Carrier BW4, BW5 Owner's Manual

USERSINFORMATIONMANUAL

OIL-BURNINGEQUIPMENT:

STEAMANDHOT-WATERBOILERS

IMPORTANT

• READ AND SAVE THESE INSTRUCTIONS FOR

REFERENCE.

• USE ONLY NUMBER 2 FUEL OIL.

CAUTION

!

• DO NOT USE GASOLINE, CRANKCASE DRAININGS,

OR ANY OIL CONTAINING GASOLINE.

• NEVER BURN GARBAGE OR P APER IN THE UNIT ,

AND NEVER LEAVE COMBUSTIBLE MATERIAL

AROUND IT.

!

WARNING

!

• KEEP YOUR BOILER AND THE SPACE AROUND

THE APPLIANCE CLEAR OF DEBRIS. DO NOT

STACK ITEMS ON OR AROUND THE APPLIANCE

WITHIN THE REQUIRED CLEARANCES TO

COMBUSTIBLES.

• ENSURE THAT THE SUPPLY OF COMBUSTION

AIR TO THE APPLIANCE IS NOT OBSTRUCTED

OR CUT OFF. ENSURE THAT THE PROPER

VENTILATION TO THE APPLIANCE AREA IS

MAINTAINED.

!

OG-BW4-01

[P/N# 240006274G Rev. B 12/2012]

INSTRUCTIONS TO OBTAIN PROPER

OPERATION OF THE BOILER

CAUTION

!

