition using two, 8-18

/4-in.

pan head screws.

Do not overtighten the screws. Damage to smoke detector

may result.

15. Return to side panel and insert tube end plug into

sampling tube.

16. Replace the unit side panel.

17. Return to Electrical/Compressor section and insert

sampling tube filters into both sampling tube holders.

(See Fig. 1.)

18. Install the snap bushing in the center knockout underneath the control terminal strips located in the bottom

right-hand corner of the control box.

19. Feed wires through snap bushing and connect to appropriate terminals as shown in Fig. 3.

20. Restore power to the unit.

21. Configure ComfortLink™ controller as specified in

Configuring the ComfortLink Controller on page 5.

22. Perform Standby , Alarm, and Sensitivity Tests on page 7.

At a minimum, the Magnet test should be performed t o

verify smoke detector wiring.

23. Replace smoke detector cover.

24. Check for alarms. Correct any problems.

2

Page 3

FOAM

GASKETS

PLASTIC

SAMPLING TUBE

PLASTIC SAMPLING TUBE

SELF-TAPPING SCREW

DETECTOR BOARD

DETECTOR COVER

CONDUIT HOLES

SAMPLING TUBE

FILTERS

Fig. 1 — Smoke Detector

DETECTOR

HOUSING

TERMINAL STRIP

POWER BOARD

COVER MOUNTING

SCREWS

SMOKE DETECTOR

Fig. 2 — Return Air Smoke Detector Location

3

Page 4

SAMPLING TUBE

SUPPORT BRACKET

Fig. 3 — Return Air Smoke Detector Wiring

Fig. 4 — Sampling Tube Support Bracket

4

Page 5

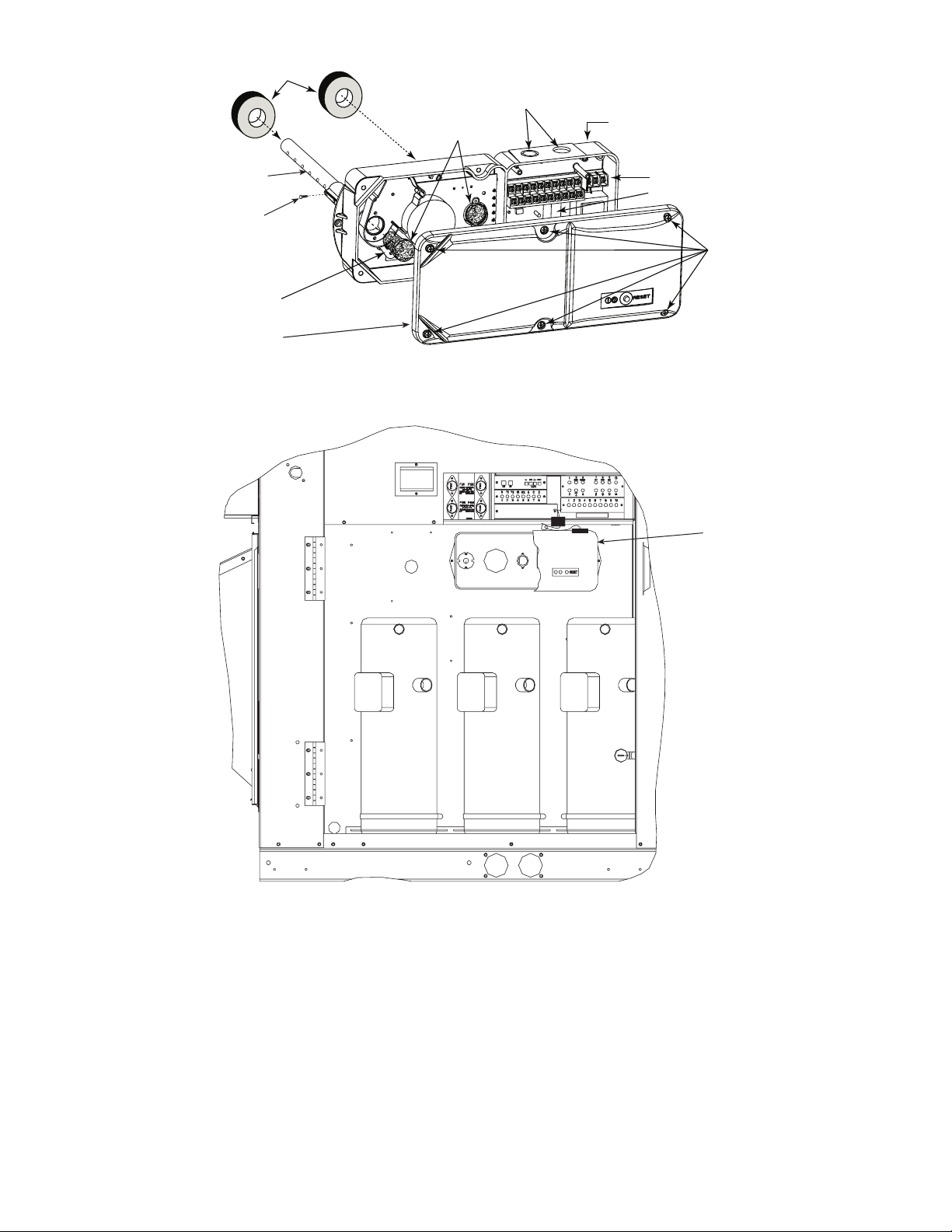

Supply Air Smoke Detector Installation —

ESCAPE

The supply air smoke detector is to be installed in the predrilled holes located on the front of the first indoor blower

(Fig. 5).

Prior to instal lation of this access ory, make sure all power

is disconnected to the unit and locked out. Failure to

disconnect power supply prior to servicing may result in

serious injury .

1. Open the indoor fan access door and secure.

2. Open the hinged electrical/compressor access door and

secure.

3. Disconnect wires located on the left-hand side of the f an

deck. On 48HG units, the indoor fan plug and the limit

switch quick connects must be disconnected. On 50HG

units, only the indoor fan plug must be disconnected.

4. Find the 2 plugs located in the blower side plate. Remove

the plugs and discard. It will be necessary to remove

some of the tape holding the plugs in place.