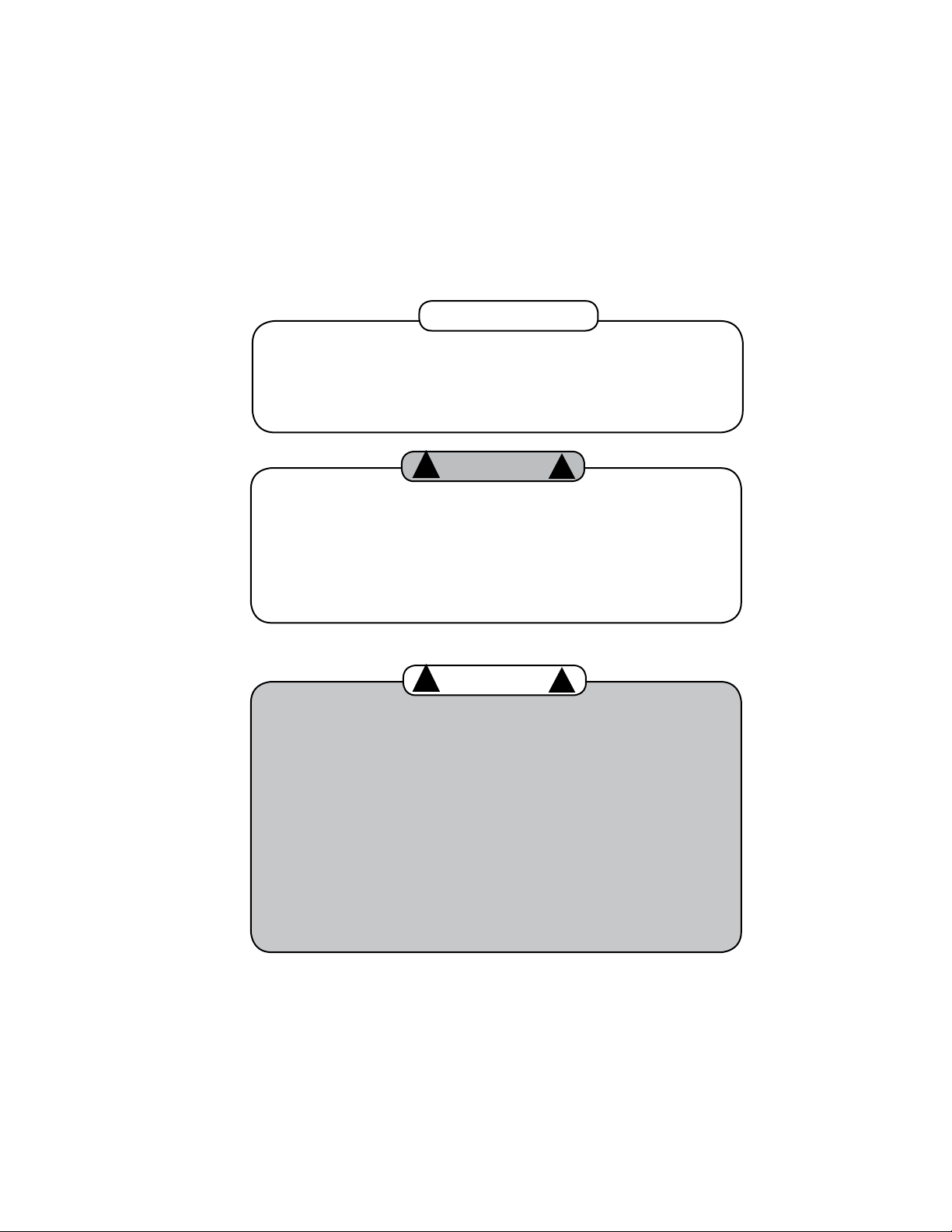

• DO NOT START THE BURNER UNLESS ALL

CLEAN-OUT DOORS ARE SECURED IN PLACE.

• DO NOT ATTEMPT TO START THE BURNER

WHEN THE COMBUSTION CHAMBER HAS

ACCUMULA TED OIL, OR IS FULL OF VAPOR, OR

IS VERY HOT.

Instruments are the only reliable method to determine proper air

adjustments. An improperly adjusted burner causes soot and

high fuel bills because of incomplete combustion of the fuel oil.

This in turn may require excessive boiler maintenance, service

costs, and in some instances, house cleaning or redecorating.

A competent service mechanic should be consulted to make the

proper adjustments with a smoke tester, CO2 indicator and draft

gauge. Bacharach or Dwyer test kits include these instruments.

!

A ¼” diameter slot is provided in the inspection cover plate to

take draft readings in the combustion chamber. A ¼” diameter

hole will be required in the fl ue pipe between the boiler and

barometric damper (if used) to take draft, CO2, smoke and

temperature readings. Adjust air shutter on oil burner to obtain

a “trace” of smoke. Measure CO2 at this point. Increase air

adjustment to lower CO2 approximately one (1) percent. Check

to ensure zero (0) smoke and correct draft is obtained for

the unit installed (reference the Boiler Installation Manual for

correct draft settings). If the proper draft can not be maintained,

changes and/or modifi cations may be required in the venting,

chimney or combustion air supply.