5. Remove cover from smoke detector. The screws will

remain captured in the cover.

6. Place foam gaskets over each sampling tube on sm oke

detector. See Fig. 1.

7. Remove one knockout from top of smoke detector.

8. Insert stripped ends of wire harness through knockout and

wire to smoke detector as shown in Fig. 6.

9. Provide strain relief for wires by attaching wire tie to

ground screw located next to the knockout in the smoke

detector. T ighten wire tie.

10. Secure sampling tube in inlet closest to the smoke detector electronics using the no. 8 self-tapping screw provided. See Fig. 1 for an example on how to connect a sampling tube. Be sure to connect the sampling tube to the

middle hole. Insert plug into the end of the sampling tube.

11. Slide smoke detector into holes in partition with the terminal block at the top and secure using two, 8-18

pan head screws.

Do not overtighten screws. Damage to smoke detector may

result.

12. Insert sampling tube filters into both sampling tube

holders. See Fig. 1.

13. Remove and save the two screws securing the indoor fan

sled to the unit.

14. Slide the indoor fan sled out until the back side of the first

blower is accessible.

15. Attach wire harness to fan side plate using the 4 screw

wire ties and no. 10 screws provided. See Fig. 5 for

clarification.

16. Slide in the indoor fan deck and secure using screws

saved from Step 13.

17. Attach wire harness to top of Circuit C filter drier (and

point B if two circuits) in Fig. 5, using wire tie provided.

Make sure that the wire harness is tight.

18. In the Electrical/Compressor section, install snap bushing

in the center knockout underneath the term inal strips located in the bottom right-hand corner of the control box.

19. Route wires from the filter drier to the control box. Wires

should follow existing wires through grommet located on

3

/4-in.

top of the filter section, down the outside of th e control

box and through the snap bushing. See Fig. 5 and 6.

20. Connect wires to terminal strips as shown in Fig. 5 and 6.

21. Restore power to the unit.

22. Configure ComfortLink™ controller as specified in Configuring the ComfortLink Controller below.

23. Perform Standby, Alarm, and Sensitivity Tests on

page 7. At a minimum, the Magnet test should be performed to verify smoke detector wiring.

24. Turn off power to the unit.

25. Replace smoke detector cover. Do not overtighten

screws.

26. Reconnect the indoor fan plug and the limit switch wires

if applicable.

27. Close the indoor fan section door.

28. Restore power to the unit and check for al arms. Correct

any problems encountered.

29. Close Electrical/Compressor section door.

Configuring the

Configuration settings for the ComfortLink controller are

changed by using the Scrolling Marquee Display. A password

may be required to edit the configurations, depending on the

previous settings configured in the unit. Default password is

“1111 ”. U se th e a rr ow k ey s t o s cr oll th e r ed LE D o n th e d is play to the “Configuration” position and press . Scroll

through the menu until UNIT is found and press .

After reaching the UNIT sub-menu, scroll to FS.SW (Fire

Shutdown Input) and press twice, change the value

to 1 (Normal Open) with the arrow keys, press again.

Press three times to return to the top level of the

menu. Additional information about changing configurations

can be found in the Control and Troubleshooting Guide for

48/50HG units.

Comfort

ENTER

Link Controller —

ENTER

ENTER

ENTER

OPERATION

The smoke detector must be tested and maintained regularly following NFP A 72 requirements. The smoke detector

should be cleaned at least once a year. Damage to equipment may result.

The smoke detector accessories contain a photoelectric

detector approved for an extended air speed range of 100 to

4000 feet per minute (0.5 to 20.3 m/s) and an operational temperature range of 32 to 131 F (0° to 55 C). Do not operate the

smoke detector out of these ranges.

The smoke detector operates on 24 VAC, 120 VAC, or

240 VAC. The thermostat power terminals on the unit are used

to power the smoke detector. Alarm and supervisory relay contacts are available for con trol pa nel int er fa ce (al arm in it iati o n),

HVAC control, and other auxiliary functions. Auxiliary relays

are also provided for fan shut down or signaling of up to 9

other detectors in the loop for multiple fan shut down. The

smoke detector is not designed for 2-wire applications.

The smoke detector can be reset by a momentary power interruption, by the reset button on the front cover, by the control

panel, or by the remote reset accessory. The smoke detector

incorporates a cover tamper feature that provides a tr ouble

signal after 20 minutes if the cover is removed or i mproperly installed. Proper installation of the cover removes t he trou-

ble condition.

5

Page 6

SUPPLY FAN,

VIEW FROM

INSIDE UNIT

USE #10 SCREWS

PROVIDED TO

ATTACH WIRE TIES

Fig. 5 — Supply Smoke Detector Location and Wire Routing

ROUTE WIRES

AS SHOWN

SUPPLY

SMOKE

DETECTOR

Fig. 6 — Supply Smoke Detector Wiring

6

Page 7

MAINTENANCE

Cleaning Procedure —

that the smoke detector system is undergoing maintenance, and

that the system will temporarily be out of service. Disable the

zone or system undergoing maintenance to prevent unwanted

alarms and possible dispatch of the fire department.

AIR FILTERS

1. Turn off power to the system.

2. Remove and inspect sampling tube filters.

3. If filters are heavily coated wi th dirt, replace them with

new filters. If they are not heavily coated, use a vacuum

cleaner or compressed air nozzle to remove dust, then

reinstall the filters.

PHOTO DETECTOR BOARD

1. Remove the screen by gently grasping on each side and

pulling straight off.

2. Lift the photo chamber in the same fashion. Vacuum the

screen and cover. Use clean, compressed air to loosen and

blow out any remaining debris.

3. Vacuum photo chamber, then use clean compressed air to

blow area clean.

4. Replace the chamber by pressing it onto the base. Press

the screen into place. It should fit tightly on the chamber.

Filter Replacement —

affect smoke detector performance even when up to 90% of the

filter is clogged. Quarterly visual inspection usually suffices to

determine whether the filters should be replaced. Only a high

percentage of contamination affects performance. If further

testing is required, compare differential pressure readings with

and without the filters installed. If the difference exceeds 10%,

then replace the filters. The pressure differential should never

fall below 0.0015 in. wg.

Notify the proper authorities

The filters do not substantially

Board Replacement

SMOKE DETECTOR BOARD REPLACEMENT

1. Remove the two detector board mounting screws.

2. Pull gently on the board to remove it.

3. To replace the board, align the board mounting features,

holes, and the interconnect terminals. Push the board into

place.