2

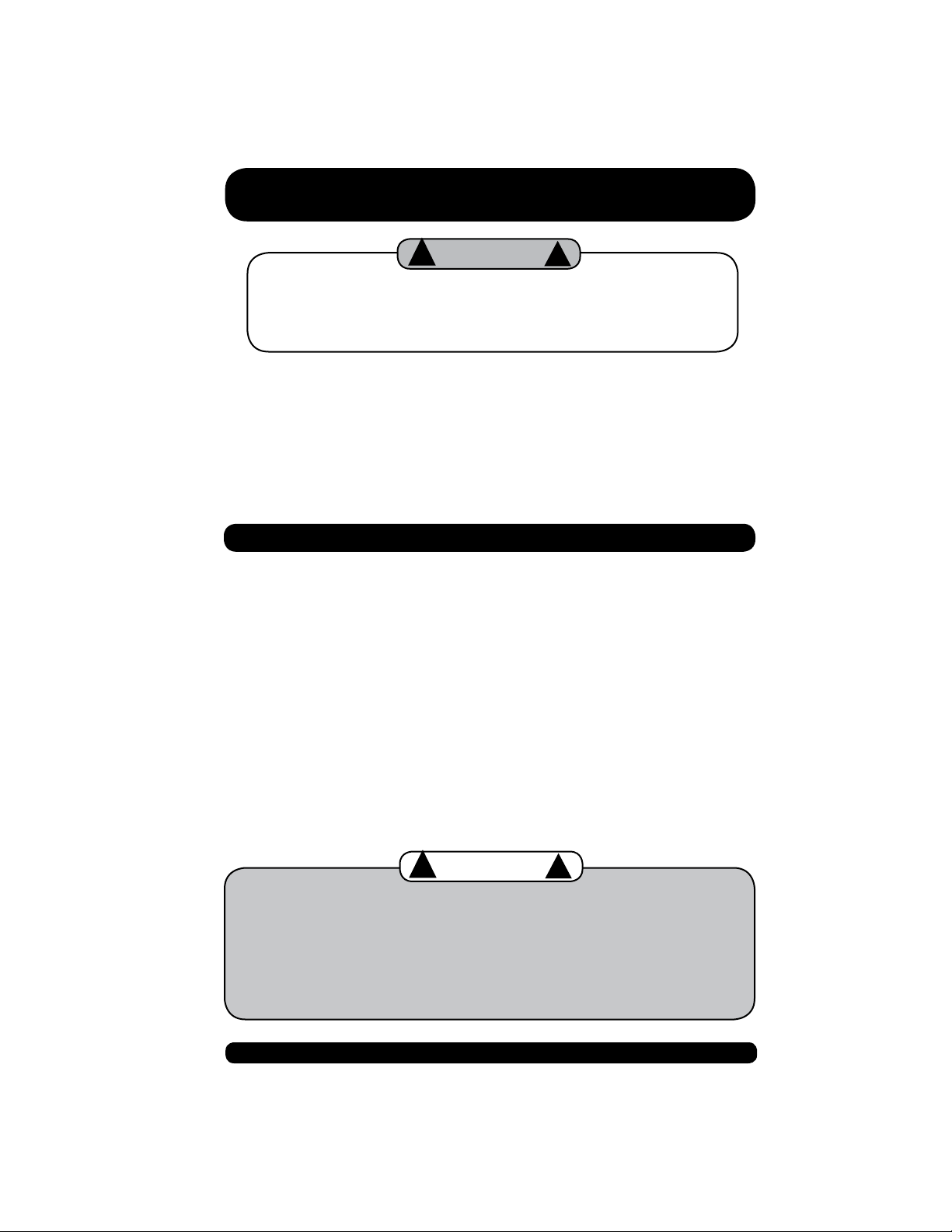

SHUTTING DOWN THE BOILER FOR

EXTENDED PERIODS OF TIME

CAUTION

!

ALWAYS KEEP THE OIL SUPPLY VALVE SHUT OFF

IF THE BURNER IS SHUT DOWN FOR AN EXTENDED

PERIOD OF TIME.

• Always turn off electrical power to the boiler via the fi eld

installed fused disconnect switch if the boiler is shut down

for an extended period of time.

• When restarting the boiler from an extended shutdown,

follow the Operating Instructions in the Installation Manual

and Operating Instructions.

GENERAL MAINTENANCE DURING OPERATION

The following preventative maintenance should be performed

by a qualifi ed service technician annually prior to the heating

season.

Preventative maintenance of an oil fi red boiler reduces

operating costs. The boiler and vent pipe should be inspected

for accumulation of soot or scale deposits periodically but at

least once every year before the start of each heating season.

When soot is present on the section walls and fl ue ways,

improper combustion will result, causing additional sooting and

scaling until fl ue ways are completely closed.

Periodic inspection and tightening of the tank-less heater/cover

plate bolts, if applicable, will reduce the risk of leaks.

!

WARNING

!

ALWAYS DISCONNECT POWER TO THE BOILER WITH

THE EMERGENCY POWER ISOLATION SWITCH WHEN

SERVICING THE BOILER. THE EMERGENCY POWER

ISOLATION SWITCH IS FIELD INSTALLED AND SHOULD

BE WITHIN 5 FEET OF THE BOILER.

3

!

Loading...

Loading...