4. Secure board with the two mounting screws.

POWER BOARD REPLACEMENT

1. Disconnect wiring from the terminal block.

2. Remove the two power board mounting screws.

3. Pull gently on the board to remove it.

4. To replace the board, align the board mounting features,

holes, and the interconnect terminals. Push the board into

place.

5. Secure board with the two mounting screws.

6. Re-connect wiring to terminal block.

TROUBLESHOOTING

Test and maintain unit smoke detectors as recommended

in NFPA 72. Before conducting these tests, notify the proper

authorities that the smoke detection system will be temporarily

out of service. Disable the system under test to prevent unwanted alarms.

Smoke Entry Tests

AIRFLOW TEST — The smoke detector is designed to operate over an extended air speed range of 100 to 4000 fpm. To

verify sufficient sampling of unit air, turn on the 48/50HG unit

indoor fan using the Service Test function (see Controls and

Troubleshooting Guide for details on Service Test) and use a

manometer to measure the differential pressure between the

two sampling tubes.

The differential pressure should measure at least

0.0015 in. wg and no more than 1.2 in. wg. Because most commercially available manometers cannot accurately measure

very low pressure differentials, applications with less than

500 fpm of unit air speed may require the use of a currentsourcing pressure transmitter or the use of aerosol smoke (see

Smoke Response Test below).

SMOKE RESPONSE TEST — Drill a

upstream from the unit smoke detector. Use the Service Test

function (see Controls and Troubleshooting Guide for details

on Service Test) to turn on the 48/50HG unit indoor fan.

Measure the air velocity with an anemometer. Air speed must

be at least 100 fpm. If the air speed is greater than 500 fpm, use

a conventional manometer to measure differential pressure between the sampling tubes.

Spray aerosol smoke into the unit through the

for 5 seconds. Wait two minutes for the unit smoke detector to

alarm. If the unit smoke detect or alarms, then air is flowing

through the detector. Remove the unit smoke detector cover

and blow out the residual aerosol smoke from the chamber and

reset the unit smoke detector. Use duct tape to seal the aerosol

smoke entry hole.

To determine if smoke is capable of entering the sensing

chamber, visually identify any obstructions. Plug the exhaust

and inlet tube holes to prevent unit air from carrying smoke

away from the detector head, then blow smoke directly at the

head to cause an alarm.

Remove the plugs after this test, or the smoke detector will

not function properly and damage may result.

1

/4-in. hole 3-ft

1

/4-in. hole

7

Page 8

Standby, Alarm and Sensitivity Tests —

The cover of the smoke detector must be removed to perform these

tests.

STANDBY AND TROUBLE TEST

Standby — Look for presence of flashing green LED.

The LED should flash approximately every

10 seconds.

Trouble — If the detector LED does not flash, then the detec-

tor lacks power (check TB4), the detector board is

missing (replace), the cover has been missing or

not secured properly for more than 20 minutes

(secure cover properly), or the unit is defective

(return for repair).

Test — The trouble condition can be caused intentionally

to verify correct operation of the system. Remove

the detector board to cause an alarm.

Cover

T amper — If the cover is removed or not properly secured for

a period longer than 20 minutes, a trouble signal is

generated to indicate the cover is missing.

ALARM TESTS

Magnet Test

1. Place the painted surface of the magnet onto the TEST

locator on the bottom of the housing.

2. The red alarm LED on the detector should switch on.

Verify system control panel alarm status and control

panel execution of all intended auxiliary functions

(i.e., fan shutdown, damper control, etc.).

3. The detector must be reset by the front cover reset button.

SENSITIVIT Y TEST — After verification of alarm capability, use a field-supplied voltmeter to check detector sensitivity.

The housing cover must be removed to perfor m this test. If

readings indicate that the detector head is outside of the acceptable range that is printed on the label of the detector, the detector chamber requires cleaning.

Copyright 2002 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book1144

Tab 1a1b6a6b

PC 111 Catalog No. 534-80096 Printed in U.S.A. Form 48/50HG-19SI Pg 8 2-02 Replaces: 48/50HG-17SI

Loading...

Loading...